Page 1

Introduction

UM2514

User manual

Evaluation board with STM32G4xxQE MCU

The STM32G474E-EVAL board is a complete demonstration and development platform for

the STMicroelectronics Arm

It features three FDCAN controllers, four I²C Fast mode plus, five USART/UARTs and one

LPUART, four SPIs, one SAI port, USB FS and IRTIM communication interfaces, UCPD,

five 12-bit ADCs, seven 12-bit DAC channels, seven comparators and six operational

amplifiers, 17 timers, 96

Flash memory, and JTAG/SWD debugging support.

The STM32G474E-EVAL, shown in Figure 1 and Figure 2, is used as a reference design for

user application development before porting to the final product. The STM32G484E-EVAL is

populated with an STM32G484QET6U MCU with Cryptography. The STM32G474E-EVAL1

is configured as a dedicated motor-control board.

The full range of hardware features available on the board helps users to optimize the

application development by the evaluation of all the peripherals (USB FS, UCPD, USART,

audio, ADC and DAC, differential ADC, TFT LCD, potentiometer/LDR, SRAM, Quad-SPI

Flash memory device, microSD™ card, Smartcard, FDCAN transceiver, high brightness

LED, motor control connectors, temperature sensor, and others). Extension headers provide

easy connection to daughterboard for specific applications.

STLINK-V3E is integrated into the board, as the embedded in-circuit debugger and

programmer for the STM32 MCU and the USB virtual COM port bridge.

The three products (STM32G474E-EVAL, STM32G484E-EVAL, STM32G474E-EVAL1) are

described in this user manual, together with STM32G474E-EVAL figures.

Figure 1. STM32G474E-EVAL top view Figure 2. STM32G474E-EVAL bottom view

®

Cortex®-M4 core-based STM32G474QET6U microcontroller.

Kbytes of internal SRAM, 32 Kbytes of CCM SRAM, 512 Kbytes of

Pictures are not contractual.

September 2019 UM2514 Rev 4 1/83

www.st.com

1

Page 2

Contents UM2514

Contents

1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Product marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Codification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3 Development environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Development toolchains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Demonstration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Delivery recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Hardware layout and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 STLINK-V3E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Drivers and firmware upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 ETM trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3.1 Supplying the board through STLINK-V3E USB port . . . . . . . . . . . . . . 20

5.3.2 Using STLINK-V3E along with powering through CN25 power jack . . . 20

5.4 Clock references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 Reset source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.6 Boot Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.6.1 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.7 Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.7.1 Limitations in using audio features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.8 USB FS port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.8.1 Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.9 RS232 and RS485 port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.9.1 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.9.2 Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.10 microSD card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.10.1 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/83 UM2514 Rev 4

Page 3

UM2514 Contents

5.10.2 Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.11 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.11.1 Board modifications to enable motor control . . . . . . . . . . . . . . . . . . . . . 32

5.11.2 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.12 FDCAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.12.1 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.12.2 Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.13 Extension connectors CN5 and CN6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.14 User LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.15 Physical input devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.15.1 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.16 Operational amplifier and comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.16.1 Operational amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.16.2 Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.16.3 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.17 Analog input, output, VREF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.17.1 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.17.2 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.17.3 VREF+ terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.17.4 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.18 SRAM device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.18.1 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.18.2 Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.19 EXT_I2C connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.20 Quad-SPI Flash memory device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.20.1 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.20.2 Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.21 MFX MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.21.1 MFX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.21.2 IDD measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.21.3 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.22 TFT LCD panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.23 UCPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.23.1 USB Type-C receptacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.23.2 Power Delivery & Local power management . . . . . . . . . . . . . . . . . . . . . 41

UM2514 Rev 4 3/83

5

Page 4

Contents UM2514

5.23.3 VBUS management and discharge mechanism . . . . . . . . . . . . . . . . . . 41

5.23.4 VBUS voltage-sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.23.5 CC management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.23.6 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.24 Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.24.1 Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.25 Smartcard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.25.1 Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.26 High brightness LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.26.1 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1 External I2C connector CN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.2 Motor control connector CN2 and CN4 . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3 SMB connector CN3, CN7 and CN8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.4 Extension connectors CN5 and CN6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5 DAC connector CN9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.6 CAN1 and CAN2 connector CN12 and CN10 . . . . . . . . . . . . . . . . . . . . . 47

6.7 RS232 and RS485 connector CN11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.8 JTAG connector CN14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.9 TAG connector CN15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.10 STDC14 connector CN16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.11 Trace debugging connector CN17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.12 MFX programming connector CN18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.13 Type-C signals connector CN19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.14 LCD connector CN20 and CN24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.15 ST-LINK-V3E USB Micro-B connector CN21 . . . . . . . . . . . . . . . . . . . . . . 51

6.16 USB Type-C connector CN22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.17 Audio blue jack (Line In) CN23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.18 Audio green jack (Line Out) CN26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.19 Power connector CN25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.20 ST-LINK-V3E programming connector CN27 . . . . . . . . . . . . . . . . . . . . . . 53

6.21 microSD connector CN28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.22 Smartcard connector CN31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4/83 UM2514 Rev 4

Page 5

UM2514 Contents

7 Schematic diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Appendix A STM32G474E-EVAL I/O Assignment . . . . . . . . . . . . . . . . . . . . . . . . 77

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

UM2514 Rev 4 5/83

5

Page 6

List of tables UM2514

List of tables

Table 1. List of available products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2. Codification explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. Setting of configuration elements for trace connector CN17 . . . . . . . . . . . . . . . . . . . . . . . 17

Table 4. Setting of configuration I/Os for PE2, PE3, PE4 and PE5 . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 5. Power supply related jumper and solder bridge settings . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 6. X3 crystal related solder bridge settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 7. X2 crystal related solder bridge settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 8. Boot selection switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 9. Configuration PA10 of STM32G474QET6U terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 10. Motor control CN2 terminal and function assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 11. Motor control CN4 terminal and function assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 12. Motor control OpAmp and DAC function assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 13. Motor control related switches and solder bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 14. Motor control related switches and solder bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 15. Port assignment for control of physical input devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 16. Configuration elements related with OpAmp4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 17. Configuration elements related with Comp4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 18. Configuration elements related with VREF+. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 19. MFX signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 20. IDD measurement related jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 21. TFT LCD connector CN20 and CN24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 22. Dead battery related jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 23. Connection between ST8024L and STM32F091VCT6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 24. EXT_I2C connector CN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 25. Motor control connector CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 26. Motor control connector CN4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 27. SMB connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 28. Analog input-output connector CN9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 29. CAN connector CN10 or CN12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 30. RS-232/RS-485 D-sub connector CN11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 31. JTAG debugging connector CN14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 32. TAG debugging connector CN15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 33. STDC14 debugging connector CN16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 34. Trace debugging connector CN17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 35. Type-C signals connector CN19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 36. USB Micro-B connector CN21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 37. USB Type C connector CN22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 38. Audio Jack Connector CN26 (on board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 39. MicroSD connector CN28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 40. Smartcard connector CN31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 41. STM32G474E-EVAL I/O Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 42. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6/83 UM2514 Rev 4

Page 7

UM2514 List of figures

List of figures

Figure 1. STM32G474E-EVAL top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. STM32G474E-EVAL bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 3. Hardware block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 4. STM32G474E-EVAL Evaluation board layout (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 5. STM32G474E-EVAL Evaluation board layout (bottom view) . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. STM32G474E-EVAL Evaluation board mechanical dimensions (top view) . . . . . . . . . . . . 16

