AN5557

Application note

STM32H745/755 and STM32H747/757 lines dual-core architecture

Introduction

Microcontrollers of the STM32H745/755 and STM32H747/757 lines feature an asymmetric dual‑core architecture to boost

performance and to enable ultra-fast data transfers through the system while achieving major power savings and enhanced

security.

These microcontrollers are based on the high-performance Arm® Cortex®-M7 and Cortex®-M4 32-bit RISC cores. The Arm

Cortex®-M7 (CPU1) is located in the D1 domain and operates up to 480 MHz. The Arm® Cortex®-M4 (CPU2) is located in the

D2 domain and operates up to 240 MHz. The system is partitioned into three power domains that operate independently, thus

obtaining the best trade-off between power consumption and core performance.

A specific development approach is needed to get the maximum advantage from the dual-core architecture: this document

provides an overview of the MCUs dual-core architecture, as well as of their memory interfaces and features. It introduces an

example based on STM32CubeMX tool, simple peripheral initialization without any communication between two cores. It also

provides firmware examples to describe how to build a communication channel between cores, and send data from CPU2 to

CPU1 using OpenAMP MW to create a digital oscilloscope (for FFT).

®

AN5557 - Rev 1 - November 2020

For further information contact your local STMicroelectronics sales office.

www.st.com

1 General information

The STM32H745/755 and STM32H747/757 lines of microcontrollers (hereinafter referred to as STM32H7

dual‑core) embed an Arm® Cortex®‑M4 with FPU and an Arm® Cortex®‑M7 with FPU core.

Note: Arm is a registered trademark of Arm Limited (or its subsidiaries) in the US and/or elsewhere.

AN5557

General information

AN5557 - Rev 1

page 2/36

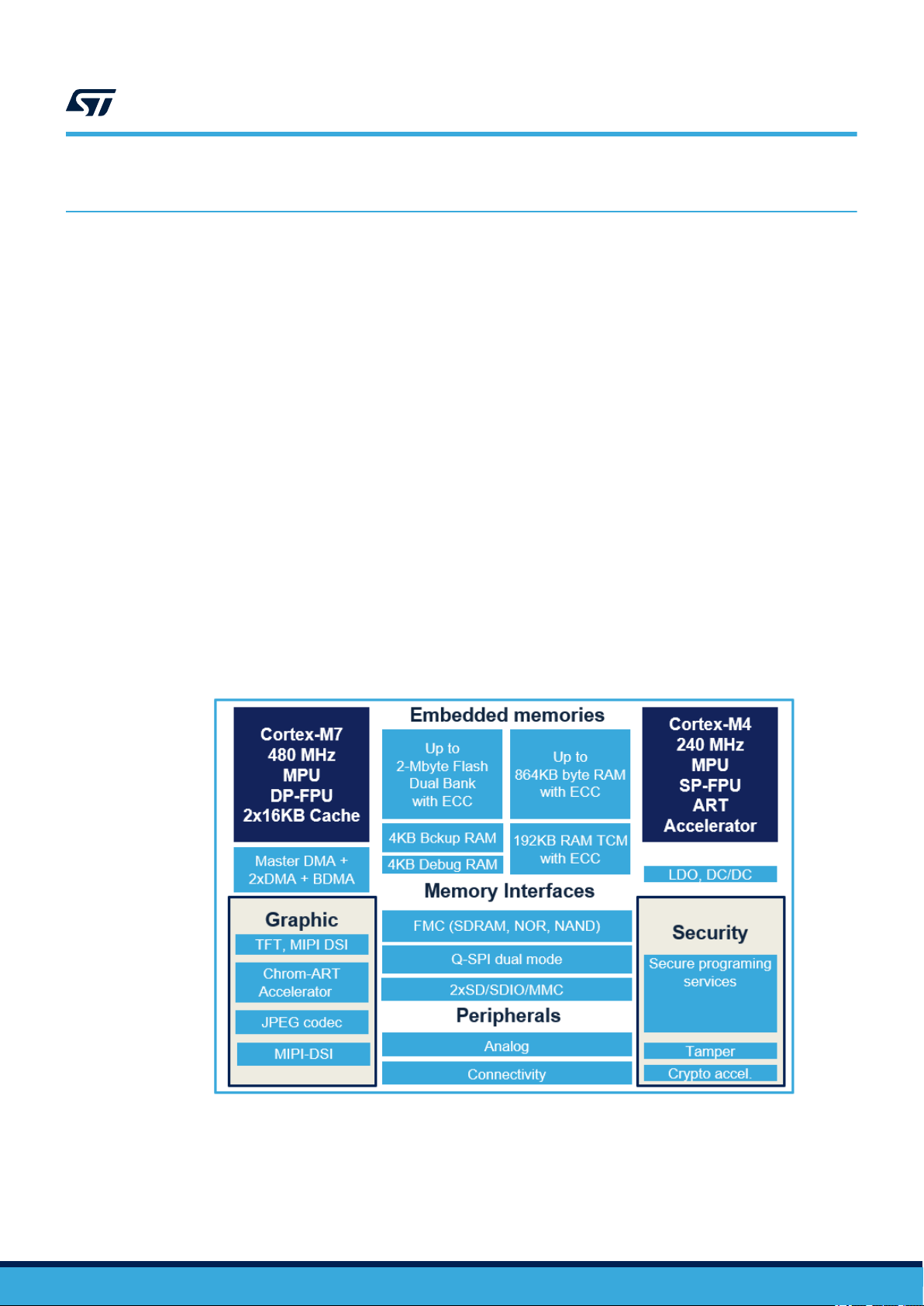

2 System overview

This section introduces the main architecture features of the STM32H7 dual‑core microcontrollers. Those devices

are based on the high-performance Arm® Cortex®‑M7 and Cortex®-M4 32-bit RISC core:

• The Arm® Cortex®-M7 with double-precision FPU processor is designed for applications that demand highprocessing performance, real-time response capability and energy efficiency. It was developed to provide

a low-cost platform that meets the needs of MCU implementation, with a reduced pin count and optimized

power consumption, while delivering outstanding computational performance and low interrupt latency. The

processor supports a set of DSP instructions which allows efficient signal processing and complex algorithm

execution. It also supports single and double precision hardware FPU (floating point unit) which optimize

the memory space as the software libraries to perform floating-point operations is reduced. The Arm

Cortex®-M7 includes a level1 cache (L1-cache) both for the instruction cache (ICACHE) and the data cache

(DCACHE) implementing a Harvard architecture bringing the best performance. An L1-cache stores a set

of data or instructions near the CPU, so the CPU does not have to keep fetching the same data that is

repeatedly used, such as a small loop.

•

The Arm® Cortex®-M4 processor is a high-performance embedded processor which supports DSP

instructions. It was developed to provide an optimized power consumption MCU, while delivering

outstanding computational performance and low interrupt latency.

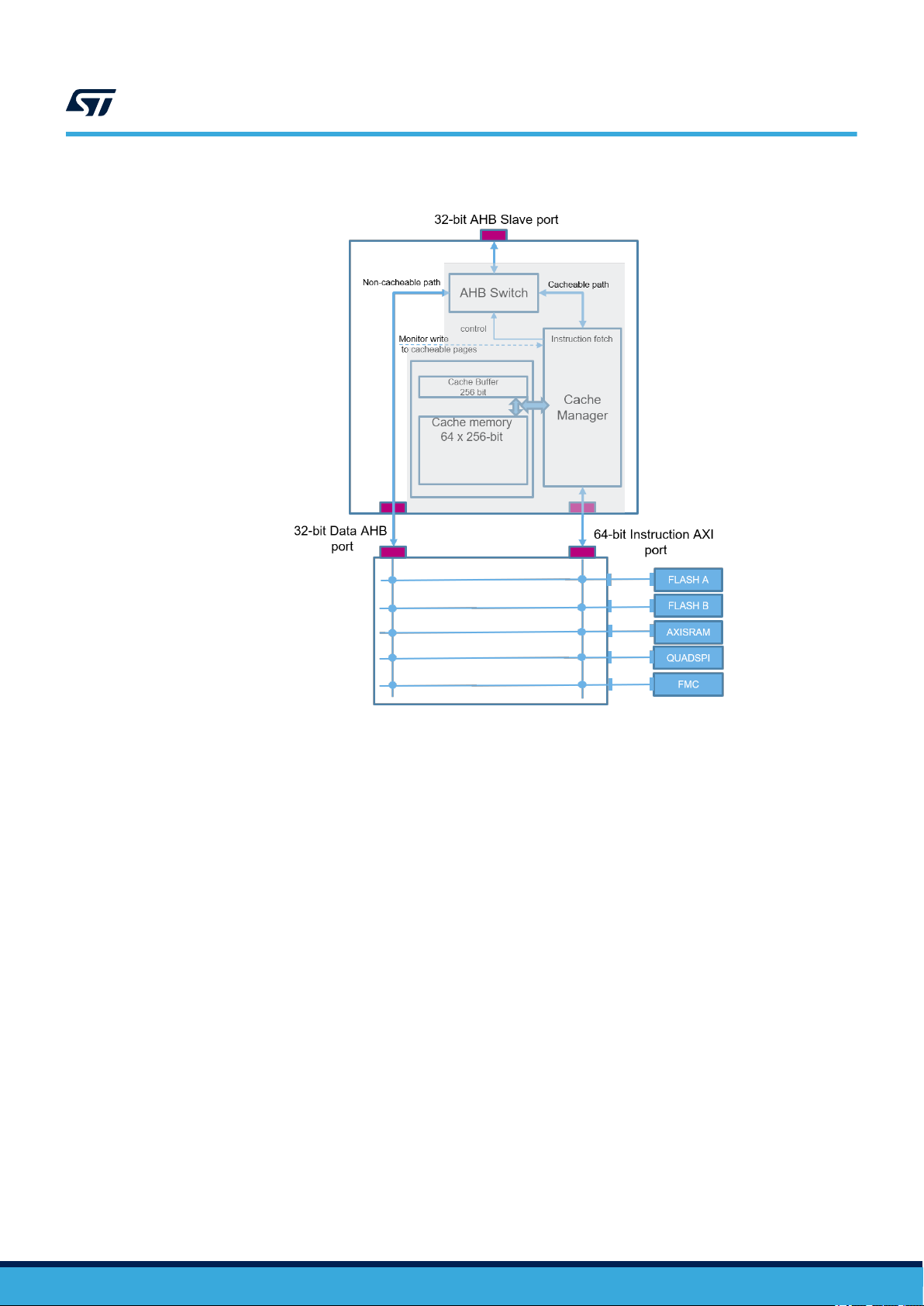

The devices embed a new dedicated hardware adaptive real-time accelerator (ART Accelerator). The acceleration

is achieved by loading selected code into an embedded cache and making it instantly available to Cortex®-M4

core, thus avoiding latency due to memory wait states. This is an instruction cache memory composed of

sixty-four 256-bit lines, a 256-bit cache buffer connected to the 64-bit AXI interface and a 32-bit interface for

non‑cacheable accesses.

