Page 1

STM32F42xx and STM32F43xx

Errata sheet

STM32F427/437 and STM32F429/439 line limitations

Silicon identification

This errata sheet applies to the revision A and Y of STMicroelectronics STM32F427/437

and STM32F429/439 microcontroller lines.

The STM32F42xx and STM32F43xx devices feature an ARM

FPU, for which an errata notice is also available (see Section 1 for details).

The full list of part numbers is shown in Table 2. The products are identifiable as shown in

Table 1:

• by the revision code marked below the order code on the device p ackage

• by the last three digits of the Internal order code printed on the box label

Order code Revision code marked on device

Table 1. Device identification

®

32-bit Cortex™-M4 core with

(1)

(2)

STM32F427xx, STM32F429xx

STM32F437xx, STM32F439xx

1. The REV_ID bits in the DBGMCU_IDCODE register show the revision code of the device (see the RM0090

STM32F4xx reference manual for details on how to find the revision code).

2. Refer to Appendix A: Revision code on device marking for details on how to identify the revision code and

the date code on the different packages.

Reference Part number

STM32F427xx

STM32F437xx

STM32F429xx

STM32F439xx

STM32F427VG, STM32F427ZG, STM32F427IG, STM32F427VI, STM32F427ZI,

STM32F427II

STM32F437VG, STM32F437ZG, STM32F437IG, STM32F437VI, STM32F437ZI,

STM32F437II

STM32F429VG , STM32F429ZG, STM32F429IG, STM32F429VI, STM32F429ZI,

STM32F429II, STM32F429BG, STM32F429BI, STM32F429NI, STM32F429NG

STM32F439VI, STM32F439VG , STM32F439ZG, STM32F439ZI, STM32F439IG,

STM32F439II, STM32F439BG, STM32F439BI, STM32F439NI, STM32F439NG

Table 2. Device summary

“A” and “Y”

September 2013 DocID023833 Rev 5 1/36

www.st.com

Page 2

Contents STM32F42xx and STM32F43xx

Contents

1 ARM 32-bit Cortex-M4 with FPU limitations . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Cortex-M4 interrupted loads to stack pointer can cause

erroneous behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 STM32F42xx and STM32F43xx silicon limitations . . . . . . . . . . . . . . . . . 8

2.1 System limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.1 Debugging Stop mode and system tick timer . . . . . . . . . . . . . . . . . . . . 10

2.1.2 Debugging Stop mode with WFE entry . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.3 Wakeup sequence from Standby mode when using more than

one wakeup source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.4 Full JTAG configuration without NJTRST pin cannot be used . . . . . . . . 11

2.1.5 MPU attribute to RTC and IWDG registers could be managed

incorrectly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.6 Delay after an RCC peripheral clock enabling . . . . . . . . . . . . . . . . . . . . 12

2.1.7 Internal noise impacting the ADC accuracy . . . . . . . . . . . . . . . . . . . . . . 12

2.1.8 Over-drive and Under-drive modes unavailability . . . . . . . . . . . . . . . . . 13

2.2 IWDG peripheral limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.1 RVU and PVU flags are not reset in STOP mode . . . . . . . . . . . . . . . . . 13

2.3 I2C peripheral limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.1 SMBus standard not fully supported . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.2 Start cannot be generated after a misplaced Stop . . . . . . . . . . . . . . . . . 14

2.3.3 Mismatch on the “Setup time for a repeated Start condition” timing

parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.4 Data valid time (t

2.3.5 Both SDA and SCL maximum rise time (t

higher than ((VDD+0.3) / 0.7) V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

) violated without the OVR flag being set . . . . . 14

VD;DAT

) violated when VDD_I2C bus

r

2.4 I2S peripheral limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4.1 In I2S slave mode, WS level must be set by the external master

when enabling the I2S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 USART peripheral limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.1 Idle frame is not detected if receiver clock speed is deviated . . . . . . . . 16

2.5.2 In full duplex mode, the Parity Error (PE) flag can be cleared by

writing to the data register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.3 Parity Error (PE) flag is not set when receiving in Mute mode

using address mark detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.4 Break frame is transmitted regardless of nCTS input line status . . . . . . 17

2/36 DocID023833 Rev 5

Page 3

STM32F42xx and STM32F43xx Contents

2.5.5 nRTS signal abnormally driven low after a protocol violation . . . . . . . . 17

2.6 OTG_FS peripheral limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.1 Data in RxFIFO is overwritten when all channels are disabled

simultaneously . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.2 OTG host blocks the receive channel when receiving IN packets and no

TxFIFO is configured . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6.3 Host channel-halted interrupt not generated when the channel is

disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6.4 Error in software-read OTG_FS_DCFG register values . . . . . . . . . . . . 18

2.7 Ethernet peripheral limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7.1 Incorrect layer 3 (L3) checksum is inserted in transmitted IPv6 packets

without TCP, UDP or ICMP payloads . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7.2 The Ethernet MAC processes invalid extension headers in the received

IPv6 frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7.3 MAC stuck in the Idle state on receiving the TxFIFO flush command

exactly 1 clock cycle after a transmission completes . . . . . . . . . . . . . . . 19

2.7.4 Transmit frame data corruption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.5 Successive write operations to the same register might not be fully

taken into account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.8 FMC peripheral limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.8.1 Dummy read cycles inserted when reading synchronous memories . . . 23

2.8.2 FMC synchronous mode and NWAIT signal disabled . . . . . . . . . . . . . . 23

2.8.3 Read access to a non-initialized FMC_SDRAM bank . . . . . . . . . . . . . . 23

2.8.4 Corruption of data read from the FMC . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.8.5 Interruption of CPU read burst access to an end of SDRAM row . . . . . 24

2.8.6 FMC NOR/PSRAM controller: asynchronous read access on bank 2 to 4

returns wrong data when bank 1 is in synchronous mode

(BURSTEN bit is set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.8.7 FMC dynamic and static banks switching . . . . . . . . . . . . . . . . . . . . . . . 25

2.9 SDIO peripheral limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.9.1 SDIO HW flow control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.9.2 Wrong CCRCFAIL status after a response without CRC is received . . . 25

2.9.3 Data corruption in SDIO clock dephasing (NEGEDGE) mode . . . . . . . . 26

2.9.4 CE-ATA multiple write command and card busy signal management . . 26

2.9.5 No underrun detection with wrong data transmission . . . . . . . . . . . . . . 26

2.10 ADC peripheral limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.10.1 ADC sequencer modification during conversion . . . . . . . . . . . . . . . . . . 27

2.11 DAC peripheral limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.11.1 DMA underrun flag management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DocID023833 Rev 5 3/36

4

Page 4

Contents STM32F42xx and STM32F43xx

2.11.2 DMA request not automatically cleared by DMAEN=0 . . . . . . . . . . . . . 27

Appendix A Revision code on device marking . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4/36 DocID023833 Rev 5

Page 5

STM32F42xx and STM32F43xx List of tables

List of tables

Table 1. Device identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 3. Corte x- M 4 cor e limitat ions an d im pa ct on mi cr ocontroller behavior. . . . . . . . . . . . . . . . . . . 7

Table 4. Summary of silicon limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5. Impacted registers and bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 6. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DocID023833 Rev 5 5/36

5

Page 6

List of figures STM32F42xx and STM32F43xx

List of figures

Figure 1. TFBGA216 top package view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2. WLCSP143 top package view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 3. LQFP208 top package view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 4. UFBGA176 top package view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5. LQFP176 top package view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 6. LQFP144 top package view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 7. LQFP100 top package view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6/36 DocID023833 Rev 5

Page 7

STM32F42xx and STM32F43xx ARM 32-bit Cortex-M4 with FPU limitations

1 ARM 32-bit Cortex-M4 with FPU limitations

An errata notice of the STM32F42xx and STM32F43xx core is available from the following

web address:

http://infocenter.arm.com/help/topic/com.arm.doc.ddi0439b_errata_01/index.html.

All the described limitations are minor and related to the revision r0p1-v1 of the CortexM4

core. Table 3 summarizes these limitations and their implications on the behavior of

STM32F42xx and STM32F43xx devices.

