Page 1

UM1631

User manual

STEVAL-IHT005V2 - 3.3 V control of ACS®/Triac with STM32™

Introduction

The STEVAL-IHT005V2 demonstration board is designed for the home appliance market,

with a focus on the demonstration of a robust solution with a 3.3 V supplied 32-bit MCU.

Targeted applications are mid-end and high-end washing machines, dishwashers and

dryers with different kinds of ACS

The demonstration board is based on the recently introduced 48-pin, 32-bit

STM32F100C4T6B MCU running at 24 MHz (RC user-trimmable internal RC clock),

featuring 16 kBytes of Flash memory, 12-bit A/D converter, 5 timers, communication

interfaces, and 4 kBytes of SRAM.

The power supply circuitry is based on the VIPer

avalanche rugged power section, operating at 60 kHz. The power supply provides negative

6 V in buck-boost topology.

The STEVAL-IHT005V2 can control 2 high power loads up to 2830 W thanks to the T1635H,

a 16 A, 600 V high temperature Triac and up to 2050 W thanks to the ACST1635-8FP

a 16 A, 800 V high temperature overvoltage protected ACST device. The high power load

control is based on phase angle control. In order to limit the inrush current and possible

current peaks, the demonstration board features a soft-start routine and a smooth power

change function for the high power loads.

The STEVAL-IHT005V2 can also control 4 low power loads up to 100 W thanks to

3 ACS108-8S, 0.8 A, 800 V overvoltage protected ACS devices and a Z0109, 1 A standard

4 quadrant 600 V Triac.

The demonstration board passed the precompliance tests for EMC directives

IEC 61000-4-4 (burst up to 8 kV) and IEC 61000-4-5 (surge up to 2 kV).

When put in standby mode, the STEVAL-IHT005V2 has an overall standby power

consumption below 500 mW at 264 V/50 Hz.

®

/Triacs.

®

16L, an offline converter with an 800 V

Figure 1. STEVAL-IHT005V2

October 2013 DocID024503 Rev 1 1/27

www.st.com

Page 2

Contents UM1631

Contents

1 Board features and objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Board features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Targeted applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Board operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 How to operate the STEVAL-IHT005V2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 MCU programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Load and gate control fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Phase angle control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Full wave control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Power supply consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Max. output current and standby consumption . . . . . . . . . . . . . . . . . . . . 12

5.2 Gate voltage impact on gate current . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 Pulsed gate control and average gate current consumption . . . . . . . . . . 13

6 Board immunity performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Hardware and software features to increase immunity . . . . . . . . . . . . . . 14

Software features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Surge tests results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2/27 DocID024503 Rev 1

Page 3

UM1631 Contents

6.3 Burst tests results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3.1 Test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3.2 Test results of the board without hardware modifications . . . . . . . . . . . 15

6.3.3 Input filter influence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3.4 Noise suppressor influence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.3.5 Gate filtering circuit influence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3.6 Immunity to relay switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appendix A STEVAL-IHT005V2 schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

A.1 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

A.2 Demonstration board layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

A.3 Test point lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

A.4 Gate resistor calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Gate resistor calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Assumptions for calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

A.5 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DocID024503 Rev 1 3/27

Page 4

Board features and objectives UM1631

1 Board features and objectives

1.1 Objectives

The board is designed for promotion of a complete solution for home appliance applications

based on STMicroelectronics™ components. Special emphasis is placed on demonstration

of the robust full 3.3 V solution. Robustness is demonstrated on 4 kV level in class A during

IEC-61000-4-4 (burst) test.

This board also allows designers to check AC switches control feasibility with a 3.3 V supply.

Gate currents can be measured and compared to the information given in AN2986.

Promoted parts are

STM32F100C4T6B - value line 32-bit MCU

T1635H-6T - 16 A 600 V 35 mA high temperature Snubberless™ Triac in TO-220

package

ACST1635-8FP - 16 A 800 V high temperature overvoltage protected AC switch in

TO-220 FPAB package

ACS108-8SA - 0.8 A 800 V 10 mA overvoltage protected ACS device in TO-92

package

Z0109MA - 1 A standard 10 mA 4Q Triac in TO-92 package

VIPer16L - an offline converter with 800 V avalanche rugged power section operating

at 60 kHz.

The ACS108 and Z0109 are controlled in ON/OFF mode with the buttons. These devices

control small loads like valves, pumps, and door locks.

The T1635H and ACST16 are controlled in phase control mode with potentiometers. These

devices control high power loads like drum motors or heating resistors.

4/27 DocID024503 Rev 1

Page 5

UM1631 Board features and objectives

1.2 Board features

The board key features and performances are

Complete solution for -3.3 V control

Input voltage range: 90-265 VAC 50/60 Hz

Negative 6 V/3.3 V VDC auxiliary power supply based on the VIPer16L in buck-boost

topology

Total power consumption in standby mode is lower than 0.5 W for 264 V/50 Hz

48-pin, 32-bit value line family STM32F100C4T6B MCU as main controller

Zero voltage switching (ZVS) interrupt to synchronize MCU events with voltage mains

1x T1635H-6T and 1 x ACST1635-8FP for phase control of high power loads

5 discrete power level states with soft change for phase angle controlled devices

1x Z0109 and 3x ACS108 for full wave control of low power loads

1x relay for demonstration of the board noise robustness

“Red” LED to show that the board is supplied from mains

“Green” LED for each ACS/ACST/Triac to show that the device is turned ON

JTAG programming connector

External wire loop for gate current measurement

2

I

C bus hardware/software ready

18 test pins

IEC 61000-4-4 precompliance test passed (burst up to 8 kV)

IEC 61000-4-5 precompliance test passed (surge up to 2 kV)

RoHS compliant

1.3 Targeted applications

Targeted applications are mid-end and high-end washing machines, dishwashers, dryers,

and coffee machines.

Optionally, this board targets any home-appliance application where the STM32 MCU

controls any type of Triac/ACST/ACS.

1.4 Operating conditions

The board operates in nominal line voltage 110 V/230 V in both 50/60 Hz power nets.