The figure below shows the main components of the STM32H7 dual‑core MCUs.

AN5557

System overview

®

Figure 1. STM32H7 dual‑core block diagram

AN5557 - Rev 1

page 3/36

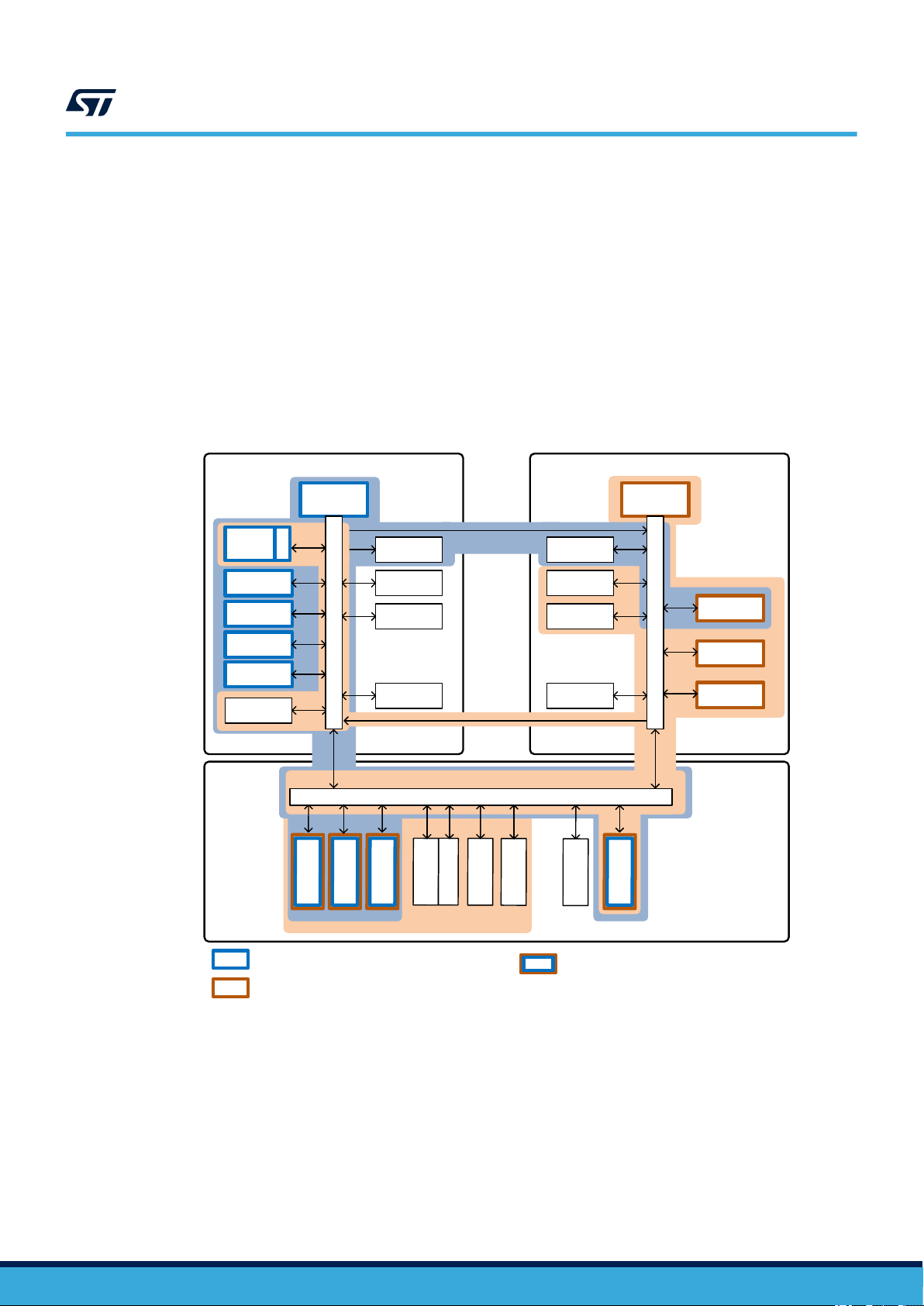

2.1 Dual-core system

The STM32H7 dual‑core devices embed two Arm® cores, a Cortex®‑M7 and a Cortex®‑M4. The Cortex®‑M4

offers optimal performance for real‑time applications while the Cortex®‑M7 core can execute high‑performance

tasks in parallel.

The two cores belong to separate power domains; the Cortex®‑M7 core belongs to D1 domain and the

Cortex®‑M4 core belongs to D2 domain. Thanks to this independency, when an application does not require

for example the Cortex®‑M4, developers can turn its power domain off without any impact on the Cortex®‑M7

core and optimize energy consumption significantly. This dual‑core architecture is highly flexible and designed to

deliver a very high level of performance in combination with the low‑power modes already available on all STM32

microcontrollers.

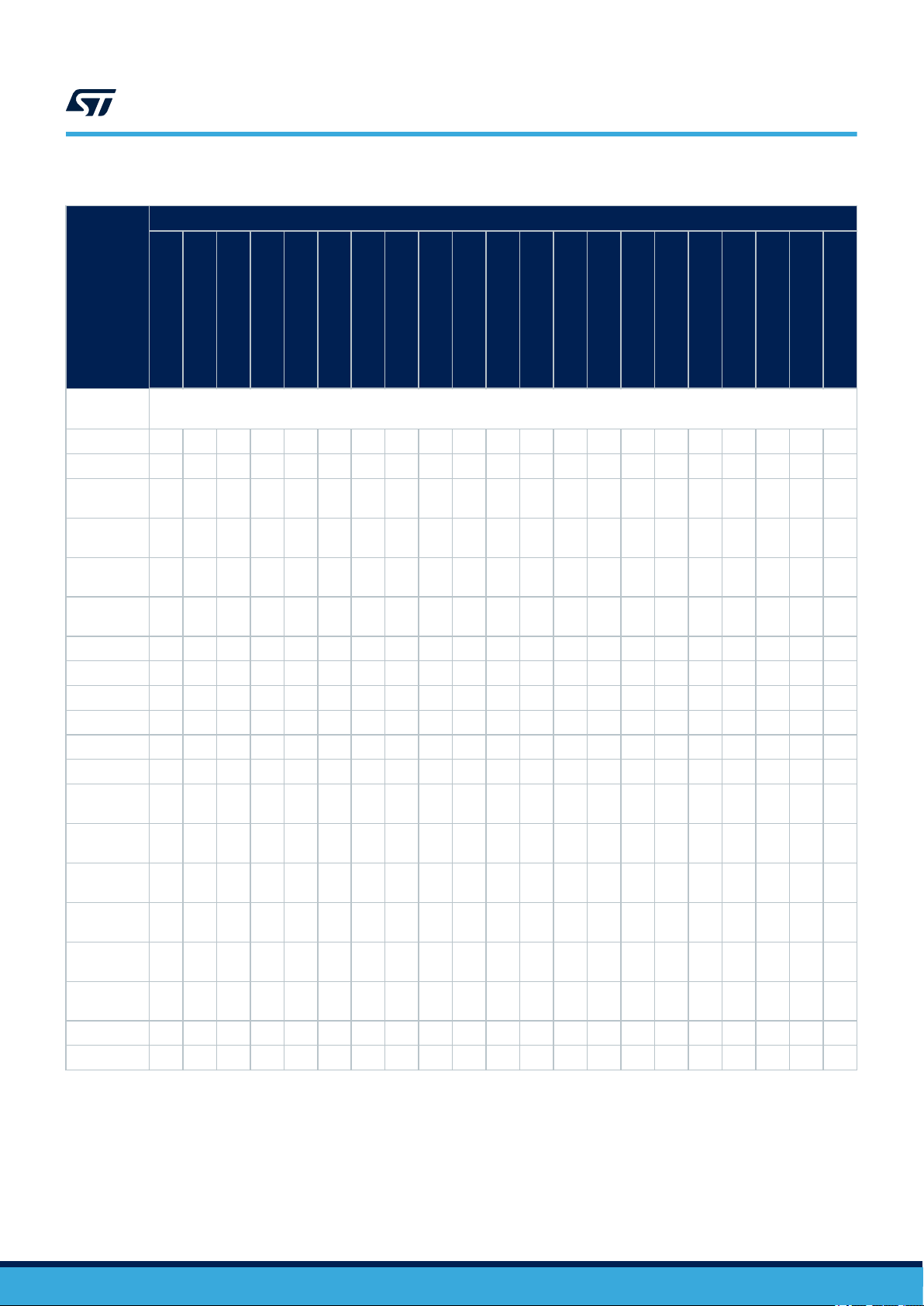

The STM32H7 dual-core devices are among STM32 microcontrollers that embed more than one bus matrix.

