Datasheet STM32G0C1CC, STM32G0C1KC, STM32G0C1MC, STM32G0C1RC, STM32G0C1VC Datasheet (STMicroelectronics)

...Page 1

STM32G0C1xC/xE

Errata sheet

STM32G0C1xC/xE device errata

Applicability

This document applies to the part numbers of STM32G0C1xC/xE devices and the device variants as stated in this page.

It gives a summary and a description of the device errata, with respect to the device datasheet and reference manual RM0444.

Deviation of the real device behavior from the intended device behavior is considered to be a device limitation. Deviation of the

description in the reference manual or the datasheet from the intended device behavior is considered to be a documentation

erratum. The term “errata” applies both to limitations and documentation errata.

Table 1. Device summary

Reference Part numbers

STM32G0C1xC STM32G0C1CC, STM32G0C1KC, STM32G0C1MC, STM32G0C1RC ,STM32G0C1VC

STM32G0C1xE STM32G0C1CE, STM32G0C1KE, STM32G0C1ME, STM32G0C1NE, STM32G0C1RE, STM32G0C1VE

Table 2. Device variants

Reference

STM32G0C1xC/xE

1. Refer to the device datasheet for how to identify this code on different types of package.

2. REV_ID[15:0] bitfield of DBGMCU_IDCODE register.

Device marking

A 0x1000

Silicon revision codes

(1)

REV_ID

(2)

ES0549 - Rev 1 - January 2021

For further information contact your local STMicroelectronics sales office.