Line voltage: 90-264 V 50/60 Hz

Operating ambient temperature 0 °C to 60 °C

Nominal loads power (for 230 V voltage)

– ACST1635-8FP - 2050 W

– T1635H-6T - 2830 W

– Z0109MA - 96 W

– ACS108-8SA - 105 W

DocID024503 Rev 1 5/27

Page 6

Safety instructions UM1631

2 Safety instructions

Warning: The high voltage levels used to operate the STEVAL-IHT005V2

board could present a serious electrical shock hazard. This

demonstration board must be used in a suitable laboratory by

qualified personnel only, familiar with the installation, use,

and maintenance of power electrical systems.

2.1 Intended use

The STEVAL-IHT005V2 demonstration board is a component designed for demonstration

purposes only, and not to be used either for domestic installation or for industrial installation.

The technical data as well as the information concerning the power supply and working

conditions should be taken from the documentation included in the kit and strictly observed.

2.2 Installation

Installation instructions for the STEVAL-IHT005V2 demonstration board must be taken from

the present user manual and strictly observed. The components must be protected against

excessive strain. In particular, no components are to be bent, or isolating distances altered

during transportation, handling or use. No contact must be made with electronic

components and contacts. The STEVAL-IHT005V2 demonstration board contains

electrostatically sensitive components that are prone to damage through improper use.

Electrical components must not be mechanically damaged or destroyed (to avoid potential

risks and health injury).

2.3 Electrical connection

Applicable national accident prevention rules must be followed when working on the mains

power supply. The electrical installation must be completed in accordance with the

appropriate requirements (e.g. cross-sectional areas of conductors, fusing, PE

connections). In particular, the programming device must be disconnected from the board

JTAG connector when the board is plugged into the mains.

2.4 Board operation

A system architecture which supplies power to the demonstration board must be equipped

with additional control and protective devices in accordance with the applicable safety

requirements (e.g. compliance with technical equipment and accident prevention rules).

Note: Do not touch the board after disconnection from the mains power supply, as several parts

and power terminals which contain possibly energized capacitors need to be allowed to

discharge completely.

6/27 DocID024503 Rev 1

Page 7

UM1631 Getting started

3 Getting started

3.1 Connection diagram

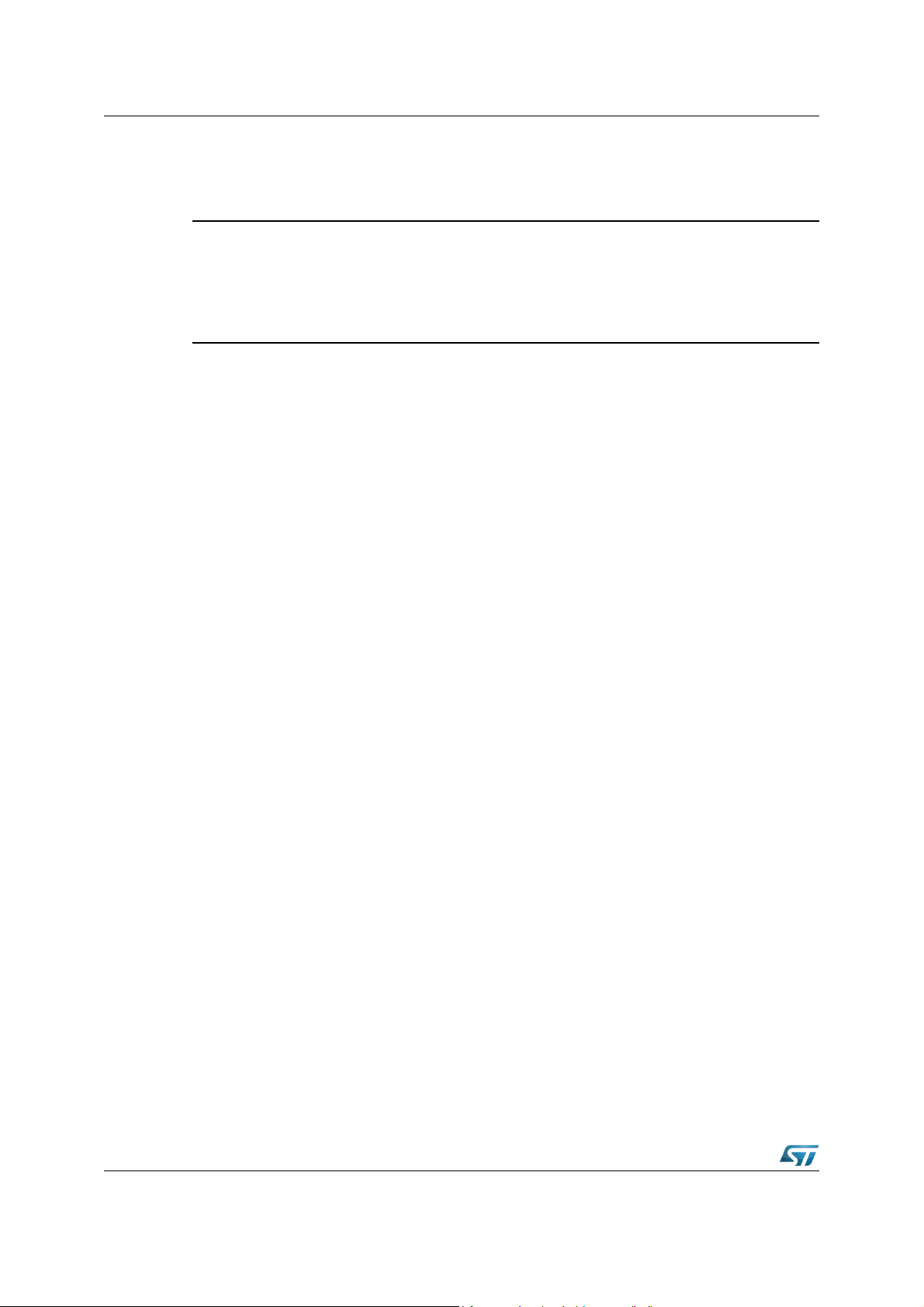

Figure 2 shows an image of the board with proper connection of each application.

Figure 2. Board connector

Note: Connect loads and voltage probes before applying line voltage.