Giving the best compromise between performance and power consumption. It also allows efficient simultaneous

operation of high‑speed peripherals and removes bus congestion when several masters are simultaneously

active (different masters located in separated bus matrices). The STM32H7 dual‑core feature three separate bus

matrices. Each bus matrix is associated to a domain:

1. The 64‑bit AXI bus matrix (in the D1 domain): It has a high‑performance capability and is dedicated to

operations requiring high transfer speed. The high bandwidth peripherals are connected to the AXI bus

matrix.

2. The 32‑bit AHB bus matrix (in the D2 domain): communication peripherals and timers are connected to this

bus matrix.

3. The 32‑bit AHB bus matrix (in the D3 domain): reset, clock control, power management and GPIOs are in

this domain.

The Cortex®‑M4 and all bus matrices can run up to 240 MHz. Only the Cortex®‑M7, the ITCM‑RAM and the

DTCM‑RAM can run up to 480 MHz. All bus matrices are connected together by means of inter‑domain buses to

allow a master located in a given domain to have access to a slave located in another domain, except for BDMA

master which access is limited to resources located in the D3 domain. An AXI bus matrix, two AHB bus matrices

and bus bridges allow interconnecting bus masters with bus slaves, as illustrated in Table 1 and Figure 2.

Note: For more details about system and bus architecture refer to the RM0399 “STM32H745/755 and

STM32H747/757 advanced Arm

®

‑

based 32‑bit MCUs”, available from the ST website www.st.com.

AN5557

Dual-core system

AN5557 - Rev 1

page 4/36

Table 1. Bus-master-to-slave interconnection

Bus master / type

AN5557

Dual-core system

LTDC

DMA2D

DMA1 - MEM

DMA1 - PERIPH

Interconnect path and type

DMA2 - MEM

DMA2 - PERIPH

(2)

USBHS1 - AHB

SDMMC2 - AHB

Eth. MAC - AHB

USBHS2 - AHB

Cortex-M4 - S-bus

Cortex-M4 - D-bus

Cortex-M4 - I-bus

Bus slave /

(1)

type

Cortex-M7 - AXIM

Cortex-M7 - ITCM

Cortex-M7 - AHBP

MDMA

SDMMC1

Cortex-M7 - DTCM

MDMA - AHBS

ITCM - - X - - - X - - - - - - - - - - - - - -

DTCM - - - X - X - - - - - - - - - - - - - -

AHB3

periphs

APB3

periphs

Flash bank

1

Flash bank

2

X - - - - X - - - X X X X X X X X X X X -

X - - - - X - - - X X X X X X X X X X X -

X - - - X X - X X X X X X X X X X X X X -

X - - - X X - X X X X X X X X X X X X X -

AXI SRAM X - - - X X - X X X X X X X X X X X X X -

QUADSPI X - - - X X - X X X X X X X X X X X X X -

FMC X - - - X X - X X X X X X X X X X X X X -

SRAM 1 X - - - - X - X - X X X X X X X X X X X -

SRAM 2 X - - - - X - X - X X X X X X X X X X X -

SRAM 3 X - - - - X - X - X X X X X X X X X X X -

AHB1

periphs

APB1

periphs

AHB2

periphs

APB2

periphs

AHB4

periphs

APB4

periphs

- X - - - X - X - X X X X - - - - X - - -

- X - - - X - X - X X X X - - - - X - - -

- X - - - X - X - X X X X - - - - X - - -

- X - - - X - X - X X X X - - - - X - - -

X - - - - X - - - X X X X X X X X X - - X

X - - - - X - - - X X X X X X X X X - - X

SRAM4 X - - - - X - - - X X X X X X X X X - - X

Backup RAM X - - - - X - - - X X X X X X X X X - - X

BDMA - AHB

1. Bold font type denotes 64-bit bus, plain type denotes 32-bit bus.

2. “X” = access possible, “-” = access not possible.

AN5557 - Rev 1

page 5/36

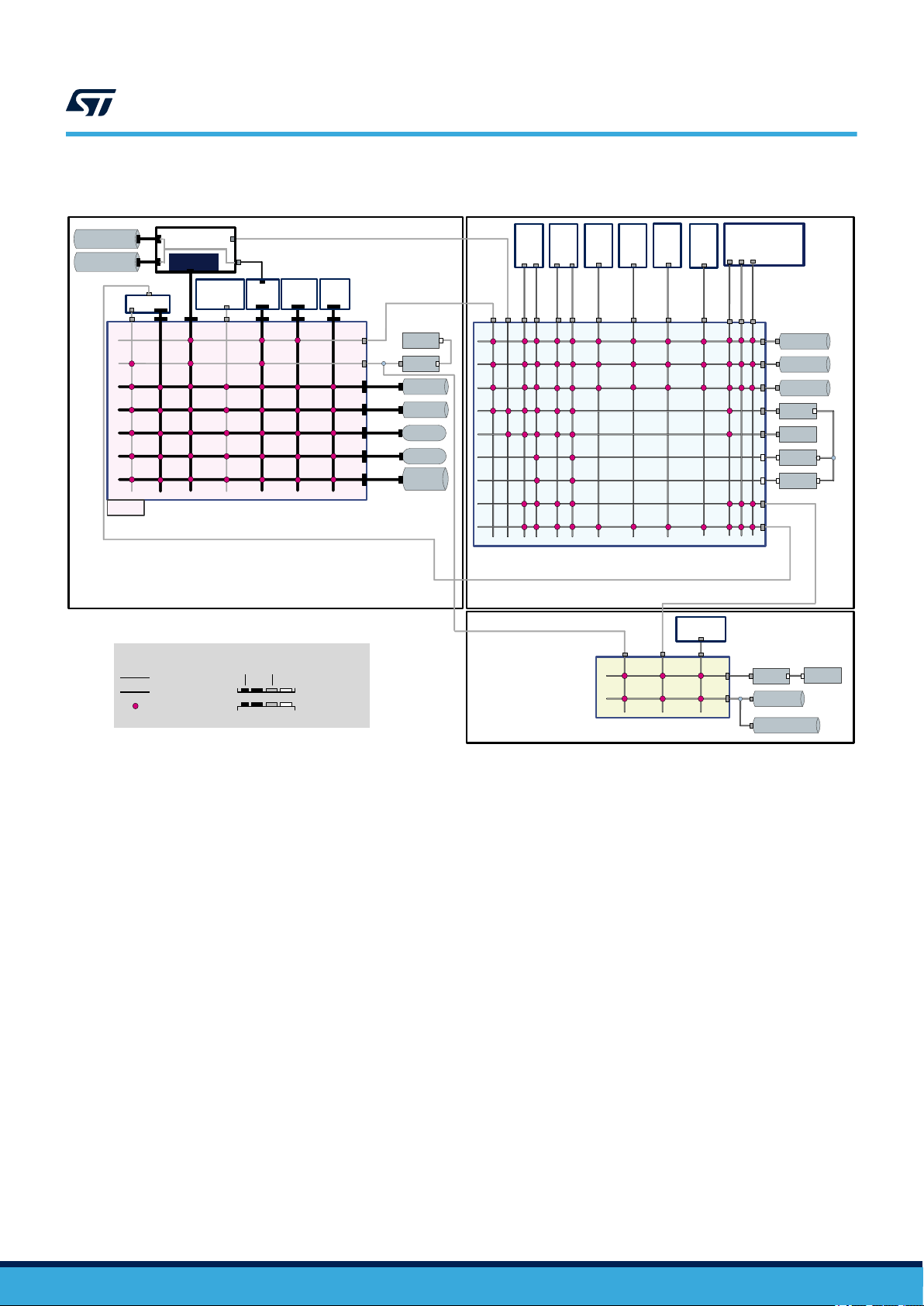

Figure 2. STM32H7 dual‑core system architecture

AN5557

Dual-core system

ITCM-RAM

DTCM-RAM

GPV

Legend

ITCM

L1-Cache

Cortex

(1)

L1-Cache

DTCM

AXIM

ART

D2-to-D1 AHB bus

32-bit bus

64-bit bus

Bus multiplexer

AHBP

®

-M7

AHBS

SDMMC1 MDMA

64-bit AXI bus matrix

D1 Domain

AHB

TCM

AXI

DMA2D

APB

Master interface

Slave interface

LTDC

D1-to-D2 AHB bus

AHB

APB3

AHB

AHB3

AXI

Flash A

AXI

Flash B

AXI

FMC

AXI

QSPI

AXI

AXI

SRAM

APB

D1-to-D3 AHB bus

DMA1

DMA2

DMA1_MEM

DMA2_MEM

DMA2_PERIPH

DMA1_PERIPH

32-bit AHB bus matrix

MAC

Ethernet

SDMMC2

D2 Domain

32-bit AHB bus matrix

D3 Domain

HS1

USB

HS2

USB

D2-to-D1 AHB bus

BDMA

®

Cortex

-M4

I-Bus

D-Bus

S-Bus

SRAM1

SRAM2

SRAM3

AHB1

AHB2

APB1

APB2

D2-to-D3 AHB bus

AHB4

SRAM4

Bckp SRAM

APB

APB4

As illustrated in the Figure 2, the STM32H7 dual‑core devices embed a reduced ART (adaptive real-time) memory

access Accelerator between the D2-to-D1 AHB and the AXI bus matrix. The ART Accelerator is mainly composed

of AHB switch, cache manager and 64 cache lines of 256 bits as shown in Figure 3.

