UM2674

User manual

How to use the 2 kW two-channel interleaved PFC based on the STNRGPF02

digital controller

Introduction

The STEVAL-IPFC02V1 2 kW interleaved PFC kit is based on the STNRGPF02 digital controller and consists of a power board,

control board and adapter board. The digital configurable ASIC can drive up to two channels in an interleaved PFC for industrial

applications.

The STNRGPF02 embedded on the control board implements mixed signal (analog/digital) average current mode control in

CCM at fixed frequency. The analog section ensures cycle-by-cycle current regulation, while digital control manages the nontime-critical operations. You can use the eDesignSuite software available on the ST website to configure the digital controller

according to specific application requirements.

Figure 1. STEVAL-IPFC02V1 evaluation kit with power, control and adapter boards

UM2674 - Rev 3 - January 2021

For further information contact your local STMicroelectronics sales office.

www.st.com

1 Safety instructions

Danger:

The evaluation board uses voltage levels that can cause serious injury and even death.

Do not touch any components immediately after disconnecting the input power supply as the

charged capacitors need time to discharge.

Due to the high power density, board components and heat sinks can become very hot and cause

severe burns when touched.

This board is intended for use by skilled technical personnel who are suitably qualified and familiar with the

installation, use and maintenance of power electronic systems. The same personnel must be aware of and must

apply national accident prevention rules.

The electrical installation shall be completed in accordance with the appropriate requirements (e.g., crosssectional areas of conductors, fusing, and GND connections).