3.2 How to operate the STEVAL-IHT005V2

Line voltage must be connected in position as described in Figure 2. The demonstration

board can be operated with or without the load. Even if no load is connected to the

demonstration board, all signals are present and can be displayed on the oscilloscope.

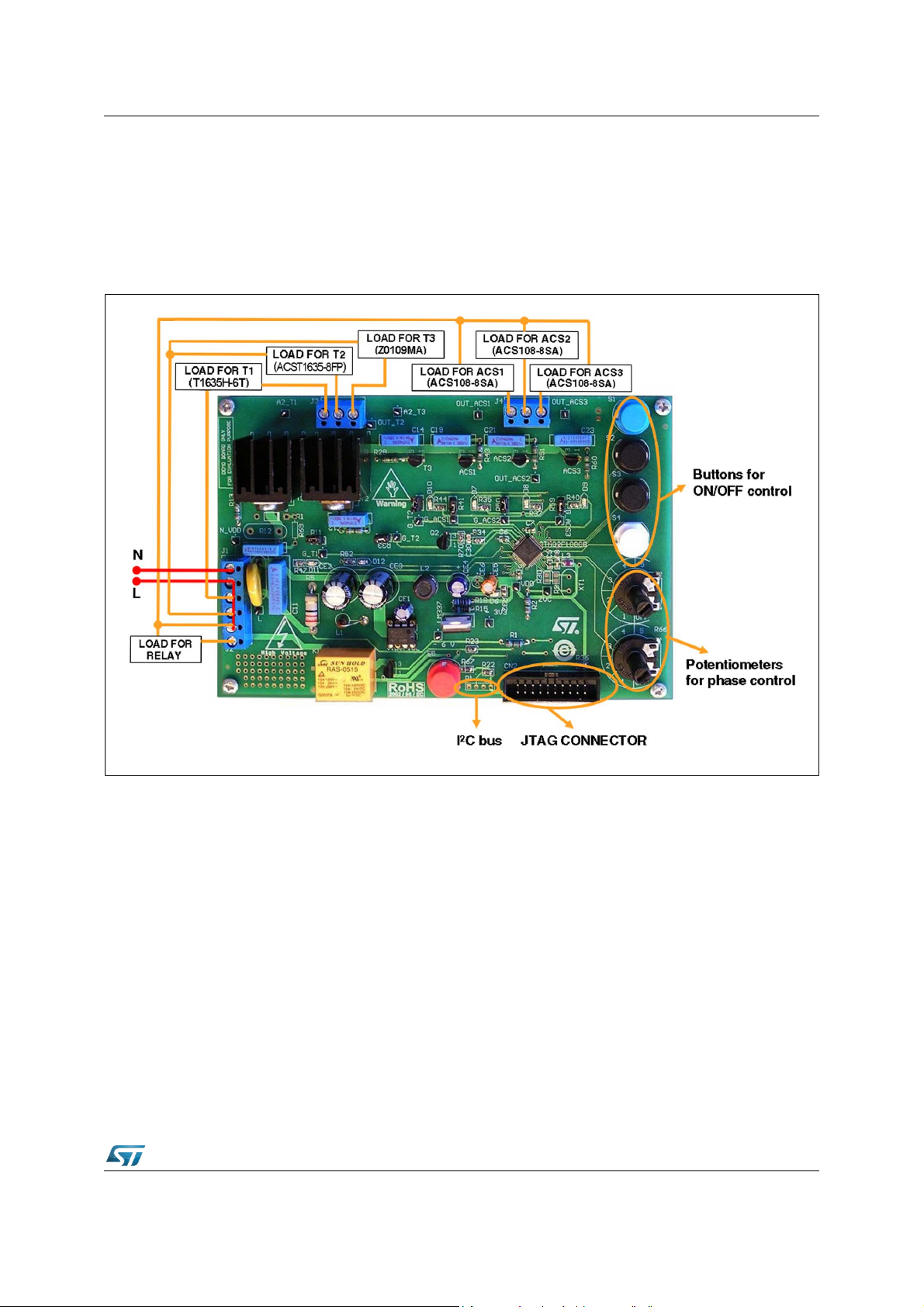

Red LED D6 signals the board is properly supplied from the mains. It also signals that high

voltage is present on the demonstration board.

It is recommended, although not required, to turn both potentiometers to the OFF position

before powering the demonstration board. The board is ready to operate after passing all

initialization routines, like mains frequency recognition, that take approximately 2 s.

Potentiometer R65 controls T1 (T1635H) and potentiometer R66 controls T2 (ACST16).

Output power level is adjusted by changing the position of the related potentiometer. Power

regulation is divided into 5 steps where position 1 means minimum power and position 5

means maximum power. LED D11 for T1 (T1635H) and LED D12 for T2 (ACST16) signal

DocID024503 Rev 1 7/27

Page 8

Getting started UM1631

that the gate control signal is applied. If the load (example motor) is running and the LED

lights up, it indicates the MCU properly controls the Triac(s).

Blue, black and white buttons control the 3x ACS108 and Z01 in ON/OFF mode with zero

voltage synchronization. The blue button S1 controls ACS1, black button S2 controls ACS2,

black button S3 controls ACS3 and white button S4 controls T3. The different colors are

used for easy recognition of the controlled device.

ACS2 and ACS3 are controlled with 2 ms gate pulses. This is sufficient for loads with RMS

current approximately in the range of 100 mA - 500 mA. Smaller loads should be controlled

with ACS1, which has continuous gate control.

T3 is controlled with 2 ms pulses and is used for comparison with ACS2 and ACS3 behavior.

LED D10 for T3 (Z01), LED (D7) for ACS1 (ACS108-8S), LED D8 for ACS2 (ACS108-8S)

and LED D9 for ACS3 (ACS108-8S) signals that the gate control signal is applied.

The red button S5 controls relay R1. Relay is controlled in the continuous DC mode. The DC

control starts in zero voltage for control coil.

Note: The coil control in zero voltage does not lead to accurate “Zero Voltage Switching” of the

power contacts.

Button control is used in a two-step control. When the button is first pushed it turns the

related device ON. A second push of the button turns the related device OFF. All devices

controlled by buttons are set in the OFF position after reset.

