Page 1

1 Intro

Tutorial

STM32 Cortex-M3

Author El. Ing. Lukas Kohler

Adviser Daniel Debrunner

Date 09.09.2009

Site BFH-TI Biel

Study Master of Science in Biomedical Engineering

University of Bern and University of Applied Sciences Biel

Page 2

Page 3

Abstract

The powerful STM32 controller from STMicroelectronics with integrated Cortex-M3 core has become more and more relevant in embedded applications. The key points are an excellent real-time

behavior, an outstanding power efficiency and superior peripherals.

The new developed Cortex-M3 has a high aim: A powerful processor with a uncomplex programming model which is able to replace the available 8 and 16-bit microcontroller. Tools and libraries

guarantee a short developing time and a high standardisation. A big part of written and used

software can be reused.

This manual guides you through programming an STM32F103RB microcontroller. The first chapters give an introduction to the STM32 and show how the development toolchain is set up and

used. In the main part of this documentation the peripheral is illustrated. It should lead you to

start straight ahead without reading application notes or data sheets.

I

Page 4

Page 5

Contents

1 Introduction 1

1.1 Overview of this Documentation 1

1.2 Timeline 1

1.3 Symbols used in this Document 1

1.4 License and Author 2

2 System Description 3

2.1 Introduction 3

2.2 Electrostatic Warning 3

2.3 Cortex-M3 Core 3

2.3.1 History 3

2.3.2 Cortex 4

2.4 Processor STM32F103RB from STMicroelectronics 6

2.4.1 Features 6

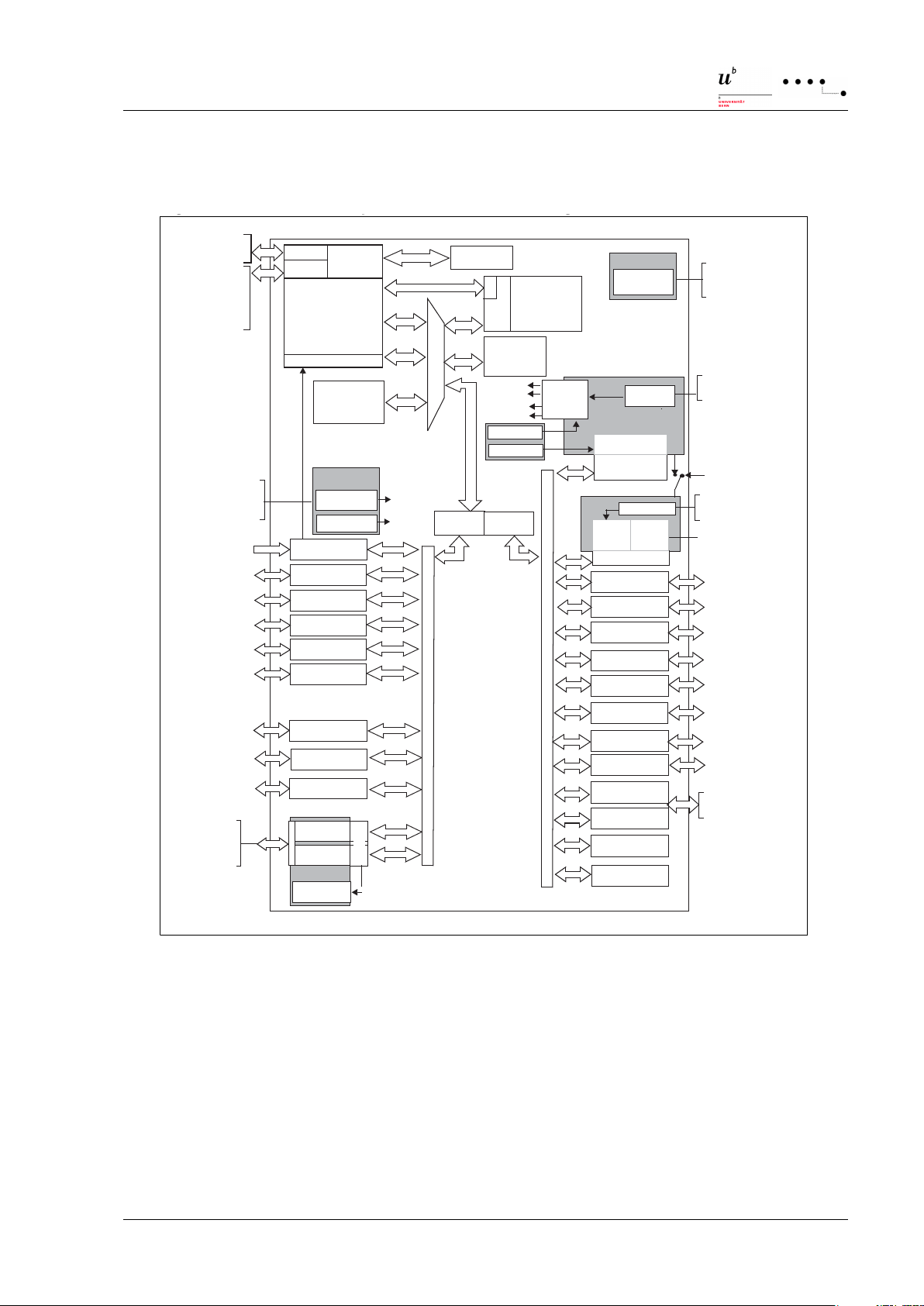

2.4.2 Performance Line Block Diagram 7

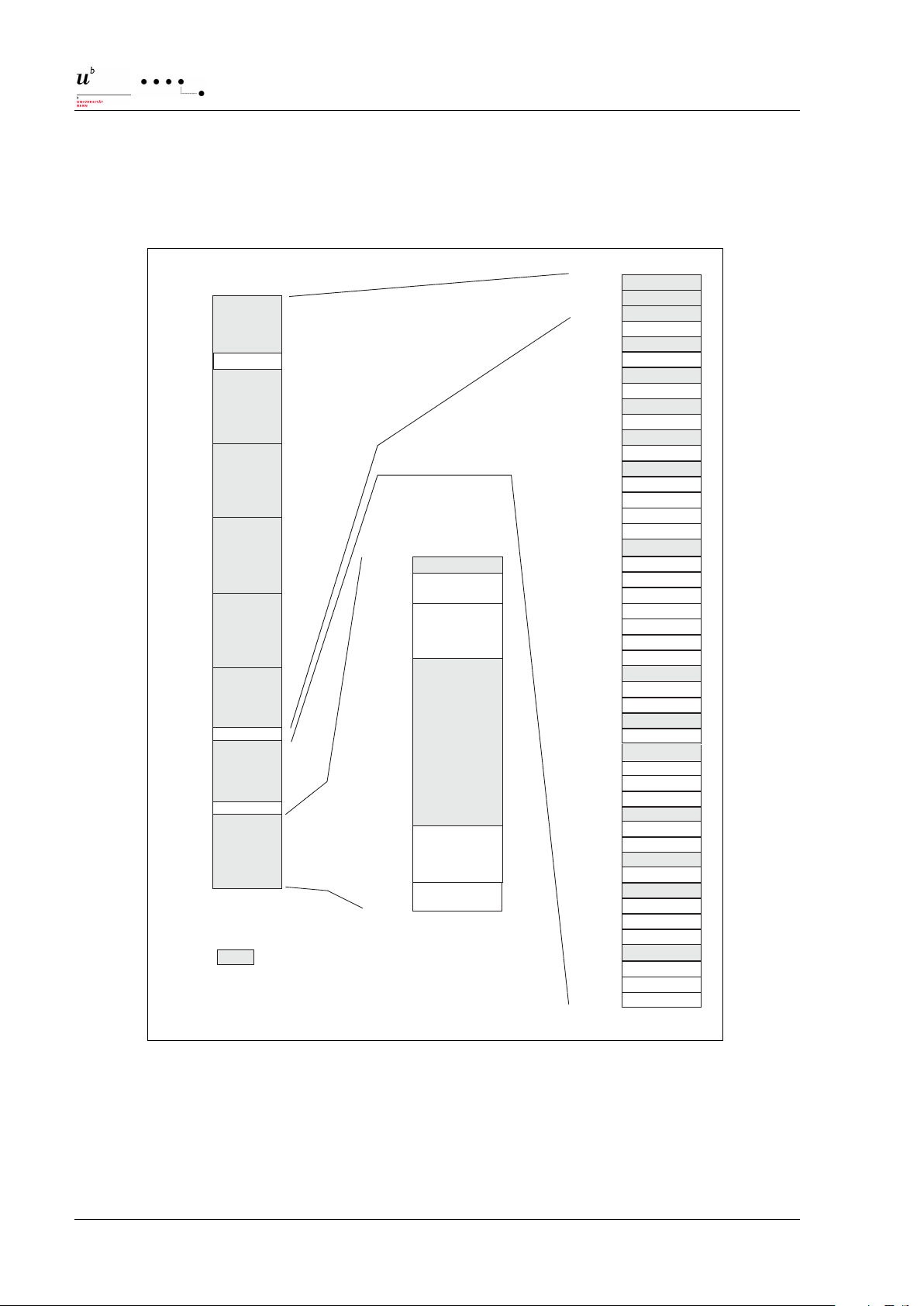

2.4.3 Memory Map 8

2.4.4 Interfaces 9

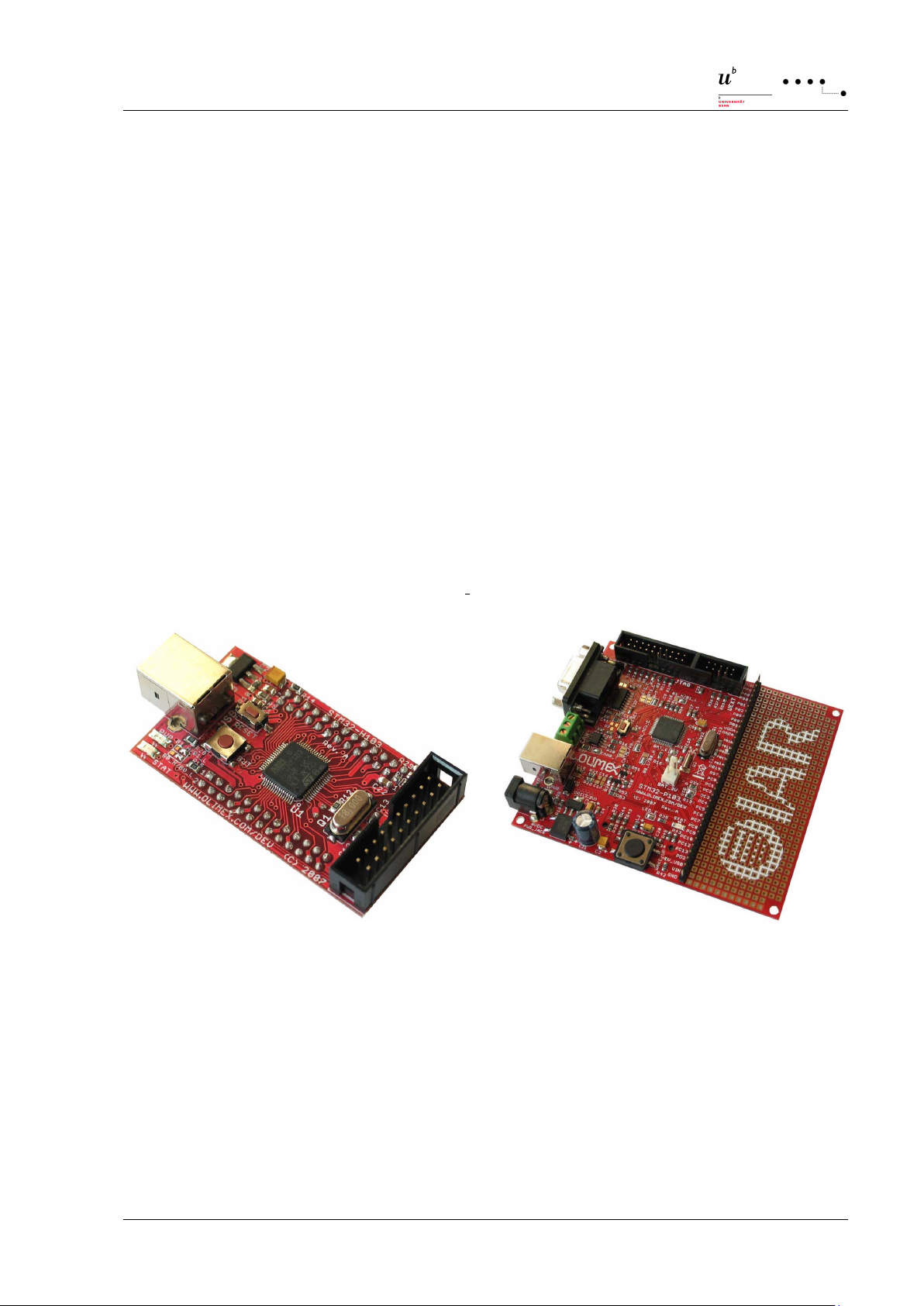

2.5 Development Boards 9

2.5.1 STM32H103 from Olimex 9

2.5.2 STM32P103 from Olimex 10

2.5.3 Setup for Developing 10

2.5.4 Board Layout and Schematic 11

2.5.5 BFH Mother Board 11

3 Keil SDK 13

3.1 Introduction 13

3.2 Install µVision3 13

3.3 Install the Driver for the JTAG Adapter 13

3.4 Install the STM32 Peripheral Library 13

3.5 Setting up a new Project 14

3.5.1 Preparation 14

3.5.2 Create a new project 14

3.5.3 Configure the Processor 15

3.5.4 Renaming the Target 16

3.6 Building 16

3.7 Simulation 17

3.7.1 Window update 18

III

Page 6

1 Intro

Contents

3.7.2 Serial Window 18

3.7.3 Performance Analyzer 18

3.8 Configuring the Target 19

3.9 Downloading 21

3.10 Debugging 21

3.11 Serial Terminal 21

3.12 Documenting Source Code 22

4 Peripherals 23

4.1 Getting Started 23

4.2 Configuration Wizard 23

4.3 Firmware Library (FWLib) 24

4.4 Register Access 25

4.5 General Purpose Input/Output (GPIO) 26

4.5.1 Configuration 26

4.5.2 Driver 27

4.5.3 Set Output 27

4.5.4 Read Input 27

4.6 Serial Interface (USART) 28

4.6.1 Ways of Operation: Polling versus Interrupts 28

4.6.2 Using Polling 28

4.6.3 Using Interrupts 29

4.6.4 Driver 29

4.6.5 Pinning 31

4.7 System Timer (SysTick) 32

4.7.1 Configuration 32

4.8 Timer (TIM) 33

4.8.1 Configuration 33

4.9 Pulse Width Modulation (PWM) 34

4.9.1 Configuration 34

4.10 External Interrupts (IRQ) 35

4.10.1 Configuration 35

4.10.2 Functionality 35

4.11 Watchdog 36

4.11.1 Configuration 36

4.12 Real Time Clock (RTC) 36

4.13 Analog to Digital Converter (ADC) 37

4.13.1 Conversion Modes 37

4.14 Controller Area Network (CAN) 40

4.14.1 CAN Analyzer 41

4.14.2 Pinning 41

4.15 Inter IC Bus (I2C) 41

4.15.1 Physical layer 42

IV STM32 Cortex-M3 Tutorial

Page 7

Contents

1 Intro

4.15.2 Communication Protocol 42

4.15.3 Pinning 44

4.16 Serial Peripheral Interface (SPI) 45

4.16.1 Physical Layer 45

4.16.2 Communication Protocol 45

4.16.3 Pinning 46

4.17 Universal Serial Bus (USB) 48

List of Figures 50

Glossary 52

Lukas Kohler V

Page 8

Page 9

1 Introduction

1.1 Overview of this Documentation

• Introduction (Chapter 1)

This chapter shows how this documentation is structured and meant to be read as well as

some project organisation.

• System Description (Chapter 2)

Here one can read all about the core Cortex-M3 and it’s implementation from STMicroelectronics into the STM32F103 processor. The development boards from Olimex as well as the

BFH mother board are presented and the interfaces shown.

• Keil SDK (Chapter 3)

This chapter shows how to set up a new project with the Keil Software Development Kit

µVision3 and how to compile, simulate, download and debug software.

• Peripherals (Chapter 4)

The biggest part of this documentation is showing how the peripherals are controlled. Example programs from using simple inputs and outputs to complex interrupts are provided.

This example based chapter shows you the way of using peripherals with simple examples.

1.2 Timeline

• Start: March 1, 2009

• Project deadline: August 30, 2009

• Presentation (BFH Biel): December 14, 2009

1.3 Symbols used in this Document

Warning: This warning should be taken seriously. Ignoring warnings could cause problems or

