STM32F078CB/RB/VB

Errata sheet

STM32F078CB/RB/VB device errata

Applicability

This document applies to STM32F078CB/RB/VB devices and the device variants as stated in this page.

It gives a summary and a description of the device errata, with respect to the device datasheet and reference manual RM0091.

Deviation of the real device behavior from the intended device behavior is considered to be a device limitation. Deviation of the

description in the reference manual or the datasheet from the intended device behavior is considered to be a documentation

erratum. The term “errata” applies both to limitations and documentation errata.

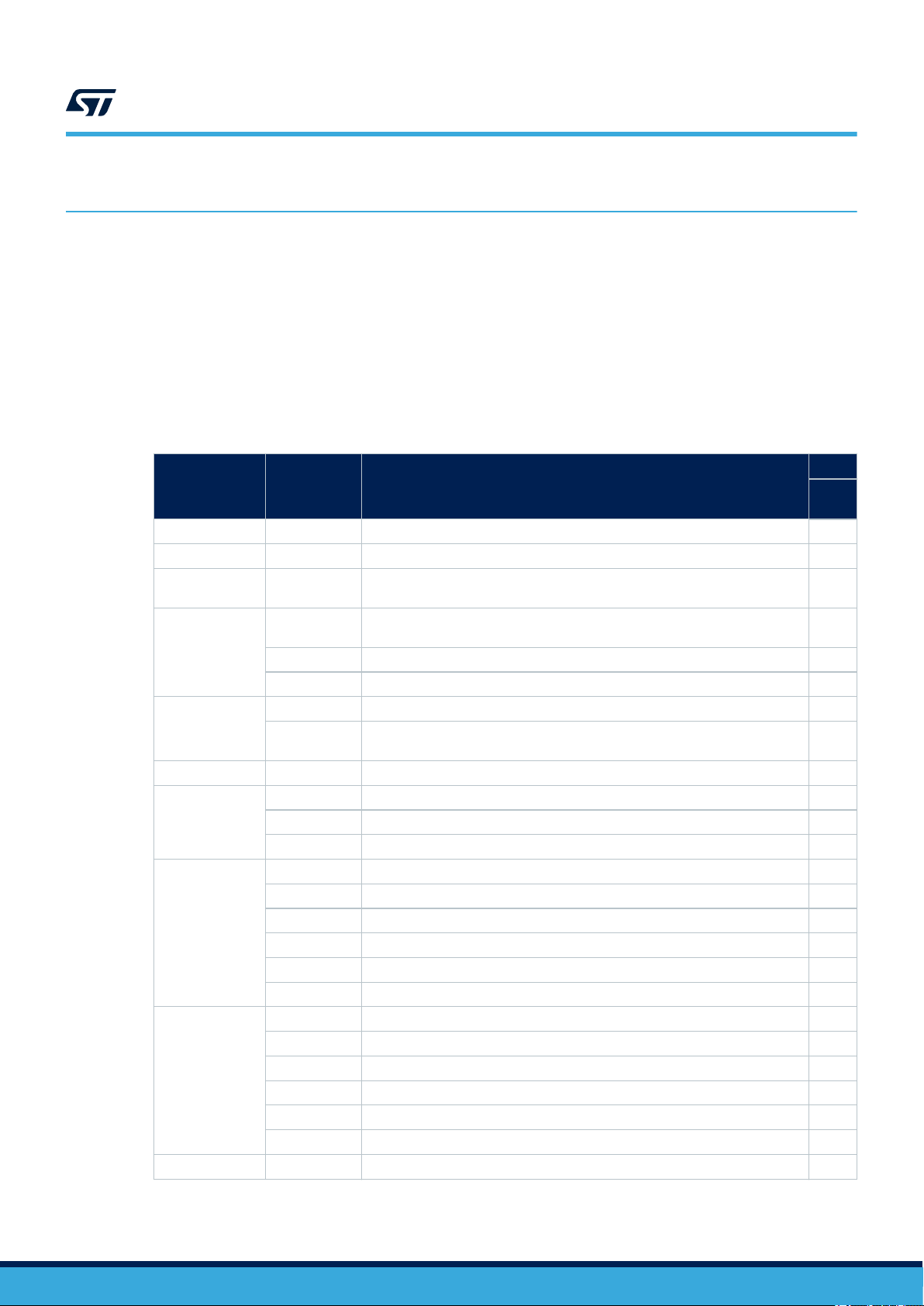

Table 1. Device variants

Reference

STM32F078CB/RB/VB

1. Refer to the device datasheet for how to identify this code on different types of package.

2. REV_ID[15:0] bitfield of DBGMCU_IDCODE register.

Device marking

Y or 1 0x2001

Silicon revision codes

(1)

REV_ID

(2)

ES0262 - Rev 4 - October 2020

For further information contact your local STMicroelectronics sales office.

www.st.com

1 Summary of device errata

The following table gives a quick reference to the STM32F078CB/RB/VB device limitations and their status:

A = workaround available

N = no workaround available

P = partial workaround available

Applicability of a workaround may depend on specific conditions of target application. Adoption of a workaround

may cause restrictions to target application. Workaround for a limitation is deemed partial if it only reduces the

rate of occurrence and/or consequences of the limitation, or if it is fully effective for only a subset of instances on

the device or in only a subset of operating modes, of the function concerned.

Table 2. Summary of device limitations

Function Section Limitation

System 2.2.1 RDP Level 1 issue

GPIO 2.3.1 GPIOx locking mechanism not working properly for GPIOx_OTYPER register P

DMA 2.4.1

2.5.1

ADC

DAC

COMP 2.7.1 Long VREFINT scaler startup time after power on N

TIM

IWDG

RTC and TAMP

I2C

2.5.2 Overrun flag is not set if EOC reset coincides with new conversion end P

2.5.3 ADEN bit cannot be set immediately after the ADC calibration A

2.6.1 DMA request not automatically cleared by clearing DMAEN A

2.6.2

2.9.1 PWM re-enabled in automatic output enable mode despite of system break P

2.9.3 Consecutive compare event missed in specific conditions N

2.9.4 Output compare clear not working with external counter reset P

2.10.1 RVU flag not reset in Stop A

2.10.2 PVU flag not reset in Stop A

2.10.3 WVU flag not reset in Stop A

2.10.4 RVU flag not cleared at low APB clock frequency A

2.10.5 PVU flag not cleared at low APB clock frequency A

2.10.6 WVU flag not cleared at low APB clock frequency A

2.11.1 Spurious tamper detection when disabling the tamper channel P

2.11.2 RTC calendar registers are not locked properly A

2.11.3 RTC interrupt can be masked by another RTC interrupt A

2.11.4 Calendar initialization may fail in case of consecutive INIT mode entry A

2.11.5 Alarm flag may be repeatedly set when the core is stopped in debug N

2.11.6 A tamper event preceding the tamper detect enable not detected A

2.12.1 10-bit slave mode: wrong direction bit value upon Read header receipt A

DMA disable failure and error flag omission upon simultaneous transfer error

and global flag clear

ADCAL bit is not cleared when successive calibrations are performed and

system clock frequency is considerably higher than the ADC clock frequency

DMA underrun flag not set when an internal trigger is detected on the clock

cycle of the DMA request acknowledge

STM32F078CB/RB/VB

Summary of device errata

Status

Rev.