UM2674

Safety instructions

UM2674 - Rev 3

page 2/28

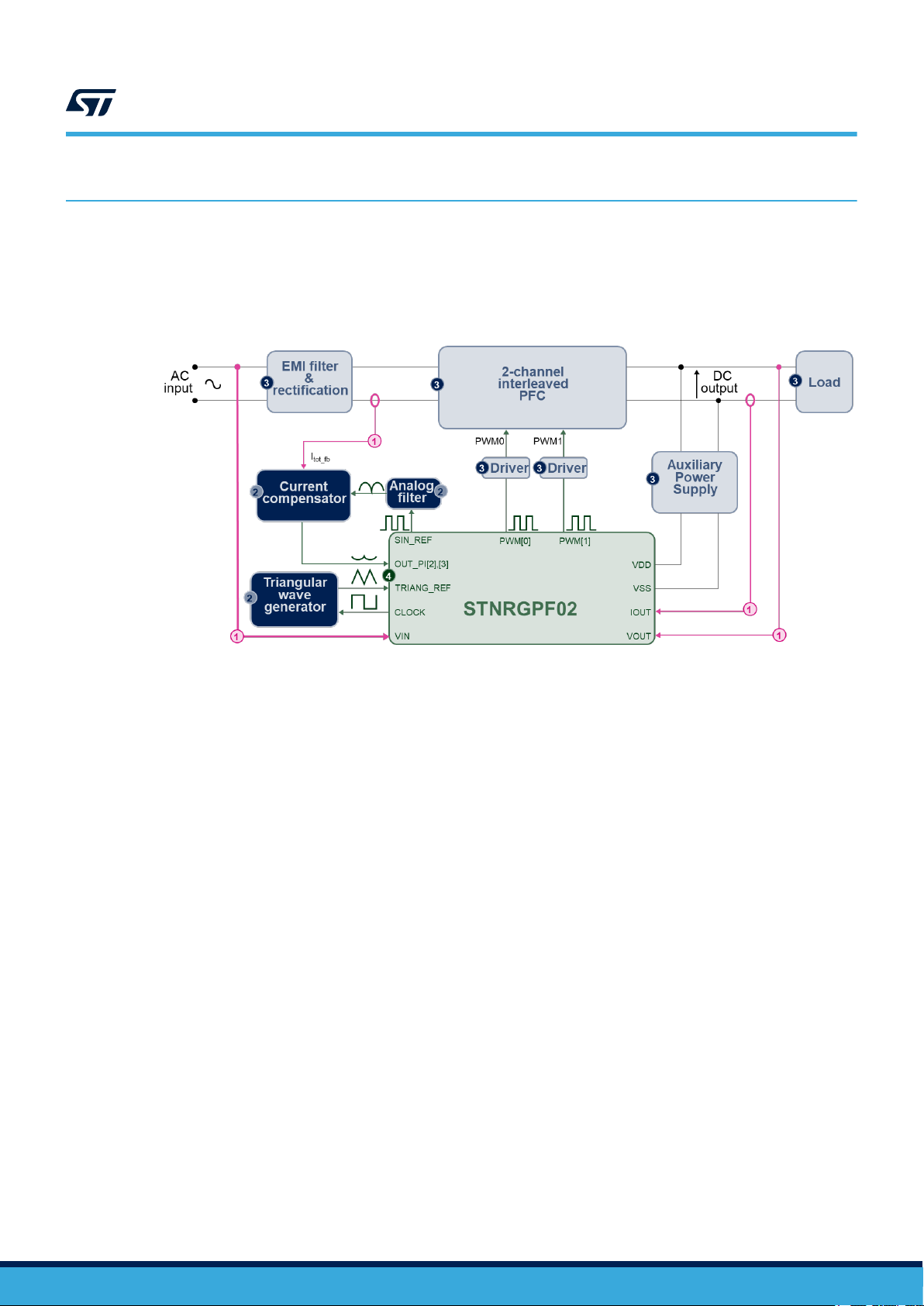

2 STEVAL-IPFC02V1 evaluation kit overview

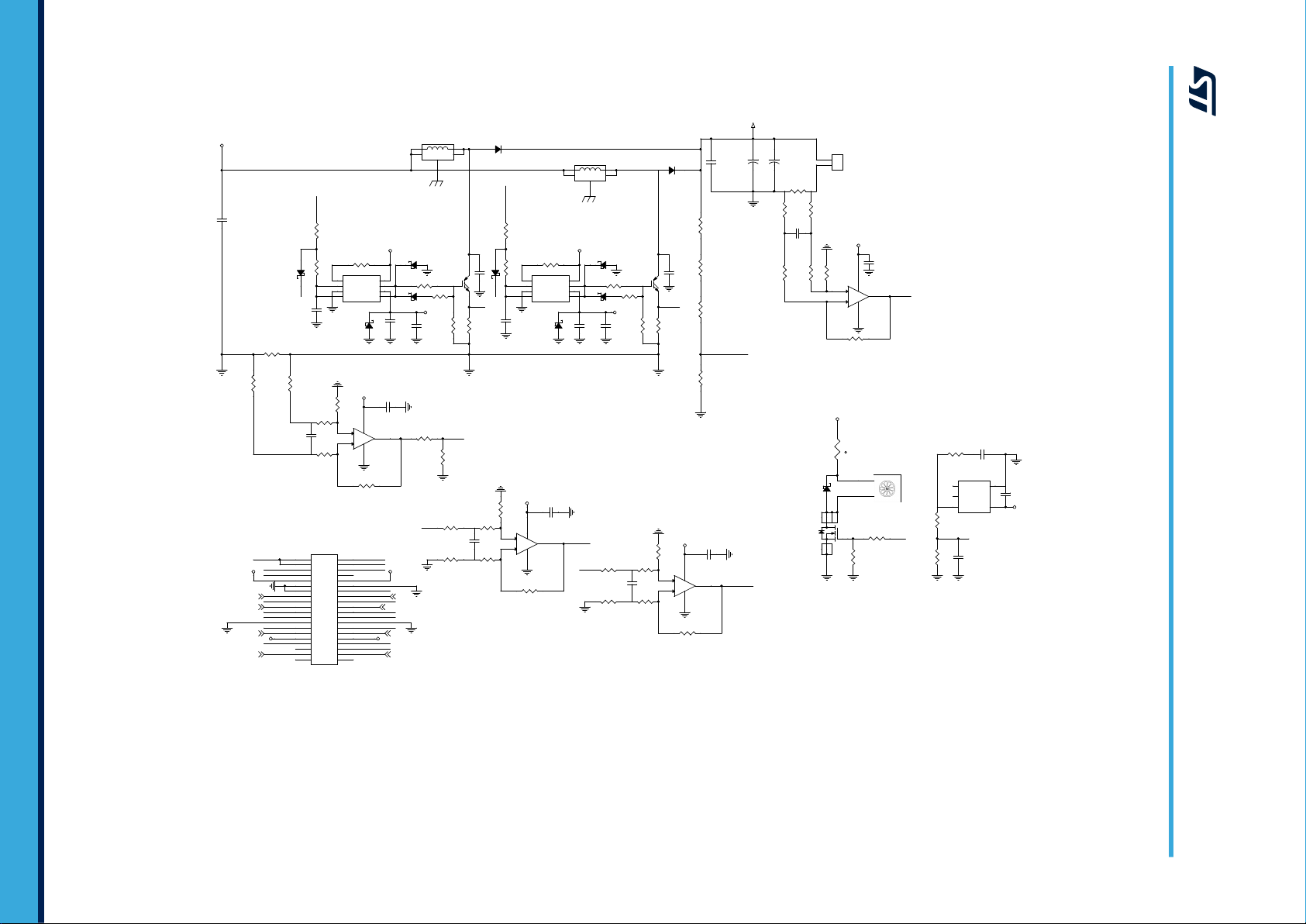

Figure 2. STEVAL-IPFC02V1 block diagram

1. I/O measurement signals

2. Analog circuitry

3. Power stages

4. Digital control section

UM2674

STEVAL-IPFC02V1 evaluation kit overview

2.1

The STEVAL-IPFC02V1 implements mixed signal (analog/digital) control, combining the flexibility of a

programmable high end digital solution with the responsiveness and accuracy of analog componentry. The

inner current loop consists of an analog proportional-integral (PI) compensator that ensures the highest possible

bandwidth and cycle-by-cycle regulation. The outer voltage loop is performed by a digital PI controller with fast

dynamic response.

Board features

The 2 kW interleaved PFC evaluation kit features:

• A modular design with the following separate boards:

– STEVAL-IPFC02P1 power board

– STEVAL-IPFC02C1 control board

– STEVAL-IPFC01A1 adapter board

• 2-channel interleaved PFC

• Input voltage range: 90 to 265 VAC (50 or 60 Hz)

• Maximum output power: 2 kW at 230 VAC; 1 kW at 115 VAC;

• Output voltage: 400 V

• Fixed frequency average current mode control and CCM operation

• Mixed-signal, semi-digital approach

• Programmable phase shedding

• Cooling System management

• Programmable fast overcurrent and thermal protection

• Digital inrush current limiter function performed with relay

• Soft startup and burst mode management

• Load current and input voltage feed forward

• Channel current balance function

UM2674 - Rev 3

page 3/28

• Two status LEDs to signal nominal and fault conditions

• Browser GUI tool (eDesignSuite) for driver customization

• Serial communication port for

– STNRGPF02 programming

– PFC parameter monitoring

UM2674

Board features

UM2674 - Rev 3

page 4/28

EARTH

AC LINE

AC LINE

How to use the STEVAL-IPFC02V1 evaluation board

3 How to use the STEVAL-IPFC02V1 evaluation board

To perform functional and efficiency testing, you need the following equipment:

• Programmable AC source with power > 2 kW

• DC electronic load or load resistor > 2 kW

• Power analyzer

• Digital oscilloscope

The STEVAL-IPFC02V1 board can be tested up to 2 kW at 230 V

range between 47 and 63 Hz.

Note: Any load or passive oscilloscope probe must be isolated from the input source of the PFC.

3.1 How to connect and start the STEVAL-IPFC02P1 power board

Step 1. Insert the STEVAL-IPFC02C1 control board in connector J100 on the STEVAL-IPFC02P1 power board.

Figure 3. STEVAL-IPFC02P1 AC supply connection

and 1 kW at 115 V

RMS

, in a frequency

RMS

UM2674

UM2674 - Rev 3

page 5/28

+400V

GND

UM2674

How to connect and start the STEVAL-IPFC02P1 power board

Step 2. Connect the load wires to the output terminals on J300 of the STEVAL-IPFC02P1 power board.

The actual load (electronic dc load, load resistors, inverter, etc.) must remain disconnected until the

soft startup sequence has completed.

The correct polarity is indicated on the board.

Figure 4. STEVAL-IPFC02P1 DC output connection

Step 3. Supply the following input voltage while no load is connected on the output:

– 90 – 265 VAC (50 or 60 Hz)

Step 4. Apply the load.

max: 2 kW at 230 VAC, 1 kW at 115 V

AC

3.1.1 STEVAL-IPFC02P1 power board startup sequence

1. The appropriate AC input voltage is applied under a no load condition.

2. When the input voltage rises above 60 V, the auxiliary power supply starts and generates the auxiliary

voltages (13 VDC and 5 VDC) for the drivers and the signal conditioning circuitry.

UM2674 - Rev 3

page 6/28

0

13V

0

V_INPUT

5V

5V

A A A A A A

5V

RELAY

ZVD

VIN_L1

R108

33k

R102

33k

RV100

S14K27 5

- +

D101

50A

2

1

3

4

D100

STPS 1L30A

D103

BAS70-04 FILM

3

1

2

R104

470k

N.M.

R107

10M

D104

BAS70-04 FILM

3

1

2

ISO100

TLP385(E

12

43

R114

3k

0.1%

R106

100k

R123

3k

0.1%

R101

150

R112

470k

C111

100pF

R121

470k

C101

0.1uF

R103

470k

N.M.

L100

2x4.5mH

2 1

3 4

C100

100nF

Y101

2.2nF

C110

100pF

R100 22

R113

470k

J100

VIN

1

2

3

R122

470k

R105

33k

Q100

STS6 NF20V

6

4

213 5

7

8

R111

10M

C102

1nF

D102

GF1M

RL100

250Vac -16A

11

1

A1

A2

3

12

2

14

Y100

2.2nF

R110

47k

F100

20A 250 Vac

R109

33k

AC-IN-L2

L1

L2

AC-IN-L1

L1 VDDIO

L2

VIN_L2

UM2674

How to connect and start the STEVAL-IPFC02P1 power board

3. Once the auxiliary voltages are nominal, the inrush current limiter phase begins by charging the output

capacitor until the DC voltage reaches the peak input voltage. The current is limited by resistor R101 until it

is shorted by the relay RL100 at the end of inrush phase.