www.st.com

Page 2

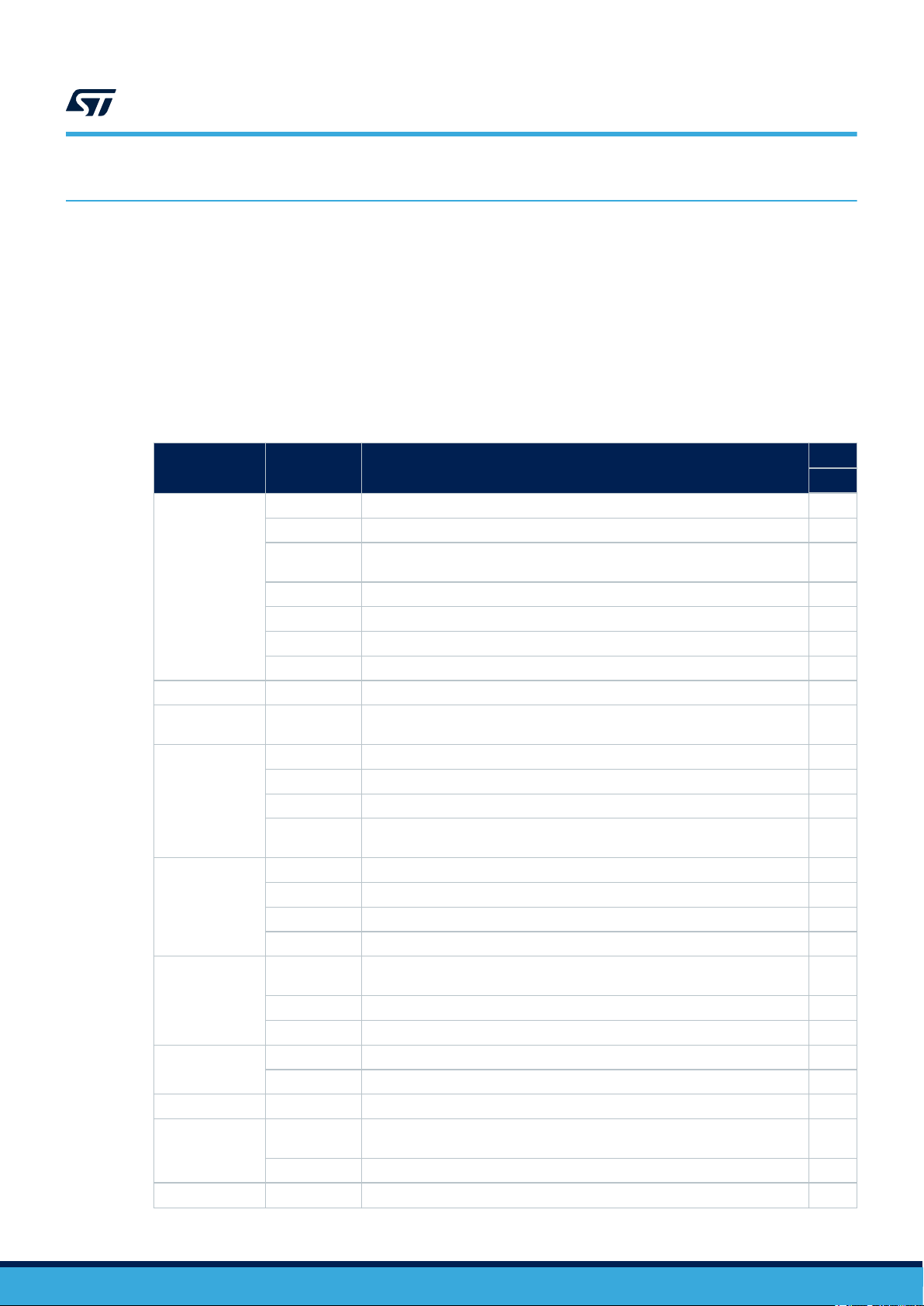

1 Summary of device errata

The following table gives a quick reference to the STM32G0C1xC/xE device limitations and their status:

A = workaround available

N = no workaround available

P = partial workaround available

Applicability of a workaround may depend on specific conditions of target application. Adoption of a workaround

may cause restrictions to target application. Workaround for a limitation is deemed partial if it only reduces the

rate of occurrence and/or consequences of the limitation, or if it is fully effective for only a subset of instances on

the device or in only a subset of operating modes, of the function concerned.

Table 3. Summary of device limitations

STM32G0C1xC/xE

Summary of device errata

Function

System

GPIO 2.3.1 Wakeup capability-enabled GPIOs not configurable after wakeup from Standby P

DMA 2.4.1

DMAMUX

ADC

TIM

LPTIM

RTC and TAMP 2.9.1 Calendar initialization may fail in case of consecutive INIT mode entry A

I2C

SPI

Section Limitation

2.2.1 Unstable LSI when it clocks RTC or CSS on LSE

2.2.2 WUFx wakeup flag wrongly set during configuration A

2.2.3

2.2.4 Wakeup from Stop not effective under certain conditions N

2.2.5 Flash memory PCROP area weakness N

2.2.6 PC13 signal transitions disturb LSE N

2.2.7 SRAM contents corrupted upon entry in Standby N

2.5.1 SOFx not asserted when writing into DMAMUX_CFR register N

2.5.2 OFx not asserted for trigger event coinciding with last DMAMUX request N

2.5.3 OFx not asserted when writing into DMAMUX_RGCFR register N

2.5.4

2.6.1 Overrun flag is not set if EOC reset coincides with new conversion end P

2.6.2 Writing ADC_CFGR1 register while ADEN bit is set resets RES[1:0] bitfield A

2.6.3 Out-of-threshold value is not detected in AWD1 Single mode A

2.6.4 ADC sampling time might be one cycle longer N

2.7.1

2.7.2 Consecutive compare event missed in specific conditions N

2.7.3 Output compare clear not working with external counter reset P

2.8.1 Device may remain stuck in LPTIM interrupt when entering Stop mode A

2.8.2 Device may remain stuck in LPTIM interrupt when clearing event flag P

2.10.1

2.10.2 Spurious bus error detection in master mode A

2.12.1 BSY bit may stay high when SPI is disabled A

Overwriting with all zeros a Flash memory location previously programmed with

all ones fails

DMA disable failure and error flag omission upon simultaneous transfer error

and global flag clear

Wrong input DMA request routed upon specific DMAMUX_CxCR register write

coinciding with synchronization event

One-pulse mode trigger not detected in master-slave reset + trigger

configuration

Wrong data sampling when data setup time (tSU;DAT) is shorter than one I2C

kernel clock period

Status

Rev. A

P

N

A

A

P

P

ES0549 - Rev 1

page 2/18

Page 3

STM32G0C1xC/xE

Summary of device errata

Function Section Limitation

SPI

USART 2.11.1 Data corruption due to noisy receive line N

FDCAN

UCPD 2.14.1 UCPD transmitter output marginality at low temperature N

2.12.2 BSY bit may stay high at the end of data transfer in slave mode

2.13.1 Desynchronization under specific condition with edge filtering enabled A

2.13.2 Tx FIFO messages inverted under specific buffer usage and priority setting A

The following table gives a quick reference to the documentation errata.

Table 4. Summary of device documentation errata

Function Section Documentation erratum

System 2.2.8 Boot select after debug interface connection

USART 2.11.2 USART prescaler feature missing in USART implementation section

Status

Rev. A

A

ES0549 - Rev 1

page 3/18

Page 4

STM32G0C1xC/xE

Description of device errata

2 Description of device errata

The following sections describe limitations of the applicable devices with Arm® core and provide workarounds if

available. They are grouped by device functions.

Note: Arm is a registered trademark of Arm Limited (or its subsidiaries) in the US and/or elsewhere.

