UM2438

User manual

Predictive maintenance reference kit with sensors and IO-Link capability

Introduction

The STEVAL-BFA001V1B

vibration, environmental and acoustic algorithms for condition monitoring and predictive maintenance applications and can be

used as a reference to base your own solutions on our hardware and software designs.

The kit is based on the STEVAL-IDP005V1 high performance industrial sensor platform featuring a compact design that is

especially suitable for monitoring motors, pumps and fans.

reference kit for condition monitoring and predictive maintenance lets you evaluate embedded

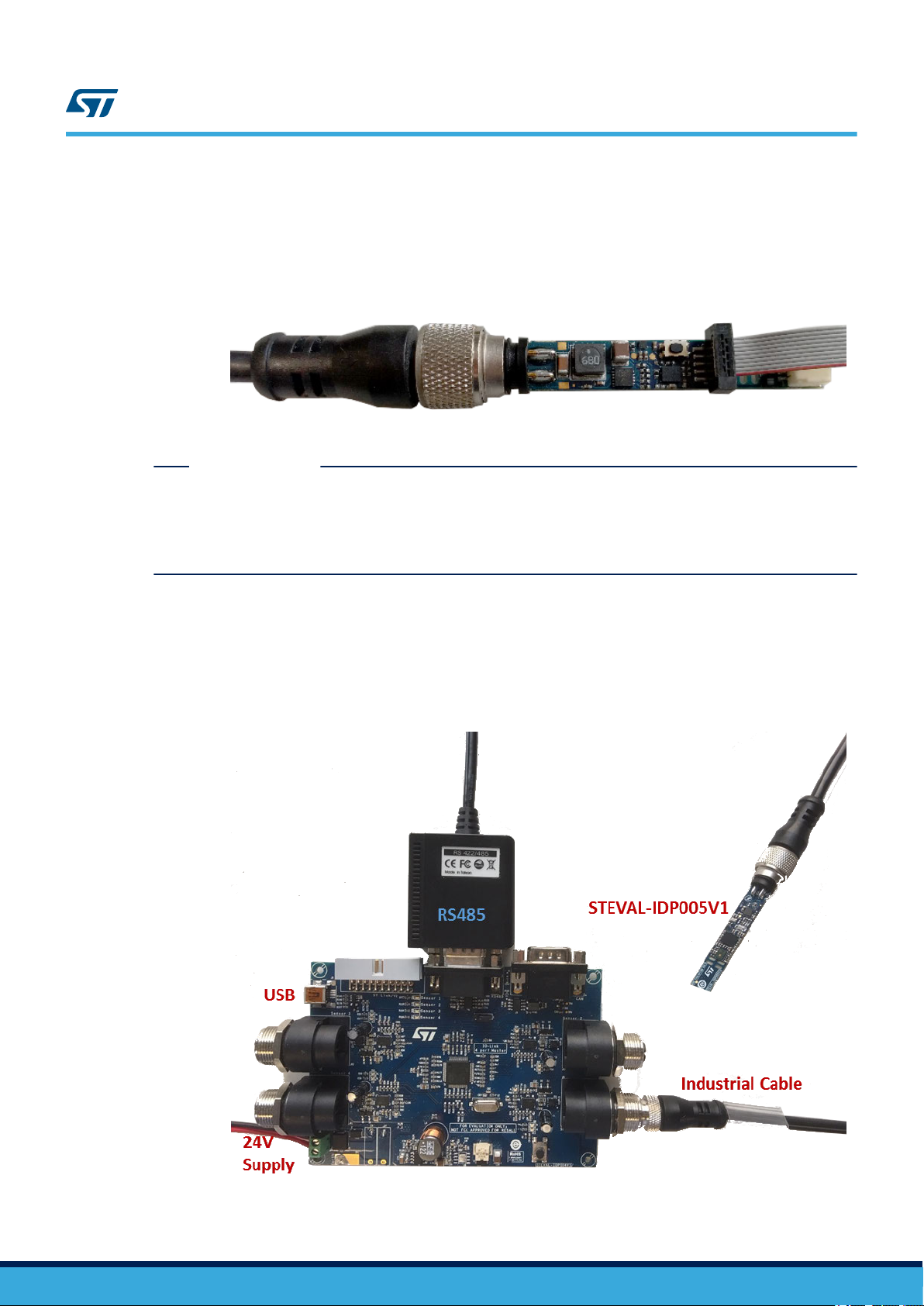

Figure 1. STEVAL-BFA001V1B predictive maintenance reference kit

UM2438 - Rev 2 - March 2019

For further information contact your local STMicroelectronics sales office.

www.st.com

1 Overview

The main board in the kit is the STEVAL-IDP005V1 sensor platform, which features a high end ARM® Cortex®-M4

32-bit microcontroller running the processing and analysis firmware for the following on-board sensors:

• an iNEMO 6DoF accelerometer and gyroscope

• a barometric pressure sensor

a relative humidity and temperature sensor

•

• a digital microphone

The sensor platform comes complete with EEPROM for data Storage, an IO-Link PHY device and power

management based on a step-down switching regulator and LDO regulator.

The firmware includes all the necessary drivers, libraries, application and demonstration software and utilities to

deliver the following functionality:

• algorithms for advanced time and frequency domain vibration analysis

• environmental (pressure, humidity and temperature) monitoring

• audio algorithms for acoustic emission (AE)

• condition monitoring and predictive maintenance demonstration software

• a GUI to help you set up monitoring environments and plot incoming data

Sensor data results can be transmitted through one of the following serial communication channels:

1. IO-Link (stack is not included in the FW): connect with an external STEVAL-IDP004V1 IO-Link master multiport evaluation board and use one of the firmware applications or the GUI bundled in the firmware package

to display sensor data and send query commands.

2. UART: display the data using a common terminal emulator like TeraTerm, through the UART communication

channel.

UM2438

Overview

RELATED LINKS

Visit the STEVAL-BFA001V1B web page for the most up to date resources and reference material

UM2438 - Rev 2

page 2/67

1.1 Package components

One reference design board (10 x 50 mm) - STEVAL-IDP005V1.

•

• One adapter for ST-LINK programming and debugging tool - STEVAL-UKI001V1.

• One 0.050” 10-pin flat cable.

• One 4-pole cable with M12 female connector.

• One 4-pole mount M12 connector plug, with male contacts.

UM2438

Package components

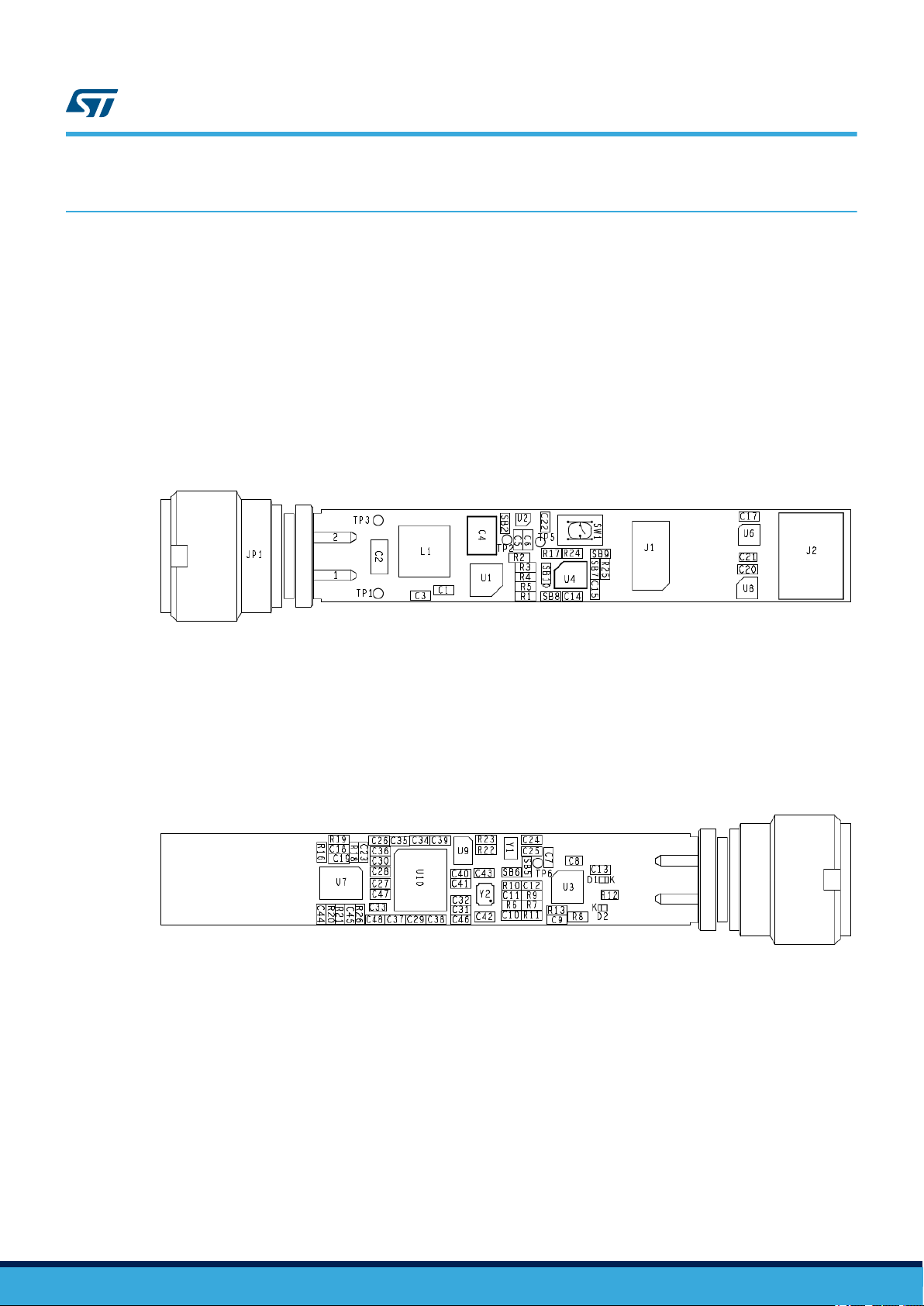

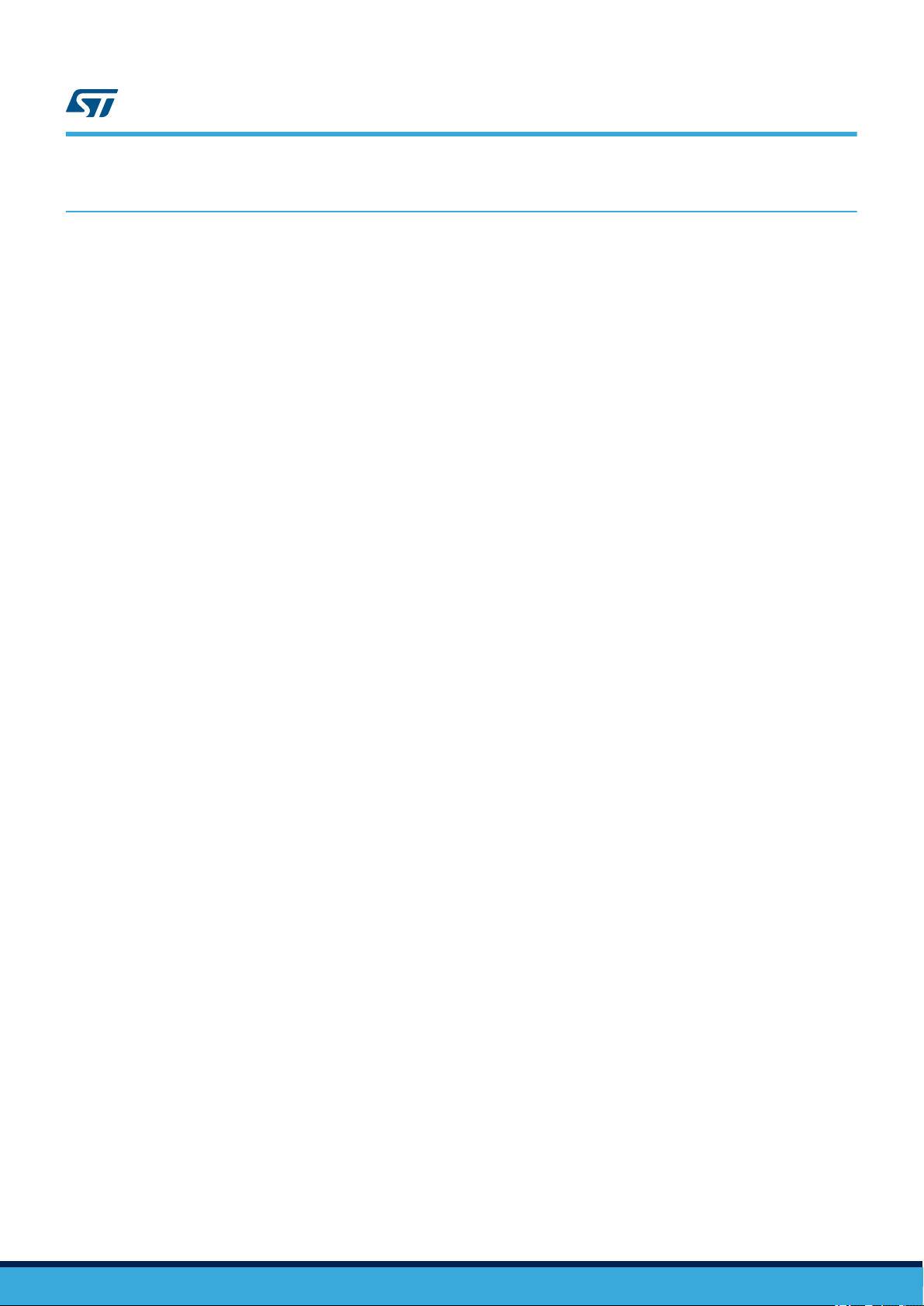

Figure 2. STEVAL-BFA001V1B package contents

1.2 System requirements

The STEVAL-IDP005V1 is already programmed with Condition Monitoring firmware. To run the demo, you need

the following items:

• A Windows™ (version 7 or higher) PC with a serial line terminal application like Putty.

• A USB type A to mini B male cable.