destroy devices.

Sample Code: Shows that a sample code exists in the directory CD:/code/ . b

Filename: hudi.c

Function: void doSomeThing()

!

1

Page 10

1 Intro

1.4 License and Author

The whole Cortex-M3 Tutorial including Source Code and Documentation by Lukas Kohler is licensed under a Creative Commons Attribution-

Noncommercial-Share Alike 3.0 United States License.

Written 2009 by Lukas Kohler k lukas.kohler@gmail.com

H 078 817 77 77

1 Introduction

2 STM32 Cortex-M3 Tutorial

Page 11

2 System Description

2.1 Introduction

This chapter describes the technical way of the development boards. Often abbreviations are used,

they are described in the glossary (Part 4.17). The microcontroller used on the different board is

always the STM32F103RB form ST with the Cortex-M3 core from ARM. The first section introduces

this core, the second the microcontroller STM32F103RB and the following the development boards

used in this document.

This chapter describes only the processor used in this document and shows the hardware setup.

The development of the software itself is described in Chapter 3.

2.2 Electrostatic Warning

Make sure that you are connected to ground before you touch any electronic circuit! Electrostatic discharges may destroy any electronic circuit.

!

2.3 Cortex-M3 Core

The target market of the Cortex-M3 core is the field that has been served by 8- or 16bit controllers.

In this market cheap but powerful controllers with little power consumption are needed.

2.3.1 History

For the last decade the ARM7 and ARM9 microcontrollers have been used as

general purpose microcontrollers. Today exist a few hundred microcontrollers

with the ARM core.

Now STMicroelectronics have launched the STM32, their first microcontroller based on the new

ARM Cortex-M3 core. This device sets new standards in performance and cost, as well as being

capable of low power operation and hard real-time control.

Currently the M3 core is licensed by 22 companies like Actel Corporation, Broadcom Corporation,

Energy Micro, Luminary Micro, NXP, STMicroelectronics, Texas Instruments, Toshiba and Zilog1.

1

Licensed M3 cores: arm.com

3

Page 12

1 Intro

2 System Description

2.3.2 Cortex

The new generation of processors comes as complete processor core that provides a standard CPU

and system architecture.

On the ARM7 systems every manufacturer had to add the basic peripherals like interrupt controller, systick timer and sleep modes. This has now been built into the Cortex-M3 core. The

Cortex-M3 provides a standardized microcontroller core which goes beyond the classical CPU to

provide the entire heart of a microcontroller (including the interrupt system, 24-bit SysTick timer,

debug system and memory map).

The Cortex family comes in three main profiles: The A profile for

high end applications (applications processors for complex OS and

user applications), R for real time and M for cost-sensitive and microcontroller applications.

The STM32 is based on the Cortex-M3 profile, which is specifically designed for high system

performance combined with low power consumption. It has a low enough cost to challenge traditional 8 and 16-bit microcontrollers.

The Cortex-M3 is a Harvard architecture (Code and Databus are separated) and has multiple buses

that allow it to perform operations in parallel. The architecture inside the Cortex-M3 is a ARMv7M RISC processor.

With only 33’000 logic cells needed to syntetisize the M3 core it is the smallest core of the ARM

family. This reduces the size of the chip and therefore cheap manufacturing processes with 0.35

µm can be used.

Interrupts

One of the key components of the Cortex-M3 core is the Nested Vector Interrupt Controller (NVIC).

The NVIC provides a standard interrupt structure for all Cortex based microcontrollers and exceptional interrupt handling. The NVIC provides dedicated interrupt vectors for up to 240 peripheral

sources where each interrupt source can be individually prioritized. The NVIC provide extremely

fast interrupt handling. The time taken from receiving an interrupt to reaching the first line of

code in your interrupt service routine is just twelve cycles.

All interrupts can be prioritized on three levels: pre-empting, sub-priority and hardware-priority.

The first two can be configured via the software and the priority can be set on 4 bits.

The interrupt service routines (ISR) can be written fully in C, therefore no Assembler is needed

any more.

Instruction Set

While the ARM7 and ARM9 CPUs have two instruction sets (the 32-bit ARM and the 16-bit

Thumb), the Cortex family is designed to support only the 16-bit Thumb-2 instruction set. The

result is a simpler assembling of the core since there is not longer need for switching between the

two instruction sets. The Thumb-2 instruction set is a rich instruction set that is designed as a

target for C/C++ compilers.

