Page 1

UM2622

User manual

How to use the STEVAL-STWINKT1 SensorTile Wireless Industrial Node for

condition monitoring and predictive maintenance applications

Introduction

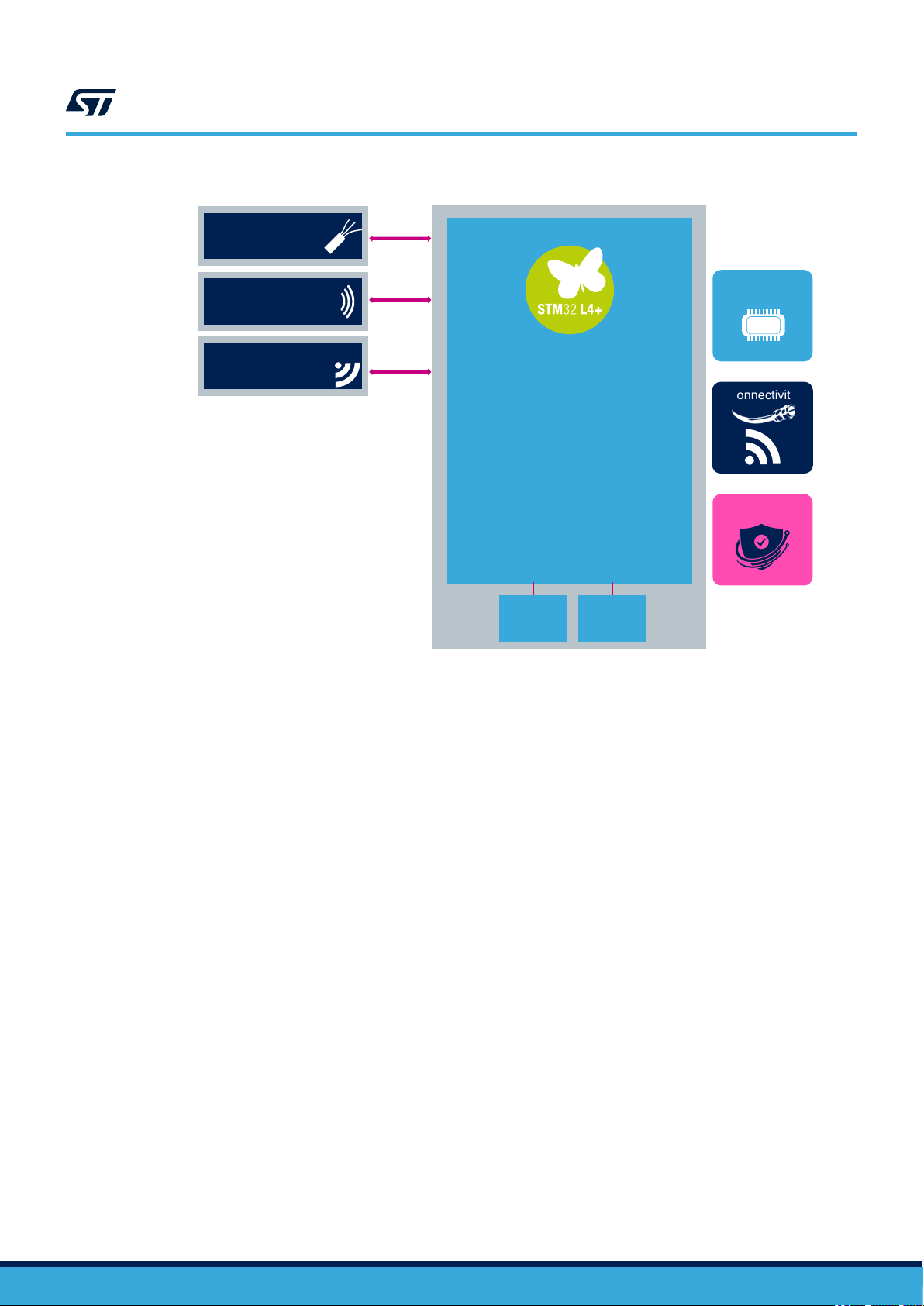

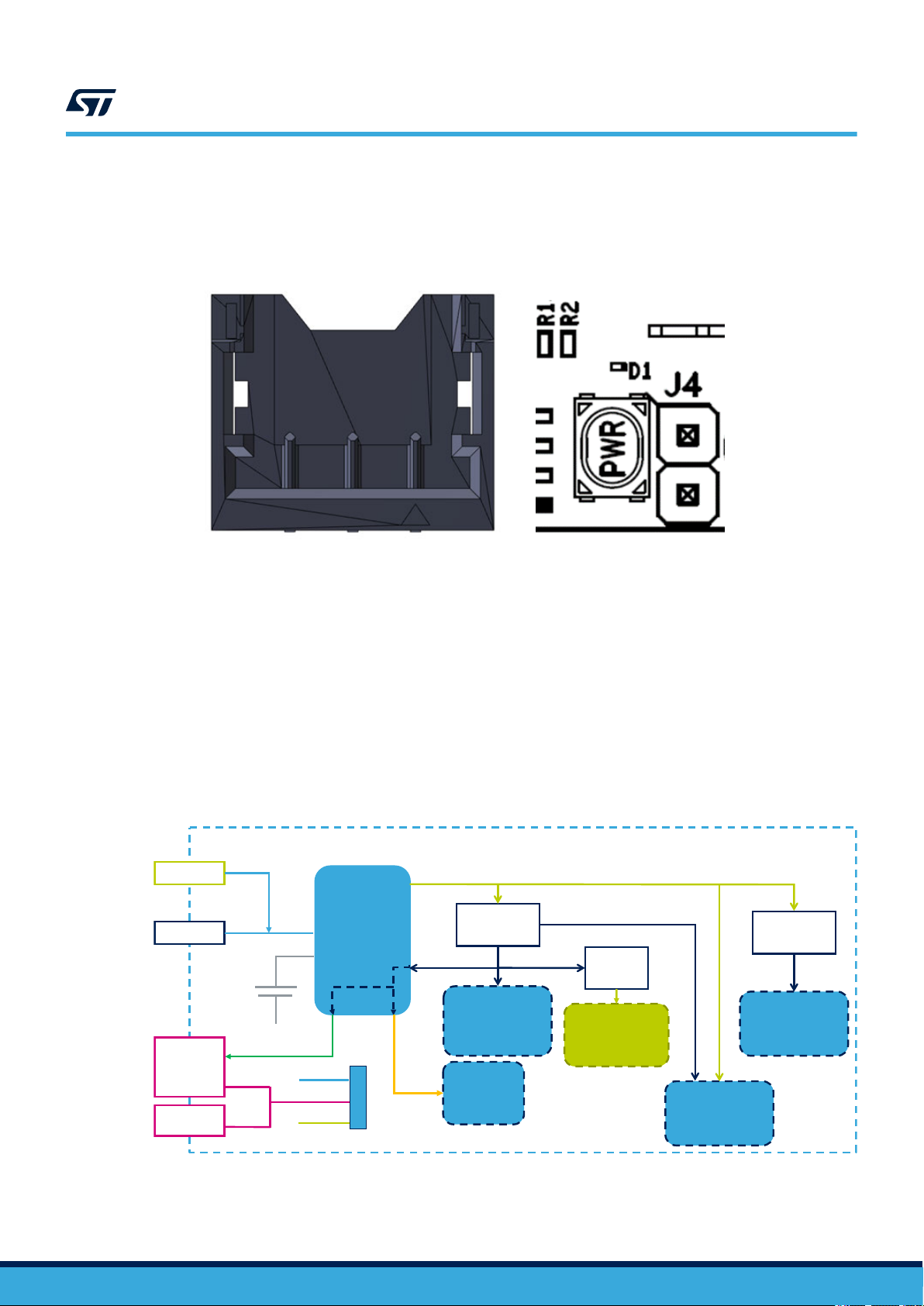

The STWIN SensorTile wireless industrial node (STEV

prototyping and testing of advanced industrial IoT applications such as condition monitoring and predictive maintenance.

The kit features a core system board with a range of embedded industrial-grade sensors and an ultra-low-power microcontroller

for vibration analysis of 9-DoF motion sensing data across a wide range of vibration frequencies, including very high frequency

audio and ultrasound spectra, and high precision local temperature and environmental monitoring.

The development kit is complemented with a rich set of software packages and optimized firmware libraries, as well as a cloud

dashboard application, all provided to help speed up design cycles for end-to-end solutions.

The kit supports BLE wireless connectivity through an on-board module, and Wi-Fi connectivity through a special plugin

expansion board (STEVAL-STWINWFV1). Wired connectivity is also supported via an on-board RS485 transceiver. The core

system board also includes an STMod+ connector for compatible, low cost, small form factor daughter boards associated with

the STM32 family, such as the LTE Cell pack.

Apart from the core system board, the kit is provided complete with a 480 mAh Li-Po battery, an STLINK-V3MINI debugger and

a plastic box.

AL-STWINKT1) is a development kit and reference design that simplifies

Figure 1. STEVAL-STWINKT1 SensorTile Wireless Industrial Node

UM2622 - Rev 6 - November 2020

For further information contact your local STMicroelectronics sales office.

www.st.com

Page 2

1 STWIN kit components

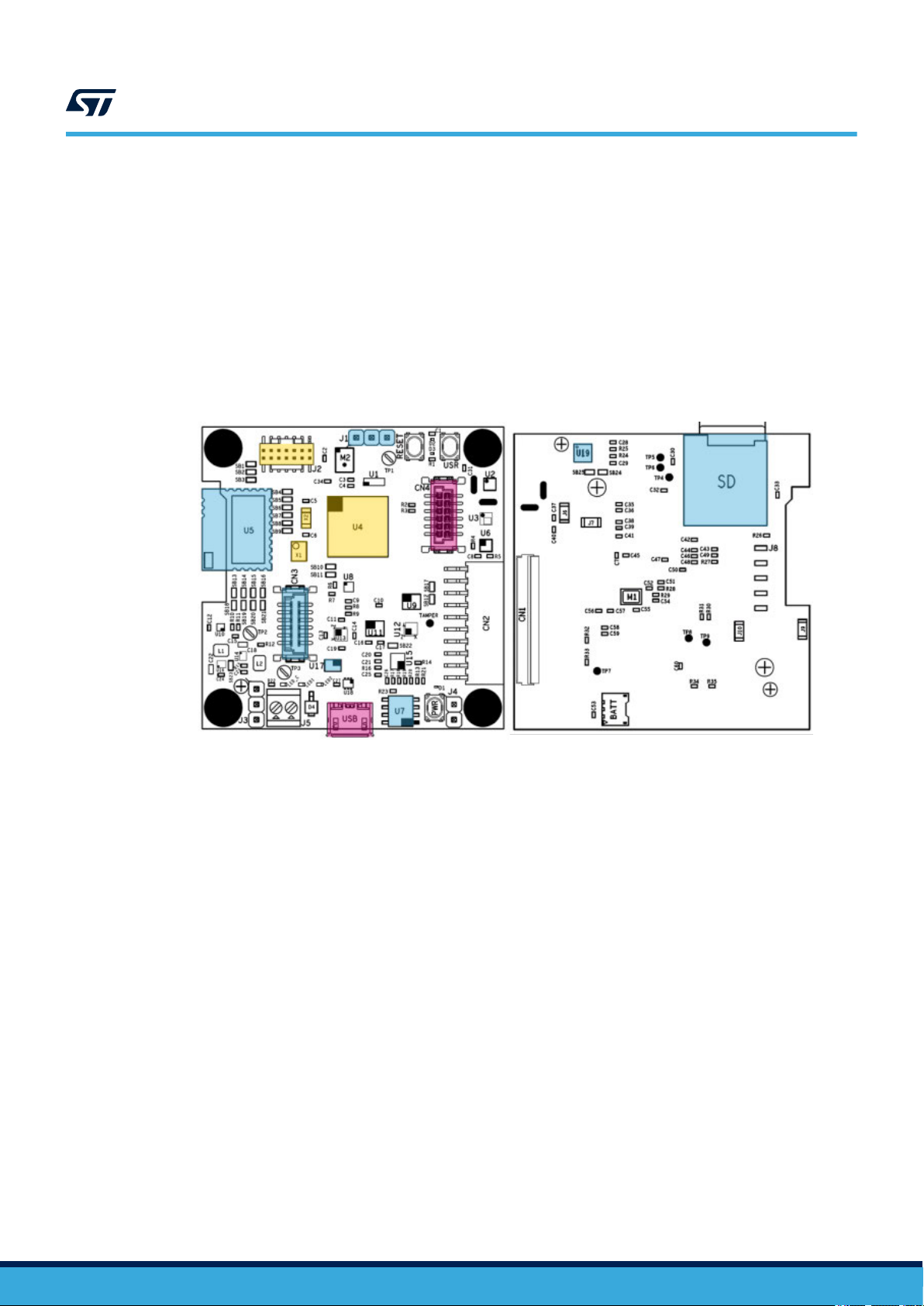

The SensorTile Wireless Industrial Node (STWIN) is packaged with the components shown below.