Figure 3. STEVAL-IDP005V1 board - top

Figure 4. STEVAL-IDP005V1 board - bottom

UM2438 - Rev 2

page 3/67

• A generic power supply (range 18 to 32 V).

•

An STM32 Nucleo 64 board with ST

-LINK V2.1 in-circuit debugger/programmer

To develop your own project, you will also need the following items:

• A Windows™ (version 7 or higher) PC with IAR, KEIL or System Workbench for STM32 firmware

development environment.

• Microsoft.NET Framework 4.5 or higher (for the GUI only).

• ST-LINK utility for binary firmware download (find the latest embedded software version on www.st.com).

1.3 How to run the demo supplied with the firmware

UM2438

How to run the demo supplied with the firmware

.

To run the demo, you must first unpack the STEV

AL-BFA001V1B

kit.

Follow the steps below to run the condition monitoring demonstration firmware (STSW-BFA001V1\Projects

\Demonstrations\Condition_Monitoring\CondMonitor_SRV) loaded on the STEVAL-IDP005V1 evaluation board:

Step 1. Plug the STEVAL-UKI001V1 onto the Nucleo board.

Step 2. Connect the STEVAL-UKI001V1 plus Nucleo board assembly to the STEVAL-IDP005V1.

Step 3. Supply power

Step 4. Connect the ST-LINK/V2-1 (on the STM32-NUCLEO 64 board) to the PC through the USB Type-A

Male to Type-B mini cable

Step 5. Open and configure your terminal emulator.

Set the following parameters:

– Name: COM Port name

– Baud Rate: 230400

– Data:8

– Parity: None

– Stop Bit: One

– Flow Control: None

Step 6. Push the Reset button on the STEVAL-UKI001V1 (or STEVAL-IDP005V1).

Step 7. Insert the new parameters and/or press ENTER, then press [Y] and [Enter] to start monitoring.

RELATED LINKS

4 How to supply power to the STEVAL-IDP005V1 board on page 15

5.1 Connection through an ST-LINK/V2-1

7.1 Outputs for the acoustic analysis project on page 29

on page 17

UM2438 - Rev 2

page 4/67

2 STEVAL-IDP005V1 hardware architecture

UM2438

STEVAL-IDP005V1 hardware architecture

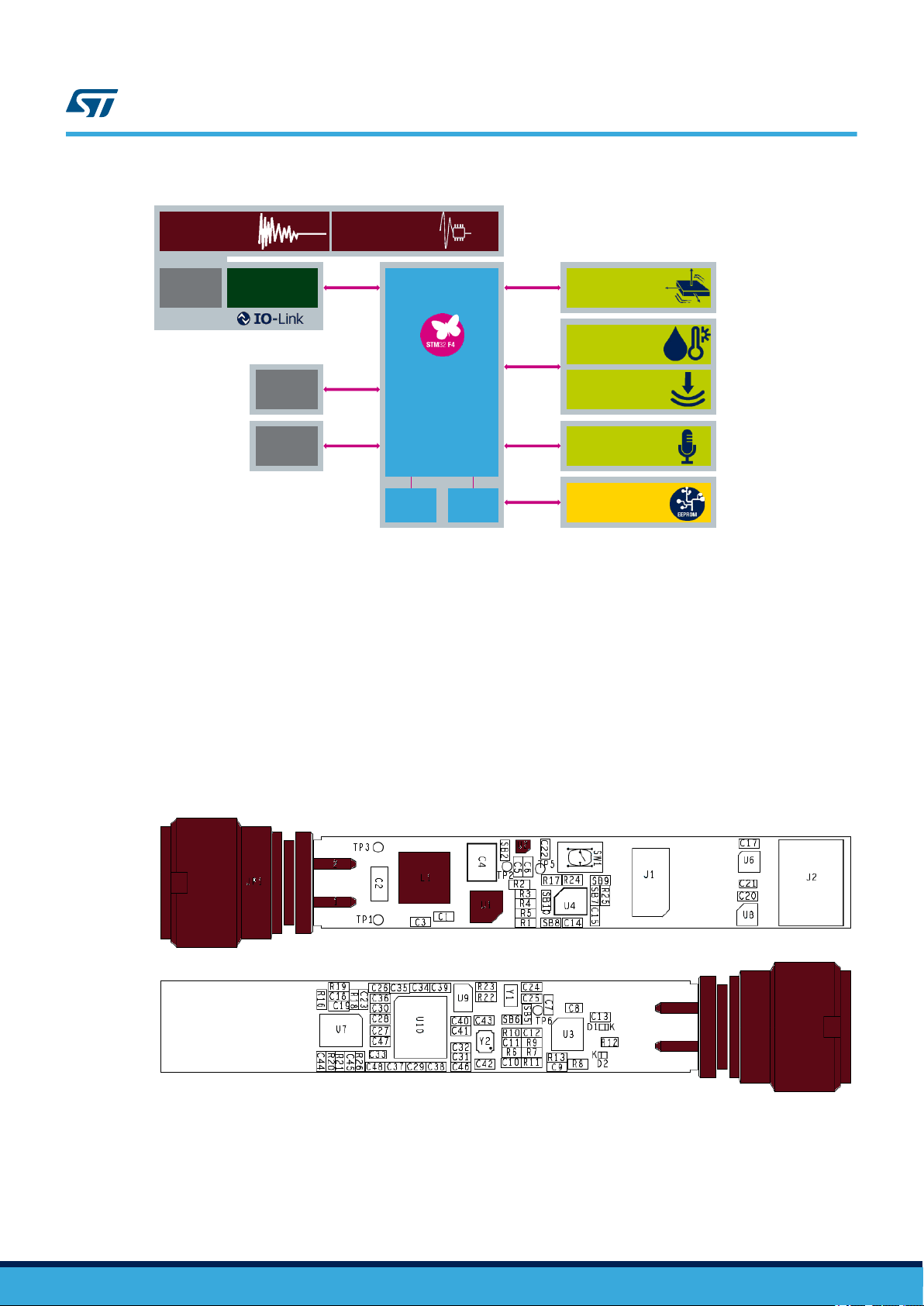

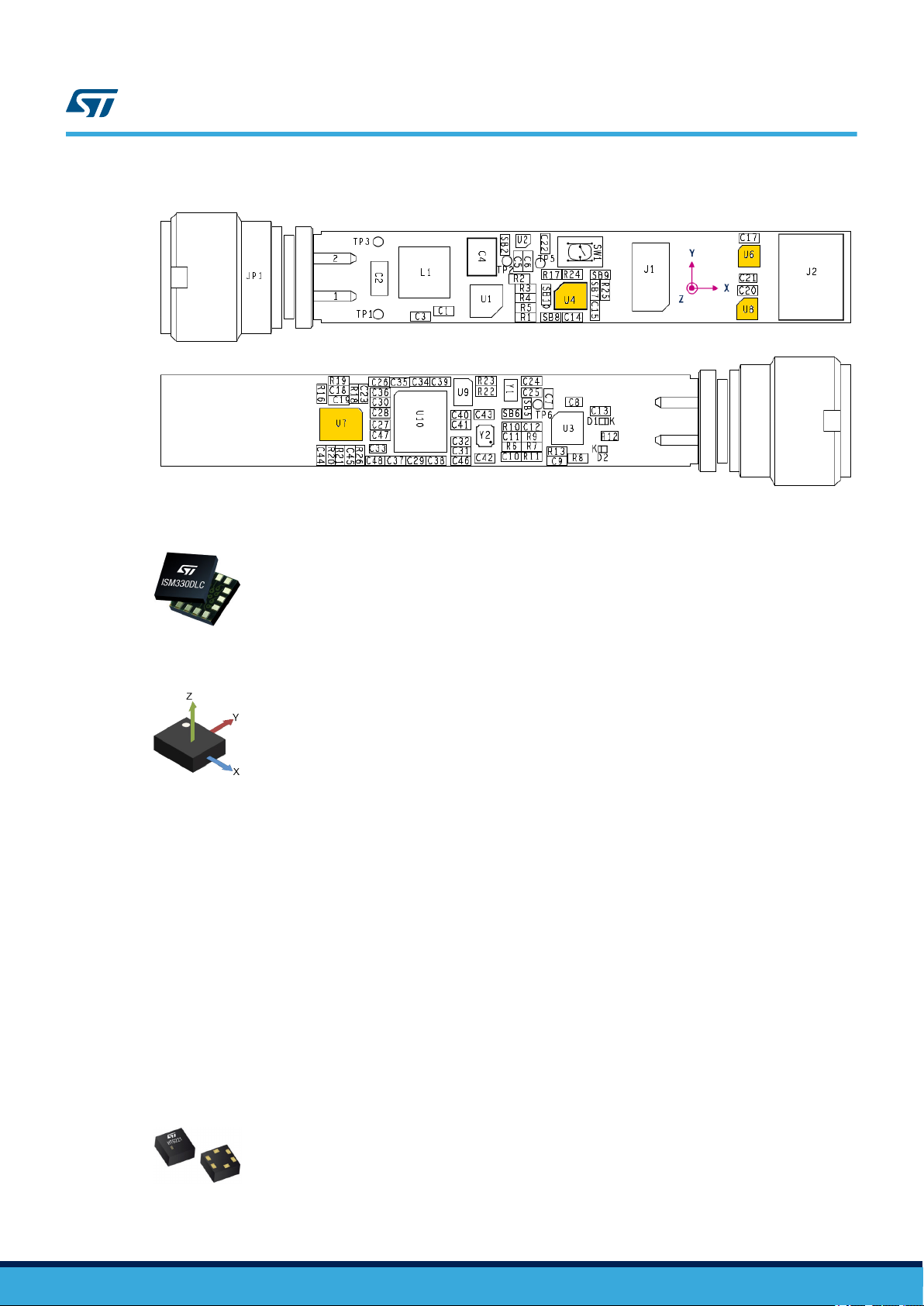

Figure 5. STEV

JP1 - IO-Link 4-position M12 A-coded connector

•

•

J1 - SWD connector

• J2 - Auxiliary connector

• SW1 - Reset button

• L1 - Shielded power inductor

• U1 - L6984 step-down switching regulator

• U2 - LDK220 LDO

• U4 - ISM330DLC 3D accelerometer and 3D gyroscope

• U6 - HTS221 humidity and temperature sensor

• U8 - LPS22HB pressure sensor

Figure 6. STEVAL-IDP005V1 bottom side components

• U3 -

• U7 - MP34DT05-A digital microphone

• U9 - M95M01-DF 1-Mbit serial SPI bus EEPROM

• U10 - STM32F469AI ARM® Cortex®-M4 32-bit MCU

• Y1 - 32.768 kHz crystal

• Y2 - 24 MHz crystal

L6362A IO-Link communication transceiver

AL-IDP005V1 top side components

UM2438 - Rev 2

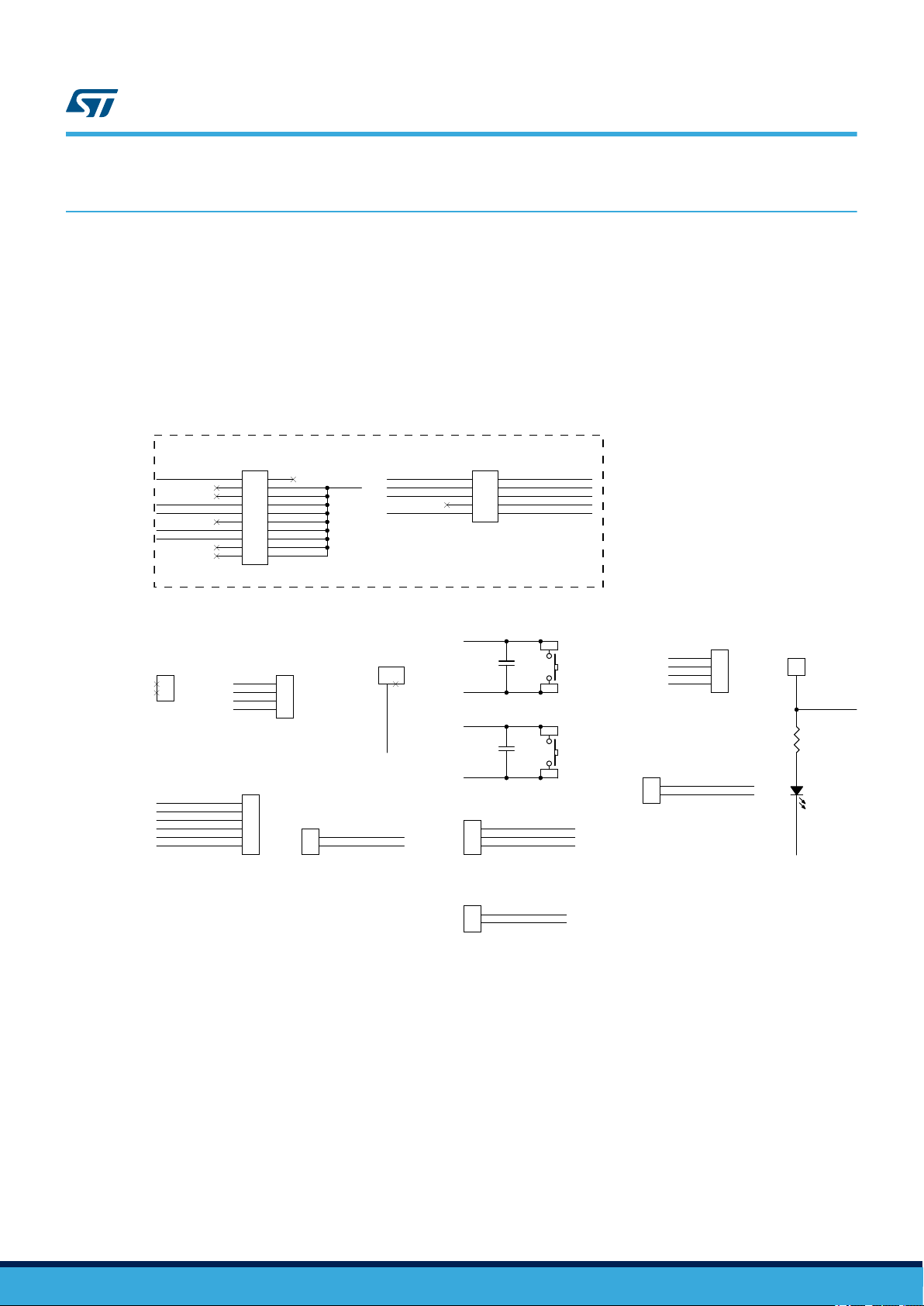

The whole system consists of the following functional subsystems:

1. Power management

2. Microcontroller

3.