Table 3. Cortex-M4 core limitations and impact on microcontroller behavior

ARM ID

752419 Cat 2

ARM

category

ARM summary of errata

Interrupted loads to SP can cause erroneous

behavior

Impact on STM32F42xx

and STM32F43xx

Minor

1.1 Cortex-M4 interrupted loads to stack pointer can cause erroneous behavior

Description

An interrupt occurring during the data-phase of a single word load to the stack pointer

(SP/R13) can cause an erroneous behavior of the device. In addition, returning from the

interrupt results in the load instruction being executed an additional time.

For all the instructions performing an update of the base register, the base register is

erroneously updated on each execution, resulting in the stack pointer being loaded from an

incorrect memory location.

The instructions affected by this limitation are the following:

• LDR SP, [Rn],#imm

• LDR SP, [Rn,#imm]!

• LDR SP, [Rn,#imm]

• LDR SP, [Rn]

• LDR SP, [Rn,Rm]

Workaround

As of today, no compiler generates these particular instructions. This limitation can only

occur with hand-written assembly code.

Both limitations can be solved by replacing the direct load to the stack pointer by an

intermediate load to a general-purpose register followed by a move to the stack pointer.

Example:

Replace LDR SP, [R0] by

LDR R2,[R0]

MOV SP,R2

DocID023833 Rev 5 7/36

35

Page 8

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

2 STM32F42xx and STM32F43xx silicon limitations

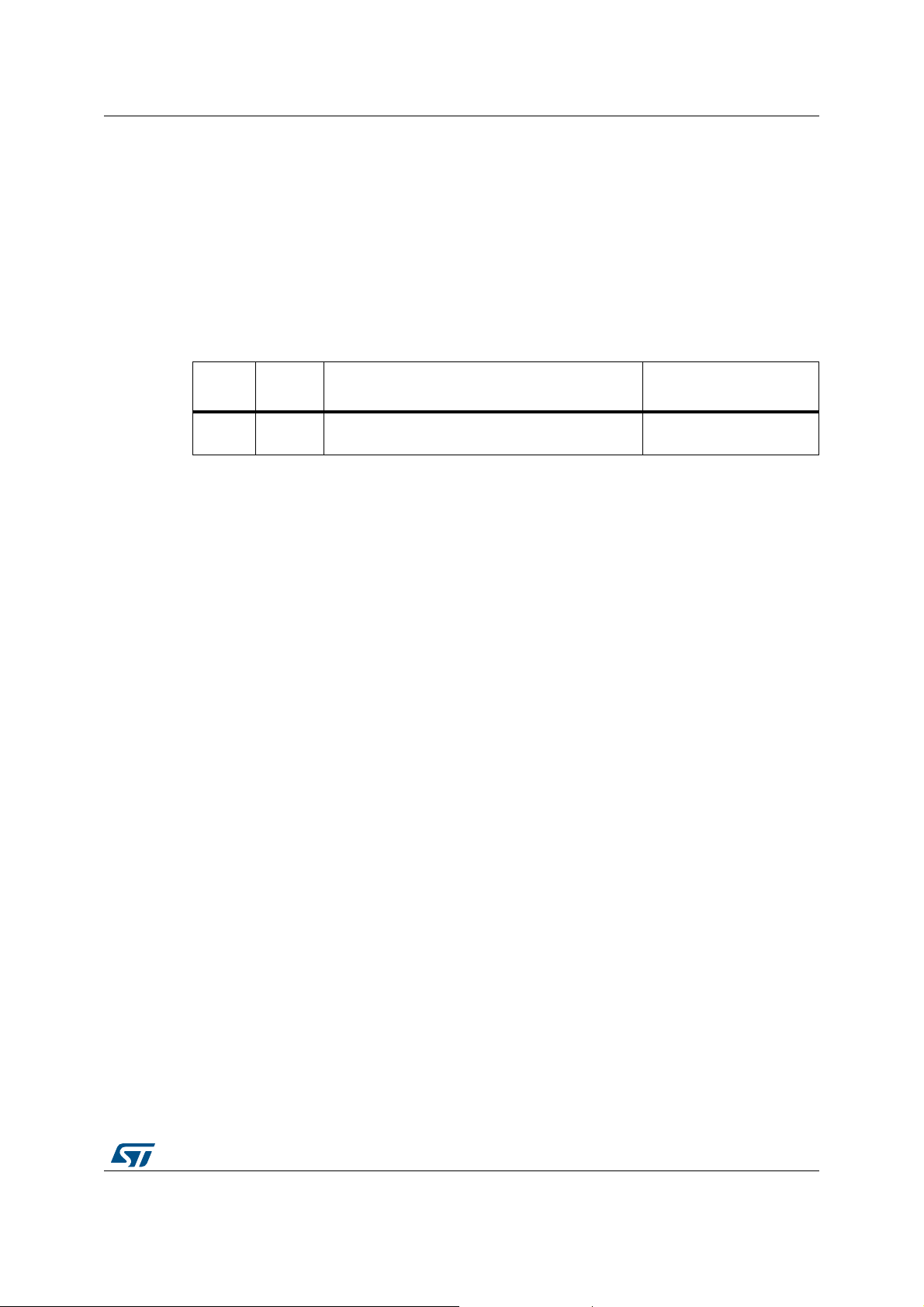

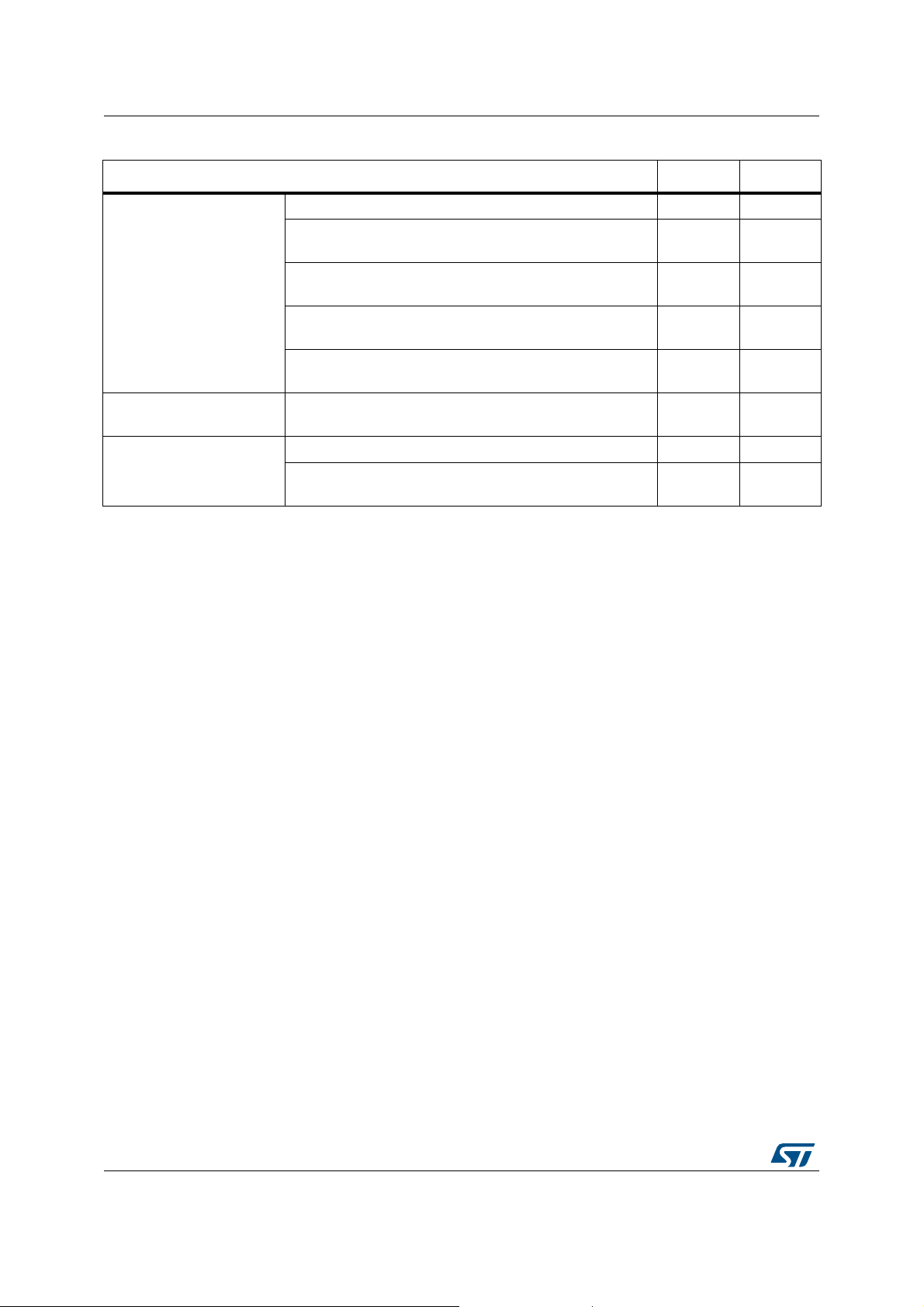

Table 4 gives quick references to all documented limitations.