Y, 1

P

A

A

N

ES0262 - Rev 4

page 2/31

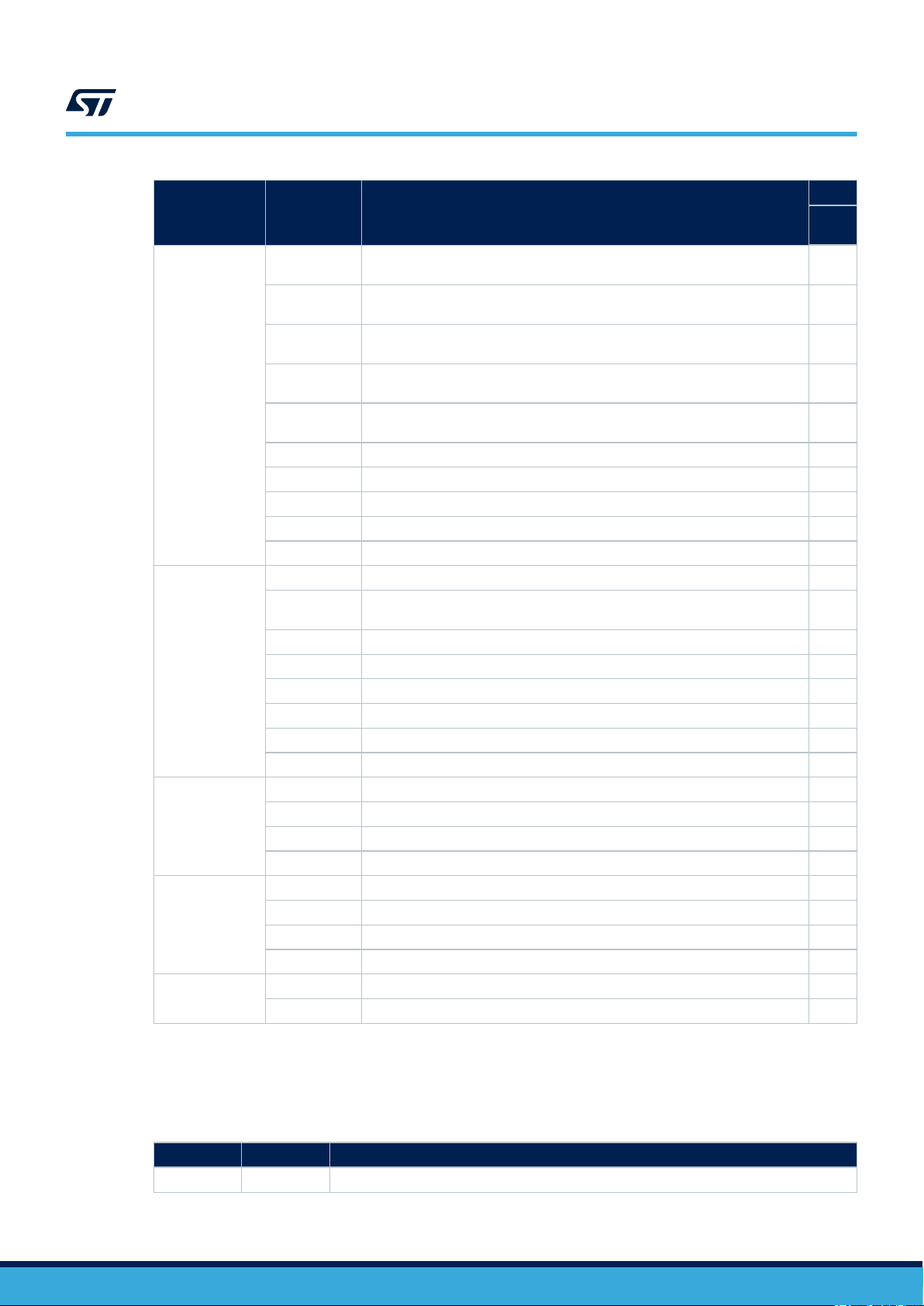

Function Section Limitation

10-bit combined with 7-bit slave mode: ADDCODE may indicate wrong slave

address detection

Wakeup frames may not wake up the MCU when Stop mode entry follows I2C

enabling

Wakeup frame may not wake up the MCU from Stop mode if tHD;STA is close

to I2C kernel clock startup time

10-bit master mode: new transfer cannot be launched if first part of the address

is not acknowledged by the slave

Wrong data sampling when data setup time (tSU;DAT) is shorter than one I2C

kernel clock period

Last byte written in TDR might not be transmitted if TE is cleared just after

writing in TDR

I2C

USART

SPI

USB

CEC

2.12.2

2.12.3

2.12.4

2.12.5

2.12.7

2.12.8 Spurious bus error detection in master mode A

2.12.9 Last-received byte loss in reload mode P

2.12.10 Spurious master transfer upon own slave address match P

2.12.11 OVR flag not set in underrun condition N

2.12.12 Transmission stalled after first byte transfer A

2.13.1 USART4 transmission does not work on PC11 N

2.13.2

2.13.3 Non-compliant sampling for NACK signal from smartcard N

2.13.4 Break request preventing TC flag from being set A

2.13.5 RTS is active while RE = 0 or UE = 0 A

2.13.6 Receiver timeout counter wrong start in two-stop-bit configuration A

2.13.7 Anticipated end-of-transmission signaling in SPI slave mode A

2.13.8 Data corruption due to noisy receive line N

2.14.1 BSY bit may stay high when SPI is disabled A

2.14.2 BSY bit may stay high at the end of data transfer in slave mode A

2.14.3 SPI CRC corruption upon DMA transaction completion by another peripheral P

2.14.4 In I2S slave mode, enabling I2S while WS is active causes desynchronization A

2.15.2 ESOF interrupt timing desynchronized after resume signaling A

2.15.3 Incorrect CRC16 in the memory buffer N

2.15.4 The USB BCD functionality limited below -20°C N

2.15.5 DCD function not compliant P

2.16.1 Transmission blocked when transmitted start bit is corrupted P

2.16.2 Missed CEC messages in normal receiving mode A

STM32F078CB/RB/VB

Summary of device errata

Status

Rev.

Y, 1

N

A

P

A

P

A

ES0262 - Rev 4

The following table gives a quick reference to the documentation errata.

Table 3. Summary of device documentation errata

Function

DMA 2.4.2 Byte and half-word accesses not supported

Section Documentation erratum

page 3/31

STM32F078CB/RB/VB

Summary of device errata

Function Section Documentation erratum

TSC 2.8.1 Inhibited acquisition in short transfer phase configuration

TIM 2.9.2 TRGO and TRGO2 trigger output failure

I2C 2.12.6 Wrong behavior in Stop mode when wakeup from Stop mode is disabled in I2C

SPI 2.14.5 CRC error in SPI slave mode if internal NSS changes before CRC transfer

USB 2.15.1 Possible packet memory overrun/underrun at low APB frequency

ES0262 - Rev 4

page 4/31

STM32F078CB/RB/VB

Description of device errata

2 Description of device errata

The following sections describe limitations of the applicable devices with Arm® core and provide workarounds if

available. They are grouped by device functions.

Note: Arm is a registered trademark of Arm Limited (or its subsidiaries) in the US and/or elsewhere.

2.1 Core

Reference manual and errata notice for the Arm® Cortex®-M4F core revision r0p0 is available from http://

infocenter.arm.com.

2.2 System

2.2.1 RDP Level 1 issue

Description

When the RDP Level 1 protection is set, there exists a logic issue that compromises protection of the Flash

memory against debugger access. When the debugger is connected to the device, the first transaction with the

Flash memory after a power on reset/power up is granted because of a race condition existing between this

debugger access and the protection mechanism of the Flash memory. As a result, the debugger may access one

data in the Flash memory after power up.

Workaround

For customers concerned by the confidentiality of their firmware, it is recommended to use the RDP Level 2

protection.

2.3 GPIO

2.3.1 GPIOx locking mechanism not working properly for GPIOx_OTYPER register

Description

Locking GPIOx_OTYPER[i] with i = 15 to 8 unduly depends on GPIOx_LCKR[i-8] instead on GPIOx_LCKR[i].

GPIOx_LCKR[i-8] locks both GPIOx_OTYPER[i] and GPIOx_OTYPER[i-8]. It is not possible to lock

GPIOx_OTYPER[i] with i = 15...8 without also locking GPIOx_OTYPER[i-8].

Workaround

The only way to lock GPIOx_OTYPER[i] with i=15 to 8 is to also lock GPIOx_OTYPER[i-8].

2.4

DMA

2.4.1 DMA disable failure and error flag omission upon simultaneous transfer error and global flag

clear

Description

Upon a data transfer error in a DMA channel x, both the specific TEIFx and the global GIFx flags are raised and

the channel x is normally automatically disabled. However, if in the same clock cycle the software clears the GIFx

flag (by setting the CGIFx bit of the DMA_IFCR register), the automatic channel disable fails and the TEIFx flag is

not raised.

This issue does not occur with ST's HAL software that does not use and clear the GIFx flag when the channel is

active, but uses and clears the HTIFx, TCIFx, and TEIFx specific event flags instead.

ES0262 - Rev 4

page 5/31

Workaround

Do not clear GIFx flags when the channel is active. Instead, use HTIFx, TCIFx, and TEIFx specific event flags and

their corresponding clear bits.

2.4.2 Byte and half-word accesses not supported

Description

Some reference manual revisions may wrongly state that the DMA registers are byte- and half-word-accessible.

Instead, the DMA registers must always be accessed through aligned 32-bit words. Byte or half-word write

accesses cause an erroneous behavior.

ST's low-level driver and HAL software only use aligned 32-bit accesses to the DMA registers.

This is a description inaccuracy issue rather than a product limitation.

Workaround

No application workaround is required.

2.5 ADC

STM32F078CB/RB/VB

ADC

2.5.1 ADCAL bit is not cleared when successive calibrations are performed and system clock

frequency is considerably higher than the ADC clock frequency

Description

The ADC calibration is launched by setting ADCAL bit of ADC_CR register. It can only be initiated when the ADC

is disabled (ADEN cleared in ADC_CR register). ADCAL bit stays at 1 during the whole calibration sequence and

is cleared by hardware as soon the calibration completes.

However, when at least two calibrations are performed in a row and the system clock frequency is considerably

higher than the ADC clock, the ADCAL bit is set again after being cleared by hardware when the first calibration

phase ends. The ADCAL bit remains set, waiting for the calibration to complete and hence for a hardware clear

that never occurs since the ADC clock is stopped.

Workaround

Avoid performing successive calibrations.

2.5.2 Overrun flag is not set if EOC reset coincides with new conversion end

Description

If the EOC flag is cleared by an ADC_DR register read operation or by software during the same APB cycle in

which the data from a new conversion are written in the ADC_DR register, the overrun event duly occurs (which

results in the loss of either current or new data) but the overrun flag (OVR) may stay low.

