Page 1

2

1

UM2501

User manual

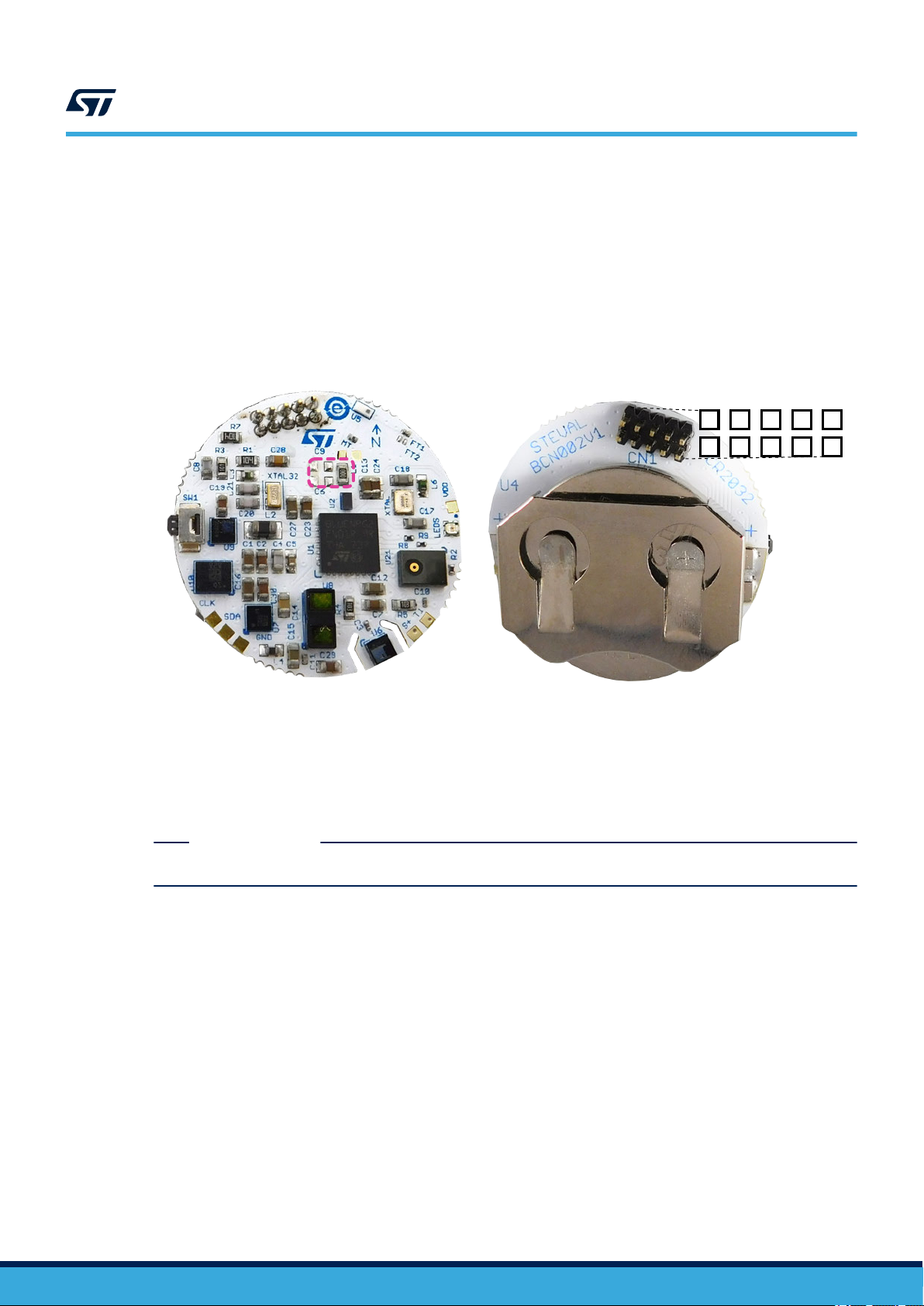

How to use the BlueNRG-Tile Bluetooth LE enabled sensor node development kit

Introduction

The STEV

board based on BlueNRG-2 SoC Bluetooth Low Energy application processor. This sensor board has accelerometer,

gyroscope, magnetometer, pressure, humidity, Time-of-Flight and microphone sensors, and is powered by a common CR2032

coin battery.

The sensor board communicates with a Bluetooth LE enabled smartphone running the ST BLE Sensor app, available on Google

Play and iTunes stores.

The STEVAL-BCN002V1D adapter board is used to program and debug the sensor board. The adapter board is powered via

USB.

1. STEVAL-BCN002V1 “BlueTile” sensor node with inertial and environmental digital MEMS sensors, a digital MEMS microphone, a time-offlight proximity sensor and a Bluetooth 5.0 wireless system-on-chip with a Cortex-M0 core

2. STEVAL-BCN002V1D host board to Flash and debug the sensor node

AL-BCN002V1B Bluetooth LE enabled sensor node development kit features the STEVAL-BCN002V1 multi-sensor

Figure 1. STEVAL-BCN002V1B BlueTile kit

UM2501 - Rev 3 - June 2020

For further information contact your local STMicroelectronics sales of

fice.

www.st.com

Page 2

1 Safety Information

Any type of usage not specified by the manufacturer may compromise the protection mechanisms in the device.

1.1 Class 1 laser product

VL53L1X contains a laser emitter; the device is designed to limit the laser output within Class 1 laser safety limits

under all conditions including single faults, in compliance with IEC 60825-1:2014 (third edition).

Recommended settings and operating conditions specified in VL53L1X datasheet and user manual MUST be

respected.

The laser output MUST NOT be increased by any means and no optics should be to used focus the laser beam.

Use of controls or adjustments or performance of procedures other than those specified in VL53L1X datasheet

and user manual may result in hazardous radiation exposure.

UM2501

Safety Information

UM2501 - Rev 3

page 2/44

Page 3

2 STEVAL-BCN002V1 BlueTile sensor node

I2C

LPS22HH

RGB LED

user button

UART

MP34DT05-A

LIS2MDL

32 MHz

I2C

I2C

VL53L1

400

kHz

1.6

I2C

Test points

TEST

VDDGND

MHz

RFTEST

PDM

inductor

10 pin

connector

32 KHz

Integrated

antenna

LSM6DSO

UART_RX line

I2C

BALF-NRG-02D3

HTS221

I2C

TEST ADC

ADC

RFTEST

SWD

SDASCL

IRQ

IRQ

I2C

3 VO LTS

+

BlueNRG-2

d

Pi-network

BlueTile is a small form-factor reference design ready for you to extend and customize, as well as a development

platform for BLE-enabled applications using the BlueNRG-2

and evaluate the performance of the sensors and the capabilities of the BLE.

Thanks to its small and thin design, BlueTile can be used in the field for data collection activities to test and

develop new algorithms.

Figure 2. STEVAL-BCN002V1 BlueTile block diagram

BlueNRG-2: Bluetooth 5.0 network and application processor

LSM6DSO: accelerometer and gyroscope

LIS2MDL: magnetometer

LPS22HH: barometer

HTS221: relative humidity and temperature sensor

VL53L1X: time-of-flight proximity sensor

MP34DT05-A: microphone

BALF-NRG-02D3: integrated balun

SDK. It is also an evaluation tool to help you assess

UM2501

STEVAL-BCN002V1 BlueTile sensor node

UM2501 - Rev 3

• The integrated SMD antenna needs clearance area and passives for proper tuning (FT1, FT2 and MT).

•

The Pi-network is only intended for flexibility and for testing. It is not populated as the integrated balun

provides the necessary matching.

• The 32kHz crystal allows lower power consumption BLE Sleep Mode.

• The inductor allows lower power consumption in BLE Active Mode.

• The STEVAL-BCN002V1 BlueTile sensor node is supplied with the default firmware (BLE_SensorDemo,

available in the SDK) already loaded. The firmware enables the streaming of sensor data to the reference

smartphone app (ST BlueMS, available on Android™ and iOS™ stores).