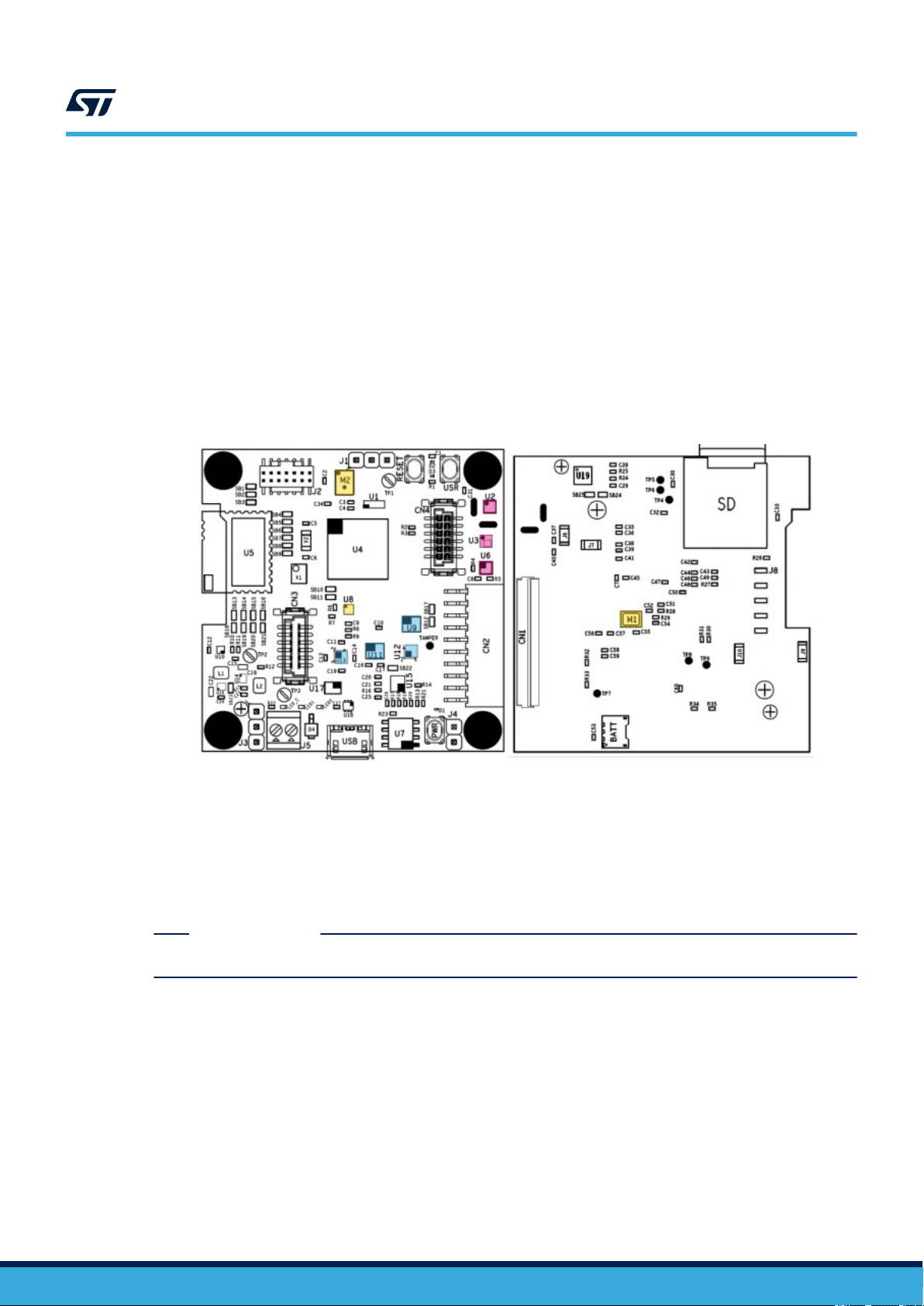

Figure 2. STWIN Core System board top and bottom

UM2622

STWIN kit components

Figure 3. Protective plastic case

UM2622 - Rev 6

page 2/43

Page 3

Figure 4. 480mAh 3.7V Li-Po Battery

Figure 5. STLink-V3Mini Debugger/Programmer for STM32

UM2622

STWIN kit components

Figure 6. Programming cable

UM2622 - Rev 6

page 3/43

Page 4

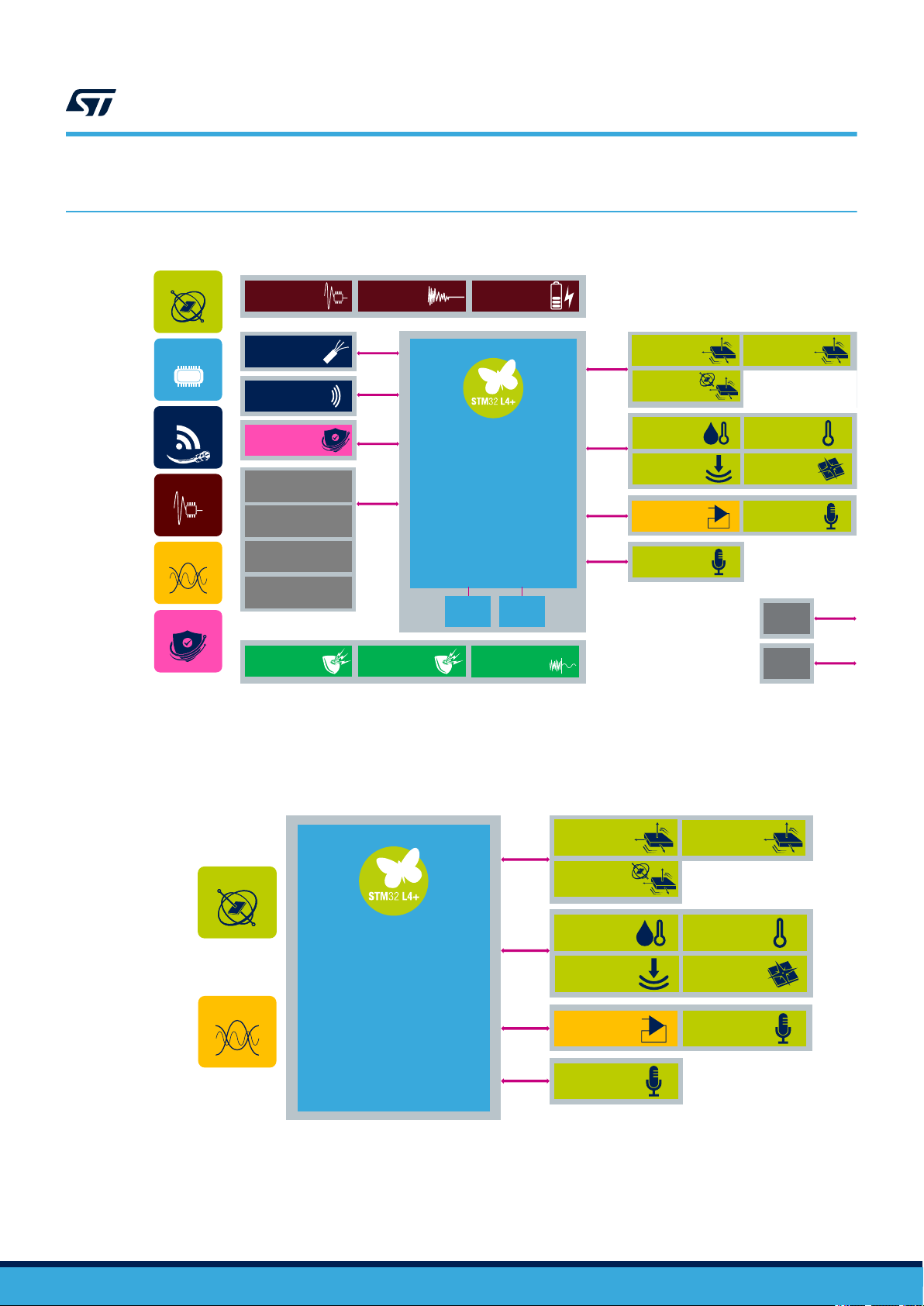

2 Functional blocks

SPI3

ADC1

USART2

Enanced

SWD

Connector

UART5

I2C2

ADC3

GPIO

Auxiliary

Connector

DFSDM1

I2C2

IMP34DT05

Digital Microphone

LPS22HH

Pressure Sensor

HTS221

Humidity and

Temperature Sensor

STTS751

Temperature Sensor

IIS2MDC

3D Magnetometer

STM32L4R9ZIJ6

Microcontroller

Ultra Low Power

Cortex M4F@120MHz

32 kHz

Crystal

16 MHz

Crystal

SPBTLE-1S

BLE Application

Processor Module

STR485LV

RS485 Interface

SPI2

MP23ABS1

Analog Microphone

TS922EIJT

Low noise, low

distortion OpAmp

20-pin STMOD+

12-pin female sensor

connector

12-pin male

connector

40-pin Flex

STSAFE

Secure Element*

I2C2

SPIx, I2S,

USARTx,...

IIS2DH

3D Accelerometer

IIS3DWB

Vibrometer

ISM330DHCX

6-Axis IMU

USBLC6-2P6

USB ESD protection

ESDALC6V1-1U2

Single Line ESD

protection

EMIF06-MSD02N16

EMI filter and ESD

protection

STBC02

Li-Ion linerar battery

charger

ST1PS01EJR

step-down switching

regulator

LDK130

Low Noise LDO

Sensing

Processing

Connectivity

Power Mng.

Analog

Secure

* not mounted

connector

connector

SPI3

ADC1

DFSDM1

I2C2

IMP34DT05

Digital Microphone

LPS22HH

Pressure Sensor

HTS221

Humidity and

Temperature Sensor

STTS751

Temperature Sensor

IIS2MDC

3D Magnetometer

STM32L4R9ZIJ6

Microcontroller

Ultra Low Power

Cortex M4F@120MHz

MP23ABS1

Analog Microphone

TS922EIJT

Low noise, low

distortion OpAmp

IIS2DH

3D Accelerometer

IIS3DWB

Vibrometer

ISM330DHCX

6-Axis IMU

Sensing

Analog

UM2622

Functional blocks

Figure 7. STEV

AL-STWINKT1 functional block diagram

2.1 Sensing

The core system board offers a comprehensive range of sensors specifically designed to support and enable the

Industry 4.0 applications.

Figure 8. STEV

UM2622 - Rev 6

The motion sensors communicate with the STM32L4R9ZIJ6 microcontroller via SPI in order to accommodate the

high data rates, while the magnetometer and environmental sensors communicate via I2C.

AL-STWINKT1 functional block diagram of sensing elements and STM32L4R9ZIJ6

page 4/43

Page 5

UM2622

Sensing

The suitably filtered signal from the MP23ABS1 analog microphone is amplified by a TS922 low noise op-amp

and then sampled by the internal 12-bit ADC in the MCU, while the signal from digital microphone is directly

managed by the digital filter for Sigma-Delta modulators (DFSDM) interface in the MCU.

Figure 9. Core system board sensor locations

U2: HTS221 relative humidity and temperature sensor

U3: LPS22HH digital absolute pressure sensor

U6: STTS751 low-voltage digital local temperature sensor

U8: TS922 rail-to-rail, high output current, dual operational amplifier

U9: ISM330DHCX 3D acc. + 3D gyro iNEMO IMU with machine learning core

U1

1: IIS3DWB ultra-wide bandwidth (up to 6 kHz), low-noise, 3-axis digital vibration sensor

U12: IIS2DH ultra-low-power high performance MEMS motion sensor

U13: IIS2MDC ultra-low-power 3-axis magnetometer

M1: MP23ABS1 analog MEMS microphone

M2: IMP34DT05 industrial grade digital MEMS microphone

2.1.1 HTS221 humidity and temperature sensor

The HTS221

signal ASIC to provide measurement information through digital serial interfaces.