2.1 Core

Reference manual and errata notice for the Arm® Cortex®-M0+ core revision r0p1 is available from http://

infocenter.arm.com.

2.2 System

2.2.1 Unstable LSI when it clocks RTC or CSS on LSE

Description

The LSI clock can become unstable (duty cycle different from 50 %) and its maximum frequency can become

significantly higher than 32 kHz, when:

• LSI clocks the RTC, or it clocks the clock security system (CSS) on LSE (which holds when the LSECSSON

bit set), and

• the VDD power domain is reset while the backup domain is not reset, which happens:

– upon exiting Shutdown mode

– if V

– if V

Workaround

Apply one of the following measures:

• Clock the RTC with LSE or HSE/32, without using the CSS on LSE

• If LSI clocks the RTC or when the LSECSSON bit is set, reset the backup domain upon each VDD power up

(when the BORRSTF flag is set). If V

registers and anti-tampering configuration.

is separate from VDD and VDD goes off then on

BAT

is tied to VDD (internally in the package for products not featuring the VBAT pin, or externally)

BAT

and a short (< 1 ms) VDD drop under VDD(min) occurs

is separate from VDD, also restore the RTC configuration, backup

BAT

2.2.2 WUFx wakeup flag wrongly set during configuration

Description

Upon configuring a wakeup pin (WKUPx), the corresponding wakeup flag (WUFx) might spuriously go high

depending on the state and configuration of the wakeup pin.

Workaround

After configuring a wakeup pin, clear its corresponding WUFx flag.

2.2.3 Overwriting with all zeros a Flash memory location previously programmed with all ones fails

Description

Any attempt to re-program with all zeros (0x0000 0000 0000 0000) a Flash memory location previously

programmed with 0xFFFF FFFF FFFF FFFF fails and the PROGERR flag of the FLASH_SR register is set.

ES0549 - Rev 1

page 4/18

Page 5

Workaround

None.

2.2.4 Wakeup from Stop not effective under certain conditions

Description

With the HSI clock divider bitfield HSIDIV[2:0] set to a value different from 000, the device fails to enter Stop mode

when SYSCLK is set to HSE clock.

With the HSI clock divider bitfield HSIDIV[2:0] set to a value different from 000, peripherals with clock request

capability fail to wake the device up from Stop modes.

Workaround

None.

2.2.5 Flash memory PCROP area weakness

Description

When the CPU accesses PCROP-protected Flash memory areas:

• Fetch requests are allowed and are responded to normally.

• Read access are properly discarded. However, the bus holds and returns the value read during previous

successful access.

STM32G0C1xC/xE

System

Workaround

None.

Note: We recommend to use the PCROP protection in the following RDP and PCROP_RDP configurations:

• RDP = Level 1 and PCROP_RDP = 1

• RDP = Level 2

2.2.6 PC13 signal transitions disturb LSE

Description

The PC13 port toggling disturbs the LSE clock.

Workaround

None.

2.2.7 SRAM contents corrupted upon entry in Standby

Description

Entry of the device in Standby mode causes the SRAM content corruption.

Workaround

None.

2.2.8 Boot select after debug interface connection

Description

Some revisions of the reference manual may omit the following information.

ES0549 - Rev 1

page 5/18

Page 6

STM32G0C1xC/xE

GPIO

After connecting the debug interface and until the device power-down, the boot source upon reset or wakeup from

a low-power mode is determined by the PA14-BOOT0 pin level before connecting the debug interface (stored by

the device), as opposed to the actual PA14-BOOT0 pin level. The device power-up restores the operation of the

PA14-BOOT0 pin as direct boot source selector.

This is a documentation issue rather than a device limitation.

Workaround

No application workaround is required or applicable.

2.3

GPIO

2.3.1 Wakeup capability-enabled GPIOs not configurable after wakeup from Standby

Description

After the devices wakes up from Standby mode, GPIOs with the wakeup capability enabled cannot further be

configured through the GPIO registers.

Workaround

Disable the wakeup capability of the GPIOs that must remain configurable through the GPIO registers after the

wakeup from Standby.

2.4

DMA

2.4.1 DMA disable failure and error flag omission upon simultaneous transfer error and global flag

clear

Description

Upon a data transfer error in a DMA channel x, both the specific TEIFx and the global GIFx flags are raised and

the channel x is normally automatically disabled. However, if in the same clock cycle the software clears the GIFx

flag (by setting the CGIFx bit of the DMA_IFCR register), the automatic channel disable fails and the TEIFx flag is

not raised.

This issue does not occur with ST's HAL software that does not use and clear the GIFx flag when the channel is

active.

Workaround

Do not clear GIFx flags when the channel is active. Instead, use HTIFx, TCIFx, and TEIFx specific event flags and

their corresponding clear bits.