Figure 3. Overview of the demonstration board operation

8/27 DocID024503 Rev 1

Page 9

UM1631 Getting started

3.3 MCU programming

Once the demonstration board has the mains cable and load cable correctly connected, it

can be powered on. The STEVAL-IHT005V2 demonstration board goes to wait-for-signal

mode immediately after powering it on.

A JTAG connector for MCU programming is used when software modifications are

necessary.

Warning: Programming device has to be galvanically isolated from

mains when programmed directly on mains.

3.4 Load and gate control fitting

Gate current pulse is generated by the MCU. The length of the pulse is set by software.

Gate current pulse length is important. Its value must be set according to the minimum load

current. The load current has to reach the AC switch latching current value to keep the

device ON after the gate pulse is removed. Latching current (I

datasheet - ACS108-8S. It is important to check this point for low power loads when RMS

current is low and it takes a long time to reach the latching current level. When gate current

is removed before the load current reaches latching current, the device may turn off. Refer

to the AN302 application note for further information on latching current.

) is specified in the AC switch

L

The maximum value and length of the gate current the board can provide depends on power

supply rating. The power supply used in the demonstration board is able to provide 120 mA

continuously in full range of the operating voltage.

DocID024503 Rev 1 9/27

Page 10

Functional description UM1631

$0

)LULQJ

DQJOH

=9&

*DWHSXOVHOHQJWK

7ULDFJDWHVLJQDO

4 Functional description

Two different types of ACS/Triac control are implemented. Phase angle control and full

wave control. The gate control signal is synchronized with zero voltage crossing signal

(ZVC). The MCU operation is also synchronized with ZVC signal. ZVC signal is sent directly

to the MCU input pin that is set as external interrupt.

4.1 Phase angle control

Control of T1 (T1635H) and T2 (ACST16) is based on phase angle control.

Figure 4. Phase angle control description

Phase angle control is based on changing the firing angle (delay). The firing angle

determines the power that is delivered to the load. The shorter the firing angle (delay), the

higher the power.

Firing angle and gate control pulse are defined by software. Tab le 1 shows initial setting of

firing angle.

Firing angle (delay) 8.5 ms 6.9 ms 5.2 ms 3.6 ms 2.0 ms

4.2 Full wave control

Control of T3 (Z0109), ACS1, ACS2, and ACS3 (all ACS108-8S) is based on full wave pulse

control.

Table 1. Firing angle delay

Level 1 Level 2 Level 3 Level 4 Level 5

10/27 DocID024503 Rev 1

Page 11

UM1631 Functional description

$0

=9&

*DWHSXOVHOHQJWK7ULDFJDWHVLJQDO

Figure 5. Full wave control description

Full wave pulse control is based on sending gate control pulse immediately after ZVC

signal. Gate control pulse length is defined by the software.

Refer to Tabl e 2 for default gate current pulse duration for all AC switches. Duration of each

pulse is set separately for 50 Hz and 60 Hz mains.

Table 2. Initial gate current pulse duration

Device Variable name for 50 Hz mains

Initial gate

pulse

duration

(ms/timer

(1)

steps)

Variable name for 60 Hz mains

Initial gate

pulse

duration

(ms/timer

steps)

ACS1 ACS_1_SWITCHTIME_50HZ 10/100 ACS_1_SWITCHTIME_60HZ 8.3/83

ACS2 ACS_2_SWITCHTIME_50HZ

2/20

ACS_2_SWITCHTIME_60HZ 1.6/16

ACS3 ACS_3_SWITCHTIME_50HZ 2/20 ACS_3_SWITCHTIME_60HZ 1.6/16

Z0109 Z0109_SWITCHTIME_50HZ 2/20 Z0109_SWITCHTIME_60HZ 1.6/16

ACST16 ACST16_SWITCHTIME_50HZ 1/10 ACST16_SWITCHTIME_60HZ 0.8/8

T1635H T1635H_SWITCHTIME_50HZ 1/10 T1635H_SWITCHTIME_60HZ 0.8/8

1. The timer step is 100 µs.

(1)

DocID024503 Rev 1 11/27

Page 12

Power supply consumption UM1631

5 Power supply consumption

5.1 Max. output current and standby consumption

Non-isolated SMPS based on the VIPer16 in buck-boost topology is designed to provide

output voltage of -6 V. Maximum output current is 120 mA. -3.3 V voltage supply necessary

to supply MCU consists of linear regulator LM337.

Standby consumption has been measured in full range of the supply voltage. The standby

power consumption fulfills the requirement of maximum total power consumption to be

below 500 mW.

Total power consumption of the board in standby mode at supply voltage of 264 Vrms/50 Hz

was 499 mW (output current 10 mA at output voltage -6 V).

The power supply uses mains voltage for self supply from high voltage current generator.

Standby power consumption can be reduced by using the configuration with VIPer16 supply

made from the low voltage side. Refer to the AN2872 application note and VIPer16

datasheet for further information on power supply design.

5.2 Gate voltage impact on gate current

Gate voltage VGT varies with load current as shown in Figure 4 Figure 6?. This variation is

significant and cannot be neglected mainly for devices that are controlled in DC mode and

with low power supply level such as 3.3 V.

Figure 6. Example of V

(0.2 A RMS) for a Z0103 (T

variation with load current in quadrants 2 and 3

GT

= 85 °C, IG0 = 7.5 mA)

j

12/27 DocID024503 Rev 1

Page 13

UM1631 Power supply consumption

ACS devices have lower VGT variation with load current than Triacs and that is why they are

more suitable for 3.3 V applications as the gate current variation is lower.

Refer to the AN2986 application note for further details and for gate resistor calculation.

5.3 Pulsed gate control and average gate current consumption

Tabl e 3 gives the initial gate current pulse widths for each AC switch, and the maximum

pulse width that may be programmed to keep the overall consumption below the maximum

capability of the VIPer16 supply.