Figure 7. PCB top side rework for motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 8. PCB bottom side rework for motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 9. I2C EXT connector CN2 (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 10. Motor control connector CN2 and CN4 (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 11. SMB connector (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 12. Analog input-output connector CN9 (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 13. CAN connector CN10 or CN12 (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 14. RS232 and RS485 connector CN11 (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 15. JTAG debugging connector CN14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 16. STDC14 debugging connector CN16 (top view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 17. Trace debugging connector CN17 (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 18. Type-C signals connector CN19 (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 19. USB Micro-B connector CN21 (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 20. USB Type C connector CN22 (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 21. Stereo headset with microphone jack CN26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 22. Power supply connector CN25 (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 23. microSD connector CN28 (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 24. Smartcard connector CN31 (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 25. MB1397_TOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 26. STM32 microcontroller I/Os . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 27. STM32 microcontroller power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 28. USB_PD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 29. USB-TYPEC_CON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 30. FMC memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 31. QSPI memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 32. Audio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 33. LCD and SD card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 34. RS232 and RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 35. FDCAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 36. Analog interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 37. Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 38. Smartcard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 39. Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 40. Extension connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 41. Debug connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 42. Multi function expander. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 43. Power board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 44. STLINK-V3E -SWD Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

UM2514 Rev 4 7/83

7

Page 8

Features UM2514

1 Features

• Common features

– 240x320 TFT color LCD display module with SPI interface

– 16-Gbyte microSD™ card bundled

– On-board current measurement

– SAI audio codec

– Temperature sensor

– 8-Mbit (512 K x 16-bit) SRAM

– Two 512-Mbit Quad-SPI NOR Flash memories

– Four color user LEDs

– One high brightness LED

– Reset and wake-up / tamper buttons

– 4-direction joystick with selection button

– Light-dependent resistor (LDR)

– Potentiometer

– Access to comparator and operational amplifier

– Board connectors:

-Analog line input jack

-Stereo headset jack

-Two connectors for external speakers

-microSD™ card

-EXT_I2C connector supporting I2C bus

-RS-232 port configurable for communication or MCU flashing

-RS-485 port

-USB Type-C™ port supporting USB FS Device

-Two CAN 2.0A/B-compliant ports

-Connector for DAC output

-JTAG/SWD connector

-ETM trace debug connector

-User interface through USB virtual COM port

-Embedded STLINK-V3E debug and flashing facility

-TAG connector 10-pin footprint

8/83 UM2514 Rev 4

Page 9

UM2514 Features

-Arm

®(a)

Cortex® 10-pin 1.27 mm-pitch debug connector over STDC14 footprint

-Coin cell battery holder

– Board expansion connectors:

-Two sets of motor control expansion connectors

-Board expansion extension connectors

– Flexible power-supply options:

-ST-LINK USB VBUS, external sources, USB Type-C™ connector, or

daughterboard

– On-board STLINK-V3E debugger/programmer with USB re-enumeration

capability: mass storage, Virtual COM port, and debug port

– Microcontroller supply voltage: fixed 3.3 V or adjustable range from 1.62 V to

3.6 V

– Comprehensive free software libraries and examples available with the

STM32CubeG4 MCU Package

– Support of a wide choice of integrated development environments (IDEs) including

IAR™, Keil

®

, GCC-based IDEs

• Board-specific features

-STM32G474QET6U microcontroller with 512 Kbytes of Flash memory and

96 Kbytes of RAM in LQFP128 package (STM32G474E-EVAL and

STM32G474E-EVAL1)

-STM32G474E-EVAL1 is the board to use for motor control application with solder

bridge and resistor configuration

-STM32G484QET6U with cryptography (STM32G484E-EVAL)

• Fully compatible with all microcontrollers of the STM32G4x1 and STM32G4x3 lines

with “QET6” part number suffix

a. Arm is a registered trademark of Arm Limited (or its subsidiaries) in the US and/or elsewhere.

UM2514 Rev 4 9/83

82

Page 10

Ordering information UM2514

2 Ordering information

To order the STM32G4x4E-EVAL Evaluation board, refer to Tab le 1. Additional information

is available in the datasheet and reference manual of the targeted STM32.

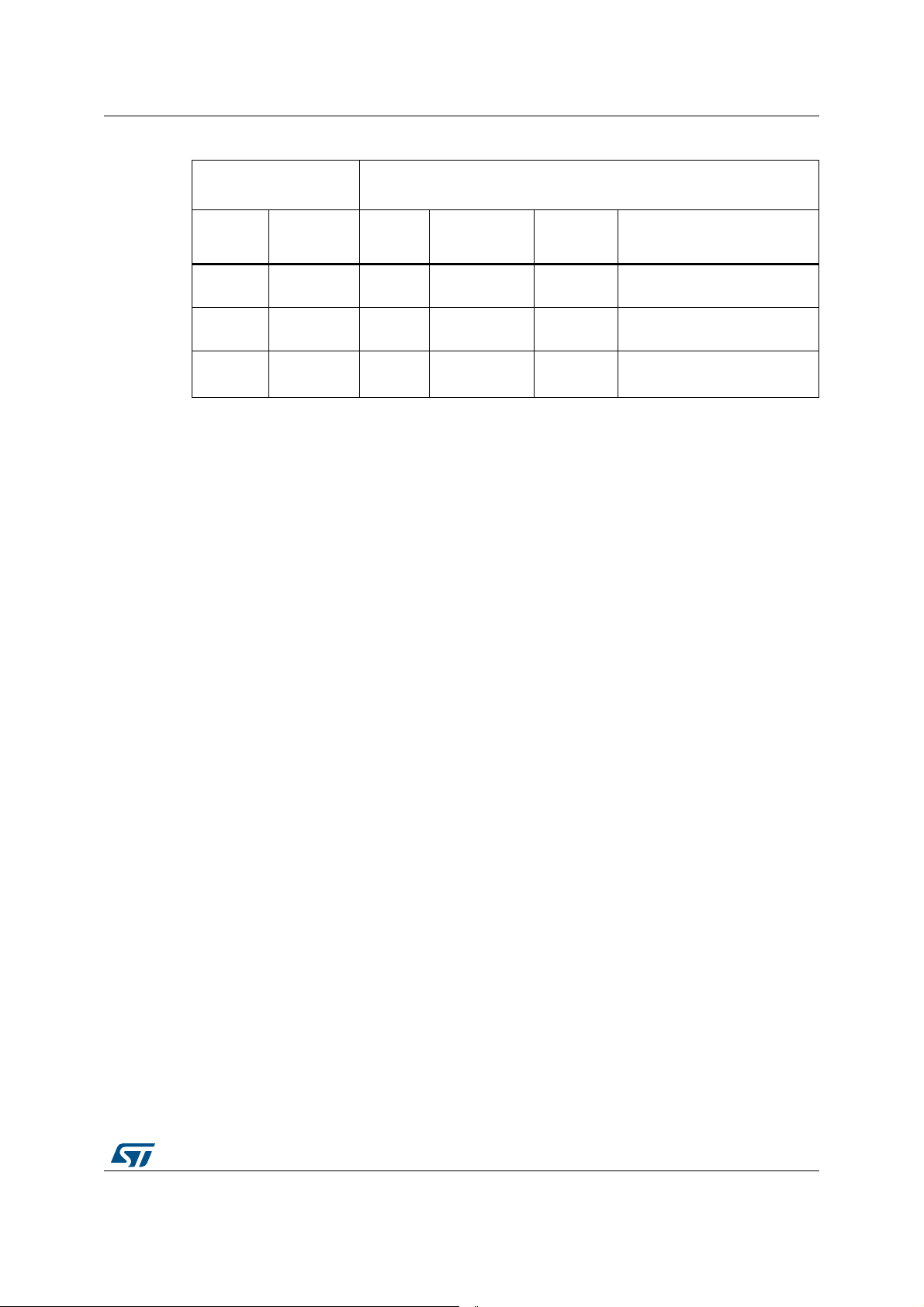

Order code Board reference Target STM32 Differentiating feature

Table 1. List of available products

STM32G474E-EVAL

STM32G474E-EVAL1

STM32G484E-EVAL STM32G484QET6U Cryptography

2.1 Product marking

Evaluation tools marked as “ES” or “E” are not yet qualified and are therefore not ready to

be used as reference design or in production. Any consequences arising from such usage

will not be at STMicroelectronics’ charge. In no event will STMicroelectronics be liable for

any customer usage of these engineering sample tools as reference designs or in

production.

