Datasheet SPC584C70E1, SPC58EC70E1, SPC584C74E1, SPC58EC74E1, SPC584C80E1 Datasheet (STMicroelectronics)

...

Features

eTQFP100 (14 x 14 x 1.0 mm)

eTQFP64 (10 x 10 x 1.0 mm)

eTQFP144 (20 x 20 x 1.0 mm)

FPBGA292 (17 x 17 x 1.8 mm)

eLQFP176 (24 x 24 x 1.4 mm)

• AEC-Q100 qualified

• High performance e200z420n3 dual core

– 32-bit Power Architecture technology CPU

– Core frequency as high as 180 MHz

– Variable Length Encoding (VLE)

• 4224 KB (4096 KB code flash + 128 KB data

flash) on-chip flash memory: supports read

during program and erase operations, and

multiple blocks allowing EEPROM emulation

• 176 KB HSM dedicated flash memory (144 KB

code + 32 KB data)

• 384 KB on-chip general-purpose SRAM (in

addition to 128 KB core local data RAM: 64 KB

included in each CPU)

• Multi-channel direct memory access controller

(eDMA) with 64 channels

• 1 interrupt controller (INTC)

• Comprehensive new generation ASIL-B safety

concept

– ASIL-B of ISO 26262

– FCCU for collection and reaction to failure

SPC584Cx, SPC58ECx

SPC58 C Line - 32 bit Power Architecture automotive MCU

Dual z4 cores 180 MHz, 4 MBytes Flash, HSM, ASIL-B

Datasheet - production data

– Memory Error Management Unit (MEMU)

for collection and reporting of error events

in memories

– Cyclic redundancy check (CRC) unit

• Crossbar switch architecture for concurrent

access to peripherals, Flash, or RAM from

multiple bus masters with end-to-end ECC

• Body cross triggering unit (BCTU)

– Triggers ADC conversions from any eMIOS

channel

– Triggers ADC conversions from up to 2

dedicated PIT_RTIs

• Enhanced modular IO subsystem (eMIOS): up

to 64 timed I/O channels with 16-bit counter

resolution

• Enhanced analog-to-digital converter system

with:

– 3 independent fast 12-bit SAR analog

converters

– 1 supervisor 12-bit SAR analog converter

– 1 10-bit SAR analog converter with STDBY

mode support

• Communication interfaces

– 18 LINFlexD modules

– 8 deserial serial peripheral interface (DSPI)

modules

– 8 MCAN interfaces with advanced shared

memory scheme and ISO CAN-FD support

– Dual-channel FlexRay controller

– 1 ethernet controller 10/100 Mbps,

compliant IEEE 802.3-2008

• Low power capabilities

– Versatile low power modes

– Ultra low power standby with RTC

– Smart Wake-up Unit for contact monitoring

– Fast wakeup schemes

• Dual phase-locked loops with stable clock

notifications

domain for peripherals and FM modulation

domain for computational shell

July 2020 DS11620 Rev 7 1/153

This is information on a product in full production.

www.st.com

SPC584Cx, SPC58ECx

• Nexus development interface (NDI) per IEEE-ISTO 5001-2003 standard, with some

support for 2010 standard

• Boot assist Flash (BAF) supports factory programming using a serial bootload through the