Table 3. Application current consumption

Device

T1635H-6T T1 30 35 50 1 5 N/A

ACST1635-8FP T2 30 35 50 1 5 N/A

Z0109MA T3 112 10 15 2 3 10

ACS108-8SA ACS1 112 10 15 10 15 10

ACS108-8SA ACS2 112 10 15 2 3 10

ACS108-8SA ACS3 112 10 15 2 3 10

1. Device is controlled in phase angle control, long pulse is not desired.

PCB

label

Gate

resistor

[]

I

GT

(Tj = 25 °C)

[mA]

I

GT

(Tj = 0 °C)

[mA]

Gate current

pulse

duration

[ms]

Maximum

average

current

[mA]

Max. gate

current pulse

duration (DC

mode) [ms]

Current consumption of the MCU and six signal LEDs, when turned ON, was estimated at

25 mA. Total current consumption of the board when all Triacs/AC switches are ON with

maximum gate current pulse is 95 mA (T1 and T2 have 1 ms gate current pulse as

described above).

(1)

(1)

DocID024503 Rev 1 13/27

Page 14

Board immunity performances UM1631

6 Board immunity performances

6.1 Hardware and software features to increase immunity

Software features

Software features to improve board immunity are

Filtering procedure for button and potentiometer control

Software watchdog

Hardware features to improve board immunity are

Input varistor

ACS-ACST technology and Transil™ as an option for T1635H-6T

47 nF input X2 capacitor

Noise suppressor circuits are implemented (10 nF X2 capacitor and 75 resistor)

R-C-R filter on gate implemented (RG/2, 10 nF, RG/2)

Layout golden rules for immunity improvement

Power tracks far from signal tracks

V

Noise suppressor and R-C-R gate filter close to AC switches and Triacs

Input MCU pins have implemented filter capacitor 10 nF

Any branch in the V

SS

map

DD

6.2 Surge tests results

Standard IEC 61000-4-5 tests were performed with surge level of 2 kV, which is required for

home appliances. Mains voltage used for the tests was 230 Vrms/50 Hz.

The ACST16 device is protected against overvoltage spikes up to 2 kV with implemented

crowbar technology. See the ACST16 datasheet for further details.

ACS devices are protected against overvoltage spikes up to 2 kV with implemented crowbar

technology. See the ACS108-8S datasheet for further details.

The Z01 Triac is protected thanks to the noise suppressor circuit and high impedance of the

load (refer to the AN437 application note for snubber design).

The T1635H is protected with Transil P6KE400CA. This is a different implementation of the

crowbar technology. The purpose here is to propose overvoltage protection with a crowbar

technology. This method presents the advantage of not aging contrary to the varistor

technology.

map has implemented a capacitor to decrease the VDD variation

14/27 DocID024503 Rev 1

Page 15

UM1631 Board immunity performances

6.3 Burst tests results

6.3.1 Test procedure

Standard IEC 61000-4-4 tests were implemented. The tests were performed at a frequency

of 100 kHz and power supply voltage of 254 Vrms/50 Hz. Parameters of the spikes:

T

= 0.7 ms, Tr = 300 ms. All affected couplings were tested. Spikes were applied against

d

the plate and related polarity (+/-) and the mains wire is mentioned: L+, L-, N+, N-, LN+,

LN-. The board was tested during OFF state (all AC switches were turned OFF).

Protective earth (PE) wire is not connected on the board which is why the couplings with PE

were not tested.

6.3.2 Test results of the board without hardware modifications

The target voltage level of the board immunity against burst spikes was 4 KV without any

influence on the board performance (class A).

MCU STM32F100C4T6B was not disturbed by the burst spikes up to 6 kV (class A). Burst

spikes up to 8 kV caused the MCU to reset but it recovers without external intervention

(class B). Reset procedure did not influence the immunity of the devices with higher

immunity.

Tabl e 4 shows immunity level of the ACS/Triacs against the burst spikes. The immunity is

defined by voltage level of spurious triggering.

Table 4. Immunity level of ACS/Triacs in class A

STEVAL-IHT005V2 VIN 254 VAC - 50 Hz L+ L- N+ N- LN+ LN-

T1635H (150 W light bulb load) > 8 kV > 8 kV > 8 kV > 8 kV > 8 kV > 8 kV

ACST16 (150 W light bulb load) > 8 kV > 8 kV > 8 kV > 8 kV > 8 kV > 8 kV

Z0109 (75 W light bulb load) 4.5 kV 4.1 kV 3.7 kV 4.6 kV 4.0 kV 3.7 kV

ACS1 (75 W light bulb load) 7.4 kV 6.7 kV > 8 kV 7.1 kV 7.3 kV 7.0 kV

ACS2 (150 W light bulb load) > 8 kV > 8 kV > 8 kV > 8 kV 7.6 kV 7.1 kV

ACS3 (150 W light bulb load) > 8 kV > 8 kV > 8 kV > 8 kV 7.6 kV 7.1 kV

6.3.3 Input filter influence

A 47 nF, X2 capacitor is implemented as the input filter. To achieve 4 kV immunity against

the burst spikes for all the AC switches, it was necessary to add two other X2 capacitors:

100 nF and 220 nF, as each of them influenced a different type of coupling. These two

capacitors are not included on the STEVAL-IHT005V2 board as only Z0109 was below 4 kV

level.

DocID024503 Rev 1 15/27

Page 16

Board immunity performances UM1631

STEVAL-IHT005V2

VIN 254 VAC - 50 Hz

Standby

+ L

ON + level 3 (5.2 ms)

Standby

+ N

ON + level 3 (5.2 ms)

Standby

+ L +N

ON + level 3 (5.2 ms)

Standby

- L

ON + level 3 (5.2 ms)

Standby

- N

ON + level 3 (5.2 ms)

Standby

- L +N

ON + level 3 (5.2 ms)

Table 5. IEC-61000-4-4 results with input filter modification

2 kV 4 kV 6 kV 8 kV

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

Note: A. No changes in functionality. The board works properly, no reset occurring.

B. Reset occurs, but the board recovers without external intervention.

C. Application does not recover without external intervention.

Two states were tested. Standby mode, when all devices are OFF, and “ON + level 3" when

all devices are turned ON: the devices controlled in full wave mode (T3, ACS1, ACS2,

ACS3) are ON for the whole period and phase angle controlled devices (T1, T2) are ON at

level 3 (5.2 ms delay after zero voltage crossing signal).

6.3.4 Noise suppressor influence

The noise suppressor circuit that consists of X2 capacitor 10 nF (C2, C12, C14, C19, C21,

C23) and resistor 75 (R13, R19, R28, R43, R51, R60) has significant influence on burst

immunity of the devices, as shown in the tests results below (to compare with Table 5

results).