MEMS sensors

4. EEPROM

5. Wired connectivity

6. External connectors

The sensors are connected to the microcontroller through separate bus SPI and I2C peripherals.

The connectivity options are:

• UART and I2C on the expansion connectors.

• IO-Link on the M12 male socket.

page 5/67

STM32F469AI

Microcontroller

32 kHz

Crystal

24 MHz

Crystal

ISM330DLC

3D Accelerometer

3D Gyroscope

HTS221

Humidity and

Temperature Sensor

LPS22HB

Pressure Sensor

SPI1

MP34DT05-A

Digital Microphone

I2S2

L6362A

IO-Link Transceiver

USART2

Enhanced

SWD

Connector

UART5

I2C2

ADC3

GPIO

M12 4-pin A-

Coded Male

Socket

Auxiliary

Connector

L6984

step-down switching

regulator

LDK220

LDO

M95M01-DF

1-Mbit SPI bus

EEPROM

SPI4

I2C1

UM2438

Power management

Figure 7. STEV

AL-IDP005V1 functional block diagram

2.1 Power management

The STEVAL-IDP005V1 power management stage can accept an 18 to 32 VDC input through the M12 A-coded 4pin male connector (JP1) and provide 3.3 VDC / 200 mA voltage output to its digital components.

U1 - L6984 step-down switching regulator

•

U2 - LDK220 LDO

•

Figure 8. Power management system

UM2438 - Rev 2

page 6/67

2.1.1 L6984

output voltage adjustability ranges from 0.9 V. The fixed 3.3 V V

“Low Consumption Mode” (LCM) maximizes the ef

“Low Noise Mode” (LNM) makes the switching frequency almost constant over the load current range. The

PGOOD open collector output can implement output voltage sequencing during the power-up phase. The

synchronous rectification, designed for high efficiency at medium - heavy load, and the high switching frequency

capability make the size of the application compact. Pulse-by-pulse current sensing on low-side power element

implements an effective constant current protection.

2.1.2 LDK220

from an input voltage in the range of 2.5 V to 13.2 V, with a typical dropout voltage of 100 mV

stabilizes it on the output. The very low drop voltage, low quiescent current and low noise make it suitable for

industrial applications. The enable logic control function puts the LDK220 in shutdown mode allowing a total

current consumption lower than 1 μA. The device also includes a short-circuit constant current limiting and

thermal protection.

UM2438

Microcontroller

The L6984 is a step-down monolithic switching regulator able to deliver up to 400 mA DC. The

requires no external resistor divider. The

OUT

ficiency at light load with controlled output voltage ripple. The

The LDK220 is a low drop voltage regulator, which provides a maximum output current of 200 mA

. A ceramic capacitor

2.2 Microcontroller

The STEVAL-IDP005V1 embeds an STM32F469AI (U10) ARM®Cortex®-M4 32-bit MCU.

The board has a Serial Wire Debug (SWD) connector (J1) for MCU programming and debugging. This connector

routes UART pins as well.

The board also has a reset button (SW1) to restart the microcontroller.

Figure 9. Microcontroller subsystem

2.2.1 STM32F469AI

The STM32F469AI microcontroller is based on the high-performance ARM® Cortex®-M4 32-bit

RISC core operating at a frequency of up to 180 MHz. The Cortex®-M4 core features a Floating point unit (FPU)

UM2438 - Rev 2

page 7/67

single precision which supports all ARM® single-precision data processing instructions and data types. It also

implements a full set of DSP instructions and a memory protection unit (MPU) which enhances application

security

The device incorporates high-speed embedded memories (Flash memory up to 2 Mbytes, up to 384 Kbytes of

SRAM), up to 4 Kbytes of backup SRAM, and an extensive range of enhanced I/Os and peripherals connected to

two APB buses, two AHB buses and a 32-bit multi-AHB bus matrix.

The device of

two PWM timers for motor control, two general-purpose 32-bit timers, and a true random number generator

(RNG).

The microcontroller features the following standard and advanced communication interfaces:

• Up to three I2Cs.

• Six SPIs, two I2Ss full duplex. To achieve audio class accuracy, the I2S peripherals can be clocked via a

• Four USARTs plus four UARTs.

• One SAI serial audio interface.

The STM32F469AI device operates in the -40 to +105 °C temperature range from a 1.7 to 3.6 V power supply.

.

fers three 12-bit ADCs, two DACs, a low-power R

dedicated internal audio PLL or via an external clock to allow synchronization.

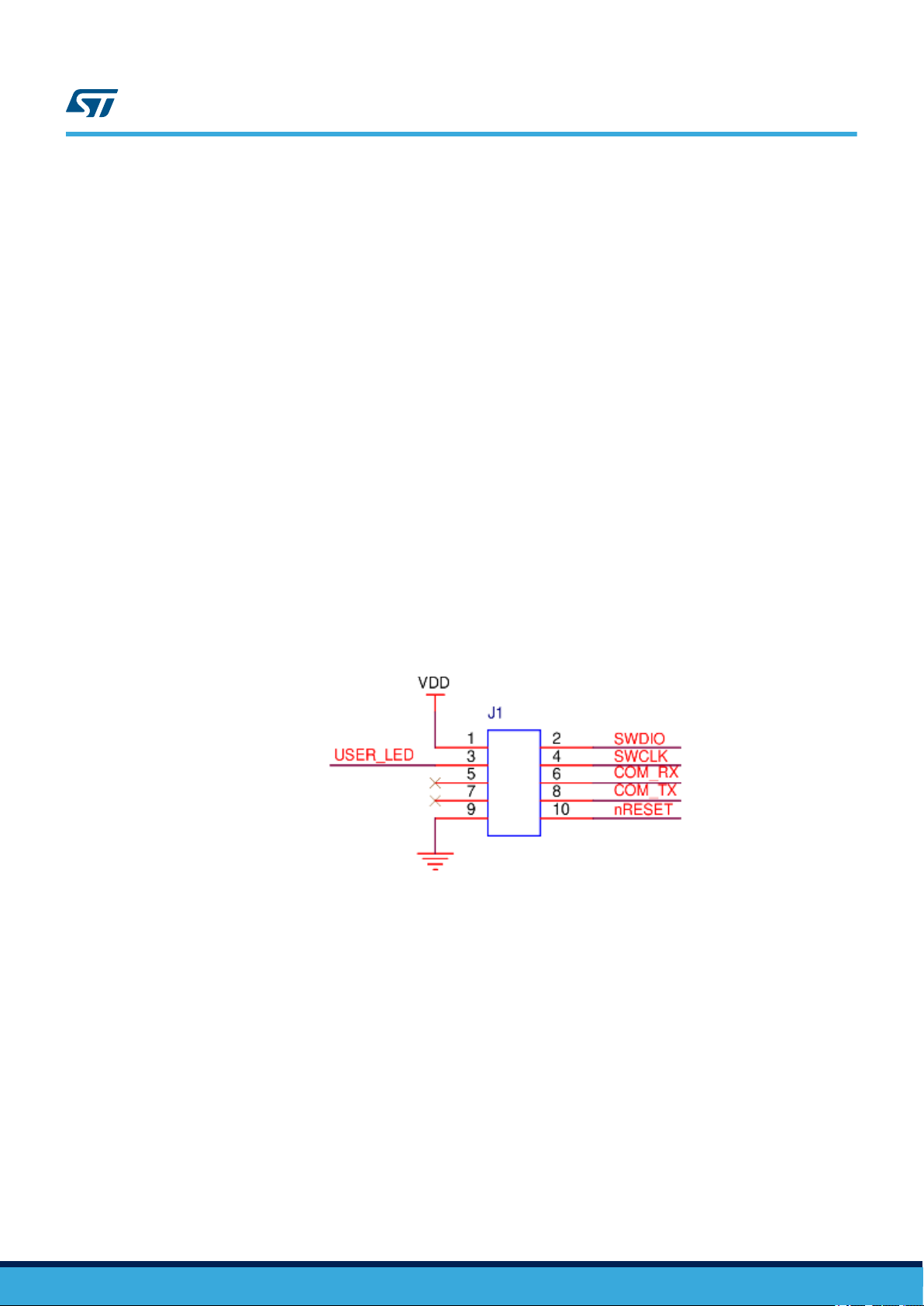

2.2.2 Enhanced SWD connector

The STEVAL-IDP005V1 has a 1.27 mm pitch, 10-contact, 2-row board-to-board connector. The connector can be

used for the following purposes:

•

To program the microcontroller via a dedicated adapter (STEVAL-UKI001V1) connected to the programming

tool (e.g. ST-LINK/V2-1).

• As an expansion connector that routes the UART pins, to allow the STEVAL-IDP005V1 to connect with a PC

COM port. A further IO for USER_LED is also routed.

UM2438

Sensors

TC, twelve general-purpose 16-bit timers including

2.3 Sensors

The STEVAL-IDP005V1 embeds several sensors to detect vibration, environmental parameters and sound

parameters. The sensor data is analysed with algorithms running on the STM32F469AI microcontroller with FPU.

The following sensors are mounted on the board:

•

U4 - ISM330DLC 3D accelerometer and 3D gyroscope

U6 - HTS221 humidity and temperature sensor

•

• U8 - LPS22HB pressure sensor

• U7 - MP34DT05-A digital microphone

Figure 10. Enhanced SWD connector

UM2438 - Rev 2

page 8/67

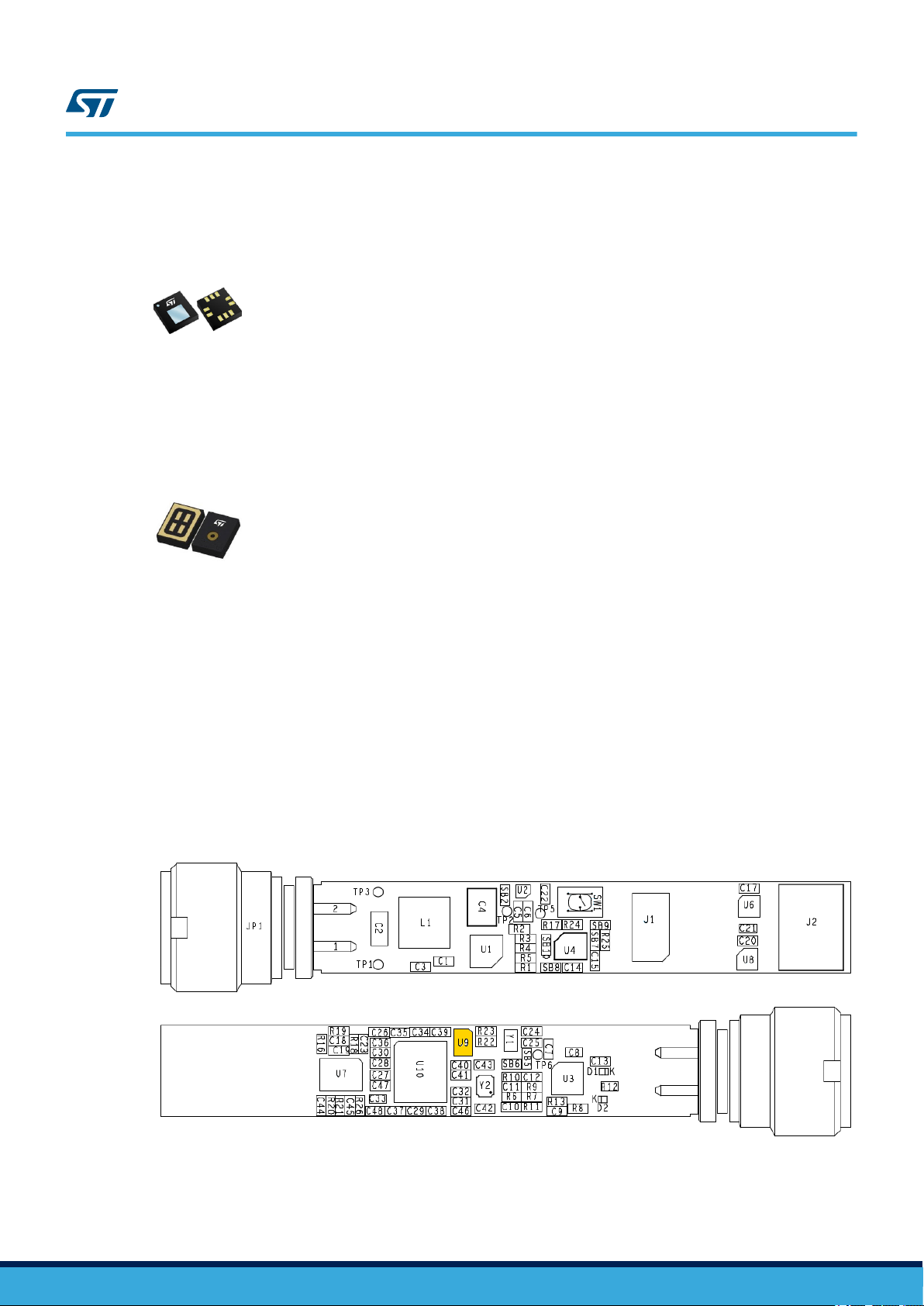

2.3.1 ISM330DLC

UM2438

Sensors

Figure 11. Sensor array subsystem

The ISM330DLC is a system-in-package featuring a high performance 3D digital accelerometer and

3D digital gyroscope tailored for Industry 4.0 applications.

ST’s family of MEMS sensor modules leverages the robust and mature manufacturing processes already used for

the production of micro machined accelerometers and gyroscopes.

The various sensing elements are manufactured using specialized micromachining processes,

while the IC interfaces are developed using CMOS technology that allows the design of a dedicated circuit which

is trimmed to better match the characteristics of the sensing element.