asynchronous CAN or LIN/UART

• Junction temperature range -40 °C to 150 °C

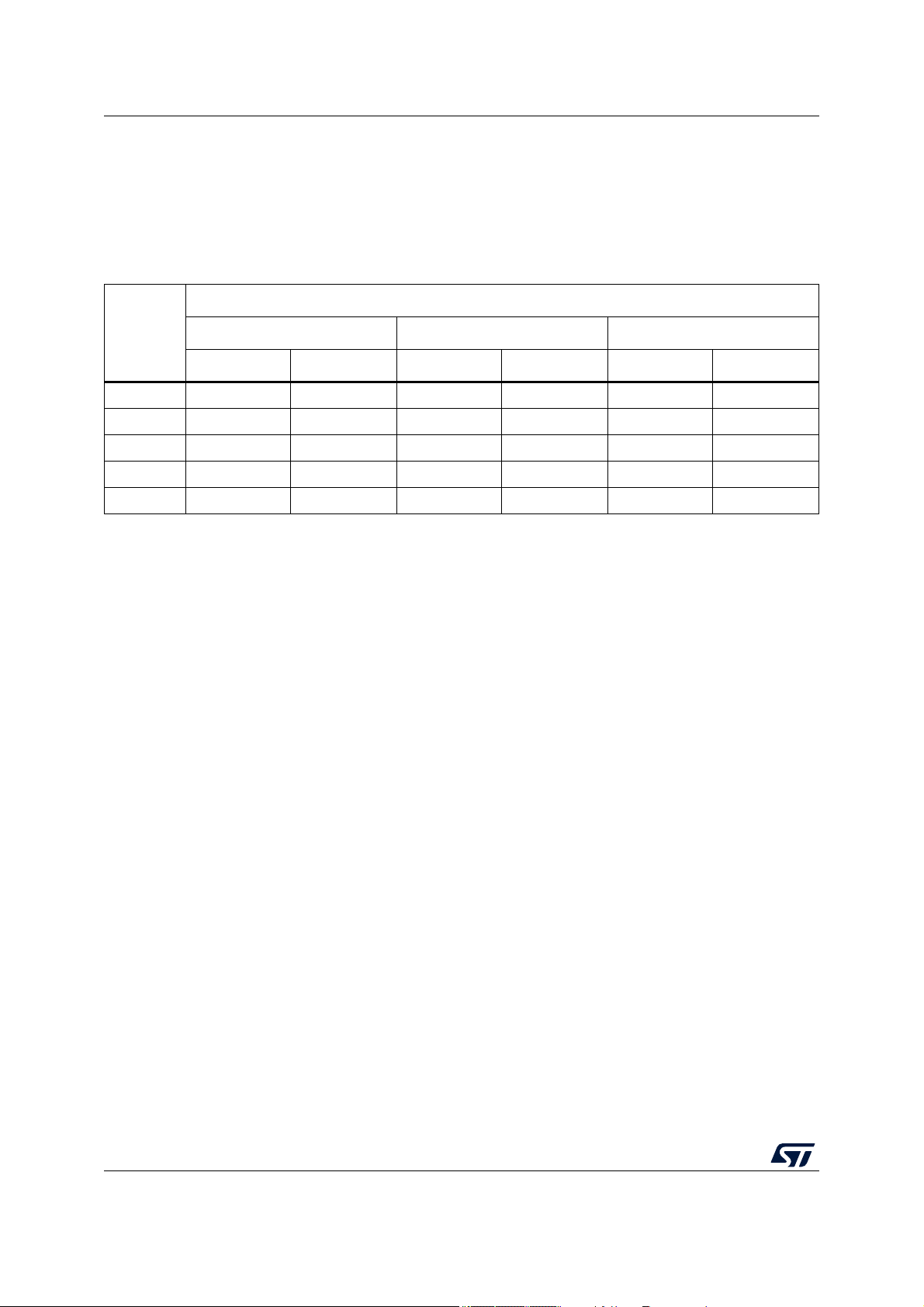

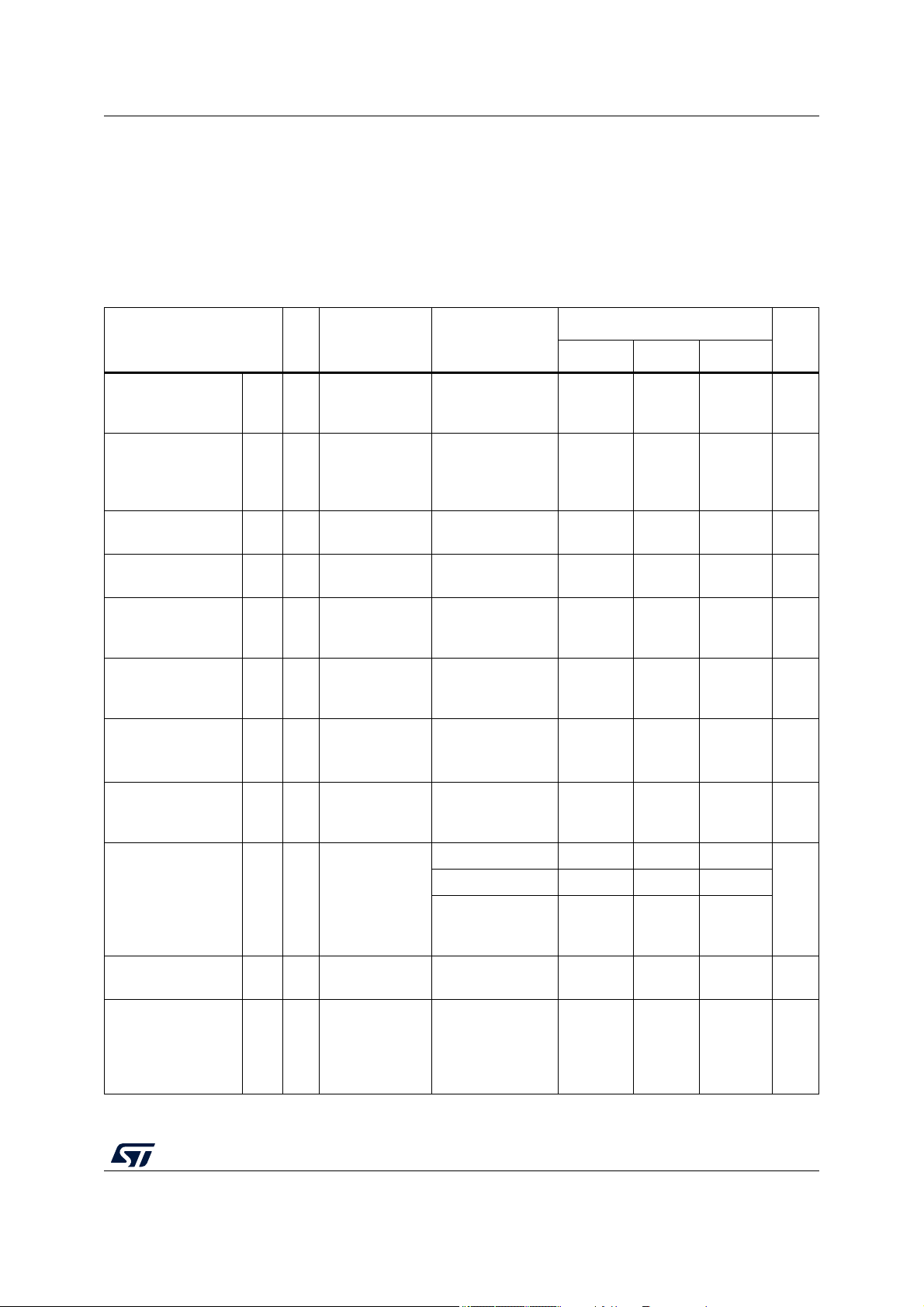

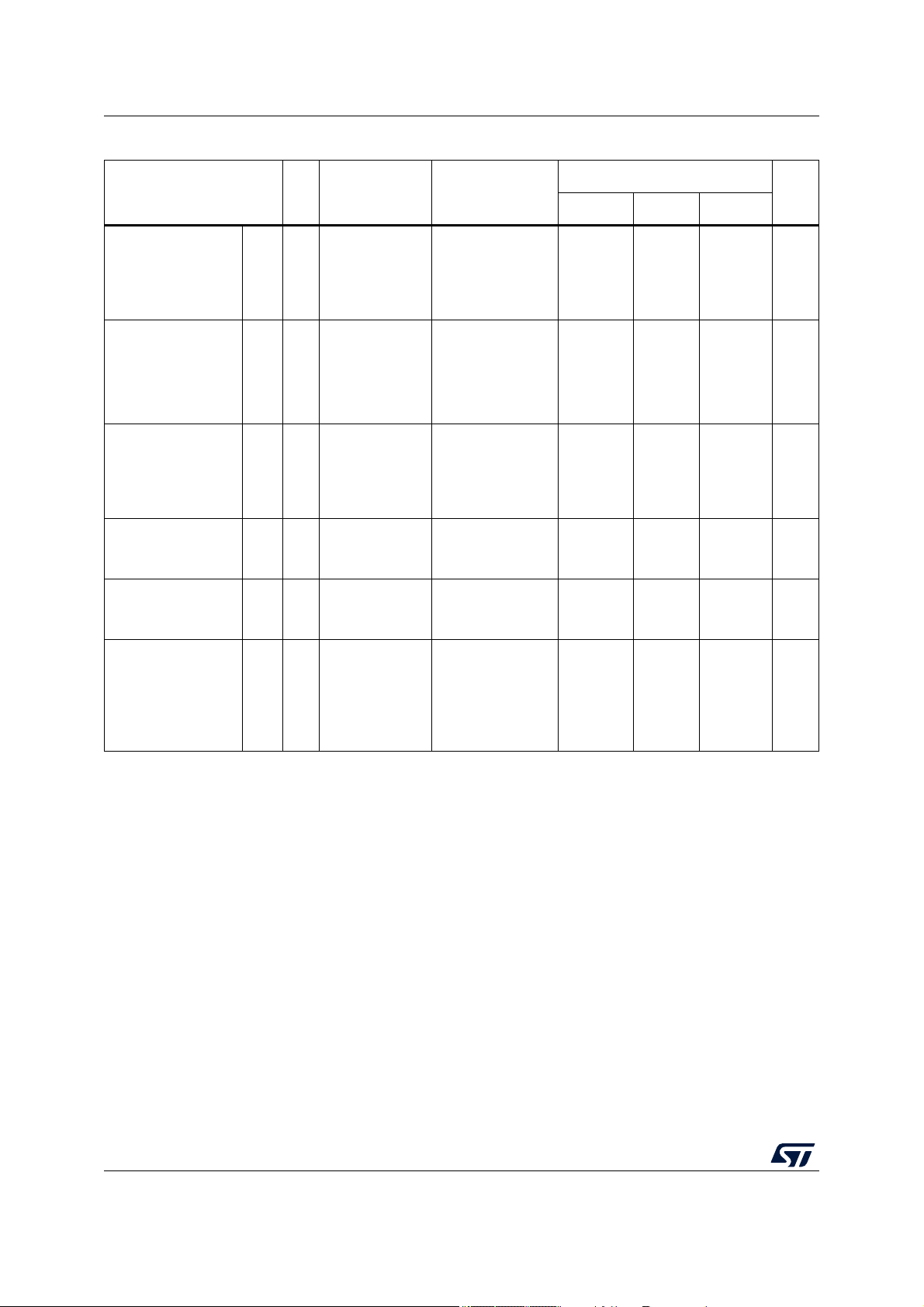

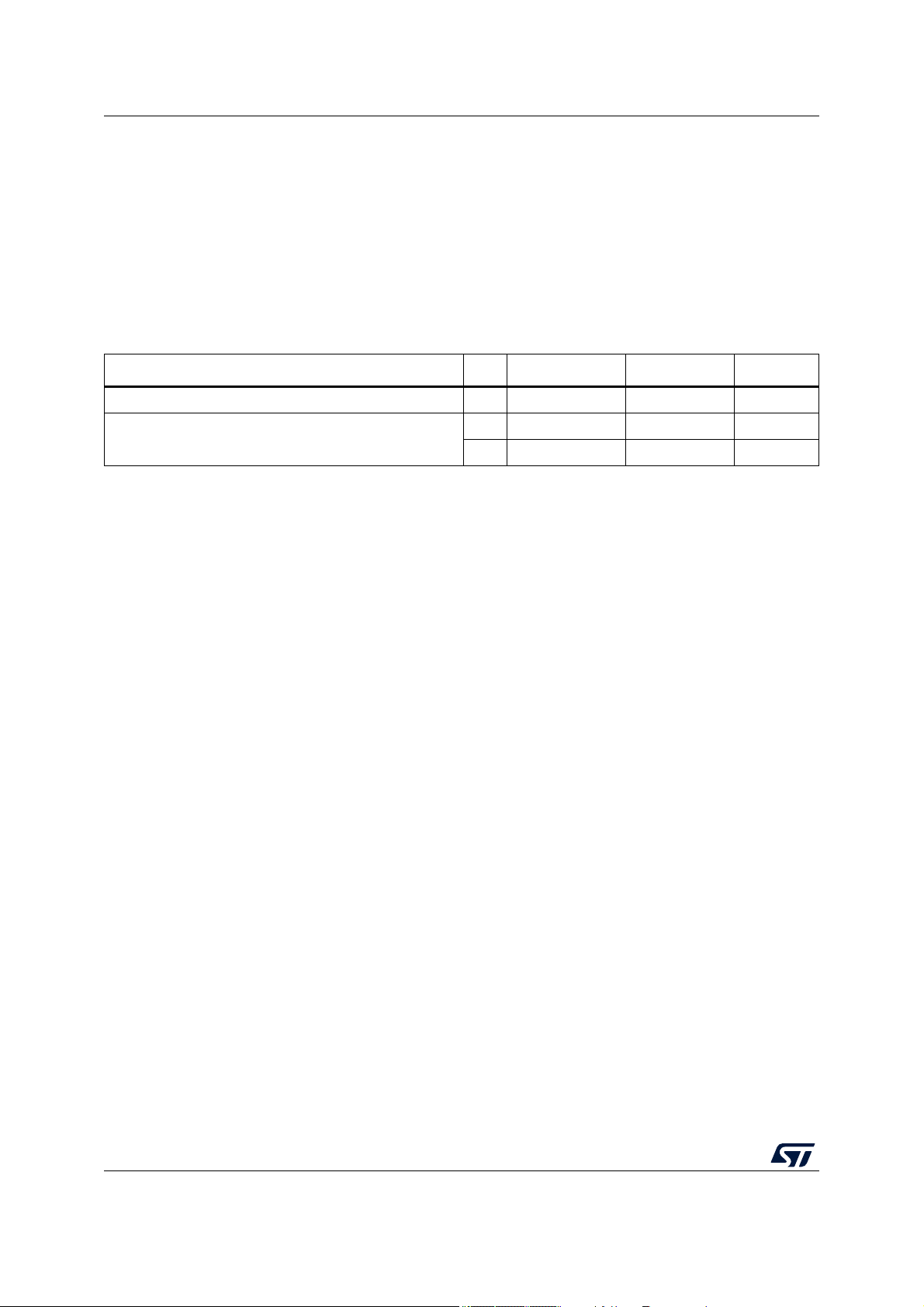

Table 1. Device summary

Part number

Package

2 MB 3 MB 4 MB

Single core Dual core Single core Dual core Single core Dual core

eTQFP64 SPC584C70E1 SPC58EC70E1 SPC584C74E1 SPC58EC74E1 SPC584C80E1 SPC58EC80E1

eTQFP100 SPC584C70E3 SPC58EC70E3 SPC584C74E3 SPC58EC74E3 SPC584C80E3 SPC58EC80E3

eTQFP144 SPC584C70E5 SPC58EC70E5 SPC584C74E5 SPC58EC74E5 SPC584C80E5 SPC58EC80E5

eLQFP176 SPC584C70E7 SPC58EC70E7 SPC584C74E7 SPC58EC74E7 SPC584C80E7 SPC58EC80E7

FPBGA292 SPC584C70C3 SPC58EC70C3 SPC584C74C3 SPC58EC74C3 SPC584C80C3 SPC58EC80C3

2/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Contents

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Device feature summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Features overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3 Package pinouts and signal descriptions . . . . . . . . . . . . . . . . . . . . . . . 13

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.1 Power domains and power up/down sequencing . . . . . . . . . . . . . . . . . 19

4.4 Electrostatic discharge (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Electromagnetic compatibility characteristics . . . . . . . . . . . . . . . . . . . . . . 21

4.6 Temperature profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.7 Device consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.8 I/O pad specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.8.1 I/O input DC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.8.2 I/O output DC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.8.3 I/O pad current specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.9 Reset pad (PORST) electrical characteristics . . . . . . . . . . . . . . . . . . . . . 37

4.10 PLLs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.10.1 PLL0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.10.2 PLL1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.11 Oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.11.1 Crystal oscillator 40 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.11.2 Crystal Oscillator 32 kHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.11.3 RC oscillator 16 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.11.4 Low power RC oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.12 ADC system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.12.1 ADC input description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

DS11620 Rev 7 3/153

5

Contents SPC584Cx, SPC58ECx

4.12.2 SAR ADC 12-bit electrical specification . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.12.3 SAR ADC 10-bit electrical specification . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.13 Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.14 LFAST pad electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.14.1 LFAST interface timing diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.14.2 LFAST LVDS interface electrical characteristics . . . . . . . . . . . . . . . . . . 58

4.14.3 LFAST PLL electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.15 Power management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.15.1 Power management integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.15.2 Voltage regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.15.3 Voltage monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.16 Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.17 AC Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.17.1 Debug and calibration interface timing . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.17.2 DSPI timing with CMOS pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.17.3 Ethernet timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.17.4 FlexRay timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.17.5 CAN timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4.17.6 UART timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4.17.7 I2C timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

5 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.1 eTQFP64 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.1.1 Package mechanical drawings and data information . . . . . . . . . . . . . 110

5.2 eTQFP100 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.1 Package mechanical drawings and data information . . . . . . . . . . . . . 115

5.3 eTQFP144 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

5.3.1 Package mechanical drawings and data information . . . . . . . . . . . . . 120

5.4 eLQFP176 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5.4.1 Package mechanical drawings and data information . . . . . . . . . . . . . 125

5.5 FPBGA292 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

5.5.1 Package mechanical drawings and data information . . . . . . . . . . . . . 128

5.6 Package thermal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

5.6.1 eTQFP64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

5.6.2 eTQFP100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

5.6.3 eTQFP144 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

4/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Contents

5.6.4 LQFP176 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

5.6.5 FPBGA292 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5.6.6 General notes for specifications at maximum junction temperature . . 133

6 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

DS11620 Rev 7 5/153

5

Introduction SPC584Cx, SPC58ECx

1 Introduction

This document describes the features of the family and options available within the family

members, and highlights important electrical and physical characteristics of the device. To

ensure a complete understanding of the device functionality, refer also to the device

reference manual and errata sheet.

6/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Description

2 Description

The SPC584Cx and SPC58ECx microcontroller is the first in a new family of devices

superseding the SPC564Cx and SPC56ECx family. SPC584Cx and SPC58ECx builds on

the legacy of the SPC564Cx and SPC56ECx family, while introducing new features coupled

with higher throughput to provide substantial reduction of cost per feature and significant

power and performance improvement (MIPS per mW). On the SPC584Cx and SPC58ECx

device, there are two processor cores e200z420 and one e200z0 core embedded in the

Hardware Security Module.