‘E’ or ‘ES’ marking examples of location:

• on the targeted STM32 that is soldered on the board (for illustration of STM32 marking,

refer to the section Package information in the STM32 datasheet at www.st.com).

• next to the evaluation tool ordering part number, that is stuck or silkscreen printed on

the board.

This board features a specific STM32 device version which allows the operation of any

bundled commercial stack/library available. This STM32 device shows a "U" marking option

at the end of the standard part number and is not available for sales.

In order to use the same commercial stack in his application, a developer may need to

purchase a part number specific to this stack/library. The price of those part numbers

includes the stack/library royalties.

MB1397

STM32G474QET6U

-

Motor-control configuration

board

10/83 UM2514 Rev 4

Page 11

UM2514 Ordering information

2.2 Codification

The meaning of the codification is explained in Tabl e 2.

STM32XXYYYZ-EVAL(T) Description Example: STM32G484E-EVAL

Table 2. Codification explanation

XX

MCU series in STM32 Arm

Cortex MCUs

STM32G4 Series

MCU product line in the series

YY

– G474: basic security

STM32G484

– G484: cryptography

Z

STM32 Flash memory size,

E for 512 Kbytes

512 Kbytes

Evaluation board configuration:

T

– EVAL: basic

– EVAL1: with motor-control

Basic

configuration board

The order code is mentioned on a sticker placed on the top side of the board.

UM2514 Rev 4 11/83

82

Page 12

Development environment UM2514

3 Development environment

3.1 System requirements

• Windows® OS (7, 8 and 10), Linux® 64-bit or macOS

• USB Type-A to Micro-B cable

3.2 Development toolchains

• Keil® MDK-ARM

• IAR™ EWARM

• GCC-based IDEs

(b)

(b)

3.3 Demonstration software

The demonstration software, included in the STM32Cube MCU Package corresponding to

the on-board MCU, is preloaded in the STM32 Flash memory for easy demonstration of the

device peripherals in standalone mode. The latest versions of the demonstration source

code and associated documentation can be downloaded from www.st.com.

®(a)

4 Delivery recommendations

Some verifications are needed before using the board for the first time, to make sure that no

damage occurred during shipment and that no components are unplugged or lost.

When the board is extracted from its plastic bag, check that no component remains in the

bag. The main components to verify are:

1. microSD card which may have been ejected from the connector CN28 (right side of the

board),

2. TFT LCD display MB895 daughterboard which must be in its CN20 and CN24

connectors

For product information related to STM32G4xxQET6U microcontroller, visit the www.st.com

website.

a. macOS® is a trademark of Apple Inc., registered in the U.S. and other countries.

®

b. on Windows

only

12/83 UM2514 Rev 4

Page 13

UM2514 Hardware layout and configuration

06Y9

9

SRZHUVXSSO\

9

SRZHUVXSSO\

$'-

SRZHUVXSSO\

670*4(7

74)3

9%$7

57&

63,

8&3'

86%)6

86$57

&$1

'$3

6$,

463,

)0&

,&

$'&'$&

23$03

&203

*3,2

$XGLRFRGHF

[VLQJOH

4XDG63,)ODVK

65$0365$0

7HPSHUDWXUHVHQVRU

(;7B,&FRQQHFWRU

$'&'$&FRQQHFWRU

3RWHQWLRPHWHU/'5

-R\VWLFNEXWWRQV

&RORU/('V

0RWRUFRQWUROFRQQHFWRU

&$1FRQQHFWRU

67/,1.9(

-7$*6:'FRQQHFWRU

7$*FRQQHFWRU

7UDFHFRQQHFWRU

67'&FRQQHFWRU

9EDWWHU\

.+]FU\VWDO

7)7/&'FRQQHFWRU

PLFUR6'FDUG

86%7\SH&FRQQHFWRU

5656FRQQHFWRU

+LJKEULJKWQHVV/('

6PDUWFDUG

5 Hardware layout and configuration

The STM32G474E-EVAL board is designed around STM32G474QET6U target

microcontroller in TQFP 128-pin package.

STM32G474QET6U with the peripheral components. Figure 4 and Figure 5 show the

locations of main components on the evaluation board.

Figure 3. Hardware block diagram

Figure 3 illustrates the connections of the

UM2514 Rev 4 13/83

82

Page 14

Hardware layout and configuration UM2514

CN21

STLINK

-

V3E

USB

CN14

JTAG/SWD

CN23

Audio In

LD8

STLINK

-V3E

COM LED

B1

Joystick

B3

Reset

Button

4 colour

LEDs

CN22

Type

-C

connector

U6

STM32G474QET6U

CN5, CN6

Extension

header

CN16

STDC14

CN11

USART

CN28

MicroSD card

B2

USRE

Button

CN26

Audio out

CN3

DIFF ADC

input

RV2

Potentiometer

LD7

STLINK

-

V3E

Power over

current alarm

CN17

ETM TRACE

CN15

TAG

CN20/CN24

TFT LCD

c

onnector

CN19

Type-C SIG

JP12

5V source

CN2

Motor control

c

onnector 1

CN1

EXT_I2C

c

onnector

CN12

CAN1

CN4

Motor control

connector 2

CN10

CAN2

CN32

DAC2

CN18

MFX

CN27

ST

-LINK

SWD

CN25

Power Jack

CN7

CN8

LD6

5V LED

RV3

VDD ADJ

LD5

HB LED

CN9

DAC

Figure 4. STM32G474E-EVAL Evaluation board layout (top view)

14/83 UM2514 Rev 4

Page 15

UM2514 Hardware layout and configuration

CN31

Smartc

ard

Figure 5. STM32G474E-EVAL Evaluation board layout (bottom view)

UM2514 Rev 4 15/83

82

Page 16

Hardware layout and configuration UM2514

Figure 6 provides the mechanical dimensions of the STM32G474E-EVAL board.

Figure 6. STM32G474E-EVAL Evaluation board mechanical dimensions (top view)

16/83 UM2514 Rev 4

Page 17

UM2514 Hardware layout and configuration

5.1 STLINK-V3E

STLINK-V3E facility for debug and flashing of STM32G474QET6U is integrated on the

STM32G474E-EVAL board. It features:

• Self-powered through a USB connector (Micro-B)

• USB 2.0 high-speed compatible interface

• Direct firmware update support (DFU)

• SWD and serial wire viewer (SWV) communication support

• Drag-and-drop Flash programming

• Two color LEDs: communication, power

The USB connector CN21 can be used to power the STM32G474E-EVAL regardless of the

STLINK-V3E facility used for debugging or programming STM32G474QET6U. This holds

also when the STLINK stand-alone tool is connected to connector CN14 or CN15 or CN16

or CN17 and used for debugging or programming the STM32G474QET6U.

Power supply provides more detail about powering the STM32G474E-EVAL.

Refer to www.st.com for details about STLINK-V3E.

5.1.1 Drivers and firmware upgrade

The STLINK-V3E requires drivers to be installed on Windows, and embeds a firmware

which needs to be updated from time to time in order to benefit from new functionality or

corrections. Refer to the Overview of ST-LINK derivatives technical note (TN1235) for

details.

Section 5.3:

Before connecting the STM32G474E-EVAL to a Windows (7, 8 10) PC via USB, a driver for

STLINK-V3E must be installed. It is available from www.st.com.

5.2 ETM trace

The connector CN17 is available to output trace signals used for debug. By default, the

evaluation board is configured such that, STM32G474QET6U signals PE2, PE3 and PE4

are connected to trace outputs TRACECLK, TRACED0, and TRACED1 of CN17, but these

signals shared with Audio codec, motor control connectors and FMC.

Tabl e 3 shows the setting of configuration elements to shunt PE3 and PE4 MCU ports to

CN17 connector, to use them as debug trace signals.

Tabl e 4 shows the setting of configuration I/Os to shunt PE2, PE3, PE4 and PE5 MCU ports

to use them as the right functions.

R210

R207

Table 3. Setting of configuration elements for trace connector CN17

Element Setting Configuration

open

closed CN17 pin 14 connects to JTAG_TDO.

open

closed CN17 pin 16 connects to JTAG_TRST.