In the ISM330DLC, the sensing element of the accelerometer and of the gyroscope are implemented on the same

silicon die, thus guaranteeing superior stability and robustness.

The ISM330DLC has a full-scale acceleration range of ±2/±4/±8/±16 g and an angular rate range of

±125/±250/±500/±1000/±2000 dps.

Delivering high accuracy and stability with ultra-low power consumption (0.75 mA in high-performance, combo

mode) enables, also in the industrial domain, long-lasting battery operated applications.

The ISM330DLC includes a dedicated configurable signal processing path with low latency

dedicated filtering specifically intended for control loop stability. Data from this dedicated signal path can be made

available through an auxiliary SPI interface, configurable for both the gyroscope and accelerometer. Highperformance, high-quality, small size and low power consumption together with high robustness to mechanical

shock makes the ISM330DLC the preferred choice of system designers for the creation and manufacturing of

versatile and reliable products.

The ISM330DLC is available in a plastic, land grid array (LGA) package.

The STSW-BFA001V1 firmware package includes applications and demonstrations firmware supporting

accelerometer part.

, low noise and

2.3.2 HTS221

element and a mixed signal ASIC to provide the measurement information through digital serial interfaces.

UM2438 - Rev 2

The HTS221 is an ultra-compact sensor for relative humidity and temperature. It includes a sensing

page 9/67

The sensing element consists of a polymer dielectric planar capacitor structure capable of detecting relative

humidity variations and is manufactured using a dedicated ST process.

The HTS221

temperature range from -40 °C to +120 °C.

2.3.3 LPS22HB

digital output barometer. The device comprises a sensing element and an IC interface which communicates

through I2C or SPI from the sensing element to the application.

The sensing element, which detects absolute pressure, consists of a suspended membrane manufactured using a

dedicated process developed by ST.

The

LPS22HB is available in a full-mold, holed LGA package (HLGA). It is guaranteed to operate over a

temperature range extending from -40 °C to +85 °C. The package is holed to allow external pressure to reach the

sensing element.

2.3.4 MP34DT05-A

UM2438

Memory

is available in a small top-holed cap land grid array (HLGA) package guaranteed to operate over a

The LPS22HB is an ultra-compact piezoresistive absolute pressure sensor which functions as a

with a capacitive sensing element and an IC interface.

The sensing element, capable of detecting acoustic waves, is manufactured using a specialized silicon

micromachining process dedicated to producing audio sensors.

The IC interface is manufactured using a CMOS process that allows designing a dedicated circuit able to provide

a digital signal externally in PDM format.

The MP34DT05-A is a low-distortion digital microphone with a 64 dB signal-to-noise ratio and -26 dBFS ±3 dB

sensitivity

The MP34DT05-A is available in a top-port, SMD-compliant, EMI-shielded package and is guaranteed to operate

over an extended temperature range from -40 °C to +85 °C.

2.4 Memory

The STEVAL-IDP005V1 has non-volatile memory which can store up to 1-Mbits of data.

•

U9 - M95M01-DF 1-Mbit serial SPI bus EEPROM

The MP34DT05-A is an ultra-compact, low-power, omnidirectional, digital MEMS microphone built

.

Figure 12.

EEPROM subsystem

UM2438 - Rev 2

page 10/67

2.4.1 M95M01-DF

The M95M01 electrically erasable programmable memory (EEPROM) id organized as 131072 x 8

bits, accessed through the SPI bus.

The M95M01-DF can operate with a supply range from 1.7 V up to 5.5 V. This device is guaranteed for the -40

°C/+85 °C temperature range.

The M95M01-DF of

application parameters that can subsequently be permanently locked in Read-only mode.

fers an additional Identification Page (256 bytes), which can be used to store sensitive

2.5 IO-Link communication

The STEVAL-IDP005V1 board has IO-Link connectivity available on the M12 A-coded connector.

IO-Link is an industrial standard for hardware connectivity

• the number of wires needed for the bus installation

•

the colors to distinguish supply voltage from the IO-Link bus line

• connector pinouts.

The standard also establishes two different data communication methods:

1. Pure serial data communication (SDCI) with a detailed protocol structure to manage sensor parameters and

sensor data.

2. A simple level transition high to low and vice versa to signal the sensor status only.

The use of an IO-Link system offers several advantages, like:

• Automatic detection and parameterization of the IO-Link device: the operating parameters of devices are

stored in the master during setup. Once connected, the master recognizes the device and enables automatic

startup. If a device like a sensor fails, it can be replaced and parameterization data stored in the master is

automatically downloaded to the replacement device.

• Device monitoring and diagnostics: IO-Link allows equipment components and systems to be monitored and

proactively managed. Diagnostics provided by IO-Link devices lets the control system track data and trends,

facilitating preventive and predictive maintenance and improving machine uptime.

• Changes on the fly: parameters can be quickly adjusted for installed devices while the machine is running,

reducing time consumption.

• Reduced component costs: by exploiting the configuration capabilities of IO-Link, a device can be configured

to have different output functions.

UM2438

IO-Link communication

. The standard specifies:

Figure 13. IO-Link subsystem

UM2438 - Rev 2

page 11/67

2.5.1 L6362A

The L6362A is an IO-Link transceiver device compliant with PHY2 (3-wire connection) supporting

COM1 (4.8 kbaud), COM2 (38.4 kbaud) and COM3 (230.4 kbaud) modes. The output stage can be configured as

high-side, low-side or push-pull by hardware connection, and it can drive resistive, capacitive and inductive loads.

The IC can interface a sensor node to a master unit using both the Serial Data Communication Interface (SDCI)

based on IO-Link protocol and the Standard I/O mode (SIO). Communication is managed using the 24 V industrial

bus voltage. The L6362A is protected against reverse polarity across VCC, GND, OUTH, OUTL and I/Q pins. The

IC is also protected against output short-circuits, overvoltage and fast transient conditions (±1 kV, 500 Ω and 18

μF coupling).

2.5.2 IO-Link connector

The IO-Link connector is M12 A-coded 4-pin.

UM2438

Auxiliary connections

Figure 14. IO-Link connector and signals

2.6 Auxiliary connections

The STEVAL-IDP005V1 comes with a 6-pin auxiliary connector for:

• VDD and GND

• SMBus (I2C)

•

One ADC channel

The above pins can still be used as GPIOs.

The mounted auxiliary connector is a JST SM06B-NSHSS-TB. This mates with a JST NSHR-06V-S, female

connector housing, that be assembled with six JST SSHL-003T-P0.2, female crimp terminal contact. These

components are not part of the kit.

UM2438 - Rev 2

page 12/67

3 STEVAL-UKI001V1

VDD_TARGET

SWCLK

3

USR_BTN

VDD_TARGET

SWCLK

CN13

4

SWO

SWO_RS232_RX

SWDIO

4-pin Male Header

5

100 mils 20-pin Header

CN2_1

8

miniswitch-KMR211GLFS

USR_BTN

NRST

590

Not Mounted

JP1

2

3-pin Male Header

6

SWO_RS232_RX

4

2

GND

C1

1-pin Male Header

6

SWCLK

CN2_2

Fit on STM32 Nucleo board

GND

RST

SWO

3

1

SW1

2

18

RS232_TX

5

7

C2

2-pin Female Header

ST_LINK_RX

GND

SWO

1

USR_LED

1

14

miniswitch-KMR211GLFS

4-pin Female Header

20

mounted on TOP

mounted on TOP

mounted on BOTTOM

SW2

10 to 20 pin Serial Wire Debug (SWD) adapter

J2

2

3

1

17

1

8

GND

VDD_TARGET

CN14

11

CN2_4

10

100nF

CN2

2

CN2_3

SWDIO

1

J3

CN3

LED (Yellow)

6-pin Female Header

NRST

3

CN2_3

9

USR_BTN

1

ST_LINK_3V3

ST_LINK_RX

2-pin Male Header

NRST

4

6

CN4

2

2-pin Female Header

2-pin Female Header

ST_LINK_TX

3

9

CN15

USR_LED

NRST

CN2_2

2

16

SWDIO

ST_LINK_3V3

CN2_1

D1

1

3

100nF

10

2-pin Male Header

R1

CN2_4

1

CN12

12

13

ST_LINK_TX

4

5

1

15

JP2

GND

2

50 mils 10-pin Header

2

closed 2-3

J1

Not Mounted

closed

VDD_TARGET

GND

4

RS232_TX

7

19

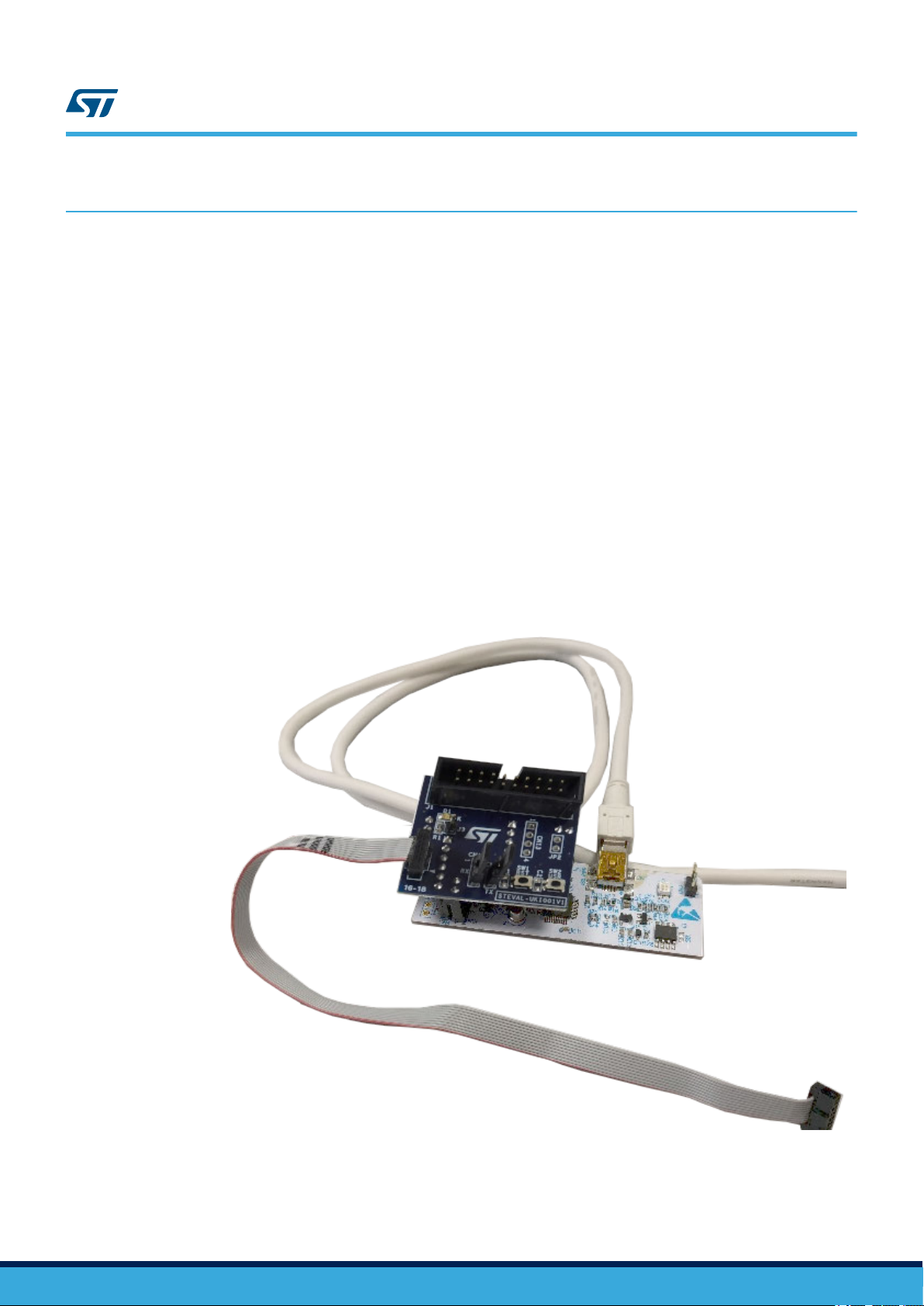

This tool is an adapter for Serial Wire Debug (SWD) from 10-pin 50-mil socket to 20-pin 100-mil socket (mounted

on ST

-LINK/V2) or to 6-pin 100-mil (mounted on ST

The ST

-LINK/V2-1 of the STM32 Nucleo-64 board offers more features. However, you need to ensure that the

target application routes the UART RX, UART TX, user button and user LED tracks correctly on the SWD.

You can use ST-LINK/V2-1 through the STEVAL-UKI001V1 board to program and debug the target application.

You can also use the ST-LINK/V2-1 as a UART interface adapter via the STM32 Virtual COM Port Driver. This

allows you to keep using the USB cable that connects the kit to your PC. To use this configuration, ensure that

pins 2 and 3 of CN14 and pins 1 and 2 of CN15 are shorted. Refer to the schematic below.

UM2438

STEVAL-UKI001V1

-LINK/V2-1 on the STM32 Nucleo-64 board).

Figure 15. STEVAL-UKI001V1 schematic

UM2438 - Rev 2

page 13/67

UM2438

STEVAL-UKI001V1

Figure 16. STEV

Figure 17. STEV

AL-UKI001V1 top view

AL-UKI001V1 bottom view

UM2438 - Rev 2

page 14/67

How to supply power to the STEVAL-IDP005V1 board

4 How to supply power to the STEVAL-IDP005V1 board

The STEVAL-BFA001V1B kit includes the necessary cable and connectors to power the STEVAL-IDP005V1

board.

Figure 18. 4-wire cable with free ends and an M12 A-coded 4-pin female connector

UM2438

Figure 19. 4-pole cable mount connector plug with male contacts

RELATED LINKS

1.3 How to run the demo supplied with the firmware on page 4

4.1 Supply power directly from a DC power supply

You can power the board directly from a DC power supply using only the cable provided in the kit.