AN5557 - Rev 1

page 6/36

Figure 3. ART block diagram

AN5557

Memory resource assignment

It accelerates cacheable AHB instruction fetch accesses, using a dedicated 64-bit AXI bus matrix port to pre-fetch

code from the internal and external memories of the D1 domain into a built-in cache. It routes all the other AHB

accesses to a dedicated 32-bit AXI bus matrix port connecting the D2-to-D1 AHB with all the internal and external

memories and peripherals of the D1 domain excluding GPV, as well as with the D1-to-D3 AHB. As a consequence

the access of DMAs, Ethernet, except CM4, is always through data 32-bit AHB path.

Note: For more details about ART Accelerator refer to the reference manual RM0399 “STM32H745/755 and

STM32H747/757 advanced Arm®-based 32-bit MCUs”, available from the ST website www.st.com.

2.2

Memory resource assignment

2.2.1 Embedded SRAM

The STM32H7 dual‑core devices feature:

• Up to 864 Kbytes of System SRAM

• 128 Kbytes of data TCM RAM, DTCM RAM

• 64 Kbytes of instruction TCM RAM, ITCM RAM

• 4 Kbytes of backup SRAM

The embedded system SRAM is split into five blocks over the three power domains: AXI SRAM, AHB SRAM1,

AHB SRAM2, AHB SRAM3 and AHB SRAM4.

• D1 domain, AXI SRAM:

– AXI SRAM is accessible through D1 domain AXI bus matrix. It is mapped at address 0x2400 0000 and

accessible by all system masters except BDMA. AXI SRAM can be used for application data which are

not allocated in DTCM RAM or reserved for graphic objects (such as frame buffers)

AN5557 - Rev 1

page 7/36

AN5557

Memory resource assignment

• D2 domain, AHB SRAM:

– AHB SRAM1 is accessible through D2 domain AHB matrix. It is mapped at address 0x3000 0000 and

accessible by all system masters except BDMA. The AHB SRAMs of the D2 domain are also aliased

to an address range below 0x2000 0000 to maintain the Cortex®‑M4 Harvard architecture. The AHB

SRAM1 also mapped at address 0x1000 0000. The AHB SRAM2 also mapped at address 0x1002

0000. The AHB SRAM3 also mapped at address 0x1004 0000. All those AHB SRAMs are accessible

by all system masters through D2 domain AHB matrix. All those AHB SRAMs are accessible by all

system masters through D2 domain AHB matrix.

AHB SRAM1 can be used as DMA buffers to store peripheral input/output data in D2 domain, or as

code location for Cortex®‑M4 CPU (application code available when D1 is powered off). AHB SRAM1

can be used as DMA buffers to store peripheral input/output data in D2 domain, or as code location for

Cortex®‑M4 CPU (application code available when D1 is powered off).

– AHB SRAM2 is accessible through D2 domain AHB matrix. It is mapped at address 0x3002 0000

and accessible by all system masters except BDMA. AHB SRAM2 can be used as DMA buffers to

store peripheral input/output data in D2 domain, or as readwrite segment for application running on

Cortex®‑M4 CPU.

– AHB SRAM3 is accessible through D2 domain AHB matrix is mapped at address 0x3004 0000

and accessible by all system masters except BDMA. AHB SRAM3 can be used as buffers to store

peripheral input/output data for Ethernet and USB, or as shared memory between the two cores.

• D3 domain, AHB SRAM:

– AHB SRAM4 is mapped at address 0x3800 0000 and accessible by most of system masters through

D3 domain AHB matrix. AHB SRAM4 can be used as BDMA buffers to store peripheral input/output

data in D3 domain. It can also be used to retain some application code/data when D1 and D2 domain

in DStandby mode, or as shared memory between the two cores.

The system AHB SRAM can be accessed as bytes, half‑words (16‑bit units) or words (32‑bit units), while the

system AXI SRAM can be accessed as bytes, half‑words, words or doublewords (64‑bit units). These memories

can be addressed at maximum system clock frequency without wait state.

2.2.2 Flash memory

The embedded Flash memory is a central resource for the whole microcontroller. The embedded Flash memory

also proposes a set of security features to protect the assets stored in the non-volatile memory at boot time, at

run-time and during firmware and configuration upgrades.

The embedded Flash memory offers two 64-bit AXI slave ports for code and data accesses, plus a 32-bit AHB

configuration slave port used for register bank accesses. The STM32H7 dual‑core devices embed 2 Mbytes of

Flash memory that can be used for storing programs and data. The Flash memory is organized as 266-bit Flash

words memory that can be used for storing both code and data constants. Each word consists of:

• One Flash word (8 words, 32 bytes or 256 bits)

• 10 ECC bits.

The Flash memory is divided into two independent banks. Each bank is organized as follows:

• 1 Mbyte of user Flash memory block containing eight user sectors of 128 Kbytes (4 K Flash memory words)

• 128 Kbytes of System Flash memory from which the device can boot 2 Kbytes (64 Flash words) of user

option bytes for user configuration

Note: For more details about memory mapping refer to the reference manual RM0399 “STM32H745/755 and

STM32H747/757 advanced Arm

®

‑

based 32‑bit MCUs”, available from the ST website www.st.com.

AN5557 - Rev 1

page 8/36

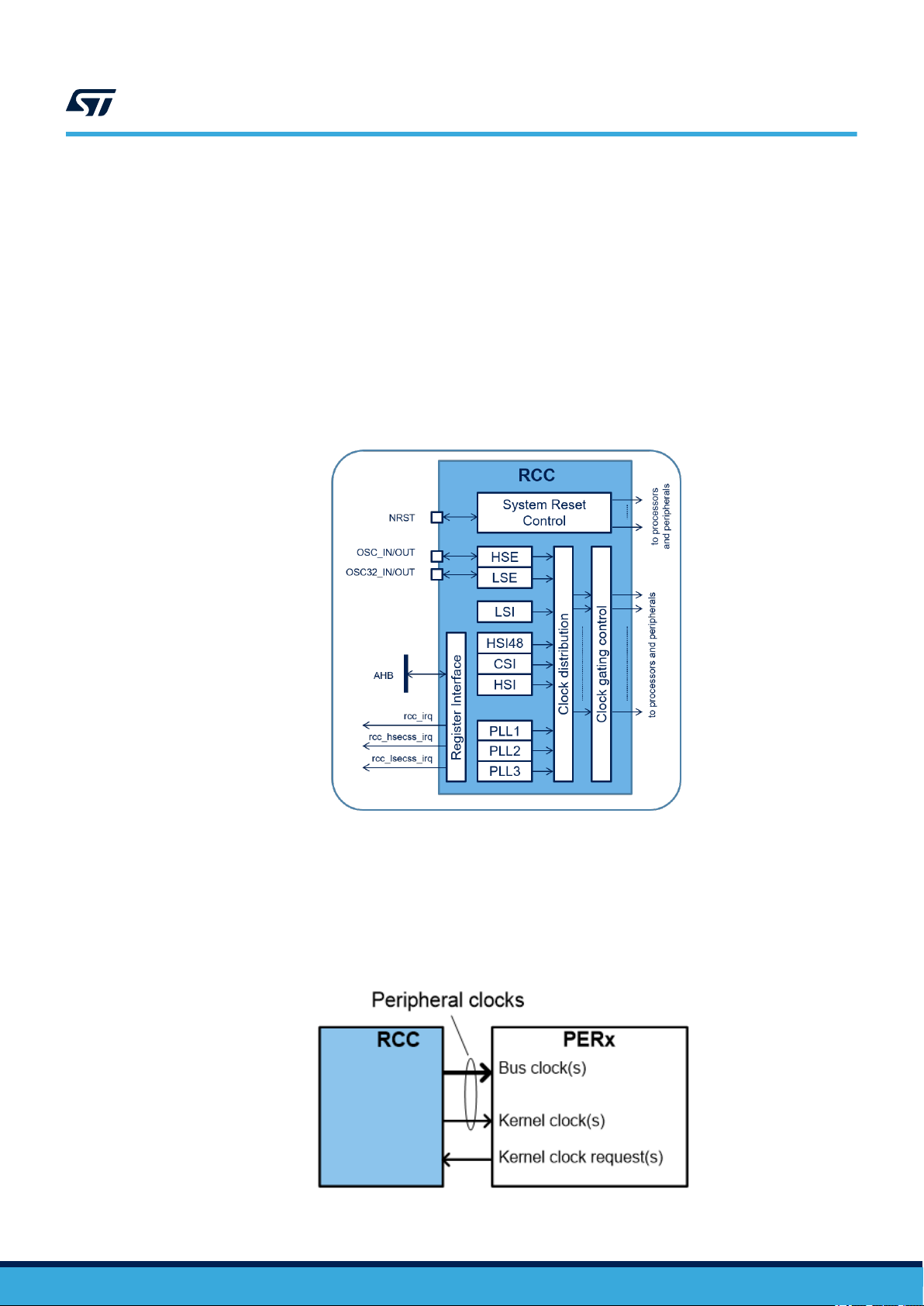

2.3 Peripherals allocation

The peripheral allocation is used by the reset and clock controller (RCC), to automatically control the clock gating

according to the CPUs and domain modes, and by the power controller (PWR) to control the supply voltages

of D1, D2 and D3 domains. As presented in Figure 4. RCC block diagram, the RCC is mainly composed by

the system reset control, the clock distribution, the clock gating control, the register interface, and different clock

sources. The clock gating control is responsible for the peripheral allocation. The RCC manages the reset, the

system and peripheral clocks generation. It uses four internal oscillators, two oscillators for an external crystal or

resonator, and three phase-locked loops (PLL). Therefore, many peripherals have their own clock, independent

of the system clock. The RCC provides high flexibility in the choice of clock sources, which allows the system

designers to meet both power consumption and accuracy requirements. The numerous independent peripheral

clocks allow a designer to adjust the system power consumption without impacting the communication baud rates,

and to keep some peripherals active in low-power mode.