The sensing element consists of a polymer dielectric planar capacitor structure capable of detecting relative

humidity variations and is manufactured using a dedicated ST process.

The HTS221 is available in a small top-holed cap land grid array (HLGA) package guaranteed to operate over a

temperature range from -40 °C to +120 °C.

is an ultra-compact relative humidity and temperature sensor with a sensing element and a mixed

RELATED LINKS

Visit the product web page for the HTS221 relative humidity and temperature sensor

2.1.2 LPS22HH MEMS pressure sensor

The LPS22HH is an ultra-compact piezoresistive absolute pressure sensor which functions as a digital output

barometer

I3CSM or SPI from the sensing element to the application.

The sensing element, which detects absolute pressure, consists of a suspended membrane manufactured using a

dedicated process developed by ST.

The LPS22HH is available in a full-mold, holed LGA package (HLGA). It is guaranteed to operate over a

temperature range extending from -40 °C to +85 °C.

. The device consists of a sensing element and an IC interface which communicates through I²C, MIPI

UM2622 - Rev 6

page 5/43

Page 6

RELATED LINKS

Visit the product web page for the LPS22HH MEMS pressure sensor

2.1.3 STTS751 digital temperature sensor

The STTS751

temperature is measured with a user-configurable resolution between 9 and 12 bits. At 9 bits, the smallest step

size is 0.5 °C, and at 12 bits, it is 0.0625 °C. At the default resolution (10 bits, 0.25 °C/LSB), the nominal

conversion time is 21 milliseconds.

Up to eight devices can share the same 2-wire SMBus without ambiguity, allowing a single application to monitor

multiple temperature zones.

is a digital temperature sensor which communicates over a 2-wire SMBus 2.0 compatible bus. The

RELATED LINKS

Visit the product web page for the STTS751 digital temperature sensor

2.1.4 TS922 rail-to-rail, high output current, dual operational amplifier

The TS922 is a rail-to-rail dual BiCMOS operational amplifier optimized and fully specified for 3 V and 5 V

operation. The very low noise, low distortion, low of

highly suitable for high quality, low voltage, or battery operated audio systems.

fset, and high output current capability render this device

UM2622

Sensing

RELATED LINKS

Visit the product web page for the TS922 rail-to-rail, high output current, dual operational amplifier

2.1.5 ISM330DHCX iNEMO IMU 3D Acc + 3D Gyro

The ISM330DHCX is a system-in-package featuring a high-performance 3D digital accelerometer and +3D digital

gyroscope tailored for Industry 4.0 applications.

The sensing elements of the accelerometer and of the gyroscope are implemented on the same silicon die, which

ensures superior stability and robustness.

Several embedded features such as programmable FSM, FIFO, sensor hub, event decoding and interrupts allow

the implementation of smart and complex sensor nodes able to deliver high performance at very low power

RELATED LINKS

Visit the product web page for the ISM330DHCX iNEMO IMU 3D Acc + 3D Gyro

2.1.6 IIS3DWB ultra-wide bandwidth (up to 6 kHz), low-noise, 3-axis digital vibration sensor

The IIS3DWB is a system-in-package featuring a 3-axis digital accelerometer with low noise over an ultra-wide

and flat frequency range. The wide bandwidth, low noise, very stable and repeatable sensitivity

capability of operating over an extended temperature range (up to +105 °C), render the device particularly

suitable for vibration monitoring in industrial applications.

The high performance delivered at low power consumption, together with the digital output and embedded digital

features like FIFO and interrupts are of primary importance in battery-operated industrial wireless sensor nodes.

, together with the

RELATED LINKS

Visit the product web page for the IIS3DWB ultra-wide bandwidth (up to 6 kHz), low-noise, 3-axis digital vibration sensor

.

2.1.7 IIS2DH ultra-low power 3-axis high-performance accelerometer

The IIS2DH is an ultra-low-power high-performance three-axis linear accelerometer with digital I2C/SPI serial

interface standard output.

The device may be configured to generate interrupt signals from two independent inertial wake-up/free-fall events,

as well as from the position of the device itself.

UM2622 - Rev 6

page 6/43

Page 7

RELATED LINKS

Visit the product web page for the IIS2DH ultra-low power 3-axis high-performance accelerometer

2.1.8 IIS2MDC 3-axis magnetometer

The IIS2MDC is a high-accuracy

range up to ±50 gauss, and includes an I²C serial bus interface that supports 100 kHz, 400 kHz, 1 MHz, and

3.4 MHz rates and an SPI serial standard interface.

The device can be configured to generate an interrupt signal from magnetic field detection.

, ultra-low-power 3-axis digital magnetic sensor. It has a magnetic field dynamic

RELATED LINKS

Visit the product web page for the IIS2MDC 3-axis magnetometer

2.1.9 MP23ABS1 analog MEMS microphone

The MP23ABS1 is a compact, low-power microphone built with a capacitive sensing element and an IC interface.

The device has an acoustic overload point of 130 dBSPL with a typical 64 dB signal-to-noise ratio, with sensitivity

at -38 dBV ±1 dB @ 94 dBSPL, 1 kHz.

RELATED LINKS

Visit the product web page for the MP23ABS1 analog MEMS microphone

UM2622

Processing and connectivity

2.1.10 IMP34DT05 digital MEMS microphone

The IMP34DT05 is an ultra-compact, low-power, omnidirectional, digital MEMS microphone built with a capacitive

sensing element and an IC interface; the device features 64 dB signal-to-noise ratio and -26 dBFS ±3 dB

sensitivity.

The IC interface includes a dedicated circuit able to provide a digital signal externally in PDM format.

RELATED LINKS

Visit the product web page for the IMP34DT05 digital MEMS microphone

2.2 Processing and connectivity

The STWIN core system board features several wired and wireless connectivity options and the STM32L4R9ZI

ultra-low-power microcontroller, which is part of the STM32L4+ series MCUs based on the high-performance Arm

Cortex-M4 32-bit RISC core, operating at up to 120 MHz and equipped with 640 Kb SRAM and 2 MB Flash

memory.

UM2622 - Rev 6

page 7/43

Page 8

USART2

STM32L4R9ZIJ6

Microcontroller

Ultra Low Power

Cortex M4F@120MHz

32 kHz

Crystal

16 MHz

Crystal

SPBTLE-1S

BLE Application

Processor Module

STR485LV

RS485 Interface

SPI2

SPI1

Secure

Processing

Connectivity

STEVAL-STWINWFV1

12-pin male com.

connector

Processing and connectivity

Figure 10. Main connectivity components and the STM32L4R9ZI processing unit

UM2622

Each connectivity component is connected to an independent bus on the STM32L4R9ZI MCU, so they can all be

configured individually

.

UM2622 - Rev 6

page 8/43

Page 9

Figure 11. MCU and connectivity element locations

U4: STM32L4R9ZI Cortex-M4F 120MHz 640Kb RAM

U5: SPBTLE-1S very low power application module for Bluetooth® Smart v4.2

U7: STSAFE-A1

U17: STG3692 high bandwidth quad SPDT switch

U19: STR485 3.3V RS485 up to 20Mbps

USB: Micro-USB connector (power supply + data)

X1: 16MHz crystal oscillator

X2: 32.768 kHz crystal oscillator

J2: STDC14 programming connector for STLINK-V3

J1: RS485 interface header connector

CN3: Connectivity expansion connector (for STEVAL-STWINWFV1)

CN4: Audio/sensor expansion connector

SD: microSD card socket

10 authentication and brand protection secure solution

UM2622

Processing and connectivity

2.2.1 STM32L4R9ZI Cortex-M4F 120MHz 640Kb RAM

The STM32L4R9ZI devices is an ultra-low-power microcontroller (STM32L4+ Series MCU) based on the highperformance Arm Cortex-M4 32-bit RISC core, which operates at a frequency of up to 120 MHz.

The Cortex-M4 core features a single-precision floating-point unit (FPU), which supports all the Arm singleprecision data-processing instructions and all the data types. The Cortex-M4 core also implements a full set of

DSP (digital signal processing) instructions and a memory protection unit (MPU) which enhances application

security

These devices embed high-speed memories (2 Mbytes of Flash memory and 640 Kbytes of SRAM), a flexible

external memory controller (FSMC) for static memories (for devices with packages of 100 pins and more), two

OctoSPI Flash memory interfaces and an extensive range of enhanced I/Os and peripherals connected to two

APB buses, two AHB buses and a 32-bit multi-AHB bus matrix.

The MCU embeds several protection mechanisms for embedded Flash memory and SRAM: readout protection,

write protection, proprietary code readout protection and a firewall.

These devices offer a fast 12-bit ADC (5 Msps), two comparators, two operational amplifiers, two DAC channels,

an internal voltage reference buffer, a low-power RTC, two general-purpose 32-bit timer, two 16-bit PWM timers

for motor control, seven general-purpose 16-bit timers, and two 16-bit low-power timers. The devices support four

digital filters for external sigma delta modulators (DFSDM). In addition, up to 24 capacitive sensing channels are

available.

They also feature standard and advanced communication interfaces such as:

• Four I2Cs

• Three SPIs

• Three USARTs, two UARTs and one low-power UART

• Two SAIs

• One SDMMC

.

UM2622 - Rev 6

page 9/43

Page 10

• One CAN

•

One USB OTG full-speed

• Camera interface

• DMA2D controller

The device operates in the -40 to +85 °C (+105 °C junction) and -40 to +125 °C (+130 °C junction) temperature

ranges from a 1.71 to 3.6 V for VDD power supply when using internal LDO regulator and a 1.05 to 1.32 V V

power supply when using external SMPS supply. A comprehensive set of power-saving modes allows the design

of low-power applications.

Some independent power supplies are supported, such as an analog independent supply input for ADC, DAC,

OPAMPs and comparators, a 3.3 V dedicated supply input for USB and up to 14 I/Os, which can be supplied

independently down to 1.08 V. A VBAT input allows backup of the RTC and the registers. Dedicated V

supplies can be used to bypass the internal LDO regulator when connected to an external SMPS.

RELATED LINKS

Visit the product web page for the STM32L4R9ZI micrcontroller

2.2.2 SPBTLE-1S application module for Bluetooth v4.2

The SPBTLE-1S is a Bluetooth low energy system-on-chip application processor certified module, compliant with

BT specifications v4.2 and BQE qualified. It supports multiple roles simultaneously and can act as a Bluetooth

smart master and slave device at the same time.

The module is based on the BlueNRG-1 system-on-chip, with the entire Bluetooth low energy stack and protocols

embedded in the module to provide a complete RF platform in a tiny form factor. The integrated radio, embedded

antenna and high frequency oscillators complete the certified solution that can help minimize the time to market of

final applications.

The SPBTLE-1S can be powered directly with a pair of AAA batteries or any power source from 1.7 to 3.6 V.

The RF power emitted is +5 dBm.

The RF channel center frequency of the module is 2402~2480 MHz.

UM2622

Processing and connectivity

DD12

power

DD12

RELATED LINKS

Visit the product web page for the SPBTLE-1S application module for Bluetooth v4.2

2.2.3 STEVAL-STWINWFV1 Wi-Fi expansion (not included in the kit) for the SensorTile wireless

industrial node (STWIN) kit

The STEV

Wireless Industrial Node (STWIN) kit.

Through the CN3 connectivity expansion connector, the STEVAL-STWINWFV1 can be plugged into the STWIN

core system board.

It is based on the ISM43362-M3G-L44-E Wi-Fi module and its main features are:

• 802.11 b/g/n compatible

• based on Broadcom MAC/Baseband/Radio device

• fully contained TCP/IP stack

• host interface: SPI up to 25 MHz

The RF power emitted is +9 dBm (limited by firmware).

The module operating band is 2400 MHz ~ 2483.5 MHz (2.4 GHz ISM Band).

AL-STWINWFV1 expansion board (sold separately) adds 2.4 GHz Wi-Fi connectivity to the SensorTile

RELATED LINKS

Visit the product web page for further details on the STEVAL-STWINWFV1

2.2.4 STR485LV 3.3V RS485 up to 20Mbps

The STR485 is a low power differential line transceiver for RS485 data transmission standard applications in halfduplex mode. Data and enable signals are compatible with 1.8 V or 3.3 V supplies.