Workaround

Clear the EOC flag, by performing an ADC_DR read operation or by software within less than one ADC

conversion cycle period from the last conversion cycle end, in order to avoid the coincidence with the end of the

new conversion cycle.

2.5.3 ADEN bit cannot be set immediately after the ADC calibration

Description

At the end of the ADC calibration, an internal reset of ADEN bit occurs four ADC clock cycles after the ADCAL bit

is cleared by hardware. As a consequence, if the ADEN bit is set within those four ADC clock cycles, it is reset

shortly after by the calibration logic and the ADC remains disabled.

ES0262 - Rev 4

page 6/31

Workaround

Apply one of the following measures:

• When the ADC calibration is complete (ADCAL = 0), keep setting the ADEN bit until the ADRDY flag goes

high.

• After the ADCAL is cleared, wait for a minimum of four ADC clock cycles before enabling the ADC

(ADEN = 1).

• Always perform the ADC calibration with ADC clock frequency = APB frequency / 2.

2.6 DAC

2.6.1 DMA request not automatically cleared by clearing DMAEN

Description

Upon an attempt to stop a DMA-to-DAC transfer, the DMA request is not automatically cleared by clearing the

DAC channel bit of the DAC_CR register (DMAEN) or by disabling the DAC clock.

If the application stops the DAC operation while the DMA request is pending, the request remains pending while

the DAC is reinitialized and restarted, with the risk that a spurious DMA request is serviced as soon as the DAC is

enabled again.

STM32F078CB/RB/VB

DAC

Workaround

Apply the following sequence to stop the current DMA-to-DAC transfer and restart the DAC:

1. Check if DMAUDR bit is set in DAC_CR.

2. Clear the DAC channel DMAEN bit.

3. Disable the DAC clock.

4. Reconfigure the DAC, DMA and the triggers.

5. Restart the application.

2.6.2 DMA underrun flag not set when an internal trigger is detected on the clock cycle of the DMA

request acknowledge

Description

When the DAC channel operates in DMA mode (DMAEN of DAC_CR register set), the DMA channel underrun

flag (DMAUDR of DAC_SR register) fails to rise upon an internal trigger detection if that detection occurs during

the same clock cycle as a DMA request acknowledge. As a result, the user application is not informed that an

underrun error occurred.

This issue occurs when software and hardware triggers are used concurrently to trigger DMA transfers.

Workaround

None.

2.7 COMP

2.7.1 Long V

Description

The V

REFINT

comparator input.

The maximum V

of the V

time depends mainly on the voltage and temperature. See the device datasheet for more details.

ES0262 - Rev 4

scaler startup time after power on

REFINT

scaler is an embedded voltage follower providing the V

scaler startup time t

REFINT

scaler after powering on the device. In worst-case conditions, it can be as much as 1 s. The startup

REFINT

(max), specified to 0.2 ms, is not respected for the first activation

S_SC

or its fractions (½, ¼ or ¾) to the

REFINT

page 7/31

STM32F078CB/RB/VB

TSC

For correct operation of the V

Workaround

None.

scaler, the comparator analog supply voltage, V

REFINT

2.8 TSC

2.8.1 Inhibited acquisition in short transfer phase configuration

Description

Some revisions of the reference manual may omit the information that the following configurations of the TSC_CR

register are forbidden:

• The PGPSC[2:0] bitfield set to 000 and the CTPL[3:0] bitfield to 0000 or 0001

• The PGPSC[2:0] bitfield set to 001 and the CTPL[3:0] bitfield to 0000

Failure to respect this restriction leads to an inhibition of the acquisition.

This is a documentation inaccuracy issue rather than a product limitation.

Workaround

No application workaround is required.

2.9 TIM

, must not be below 2 V.

DDA

2.9.1 PWM re-enabled in automatic output enable mode despite of system break

Description

In automatic output enable mode (AOE bit set in TIMx_BDTR register), the break input can be used to do a cycleby-cycle PWM control for a current mode regulation. A break signal (typically a comparator with a current

threshold ) disables the PWM output(s) and the PWM is re-armed on the next counter period.

However, a system break (typically coming from the CSS Clock security System) is supposed to stop definitively

the PWM to avoid abnormal operation (for example with PWM frequency deviation).

In the current implementation, the timer system break input is not latched. As a consequence, a system break

indeed disables the PWM output(s) when it occurs, but PWM output(s) is (are) re-armed on the following counter

period.

Workaround

Preferably, implement control loops with the output clear enable function (OCxCE bit in the TIMx_CCMR1/CCMR2

register), leaving the use of break circuitry solely for internal and/or external fault protection (AOE bit reset).

2.9.2 TRGO and TRGO2 trigger output failure

Description

Some reference manual revisions may omit the following information.

The timers can be linked using ITRx inputs and TRGOx outputs. Additionally, the TRGOx outputs can be used as

triggers for other peripherals (for example ADC). Since this circuitry is based on pulse generation, care must be

taken when initializing master and slave peripherals or when using different master/slave clock frequencies:

• If the master timer generates a trigger output pulse on TRGOx prior to have the destination peripheral clock

enabled, the triggering system may fail.

• If the frequency of the destination peripheral is modified on-the-fly (clock prescaler modification), the

triggering system may fail.

As a conclusion, the clock of the slave timer or slave peripheral must be enabled prior to receiving events from

the master timer, and must not be changed on-the-fly while triggers are being received from the master timer.

This is a documentation issue rather than a product limitation.

ES0262 - Rev 4

page 8/31

Workaround

No application workaround is required or applicable as long as the application handles the clock as indicated.

2.9.3 Consecutive compare event missed in specific conditions

Description

Every match of the counter (CNT) value with the compare register (CCR) value is expected to trigger a compare

event. However, if such matches occur in two consecutive counter clock cycles (as consequence of the CCR

value change between the two cycles), the second compare event is missed for the following CCR value

changes:

in edge-aligned mode, from ARR to 0:

•

– first compare event: CNT = CCR = ARR

– second (missed) compare event: CNT = CCR = 0

•

in center-aligned mode while up-counting, from ARR-1 to ARR (possibly a new ARR value if the period is

also changed) at the crest (that is, when TIMx_RCR = 0):

– first compare event: CNT = CCR = (ARR-1)

– second (missed) compare event: CNT = CCR = ARR

•

in center-aligned mode while down-counting, from 1 to 0 at the valley (that is, when TIMx_RCR = 0):

– first compare event: CNT = CCR = 1

– second (missed) compare event: CNT = CCR = 0

This typically corresponds to an abrupt change of compare value aiming at creating a timer clock single-cyclewide pulse in toggle mode.

As a consequence:

• In toggle mode, the output only toggles once per counter period (squared waveform), whereas it is expected

to toggle twice within two consecutive counter cycles (and so exhibit a short pulse per counter period).

• In center mode, the compare interrupt flag does note rise and the interrupt is not generated.

Note: The timer output operates as expected in modes other than the toggle mode.

STM32F078CB/RB/VB

TIM

Workaround

None.

2.9.4 Output compare clear not working with external counter reset

Description

The output compare clear event (ocref_clr) is not correctly generated when the timer is configured in the following

slave modes: Reset mode, Combined reset + trigger mode, and Combined gated + reset mode.

The PWM output remains inactive during one extra PWM cycle if the following sequence occurs:

1. The output is cleared by the ocref_clr event.

2. The timer reset occurs before the programmed compare event.

Workaround

Apply one of the following measures:

• Use BKIN (or BKIN2 if available) input for clearing the output, selecting the Automatic output enable mode

(AOE = 1).

• Mask the timer reset during the PWM ON time to prevent it from occurring before the compare event (for

example with a spare timer compare channel open-drain output connected with the reset signal, pulling the

timer reset line down).

ES0262 - Rev 4

page 9/31

2.10 IWDG

2.10.1 RVU flag not reset in Stop

Description

Successful write to the IWDG_RLR register raises the RVU flag and prevents further write accesses to the

register until the RVU flag is automatically cleared by hardware. However, if the device enters Stop mode while

the RVU flag is set, the hardware never clears that flag, and writing to the IWDG_RLR register is no longer

possible.

Workaround

Ensure that the RVU flag is cleared before entering Stop mode.

2.10.2 PVU flag not reset in Stop

Description

Successful write to the IWDG_PR register raises the PVU flag and prevents further write accesses to the register

until the PVU flag is automatically cleared by hardware. However, if the device enters Stop mode while the PVU

flag is set, the hardware never clears that flag, and writing to the IWDG_PR register is no longer possible.

STM32F078CB/RB/VB

IWDG

Workaround

Ensure that the PVU flag is cleared before entering Stop mode.

2.10.3 WVU flag not reset in Stop

Description

Successful write to the IWDG_WINR register raises the WVU flag and prevents further write accesses to the

register until the WVU flag is automatically cleared by hardware. However, if the device enters Stop mode while

the WVU flag is set, the hardware never clears that flag, and writing to the IWDG_WINR register is no longer

possible.

Workaround

Ensure that the WVU flag is cleared before entering Stop mode.