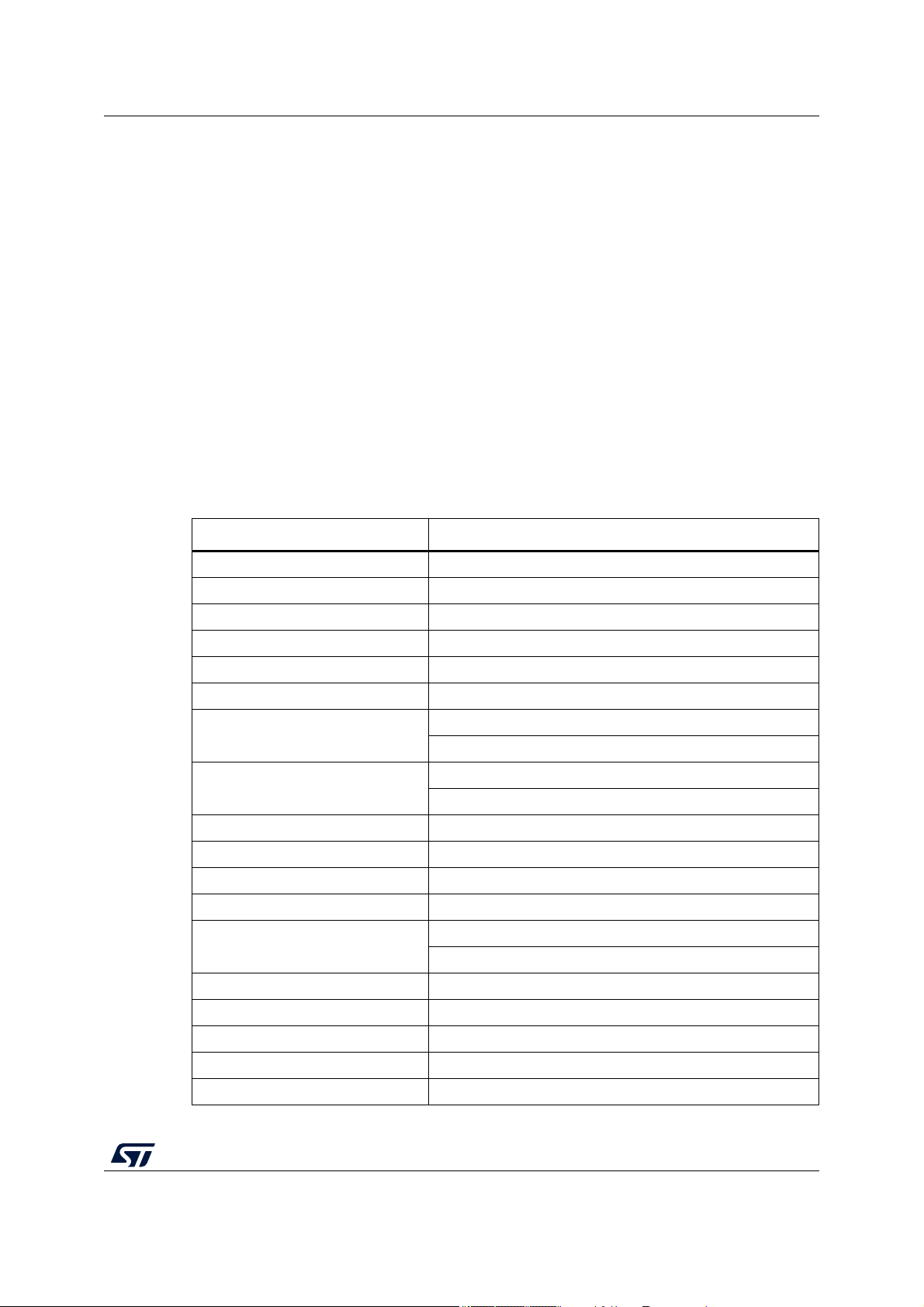

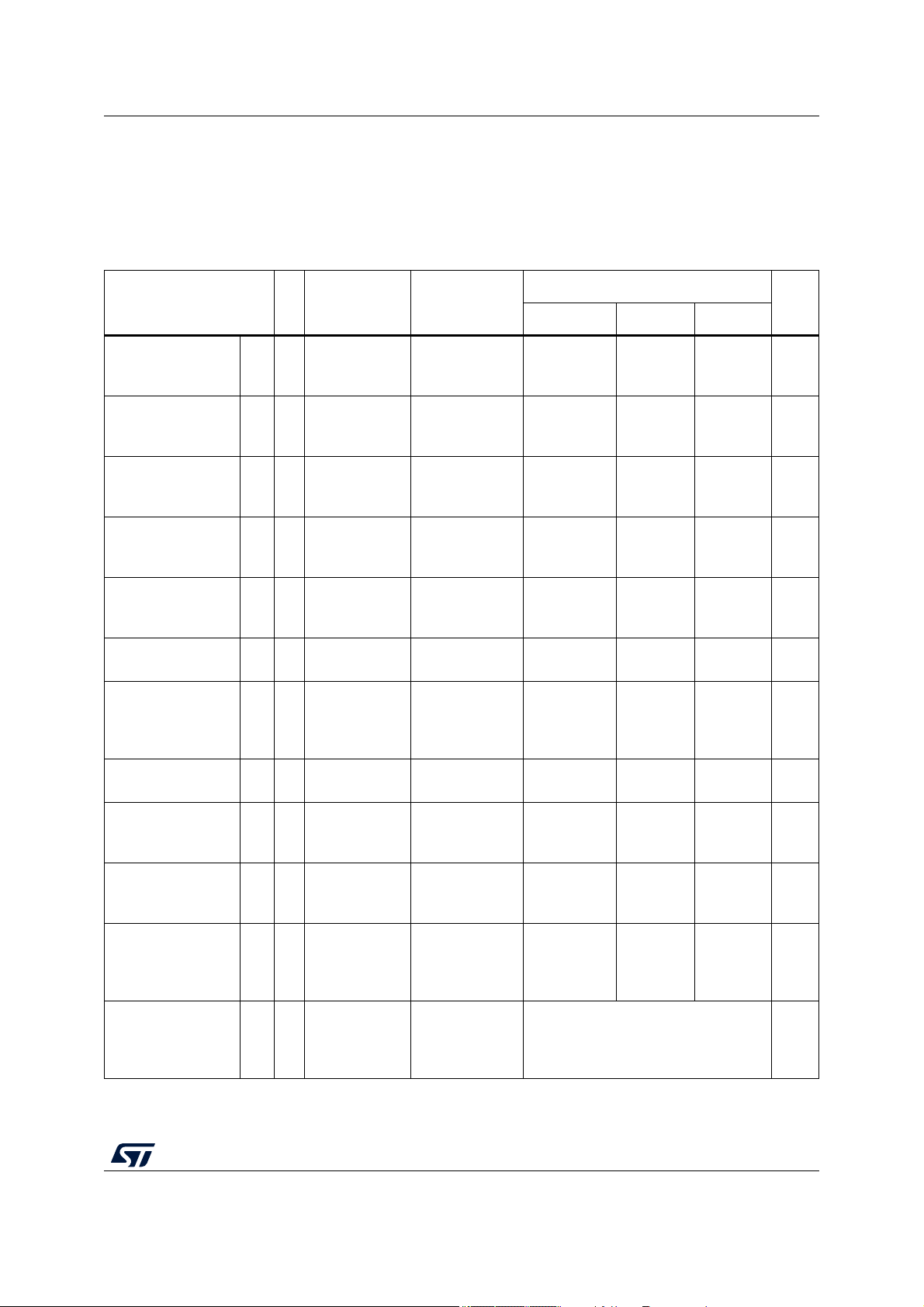

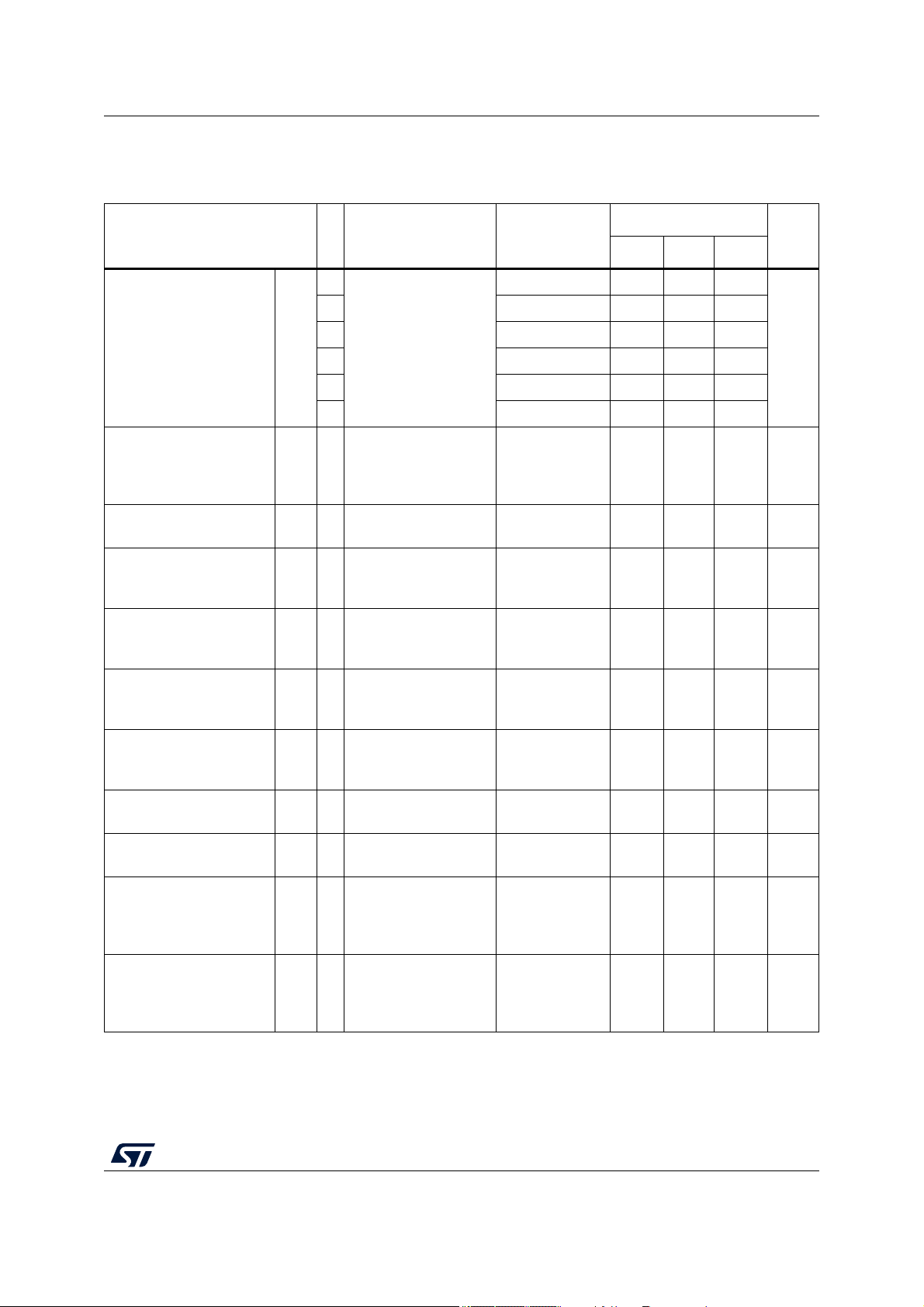

2.1 Device feature summary

Table 2 lists a summary of major features for the SPC584Cx and SPC58ECx device. The

feature column represents a combination of module names and capabilities of certain

modules. A detailed description of the functionality provided by each on-chip module is

given later in this document.

Feature Description

Table 2. Features List

SPC58 family 40 nm

Number of Cores 2

Local RAM 2x 64 KB Data

Single Precision Floating Point Yes

SIMD No

VLE Yes

Cache

MPU

Semaphores Yes

CRC Channels 2 x 4

Software Watchdog Timer (SWT) 3

Core Nexus Class 3+

Event Processor

Run control Module Yes

System SRAM 384 KB (including 256 KB of standby RAM)

8 KB Instruction

4 KB Data

Core MPU: 24 per CPU

System MPU: 24 per XBAR

4 x SCU

4 x PMC

Flash 4096 KB code / 128 KB data

Flash fetch accelerator 2 x 4 x 256-bit

DMA channels 64

DS11620 Rev 7 7/153

12

Description SPC584Cx, SPC58ECx

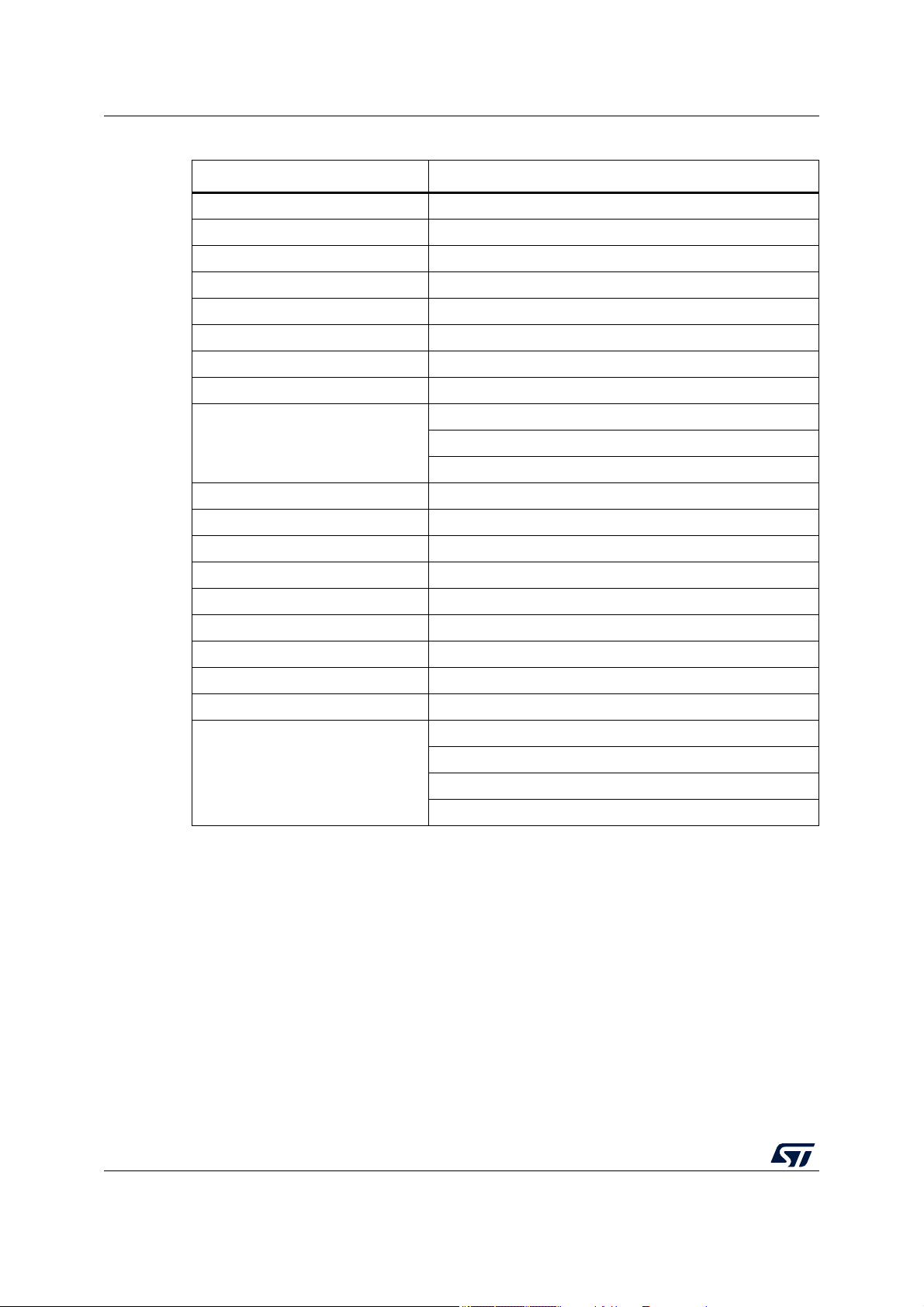

Table 2. Features List (continued)

Feature Description

DMA Nexus Class 3

LINFlexD 18

MCAN (ISO CAN-FD compliant) 8

DSPI 8

I2C 1

FlexRay 1 x Dual channel

Ethernet 1 MAC with Time Stamping, AVB and VLAN support

SIPI / LFAST Debugger High Speed

8 PIT channels

System Timers

eMIOS 2 x 32 channels

BCTU 64 channels

Interrupt controller 1 x 568 sources

ADC (SAR) 5

4 AUTOSAR® (STM)

RTC/API

Temp. sensor Yes

Self Test Controller Yes

PLL Dual PLL with FM

Integrated linear voltage regulator Yes

External Power Supplies 5 V, 3.3 V

Low Power Modes

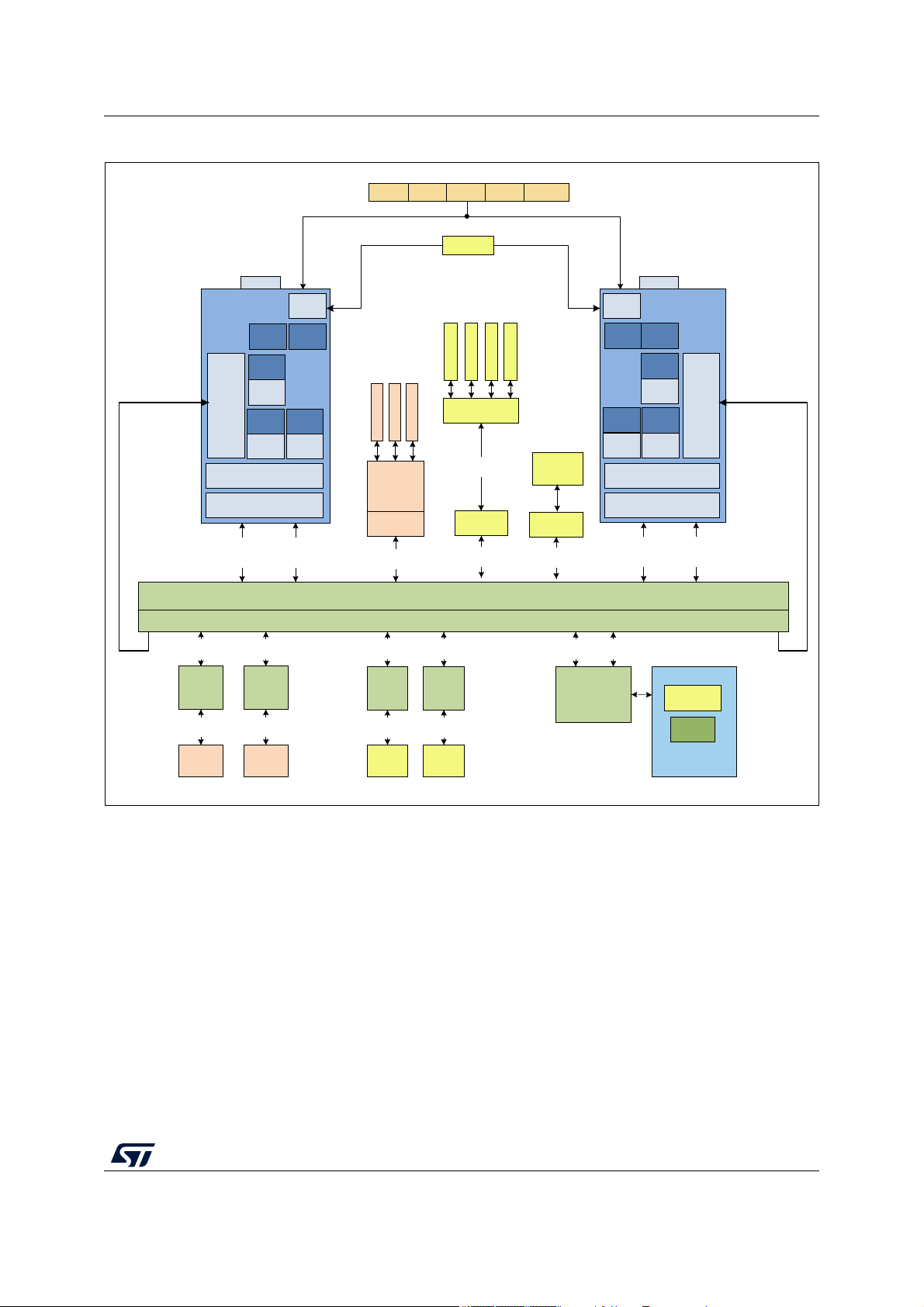

2.2 Block diagram

The figures below show the top-level block diagrams.

HALT Mode

STOP Mode

Smart Standby with output controller, analog and digital inputs

Standby Mode

8/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Description

Delayed Lock-step with Redundancy Checkers

Delayed Lock-step with Redundancy Checkers

Instruction

32 ADD

64 DATA

Load / Store

32 ADD

64 DATA

M4

M5

FLASH

4 MB

EEPROM

4x32 KB

Non Volatile Memory

Multiple RWW partitions

256 Page Line

EFPU2VLE

Core Memory Protection Unit

(CMPU)

e200 z420n3

– 180 MHz

dual issue

Main Core_0

Nexus3p

BIU with E2E ECC

Decorated Storage Access

SWT_0 IAC

S5

System Memory Protection Unit

Cross Bar Switch (XBAR) AMBA 2.0 v6 AHB – 64 bits

Unified

Backdoor

Interface

With

E2E ECC

S7

Periph.

Bridge 2

E2E ECC

Peripheral

Cluster 2

32 ADD

64 DATA

32 ADD

32 DATA

Periph.