UM2622 - Rev 6

page 10/43

Page 11

UM2622

Power management

Two speeds are selectable via the SLR pin: fast data rate up to 20 Mbps or slow data rate up to 250 kbps for

extended cables.

Excessive power dissipation caused by bus contention or faults is prevented by a thermal shutdown circuit that

forces the driver outputs into a high impedance state. The receiver has a fail-safe feature that guarantees a high

output state when the inputs are left open, shorted or idle.

RELATED LINKS

Visit the product web page for the STR485LV 3.3V RS485 up to 20Mbps

2.2.5 USB connector

The Micro-USB connector on the board can be used for both power supply and data transfer (USB Device only).

Dif

ferent examples of USB class implementation can be found in STSW-STWINKT01 software package.

2.2.6 STSAFE-A110 (footprint only) authentication, state-of-the-art security for peripherals and IoT

devices

The STSAFE-A1

data management services to a local or remote host. It consists of a full turnkey solution with a secure operating

system running on the latest generation of secure microcontrollers.

The STSAFE-A110 can be integrated in IoT devices, smart-home, smart-city and industrial applications,

consumer electronics devices, consumables and accessories.

10 is a highly secure solution that acts as a secure element providing authentication and secure

RELATED LINKS

Visit the product web page for the STSAFE-A110 authentication, state-of-the-art security for peripherals and IoT devices

2.2.7 microSD card socket

On the bottom side of the STWIN core system board is a microSD Card socket that is accessible even when the

board is mounted in the plastic box. The card is accessed through a 4-bit wide SDIO port for maximum

performance.

A couple of firmware examples involving high speed data logging on the SD card are available in the STSW

STWINKT01 software package.

2.2.8 Clock sources

There are two external clock sources on the STWIN core system board:

•

X1: 16 MHz high speed external (HSE) oscillator for the MCU.

• X2: 32.768 kHz low speed external (LSE) oscillator for the RTC embedded in the MCU.

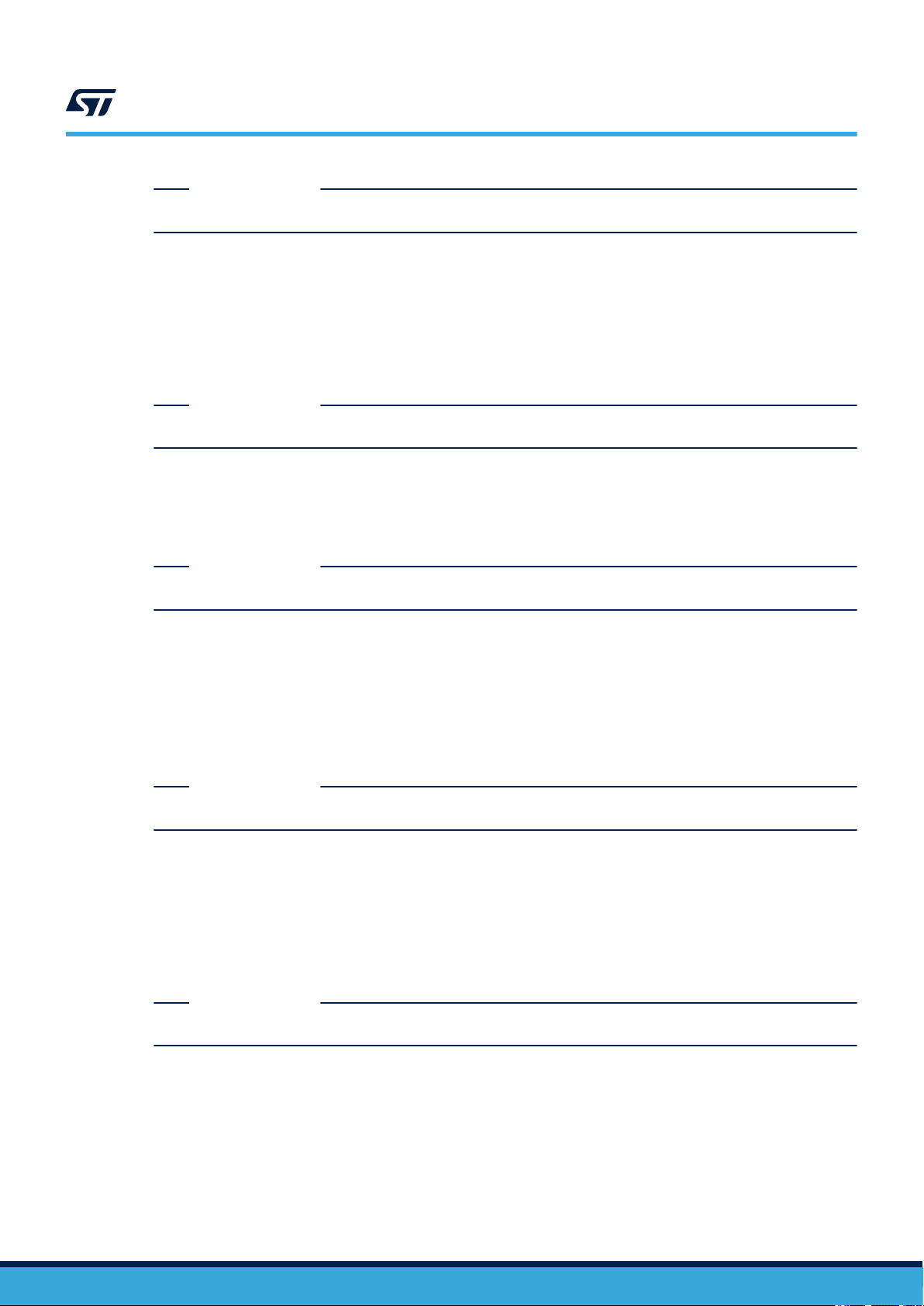

2.3 Power management

The STWIN core system board includes a range of power management features that enable very low power

consumption in final applications.

The main supply is through a lithium ion polymer battery (3.7 V

(STBC02) with Vin [4.8 -5.5 V].

-

, 480 mAh) and the integrated battery charger

UM2622 - Rev 6

page 11/43

Page 12

Figure 12. Power and protection components

STM32L4R9ZIJ6

Microcontroller

Ultra Low Power

Cortex M4F@120MHz

LDK130

Low Noise LDO

ESDALC6V1-1U2

Single Line ESD

protection

USBLC6-2P6

USB ESD protection

EMIF06-MSD02N16

EMI filter and ESD

protection

ST1PS01EJR

step-down

switching regulator

STBC02

Li-Ion linerar

battery charger

UM2622

Power management

Figure 13. Power and protection component locations

U1: EMIF06-MSD02N16

U10: LDK130 300 mA very low noise LDO

U14, U16: ST1PS01 400 mA Synchronous step-down converter

U15: STBC02 Li-Ion linear battery charger

U18: USBLC6-2 low capacitance ESD protection for USB

D1, D2, D3: Single-line low capacitance Transil for ESD protection

D4: Power Schottky rectifier (1A)

BATT: Battery connector

J4: Battery pins

J5: 5V Ext power supply connector

J6, J7, J9, J10: Current monitoring SMD jumper

PWR: Power button

6-line EMI filter and ESD protection for T-Flash and microSD card interfaces

UM2622 - Rev 6

page 12/43

Page 13

2.3.1 Battery connectors

3 2 1

2

1

VBAT

BAT_NTC

GND

VBAT

GND

STWIN core system board

USB

3V3 DCDC

U14

CN3 (Wi-Fi)

STSAFE

5V

SYS (5V or VBAT)

CN2

(AMicArray)

CN2

CN1

VBAT

J5

STBC02

Battery

Charger

Analog Mic

OpAmp

U10

2.7 LDO

DCDC_1

DCDC_2

3V3_Ext

U16

3V3 DCDC

VEXT

J3

µSDCard

RS485

SYS

V_USB

5V

STM32L4+

Sensors

BLE

The battery supply voltage (VBAT) may be provided by connecting the 480 mA LiPo battery included in the

STWIN kit to the dedicated battery connector

UM2622

Power management

, or by supplying an external voltage through the J4 connector.

Figure 14. Battery and J4 connectors for VBAT supply

2.3.2 Power supply

The STWIN core system board can receive power from different sources:

V_USB: through micro USB connector [5 V]

•

• Vin: through J5 connector [4.8-5.5 V]. The current on this port needs to be limited to 2 A

• VBAT: lithium ion polymer battery (3.7 V, 480 mAh), STBC02 battery charger integrated in the board

The battery is always optional. The STBC02 battery charger automatically checks the available power inputs and

selects one to power the system. When the battery is connected as well as one of the other sources, the STBC02

automatically charges the battery.

When battery-powered, the equipment is intended to work properly with an operating temperature of 35°C.

Without the battery, the equipment is intended to work properly with an operating temperature of 45°C.

Figure 15. Power circuits

UM2622 - Rev 6

page 13/43

Page 14

2.3.3 Power ON/OFF procedure

If the STWIN core system board is not powered via battery, then the board will turn on and off when you connect

and disconnect an external supply

, respectively.

Follow the steps below to power the board on and off when it is powered by a LiPo battery.

Step 1. Push the PWR button for about a second to power the board on.

Power on is managed by the STBC02 battery charger WAKE-UP hardware feature.

Step 2. Push the PWR button again to turn the board off.

In the application code examples provided with the software, the microcontroller detects the push

action and activates the battery charger SHUTDOWN command to switch the power supply off.

2.3.4 Power consumption evaluation

There are several test points and jumpers on the STWIN core system board available to monitor the electrical

performance of running applications. In particular

in each of the four main power supply domains on the board.

The best way to evaluate general power consumption is to remove both the battery and the USB cable and

provide 5 V directly on the J5 connector.

J6: Sensor current monitoring

J4: Battery supply

J7: STM32 digital power supply current monitoring

J9: SPBTLE-1S BLE module current monitoring

J10: STEVAL-STWINWFV1 (Wi-Fi expansion) and STSAFE-A110 current monitoring

TP1, TP2: GND

TP3: DCDC_1 (3.3V)

UM2622

Power management

, there are four jumpers for monitoring the current consumption

Figure 16. Power monitoring points

UM2622 - Rev 6

page 14/43

Page 15

2.4 Buttons, LEDs and connectors

140

Figure 17. Buttons, LEDs and connectors

USR: User button

PWR: connected to the STBC02 for integrated W

RESET: connected to STM32 MCU reset pin (BLACK)

LED_C: Red LED connected to STBC02 and used for battery status feedback

LED1: Green LED connected to STM32

LED2: Orange LED connected to STM32

CN1: 40-pin flex general purpose expansion

CN2: STMod+ connector

CN3: 12-pin male connectivity expansion connector, suitable for the STEVAL-STWINWFV1 expansion board

CN4: 12-pin female sensor expansion connector, suitable for the STEVAL-STWINMAV1 analog microphone array expansion

board

Batt

UM2622

Buttons, LEDs and connectors

AKE-UP function and the STM32L4R9ZI MCU as generic USR button

2.4.1 Flex expansion connector

This is a general purpose expansion connector.