2.10.4 RVU flag not cleared at low APB clock frequency

Description

Successful write to the IWDG_RLR register raises the RVU flag and prevents further write accesses to the

register until the RVU flag is automatically cleared by hardware. However, at APB clock frequency lower than

twice the IWDG clock frequency, the hardware never clears that flag, and writing to the IWDG_RLR register is no

longer possible.

Workaround

Set the APB clock frequency higher than twice the IWDG clock frequency.

2.10.5 PVU flag not cleared at low APB clock frequency

Description

Successful write to the IWDG_PR register raises the PVU flag and prevents further write accesses to the register

until the PVU flag is automatically cleared by hardware. However, at APB clock frequency lower than twice the

IWDG clock frequency, the hardware never clears that flag, and writing to the IWDG_PR register is no longer

possible.

ES0262 - Rev 4

page 10/31

Workaround

Set the APB clock frequency higher than twice the IWDG clock frequency.

2.10.6 WVU flag not cleared at low APB clock frequency

Description

Successful write to the IWDG_WINR register raises the WVU flag and prevents further write accesses to the

register until the WVU flag is automatically cleared by hardware. However, at APB clock frequency lower than

twice the IWDG clock frequency, the hardware never clears that flag, and writing to the IWDG_WINR register is

no longer possible.

Workaround

Set the APB clock frequency higher than twice the IWDG clock frequency.

STM32F078CB/RB/VB

RTC and TAMP

2.11

RTC and TAMP

2.11.1 Spurious tamper detection when disabling the tamper channel

Description

If the tamper detection is configured for detecting on the falling edge event (TAMPFLT = 00 and TAMPxTRG = 1)

and if the tamper event detection is disabled when the tamper pin is at high level, a false tamper event is

detected, which may result in the erasure of backup registers.

Workaround

None for the false detection of tamper event. The erasure of the backup registers can be avoided by setting the

TAMPxNOERASE bit before clearing the TAMPxE bit, in two separate RTC_TAMPCR write accesses.

2.11.2 RTC calendar registers are not locked properly

Description

When reading the calendar registers with BYPSHAD = 0, the RTC_TR and RTC_DR registers may not be locked

after reading the RTC_SSR register. This happens if the read operation is initiated one APB clock period before

the shadow registers are updated. This can result in a non-consistency of the three registers. Similarly, the

RTC_DR register can be updated after reading the RTC_TR register instead of being locked.

Workaround

Apply one of the following measures:

• use BYPSHAD = 1 mode (bypass shadow registers), or

• if BYPSHAD = 0, read SSR again after reading SSR/TR/DR to confirm that SSR is still the same, otherwise

read the values again.

2.11.3 RTC interrupt can be masked by another RTC interrupt

Description

One RTC interrupt request can mask another RTC interrupt request if they share the same EXTI configurable line.

For example, interrupt requests from Alarm A and Alarm B or those from tamper and timestamp events are OR-ed

to the same EXTI line (refer to the EXTI line connections table in the Extended interrupt and event controller

(EXTI) section of the reference manual).

The following code example and figure illustrate the failure mechanism: The Alarm A event is lost (fails to

generate interrupt) as it occurs in the failure window, that is, after checking the Alarm A event flag but before the

effective clear of the EXTI interrupt flag by hardware. The effective clear of the EXTI interrupt flag is delayed with

respect to the software instruction to clear it.

ES0262 - Rev 4

page 11/31

STM32F078CB/RB/VB

Alarm interrupt service routine:

void RTC_Alarm_IRQHandler(void)

{

CLEAR_ALARM_EXTI(); /* Clear the EXTI line flag for RTC alarms*/

If(ALRAF) /* Check if Alarm A triggered ISR */

{

CLEAR_FLAG(ALRAF); /* Clear the Alarm A interrupt pending bit */

PROCESS_AlarmAEvent(); /* Process Alarm A event */

}

If(ALRBF) /* Check if Alarm B triggered ISR */

{

CLEAR_FLAG(ALRBF); /* Clear the Alarm B interrupt pending bit */

PROCESS_AlarmBEvent(); /* Process Alarm B event */

}

}

Figure 1. Masked RTC interrupt

Failure window:

Alarm A Flag is being set after the software checks

its value

Alarm A Flag does not raise EXTI flag because this

one is not yet hardware cleared.

RTC and TAMP

Alarm B Flag

Alarm A Flag

EXTI Flag

Alarm A is never processed

because no interrupt is generated

through EXTI

ISR execution

CLEAR_

ALARM_

EXTI();

If (ALRBF)

If

{

(ALRA

CLEAR_FLAG(ALRBF);

F)

PROCESS_AlarmBEvent();

}

Workaround

In the interrupt service routine, apply three consecutive event flag ckecks - source one, source two, and source

one again, as in the following code example:

void RTC_Alarm_IRQHandler(void)

{

CLEAR_ALARM_EXTI(); /* Clear the EXTI's line Flag for RTC Alarm */

If(ALRAF) /* Check if AlarmA triggered ISR */

{

CLEAR_FLAG(ALRAF); /* Clear the AlarmA interrupt pending bit */

PROCESS_AlarmAEvent(); /* Process AlarmA Event */

}

If(ALRBF) /* Check if AlarmB triggered ISR */

{

CLEAR_FLAG(ALRBF); /* Clear the AlarmB interrupt pending bit */

PROCESS_AlarmBEvent(); /* Process AlarmB Event */

}

If(ALRAF) /* Check if AlarmA triggered ISR */

{

CLEAR_FLAG(ALRAF); /* Clear the AlarmA interrupt pending bit */

PROCESS_AlarmAEvent(); /* Process AlarmA Event */

}

}

ES0262 - Rev 4

page 12/31

STM32F078CB/RB/VB

2.11.4 Calendar initialization may fail in case of consecutive INIT mode entry

Description

If the INIT bit of the RTC_ISR register is set between one and two RTCCLK cycles after being cleared, the INITF

flag is set immediately instead of waiting for synchronization delay (which should be between one and two

RTCCLK cycles), and the initialization of registers may fail.

Depending on the INIT bit clearing and setting instants versus the RTCCLK edges, it can happen that, after being

immediately set, the INITF flag is cleared during one RTCCLK period then set again. As writes to calendar

registers are ignored when INITF is low, a write during this critical period might result in the corruption of one or

more calendar registers.

Workaround

After existing the initialization mode, clear the BYPSHAD bit (if set) then wait for RSF to rise, before entering the

initialization mode again.

Note: It is recommended to write all registers in a single initialization session to avoid accumulating synchronization

delays.

2.11.5 Alarm flag may be repeatedly set when the core is stopped in debug

Description

I2C

When the core is stopped in debug mode, the clock is supplied to subsecond RTC alarm downcounter even

though the device is configured to stop the RTC in debug.

As a consequence, when the subsecond counter is used for alarm condition (the MASKSS[3:0] bitfield of the

RTC_ALRMASSR and/or RTC_ALRMBSSR register set to a non-zero value) and the alarm condition is met just

before entering a breakpoint or printf, the ALRAF and/or ALRBF flag of the RTC_SR register is repeatedly set by

hardware during the breakpoint or printf, which makes any tentative to clear the flag(s) ineffective.

Workaround

None.

2.11.6 A tamper event preceding the tamper detect enable not detected

Description

When the tamper detect is enabled, set in edge detection mode (TAMPFLT[1:0]=00), and

• set to active rising edge (TAMPxTRG=0): if the tamper input is already high (tamper event already occurred)

at the moment of enabling the tamper detection, the tamper event may not be detected. The probability of

detection increases with the APB frequency.

• set to active falling edge (TAMPxTRG=1): if the tamper input is already low (tamper event already occurred)

at the moment of enabling the tamper detection, the tamper event is not detected.

Workaround

The I/O state should be checked by software in the GPIO registers after enabling the tamper detection, in order to

ensure that no active edge occurred before enabling the tamper event detection.

2.12 I2C

2.12.1 10-bit slave mode: wrong direction bit value upon Read header receipt

Description

Under specific conditions, the transfer direction bit DIR (bit 16 of status register I2C_ISR) remains low upon

receipt of 10-bit addressing Read header, while normally it should be set high. Nevertheless, I2C operates

correctly in slave transmission mode, and data can be sent using the TXIS flag.

ES0262 - Rev 4

page 13/31

STM32F078CB/RB/VB

I2C

The failure described occurs when the following conditions are all met:

• I2C is configured in 10-bit addressing mode (OA1MODE is set in the I2C_OAR1 register).

• High LSBs of the slave address are equal to the 10-bit addressing Read header value (that is, OA1[7:3] =

11110, OA1[2] = OA1[9], OA1[1] = OA1[8], and OA1[0] = 1, in the I2C_OAR1 register).

• I2C receives 10-bit addressing Read header (0X 1111 0XX1) after repeated START condition, to enter slave

transmission mode.

Workaround

Avoid using the following 10-bit slave addresses:

• OA1[9:0] = 0011110001

• OA1[9:0] = 0111110011

• OA1[9:0] = 1011110101

• OA1[9:0] = 1111110111

If the use of one of these slave addresses cannot be avoided, do not use the DIR bit in the firmware.