Bridge 1

E2E ECC

Peripheral

Cluster 1

32 ADD

64 DATA

32 ADD

32 DATA

PRAMC_3

with E2E

ECC

32 ADD

64 DATA

SRAM

Array 3

128 KB

32 ADD

64 DATA

PRAMC_2

with E2E

ECC

32 ADD

64 DATA

SRAM

Array 2

256 KB

32 ADD

64 DATA

PFLASHC_1

Set-Associative Prefetch

Buffers

with E2E ECC

32 ADD

64 DATA

S4

S2 S0

S1

S6

M0 M1

S3

SPUDCIJTAGCJTAGM NPC

32 ADD

64 DATA

FlexRay_0

M3

Nexus Data

Trace

ETHERNET_0

Nexus Data

Trace

HSM

32 ADD

64 DATA

32 ADD

64 DATA

M2

Concentrator_1

E2E ECC

PAMU

SWT_2 IAC

Delayed Lock-step with Redundancy Checkers

Instruction

32 ADD

64 DATA

Load / Store

32 ADD

64 DATA

e200 z420n3 – 180 MHz

dual issue

Main Core_2

Nexus3p

VLE EFPU2

Unified

Backdoor

Interface

With

E2E ECC

Core Memory Protection Unit

(CMPU)

BIU with E2E ECC

Decorated Storage Access

INTC

I-Cache

Control

8 KB

2 way

D-MEM

Control

64 KB

D-MEM

D-Cache

Control

4 KB

2 way

I-Cache

Control

8 KB

2 way

D-MEM

Control

64 KB

D-MEM

D-Cache

Control

4 KB

2 way

SIPI_1

Nexus Data

Trace

32 ADD

64 DATA

M6

32 ADD

64 DATA

DMA CHMUX_1

64 Ch

eDMA_1

DMA CHMUX_2

DMA CHMUX_0

DMA CHMUX_3

Figure 1. Block diagram

DS11620 Rev 7 9/153

12

Description SPC584Cx, SPC58ECx

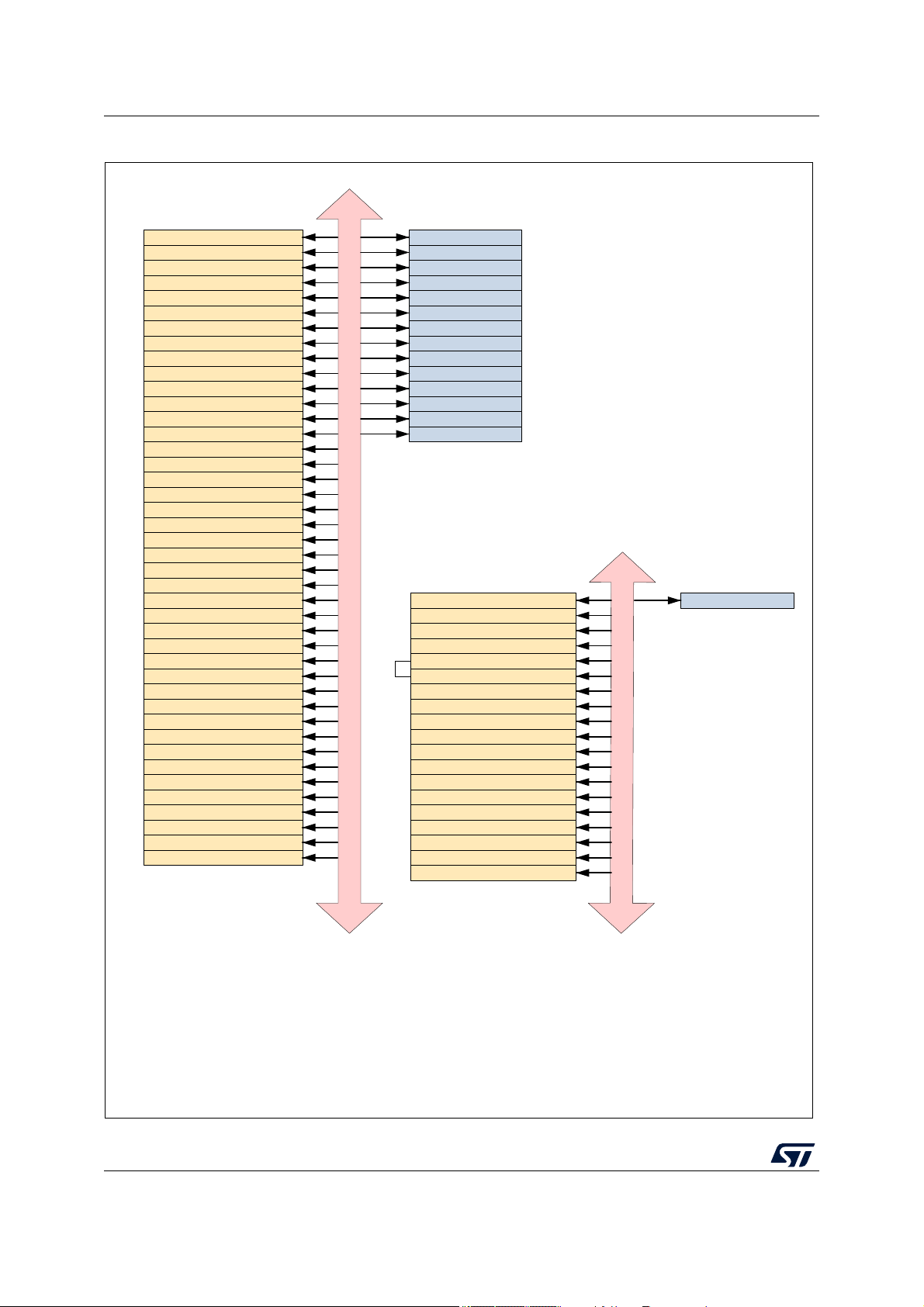

Note:

In this diagram, ON-platform modules are shown in orange color and OFF-platform modules

are shown in blue color.

3%5,'*(B±3HULSKHUDO&OXVWHU

3%5,'*(B±3HULSKHUDO&OXVWHU

%&78B

H0,26B

3%5,'*(B

;%$5B

;%,&B&RQFHQWUDWRUB

6038B

;%,&B

3&0B

3)/$6+B

6(0

,17&B

6:7B

670B

H'0$B

35$0B

7'0B

67'%<B&78B

H0,26B

(7+(51(7B

6$5B$'&BELWB

6$5B$'&BELWB67'%<

6$5B$'&BELWB%

)/(;5$<B

,&B

'63,B

/,1)OH['B

&$1B68%BB0(66$*(B5$0

&$1B68%BB0B&$1B

&&&8

+60

'76

-'&

67&8

-7$*0

0(08

,0$

&5&B

'0$08;B

3,7B

57&$3,

:.38

0&B3&8

30&B',*

0&B5*0

5&26&B',*

5&.B',*

26&B',*

26&.B',*

3//B',*

&08BB3//B;26&B,5&26&

0&B&*0

0&B0(

6,8/

)/$6+B

)/$6+B$/7B

3$66

66&0

3%5,'*(B

6$5B$'&BELWB

'63,B

/,1)OH['B

&$1B68%BB0(66$*(B5$0

&$1B68%BB0B&$1B

)&&8

&5&B

'0$08;B

3,7B

&08BB&25(B;%$5

&08BB+3%0

&08BB3%5,'*(

&08BB6$5$'&

&08BB)%5,'*(

&08BB(0,26

&08BB3)%5,'*(

6,3,B

/)$67B

Figure 2. Periphery allocation

10/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Description

2.3 Features overview

On-chip modules within SPC584Cx and SPC58ECx include the following features:

• Two main CPUs, dual issue, 32-bit CPU core complexes (e200z4).

– Power Architecture embedded specification compliance

– Instruction set enhancement allowing variable length encoding (VLE), encoding a

mix of 16-bit and 32-bit instructions, for code size footprint reduction

– Single-precision floating point operations

– 64 KB local data RAM for Core_0 and Core_2

– 8 KB I-Cache and 4 KB D-Cache for Core_0 and Core_2

• 4224 KB (4096 KB code flash + 128 KB data flash) on-chip flash memory

– Supports read during program and erase operations, and multiple blocks allowing

EEPROM emulation

• 176 KB HSM dedicated flash memory (144 KB code + 32 KB data)

• 384 KB on-chip general-purpose SRAM (+ 128 KB local data RAM: 64 KB included in

each CPU)

• Multi channel direct memory access controllers

– 64 eDMA channels

• One interrupt controller (INTC)

• Dual phase-locked loops with stable clock domain for peripherals and FM modulation

domain for computational shell

• Crossbar switch architecture for concurrent access to peripherals, Flash, or RAM from

multiple bus masters with end-to-end ECC

• Hardware security module (HSM) with HW cryptographic co-processor

• System integration unit lite (SIUL)

• Boot assist Flash (BAF) supports factory programming using a serial bootload through the

asynchronous CAN or LIN/UART.

• Hardware support for safety ASIL-B level related applications

• Enhanced modular IO subsystem (eMIOS): up to 64 (2 x 32) timed I/O channels with

16-bit counter resolution

– Buffered updates

– Support for shifted PWM outputs to minimize occurrence of concurrent edges

– Supports configurable trigger outputs for ADC conversion for synchronization to

channel output waveforms

– Shared or independent time bases

– DMA transfer support available

• Body cross triggering unit (BCTU)

– Triggers ADC conversions from any eMIOS channel

– Triggers ADC conversions from up to 2 dedicated PIT_RTIs

– One event configuration register dedicated to each timer event allows to define the

corresponding ADC channel

– Synchronization with ADC to avoid collision

DS11620 Rev 7 11/153

12

Description SPC584Cx, SPC58ECx

• Enhanced analog-to-digital converter system with:

– Three independent fast 12-bit SAR analog converters

– One supervisor 12-bit SAR analog converter

– One 10-bit SAR analog converter with STDBY mode support

• Eight deserial serial peripheral interface (DSPI) modules

• Eighteen LIN and UART communication interface (LINFlexD) modules

– LINFlexD_0 is a Master/Slave

– All others are Masters

• Eight modular controller area network (MCAN) modules, all supporting flexible data rate

(ISO CAN-FD compliant)

• Dual-channel FlexRay controller

• One ethernet controller 10/100 Mbps, compliant IEEE 802.3-2008

– IEEE 1588-2008 Time stamping (internal 64-bit time stamp)

– IEEE 802.1AS and IEEE 802.1Qav (AVB-Feature)

– IEEE 802.1Q VLAN tag detection

– IPv4 and IPv6 checksum modules

• Nexus development interface (NDI) per IEEE-ISTO 5001-2003 standard, with some

support for 2010 standard.

• Device and board test support per Joint Test Action Group (JTAG) (IEEE 1149.1 and

IEEE 1149.7), 2-pin JTAG interface.

• Standby power domain with smart wake-up sequence

12/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Package pinouts and signal descriptions

3 Package pinouts and signal descriptions

Refer to the SPC584Cx and SPC58ECx IO_ Definition document.

It includes the following sections:

1. Package pinouts

2. Pin descriptions

a) Power supply and reference voltage pins

b) System pins

c) LVDS pins

d) Generic pins

DS11620 Rev 7 13/153

13

Electrical characteristics SPC584Cx, SPC58ECx

4 Electrical characteristics

4.1 Introduction

The present document contains the target Electrical Specification for the 40 nm family 32-bit

MCU SPC584Cx and SPC58ECx products.

In the tables where the device logic provides signals with their respective timing

characteristics, the symbol “CC” (Controller Characteristics) is included in the “Symbol”

column.

In the tables where the external system must provide signals with their respective timing

characteristics to the device, the symbol “SR” (System Requirement) is included in the

“Symbol” column.

The electrical parameters shown in this document are guaranteed by various methods. To

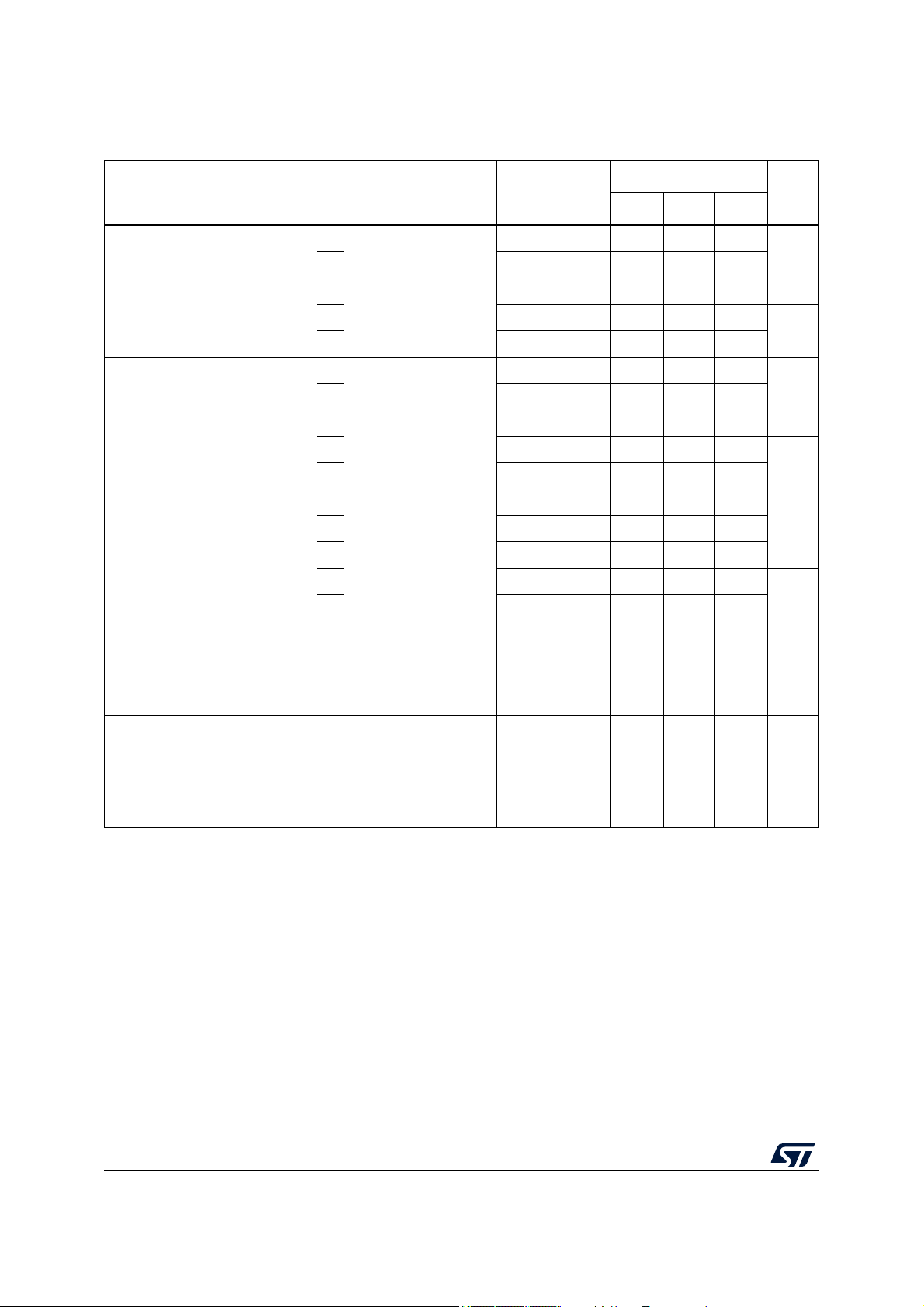

give the customer a better understanding, the classifications listed in Table 3 are used and

the parameters are tagged accordingly in the tables where appropriate.

Classification tag Tag description

Table 3. Parameter classifications

P Those parameters are guaranteed during production testing on each individual device.

C Those parameters are achieved by the design characterization by measuring a statistically

relevant sample size across process variations.

T Those parameters are achieved by design validation on a small sample size from typical

devices.

D Those parameters are derived mainly from simulations.

14/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

4.2 Absolute maximum ratings

Table 4 describes the maximum ratings for the device. Absolute maximum ratings are stress

ratings only, and functional operation at the maxima is not guaranteed. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Stress beyond the listed maxima, even momentarily, may affect device reliability or cause

permanent damage to the device.