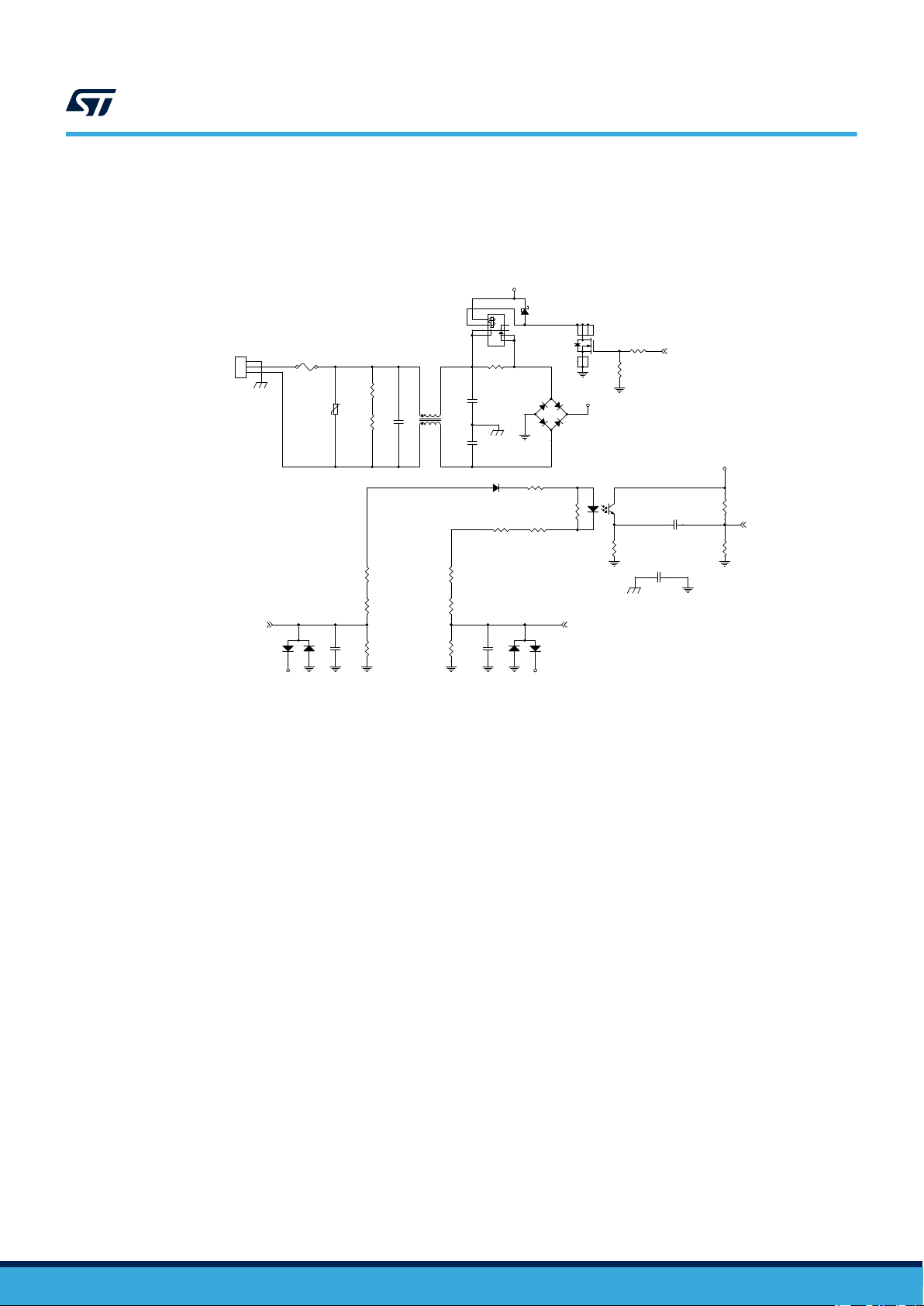

Figure 5. STEVAL-IPFC02P1 input section

4. After the inrush limiter phase, the soft startup procedure is activated and the output voltage rises up to 436

VDC, at which point the PFC enters burst mode to regulate the output voltage between 416 and 436 VDC.

5. The green LED D2 on the control board indicates when the sequence has finished and the PFC is ready for

the load to be connected.

6. Once you connect the load:

– the output voltage is regulated to 400 V ±2 V.

– for 185 – 265 VAC, the maximum output power is 2000 W

– for 90 – 140 VAC, the maximum output power is 1000 W

UM2674 - Rev 3

page 7/28

PFC controller customization with eDesignSuite

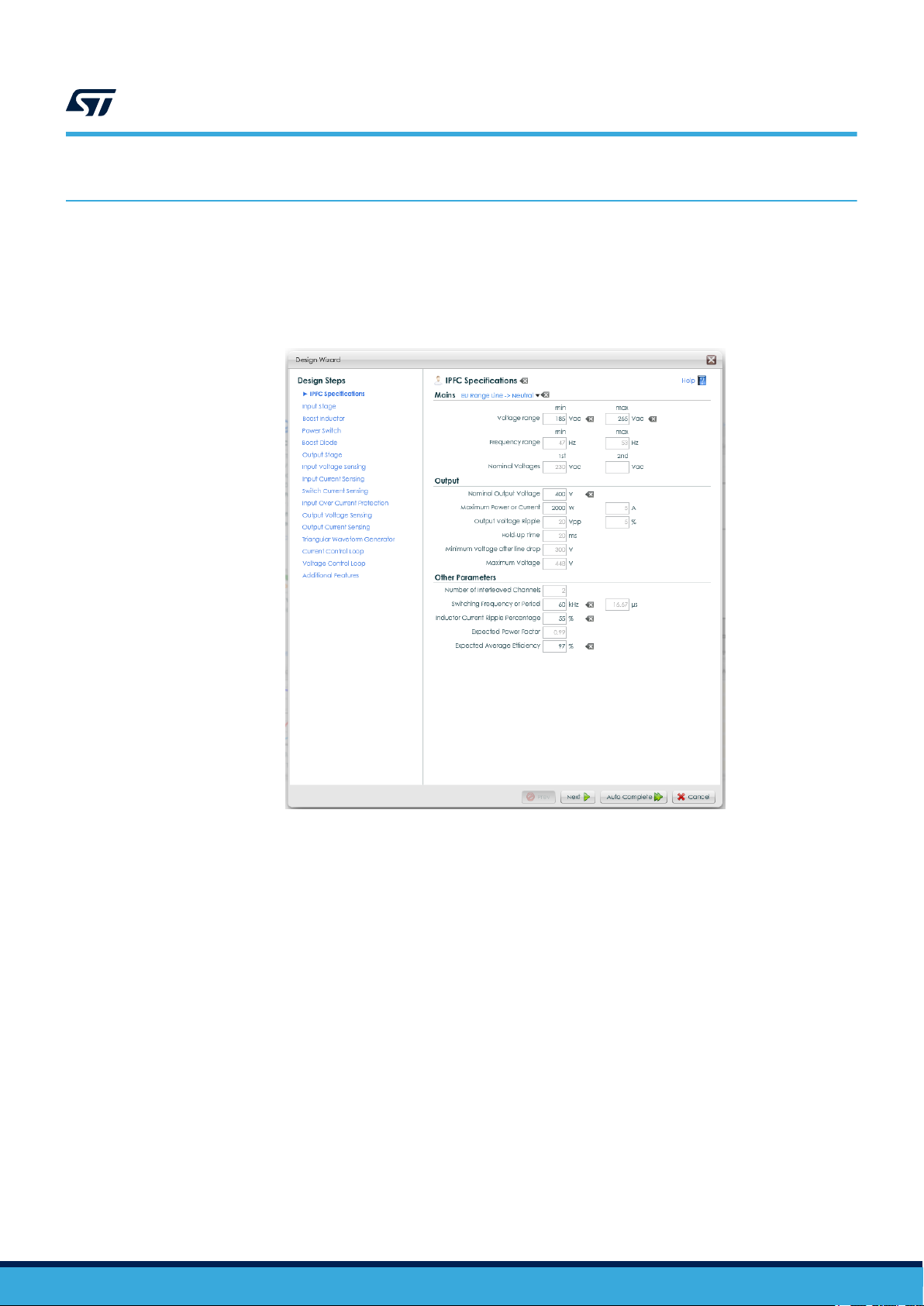

4 PFC controller customization with eDesignSuite

The eDesignSuite software tool developed by STMicroelectronics helps you configure ST products for power

conversion applications. You can use it to customize the PFC controller for a specific application by entering the

main specifications for your application and generating an automatic design, or by following a guided process for

more specific designs.

Figure 6. PFC specifications

UM2674

UM2674 - Rev 3

page 8/28

UM2674

Status LEDs and fault conditions

5 Status LEDs and fault conditions

The STEVAL-IPFC02C1 control board has the following status LEDs:

• a green LED connected to STNRGPF02 pin 15 (PFC_OK)

• a red LED connected to STNRGPF02 pin 14 (PFC_FAULT)

5.1 Normal operation

During normal operation, the green LED (D2) on the STEVAL-IPFC02C1 control board remains lit to indicate that

the PFC is operating under allowable conditions.

5.2 Fault conditions

When a fault is detected, the red LED (D1) on the STEVAL-IPFC02C1 control board lights up and the green LED

(D2) turns off. The device stops all switching activities and turns off the fan.

After a fault condition, the board must be reset by switching off the AC input voltage and discharging the output

capacitors.

Note: Warning: Do not short the output terminals to discharge the capacitors as the high discharge current may

damage the output current sensing circuitry.