4 STM32 Cortex-M3 Tutorial

Page 13

2.3 Cortex-M3 Core

1 Intro

Cortex CPU

The heart of the Cortex core is a 32-bit RISC CPU. This CPU has a simplified version of the

ARM7/9 programmer’s model, but a richer instruction set with good integer maths support, better bit manipulation and ’harder’ real-time performance has been added.

Pipeline

The Cortex CPU can execute most instructions in a single cycle. Like the ARM7 and ARM9 CPUs

this is achieved with a three stage pipeline. Whilst one instruction is being executed, the next is

being decoded and a third is being fetched from memory.

Multiplication

A 32-bit multiplication can be done within one cycle since the Cortex-M3 offers a hardware multiplication unit.

Producer

The IP core form ARM can be implemented by different manufacturers. In this document only

the STM32F103RB from ST is described. The Core exists as well for VHDL implementation as M1

ARM 32-bit Cortex-M3 CPU only core without peripherals. The peripherals are implemented by

the manufacturers.

Power Consumption

The STM32 is a low power as well as high performance microcontroller . It can run from a 2V

supply and at 72MHz with everything switched on it consumes just 36mA. In combination with

the Cortex low power modes the STM32 has a standby power consumption of only 2µA.

Startup-Code

For the Cortex-M3 is no longer assembler startup code is needed, everything can be coded in C.

Debug-Interface

The debug interface has been changed to a scalable interface with advantages according to the

ARM7/9 family. The Cortex-M3 has a Debug Access Port (DAP) which can be used in the JTAG or

in the Serial Wire Debug Mode with only two lines (clock and data).

ARM7 processors have only a very limited amount of two Hardware-Breakpoints. In the Cortex-M3

this has been updated to 8 breakpoints. Beside the breakpoints, Fault Conditions and Exceptions

can be set. Faults and Exceptions can be supervised without the need of using breakpoints.

The debug interface works as well in the Sleep-mode.

Lukas Kohler 5

Page 14

1 Intro

2 System Description

2.4 Processor STM32F103RB from STMicroelectronics

2.4.1 Features

The STM32F103RB from STMicroelectronics is a processor with a ARM 32-bit Cortex-M3 CPU

and peripherals. STMicroelectronics is reshaping the 16/32-bit MCU market with they’r STM32

family.

The key benefits of the STM32F103RB are:

• Leading performance, real time behavior

• A lot of peripherals

• Outstanding power efficiency

• In production since 2007 7→ proved design

• 70 part numbers across 4 product lines

• SW Libraries are free available from www.st.com/mcu

• Core: CPU clock internal up to 72Mhz, single-cycle multiplication and hardware division

• Memory: 128KBytes flash, 20KByte ram and memory controller

• LCD parallel interface

• Low power states (sleep, stop and standby)

• 7 DMA channels

• RTC

• WDT

• PWM

• 3x Timers and SysTick

• Communication interface:

– 2x SPI

– 2x I2C

– 3x I2S

– 3x USART

– USB 2.0

– CAN

• Up to 51 GPIO (multiplexed with peripherals, 5V tolerable [but not for analog inputs!])

• 2x ADC 12 bit

• Operating voltage 2.0-3.6V

• Temperature: -40C +85C

• Debugging: JTAG and serial wire interface

A lot of information, data sheets and examples can be found at

http://www.st.com/mcu/familiesdocs-110.html.

6 STM32 Cortex-M3 Tutorial

Page 15

2.4 Processor STM32F103RB from STMicroelectronics

1 Intro

Figure 1. STM32F103xx performance line block diagram

USBDP/CA N_TX

PA[15: 0]

EXTI

WWDG

12bit ADC1

16AF

JTDI

JTCK/ SWCLK

JTMS/SWDIO

NJTRSTTRST

JTDO

NRST

V

DD

= 2 to 3.6V

80AF

PB[15: 0]

PC[15: 0]

AHB2

MOSI,MISO,SCK,NSS

SRAM

2x(8x16bit)

WAKEUP

GPIOA

GPIOB

GPIOC

F

max

: 72 M

Hz

V

SS

SCL,SDA

I2C2

V

REF+

GP DMA

TIM2

TIM3

XTAL OSC

4-16 MHz

XTAL 32 kHz

OSC_IN

OSC_OUT

OSC32_OUT

OSC32_IN

PLL &

APB1 : F

max

=24 / 36 MHz

PCLK1

HCLK

CLOCK

MANA GT

PCLK2

as AF

as AF

Flash 128 KB

VOLT. REG.

3.3V TO 1.8V

POWER

Backu p i nterf ace

as AF

TIM 4

BusM atrix

64 bit

Interface

20 KB

RTC

RC 8 MHz

Cortex-M3 CPU

Ibus

Dbus

pbu s

obl

flash

SRAM 512B

Trace

Cont rolle r

USART1

USART2

SPI2

bxCAN

7 ch annels

Back up

reg

4 Chann els

TIM1

3 com pl. Chann els

SCL,SDA ,SMBA

I2C1

as AF

RX,TX, CTS, RTS,

USART3

Temp sens or

V

REF-

PD[15: 0]

GPIOD

PE[15: 0]

GPIOE

AHB:F

max

=48/72 MHz

ETR and BKIN

4 Chann els

4 Chann els

4 Chann els

FCLK

RC 40 kHz

Stand by

IWDG

@VBAT

POR / PDR

SUPPLY

@VDDA

VDDA

VSSA

@VDDA

V

BAT

RX,TX, CTS, RTS,

Smart Card as AF

RX,TX, CTS, RTS,

CK, SmartCard as AF

APB2 : F

max

=48 / 72 MHz

NVIC

SPI1

MOSI,MISO,

SCK,NSS as AF

12bit ADC2

IF

IFIF

int erface

@VDDA

SUPERVISION

PVD

Rst

Int

@VDD

AHB2

APB2

APB 1

AWU

TAMPER-RTC

@VDD

USB 2.0 FS

USBDM/CAN_RX

System

ai14390d

TRACECLK

TRACED[0:3]

as AS

SW/JTAG

TPIU

Trace/trig

CK, SmartCard as AF

2.4.2 Performance Line Block Diagram

The block diagram in Figure 2.1 shows how the components and the core are connected together.

Lukas Kohler 7

Figure 2.1: STM32F103xx Performance Line Block Diagram

Page 16

1 Intro

2.4.3 Memory Map

The memory map is shown in Figure 9.

Figure 9. Memory map

reserved

0x4000 0000

0x4000 0400

0x4000 0800

0x4000 0C00

0x4000 2800

0x4000 2C00

0x4000 3000

0x4000 3400

0x4000 3800

0x4000 3C00

0x4000 4400

0x4000 4800

0x4000 4C00

0x4001 0C00

0x4001 1000

0x4001 1400

0x4001 1800

0x4002 1400

APB memory space

DMA

0x4002 1000

TIM2

Reserved

0x4001 0800

0x4001 1C00

0x4001 2400

0x4001 2800

0x4001 2C00

0x4001 3000

0x4001 3400

0x4001 3800

TIM3

TIM4

reserved

RTC

WWDG

IWDG

reserved

SPI2

USART2

USART3

AFIO

Port A

Port C

Port D

reserve d

ADC1

reserved

USART1

reserved

0x4002 0400

0x4002 0000

0x4001 3C00

0x4000 5400

0x4000 5800

reserved

ADC2

TIM1

SPI1

reserved

I2C1

BKP

0x4000 6000

0x4000 5C00

Port E

PWR

Port B

I2C2

reserved

bxCAN

EXTI

reserved

RCC

reserved

Flash In terface

reserved

reserved

reserved

0x4000 6400

0x4000 6800

0x4000 6C00

0x4000 7000

0x4000 7400

0x4001 0000

0x4001 0400

0x4002 2000

0x4002 2400

0x4002 3000

0x4002 3400

0x6000 0000

0xE010 0000

reserved

0xFFFF FFFF

USB Regi sters

CRC

0

1

2

3

4

5

6

7

0x2000 0000

0x4000 0000

0x6000 0000

0x8000 0000

0xA000 0000

0xC000 0000

0xE000 0000

0xFFFF FFFF

0x0000 0000

Peripherals

SRAM

Flash memory

reserved

reserved

0x0800 0000

0x0801 FFFF

0x1FFF F000

0x1FFF FFFF

System memory

Option Bytes

0x1FFF F800

0x1FFF F80F

Cortex- M3 Internal

Perip heral s

0xE010 0000

ai14394f

shared 512 byte

USB/CAN SRAM

Aliased to Flash or system

memory depending on

BOOT pins

0x0000 0000

The memory map shows how the memory in the STM32F103RB is configured. This needs to be

known for programming the processor.

• Flash Memory: 0x0800 0000 - 0x0801 FFFF

• System Memory: 0x1FFF F000 - 0x1FFF F800

8 STM32 Cortex-M3 Tutorial

Figure 2.2: STM32F103xx memory map

2 System Description

Page 17

2.5 Development Boards

1 Intro

2.4.4 Interfaces

To be able to communicate with other devices we need interfaces:

• JTAG - Debug Interface:

The JTAG interface allows downloading the compiled code into the microcontroller and

debugging the code in real time. To be able to do this operation you have to use an JTAG

adapter to the USB or parallel port to the computer.

• USB - Universal Serial Bus:

Using a library one can communicate with an USB master. If you power the device over

USB, no wallplug or external power supply is needed.

• RS232, CAN, SPI I2C, I2S:

The serial interfaces can be used to communicate with any kind of devices or can be used

as debug/status interface.

2.5 Development Boards

We use the Olimex boards with our own BFH mother board extension. On both of these boards

the ARM Cortex M3 STM32F103RB produced by ST Microelectronics is present.

Both boards offer a LED on port PC12 (if LED E is bridged) and a button on PA0 (wake-up).

Figure 2.3: Development Board STM32H103 from

Olimex

Figure 2.4: Development Board STM32P103 from

Olimex

2.5.1 STM32H103 from Olimex

The STM32H103 is the minimal version of the Olimex STM32 board. It contains only a STM32F103RB

processor, USB connector with power adapter and LEDs. The STM32H103 can be connected via

the extension headers to the BFH mother board to connect to other interfaces. See Chapter 2.5.5

for more details.

Lukas Kohler 9

Page 18

1 Intro

2 System Description

2.5.2 STM32P103 from Olimex

The STM32P103 development board from Olimex is the extended version of the STM32H103. The

board includes:

• USB connector with power supply

• CAN driver and connector

• RS232 driver and connector

• JTAG with ARM 2x10 pin layout

• Reset button, user button, power and user LED

• SD/MMC card connector

• Voltage regulator 3.3V from USB or extension power jack connector (maximum power con-

sumption 0.25W at full speed)

• 8MHz and 32,768kHz oscillator (external clock and backup clock for RTC)

• UEXT connector that allows to connect to other modules

• Prototyping area

• Reset and wakeup circuit

• Dimensions: 100x90mm

2.5.3 Setup for Developing

In order to be able to develop software for the STM32F103RB , Keil µVision3 has to be installed

on a PC. If this is not yet the case install it according to Chapter 3. µVision3 is the tool used for

writing, compiling and testing software. The compiled source is then downloaded via a JTAG

adapter to the development board. Therefore the driver of the JTAG adapter has to be installed

too.