page 3/44

Page 4

1a

2a

4a

5a

6a

2b

2c

2d

2e

2f

3b

4b

4c

4d

4e

4f

4g

4h

1b

5b

6b

7a

7b

8

RESETN

UART RX

UART TX

SWD CLK

SWD IO

IO IO IO IO

GND

BOOT

GND GND VDD

1

2

10

UM2501

System architecture

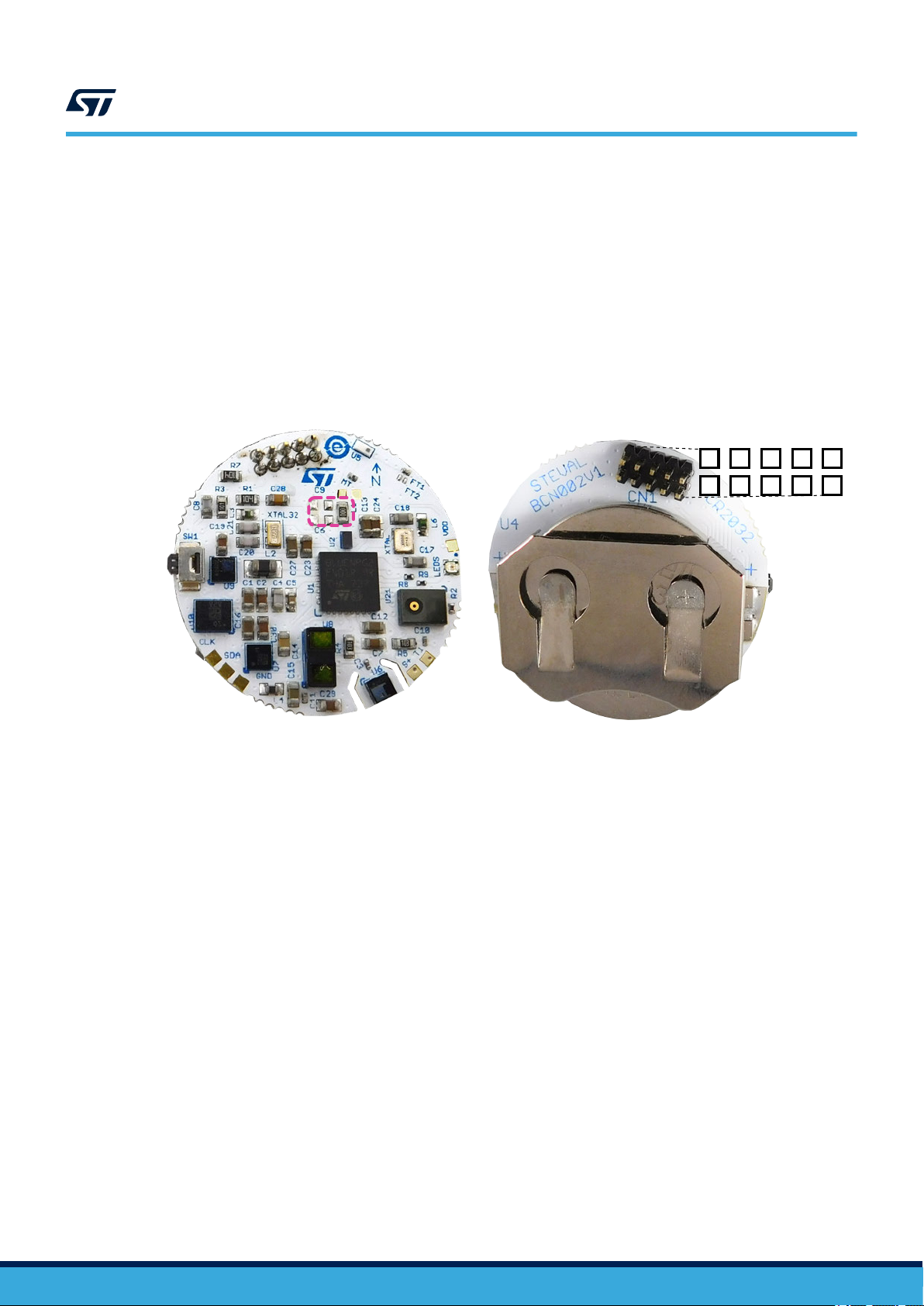

Figure 3. STEV

1a. BlueNRG-2 Bluetooth 5.0 network and application processor 1b. BALF-NRG-02D3 integrated balun and matching network

2a. LPS22HH ambient pressure sensor 2b. LSM6DSO smart accelerometer and gyroscope 2c. LIS2MDL magnetometer 2d.

VL53L1X proximity by time-of-flight 2e. HTS221 relative humidity and temperature 2f. MP34DT05-A top-port digital microphone

3a. User button 3b. RGB LED

4a. I2C SCL 4b. I2C SDA 4c. GND 4d. ADC 4e. TEST 4f. VDD 4g. GND 4h. RFTEST

5a. II-network (not mounted) 5b. SMD antenna

6a. Inductor to enable lowest power BLE active mode 6b. 32kHz crystal to enable lowest power BLE sleep mode

7a. Battery holder 7b. CR2032 battery (not included)

8. 10-pin connector

FCC ID: S9NSTEBCN2V1 IC ID: 8976C-STEBCN2V1

AL-BCN002V1 sensor node front and rear components

The BlueTile sensor node is supplied with the firmware already loaded. The default firmware includes two

libraries:

1.

MotionFX fusion library for orientation estimation (visualized with a rotating cube).

2. BlueVoice library to stream the voice captured by the MEMS microphone over the BLE connection

(reproduced by the smartphone speaker, if not in vibration mode).

The STBLESensor app can be used to plot and log sensor data in real time on your smartphone.

RELATED LINKS

STBLE sensor documentation

2.1 System architecture

The BlueTile is powered by a coin-cell battery (CR2032). The voltage is not regulated because the sensors and

the BlueNRG-2

embedded linear power regulator and switching mode power converter (DC-DC).

2.1.1 Power section for BlueNRG-2

The BlueNRG-2 in active mode can use the embedded linear voltage regulator (LDO) or the embedded DC-DC

converter (DC-DC).

•

LDO regulator [Active mode, CPU Flash and RAM on]:

– RX 14.5 mA at 3 V, TX 17.2 mA when output power is +2 dBm

– range is 12-28.8 mA when output is -14 to +8 dBm

• DC-DC converter [Active mode, CPU Flash and RAM on]:

– RX 7.7 mA at 3 V, TX 9 mA at 3 V when output power is +2 dBm

– range is 6.6-15.1 mA when output is -14 to +8 dBm

UM2501 - Rev 3

can all operate at the voltage range of the battery. In any case, the BlueNRG-2 has its own

page 4/44

Page 5

System architecture

Note: The BlueTile sensor node includes the inductor needed by the DC-DC converter to allow lower power

consumption in active mode.

In Sleep Mode, the BlueNRG-2 device can use its internal 32 kHz ring oscillator (RO) or the external 32 kHz

crystal oscillator (XO) available on the BlueT

mode:

• Sleep Mode [32 kHz ring oscillator, 24 kB RAM retention]: 2.1 µA at 3 V

• Sleep Mode [32 kHz crystal oscillator, 24 kB RAM retention]: 0.9 µA at 3 V

ile sensor node, which offers lower power consumption in sleep

2.1.2 Radio frequency section

The radio frequency section of the BlueTile includes the following elements:

1.

A BALF-NRG-02D3 ultra-miniature balun which integrates matching network and harmonics filter.

2. A Pi-network which allows additional filtering and provides access points for testing.

Note: This network is not populated, as the integrated balun provides the necessary matching.

3. An SMD 2.4 GHz antenna, which requires a certain clearance area on the PCB and specific passives for

precise tuning (FT1, FT2 and MT).

2.1.3 MEMS sensor section

The MEMS sensor section of the BlueTile sensor node includes inertial and environmental MEMS sensors

connected with the BlueNRG-2 via an I2C bus operating at 400 kHz.

The MEMS microphone is connected with BlueNRG-2 through a dedicated line to transfer the PDM (Pulse

Density Modulated) stream at 1.6 MHz, which is converted to PCM (Pulse Coded Modulation) by the integrated

digital filter in the ADC block on the BlueNRG-2.

All sensors can generate interrupts, but only the interrupts from the LIS2MDL magnetometer and the LSM6DSO

accelerometer and gyroscope are connected with the BlueNRG-2 through dedicated and independent lines.

•

The LIS2MDL magnetometer interrupt line is push-pull only and must have its own independent line. The

interrupt pin of this sensor is connected with BlueNRG-2 to enable applications such as “reed-switch”, which

is activated by an external magnet.

• The LSM6DSO smart accelerometer and gyroscope interrupt pin is an input at boot. It has an internal pulldown. If the pin is low at boot, the I2C interface is selected, otherwise the I3C interface is selected. The pin

can be reconfigured as open-drain, but the external pull-up would cause additional power consumption. The

interrupt pin of this sensor is connected to BlueNRG-2 to exploit the smart embedded processing

functionality (single/double tap recognition, free-fall, wakeup, portrait/landscape, 6D/4D orientation detection;

activity/inactivity, stationary/motion detection; pedometer, step detector and step counter; up to 16 finite state

machines to process).

• The LPS22HH barometer interrupt pin exhibits the same behavior as the LSM6DSO interrupt pin: it is an

input pin at boot and must be low to activate the I2C interface. It can be configured as push-pull or opendrain after boot. The interrupt pin of this sensor is not connected to BlueNRG-2.

• The HTS221 relative humidity and temperature interrupt pin is push-pull at boot and can be reconfigured as

open-drain after boot. The interrupt pin of this sensor is not connected to BlueNRG-2.

• The VL53L1X time-of-flight proximity interrupt line is open-drain only and would require an external pull-up.

The interrupt pin of this sensor is not connected to BlueNRG-2.

The dynamics of the environmental parameters are relatively slow, so interrupts are not necessary. The

application only needs to wake up every few seconds and perform one-shot measurements with the LPS22HH

barometer or HTS221 relative humidity and temperature sensor, and trigger an action if specific conditions are

met.

It is also not convenient to keep the VL53L1X proximity time-of-flight sensor active, the power consumption or the

latency would be too high. The power consumption of VL53L1X ranges from 0.5 mA for 1 Hz measurements, up

to 7 mA for 10 Hz measurements.

UM2501

2.1.4 Pinout descriptions

In the following figure, you can see 6 pads along the edge of the board:

•

RFTEST (4h) and GND (4g) connected to the RF section for test purposes.

• TEST (4e) connected to the analog TEST output of BlueNRG-2 for test purposes.

• VDD (4f) and GND (4c), for test purposes or to power additional external components.

• ADC (4d) to accept analog input signals from additional external components.

UM2501 - Rev 3

page 5/44

Page 6

1a

2a

4a

5a

6a

2b

2c

2d

2e

2f

3b

4b

4c

4d

4e

4f

4g

4h

1b

5b

6b

7a

7b

8

RESETN

UART RX

UART TX

SWD CLK

SWD IO

IO IO IO IO

GND

BOOT

GND GND VDD

1

2

10

Features of the BlueNRG-2 device

• I2C SCL (4a) and I2C SDA (4b) to connect additional external components via I2C.

UM2501

Figure 4. STEV

1a. BlueNRG-2 Bluetooth 5.0 network and application processor 1b. BALF-NRG-02D3 integrated balun and matching network

2a. LPS22HH ambient pressure sensor 2b. LSM6DSO smart accelerometer and gyroscope 2c. LIS2MDL magnetometer 2d.

VL53L1X proximity by time-of-flight 2e. HTS221 relative humidity and temperature 2f. MP34DT05-A top-port digital microphone

3a. User button 3b. RGB LED

4a. I2C SCL 4b. I2C SDA 4c. GND 4d. ADC 4e. TEST 4f. VDD 4g. GND 4h. RFTEST

5a. II-network (not mounted) 5b. SMD antenna

6a. Inductor to enable lowest power BLE active mode 6b. 32kHz crystal to enable lowest power BLE sleep mode

7a. Battery holder 7b. CR2032 battery (not included)

8. 10-pin connector

FCC ID: S9NSTEBCN2V1 IC ID: 8976C-STEBCN2V1

AL-BCN002V1 sensor node front and rear components

On the debug connector on the rear of the board, there are 10 pins:

VDD (pin 2) and GND (pin 4, 6, 10) to accept power from the host motherboard.