The following conditions will trigger a fault protection:

• Highly distorted input voltage waveforms that inhibit frequency measurement. For example, if the mains

frequency out of the accepted range (e.g., 47-63 Hz).

• Overcurrent condition on at least one PFC channel. This protection prevents PFC inductor saturation.

• Overvoltage protection on output voltage if the output voltage exceeds 450 V

• Overvoltage protection on input voltage:

– for 115 VAC nominal supply: above 140 V

– for 230 VAC nominal supply: above 265 V

• Over-temperature protection when the ambient temperature of the board exceeds the threshold setting.

DC

5.3 Wait conditions

In addition to the conditions that trigger PFC_OK and PFC_FAULT, there are other conditions that are indicated

with both LEDs are off:

• Undervoltage condition on the output when the DC bus voltage falls below 340 V.

• Undervoltage condition on input when the input rms voltage falls below 90 VAC for 115 VAC nominal (or

185 VAC for 230 VAC nominal).

• Input voltage dropout when the input voltage signal disappears for more than 25 ms.

Under these conditions, the STNRGPF02 will drive both LEDs on the control board off and will wait until the

conditions have cleared before repeating the startup sequence.

UM2674 - Rev 3

page 9/28

0

13V

0

V_INPUT

5V

5V

A A A A A A

5V

RELAY

ZVD

VIN_L1

R10 8

33k

R10 2

33k

RV100

S1 4K275

- +

D101

50A

2

1

3

4

D100

STP S1L30 A

D103

BAS70-0 4FILM

3

1

2

R10 4

470 k

N.M.

R10 7

10M

D104

BAS70-0 4FILM

3

1

2

ISO10 0

TLP385 (E

12

43

R11 4

3k

0.1%

R10 6

100 k

R12 3

3k

0.1%

R10 1

150

R11 2

470 k

C11 1

100 pF

R12 1

470 k

C10 1

0.1u F

R10 3

470 k

N.M.

L100

2x4.5 mH

2 1

3 4

C10 0

100 nF

Y101

2.2n F

C11 0

100 pF

R10 0 22

R11 3

470 k

J1 00

VIN

1

2

3

R12 2

470 k

R10 5

33k

Q10 0

STS 6NF20 V

6

4

213 5

7

8

R11 1

10M

C10 2

1nF

D102

GF1 M

RL100

250 Vac -16A

11

1

A1

A2

3

12

2

14

Y100

2.2n F

R11 0

47k

F10 0

20A 25 0Vac

R10 9

33k

AC-IN-L2

L1

L2

AC-IN-L1

L1 VDDIO

L2

VIN_L2

UM2674 - Rev 3

6 STEVAL-IPFC02V1 schematic diagrams

Figure 7. STEVAL-IPFC02P1 schematic - input section

page 10/28

Schematic diagrams

UM2674

5V

13V

+40 0V

D203

STPS1L30A

D204

TMMBAT46FILM

C206

4.7 uF

+

C203

470uF

12

R205

2.7

L201

2198.00 37

1

5

4

3

10

8

7

6

R203

24k

R202

12k

C200

470nF

C207

4.7 uF

L200

4.7 uH

1 2

D202

STTH1L06A

R200

22

D200

SM6T220A

C210

1nF

D201

STPS2150A

C209

4.7 nF

R207

3.3 k

U200

L4931ABD50-TR

VOUT

1

GND1

2

GND2

3

NC

4

INHIBIT

5

GND3

6

GND4

7

VIN

8

+

C205

10uF

12

R204

2.7

R206

24k

U201

ALTAIR05T-800

COMP

7

DRAIN4

16

IREF

5

FB

6

VDD

3

GND4SRC1

1

SRC2

2

DRAIN315DRAIN214DRAIN1

13

+

C201

470uF

12

R201

33k

C208

470nF

+

C202

470uF

12

C204

470nF

6.5V

UM2674 - Rev 3

Figure 8. STEVAL-IPFC02P1 schematic - auxiliary power supply

page 11/28

Schematic diagrams

UM2674

13V

V_INPUT

5V

13V

+400 V

0

A

5V

13V

5V

5V

5V

13V13V

5V 5V

A A

5V 5V

ZVD ZVD

VIN_L1 VIN_L1

VIN_L2 VIN_L2

RELAY

C30 4

1uF

D306

STP S1 L30A

C31 1

0.1u F

L301

209 7.00 16

34

12

25

C30 9

100 pF

C31 2

0.1u F

D309

TMMBAT46FILM

C31 9

0.1u F

R34 6

62k

0.1%

D303

STP S1 L30A

R32 8

*

N.M.

C32 3

0.1u F

R33 5 22

R30 1

100

R34 0

2.2k 0.1%

D301

STP SC 120 65D

R34 1

100

D310 TMMBAT46FILM

R34 2

2.2k 0.1%

R32 7

2.2k 0.1%

D307

STP S1 L30A

U302

STLM20 W87 F

NC

1

GND

2

VOUT3VCC

4

GND1

5

R30 2

100

U306

PM88 34

EN1

1

PWM1

2

GND

3

PWM24OUT2

5

Vcc

6

OUT1

7

EN2

8

U305

PM88 34

EN1

1

PWM1

2

GND

3

PWM24OUT2

5

Vcc

6

OUT1

7

EN2

8

R33 9

100

R30 5

1k

C30 5

10n F

R33 4

2.2k 0.1%

-

+

U303

TSV91 1ILT

3

4

1

52

C31 0

100 pF

R34 9

510

R31 7

10k

-

+

U301

TSV91 1ILT

3

4

1

52

R33 3

100

C30 6

0.1u F

R31 0 33

R32 5

2.2k 0.1%

R30 8

10k

0.1%

C31 6

0.1u F

C31 8

150 pF

R32 0

6m

R31 1 33

+

C30 2

680 uF

12

R30 3

470 k

R31 5

10k

C307 10 0pF

L300

209 7.00 16

34

12

25

R30 7

10k

0.1%

R35 0

510

-

+

U304

TSV91 1ILT

3

4

1

52

D304

STP S1 L30A

D308

STP S1 L30A

R30 0

40m

R34 7 0

D300

STP SC 120 65D

R31 9

56k

0.1%

C31 5

0.1u F

C32 1

150 pF

R31 2 10

J30 0

VOUT

1

2

C30 8

100 pF

R32 4

82k

0.1%

Q30 0

STG W20 H65F B

23

1

C32 0

0.1u F

R30 6

470 k

R34 8 0

D305

STP S1 L30A

C31 3

0.1u F

R31 4

470 k

R32 2

100

C31 4

10n F

Q30 1

STG W20 H65F B

23

1

R32 9

470

R34 3

62k

0.1%

R33 0

82k

0.1%

R30 4

1k

R34 4

100

R31 3 10

J30 1

con 40-2 x20-strip-fe male

33

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

34

35 36

37 38

39 40

R31 6

10m

R32 1

100

C30 0

0.56 uF

Q30 2

STS 6NF2 0V

6

4

213 5

7

8

R31 8

10m

R33 1

62k

0.1%

R32 3

3.3k

0.1%

R33 2

11k

R33 6

62k

0.1%

R30 9

56k

0.1%

-

+

U300

TSV91 1ILT

3

4

1

52

t

RT1

16

D302

STP S1 L30A

R34 5

2.2k 0.1%

Y300

LAM 4 K 150 12

+

1

-

2

R33 8

10k

R32 6 0

R33 7

33k

C31 7

0.1u F

+

C30 1

680 uF

12

C32 2

0.1u F

VBUS

FAN TEMP

CS0

LOAD

CS1

CS1

CS0

I_1

I_0

OCP

PWM0

PWM1

OCP

I_tot

PW M0 PW M0

PW M1

I_0

PW M0

I_1

I_tot

FAN F AN

TEMP TEMP

VBUS VBUS

LOAD LOAD

OCP OCP

I_tot

RELAY

UM2674 - Rev 3

Figure 9. STEVAL-IPFC02P1 schematic - boost interleaving section

page 12/28

Schematic diagrams

UM2674

PROGRAMMING PORT

5V

AAA

A

5V

5V

5V

5V

5V

5V

5V

5V

A

5V

A

A

A

A

5V5V

A

5V

VDDA

A A

OUT_P I

-

+

U5B

LMV358IDT

7

6

5

4 8

R32

10k

R21

10k

R42 10 0k

-

+

U4

TSV911 ILT

3

4

1

52

R20

27k

D1

RED

C40

100p F

R26

56k

R55

N.M.