Legend for Table 4: A = workaround available; N = no workaround available; P = partial

workaround available, ‘-’ and grayed = fixed.

Table 4. Summary of silicon limitations

Links to silicon limitations Revision A Revision Y

Section 2.1.1: Debugging Stop mode and system tick timer AA

Section 2.1.2: Debugging Stop mode with WFE entry AA

Section 2.1: System

limitations

Section 2.2: IWDG

peripheral limitation

Section 2.3: I2C peripheral

limitations

Section 2.1.3: Wakeup sequence from Standby mode

when using more than one wakeup source

Section 2.1.4: Full JTAG configuration without NJTRST pin

cannot be used

Section 2.1.5: MPU attribute to RTC and IWDG registers

could be managed incorrectly

Section 2.1.6: Delay after an RCC peripheral clock

enabling

Section 2.1.7: Internal noise impacting the ADC accuracy AA

Section 2.1.8: Over-drive and Under-drive modes

unavailability

Section 2.2.1: RVU and PVU flags are not reset in STOP

mode

Section 2.3.1: SMBus standard not fully supported AA

Section 2.3.2: Start cannot be generated after a misplaced

Stop

Section 2.3.3: Mismatch on the “Setup time for a repeated

Start conditio n” ti ming parameter

Section 2.3.4: Data valid time (tVD;DAT) violated without

the OVR flag being set

Section 2.3.5: Both SDA and SCL maximum rise time (tr)

violated when VDD_I2C bus higher than ((VDD+0.3) /

0.7) V

AA

AA

AA

AA

N

AA

AA

AA

AA

AA

-

Section 2.4: I2S peripheral

limitation

8/36 DocID023833 Rev 5

Section 2.4.1: In I2S slave mode, WS level must be set by

the external master when enabling the I2S

AA

Page 9

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

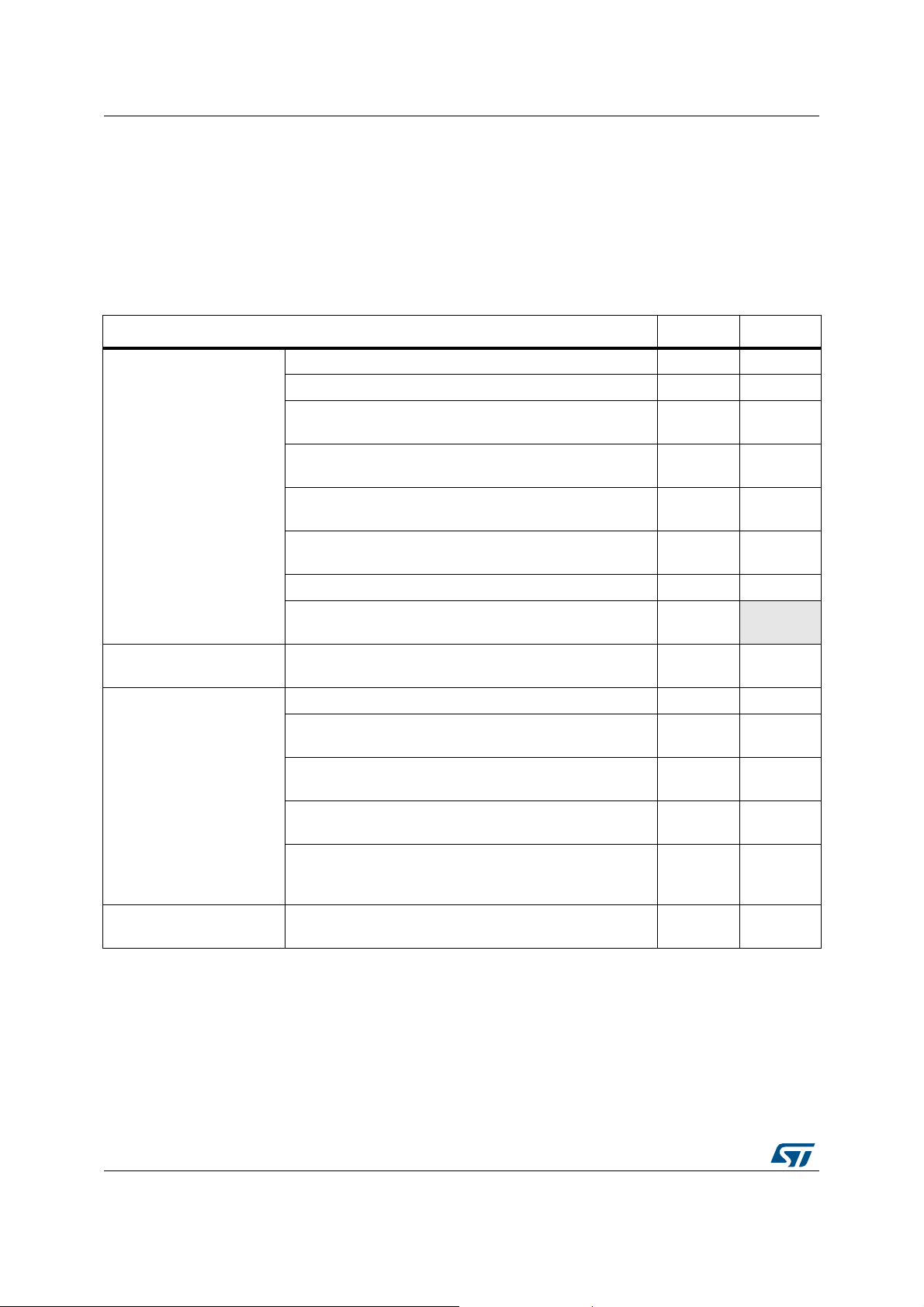

Table 4. Summary of silicon limitations (continued)

Links to silicon limitations Revision A Revision Y

Section 2.5: USART

peripheral limitations

Section 2.6: OTG_FS

peripheral limitations

Section 2.5.1: Idle frame is not detected if recei ve r clock

speed is deviated

Section 2.5.2: In full duplex mode, the Parity Error (PE) flag

can be cleared by writing to the data register

Section 2.5.3: Parity Error (PE) flag is not set when

receiving in Mute mode using address mark detection

Section 2.5.4: Break frame is transmitted regardless of

nCTS input line status

Section 2.5.5: nRTS signal abnormally driven low after a

protocol violation

Section 2.6.1: Data in RxFIFO is overwritten when all

channels are disabled simultaneously

Section 2.6.2: OTG host blocks the receive channel when

receiving IN packets and no TxFIFO is configured

Section 2.6.3: Host channel-halted interrupt not generated

when the channel is disabled

Section 2.6.4: Error in software-read OTG_FS_DCFG

register values

Section 2.7.1: Incorrect layer 3 (L3) checksum is inserted

in transmitted IPv6 packets without TCP, UDP or ICMP

payloads

NN

AA

NN

NN

AA

AA

AA

AA

AA

AA

Section 2.7: Ethernet

peripheral limitations

Section 2.8: FMC peripheral

limitation

Section 2.7.2: The Ethernet MAC processes invalid

extension headers in the received IPv6 frames

NN

Section 2.7.3: MAC stuck in the Idle state on receiving the

TxFIFO flush command exactly 1 clock cycle after a

AA

transmission completes

Section 2.7.4: Transmit frame data corruption AA

Section 2.7.5: Successive write operations to the same

register might not be fully taken into account

Section 2.8.1: Dummy read cycles inserted when reading

synchronous memories

Section 2.8.2: FMC synchronous mode and NWAIT signal

disabled

Section 2.8.3: Read access to a non-initialized

FMC_SDRAM bank

Section 2.8.4: Corruption of data read from the FMC A

Section 2.8.5: Interruption of CPU read burst access to an

end of SDRAM row

AA

NN

AA

PP

-

AA

Section 2.8.6: FMC NOR/PSRAM controller: asynchronous

read access on bank 2 to 4 returns wrong data when bank

AA

1 is in synchronous mode (BURSTEN bit is set)