AN5557

Peripherals allocation

Figure 4. RCC block diagram

AN5557 - Rev 1

Many peripheral in STM32H7 dual

bus interface, and the clock for the peripheral specific interface. Generally, the clocks for the data and control

streams via the processor bus interface are named ‘Bus clock’, and the clock for the peripheral specific interface

are named ‘kernel clocks’.

As shown in Figure 5, the peripheral clocks represent the clocks received by the peripheral: ‘bus clock’ and

‘kernel clock’.

‑core, have different clocks for the data and control streams via the processor

Figure 5. Peripheral clock exchange

page 9/36

AN5557

Peripherals allocation

Having a separate bus clock and kernel clock allows the application to change the interconnect and processor

working frequency without affecting the peripheral. For some peripheral it is also possible to disable the bus

clock as long as the peripheral does not need to transfer data to the system. So, it gives a good flexibility on

the frequency selection for the bus processor and memories, and the real need of the peripheral interface. For

example, the UARTs have a kernel clock which is used, among other things, by the baud rate generator for

the serial interface communication, and an APB clock for the register interface. Thus if the system clock has

changed the baud rate is not affected. In addition, some peripherals are able to request the kernel clock when

they detected specific events.

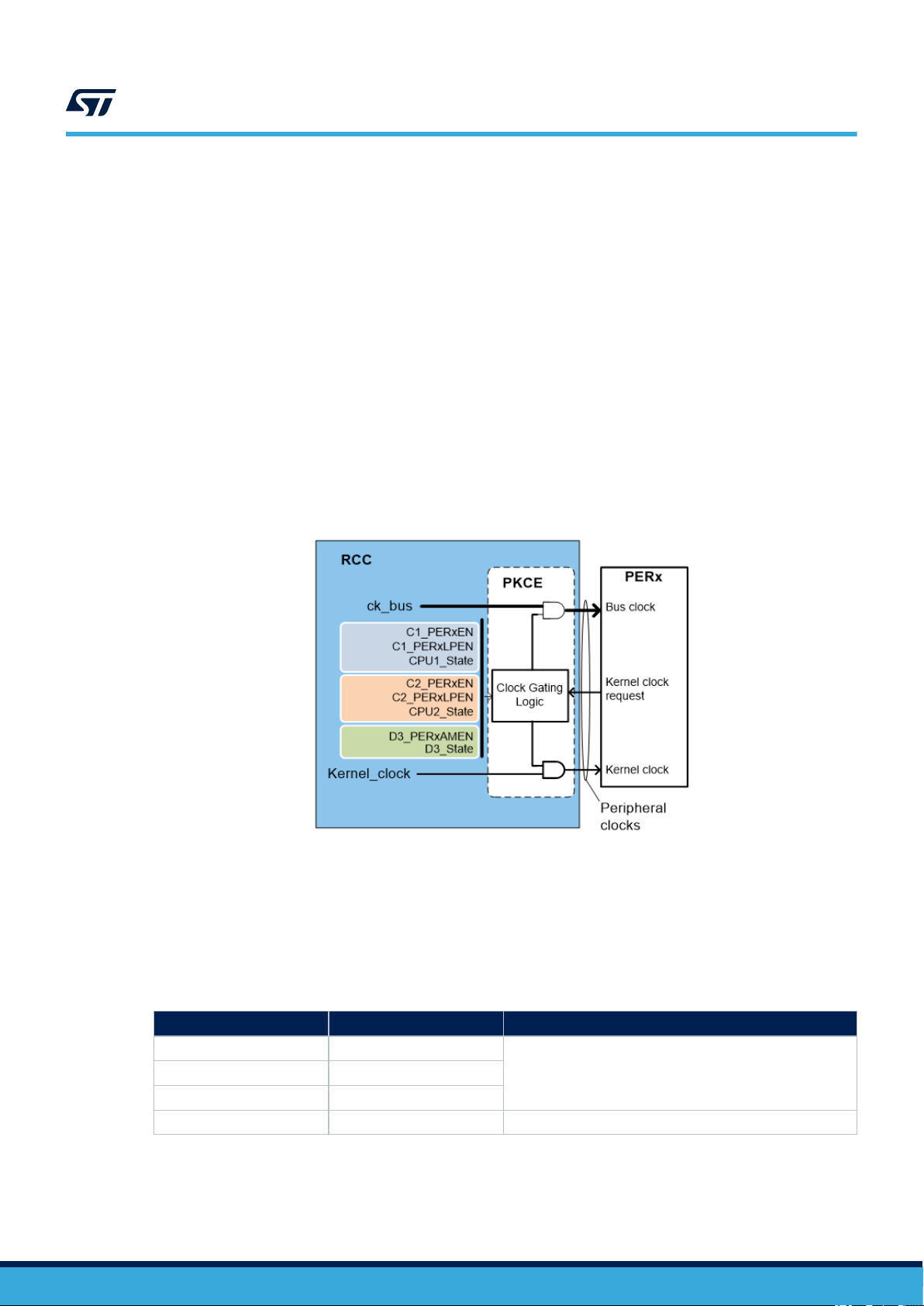

As mentioned before, the peripherals generally receive two types of clocks: bus clock and kernel clock. Those

clocks can be one or several for each peripheral. Each processor can control the clock gating of the peripheral

clocks via dedicated registers located into the RCC.

As illustrated in Figure 6, the gating of the peripheral clocks depends on several parameters:

• The clock enables bits, each processor has a dedicated control bit for that, named C1_PERxEN and

C2_PERxEN

• The low-power clock enables bits : C1_PERxLPEN and C2_PERxLPEN

• The processors states: CRUN, CSLEEP or CSTOP

• The autonomous bits for peripherals located in D3 domain: D3_PERxAMEN

Figure 6. Peripheral clock gating

AN5557 - Rev 1

In Table 2, the operation of peripheral allocation is describing as below:

• When setting the bit C1_PERxEN to ‘1’ indicates that the peripheral PERx is enabled for the CPU1

• When setting the bit C2_PERxEN to ‘1’ indicates that the peripheral PERx is enabled for the CPU2

• When both C1_PERxEN/C2_PERxEN are set, the peripheral clock follows the two CPU states. For

example, if CPU1 is in stop, and CPU2 is in run the clock to the peripheral remains enabled

Table 2. Peripheral clock allocation

CPU1

CRUN CSTOP

CSTOP CRUN

CSTOP CSTOP Disabled

CPU2 Peripheral clock

EnabledCRUN CRUN

page 10/36

It is important to notice that the RCC offers two register sets, allowing each processor to enable or allocate

peripherals. The peripheral allocation informs the RCC that the CPU1 or CPU2 enabled a peripheral. This

information is used by the RCC for the clock control in low-power modes. So before using a peripheral the CPUs

must allocate it. The same peripheral can be allocated by both processors, it is up to the application to avoid

resources conflicts.

As introduced in the figure below, some peripherals are implicitly allocated to a processor:

• The FLASH, D1SRAM1, ITCM, DTCM1 and DTCM2 are implicitly allocated to CPU1, the CPU2 can allocate

any of them, but by default they are not allocated to CPU2.

• The D2SRAM1, D2SRAM2 and D2SRAM3 are implicitly allocated to CPU2, the CPU1 can allocate any of

them, but by default they are not allocated to CPU1.

Note: Implicitly means architecturally tied to a processor.

Figure 7. Peripheral allocation

AN5557

Peripherals allocation

FLASH

AXISRAM

ITCM

DTCM1

DTCM2

ART

D3

FLITF

D1

CPU1

IWDG1

SDMMC1

PER...

PER...

Bus Matrix 1

PER...

IWDG2

RCC

...

DMA1

CPU1_SS

CPU2_SS

Bus Matrix 3

DMAMUX

I2C4

SAI4

SPI5

SAI1

I2C2

PER...

PER...

...

D2

CPU2

Bus Matrix 2

SRAM1

...

SRAM4

SRAM2

SRAM3

Peripherals implicitly allocated to CPU1

Peripherals implicitly allocated to CPU2

Peripherals implicitly allocated to both

CPUs

Some other peripherals are implicitly allocated to both processors, this is the case for the IWDG1, IWDG2, RCC,

PWR, AIEC and D3SRAM1. When a CPU allocates a peripheral, this peripheral is linked to the processor state

for the low-power modes. The CPU, plus the peripherals allocated by this CPU, and the associated interconnect

is considered by the RCC as a CPU sub-system. The D1 and D2 domain core voltage can be switched-off. To

give a simple example of the use of the peripheral allocation by the RCC, the RCC doesn't allow a domain to

be switched-off, if one of the peripheral of this domain is used by the processor of the other domain which is not

switched-off.

Note: For more details about peripherals allocation, refer to the application note AN5215 “STM32H747/757 advanced

power management”, available from the ST website www.st.com.

AN5557 - Rev 1

page 11/36

2.4 D1 sub-system

The D1 domain is intended for high speed processing and graphics features. Thanks to the AXI bus matrix, this

domain encompasses high bandwidth features and smart management. As shown in the figure below, it contains

the Cortex®‑M7 core running at up to 480 MHz with 16-Kbyte I-cache and 16-Kbyte D-cache, the embedded

memories, the external memories like FMC, Quad-SPI and SD/MMC, the graphic components like JPEG Codec,

DMA2D and LTDC/DSI controller.