If the requirements above are fulfilled you can connect a USB cable from the PC to the development board STM32P103 or STM32H103. This connection is used for the power supply.

Connect the JTAG adapter to the development board STM32P103 or STM32H103 and connect a

USB cable from the JTAG adapter to the PC. This is used for downloading the software into the

processor and for debugging with the Keil toolchain (see Figure 2.5).

JTAG Adaptor

The JTAG Adaptor is needed for downloading the software into the processor and for debugging

with the Keil toolchain. According to Keil, different adapters can be used, such as:

• uLink from Keil

• jLink from Segger

• J-Link from IAR

I used the J-Link from IAR.

10 STM32 Cortex-M3 Tutorial

Page 19

2.5 Development Boards

1 Intro

Figure 2.5: Developing Software

2.5.4 Board Layout and Schematic

For schematics and board layouts please refer to the documents in

CD:/hardware/EvalBoards/Olimex/ .

2.5.5 BFH Mother Board

On the mother board the Olimex STM32H103 board is mounted on. The mother board has a

power supply and drivers for interfaces.

• The mother board uses the power supply form the STM32H103 board. Just connect the

STM32H103 with USB and the mother board is powered.

• 4 LEDs, lighting when tied to LOW (D1, connected with J24; D2-J25; D3-J28; D4-J28)

• 2 Buttons with a pull-up resistor, pressed gives a LOW state (S1, connected with J2; S2-J12)

• 1 Serial driver (RS232) (Rx-PA3; Tx-PA2; RTS-PA1; CTS-PA0 if DIPs are set according to

Figure 2.7)

• 2 potentiometer for analog inputs (R8-PC0; R9-PC1 when J26 and J27 are set)

Lukas Kohler 11

Page 20

1 Intro

2 System Description

• 1 CAN (Rx-PB8; Tx-PB9 if J1 and J3 are set; Resister on J6 (see Figure 2.8))

Figure 2.6: BFH Mother Board with STM32H103 from Olimex

Figure 2.7: RS232 directly connected (Pin 2: Rx, 3:

Tx, 5: GND)

Figure 2.8: CAN interface (Pin 2: CANL, 3/6:GND, 7:

CANH)

12 STM32 Cortex-M3 Tutorial

Page 21

3 Keil SDK

3.1 Introduction

The development of the firmware1we will write for the STM32 is done with the µVision3 from

Keil. This chapter shows how a simple project can be created, simulated and downloaded to the

target hardware.

3.2 Install µVision3

µVision3 can be found on the CD delivered with this documentation. Install µVision3 as well the

demo projects. This documentation refers to a standard installation done in the folder

C:/Keil/ARM/Boards/ST/STM32F10X EVAL/ .

A quick guide about µVision3 can be found at www.keil.com.

3.3 Install the Driver for the JTAG Adapter

Install the driver according the JTAG Adapter you are using.

3.4 Install the STM32 Peripheral Library

ST offers a free ARM-based 32-bit MCU STM32F10xxx standard peripheral library for programmers. This can be downloaded from www.st.com.

Direct Link: STM32F10x StdPeriph Lib

This library is used for accessing the peripherals like SPI or CAN. The STM32 Peripheral Library

from ST comes as well with different examples.

Unpack the library and copy the /Libraries/STM32F10x StdPeriph Driver/inc/ to

C:/Keil/ARM/INC/ST/STM32F10x and /Libraries/STM32F10x StdPeriph Driver/src to

C:/Keil/ARM/INC/RV31/LIB/ST/STM32F10x/ . This has to be done only once to update the

libraries.

Keil offers as well a peripheral configuration wizard but not for all peripherals. Chapter 4 introduces the peripherals and shows how they are configured - ether by the configuration wizard

from Keil or using the libraries from ST.

1

Software for microcontroller

13

Page 22

1 Intro

3 Keil SDK

3.5 Setting up a new Project

3.5.1 Preparation

Create a new directory for the project. Copy the files copy STM32 Init.c , STM32 Init.h ,

STM32 Reg.h and renameMe.c from /code/library into the new folder. Rename renameMe.c

to gpio.c . gpio.c This will be the main file.

• STM32 Init.c and STM32 Init.h : Configuration files for the STM32 processor

• STM32 Reg.h : Register file with defined addresses

3.5.2 Create a new project

Open µVision3 and create a new project by Project 7→ µVision3 Project... as shown in Figure 3.1 and

save it as gpio.uv2 .

Figure 3.1: Create a new project

The SDK needs to know your microcontroller and therefore you must specify the device to

STM32F103RB from STMicroelectronics (Figure 3.2).

Figure 3.2: Specify the device: STM32F103RB

The STM32 requires startup code which can be added automatically as shown in Figure 3.3. Click

on Yes.

14 STM32 Cortex-M3 Tutorial

Page 23

3.5 Setting up a new Project

1 Intro

Figure 3.3: Add the startup code to the project

The project has now been created. Now we need to add the files STM32 Init.c and gpio.c to

the project. Double click on Source Group 1 and add these two files.

3.5.3 Configure the Processor

Since we have added STM32 Init.c to the project we can use the Configuration Wizard to configure the processor. Double click STM32 Init.c and select Configuration Wizard (Figure 3.4). We

need the Clock Configuration and the General purpose I/O Configuration to be checked.

In the Clock Configuration do the following settings according to Figure 3.4

• Clock Control Register Configuration (RCC CR)

• Clock Configuration Register Configuration (RCC CFGR)

• HSE: External High Speed Clock [Hz]: 8000000 (8MHz) (given by the board)

Figure 3.4: Configuration wizard

General purpose I/O Configuration: We need to configure the GPIO to fast outputs:

• Check GPIOB: GPIO port B used and set all pins to General Purpose Output push-pull (max

speed 50MHz)

Embedded Flash Configuration: Set the settings acording to Figure 3.5.

Lukas Kohler 15

Page 24

1 Intro

3 Keil SDK

STM32F10x.s

assembler

STM32_Init.c

compiler

gpio.c

compiler

linker

STM32F10x.o

STM32F10x.lst

STM32_Init.o gpio.o

gpio.hex

gpio.map

Figure 3.5: Configuration wizard: Flash

3.5.4 Renaming the Target

Click on Project 7→ Manage 7→ Components, ... Rename Target 1 to Simulator by a double click on it

and press OK. We will use this setting for simulating the program on the PC.

3.6 Building

Open the main file gpio.c and insert the minimal code for a counter on GPIOB from Listing 3.1.

The building process starts by clicking on Project 7→ Rebuild all target files. This will assemble

STM32F10x.s and generate an object file (*.o) and its listing report (*.lst) according to Figure 3.6.

The c-files are compiled and object file (*.o) generated. The linker then puts together all the object

files and generates (with an ELF converter) the binary file and its report (*.map). The compiled

file can now be used for the simulation and not jet for downloading since we haven’t configured

the linker properly.

Figure 3.6: Building Process

The build creates an Executable File *.elf which is placed in the Output folder. When you use a

JTAG adapter, the ELF file is required to download to the board using JTAG. The build creates an

Intel HEX executable file which is placed in the same output folder for external program downloading through the serial port.

16 STM32 Cortex-M3 Tutorial

Page 25

3.7 Simulation

1 Intro

Listing 3.1: Minimal Code for a Counter on GPIOB

1 /∗ Name: gpio . c / P r o je c t gpi o 1

∗ De sc ri pt i on : Counter on GPIOB

∗ Vers io n : V1 .0 0 / 1 5. 07 .2 00 9 ∗/

# in c l ude <s t m3 2 f1 0 x l ib . h> // STM32F10x Lib ra r y D e fi ni ti on s

6 # inc l ude "STM32_Init.h" // STM32 I n it i a l i z a t i o n

i n t main ( void ) {

i n t i , j = 0 ; // c o unt er v a ri ab le s

s t m3 2 I n it ( ) ; // STM32 se t up

11

wh ile ( 1 ) { // Loop fo re ve r

j ++; // i nc re a s e f i r s t c oun te r

i f ( j ==1000 ) {

GPIOB−>ODR = ( GPIOB−>ODR & 0 xFFFF0000 ) | i ; // w ri te i t o GPIOB

16 j = 0;

i f ( i ==0xFFFF ) i = 0;

i ++;

}

}

21 }

3.7 Simulation

Before we download the project to the development board we’ll do a simulation in µVision3 to

see if everything works. Therefore click on Debug 7→ Start/Stop Debug Session or it’s icon. This will

open the debug mode and show a warning that you are using the evaluation mode. Click OK and

open the GPIOB port with Peripherals 7→ General Purpose I/O 7→ GPIOB.

Figure 3.7 shows the debug mode. In the top left corner the simulation is handled. To let the simulation run until a breakpoint is reached, press Run. In our example you’ll see the GPOIB counting

up binary and the variable i in the Watch Window increasing. You can change the variables in the

Watch Window by double clicking on them. A breakpoint can be set by a double click on the left

area of the code window. A running simulation can be interrupted by pressing the stop icon.

Pressing reset will set the CPU to its initial State.

In case you want to step through your code it’s not very nice to use breakpoints since these are

limited to 8. Therefore use the step commands. Step into will enter into every called function. Step

over doesn’t enter the function. Step out lets the code in the function execute, leave the function

and wait for further commands. Run to cursor line lets the code run until the line is reached where

the cursor is.

Lukas Kohler 17

Page 26

1 Intro

3 Keil SDK

Watch Window

GPIOB

Command

Window

actual Position

R

e

s

e

t

R

u

n

S

t

o

p

I

n

t

o

O

v

e

r

O

u

t

S

t

a

r

t

/

S

t

o

p

D

e

b

u

g

S

e

s

s

i

o

n

Simulation Step

R

u

n

t

o

C

u

r

s

o

r

l

i

n

e

3.7.1 Window update

ate selectThe peripherals are updated when an event from the user occours, e.g. clicking on an

input check box. For a periodical update select View 7→ Periodic Window Update.

3.7.2 Serial Window

To simulate a serial interface open View 7→ Serial Window 7→ UART x.

3.7.3 Performance Analyzer

To analyse the efficiency of your code open View 7→ Performance Analyzer. This window shows the

time and amount a function is called.