Symbol C Parameter Conditions

V

DD_LV

V

DD_HV_IO_MAIN

V

DD_HV_IO_FLEX

V

DD_HV_OSC

V

DD_HV_FLA

V

SS_HV_ADV

V

DD_HV_ADV

V

SS_HV_ADR_S

SR D

SR D

SR D

SR D

SR D

Table 4. Absolute maximum ratings

Core voltage

operating life

(1)

range

I/O supply

voltage

(2)

ADC ground

voltage

ADC Supply

voltage

(2)

SAR ADC

ground

reference

— –0.3 — 1.4 V

— –0.3 — 6.0 V

Reference to

digital ground

Reference to

V

SS_HV_ADV

— –0.3 — 0.3 V

Value

Unit

Min Typ Max

–0.3 — 0.3 V

–0.3 — 6.0 V

V

DD_HV_ADR_S

V

SS-VSS_HV_ADR_S

V

SS-VSS_HV_ADV

V

IN

T

TRIN

I

INJ

SR D

SR D

SR D

SR D

SR D

SR T

SAR ADC

voltage

reference

V

SS_HV_ADR_S

(2)

differential

voltage

V

SS_HV_ADV

differential

voltage

I/O input voltage

(2)(3) (4)

range

Digital Input pad

transition time

(5)

Maximum DC

injection current

for each

analog/digital

PAD

(6)

Reference to

V

SS_HV_ADR_S

–0.3 — 6.0 V

— –0.3 — 0.3 V

— –0.3 — 0.3 V

— –0.3 — 6.0

Relative to V

Relative to

V

DD_HV_IO

V

DD_HV_ADV

and

ss

–0.3 — —

V

——0.3

———1ms

—–5—5mA

DS11620 Rev 7 15/153

16

Electrical characteristics SPC584Cx, SPC58ECx

Table 4. Absolute maximum ratings (continued)

Value

Symbol C Parameter Conditions

Maximum non-

operating

T

STG

SR T

Storage

— –55 — 125 °C

temperature

range

Maximum non-

operating

T

PAS

SR C

temperature

—–55—150

during passive

lifetime

Min Typ Max

(7)

Unit

°C

T

STORAGE

SR —

Maximum

storage time,

assembled part

programmed in

ECU

No supply; storage

temperature in

range –40 °C to

60 °C

— — 20 years

Maximum solder

T

SDR

SR T

temperature Pbfree packaged

(8)

———260°C

Moisture

MSL SR T

sensitivity

(9)

level

———3—

Typical range for

X-rays source

during

inspection:80 ÷

130 KV; 20 ÷

—— 1grey

dose SR T

T

XRAY

Maximum

cumulated

XRAY dose

50 μA

1. V

2. V

3. The maximum input voltage on an I/O pin tracks with the associated I/O supply maximum. For the injection current

4. Relative value can be exceeded if design measures are taken to ensure injection current limitation (parameter IINJ).

5. This limitation applies to pads with digital input buffer enabled. If the digital input buffer is disabled, there are no maximum

6. The limits for the sum of all normal and injected currents on all pads within the same supply segment can be found in

7. 175°C are allowed for limited time. Mission profile with passive lifetime temperature >150°C have to be evaluated by ST to

8. Solder profile per IPC/JEDEC J-STD-020D.

9. Moisture sensitivity per JDEC test method A112.

: allowed 1.335 V - 1.400 V for 60 seconds cumulative time at the given temperature profile. Remaining time allowed

DD_LV

1.260 V - 1.335 V for 10 hours cumulative time at the given temperature profile. Remaining time as defined in Section 4.3:

Operating conditions.

: allowed 5.5 V – 6.0 V for 60 seconds cumulative time at the given temperature profile, for 10 hours cumulative

DD_HV

time with the device in reset at the given temperature profile. Remaining time as defined in Section 4.3: Operating

conditions.

condition on a pin, the voltage will be equal to the supply plus the voltage drop across the internal ESD diode from I/O pin

to supply. The diode voltage varies greatly across process and temperature, but a value of 0.3 V can be used for nominal

calculations.

limits to the transition time.

Section 4.8.3: I/O pad current specifications.

confirm that are granted by product qualification.

16/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

4.3 Operating conditions

Table 5 describes the operating conditions for the device, and for which all the specifications

in the data sheet are valid, except where explicitly noted. The device operating conditions

must not be exceeded or the functionality of the device is not guaranteed.

Symbol C Parameter Conditions

Table 5. Operating conditions

(1)

Value

Min Typ Max

Unit

(2)

F

SYS

T

A_125 Grade

T

J_125 Grade

T

A_105 Grade

T

J_105 Grade

V

DD_LV

V

DD_HV_IO_MAIN

V

DD_HV_IO_FLEX

V

DD_HV_FLA

V

DD_HV_OSC

V

DD_HV_ADV

(4)

(4)

(4)

(4)

SR P

SR D

SR P

SR D

SR D

SR P

SR P

SR P

Operating

system clock

frequency

(3)

Operating

Ambient

temperature

Junction

temperature

under bias

Ambient

temperature

under bias

Operating

Junction

temperature

Core supply

voltage

(5)

IO supply

voltage

ADC supply

voltage

———180MHz

— –40 — 125 °C

TA= 125 °C –40 — 150 °C

— –40 — 105 °C

TA= 105 °C –40 — 130 °C

— 1.14 1.20 1.26

(6) (7)

V

— 3.0 — 5.5 V

— 3.0 — 5.5 V

V

SS_HV_ADV

V

SS

V

DD_HV_ADR_S

V

DD_HV_ADR_S

V

DD_HV_ADV

V

SS_HV_ADR_S

SR D

ADC ground

differential

— –25 — 25 mV

voltage

SAR ADC

SR P

reference

— 3.0 — 5.5 V

voltage

SAR ADC

SR D

reference

differential

———25mV

voltage

SAR ADC

SR P

ground

reference

—V

SS_HV_ADV

V

voltage

DS11620 Rev 7 17/153

19

Electrical characteristics SPC584Cx, SPC58ECx

Table 5. Operating conditions (continued)

(1)

Value

Symbol C Parameter Conditions

Min Typ Max

Unit

V

SS_HV_ADR_S

V

SS_HV_ADV

SR D

V

SS_HV_ADR_S

differential

voltage

— –25 — 25 mV

Slew rate on

V

RAMP_HV

SR D

HV power

———100V/ms

supply

V

IN

SR P

I/O input

voltage range

—0—5.5V

Injection

current (per

I

INJ1

SR T

pin) without

performance

degradation

(9) (10)

Digital pins and

analog pins

(8)

–3.0 — 3.0 mA

Dynamic

Injection

current (per

I

INJ2

SR D

pin) with

performance

degradation

(11)

1. The ranges in this table are design targets and actual data may vary in the given range.

2. The maximum number of PRAM wait states has to be configured accordingly to the system clock frequency. Refer to

Table 6.

3. Maximum operating frequency is applicable to the cores and platform of the device. See the Clock Chapter in the

Microcontroller Reference Manual for more information on the clock limitations for the various IP blocks on the device.

4. In order to evaluate the actual difference between ambient and junction temperatures in the application, refer to

Section 5.6: Package thermal characteristics.

5. Core voltage as measured on device pin to guarantee published silicon performance.

6. Core voltage can exceed 1.26 V with the limitations provided in Section 4.2: Absolute maximum ratings, provided that

HVD134_C monitor reset is disabled.

7. 1.260 V - 1.290 V range allowed periodically for supply with sinusoidal shape and average supply value below or equal to

1.236 V at the given temperature profile.

8. Full device lifetime. I/O and analog input specifications are only valid if the injection current on adjacent pins is within these

limits. See Section 4.2: Absolute maximum ratings for maximum input current for reliability requirements.

9. The I/O pins on the device are clamped to the I/O supply rails for ESD protection. When the voltage of the input pins is

above the supply rail, current will be injected through the clamp diode to the supply rails. For external RC network

calculation, assume typical 0.3 V drop across the active diode. The diode voltage drop varies with temperature.

10. The limits for the sum of all normal and injected currents on all pads within the same supply segment can be found in

Section 4.8.3: I/O pad current specifications.

11. Positive and negative Dynamic current injection pulses are allowed up to this limit. I/O and ADC specifications are not

granted. See the dedicated chapters for the different specification limits. See the Absolute Maximum Ratings table for

maximum input current for reliability requirements. Refer to the following pulses definitions: Pulse1 (ISO 7637-2:2011),

Pulse 2a(ISO 7637-2:2011 5.6.2), Pulse 3a (ISO 7637-2:2011 5.6.3), Pulse 3b (ISO 7637-2:2011 5.6.3).

Digital pins and

analog pins

(10)

–10 — 10 mA

18/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

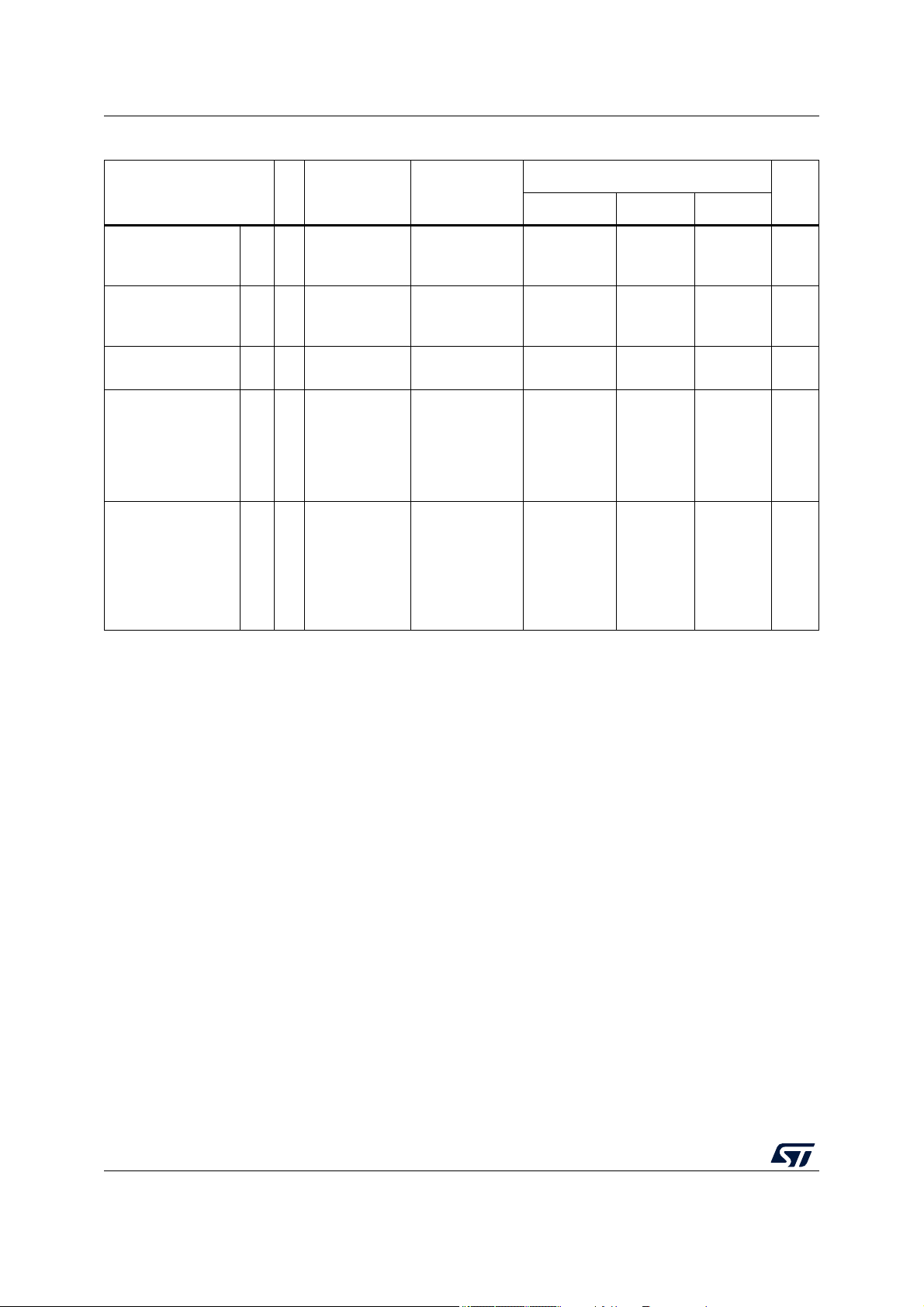

Table 6. PRAM wait states configuration

PRAMC WS Clock Frequency (MHz)

1<

0<

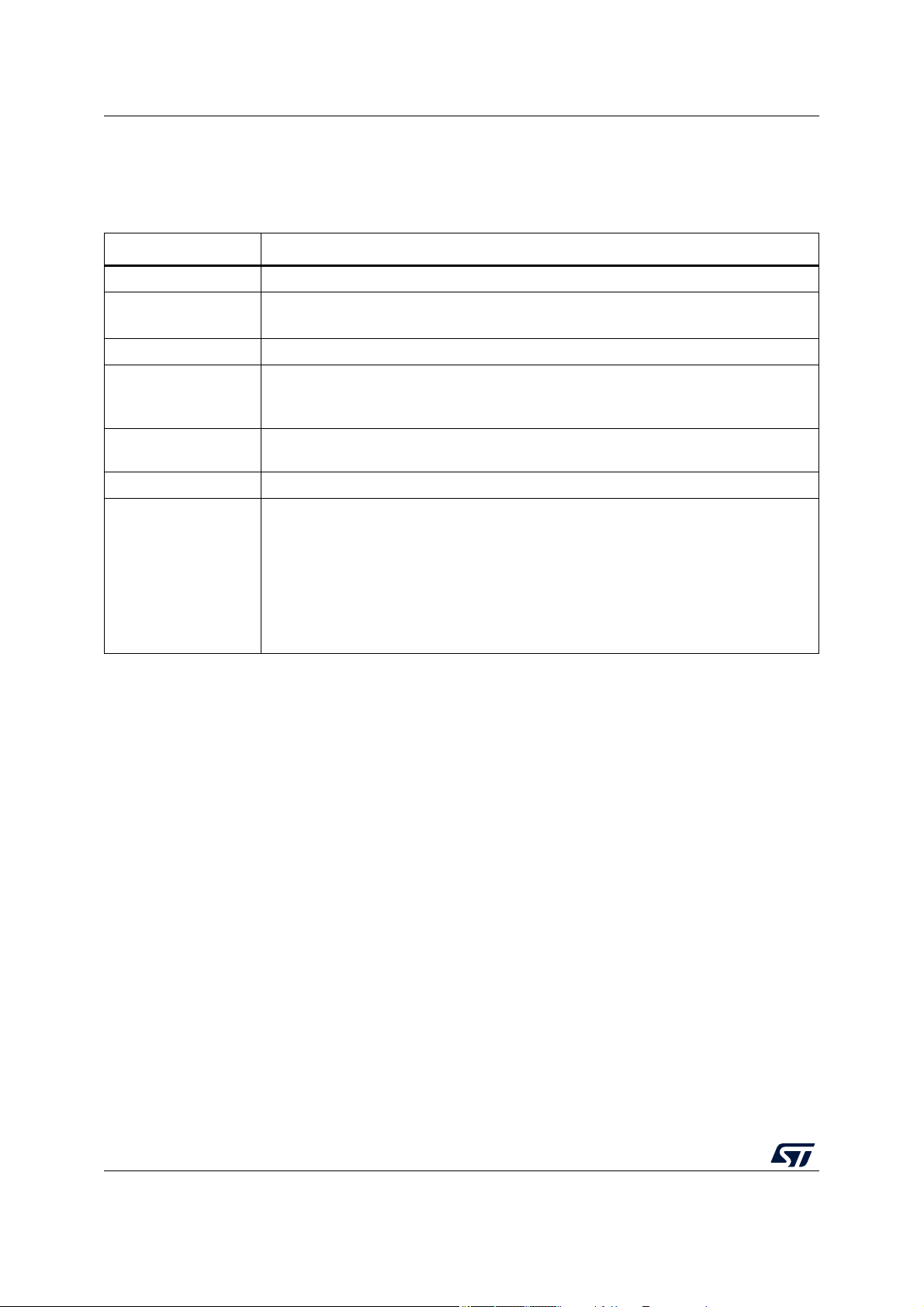

4.3.1 Power domains and power up/down sequencing

The following table shows the constraints and relationships for the different power domains.