Section 2.8.7: FMC dynamic and static banks switching AA

DocID023833 Rev 5 9/36

35

Page 10

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

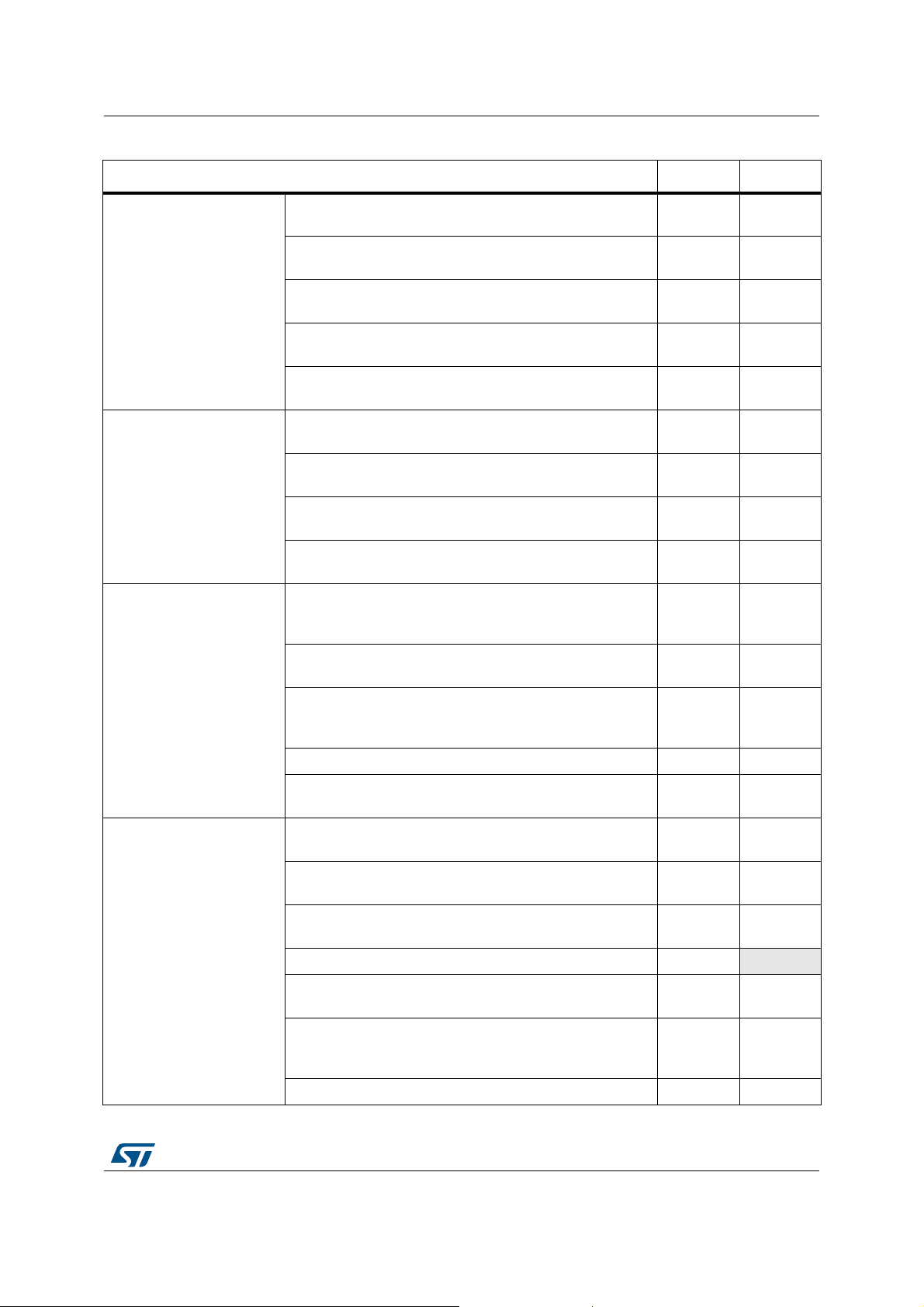

Table 4. Summary of silicon limitations (continued)

Links to silicon limitations Revision A Revision Y

Section 2.9.1: SDIO HW flow control NN

Section 2.9.2: Wrong CCRCFAIL status after a response

without CRC is received

Section 2.9: SDIO

peripheral limitations

Section 2.10: ADC

peripheral limitations

Section 2.11: DAC

peripheral limitations

Section 2.9.3: Data corruption in SDIO clock dephasing

(NEGEDGE) mode

Section 2.9.4: CE-ATA multiple write command and card

busy signal management

Section 2.9.5: No underrun detection with wrong data

transmission

Section 2.10.1: ADC sequencer modification during

conversion

Section 2.11.1: DMA underrun flag management AA

Section 2.11.2: DMA request not automatically cleared by

DMAEN=0

2.1 System limitations

2.1.1 Debugging Stop mode and system tick timer

Description

If the system tick timer interrupt is enabled during the Stop mode debug (DBG_STOP bit set

in the DBGMCU_CR register), it will wake up the system from Stop mode.

AA

NN

AA

AA

AA

AA

Workaround

To debug the Stop mode, disable the system tick timer interrupt.

2.1.2 Debugging Stop mode with WFE entry

Description

When the Stop debug mode is enabled (DBG_STOP bit set in the DBGMCU_CR register),

this allows software debugging during Stop mode.

However, if the application software uses the WFE instruction to enter Stop mode, after

wakeup some instructions could be missed if the WFE is followed by sequential instructions.

This affects only Stop debug mode with WFE entry.

Workaround

To debug Stop mode with WFE entry, the WFE instruction must be inside a dedicated

function with 1 instruction (NOP) between the execution of the WFE and the Bx LR.

Example:

__asm void _WFE(void) {

WFE

10/36 DocID023833 Rev 5

Page 11

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

NOP

BX lr }

2.1.3 Wakeup sequence from Standby mode when using more than one wakeup source

Description

The various wakeup sources are logically OR-ed in front of the rising-edge detector which

generates the wakeup flag (WUF). The WUF needs to be cleared prior to Standby mode

entry, otherwise the MCU wakes up immediately.

If one of the configured wakeup sources is kept high during the clearing of the WUF (by

setting the CWUF bit), it may mask further wakeup events on the input of the edge detector.

As a consequence, the MCU might not be able to wake up from Standby mode.

Workaround

To avoid this problem, the following sequence should be applied before entering

Standby mode:

• Disable all used wakeup sources,

• Clear all related wakeup flags,

• Re-enable all used wakeup sources,

• Enter Standby mode

Note: Be aware that, when applying this workaround, if one of the wakeup sources is still kept

high, the MCU enters Standby mode but then it wakes up immediately generating a power

reset.

2.1.4 Full JTAG configuration without NJTRST pin cannot be used

Description

When using the JT AG d ebug port in debug mod e, the connection with th e debugger is lost if

the NJTRST pin (PB4) is used as a GPIO. Only the 4-wire JTAG port configuration is

impacted.

Workaround

Use the SWD debug port instead of the full 4-wire JTAG port.

DocID023833 Rev 5 11/36

35

Page 12

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

2.1.5 MPU attribute to RTC and IWDG registers could be managed incorrectly

Description

If the MPU is used and the non buffera ble attribu te is set to the RTC or IWDG memory map

region, the CPU access to the RTC or IWDG registers could be treated as bufferable,

provided that there is no APB prescaler configured (AHB/APB prescaler is equal to 1).

Workaround

If the non bufferable attribute is required for these registers, the software could perform a

read after the write to guaranty the completion of the write access.

2.1.6 Delay after an RCC peripheral clock enabling

Description

A delay between an RCC peripheral clock enable and the effective peripheral enabling

should be taken into account in order to manage the peripheral read/write to registers.

This delay depends on the peripheral’s mapping:

• If the peripheral is mapped on AHB: the delay should be equal to 2 AHB cycles.