Figure 3.7: Debug Mode

18 STM32 Cortex-M3 Tutorial

Page 27

3.8 Configuring the Target

1 Intro

3.8 Configuring the Target

After the simulation on the computer we know that our program works and in case of errors

we have corrected them. Now there is need of configuring the linker and the debug utilities.

Therefore quit the debug mode first. Klick first on the icon 1 according to Figure 3.11. You already

know the appearing window. Now click on New Project Target, name it STM32H103 and click OK.

Select now the created target on the left side of the icon 1. Klick now on the icon 2 according to

Figure 3.11. !

The processor won’t run if is not configured as shown in the Figures 3.11 - 3.15!

Go to the tab Debug and select Use: Your JTAG Adapter. In the tab Utilities select Use Target Driver

for Flash Programming: Your JTAG Adapter. Click on Settings and there on Add. Select STM32F10x

Med-density Flash2and click Add and twice OK.

Figure 3.8: Options for Output Figure 3.9: Options for Listing

Figure 3.10: Options for Linker

2

In µVision before version 3.7 select STM32F10x 128kB Flash

Lukas Kohler 19

Page 28

1 Intro

Figure 3.11: Options for Target

3 Keil SDK

Figure 3.13: Options for Debug Settings

Figure 3.12: Options for Debug

Figure 3.15: Options for Utilities Settings

Figure 3.14: Options for Utilities

Connect now the BFH motherboard with the mounted STM32-H103 to the computer according to

Chapter 2.5.5.

20 STM32 Cortex-M3 Tutorial

Page 29

3.9 Downloading

1 Intro

3.9 Downloading

The command Flash 7→ Download or its icon download the compiled file to the STM32 and let it

run if the option Reset and Run is set (see Figure 3.15). If the program doesn’t start push the reset

button on the STM32-H103 board. A program downloaded into the flash will stay in the flash

even if the power supply is removed.

Our program will count up on GPIOB. Connect therefore the J24 with PB8, J25 with PB9, J28-PB10,

J29-PB11. If you connect a LED to PB0 you won’t see anything since the switching frequency is to

high. That’s why we use PB8..PB11. You should see the binary counter on D1 - D4.

3.10 Debugging

In the debugging mode you have the same options as in the Simulation mode. Refer therefore to

Chapter 3.7.

3.11 Serial Terminal

hTerm ( CD:/tools/hterm/HTerm.exe ) is a powerfull tool for analysing serial communication.

No installation is needed. Select the Port you want to communicate and the desired baud rate,

press connect and hTerm will display you the received data.

Figure 3.16: hTerm

Lukas Kohler 21

Page 30

1 Intro

3 Keil SDK

3.12 Documenting Source Code

Documenting the source code is very important that other users of the code are able to understand

it. In this documentation Doxygen has been used. Listing 3.2 shows the used commands for

Doxygen. After running Doxygen a html help is generated. It is stored at

CD:/code/doc/html/index.html.

Listing 3.2: Source Code Documentation with Doxygen

/∗∗

∗ @ f i le u sa r t1 . c

∗ @b ri e f USART usage f or STM32: put Char ( ) .

4 ∗

∗ <H3>P ro je c t : us art 1</H3>

∗

∗ Sends p er i o di c al ly th e c ha r a ct er ’ ∗ ’ with 9600Baud t o i t s h ost .

∗ S e t ti n g s ( s ee C onf ig u ra t io n Wizard o f STM 32 Ini t ) :

9 ∗ − 9600 Baud

∗ − 8/1/N

∗

∗ @author Lukas Kohl e r / BFH−TI

∗ @date 15 . 0 7. 20 09

14 ∗/

22 STM32 Cortex-M3 Tutorial

Page 31

4 Peripherals

4.1 Getting Started

The STM32F103RB is a very complex processor. There is not just one datasheet for all information.

• Datasheet: CD:/datasheet/ST/STM32F103x8B.pdf

Gives a general introduction to the STM32F103RB processor. Pinouts, electrical, thermal and

package characteristics are described there. Refer to the datasheet if you want to calculate

the power consumption or to see the pin relation between GPIO and pins (e.g. to which pin

is GPIOA1 connected to).

• Reference manual RM008: CD:/datasheet/ST/RM0008 Reference Manual.pdf

Describes the function inside the processor, such as periphery, clock management or power

control. Refer to this manual for programming.

• CD:/code/self/ offers proved examples for µVision3.

• The Firmware Library stm32f10x stdperiph lib (see also Chapter 4.3) offers examples

CD:/code/stm32f10x stdperiph lib/Project/STM32F10x StdPeriph Examples/

• Insider’s Guide from Hitex CD:/datasheet/hitex-guide STM32

Gives a general introduction to the STM32F103RB processor.

• More help can be found on http://www.st.com/mcu/devicedocs-STM32F103RB-110.html

and http://www.stm32circle.com

4.2 Configuration Wizard

gpio2 F GPIO usage by register acces and Configuration Wizard.

Keil offers a Configuration Wizard (see Figure 4.1) which lets the user configure the processor

registers without need of knowing the specific registers. This wizard can be used only for simple

programs like controlling GPIO or serial interface. In case you need to use more complex functions

like SPI, I2C or even DMA we suggest you to use the firmware library from STMicroelectronics

(see Chapter 4.3). In this document the Configuration Wizard is used whenever possible.

The access of the register can’t be done by the Configuration Wizard, the Firmware Library (see

Chapter 4.3) or direct register access (see Chapter 4.4) has to be used.

b

23

Page 32

1 Intro

b

4 Peripherals

4.3 Firmware Library (FWLib)

gpioFwLib F GPIO usage by register access.

STMicroelectronics offers a firmware library which allows you to access to peripherals and registers easily and with a clean interface. The installation is shown in Chapter 3.4. The principle of

using the FWLib is easy and straight forward since the policy is equal for all peripherals. This

principle is shown here with the GPIO.

1. Include the FWLib to the project by adding ether the precompiled library or the uncompiled

c files like stm32f10x PERIPHERAL.c . The c library files are located at

C:/Keil/ARM/RV31/LIB/ST/STM32F10x and should be added by the Keil project in the

folder lib.

2. Add #include <stm32f10x_PERIPHERAL.h> at the begin of your main file (where PE-

RIPHERAL stands for the peripheral you want to use, e.g. SPI or GPIO). The header files are

located at C:/Keil/ARM/INC/ST/STM32F10x and automaticly included by

µVision.

3. Use the functions from the FWLib (like GPIO Init()). The functions are described in the file

stm32f10x stdperiph lib um.chm that comes with the FWLib.

The FWLib offers structures for the peripherals. This structure is created and initialized with:

Listing 4.1: Structure creation and initialization

15 G PIO I n itT y pe D e f GP IO I ni tS tr uc t ur e ;

GP IO S tr uc tI ni t(& GPI O In it St ru ct ur e ) ;

The properties then are set with:

Listing 4.2: Setting the Properties

GP IO I ni tS tr uc tu r e . GPIO Pin = GPIO Pin 5 | G P IO Pin 7 ;

GP IO I ni tS tr uc tu r e . GPIO Speed = GPIO Speed 50MHz ;

GP IO I ni tS tr uc tu r e . GPIO Mode = GPIO Mode AF PP ;

20 GP I O I n it (GPIOA, &G PI O In it St ru ct ur e ) ;

The FWLib is used in this document for the examples ADC, CAN, I2C and SPI.

24 STM32 Cortex-M3 Tutorial

Page 33

4.4 Register Access

1 Intro

4.4 Register Access

gpioRegister F GPIO usage by register access. Instead of using the FwLib the registers can be

accessed directly.

The properties then are set with:

Listing 4.3: Setting the GPIO Register by direct access

/∗∗

∗ Se t up t he GPIO r eg is t e r s (GPIOA as i n put and GPIOB as out p ut )

∗/

voi d i ni tG pi o Re gi st e r ( void ) {

25 // GPIOA: In pu t w i t h p u ll up /pulldown

GPIOA−>CRH = 0 x888 8 88 88 ;

GPIOA−>CRL = 0 x8888 88 8 8 ;

// GPIOB : Output push−p ull , 50MHz

GPIOB−>CRH = 0 x3 33 33 3 33 ;

30 GPIOB−>CRL = 0 x33 3 33 33 3 ;

}

b

Lukas Kohler 25

Page 34

1 Intro

4 Peripherals

4.5 General Purpose Input/Output (GPIO)

GPIOs are used for reading an input or setting an output. The GPIOs of the STM32F103RB can all

be used as digital or analog inputs.b

b

b

gpio1 F Shows a counter on GPIOB.

gpio2 F Reads the inputs of GPIOA and puts them on GPIOB.

gpio3 F Pressing buttons S1, S2 move the lit LED. S1 moves the lit LED to the right, S2 to the left.

4.5.1 Configuration

The configuration is done with the Settings Wizard (see Chapter 3.5.2 for more information), shown

in Figure 4.1.

GPIOA to GPIOD can be set to different modes:

• Input

– Analog: Used to route the signal to an AD converter (see Chapter4.13)

– Floating: Used as a ”normal” input

– Input with pull-up / pull-down resister

• Output

– Push-pull (max speed 2MHz, 10MHz or 50MHz): Used as a ”normal” output

– Open-drain (max speed 2MHz, 10MHz or 50MHz): Used in a system with different

nodes having access to the same wire.

• Alternate Function (AF): Used for Oscillator, CAN, JTAG, ADC, Timer, USART, I2C and SPI

– Alternate Function push-pull (max speed 2MHz, 10MHz or 50MHz)

– Alternate Function open-drain (max speed 2MHz, 10MHz or 50MHz)

Figure 4.1: GPIO Configuration Wizard

26 STM32 Cortex-M3 Tutorial

Page 35

4.5 General Purpose Input/Output (GPIO)

1 Intro

Figure 9. Basic structure of a standard I/O port bit

Alternate Function Output

Alternate Function Input

Push-pull,

open-drain or

disabled

Input data register

Output data register

Read/write

From on-chip

peripheral

To on-chip

peripheral

Output

control

Analog Input

on/off

on/off

I/O pin

V

DD

V

DD

V

SS

V

SS

TTL Schmitt

trigger

V

SS

V

DD

Protection

diode

Protection

diode

on/off

Input driver

Output driver

P-MOS

N-MOS

Read

Bit set/reset registers

Write

ai14781

4.5.2 Driver

4.5.3 Set Output

GPIOB−>ODR = (GPIOB−>ODR & 0 xFFFF0000 ) | yourValu e ; // p ut s yourValue on

GPIOB

4.5.4 Read Input

in p ut = (GPIOA−>IDR & 0 x0000FFF F ) ; // r e ad in put s on GPIOA

Lukas Kohler 27

Figure 4.2: GPIO driver

Listing 4.4: Set Output

Listing 4.5: Read Input

Page 36

1 Intro

4 Peripherals

4.6 Serial Interface (USART)

The serial interface is used to communicate with other devices. Nowadays it is often used as

debug interface to send information to a host like a PC. UARTs are commonly used in conjunction

with other communication standards such as EIA RS-232.b

b

b

b

b

usart1 F sends periodically the character ”*” with 9600Baud to its host.

usart2 F sends periodically the ASCII characters with 9600Baud to its host.

usart3 F polls the incoming data and sends them back to its sender (9600Baud)

usart4 F sends periodically the string ”Hello World” with 115200Baud to its host using printf().

usartIrq1 F the data and sends them back to its sender (9600Baud, uses IRQ)

4.6.1 Ways of Operation: Polling versus Interrupts

The serial interface can be read and written in two different ways:

• Polling: The input register is read periodically for new data.