Default setting.

CN17 pin 14 connects to TRACED0.

Default setting.

CN17 pin 16 connects to TRACED1.

UM2514 Rev 4 17/83

82

Page 18

Hardware layout and configuration UM2514

Table 4. Setting of configuration I/Os for PE2, PE3, PE4 and PE5

Element Setting Configuration

R147

SB111

SB103

R147 in

SB111 open

SB103 open

R147 out

SB111 closed

SB103 open

Default setting.

PE2 connects to TRACECLK.

Default setting.

PE2 connects to SAI_MCLK_A.

R147 out

SB111 open

PE2 connects to MC1|MC2_PFC_Sync.

SB103 closed

R145 in

SB110 open

SB118 open

Default setting.

PE3 connects to TRACED0.

R146 out

R145 out

R145

SB110

SB118

R146

SB110 closed

SB118 open

R146 out

R145 out

SB110 open

SB118 closed

Default setting.

PE3 connects to SAI_SD_B.

PE3 connects to MC1|MC2_PFC_pwm.

R146 out

R145 out

SB110 open

SB118 open

Default setting.

PE3 connects to memory address line A19.

R146 in

R144 in

SB107 open

SB109 open

Default setting.

PE4 connects to TRACED1.

R143 out

R144 out

R144

SB107

SB109

R143

SB107 closed

SB109 open

R143 out

R144 out

SB107 open

SB109 closed

Default setting.

PE4 connects to SAI_FS_A.

PE4 connects to MC1_ICL_SHUTOUT.

R143 out

R144 out

SB107 open

SB109 open

Default setting.

PE4 connects to memory address line A20.

R143 in

18/83 UM2514 Rev 4

Page 19

UM2514 Hardware layout and configuration

Table 4. Setting of configuration I/Os for PE2, PE3, PE4 and PE5 (continued)

Element Setting Configuration

SB28 closed

SB28

SB97

SB97 open

SB28 open

SB97 closed

Warning: Generally we have one default setting for best performance

5.3 Power supply

The STM32G474E-EVAL board is designed to be powered from a 5 V DC power source. It

incorporates a precise PTC and transil to protect the board from damage due to wrong

power supply. One of the following five 5

board configuration:

• Power jack CN25:

Marked PSU on the board (JP12 jumper setting on E5V on silkscreen). The positive

pole is on the center pin as illustrated in Figure 22.

The External power supply from Power jack CN25 is from 5 V to 18 V input voltage.

The dedicated DC/DC regulator ST1S41PHR is used for about 5.2 V output voltage

and provided up to 3 A current.

• Micro-B USB receptacle CN21 of STLINK-V3E with enumeration:

Up to 500 mA can be supplied to the board (JP12 jumper setting on STLK on

silkscreen).

Offers the enumeration feature described in Section 5.3.1.

• Micro-B USB receptacle CN21 of STLINK-V3E without enumeration:

Up to 1000 mA can be supplied to the board directly without enumeration (JP12 jumper

setting on CHGR on silkscreen).

• USB Type-C receptacle CN22 of USB PD interface:

Marked TYPE-C on the board (JP12 jumper setting on U5V on silkscreen). Up to

500 mA can be supplied to the board in this way.

• Pin 49 of CN5 and Pin 49 of CN6 extension connectors for custom daughterboard:

Marked 5V_D on the board (JP12 jumper setting on D5V on silkscreen).

Default setting.

PE5 connects to TRACED2

PE5 connects to MC1_DissipativeBrake

of many shared features, but it is easy for users to configure

features as we have many default settings for MCU ports

(solder bridge or resistor is soldered).

V DC power inputs can be used, upon appropriate

The LD6 green LED turns on when the voltage on the power line marked as 5 V is present.

All supply lines required for the operation of the components on the STM32G474E-EVAL

are derived from that 5

V line.

Tabl e 5: Power supply related jumper and solder bridge settings describes the settings of all

jumpers related to powering the STM32G474E-EVAL and extension board. VDD_MCU is

STM32G474QET6U digital supply voltage line. It can be connected to a fixed 3.3

UM2514 Rev 4 19/83

V or with

82

Page 20

Hardware layout and configuration UM2514

an adjustable voltage regulator controlled by RV3 potentiometer and producing a range of

voltages between 1.62

V and 3.6 V.

5.3.1 Supplying the board through STLINK-V3E USB port

To power the STM32G474E-EVAL this way, the USB host (a PC) gets connected to the

Micro-B USB receptacle of the STM32G474E-EVAL board via a USB cable. The connection

event starts the USB enumeration procedure. In its initial phase, the host USB port current

supply capability is limited to 100

STM32G474E-EVAL draws power at that time: the U25 STMPS2151 power switch is set to

the OFF position, which isolates the rest of the STM32G474E-EVAL from the power source.

In the next phase of the enumeration procedure, the host PC informs the STLINK-V3E

facility of its capability to supply current up to 300

V3E sets the U25 STMPS2151 switch to ON position to supply power to the rest of the

STM32G474E-EVAL board. If the PC USB port is not capable of supplying current up to

300

mA, the CN25 power jack is available to supply the board.

If a short-circuit occurs on the board, the STMPS2151 power switch protects the USB port

of the host PC against a current demand exceeding 500

lights up.

The STM32G474E-EVAL board can also be supplied from a USB power source not

supporting enumeration, such as a USB charger. In this particular case, jumper JP12 must

be fitted with a jumper hat as shown in

bridge settings. STLINK-V3E bypasses STMPS2151 power regardless of enumeration

procedure result and passes the power unconditionally to the board.

mA. It is enough because only STLINK-V3E part of the

mA. If the answer is positive, the STLINK-

mA. In such an event, the LD7 LED

Tabl e 5: Power supply related jumper and solder

The LD6 green LED turns on whenever the whole board is powered.

5.3.2 Using STLINK-V3E along with powering through CN25 power jack

When the board requires a current higher than 300 mA, the host PC, connected to STLINKV3E USB port for debugging or programming, cannot supply the STM32G474QET6U MCU.

In such a case, the board can be powered through CN25 (marked PSU on the board).

To do this, it is important to power the board before connecting it with the host PC, which

requires the following sequence to be respected:

1. Set the jumper JP12 in E5V position

2. Connect the external power source to CN25

3. Check that the green LED LD6 is turned on

4. Connect host PC to USB connector CN21

Caution: In case the board requires more than 300 mA and the host PC is connected via USB before

the board is powered from CN25, the following risk events are possible (listed in reverse

severity order):

1. The host PC is capable of supplying 300 mA (the enumeration succeeds) but it

features no over-current protection on its USB port. It is damaged due to over- current.

2. The host PC is capable of supplying 300 mA (the enumeration succeeds) and it has a

built-in over-current protection on its USB port, limiting or shutting down the power out

of its USB port when the excessive current demand from the STM32G474E-EVAL is

detected. This causes an operating failure of the STM32G474E-EVAL.

3. The host PC is not capable of supplying 300 mA (the enumeration fails). The STLINKV3E does not supply the rest of the STM32G474E-EVAL from its USB port VBUS line.

20/83 UM2514 Rev 4

Page 21

UM2514 Hardware layout and configuration

67/. &+*5(989 '69

67/. &+*5(989 '69

67/. &+*5(989 '69

67/. &+*5(989 '69

67/. &+*5(989 '69

Tabl e 5 details jumper and solder bridge settings used for the configuration of the power

supply of the STM32G474E-EVAL.

Table 5. Power supply related jumper and solder bridge settings

Jumper /

solder bridge

JP12

Power source

selector

setting Configuration

Default setting.

STM32G474E-EVAL is supplied through CN21

Micro-B USB receptacle. Depend on host PC USB

port’s powering capability declared in the

enumeration.

STM32G474E-EVAL is supplied through CN22 USB

Type-C receptacle.

STM32G474E-EVAL is supplied through pin 49 of

CN5 and pin 49 of CN6 extension connectors.

Default setting.

STM32G474E-EVAL is supplied through CN 25 power

jack.