•

• SWD IO (pin 1) and SWD CLK (pin 3) to Flash and debug through the host motherboard.

– SWD pins can be used as digital GPIOs when the BlueTile is not connected to its host board.

• UART TX (pin 5) and UART RX (pin 7).

– UART pins can be used as digital GPIOs when the BlueTile is not connected to its host board.

• BOOT (pin 8) and RESETN (pin 9) to control the boot and keep BlueNRG-2 under reset.

– The boot pin can also be used as a digital GPIO when the BlueTile is not connected to its host board,

but it needs to be pull-down at start-up.

2.2 Features of the BlueNRG-2 device

BlueNRG-2 integrates a Bluetooth Low Energy radio (BLE), an ARM® Cortex®-M0 core, 12+12 kB of RAM,

UM2501 - Rev 3

256 kB of Flash memory

fast 400 kHz), UART interfaces; two multi-function timers (MFT), a DMA controller, RTC and watchdog, and an

ADC with PDM stream processor.

The public key cryptography (PKA) and random number generator (RNG) are reserved for the BLE protocol stack,

but the user application can also read the RNG.

The ADC is 10-bit and features single or continuous acquisition at max. 1 MHz sampling frequency, two single

ended or one differential signal (ADC1 and ADC2 pins), embedded channels for temperature and battery voltage

sensing, embedded digital filter with down sampling. The embedded digital filter can be used to process the PDM

stream from a digital MEMS microphone (1.6 MHz or 0.8 MHz) and convert it to audio PCM (8 kHz to 50 kHz

when 1.6 MHz clock is used for the microphone).

BlueNRG-2 uses the embedded digital filter of the ADC peripheral for PDM to PCM conversion when reading the

PDM output of the MEMS microphone MP34DT05-A.

, SPI (max 1 MHz in slave mode, 8 MHz in master mode), two I2Cs (standard 100 kHz or

page 6/44

Page 7

The low-speed clock is used in low-power mode and can be supplied by the internal RC oscillator or by an

external crystal (32 kHz ±50 ppm). The high-speed clock is supplied by a fast-starting internal RC oscillator

(16 MHz) while the external crystal is starting up. The high-speed external crystal (16 or 32 MHz) is required to

enable the BLE radio.

Only the 32 MHz XO can support the highest computational loads, allowing the Cortex-M0, the DMA and the APB

tree to run at 32 MHz, while the rest of the clock tree runs at 16 MHz. When a 16 MHz XO is used, the Cortex-M0

and all the clock tree runs at 16 MHz.

2.2.1 BlueNRG-2 states

• Preactive:

–

After power-on-reset, all digital power supplies are stable.

– Internal 16 MHz and 32 kHz RC oscillators are used.

– Reachable from Reset, Standby and Sleep states.

– Goes to Active state.

• Active:

– The external high-frequency crystal is used (16 MHz ±50ppm or 32 MHz) to enable BLE

communication.

– Internal 16MHz RC oscillator is switched off

– BlueNRG-2 uses a 32 MHz ±10ppm crystal (higher crystal accuracy = lower power consumption).

– The radio can be activated for transmission (TX) or reception (RX). This is the state used by

BlueNRG-2 when the user application is running or there is a BLE event to serve.

– The programmed GPIO configuration is restored.

– reachable only from Preactive only.

• Standby:

– RAM retention is used (12 or 24 kB).

– 5 different GPIOs can be used to wake-up: IO9, IO10, IO11 with an internal pull-up; IO12, IO13 which

require an external drive).

– BlueNRG-2 IO11 is connected to the user button, IO12 connected to the interrupt pin of LIS2MDL

magnetometer, and IO13 connected to the interrupt pin of the LSM6DSO accelerometer and

gyroscope.

– Wake-up time is typically 200µs.

– reachable from Active.

– can go to Preactive.

• Sleep:

– RAM retention is used (12 or 24 kB).

– The low-frequency oscillator is switched on to serve periodic BLE connection events.

– 5 different GPIOs can also be used to wake-up, as in Standby state.

– This is the state used by the BlueNRG-2 tile to save power when the user application is not running

and the device is waiting for a BLE event to serve.

– The programmed GPIO configuration is not maintained (this may affect connected sensors; for

example, see pin IO7 of BlueNRG-2 connected to XSHUT pin of VL53L1X).

– Reachable from Active.

– Can go to Preactive.

UM2501

Features of the BlueNRG-2 device

2.2.2 BLE firmware stack and memory map

Program memory, data memory, registers and I/O ports are organized in a linear 32-bit address space.

•

The SRAM is divided in two banks:

– 12 KB from 0x2000_0000 to 0x2000_2FFF (retention always-on).

– 12 KB from 0x2000_3000 to 0x2000_5FFF (retention optional).

– The FULL BLE stack needs 9.6 KB of SRAM.

– The BASIC BLE stack needs 8.0 KB of SRAM.

UM2501 - Rev 3

page 7/44

Page 8

UM2501

Inertial MEMS sensors

• The Flash is 256 KB from 0x1004_0000 to 0x1007_FFFF

–

The FULL BLE stack needs 77 KB, leaving 179 KB for the user application. The FULL BLE stack

supports concurrent peripheral and central roles (N=0,1,2 connections to other centrals and 8-N

connections to other peripherals), LE secure connections, controller privacy, and extended data length.

– The BASIC BLE stack needs 58 KB, leaving 198 KB for the user application. The BASIC BLE supports

the peripheral role only (1 connection to a central), legacy security only, no controller privacy and no

extended data length.

– The OTA manager for over-the-air firmware updates adds 10 KB to the size of the BLE stack.

The OTA manager may be independent of the user application, or embedded in the user application:

• When the OTA manager is independent of the user application, the Flash is divided in two sections:

1. A relatively small section for the OTA application; the size is the sum of the BLE stack size and the

OTA manager size.

2. A larger section for the user application.

• When the OTA manager is embedded in the user application, the Flash is divided in three sections:

1. A section that holds the current application; the size is the sum of BLE stack size, OTA manager size

and user application size.

2. A section for the new updated application; the size is the same as the first section.

3. A very small section for the reset application that decides decides which application to run after boot,

depending on what is available and valid in the first two sections.

An independent OTA manager leaves more room for the user application, but there is no application to run if the

update does not finish successfully.

An embedded OTA manager can still use the previous application if the update does terminate successfully, but

the space available for the user application is less than half the size of the Flash.

Note: After a successful update, the new application can be copied over the old application, or the role of the first two

sections can be exchanged.

2.3 Inertial MEMS sensors

Each sensor is made of a Micro Electro Mechanical system (MEMS) with a sensing element and a dedicated

ASIC with analog acquisition chain, analog-to-digital converter (ADC), and digital signal processing (DSP) and

control logic.

2.3.1 LSM6DSO 3D accelerometer and 3D gyroscope

2.3.1.1 LSM6DSO interrupts

The LSM6DSO delivers best-in-class motion sensing able to support more sophisticated functionality than simply

orienting devices to portrait and landscape mode.

The following event-detection interrupts are supported:

•

Free-fall event:

– detected when acceleration data from all enabled axes are below threshold settings for a certain

duration

• Wake-up event:

– detected when the filtered data from any of the enabled axes are above threshold settings for a certain

duration

– choose between high-pass filtered data, slope detection filter (difference between consecutive

samples, divided by two), low-pass filtered data plus an offset for each axis, or unfiltered data plus an

offset.

• 6D/4D orientation event:

– detected when an axis (positive or negative) is above the threshold setting, while the other two are

below the threshold for a certain duration

– 4D is a subset of 6D; the Z axis is not used.

– choose between unfiltered data or low-pass filtered data

UM2501 - Rev 3

page 8/44

Page 9

UM2501

Inertial MEMS sensors

• Single/double tap event:

–

detected when the output of the slope detection filter exceeds the threshold setting and then returns

below the same setting within a “shock” time interval

– double tap event is detected when a first tap is detected and a second tap is detected after a “quiet”

time interval, but before a maximum “duration” interval

– for reliable detection, configure the device to use a high sampling rate, like 400 Hz.

– if two or more enabled axes are over their respective thresholds, the axis with the highest priority

setting is used

– can be used to enable user interaction in addition to the button present on the BlueTile

• Activity/inactivity event:

– uses the same data as the wake-up event

– if inactivity is detected (data below the threshold setting for a certain time interval), the device

automatically goes to Low-power Mode and reduces the accelerometer sampling rate down to 12.5 Hz

to minimize power consumption

– if a wake-up event is detected, the device automatically returns to the programmed accelerometer

operating mode and sampling rate

– can be configured to put the gyroscope in power-down or sleep mode when the accelerometer is in

low-power mode

• Stationary/motion event

• a special activity/inactivity event in which event detection is the same, but the device does not change power

mode or sampling rate

2.3.1.2 LSM6DSO advanced functionality

Certain digital processing blocks allow advanced functions and algorithms when the output data rate is 26 Hz or

higher

.

• Pedometer functions: step detector and step counter.

– when a step is detected, an interrupt is generated and a corresponding counter is incremented by 1

(max value is 65535)

– can also set the interrupt to only be triggered when at least one step is detected in a configurable time

interval

– de-bounce functionality to avoid false detections, where N consecutive steps are detected before the

first interrupt is generated (default is N=10)

– two additional blocks can facilitate the identification of false-positives:

only trigger when statistical data matches the walking pattern

adapt the embedded algorithm to slow pace walking patterns

• Significant motion detection: to signal a possible change in user location

– based on the pedometer function, which is automatically enabled

– interrupt is generated when the difference between the number of steps after initialization or reset is

higher than the de-bounce threshold (default is 10).