• Interrupts: The input register generates an interrupt in case that there is new data available.

The ISR (see Chapter 4.10) then is called and in there the data are sent. This method is more

efficient but more complex.

4.6.2 Using Polling

Configuration

The configuration is done with the Settings Wizard (see Chapter 3.5.2 for more information), shown

in Figure 4.3.

Figure 4.3: USART Configuration Wizard

Send Data

Copy the files serial.c and serial.h and use the function int ser putchar (int c).

Listing 4.6: Send Data

wh ile ( ! ( USARTx−>SR & USART FLAG TXE) ) ; // wa i t u nt i l ready

35 USARTx−>DR = ( yo ur Cha r acte r & 0 x1FF ) ; // sen d s you rC har a cte r

28 STM32 Cortex-M3 Tutorial

Page 37

4.6 Serial Interface (USART)

1 Intro

Read Data

Copy the files serial.c and serial.h and use the function int ser getchar (void).

Listing 4.7: Receive Data

wh ile ( ! ( USARTx−>SR & USART FLAG RXNE) ) ; // wai t u nt il a ch ar ha s been

re ce iv e d

you rCha ra cte r = ( USARTx−>DR & 0x1FF ) ; // re a d c ha ra ct er from the b uf fe r

4.6.3 Using Interrupts

Configuration

The configuration is done with the Settings Wizard shown in Figure 4.4. The function

void USART2 IRQHandler (void) is called when an interrupt, configured in the Settings Wizard,

occurs. Refer to the example usartIrq1 for more information.

Figure 4.4: USART Configuration Wizard (using Interrupts)

4.6.4 Driver

The data are transmitted on the system voltage level1to the converter and there converted to the

RS232 level2. The RS232 interface can then be connected to any PC. For a minimum communication three wires are required:

• TxD: Tranceive Data

• RxD: Receive Data

• GND: Common Ground

Figure 4.5 shows the driver included in the STM32F103RB .

1

System voltage: +3.3V (=HIGH) and 0V (= LOW)

2

RS232 level: +12V (=LOW = 0) and -12V (= HIGH = 1)

Lukas Kohler 29

Page 38

1 Intro

4 Peripherals

Universal synchronous asynchronous receiver transmitter (USART) RM0008

Figure 236. USART block diagram

WAKE

UP

UNIT

RECEIVER

CONTROL

SR

TRANSMIT

CONTROL

TXETC RXNEIDLEORE NE FE

USART

CONTROL

INTERRUPT

CR1

M WAKE

Receive Data Register (RDR)

Receive Shift Register

Read

Transmit Data Register (TDR)

Transmit Shift Register

Write

SW_RX

TX

(DATA REGISTER) DR

TRANSMITTER

CLOCK

RECEIVER

CLOCK

RECEIVER RATE

TRANSMITTER RATE

f

PCLKx(x=1,2)

CONTROL

CONTROL

/16

CONVENTIONAL BAUD RATE GENERATOR

SBKRWURETE

IDLERXNE

TCIETXEIE

CR1

UE PCE PS

PEIE

PE

PWDATA

IRLP

SCEN

IREN

DMAR

DMAT

USART Address

CR2

CR3

IrDA

SIR

ENDEC

BLOCK

LINE

CKEN CPOL

CPHA LBCL

SCLK CONTROL

SCLK

CR2

GT

STOP[1:0]

NACK

DIV_Mantissa

15

0

RE

USART_BRR

/USARTDIV

TE

HD

(CPU or DMA)

(CPU or DMA)

PRDATA

Hardware

flow

controller

CTS LBD

RX

IRDA_OUT

IRDA_IN

nRTS

nCTS

GTPR

PSC

IE

IE

DIV_Fraction

4

USARTDIV = DIV_Mantissa + (DIV_Fraction / 16)

Figure 4.5: USART driver

Figure 4.6: USART Names of the additional communication wires

30 STM32 Cortex-M3 Tutorial

Page 39

4.6 Serial Interface (USART)

1 Intro

The baud rate generator generates the internal clock for sending and receiving data. The serial

protocol is shown in Figure 4.7 (1 start bit, 8 data bits, 1 stop bit and 1 parity).

Figure 4.7: USART Serial Protocol

4.6.5 Pinning

USART1

Default

Wire GPIO Pin

CK PA8 41

TX PA9 42

RX PA10 43

CTS PA11 44

RTS PA12 45

USART2

Default

Wire GPIO Pin

CTS PA0 14

RTS PA1 15

TX PA2 16

RX PA3 17

CK PA4 18

USART3

Remapped

Wire GPIO Pin

CK - TX PB6 58

RX PB7 59

CTS - RTS - -

Remapped 7→ only on LQFP100!

Wire GPIO Pin

CTS PD3 RTS PD4 TX PD5 RX PD6 CK PD7 -

Default

Wire GPIO Pin

TX PB10 29

RX PB11 30

CK PB12 33

CTS PB13 34

RTS PB14 35

Lukas Kohler 31

Remapped

Wire GPIO Pin

TX PC10 51

RX PC11 52

CK PC12 53

CTS - RTS - -

Page 40

1 Intro

b

4 Peripherals

4.7 System Timer (SysTick)

sysTick F sets up a system timer routine and shows a running light on GPIOB. The system

timer is a periodical timer that can be set up easily with the configuration wizard

(see Figure 4.8).

The Cortex core includes a 24-bit down counter, with auto reload and end of count interrupt. This

is intended to provide a standard timer for all Cortex-based microcontrollers. The SysTick timer

is intended to be used to provide a system tick for an RTOS, or to generate a periodic interrupt for

scheduled tasks. The SysTick Control and status register in the Cortex-M3 System control space

unit allows you to select the SysTick clock source. By setting the CLKSOURCE bit the SysTick

timer will run at the CPU frequency. When cleared the timer will run at 1/8 CPU frequency.

4.7.1 Configuration

Enable the System Timer Configuration in the configuration wizard and select a clock source. Choose

the time interval and enable the interrupt. The function void SysTick Handler (void) above

the main()-routine gets called when the sysTick interrupt occurs.

Figure 4.8: System Timer Configuration Wizard

32 STM32 Cortex-M3 Tutorial

Page 41

4.8 Timer (TIM)

1 Intro

4.8 Timer (TIM)

timer F Running light on GPIOB

The STM32 offers different kind of individually configurable timers:

• General-purpose timer (TIMx): They may be used for a variety of purposes, including mea-

suring the pulse lengths of input signals (input capture) or generating output waveforms

(output compare and PWM).

• Basic timer (TIM6 and TIM7): They may be used as generic timers for time-base generation

but they are also specifically used to drive the digital-to-analog converter (DAC). In fact,

the timers are internally connected to the DAC and are able to drive it through their trigger

outputs.

• Advanced-control timers (TIM1 and TIM8): It may be used for a variety of purposes, in-

cluding measuring the pulse lengths of input signals (input capture) or generating output

waveforms (output compare, PWM, complementary PWM with dead-time insertion).

The timers consist of a 16-bit auto-reload counter driven by a programmable prescaler. The timers

are completely independent, and do not share any resources. They can be synchronized together

(not TIM6 and TIM7).

b

In the µVision configuration wizard the timers TIM1 ... TIM4 can be configured directly. The other

timers have to be configured using the FwLib.

4.8.1 Configuration

In the configuration wizard (see Figure 4.9) the timer interrupt has to be enabled and configured.

Figure 4.9: Timer Configuration Wizard

The function void TIM1 UP IRQHandler (void) gets called after the TIM1 period has expired.

Lukas Kohler 33

Page 42

1 Intro

b

4 Peripherals

4.9 Pulse Width Modulation (PWM)

pwm1 F Lets PB8 blink with 1Hz 50% duty-cycle and PB9 with 25% using the PWM function of

the timer TIM4.b

pwm2 F LEDs PB8, PB9 are dimmed using the PWM function of TIM4 channel3 and channel4

4.9.1 Configuration

The timer TIM4 is used for the PWM signal. The channel 3 is mapped by default to PB8 and

channel 4 to PB9.

Figure 4.10: PWM Configuration Wizard

34 STM32 Cortex-M3 Tutorial

Page 43

4.10 External Interrupts (IRQ)

1 Intro

4.10 External Interrupts (IRQ)

b

extInt F Pin PA0 is configured to generate an external interrupt. Pressing this button will toggle

a LED.

One of the key improvements of the Cortex core over the earlier ARM CPUs is its interrupt structure and exception handling. The ARM7 and ARM9 cores had two interrupt lines: The fast interrupt and the general purpose interrupt line. These two interrupt lines had to support all of

the interrupt sources within a given manufacturer’s microcontroller. How this was done varied

according to the implementation, so while the techniques used were broadly the same, the implementation differed between manufacturers.

Since the interrupt scheme is implemented in the Cortex-M3 core, the way of operating is for all

microcontroller s using this core equal.

4.10.1 Configuration

In the configuration wizard (see Figure 4.11) the external interrupts have to be enabled and con-

figured to a input pin. !

Note that this input in the GPIO section as well has to be configured as an input!

Figure 4.11: External Interrupt Configuration Wizard

4.10.2 Functionality

An event (rising or/and falling edge, according to the configuration) on EXTI0 will call the function void EXTI0 IRQHandler(void). In this function, the interrupt service routine (ISR) first

check which ISR is pending by reading the pending register EXTI PR. At the end of the ISR you

have to clear the pending ISR in the EXTI PR. See Listing 4.8 for an ISR example.

Listing 4.8: ISR

voi d EXTI0 IRQHandle r ( void ) {

i f ( EXTI−>PR & (1< < 0) ) { // EXTI0 i nt er ru p t pending ?

40 // your ISR co de h e re

EXTI−>PR | = (1< < 0) ; // cl ea r pending i nt e r ru pt

}

}

Lukas Kohler 35

Page 44

1 Intro

b

4 Peripherals

Note that the inputs form PA0, PB0, .. PG0 are mapped together to EXTI0. The same is the issue

for all the inputs with the same number.