The internal memory resources are:

• AXI SRAM (D1 domain) accessible through D1 domain AXI bus matrix:

– AXI SRAM (512-Kbyte) mapped at address 0x2400 0000

– Supports bytes, half-words, full-words or double-words accesses

• ITCM accessible through D1 domain 64-bit ITCM bus

• DTCM accessible through D1 domain 2x32-bit DTCM bus

• Flash memory: two 1MB independent Flash banks

AN5557

D1 sub-system

Figure 8. D1 domain block diagram

AN5557 - Rev 1

page 12/36

2.5 D2 sub-system

The D2 domain is intended for generic peripheral usage (ADC, FDCAN, etc.), communication and data gathering

that it can be processed later in D1 domain. As shown in the figure below, It contains the Cortex®-M4 core running

at up to 240MHz, the embedded memories, the AHB bus matrix, masters like DMA, USB, Ethernet and other

peripherals like FDCAN, UART, SPI, SD/MMC and Timers. Most of the memories dedicated to I/O processing and

most of the peripherals that are less bandwidth demanding. The D2 SRAMs are optimal location for Cortex®-M4

core application data and code. The D2 SRAMs can be used by local DMAs for data transfer from/to peripherals

in this domain. The Data can be transferred to D1 processing domain at end of transfer via MDMA.

AHB SRAM (D2 domain) is accessible through D2 domain AHB matrix:

• AHB SRAM1 (128 KByte) mapped at address 0x3000 0000 and 0x1000 000

• AHB SRAM2 (128 KByte) mapped at address 0x3002 0000 and 0x1002 000

• AHB SRAM3 (32 KByte) mapped at address 0x3004 0000 and 0x1004 000

These memories support bytes, half-words or full-words accesses.

The SRAM1, SRAM2, and SRAM3 can be used for code execution or as buffers to store in/out data of peripherals

located in the D2 domain such as Ethernet and USB. These data can be buffers and descriptors or I2S audio

frames or others.

AN5557

D2 sub-system

Figure 9. D2 domain block diagram

AN5557 - Rev 1

page 13/36

2.6 D3 system domain

The D3 domain provides system management and low power operating modes feature. As shown in

Figure 10. D3 domain block diagram. It contains the embedded memories, the AHB bus matrix, a basic DMA

(BDMA), peripherals like I2C, SPI, ADC, LPTIM, LPUART and system peripherals like RCC, PWR, GPIO. Those

low-power peripherals and memories designed to manage low-power modes. D3 domain is designed to be

autonomous, and embeds a 64-Kbyte RAM, a basic DMA controller (BDMA), plus low-power peripherals to run

basic functions while D1 and D2 domains can be switched off to save power. So, the D3 SRAM can be used to

retain data while the D1 and D2 domains enter DStandby mode.

AHB SRAM (D3 domain) accessible through D3 domain AHB matrix:

• AHB SRAM4 (64 KByte) mapped at address 0x3800 0000 and accessible by most of system masters. It

supports bytes, half-words or full-words accesses.

AN5557

D3 system domain

Figure 10. D3 domain block diagram

AN5557 - Rev 1

page 14/36

3 Resources for dual-core application

3.1 Dual-core communication

When application is running on different CPUs may be independent or cooperating. In many cases they need

mechanisms for:

• Data sharing (events happening)

• Resources sharing and synchronization

The Inter-processors communication (IPC) is the mechanism used by different processors to communicate or

exchange data. These mechanisms ensure safe parallel computation synchronization and application modularity.

This mechanism allows message passing by send and receive messages from other process. It uses a common

memory area with other process. The synchronization with other processors is allowed by semaphores and

interrupts.

There are three possible solutions to be implemented with STM32H7 which are setup communication/

synchronization protocol using the device resources, the FreeRTOS IPC module (from STM32Cube H7 Firmware)

or the OpenAMP framework.

The IPC Module works with FreeRTOS or OS-less application. This module uses the stream buffers to transfer

the data between CPUs and a shared memory region between the core to allocate Stream buffers.

As shown in the figure below, the FreeRTOS IPC module is a set of APIs used by application tasks to exchange

data with a dedicated Stream buffer per Task (only one sender and one receiver).

AN5557

Resources for dual-core application

3.2 Dual-core boot

At startup, the boot memory space is selected by the BOOT pin and BOOT_ADDx option bytes, allowing to

program any boot memory address from 0x0000 0000 to 0x3FFF FFFF which includes all Flash address space,

all RAM address space (ITCM, DTCM RAMs and SRAMs) and the System memory bootloader.

The boot address is provided by option byte and default programmed value to allow:

• CM7 Boots from Flash memory at 0x0800 0000 when Boot0=0

• CM4 Boots from Flash memory at 0x0810 0000 when Boot0=0

• Boot respectively from System memory or SRAM1 when Boot0=1

The values on the BOOT pin are latched on the 4th rising edge of SYSCLK after reset release. It is up to the user

to set the BOOT pin after reset as shown in the figure below.

Figure 11. FreeRTOS IPC block diagram

AN5557 - Rev 1

page 15/36

AN5557

Dual-core boot

Figure 12. Boot selection mechanism

If the programmed boot memory address is out of the memory mapped area or a reserved area, the default boot

fetch address is:

• BCM7_ADD0: FLASH at 0x0800 0000

• BCM4_ADD0: FLASH at 0x0810 0000

• BCM7_ADD1: System Memory at 0x1FF0 0000

• BCM4_ADD1: SRAM1 at 0x1000 0000

When Flash level 2 protection is enabled, only boot from Flash or system is available. If boot address is out

of the memory range or RAM address, then the default fetch is forced from Flash at address 0x0800 0000 for

Cortex®‑M7 and Flash at address 0x0810 0000 for Cortex®-M4. In the STM32H7 dual‑core, to maximize energy

efficiency, each core operates in its own power domain and can be turned off individually when not needed. The

two cores can boot alone or in the same time according to the option bytes as shown in Table 4.

Table 3. Boot order

BCM7

0 0

0 1

1 0

1 1

BCM4 Boot order

Cortex®-M7 is booting and Cortex®-M4 clock is gated

Cortex®-M7 clock is gated and Cortex®-M4 is booting

Cortex®-M7 is booting and Cortex®-M4 clock is gated

Both Cortex®-M7 and Cortex®-M4 are booting

The enabled CPU is defined as the master, it is responsible for system initialization. The other CPU perform

specific initialization. This allows to implement safe booting and proper initialization on power-up.

As shown in Figure 13, three boot cases are provided to build any firmware application where both cores are

used.

The first case is BCM7 = 1 and BCM4 = 0. This is mainly dedicated for parts where CPU1 (Cortex-M7) is booting

and CPU2 (Cortex‑M4) clock is gated. System Init, System clock, voltage scaling and L1-Cache configuration are

done by CPU1 (Cortex-M7) seen as the master CPU. Once done, CPU2 (Cortex-M4) is released through hold

boot function.

The second case is BCM7 = 0 and BCM4 = 1. This is mainly dedicated for parts where CPU2 (Cortex-M4)

is booting and CPU1(Cortex-M7) clock is gated. System Init, System clock and voltage scaling are done by

CPU2(Cortex-M4) seen as the master CPU. Once done, CPU1 (Cortex-M7) is released through hold boot

function which is an RCC feature.

The third case is BCM7 = 1 and BCM4 = 1. This is mainly dedicated for devices where CPU1 (Cortex-M7) and

CPU2 (Cortex-M4) are booting at once. System Init, System clock, voltage scaling and L1-Cache configuration

are done by CPU1 (Cortex-M7). As we do not have to run the System Init twice, the CPU2 (Cortex-M4) can run

another Init needed by the application. Also, customer can choose to use the low power mode and put CPU2

(Cortex-M4) in deep sleep mode by putting Domain D2 in STOP mode to save power consumption.

AN5557 - Rev 1

page 16/36

AN5557

Building example based on STM32CubeMX

Figure 13. Boot mode

Note: For more details about boot mode and boot templates refer to the reference manual RM0399 “STM32H745/755

and STM32H747/757 advanced Arm®-based 32-bit MCUs” and the STM32Cube_FW_H7 firmware, available

from the ST website www.st.com.

3.3 Building example based on STM32CubeMX

The STM32CubeMX is a graphical tool that allows a very easy configuration of STM32 microcontrollers. It

provides the means to configure pin assignments, the clock tree, integrated peripherals, and simulate the power

consumption of the resulting project. It uses a rich library of data from the STM32 microcontrollers portfolio.

The application is intended to ease the initial phase of development, developers to select the best product with

regards to features and power.

AN5557 - Rev 1

page 17/36

3.3.1 Create new project using STM32CubeMX

Run STM32CubeMX tool, the home page appears as shown in the figure below.

Figure 14. STM32CubeMx main screen

AN5557

Building example based on STM32CubeMX

Click on MCU selector access then enter the MCU part number, or the available products can be filtered based on

the specific requirements, as illustrated in the figure below. Then, double click on the chosen product from the list.

Figure 15. MCU selector screen

AN5557 - Rev 1

page 18/36

3.3.2 Pinout configuration

The next step is the peripheral allocation for each CPU which can be applied in the Pinout and Configuration

tab. Then select the peripherals to be used and, where is applicable, assign pins to their inputs and outputs.

Independent GPIOs can also be configured. Signals are assigned to default pins, but they can be transferred to

alternate locations, which are displayed by CTRL-clicking on the pin. For example, when the I2C1 peripheral is

enabled, the tool automatically assigns it to the default pins. We notice in the figure below that some peripherals

are allocated to their default location and are no selectable. Like IWDG1 is in Cortex-M7 and D3 power domain.

Other peripherals, like ADC1 is in D2 power domain but it can be allocated to Cortex-M7 or Cortex-M4. The

tool automatically takes into account the most bonds between the peripherals and the software components it

manages.