Step 1. Connect the cable to an 18 – 32 VDC power supply:

Pin 1 (brown wire) to positive

–

– Pin 3 (blue wire) to negative

Figure 20. STEV

AL-IDP005V1 power supply connection (without IO-Link master board)

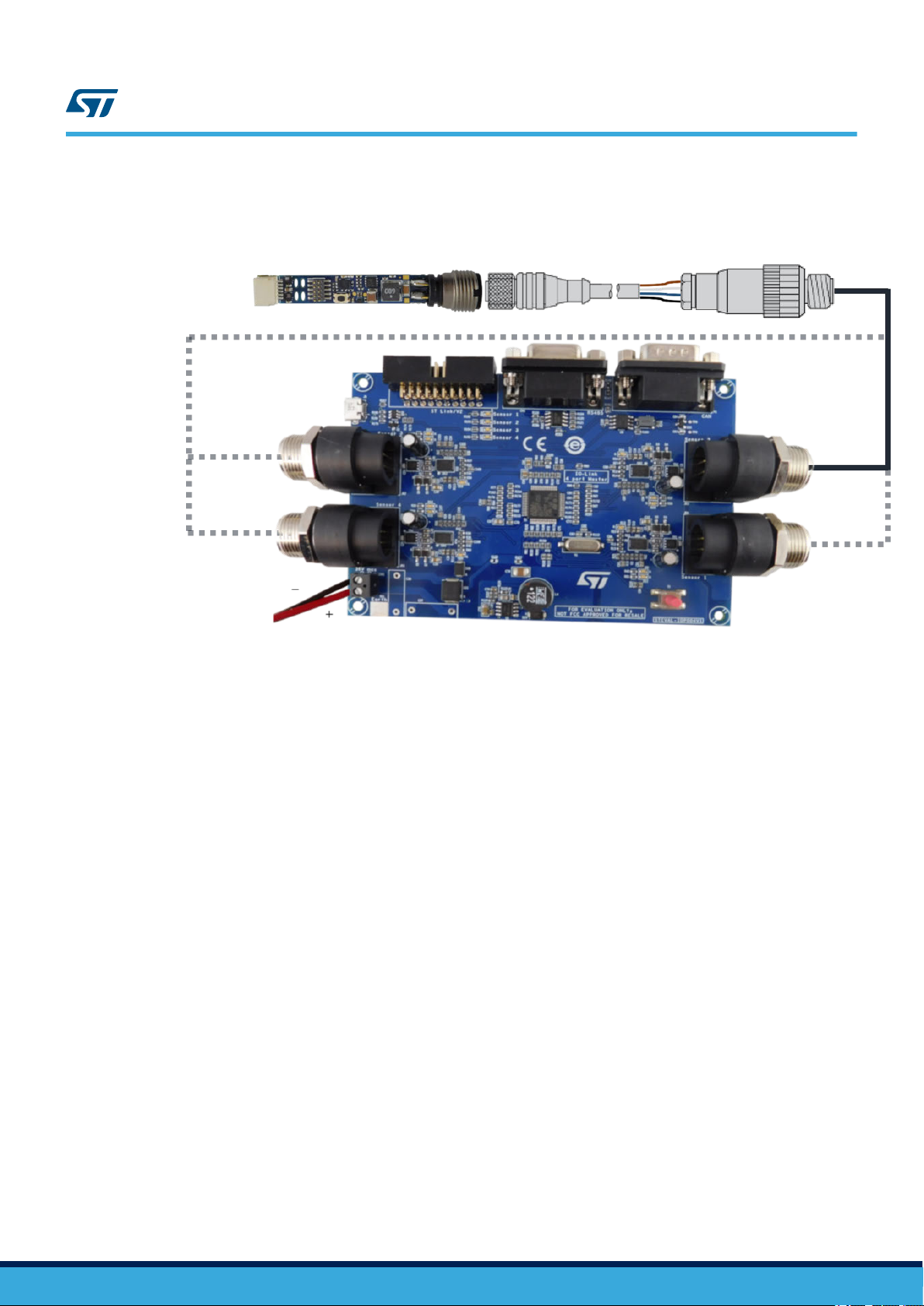

4.2 Supply power through an IO-Link master board

You can supply power via an IO-Link master board using the cable and connectors provided in the kit.

Step 1. Attach the 4-pole cable mount connector plug with male contacts to the cable.

Step 2. Connect the female end to the STEV

master board.

UM2438 - Rev 2

AL-IDP005V1 board and the male end to the STEVAL-IDP004V1

page 15/67

UM2438

Supply power through an IO-Link master board

Step 3. Power the STEV

connector CON1.

Figure 21.

AL-IDP004V1

IO-Link master board with an 18 to 32 VDC supply through screw

STEVAL-IDP005V1 power supply connection (through IO-Link master board)

UM2438 - Rev 2

page 16/67

5 STEVAL-IDP005V1 board connections

The STEVAL-IDP005V1 needs to be linked with a PC to manage the data coming from the board. The connection

can either be through a serial communication adapter (ST

STEV

AL-IDP004V1).

(

5.1 Connection through an ST-LINK/V2-1

The ST-LINK/V2-1 in-circuit debugger/programmer on the STM32 Nucleo-64 board lets you update the STEVALIDP005V1 firmware. It also allows UART communication with a PC.

To enable UART communication

Step 1. Install the STM32 Virtual COM Port Driver (STSW-STM32102) on your PC.

Step 2. Run a terminal emulator like PuTTY, Tera Term, etc.

To set up a connection for firmware update.

Step 3. Plug the STEVAL-UKI001V1 on ST-LINK/V2-1 in a manner that the connectors with the same

identification are overlapped.

Step 4. Connect the ST-LINK/V2-1 to the PC through the USB Type-A Male to Type-B mini cable.

Step 5. Respecting the polarity, connect an end of the 10-pin flat IDC wire cable to J2 of the STEVAL-

UKI001V1.

-LINK/V2-1) or an IO-Link master multi-port board

UM2438

STEVAL-IDP005V1 board connections

Figure 22. ST-LINK/V2-1 connection

UM2438 - Rev 2

Step 6. On the STEVAL-UKI001V1, short the CN14 pin 2-3 and the CN15.

Step 7. Use the 4-wire cable with free ends and an M12 A-coded 4-pin female connector (e.g. Telemecanique

Sensors XZCP1141L2).

page 17/67

UM2438

Connection through an STEVAL-IDP004V1

Step 8. Connect the M12 A-coded 4-pin female connector of the cable to JP1 (IO-Link connector) of the

STEV

AL-IDP005V1.

Step 9. Connect wire 1 (VIN) and wire 3 (GND) of the cable to a power supply able to provide 18 to 32 VDC.

Step 10. Respecting the polarity

the STEV

AL-IDP005V1.

The STEVAL-IDP005V1 is ready to be programmed with new firmware.

RELATED LINKS

1.3 How to run the demo supplied with the firmware on page 4

6.2.4.3 Demonstrations folders on page

8 How to run projects via IO-Link on page 42

7.1 Outputs for the acoustic analysis project on page 29

, connect the free end of the 10-pin flat IDC wire cable to J1 (SWD connector) of

Figure 23. IO-Link and SWD connection

25

5.2 Connection through an STEVAL-IDP004V1

The physical IO-Link connection between STEVAL-IDP005V1 and the PC is made using the STEVAL-IDP004V1

multiport master board with an L6360 master IC for each IO-Link port.

Step 1. Ensure that none of the boards are connected to a power supply.

Figure 24. STEV

AL-IDP004V1 vs STEVAL-IDP005V1 connections

UM2438 - Rev 2

page 18/67

UM2438

Connection through an STEVAL-IDP004V1

Step 2. Assemble the T

elemecanique Sensors XZCP1

141L2 (4-wire cable) with the T

elemecanique Sensors

XZCC12MDM40B (4-pole connector).

You can also use a preassembled 4-wire cable (not provided in the package) with M12 A-coded 4-pin

connectors, male on one end and female on the other.

Step 3. Plug the female M12 connector of the cable to the STEVAL-IDP005V1.

Step 4. Plug the male M12 connector of the cable to a free port of the four ones that are in the STEVAL-

IDP004V1.

Step 5. Connect the RS485 dongle (not present in the package) and install the related driver to create the

physical connection between PC and master board.

For correct communication, use the reference pinout on the DB9 connector shown below.

Table 1. RS485 Connector pinout

PIN Number PIN Description

1 , 4 Inverting receiver input and inverting driver output

2 , 8 Non inverting receiver input and non-inverting driver output

6 , 7 , 9 Not connected

3 , 5 Ground

Step 6. Connect an 18 to 32 V (typ. 24 V) supply voltage through screw connector CON1 on the board to run

the system.

RELATED LINKS

6.2.4.3 Demonstrations folders on page 25

8 How to run projects via IO-Link on page 42

Graphical Interface overview on page 43

9

UM2438 - Rev 2

page 19/67

6 Firmware overview

UM2438

Firmware overview

The STSW

applications using inertial, environmental and microphone sensors. The firmware includes sample condition

monitoring and predictive maintenance applications based on 3D digital accelerometer, environmental and

acoustic MEMS sensors.

The software uses the following lower layers:

•

•

• Medium level board support package (BSP) layer to provide on-board sensor control and data reception at

The middleware libraries built on top of the lower layers provide the following features:

• Middleware, including algorithms for advanced time and frequency domain signal processing for vibration

• Middleware with microphone algorithms:

• Sample application to monitor environmental, acoustic and vibration data and read algorithm outputs through

• Sample application with programmable warning and alarm thresholds in the time domain and across spectral

• Application example firmware to communicate with STEVAL-IDP004V1 (IO-Link master multi-port evaluation

-BFA001V1 software is an expansion of the STM32Cube platform with functions to help you develop

Low level STM32Cube HAL layer to provide all the MCU communication peripherals APIs compatible with

STM32Cube framework.

Low level drivers to facilitate sensor configuration and data reception with dedicated APIs that are

compatible with STM32Cube framework.

the application level.

analysis:

– For the frequency domain:

◦ Programmable FFT size (256, 512, 1024, 2048)

◦ Programmable FFT input data overlapping

◦ Programmable FFT input data windowing (Flat Top, Hanning, Hamming)

◦ Programmable FFT output averaging

◦ Programmable FFT subrange analysis

– For the time domain:

◦ HP filtering to reduce accelerometer offset

◦ Accelerometer max peak evaluation

◦ Accelerometer integration to evaluate Speed

◦ Moving RMS speed evaluation

– PDM to PCM

– Sound pressure

– Audio FFT

a terminal emulator.

bands.

board) and dedicated PC GUI.

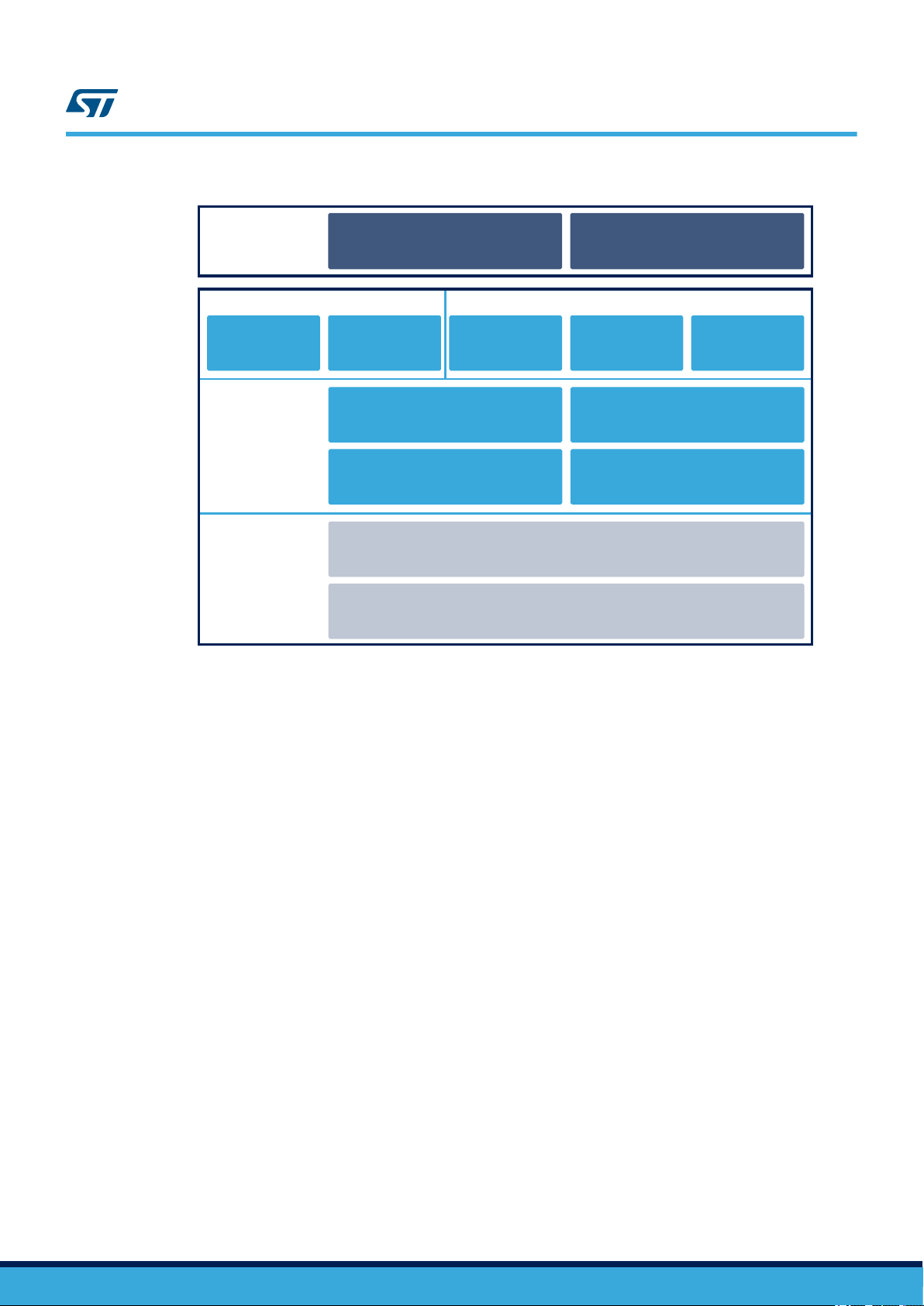

6.1 Firmware architecture

The firmware is based on the STM32Cube™ framework for applications running on the STM32 microcontroller.