C27

820p F

D2

GRE EN

R54 10k

R41

N.M.

R30

22k

C42

1nF

C31

8.2n F

R15

10k

C7

1uF

+

C1

4.7u F

10V

C28

2.2 nF

R24 4. 3k

R22

10k

C3

10nF

C5

100n F

C8

100p F

C12

15nF

C4

10nF

R48

N.M.

R27

56k

R50

4.7k

C29 15 0pF

C30

15pF

-

+

U5A

LMV358IDT

1

2

3

4 8

R52

1k

R25 270 K

C35

1.5n F

R49

1.5k

R23

7.5k

C32 100n F

R1 1.8k

J5

CON4

1

2

3

4

R6 3.3k

R4 10 k

C10

33pF

R2 1.8k

C37

33pF

R40 0

R14

10k

R35 3.3k

R36

4.7k

C9

150p F

R8 10k

R29 0

L1

120 ohm-1 00MHz

R44 0

U1

STNR GPF 02

VDD

11

VDDA

29

VCOUT

13

VSS

12

VSSA

30

PWM[0]

1

SIN_REF

4

SET_O

5

OCP

19

PWM[1]

16

SCR [2]

8

PTX

22

RTX

23

FAN

20

RELAY/SCR[1]

21

PFC _FAULT

14

PFC _OK

15

RES [3]

10

RES [2]

9

VIN[0]

31

TEMP

32

IOUT

33

VOUT

34

I[0]

35

I[1]

36

RES [1]

37

VIN[1]

38

OUT_PI[3]

24

OUT_PI[2]

25

TRIANG_REF

26

OCP [1]

27

OCP [0]

28

CLOCK

2

OFFS ET

3

ENABLE

6

SYNCR

7

ZVD

17

SET_I

18

C11

1nF

R7 10k

R31

0

C24

100n F

C23

1uF

R37

2.7k

R43 10 0k

R28

5.6k

R9 10k

D3

BAS70- 05/S OT

C13

220n F

R45

N.M.

R33

N.M.

C41

1nF-N .M.

C39

220n F

C18 100n F

C2

100n F

R53

1k

C36

330p F

C38

220n F

R34

15k

J2

CON4

1

2

3

4

J1

CON4 0A

1 2

3 4

5 6

7 8

9 10

11 1 2

13 1 4

15 1 6

17 1 8

19 2 0

21 2 2

23 2 4

25 2 6

27 2 8

29 3 0

31 3 2

33 3 4

35 3 6

37 3 8

39 4 0

OFFS ET

PW M0

OUT_P I

TRIANG RE F

CLOCK

TRIANG RE F

SIN_RE F

I_ref

GRE EN LED

RED LE D

PW M1

PW M0

ZVD

SCR _1

FAN

I_ref

VIN_L1

VBUS

LOAD

I_tot

PW M0

SCR _1

LOAD

VIN_L1

LOAD

VIN_L1

TEMP

VBUS

TEMP

VBUS

ZVD

FAN

SIN_RE F

SET

PW M0

I_0

I_1

RTX

PTX

I_tot

I_0

I_1

SCR _2

OFFS ET

OCP OCP

PW M0

CLOCK

CLOCK

SCR _2

NRST

RED LE D

GRE EN LED

PW M1

ZVD SET

OCP FAN

SCR _1

OCP [1]

VDDA

TEMP

I_0_F

OCP [0]