Table 6. Immunity of the high power devices without RC noise suppressor

STEVAL-IHT005V2

VIN 254 VAC - 50 Hz

T1635H (150 W light bulb load) 1.7 kV 1.6 kV 1.9 kV 1.7 kV 2.1 kV 1.7 kV

ACST16 (150 W light bulb load) 4.6 kV 3.5 kV 4.8 kV 3.1 kV 3.3 kV 3.1 kV

L+ L- N+ N- LN+ LN-

16/27 DocID024503 Rev 1

Page 17

UM1631 Board immunity performances

6.3.5 Gate filtering circuit influence

The gate filtering circuit has an influence mainly on sensitive devices. When the gate

filtering circuit is removed, the immunity of Z01 decreases to 2 kV and immunity of ACS108

is decreased to 4 kV. Gate filtering circuit is not mandatory to pass IEC-61000-4-4 tests for

ACS108.

There is no influence on 35 mA I

GT

6.3.6 Immunity to relay switching

Relay is connected on the board. The relay cannot be controlled in zero voltage mode.

Switching of the relay produces very high dV/dt, other devices must be immune to this type

of noise. Immunity tests of the devices against relay switching have been performed.

Figure 7 shows turn-off behavior of the relay. (The dV/dt observed during turn-off is

1 kV/µs.) Observed peak voltage during turn-off was +/-1300 V. The dV/dt observed during

turn-on was 4 kV/µs. The load was 1.4 H inductor with serial resistance 12 , (RMS current

0.52 A). The Triacs and ACS/ACST switches were not disturbed by these spikes.

Figure 7. dV/dt behavior during relay turn-off

devices, when the gate filtering circuit is removed.

DocID024503 Rev 1 17/27

Page 18

Board immunity performances UM1631

Figure 8. dV/dt behavior during turn-on

18/27 DocID024503 Rev 1

Page 19

UM1631 STEVAL-IHT005V2 schematic

Appendix A STEVAL-IHT005V2 schematic

A.1 Schematic

Figure 9. STEVAL-IHT005V2 schematic

OUT_ACS1

ACS_3

BUTTON_Z0109

LED_Z0109

R44

NRST_JTAG

1

testpoint

C21

ACS2

DD

V

C22

10 nF

G_ACS2

1

testpoint

LED_ACST1635

2

3

BUTTON_ACS_

BUTTON_ACS_

LED_T1635H

LED

D11

R47

DD

V

R45

R46

V

X2 10 nF/305

R51

COM

G

R48 R49

R50

2

ACS_

LED_ACS_1

LED_ACS_2

1

BUTTON_ACS_

LED

D12

DD

V

20

123

J4

-8S

ACS108

OUT

1

testpoint

OUT_ACS 2

3

D_Z0109

LE

LED_ACS_

DD

V

DD

V

DD

V

LED_ACST1635

LED

R52

DD

V

DD

V

Header_3

C23

VDD

Cap

10 nF

G_ACS3

testpoint

R67

R56

R55

R54

R53

OUT_ACS3

0 nF

X2

1

ACS3

M

CO

R58

C24

R57

R59

1

Y

BUTTON_RELA

BUTTON_Z0109

3

BUTTON_ACS_

2

BUTTON_ACS_

BUTTON_ACS_1

/305 V

G

ACS_3

C36

C35

C34

C33

1

testpoint

R60

ACS108-8S

OUT

DD

V

DD

V

10 nF

10 nF

10 nF

10 nF

10 nF

C32

R66

GND

S5

12

GND

12

GND

12

GND

12

GND

12

POTENTIOMETER_ACST1635

10 nF

C38

GND

RPot

R65

RPot

10nFC37

TENTIOMETER_T1635H

PO

100 nF

C29

R68

button

34

100 nF

C28

R64

S4

button

34

C27

R63

100 nF

S3

button

34

100 nF

C26

R62

S2

button

34

100 nF

C25

R61

S1

button

34

GND

GND

GND

GND

GND

GND

GND

GND

VDD

G_T1

Viper16L

X2

C2

R69

C10

10 nF

1

testpoint

R3

4

ZVC signal

R1 R2

R12

10 nF/

T1

R11

T1635H

R4

FB

Drain7Drain

8

1 nF

C31

1

ZVC

L

relay_out

testpoint

N/A

305 V

2

R8 R10

C1

CE1

2

DD

V

testpoint

J2

R13

T1635H

TR1

P6KE400CA

-6 V

1

-6 V

D3

1

L1

GND

D2

D1

R5

1

L

1

testpoint

U2

100 nF

S

LIM

COMP

1 mH

123

-3.3 V

1

-6 V

-3.3 V

3

OUT

IN

2

STTH1R06

R6

3

5

CE3

CE2

1N4007

1N4007

R14

Header_3

DD

V

testpoint

R15

ADJ

CE4

N/A

F/450 V F/450 V

C11

Varistor

A2_T1

1

C13

Cap

10 nF

GND

CE5

Res

1

LM337

CE6

D4

1 mH

L2

N.A.