2.5 DMAMUX

2.5.1 SOFx not asserted when writing into DMAMUX_CFR register

Description

The SOFx flag of the DMAMUX_CSR status register is not asserted if overrun from another DMAMUX channel

occurs when the software writes into the DMAMUX_CFR register.

This can happen when multiple DMA channels operate in synchronization mode, and when overrun can occur

from more than one channel. As the SOFx flag clear requires a write into the DMAMUX_CFR register (to set

the corresponding CSOFx bit), overrun occurring from another DMAMUX channel operating during that write

operation fails to raise its corresponding SOFx flag.

ES0549 - Rev 1

page 6/18

Page 7

Workaround

None. Avoid the use of synchronization mode for concurrent DMAMUX channels, if at least two of them potentially

generate synchronization overrun.

2.5.2 OFx not asserted for trigger event coinciding with last DMAMUX request

Description

In the DMAMUX request generator, a trigger event detected in a critical instant of the last-generated DMAMUX

request being served by the DMA controller does not assert the corresponding trigger overrun flag OFx. The

critical instant is the clock cycle at the very end of the trigger overrun condition.

Additionally, upon the following trigger event, one single DMA request is issued by the DMAMUX request

generator, regardless of the programmed number of DMA requests to generate.

The failure only occurs if the number of requests to generate is set to more than two (GNBREQ[4:0] > 00001).

Workaround

Make the trigger period longer than the duration required for serving the programmed number of DMA requests,

so as to avoid the trigger overrun condition from occurring on the very last DMA data transfer.

STM32G0C1xC/xE

DMAMUX

2.5.3 OFx not asserted when writing into DMAMUX_RGCFR register

Description

The OFx flag of the DMAMUX_RGSR status register is not asserted if an overrun from another DMAMUX request

generator channel occurs when the software writes into the DMAMUX_RGCFR register. This can happen when

multiple DMA channels operate with the DMAMUX request generator, and when an overrun can occur from more

than one request generator channel. As the OFx flag clear requires a write into the DMAMUX_RGCFR register

(to set the corresponding COFx bit), an overrun occurring in another DMAMUX channel operating with another

request generator channel during that write operation fails to raise the corresponding OFx flag.

Workaround

None. Avoid the use of request generator mode for concurrent DMAMUX channels, if at least two channels are

potentially generating a request generator overrun.

2.5.4 Wrong input DMA request routed upon specific DMAMUX_CxCR register write coinciding with

synchronization event

Description

If a write access into the DMAMUX_CxCR register having the SE bit at zero and SPOL[1:0] bitfield at a value

other than 00:

• sets the SE bit (enables synchronization),

• modifies the values of the DMAREQ_ID[5:0] and SYNC_ID[4:0] bitfields, and

• does not modify the SPOL[1:0] bitfield,

and if a synchronization event occurs on the previously selected synchronization input exactly two AHB clock

cycles before this DMAMUX_CxCR write, then the input DMA request selected by the DMAREQ_ID[5:0] value

before that write is routed.

ES0549 - Rev 1

Workaround

Ensure that the SPOL[1:0] bitfield is at 00 whenever the SE bit is 0. When enabling synchronization by setting

the SE bit, always set the SPOL[1:0] bitfield to a value other than 00 with the same write operation into the

DMAMUX_CxCR register.

page 7/18

Page 8

2.6 ADC

2.6.1 Overrun flag is not set if EOC reset coincides with new conversion end

Description

If the EOC flag is cleared by an ADC_DR register read operation or by software during the same APB cycle in

which the data from a new conversion are written in the ADC_DR register, the overrun event duly occurs (which

results in the loss of either current or new data) but the overrun flag (OVR) may stay low.

Workaround

Clear the EOC flag, by performing an ADC_DR read operation or by software within less than one ADC

conversion cycle period from the last conversion cycle end, in order to avoid the coincidence with the end of

the new conversion cycle.

2.6.2 Writing ADC_CFGR1 register while ADEN bit is set resets RES[1:0] bitfield

Description

Modifying the ADC_CFGR1 register while ADC is enabled (ADEN set in ADC_CR) and no conversion is ongoing

(ADSTART cleared in ADC_CR) resets RES[1:0] to 00 whatever the bitfield previous value.

STM32G0C1xC/xE

ADC

Workaround

Apply the following sequence:

1. Set ADDIS to disable the ADC, and wait until ADEN is cleared.

2. Program the ADC_CFGR1 register according to the application requirements.

3. Set ADEN bit.

2.6.3 Out-of-threshold value is not detected in AWD1 Single mode

Description

AWD1 analog watchdog does not detect that the result of a converted channel has reached the programmed

threshold when the ADC operates in Single mode, performs a sequence of conversions, and one of the converted

channels other than the first one is monitored by the AWD1 analog watchdog.