I_1_F

VIN_L2

VIN_L2

VIN_L2I_1

I_0

I_tot

page 13/28

UM2674 - Rev 3

Figure 10. STEVAL-IPFC02C1 schematic

Schematic diagrams

UM2674

J4 01

CON6

12345

6

R40 2

470 k

J4 00

CON4

123

4

567

8

D400

LED

R40 1 330

Q40 0

MMBT222 2ALT1G

1

32

R40 3

1k

GRE EN

BLACK

YELLOW

ORANGE

RED

BROWN

YELLOW

ORANGE

RED

UM2674 - Rev 3

Figure 11. STEVAL-IPFC01A1 schematic

page 14/28

Schematic diagrams

UM2674

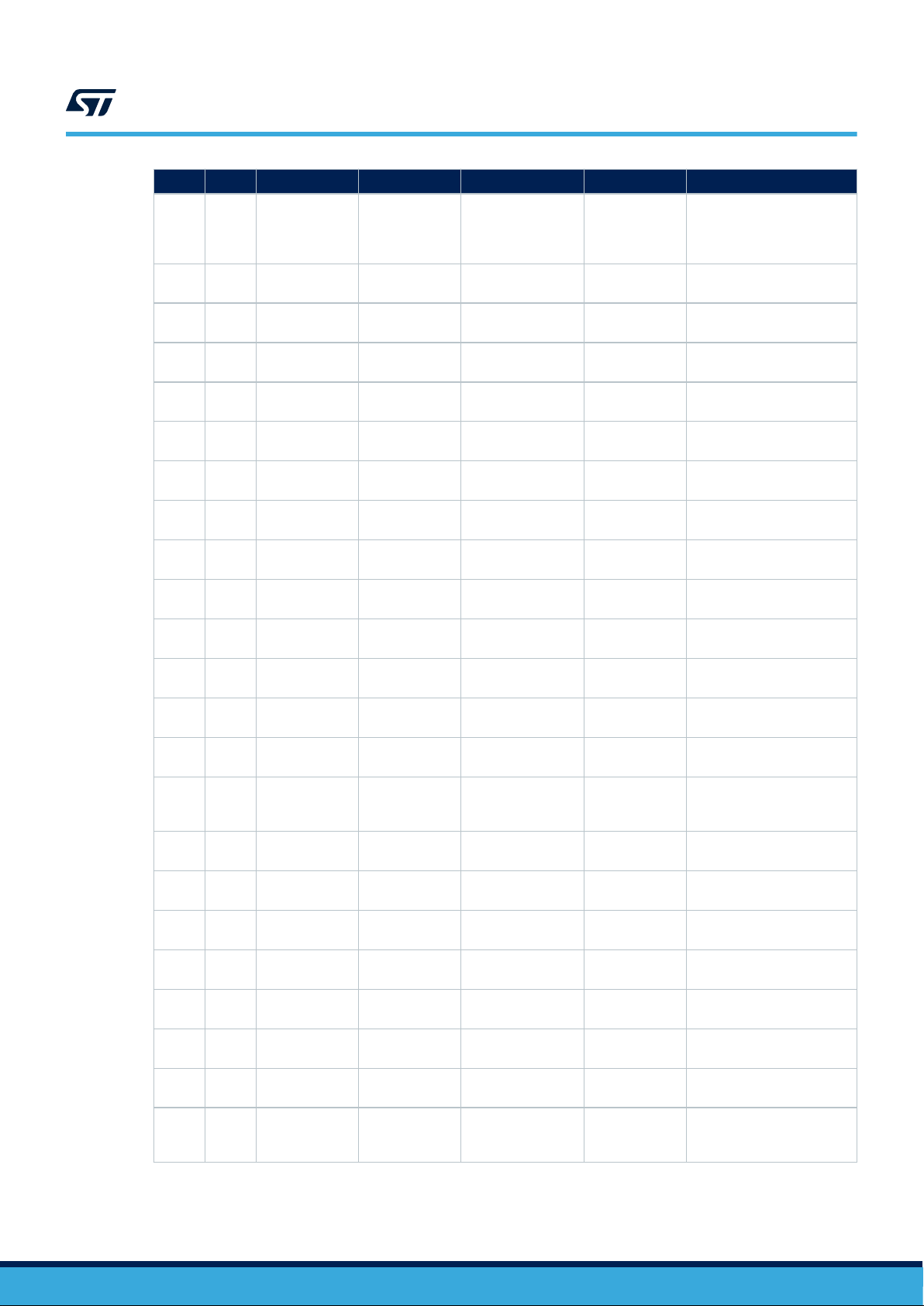

7 STEVAL-IPFC02V1 bill of materials

Table 1. STEVAL-IPFC02V1 bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

1 1 -

2 1 -

3 1 -

7.1 STEVAL-IPFC02P1 power board bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

1 1 C100

2 1 C101

3 1 C102

4 4

5 3

6 3

7 1 C205 10µF, 16V

8 2 C206, C207

9 1 C209

10 1 C210 1nF, 25V, ±10%

C110, C111,

C309, C310

C200, C204,

C208

C201, C202,

C203

STEVALIPFC02P1

STEVALIPFC02C1

STEVALIPFC01A1

Power board ST not available separately

Control board ST not available separately

Adapter board ST not available separately

Table 2. STEVAL-IPFC02P1 bill of materials

Safety Capacitors

100nF, 275VAC,

±20%

0.1µF, 25V,

±10%

1nF, 760VAC,

±20%

100pF, 50V,

±5%

470nF, 25V,

±10%

470µF, 25V,

±20%

4.7µF, 50V,

±20%

4.7nF, 25V,

±10%

MPP L/

S=15mm, Radial,

17.5x5x12mm, LS

15mm

CAP CER X7R

0603, 0603 (1608

Metric)

CAP CER Y5U

RADIAL, Radial,

Disc

CAP CER C0G/NP0

0603, 0603 (1608

Metric)

CAP CER X7R

0603, 0603 (1608

Metric)

Cap Pol Radial

(Electrolytic); 3.50

mm C X 8.00 mm

Dia X 20.00 mm

H body, Radial,

8x20mm

Cap Pol Radial

(Electrolytic); 1.50

mm C X 4.00 mm

Dia X 7.00 mm

H body, Radial,

4x7mm

CAP CER X7R

1210, 1210 (3225

Metric)

CAP CER X7R

0603, 0603 (1608

Metric)

CAP CER X7R

0603, 0603 (1608

Metric)

UM2674

Bill of materials

Panasonic ECQ-UAAF104MA

KEMET C0603C104K3RACTU

Vishay BC

Components

Murata

Electronics

North America

Wurth

Electronics Inc.

Any -

- -

Taiyo Yuden UMK325B7475MM-T

Wurth

Electronics Inc.

Samsung

ElectroMechanics

VY1102M35Y5UG63V0

GRM1885C1H101JA01D

885012206075

885012206063

CL10B102KA8NNNC

UM2674 - Rev 3

page 15/28

UM2674

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

CAP FILM

RAD, Radial,

26.5x6x15mm LS

22.5

ALU SNAP IN,

Radial, Can - Snap-InKEMET ALA7DA681DF450

EPCOS (TDK) B32673P6564K000

11 1 C300

12 2 C301, C302

0.56µF, 630Vdc,

±10%

680µF, 450V,

±20%

13 1 C304

14 2 C305, C314

C306, C313,

15 7

16 2 C307, C308

17 4

18 2 C318, C321

19 9

20 1 D101 50A, 1kV, 50A

21 1 D102 GF1M, 1kV, 1A

22 2 D103, D104 70V, 70mA (DC)

23 1 D200 220V

24 1 D201 150V, 2A

25 1 D202 600V, 1A

26 3

C315, C316,

C317, C319,

C320

C311, C312,

C322, C323

D100, D203,

D302, D303,

D304, D305,

D306, D307,

D308

D204, D309,

D310

1µF, 277V-a.c.,

520V c.c., ±10%

10nF, 50V,

±10%

0.1µF, 50V,

±10%

100pF, 630Vdc,

±5%

0.1µF, 50V, ±5%

150pF, 50 VDC,

±1%

STPS1L30A,

30V, 1A

100V, 150mA

(DC)

CAP FILM RADIAL,

Radial

CAP CER X7R

0603, 0603 (1608

Metric)

CAP CER X7R

0603, 0603 (1608

Metric)

CAP FILM RADIAL,

Radial

CAP CER X7R

0603, 0603 (1608

Metric)

Multilayer Ceramic

Capacitors MLCC SMD/SMT 50volts

150pF C0G 1%,

0603 (1608 metric)

DIODE SCHOTTKY

SMA, DO-214AC,

SMA

BRIDGE RECT

1PHASE GBJ, 4SIP, GBJ

DIODE GEN PURP

SMA, DO-214AC,

SMA

DIODE ARRAY

SCHOTTKY

SOT23-3,

TO-236-3, SC-59,

SOT-23-3

TRANSIL DIODE

SMB, DO-214AA,

SMB

DIODE SCHOTTKY

SMA, DO-214AC,

SMA

Ultrafast high

voltage rectifier

SMA, DO-214AC,

SMA

DIODE SCHOTTKY

MINMLF, DO-213AA

(Glass)

EPCOS (TDK) B32673Z5105K000

Murata

Electronics

North America

KEMET C0603C104K5RACTU

KEMET PFR5101J630J11L4BULK

KEMET C0603C104J5RACTU

KEMET C0603C151F5GACTU

ST STPS1L30A

Micro

Commercial Co

ON

Semiconductor

ST BAS70-04FILM

ST SM6T220A

ST STPS2150A

ST STTH1L06A

ST TMMBAT46FILM

GRM188R71H103KA01D

GBJ5010-BP

GF1M

UM2674 - Rev 3

page 16/28

UM2674

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

27 2 D300, D301 650V, 12A

28 1 F100

29 1 ISO100 TLP385(E

30 1 J100 VIN

31 1 J300 VOUT

32 1 J301

33 1 L100 2x4.5mH, 18A

34 1 L200

35 1 L201

36 2 L300, L301

37 2 Q100, Q302 20V, 6A

38 2 Q300, Q301

39 1 R100 22, 1/4W, ±1%

40 1 R101 150, 5W, ±5%

41 3

42 2

R102, R201,

R337

R103, R104 (not

mounted)

20A 250Vac,

250VAC 72VDC,

20A

con40-2x20strip-female

4.7µH, 1.9A,

±20%

11W, 80kHz,

2.2mH, 13V,

0.47A, ±10%

350µH 12A

1kW

650V, 40A,

168W

33k, 0.1W,

1/10W, ±1%

470k, 0.25W,

1/4W, ±1%

DIODE SCHOTTKY

TO220AC,

TO-220-2

FUSE BOARD MNT,

0.390" L x 0.120"

W x 0.125" H

(9.80mm x 3.05mm

x 3.18mm)

TRANSISTOR

OPTOCOUPLER; 4PIN SO, 6-SOIC

(0.295", 7.50mm

Width), 4 Leads

SCREW TERM

BLOCK PCB 3POS

7.5MM GREEN

SCREW TERM

BLOCK PCB 2POS

7.62MM

CONN RCPT

40POS .100" DUAL

GOLD

CMC 4.5MH 18A

2LN TH, Vertical, 4

PC Pin

Unshielded Wirewound SMD

Inductor 4.7 µH

±20% Wire-Wound

1.9A Idc, SMD

4.3x4x3.2mm

Switch Mode

Transformer,

Through hole

Power inductor,

PK

through hole

MOSFET N-CH

8SOIC, 8-SOIC

(0.154", 3.90mm

Width)

IGBT TO247,

TO-247-3

CHIP RESISITOR

SMD 1206, 1206

(3216 Metric)

RES RADIAL,

Radial

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

RES SMD 1206,

1206 (3216 Metric)

ST STPSC12065D

Bel Fuse Inc. SMM 20

Toshiba

Semiconductor

and Storage

Phoenix Contact 1717033

RS Pro 7901130

Samtec Inc. ESQ-120-37-G-D

Wurth

Electronics Inc.