Pin No. Description STM32 pin Default Signal

1 USART3_CTS PB13 -

2 STMOD2 PD8/ PC3 USART3_TX/ SPI2_MOSI

3 STMOD3 PD9/ PD3 USART3_RX/ SPI2_MISO

4 STMOD4 PD1/ PB1 SPI2_CLK/ USART3_RTS

5 GND - -

6 VEXT - -

Figure 18. CN1 Flex connector top view

able 1. CN1 pin descriptions

T

UM2622 - Rev 6

page 15/43

Page 16

Pin No. Description STM32 pin Default Signal

7 I2C4_SCL PD12 -

8 SPI2_MOSI_p2 PB15 -

9 SPI2_MISO_p2 PC2 -

10 I2C4_SDA PD13 -

11 PC5/WKUP5 PC5 WKUP5

12 EX_RESET PD11 -

13 EX_ADC PA5 -

14 EX_PWM PA15 -

15 VEXT - -

16 GND - -

17 PG12 PG12 EX_CN (ex tint)

18 PG10 PG10 TIM

19 PG9 PG9 TIM

20 PB14 PB14 TIM, DSFDMD2

21 PA9 PA9 -

22 PA10 PA10 -

23 PB11 PB11 DSI_TE,TIM,LPUART_TX

24 PC13 PC13 TAMP, WKUP

25 PB9 PB9

26 PB8 PB8

27 PE9 PE9 TIM, DSFDMCLK

28 3V3_Ext - -

29 DSI_D1_N -

30 DSI_D1_P -

31 GND - -

32 DSI_D0_N -

33 DSI_D0_P -

34 SYS - -

35 DSI_CLK_N -

36 DSI_CLK_P -

37 3V3_Ext - -

38 PA0 PA0 ADC_IN5

39 PA1 PA1 ADC_IN6

40 SYS - -

CAN, TIM, DSFDM,I2C1

STM32 Display Serial Interface (DSI) Host

STM32 Display Serial Interface (DSI) Host

STM32 Display Serial Interface (DSI) Host

UM2622

Buttons, LEDs and connectors

SAI2

UM2622 - Rev 6

RELATED LINKS

View the vendor documentation on handling FH34SRJ series connectors

page 16/43

Page 17

2.4.2 STMod+ connector

UM2622

Buttons, LEDs and connectors

Figure 19. STMod+ connector top views

Daughterboard Host board

Male connector Female connector

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

PCB

Edge

Border

PCB

Edge

Border

7.62 mm2.77 mm

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Table 2. STMod+ connector pin assignments and descriptions

STMod+ Pin number

1

SPIx_NSS

2

SPIx_MOSIp

3

SPIx_MISOp

Function

(2)

4 SPIx_SCK / UARTy_RTS Output / Output Output / Output

5 GND Ground Reference Ground reference

6

+5 V Power Supply

7 I2Cz_SCL Input / Output Input / Output

8

SPIx_MOSIs

9

SPIx_MISOs

10 I2Cz_SDA Input / Output Input / Output

(6)

11

INT

Input

12 RESET Output Output

13 ADC Input Input

14 PWM Output Output

15

+5 V Power Supply

16 GND Ground Reference Ground reference

GPIO

GPIO

GPIO

GPIO

(7)

(7)

(7)

(7)

17

18

19

1.

If two functions are provided on a STMod+ connector pin, you can connect two different I/O ports from STM32: the firmware

20

manages the conflicts that may arise. MOSIs means used in Serial Daisy Chained-SPI mode and MOSIp means used in

Parallel SPI mode. More alternate functions may be available from STM32, refer to the User manual of the host board and

the corresponding STM32 datasheet available on www.st.com.

2. Instead of SPIx_NSS, a GPIO can be used as SPI Chip Select.

3. Pins 2 and 8 are the same SPIx_MOSI signals, but they must come from two different I/O ports.

(1)

Ty_CTS

/ UAR

(3)

Ty_TX Output / Output

/ UAR

(4)

Ty_RX Input / Input

/ UAR

(5)

(3)

Output

(4)

Input / Output

(5)

of the primary host mapped

Description

Output / Input

Output / Output

Input / Input

Power supply

Output

Input / Output

Input

Power supply

Output / Input

Output / Input

Output / Input

Output / Input

UM2622 - Rev 6

page 17/43

Page 18

4. Pins 3 and 9 are the same SPIx_MISO signals, but they must come from two different I/O ports.

b6 b1

a6 a1

b6b1

a6a1

5.

Power Supply is Output or Input, depending on host / daughterboard configuration.

6. INT is an interrupt line.

7. GPIO ports with many alternate functions (like UART, I²C, SPI and analog inputs/outputs) are privileged to offer optimum

flexibility.

RELATED LINKS

Read TN1238: STMod+ interface specification available on the ST website for more information

2.4.3 Connectivity expansion connector

Figure 20. CN3 connectivity connector top view

UM2622

Buttons, LEDs and connectors

This connector is suitable for the STEVAL-STWINWFV1 Wi-Fi expansion board.

Pin Description STM32 pin Pin Default Signal STM32 pin

a1 GND - b1 WIFI_DRDY PE11

a2 CS/USART3_CTS PB13 b2 WIFI_WAKEUP PD7

a3 SPI1_CLK/USART3_RTS PB1 b3 WIFI_BOOT0 PF12

a4 SPI1_MISO/USART3_RX PD9 b4 WIFI_RST PC6

a5 SPI1_MOSI/USART3_TX PD8 b5 I2C3_SDA PG8

a6 3V3 Output (VDD_WIFI) - b6 I2C3_SCL PG9

2.4.4 Sensor expansion connector

Table 3. CN3 pin descriptions

Figure 21. CN4 sensor connector top view

This connector is suitable for the STEV

UM2622 - Rev 6

AL-STWINMAV1 analog microphone expansion board.

page 18/43

Page 19

Pin Description STM32 pin Pin Default Signal STM32 pin

a1 5V/Batt Output - b1 DFSDM1_D7 PB10

a2 3V3 Output - b2 DFSDM1_CKOUT PE9

a3 SAI1_FS_A - DFSDM_D3 PE4 b3 I2C2_SCL PF1

a4 GND - b4 I2C2_SDA PF0

a5 SAI1_SD_A/ SAI1_SD_B/DFSDM_D2 PE6 b5 SAI1_SCK_A PE5

a6 GND - b6 SAI1_MCLK_A/DFSDM_D5 PE2

2.5 Protective plastic box

The plastic case is designed to protect and hold the STWIN core system board and the LiPo battery together.

The case can also house two magnets (not included in the STEV

wireless industrial node on appropriate metallic areas in the monitored equipment.

RELATED LINKS

The system was tested with the following 25x8x3mm magnets

UM2622

Protective plastic box

Table 4. CN4 pin descriptions

AL-STWINKT1 kit), allowing you to stick the

2.6 STLINK-V3MINI debugger and programmer for STM32

The STLINK-V3MINI is a standalone debugging and programming mini probe for STM32 microcontrollers, with

AG/SWD interfaces for communication with any STM32 microcontroller located on an application board.

JT

It provides a Virtual COM port interface for host PCs to communication with target MCUs via UART.

The STLINK-V3MINI is supplied with an STDC14 to STDC14 flat cable.

Figure 22. STLINK-V3MINI and STDC14 cable

UM2622 - Rev 6

page 19/43

Page 20

3 How to program the board

3.1 How to program STWIN with STLINK-V3MINI

Follow the procedure below to program the STWIN core system board.

Step 1. Connect the STWIN core system board to the STLINK-V3MINI programmer using the 14-pin flat cable.

The programmer and the cable are included in the STEV

Step 2. Connect both the boards to a PC using micro USB cables.

Figure 23. STLINK-V3MINI connected to STWIN core system board

UM2622

How to program the board

AL-STWINKT1 hardware kit.

Step 3. Download the firmware onto the core system board; you can either:

–

download one of the sample application binaries provided using STM32CubeProgrammer or ST-

LINK Utility

– recompile one of the projects with your preferred IDE (EWARM, Keil, STM32CubeIDE)

3.2 How to program STWIN without STLINK-V3MINI using STM32CubeProgrammer

"USB mode"

The STEV

To enter "Firmware upgrade" mode you must follow the procedure below:

Step 1. Unplug the STWIN core system board.

Step 2. Press the USR button.

Step 3. While keeping the button pressed, connect the USB cable to the PC.

AL-STWINKT1 can also be reprogrammed via USB using the STM32CubeProgrammer "USB mode".

Now the board is in DFU mode.

UM2622 - Rev 6

page 20/43

Page 21

UM2622

How to program STWIN without STLINK-V3MINI using STM32CubeProgrammer "USB mode"

Step 4. Y

ou can upgrade the firmware by following the steps below:

Step 4a. Open STM32CubeProgrammer.

Step 4b. Select [USB] on the top-right corner.

Figure 24. STM32CubeProgrammer - USB mode selection

Step 4c. Click on

[Connect].

UM2622 - Rev 6

page 21/43

Page 22

UM2622

How to program STWIN without STLINK-V3MINI using STM32CubeProgrammer "USB mode"

Figure 25. STM32CubeProgrammer - connection

Step 4d. Go to the [Erasing & Programming] tab.

Step 4e. Search for the new .bin or .hex binary file to be flashed into the board.

Step 4f. Click on

[Start Programming].

Figure 26. STM32CubeProgrammer - programming

UM2622 - Rev 6

page 22/43

Page 23

4 STWIN assembly steps

To assemble your SensorTile Wireless Industrial Node, you need the following components:

•

STWIN core system board

• 4x M3 bolts and nuts

• Plastic box (2 parts)

• Battery

• 2x Magnets (optional - not included in the kit):

– RS Stock No. 177-4040 Brand Eclipse Mfr Part No.N859

Figure 27. Exploded cad drawing of STWIN node components

UM2622

STWIN assembly steps

UM2622 - Rev 6

page 23/43

Page 24

STWIN assembly steps

Step 1. (Optional) Insert the magnets in the rectangular recesses in the bottom of the main case.

Figure 28. Optional magnets inserted in main case

UM2622

Step 2. Slide the U-shaped bracket into the main case.

This will secure the magnets if they are present.

Step 3. Insert the STWIN core system board with the correct orientation.

Figure 29. Core system board inserted in main case

UM2622 - Rev 6

page 24/43

Page 25

STWIN assembly steps

Step 4. Fasten the core system board to the case using the nuts and bolts provided with the kit.

Figure 30. Core system board fastened with bolts

UM2622

UM2622 - Rev 6

page 25/43

Page 26

UM2622

How to run the default Predictive_Maintenance_BLE application

5 How to run the default Predictive_Maintenance_BLE application

The Predictive_Maintenance_BLE application is part of the FP-IND-PREDMNT1 STM32Cube function pack.

It allows developing a sensor node for condition monitoring and predictive maintenance applications, featuring

digital or analog microphone, environmental and motion sensors, and performing real-time monitoring of

parameters and equipment status via BLE connectivity

It also shows an example of the signal processing (MotionSP) middleware for vibration analysis in time domain

(speed RMS and acceleration peak) and frequency domain (FFT with programmable size, averaging, overlapping

and windowing).

Predictive_Maintenance_BLE is compatible with STBLESensor application for Android/iOS.

The software gathers the temperature, humidity, pressure, audio, motion sensor drivers for the HTS221,

LPS22HH, MP23ABS1, IIS3DWB, ISM330DHCX devices.

When you first press the reset button, the Predictive_Maintenance_BLE application:

• checks whether all the sensors are present and working

• reads the Meta Data Manager

• initializes the connectivity and creates a random BLE MAC address

• initializes the BLE hardware service (adding the temperature, humidity, pressure, 3Dgyroscope, 3D

magnetometer, 3D accelerometer and microphone characteristics) and the BLE software service

• initializes the BLE console service adding the stdin/stdout and stderr characteristics

• shows the vibration parameter values present in the Flash memory and sets the accelerometer parameters

For control and debugging, you can link the STWN core system to the PC through a USB cable and set a terminal

window up for the appropriate UART communication port, used to control the initialization and the execution

phases, setting the parameteres as follows: 8N1, 115200 bauds, no hardware flow control, line endings LF or CRLF (Transmit) and LF (receive).

When an Android/iOS device is connected to the STWIN Core System board, you can control data transmitted

through the board.

.