The package provides a board support package (BSP) for the MEMS and Microphone sensors and other devices

used for IO-Link communication. The package also contains middleware for signal and audio processing.

UM2438 - Rev 2

page 20/67

Demonstrations

Applications

Condition

Monitoring

Predictive

Maintenance

Acoustic

Analysis

Vibration

Analysis

Environmental

Monitoring

Vibration Signal Processing

Audio Lib

STM32Cube Hardware

Abstraction Layer

Board Support

Package

Middleware

Hardware

Abstraction

Hardware

STM32F469AI, ISM330DLC, LPS22HB, HTS221, MP34DT05-A

STEVAL-IDP005V1

User interfaces

and utilities

STEVAL-IDP005V1 GUI

UART / Windows terminal

(vibration, acoustic and

environmental data monitoring)

UM2438

Firmware architecture

Figure 25. STSW

A001V1 firmware architecture

-BF

The following firmware layers access and use the hardware components:

• STM32Cube HAL layer: generic Application Programming Interfaces (APIs) which interact with higher level

applications, libraries and stacks. The APIs are based on the common STM32Cube framework so other

layers like middleware can function without requiring specific hardware information for a given

microcontroller unit (MCU).

• Board support package (BSP) layer: provides firmware support for the STM32 (excluding MCU) peripherals.

These APIs provide a programming interface for certain board-specific components like LEDs, user buttons,

etc. The APIs can also fetch board serial and version information, as well as support initializing, configuring

and reading data from sensors. The BSP provides the drivers for the STEV

to connect to the microcontroller peripherals.

This firmware package expands the functionality of the STM32Cube platform with the following features for

specific industrial applications:

• Low and middle level drivers to connect all the on-board MEMS sensors:

– Pressure and temperature sensor (LPS22HB)

– Humidity and temperature sensor (HTS221)

– Accelerometer/Gyroscope motion sensors (ISM330DLC)

– Digital Microphone audio sensor (MP34DT05-A)

• Complete BSP functions to allow applications to access sensors. The data acquisition from different sensors

is provided via SPI and I2C.

• Six different sample firmware projects divided into two main groups:

– Applications: examples that use motion, environmental and acoustic measurements, including

• Command line interface (CLI) using a debug console on an external terminal via UART communication with

middleware algorithms focused on vibration and acoustic analysis and environmental monitoring.

– Demonstrations: projects designed to demonstrate condition monitoring and predictive maintenance

with the STEVAL-IDP005V1. The projects include IO-Link connectivity with the master board (STEVAL-

IDP004V1).

a PC.

AL-IDP005V1 board peripherals

UM2438 - Rev 2

page 21/67

6.2 Firmware folder structure

The STSW-BFA001V1 package is developed using the standard STM32Cube™ framework structure shown

below.

UM2438

Firmware folder structure

Figure 26. STSW

6.2.1 Documentation

The documentation folder contains a compiled HTML file generated from doxygen comments in the source code.

The folder also has documentation regarding the firmware framework, drivers for the on-board components and

APIs to manage the different functions.

Note: For more information, open the STEV

6.2.2 Drivers

All firmware packages compliant with the STM32Cube framework contain the following main groups:

•

BSP: board-specific drivers for the HW components.

• CMSIS: vendor-independent hardware abstraction layer for the ARM Cortex-M series, including DSP

libraries used for the projects.

STM32F4xx_HAL_Drivers: microcontroller HAL libraries.

•

The board support package files are grouped into two main folders with the low level hardware device drivers and

the board-specific medium level drivers:

• Components: includes a set of platform-independent device drivers for LPS22HB, HTS221, ISM330DLC,

M95M01-DF, as well as common files.

• STEVAL-IDP005V1: includes a set of medium level drivers for each hardware subsystem. You can use the

drivers in your application to control and configure the functionality of different measurement datatypes.

These APIs abstract the on-board hardware and connectivity devices contained in the steval_idp005v1 module for

use by applications.

-BFA001V1 firmware folder structure

AL-IDP005V1_FW.chm help file in the documentation folder.

6.2.3 Middleware

The Middlewares folder contains two specific libraries that give higher level applications access to APIs for

acoustic and motion signal processing analysis.

6.2.4 Projects

The Projects directory contains several user projects under Applications and Demonstrations subfolders.

UM2438 - Rev 2

page 22/67

Figure 27. Projects folders

UM2438

Firmware folder structure

All the projects are available for the following integrated development environments (IDE):

• IAR Embedded Workbench® for ARM® (EW

• Microcontroller Development Kit for ARM® (MDK-ARM) by Keil

• System Workbench for STM32 (SW4STM32) by AC6 (free IDE)

6.2.4.1 Standard files for all projects

The standard STM32Cube application files have the same configuration as any standard example using the

STM32 HAL libraries, plus the peripherals used for demonstration purposes in the following files:

• main.c: APIs for system clock configuration and all the standard include files for the other APIs defined in

HAL libraries, BSP and Middleware.

• stm32f4xx_hal_msp.c: APIs for application-level peripheral initialization.

stm32f4xx_hal_it.c: APIs for all interrupt handlers.

•

6.2.4.2 Applications folder

The Applications folder includes separate projects and reference firmware to monitor (through serial

communication via the

STEVAL-UKI001V1

1. Vibration data: with vibration analysis based on accelerometer data for diagnostic purposes.

2. Audio data: retrieves sound data such as sound pressure level and sound power spectrum.

3. Environmental data: retrieves environmental data such as humidity, temperature and pressure.

ARM) by IAR systems

®

®

) the following types of data from the STEVAL-IDP005V1:

UM2438 - Rev 2

page 23/67

Figure 28. Applications folders

UM2438

Firmware folder structure

6.2.4.2.1 Application-specific files for projects in the Applications folder

The application-specific APIs for vibration analysis are found in the following files:

• main.c:

– APIs for sending application information to a terminal screen (via Service UART)

– APIs for sensor initialization (accelerometer)

– APIs for sensor measurement (accelerometer)

– APIs for accelerometer parameters that can be configured by the user, and accelerometer INT

management

– APIs for time domain and frequency domain analyses

• data_communication_srv.c: APIs for the CLI configuration command and to monitor the processing outputs

requested by the user.

• audio_application.c: to interface with middleware functions.

UM2438 - Rev 2

page 24/67

6.2.4.3 Demonstrations folders

The Demonstrations folder includes three projects for the STEVAL-IDP005V1:

1. Predictive Maintenance with serial communication via STEVAL-UKI001V1.

Condition Monitoring:

2.

a. with serial communication via IO-Link

b. with serial communication via UART through the STEVAL-UKI001V1

UM2438

Firmware folder structure

Figure 29. User files for vibration analysis

UM2438 - Rev 2

page 25/67

Figure 30. Demonstrations folders

UM2438

Firmware folder structure

UM2438 - Rev 2

The project for Predictive Maintenance analyzes vibration data against threshold parameters for the same

measurement datatype evaluated. The project includes a algorithm to determine status information with respect to

time and frequency domain parameters.

There are two Condition Monitoring projects designed to retrieve and analyze sensor data to evaluate equipment

status.

The two projects dif

fer in how the data is transmitted.

page 26/67

1. The Conditon_Monitoring_SRV project uses standard communication with a PC via the STEVAL-UKI001V1

mounted on STLINK/V2-1.

2.

The Conditon_Monitoring_IOL project uses the IO-Link communication PHY, interfacing the STEV

IDP005V1 with the STEV

AL-IDP004V1 master board and sending the received data via a RS485-USB

adapter to a PC. This methods lets you monitor the system with the STSW-IO-LINK GUI.

RELATED LINKS

5.1 Connection through an ST-LINK/V2-1 on page 17

5.2 Connection through an STEVAL-IDP004V1 on page 18

9 Graphical Interface overview

6.2.4.3.1 Application-specific files for the Conditon_Monitoring_SRV project

The application-specific APIs for the Conditon_Monitoring_SRV project are found in the following files:

• main.c

– APIs for sending the application information to the terminal screen (via Service UART)

–

APIs for sensor initialization (accelerometer, humidity, pressure and temperature)

– APIs for sensor measurement (accelerometer, humidity, pressure and temperature)

– APIs for external memory Init (EEPROM)

– APIs for accelerometer parameters that can be configured by the user, and accelerometer INT

management

– APIs for time domain and frequency domain analyses

• data_communication_srv.c: APIs to run the CLI configuration command and to monitor requested processing

outputs.

• MotionSP_Manager.c: to interface with middleware functionality.

on page 43

UM2438

Firmware folder structure

AL-

Figure 31. User files for Conditon_Monitoring_SRV project

6.2.4.3.2 Application-specific files for the Conditon_Monitoring_IOL project

The application-specific APIs for the Conditon_Monitoring_IOL project are found in the following files:

•

main.c

– APIs for sending the application information to the terminal screen (via IO-Link PHY device)

APIs for sensor initialization (accelerometer, humidity, pressure and temperature)

–

– APIs for sensor measurement (accelerometer, humidity, pressure and temperature)

UM2438 - Rev 2

page 27/67

Firmware folder structure

– APIs for time domain and frequency domain analyses

•

data_communication_iol.c: APIs designed to receive many customized commands from a board with IO-Link

, and to send sensor and processing datatypes. Master-slave node communication is managed

Master

through the IO-Link channel.

•

MotionSP_Manager.c: to interface with middleware functionality.

UM2438

UM2438 - Rev 2

page 28/67

7 How to run projects via Service UART

Perform the following steps for any of the projects available for Service UART:

Step 1. Connect the STEV

Nucleo-64 and download the dedicated firmware.

Step 2. Run a terminal emulator like PuTTY on your PC

Be sure to use the correct COM port and UAR

Step 3. Press the reset button to restart the application.

AL-IDP005V1 to an ST

7.1 Outputs for the acoustic analysis project

The terminal emulator for acoustic analysis shows the following information:

-LINK/V2-1 in-circuit debugger/programmer on the STM32

T parameters: 921600/8-N-1

UM2438

How to run projects via Service UART

Figure 32. T

The log file from the terminal emulator will store the following information:

• the measured sound pressure and its acquisition time

• the measured average power spectrum with its peak and its acquisition time.

erminal emulator screenshot for acoustic analysis firmware

UM2438 - Rev 2

page 29/67

Outputs for the acoustic analysis project

Figure 33. Acoustic analysis terminal emulator log file

UM2438

UM2438 - Rev 2

RELATED LINKS

1.3 How to run the demo supplied with the firmware on page 4

5.1 Connection through an ST-LINK/V2-1 on page

17

page 30/67

Outputs for the environmental monitoring project

7.2 Outputs for the environmental monitoring project

The terminal emulator will show the following information:

Figure 34. Terminal emulator screenshot while running environmental monitoring firmware

UM2438

UM2438 - Rev 2

The log file from the terminal emulator will store the following information:

• the measured sound pressure and its acquisition time

page 31/67

Outputs for the environmental monitoring project

Figure 35. Environmental monitoring terminal emulator log file

UM2438

UM2438 - Rev 2

page 32/67

7.3 Outputs for the vibration analysis project

The terminal emulator will show the following information:

Figure 36. Terminal emulator screenshot while running vibration analysis firmware

UM2438

Outputs for the vibration analysis project

UM2438 - Rev 2

The bottom part of the screen lists the stored parameters for the analysis and prompts you to change any of these

parameters. The configurable parameters are:

odr

Use the same values available for the specific accelerometer (ISM330DLC) to ensure high performance: 13 (for

12.5), 26, 52, 104, 208, 416, 833, 1660, 3330, 6660. See the ISM330DLC datasheet for further details.

fs

The configurable values are: 2, 4 (default), 8, 16. See ISM330DLC datasheet for further details.

hpf

Cutof

f frequency for internal hardware High Pass Filter (HPF) as per the following table:

Table 2. HPF configuration

HPF configuration Cutoff frequency selected

0 ODR/4

1 ODR/100

2 ODR/9

page 33/67

UM2438

Outputs for the vibration analysis project

HPF configuration Cutoff frequency selected

3 (Default) ODR/400

4 NO_HPF

size

FFT input array accelerometer size: 256, 512, 1024, or 2048 (default)

ovl

Overlapping between the following FFT input array in percentage; use a value between 5% and 95% (75% default)

tacq

T

otal acquisition time (in ms) to evaluate all the parameters for the time domain and frequency domain analysis in

the same time.

tau

Time parameter to include for the moving root mean square (RMS) evaluation (for speed and/or acceleration);

choose a value from: 25, 50, 100, 150, 250, 500 (default), 1000, 1500 and 2000.

subrng

Subrange FFT numbers to evaluate the frequency domain analysis results in each subrange frequency sector;

choose a value from 8, 16 (default), 32, or 64 (this parameter is used by the condition monitoring project.

wind

Filter windowing type; choose from:

0 - Hanning (default)

•

• 1 - Hamming

• 2 - Flat Top

tdtype

Time domain datatype format:

• 0 - Speed RMS only

• 1 - Acceleration RMS only

• 2 - Speed RMS and Acceleration RMS

Once you have inserted the new parameters, the Command Line Interface prompts you to type [y] and press

[Enter] to confirm the new values.

UM2438 - Rev 2

page 34/67

Outputs for the vibration analysis project

Figure 37. Default parameter list and starting point

UM2438

UM2438 - Rev 2

After the parameter setting phase, all the configurations are started and checked, and some information is also

returned about the MotionSP algorithm that is about to be launched.

page 35/67

Figure 38. MotionSP Initialization

UM2438

Outputs for the vibration analysis project

The terminal emulator will show the following information:

• Time domain analysis X-Y

-Z arrays according to the tdtype and tacq (timing window) parameters,

transmitting the data every 5 ms. The figure below lists the following information:

– the real ODR evaluated by the algorithm in order to have a more accurate value for the FFT arrays;

– the time domain datalog with the timestamp in the first column, and the X-Y-Z value chosen, in order to

plot the RMS speed trend mm/s.

UM2438 - Rev 2

page 36/67

UM2438

Outputs for the vibration analysis project

Figure 39. T

ime domain data

• Frequency Domain X-Y-Z arrays according to the parameter settings for the configured timing window (tacq)

as well as the bin frequency information. The output shows the acceleration power spectrum in m/s².