4.11 Watchdog

iwdg F Shows how the watchdog is configurated.

4.11.1 Configuration

Select the timeout time in the configuration wizard. During this time your program has to clear

the watchdog by loading a specific value into IWDG7→KR. If this desn’t happen the watchdog will

reset the CPU.

Figure 4.12: Watchdog Configuration Wizard

b

b

b

4.12 Real Time Clock (RTC)

rtc1 F RTC is configured to generate a second and an alarm interrupt which turns a LED on.

rtc2 F 24h clock, time is sent over the serial interface to its host (115200Baud).

rtc3 F rtc2 including resetting of the RTC when a button is pressed.

The RTC provides a stable clock for the processor. It is able to generate a second interrupt which

gets called every second. An alarm can be set to a specific time. Is this time up an interrupt is generated. An overflow interrupt occurs when the 32-bit RTC counter overflows. Unfortunately the

RTC doesn’t offer registers for time and date, only for the time in seconds in the two 16-bit register

RTC CNTH (higher 16-bits) and RTC CNTL (lower 16-bits). The alarm registers (RTC ALRH and

RTC ALRL) is similar to the time register.

Figure 4.13: RTC Configuration Wizard

36 STM32 Cortex-M3 Tutorial

Page 45

4.13 Analog to Digital Converter (ADC)

1 Intro

Hour Minute Second RTC CNTH RTC CNTL Seconds

00 00 01 0x0000 0x0001 1s

00 01 01 0x0000 0x003D 3601s

23 00 01 0x0001 0x4371 82801

Table 4.1: Configuration of the register RTC CNTL and RTC CNTH

Listing 4.9: RTC ISR

voi d RTC IRQHandler ( void )

45 {

i f (RTC−>CRL & (1 <<0) ) { // c h eck second f la g

RTC−>CRL &= ˜ (1 < < 0) ; // c le a r second f la g

// your code

}

50

i f (RTC−>CRL & (1 <<1) ) { // c h eck alarm f la g

RTC−>CRL &= ˜ (1 < < 1) ; // c le a r alarm f la g

// your code

}

55

i f (RTC−>CRL & (1 <<2) ) { // c h eck Overf low f la g

RTC−>CRL &= ˜ (1 < < 2) ; // c le a r Overflow f la g

// your code

}

60 } // end RTC IRQHandler

4.13 Analog to Digital Converter (ADC)

ad1 F reads the values and writes them on the serial interface (115200Baud)

4.13.1 Conversion Modes

The AD converters of the STM32F103RB can operate in two different modes:

• Singleshot: The program triggers to read the value once.

• Scan Mode: In scan mode, automatic conversion is performed on a selected group of analog

inputs.

STM32F103RB have two 12-bit Analog to Digital Converters which share up to 16 external channels. Additional logic functions embedded in the ADC interface allow:

• Simultaneous sample and hold

• Interleaved sample and hold

• Single shot

The ADC can be served by the DMA controller. An analog watchdog feature allows very precise monitoring of the converted voltage of one, some or all selected channels. An interrupt is

generated when the converted voltage is outside the programmed thresholds.

b

Lukas Kohler 37

Page 46

1 Intro

4 Peripherals

The events generated by the standard timers (TIMx) and the Advanced Control timer (TIM1) can

be internally connected to the ADC start trigger, injection trigger, and DMA trigger respectively,

to allow the application to synchronize A/D conversion and timers.

Listing 4.10: ADC Init

/∗ I n i t i a l i z e s th e Analog/ Di g i ta l c o nv er te r

PC1 (ADC Channel10 ) i s used as a na lo g inp u t ∗/

voi d a dc I ni t ( void ) {

65 RCC−>APB2ENR |= RCC APB2ENR ADC1EN; // en abl e p er ip he ra l c lo ck

f o r ADC1

ADC1−>SQR1 = 0 x0 0 00 00 00 ; // only one co nve rs ion

ADC1−>SMPR2 = 0 x 00 00 00 2 8 ; // s et sample ti me c ha nn el1

( 5 5 ,5 c y c le s )

ADC1−>SQR3 = 1 0; // s et ch a nnel 1 0 as 1 st

co n ver sio n

70

ADC1−>CR1 = 0 x00 00 0 10 0 ; // u s e i n dep e nde n t mode,

SCAN mode

ADC1−>CR2 = 0 x000E0003 ; // data a li gn r ig ht , c ont

co n ver sio n

// EXTSEL = SWSTART

// e n abl e ADC, no e xt er na l

Tr ig g er

75 ADC1−>CR2 |= 0 x0 0 50 00 00 ; // s t a r t SW c o nve rsi on

}

Listing 4.11: Read ADC Values

/∗ re ad a con v erte d valu e from th e Analog/ Di g it al c on v er te r ∗/

unsigned ch a r adc G e t ( void ) {

unsigned s ho r t v al ;

80

wh ile ( ! ( ADC1−>SR & ADC SR EOC) ) ; // wai t t i l l end o f

co n ver sio n

va l = ADC1−>DR & ADC DR DATA; // Get co nve rs io n r es ul t

va l = ( val >> 4 ) & 0 xFF ; // S ca le an a lo g va lue t o 8

b i ts

85 r et u rn ( v a l ) ;

}

38 STM32 Cortex-M3 Tutorial

Page 47

4.13 Analog to Digital Converter (ADC)

1 Intro

Figure 20 shows a single ADC block diagrams and Tab l e 4 3 gives the ADC pin description.

Figure 20. Single ADC block diagram

ADCx_IN0

ADCx_IN1

Analog to digital

converter

ADCx_IN15

Analog

MUX

ADCCLK

ADC Interrupt to NVIC

GPIO

Ports

Analog watchdog

Address/data bus

Low Threshold (12 bits)

Compare Result

High Threshold (12 bits)

Flags

enable bits

EOC

AWD

Analog watchdog event

V

DDA

V

SSA

V

REF+

V

REF-

Interrupt

TIM1_CH2

TIM1_CH3

TIM2_CH2

TIM3_CH4

From ADC prescaler

(16 bits)

End of conversion

channels

Injected

channels

End of injected conversion

JEOC

EOCIE

AWDIE

JEOCIE

up to 4

up to 16

Regular data register

(4 x 16 bits)

Injected data registers

Regular

Start trigger

(regular group)

EXTSEL[2:0] bits

EXTRIG

TIM1_CH1

TIM4_TRGO

EXTI_15

TIM1_CH4

TIM2_TRGO

TIM2_CH1

TIM3_TRGO

Start trigger

(injected group)

JEXTSEL[2:0] bits

TIM1_TRGO

TIM4_CH4

JEXTRIG

bit

bit

DMA request

Temp. sensor

V

REFINT

TIM2_CH3

TIM1_CH3

TIM8_CH1

TIM8_CH4

TIM3_CH1

TIM5_TRGO

TIM1_CH4

TIM4_CH3

TIM8_CH2

TIM8_TRGO

JEXTSEL[2:0] bits

TIM1_TRGO

TIM5_CH1

Triggers for ADC3

(1)

Start trigger

(injected group)

JEXTRIG

bit

Start trigger

(regular group)

EXTRIG

bit

EXTSEL[2:0] bits

TIM5_CH4

TIM5_CH3

EXTI_11

TIM8_TRGO

(2)

ADCx_ETRGREG_REMAP bit

TIM8_CH4

(2)

ADCx-ETRGINJ_REMAP bit

ai14802d

Figure 4.14: Single ADC Block Diagram

Lukas Kohler 39

Page 48

1 Intro

4 Peripherals

SRAM memory for data transmission and reception, and so they cannot be used

concurrently (the shared SRAM is accessed through CAN and USB exclusively). The USB

and CAN can be used in the same application but not at the same time.

In today’s CAN applications, the number of nodes in a network is increasing and often

several networks are linked together via gateways. Typically the number of messages in the

system (and thus to be handled by each node) has significantly increased. In addition to the

application messages, Network Management and Diagnostic messages have been

introduced.

● An enhanced filtering mechanism is required to handle each type of message.

Furthermore, application tasks require more CPU time, therefore real-time constraints

caused by message reception have to be reduced.

● A receive FIFO scheme allows the CPU to be dedicated to application tasks for a long

time period without losing messages.

The standard HLP (Higher Layer Protocol) based on standard CAN drivers requires an

efficient interface to the CAN controller.

Figure 190. CAN network topology

CAN node 1

CAN node 2

CAN node n

CANCAN

High

Low

CANCAN

Rx Tx

CAN

Transceiver

CAN

Controller

MCU

CAN Bus

Application

4.14 Controller Area Network (CAN)

Controller-area network (CAN or CAN-bus) is a vehicle bus standard designed to allow microcontrollers and devices to communicate with each other within a vehicle without a host computer.

It was designed specifically for automotive applications but is now also used in other areas. Development of the CAN-bus started originally in 1983 at Robert Bosch GmbH. The protocol was

officially released in 1986 at the Society of Automotive Engineers (SAE) congress in Detroit, Michigan. The first CAN controller chips, produced by Intel and Philips, came on the market in 1987.

Bosch published the CAN 2.0 specification in 1991.

The STM32F103RB CAN is compliant with specifications 2.0A and B (active) with a bit rate up to

1 Mbit/s. It can receive and transmit standard frames with 11-bit identifiers as well as extended

frames with 29-bit identifiers. It has three transmit mailboxes, two receive FIFOs with 3 stages

and 14 scalable filter banks.

can1 F Sends the string hello with 500Bit/s over the CAN. Receives the internal looped signalb

using polling (mode: CAN Mode LoopBack). Therefore no message can be received! Uses the

serial interface at 115200Baud.

can2 F As can1 but able to receive CAN data (mode: CAN Mode Normal).b

Figure 4.15: CAN Network Topology

!

By default the CAN and USB share same pins PA11/EXT1-1 and PA12/EXT1-3, so you can’t use

!

both CAN and USB on same time. A remap (see example) can be done to PB8/PB9.

Make sure you set up a filter even if you want to receive all CAN messages.

40 STM32 Cortex-M3 Tutorial

Page 49

4.15 Inter IC Bus (I2C)

1 Intro

4.14.1 CAN Analyzer

To understand the data transmitted on the CAN

you need a CAN Analyzer. I used the PCANUSB from www.peak-system.com. This CAN in-

terface allows you to see the messages transmitted on the CAN bus.