Supply1 (on rows) can exceed Supply2 (on columns), only if the cell at the given row and

column is reporting ‘ok’. This limitation is valid during power-up and power-down phases, as

well as during normal device operation.

Table 7. Device supply relation during power-up/power-down sequence

Supply2

V

DD_HV_IO_MAIN

V

DD_HV_FLA

V

DD_HV_OSC

V

V

Supply1

DD_HV_IO_FLEX

DD_HV_IO_MAIN

V

DD_HV_FLA

V

DD_HV_OSC

V

DD_HV_ADV

V

DD_HV_ADR

V

DD_LV

V

DD_HV_IO_FLEX

ok not allowed ok ok

ok ok ok ok

ok ok not allowed ok

ok ok not allowed not allowed

180

120

V

DD_HV_ADV

V

DD_HV_ADR

During power-up, all functional terminals are maintained in a known state as described in

the device pinout Microsoft Excel file attached to the IO_Definition document.

DS11620 Rev 7 19/153

19

Electrical characteristics SPC584Cx, SPC58ECx

4.4 Electrostatic discharge (ESD)

The following table describes the ESD ratings of the device:

• All ESD testing are in conformity with CDF-AEC-Q100 Stress Test Qualification for

Automotive Grade Integrated Circuits,

• Device failure is defined as: “If after exposure to ESD pulses, the device does not meet

the device specification requirements, which include the complete DC parametric and

functional testing at room temperature and hot temperature, maximum DC parametric

variation within 10% of maximum specification”.

Parameter C Conditions Value Unit

ESD for Human Body Model (HBM)

ESD for field induced Charged Device Model (CDM)

1. This parameter tested in conformity with ANSI/ESD STM5.1-2007 Electrostatic Discharge Sensitivity Testing.

2. This parameter tested in conformity with ANSI/ESD STM5.3-1990 Charged Device Model - Component Level.

(1)

Table 8. ESD ratings

T All pins 2000 V

(2)

T All pins 500 V

T Corner Pins 750 V

20/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

4.5 Electromagnetic compatibility characteristics

EMC measurements at IC-level IEC standards are available from STMicroelectronics on

request.

DS11620 Rev 7 21/153

21

Electrical characteristics SPC584Cx, SPC58ECx

4.6 Temperature profile

The device is qualified in accordance to AEC-Q100 Grade1 requirements, such as HTOL

1,000 h and HTDR 1,000 hrs, T

Mission profile exceeding AEC-Q100 Grade 1, and with junction Temperature equal to or

lower than 150 °C have to be evaluated by ST to confirm that are covered by product

qualification. Contact your STMicroelectronics Sales representative for validation.

=150°C.

J

22/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

4.7 Device consumption

Symbol C Parameter Conditions

I

I

DD_MAIN_CORE_AC

(2),(3)

DD_LKG

(3)

I

DD_LV

I

DD_HV

I

DD_LV_GW

I

DD_HV_GW

I

DD_LV_BCM

I

DD_HV_BCM

I

DD_HSM_AC

Table 9. Device consumption

C

DT

DT

CC

Leakage current on the

V

supply

DT

DD_LV

DT

PT

Dynamic current on

CC P

CC P

the V

very high consumption

Total current on the

V

DD_HV

DD_LV

profile

supply

supply,

(4)

(4)

Dynamic current on

CC T

the V

DD_LV

supply,

gateway profile

(5)

Dynamic current on

CC T

the V

DD_HV

supply,

gateway profile

(5)

Dynamic current on

CC T

the V

DD_LV

body profile

supply,

(6)

Dynamic current on

CC T

CC T

CC T

the V

body profile

Main Core dynamic

HSM platform dynamic

operating current

DD_HV

current

supply,

(6)

(7)

(8)

=40°C — — 14

T

J

=25°C — — 10

J

=55°C — — 20

J

=95°C — — 50

J

= 120 °C — — 90

J

= 150 °C — — 180

J

— — — 210 mA

f

MAX

— — — 170 mA

———37mA

— — — 150 mA

———44mA

f

MAX

f

/2 — — 20 mA

MAX

(1)

Value

Unit

Min Typ Max

mA

——64mA

——50mA

I

DDHALT

I

DDSTOP

(9)

(10)

CC T

CC T

Dynamic current on

DD_LV

supply

the V

+Total current on the

DD_HV

supply

V

Dynamic current on

DD_LV

supply

the V

+Total current on the

DD_HV

supply

V

DS11620 Rev 7 23/153

— — 71 100 mA

— — 15 30 mA

25

Electrical characteristics SPC584Cx, SPC58ECx

Table 9. Device consumption (continued)

(1)

Value

Symbol C Parameter Conditions

Min Typ Max

Unit

I

DDSTBY8

I

DDSTBY32

I

DDSTBY256

D

Total standby mode

CC

current on V

DT

V

DT

DD_HV

RAM

supply, 8 KB

DD_LV

(11)

and

PT

D

Total standby mode

CC

V

supply, 32 KB

DD_HV

DT

RAM

current on V

DT

DD_LV

(11)

and

PT

D

Total standby mode

CC

DT

V

DD_HV

256 KB RAM

current on V

DT

DD_LV

supply,

(11)

and

PT

TJ= 25 °C — 85 160

= 40 °C — — 250

J

= 55 °C — — 370

J

= 120 °C — 1.2 2.2

J

= 150 °C — 2.9 5.0

J

TJ= 25 °C — 100 180

= 40 °C — — 270

J

= 55 °C — — 410

J

= 120 °C — — 2.4

J

= 150 °C — — 5.5

J

TJ= 25 °C — 150 250

= 40 °C — — 390

J

= 55 °C — — 590

J

= 120 °C — 2.0 3.5 mA

J

= 150 °C — 5.1 8

J

µACT

mA

µACT

mA

µACT

SSWU running over all

STANDBY period with

I

DDSSWU1

CC D

OPC/TU commands

execution and keeping

ADC off

(12)

TJ=40°C — 1.0 3.5 mA

SSWU running over all

STANDBY period with

I

DDSSWU2

1. The ranges in this table are design targets and actual data may vary in the given range.

2. The leakage considered is the sum of core logic and RAM memories. The contribution of analog modules is not considered,

and they are computed in the dynamic I

3. I

4. Use case: 2 x e200Z4 @180 MHz, HSM @90 MHz, all IPs clock enabled, Flash access with prefetch disabled, Flash

5. Gateway use case: Two cores running at 160 MHz, DMA, PLL, FLASH read only 25%, 8xCAN, 1xEthernet, HSM,

6. BCM use case: One Core running at 160 MHz, no lockstep no, DMA, PLL, FLASH read only 25%, 2xCAN, HSM,

(leakage current) and I

DD_LKG

consumption contributors. The tests used in validation, characterization and production are verifying that the total

consumption (leakage+dynamic) is lower or equal to the sum of the maximum values provided (I

parameters, measured separately, may exceed the maximum reported for each, depending on the operative conditions and

the software profile used.

consumption includes parallel read and program/erase, all SARADC in continuous conversion, DMA continuously triggered

by ADC conversion, 4 DSPI / 8 CAN / 2 LINFlex and 2 DSPI transmitting, 2 x EMIOS running (8 channels in OPWMT

mode), FIRC, SIRC, FXOSC, PLL0-1 running. The switching activity estimated for dynamic consumption does not include

I/O toggling, which is highly dependent on the application. Details of the software configuration are available separately.

The total device consumption is I

2xSARADC.

4xSARADC.

CC D

(dynamic current) are reported as separate parameters, to give an indication of the

DD_LV

DD_LV

OPC/TU/ADC

commands execution

and keeping ADC

DD_LV

+ I

DD_HV

and I

+ I

(13)

on

DD_HV

DD_LKG

parameters.

TJ=40°C — 3.5 5.0 mA

for the selected temperature.

DD_LKG+IDD_LV

). The two

24/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

7. Dynamic consumption of one core, including the dedicated I/D-caches and I/D-MEMS contribution.

8. Dynamic consumption of the HSM module, including the dedicated memories, during the execution of Electronic Code

Book crypto algorithm on 1 block of 16 byte of shared RAM.

9. Flash in Low Power. Sysclk at 160 MHz, PLL0_PHI at 160 MHz, XTAL at 40 MHz, FIRC 16 MHz ON, RCOSC1M off.

FlexCAN: instances: 0, 1, 2, 3, 4, 5, 6, 7 ON (configured but no reception or transmission), Ethernet ON (configured but no

reception or transmission), ADC ON (continuously converting). All others IPs clock-gated.

10. Sysclk = RC16 MHz, RC16 MHz ON, RC1 MHz ON, PLL OFF. All possible peripherals off and clock gated. Flash in power

down mode.

11. STANDBY mode: device configured for minimum consumption, RC16 MHz off, RC1 MHz on, OSC32K off, SSWU off.

12. SSWU1 mode adder: FIRC = ON, SSWU clocked at 8 MHz and running over all STANDBY period, ADC off. The total

standby consumption can be obtained by adding this parameter to the IDDSTBY parameter for the selected memory size

and temperature.

13. SSWU2 mode adder: FIRC = ON, SSWU clocked at 8 MHz and running over all STANDBY period, ADC on in continuous

conversion. The total standby consumption can be obtained by adding this parameter to the I

selected memory size and temperature.

parameter for the

DDSTBY

DS11620 Rev 7 25/153

25

Electrical characteristics SPC584Cx, SPC58ECx

4.8 I/O pad specification

The following table describes the different pad type configurations.

Pad type Description

Weak configuration Provides a good compromise between transition time and low electromagnetic emission.

Medium configuration

Strong configuration Provides fast transition speed; used for fast interface.

Very strong

configuration

Table 10. I/O pad specification descriptions

Provides transition fast enough for the serial communication channels with controlled

current to reduce electromagnetic emission.

Provides maximum speed and controlled symmetric behavior for rise and fall transition.

Used for fast interface including Ethernet and FlexRay interfaces requiring fine control of

rising/falling edge jitter.

Differential

configuration

Input only pads These low input leakage pads are associated with the ADC channels.

Standby pads

A few pads provide differential capability providing very fast interface together with good

EMC performances.

These pads (LP pads) are active during STANDBY. They are configured in CMOS level

logic and this configuration cannot be changed. Moreover, when the device enters the

STANDBY mode, the pad-keeper feature is activated for LP pads. It means that:

– if the pad voltage level is above the pad keeper high threshold, a weak pull-up resistor

is automatically enabled

– if the pad voltage level is below the pad keeper low threshold, a weak pull-down resistor

is automatically enabled.

For the pad-keeper high/low thresholds please consider (VDD_HV_IO_MAIN / 2) +/-20%.

Note: Each I/O pin on the device supports specific drive configurations. See the signal description

table in the device reference manual for the available drive configurations for each I/O pin.

PMC_DIG_VSIO register has to be configured to select the voltage level (3.3 V or 5.0 V) for

each IO segment.

Logic level is configurable in running mode while it is CMOS not-configurable in STANDBY

for LP (low power) pads, so if a LP pad is used to wakeup from STANDBY, it should be

configured as CMOS also in running mode in order to prevent device wrong behavior in

STANDBY.

4.8.1 I/O input DC characteristics

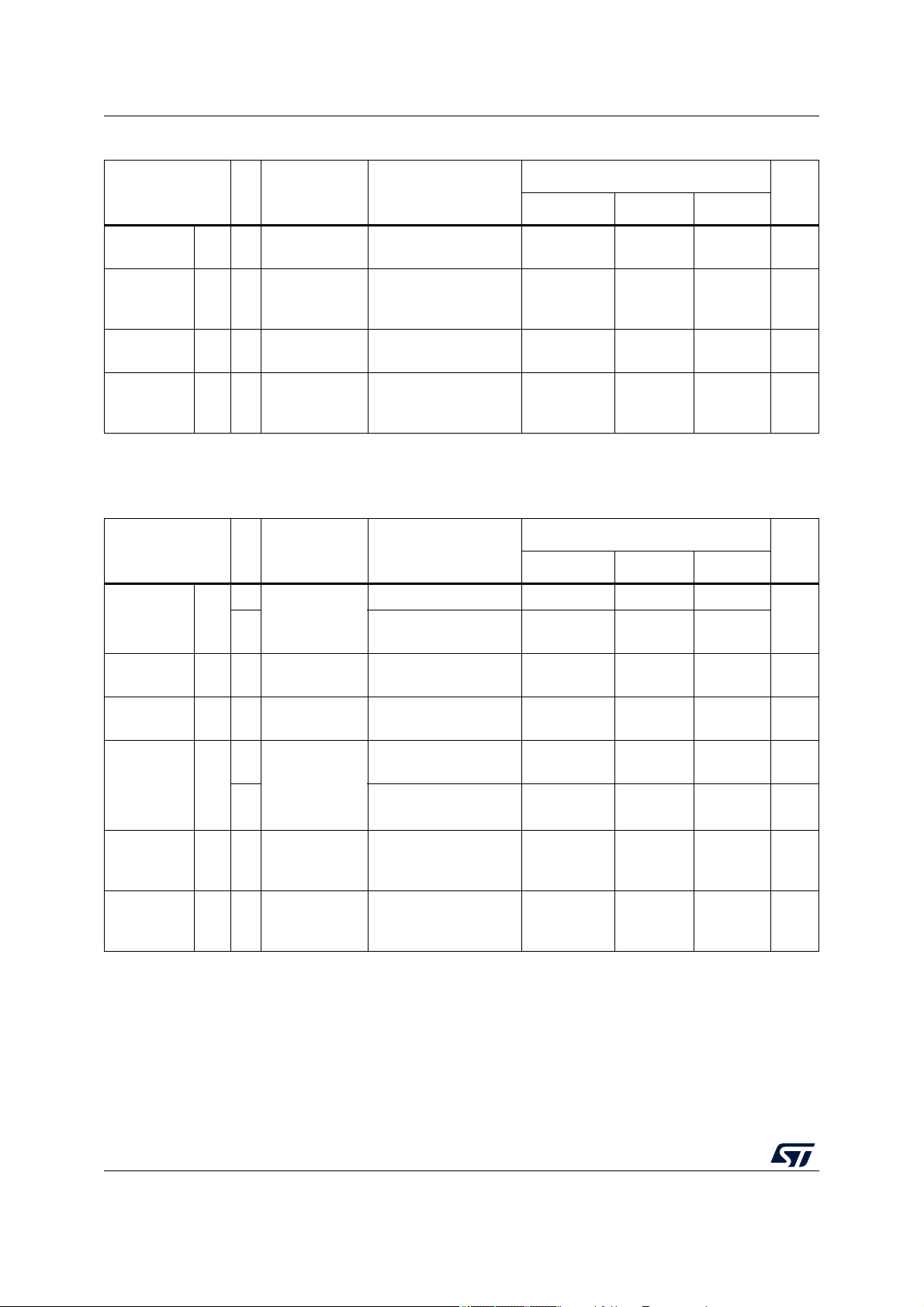

The following table provides input DC electrical characteristics, as described in Figure 3.