UM2622 - Rev 6

page 26/43

Page 27

D4

D0

SB12 0R

C26

4.7uF

5

B2

C1

NC

DCDC_1

BUTTON_PWR

SW2_OA

D5

J5

CON2

DCDC_1

BAT_NTC

E2

SB22 NC

3V3_Ext

5

R18

56K

3

GND

OTG_FS_DP

VBUS

D2

1

2

R13 NC (10k )

SW

R12

100k

F4

D3

SYS

D2

5

E4

GND

V_USB

1

E3

SW_SEL

F5

1

U16

ST1PS01EJR

GND

V_USB

2

1

nRESET

C22

22uF

EXT 5V

3.3V DC-DC

2.7V Analog LDO

SYS

2V 7A

EN

A4

E1

1

ISET

DCDC_1

1

CEN

BAT2

R17

2k

D1

B5

B3

C21 10uF

BATSNS

OUT

5V

TP2

TH

E3

R20 100k

VOUT

D1

ESDALC6V1-1U2

TP3

TH

B4

SW1_I

VBat

C2

D2

4

R19 0R

3V3_LDO

C18

22uF

PGOOD

AGND

C20 1uF

2

A1

PWR

C23

10uF

A2

A1

A1

RESET_NOW

VBat

6

IN

D1

D0

A3

L2 2.2uH

C12

1uF

USBLC6-2P6

L1 2.2uH

USB

C15

1uF

5V

2

SW2_I

VBat

DCDC_1

C1

1

1

SW1_OA

C24

10uF

C_EN

GND

100mA

NC2

2

Battery management

1

OTG_FS_DM

CHG

GND

BAT_NTC

TP7

R15 1M

DCDC_1

A3

BATMS

C27

100nF

D1

SYS

1

D1

SW1_OB

E3

3

3

IN1

SB23 0R

B2

SYS1

EN

NTC

R11 20K

R21 0R

U10 LDK130PU-R

WAKEUP

C5

4

U14

ST1PS01EJR

B1

R14 100k

D4

2

uC_ADC_BATT

SW2_OB

2

E1

C3

LED_C

Red

3

VIN

BATT

Battery Connector

F2

DCDC_1

BATSNSFV

U15

STBC02AJR

3V3 400mA

3V3 400mA.

Battery monitor

(4.2V -> 3V)

SH2

DCDC_2_EN

R10 47.5K

CHRG

C3

TP1

TH

NC

3V3_SD_485

R22

2k

F1

C3

DCDC_1

IPRE

1

A3

1

R23

100K

V_USB

DCDC_2

4

LDO

2

D4

C25 10uF

6

BUTTON_PWR

VBat

EN

A5

SH1

2

RST_PENDING

BATMS

SW

J4

STRIP254P-M-2

F3

SB17 NC

C4

DCDC_2

SW_SEL

PGOOD

SW_SEL

SYS2

C1

PGOOD

VOUT

D2

2

E1

VIN

D3

1

3V3 150mA

BATMS

ADJ

E5

R16

20K

4

B2

IN2

BAT1

3

U18

USB-MICRO

10mA

UM2622 - Rev 6

6 Schematic diagrams

page 27/43

AL-STWINKT1 schematic - power

Figure 31. STEV

Schematic diagrams

UM2622

Page 28

NC

10

STMOD4

SPI2_MISO_p2

3

4S1

3-4SEL

40

8

16

DSI_D1_N

20

18

21

EX_RESET

7

7

PC5/WKUP5

13

2

12

19

PG10

PB14

3-4SEL

15

17

EX_PWM

SYS

PG10

17

3V3_Ext

10

PG12

USART3_RTS

10

3

DSI_CLK_N

D3

PG9

18

1

PB11

16

29

VEXT

26

SPI2_MOSI

15

PA9

PB9

USART3_CTS

9

20

C60

100nF

31

STMOD2

I2C4_SCL

4

CN1

FH34SRJ-40S-0.5SH(99)