STM32G474E-EVAL is supplied through CN21

Micro-B USB receptacle.

Setting for powering the board through CN21 using

USB charger.

JP7

Vbat connection

JP6

VDDA

connection

JP11

VDD_MCU

connection

Default setting.

Vbat is connected to VDD.

Vbat is connected to battery.

VDDA terminal of STM32G474QET6U is connected

with VDD_MCU.

Default setting.

VDDA terminal of STM32G474QET6U is connected

to 3.3 V.

Default setting.

VDD_MCU (VDD terminals of STM32G474QET6U)

is connected to fixed 3.3 V.

VDD_MCU is connected to voltage in the range from

+1.62 V to +3.61 V, adjustable with potentiometer

RV3.

UM2514 Rev 4 21/83

82

Page 22

Hardware layout and configuration UM2514

Note: On all STLINK-V3E boards, the target application is now able to run even if the STLINK-V3E

is either not connected to a USB host, or is powered through a USB charger (or through a

not-enumerating USB host).

5.4 Clock references

Two clock references are available on the STM32G474E-EVAL Evaluation board for the

STM32G474QET6U target microcontroller.

• 32.768 kHz crystal X3, for embedded RTC

• 24 MHz crystal X2, for main clock generator

The main clock generation is possible via an internal RC oscillator or from STLK_MCO,

disconnected by removing resistors R312, R313 and R317 when internal RC clock is used.

Table 6. X3 crystal related solder bridge settings

SB88

SB87

SB82

SB81

Solder

bridge

Solder

bridge

Setting Configuration

Default setting.

Open

Closed

Open

Closed

PC14 OSC32_IN terminal is not routed to extension connector

CN5. X3 is used as clock reference.

PC14 OSC32_IN is routed to extension connector CN5. Resistor

R315 must be removed, for X3 quartz circuit not to disturb clock

reference or source on daughter board.

Default setting.

PC15 OSC32_OUT terminal is not routed to extension connector

CN5. X3 is used as clock reference.

PC15 OSC32_OUT is routed to extension connector CN5. Resistor

R314 must be removed, for X3 quartz circuit not to disturb clock

reference on daughter board.

Table 7. X2 crystal related solder bridge settings

Setting Configuration

Default setting.

open

closed

open

closed

PF0 OSC_IN terminal is not routed to extension connector CN5. X2

is used as clock reference.

PF0 OSC_IN is routed to extension connector CN5. Resistor R317

and R312 must be removed, in order not to disturb clock reference

or source on daughterboard.

Default setting.

PF1 OSC_OUT terminal is not routed to extension connector CN5.

X2 is used as clock reference.

PF1 OSC_OUT is routed to extension connector CN5. Resistor

R313 must be removed, in order not to disturb clock reference or

source on daughter board.

22/83 UM2514 Rev 4

Page 23

UM2514 Hardware layout and configuration

!

!

5.5 Reset source

The general reset of the STM32G474E-EVAL board is active low. The reset sources are:

• reset button B3

• JTAG/SWD connector CN14, ETM trace connector CN17, STDC14 connector CN16

and TAG connector CN15 (reset from debug tools)

• Through extension connector CN5 pin 30 (reset from daughter board)

• Embedded STLINK-V3E

5.6 Boot Option

After reset, the STM32G474QET6U MCU can boot from the following embedded memory

locations:

• Main (user, non-protected) Flash memory

• System (protected) Flash memory

• RAM, for debugging

The boot option is configured by setting switch SW7 (BOOT0) and the boot base address

programmed in the nBOOT1, nBOOT0 and nSWBOOT0 of FLASH_OPTR option bytes.

Table 8. Boot selection switch

Switch Setting Description

SW7

5.6.1 Limitations

BOOT0 PB8 is exclusive with FDCAN1, JP1 must be opened to disconnect FDCAN1_RX

signal.

5.7 Audio

A WM8894 codec is connected to SAI interface of the STM32G474QET6U. It supports the

TDM feature of the SAI port. The TDM feature enables the STM32G474QET6U to

simultaneously stream two independent stereo audio channels to two separate stereo

analog audio outputs. The codec communicates with the STM32G474QET6U via the I2C3

bus, which is shared with MFX, Temperature Sensor, EXT_I2C connector.

BOOT0 line is tied high. STM32G474QET6U boots from system Flash

memory (nBOOT1 bit of FLASH_OPTR register is set high) or from

RAM (nBOOT1 is set low).

Default setting.

BOOT0 line is tied low. STM32G474QET6U boots from Main Flash

memory.

-

UM2514 Rev 4 23/83

82

Page 24

Hardware layout and configuration UM2514

The audio connections are:

• The analog line input is connected to ADC of WM8994ECS/R through blue audio jack

CN23.

• The analog line output is connected to DAC of WM8994ECS/R via green audio jack

CN26.

• Two external speakers can be connected to WM8994ECS/R via JP17 for right speaker

and JP16 for left speaker, not fitted as default.

The I2C-bus address of WM8994 codec are 0x34 or 0x35.

5.7.1 Limitations in using audio features

Due to the share of PE2, PE3, PE4 and PF6 terminals of STM32G474QET6U by multiple

peripherals, refer to

• If the SAI_MCLKA, SAI_SDB and SAI_FSA are used as part of SAI port, it cannot be

used as TRACE and FMC peripheral.

• If the SAI port of STM32G474QET6U is used for streaming audio to the WM8994

codec IC, STM32G474QET6U cannot control the motor.

Tabl e 4. The following limitations apply in using the audio features:

5.8 USB FS port

The STM32G474E-EVAL board supports USB full-speed (FS) as a USB device

communication via USB Type-C receptacle CN22.

When a USB host connection to the USB Type-C receptacle CN22 of STM32G474E-EVAL

is detected, the STM32G474E-EVAL board starts behaving as a USB device. Depending on

the powering capability of the USB host, the board can take power from VBUS terminal of

CN22. In the board schematic diagrams, the corresponding power voltage line is called

U5V.

5.8.1 Operating voltage

The USB-related operating supply voltage of STM32G474QET6U (VDD_USB line) must be

within the range from 3.0

V to 3.6 V.

5.9 RS232 and RS485 port

The STM32G474E-EVAL board offers one RS-232 communication or RS-485

communication port. They use the same DB9 male connector CN11. RX and TX signals of

USART1 port of STM32G474QET6U are shared with USBPD and VCP.

configuration PA10 of STM32G474QET6U terminals.

5.9.1 Limitations

Due to the sharing of PA9 and PA10 terminals of STM32G474QET6U by multiple

peripherals, if RS-232 or RS485 port use as part of USART1 port, it cannot be used as

USBPD and VCP peripheral.

Table 9 shows the

24/83 UM2514 Rev 4

Page 25

UM2514 Hardware layout and configuration

5.9.2 Operating voltage

The RS-232 or RS-485 operating supply voltage of STM32G474QET6U (VDD line) must be

within the range from 1.62

Table 9. Configuration PA10 of STM32G474QET6U terminals

V to 3.6 V.

USART1_RX is connected to RS-232 RXD of

transceiver.

JP9

USART1_RX

connection

JP10

VCP_RX

connection

5.10 microSD card

The CN28 slot for microSD card is routed to STM32G474QET6U SPI port, accepting 8GB

(or more) Micro SD card. One 16-Gbyte microSD card is delivered as part of STM32G474EEVAL. The card insertion switch is routed to the MFX_GPIO5 of MFX MCU port and it must

be set with internal pull-up.

5.10.1 Limitations

Due to the share of I/O port, the following limitations apply:

• The microSD card cannot be operated simultaneously with motor control connector 2.

USART1_RX is connected to RS-485 RO of

transceiver.

Default setting.

USART1_RX is not connected to RS-232 or RS-485

of transceiver.

Default setting.

VCP_RX is connected to STLINK-V3E

STLK_VCP_TX.

VCP_RX is not connected to STLINK-V3E

STLK_VCP_TX.

5.10.2 Operating voltage

The supply voltage for STM32G474E-EVAL microSD card operation must be within the

range from 1.62

V to 3.6 V.