Workaround

Apply one of the following measures:

• Use a conversion sequence of one single channel.

• Configure the monitored channel as the first one of the sequence.

2.6.4 ADC sampling time might be one cycle longer

Description

For sampling time set to 1.5 or 3.5 cycles, the sampling in a single ADC conversion or in the first conversion of a

sequence takes one extra cycle.

ES0549 - Rev 1

Workaround

None.

page 8/18

Page 9

STM32G0C1xC/xE

2.7 TIM

2.7.1 One-pulse mode trigger not detected in master-slave reset + trigger configuration

Description

The failure occurs when several timers configured in one-pulse mode are cascaded, and the master timer is

configured in combined reset + trigger mode with the MSM bit set:

OPM = 1 in TIMx_CR1, SMS[3:0] = 1000 and MSM = 1 in TIMx_SMCR.

The MSM delays the reaction of the master timer to the trigger event, so as to have the slave timers cycleaccurately synchronized.

If the trigger arrives when the counter value is equal to the period value set in the TIMx_ARR register, the

one-pulse mode of the master timer does not work and no pulse is generated on the output.

Workaround

None. However, unless a cycle-level synchronization is mandatory, it is advised to keep the MSM bit reset, in

which case the problem is not present. The MSM = 0 configuration also allows decreasing the timer latency to

external trigger events.

2.7.2 Consecutive compare event missed in specific conditions

TIM

Description

Every match of the counter (CNT) value with the compare register (CCR) value is expected to trigger a compare

event. However, if such matches occur in two consecutive counter clock cycles (as consequence of the CCR

value change between the two cycles), the second compare event is missed for the following CCR value

changes:

in edge-aligned mode, from ARR to 0:

•

– first compare event: CNT = CCR = ARR

– second (missed) compare event: CNT = CCR = 0

•

in center-aligned mode while up-counting, from ARR-1 to ARR (possibly a new ARR value if the period is

also changed) at the crest (that is, when TIMx_RCR = 0):

– first compare event: CNT = CCR = (ARR-1)

– second (missed) compare event: CNT = CCR = ARR

•

in center-aligned mode while down-counting, from 1 to 0 at the valley (that is, when TIMx_RCR = 0):

– first compare event: CNT = CCR = 1

– second (missed) compare event: CNT = CCR = 0

This typically corresponds to an abrupt change of compare value aiming at creating a timer clock single-cyclewide pulse in toggle mode.

As a consequence:

• In toggle mode, the output only toggles once per counter period (squared waveform), whereas it is expected

to toggle twice within two consecutive counter cycles (and so exhibit a short pulse per counter period).

• In center mode, the compare interrupt flag does note rise and the interrupt is not generated.

Note: The timer output operates as expected in modes other than the toggle mode.

Workaround

None.

2.7.3 Output compare clear not working with external counter reset

Description

The output compare clear event (ocref_clr) is not correctly generated when the timer is configured in the following

slave modes: Reset mode, Combined reset + trigger mode, and Combined gated + reset mode.

ES0549 - Rev 1

page 9/18

Page 10

The PWM output remains inactive during one extra PWM cycle if the following sequence occurs:

1. The output is cleared by the ocref_clr event.

2. The timer reset occurs before the programmed compare event.

Workaround

Apply one of the following measures:

• Use BKIN (or BKIN2 if available) input for clearing the output, selecting the Automatic output enable mode

(AOE = 1).

• Mask the timer reset during the PWM ON time to prevent it from occurring before the compare event (for

example with a spare timer compare channel open-drain output connected with the reset signal, pulling the

timer reset line down).

2.8 LPTIM

2.8.1 Device may remain stuck in LPTIM interrupt when entering Stop mode

Description

This limitation occurs when disabling the low-power timer (LPTIM).

When the user application clears the ENABLE bit in the LPTIM_CR register within a small time window around

one LPTIM interrupt occurrence, then the LPTIM interrupt signal used to wake up the device from Stop mode may

be frozen in active state. Consequently, when trying to enter Stop mode, this limitation prevents the device from

entering low-power mode and the firmware remains stuck in the LPTIM interrupt routine.

This limitation applies to all Stop modes and to all instances of the LPTIM. Note that the occurrence of this issue

is very low.

STM32G0C1xC/xE

LPTIM

Workaround

In order to disable a low power timer (LPTIMx) peripheral, do not clear its ENABLE bit in its respective LPTIM_CR

register. Instead, reset the whole LPTIMx peripheral via the RCC controller by setting and resetting its respective

LPTIMxRST bit in RCC_APByRSTRz register.