Figure 40. Frequency domain data

UM2438 - Rev 2

• Frequency Domain final results, including the average number of FFTs used during processing processing.

Figure 41. FFT results

• The maximum X-Y-Z acceleration peak.

page 37/67

UM2438

Outputs for the vibration analysis project

Figure 42. Maximum X-Y

-Z acceleration peak

• The final step lets you change some parameters again and run a new analysis.

Figure 43. Summary window

UM2438 - Rev 2

page 38/67

7.4 Condition Monitoring via Service UART

The terminal emulator will show the following information:

Figure 44. Condition Monitoring header log

UM2438

Condition Monitoring via Service UART

UM2438 - Rev 2

This project includes the components developed for vibration analysis, environmental measurement and a

specific frequency domain analysis that uses subranges to show the harmonics contributing across the power

spectrum bandwidth.

• The environmental sensor measurements are listed below:

page 39/67

Figure 45. Environmental data

7.5 Predictive Maintenance via Service UART

Predictive Maintenance is based on continuous comparison of vibration data with threshold values, which may be

provided by the machinery manufacturer. The objective is to monitor potentially damaging conditions that cannot

be identified in conventional scheduled maintenance.

The STEVAL-IDP005V1 firmware lets you modify time domain and frequency domain conditions:

Time domain thresholds with three different warning thresholds and three different alarm thresholds to

1.

continuously compare against the following processed data:

– Speed RMS

– Acceleration Peak

2. Frequency domain thresholds with warning and alarm thresholds for all the subranges. The thresholds can

be set using the command line interface, while the threshold values are stored in the MotionSP_thresholds.h

file.

When you run the application, the terminal window will show the following results:

• Time Domain thresholds status for the X-Y-Z RMS speed Status, with values derived from the comparisons.

UM2438

Predictive Maintenance via Service UART

Figure 46. RMS speed threshold status

• Time Domain threshold status for the X-Y-Z acceleration peak, with values derived from the comparisons.

Figure 47. Acceleration peak threshold status

• Frequency domain results are grouped into subranges according to the subrng parameter, which is more

useful for vibration analysis that can also verify the relative maximum values across the frequency

bandwidth. The information is provided for each axis, with the frequency and maximum amplitude for each

subrange.

Figure 48. Frequency domain analysis with subranges

UM2438 - Rev 2

page 40/67

Predictive Maintenance via Service UART

• The final step lets you change some parameters again and run a new analysis.

•

Frequency domain warning and alarm thresholds status for all axes and for each configured subrange,

including the relative maximum value detected in terms of frequency and amplitude. The following figure

shows an example with subrng=8 and an alarm condition in the second subrange on the z axis.

UM2438

Figure 49.

Frequency domain subranges threshold status

• Next, the output shows general status messages related to time or frequency domain comparisons with

thresholds, as shown below:

Figure 50. Threshold status summary

UM2438 - Rev 2

• The final step lets you change some parameters again and run a new analysis.

page 41/67

8 How to run projects via IO-Link

The STEVAL-IDP005V1 is also able to communicate through its embedded IO-Link PHY device, so the board can

receive and transmit data and commands to and from the STEV

PHY master

In the firmware package, the CondMonitor_IOL project (in STSW-BFA001V1\Projects\Demonstrations\

Condition_Monitoring\CondMonitor_IOL) can communicate via IO-Link using dedicated functions (no stack

libraries are implemented) to package the post processing results and sensor parameters. With IO-Link

connectivity, the project can also output results to a GUI.

Follow the procedure below to run the application with IO-Link:

Step 1. Connect the STEVAL-IDP005V1 to the STEVAL-IDP004V1 IO-Link master board using a standard 4-

Step 2. Connect the STEVAL-IDP004V1 to the power supply @ VIN = 18 to 32 V.

Step 3. Connect the STEVAL-IDP005V1 to the STEVAL-UKI001V1 and update the firmware.

Step 4. Turn on the power supply for the IO-Link master board and update the STEVAL-IDP005V1 firmware.

Step 5. Disconnect the assembly used for the firmware update, but leave the two boards with IO-Link and

Step 6. Connect the USB cable to your PC and run the GUI to experience the functionality as condition

.

wire cable with M12 A-coded 4-pin connectors, male on one end and female on the other.

Use the binary file in STSW-BFA001V1\Projects\Demonstrations\Condition_Monitoring

\CondMonitor_IOL\Binary

Use the STEVAL_IDP005V1_CondMonitor_IOL.bin or *.hex binary file

connect the RS-485 adapter for USB.

monitoring by Service UART.

AL-IDP004V1

UM2438

How to run projects via IO-Link

master board based on the IO-Link

RELATED LINKS

5.1 Connection through an ST-LINK/V2-1 on page 17

5.2 Connection through an STEVAL-IDP004V1 on page

9 Graphical Interface overview on page 43

18

UM2438 - Rev 2

page 42/67

9 Graphical Interface overview

The tool is designed to let you simultaneously monitor the different values measured by each sensor node

connected to the STEV

The GUI handles commands and data exchange in string format between a PC and the STEV

command received by the master is processed into byte format and sent to the sensor node.

As the sensor node has several sensors, a set of commands are available to show information like humidity and

pressure values, vibration frequency spectra and time domain acceleration analyses.

In the [

Vibration Analysis] tab, you can select one of the following analyses:

• ENV for environmental data

• RMS/PEAK for time domain results

• ACC FFT for frequency spectrum results

RELATED LINKS

6.2.4.3 Demonstrations folders on page 25

8 How to run projects via IO-Link on page

5.2 Connection through an STEVAL-IDP004V1 on page 18

AL-IDP004V1 IO-Link master board.

42

UM2438

Graphical Interface overview

AL-IDP004V1. Each

9.1 Data commands for sensor queries

Data communication between the STEVAL-IDP005V1 and STEV

serial connection at 230.4 kbaud.

Communication is initiated by the master node with a data frame signaling the STEVAL-IDP005V1 that a

communication request has been received by the host. The sensor node flags the request and sends the

appropriate data when it has been processed and ready to be sent.

The communication commands are defined in the Master_DeviceCOMM.h file in the STEVAL-IDP004V1

firmware. The command structures are shown below

1. FRAME_TYPE_CMD (0x21): this command is sent from master to the device. It communicates that a

command will be sent to the sensor node, which will return an acknowledge byte ACK_CMD when the

sensor node is ready. Once communication initiates, the master node can send the following requests to the

sensor:

– GET_SENSOR_TYPE (0x38): requests the sensor type and FW version on the board.

– GET_ACC_ RAW (0x31): requests accelerometer data from the sensor.

– GET_ACC_TDM (0x32): requests time domain data from the sensor (Peak,RMS).

– GET_ENV_MEASURE (0x33): requests accelerometer data from the sensor.

– GET_ACC_FFT (0x36): requests vibration power spectrum.

– GET_SENSOR_MCU_ID (0x3C): requests the MCU ID of the sensor.

2. FRAME_TYPE_DATA (0x22): this command is sent from master to the device. It communicates that a data

frame will be sent to the sensor node, which will return an acknowledge byte ACK_DATA when the sensor

node when is ready. Once communication initiates, the master send the following commands to the sensor:

– SET_PRM_CPT (0x40): sets the computation parameter for time domain calculation.

– SET_PRM_ACC (0x41): sets the accelerometer data acquisition parameters (ODR, operating mode

and filtering frequency).

Both sets of data are stored in the flash. The microcontroller reads the locations and updates its own settings after

a reset.

AL-IDP004V1 is managed through a simple

.

9.2 How to use the STEVAL-IDP005V1 GUI

To perform this task, your PC must be connected with the Demonstration kit via the RS485 cable.

Follow the steps below to exchange data with the sensor node:

UM2438 - Rev 2

page 43/67

Step 1. Set PC-Master Board communication parameters.

–

Name: COM Port name

Baud Rate: 230400 Baud

–

–

Data: 8

– Parity: None

– Stop Bit: One

– Flow Control: None

Figure 51. Communication parameter settings

UM2438

How to use the STEVAL-IDP005V1 GUI

UM2438 - Rev 2

Step 2. Click on one or more [Sensor] tabs according to the connected devices in the master board section

[Sensor 2] and [Sensor 3]) and click [Connect].

(e.g.,

page 44/67

UM2438

How to use the STEVAL-IDP005V1 GUI

Figure 52. STEV

AL-IDP005V1 home page connection

In this phase, the GUI programs the master IC with the default configuration and then sends the

command IDS to identify the sensor node for each port on the network. If the sensor is recognized, the

corresponding button on the GUI changes color and the “CONNECTED” label appears with firmware

version information.

Step 3. Select the [Vibration Analysis] tab.

UM2438 - Rev 2

page 45/67

UM2438

How to use the STEVAL-IDP005V1 GUI

Figure 53. V

ibration analysis tab

Step 4. Check one or more of the following fields for each active sensor that you wish to analyze:

– ENV MSR (for environmental data shown in the [

ENV Measures] tab)

– RMS/PEAK (for time domain analysis values in 3D dedicated sector)

– ACC FFT (for frequency domain analysis, available in 3D plot)

You can select all of the analyses by clicking on the button to the right of the fields.

Step 5. Select one of the following options to run the application:

– [MEASURE START] for a single pass

– [LOOP MEASURE START] for loop mode acquisition

UM2438 - Rev 2

page 46/67

How to use the STEVAL-IDP005V1 GUI

Figure 54. Frequency domain and time domain results

UM2438

UM2438 - Rev 2

page 47/67

How to use the STEVAL-IDP005V1 GUI

Figure 55. Environmental Measurement results

UM2438

9.2.1 How to modify the default L6360 settings

Step 1. Press [Connect] to connect the PC and the master board.

Step 2. Select the [L6360 Registers] tab.

Step 3. Click on the relevant Master port in the

This will call up the current IC register settings for the selected port.

[View Master Registers V

alues] section

UM2438 - Rev 2

page 48/67

How to use the STEVAL-IDP005V1 GUI

Figure 56. L6360 register update

UM2438

Step 4. Change the register settings.

Once the configuration has been changed, the decimal format is updated in the [Memorize/Program

Registers V

alues] section.

Step 5. Click on the blue button for the modified Master in the [Memorize/Program Registers Values] section.

9.2.2 How to save the log files

The [Flow ]

Follow the procedure below to store the communication history in log file

Step 1. Select the [Measures Files] tab.

Step 2. Check the [Enable Saving ] [To] [ File Sensor X Measures] box.

Step 3. Click the corresponding square blue button and select the folder path and file name for the log file.

[Comm] tab shows the command and data communication history during the session with the GUI.

Figure 57. Log file storage

UM2438 - Rev 2

page 49/67

UM2438

How to use the STEVAL-IDP005V1 GUI

Step 4. Run the analysis in single or loop mode.

In loop mode, each measurement does not overwrite the previous run.

When the sequence is completed, the log for is saved to the file.