5.11 Motor control

The CN2 (MC1) and CN4 (MC2) connectors are designed to receive a motor control

module. Available signals on these connectors include emergency stop, motor speed, 3phase motor current, bus voltage, heatsink temperature coming from the motor driving

board and 6 channels of PWM control signal going to the motor driving circuit.

The dedicated motor control STM32G474E-EVAL1 board is supported for motor control

module application only.

UM2514 Rev 4 25/83

82

Page 26

Hardware layout and configuration UM2514

If the STM32G474E-EVAL board is used, some PCB reworks are needed for motor control

applications: the goal is to disconnect peripherals sharing I/Os with motor control

connectors, and to connect these I/Os to motor control connectors.

Tabl e 10 and Ta bl e 11

show the assignment of CN2 and CN4 of the STM32G474QET6U terminals.

Tabl e 10 and Ta bl e 11 also list the modifications to be made on the board versus its by-

default configuration. See Section 5.11.1 for further details.

Table 10. Motor control CN2 terminal and function assignment

Motor control

connector CN2

Ter min al

1

Terminal

name

Emergency

Stop

Port

name

PE15 TIM1_BKIN - Close SB69, and remove R60

STM32G474QET6 microcontroller

Function

Alternate

function

Board modifications for

enabling motor control

2 GND - GND - -

3 PWM_1H PE9 TIM1_CH1 - Close SB78, and remove R79

4 GND - GND - -

5 PWM_1L PE8 TIM1_CH1N - Close SB79, and remove R82

6 GND - GND - -

7 PWM_2H PE11 TIM1_CH2 - Close SB76, and remove R71

8 GND - GND - -

9 PWM_2L PE10 TIM1_CH2N - Close SB77, and remove R75

10 GND - GND - -

11 PWM_3H PE13 TIM1_CH3 - Close SB73, and remove R63

12 GND - GND - -

13 PWM_3L PE12 TIM1_CH3N - Close SB74, and remove R69

14 Bus Voltage PC1 ADC12_IN7 -

Close SB115, and remove

R130

15

16

17

18

19

20

PhaseA

current+

PhaseA

current-

PhaseB

current+

PhaseB

current-

PhaseC

current+

PhaseC

current-

PC2 ADC12_IN8 -

-GND - -

PC3 ADC12_IN9 -

-GND - -

PC0 ADC12_IN6 - Close SB99, and open SB29

-GND - -

21 ICL Shutout PE4 GPIO -

26/83 UM2514 Rev 4

Close SB113, and remove

R133

Close SB114, and remove

R131

Close SB109, and open

(1)

SB107

Page 27

UM2514 Hardware layout and configuration

Table 10. Motor control CN2 terminal and function assignment (continued)

Motor control

connector CN2

Ter min al

Terminal

name

Port

name

STM32G474QET6 microcontroller

Function

Alternate

function

Board modifications for

enabling motor control

22 GND - GND - -

23

24

Dissipative

Brake

PFC ind.

current

PE5 GPIO - Close SB97, and open SB28

PD8 ADC45_IN12 -

Close SB55, remove R34,

solder R5, and remove R113

25 +5 V - +5 V - -

26

Heatsink

Te mp .

PC4 ADC2_IN5 -

27 PFC Sync PE2 TIM3_CH1 -

Close SB100, and remove

R116

Close SB103, open SB111

(1)

solder R8, and remove R126

28 +3.3 V - +3.3 V - -

29 PFC PWM PE3 TIM3_CH2 -

30

PFC

Shutdown

PD2 TIM3_ETR -

Close SB118, open SB110,

solder R11, and remove R151

Solder SB17, and remove

SB123

31 Encoder A PA0 TIM2_CH1 - Close SB98, and open SB26

(1)

,

32 PFC Vac PD9 ADC45_IN13 -

Close SB56, remove R37,

solder R12, and remove R155

33 Encoder B PD4 TIM2_CH2 - Close SB89, and remove R94

34

Motor control

connector CN4

Ter min al

1

Encoder

Index

PD7 or

PA1 5

Table 11. Motor control CN4 terminal and function assignment

Terminal

name

Emergency

Stop

Port

name

PB7 TIM8_BKIN - -

TIM2_CH3 or

TIM2_ETR

-

STM32G474QET6 microcontroller

Function

Alternate

function

Close SB92, remove R101 or

close SB62, and remove R54

Board modifications for

enabling motor control

2 GND - GND - -

3 PWM_1H PC6 TIM8_CH1 - Close SB49, and open SB9

4 GND - GND - -

5 PWM_1L PC10 TIM8_CH1N - Close SB64, and open SB12

6 GND - GND - -

7 PWM_2H PC7 TIM8_CH2 - Close SB50, and open SB6

(1)

(1)

(1)

UM2514 Rev 4 27/83

82

Page 28

Hardware layout and configuration UM2514

Table 11. Motor control CN4 terminal and function assignment (continued)

Motor control

connector CN4

Ter min al

Terminal

name

Port

name

STM32G474QET6 microcontroller

Function

Alternate

function

Board modifications for

enabling motor control

8 GND - GND - -

9 PWM_2L PC11 TIM8_CH2N - Close SB68, and open SB13

10 GND - GND - -

11 PWM_3H PC8 TIM8_CH3 -

Close SB51, and remove

(1)

R26

12 GND - GND - -

13 PWM_3L PC12 TIM8_CH3N - Close SB66, and open SB15

14 Bus Voltage PE14 ADC4_IN1 - Close SB72, and remove R62

15

16

17

18

PhaseA

current+

PhaseA

current-

PhaseB

current+

PhaseB

current-

PD13 ADC345_IN10 - Close SB60, and remove R41

-GND - -

PD12 ADC345_IN9 - Close SB59, and remove R42

-GND - -

(1)

(1)

19

20

PhaseC

current+

PhaseC

current-

PD10 ADC345_IN7 - Close SB57, and remove R38

-GND - -

21 ICL Shutout PD15 GPIO - Close SB61, and remove R40

22 GND - GND - -

23

24

Dissipative

Brake

PFC ind.

current

PF10 GPIO -

PD8 ADC45_IN12 -

Close SB112, and remove

(1)

R136

Close SB55, remove R34,

solder R113, and remove R5

25 +5 V - +5 V - -

26

27 PFC Sync PE2 TIM3_CH1 -

Heatsink

Te mp .

PE7 ADC3_IN4 - Close SB83, and remove R84

Close SB103, open SB111

(1)

solder R126, and remove R8

28 +3.3 V - +3.3 V - -

29 PFC PWM PE3 TIM3_CH2 -

30

PFC

Shutdown

PD2 TIM3_ETR - Solder R128, and remove R10

Close SB118, open SB110,

solder R151, and remove R11

31 Encoder A PF6 TIM5_CH1 - Close SB52, and remove R43

,

28/83 UM2514 Rev 4

Page 29

UM2514 Hardware layout and configuration

Table 11. Motor control CN4 terminal and function assignment (continued)

Motor control

connector CN4

Ter min al

Terminal

name

Port

name

STM32G474QET6 microcontroller

Function

Alternate

function

32 PFC Vac PD9 ADC45_IN13 -

33 Encoder B PF7 TIM5_CH2 -

34

1. For quality purpose, remove the unused components located on the board.

Encoder

Index

PF8 or

PD11

TIM5_CH3 or

TIM5_ETR

-

Board modifications for

enabling motor control

Close SB56, remove R37,

solder R155, and remove R12

Close SB108, and remove

R138

Close SB106, remove R135 or

close SB58, and remove R39

UM2514 Rev 4 29/83

82

Page 30

Hardware layout and configuration UM2514

Tabl e 12 shows OpAmp and DAC of the STM32G474QET6U terminals.