2.8.2 Device may remain stuck in LPTIM interrupt when clearing event flag

Description

This limitation occurs when the LPTIM is configured in interrupt mode (at least one interrupt is enabled) and

the software clears any flag in LPTIM_ISR register by writing its corresponding bit in LPTIM_ICR register. If the

interrupt status flag corresponding to a disabled interrupt is cleared simultaneously with a new event detection,

the set and clear commands might reach the APB domain at the same time, leading to an asynchronous interrupt

signal permanently stuck high.

This issue can occur either during an interrupt subroutine execution (where the flag clearing is usually done), or

outside an interrupt subroutine.

Consequently, the firmware remains stuck in the LPTIM interrupt routine, and the device cannot enter Stop mode.

Workaround

To avoid this issue, it is strongly advised to follow the recommendations listed below:

• Clear the flag only when its corresponding interrupt is enabled in the interrupt enable register.

• If for specific reasons, it is required to clear some flags that have corresponding interrupt lines disabled in

the interrupt enable register, it is recommended to clear them during the current subroutine prior to those

which have corresponding interrupt line enabled in the interrupt enable register.

• Flags must not be cleared outside the interrupt subroutine.

Note: The proper clear sequence is already implemented in the HAL_LPTIM_IRQHandler in the STM32Cube.

ES0549 - Rev 1

page 10/18

Page 11

STM32G0C1xC/xE

RTC and TAMP

2.9 RTC and TAMP

2.9.1 Calendar initialization may fail in case of consecutive INIT mode entry

Description

If the INIT bit of the RTC_ICSR register is set between one and two RTCCLK cycles after being cleared, the

INITF flag is set immediately instead of waiting for synchronization delay (which should be between one and two

RTCCLK cycles), and the initialization of registers may fail. Depending on the INIT bit clearing and setting instants

versus the RTCCLK edges, it can happen that, after being immediately set, the INITF flag is cleared during one

RTCCLK period then set again. As writes to calendar registers are ignored when INITF is low, a write occurring

during this critical period might result in the corruption of one or more calendar registers.

Workaround

After existing the initialization mode, clear the BYPSHAD bit (if set) then wait for RSF to rise, before entering the

initialization mode again.

Note: It is recommended to write all registers in a single initialization session to avoid accumulating synchronization

delays.

2.10 I2C

2.10.1 Wrong data sampling when data setup time (t

Description

The I2C-bus specification and user manual specify a minimum data setup time (t

• 250 ns in Standard mode

• 100 ns in Fast mode

• 50 ns in Fast mode Plus

The device does not correctly sample the I2C-bus SDA line when t

(I2C-bus peripheral clock) period: the previous SDA value is sampled instead of the current one. This can result in

a wrong receipt of slave address, data byte, or acknowledge bit.

Workaround

Increase the I2C kernel clock frequency to get I2C kernel clock period within the transmitter minimum data setup

time. Alternatively, increase transmitter’s minimum data setup time. If the transmitter setup time minimum value

corresponds to the minimum value provided in the I2C-bus standard, the minimum I2CCLK frequencies are as

follows:

• In Standard mode, if the transmitter minimum setup time is 250 ns, the I2CCLK frequency must be at least

4 MHz.

• In Fast mode, if the transmitter minimum setup time is 100 ns, the I2CCLK frequency must be at least

10 MHz.

• In Fast-mode Plus, if the transmitter minimum setup time is 50 ns, the I2CCLK frequency must be at least

20 MHz.

) is shorter than one I2C kernel clock period

SU;DAT

) as:

SU;DAT

is smaller than one I2C kernel clock

SU;DAT

2.10.2 Spurious bus error detection in master mode

Description

In master mode, a bus error can be detected spuriously, with the consequence of setting the BERR flag of the

I2C_SR register and generating bus error interrupt if such interrupt is enabled. Detection of bus error has no effect

on the I2C-bus transfer in master mode and any such transfer continues normally.

ES0549 - Rev 1

page 11/18

Page 12

Workaround

If a bus error interrupt is generated in master mode, the BERR flag must be cleared by software. No other action

is required and the ongoing transfer can be handled normally.

2.11 USART

2.11.1 Data corruption due to noisy receive line

Description

In UART mode with oversampling by 8 or 16 and with 1 or 2 stop bits, the received data may be corrupted if a

glitch to zero shorter than the half-bit occurs on the receive line within the second half of the stop bit.

Workaround

None.

2.11.2 USART prescaler feature missing in USART implementation section

STM32G0C1xC/xE

USART

Description

Some reference manual revisions may omit the information that the USART prescaler is not present in all USART

instances. This information is provided in the USART implementation section of the corresponding reference

manual.