AN5557

Building example based on STM32CubeMX

Figure 16. Pinout and configuration screen

AN5557 - Rev 1

page 19/36

3.3.3 Clock configuration

The clock configuration tab provides a schematic overview of the clock paths, along with all clock sources,

dividers, and multipliers. Actual clock speeds are visible. Active and enabled clock signals are highlighted in blue.

Drop-down menus and buttons serve to modify the actual clock configuration. As shown in Figure 17, for example

it can chose the PLLCLK clock source in the System Clock Mux to generate the clock to Cortex-M7 (CPU1)

and Cortex-M4 (CPU2) clocks. If a configured value is out of specification, it immediately turns red to highlight a

problem. It also works the other way; enter the required clock speed in a blue frame and the software attempts to

reconfigure multipliers and dividers to provide the requested value. Right-click on a clock value in blue and select

"lock" to lock it to prevent modifications.

AN5557

Building example based on STM32CubeMX

Figure 17. Clock configuration screen

AN5557 - Rev 1

page 20/36

3.3.4 Project configuration and code generation

As introduced in Figure 18, switch to the Project manager tab, then select Project to fill Project Name, Project

Location fields and select the suitable Toolchain/IDE. The user can click on Code Generator or Advanced Settings

to change for example the generated files settings.

Figure 18. Project manager screen

AN5557

Building example based on STM32CubeMX

When all inputs, outputs, and peripherals are configured, the code is ready to be generated by clicking on

GENERATE CODE.

AN5557 - Rev 1

page 21/36

3.3.5 Power consumption calculator

Click on Tools tab to find the Power consumption calculator, as illustrated in Figure 19. This configuration

pane is mostly informative, summarizing the selected MCU and the default power source. Parameters such

as temperature and voltage may even be defined, depending on the MCU selected and the available power

consumption data. The Battery selection pane is used to select or define a battery type. The battery source

is optional and, if defined, may be used in only selected sequence steps, simulating a device that works both

independently and connected to an external power source. Information and help sections include useful notes

for the user. In PCC tab click on New Step, select the system power mode, the domain CPU power mode, the

memory fetch type and other preferences adequate with his application.

AN5557

Debugging the multicore application

Figure 19. PCC screen

Note: Note: For more information about STM32CubeMx configuration refer to User Manual UM1718 “STM32CubeMX

for STM32 configuration and initialization C code generation” available from the ST website www.st.com.

3.4

Debugging the multicore application

The debug can be controlled via a JTAG/Serial-wire debug access port, using industry standard debugging tools.

The debug infrastructure allows debugging one core at a time, or both cores in parallel. The trace port performs

data capture for logging and analysis. A 4-Kbyte embedded trace FIFO (ETF) allows recording data and sending

them to any com port. In Trace mode, the trace is transferred by DMA to system RAM or to a high-speed interface

(such as SPI or USB). It can even be monitored by a software running on one of the cores. Unlike hardware FIFO

mode, this mode is invasive since it uses system resources which are shared by the processors.

The devices offer a comprehensive set of debug and trace features on both cores to support software

development and system integration:

• Breakpoint debugging

• Code execution tracing

• Software instrumentation

• JTAG debug port

• Serial-wire debug port

• Trigger input and output

• Serial-wire trace port

• Trace port

•

Arm® CoreSight™ debug and trace components

AN5557 - Rev 1

page 22/36

AN5557

Debugging the multicore application

The debug components are distributed across the power domains D1 , D2 and D3 as illustrated in the figure

below.

Figure 20. Block diagram of the device debug

3.4.1 Embedded trace macrocell (ETM)

The Real-time trace module providing instruction trace of a processor. As shown in the figure below, the

ETM is used with the TPIU comprising a clock and four data outputs TRACECLK, four data outputs and

TRACEDATA(3:0).

Figure 21. Block diagram of ETM debug

AN5557 - Rev 1

page 23/36

3.4.2 Instrumentation trace macrocell (ITM)

The ITM is a CoreSight™ block that generates trace information into packets, as illustrated in the figure below.

The following sources of the ITM trace packet are:

• Software trace. Software can write directly to ITM stimulus registers to generate packets.

• Hardware trace. The DWT generates these packets, and the ITM outputs them.

• Local Time stamping: Provides timing information on the ITM trace packets

• Global Time stamping: generated using the system-wide 64-bit count value coming from the Timestamp

Generator component

Figure 22. Block diagram of ITM debug

AN5557

Debugging the multicore application

3.4.3 Data watchpoint trace (DWT)

The DWT is a CoreSight™ component that provides watchpoints, data tracing, and system profiling for the

processor, as presented in the figure below.

The main components of the DWT are Data watchpoint and data tracing. It is responsible for:

• Halt the core when a memory area is accessed (Read, Write or both)

• Send data address and/or PC via ITM

• ETM Trigger

It also contains Counters for Clock cycles, Folded instructions, load store unit (LSU), Sleep cycles and number of

cycles per instruction.

3.4.4 Trace funnel (CSTF)

The trace funnel (CSTF) is a CoreSight™ component that combines the four trace sources into one single ATB.

The CSTF has four ATB slave ports, and one ATB master port. An arbiter selects the slave ports according to a

programmable priority. This slave ports are connected as follows:

• S0: Cortex-M7 ETM

• S1: Cortex-M7 ITM

• S2: Cortex-M4 ETM

• S3: Cortex-M4 ITM

The trace funnel registers allow the slave ports to be individually enabled, and their priority settings to be

configured. The priorities can be modified only when trace is disabled.

Figure 23. Block diagram of DWT debug

AN5557 - Rev 1

page 24/36

3.4.5 Cross trigger interfaces (CTI)

The Cross-Trigger Interfaces is a CoreSight™ component. As introduced in the figure below, it enables the

debug logic and ETM to interact with each other and with other components of the CoreSight™. It allows cores

synchronization (Run/Halt) and triggers for the traces modules.

3.4.6 Embedded trace FIFO (ETF)

The ETF is an 8-kbyte memory which captures trace data from four trace sources, namely the ETM and ITM of

each CPU core. Once the trace stopped, the buffer can be read out via three methods:

• The Trace Port: with the TPIU enabled, the contents of the buffer are output over the trace port

• The debugger via the Debug Port

• One of the cores

AN5557

Debugging the multicore application

Figure 24. Block diagram of CTI debug

3.4.7 Microcontroller debug unit (DBGMCU)

The DBGMCU is not a CoreSight™ component and the DBGMCU registers are not reset by system reset but only

by power on reset.

The main functionalities of the DBGMCU unit are:

• Emulated low power mode: Maintain the clock to the processor and debug component active in low power

mode

• Stop the clock to certain peripherals when either processor is stopped in debug mode

• DBGMCU registers are accessible to the debugger via the APB-D bus at base address 0xE00E1000 and by

both processor cores at base address 0x5C001000

Note: For more details about STM32H7 dual‑core debugging refer to the application note AN5286 “STM32H7x5/x7

dual-core microcontroller debugging” available from the ST website www.st.com.

AN5557 - Rev 1

page 25/36

4 Application partitioning examples

As shown in the figure below, the device can be divided in three main blocks. The D1 domain provides processing

and graphics features. The D2 domain provides peripheral management. The D3 domain provides system

management and low power operating modes feature. The dual‑core synchronization and communication is

managed by the Inter-Processor Communication layer.

Figure 25. STM32H7 dual‑core functional partitioning

AN5557

Application partitioning examples

4.1

Dual-core application design considerations

The dual‑core application design considerations can be divided in three main parts which are system design

considerations, software design considerations and dual-core application design.

The system design considerations are mainly based on four methodologies. First, the processors and domains

resources assignment to different tasks, second the memory mapping, then the interrupts distribution and the

inter-processor communication/ synchronization.

The software design considerations are based on three process, which are task partitioning, data sharing and

overheads avoidance. First, the task partitioning should allow dependencies/ concurrency reduction and avoid

overheads that limit execution time benefits. Then, the Data sharing that use a proper data layout in memory to

minimize overhead and respect dependency relationships for data synchronization and coherency. Finally, avoid

overheads by maximizing data locality and minimizing contention and wait for resources.

The dual-core application design consist in three principal steps:

• The first step is to analyze the serial implementation bottleneck and identify the part of the program to

improve.

• The second step is to set the critical application requirements to meet performance/power compromise.

• The third step is to identify the appropriate parallel design, it can be a fully independent tasks or

collaborating tasks.

AN5557 - Rev 1

page 26/36

4.2 Task partitioning schema

The main task partitioning schema are the parallel partitioning, the data processing partitioning, and the pipelined

partitioning.

The task parallel partitioning is used when tasks can be decomposed into independent sub-tasks and then

allocated to a CPU for execution, as illustrated in Figure 26. Task parallel partitioning. Those tasks are executed

concurrently on either the same or different sets of data. The parallelization of the design is related to the number

of independent tasks.

AN5557

Task partitioning schema

Figure 26. Task parallel partitioning

The data processing partitioning is used when different subsets of the same data can be processed in parallel

by the two CPUs, as illustrated in Figure 27. This partition is relevant for regular data structures like arrays and

matrices because it is easy to handle each element in parallel. It focuses on distributing the data across the

CPUs, which operate on the data in parallel. The parallelization of the design is related to data input size.

Figure 27. Data processing partitioning

The pipelined partitioning allows the execution of multiple instructions on the same data, which is allocated on

different CPUs, as shown in Figure 28. This partitioning split up the processing into stages and each stage

operate a specific part of the algorithm at a time, the output of one stage is the input of the next stage.

Figure 28. Pipelined partitioning

AN5557 - Rev 1

page 27/36

Example 1: JPEG images streaming over network

4.3 Example 1: JPEG images streaming over network

The application tasks can be split on the two CPUs, As shown in the figure below. The JPEG images transfer task

allocated to CPU1 and the Covert RGB to YCbCr task allocated to CPU2. The peripheral resources used by this

application are Flash, AXISRAM, SRAMs, DCMI, DMA1, MDMA and Ethernet.