2.12.2 10-bit combined with 7-bit slave mode: ADDCODE may indicate wrong slave address detection

Description

Under specific conditions, the ADDCODE (address match code) bitfield in the I2C_ISR register indicates a wrong

slave address.

The failure occurs when the following conditions are all met:

• A 10-bit slave address OA1 is enabled (OA1EN = 1 and OA1MODE = 1).

• A 7-bit slave address OA2 is enabled (OA2EN = 1) and it matches the non-masked bits of OA1[7:1], that is,

one of the following configurations is set:

– OA2EN = 1 and OA2MSK = 0 and OA1[7:1] = OA2[7:1]

– OA2EN = 1 and OA2MSK = 1 and OA1[7:2] = OA2[7:2]

– OA2EN = 1 and OA2MSK = 2 and OA1[7:3] = OA2[7:3]

– OA2EN = 1 and OA2MSK = 3 and OA1[7:4] = OA2[7:4]

– OA2EN = 1 and OA2MSK = 4 and OA1[7:5] = OA2[7:5]

– OA2EN = 1 and OA2MSK = 5 and OA1[7:6] = OA2[7:6]

– OA2EN = 1 and OA2MSK = 6 and OA1[7] = OA2[7]

– OA2EN = 1 and OA2MSK = 7

– GCEN = 1 and OA1[7:1] = 0000000

– ALERTEN = 1 and OA1[7:1] = 0001100

– SMBDEN = 1 and OA1[7:1] = 1100001

– SMBHEN = 1 and OA1[7:1] = 0001000

• The MCU is addressed by a bus master with its 10-bit slave address OA1.

Upon the address receipt, the ADDCODE value is OA1[7:1] equal to the 7-bit slave address, instead of 0b11110 &

OA1[9:8].

Workaround

None. If several slave addresses are enabled, mixing 10-bit and 7-bit addresses, the OA1 [7:1] part of the 10-bit

slave address must be different than the 7-bit slave address.

2.12.3 Wakeup frames may not wake up the MCU when Stop mode entry follows I2C enabling

Description

If I2C is enabled (PE = 1) and wakeup from Stop mode is enabled in I2C (WUPEN = 1) while a transfer occurs on

the I2C-bus and Stop mode is entered during the same transfer while SCL = 0, I2C is not able to detect the

following START condition. As a consequence, the MCU does not wake up from Stop mode when it is addressed

on the I2C-bus and it does not acknowledge the receipt of the address.

ES0262 - Rev 4

page 14/31

STM32F078CB/RB/VB

Workaround

After enabling I2C (by setting PE to 1), do not enter Stop mode until any I2C-bus transaction in progress ends.

I2C

2.12.4 Wakeup frame may not wake up the MCU from Stop mode if t

startup time

Description

Under specific conditions and if the START condition hold time t

internal oscillator selected for I2C kernel clock, I2C is not able to detect the address match and, as a

consequence, to wake up the MCU from Stop mode.

The failure described occurs when one of the following condition is met:

1. Timeout detection is enabled (TIMOUTEN = 1 or TEXTEN = 1) and the frame before the wakeup frame is

finished abnormally due to I2C timeout detection (TIMOUT = 1).

2. Slave arbitration is lost during the frame preceding the wakeup frame (ARLO = 1).

3. The MCU enters Stop mode while another slave is addressed, after the address phase and before STOP

condition (BUSY = 1).

4. The MCU is in Stop mode and another slave is addressed before the MCU itself is addressed.

Note: The conditions 2, 3 and 4 can only occur in a multi-slave network.

In Stop mode, the internal oscillator selected for I2C kernel clock is switched on by I2C when START condition is

detected. The I2C kernel clock is then used to receive the address. The internal oscillator is switched off upon the

address receipt if the address received does not match the own slave address. If one of the conditions listed is

met and if the SCL falling edge following the START condition occurs within the first cycle of the I2C kernel clock,

the address is received incorrectly and the address match wakeup interrupt is not generated.

Workaround

None at MCU level.

Upon non-acknowledge by the MCU of a wakeup frame, the I2C-bus master with programmable START condition

hold time can set that hold time such that it exceeds one MCU internal oscillator period, then resend the wakeup

frame.

is very close to the startup time of the

HD;STA

is close to I2C kernel clock

HD;STA

2.12.5 10-bit master mode: new transfer cannot be launched if first part of the address is not

acknowledged by the slave

Description

An I2C-bus master generates STOP condition upon non-acknowledge of I2C address that it sends. This applies to

7-bit address as well as to each byte of 10-bit address.

When the MCU set as I2C-bus master transmits a 10-bit address of which the first byte (5-bit header + 2 MSBs of

the address + direction bit) is not acknowledged, the MCU duly generates STOP condition but it then cannot start

any new I2C-bus transfer. In this spurious state, the NACKF flag of the I2C_ISR register and the START bit of the

I2C_CR2 register are both set, while the START bit should normally be cleared.

Workaround

In 10-bit-address master mode, if both NACKF flag and START bit get simultaneously set, proceed as follows:

1. Wait for the STOP condition detection (STOPF = 1 in I2C_ISR register).

2. Disable the I2C peripheral.

3. Wait for a minimum of three APB cycles.

4. Enable the I2C peripheral again.

ES0262 - Rev 4

page 15/31

STM32F078CB/RB/VB

2.12.6 Wrong behavior in Stop mode when wakeup from Stop mode is disabled in I2C

Description

The correct use of the I2C peripheral, if the wakeup from Stop mode by I2C is disabled (WUPEN = 0), is to

disable it (PE = 0) before entering Stop mode, and re-enable it when back in Run mode.

Some reference manual revisions may omit this information.

Failure to respect the above while the MCU operating as slave or as master in multi-master topology enters Stop

mode during a transfer ongoing on the I2C-bus may lead to the following:

1. BUSY flag is wrongly set when the MCU exits Stop mode. This prevents from initiating a transfer in master

mode, as the START condition cannot be sent when BUSY is set.

2. If clock stretching is enabled (NOSTRETCH = 0), the SCL line is pulled low by I2C and the transfer stalled

as long as the MCU remains in Stop mode.

The occurrence of such condition depends on the timing configuration, peripheral clock frequency, and I2Cbus frequency.

This is a description inaccuracy issue rather than a product limitation.

Workaround

No application workaround is required.

I2C

2.12.7 Wrong data sampling when data setup time (t

Description

The I2C-bus specification and user manual specify a minimum data setup time (t

• 250 ns in Standard mode

• 100 ns in Fast mode

• 50 ns in Fast mode Plus

The device does not correctly sample the I2C-bus SDA line when t

(I2C-bus peripheral clock) period: the previous SDA value is sampled instead of the current one. This can result in

a wrong receipt of slave address, data byte, or acknowledge bit.

Workaround

Increase the I2C kernel clock frequency to get I2C kernel clock period within the transmitter minimum data setup

time. Alternatively, increase transmitter’s minimum data setup time. If the transmitter setup time minimum value

corresponds to the minimum value provided in the I2C-bus standard, the minimum I2CCLK frequencies are as

follows:

• In Standard mode, if the transmitter minimum setup time is 250 ns, the I2CCLK frequency must be at least

4 MHz.

• In Fast mode, if the transmitter minimum setup time is 100 ns, the I2CCLK frequency must be at least

10 MHz.

• In Fast-mode Plus, if the transmitter minimum setup time is 50 ns, the I2CCLK frequency must be at least

20 MHz.

) is shorter than one I2C kernel clock period

SU;DAT

) as:

SU;DAT

is smaller than one I2C kernel clock

SU;DAT

2.12.8 Spurious bus error detection in master mode

Description

In master mode, a bus error can be detected spuriously, with the consequence of setting the BERR flag of the

I2C_SR register and generating bus error interrupt if such interrupt is enabled. Detection of bus error has no

effect on the I2C-bus transfer in master mode and any such transfer continues normally.

Workaround

If a bus error interrupt is generated in master mode, the BERR flag must be cleared by software. No other action

is required and the ongoing transfer can be handled normally.

ES0262 - Rev 4

page 16/31

2.12.9 Last-received byte loss in reload mode

Description

If in master receiver mode or slave receive mode with SBC = 1 the following conditions are all met:

• I2C-bus stretching is enabled (NOSTRETCH = 0)

• RELOAD bit of the I2C_CR2 register is set

• NBYTES bitfield of the I2C_CR2 register is set to N greater than 1

• byte N is received on the I2C-bus, raising the TCR flag

• N - 1 byte is not yet read out from the data register at the instant TCR is raised,

then the SCL line is pulled low (I2C-bus clock stretching) and the transfer of the byte N from the shift register to

the data register inhibited until the byte N-1 is read and NBYTES bitfield reloaded with a new value, the latter of

which also clears the TCR flag. As a consequence, the software cannot get the byte N and use its content before

setting the new value into the NBYTES field.

For I2C instances with independent clock, the last-received data is definitively lost (never transferred from the

shift register to the data register) if the data N - 1 is read within four APB clock cycles preceding the receipt of the

last data bit of byte N and thus the TCR flag raising. Refer to the product reference manual or datasheet for the

I2C implementation table.