– function is reset after each interrupt

• Relative tilt detection

– generates an interrupt when there a change in the tilt of the device exceeds 35 degrees

– reference position is set when the detection logic is enabled and reset when the interrupt is generated

– detection logic requires a 2-second settling time after it is enabled or re-initialized

2.3.1.3 LSM6DSO finite state machines

The LSM6DSO can run up to 16 simultaneous finite state machines (FSMs) that consist of a sequence of

instructions or actions (parameter setting, interrupt generation, etc.), or a RESET

• if the RESET condition is satisfied, the FSM returns to the reset point

• if the NEXT condition is satisfied, the FSM moves to the next instruction

• otherwise, the RESET-NEXT conditions are re-tested.

FSM data may be accelerometer, gyroscope, integrated gyroscope or external sensor data, and can be

decimated. A data vector consists of X, Y, Z values and a vector norm V (square root of sum of squares).

UM2501 - Rev 3

-NEXT condition:

page 9/44

Page 10

Each FSM has the following features:

•

3 different 8-bit masks to allow tests on positive and negative values of X, Y, Z and V.

• 3 different thresholds and 1 programmable hysteresis value that is automatically added to or subtracted from

the selected threshold based on the test condition.

• 4 different counters/timers to manage event durations.

2.3.1.4 LSM6DSO smart FIFO buffer

The LSM6DSO accelerometer has a first-in first-out (FIFO) data buf

words of 7 bytes each (1 tag byte plus 6 data bytes). The tag drives the decoding and includes a parity bit for

validation, while the data can derive from any combination of accelerometer, gyroscope, up to 4 external sensors,

embedded temperature sensor, timestamp counter and pedometer step counter. The data rates can be set

independently for each source.

For the accelerometer, you can choose to store high-pass filtered data, slope detection filter data, low-pass

filtered data or unfiltered data plus an optional offset (independent for each axis). The low and high-pass filters

are configurable.

For the gyroscope, you can enable a first optional high-pass filter, and a second optional and programmable lowpass filter.

To maximize the amount of data stored in the FIFO, you can enable an adaptive lossless delta pulse-codedmodulation (DPCM) compression algorithm for the accelerometer and the gyroscope data. When the difference

between consecutive data words is small, instead of sending a new data word (16 bits/axis), only the difference

with respect to the previous is sent (8 bits = 2:1 compression or 5 bits/axis = 3:1 compression).

When DPCM compression is enabled, it is also possible to select when DPCM is reset by storing uncompressed

data in the FIFO: never, every 8, 16 or 32 words. This is useful when the FIFO is used as a circular buffer

(Continuous mode) and words may be overwritten, as the decoder can only work if previous data words can be

traced back to an uncompressed data word for reference.

DPCM compression works on 3 data words (sampled at time t, t-1 and t-2) and introduces a latency of 2 data

words. The compression factor depends on the difference between a data word and the previous data word.

• When DPCM is disabled, the compression buffer is flushed and the output is the non-compressed data word

at time t-2, then data word at time t-1 and data words at current time t thereafter (tag “NC_T_2”, “NC_T_1”,

and “NC”).

• When DPCM is enabled, the first output is the non-compressed data word at time t-2 (tag “NC_T_2”), used

as the reference to start decoding. Subsequent outputs depend on D2 (difference between data word at t-2

and previous decoded word), D1 (difference between data word at t-1 and t-2), and D0 (difference between

data word at t and t-1):

– If any difference in D2 exceeds 128 LSB on any axis:

◦ the uncompressed data word at time t-2 is written to the FIFO by storing the 16-bit signed value of

each axis (low and high bytes for X, Y and Z: XL XH YL YH ZL ZH, for a total of 6 bytes)

◦ tag NC_T_2

– If any difference in D2 and D1 exceeds 16 LSB, but is within 128 LSB for all axes:

◦ a 2:1 compression ratio is applied by storing the 8-bit signed difference to reconstruct 2 data

values for each axis at time t-1 and t-2 (D1x D1y D1z, then D2x D2y D2z, for a total of 6 bytes)

◦ tag 2xC

◦ the data at time t-2 is derived by summing D2 to the previously decoded data word

◦ the data at time t-1 is derived by summing D1 to the data at time t-2 just derived

– If all differences in D2, D1 and D0 are within 16LSB for all axis:

◦ a 3:1 compression ratio is applied by storing the 5-bit signed difference to derive 3 data values for

each axis at time t, t-1 and t-2 (D0x D0y D0z and a dummy bit to make 16 bits, then D1x D1y D1z

and a dummy bit, then D2x D2y D2z and a dummy bit, for a total of 6 bytes)

◦ tag 3xC

◦ the data at time t-2 is derived by summing D2 to the previous decoded data word

◦ the data at time t-1 is derived by summing D1 to the data at time t-2 just derived

◦ the data at time t is derived by summing D0 to the data at time t-1 just derived

Interrupts can be generated when the FIFO buffer stores a given number of samples (FIFO threshold level), or

when it is full, or when it overflows (overrun). The FIFO can work in the following modes:

UM2501

Inertial MEMS sensors

fer that can store up to 3 KB of data, or 512

UM2501 - Rev 3

page 10/44

Page 11

Inertial MEMS sensors

• Bypass Mode:

–

the FIFO buffer is disabled and cleared

• FIFO Mode:

– the FIFO buffer collects data until it is full, then stops

• Continuous Mode:

– the FIFO buffer collects data continuously

– when it is full, the oldest samples are overwritten as in a circular buffer

– FIFO full and FIFO threshold level interrupts allow the host microcontroller to read the data before it is

overwritten

• Continuous-to-FIFO Mode:

– the FIFO buffer collects data continuously but switches to FIFO Mode as soon as the selected interrupt

occurs

– this mode is especially useful to capture data before and after a specific event

• Bypass-to-Continuous Mode:

– the FIFO buffer is disabled, but switches to Continuous Mode as soon as the selected interrupt occurs

– this mode is useful to capture data after an event has occurred

• Bypass-to-FIFO Mode:

– the FIFO buffer is disabled, but switches to FIFO mode as soon as the selected interrupt occurs

– this mode is useful to capture data after an event has occurred

– data collection stops once the FIFO is filled

UM2501

UM2501 - Rev 3

page 11/44

Page 12

2.3.2 LIS2MDL 3-axis magnetometer

2.3.2.1 LIS2MDL dynamic range, resolution and accuracy

The LIS2MDL

Gauss if the magnetic field is not aligned with one of the axes), which is well above Earth’s magnetic field (which

is typically in the range of 0.25 to 0.65 Gauss).

The output is 16 bits (1.5 mGauss/LSB ±7%), and the RMS noise level in High-performance Mode is 3 mGauss

(2 LSB). The high resolution and accuracy allows e-compass orientation estimation and distance measurements

from a reference magnet (in its simplest form, the magnetometer can emulate a magnetically activated Reedswitch).

The LIS2MDL magnetometer can perform a single-shot measurement and then return to Power-down Mode, or

operate in Continuous Mode with a programmable sampling rate (10, 20, 50 or 100 Hz).

Single-shot measurements can be performed at max. 100 Hz in high-performance mode, or max. 150 Hz in lowpower mode. In low-power mode, the power consumption is reduced to 25%, while in high-performance mode the

RMS noise is halved. An optional low-pass filter can be activated to further reduce RMS noise, without increasing

the power consumption, the bandwidth in this case is reduced from output data rate ODR/2 down to ODR/4.

2.3.2.2 LIS2MDL intrinsic offset automatic cancellation

The LIS2MDL

an initial operating condition; a reset pulse may be used to enable the compensation of the intrinsic magnetic

offset.

• If intrinsic offset compensation is disabled, there is no reset pulse. The set pulse can be generated at poweron only (Set_FREQ=1), or every 64 measurements (Set_FREQ=0).

• If intrinsic offset compensation is enabled, set and reset pulses are generated alternately on consecutive

samples. After the set pulse, the measured output is the magnetic field H plus offset; after the reset pulse,

the measured output is H minus offset.

– In Continuous Mode, the device averages consecutive measurements to compensate for the offset, the

– output =

– In Single-shot Mode, the host microcontroller averages two consecutive measurements. The averaged

When intrinsic offset compensation is performed, the residual offset is in the range of ±60 mgauss, and the

dependency on temperature is ±0.3 mgauss/°C.

is a 3D digital magnetometer with a ±50 Gauss dynamic magnetic field range (reduced to ±25

is based on anisotropic magneto-resistive (AMR) technology, in which a set pulse is required to set

output will be equal to the magnetic field H.

ffset

H + o

+ H − offset

2

= H

measurements must occur within a short time of each other for the compensation to be ef

UM2501

Inertial MEMS sensors

fective.

2.3.2.3 LIS2MDL extrinsic offset (hard iron) compensation

Hard-iron compensation is a constant offset added to magnetic field measurements to compensate distortion

caused by ferromagnetic materials or high currents. This of

analysing the output of the magnetometer.

When it is available, this offset can be programmed in specific registers (OFFSET_X_REG_H/L,

OFFSET_Y_REG_H/L, OFFSET_Z_REG_H/L) so that it is automatically subtracted by the LIS2MDL device.

RELATED LINKS

DT0059: Ellipsoid or sphere fitting for sensor calibration

MotionMC software library in the X-CUBE-MEMS1 Sensor and motion algorithm software expansion for STM32Cube

2.3.2.4 LIS2MDL interrupt generation

The LIS2MDL

the subtraction of hard-iron offset) exceeds a programmed threshold (INT_THS_H/L_REG) in the positive or

negative direction.

Comparisons can be enabled independently for each axis (XIEN, YIEN, ZIEN flags):

• when the output data is above the positive threshold, the corresponding flag is set (P_TH_S_X/Y/Z)

• when the output data is below the negative threshold, the corresponding flag is set (N_TH_S_X/Y/Z).

A specific interrupt can be generated if there is a measurement range overflow at the internal ADC.

magnetometer sensor can be configured to generate an interrupt when output data (before or after

fset can be computed by the host microcontroller by

UM2501 - Rev 3

page 12/44

Page 13

2.4 Environmental MEMS sensors

2.4.1 LPS22HH barometer

2.4.1.1 LPS22HH acquisition chain

The LPS22HH pressure sensor can perform a one-shot measurement and then return to Power-down Mode, or it

can operate in Continuous Mode with a programmable sampling rate (1, 10, 25, 50, 75, 100 or 200 Hz).