1-2SEL

13

PA0

3

PG9

DSI_D0_P

25

3

DSI_D1_P

USART3_CTS

1S1

12

STMOD2

5

30

8

U17

STG3692

19

1

I2C4_SDA

GND

VEXT

32

SPI2_MISO

SYS

STMOD2

14

1-2SEL

4S2

14

SPI2_CLK

STMOD4

7

USART1

WKUP5

TIM, DSFDMCLK

TIM

TAMP, WKUP

DSI_TE,TIM,LPUART_TX

DCDC_1

4

11

2S1

VCC

I2C4_SDA

2

33

2

EX_PWM

17

4

11

27

STMOD3

DSI_D0_N

1

STMOD3

9

PA1

SPI2_MISO_p2

35

38

2S2

6

14

I2C4_SCL

34

PC5/WKUP5

5V

24

STMod+ interface

PE9

6

SPI2_MOSI_p2

PB8

9

2

28

PG12

1

EX_RESET

36

D2

1S2

13

PB14

16

J3

CN2

PA10

6

39

VEXT

3S1

23

5

PC13

3S2

STMOD4

D1

USART3_RX

5

STMOD3

37

SPI2_MOSI_p2

EX_ADC

15

EX_ADC

SAI2

CAN, TIM, DSFDM,I2C1

TIM,DSFDMD2

TIM

ADC_IN5

ADC_IN6

EX_CN

USART3_TX

22

11

8

DSI_CLK_P

DCDC_1

12

D4

UM2622 - Rev 6

Figure 32. STEV

AL-STWINKT1 schematic - connectors

page 28/43

Schematic diagrams

UM2622

Page 29

INT2_DH

I2C2_SDA

CS

VDD

SCL/SPC

C13

100nF

INT1

3V3_Sensors

4

C14

100nF

SPI3_MISO

OCS_Aux

VDD

R4

7.5k

C1

9

14

2

CS

2

SPI3_MISO

8

5

5

SDO_Aux

1

OCS_Aux

SCL

6

RES

12

C8

100nF

6

3

SDA

5

INT2_DHC

1

INT2_ADWB

TP4

U9

ISM330DHCX

SPI3_CLK

GND1

NC1

11

C58

10uF

8

GND2

SCx

3

CS

VDD

CS

13

VDD

INT

3V3_Sensors

7

I2C2_SCL

C31

100nF

5

4

10

4

SDO/SA0

I2C2_SCL

GND

INT1

GND

5

U6

SDO/SA0

U2HTS221

INT2

SPI3_MOSI

9

C56

100nF

3

9

I2C2_SCL

3

12

3V3_Sensors

4

C17

100nF

I2C2_SDA

SCL

3

3V3_Sensors

8

3V3_Sensors

SPI3_MOSI

TP6

10

C40

100nF

1

C57

100nF

SDA

U3

LPS22HH

3

6

DRDY

5

11

I2C2_SDA

3V3_Sensors

GND2

5

SCx

3V3_Sensors

2

INT1

R5

7.5k

SPI3_CLK

U12

TP8

3V3_Sensors

9

CS_DH

SPI3_MOSI

CS_ADWB

SCL

SDO/SA0

J6

Sensors and digital mic current monitoring

13

4

12

SPI3_CLK

7

VDDIO

CS

INT_DRDY

6-Axis

Acc + Gyro

Pressure

SPI3_MISO

INT1_ADWB

SDO_Aux

3V3_Sensors

2

8

6

14

SDA

3V3_Sensors

GND2

1

4

7

TP5

SDA/SDI/SDO

C11

10uF

SCL/SPC

SDO/SA0

1

9

10

SPI3_CLK

1

U11

SPI3_MOSI

1

INT_HTS

2

2

I2C2_SMBA

6

SDA/I/O

I2C2_SCL

VDD

VDDIO

3V3_Sensors

VDDIO

SDA/I/O

12

I2C2_SDA

3V3_Sensors

CS

7

6

I2C Addr: 1001000b

I2C Addr: 0011110b

I2C Addr: 1011111b

I2C Addr: 1011101b

8

3V3_Sensors

GND1

EV

11

SCL

INT_M

7

10

INT2

VDDIO

C19

0.22uF

C59

100nF

SPI3_MISO

3V3_Sensors

10

GND

GND3

NC2

Therm

2

INT2

3V3_Sensors

3V3_Sensors

1

SDA

Magnetometer

Vibrometer

Humidity & Temperature

U13IIS2MDC

3V3_Sensors

GND1

VDD

NC3

3V3_Sensors

2

C37

4.7uF

C16

100nF

3

VDD

INT1_DHC

6

I2C2_SCL

INT_STT

CS_DHC

DCDC_1

SDx

SCL

4

GND2

I2C2_SDA

SDx

TP9

VDD_IO

GND

RES

3V3_Sensors

11

GND2

Accelerometer

Temperature

IIS3DWB

STTS751

IIS2DH

UM2622 - Rev 6

Figure 33. STEV

AL-STWINKT1 schematic - sensors

page 29/43

Schematic diagrams

UM2622

Page 30

U4

X1

16MHz

STM32L4R9ZIJ6

CS_WIFI

I2C3_SDA

2

F10

J1

G5

M6

SAI1_MCLK_A

PF12

PB1

C6

VDDUSB

A9

C11

R3

4.7k

PH1-OSC_OUT

INT1_DHC

H9

G3

PGOOD

WIFI_BOOT0

L6

PD15

SWDIO

R34

1k

G7

D2

ESDALC6V1-1U2

RESET

PF0

BOOT0-PE0

E9

PA0

PB10

F7

K8

PC0

C1

VDD_uC

VSS4

SPI1_MOSI

1

J9

PB11

B2

K9

LED2

SDMMC_D3

10

2

PA10

C49

6.8pF

OSC32_OUT

PA9

PG5

PF2

PG9

INT1_ADWB

E11

PG10

PG7

C45

100nF

LED2

Orange

R2

4.7k

INT_M

Differential pairs

100 OHM

R32

4.7k

D3

ESDALC6V1-1U2

LED2

SPI3_MISO

B1

EX_PWM

PA10

I2C2_SMBA

VBATVSSDSI

CHRG

R33

4.7k

INT_STT

CS_ADWB

D4

VDDA

C5

5.6pF

PC14-OSC32_IN

D1

H6

PF15

SPI2_MISO

WIFI_DRDY

B8

PD12

I2C4_SDA

PF7

PA15

SDMMC_D1

H10

L2

PD3

PA1

PE2

A8

C3

VDD_uC

PD7

PB9

PD9

7

PC13

VDD5

J2

PE11

PC1

L11

USART2_TX

BOOT0-PE0

PC9

PA14/SWCLK

C12

PD8

SPI2_MOSI_p2

H7B12

PB8

PE3

M10

PA5

L4

C48

1uF

RESET

OSC32_OUT

STSAFE_RESET

VDD1

C35

100nF

PB14

R35

560R

PC2

PD14

I2C4_SCL

DSI_D0_P

G12

VDD4

PF5

1

2

USART3_RTS

DAC1_OUT1

DFSDM1_CKOUT

5

H12

PD0

M3

E2

PE15

PF1

PF14

PC11

PE5

PG10

E3

C41

4.7uF

SWDCLK

PD6

INT2_ADWB

G8

PA0/WKUP1

PF6

USART2_TX

SDMMC_D0

K3

PA8

F11

D11

VSS5

E12

NRST

H3

4

PB5

PB3

PC4

G4

4

L5

VDD2

PB12

A10

USART2_RX

PG3

PA6

K10

OSC_IN

11

C39

100nF

J12

PB14

VREF+

C10

D12

PC6

OSC32_IN

PA11

INT2_DHC

E1

A6

M8

VDDIO2_1

PG1

USART3_TX

4

A11

VSS3

INT2_DH

DSI_CLK_N

K12

PG6

PE7

G6

E4

DFSDM1_D7

F9

3

1

SAI1_SD_B

BUTTON_PWR

M7

WIFI_WAKEUP

1

PE14

SDMMC_CK

G9

C7

SAI1_SD_A

PD4

PE8

CS_DH

PB2

2V7A

H5

DSIHOST_D0P

SPI1_CLK

PG2

PE4

D3

J10

SD_DETECT

PC8

PD1

PC10

B7

E10

I2C4_SCL

8

BOOT0-PE0

D8

SPI3_MOSI

D5

B3

I2C2_SCL

SWDCLK

PE13

PF9

OSC32_IN

K5

K1

J4

12

A7

H4

BLE_RST

USART3_RX

B10

VDD6

D6

F4

VDD_uC

PG12

1

INT_HTS

DSIHOST_D1P

RTC_TAMP1

H11

PA3

SAI1_FS_A/DFSDM_D3

B9

J6

C2

C9

uC_ADC_BATT

PG8

DSI_D1_N

SPI2_CLK

PB6

VSS6

G11

2

G2

ADC1_IN2

PA4

VSS9

J7

STM32 Current monitoring

PA1

M4

K4

A5

B4

F12

PB4

SPI1_MISO

2

VDD_uC

PE12

R1

10k

C4

PD10

PC3

H8

14

OSC_OUT

PB15

6

9

A12

PE10

PG0

M5

D7

PF3

VDDIO2_2

H1

I2C2_SDA

E5

PH0-OSC_IN

1

OSC_OUT

I2C3_SCL

PC5/WKUP5

USART3_CTS

PH3-BOOT0

A4

L12

I2C2_SDA

L10

PF10

I2C4_SDA

C38

100nF

C1

100nF

DSIHOST_D0N

PA13/SWDIO

EX_ADC

PC13/WKUP2

3-4SEL

1

C6

5.6pF

SPI2_MOSI

EX_RESET

BLE_SPI_CS

DSI_D0_N

PD13

DSIHOST_D1N

DSIHOST_CKP

H2

G10

SDMMC_D2

3

PF13

K7

PG13

OTG_FS_DM

K11

K2

2V7A

PC12

PE12

D9

J11

BLE_TEST9

PG12

C50

100nF

E8

LED1

D10

A1

PB0

VSS1

USART2_RTS

2

C46

10nF

L9

PB7

PC7

PD2

B6

VDD_uC

C43

6.8pF

RESET

J8

PF8

VDD3

F1

G1

PC5/WKUP5

C42

100nF

C32

100nF

SW_SEL

PA9

A2

1

13

PE0

D2

VSS2

PC15-OSC32_OUT

DCDC_2_EN

C_EN

M1

F2

2

E6

2

2

VDD_uC

PB11

AGND

EXTI_LINES

EXTI0 --> USR Button

EXTI1 --> BLE

EXTI2 --> INT2_DH or INT2_ADWB

EXTI3 --> BLE_TEST9

EXTI4 --> INT2_DHC

EXTI5 --> WKUP_INT

EXTI6 --> HTS

EXTI7 --> PGOOD

EXTI8 --> INT1_DLC

EXTI9 --> Mag

EXTI10 --> PWR_BTN

EXTI11 --> WiFi

EXTI12 --> EX_CN

EXTI13 --> TAMP,WKUP Ext

EXTI14 --> INT1_ADWB

EXTI15 --> INT_STT

USR/BOOT

VCAPDSI

BLE_TEST8

ADC1_IN1

PB8

RESET

1-2SEL

VDD7

PG4

K6

DSI_CLK_P

PF11

VDD_uC

PE6/WKUP3

F5

PG9

VSS8

1

USART2_RX

PA2/WKUP4

B5

CHRG

LED1

Green

SDMMC_CMD

J7

M12

PA7

J2

STDC14

PE9

M9

SAI1_SCK_A

DSIHOST_CKN

A3

PB9

M2

DCDC_1

3

WIFI_RST

E7

J3

C8

PE1

OTG_FS_DP

LED1

C34

100nF

L3

X2

32.7680KHZ

SP1

L8

PD11

VSS7

C5

SPI3_CLK

PD5

OSC_IN

F6

B11

M11

I2C2_SCL

PF4

CS_DHC

PE9

Close to

VREF/VDDA

Close to VDD/VDDIO2

Close to

VDDUSB

SWDIO

BLE_INT

C44

100nF

PA12

J5

L7

PB13

DSI_D1_P

C7

2.2uF

VSSA/VREF-

C36

1uF

L1

F3

USR

3

4

DFSDM1_DATIN5

C47

100nF

SPI2_MISO_p2

F8

UM2622 - Rev 6

Figure 34. STEV

AL-STWINKT1 schematic - MCU

page 30/43

Schematic diagrams

UM2622

Page 31

AudioCoupon Connector

HP Filter --> fc = 15.9 Hz

LP Filter --> fc = 99.4 KHz

DAC for mic bias

DFSDM_D2

DFSDM_D5

DCDC_1

3V3_Sensors

2V7A

2V7A

2V7A

SYS

DFSDM1_DATIN5

DFSDM1_CKOUT

DFSDM1_CKOUT

DFSDM1_D7

SAI1_FS_A/DFSDM_D3

SAI1_MCLK_A

SAI1_SD_A SAI1_SCK_A

I2C2_SDA

I2C2_SCL

SAI1_SD_B

DAC1_OUT1

ADC1_IN2

ADC1_IN1

PE12

R74.7k

C2

100nF

C51

100nF

R8

1M

CN4

M55-6001242R

a1 b1

a2 b2

a3 b3

a4 b4

a5 b5

a6 b6

C9

10nF

U8

TS922EIJT

Vcc-

C2

+IN2

C3

OUT2

A3

-IN2

B3

Vcc+

A2

OUT1

A1

-IN1

B1

+IN1

C1

C54

10nF

C55

1uF

R28

10k

M1

DOUT

1

GND1

2

GND2

3

VDD

5

GND3

4

SB110R

C10

100nF

C52

1uF

M2

DOUT

4

LR2GND

5A

VDD

1

CLK

3

GND5BGND5DGND

5C

R6100k

R9

1M

SB10NC

R29160

C30

1uF

MREF

M1

M1P_FILT

M1P_FILT

MREF

M1P

MREF_DIV

MREF

RE

CLK_Ex

EP

11

2

10A

SDMMC_D2

CMD

USART2_RTS

3

SB25 0R

11

U1 EMIF06-MSD02N16

4

RDAT3_GND

DETGNDA

SDMMC_CMD

17

10

C29

10nF

7

DAT0_Ex

SD

Micro-SD

6

CLK_In

3V3_SD_485

SDMMC_D0

9A

SDMMC_D1

15

VCC

SDMMC_D3

VCC

1 10

C3

100nF

USART2_TX

VDD

14

GND

DAT2_Ex

1

6

DAT1

DAT2_In

3

GND

SD Card

RS485

SB24 NC

Card Removed --> CLOSE

Card Inserted --> OPEN

DETGNDB

5

9B

3

DE

B

CD/DAT3

DAT2

J1

NC

1

5

CMD_In

DAT1_Ex

6

3V3_SD_485

SD_DETECT

C28

100nF

SD_DETECT

CLK

9

4

2

DAT3_In

GND

DAT0

8

R24 62

DETCA

2

C4

10uF

5

DETCB

8

13

12

4

DAT1_In

VL

RDATA_VCC

CMD_Ex

7

16

R

U19 STR485LV

R25 62

SLR

10B

3

D

USART2_RX

DAT0_In

DAT3_Ex

1

9

WP/CD

8

A

7

SDMMC_CK

2

3V3_SD_4853V3_SD_485

IMP34DT05

MP23ABS1

UM2622 - Rev 6

Figure 35. STEV

AL-STWINKT1 schematic - audio, RS485, SD card

page 31/43

Schematic diagrams

UM2622

Page 32

SB18 0R

4.7k

SB8 0R

BLE_SPI_SCK

100nF

Wi-Fi Current monitoring

USART3_TX

BLE Current monitoring

2

SB20 0R

47k

BLE_RST

2

21

VDD_BLE

ADC IN1

DIO9/TCK/SWTCK

DCDC_2

WIFI_RST

16

a4

BLE_SPI_MISO

SB5 0R

WIFI

DIO11/UART_RXD

9

SB9 NC

VDD_BLE

SB21 0R

J10

CS_WIFI

1

4.7k

BLE_SPI_MOSI

13

SB2 NC

SPI1_MISO

5

b3

2

18

U5 SPBTLE-1S

10

7

BLE_SWDCLK

DIO8/UART_TXD

b6

WIFI_WAKEUP

I2C3_SCL

11

1

DIO0/SPI_CLK

SB7 NC

22

1

VDD_BLE

BLE_SPI_SCK

BLE_SWDIO

4

VDD_WIFI

BLE_INT

SB13 NC

WIFI_DRDY

a6

BLE_TEST9

ANATEST1

NC#22

SPI2_MISO

DIO1/SPI_CS

BLE_SPI_MISO

DIO14/ANATEST0

BLE_RST

STRIP254P-M-5-90-SMD

USART2_TX

Default OFF

8

BLE

R30

Default OFF

DCDC_2

b2

BLE_SPI_CS

3

19

b5

DIO6/UART_RTS

R26

I2C3_SDA

BLE_SPI_MOSI

Default ON

USART3_CTS

23

NC#23

DCDC_1

4

SPI1_MOSI

Male Conn

BLE_SWDIO

DIO2/SPI_MISO

a2

12

R27

6

SPI1_MOSI

15

TAMPER

SB15 NC

a5

BLE_TEST8

a1

SB4 0R

DIO3/SPI_MOSI

DIOA12

SB19 0R

BLE_SWDCLK

14

R31

20

RTC_TAMP1

SPI2_MOSI

SPI2_CLK

Default ON

b4

USART2_RX

M55-7001242R

b1

DIO7/BOOT/UART_CTS

USART3_RX

C33

I2C3_SCL

WIFI_BOOT0

17

SB3 NC

BLE_INT

4.7k

BLE_CS

SPI1_MISO

DIO5/I2C_SDA

NC#21

VDD_WIFI

BT_RESET

2

USART3_RTS

CN3

DIO4/I2C_CLK

SB16 NC

SCL

4

7

STSAFE-A110

NC#2

100nF

I2C3_SCL

2

6

VCC

5

RESET NC#3

SO8N

8

DCDC_2

3

C53

STSAFE_RESET

U7 STSAFE-A110

1

NC#1

SDAGND

I2C3_SDA

SPI1_CLK

GND

a3

BLE_CS

J9

J8

I2C3_SDA

1

SB6 0R

VBLUE

DIO10/TMS/SWTDI

5

VDD_BLE

SPI1_CLK

SB14 NC

ADC IN2

SB1 NC

3

UM2622 - Rev 6

Figure 36. STEV

AL-STWINKT1 schematic - BLE, Wi-Fi, STSAFE-A110

page 32/43

Schematic diagrams

UM2622

Page 33

7 Bill of materials

Table 5. Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

1 1 BATT

2 1 CN1 Hirose FH34SRJ-40S-0.5SH(99)

3 1 CN2 HEADER 10 Samtec SQT-110-01-F-D-RA

4 1 CN3

5 1 CN4

C1, C2, C3, C8,

C10, C13, C14,

C16, C17, C27,

C28, C31, C32,

6 30

7 7

8 2 C5, C6 5.6pF, 10V, ±1%

9 1 C7 2.2µF, 10V, ±20%

10 4 C9, C29, C46, C54 10nF, 25V, ±10%

11 8

12 2 C18, C22 22µF, 10V, ±20%

13 1 C19 0.22µF, 16V, ±10%

14 3 C26, C37, C41 4.7µF, 10V, ±20%

15 2 C43, C49 6.8pF, 10V, ±5%

16 3 D1, D2, D3

17 1 D4 1A

C33, C34, C35,

C38, C39, C40,

C42, C44, C45,

C47, C50, C51,

C53, C56, C57,

C59, C60

C4, C11, C21,

C23, C24, C25,

C58

C12, C15, C20,

C30, C36, C48,

C52, C55

100nF, 16V, ±10%

10µF, 10V, ±20%

1µF, 10V, ±10%

Battery Connector

Amass

M55 series 12 pin

connector

M55 series 12 pin

connector - Female,

1.27pitch

CAP CER X7R 0402,

0402 (1005 Metric)

CAP CER X5R 0402,

0402 (1005 Metric)

CAP CER C0G/NP0

0402, 0402 (1005

Metric)

CAP CER X5R 0402,

0402 (1005 Metric)

CAP CER X7R 0402,

0402 (1005 Metric)

CAP CER X5R 0402,

0402 (1005 Metric)

CAP CER X5R 0603,

0603 (1608 Metric)

CAP CER X7R 0402,

0402 (1005 Metric)

CAP CER X5R 0402,

0402 (1005 Metric)

CAP CER C0G/NP0

0402, 0402 (1005

Metric)

Single-line low

capacitance T

for ESD protection,

ST0201

Power Schottky

rectifier

, 1.27pitch

ransil™

, STmite

Molex 78171-0003

Harwin M55-7001242R

Harwin M55-6001242R

Murata

Electronics North

America

Samsung ElectroMechanics

America, Inc.

Yageo CC0402BRNPO9BN5R6

Wurth Electronics

Inc.

AVX Corporation 04023C103KAT2A

Taiyo Yuden JMK105BJ105KV-F

Taiyo Yuden LMK107BBJ226MA-T

Murata

Electronics North

America

Murata

Electronics North

America

Murata

Electronics North

America

ST ESDALC6V1-1U2

ST STPS120M

GRM155R71C104KA88J

CL05A106MP8NUB8

Wurth-885012105013

GRM155R71C224KA12D

GRM155R61A475MEAAD

GRM0225C1E6R8CA03L

UM2622

Bill of materials

UM2622 - Rev 6

page 33/43

Page 34

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

18 1 J1 N.M.

19 1 J2 STDC14

20 1 J3 CON5_1 V_EXT selector - -

21 1 J4 STRIP254P-M-2 - -

22 1 J5 CON2

23 1 J6

24 1 J7

25 1 J8 N.M.