Table 12. Motor control OpAmp and DAC function assignment

Motor control connector

CN2

Terminal Terminal name

Port

name

STM32G474QET6 microcontroller

Function

Alternate

function

1 OPAMP1_INP PA1 OPAMP1_VINP -

2 OPAMP1_INN PA3 OPAMP1_VINM -

3 OPAMP1_OUT PA2 OPAMP1_VOUT -

4 O PAMP2_IN1P PA 7 OPA MP2_VINP -

5 OPAMP2_IN2P PD14 OPAMP2_VINP -

6 OPAMP2_INN PC5 OPAMP2_VINM - -

7 OPAMP2_OUT PA6 OPAMP2_VOUT -

8 OPAMP4_IN1P PB11 OPAMP4_VINP -

9 OPAMP4_IN2P PB13 OPAMP4_VINP -

10 OPAMP4_INN PB10 OPAMP4_VINM -

Board modifications for

enabling motor control

Close SB95, and open

SB27

Close SB105, and

remove R129

Close SB117, and

remove R150

Close SB101, and

remove R118

Close SB70, and remove

R29

Close SB104, and

remove R121

Close SB67, and open

SB8

Close SB63, and open

SB5

Close SB71, and open

SB11

11 OPAMP4_OUT PB12 OPAMP4_VOUT -

12 OPAMP3_INP PB0 OPAMP3_VINP -

13 OPAMP3_INN PB2 OPAMP3_VINM -

14 OPAMP3_OUT PB1 OPAMP3_VOUT -

15 DAC_OUT1 PA4 DAC1_OUT1 -

16 DAC_OUT2 PA5 DAC1_OUT2 - -

Tabl e 13 and Ta bl e 14 show motor control related switches and solder bridges.

30/83 UM2514 Rev 4

Close SB65 and open

SB7

Close SB94, and remove

R108

Close SB80, and open

SB18

Close SB91, and remove

R102

Close SB93, and open

SB25

Page 31

UM2514 Hardware layout and configuration

OAM

Position

SW5

SW5

Table 13. Motor control related switches and solder bridges

Other conditions Description

R72,R58 mounted

SB14 open

72,R58 un-mounted

SB14 closed

SW1 position

SW1 position

-

MC1_CurrentA+ connect to OPAMP1_INP(PA1)

MC1_CurrentB+ connect to OPAMP2_IN1P(PA7)

MC1_CurrentB+ connect to OPAMP1_INP(PA1)

MC1_CurrentC+ connect to OPAMP2_IN2P(PD14)

MC1_CurrentC+ connect to OPAMP4_IN1P(PB11)

MC1_CurrentA+ connect to ADC12(PC2)

MC1_CurrentB+ connect to ADC12(PC3)

MC1_CurrentC+ connect to ADC12(PC0)

SW6

SW6

R110,R114 mounted

SB19 open

R110,R114 un-mounted

SB19 closed

SW1 position

SW1 position

-

MC2_CurrentA+ connect to OPAMP3_INP(PB0)

MC2_CurrentB+ connect to OPAMP4_IN2P(PB13)

MC2_CurrentB+ connect to OPAMP3_INP(PB0)

MC2_CurrentC+ connect to OPAMP4_IN1P(PB11)

MC2_CurrentC+ connect to OPAMP2_IN2P(PD14)

MC2_CurrentA+ connect to ADC345(PD10)

MC2_CurrentB+ connect to ADC345(PD12)

MC2_CurrentC+ connect to ADC345(PD13)

UM2514 Rev 4 31/83

82

Page 32

Hardware layout and configuration UM2514

PGM Position Other conditions Description

SW2

SW2

SW3

SW3

Table 14. Motor control related switches and solder bridges

-

SW4 position

SW4 position

-

SW4 position

SW4 position

OPAMP1_INP,OPAMP2_IN1P,OPAMP2_IN2P pull up source

connect to 3.3 V power

OPAMP1_INP, OPAMP2_IN1P,OPAMP2_IN2P pull up source

connect to DAC_OUT1(PA4)

OPAMP1_INP, OPAMP2_IN1P pull up source connect to

DAC_OUT1(PA4)

OPAMP2_IN2P pull up source connect to DAC_OUT2(PA5)

OPAMP4_INP,OPAMP4_IN1P,OPAMP4_IN2P pull up source

connect to 3.3 V power

OPAMP3_INP, OPAMP4_IN1P,OPAMP4_IN2P pull up source

connect to DAC_OUT2(PA5)

OPAMP3_INP, OPAMP4_IN2P pull up source connect to

DAC_OUT2(PA5)

OPAMP2_IN1P pull up source connect to DAC_OUT1(PA4)

5.11.1 Board modifications to enable motor control

Figure 7 (top side) and Figure 8 (bottom side) illustrate the board modifications listed in

Tabl e 10 and Ta bl e 11, required for the operation of motor control. Blue color denotes a

component to be removed. Red color denotes a component to be fitted.

5.11.2 Limitations

Motor control operation is exclusive with Octo-SPIP1 Flash memory device, audio codec,

potentiometer, LDR, Micro SD card, LED1 to LED4 drive, MEMs, MFX, PMOD, USB

OTG_FS, TFT LCD connector, DSI LCD connector and touch sensing.

Refer to Section 5.16.3 for OPAMP1, 2 and 4 limitations.

32/83 UM2514 Rev 4

Page 33

UM2514 Hardware layout and configuration

Figure 7. PCB top side rework for motor control

Figure 8. PCB bottom side rework for motor control

5.12 FDCAN

The STM32G474E-EVAL board supports two CAN2.0A/B channel compliant with FDCAN

specification. The CN10 and CN12 are available as CAN interface.

Two CAN transceiver are fitted between the CN10 and CN12 connectors and the CAN

controller port of STM32G474QET6U.

UM2514 Rev 4 33/83

82

Page 34

Hardware layout and configuration UM2514

5.12.1 Limitations

CAN operation is exclusive with BOOT0 and motor control connector 2.

5.12.2 Operating voltage

The supply voltage for STM32G474E-EVAL CAN operation must be more than 1.8 V.

5.13 Extension connectors CN5 and CN6

The CN5 and CN6 headers complement to give access to all GPIOs of the

STM32G474QET6U microcontroller. In addition to GPIOs, the following signals and power

supply lines are also routed on CN5 or CN6:

• GND

• 5V

• 5V_D

• VDD

• RESET#

• Clock terminals PC14-OSC32_IN, PC15-OSC32_OUT, PF0-OSC_IN, PF1-OSC_OUT

Each header has two rows of 30 pins, with 1.27 mm pitch and 2.54 mm row spacing. For

extension modules, SAMTEC RSM-130-02-L-D-xxx and SMS-130-x-x-D can be

recommended as SMD and through-hole receptacles, respectively (x is a wild card).

5.14 User LEDs

Four general-purpose color LEDs (LD1, LD2, LD3, LD4) are available as light indicators.

Each LED is in light-emitting state with low level of the corresponding ports of the

STM32G474QET6U MCU.

And the LD1 and LD3 LEDs are exclusive with MC operation, LD2 and LD4 are controlled

by MFX_GPIO6 and MFX_GPIO7.

5.15 Physical input devices

The STM32G474E-EVAL board provides a number of input devices for physical human

control.

• four-way joystick controller with select key (B1)

• wake-up/ tamper button (B2)

• reset button (B3)

• 10 k

• light-dependent resistor, LDR (R174)

Ω potentiometer (RV2)

The potentiometer and the light-dependent resistor can be routed, mutually exclusively, to

PB11 port of the STM32G474QET6U.

configuration jumpers.

34/83 UM2514 Rev 4

Table 15 depicts the setting of associated

Page 35

UM2514 Hardware layout and configuration

As illustrated in the schematic diagram in Figure 36, the PB11 port is routed, in the

STM32G474QET6U, to the non-inverting input of comparator Comp6 or non-inverting input

of operational amplifier OpAmp4.

Jumper setting Routing

JP5

Table 15. Port assignment for control of physical input devices

Default setting.

Potentiometer is routed to pin PB11 of STM32G474QET6U.

LDR is routed to pin PB11 of STM32G474QET6U.

5.15.1 Limitations

The potentiometer and the light-dependent resistor are exclusive with high brightness LED

and MC operation. And they are mutually exclusive.