Measurements can be taken in normal Low-noise Mode, or in Low-power Mode to minimize current consumption.

When continuous mode is selected, Low-noise Mode is not available at 100 and 200 Hz. In all cases, an optional

low-pass filter can be enabled with a programmable cutoff frequency to reduce the noise level (the bandwidth is

reduced from output data rate ODR/2 down to ODR/9 or ODR/20).

The low-pass filter is reset when it is enabled. After reset, a specific settling time is required before the first

accurate sample on the output is available (9 or 20 samples must be discarded, respectively).

Two programmable offsets can be subtracted from measured data:

• First, offset compensation (always): the offset measured with one-point calibration (OPC) can be stored in

specific registers (RPDS) and then subtracted from subsequent measurements (OPC-compensated data =

data – RPDS*256). The low-pass filter, if enabled, will filter OPC-compensated data. Filtered and unfiltered

OPC-compensated data is stored in the FIFO.

• Second, auto-zero mode (optional): the offset-compensated (and possibly filtered) pressure measurements

are stored in specific registers (REF_P) when auto-zero is enabled (AUTOZERO or AUTOREFP set to 1)

and then subtracted from subsequent measurements (AZ-compensated data = data – REF_P). Filtered and

unfiltered OPC-compensated data or AZ-compensated data is stored in output registers.

UM2501

Environmental MEMS sensors

2.4.1.2 LPS22HH interrupt generation and FIFO buffer

The LPS22HH pressure sensor can be configured to generate interrupt events related to pressure acquisitions

and FIFO status (watermark reached, full, overrun, etc.).

The interrupt can be generated when a new pressure or temperature sample is available, or when the AZcompensated data exceeds a programmed threshold (THS_P) in the positive (PHE flag enables the comparison

with +THS_P) or negative (PLE flag enables the comparison with –THS_P) direction. The following configurations

are available:

1.

AUTOZERO=0 and AUTOREFP=0: interrupt logic is disabled; filtered and unfiltered OPC-compensated data

goes to FIFO and output registers.

2. AUTOZERO=1: interrupt logic is enabled; REF_P is set when interrupt is enabled; AZ-compensated data

goes to the interrupt logic and to the output registers, while filtered and unfiltered OPC-compensated data

goes to FIFO.

3. AUTOREFP=1: interrupt logic is enabled; REF_P is set when interrupt is enabled; AZ-compensated data

goes to interrupt logic, while filtered and unfiltered OPC-compensated data goes to FIFO and output

registers.

The FIFO buffer can store up to 128 pressure samples (24 bits each) and 128 temperature samples (16 bits

each). FIFO depth can be limited by stopping at the programmable watermark level. The FIFO can work in the

following modes:

• Bypass Mode:

– the FIFO buffer is disabled and cleared

• FIFO Mode:

– the FIFO buffer collects data until it is full or the watermark setting is reached, then stops

• Continuous (or Dynamic Stream) Mode:

– the FIFO buffer collects data continuously

– when it is full or the watermark setting is reached, the oldest samples are overwritten as in a circular

buffer

– FIFO full and FIFO threshold level interrupts allow the host microcontroller to read the data before it is

overwritten

UM2501 - Rev 3

page 13/44

Page 14

Environmental MEMS sensors

• Continuous (Dynamic Stream)-to-FIFO Mode:

–

the FIFO buffer collects data continuously but switches to FIFO Mode as soon as the selected interrupt

occurs

– this mode is especially useful to capture data before and after a specific event

• Bypass-to-Continuous (Dynamic Stream) Mode:

– the FIFO buffer is disabled, but switches to Stream Mode as soon as the selected interrupt occurs

– this mode is useful to capture data after an event has occurred

• Bypass-to-FIFO Mode:

– the FIFO buffer is disabled, but switches to FIFO mode as soon as the selected interrupt occurs

– this mode is useful to capture data after an event has occurred

UM2501

UM2501 - Rev 3

page 14/44

Page 15

2.4.2 HTS221 temperature sensor

2.4.2.1 LPS22HH vs HTS221 ambient temperature measurement

The temperature sensor in the LPS22HH device is designed to compensate for temperature ef

pressure measurements, while the temperature sensor in the HTS221 device is designed and characterized for

ambient temperature measurements.

The BlueTile takes ambient temperature data from the HTS221 because it is more accurate over a larger range

than the LPS22HH. However, applications requiring a high data rate (above 12.5 Hz) can take data from the

LPS22HH temperature sensor.

Table 1. Comparison of HTS221 and LPS22HH temperature sensor characteristics

UM2501

Environmental MEMS sensors

fects in ambient

Device

HTS221 -40 to +120 °C 64 LSB/°C

LPS22HH -40 to +85 °C 100 LSB/°C ±1.5 °C (0 to 80 °C)

Temperature sensor

operating range

2.4.2.2 HTS221 acquisition chain

While all the board components have an embedded temperature sensor to monitor the temperature of the silicon,

the embedded HTS221

has the physical properties and accuracy necessary for the measurement of ambient

temperature.

The raw output of the humidity acquisition chain is stored in two 8-bit registers (HUMIDITY_OUT_H and

HUMIDITY_OUT _L), which are concatenated into a 16-bit two’s complement value (H_OUT). The raw output is

already temperature compensated and calibration coefficients to derive Relative Humidity (RH) from raw humidity

data are stored in the device. Factory calibration is performed at two different humidity levels and one

temperature.

The following sequence is used to calculate RH:

1. First true RH during calibration: H0

2. Second true RH during calibration: H1

3. First raw H output during calibration: H0

4. Second raw H output during calib.: H1

5. Current raw H output: H_O

6. Current RH% by linear interpolation: RH = R

The raw output of the temperature acquisition chain is stored in two 8-bit registers (TEMP_OUT_H and

TEMP_OUT _L) which are concatenated into a 16-bit two’

derive the Temperature in °C from raw temperature data are stored in the device. Factory calibration is performed

at two different temperatures.

Follow the sequence below to calculate the temperature in °C:

1. MSB of true temperatures during calibration: T1T0M

2. First true T in Celsius deg. (two’s comp): T0

3. Second true T in Celsius deg. (two’s comp): T1_°C_x8 setT1°C =

4. First raw T output during calibration: T0

5. Second raw T output during calibration: T1

6. Current raw T output during calibration: T_O

7. Current Temperature in °C: T = T0d

Sensitivity

UT

setH = H_O

Temperature absolute

accuracy

±1°C (0 to 60 °C)

±0.5 °C (15 to 40 °C);

_rH_x2

setRH0

_rH_x2

_T0_OUT

_T0_OUT

UT

H0 +

_°C_x8

_OUT

setT0

_OUT

UT

T1d

eg +

eg − T0deg

Long term

=

setRH1

setH0

setH1

RH1 −

1, 7, 12.5 Hz

1, 10, 25, 50, 75,

100, 200 Hz.

_rH_x2

H0

2

H0_rH_x2

=

2

= H0_T0_OUT

= H1_T0_OUT

H − H0

*

RH0

H1 −

Data rate Response time

15 s (time to

63%).

- -

H0

s complement value (T_OUT). Calibration coefficients to

SB

setT0

setMSB1

°C =

= T1T0MSB&0x03,MSB0 =

_°C_x8 + MSB0*256

T0

8

T1

_°C_x8 + MSB1*256

8

T1T0M

= T0_OUT

setT1

= T1_OUT

setT = T _ O

T1 −

UT

* T − T0

T0

drift

0.05 °C/

year

.

SB

4

UM2501 - Rev 3

page 15/44

Page 16

2.4.2.3 HTS221 system integration

To get reliable and consistent measurements, the system design should maximize sensor exposure to the

external environment while minimizing error sources.

•

Mechanical design:

– if there is one vent hole in the BlueTile housing, the hole diameter should be maximized and the dead

volume enclosed should be minimized

– two or multiple vent holes are preferable in order to create a laminar airflow and minimize the response

time

– avoid materials that absorb humidity

• Mechanical stress:

– Avoid flexing or bending the BlueTile board

• Heat:

– Heat convection or temperature gradients on the board may affect the sensor

– Metal lines and planes, such as the ground plane, should be kept far from the sensor

– Milled slits further increase decoupling

– Insulation may be required to isolate the BlueTile from convective and conducted heat

• Light exposure may induce a change in temperature and humidity.

To accelerate sensor recovery time in case of condensation, the firmware running on the host microcontroller can

be coded to switch the heating element on for a certain duration. Humidity and temperature data should not be

read during the heating cycle.

The BlueTile is designed for ultra-low power operation and a long battery life (1 month to 1 year on a typical

CR2032 coin battery, depending on the application). Power and heat generated on-board is therefore very limited.

Possible sources of conducted heat such as the BlueNRG-2 and the LED are placed as far as possible from

MEMS sensors to avoid any impact on measurements. Slits are also present to further isolate the HTS221

temperature sensor from neighboring components.

UM2501

Environmental MEMS sensors

RELATED LINKS

AN4722: HTS221 digital humidity sensor: hardware guidelines for system integration

UM2501 - Rev 3

page 16/44

Page 17

2.5 MP34DT05-A digital MEMS microphone

2.5.1 Features of the MEMS microphone

The MP34DT05-A omnidirectional top-port digital microphone has the following features:

122.5 dBSPL acoustic overload point (AOP), or 0 dBFS (100% of digital Full Scale(FS))

•

• -26dBFS ±3dB (5% of FS) sensitivity at 1 kHz and 94 dBSPL

• 64dB A-weighted SNR

• The equivalent input noise floor is 30 (94-64) dBSPL, or -90 (-26-64) dBFS (0.003% of FS).

• The total harmonic distortion plus noise THD+N:

– 0.2% at 94 dBSPL

– 0.7% at 110 dBSPL

– 6% at 120 dBSPL

• The frequency response is generally flat from 100 Hz to 5 kHz, up to +0.5 dB at 20 kHz.