RS PRO 7409372

AQ Magnetica

OR

Würth Elektronik

AQ Magnetica

OR

Würth Elektronik

ST STS6NF20V

ST STGW20H65FB

- -

TE Connectivity

Passive Product

- -

- -

TLP385(E

7448051804

2198.0037

OR

750318021

2097.0016

OR

750318020

SQMW5150RJ

UM2674 - Rev 3

page 17/28

UM2674

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

43 3

44 1 R106

45 2 R107, R111

46 1 R110

47 7

48 2 R114, R123

49 2 R200, R335

50 1 R202

51 2 R203, R206

52 2 R204, R205

53 1 R207

54 1 R300 40mΩ, 7W, ±1%

55 8

56 2 R304, R305

57 2 R307, R308

58 2 R309, R319

59 2 R310, R311

60 2 R312, R313

R105, R108,

R109

R112, R113,

R121, R122,

R303, R306,

R314

R301, R302,

R321, R322,

R333, R339,

R341, R344

33k, 0.25W,

1/4W, ±1%

100k, 0.25W,

1/4W, ±1%

10M, 0.1W,

1/10W, ±1%

47k, 0.1W,

1/10W, ±1%

470k, 0.25W,

1/4W, ±1%

3k, 0.1W,

1/10W, ±0.1%

22, 0.25W,

1/4W, ±1%

12k, 0.1W,

1/10W, ±1%

24k, 0.1W,

1/10W, ±1%

2.7, 0.5W, 1/2W,

±1%

3.3k, 0.25W,

1/4W, ±1%

100, 0.1W,

1/10W, ±1%

1k, 0.1W,

1/10W, ±1%

10k, 0.1W,

1/10W, ±0.1%

56k, 0.1W,

1/10W, ±0.1%

33, 0.25W,

1/4W, ±1%

10, 0.25W,

1/4W, ±1%

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

RES SMD 0603,

0603 (1608 Metric)

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

RES SMD 1206,

1206 (3216 Metric)

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

RES 2818,

Nonstandard

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

RES SMD 10K

OHM 0603, 0603

(1608 Metric)

RES SMD 56K

OHM 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

- -

- -

- -

- -

- -

Panasonic

Electronic

Components

- -

- -

- -

Susumu RL1632R-2R70-F

Any -

Vishay Dale WSHM2818R0400FEA

- -

- -

Panasonic

Electronic

Components

Panasonic

Electronic

Components

- -

- -

ERA-3AEB302V

ERA-3AEB103V

ERA-3AEB563V

UM2674 - Rev 3

page 18/28

UM2674

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

61 2 R315, R317

62 2 R316, R318 10mΩ, 2W, ±1%

63 1 R320 6mΩ, 3W, ±1%

64 1 R323

65 2 R324, R330

66 6

67 1 R326

68 1

69 1 R329

70 4

71 1 R332

72 1 R338

73 2 R347, R348

74 2 R349, R350

75 1 RL100 250Vac-16A

76 1 RT1

77 1 RV100

78 1 U200 5V, 250mA

R325, R327,

R334, R340,

R342, R345

R328 (not

mounted)

R331, R336,

R343, R346

10k, 0.25W,

1/4W, ±1%

3.3k, 0.1W,

1/10W, ±0.1%

82k, 0.1W,

1/10W, ±0.1%

2.2K, 0.1W,

1/10W, ±0.1%

0, 0.1W, 1/10W,

±1%

*, 0.1W, 1/10W,

±1%

470, 0.1W,

1/10W, ±1%

62k, 0.1W,

1/10W, ±0.1%

11k, 0.1W,

1/10W, ±1%

10k, 0.1W,

1/10W, ±1%

0, 0.25W, 1/4W,

±1%

510, 0.1W,

1/10W, ±1%

16Ω, 1.7A,

±20%

S14K275,

275VAC

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

RES 3264 current

sensing, 2512 (6432

Metric)

RES 2512, 2512

(6432 Metric)

RES SMD 0603,

0603 (1608 Metric)

RES SMD 0603,

0603 (1608 Metric)

RES SMD 0603,

0603 (1608 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

RES SMD 0603,

0603 (1608 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

CHIP RESISTOR

SMD 1206, 1206

(3216 Metric)

CHIP RESISTOR

SMD 0603, 0603

(1608 Metric)

RELAY GEN

PURPOSE SPDT

16A 18V

ICL 8.5MM,

Diameter 8.5mm

VARISTOR 430V

4.5KA DISC 14MM,

Disc 14mm

IC REG LINEAR

8SO, 8-SOIC

(0.154", 3.90mm

Width)

- -

Ohmite MCS3264R010FER

Panasonic

Electronic

Components

Panasonic

Electronic

Components

Panasonic

Electronic

Components

Panasonic

Electronic

Components

- -

- -

- -

Panasonic

Electronic

Components

- -

- -

- -

- -

TE Connectivity

Potter &

Brumfield

Relays

EPCOS (TDK) B57153S0160M000

EPCOS (TDK) B72214S0271K101

ST L4931ABD50-TR

ERJ-MS4HF6M0U

ERA-3AEB332V

ERA-3AEB823V

ERA-3AEB222V

ERA-3AEB623V

RT314018

UM2674 - Rev 3

page 19/28

UM2674

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

IC PRIMARY

79 1 U201 -

80 4

81 1 U302 -

82 2 U305, U306 4A

83 2 Y100, Y101

84 1 Y300

85 5

86 1

87 4 Spacer D01496

88 4 Nut

89 2 Screws M3 x 10 mm Steel screw

90 2 Steel washers M3

U300, U301,

U303, U304

Y3 lock-inretaining springs

Thermal Film

140 x 25 mm

-

2.2nF, 250VAC,

±20%

LAM 4 K 150 12,

12V

THFU 1 retaining springs

-

DTRNNE 34814M3M3 Hexagon Full

SWITCHING REG

16SOIC, 16-SOIC

(0.154", 3.90mm

Width)

IC OPAMP GP

8MHZ RRO

SOT23-5, SC-74A,

SOT-753

SENS TEMP ANLG

VOLT SOT-323-5,

5-TSSOP, SC-70-5,

SOT-353

IC MOSFET DVR

DUAL 8SOIC, 8SOIC (0.154",

3.90mm Width)

CAP CER RADIAL,

Radial, Disc

Heatsink 40 x 40

x150 mm, with axial

fan 12V, integrated

Thermal

conductivity Thin

film 140 X 25 mm

Hex Threaded

Spacer

Nut Double ChamferTRFASTENINGS

Steel Plain M3

Washer

ST ALTAIR05T-800

ST TSV911ILT

ST STLM20W87F

ST PM8834

Murata

Electronics

North America

FISCHERELEK

TRONIK

Fischer

Elektronik

BERGQUIST BP100-0.005-00-12/12

DURATOOL D01496

TR

FASTENINGS

ANY ANY

DE2E3KY222MA3BM02F

LAM 4 K 150 12

THFU 1

DTRNNE 34814 M3

M310 PRSTMCZ100-

7.2 STEVAL-IPFC02C1 control board bill of materials

Table 3. STEVAL-IPFC02C1 bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

X7R Ceramic

Capacitor, SMD

0805

X7R Ceramic

Capacitor, SMD

0603

X7R Ceramic

Capacitor, SMD

0603

X7R Ceramic

Capacitor, SMD

0603

UM2674 - Rev 3

1 1 C1

2 5

3 2 C3, C4

4 2 C7, C23 1µF, 25V, ±10%

C2, C5, C18,

C24, C32

4.7µF, 16V,

±10%

100nF, 50V,

±10%

10nF, 25V,

±10%

ANY ANY

ANY ANY

AVX 06033C103KAT2A

ANY ANY

page 20/28

UM2674

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

5 2 C8, C40

6 2 C9, C29

7 2 C10, C37 33pF, 50V, ±5%

8 2 C11, C42 1nF, 50V, ±5%

9 1 C12

10 3 C13, C38, C39

11 1 C27

12 1 C28

13 1 C30 15pF, 50V, ±5%

14 1 C31

15 1 C35 1.5nF, 50V, ±5%

16 1 C36

17 1

18 1 D1

19 1 D2

20 1 D3

21 1 J1

C41 (not

mounted)