• If the peripheral is mapped on APB: the delay should be equal to 1 + (AHB/APB

prescaler) cycles.

Workarounds

1. Use the DSB instruction to stall the Cortex-M CPU pipeline until the instruction is

completed.

2. Insert “n” NOPs between the RCC enable bit write and the peripheral register writes

(n = 2 for AHB peripherals, n = 1 + AHB/APB prescaler in case of APB peripherals).

2.1.7 Internal noise impacting the ADC accuracy

Description

An internal noise generated on VDD supplies and propagated internally may impact the ADC

accuracy.

This noise is always active whatever the power mode of the MCU (RUN or Sleep).

Workarounds

To adapt the accuracy level to the application requirements, set one of the following options:

• Option1

Set the ADCDC1 bit in the PWR_CR register.

• Option2

Set the corresponding ADCxDC2 bit in the SYSCFG_PMC register.

Only one option can be set at a time.

For more details on option 1 and option2 mechanisms, refer to AN4073.

12/36 DocID023833 Rev 5

Page 13

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

2.1.8 Over-drive and Under-drive modes unavailability

Description

The Over-drive and Under-drive modes are not available on revision A devices.

Workaround

None.

This limitation is fixed in silicon revision Y.

2.2 IWDG peripheral limitation

2.2.1 RVU and PVU flags are not reset in STOP mode

Description

The RVU and PVU flags of the IWDG_SR register are set by hardware after a write access

to the IWDG_RLR and the IWDG_PR registers, respectively. If the Stop mode is entered

immediately after the write access, the RVU and PVU flags are not reset by hardwa re .

Before performing a second write operation to the IWDG_RLR or the IWDG_PR register,

the application software must wait for the RVU or PVU flag to be reset. However, since the

RVU/PVU bit is not reset after exiting the Stop mode, the software goes into an infinite loop

and the independent watchdog (IWDG) generates a reset after the programmed timeout

period.

Workaround

Wait until the RVU or PVU flag of the IWDG_SR register is reset before entering the Stop

mode.

2.3 I2C peripheral limitations

2.3.1 SMBus standard not fully supported

Description

The I2C peripheral is not fully compliant with the SMBus v2.0 standard since It does not

support the capability to NACK an invalid byte/command.

Workarounds

A higher-level mechanism should be used to verify that a write operatio n is being performed

correctly at the target device, such as:

1. Using the SMBAL pin if supported by the host

2. the alert response address (ARA) protocol

3. the Host notify protocol

DocID023833 Rev 5 13/36

35

Page 14

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

2.3.2 Start cannot be generated after a misplaced Stop

Description

If a master generates a misplaced Sto p on the bus (bus error), the peripheral cannot

generate a Start anymore.

Workaround

In the I²C standard, it is allowed to send a Stop only at the end of the full byte (8 bits +

acknowledge), so this scenario is not allowed. Other derived protocols like CBUS allow it,

but they are not supported by the I²C periphe ra l.

A software workaround consists in asserting the software reset using the SWRST bit in the

I2C_CR1 control register.

2.3.3 Mismatch on the “Setup time for a repeated Start condition” timing parameter

Description

In case of a repeated St art, the “Setup time for a re peated Start condition” (named Tsu;sta in

the I²C specification) can be slightly violated when the I²C operates in Master Standard

mode at a frequency between 88 kHz and 100 kHz.

The limitation can occur only in the following configuration:

• in Master mode

• in Standard mode at a frequency between 88 kHz and 100 kHz (no limitation in Fast-

mode)

• SCL rise time:

– If the slave does not stretch the clock and the SCL rise time is more than 300 ns (if

the SCL rise time is less than 300 ns, the limitation cannot occur)

– If the slave stretches the clock

The setup time can be violated independently of the APB peripheral frequency.

Workaround

Reduce the frequency down to 88 kHz or use the I²C Fast-mode, if supported by the slave.

2.3.4 Data valid time (t

Description

The data valid time (t

as the maximum data hold time of the curre nt data (t

below. Thi s violation cannot be detected because th e OVR flag is not set (no transmit buf fer

underrun is detected).

This limitation can occur only under the following conditions:

• in Slave transmit mode

• with clock stretching disabled (NOSTRETCH=1)

• if the software is late to write the DR data register, but not late enough to set the OVR

flag (the data register is written before)

VD;DAT

VD;DAT

) violated without the OVR flag being set

, t

) described by the I²C standard can be viola ted (as well

VD;ACK

)) under the conditions described

HD;DAT

14/36 DocID023833 Rev 5

Page 15

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

Workaround

If the master device allows it, use the clock stretchin g mech an ism by pr og ra m m ing the bit

NOSTRETCH=0 in the I2C_CR1 register.

If the master device does not allow it, ensure that the software is fast enough when polling

the TXE or ADDR flag to immediately write to the DR data register. For instance, use an

interrupt on the TXE or ADDR flag and boost its priority to the higher level.

2.3.5 Both SDA and SCL maximum rise time (tr) violated when VDD_I2C bus higher than ((VDD+0.3) / 0.7) V

Description

When an external legacy I2C bus voltage (VDD_I2C) is set to 5 V while the MCU is powered

from V

reaches the V

prevents the external pull-up resistor (R

maximum timing (t

The rise time (t

0.7VDD_I2C.

, the internal 5-Volt tolerant circuitry is activated as soon the input voltage (VIN)

DD

+ diode threshold level. An additional internal large capacitance then

DD

) which is 300 ns in fast mode and 1000 ns in Standard mode.

r

) is measured from VIL and VIH with levels set at 0.3VDD_I2C and

r

) from rising the SDA and SCL signals within the

P

Workaround

The external VDD_I2C bus voltage should be limited to a maximum value of

((VDD+0.3) / 0.7) V. As a result, when the MCU is powered from V

should not exceed 5.14 V to be compliant with I

2

C specifications.

=3.3 V, VDD_I2C

DD

2.4 I2S peripheral limitation

2.4.1 In I2S slave mode, WS level must be set by the external master when enabling the I2S

Description

In slave mode, the WS signal level is used only to start the communication. If the I2S (in

slave mode) is enabled while the master is already sending the clock and the WS signal

level is low (for I2S protocol) or is high (for the LSB or MSB-justified mode), the slave starts

communicating data immediately. In this case, the master and slave will be desynchronized

throughout the whole communication.

Workaround

The I2S peripheral must be enabled when the external master sets the WS line at:

• High level when the I2S protocol is selected.

• Low level when the LSB or MSB-justified mode is selected.

DocID023833 Rev 5 15/36

35

Page 16

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

2.5 USART peripheral limitations

2.5.1 Idle frame is not detected if receiver clock speed is deviated

Description

If the USART receives an idle frame followed by a character, and the clock of the transmitter

device is faster than the USART receiver clock, the USART receive signal falls too early

when receiving the character start bit, with the result that the idle frame is not detected

(IDLE flag is not set).

Workaround

None.

2.5.2 In full duplex mode, the Parity Error (PE) flag can be cleared by writing to the data register

Description

In full duplex mode, when the Parity Error flag is set by the receiver at the end of a

reception, it may be cleared while transmitting by reading the USART_SR register to check

the TXE or TC flags and writing data to the data register.

Consequently, the software receiver can read the PE flag as '0' even if a parity error

occurred.

Workaround

The Parity Error flag should be checked after the end of reception and before transmission.

2.5.3 Parity Error (PE) flag is not set when receiving in Mute mode using address mark detection

Description

The USART receiver is in Mute mode and is configured to exit the Mute mode using the

address mark detection. When the USART receiver recognizes a valid a ddress with a p arity

error, it exits the Mute mode without setting the Parity Error flag.

Workaround

None.

16/36 DocID023833 Rev 5

Page 17

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

2.5.4 Break frame is transmitted regardless of nCTS input line status

Description

When CTS hardware flow control is enabled (CTSE = 1) and the Send Break bit (SBK) is

set, the transmitter sends a break frame at the end of the current transmission regardless of

nCTS input line status.

Consequently, if an external receiver device is not ready to accept a frame, the transmitted

break frame is lost.

Workaround

None.

2.5.5 nRTS signal abnormally driven low after a protocol violation

Description

When RTS hardware flow control is enabled, the nRTS signal goes high when data is

received. If this data was not read and new data is sent to the USART (protocol violation),

the nRTS signal goes back to low level at the end of this new data.