C3

R7

N/A

X2 47 nF/305 V

testpoint

305 V

C12

X2 10 nF/

T2

R17R16

DD

V

1

ACST1635

DD

V

0 V

R18

Res

N/A

STTH1R06

1 nFC4

N

J1

123

J3

R19

ACST1635

OUT_T2

testpoint

DD

V

DD

V

DD

V

DD

V

DD

V

testpoint

1

123

Header_3

1

testpoint

I2C_SCL

BUTTON_RELAY

R20

R22

P1

N_VDD

Header_3

DD

V

G_T3

testpoint

I2C_SDA

4

R21

R23

BC557A

Q1

C14

R25R24

10 nF C16

R26

1

PB4

LED_T1635H

2C_SDA

I

I2C_SCL

123

NRST

NRST_JTAG

relay

relay_out

X2

Z0109

C15

A2_T3

1

10 nF/

305 V

T3

Z0109

PB3

PA1 5

relay

C5

100 nF

DD

V

GND

GND

Header 4

100 nF

3

1

testpoint

R28

V

10k

R27

Relay

K1

DD

PA1 4

38

39

40

41

42

43

44

45

46

47

G_T2

DD

V

C6

STM32F100CB

36

37

PA1 4

PA1 5

PB3

PB4

PB5

PB6

PB7

BOOT0

PB8

PB9

3

3

48

VSS_

VDD_

1

C17

GND

D5

1N4007

-RAS 0515

R29

4

2

DD

V

ACST1635

R33

1

testpoint

BC547A

Q2

1 nF

C30

100 nF

35

VSS_2

VDD_2

PC13

VBAT

2

2

PA1 3

PA1 334PA1 233PA1132PA1 0

PC143PC154PD0

ZVC signal

N/A

R30

N/A

R9

XT1

N/A

D6

ON/OFF signal

DD

V

R70

GND

R34

Z0109

1

T1635H

ACS_

26

25

28

31

29

PA930PA8

PB1427PB13

PB12

PB15

VDD_1

24

VSS_1

23

PB11

22

PB10

21

PB2

20

PB1

19

PB0

18

PA7

17

PA6

16

PA5

15

PA4

14

PA3

13

VSSA8NRST7PD1

VDDA9PA010PA111PA2

6

5

12

C9

10 nF

NRST

C8

L3

N/A

DD

V

1

C18

N/A

GND

-6 V

LED_ACS_1

LED

D7

LED

D8

R35

R32

DD

DD

V

V

-6 V

DD

V

V

PB4

-6

CN1

PA15

DD

V

12345678910111213141516171819

JTAG

V

R37

DD

LED_ACS_2

PA13

DD

V

GND

10 nF

GND

GND

G_ACS1

testpoint

C7

LED

V

PB3

PA14

ACS1

C20

1

100 nF

GND

D9

R40

DD

10 nF/305 V

X2

C19

R43

-8S

ACS108

OUT

COM

G

R39

R38

R41

1

ACS_

ACS_2

GND

POTENTIOMETER_T1635H

POTENTIOMETER_ACST1635

LED_ACS_3

LED

D10

DD

V

R42

PB3

AM07459V1

DocID024503 Rev 1 19/27

Page 20

STEVAL-IHT005V2 schematic UM1631

A.2 Demonstration board layout

Figure 10. STEVAL-IHT005V2 - top layer

Figure 11. STEVAL-IHT005V2 - bottom layer

20/27 DocID024503 Rev 1

Page 21

UM1631 STEVAL-IHT005V2 schematic

R

g

1

1

R

gt– ol

100

---------------+

------------------------------ -

V

DD M– inVGT M– ax

– VOL–

l

G

0C

----------------------------------------------------------------- -

A.3 Test point lists

Name Definition

G_T1 Control signal of T1 (T1635H)

ZVC “Zero Voltage Crossing” signal

-6 V Reference of SMPS output voltage

N_VDD Neutral reference and VDD

-3.3 V Reference for MCU power supply

A2_T1 A2 terminal of T1

VDD MCU power supply voltage

OUT_T2 OUT terminal of T2 (ACST16)

G_T3 Control signal of T3 (Z0109)

A2_T3 A2 terminal of T3

G_T2 Control signal of T2 (ACST16)

G_ACS1 Control signal of ACS1

OUT_ACS1 OUT terminal of ACS1

G_ACS2 Control signal of ACS2

OUT_ACS2 OUT terminal of ACS2

G_ACS3 Control signal of ACS3

Table 7. Test points definition

OUT_ACS3 OUT terminal of ACS3

Line LINE voltage

A.4 Gate resistor calculation

The gate resistor value must be defined within the equation below to ensure to apply a gate

current higher than specified I

Gate resistor calculation

for the worst operating conditions:

GT

DocID024503 Rev 1 21/27

Page 22

STEVAL-IHT005V2 schematic UM1631

Assumptions for calculation

Note: V

V

is minimum supply voltage (typically 3 V for 3.3 V power supply taking into

DD_Min

account dispersion of resistors at LM337).

V

GT_Max

= 1.0 V (maximum gate voltage that must be applied between gate and A1 or

COM).

V

= 0.4 V maximum MCU I/O port voltage when turned to low level (given by the

OL

datasheet (0.4 V for STM32F100)).

value of 0.4 V is used also for BC547B buffer transistor control.

OL

R

I

is tolerance of used resistor (typically 1% or 5%).

g_tol

(0 °C) is gate current for minimum ambient temperature (normally 0 °C) (refer to

G

Triac family datasheet curve).

Standard resistor choices, according to the above equation and assumptions, are shown in

Tabl e 8.

T1635H

ACST16

ACS108

Table 8. Gate resistor definition for each device

Tolerance of Rg (%) Rg ()R

1 31.7 2 x 15

5 30.4 2 x 15

1 31.7 2 x 15

5 30.4 2 x 15

1 112.2 2 x 56

5 107.8 2 x 51

standard ()

g

Z0109

1 112.2 2 x 56

5 107.8 2 x 51

In the STEVAL-IHT005V2 demonstration board tolerance resistors of 1% are used.

22/27 DocID024503 Rev 1

Page 23

UM1631 STEVAL-IHT005V2 schematic

A.5 Bill of material

Table 9. Bill of material

Quan-

tity

1C3 N/A Capacitor

1 P1 N/A Header, 4-pin

2 C17, C18 N/A Capacitor

2 R6, R7 N/A Resistor

2 R9, R30 N/A Resistor

1 C11 X2 47 nF/305 V Capacitor EPCOS B32922C3473K000

6

1 C1 100 nF/50 V 0805 SMD Capacitor Any

3 C4, C30, C31 1 nF/50 V 0805 SMD Capacitor Any

1C8 1 F/16 V 0603 SMD Capacitor Any

1 C9 10 nF/50 V 0603 SMD Capacitor Any

1CE1 10 F/50 V Electrolytic capacitor Any

1 CE4 220 F/16 V Electrolytic capacitor Any

1CE5 10 uF/16 V Electrolytic capacitor Any

1 CE6 N/A Electrolytic capacitor Any

1 CN2 MLW20G Connector Any

Designator Value Description Vendor Order code

C2, C12, C14,

C19, C21, C23

X2 10 nF/305 V Capacitor EPCOS B32921C3103K000

1 D6 LED 0805 red 20 mA Typical LED Any

1 K1 RAS 0515 Single-pole relay Any

1 L1 1 mH 0.13 A Inductor Any

1 L2 1 mH 0.28 A Inductor Any

1L3

1 Q1 BC557A

1 Q2 BC547A

1 R12 N/A Varistor Any

1 R14 595-275 Varistor Any

1 R15 1.2 k 0.6 W Resistor Any

1 R18 2 k 0.6 W Resistor Any

1 R28 56 0.6 W Resistor Any

1 R31 4.7 k0.6 W Resistor Any

1 R32 2 k 0805 SMD Resistor Any

1 H 0805 SMD

0.09 A

Inductor Any

PNP bipolar

transistor

NPN bipolar

transistor

Any

Any

DocID024503 Rev 1 23/27

Page 24

STEVAL-IHT005V2 schematic UM1631

Table 9. Bill of material (continued)