4.14.2 Pinning

Figure 4.16: CAN Analyzer Software

Default

Wire GPIO Pin

CANRX PA11 44

CANTX PA12 45

Remapped

Wire GPIO Pin

CANRX PB8/PD0 61/5

CANTX PB9/PD1 62/6

4.15 Inter IC Bus (I2C)

i2c1 F Writes data to the I

STM32F103RB have two I2C bus interfaces which can operate in multimaster and slave modes.

They can support standard and fast modes. They support dual slave addressing (7-bit only) and

both 7/10-bit addressing in master mode. A hardware CRC generation/verification is embedded.

They can be served by DMA and they support SM Bus 2.0/PM Bus.

Introduction

The I2C interface3is a serial interface with three wires.

2

C bus b

The clock on the one directional wire SLC is generated by the master with a fix frequency. This

line is stable (normally high) when no data are transmitted on th data line. The second wire SDA

is bi directional and used for the data communication between the master and the slave4.

The wiring is according to Figure 4.17.

3

IIC, I2C (Inter IC Bus) were developed and registered by Phillips and saved as a trademark. Atmel uses the name

TWI.

4

The slave is controlled by the master.

Lukas Kohler 41

Page 50

1 Intro

4 Peripherals

Figure 4.17: I2C Wiring

The third line is used when a slave want to tell the master something. An interrupt is generated

then.

4.15.1 Physical layer

I2C Definitions

• Data can only be transmitted when the bus is not active.

• As long as the clock is high, the data line is not allowed to change.

• When no data are transmitted, SCL and SDA are high.

Figure 4.18: I2C Communication Protocol

4.15.2 Communication Protocol

5

1. The data transfer starts with the start bit. The clock is High, data changes from High to Low,

see Figure 4.20

2. The slave address is transmitted.

3. The R/W Bit (see Figure 4.21 and 4.22) defines if data are read from the slave (R/W = 0) or

if data are written to the slave (R/W = 1).

5

A change of the data during a high clock is interpreted as a control command.

42 STM32 Cortex-M3 Tutorial

Page 51

4.15 Inter IC Bus (I2C)

1 Intro

AI00587

DATA

CLOCK

DATA LINE

STABLE

DATA VALID

START

CONDITION

CHANGE OF

DATA ALLOWED

STOP

CONDITION

DATA OUTPUT

BY RECEIVER

DATA OUTPUT

BY TRANSMITTER

SCL FROM

MASTER

START

CLOCK PULSE FOR

ACKNOWLEDGEMENT

12 89

MSB LSB

DATA

CLOCK

DATA LINE

STABLE

DATA VALID

START

CONDITION

CHANGE OF

DATA ALLOWED

STOP

CONDITION

M41T81

=0) is

and the internal address pointer is incremented to

the next address locati on on the reception of an

acknowledge clock. The M41T81 slave receiver

will send an acknowledge clock to the master

transmitter after it has received t he sla ve address

see Figure 13, page 12 and aga in after it has re-

ceived the word address and each data byte.

AI00895

BUS ACTIVITY:

ACK

S

ACK

ACK

ACK

NO ACK

STOP

START

PSDA LINE

BUS ACTIVITY:

MASTER

R/W

DATA n DATA n+1 DATA n+X

SLAVE

ADDRESS

AI00591

BUS ACTIVITY:

ACK

S

ACK

ACK

ACK

ACK

STOP

START

PSDA LINE

BUS ACTIVITY:

MASTER

R/W

DATA n DATA n+1 DATA n+X

WORD

ADDRESS (An)

SLAVE

ADDRESS

=0) and the Acknowledge Bit, the word ad-

=1). At this point the master transmitter be-

This cycle of reading con secutive addresses will

continue until the master rec eiver sends a STOP

condition to the slave transmitter.

The system-to-user transfer of clock data will be

halted whenever the address being read is a clock

address (00h to 07h). The update will resume due

to a Stop Condition or when the pointer increments

to any non-clock address (08h-13h).

Note: This is true both in READ Mode and WRITE

Mode.

An alternate READ Mode may also be implement-

ed whereby the master reads the M41T81 slave

without first writing to the (volatile) a ddress point-

er. The first address that is read is the last one

stored in the pointer (see Figure 15, page 13).

AI00602

R/W

SLAVE ADDRESS

START A

0100011

MSB

LSB

AI00899

BUS ACTIVITY:

ACK

S

ACK

ACK

ACK

NO ACK

STOP

START

P

SDA LINE

BUS ACTIVITY:

MASTER

R/W

DATA n DATA n+1

DATA n+X

WORD

ADDRESS (An)

SLAVE

ADDRESS

S

START

R/W

SLAVE

ADDRESS

ACK

4. The number of data bits between the start and the stop bit is not limited but has to be a full

byte number (8/16 bit).

5. After every data block (8/16 data bit) the receiver pulls the ACK to GND when he has

received the message. The receiver can be the master or the slave (see Figure 4.19)

6. With the stop bit the transfer is quit. Clock is High, Data changes from Low to High.

Figure 4.19: I2C ACK Sequence

Figure 4.20: I2C data transfer sequence

Figure 4.21: I2C writing data from Master to the Slave.

Lukas Kohler 43

Figure 4.22: I2C reading data from the Slave

Page 52

1 Intro

!

4 Peripherals

4.15.3 Pinning

Both wires SCL and SDA are open collector outputs and require a pull-up resistor.

I2C1

Wire GPIO Pin

SCL PB6 58

SDA PB7 59

SMBAI PB5 57

I2C2

Wire GPIO Pin

SCL PB10 29

SDA PB11 30

SMBAI PB12 33

44 STM32 Cortex-M3 Tutorial

Page 53

4.16 Serial Peripheral Interface (SPI)

1 Intro

4.16 Serial Peripheral Interface (SPI)

spi1 F Writes data to SPI1 and SPI2 (polling)

spi2 F Reads the values from the accelerometer MMA7455L over the SPI interface and writes

the data on the serial interface (polling).

spi3 F spi2 realized with interrupts (IRQ).

STM32F103RB have 2 SPIs which are able to communicate up to 18 Mbits/s in slave and master

modes in fullduplex and simplex communication modes. The 3-bit prescaler gives 8 master mode

frequencies and the frame is configurable from 8-bit to 16-bit. The hardware CRC generation/verification supports basic SD Card/MMC modes.

4.16.1 Physical Layer

b

b

b

The synchronous serial interface SPI allows a data transfer in both directions. Therefore following

wires are required:

• SCK: Clock (generated by the master)

• MISO: Master in, Slave out

• MOSI: Master out, Slave in

• NPCK or NSS: Chip select for the slave, this wire is not generated by the SPI driver, a normal

GPIO pin has to be used.

In case more than one slave is accessed, an enable wire (NPCK or NSS) for each slave is required.

Figure 4.23 shows a basic SPI network.

4.16.2 Communication Protocol

The clock signal is only generated by the master device (normally the main microcontroller). If no

data are transmitted the clock is not active.

The data communication is shown in Figure 4.25. The chip select line NSS goes low in order to

start the communication. This wire is needed since SPI don’t use an address like I2C.

The master sends its data on the MOSI line to the slave, the slave its data on the MISO line to the

master. Data are only allowed to change while a falling (CPOL = 0) or rising (CPOL = 1) flank of

SCK.

The SPI can as well be used as I2S bus for point to point communication. Refer to the reference

manual if you want to use this feature.

Lukas Kohler 45

Page 54

1 Intro

4.16.3 Pinning

MOSI

MISO

Baud rate generator

SCK

Master control logic

Communication

control

SPE BR2 BR1 BR0 MSTR CPOL CPHA

BR[2:0]

RXNE

LSB

BIDI

MODE

BIDI

OE

SSM SSI

BSY OVR

MOD

RXNETXE

ERR

TXE

00

DFF

0

SSOE

CRC

EN

0

RX

ONLY

CRC

Next

CRC

ERR

0

1

NSS

IE

F

FIRST

SPI_CR1

SPI_CR2

SPI_SR

TXDM

AEN

RXDM

AEN

IEIE

Address and data bus

Read

Rx buffer

Shift register

LSB first

Tx buffer

Write

ai14744

4 Peripherals

SPI1

Wire GPIO Pin

NSS PA4 20

SCK PA5 21

MISO PA6 22

MOSI PA7 23

SPI2

Wire GPIO Pin

NSS PB12 33

SCK PB13 34

MISO PB14 35

MOSI PB15 36

Figure 4.23: SPI Connection between a Master a Slave

46 STM32 Cortex-M3 Tutorial

Figure 4.24: SPI Driver

Page 55

4.16 Serial Peripheral Interface (SPI)

1 Intro

CPOL = 1

CPOL = 0

MSBit

LSBit

MSBit

LSBit

MISO

(from master)

MOSI

(from slave)

NSS

(to slave)

Capture strobe

CPHA =1

CPOL = 1

CPOL = 0

MSBit

LSBit

MSBit

LSBit

MISO

(from master)

MOSI

NSS

(to slave)

Capture strobe

CPHA =0

Note: These timings are shown with the LSBFIRST bit reset in the SPI_CR1 register.

(from slave)

8 or 16 bits depending on Data Frame Format (see SPI_CR1)

8 or 16 bits depending on Data Frame Format (see SPI_CR1)

Figure 4.25: SPI data communication between Master and Slave

Lukas Kohler 47

Page 56

1 Intro

4 Peripherals

4.17 Universal Serial Bus (USB)

The STM32F103RB embeds a full speed USB (12 Mbs) device peripheral compatible with the USB.

It has software configurable endpoint setting and suspend/resume support. The dedicated 48

MHz clock source is generated from the internal main PLL.!

The CAN and USB share same pins PA11/EXT1-1 and PA12/EXT1-3, so you can’t use both CAN

and USB on same time with the standard pin mapping.

The implementation of the USB framework would go beyond the scope of this work and is therefore not covered.

48 STM32 Cortex-M3 Tutorial

Page 57

List of Figures

2.1 STM32F103xx Performance Line Block Diagram . . . . . . . . . . . . . . . . . . . . 7

2.2 STM32F103xx memory map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Development Board STM32H103 from Olimex . . . . . . . . . . . . . . . . . . . . . 9

2.4 Development Board STM32P103 from Olimex . . . . . . . . . . . . . . . . . . . . . 9

2.5 Developing Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 BFH Mother Board with STM32H103 from Olimex . . . . . . . . . . . . . . . . . . . 12

2.7 RS232 directly connected (Pin 2: Rx, 3: Tx, 5: GND) . . . . . . . . . . . . . . . . . . 12

2.8 CAN interface (Pin 2: CANL, 3/6:GND, 7: CANH) . . . . . . . . . . . . . . . . . . 12

3.1 Create a new project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Specify the device: STM32F103RB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Add the startup code to the project . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Configuration wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Configuration wizard: Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.6 Building Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7 Debug Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.8 Options for Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19