Appropriate frequency response is important to maximize the performance of beamforming applications that can

determine the direction of incoming sounds and reject noise coming from certain directions

RELATED LINKS

AcousticBF software library in the X-CUBE-MEMSMIC1 Digital MEMS microphones acquisition and processing software

expansion for STM32Cube

UM2501

MP34DT05-A digital MEMS microphone

2.5.2 PDM to PCM conversion

The output of the digital MEMS microphone is a bit stream (1.6 MHz on the BlueTile), where frequency of ones is

proportional to the sound pressure level: this is known as pulse-density modulation (PDM). However

usually represented by words with at least 16 bits, at a rate equal or greater than twice the max. audio frequency,

typically 16, 24 or 48 kHz: this is known as pulse-coded modulation (PCM).

The PDM-to-PCM conversion can be performed with low-pass filtering. In its simplest form, it is equivalent to

averaging, or counting the number of ones over the sampling time of the PCM word.

In the BlueTile the conversion is performed by hardware in a dedicated block in the ADC peripheral in BlueNRG-2

device, but the conversion can also be performed by software.

RELATED LINKS

AN4957: How to synchronize the DFSDMs filters and how to program the pulse skipper on the STM32F413/423 line devices

AN3998: PDM audio software decoding on STM32 microcontrollers

PDM2PCM software library in the X-CUBE-MEMSMIC1 Digital MEMS microphones acquisition and processing software

expansion for STM32Cube

, audio is

UM2501 - Rev 3

page 17/44

Page 18

2.6 VL53L1X Time-of-Flight sensor

2.6.1 Features of the Time-of-Flight sensor

The VL53L1X is a state-of-the-art laser-ranging sensor in a miniaturized package, with a 940 nm Class 1 verticalcavity surface-emitting laser (VCSEL), a receiving 16x16 array of single-photon-avalanche-detectors (SP

physical infrared filters and optics to achieve the best ranging performance.

The VL53L1X measures the time it takes for photons emitted by the laser to be reflected back to the sensor.

The field-of-view (FoV) is programmable from 15 to 27 degrees, which sets the region of interest (ROI) in the

SPAD array from 4x4 to 16x16 detectors, respectively. The position of the ROI in the array can also be set, in

order to orient the FoV cone in a specific direction.

The sensor returns the following data:

• ranging distance in mm

• the return signal rate and the ambient signal rate (kilo-count-per-second (kcps) per SPAD)

• range status

2.6.2 Calibration for best performance

For best performance, run the calibration functions at least once after assembly is completed. Calibration data is

stored in the host microcontroller and loaded in the VL53L1X on each startup.

If you call one or more calibration functions, you must observe the sequence below:

•

RefSPAD calibration:

– Optimizes device dynamics and accuracy.

– Especially recommended if a protective glass cover is used on top of the device.

– SPAD cells are classified as non-attenuated, attenuated by 5 or attenuated by 10.

– SPAD are then selected to avoid internal signal saturation.

– This part-to-part value is computed during the final test at ST and stored in the non-volatile memory

(NVM); it is automatically loaded after boot.

• Offset calibration:

– Should always be performed after assembly.

– Compensates for part-to-part variations, reflow effects, and cover glass effects.

• Crosstalk calibration:

– Performed whenever there is a protective cover glass on top of the device, which may reflect laser light

back to the sensor.

– Crosstalk can be compensated internally by the VL53L1X .

UM2501

VL53L1X Time-of-Flight sensor

AD),

2.6.3 Ranging Mode configuration, distance and accuracy

The sensor performs ranging continuously and autonomously with a programmable inter-measurement period. If

the interrupt pin is connected, the host receives an interrupt whenever a new measurement is available. The intermeasurement period must be longer than the selected timing budget plus 4 ms.

The measurement timing budget can be set from 20 to 1000 ms. Increasing the timing budget increases the

maximum distance and reduces the repeatability error (standard deviation of measurements), but power

consumption also increases:

•

20 ms is the minimum timing budget, can be used only in Short Distance Mode

• 33 ms is the timing budget that can be used for all distance modes

• 140 ms is the minimum timing budget which allows maximum distance of 4 m in Long Distance Mode (dark

ambient light and a 54% gray target).

The minimum accurate ranging distance is 40 mm, while the maximum ranging distance depends on several

factors such as the ambient light (the lower the better), the reflectance of the target (the higher the better), on the

timing budget (the higher the better), on the selected ROI (the larger the better) and on the selected ranging

mode:

• Short Distance Mode:

– ranging distance up to 1.3 m

– independent of ambient light and target reflectance

UM2501 - Rev 3

page 18/44

Page 19

UM2501

VL53L1X Time-of-Flight sensor

• Medium Distance Mode:

–

ranging distance up to 2.9 m in the dark

– limited to 0.7 m in strong ambient light (200 kcps/SPAD, direct illumination on the sensor in a sunny

day, infrared component removed by glass)

• Long Distance Mode:

• ranging distance from 1.7 to 3.6 m max. in the dark for targets with 17 to 88% reflectance

• limited to 0.7 m in strong ambient light

• longest ranging distance is 4 m when timing budget is at least 140 ms

The ranging error is the sum of the accuracy and the repeatability error, and is typically between ±20mm in the

dark, and ±25mm in strong ambient light:

The software driver provided by ST uses two parameters to qualify the ranging measurement:

• VL531L1X_CHECKENABLE_SIGMA_FINAL_RANGE:

– standard deviation in mm, default is 15mm

– decrease to reduce repeatability error, but maximum ranging distance is also reduced

• VL53L1X_CHECKENABLE_SIGNAL_RATE_FINAL_RANGE:

– rate of photons reflected by target in Mcps, default is 1 Mcps

– increase to reduce repeatability error, but maximum ranging distance is also reduced

2.6.4 Power up and boot sequence

In the BlueTile, the XSHUT pin connected to the host BlueNRG-2 (IO7 pin) is used to power of

between measurements. The maximum boot time is 1.2 ms.

Note: When the sensor is powered off, the configuration is lost. The sensor must be re-configured on each wake-up.

To minimize power consumption, the application firmware may skip the configuration step after wake-up and use

the default (long ranging mode, 30 ms timing budget). The application may also perform an early readout, not

waiting for the data ready flag, and immediately shut down the sensors. This reduces power consumption but also

limits accuracy. The minimum ranging distance in this case is around 70 mm.

f the sensor

UM2501 - Rev 3

page 19/44

Page 20

UM2501

STEVAL-BCN002V1D host board for programming and debugging

3 STEVAL-BCN002V1D host board for programming and debugging

The STEVAL-BCN002V1D is used to Flash and debug the STEVAL-BCN002V1 BlueTile sensor node.

Figure 5. STEV

AL-BCN002V1D top and bottom

UM2501 - Rev 3

During Flashing and debugging, remove the battery as the BlueNRG-2 device on the BlueTile is powered by the

host board, which receives its supply voltage through its USB connector or on the USB connector of the ST-LINK

V3 Stamp if you are using it.

The BOOT and RESET pin of the BlueNRG-2 on the BlueTile are controlled by the STM32L1 on the host board,

or by the ST-LINK V3 Stamp if used, or by the user (user button and connector CN5).

page 20/44

Page 21

UM2501

STEVAL-BCN002V1D host board for programming and debugging

Figure 6. STEV

USBLC6-2P6: ESD protection

LD39015M33: LDO 3V3 - outputs to VDD

STM32L151: Cortex-M3 microcontroller

X2: 10-pin connector to JTAG/SWD of external ST-LINK

CN3: 2-pin connector to UART of Nucleo ST-LINK

CN5: 2-pin connector - force to VDD

CN7: 5-pin connector to JTAG/SWD of Nucleo ST-LINK

JTAG/SWD: 20-pin connector to JTAG/SWD of external ST-LINK

User button: force to GND

SW2 for UART RX/ SW3 for UART TX:

- 1-2 for ST-LINK V3

- 2-3 for STM32L1

X4: 10-pin connector - outputs to BlueNRG-2 device on the BlueTile board

AL-BCN002V1D block diagram

The BlueNRG-2 is programmed through the UAR

T from the STM32L1 on the host board, or from the ST-LINK V3

Stamp module if used.

Switches SW2 and SW3 must be in the following positions:

• 2-3 when the STM32L1 of the host board is used

• 1-2 when ST-LINK V3 is used

The BlueNRG-2 can also be programmed and debugged using the SWD of the Nucleo ST-LINK, or the SWD of

an external ST-LINK or other debugger.

UM2501 - Rev 3

page 21/44

Page 22

1

2

11

4

10

5

3

6

8

7

6

9

10

UM2501

STEVAL-BCN002V1D host board for programming and debugging

Figure 7. Configuration with STEV

1. STEVAL-BCN002V1 BlueTile sensor node

2. ST-LINK Stamp V3

3. ST-LINK Stamp V3 USB port (also power source for the microcontroller)

4. STM32 Nucleo development board

5. STEVAL-BCN002V1D host board (bottom side)

6. STEVAL-BCN002V1D USB port (also power source for host board microcontroller)

7. STM32L151 host board microcontroller

8. Nucleo ST-LINK (the rest of the Nucleo board may be detached)

9. Nucleo ST-LINK USB port

10. 5 pin JTAG/SWD for Nucleo ST-LINK (connected)

11. 20 pin JTAG/SWD for external ST-LINK V2 (not connected)

AL-BCN002V1 sensor node and STEVAL-BCN002V1D host board

plugged onto a NUCLEO ST-LINK

UM2501 - Rev 3

To Flash and debug the STEVAL-BCN002V1 BlueTile sensor node, the following software must be installed on

your computer:

•

STSW-STM32102 STM32 Virtual COM port driver (VCOM); (not needed for Windows 10).