Consequently, the sender gets the wrong information that the USART is ready to receive

further data.

On USART side, an overrun is detected, which indicates that data has been lost.

Workaround

Workarounds are required only if the other USART device violates the communication

protocol, which is not the case in most applications.

Two workarounds can be used:

• After data reception and before reading the data in the data register, the software takes

over the control of the nRTS signal as a GPIO and holds it high as long as needed. If

the USART device is not ready, the software holds the nRTS pin high, and releases it

when the device is ready to receive new data.

• The time required by the softwar e to r ead the received da t a must always be lo wer than

the duration of the second data reception. For example, this can be ensured by treating

all the receptions by DMA mode.

2.6 OTG_FS peripheral limitations

2.6.1 Data in RxFIFO is overwritten when all channels are disabled simultaneously

Description

If the available RxFIFO is just large enough to host 1 packet + its data status, and is

currently occupied by the last received data + its status and, at the same time, the

application requests that more IN channels be disabled, the OTG_FS peripheral does not

first check for available space before inserting the disabled status of the IN channels. It just

inserts them by overwriting the existing data payload.

DocID023833 Rev 5 17/36

35

Page 18

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

Workaround

Use one of the following recommendations:

1. Configure the RxFIFO to host a minimum of 2 × MPSIZ + 2 × data status entries.

2. The application has to check the RXFLVL bit (RxFIFO non-empty) in the

OTG_FS_GINTSTS register before disabling each IN channel. If this b it is not set, then

the application can disable an IN channel at a time. Each time the application disables

an IN channel, however, it first has to check that the RXFLVL bit = 0 condition is true.

2.6.2 OTG host blocks the receive channel when receiving IN packet s and no TxFIFO is configured

Description

When receiving data, the OTG_FS core erroneously checks for available TxFIFO space

when it should only check for RxFIFO space. If the OTG_FS core cannot see any space

allocated for data transmission, it blocks the reception channel and no data is received.

Workaround

Set at least one TxFIFO equal to the maximum packet size. In this way, the host application,

which intends to supports only IN traffic, also has to allocate some space for the TxFIFO.

Since a USB host is expected to support any kind of connected endpo int, it is good practice

to always configure enough TxFIFO space for OUT endpoints.

2.6.3 Host channel-halted interrupt not generated when the channel is disabled

Description

When the application enables, then immediately disables the host channel before the

OTG_FS host has had time to begin the transfer sequence, the OT G_FS core, as a host,

does not generate a channel-halted interrupt. The OTG_FS core continues to operate

normally.

Workaround

Do not disable the host channel immediately after enabling it.

2.6.4 Error in software-read OTG_FS_DCFG register values

Description

When the application writes to the DAD and PFIVL bitfields in the OTG_FS_DCFG register,

and then reads the newly written bitfield values, the read values may not be correct.

The values written by the application, however, are correctly retained by the core, and the

normal operation of the device is not affected.

Workaround

Do not read from the OTG_FS_DCFG register’s DAD and PFIVL bitfields just after

programming them.

18/36 DocID023833 Rev 5

Page 19

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

2.7 Ethernet peripheral limitations

2.7.1 Incorrect layer 3 (L3) checksum is inserted in transmitted IPv6 packets without TCP, UDP or ICMP payloads

Description

The application provides the per-frame control to instruct the MAC to insert the L3

checksums for TCP, UDP and ICMP packets. When automatic checksum insertion is

enabled and the input packet is an IPv6 packet without the TCP, UDP or ICMP payload, then

the MAC may incorrectly insert a checksum into the packet. For IPv6 packets without a TCP,

UDP or ICMP payload, the MAC core considers the next header (NH) field as th e extension

header and continues to parse the extension header. Sometimes, the payload data in such

packets matches the NH field for TCP, UDP or ICMP and, as a result, the MAC core inserts

a checksum.

Workaround

When the IPv6 packets have a TCP, UDP or ICMP payload, enable checksum insertion for

transmit frames, or bypass checksum insertion by using the CIC (checksum insertion

control) bits in TDES0 (bits 23:22).

2.7.2 The Ethernet MAC processes invalid extension headers in the received IPv6 frames

Description

In IPv6 frames, there can be zero or some extension headers preceding the actual IP

payload. The Ethernet MAC processes the following extension headers defined in the IPv6

protocol: Hop-by-Hop Options header, Routing header and Destination Options header.

All extension headers, except the Hop-by-Hop extension header, can be present multiple

times and in any order before the actual IP payload. The Hop-by-Hop extension header, if

present, has to come immediately after the IPv6’s main header.

The Ethernet MAC processes all (valid or invalid) extension headers including the Hop-byHop extension headers that are present after the first exte nsion heade r. For this reason, the

GMAC core will accept IPv6 frames with invalid Hop-by-Hop extension headers. As a

consequence, it will accept any IP payload as valid IPv6 frames with TCP, UDP or ICMP

payload, and then incorrectly update the Receive status of the corresponding frame.

Workaround

None.

2.7.3 MAC stuck in the Idle state on receiving the TxFIFO flush command exactly 1 clock cycle after a transmission completes

Description

When the software issues a TxFIFO flush command, the transfer of frame data stops (even

in the middle of a frame transfer). The TxFIFO read controller goes into the Idle state

(TFRS=00 in ETH_MACDBGR) and then resumes its normal operation.

DocID023833 Rev 5 19/36

35

Page 20

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

However, if the TxFIFO read controller receives the TxFIFO flush command exactly one

clock cycle after receiving the status from the MAC, the controller remains stuck in the Idle

state and stops transmitting frames from the TxFIFO. The system can recover from this

state only with a reset (e.g. a soft reset).

Workaround

Do not use the TxFIFO flush feature.

If TXFIFO flush is really needed, wait until the TxFIFO is empty prior to using the TxFIFO

flush command.

2.7.4 Transmit frame data corruption

Frame data corrupted when the TxFIFO is repea tedly transitioning from non-empty to empty

and then back to non-empty.

Description

Frame data may get corrupted when the TxFIFO is repeate dly transitioning fr om non-empty

to empty for a very short period, and then from empty to non-empty, without causing an

underflow.

This transitioning from non-empty to empty and back to non-empty happens when the rate

at which the data is being written to the TxFIFO is almost equal to or a little less than the

rate at which the data is being read.

This corruption cannot be detected by the receiver when the CRC is inserted by the MAC,

as the corrupted data is used for the CRC computation.

Workaround

Use the Store-and- Forward mode: TSF =1 (bit 21 in ETH_DMAOMR). In th is mode, the dat a

is transmitted only when the whole packet is available in the TxFIFO.

2.7.5 Successive write operations to the same register might not be fully taken into account

Description

A write to a register might not be fully taken into account if a previous write to the same

register is performed within a time period of four TX_CLK/RX_CLK clock cycles. When this

error occurs, reading the register returns the most recently written value, but the Ethernet

MAC continues to operate as if the latest write operation never occurred.

See Table 5: Impacted registers and bits for the registers and bit s imp acted by this limitation.

20/36 DocID023833 Rev 5

Page 21

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

Register name Bit number Bit name

DMA registers

ETH_DMABMR 7 EDFE

ETH_DMAOMR

GMAC registers

ETH_MACCR

Table 5. Impacted registers and bits

26 DTCEFD

25 RSF

20 FTF

7FEF

6FUGF

4:3 RTC

25 CSTF

23 WD

22 JD

19:17 IFG

16 CSD

14 FES

13 ROD

12 LM

11 DM

10 IPCO

9RD

7 APCS

6:5 BL

4DC

3TE

2RE

ETH_MACFFR MAC frame filter register

ETH_MACHTHR 31:0 Hash Table High Register

ETH_MACHTLR 31:0 Hash Table Low Register

31:16 PT

7ZQPD

5:4 PLT

ETH_MACFCR

3UPFD

2RFCE

1TFCE

0FCB/BPA

DocID023833 Rev 5 21/36

35

Page 22

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

Table 5. Impacted registers and bits (continued)

Register name Bit number Bit name

ETH_MACVLANTR

ETH_MACRWUFFR all remote wakeup registers

ETH_MACPMTCSR

ETH_MACA0HR MAC address 0 high register

ETH_MACA0LR MAC address 0 low register

ETH_MACA1HR MAC address 1 high register

ETH_MACA1LR MAC address 1 low register

ETH_MACA2HR MAC address 2 high register

ETH_MACA2LR MAC address 2 low register

ETH_MACA3HR MAC address 3 high register

ETH_MACA3LR MAC address 3 low register

IEEE 1588 time stamp registers

16 VLANTC

15:0 VLANTI

31 WFFRPR

9GU

2WFE

1MPE

0PD

18 TSPFFMAE

ETH_PTPTSCR

17:16 TSCNT

15 TSSMRME

14 TSSEME

13 TSSIPV4FE

12 TSSIPV6FE

1 1 TSSPTPOEFE

10 TSPTPPSV2E

9 TSSSR

8 TSSARFE

5TSARU

3 TSSTU

2 TSSTI

1TSFCU

0TSE

22/36 DocID023833 Rev 5

Page 23

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

Workaround

Two workarounds could be applicable:

• Ensure a delay of four TX_CLK/RX_CLK clock cycles between the successive write

operations to the same register.