26 1 J9

27 1 J10

28 1 LED_C Red LED, LED_0402

29 1 LED1 Green LED, LED_0402

30 1 LED2 Orange LED, LED_0402

31 2 L1, L2 2.2uH, ±20% Inductor, 2520 Wurth Wurth-74438323022

32 1 M1 1.3A MEMS audio sensor ST MP23ABS1TR

33 1 M2 MEMS audio sensor ST IMP34DT05

34 2 USR, PWR

35 1 RESET

36 1 R1

37 8

38 2 R4, R5

39 4 R6, R12, R14, R20

40 3 R8, R9, R15

41 1 R10

42 2 R11, R16

R2, R3, R7, R26,

R30, R31, R32,

R33

0 OHM 1206 or

2.54 Jumper

0 OHM 1206 or

2.54 Jumper

0 OHM 1206 or

2.54 Jumper

0 OHM 1206 or

2.54 Jumper

4.2x3.2x2.5mm,

white

4.2x3.2x2.5mm,

black

10k, 100ppm/C,

1/16W

, ±1%

4.7k, 100ppm/C,

1/16W

, ±1%

7.5k, 100ppm/C,

1/16W

, ±5%

100k, 100ppm/C,

1/16W

, ±1%

1M, 100ppm/C,

±1%

47.5K, 100ppm/C,

1/16W

, ±1%

20K, 100ppm/C,

1/16W

, ±1%

Stripline for RS485 (not

mounted)

STDC14 - ARM MIPI10

compatible

Morsettiera a 2 vie,

passo 2.54mm

Sensors and digital mic

current monitoring:

RES SMD

STM32 Current

monitoring: RES SMD

STRIP254P-M-5-90SMD (not mounted)

BLE Current

monitoring: RES SMD

Wi-Fi Current

monitoring: RES SMD

SW PUSHBUTTONSPST

-2

SW PUSHBUTTONSPST

-2

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

- -

Samtec FTSH-107-01-L-DV-K

- -

Yageo AF1206JR-070RL

Yageo AF1206JR-070RL

- -

Yageo AF1206JR-070RL

Yageo AF1206JR-070RL

Vishay

Semiconductor

Opto Division

Panasonic

Electronic

Components

Panasonic

Electronic

Components

ALPS SKRPABE010

ALPS SKRPADE010

Yageo RC0402FR-0710KL

TE Connectivity

Passive Product

Yageo RC0402JR-077K5L

TE Connectivity

Passive Product

TE

CONNECTIVITY

Yageo RC0402FR-0747K5L

Yageo RC0402FR-0720KL

VLMS1500-GS08

LNJ347W83RA

LNJ847W86RA

CRG0402F4K7

CRG0402F100K

CRG0402F1M0

UM2622

UM2622 - Rev 6

page 34/43

Page 35

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

43 1 R13 10k N.M., ±1%

44 2 R17, R22

45 1 R18

46 2 R19, R21 0R

47 1 R23

48 2 R24, R25

49 1 R27

50 1 R28

51 1 R29

52 1 R34

53 1 R35

SB1, SB2, SB3,

54 13

55 12

56 1 SD Micro-SD Wurth Electronics 693071010811

57 1 SP1 N.M. (not mounted) - -

58 7

59 1 TP1

60 2 TP2, TP3 N.M.

61 1 USB

62 1 U1

63 1 U2

SB7, SB9, SB10,

SB13, SB14,

SB15, SB16,

SB17, SB22, SB24

SB4, SB5, SB6,

SB8, SB1

SB18, SB19,

SB20, SB21,

SB23, SB25

TP4, TP5, TP6,

TP7, TP8, TP9,

T

AMPER

1, SB12,

2k, 100ppm/C,

±1%

56K, 100ppm/C,

±1%

100K, 100ppm/C,

±1%

62, 100ppm/C,

1/16W

, ±1%

47k, 100ppm/C,

1/16W

, ±1%

10k, 100ppm/C,

1/16W

, ±1%

160, 100ppm/C,

1/16W

, ±1%

1k, 100ppm/C,

1/16W

, ±1%

560R, 100ppm/C,

1/16W

, ±1%

0 OHM N.M.

0R

1mm N.M.

RES, SMD, 0402 (not

mounted), 0402 (1005

Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402, 0402

(1005 Metric)

RES SMD 0402 (not

mounted), 0402 (1005

Metric)

RES SMD 0402, 0402

(1005 Metric)

TEST POINT 1MM

SMD PADSTASCK (not

mounted)

Test Point Through

Hole

Test Point Through

Hole (not mounted)

USB Micro-B, USBMicro-B

6-line IPAD™, EMI

filter and ESD

protection

Humidity, Temperature,

HLGA-6L(2 x 2 x 0.9

mm)

TE

CONNECTIVITY

Yageo RT0402FRE072KL

Yageo RC0402FR-0756KL

Vishay Dale CRCW04020000Z0ED

Yageo RC0402FR-07100KL

Yageo RC0402FR-0762RL

Samsung ElectroMechanics

America, Inc.

Yageo RC0402FR-0710KL

TE Connectivity

Passive Product

Yageo RC0402FR-071KL

Yageo RC0402FR-07560RL

Vishay Dale CRCW04020000Z0ED

Vishay Dale CRCW04020000Z0ED

- -

Keystone

Electronics

- -

GCT USB3075-30-A

ST EMIF06-MSD02N16

ST HTS221TR

CRG0402F10K

RC1005F473CS

CRG0402F160R

5001

UM2622

UM2622 - Rev 6

page 35/43

Page 36

UM2622

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

MEMS NANO

64 1 U3

65 1 U4

66 1 U5 ST BlueNRG-1 module ST SPBTLE-1S

67 1 U6

68 1 U7 N.M.

69 1 U8

70 1 U9

71 1 U10

72 1 U11

73 1 U12

74 1 U13

75 2 U14, U16

76 1 U15

77 1 U17

78 1 U18 USB Protection ST USBLC6-2P6

79 1 U19

80 1 X1 16MHz 16.00MHz Crystal 8pF NDK NX3225GA-16MHZ-STD-CRG-1

81 1 X2 32.7680KHZ

82 1

83 1

84 1

85 1

STEVALSTWINKT1

STEVALSTWINKT1

STEVALSTWINKT1

STEVALSTWINKT1

480mAh Battery LiPo Himax LiPo-752535

PRESSURE SENSOR:

260-1, (2 x 2 x 0.73

mm)

STM32L496,

UFBGA144

Digital temperature

sensor

, UDFN-6L

Secure element (not

mounted), SO8N

OpAmp - excellent

audio performance /

low distortion (0.005%)

3D accelerometer and

3D gyroscope,

LGA-14L (2.5 x 3 x

0.83 mm)

300 mAvery low noise

LDO, DFN6

Accelerometor Ultra

Wide Bandwidth,

LGA-14L (2.5 x 3 x

0.83 mm)

Accelerometor Ultralow-power

(2.0x2.0x1 mm)

MEMS Magnetometer,

(2.0x2.0x0.7)

400mA step-down

switching regulator

Flip-chip

Li-Ion Linear Battery

Charger with LDO

3.3V

(2.59x2.25 mm)

Low voltage high

bandwidth quad SPDT

switch

Low power transceiver

for RS-485, DFN10

CRYSTAL 32.7680KHz

6PF SMD

STLINK-V3MINI ST STLINK-V3MINI

Programming Cable

(Included in ST

Plastic Box - -

, LGA-12

, Flip Chip30

-LINK)

ST LPS22HHTR

ST STM32L4R9ZIJ6

ST STTS751-0DP3F

ST STSAFE-A110

ST TS922EIJT

ST ISM330DHCX

ST LDK130PU-R

ST IIS3DWB

ST IIS2DHTR

ST IIS2MDCTR

,

ST ST1PS01EJR

ST STBC02AJR

ST STG3692

ST STR485LV

NDK

- -

NX3215SA-32.768K-STDMUA-14

UM2622 - Rev 6

page 36/43

Page 37

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

86 4

87 4

STEVALSTWINKT1

STEVALSTWINKT1

12mm M3

M3 HEX Nut - steel - -

Pan head phillips steel

- -

UM2622

UM2622 - Rev 6

page 37/43

Page 38

Revision history

Date Version Changes

11-Sep-2019 1 Initial release.

04-Feb-2020 2

04-Jun-2020 3

07-Sep-2020 4

28-Sep-2020 5 Updated Section 2.3 Power management and Section 2.3.2 Power Supply.

13-Nov-2020 6

UM2622

Table 6. Document revision history

Updated Section 2.1 Sensing and Section 2.1.6 IIS3DWB ultra-wide bandwidth (up to 6 kHz),

lownoise, 3-axis digital vibration sensor

Added Section 4 How to run the default Predictive_Maintenance_BLE application.

Updated Figure 1. STEVAL-STWINKT1 SensorTile Wireless Industrial Node, Section 2.2.5 STSAFEA110 (footprint only) authentication, state-of-the-art security for peripherals and IoT devices, Section

5 Schematic diagrams and Section 6 Bill of materials.

Updated Section 2.3.2 Power Supply.

Added Section 3.1 How to program STWIN with STLINK-V3MINI and Section 3.2 How to program

STWIN without STLINK-V3MINI using STM32CubeProgrammer "USB mode".

Updated Section 2.2 Processing and connectivity and Section 2.2.2 SPBTLE-1S application

module for Bluetooth v4.2.

Added Section 2.2.3 STEV

SensorTile wireless industrial node (STWIN) kit.

AL-STWINWFV1 Wi-Fi expansion (not included in the kit) for the

.

UM2622 - Rev 6

page 38/43

Page 39

UM2622

Contents

Contents

1 STWIN kit components ............................................................2

2 Functional blocks..................................................................4

2.1 Sensing ......................................................................4

2.1.1 HTS221 humidity and temperature sensor .....................................5

2.1.2 LPS22HH MEMS pressure sensor ...........................................5

2.1.3 STTS751 digital temperature sensor..........................................6

2.1.4 TS922 rail-to-rail, high output current, dual operational amplifier.....................6

2.1.5 ISM330DHCX iNEMO IMU 3D Acc + 3D Gyro ..................................6

2.1.6 IIS3DWB ultra-wide bandwidth (up to 6 kHz), low-noise, 3-axis digital vibration sensor ...6

2.1.7 IIS2DH ultra-low power 3-axis high-performance accelerometer.....................6

2.1.8 IIS2MDC 3-axis magnetometer ..............................................7

2.1.9 MP23ABS1 analog MEMS microphone........................................7

2.1.10 IMP34DT05 digital MEMS microphone ........................................7

2.2 Processing and connectivity .....................................................7

2.2.1 STM32L4R9ZI Cortex-M4F 120MHz 640Kb RAM................................9

2.2.2 SPBTLE-1S application module for Bluetooth v4.2 ..............................10

2.2.3 STEV

2.2.4 STR485LV 3.3V RS485 up to 20Mbps .......................................10

2.2.5 USB connector .........................................................11

2.2.6 STSAFE-A110 (footprint only) authentication, state-of-the-art security for peripherals and

2.2.7 microSD card socket ..................................................... 11

2.2.8 Clock sources ..........................................................11

AL-STWINWFV1 Wi-Fi expansion (not included in the kit) for the SensorTile wireless

industrial node (STWIN) kit ................................................10

IoT devices ............................................................11

2.3 Power management ...........................................................11

2.3.1 Battery connectors ......................................................13

2.3.2 Power supply ..........................................................13

2.3.3 Power ON/OFF procedure ................................................14

2.3.4 Power consumption evaluation .............................................14

2.4 Buttons, LEDs and connectors ..................................................15

2.4.1 Flex expansion connector .................................................15

UM2622 - Rev 6

page 39/43

Page 40

UM2622

Contents

2.4.2 STMod+ connector ......................................................17

2.4.3 Connectivity expansion connector...........................................18

2.4.4 Sensor expansion connector...............................................18

2.5 Protective plastic box ..........................................................19

2.6 STLINK-V3MINI debugger and programmer for STM32 .............................19

3 How to program the board ........................................................20

3.1 How to program STWIN with STLINK-V3MINI .....................................20

3.2 How

to program STWIN without STLINK-V3MINI using STM32CubeProgrammer "USB

mode" .......................................................................20