26/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

V

IL

V

IN

V

IH

V

INTERNAL

V

DD

V

HYS

(SIUL register)

Figure 3. I/O input electrical characteristics

Table 11. I/O input electrical characteristics

Symbol C Parameter Conditions

V

V

V

hysttl

V

ihcmos

V

ilcmos

V

hyscmos

ihttl

ilttl

SR P

SR P

CC C

SR P

SR P

CC C

Input high level

TTL

Input low level

TTL

Input hysteresis

TTL

Input high level

CMOS

Input low level

CMOS

Input hysteresis

CMOS

Value

Unit

Min Typ Max

TTL

V

—2—

DD_HV_IO

+ 0.3

V

— –0.3 — 0.8 V

—0.3——V

CMOS

DD

V

V

V

—0.65 * V

DD

—

DD_HV_IO

+ 0.3

— –0.3 — 0.35 * V

—0.10 * VDD——V

COMMON

I

LKG

I

LKG

I

LKG

CC P

CC P

CC P

Pad input

leakage

Pad input

leakage

Pad input

leakage

INPUT-ONLY pads

=150°C

T

J

STRONG pads

=150°C

T

J

VERY STRONG pads,

T

=150°C

J

——200nA

— — 1,000 nA

— — 1,000 nA

DS11620 Rev 7 27/153

36

Electrical characteristics SPC584Cx, SPC58ECx

Table 11. I/O input electrical characteristics (continued)

Value

Symbol C Parameter Conditions

Min Typ Max

Unit

C

P1

V

drift

W

FI

CC D

CC D

SR C

Pad

capacitance

Input Vil/Vih

temperature

drift

Wakeup input

filtered pulse

———10pF

In a 1 ms period, with a

temperature variation

<30 °C

(1)

———20ns

——100mV

Wakeup input

W

NFI

1. In the range from WFI (max) to W

voltage. Refer to the device pinout IO definition excel file for the list of pins supporting the wakeup filter feature.

SR C

not filtered

(1)

pulse

(min), pulses can be filtered or not filtered, according to operating temperature and

NFI

— 400 — — ns

Table 12. I/O pull-up/pull-down electrical characteristics

Value

Symbol C Parameter Conditions

Min Typ Max

(1)

= 0.69 *

(2)

= 5.0 V ±

10%

——130

15 — —

33 — 93 KΩ

I

WPU

R

WPU

CC

CC D

T

Weak pull-up

current

P

absolute value

Weak Pull-up

resistance

V

IN

V

IN

V

DD_HV_IO

V

DD_HV_IO

= 1.1 V

Unit

μA

R

I

WPD

WPU

CC D

CC

Weak Pull-up

resistance

T

Weak pull-

down current

absolute value

P

Weak Pull-

R

WPD

CC D

down

resistance

Weak Pull-

R

WPD

CC D

down

resistance

1. Maximum current when forcing a change in the pin level opposite to the pull configuration.

2. Minimum current when keeping the same pin level state than the pull configuration.

V

DD_HV_IO

VIN = 0.69 *

V

DD_HV_IO

VIN = 0.9 V

V

DD_HV_IO

V

DD_HV_IO

= 3.3 V ±

10%

= 5.0 V ±

10%

= 3.3 V ±

10%

(1)

19 — 62 KΩ

——130μA

(2)

15 — —

29 — 60 KΩ

19 — 60 KΩ

Note: When the device enters into standby mode, the LP pads have the input buffer switched-on.

As a consequence, if the pad input voltage VIN is V

SS<VIN<VDD_HV

, an additional

consumption can be measured in the VDD_HV domain. The highest consumption can be

seen around mid-range (VIN ~=VDD_HV/2), 2-3mA depending on process, voltage and

temperature.

28/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

10%

V

out

V

INTERNAL

V

HYS

(SIUL register)

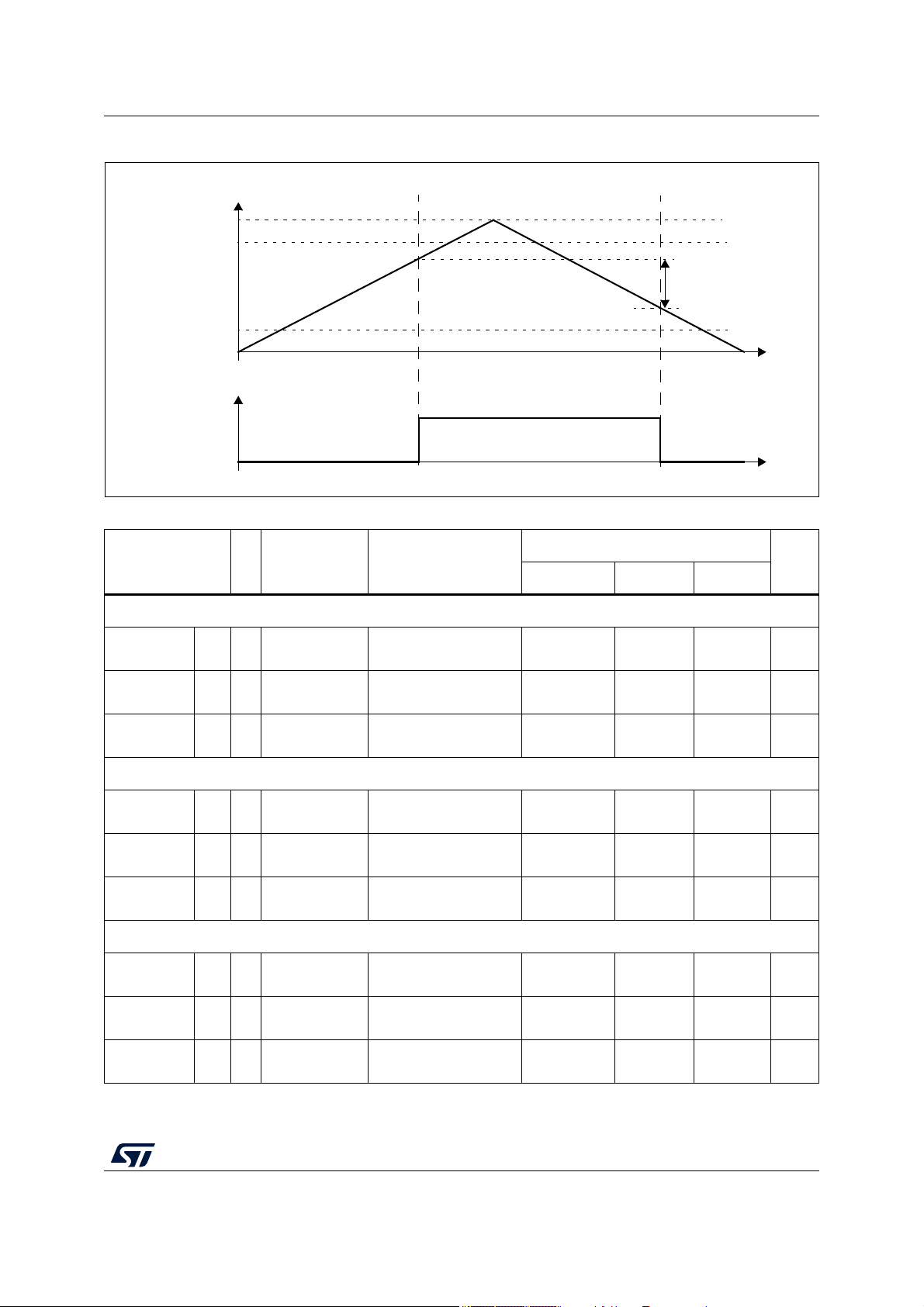

20%

80%

90%

t

R10-90

t

R20-80

t

F10-90

t

F20-80

tTR(max) = MAX(t

R10-90

; t

F10-90

)

t

TR

(min) = MIN(t

R10-90

; t

F10-90

)

t

TR20-80

(max) = MAX(t

R20-80

; t

F20-80

)

t

TR20-80

(min) = MIN(t

R20-80

; t

F20-80

)

t

SKEW20-80

= |t

R20-80-tF20-80

|

t

SKEW20-80

t

SKEW10-90

= |t

R10-90-tF10-90

|

This situation may occur if the PAD is used as a ADC input channel, and VSS<VIN<V

The applications should ensure that LP pads are always set to VDD_HV or VSS, to avoid

the extra consumption. Please refer to the device pinout IO definition excel file to identify the

low-power pads which also have an ADC function.

4.8.2 I/O output DC characteristics

Figure 4 provides description of output DC electrical characteristics.

Figure 4. I/O output DC electrical characteristics definition

DD_HV

.

Note: 10%/90% is the default condition for any parameter if not explicitly mentioned differently.

The following tables provide DC characteristics for bidirectional pads:

• Table 13 provides output driver characteristics for I/O pads when in WEAK/SLOW

configuration.

• Table 14 provides output driver characteristics for I/O pads when in MEDIUM

configuration.

• Table 15 provides output driver characteristics for I/O pads when in STRONG/FAST

configuration.

• Table 16 provides output driver characteristics for I/O pads when in VERY

STRONG/VERY FAST configuration.

DS11620 Rev 7 29/153

36

Electrical characteristics SPC584Cx, SPC58ECx

Table 13. WEAK/SLOW I/O output characteristics

Symbol C Parameter Conditions

=0.5mA

I

ol

VDD=5.0V ± 10%

=3.3V ± 10%

V

DD

Ioh=0.5mA

=5.0V ± 10%

V

DD

=3.3V ± 10%

V

DD

V

= 5.0 V ± 10% 380 — 1040

DD

= 3.3 V ± 10% 250 — 700

V

DD

V

V

R

ol_W

oh_W

_W

CC D

CC D

CC P

Output low

voltage for Weak

type PADs

Output high

voltage for Weak

type PADs

Output

impedance for

Weak type PADs

CL = 25 pF

=5.0V ± 10%

V

DD

=3.3V ± 10%

V

DD

CL = 50 pF

V

=5.0V ± 10%

DD

=3.3V ± 10%

V

DD

F

max_W

CC T

Maximum output

frequency for

Weak type PADs

CL = 25 pF

t

TR_W

CC T

Transition time

output pin

weak

configuration,

10%-90%

= 5.0 V + 10%

V

DD

VDD= 3.3 V + 10%

CL = 50 pF

V

=5.0V ± 10%

DD

=3.3V ± 10%

V

DD

Difference

|t

SKEW_W

| CC T

between rise

and fall time,

90%-10%

Value

Unit

Min Typ Max

— — 0.1*V

0.9*V

DD

——V

DD

V

Ω

——2MHz

——1MHz

25 — 120 ns

50 — 240 ns

———25%

=5.0V ± 10%

I

DCMAX_W

CC D

Maximum DC

current

Table 14. MEDIUM I/O output characteristics

V

DD

VDD=3.3V ± 10%

Symbol C Parameter Conditions

V

V

ol_M

oh_M

CC D

CC D

Output low

voltage for

Medium type

PAD s

Output high

voltage for

Medium type

PAD s

=2.0mA

I

ol

VDD=5.0 V ± 10 %

=3.3 V ± 10 %

V

DD

=2.0 mA

I

oh

VDD=5.0V ± 10%

=3.3V ± 10%

V

DD

30/153 DS11620 Rev 7

——0.5mA

Value

Unit

Min Typ Max

— — 0.1*V

0.9*V

DD

——V

DD

V

SPC584Cx, SPC58ECx Electrical characteristics

Table 14. MEDIUM I/O output characteristics (continued)

Value

Symbol C Parameter Conditions

Min Typ Max

Unit

R

_M

F

max_M

t

TR_M

|t

SKEW_M

I

DCMAX_M

CC P

CC T

CC T

| CC T

CC D

Output

impedance for

Medium type

PAD s

Maximum output

frequency for

Medium type

PAD s

Transition time

output pin

MEDIUM

configuration,

10%-90%

Difference

between rise

and fall time,

90%-10%

Maximum DC

current

= 5.0 V ± 10% 90 — 260

V

DD

VDD= 3.3 V ± 10% 60 — 170

CL = 25 pF

=5.0V ± 10%

V

DD

=3.3V ± 10%

V

DD

——12MHz

CL = 50 pF

V

=5.0V ± 10%

DD

=3.3V ± 10%

V

DD

——6MHz

CL = 25 pF

=5.0V ± 10%

V

DD

=3.3V ± 10%

V

DD

8 — 30 ns

CL = 50 pF

V

=5.0V ± 10%

DD

12 — 60 ns

VDD=3.3V ± 10%

———25%

VDD=5.0V ± 10%

=3.3V ± 10%

V

DD

——2mA

Ω

Table 15. STRONG/FAST I/O output characteristics

Symbol C Parameter Conditions

V

ol_S

CC D

Output low

voltage for

Strong type

PAD s

V

DD

VDD=3 .3 V ± 10%

Output high

V

V

oh_S

CC D

voltage for

Strong type

PAD s

Output

R

_S

CC P

impedance for

Strong type

PAD s

DD

VDD=3.3V ± 10%

V

DD

V

DD

Value

Unit

Min Typ Max

=8.0mA

I

ol

=5.0V ± 10%

I

=5.5mA

ol

=8.0mA

I

oh

=5.0V ± 10%

Ioh=5.5mA

— — 0.1*V

— — 0.15*V

0.9*V

0.85*V

——V

DD

——V

DD

DD

DD

V

V

= 5.0 V ± 10% 20 — 65

Ω

= 3.3 V ± 10% 28 — 90

DS11620 Rev 7 31/153

36

Electrical characteristics SPC584Cx, SPC58ECx

Table 15. STRONG/FAST I/O output characteristics (continued)

Value

Symbol C Parameter Conditions

Min Typ Max

Unit

F

max_S

t

TR_S

I

DCMAX_S

|t

SKEW_S

CC T

CC T

CC D

| CC T

Maximum output

frequency for

Strong type

PAD s

Transition time

output pin

STRONG

configuration,

10%-90%

Maximum DC

current

Difference

between rise

and fall time,

90%-10%

CL = 25 pF

=5.0 V ± 10%

V

DD

CL = 50 pF

=5.0 V ± 10%

V

DD

CL = 25 pF

=3.3V ± 10%

V

DD

CL = 50 pF

=3.3V ± 10%

V

DD

CL = 25 pF

=5.0V ± 10%

V

DD

CL = 50 pF

V

=5.0V ± 10%

DD

CL = 25 pF

V

=3.3V ± 10%

DD

CL = 50 pF

V

=3.3V ± 10%

DD

——50MHz

——25MHz

——25MHz

— — 12.5 MHz

3—10

5—16

1.5 — 15

2.5 — 26

VDD= 5 V ± 10% — — 8 mA

=3.3V ± 10% — — 5.5

V

DD

———25

ns

%

Table 16. VERY STRONG/VERY FAST I/O output characteristics

Symbol C Parameter Conditions

=9.0mA

I

ol

VDD=5.0 V ± 10%

Iol=9.0mA

=3.3 V ± 10%

V

DD

=9.0mA

I

oh

=5.0V ± 10%

V

DD

Ioh=9.0mA

=3.3V ± 10%

V

DD

= 5.0 V ± 10% 20 — 60

V

DD

= 3.3 V ± 10% 18 — 50

V

DD

V

V

ol_V

oh_V

R

_V

CC D

CC D

CC P

Output low

voltage for Very

Strong type

PAD s

Output high

voltage for Very

Strong type

PAD s

Output

impedance for

Very Strong type

PAD s

32/153 DS11620 Rev 7

Value

Min Typ Max

— — 0.1*V

— — 0.15*V

0.9*V

0.85*V

DD

DD

——V

——V

DD

DD

Unit

V

V

Ω

SPC584Cx, SPC58ECx Electrical characteristics

Table 16. VERY STRONG/VERY FAST I/O output characteristics (continued)