5.16 Operational amplifier and comparator

5.16.1 Operational amplifier

STM32G474QET6U provides on-board operational amplifier, OpAmp4, is made accessible

on STM32G474E-EVAL. OpAmp4 has its inputs and its output routed to I/O ports PB11,

PB10 and PB12, respectively.

The PB12 output of the operational amplifier can be accessed on test point TP2. Refer to

the schematic diagram in

The gain of OpAmp4 is determined by the ratio of the variable resistor RV1 and the resistor

R157, as shown in the following equation:

With the RV1 ranging from 0 to 10 kΩ and R157 being 1 kΩ, the gain can vary from 1 to 11.

The R158 resistor in series with PB12 is beneficial for reducing the output offset.

Tabl e 16 shows the configuration elements and their settings to access the OpAmp4

function.

Element Setting Configuration

SB11

SB71

Table 16. Configuration elements related with OpAmp4

SB11 closed

SB71 open

SB11 open

SB71 closed

Figure 36.

Gain = 1+ RV1/R157

Default setting.

Pin PB10 of STM32G474QET6U is routed to OpAmp4_VINM.

Pin PB10 of STM32G474QET6U is routed to OpAmp4_INN of

MC.

UM2514 Rev 4 35/83

82

Page 36

Hardware layout and configuration UM2514

Table 16. Configuration elements related with OpAmp4 (continued)

Element Setting Configuration

SB8

SB67

SB10

SB7

SB65

5.16.2 Comparator

STM32G474QET6U provides on-board comparator, Comp4, is made accessible on

STM32G474E-EVAL. Comp4 has its non-inverting input and its output routed to I/O ports

PB11 and PC6, respectively.

The PC6 output of the comparator can be accessed on test point TP1. Refer to the

schematic diagram in

SB8 closed

SB67 open

SB10 open

SB8 open

SB67 closed

SB10 open

SB8 open

SB67 open

SB10 closed

SB7 closed

SB65 open

SB7 open

SB65 closed

Figure 36.

Pin PB11 of STM32G474QET6U is routed to OpAmp4_VINP or

COMP6_INP.

PB11 of STM32G474QET6U is routed to OpAmp4_IN1P of MC.

Default setting.

Pin PB11 of STM32G474QET6U is routed to BK_Sense for high

brightness LED.

Default setting.

Pin PB12 of STM32G474QET6U is routed to OpAmp4_VOUT.

Pin PB12 of STM32G474QET6U is routed to OpAmp4_IN2P of

MC.

Tabl e 17 shows the configuration elements and their settings to access the Comp4 function

(pin PB11 for Comp6_INP refer to Tabl e 16).

Element Setting Configuration

SB9

SB49

5.16.3 Limitations

Issue observed

The OPAMP offset value is minimized using a trimming circuitry. At startup, the trimming

values are initialized with the preset factory trimming values. The trimming values of

OPAMP1, OPAMP2 and OPAMP4 are not programmed correctly, resulting in a large offset

compared to the one specified.

Proposed workaround

The offset values of OPAMP1, OPAMP2 and OPAMP4 must be calibrated by software,

applying the calibration procedure described in the STM32G4 Series advanced Arm®-

Table 17. Configuration elements related with Comp4

SB9 closed

SB49 open

SB9 closed

SB49 open

Default setting.

Pin PC6 of STM32G474QET6U is routed to Comp6_OUT.

Pin PC6 of STM32G474QET6U is routed to MC2_PWM_1H.

36/83 UM2514 Rev 4

Page 37

UM2514 Hardware layout and configuration

based 32-bit MCUs reference manual (RM0440), in the Calibration section of the

Operational amplifiers (OPAMP) chapter. Such a procedure is already implemented in the

STM32CubeG4 MCU Package.

Parts impacted

This applies only to the MB1397-based boards within the following range of serial numbers:

MB1397-G474E: A191000001-A191000170

MB1397-G474EMC: A191000001- A191000100

MB1397-G484E: A191000001-A191000030

Other issues

The OpAmp4 is exclusive with high brightness LED and MC operation.

The Comp6 is exclusive with high brightness LED and MC operation.

5.17 Analog input, output, VREF

5.17.1 Analog input

STM32G474QET6U provides on-board Differential analog-to-digital converter, Differential

ADC. The port PA0 and PA1 can be configured to operate as Differential ADC input which is

routed to the CN7 and CN8 SMB connectors or CN3 SMB connector via a Single-Ended to

Differential circuit. The default setting is Analog input signal from CN3 SMB connector.

Parameters of the ADC input low-pass filter formed with R310/C171 and R152/C35 can be

modified by replacing these components according to application requirements.

5.17.2 Analog output

STM32G474QET6U provides on-board digital-to-analog converter, DAC. The port PA4 can

be configured to operate as DAC output. PA4 is routed to the two-way header CN9 to fetch

signals from PA4 to ground it by fitting a jumper into CN9.

Parameters of the DAC output low-pass filter formed with R153 and C36 can be modified by

replacing these components according to application requirements.

5.17.3 VREF+ terminal

The VREF+ terminal of STM32G474QET6U is used as reference voltage for both ADC and

DAC. It is routed to VDDA or VREF_EXT through solder bridges configuration shown as

Tabl e 18.

VREF_EXT is high resolution of voltage reference from U53 TL1431ACL5T.

Element Setting Configuration

SB84

SB85

Table 18. Configuration elements related with VREF+

SB84 closed

SB85 open

SB84 closed

SB85 open

Default setting.

VREF_EXT is routed to VREF+.

VDDA is routed to VREF+.

UM2514 Rev 4 37/83

82

Page 38

Hardware layout and configuration UM2514

5.17.4 Limitations

The Differential ADC is exclusive with MFX_IRQ_OUT and MC operation.

The DAC is exclusive with MC operation.

5.18 SRAM device

IS61WV51216BLL, an 8-Mbit static RAM (SRAM), 512K x16-bit, is fitted on the

STM32G474E-EVAL main board, in U11 position. The STM32G474E-EVAL main board as

well as the addressing capabilities of FMC allow hosting SRAM devices up to 64 Mbytes.

This is the reason why the schematic diagram in

devices.

The SRAM device is attached to the 16-bit data bus and accessed with FMC. The base

address is 0x6000 0000, corresponding to NOR/SRAM1 bank1. The SRAM device is

selected with FMC_NE1 chip select. FMC_NBL0 and FMC_NBL1 signals allow selecting 8bit and 16-bit data word operating modes.

5.18.1 Limitations

The SRAM addressable space is limited if some or all of A20 FMC address lines is shunted

to the CN17 connector for debug trace purposes. In such a case, the disconnected

addressing inputs of the SRAM device are pulled down by resistors.

information on the associated configuration elements.

Figure 30 mentions several SRAM

Section 5.2 provides

The SRAM is exclusive with MC operation.

5.18.2 Operating voltage

The SRAM device operating voltage is in the range from 2.4 V to 3.6 V.

5.19 EXT_I2C connector

EXT_I2C connector CN1 can be connected to I²C bus daughter board. MFX_GPIO15 of

MFX MCU provide EXT_RSET signal. And solder bridge SB1 is used to connector 5

power supply for daughter board.

5.20 Quad-SPI Flash memory device

Two 512-Mbit Quad-SPI Flash memory device MT25QL512ABB8ESF-0SIT are fitted on the

STM32G474E-EVAL main board, in U12 and U54 position. It allows evaluating

STM32G474QET6U Quad-SPI interface.

5.20.1 Limitations

Quad-SPI Flash memory device operation is exclusive with motor control.

5.20.2 Operating voltage

V

Voltage of Quad-SPI Flash memory device MT25QL512ABB8ESF-0SIT is in the range of

2.7

V to 3.6 V.

38/83 UM2514 Rev 4

Page 39

UM2514 Hardware layout and configuration

5.21 MFX MCU

The MFX MCU is used as MFX (Multi function expander) and IDD measurement.

5.21.1 MFX

MFX circuit on the STM32G474E-EVAL board acts as IO-expander. The communication

interface between MFX and STM32G474QET6U is I2C3 bus. The signals connected to

MFX are listed in

Tabl e 19.

Table 19. MFX signals