This is a documentation issue rather than a product limitation.

Workaround

No application workaround is required or applicable.

2.12 SPI

2.12.1 BSY bit may stay high when SPI is disabled

Description

The BSY flag may remain high upon disabling the SPI while operating in:

• master transmit mode and the TXE flag is low (data register full).

• master receive-only mode (simplex receive or half-duplex bidirectional receive phase) and an SCK strobing

edge has not occurred since the transition of the RXNE flag from low to high.

• slave mode and NSS signal is removed during the communication.

Workaround

When the SPI operates in:

• master transmit mode, disable the SPI when TXE = 1 and BSY = 0.

• master receive-only mode, ignore the BSY flag.

• slave mode, do not remove the NSS signal during the communication.

2.12.2 BSY bit may stay high at the end of data transfer in slave mode

Description

BSY flag may sporadically remain high at the end of a data transfer in slave mode. This occurs upon coincidence

of internal CPU clock and external SCK clock provided by master.

ES0549 - Rev 1

page 12/18

Page 13

STM32G0C1xC/xE

In such an event, if the software only relies on BSY flag to detect the end of SPI slave data transaction (for

example to enter low-power mode or to change data line direction in half-duplex bidirectional mode), the detection

fails.

As a conclusion, the BSY flag is unreliable for detecting the end of data transactions.

Workaround

Depending on SPI operating mode, use the following means for detecting the end of transaction:

• When NSS hardware management is applied and NSS signal is provided by master, use NSS flag.

• In SPI receiving mode, use the corresponding RXNE event flag.

• In SPI transmit-only mode, use the BSY flag in conjunction with a timeout expiry event. Set the timeout such

as to exceed the expected duration of the last data frame and start it upon TXE event that occurs with the

second bit of the last data frame. The end of the transaction corresponds to either the BSY flag becoming

low or the timeout expiry, whichever happens first.

Prefer one of the first two measures to the third as they are simpler and less constraining.

Alternatively, apply the following sequence to ensure reliable operation of the BSY flag in SPI transmit mode:

1. Write last data to data register.

2. Poll the TXE flag until it becomes high, which occurs with the second bit of the data frame transfer.

3. Disable SPI by clearing the SPE bit mandatorily before the end of the frame transfer.

4. Poll the BSY bit until it becomes low, which signals the end of transfer.

Note: The alternative method can only be used with relatively fast CPU speeds versus relatively slow SPI clocks

or/and long last data frames. The faster is the software execution, the shorter can be the duration of the last data

frame.

FDCAN

2.13

FDCAN

2.13.1 Desynchronization under specific condition with edge filtering enabled

Description

FDCAN may desynchronize and incorrectly receive the first bit of the frame if:

• the edge filtering is enabled (the EFBI bit of the FDCAN_CCCR register is set), and

• the end of the integration phase coincides with a falling edge detected on the FDCAN_Rx input pin

If this occurs, the CRC detects that the first bit of the received frame is incorrect, flags the received frame as faulty

and responds with an error frame.

Note: This issue does not affect the reception of standard frames.

Workaround

Disable edge filtering or wait for frame retransmission.

2.13.2 Tx FIFO messages inverted under specific buffer usage and priority setting

Description

Two consecutive messages from the Tx FIFO may be inverted in the transmit sequence if:

• FDCAN uses both a dedicated Tx buffer and a Tx FIFO (the TFQM bit of the FDCAN_TXBC register is

cleared), and

• the messages contained in the Tx buffer have a higher internal CAN priority than the messages in the Tx

FIFO.

ES0549 - Rev 1

page 13/18

Page 14

STM32G0C1xC/xE

Workaround

Apply one of the following measures:

• Ensure that only one Tx FIFO element is pending for transmission at any time:

The Tx FIFO elements may be filled at any time with messages to be transmitted, but their transmission

requests are handled separately. Each time a Tx FIFO transmission has completed and the Tx FIFO gets

empty (TFE bit of FDACN_IR set to 1) the next Tx FIFO element is requested.

• Use only a Tx FIFO:

Send both messages from a Tx FIFO, including the message with the higher priority. This message has to

wait until the preceding messages in the Tx FIFO have been sent.