• Make several successive write operations without delay , then read the register when all

the operations are complete, and finally reprogram it after a delay of four

TX_CLK/RX_CLK clock cycles.

2.8 FMC peripheral limitation

2.8.1 Dummy read cycles inserted when reading synchronous memories

Description

When performing a burst read access to a synchronous memory, two dummy read accesses

are performed at the end of the burst cycle whatever the type of AHB burst access.

However, the extra data values which are read are not used by the FMC and there is no

functional failure.

Workaround

None.

2.8.2 FMC synchronous mode and NWAIT signal disabled

Description

When the FMC synchronous mode operates with the NWAIT signal disabled, if the polarity

(WAITPOL in the FMC_BCRx register) of the NWAIT signal is identical to that of the NWAIT

input signal level, the system hangs and no fault is generated.

Workaround

PD6 (NWAIT signal) must not be connected to AF12 and the NWAIT polarity must be

configured to active high (set WAITPOL bit to 1 in FMC_BCRx register).

2.8.3 Read access to a non-initialized FMC_SDRAM bank

Description

When a read access is performed to an SDRAM bank while the SDRAM controller is not yet

initialized, the system hangs and no fault is generated.

Workaround

Read access to an SDRAM bank must be performed only when the SDRAM controller

initialization is complete.

DocID023833 Rev 5 23/36

35

Page 24

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

2.8.4 Corruption of data read from the FMC

Description

When the FMC is used as stack, heap or variable data, an interrupt occurring during a CPU

read access to the FMC may results in read data corruption or hard fault exception. This

problem does not occur when read accesses are performed by another master or when

FMC accesses are done when the interrupts are disabled.

Workaround

Two workarounds can be applied:

• Do not use the FMC as stack or heap, and make sure CPU read accesses to the FMC

are performed while interrupts are disabled

• Use only DMAs to perform read accesses to the FMC.

This limitation is fixed in silicon revision Y.

2.8.5 Interruption of CPU read burst access to an end of SDRAM row

Description

If an interrupt occurs during an CPU AHB burst read access to an end of SDRAM row, it

may result in wrong data read from the next row if all the conditions below are met:

• The SDRAM data bus is 16-bit or 8-bit wide. 32-bit SDRAM mode is not affected.

• RBURST bit is reset in the FMC_SDCR1 register (read FIFO disabled).

• An interrupt occurs while CPU is performing an AHB incrementing bursts read access

of unspecified length (using LDM = Load Multiple instruction).

• The address of the burst operation includes the end of an SDRAM row.

Workaround

Enable the read FIFO by setting the RBURST bit in the FMC_SDCR1 register.

2.8.6 FMC NOR/PSRAM controller: asynchronous read access on bank 2 to 4 returns wrong data when bank 1 is in synchronous mode (BURSTEN bit is set)

Description

If an interrupt occurs during a CPU AHB read access to one NOR/PSRAM bank (bank2 to 4)

which is enabled in asynchronous mode, while bank 1 of the NOR/PSRAM controller is

configured in synchronous read mode (BURSTEN bit set to ‘1’), then the FMC NOR/PSRAM

controller returns wrong data.

This limitation does not occur when using the DMA or when only bank1 is used in

synchronous mode.

Workaround

If multiple banks are enabled in mixed asynchronous and synchronous modes, use any

NOR/PSRAM bank for synchronous read accesses, except for bank 1. As a consequence

the continuous clock feature is not available in asynchronous mode.

24/36 DocID023833 Rev 5

Page 25

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

This limitation will be fixed in next silicon revision.

2.8.7 FMC dynamic and static banks switching

Description

The dynamic and static banks cannot be accessed concurrently.

Workaround

Do not use dynamic and static banks at the same time. The SDRAM device must be in selfrefresh before switching to the static memory mapped on the NOR/PSRAM or NAND/PCCard controller. Before switching from static memory to SDRAM, issue a Normal command

to wake-up the device from self-refresh mode.

2.9 SDIO peripheral limitations

2.9.1 SDIO HW flow control

Description

When enabling the HW flow control by setting bit 14 of the SDIO_CLKCR register to ‘1’,

glitches can occur on the SDIOCLK output clock resulting in wrong data to be written into

the SD/MMC card or into the SDIO device. As a consequence, a CRC error will be reported

to the SD/SDIO MMC host interface (DCRCFAIL bit set to ‘1’ in SDIO_STA register).

Workaround

None.

Note: Do not use the HW flow control. Overrun errors (Rx mode) and FIFO underrun (Tx mod e)

should be managed by the application software.

2.9.2 Wrong CCRCFAIL status after a response without CRC is received

Description

The CRC is calculated even if the response to a command does not contain any CRC field.

As a consequence, after the SDIO command IO_SEND_OP_COND (CMD5) is sent, the

CCRCFAIL bit of the SDIO_STA register is set.

Workaround

The CCRCFAIL bit in the SDIO_STA register shall be ignored by the software. CCRCFAIL

must be cleared by setting CCRCFAILC bit of the SDIO_ICR register after reception of the

response to the CMD5 command.

DocID023833 Rev 5 25/36

35

Page 26

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

2.9.3 Data corruption in SDIO clock dephasing (NEGEDGE) mode

Description

When NEGEDGE bit is set to ‘1’, it may lead to invalid data and command response read.

Workaround

None. A configuration with the NEGEDGE bit equal to ‘1’ should not be used.

2.9.4 CE-ATA multiple write command and card busy signal management

Description

The CE-ATA card may inform the host that it is busy by driving the SDIO_D0 line low, two

cycles after the transfer of a write command (RW_MULTIPLE_REGISTER or

RW_MULTIPLE_BLOCK). When the card is in a busy state, the host must not send any

data until the BUSY signal is de-asserted (SDIO_D0 released by the card).

This condition is not respected if the data state machine leaves the IDLE state (Write

operation programmed and started, DTEN = 1, DTDIR = 0 in SDIO_DCTRL register and

TXFIFOE = 0 in SDIO_STA register).

As a consequence, the write transfer fails and the data lines are corrupted.

Workaround

After sending the write command (RW_MULTIPLE_REGISTER or

RW_MUL TIPLE_BLOCK), the ap plication must check that the card is not busy by polling the

BSY bit of the ATA status register using the FAST_IO (CMD39) command before enabling

the data state machine.

2.9.5 No underrun detection with wrong data transmission

Description

In case there is an ongoing data transfer from the SDIO host to the SD card and the

hardware flow control is disabled (bit 14 of the SDIO_CLKCR is not set), if an underrun

condition occurs, the controller may transm it a co rr up te d da ta block (with wron g da ta word)

without detecting the underrun condition when the clock frequencies have the following

relationship:

[3 x period(PCLK2) + 3 x period(SDIOCLK)] >= (32 / (BusWidth)) x period(SDIO_CK)

Workaround

Avoid the above-mentioned clock frequency relationship, by:

• Incrementing the APB frequency

• or decreasing the transfer bandwidth

• or reducing SDIO_CK frequency

26/36 DocID023833 Rev 5

Page 27

STM32F42xx and STM32F43xx STM32F42xx and STM32F43xx silicon limitations

2.10 ADC peripheral limitations

2.10.1 ADC sequencer modification during conversion

Description

If an ADC conversion is started by software (writing the SWSTART bit), and if the

ADC_SQRx or ADC_JSQRx registers are modified during the conversion, the current

conversion is reset and the ADC does not restart a new conversion sequen ce automatically.