Workaround

STM32F078CB/RB/VB

I2C

• In master mode or in slave mode with SBC = 1, use the reload mode with NBYTES = 1.

• In master receiver mode, if the number of bytes to transfer is greater than 255, do not use the reload mode.

Instead, split the transfer into sections not exceeding 255 bytes and separate them with repeated START

conditions.

• Make sure, for example through the use of DMA, that the byte N - 1 is always read before the TCR flag is

raised. Specifically for I2C instances with independent clock, make sure that it is always read earlier than

four APB clock cycles before the receipt of the last data bit of byte N and thus the TCR flag raising.

The last workaround in the list must be evaluated carefully for each application as the timing depends on factors

such as the bus speed, interrupt management, software processing latencies, and DMA channel priority.

2.12.10 Spurious master transfer upon own slave address match

Description

When the device is configured to operate at the same time as master and slave (in a multi- master I2C-bus

application), a spurious master transfer may occur under the following condition:

• Another master on the bus is in process of sending the slave address of the device (the bus is busy).

• The device initiates a master transfer by bit set before the slave address match event (the ADDR flag set in

the I2C_ISR register) occurs.

• After the ADDR flag is set:

– the device does not write I2C_CR2 before clearing the ADDR flag, or

– the device writes I2C_CR2 earlier than three I2C kernel clock cycles before clearing the ADDR flag

In these circumstances, even though the START bit is automatically cleared by the circuitry handling the ADDR

flag, the device spuriously proceeds to the master transfer as soon as the bus becomes free. The transfer

configuration depends on the content of the I2C_CR2 register when the master transfer starts. Moreover, if the

I2C_CR2 is written less than three kernel clocks before the ADDR flag is cleared, the I2C peripheral may fall into

an unpredictable state.

ES0262 - Rev 4

Workaround

Upon the address match event (ADDR flag set), apply the following sequence.

Normal mode (SBC = 0):

1. Set the ADDRCF bit.

2. Before Stop condition occurs on the bus, write I2C_CR2 with the START bit low.

page 17/31

Slave byte control mode (SBC = 1):

1. Write I2C_CR2 with the slave transfer configuration and the START bit low.

2. Wait for longer than three I2C kernel clock cycles.

3. Set the ADDRCF bit.

4. Before Stop condition occurs on the bus, write I2C_CR2 again with its current value.

The time for the software application to write the I2C_CR2 register before the Stop condition is limited, as the

clock stretching (if enabled), is aborted when clearing the ADDR flag.

Polling the BUSY flag before requesting the master transfer is not a reliable workaround as the bus may become

busy between the BUSY flag check and the write into the I2C_CR2 register with the START bit set.

2.12.11 OVR flag not set in underrun condition

Description

In slave transmission with clock stretching disabled (NOSTRETCH = 1 in the I2C_CR1 register), an underrun

condition occurs if the current byte transmission is completed on the I2C bus, and the next data is not yet written

in the TXDATA[7:0] bitfield. In this condition, the device is expected to set the OVR flag of the I2C_ISR register

and send 0xFF on the bus.

However, if the I2C_TXDR is written within the interval between two I2C kernel clock cycles before and three APB

clock cycles after the start of the next data transmission, the OVR flag is not set, although the transmitted value is

0xFF.

STM32F078CB/RB/VB

USART

Workaround

None.

2.12.12 Transmission stalled after first byte transfer

Description

When the first byte to transmit is not prepared in the TXDATA register, two bytes are required successively,

through TXIS status flag setting or through a DMA request. If the first of the two bytes is written in the I2C_TXDR

register in less than two I2C kernel clock cycles after the TXIS/DMA request, and the ratio between APB clock

and I2C kernel clock frequencies is between 1.5 and 3, the second byte written in the I2C_TXDR is not internally

detected. This causes a state in which the I2C peripheral is stalled in master mode or in slave mode, with clock

stretching enabled (NOSTRETCH = 0). This state can only be released by disabling the peripheral (PE = 0) or by

resetting it.

Workaround

Apply one of the following measures:

• Write the first data in I2C_TXDR before the transmission starts.

• Set the APB clock frequency so that its ratio with respect to the I2C kernel clock frequency is lower than 1.5

or higher than 3.

2.13 USART

2.13.1 USART4 transmission does not work on PC11

ES0262 - Rev 4

Description

USART4_RX does not work as output on PC11.

As a consequence, single-wire half-duplex mode is not supported with pin PC11.

Workaround

Use USART4_RX mapped on PA0 instead on PC11.

page 18/31

STM32F078CB/RB/VB

2.13.2 Last byte written in TDR might not be transmitted if TE is cleared just after writing in TDR

Description

If the USART clock source is slow (for example LSE) and TE bit is cleared immediately after the last write to TDR,

the last byte may not be transmitted.

Workaround

Apply one of the following measures:

• Wait until TXE flag is set before clearing TE bit.

• Wait until TC flag is set before clearing TE bit.

2.13.3 Non-compliant sampling for NACK signal from smartcard

Description

According to ISO/IEC 7816-3 standard, when a character parity error is detected, the receiver must assert a

NACK signal, by pulling the transmit line low for one ETU period, at 10.3 to 10.7 ETU after the character START

bit falling edge. The transmitter is expected to sample the line for NACK (for low level) from 10.8 to 11.2 ETU after

the character START bit falling edge.

Instead, the USART peripheral in Smartcard mode samples the transmit line for NACK from 10.3 to 10.7 ETU

after the character START bit falling edge. This is unlikely to cause issues with receivers (smartcards) that respect

the ISO/IEC 7816-3 standard. However, it may cause issues with respect to certification.

USART

Workaround

None.

2.13.4 Break request preventing TC flag from being set

Description

After the end of transmission of data (D1), the transmission complete (TC) flag is not set when the following

condition is met:

• CTS hardware flow control is enabled

• D1 transmission is in progress

• D1 transmission is in progress

• D1 transmission is in progress

As a consequence, an application relying on the TC flag fails to detect the end of data transfer.

Workaround

In the application, only allow break request after the TC flag is set.

2.13.5 RTS is active while RE = 0 or UE = 0

Description

The RTS line is driven low as soon as RTSE bit is set, even if the USART is disabled (UE = 0) or the receiver is

disabled (RE = 0), that is, not ready to receive data.

ES0262 - Rev 4

Workaround

Upon setting the UE and RE bits, configure the I/O used for RTS into alternate function.

page 19/31

2.13.6 Receiver timeout counter wrong start in two-stop-bit configuration

Description

In two-stop-bit configuration, the receiver timeout counter starts counting from the end of the second stop bit of

the last character instead of starting from the end of the first stop bit.

Workaround

Subtract one bit duration from the value in the RTO bitfield of the USARTx_RTOR register.

2.13.7 Anticipated end-of-transmission signaling in SPI slave mode

Description

In SPI slave mode, at low USART baud rate with respect to the USART kernel and APB clock frequencies, the

transmission complete flag TC of the USARTx_ISR register may unduly be set before the last bit is shifted on the

transmit line.

This leads to data corruption if, based on this anticipated end-of-transmission signaling, the application disables

the peripheral before the last bit is transmitted.

Workaround

STM32F078CB/RB/VB

SPI

Upon the TC flag rise, wait until the clock line remains idle for more than the half of the communication clock

cycle. Then only consider the transmission as ended.

2.13.8 Data corruption due to noisy receive line

Description

In UART mode with oversampling by 8 or 16 and with 1 or 2 stop bits, the received data may be corrupted if a

glitch to zero shorter than the half-bit occurs on the receive line within the second half of the stop bit.

Workaround

None.

2.14

SPI

2.14.1 BSY bit may stay high when SPI is disabled

Description

The BSY flag may remain high upon disabling the SPI while operating in:

• master transmit mode and the TXE flag is low (data register full).

• master receive-only mode (simplex receive or half-duplex bidirectional receive phase) and an SCK strobing

edge has not occurred since the transition of the RXNE flag from low to high.

• slave mode and NSS signal is removed during the communication.

Workaround

ES0262 - Rev 4

When the SPI operates in:

• master transmit mode, disable the SPI when TXE = 1 and BSY = 0.

• master receive-only mode, ignore the BSY flag.

• slave mode, do not remove the NSS signal during the communication.

page 20/31

STM32F078CB/RB/VB

2.14.2 BSY bit may stay high at the end of data transfer in slave mode

Description

BSY flag may sporadically remain high at the end of a data transfer in slave mode. This occurs upon coincidence

of internal CPU clock and external SCK clock provided by master.

In such an event, if the software only relies on BSY flag to detect the end of SPI slave data transaction (for

example to enter low-power mode or to change data line direction in half-duplex bidirectional mode), the detection

fails.

As a conclusion, the BSY flag is unreliable for detecting the end of data transactions.

Workaround

Depending on SPI operating mode, use the following means for detecting the end of transaction:

• When NSS hardware management is applied and NSS signal is provided by master, use NSS flag.

• In SPI receiving mode, use the corresponding RXNE event flag.

• In SPI transmit-only mode, use the BSY flag in conjunction with a timeout expiry event. Set the timeout such

as to exceed the expected duration of the last data frame and start it upon TXE event that occurs with the

second bit of the last data frame. The end of the transaction corresponds to either the BSY flag becoming

low or the timeout expiry, whichever happens first.