• Use two dedicated Tx buffers (for example, use Tx buffer 4 and 5 instead of the Tx FIFO). The following

pseudo-code replaces the function in charge of filling the Tx FIFO:

Write message to Tx Buffer 4

Transmit Loop:

Request Tx Buffer 4 - write AR4 bit in FDCAN_TXBAR

Write message to Tx Buffer 5

Wait until transmission of Tx Buffer 4 complete (IR bit in FDCAN_IR),

read TO4 bit in FDCAN_TXBTO

Request Tx Buffer 5 - write AR5 bit of FDCAN_TXBAR

Write message to Tx Buffer 4

Wait until transmission of Tx Buffer 5 complete (IR bit in FDCAN_IR),

read TO5 bit in FDCAN_TXBTO

UCPD

2.14 UCPD

2.14.1 UCPD transmitter output marginality at low temperature

Description

At low temperature, the UCPD transmitter high level may go as low as 1.04 V, not respecting the specified

minimum of 1.05 V. The external load (Rp/Rd) can mitigate this slight marginality observed on a low percentage of

parts.

Workaround

None.

ES0549 - Rev 1

page 14/18

Page 15

Revision history

STM32G0C1xC/xE

Table 5. Document revision history

Date Version Changes

12-Jan-2021 1 Initial release.

ES0549 - Rev 1

page 15/18

Page 16

STM32G0C1xC/xE

Contents

Contents

1 Summary of device errata..........................................................2

2 Description of device errata........................................................4

2.1 Core .........................................................................4

2.2 System .......................................................................4

2.2.1 Unstable LSI when it clocks RTC or CSS on LSE ................................4

2.2.2 WUFx wakeup flag wrongly set during configuration ..............................4

2.2.3 Overwriting with all zeros a Flash memory location previously programmed with all ones

fails ...................................................................4

2.2.4 Wakeup from Stop not effective under certain conditions ..........................5

2.2.5 Flash memory PCROP area weakness ........................................5

2.2.6 PC13 signal transitions disturb LSE ..........................................5

2.2.7 SRAM contents corrupted upon entry in Standby ................................5

2.2.8 Boot select after debug interface connection....................................5

2.3 GPIO.........................................................................6

2.3.1 Wakeup capability-enabled GPIOs not configurable after wakeup from Standby ........6

2.4 DMA .........................................................................6

2.4.1 DMA disable failure and error flag omission upon simultaneous transfer error and global

flag clear ...............................................................6

2.5 DMAMUX .....................................................................6

2.5.1 SOFx not asserted when writing into DMAMUX_CFR register ......................6

2.5.2 OFx not asserted for trigger event coinciding with last DMAMUX request ..............7

2.5.3 OFx not asserted when writing into DMAMUX_RGCFR register .....................7

2.5.4 Wrong input DMA request routed upon specific DMAMUX_CxCR register write coinciding

with synchronization event .................................................7

2.6 ADC .........................................................................8

2.6.1 Overrun flag is not set if EOC reset coincides with new conversion end ...............8

2.6.2 Writing ADC_CFGR1 register while ADEN bit is set resets RES[1:0] bitfield ............8

2.6.3 Out-of-threshold value is not detected in AWD1 Single mode .......................8

2.6.4 ADC sampling time might be one cycle longer ..................................8

2.7 TIM ..........................................................................9

2.7.1 One-pulse mode trigger not detected in master-slave reset + trigger configuration .......9

2.7.2 Consecutive compare event missed in specific conditions .........................9

ES0549 - Rev 1

page 16/18

Page 17

STM32G0C1xC/xE

Contents

2.7.3 Output compare clear not working with external counter reset ......................9

2.8 LPTIM .......................................................................10

2.8.1 Device may remain stuck in LPTIM interrupt when entering Stop mode ..............10

2.8.2 Device may remain stuck in LPTIM interrupt when clearing event flag ...............10

2.9 RTC and TAMP ...............................................................11

2.9.1 Calendar initialization may fail in case of consecutive INIT mode entry ............... 11

2.10 I2C .........................................................................11

2.10.1 Wrong data sampling when data setup time (t

period ................................................................ 11

2.10.2 Spurious bus error detection in master mode ..................................11

) is shorter than one I2C kernel clock

SU;DAT

2.11 USART ......................................................................12

2.11.1 Data corruption due to noisy receive line......................................12

2.11.2 USART prescaler feature missing in USART implementation section ................12

2.12 SPI .........................................................................12

2.12.1 BSY bit may stay high when SPI is disabled ...................................12

2.12.2 BSY bit may stay high at the end of data transfer in slave mode....................12

2.13 FDCAN ......................................................................13

2.13.1 Desynchronization under specific condition with edge filtering enabled...............13

2.13.2 Tx FIFO messages inverted under specific buffer usage and priority setting...........13

2.14 UCPD .......................................................................14

2.14.1 UCPD transmitter output marginality at low temperature..........................14

Revision history .......................................................................15

ES0549 - Rev 1

page 17/18

Page 18

STM32G0C1xC/xE

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2021 STMicroelectronics – All rights reserved

ES0549 - Rev 1

page 18/18

Loading...

Loading...