UM2438 - Rev 2

page 50/67

VIN

VIN

MEM_SI

VIN: 18 V - 32 V

PRESS_DRDY

PRES_SCL

HUM-TEMP_SDA

HUM-TEMP_DRDY

Power Management

4. EEPROM

ENV_SD

HUM-TEMP_DRDY

PRES_SDA

MIC_DOUT

EEPROM_SDO

MIC_CLK

AUX_CLK

ACC_SDI

2. IO-Link

IO-Link_DIAG

OUT/IQ

MEM_W

ACC_CK

MIC_CK

EEPROM_SCK

EEPROM_HOLD

ACC_SO

ACC_CS

ACC_INT2

SensorsMicrocontroller

IO-Link_COM_TX

MEM_HOLD

ACC_INT1

MEM_CS

ACC_SPC

OL

EEPROM

SMBDATA

ACC_INT2

AUX_IO

SMBALERT

ACC_INT1

AUX_ALERT

ACC_SDO

3. Sensors

DIAG

IN2

PRES_INT_DRDY

ACC_CS

AUX_DATA

HUM-TEMP_SCL

IO-Link_COM_RX

ACC_SI

IO-Link_OL

SMBCLK

EEPROM_CS

ENV_CK

MEM_SO

MEM_CK

5. Microcontroller

EPPROM_W

SMB_IO

EEPROM_SDI

MIC_SD

IO-Link

1. Power Management

VDD: 3.3 V

UM2438 - Rev 2

A Schematic diagrams

Figure 58. STEVAL-IDP005V1 schematic – General purpose industrial sensor

page 51/67

Schematic diagrams

UM2438

VIN

7

TP5

Vdc-dc

LX

6

Vdc-dc

5

GND

IN

6

step-down switching regulator

LDO

SB2

C4

L1

R4

EN

4

9

68uH

LDK220

Vdc-dc

TP2

R3

U2

VIN

LNM

1M

C1

VDD

1uF

1

909k

R5

10

EP

11

100k

U1

1uF

200 mA

3.3 V

3.6 V

ADJ/NC

EN

4

R2

GND

5

100nF

3

TON

0R

Vldo

VBIAS

8

VCC

TP3

205k

1uF

1

OUT

3.3uF

R1

68k

TP1

22uF

NC

2

PGOOD

FB

2

C6

C3

3

L6984

C5

Vldo

C2

VDD

18 V - 32 V

UM2438 - Rev 2

Figure 59. STEVAL-IDP005V1 schematic – Power management

page 52/67

Schematic diagrams

UM2438

12

100R

100R

R13

DIAG

OL

1uF

22k

R9

Not Mounted

OUT/IQ

1

2

U3

Not Mounted

4k7

JP1

10pF

EN/DIAG

5

C7

VDD

47nF

R10

SB5

0R

8

SEL

OUTL

I/Q

10

TP6

NSR05T40P2

C13

3

IN2

11

Vcc

100R

SB6

0R

C10

10pF

R11

IN2

4

C9

3

D2

GND

7

R7

NSR05T40P2

4

Not Mounted

C12

C8R8

4k7

10pF

R6

100k

10pF

OUT/IQ

OL

6

D1

IN1

2

9

1

Vdd

OUTH

100R

R12

L6362A

C11

VIN

UM2438 - Rev 2

Figure 60. STEVAL-IDP005V1 schematic – IO-Link

page 53/67

Schematic diagrams

UM2438

100nF

MEMS Pressure Sensor

SDO/SA0

CS

6

U6

VDD

AUX_DATA

2

C20

ACC_SDI

5

VDD

4.7uF

U7

HTS221

GND

5

3

I²C

AUX_CLK

Auxiliary Connector

Vdd_IO

2

U4

ACC_SPC

SDO/SA0

1

VDD

10k

I²C

I²S

3D accelerometer

INT_DRDY

VDD

ACC_INT1

5

9

INT2

SMBus

VDD

VDD

12

10

OCS_Aux

1

C21

SPI

2

100nF

J2

MEMS microphone

4

PRES_INT_DRDY

PRES_SDA

CS

7

C19

11

SDO_Aux

ISM330DLC

C17

6

GND1

1

VDD

100nF

R24

1uF

ACC_SDO

SCL

13

AUX_IO

10k

LPS22HB

1

2

SDx

2

10

8

GND1

CLK

3

LR

HUM-TEMP_DRDY

PRES_SCL

6

SDA

100nF

INT1

SCx

3

SCL/SPC

RES

3

7

3

SCL/SPC

C14

SDA/SDI/SDO

5

Humidity and Temperature Sensor

DRDY

4

4

DOUT

ACC_CS

C18

MP34DT05-A

HUM-TEMP_SCL

U8

14

R16

VDD

GND2

SDA/SDI/SDO

CS

6

Auxiliary SMBus

GND

5

C15

ACC_INT2

4

1

VDD

AUX_ALERT

100nF

VDDIO

VDD

4

HUM-TEMP_SDA

MIC_CLK

MIC_DOUT

8

VDD

9

GND2

UM2438 - Rev 2

Figure 61. STEVAL-IDP005V1 schematic – Sensors

page 54/67

Schematic diagrams

UM2438

1-Mbit SPI bus EEPROM with high-speed clock

UM2438 - Rev 2

Figure 62. STEVAL-IDP005V1 schematic – EEPROM

page 55/67

Schematic diagrams

UM2438

SB9

COM_TX

C23

2k

VDD

IO-Link_COM_RX

ACC_CK

E12

I2C1_SCL

PB14

nRESET

PC7

G7

OSC32_OUT

PI2

PA0-WKUP

PA1

PA6

Y1

PD12

PB11

SB10

PA15

3

PA10

Take care about the MCU boot configuration table

PD3

PD13

SWDIO

N1

PB7

PC10

D5

E11

PC14-OSC32_IN

R18

Not Mounted

VDD

D9

PDR_ON

PI7

K5

PI10

A2

E7

M2

4

PD8

L4

C10

PI6

SWD Connector

COM_TX

9

H4

SWCLK

PI0

IO-Link_COM_TX

STM32F469AI

PD9

PB13

D6

Not Mounted

PA8

E1

DSIHOST_CKN

D12

PA5

DSIHOST_D0N

H2

E5

PI1

C3

I2C1_SCL

PA12

F6

L12

PB6

G8

1

PA9

E2

Reset

N5

B11

DSIHOST_D1P

SW1

10k

5

PD6

C26

PD10

M3

MIC_SD

PC11

B3

A9

PB8

B9

PC13

MEM_CS

10

K9

PA2

PB15

N2

VDD

PB0

F10

BOOT1

DSIHOST_D0P

2

R17

PA7

PC0

J9

PB2-BOOT1

PB3

D10

PI5

BOOT0

I2C1_SDA

32.768 kHz

U10A

6

PB10

PC12

MIC_CK

PD1

VDD

N10

10pF

J1

SWCLK

nRESET

H3

COM_RX

MEM_HOLD

J8

A3

PD2

C5

N9

P9

L2

C24

8

PC6

F3

DSIHOST_CKP

J3

C4

nRESET

P1

PB12

L9

PA3

7

DSIHOST_D1N

I2C1_SDA

F11

NRST

VDD

C25

P10

A1

PI3

PA13

D1

COM_RX

U10B

100nF

R19

2k

F7

PA11

PD14

L3

A12

PC1

10k

10pF

PD7

A5

PD0

PC15-OSC32_OUT

E6

OSC32_IN

PD15

SB8

0R

H5

PC9

F4

PI11

ENV_SD

K3

L10

VDD

BOOT0

F8

BOOT0

PB1

C22

B2

PI4

M9

PA14

D4

J1

USER_LED

USER_LED

P11

A8

PB4

B4

PD5

C6

OSC32_OUT

SWDIO

OSC32_IN

10pF

J2

C8

PB5

B8

PD4

ACC_SO

K4

PD11

J4

10k

F5

PC8

BOOT1

ACC_SI

STM32F469AI

MEM_W

E3

H9

PA4

PB9

E9

10pF

ENV_CK

L8

PI9

G9

SB7

0R

UM2438 - Rev 2

Figure 63. STEVAL-IDP005V1 schematic – Microcontroller (part A)

page 56/67

Schematic diagrams

UM2438

SMBCLK

100nF

PF11

K7

C2

VDD_3

L1

VDDDSI

B12

PE6

PF13

J7

C27

I2C2_SMBA

I2C2_SDA

OSC_OUT

PE9

K6

M1

PG9

D7

PE13

C9

PE2

F9

K10

PG4

16pF

R21

PE15

P5

SMBDATA

PG8

G6B10

VSS_9

C30

F1

VDDUSB

PH12

N12

100nF

PG15

D8

PE8

M7

4.7uF

10pF

100nF

H10

PF2

STM32F469AI

VSS_5

VSS_6

N8

OSC_IN

G2

PE0

PH11

N3

SMBALERT

G12

F12

VSS_10

PF12

M8

MEM_SI

2.2uF

C38

K2

VDD12DSI

100nF

ACC_CS

PG12

A6

M10

L5

VDD

K12

PE12

H12

I2C2_SDA

100nF

PG2

G5

C43

PE1

G10

PF1

PE3

C35

1

R26

2k

VDD_2

P2

C28

2.2uF

K1

J10

B7

VSS_1

C1

MEM_SO

100nF

10pF

U10C

PG11

B6

VDD

VSSDSI

VBAT

PH4

R20

R25100R

PE4

PF5

PE14

100nF

U10D

3

VCAP1

N4

D2

VCAP2

H7

VSS_4

PF0

P3

VDD_4

P8

VSS_2

VSS_3

F2

K8

PG6

G3

H11

PF4

MEM_CK

VDD

C33

C12

PH5

ACC_INT1

I2C2_SMBA

E10

4

C34

24 MHz

K11

PH0-OSC_IN

C32

J6

PG7

2k

N6

VCAPDSI

PF10

C29

VSS

A4

PF14

L7

OSC_OUT

PF3

PH1-OSC_OUT

PH2

2.2uF

Y2

VSS_11

N11

VSSA

ACC_INT2

L6

C45

PE10

P6

100nF 100nF

VDD

PH15

E4

A11

VDD_6

100nFH6100nF

PG0

PG10

C7

C42

C39

PE11

C37

A7

B5

VDD_1

PH14

D3

1uF

PG13

C47

PH10

M4

J12

VDD_8

C48

J5

L11

H1

2

SMB_IO

VSS_7

P4

VSS_8

P12

VDDA

PH3

OSC_IN

HUM-TEMP_DRDY

D11

PE7

N7

IO-Link_DIAG

C11

PE5

VDD

VDD_5

PH13

B1

100nF

A10

VDD

VDD

PF15

H8

10pF

PG3

G4

C31

E8

C36

I2C2_SCL

PG5

G1

PH9

J11

G11

VDD_7

M12

M11

C41

PRESS_DRDY

2k

I2C2_SCL

IO-Link_OL

C46

M6

C44

PH8

M5

16pF

STM32F469AI

PG1

P7

C40

UM2438 - Rev 2

Figure 64. STEVAL-IDP005V1 schematic – Microcontroller (part B)

Schematic diagrams

page 57/67

UM2438

B Bill of materials

Item Q.ty Ref. Value Description Manufacturer Part Number

1 1 C1

2 1 C2

3 5

4 1 C4 22uF, 16V, ±20% X7R, SMD 1210 MULTICOMP MC1210B226M160CT

5 1 C7 47nF, 10V, ±10% X7R, SMD 0402 Murata GRM155R71A473KA01D

6 1 C8 1uF, 50V, ±10% X5R, SMD 0603 Murata GRT188R61H105KE13D

7 9

8 1 C13 TBD, 10V, SMD 0402

9 17

10 1 C15

11 2 C21, C33

12 2 C24, C25 10pF, 50V, ±5% C0G, SMD 0402 Kemet C0402C100J5GACTU

13 3

14 2 C42, C43 16pF, 50V, ±5% C0G, SMD 0402 Murata GRM1555C1H160JA01D

15 2 D1, D2 NSR05T40P2

16 1 JP1 IO-Link CONN

17 1 J1 SWD Connector

18 1 J2

19 1 L1

20 1 R1 1M, 0.1 W, ±1% SMD 0402 Any

C3, C5,

C6, C19,

C31

C9, C10,

C1

1, C12,

C23, C26,

C44, C45,

C48

C14, C17,

C18, C20,

C22, C28,

C32, C34,

C35, C36,

C37, C38,

C39, C40,

C41, C46,

C47

C27, C29,

C30

UM2438

Bill of materials

Table 3. Bill of materials

100nF, 50V,

±10%

3.3uF, 50V,

±10%

1uF, 10V, ±10% X7S, SMD 0402 TDK C1005X7S1A105K050BC

10pF, 10V

100nF, 10V,

±10%

100nF, 10V,

±10%

4.7uF, 10V,

±10%

2.2uF, 10V,

±10%

Auxiliary

Connector

68uH, Isat = 0.4

A / Rdc = 0.34

ohm, ±30%

, ±1% C0G, SMD 0402 MULTICOMP MCMT15N100F100CT

X7R, SMD 0402 TDK CGA2B3X7R1H104K050BB

X7R, SMD 1206 TDK C3216X7R1H335K160AC

X7R, SMD 0402 Wurth Elektronik 885012205018

X7R, SMD 0805 TDK C1005X7R1A104K050BB

X7S, SMD 0603 TDK C1608X7S1A475K080AC

X7R, SMD 0402 Murata GRM155Z71A225KE44D

Schottky Barrier

Diode, SOD-923

IO-Link 4

position M12 Acoded connector

SMT Pitch 1.27

mm (5x2)

SMT Pitch 1 mm

(8x6.8)

Shielded Power

Inductor

, SMD

(4.8x4.8x2.8

mm)

On Semiconductor NSR05T40P2T5G

Binder 9043121204

Samtec FTS-105-01-L-DV

JST Sales America Inc. SM06B-NSHSS-TB

urth Elektronik

W

744043680

UM2438 - Rev 2

page 58/67

UM2438

Bill of materials

Item Q.ty Ref. Value Description Manufacturer Part Number

21 3

22 1 R3

23 1 R4

24 1 R5 68k, 0.1 W, ±1% SMD 0402 Any

25 1 R6

26 2 R7, R8 4k7, 0.1 W, ±1% SMD 0402 Any

27 5

28 1 R12 22k, 0.1 W, ±1% SMD 0603 Any

29 5

30 5

31 2 SB2, SB5 0R, 0.1 W, ±1% SMD 0402 Any

32 3

33 1 SW1 Reset

34 1 U1 L6984

35

36 1 U3 L6362A

37 1 U4 ISM330DLC

38 1

39

40 1 U8 LPS22HB

R2, R22,

R23

R9, R10,

R1

1, R13,

R25

R16, R17,

R24, SB9,

SB10

R18, R19,

R20, R21,

R26

SB6, SB7,

SB8

1 U2 LDK220

U6 HTS221

1 U7 MP34DT05-A

100k, 0.1 W,

±1%

909k, 0.1 W,

±1%

205k, 0.1 W,

±1%

100k, 0.1 W,

±1%

100R, 0.1 W,

±1%

10k, 0.1 W, ±1% SMD 0402 Any

2k, 0.1 W, ±1% SMD 0402 Any

0R, 0.1 W, ±1% SMD 0402 Any

SMD 0402 Any

SMD 0402 Any

SMD 0402 Any

SMD 0402 Any

SMD 0402

smd (L 4.6 x W

2.2 x H 1.9 mm)

Step-Down

Switching

Regulator

VDFPN10

(3x3x1.0 mm)

LDO, DFN6

(1.2x1.3x0.5

mm)

IO-Link

Communication

T

VFDFPN 12L

(3x3x0.90 mm)

3D

Accelerometer,

LGA-14L

(2.5x3x0.83 mm)

Humidity and

Temperature

Sensor,

HLGA-6L

(2x2x0.9 mm)

Microphone,

HCLGA-4LD

(3x4x1 mm)

Pressure Sensor,

HLGA-10L

(2x2x0.76 mm)

,

ransceiver

Any

C & K KMR211G LFS

ST L6984ATR

ST LDK220PU33R

,

ST L6362A

ST ISM330DLCTR

ST HTS221TR

ST MP34DT05TR-A

ST LPS22HBTR

TR

UM2438 - Rev 2

page 59/67

UM2438

Bill of materials

Item Q.ty Ref. Value Description Manufacturer Part Number

EEPROM,

41 1 U9 M95M01-DF

42 1 U10 STM32F469AI

43 1 Y1

32.768 kHz,

±20ppm

WLCSP8

(2.578x1.716

mm)

ARM®Cortex®M4 32-bit MCU,

WLCSP 168L

DIE 434 (12X14

P 0.4mm)

Crystal, smd

(2.05x1.2x0.55mm)NDK

ST M95M01-DFCS6TP/K

ST STM32F469AIY6TR

NX2012SA 32.768kHz

EXS00A-MU00389

44 1 Y2 24 MHz, ±20ppm

Crystal, smd

(2x1.6x0.45 mm)

NDK

NX2016SA 24.000MHz

EXS00A-CS05544

UM2438 - Rev 2

page 60/67

Revision history

Date Version Changes

19-Jul-2018 1 Initial release.

20-Mar-2019 2

UM2438

Table 4. Document revision history

Updated Section Introduction

Updated Section 1 Overview

Updated Figure 27, Figure 28, Figure 29, Figure 30, Figure 31, Figure 32, Figure 34, Figure 36,