Prefer one of the first two measures to the third as they are simpler and less constraining.

Alternatively, apply the following sequence to ensure reliable operation of the BSY flag in SPI transmit mode:

1. Write last data to data register.

2. Poll the TXE flag until it becomes high, which occurs with the second bit of the data frame transfer.

3. Disable SPI by clearing the SPE bit mandatorily before the end of the frame transfer.

4. Poll the BSY bit until it becomes low, which signals the end of transfer.

Note: The alternative method can only be used with relatively fast CPU speeds versus relatively slow SPI clocks

or/and long last data frames. The faster is the software execution, the shorter can be the duration of the last data

frame.

SPI

2.14.3 SPI CRC corruption upon DMA transaction completion by another peripheral

Description

When the following conditions are all met:

• CRC function for the SPI is enabled

• SPI transaction managed by software (as opposed to DMA) is ongoing and CRCNEXT flag set

• another peripheral using the DMA channel on which the SPI is mapped completes a DMA transfer,

the CRCNEXT bit is unexpectedly cleared and the SPI CRC calculation may be corrupted, setting the CRC error

flag.

Workaround

Ensure that the DMA channel on which the SPI is mapped is not concurrently in use by another peripheral.

2.14.4

In I2S slave mode, enabling I2S while WS is active causes desynchronization

Description

In I2S slave mode, the WS signal level is used to start the communication. If the I2S peripheral is enabled while

the WS line is active (low for I2S protocol, high for LSB- or MSB-justified mode), and if the master is already

sending the clock, the I2S peripheral (slave) starts communicating data from the instant of its enable, which

causes desynchronization between the master and the slave throughout the whole communication.

ES0262 - Rev 4

page 21/31

STM32F078CB/RB/VB

Workaround

Enable I2S peripheral while the WS line is at:

• high level, for I2S protocol.

• low level, for LSB- or MSB-justified mode.

2.14.5 CRC error in SPI slave mode if internal NSS changes before CRC transfer

Description

Some reference manual revisions may omit the information that the device operating as SPI slave must be

configured in software NSS control if the SPI master pulses the NSS (for (for example in NSS pulse mode).

Otherwise, the transition of the internal NSS signal after the CRCNEXT flag is set might result in wrong CRC

value computed by the device and, as a consequence, in a CRC error. As a consequence, the NSS pulse mode

cannot be used along with the CRC function.

This is a documentation error rather than a product limitation.

Workaround

No application workaround is required as long as the device operating as SPI slave is duly configured in software

NSS control.

USB

2.15 USB

2.15.1 Possible packet memory overrun/underrun at low APB frequency

Description

Some data sheet and/or reference manual revisions may omit the information that 10 MHz minimum APB clock

frequency is required to avoid USB data overrun/underrun issues.

Operating the USB peripheral with lower APB clock frequency may lead to:

Overrun for out transactions - the USB peripheral fails to store the received data into the PBM before the

•

next byte is received on the USB (PBM overrun). The USB cell detects an internal error condition, discards

the last received byte, stops writing into the PBM, sends no acknowledge (forcing the host to retry the

transaction), and informs the application by setting the PMAOVR flag/interrupt.

•

Underrun for in transactions - the USB peripheral fails to read from the PBM the next byte to transmit before

the transmission of the previous one is completed on the USB. The USB cell detects an internal error

condition, stops reading from PBM, generates a bit stuffing error on the USB (forcing the host to retry the

transaction), and informs the application by setting the PMAOVR flag/interrupt.

This is a documentation issue rather than a device limitation.

Workaround

No application workaround is required if the minimum APB clock frequency of 10 MHz is respected.

2.15.2 ESOF interrupt timing desynchronized after resume signaling

Description

ES0262 - Rev 4

Upon signaling resume, the device is expected to allow full 3 ms of time to the host or hub for sending the initial

SOF (start of frame) packet, without triggering SUSP interrupt. However, the device only allows two full

milliseconds and unduly triggers SUSP interrupt if it receives the initial packet within the third millisecond.

Workaround

When the device initiates resume (remote wakeup), mask the SUSP interrupt by setting the SUSPM bit for 3 ms,

then unmask it by clearing SUSPM.

page 22/31

2.15.3 Incorrect CRC16 in the memory buffer

Description

Memory buffer locations are written starting from the address contained in the ADDRn_RX for a number of bytes

corresponding to the received data packet length, CRC16 inclusive (that is, data payload length plus two bytes),

or up to the last allocated memory location defined by BL_SIZE and NUM_BLOCK, whichever comes first. In the

former case, the CRC16 checksum is written wrongly, with its least significant byte going to both memory buffer

byte locations expected to receive the least and the most significant bytes of the checksum.

Although the checksum written in the memory buffer is wrong, the underlying CRC checking mechanism in the

USB peripheral is fully functional.

Workaround

Ignore the CRC16 data in the memory buffer.

2.15.4 The USB BCD functionality limited below -20°C

Description

Primary and secondary detection can return an incorrectly detected port type.

This limitation may be observed on a small number of devices when the temperature is below -20°C.

STM32F078CB/RB/VB

CEC

Workaround

None.

2.15.5 DCD function not compliant

Description

The DCD (data contact detect) function on the device is not compliant with the USB Battery Charging 1.2

Compliance Plan rev 1.0 specification.

Workaround

Do not use the DCD function. Instead, upon attaching a USB device, wait for at least TDCD_TIMEOUT amount of

time before starting primary detection. This is in line with the Battery Charging Specification rev1.2

recommendation for portable devices that do not support the DCD function.

2.16

CEC

2.16.1 Transmission blocked when transmitted start bit is corrupted

Description

When the HDMI-CEC communication start bit transmitted by the device is corrupted by another device on the

CEC line, the CEC transmission is stalled.

This failure is unlikely to happen as the CEC start bit corruption by another device can only occur if that device

does not respect the CEC communication protocol.

The start bit timing standard tolerances are shown in the following figure. The start bit is initiated by the device by

driving the CEC line low (reference point). After 3.7 ms, the device releases the CEC line and starts checking its

level. The following conditions must be met for the start bit to be valid:

• the CEC line goes high no later than 3.9 ms (4.05 ms with extended tolerance) from the reference point

• a falling edge on the CEC line does not occur earlier than 4.3 ms (4.15 ms with extended tolerance) from the

reference point

If one of these conditions is not met, the transmission is aborted and never automatically retried. No error flag is

set and the TXSOM (Tx start of message) bit is not cleared.

ES0262 - Rev 4

page 23/31

high impedance

low impedance

STM32F078CB/RB/VB

CEC

Figure 2. HDMI-CEC start bit format with tolerances

CEC line

0

Reference point

Workaround

The only way to detect this error is for the application software to start a timeout when setting the TXSOM bit,

restart it upon ARBLST or any RX event (as the transmission can be delayed by interleaved reception), and stop

it upon TXBR (proof that the start bit was transmitted successfully) or TXEND event, or upon any TX error (which

clears TXSOM). If the timeout expires (because none of those events occurred), the application software must

restart the HDMI-CEC peripheral and retransmit the message.

2.16.2 Missed CEC messages in normal receiving mode

Description

In normal receiving mode, any CEC message with destination address different from the own address should

normally be ignored and have no effect to the CEC peripheral. Instead, such a message is unduly written into the

reception buffer and sets the CEC peripheral to a state in which any subsequent message with the destination

address equal to the own address is rejected (NACK), although it sets RXOVR flag (because the reception buffer

is considered full) and generates (if enabled) an interrupt. This failure can only occur in a multi-node CEC

framework where messages with addresses other than own address can appear on the CEC line.

Workaround

Use listen mode (set LSTEN bit) instead of normal receiving mode. Discard messages to single listeners with

destination address different from the own address of the HDMI-CEC peripheral.