Figure 29. Task partition of example 1

AN5557

The peripheral allocation informs the RCC that a CPU enabled a peripheral. This information is used for

low-power modes and the allocated peripheral remains accessible to the second CPU. In addition to implicitly

allocated peripherals for example Flash or AXISRAM, additional resources need to be allocated depending on

application needs (JPEG HW codec, MDMA, DMAs, DCMI…). For shared resources like SRAM1 or AXISRAM a

software protection might be required to avoid data corruption, the use of memory protection unit (MPU) regions

can be defined to isolate data and peripherals tasks.

The user must take care about Data coherency between CM7 and CM4. This is done either by cache

maintenance or configure the shared memory as non-cachable memory.

The CPU2 can offload CPU1 from tasks such as image acquisition and image pre-processing. To enhance

performance, designers should maximize data locality by using D2 SRAMs for CPU2, managing data transfers

and encoding via DMAs (DMA1/MDMA) and JPEG HW codec. Also, the DMA can offload CPU2 when acquiring

data from DCMI interface and the MDMA can fetch data from D2 SRAM to encode them via JPEG HW codec.

Then, the encoded images is streamed over Ethernet.

Note: For more details about data coherency, refer to AN4839 "Level 1 cache on STM32F7 Series and STM32H7

Series" available from ST website .

AN5557 - Rev 1

page 28/36

Example 2: Sensor data acquisition and data streaming to cloud

4.4 Example 2: Sensor data acquisition and data streaming to cloud

The application tasks may be split over the two CPUs, As shown in the figure below. In addition, those tasks

can be divided in two modes: active mode and low power mode. The user interface management is allocated to

CPU1. The sensors management and Data logging to cloud are allocated to CPU2. The sensors management

is allocated to low power autonomous D3 domain. The peripheral resources used by this application are Flash,

AXISRAM, SRAMs, SPI/I2C, LTDC/DSI, DMA2D, DMA, BDMA, Ethernet and FMC.

Figure 30. Task partition of example 2

AN5557

4.5

The allocated graphical sub-system to CPU1 are LTDC/DSI, DMA2D and FMC. The Ethernet, and Flash are

allocated to CPU2. The BDMA and sensor management interfaces (SPI, I2C…) should be allocated to D3

autonomous mode.

In order to enhance power consumption, Flash allocation to CPU2 can be released (refer to

Section 2.3 Peripherals allocation) when it is not used to allow D1 domain to switch OFF clock and power.

The CPU1 may be overloaded by computationally intensive operation like encryptions and communication to

cloud, in this case CPU2 ensure responsiveness by isolating user interface from time-consuming tasks to offload

CPU1.

To enhance power consumption, the dependencies between domains should be reduced as domains can be

independently switched OFF. For example, D1 domain resources are mainly used by CPU1 for user interface

management, D1 may be switched OFF if CPU1 is in low power mode. D1 and D2 domains can be switched OFF

while sensors can be managed by D3 in autonomous mode. Also, a proper data mapping can reduce the need to

move data from one memory to another like sensor data mapping in SRAM4.

Example 3: Motor control and real-time communication

The application tasks can be split on the two CPUs, As shown in the figure below. The Motor control is allocated

to CPU1. The real-time communication is allocated to CPU2. The peripheral resources used by this application

are Flash, AXISRAM, SRAMs, TIMERs, CAN, UART, ADCs/DFSDM, DMAs and Ethernet.

Figure 31. Task partition of example 3

AN5557 - Rev 1

The allocated motor control sub-system to CPU1 are DMA1, DFSDM, TIMERs and SRAM1. The allocate

communication sub-system to CPU2 are DMA2, USART, FDCAN and Ethernet. Designers should avoid resources

sharing between application to reduce wait time for resource availability. For example, DMA1 is allocated to CPU1

and DMA2 is allocated for CPU2.

It is possible to isolate time critical tasks from other tasks by making them independently running on a different

processor. For example, the MPU configuration can be set on the two processors to avoid data corruption.

page 29/36

5 Conclusion

The STM32H7 dual-core embedded the Arm® Cortex®-M7 and the Cortex®-M4 32-bit RISC cores running up to

480 MHz and up to 240 MHz respectively. Those STM32H7 dual-core microcontrollers are more powerful and

offer high flexible architecture than predecessors in STM32H7 Series. It provides more processing and open

application partitioning. To get benefits from the two CPUs, the system architecture incorporates instruction and

data cache for Cortex®-M7 and Adaptive real-time accelerator for Cortex®-M4. Also, it allows high-performance

tasks execution while optimizing the overall power consumption. Each core belongs to independent power

domain, this provides safe boot modes and enhance the power consumption significantly.

This application note has shown the system architecture of the STM32H7 dual-core, which is split in three power

domains. In addition, it presents the memory resources and how it can be accessible by the cores and other

masters. Besides, it introduces the peripheral allocation for each CPU and shown an example of this process

through STM32CubeMx tool. Moreover, it reveales the dual-core design consideration and provides resources

partitioning based on some applicative examples.

AN5557

Conclusion

AN5557 - Rev 1

page 30/36

Revision history

AN5557

Table 4. Document revision history

Date Version Changes

13-Nov-2020 1 Initial release

AN5557 - Rev 1

page 31/36

AN5557

Contents

Contents

1 General information ...............................................................2

2 System overview ..................................................................3

2.1 Dual-core system ..............................................................4

2.2 Memory resource assignment ....................................................7

2.2.1 Embedded SRAM ........................................................7

2.2.2 Flash memory ...........................................................8

2.3 Peripherals allocation ...........................................................9

2.4 D1 sub-system................................................................12

2.5 D2 sub-system................................................................13

2.6 D3 system domain ............................................................14

3 Resources for dual-core application ..............................................15

3.1 Dual-core communication.......................................................15

3.2 Dual-core boot ...............................................................15

3.3 Building example based on STM32CubeMX .......................................17

3.3.1 Create new project using STM32CubeMX ....................................18

3.3.2 Pinout configuration .....................................................19

3.3.3 Clock configuration ......................................................20

3.3.4 Project configuration and code generation ....................................21

3.3.5 Power consumption calculator .............................................22

3.4 Debugging the multicore application..............................................22

3.4.1 Embedded trace macrocell (ETM)...........................................23

3.4.2 Instrumentation trace macrocell (ITM) ........................................24

3.4.3 Data watchpoint trace (DWT) ..............................................24

3.4.4 Trace funnel (CSTF) .....................................................24

3.4.5 Cross trigger interfaces (CTI) ..............................................25

3.4.6 Embedded trace FIFO (ETF)...............................................25

3.4.7 Microcontroller debug unit (DBGMCU) .......................................25

4 Application partitioning examples.................................................26

4.1 Dual-core application design considerations .......................................26

4.2 Task partitioning schema.......................................................27

AN5557 - Rev 1

page 32/36

AN5557

Contents

4.3 Example 1: JPEG images streaming over network..................................28

4.4 Example 2: Sensor data acquisition and data streaming to cloud......................29

4.5 Example 3: Motor control and real-time communication .............................29

5 Conclusion ......................................................................30

Revision history .......................................................................31

Contents ..............................................................................32

List of tables ..........................................................................34

List of figures..........................................................................35

AN5557 - Rev 1

page 33/36

AN5557

List of tables

List of tables

Table 1. Bus-master-to-slave interconnection....................................................... 5

Table 2. Peripheral clock allocation............................................................. 10

Table 3. Boot order........................................................................ 16

Table 4. Document revision history .............................................................31

AN5557 - Rev 1

page 34/36

AN5557

List of figures

List of figures

Figure 1. STM32H7 dual‑core block diagram ......................................................3

Figure 2. STM32H7 dual‑core system architecture ..................................................6

Figure 3. ART block diagram .................................................................7

Figure 4. RCC block diagram .................................................................9

Figure 5. Peripheral clock exchange ............................................................9

Figure 6. Peripheral clock gating ............................................................. 10

Figure 7. Peripheral allocation ............................................................... 11

Figure 8. D1 domain block diagram ........................................................... 12

Figure 9. D2 domain block diagram ........................................................... 13

Figure 10. D3 domain block diagram ........................................................... 14

Figure 11. FreeRTOS IPC block diagram ........................................................ 15

Figure 12. Boot selection mechanism ...........................................................16

Figure 13. Boot mode ...................................................................... 17

Figure 14. STM32CubeMx main screen ......................................................... 18

Figure 15. MCU selector screen............................................................... 18

Figure 16. Pinout and configuration screen ....................................................... 19

Figure 17. Clock configuration screen ........................................................... 20

Figure 18. Project manager screen............................................................. 21

Figure 19. PCC screen .....................................................................22

Figure 20. Block diagram of the device debug ..................................................... 23

Figure 21. Block diagram of ETM debug ......................................................... 23

Figure 22. Block diagram of ITM debug.......................................................... 24

Figure 23. Block diagram of DWT debug......................................................... 24

Figure 24. Block diagram of CTI debug .......................................................... 25

Figure 25. STM32H7 dual‑core functional partitioning ................................................26

Figure 26. Task parallel partitioning ............................................................ 27

Figure 27. Data processing partitioning .......................................................... 27

Figure 28. Pipelined partitioning............................................................... 27

Figure 29. Task partition of example 1 ........................................................... 28

Figure 30. Task partition of example 2 ........................................................... 29

Figure 31. Task partition of example 3 ........................................................... 29

AN5557 - Rev 1

page 35/36

AN5557

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2020 STMicroelectronics – All rights reserved

AN5557 - Rev 1

page 36/36

Loading...

Loading...