100pF, 50V,

±5%

150pF, 50V,

±5%

15nF, 50V,

±10%

220nF, 50V,

±10%

820pF, 50V,

±5%

2.2 nF, 50V,

±5%

8.2nF, 50V,

±10%

330pF, 50V,

±5%

1nF, 50V, ±5%

RED, 1,85,

20mA

GREEN, 2.1V,

20mA

BAS70-05, 70V,

70mA

CON40A,

250Vac, 3A

C0G Ceramic

Capacitor, SMD

0603

C0G Ceramic

Capacitor, SMD

0604

C0G Ceramic

Capacitor, SMD

0603

C0G Ceramic

Capacitor, SMD

0603

X7R Ceramic

Capacitor, SMD

0603

X7R Ceramic

Capacitor, SMD

0603

COG Ceramic

Capacitor, SMD

0603

C0G Ceramic

Capacitor, SMD

0603

COG Ceramic

Capacitor, SMD

0603

X7R Ceramic

Capacitor, SMD

0603

C0G Ceramic

Capacitor, SMD

0603

COG Ceramic

Capacitor, SMD

0603

X7R Ceramic

Capacitor, SMD

0603

High efficiency red

diffused LED 3mm,

SMD 0805

High efficiency

green diffused LED

3mm, SMD 0805

Low capacitance,

series inductance

and resistance

Schottky diode,

SOT23

Right angle PIN

header connector,

dual row, T. H.

lead spacing 2.54 x

2.54mm

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

Kingbright KP-2012SRC-PRV

Kingbright KPHCM-2012CGCK

ST BAS70-05FILM

Wurth Elektronik 61304021021

UM2674 - Rev 3

page 21/28

UM2674

Bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

22 2 J2, J5

23 1 L1

24 2 R1, R2

25 6

26 4

27 2 R6, R35

28 1 R20

29 1 R23

30 1 R24

31 1 R25

32 2 R26, R27

33 1 R28

34 4

35 1 R30

36 5

37 1 R34

38 2 R36, R50

39 1 R37

40 2 R42, R43

41 1 R49

42 2 R52, R53

43 1 U1 5V

44 1 U4 5V

R4, R8, R9,

R21, R22, R32

R7, R14, R15,

R54

R29, R31, R40,

R44

R33, R41, R45,

R48, R55 (not

mounted)

CON4, 250Vac,

3A

120 Ω-100MHz,

500 mA, ±25%

1.8k, 50V, 0.1,

±1%

10k, 50V, 0.1W,

±1%

10k, 50V, 0.1W,

±0.1%

3.3k, 50V, 0.1W,

±1%

27k, 50V, 0.1W,

±1%

7.5k, 50V, 0.1W,

±1%

4.3k, 50V, 0.1W,

±1%

270K, 50V,

0.1W, ±1%

56k, 50V, 0.1W,

±1%

5.6k, 50V, 0.1W,

±1%

0, 50V, 0.1W,

±1%

22k, 50V, 0.1W,

±1%

(not mounted),

50V, 0.1W, ±1%

15k, 50V, 0.1W,

±1%

4.7k, 50V, 0.1W,

±1%

2.7k, 50V, 0.1W,

±1%

100k, 50V,

0.1W, ±1%

1.5k, 50V, 0.1W,

±1%

1k, 50V, 0.1W,

±1%

T. H. PIN Header

Connector, single

row, T. H. lead

spacing 2.54mm

Ferrite, SMD 0603 Wurth Elektronik 74279262

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0604

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Metal film resistor,

SMD 0603

Digital controller,

TSSOP38

Single rail to rail

I/O 8MHz OpAmp,

SOT23-5L

Wurth Elektronik 61300411121

ANY ANY

ANY ANY

Panasonic ERA3APB103V

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ANY ANY

ST STNRGPF02

ST TSV911ILT

UM2674 - Rev 3

page 22/28

Item Q.ty Ref. Part / Value Description Manufacturer Order code

45 1 U5 5V

Low power I/O rail

to rail dual OpAmp,

SO8

7.3 STEVAL-IPFC01A1 adapter board bill of materials

Table 4. STEVAL-IPFC01A1 bill of materials

Item Q.ty Ref. Part / Value Description Manufacturer Order code

1 1 D400 LED

2 1 J400 CON4

3 1 J401 CON6

4 1 Q400 40 V, 0.6 A

5 1 R401 330

6 1 R402 470k

7 1 R403 1K

High Efficiency Red

LED 3mm, through

hole

4-contact 2.54mm

female SIL Boardto-board Socket,

through hole

Right angle male

connector 1 way

6 circuits 2.54mm,

through hole

General Purpose

Transistors, NPN

Silicon

Metal film resistor,

0805

Metal film resistor,

0805

Metal film resistor,

0805

ST LMV358IDT

Kingbright L-7104ID

HARWIN M20-7890446

ANY ANY

ON

Semiconductor

ANY ANY

ANY ANY

ANY ANY

SMMBT2222ALT1G

UM2674

Bill of materials

UM2674 - Rev 3

page 23/28

Revision history

Date Version Changes

16-Mar-2020 1 Initial release.

10-Jul-2020 2 Updated Table 2.STEVAL-IPFC02P1 bill of materials.

22-Jan-2021 3 Updated Figure 10. STEVAL-IPFC02C1 schematic and Table 2. STEVAL-IPFC02P1 bill of materials

UM2674

Table 5. Document revision history

UM2674 - Rev 3

page 24/28

UM2674

Contents

Contents

1 Safety instructions ................................................................2

2 STEVAL-IPFC02V1 evaluation kit overview .........................................3

2.1 Board features .................................................................3

3 How to use the STEVAL-IPFC02V1 evaluation board................................5

3.1 How to connect and start the STEVAL-IPFC02P1 power board ........................5

3.1.1 STEVAL-IPFC02P1 power board startup sequence ..............................6

4 PFC controller customization with eDesignSuite ...................................8

5 Status LEDs and fault conditions ..................................................9

5.1 Normal operation...............................................................9

5.2 Fault conditions ................................................................9

5.3 Wait conditions ................................................................9

6 STEVAL-IPFC02V1 schematic diagrams ...........................................10

7 STEVAL-IPFC02V1 bill of materials................................................15

7.1 STEVAL-IPFC02P1 power board bill of materials ...................................15

7.2 STEVAL-IPFC02C1 control board bill of materials ..................................20

7.3 STEVAL-IPFC01A1 adapter board bill of materials..................................23

Revision history .......................................................................24

UM2674 - Rev 3

page 25/28

UM2674

List of figures

List of figures

Figure 1. STEVAL-IPFC02V1 evaluation kit with power, control and adapter boards ...........................1

Figure 2. STEVAL-IPFC02V1 block diagram ......................................................3

Figure 3. STEVAL-IPFC02P1 AC supply connection .................................................5

Figure 4. STEVAL-IPFC02P1 DC output connection .................................................6

Figure 5. STEVAL-IPFC02P1 input section .......................................................7

Figure 6. PFC specifications .................................................................8

Figure 7. STEVAL-IPFC02P1 schematic - input section .............................................. 10

Figure 8. STEVAL-IPFC02P1 schematic - auxiliary power supply ....................................... 11

Figure 9. STEVAL-IPFC02P1 schematic - boost interleaving section ..................................... 12

Figure 10. STEVAL-IPFC02C1 schematic ........................................................13

Figure 11. STEVAL-IPFC01A1 schematic ........................................................ 14

UM2674 - Rev 3

page 26/28

UM2674

List of tables

List of tables

Table 1. STEVAL-IPFC02V1 bill of materials ...................................................... 15

Table 2. STEVAL-IPFC02P1 bill of materials ...................................................... 15

Table 3. STEVAL-IPFC02C1 bill of materials ...................................................... 20

Table 4. STEVAL-IPFC01A1 bill of materials ...................................................... 23

Table 5. Document revision history .............................................................24

UM2674 - Rev 3

page 27/28

UM2674

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2021 STMicroelectronics – All rights reserved

UM2674 - Rev 3

page 28/28

Loading...

Loading...