3.5 3.7 3.9 4.3 4.5 4.7

time (ms)

ES0262 - Rev 4

page 24/31

Revision history

Table 4. Document revision history

Date Version Changes

12-Jan-2014 Initial release

Added

:

USART:

• Section: Start bit detected too soon when sampling for NACK signal

from the smartcard

• Section: Break request can prevent the Transmission Complete flag

(TC) from being set

• Section: RTS is active while RE or UE = 0

• Section: Receiver timeout counter starting in case of 2 stops bit

configuration

I2C:

• Section: Spurious bus error detection in master mode

• Section: 10-bit master mode: new transfer cannot be launched if first

part of the address is not acknowledged by the slave

SPI:

• Section: BSY bit may stay high when SPI is disabled

• Section: BSY bit may stay high at the end of a data transfer in slave

mode

• Section: Wrong CRC transmitted in master mode with delayed SCK

feedback

• Section: CRC error in SPI slave mode if internal NSS changes before

CRC transfer

• Section: SPI CRC corrupted upon DMA transaction completion by

another peripheral

12-Oct-2018 2

USB:

• Section: DCD (data contact detect) function not compliant

RTC:

• Section: Spurious tamper detection when disabling the tamper channel

• Section: A tamper event preceding the tamper detect enable not

detected

• Section: RTC calendar registers are not locked properly

ADC:

• Section: Overrun flag not set if EOC reset coincides with new

conversion end

• Section: ADEN bit cannot be set immediately after the ADC calibration

HDMI-CEC:

• Section: Transmission blocked when transmitted start bit is corrupted

TSC:

• Section: Inhibited acquisition in short transfer phase configuration

IWDG:

• Section: RVU, PVU and WVU flags are not reset in STOP mode

• Section: RVU, PVU and WVU flags are not reset with low-frequency

APB

Modified:

• Document structure

• Cover page and Table 2 organization

Removed:

STM32F078CB/RB/VB

ES0262 - Rev 4

page 25/31

Date Version Changes

GPIO:

• Extra consumption on GPIOs PC0..5 on 48/49 pin package. (This

limitation does not exist on the product. It was kept in the previous

revisions of the document for historical reasons)

• Appendix A (package marking drawings are now available in the data

sheet)

Added:

• Section: Last-received byte loss in reload mode

• REV_ID bitfield information on the cover page information on

workaround qualifiers in Section: Summary of device limitations

• Section: Missed CEC messages in normal receiving mode

Modified:

• order of functions and their names - alignment with the reference

manual

• minor modifications in titles and/or text of existing limitation descriptors

04-May-2018 3

12-Oct-2020 4

in I2C, SPI/I2S and USART sections

• workaround of the limitation in Section: In I2S slave mode, enabling I2S

while WS is active causes desynchronization re-qualified to “P”

• workaround description in Section: Wrong data sampling when data

setup time (t

• document ID in the footer of all pages to ES0262

• renaming of introductory section on the cover page

Removed:

• limitation “Wrong CRC transmitted in master mode with delay on SCK

feedback” in SPI/I2S section, kept in previous versions for historical

reasons.

Added errata:

• RDP Level 1 issue

• ADCAL bit is not cleared when successive calibrations are performed

and system clock frequency is considerably higher than the ADC clock

frequency

• PWM re-enabled in automatic output enable mode despite of system

break

• TRGO and TRGO2 trigger output failure

• Consecutive compare event missed in specific conditions

• Output compare clear not working with external counter reset

• Calendar initialization may fail in case of consecutive INIT mode entry

• Alarm flag may be repeatedly set when the core is stopped in debug

• Spurious master transfer upon own slave address match

• OVR flag not set in underrun condition

• Transmission stalled after first byte transfer

• Anticipated end-of-transmission signaling in SPI slave mode

• Data corruption due to noisy receive line

Modified errata:

• Overrun flag is not set if EOC reset coincides with new conversion end

• RVU flag not reset in Stop

• PVU flag not reset in Stop

• WVU flag not reset in Stop

• RVU flag not cleared at low APB clock frequency

• PVU flag not cleared at low APB clock frequency

• WVU flag not cleared at low APB clock frequency

• Spurious master transfer upon own slave address match

• CRC error in SPI slave mode if internal NSS changes before CRC

transfer

) is shorter than one I2C kernel clock period

SU;DAT

STM32F078CB/RB/VB

ES0262 - Rev 4

page 26/31

Date Version Changes

• DCD function not compliant

STM32F078CB/RB/VB

ES0262 - Rev 4

page 27/31

STM32F078CB/RB/VB

Contents

Contents

1 Summary of device errata..........................................................2

2 Description of device errata........................................................5

2.1 Core .........................................................................5

2.2 System .......................................................................5

2.2.1 RDP Level 1 issue .......................................................5

2.3 GPIO.........................................................................5

2.3.1 GPIOx locking mechanism not working properly for GPIOx_OTYPER register ..........5

2.4 DMA .........................................................................5

2.4.1 DMA disable failure and error flag omission upon simultaneous transfer error and global

flag clear ...............................................................5

2.4.2 Byte and half-word accesses not supported ....................................6

2.5 ADC .........................................................................6

2.5.1 ADCAL bit is not cleared when successive calibrations are performed and system clock

frequency is considerably higher than the ADC clock frequency .....................6

2.5.2 Overrun flag is not set if EOC reset coincides with new conversion end ...............6

2.5.3 ADEN bit cannot be set immediately after the ADC calibration ......................6

2.6 DAC .........................................................................7

2.6.1 DMA request not automatically cleared by clearing DMAEN ........................7

2.6.2 DMA underrun flag not set when an internal trigger is detected on the clock cycle of the

DMA request acknowledge .................................................7

2.7 COMP........................................................................7

2.7.1 Long V

scaler startup time after power on.................................7

REFINT

2.8 TSC..........................................................................8

2.8.1 Inhibited acquisition in short transfer phase configuration ..........................8

2.9 TIM ..........................................................................8

2.9.1 PWM re-enabled in automatic output enable mode despite of system break............8

2.9.2 TRGO and TRGO2 trigger output failure.......................................8

2.9.3 Consecutive compare event missed in specific conditions .........................9

2.9.4 Output compare clear not working with external counter reset ......................9

2.10 IWDG .......................................................................10

2.10.1 RVU flag not reset in Stop.................................................10

ES0262 - Rev 4

page 28/31

STM32F078CB/RB/VB

Contents

2.10.2 PVU flag not reset in Stop.................................................10

2.10.3 WVU flag not reset in Stop ................................................10

2.10.4 RVU flag not cleared at low APB clock frequency ...............................10

2.10.5 PVU flag not cleared at low APB clock frequency ...............................10

2.10.6 WVU flag not cleared at low APB clock frequency .............................. 11

2.11 RTC and TAMP ...............................................................11

2.11.1 Spurious tamper detection when disabling the tamper channel..................... 11

2.11.2 RTC calendar registers are not locked properly ................................11

2.11.3 RTC interrupt can be masked by another RTC interrupt .......................... 11

2.11.4 Calendar initialization may fail in case of consecutive INIT mode entry...............13

2.11.5 Alarm flag may be repeatedly set when the core is stopped in debug ................13

2.11.6 A tamper event preceding the tamper detect enable not detected...................13

2.12 I2C .........................................................................13

2.12.1 10-bit slave mode: wrong direction bit value upon Read header receipt ..............13

2.12.2 10-bit combined with 7-bit slave mode: ADDCODE may indicate wrong slave address

detection ..............................................................14

2.12.3 Wakeup frames may not wake up the MCU when Stop mode entry follows I2C enabling . 14

2.12.4 Wakeup frame may not wake up the MCU from Stop mode if t

clock startup time .......................................................15

2.12.5 10-bit master mode: new transfer cannot be launched if first part of the address is not

acknowledged by the slave ................................................15

2.12.6 Wrong behavior in Stop mode when wakeup from Stop mode is disabled in I2C .......16

2.12.7 Wrong data sampling when data setup time (t

) is shorter than one I2C kernel clock

SU;DAT

period ................................................................16

2.12.8 Spurious bus error detection in master mode ..................................16

2.12.9 Last-received byte loss in reload mode .......................................17

2.12.10 Spurious master transfer upon own slave address match .........................17

2.12.11 OVR flag not set in underrun condition .......................................18

is close to I2C kernel

HD;STA

2.12.12 Transmission stalled after first byte transfer ...................................18

2.13 USART ......................................................................18

2.13.1 USART4 transmission does not work on PC11 .................................18

2.13.2 Last byte written in TDR might not be transmitted if TE is cleared just after writing in TDR 19

2.13.3 Non-compliant sampling for NACK signal from smartcard.........................19

2.13.4 Break request preventing TC flag from being set ...............................19

ES0262 - Rev 4

page 29/31

STM32F078CB/RB/VB

Contents

2.13.5 RTS is active while RE = 0 or UE = 0 ........................................19

2.13.6 Receiver timeout counter wrong start in two-stop-bit configuration ..................20

2.13.7 Anticipated end-of-transmission signaling in SPI slave mode ......................20

2.13.8 Data corruption due to noisy receive line......................................20

2.14 SPI .........................................................................20

2.14.1 BSY bit may stay high when SPI is disabled ...................................20

2.14.2 BSY bit may stay high at the end of data transfer in slave mode....................21

2.14.3 SPI CRC corruption upon DMA transaction completion by another peripheral .........21

2.14.4 In I2S slave mode, enabling I2S while WS is active causes desynchronization .........21

2.14.5 CRC error in SPI slave mode if internal NSS changes before CRC transfer ...........22

2.15 USB.........................................................................22

2.15.1 Possible packet memory overrun/underrun at low APB frequency ..................22

2.15.2 ESOF interrupt timing desynchronized after resume signaling .....................22

2.15.3 Incorrect CRC16 in the memory buffer .......................................23

2.15.4 The USB BCD functionality limited below -20°C ................................23

2.15.5 DCD function not compliant................................................23

2.16 CEC ........................................................................23

2.16.1 Transmission blocked when transmitted start bit is corrupted ......................23

2.16.2 Missed CEC messages in normal receiving mode ..............................24

Revision history .......................................................................25

ES0262 - Rev 4

page 30/31

STM32F078CB/RB/VB

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2020 STMicroelectronics – All rights reserved

ES0262 - Rev 4

page 31/31

Loading...

Loading...