• STSW-BNRGFLASHER utility to Flash the STEVAL-BCN002V1 or the STSW-BNRG1STLINK (or other IDE)

utility to Flash and debug using an ST-LINK.

page 22/44

Page 23

UM2501

How to Flash using the STEVAL-BCN002V1D host board only

Figure 8. Different ways to Flash and debug using the BlueT

Option A: host board only

- SW2 and SW3 in positions 2-3

- Flasher in UART Mode

- GUI: STSW-BNRGFLASHER

Option B: host board and Nucleo ST-LINK

- SW2 and SW3 in positions 1-2

- GUI: STSW-BNRG1STLINK or any IDE

Option C: host board and standalone ST-LINK/V2 debugger/programmer (or other JTAG/SWD debugger)

- GUI: STSW-BNRG1STLINK or any IDE

- USB connection on host board powers BlueTile board

Option D: host board with soldered ST-LINK V3 module

- GUI: STSW-BNRG1STLINK or any IDE

- USB connection on host board powers BlueTile board

ile host board and optional ST-LINK

3.1 How to Flash using the STEVAL-BCN002V1D host board only

This configuration is the simplest and most straightforward way to Flash the BlueTile.

Note:

No debugging is possible in this configuration.

Step 1. Remove the battery from the STEVAL-BCN002V1 BlueTile sensor board.

Figure 9. STEVAL-BCN002V1 sensor node bottom with battery removed

UM2501 - Rev 3

page 23/44

Page 24

3

1

2

4

UM2501

How to Flash using the STEVAL-BCN002V1D host board only

Step 2. Plug CN1 on the BlueT

Do not plug the sensor node onto the host board with the battery inserted.

Figure 10. Connectors to mount the sensor node on the host board

ile sensor board onto the matching connector on the host board.

Step 3. Set switches SW2 and SW3 to position 2-3.

This connects the BlueNRG-2

to the STM32L151 microcontroller on the host board.

Step 4. Plug the USB of the host board to the computer.

This powers the target microcontroller and establishes the UART VCOM communication.

Step 5. Run the STSW-BNRGFLASHER utility.

The utility exploits the STM32L151 microcontroller on the host board.

Figure 11. Configuration for Flash only

1. Flasher in UART Mode

2. STEVAL-BCN002V1D host board

3. SW2 and SW3 in position 2-3

4. STEVAL-BCN002V1 sensor node

UM2501 - Rev 3

page 24/44

Page 25

UM2501

How to Flash and debug using the STEVAL-BCN002V1D host board and the NUCLEO ST-LINK V2

3.2 How to Flash and debug using the STEVAL-BCN002V1D host board and the

NUCLEO ST

This method represents a straightforward and inexpensive way to Flash and debug with a Nucleo board and any

IDE

Step 1. Remove the battery from the STEV

Step 2. Plug CN1 on the BlueTile sensor board onto the matching connector on the host board.

Step 3. Plug the host board onto the Nucleo ST-LINK.

-LINK V2

AL-BCN002V1 BlueTile sensor board.

– Red arrow: 5-pin SWD connecto

– Blue arrows: alignment connectors

Figure 12. Connectors to mount the host board on the Nucleo ST-LINK debugger

Step 4. Plug the USB of the host board.

This powers the target microcontroller

Step 5. Plug the USB of the NUCLEO ST-Link to the computer.

This establishes the UART VCOM communication.

.

UM2501 - Rev 3

page 25/44

Page 26

3

1

2

4

UM2501

How to Flash and debug using the STEVAL-BCN002V1 host board and the ST-LINK/V2 debugger/programmer

Step 6. Run the STSW

The utility exploits the microcontroller on the NUCLEO ST-LINK.

Any other IDE can be used instead of the utility.

Figure 13. Configuration to Flash and debug with Nucleo ST-LINK programmer/debugger

1. STSW-BNRG1STLINK or any other IDE

2. STEVAL-BCN002V1D host board

3. STEVAL-BCN002V1 sensor node

4. STM32 Nucleo board

-BNRG1STLINK utility.

3.3 How to Flash and debug using the STEVAL-BCN002V1 host board and the ST-

LINK/V2 debugger/programmer

This method allows you to Flash and debug with any JTAG/SWD in-circuit debugger.

Step 1. Remove the battery from the STEVAL-BCN002V1 BlueTile sensor board.

Step 2. Plug CN1 on the BlueTile sensor board onto the matching connector on the host board.

Step 3. Plug the 20-pin JTAG/SWD connector on the host board to your ST-LINK/V2 in-circuit programmer/

debugger.

Step 4. Plug the USB of the host board.

This powers the target microcontroller.

Step 5. Plug the USB of the external ST-LINK/V2 to your computer.

This establishes the UART VCOM communication.

Step 6. Run the STSW-BNRG1STLINK utility.

The utility exploits the microcontroller on the external ST-LINK programmer/debugger.

Any other IDE can be used instead of the utility.

3.4 How to Flash and debug using the STEVAL-BCN002V1 host board with ST-LINK

Stamp V3 module

This method requires the ST-LINK Stamp V3 module to be soldered onto the host board.

Step 1. Remove the battery from the STEV

Step 2. Plug CN1 on the BlueTile sensor board onto the matching connector on the host board with soldered

ST-LINK Stamp V3 module.

Step 3. Set switches SW2 and SW3 to position 1-2.

This connects the BlueNRG-2 to the microcontroller on the ST-Link Stamp V3.

AL-BCN002V1 BlueTile sensor board.

UM2501 - Rev 3

Step 4. Plug the USB of the ST-LINK V3 to your computer.

This powers the target microcontroller and establishes the UART VCOM communication.

page 26/44

Page 27

UM2501

How to Flash and debug using the STEVAL-BCN002V1 host board with ST-LINK Stamp V3 module

Step 5. Run the STSW

-BNRG1STLINK utility.

The utility exploits the microcontroller on the ST-LINK Stamp V3 module.

Any other IDE can be used instead of the utility.

RELATED LINKS

UM2406: The BlueNRG-1, BlueNRG-2 Flasher SW package

AN4820: BlueNRG-1 and BlueNRG-2 low power modes

UM2501 - Rev 3

page 27/44

Page 28

4 Application firmware

The BlueTile is offered together with a software development kit (SDK) with documentation with examples on how

to use the BlueNRG-2 radio stack and hardware peripherals, PC utilities to easily configure the examples

provided and test all BlueNRG-2 functionalities, and few sample applications:

•

BLE_Beacon to advertise programmable data

• BLE_HID_Peripheral to emulate a wireless keyboard or mouse

• BLE_SensorDemo (default BlueTile firmware) to enable the streaming of sensor data to the STBLESensor

app

• DTM to enable the real-time interaction between a dedicated graphical user interface (STSW-BNRGUI) and

the BlueNRG-2 wireless system-on-chip

Figure 14. SDK directory structure with examples and IDE project files

1. Expand the BLE_Examples folder

2. Choose an appropriate demo application (BLE_SensorDemo is the default demo firmware)

3. Open the project file for your preferred IDE

UM2501

Application firmware

UM2501 - Rev 3

The BLE_SensorDemo is structured as follows:

Initialization of the BlueNRG-2 system (Clock, GPIO, Peripherals), the Bluetooth low-energy stack, and

•

MEMS sensors.

• An infinite main loop which calls:

– the Bluetooth low-energy stack tick function for processing BLE events, usually to change the state of

the system

– user tick function (User_AppTick) executes specific actions based on the state of the system

User actions are usually executed on a regular basis at specific intervals. After the action is executed, the

BlueNRG-2 can be set to Sleep Mode with active timers (SLEEPMODE_WAKETIMER is used) to minimize the

power consumption and wake up at the right moment, or it can be kept in Active Mode but with the CPU halted

(SLEEPMODE_CPU_HALT) to keep GPIOs configured and peripherals active.

In BLE_SensorDemo, the state of the system corresponds to which notification from the server (BlueTile sensor

node) to the client (the remote app running on the smartphone) is enable. The following notifications and states

can be enabled:

• Environmental data from LPS22HH barometer and HTS221 relative humidity and temperature sensor

– When enabled, this notification is performed every 100 ms (10 Hz).

page 28/44

Page 29

UM2501

Application firmware

• Inertial data from LSM6DSO accelerometer and gyroscope, and LIS2MDL magnetometer

. Inertial data is

processed on-board by the embedded MotionFX fusion library dedicated to orientation estimation, the output

quaternion is also notified.

– When enabled, these notifications are perfromed every 40 ms (25 Hz).

• Inertial data with fusion, as in the previous item, but VL53L1X time-of-flight ranging data is also added.

– When enabled, these notifications are performed every 40m s (25 Hz).

• Audio data from MP34DT05-A microphone. Audio data is processed on-board by the embedded BlueVoice

library dedicated to DPCM encoding at 32 kbps.

– When enabled, notifications are sent every 10 ms (100 Hz).

• Accelerometer events data from LSM6DSO accelerometer: events are detected by the built-in logic in the

MEMS sensors. The host BlueNRG-2 does not process accelerometer data to perform event detection.

– This notification only occurs when the enabled event is detected.

• LED control: the app sends commands to the BlueTile in order to control the LED status.

– The write occurs when the user taps the corresponding button on the app.

Table 2. Power consumption of BlueTile devices

Device Active phase

BlueNRG-2 1.9 mA (Active mode) 0.9 µA (Sleep mode)

LSM6DSO 280 µA (LowP, 50Hz) 3 µA (power-down)

LIS2MDL 475 µA (HighP, 50Hz, NoCanc) 1.5 µA (power-down)

HTS221 0.8 µA (AvgH=4, AvgT=2, 1Hz) 0.5 µA (power-down)

LPS22HH 4 µA (LowP, one-shot 1Hz) 0.9 µA (power-down)

MP34DT05-A 650 µA (normal) 5 µA (power-down)

VL53L1X <7 mA (<40 ms budget) 5 µA (power-down)

LED 1 mA 0 mA

Inactive phase

(power not gated by MCU)

RELATED LINKS

UM2058: BlueNRG GUI SW package

UM2109: BlueNRG-1 ST-LINK Utility software description

UM2501 - Rev 3

page 29/44

Page 30

5 Typical system performance

UM2501

Typical system performance

The current consumption of the BlueNRG-2

can be accurately predicted under different conditions using the

STSW-BNRG001 PC application.