If an ADC conversion is started by hardware trigger, this limitation does not apply. The ADC

restarts a new conversion sequence automatically.

Workaround

When an ADC conversion sequence is started by software, a new conversio n sequence can

be restarted only by setting the SWSTART bit in the ADC_CR2 register.

2.11 DAC peripheral limitations

2.1 1 .1 DMA underrun flag management

Description

If the DMA is not fast enough to input the next digital data to the DAC, as a consequence,

the same digital data is converted twice. In these conditions, the DMAUDR flag is set, which

usually leads to disable the DMA data transfers. This is not the case: the DMA is not

disabled by DMAUDR=1, and it keeps servicing the DAC.

Workaround

To disable the DAC DMA stream, reset the EN bit (corresponding to the DAC DMA stream)

in the DMA_SxCR register.

2.11.2 DMA request not automatically cleared by DMAEN=0

Description

if the application wants to stop the current DMA-to-DAC transfer, the DMA request is not

automatically cleared by DMAEN=0, or by DACEN=0.

If the application stops the DAC operation while the DMA request is high, the DMA request

will be pending while the DAC is reinitialized and restarted; with the risk that a spurious

unwanted DMA request is serviced as soon as the DAC is re-enabled.

DocID023833 Rev 5 27/36

35

Page 28

STM32F42xx and STM32F43xx silicon limitations STM32F42xx and STM32F43xx

Workaround

To stop the current DMA-to-DAC transfer and restart, the following sequence should be

applied:

1. Check if DMAUDR is set.

2. Clear the DAC/DMAEN bit.

3. Clear the EN bit of the DAC DMA/St ream

4. Reconfigure by software the DAC, DMA, triggers etc.

5. Restart the application.

28/36 DocID023833 Rev 5

Page 29

STM32F42xx and STM32F43xx Revision code on device marking

-36

7EEK9EAR

$ATECODE9EAR7EEK

!DDITIONALINFORMATIONFIELD

INCLUDING2EVISIONCODE

Appendix A Revision code on device marking

Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5, Figure 6 , Figure 7 show the m ar kin g

compositions for the TFBGA216, WLCSP143, LQFP208, UFBGA176, LQFP176, LQFP144

and LQFP100 packages, respectively.The only fields shown are the Additional field

containing the revision code and the Year and Week fields making up the date code.

Figure 1. TFBGA216 top package view

DocID023833 Rev 5 29/36

35

Page 30

Revision code on device marking STM32F42xx and STM32F43xx

MS32786V1

Additional information field

including Revision code

Date code = Year+Week

Year

Week

Figure 2. WLCSP143 top package view

Figure 3. LQFP208 top package view

!DDITIONALINFORMATIONFIELD

INCLUDING2EVISIONCODE

7EEK9EAR

$ATECODE9EAR7EEK

30/36 DocID023833 Rev 5

-36

Page 31

STM32F42xx and STM32F43xx Revision code on device marking

-36

!DDITIONALINFORMATIONFIELD

INCLUDINGREVISIONCODE

7EEK9EAR

34LOGO

Figure 4. UFBGA176 top package view

DocID023833 Rev 5 31/36

35

Page 32

Revision code on device marking STM32F42xx and STM32F43xx

Figure 5. LQFP176 top package view

7EEK9EAR

$ATECODE9EAR7EEK

AI

32/36 DocID023833 Rev 5

Page 33

STM32F42xx and STM32F43xx Revision code on device marking

!DDITIONALINFORMATIONFIELD

INCLUDING2EVISIONCODE

AIB

7EEK9EAR

$ATECODE9EAR7EEK

Figure 6. LQFP144 top package view

DocID023833 Rev 5 33/36

35

Page 34

Revision code on device marking STM32F42xx and STM32F43xx

!DDITIONALINFORMATIONFIELD

INCLUDING2EVISIONCODE

AIB

7EEK9EAR

$ATECODE9EAR7EEK

Figure 7. LQFP100 top package view

34/36 DocID023833 Rev 5

Page 35

STM32F42xx and STM32F43xx Revision history

Revision history

Table 6. Document revision history

Date Revision Changes

11-Feb-2013 1 Initial release.

25-Feb-2013 2

26-Apr-2013 3

19-Sep-2013 4

23-Sep-2013 5

Document converted to new template.

Added Section 2.8.4: Corruption of data read from the FMC

Added Silicon revision Y.

Removed the reference to ‘Cortex-M4F’ in the whole document.

Updated Section 2.8.1: Dummy read cycles inserted when reading

synchronous memories.

Added Section 2.1.3: Wakeup sequence from Standby mode when

using more than one wakeup source, Section 2.7.5: Successive write

operations to the same register might not be fully taken into account

and Section 2.8.3: FSMC NOR Flash/PSRAM controller

asynchronous access on bank 2 to 4 when bank 1 is in synchronous

mode (CBURSTRW bit is set).

Removed limitation 2.10.3 SDIO clock divider BYPASS mode may

not work properly. Updated Section 2.9.5: No underrun detection

with wrong data transmission.

Added STM32F429xx and STM32F439xx devices.

Removed FSMC limitations.

Added Section 2.3.5: Both SDA and SCL maximum rise time (tr)

violated when VDD_I2C bus higher than ((VDD+0.3) / 0.7) V.

Updated Section 2.8.5: Interruption of CPU read burst access to an

end of SDRAM row.

Added Section 2.8.1: Dummy read cycles inserted when reading

synchronous memories, Section 2.8.2: FMC synchronous mode and

NWAIT signal disabled, Section 2.8.3: Read access to a noninitialized FMC_SDRAM bank, Section 2.8.4: Corruption of data read

from the FMC, Section 2.8.5: Interruption of CPU read burst access

to an end of SDRAM row, Section 2.8.6: FMC NOR/PSRAM

controller: asynchronous read access on bank 2 to 4 returns wrong

data when bank 1 is in synchronous mode (BURSTEN bit is set) and

Section 2.8.7: FMC dynamic and static banks switching.

Added Figure 1: TFBGA216 top package view, Figure 2: WLCSP143

top package view, and Figure 3: LQFP208 top package view.

Updated workaround in Section 2.8.6: FMC NOR/PSRAM controller:

asynchronous read access on bank 2 to 4 returns wrong data when

bank 1 is in synchronous mode (BURSTEN bit is set).

DocID023833 Rev 5 35/36

35

Page 36

STM32F42xx and STM32F43xx

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, sele cti on an d use o f the S T prod ucts and s ervice s des crib ed he rein , and ST assumes n o

liability whatsoever relati ng to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third part y p ro duct s or se rvic es it sh al l n ot be dee med a li cens e gr an t by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of such

third party products or services or any intellectual property containe d therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

ST PRODUCTS ARE NOT DESIGNED OR AUTHORIZED FOR USE IN: (A) SAFETY CRITICAL APPLICATIONS SUCH AS LIFE

SUPPORTING, ACTIVE IMPLANTED DEVICES OR SYSTEMS WITH PRODUCT FUNCTIONAL SAFETY REQUIREMENTS; (B)

AERONAUTIC APPLICATIONS; (C) AUTOMOTIVE APPLICATIONS OR ENVIRONMENTS, AND/OR (D) AEROSPACE APPLICATIONS

OR ENVIRONMENTS. WHERE ST PRODUCTS ARE NOT DESIGNED FOR SUCH USE, THE PURCHASER SHALL USE PRODUCTS AT

PURCHASER’S SOLE RISK, EVEN IF ST HAS BEEN INFORMED IN WRITING OF SUCH USAGE, UNLESS A PRODUCT IS

EXPRESSLY DESIGNATED BY ST AS BEING INTENDED FOR “AUTOMOTIVE, AUTOMOTIVE SAFETY OR MEDICAL” INDUSTRY

DOMAINS ACCORDING TO ST PRODUCT DESIGN SPECIFICATIONS. PRODUCTS FORMALLY ESCC, QML OR JAN QUALIFIED ARE

DEEMED SUITABLE FOR USE IN AEROSPACE BY THE CORRESPONDING GOVERNMENTAL AGENCY.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2013 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philip pines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

36/36 DocID023833 Rev 5

Loading...

Loading...