Quan-

tity

1R5 22 - 5% 2 W Resistor Any

1 R69 100 0.6 W Resistor Any

1 S1 P-DT6BL Button Any

2 S2, S3 P-DT6SW Button Any

1S4 P-DT6WS Button Any

1S5 P-DT6RT Button Any

1XT1 N/A

2CE2, CE3 4.7 F/450 V Electrolytic capacitor Any

2 R1, R2 220 k - 1% 0.6 W Resistor Any

2 R3, R4 56 k 0805 SMD Resistor Any

2 R65, R66 50 k Potentiometer + shaft Any

3 C5, C6, C7 100 nF/50 V 0603 SMD Capacitor Any

3 D1, D2, D5 1N4007 SMA Default diode Any

3 R23, R34, R70 1 k 0805 SMD Resistor Any

4 J1, J2, J3, J4 ARK300V-3P Three-pole terminal Any

4

5

Designator Value Description Vendor Order code

R8, R10, R16,

R17

R13, R19, R43,

R51, R60

Crystal oscillator

(HC49/U 8 MHz)

15 0805 SMD Resistor Any

75 0.6 W Resistor Any

Any

R61, R62, R63,

5

R64, R68

C10, C13, C16,

6

C20, C22, C24

C15, C25, C26,

6

C27, C28, C29

D7, D8, D9,

6

D10, D11, D12

R11, R26, R33,

6

R41, R50, R59

R21, R27, R36,

6

R42, R45, R46

R35, R37, R40,

6

R44, R47, R52

C32, C33, C34,

7

C35, C36, C37,

C38

24/27 DocID024503 Rev 1

100 0805 SMD Resistor Any

10 nF/50 V 0805 SMD Capacitor Any

100 nF/50 V 0805 SMD Capacitor Any

LED 0805 green

20 mA

0R STIP line 2x +

jumper

10 k 0805 SMD Resistor Any

510 0805 SMD Resistor Any

10 nF/50 V 0805 SMD Capacitor Any

Typical LED Any

Short-circuit

connector

Any

Page 25

UM1631 STEVAL-IHT005V2 schematic

Table 9. Bill of material (continued)

Quan-

tity

7

9

18

1T1 16 A Triac

1 T2 16 A ACST ST ACST1635-8FP

1 T3 1 A Triac Standard 4Q Triac ST Z0109MA

1 TR1 P6KE400CA Transil ST P6KE400CA

Designator Value Description Vendor Order code

R20, R22, R53,

R54, R55, R56,

R67

R24, R25, R29,

R38, R39, R48,

R49, R57, R58

-3V3, -6 V,

A2_T1, A2_T3,

G_ACS1,

G_ACS2,

G_ACS3, G_T1,

G_T2, G_T3, L,

N_VDD,

OUT_ ACS1,

OUT_ACS2,

OUT_ACS3,

OUT_T2, VDD,

ZVC

4.7 k0805 SMD Resistor Any

56 0805 SMD Resistor Any

Test point Test point RS 262-2179

High temperature

Triac

STMicroelectronics T1635H-6T

1U1

1 U2 Voltage regulator ST LM337

1 U3 32-bit MCU ST STM32F100C4T6B

2 D3, D4 Fast diode ST STTH1R06

ACS1, ACS2,

3

ACS3

2

4

4 M3 screw, 6 mm long Any

0.8 A AC switch ST ACS108-8SA

20 x 20 x 30 mm

~6 K/W

Monolithic AC-DC

converter

Heatsink Any

Distance columns,

10 mm, KDI6M3X10

ST VIPer16LN

Any

DocID024503 Rev 1 25/27

Page 26

Revision history UM1631

Revision history

Date Revision Changes

01-Oct-2013 1 Initial release.

Table 10. Document revision history

26/27 DocID024503 Rev 1

Page 27

UM1631

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

ST PRODUCTS ARE NOT DESIGNED OR AUTHORIZED FOR USE IN: (A) SAFETY CRITICAL APPLICATIONS SUCH AS LIFE

SUPPORTING, ACTIVE IMPLANTED DEVICES OR SYSTEMS WITH PRODUCT FUNCTIONAL SAFETY REQUIREMENTS; (B)

AERONAUTIC APPLICATIONS; (C) AUTOMOTIVE APPLICATIONS OR ENVIRONMENTS, AND/OR (D) AEROSPACE APPLICATIONS

OR ENVIRONMENTS. WHERE ST PRODUCTS ARE NOT DESIGNED FOR SUCH USE, THE PURCHASER SHALL USE PRODUCTS AT

PURCHASER’S SOLE RISK, EVEN IF ST HAS BEEN INFORMED IN WRITING OF SUCH USAGE, UNLESS A PRODUCT IS

EXPRESSLY DESIGNATED BY ST AS BEING INTENDED FOR “AUTOMOTIVE, AUTOMOTIVE SAFETY OR MEDICAL” INDUSTRY

DOMAINS ACCORDING TO ST PRODUCT DESIGN SPECIFICATIONS. PRODUCTS FORMALLY ESCC, QML OR JAN QUALIFIED ARE

DEEMED SUITABLE FOR USE IN AEROSPACE BY THE CORRESPONDING GOVERNMENTAL AGENCY.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2013 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

DocID024503 Rev 1 27/27

Loading...

Loading...