Below are few examples of estimated power conditions similar to those used in the BLE_SensorDemo reference

firmware:

• Advertise at +8 dBm, 30 bytes every 1000 ms: 30 µA

• Advertise at +8 dBm, 30 bytes every 250 ms: 115 µA

• Connected as slave, +8 dBm, 2x 20 bytes every 10 ms (100 Hz): 1510 µA

• Connected as slave, +8 dBm, 1x 20 bytes every 40 ms (25 Hz): 220 µA

• Connected as slave, +8 dBm, 1x 20 bytes every 100 ms (10 Hz): 90 µA

Note: This estimate does not include MEMS sensor consumption and data readout and processing consumption.

The estimate does not include MEMS sensor consumption and data readout and processing consumption. For

sensors, the power consumption in the active phase depends on the configuration (low-power or highperformance, output data rate, internal filter setting, etc).

The following figure shows the average power consumption of the BlueTile, when the BlueTile is running the

reference firmware (BLE_SensorDemo) and it is connected to the ST BlueMS app running on the smartphone.

Figure 15. Average current consumption of BlueTile BCN002V1 when connected to ST BlueMS app on the

smartphone.

Mode: Standby | freq.: n/a | consumption: 25 µA

Mode: Advertise | freq.: 0.25 Hz | consumption: 170 µA

Mode: Battery data | freq.: 1 Hz | consumption: 0.3 mA

Mode: Environmental data | freq.: 10 Hz | consumption: 0.3 mA

Mode: Accelerometer events | freq.: sporadic | consumption: 0.3 mA

Mode: LED control (1mA 43% duty when on) | freq.: sporadic | consumption: 0.3 mA

Mode: Inertial data and MotionFX fusion | freq.: 25 Hz | consumption: 1.4 mA

Mode: BlueVoice 32kbps | freq.: 100 Hz | consumption: 3.6 mA

Mode: Inertial and Fusion with Time-of-Flight | freq.: 25 Hz | consumption: 8 mA

UM2501 - Rev 3

RELATED LINKS

4 Application firmware on page 28

page 30/44

Page 31

6 Schematic diagrams

SWDIO

SWDCLK

GND

GND

GND

INT_3X

INT_COM

UART_RX

100n

GND

100k

VDD

25

RESETN

26

SMPSFILT127SMPSFILT2

28

VDD1V2

29

DIO13

DIO12

30

TEST

31

32

DIO11

1

DIO10

2

DIO9

3

DIO8

4

DIO7

5

DIO6

6

VBAT3

7

DIO5

8

DIO4

VDD

L3

C7

GND

XTAL

GND

GND

1µ

GND

EXP

EXP

RX_P

B1

RX_N

B2

ANT

A1

GND

A2

U2

3.9n

VDD

C20

U1G1

2n

R1

L2

C2

FT1

FT2

MT

C4

9

DIO3

DIO210DIO111DIO0

12

13

ANATEST0/DIO14

14

ANATEST1

ADC115ADC2

16

C12

VDD

MLG0603P9N1H

GRM0332C1H7R0CA01

100n

BALF-NRG-02D3

Balun

Bluetooth low-energy chip

Chip Antenna

BLUENRG-2

GND

C23

I2C_CLK

I2C_SDA

10µH

100n

GND

7 pF

n.m.

9.1 nH

22p

C24

GND

100k

n.m.

0

n.m.

GND

17

FXTAL1

18

FXTAL0

VBAT2

19

RF1

20

RF0

21

22

SXTAL1

23

SXTAL0

24

VBAT1

10n

GND

15p

GND

ANT016008LCS2442MA1

U5

XTAL32

VDD

GND

VDD

150n

GND

NX2012SA-32.768K-STD-MUB-1

GND

GND

C6

L1

C28

CX2016DB32000D0FLJCC

BOOT

PDM_DATA

PDM_CLK

L_B

L_G

L_R

TEST1

L6

C27

R7

C13

C17

ADC

NRST

UART_TX

BOOT

GND

GND

GND

GND

C5

C1

100p

1µ

C21

22p

C9

1µ

15p

C18

1µ

UM2501

Schematic diagrams

Figure 16. STEV

AL-BCN002V1 schematic (1 of 3)

page 31/44

UM2501 - Rev 3

Page 32

100n

VL53L1CBV0FY

BLM15GG471SN1D

L4

VDD

GND

LSM6DSO

1

SCL

P2

VDD

P1

I2C_SDA

INT_COM

INT_3X

BOOT

V+

V+

PDM_CLK

U10

P6

VDD

VDD

V+

V+

P3

CS

DRDY

GND

GND

GND

GND

GND

GND

C30

C11

C10

C16

µ

GND

GND

GND

GND

GND

GND

GND

VDD

VDD

GND

VDD

VDD

VDD

10p

V+

VDD

P_1

AVDDVCSEL

P_2

AVSSVCSEL

GND

P_3

GND2

P_4

XSHUT

P_5

GND3

P_6

GPIO1

P_7

DNC

P_8

SDA

P_9

SCL

P_10

AVDD

P_11

GND4

P_12

100n

µ

CLK

4.7

V+

I2C_CLK

VDD

I2C_CLK

VDD

Digital Microphone

Magnetometer

Accelerometer / Gyroscope

Pressure

Humidity / Temperature

Proximity

GND

LPS22HH

Decoupling / Filtering

GND

I2C_CLK

U6

C19

VDDI2C_CLK

PDM_DATA

VDD

220n

I2C_SDA

HTS221

100n

GND

I2C_SDA

I2C_SDA

VDD

VDD

I2C_CLK

LIS2MDL

SDO

P5

B3

DOUT

B4

GND

G1*4

LR

B2

VDD

B1

CS

P12

SCL

P13

SDA

P14

U7

U9

P7

INT/DRDY

SCL

P1

CS

P3

SDA

P4

C1

P5

P1

VDD_IO

SCL

P2

CS

P6

P7

INT/DRDY

GNDP5SDA

P4

VDD

P8

INT2

P9

OCS

P10

NC

P11

GND

P6*2

GND

VDDIOP5GND1P6GND2

P7

VDD

GND

100n

GND

VDD

P9

VDD_IO

P10

GND

100n

MP34DT05-A

GND1

P8

GND2

P9

VDD

P10

RESP3SDA

P4

VDD

U8

C29

C3

C15

VDD

VDD

C14

SDO

P1

SDX

P2

SCX

P3

INT1

P4

U21

I2C_SDA

VDD

VDD

VDD

GND

Test points

P1

P1

P2

P2

P3

P3

P4

P4

P5

P5

P6

P6

P7

P7

P8

P8

P9

P9

P10

P10

U4

S

P+2

R3

ADC

C8

VDD

+

P+1

P-

-

SWDIO

SWDCLK

NRST

TEST1

L_G

L_B

UART_RX

I2C_SDA

P1

P1

P2

P2

P3

P3

P4

P4

onnectorebug cdARM10

RGB LEDPull-ups

CR2032 3 V battery

Push uttonb

SML-LX0404SIUPGUSB

GND

GND

GND

GND

VDD

VDD

R4

R5

R2

T1S+

R8

GNDSDACLK

R9

SW1

UART_RX

UART_TX

BOOT

B3U-3000P(M)

VDD

GND

10k

10k

VDD

VDD

525

75

135

VDD

I2C_SDA

L_R

FTS-105-01-F-D

100p

GND

I2C_CLK

100

VDD

I2C_CLK

GND

BAT-HLD-001

CN1

UM2501

Schematic diagrams

Figure 17. STEV

AL-BCN002V1 schematic (2 of 3)

UM2501 - Rev 3

Figure 18. STEV

AL-BCN002V1 schematic (3 of 3)

page 32/44

Page 33

7 Bill of materials

UM2501

Bill of materials

Table 3. STEV

Item Q.ty Ref. Part / Value Description Manufacturer Order code

1 1 U1

2 1 U9

3 1 U6

4 1 U7

5 1 U10

6 1 U8

7 1 U2 50 Ω nominal input

8 1 U21 MEMS audio sensor ST MP34DT05TR-A

9 1 XTAL

10 1 XTAL32

11 1 U4 20 mm - coin Battery holder

12 5

13 2 C17, C18 15 pF 5 V ±5%

14 7

15 1 C5 0.15 µF 10 V ±10%

16 1 L1 0 Ω Resistor SMD R0603

17 1 L2 10 µH

18 1 C28 0.01 µF 16 V ±10%

19 2 C4, C8 100 pF 50 V±5

20 2 R4, R5 10 k ±10% Resistor SMD R0603

22 2 C6, C9 Do not mount

23 1 U5 2.4 GHz

24 1 FT2 Do not mount

C1, C12, C13,

C16, C27

C2, C7, C19,

C23, C24, C29,

C30

32.0000 MHz 8 pF

SMD

32.7680 KHz 12.5

pF SMD

1 µF 10 V ±10%

0.1 µF 16 V ±10%

AL-BCN002V1 bill of materials

Bluetooth®

energy wireless

system-on-chip

Low-Power Pressure

sensor

Capacitive digital

sensor for humidity

and temperature

Digital output

magnetic sensor

iNEMO inertial

module

Time-of-Flight (ToF)

ranging sensor

Conjugate match

balun

Crystal

Crystal

MLCC - SMD/SMT

0603 X5R

MLCC - SMD/SMT

0603 C0G

MLCC - SMD/SMT

0603 X7R

MLCC - SMD/SMT

X5

Fixed Inductors

Power Supply Choke

MLCC - SMD/SMT

0603 X7R

MLCC - SMD/SMT

0603 C0G

BT WLAN Zigbee

Antenna chip

low

ST BLUENRG-232

ST LPS22HH

ST HTS221

ST LIS2MDL

ST LSM6DSO

ST VL53L1CBV0FY

ST BALF-NRG-02D3

AVX Corp/

Kyocera Corp

NDK America,

Inc.

Linx

T

echnologies Inc.

Murata GRM188R61A105KA61D

TDK C1608NP01H150J080AA

Walsin

T

echnologies

Murata GRM155R61A154KE19J

Walsin

T

echnologies