Value

Symbol C Parameter Conditions

Min Typ Max

Unit

F

max_V

t

TR_V

t

TR20-80_V

t

TRTTL_V

CC T

CC T

CC T

CC T

Maximum output

frequency for

Very Strong type

PAD s

10–90%

threshold

transition time

output pin VERY

STRONG

configuration

20–80%

threshold

transition time

output pin VERY

STRONG

configuration

(Flexray

Standard)

TTL threshold

transition time

for output pin in

VERY STRONG

configuration

(Ethernet

standard)

CL = 25 pF

=5.0V ± 10%

V

DD

CL = 50 pF

= 5.0 V ± 10%

V

DD

CL = 25 pF

=3.3V ± 10%

V

DD

CL = 50 pF

=3.3V ± 10%

V

DD

CL = 25 pF

=5.0V ± 10%

V

DD

CL = 50 pF

=5.0V ± 10%

V

DD

CL = 25 pF

V

=3.3V ± 10%

DD

CL = 50 pF

V

=3.3V ± 10%

DD

CL = 25 pF

=5.0V ± 10%

V

DD

CL = 15 pF

=3.3V ± 10%

V

DD

CL = 25 pF

=3.3V ± 10%

V

DD

——50MHz

——25MHz

——50MHz

——25MHz

1—6

3—12

ns

1.5 — 6

3—11

0.8 — 4.5

ns

1—4.5

0.88 — 5 ns

Σt

TR20-80_V

|t

SKEW_V

I

DCMAX_V

CC T

| CC T

CC D

Sum of

transition time

20–80% output

pin VERY

STRONG

configuration

Difference

between rise

and fall delay

Maximum DC

current

CL = 25 pF

=5.0V ± 10%

V

DD

CL = 15 pF

VDD=3.3V ± 10%

CL = 25 pF

VDD= 5.0 V ± 10%

= 5.0 V±10%

V

DD

V

=3.3V ± 10%

DD

——9

——9

0—1.2ns

——9mA

DS11620 Rev 7 33/153

ns

36

Electrical characteristics SPC584Cx, SPC58ECx

4.8.3 I/O pad current specifications

The I/O pads are distributed across the I/O supply segment. Each I/O supply segment is

associated to a V

DD/VSS

attached to the IO_Definition document.

Table 17 provides I/O consumption figures.

In order to ensure device reliability, the average current of the I/O on a single segment

should remain below the I

In order to ensure device functionality, the sum of the dynamic and static current of the I/O

on a single segment should remain below the I

Pad mapping on each segment can be optimized using the pad usage information provided

on the I/O Signal Description table.

Symbol C Parameter Conditions

supply pair as described in the device pinout Microsoft Excel file

RMSSEG

maximum value.

DYNSEG

maximum value.

Table 17. I/O consumption

(1)

Val ue

Unit

Min Typ Max

I

RMSSEG

I

RMS_W

I

RMS_M

I

RMS_S

SR D

CC D

CC D

CC D

Average consumption

Sum of all the DC I/O current

within a supply segment

RMS I/O current for WEAK

configuration

RMS I/O current for MEDIUM

configuration

RMS I/O current for STRONG

configuration

(2)

———80mA

= 25 pF, 2 MHz,

C

L

=5.0V ± 10%

V

DD

= 50 pF, 1 MHz,

C

L

VDD=5.0V ± 10%

C

= 25 pF, 2 MHz,

L

VDD=3.3V ± 10%

= 25 pF, 1 MHz,

C

L

= 3.3 V ± 10%

V

DD

C

= 25 pF, 12 MHz,

L

= 5.0 V ± 10%

V

DD

C

= 50 pF, 6 MHz,

L

V

= 5.0 V ± 10%

DD

= 25 pF, 12 MHz,

C

L

= 3.3 V ± 10%

V

DD

= 25 pF, 6 MHz,

C

L

VDD= 3.3 V ± 10%

C

= 25 pF, 50 MHz,

L

VDD= 5.0 V ± 10%

= 50 pF, 25 MHz,

C

L

= 5.0 V ± 10%

V

DD

= 25 pF, 25 MHz,

C

L

VDD= 3.3 V ± 10%

——1.1

——1.1

mA

——1.0

——1.0

——5.5

——5.5

mA

——4.2

——4.2

——21

——21

mA

——10

C

L

V

34/153 DS11620 Rev 7

= 25 pF, 12.5 MHz,

= 3.3 V ± 10%

DD

——10

SPC584Cx, SPC58ECx Electrical characteristics

Table 17. I/O consumption (continued)

(1)

Val ue

Symbol C Parameter Conditions

= 25 pF, 50 MHz,

C

L

= 5.0 V ± 10%

V

DD

= 50 pF, 25 MHz,

C

L

I

RMS_V

CC D

RMS I/O current for VERY

STRONG configuration

VDD= 5.0 V ± 10%

C

= 25 pF, 50 MHz,

L

VDD= 3.3 V ± 10%

= 25 pF, 25 MHz,

C

L

= 3.3 V ± 10%

V

DD

Dynamic consumption

(3)

Min Typ Max

——23

——23

——16

——16

Unit

mA

I

DYN_SEG

I

DYN_W

I

DYN_M

I

DYN_S

SR D

CC D

CC D

CC D

Sum of all the dynamic and DC

I/O current within a supply

segment

Dynamic I/O current for WEAK

configuration

Dynamic I/O current for

MEDIUM configuration

Dynamic I/O current for

STRONG configuration

VDD= 5.0 V ± 10% — — 195

= 3.3 V ± 10% — — 150

V

DD

=25pF, VDD=5.0V ±

C

L

10%

=50pF, VDD=5.0V ±

C

L

10%

C

=25pF, VDD=3.3V ±

L

10%

=50pF, VDD=3.3V ±

C

L

10%

CL=25pF, VDD=5.0V ±

10%

C

=50pF, VDD=5.0V ±

L

10%

=25pF, VDD=3.3V ±

C

L

10%

=50pF, VDD=3.3V ±

C

L

10%

C

=25pF, VDD=5.0V ±

L

10%

=50pF, VDD=5.0V ±

C

L

10%

=25pF, VDD=3.3V ±

C

L

10%

— — 16.7

— — 16.8

— — 12.9

— — 12.9

— — 18.2

— — 18.4

— — 14.3

— — 16.4

——57

— — 63.5

——31

mA

mA

mA

mA

C

=50pF, VDD=3.3V ±

L

10%

— — 33.5

DS11620 Rev 7 35/153

36

Electrical characteristics SPC584Cx, SPC58ECx

Table 17. I/O consumption (continued)

(1)

Val ue

Symbol C Parameter Conditions

Min Typ Max

=25pF, VDD=5.0V ±

C

L

10%

=50pF, VDD=5.0V ±

C

I

DYN_V

CC D

Dynamic I/O current for VERY

STRONG configuration

L

C

L

10%

=25pF, VDD=3.3V ±

10%

=50pF, VDD=3.3V ±

C

L

10%

1. I/O current consumption specifications for the 4.5 V ≤ V

VSIO[VSIO_xx] = 0 for 3.0 V

2. Average consumption in one pad toggling cycle.

3. Stated maximum values represent peak consumption that lasts only a few ns during I/O transition. When possible (timed

output) it is recommended to delay transition between pads by few cycles to reduce noise and consumption.

≤

V

DD_HV_IO

≤ 3.6 V.

DD_HV_IO

≤ 5.5 V range are valid for VSIO_[VSIO_xx] = 1, and

——62

——70

——52

——55

Unit

mA

36/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

V

IL

V

DD

PORST

V

IH

device start-up phase

V

DD_POR

PORST driven low by

device reset

forced by external circuitry

PORST

undriven

device reset by

internal power-on reset

internal power-on reset

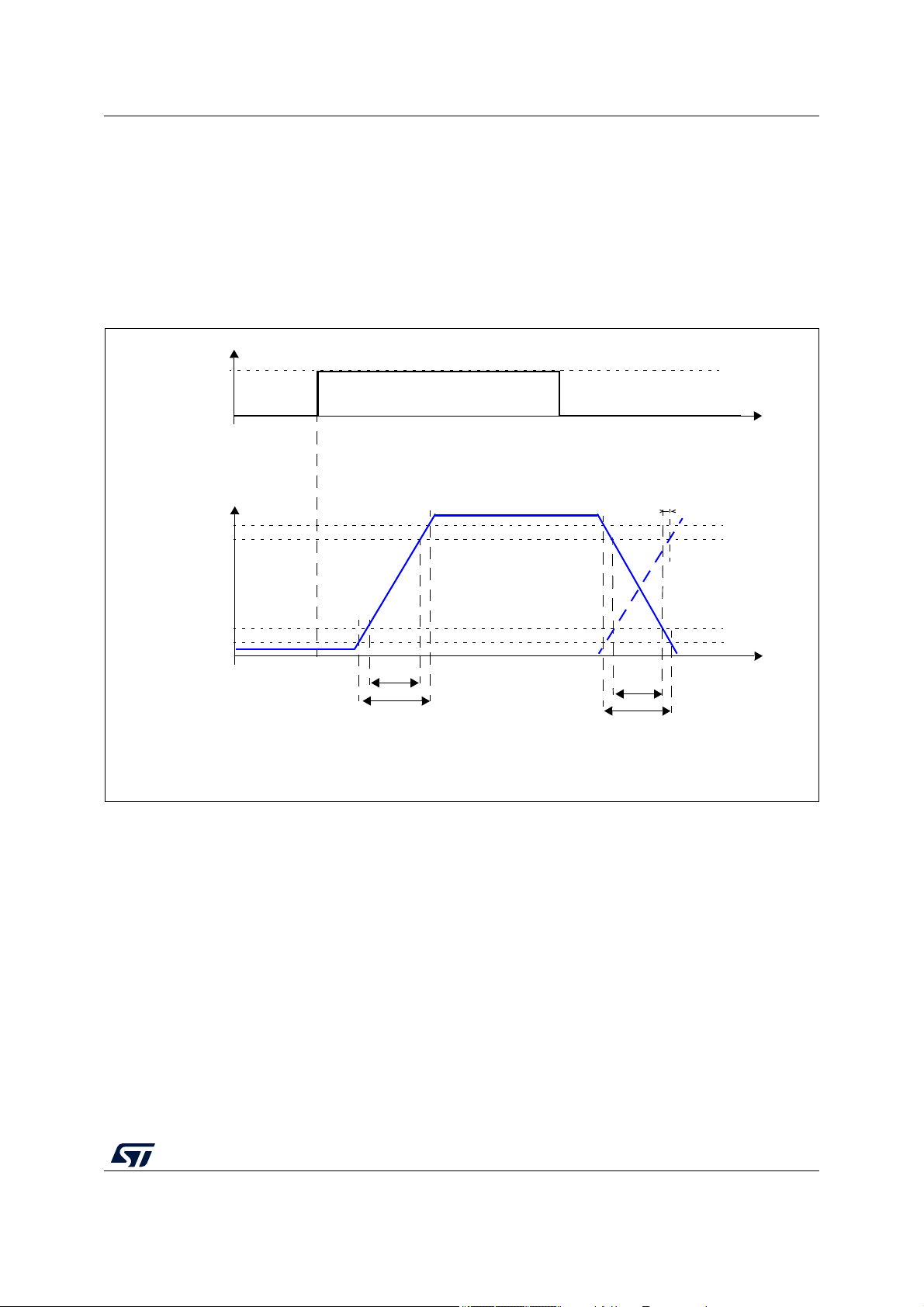

4.9 Reset pad (PORST) electrical characteristics

The device implements dedicated bidirectional reset pins as below specified. PORST pin

does not require active control. It is possible to implement an external pull-up to ensure

correct reset exit sequence. Recommended value is 4.7 KΩ.

Figure 5. Startup Reset requirements

Figure 6 describes device behavior depending on supply signal on PORST:

1. PORST

low pulse has too low amplitude: it is filtered by input buffer hysteresis. Device

remains in current state.

2. PORST

low pulse has too short duration: it is filtered by low pass filter. Device remains

in current state.

3. PORST

a) PORST

low pulse is generating a reset:

low but initially filtered during at least WFRST. Device remains initially in

current state.

b) PORST

potentially filtered until WNFRST. Device state is unknown. It may either

be reset or remains in current state depending on extra condition (temperature,

voltage, device).

c) PORST

asserted for longer than WNFRST. Device is under reset.

DS11620 Rev 7 37/153

39

Electrical characteristics SPC584Cx, SPC58ECx

V

IL

V

IH

V

DD

filtered by

hysteresis

filtered by

lowpass filter

W

FRST

W

NFRST

filtered by

lowpass filter

W

FRST

unknown reset

state

device under hardware reset

internal

reset

1 2 3a 3b 3c

V

HYS

V

PORST

Figure 6. Noise filtering on reset signal

Symbol C Parameter Conditions

V

IHRES

V

ILRES

V

HYSRES

V

DD_POR

SR P Input high level

SR P Input low level

CC C Input hysteresis

CC D Minimum supply

Table 18. Reset PAD electrical characteristics

V

TTL

TTL

TTL

for strong pull-

down activation

DD_HV

V

DD_HV

V

DD_HV

V

DD_HV

V

DD_HV

V

DD_HV

V

DD_HV

V

DD_HV

Value

Unit

Min Typ Max

=5.0V ± 10%

=3.3V ± 10%

2—V

DD_HV_IO

+0.3

V

= 5.0 V ± 10% -0.3 — 0.8 V

= 3.3 V ± 10% -0.3 — 0.6

=5.0V ± 10% 0.3 — — V

=3.3V ± 10% 0.2 — —

= 5.0 V ± 10% — — 1.6 V

= 3.3 V ± 10% — — 1.05

38/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

Table 18. Reset PAD electrical characteristics (continued)

Value

Symbol C Parameter Conditions

Min Typ Max

Unit

I

OL_R

I

WPU

I

WPD

CC P Strong pull-down

current

(1)

CC P Weak pull-up

current absolute

PV

value

PV

PV

CC P Weak pull-down

current absolute

value

PV

PV

PV

V

V

=5.0V ± 10% 12 — — mA

DD_HV

=3.3V ± 10% 8 — —

DD_HV

VIN=1.1V

V

V

V

V

DD_HV

IN

DD_HV

IN

V

DD_HV_IO

DD_HV

=0.69 * V

IN

DD_HV

=5.0V ± 10%

=3.3V ± 10%

=5.0V ± 10%

=3.3V ± 10%

VIN= 0.69 *

V

DD_HV_IO

V

V

V

V

=5.0V ± 10%

DD_HV

IN

V

DD_HV_IO

=3.3V ± 10%

DD_HV

IN

=5.0V ± 10%

DD_HV

IN

DD_HVDD_HV

(2)

=1.1V

= 0.69 *

(3)

DD_HV_IO

(2)

= 0.69 *

(2)

=0.9V

=0.9V

=3.3V

— — 130 μA

——70

15 — —

15 — —

— — 130 μA

——80

15 — —

15 — —

± 10%

W

FRST

W

NFRST

1. I

applies to PORST: Strong Pull-down is active on PHASE0 for PORST. Refer to the device pinout IO definition excel file

ol_r

for details regarding pin usage.

2. Maximum current when forcing a change in the pin level opposite to the pull configuration.

3. Minimum current when keeping the same pin level state than the pull configuration.

CC P Input filtered

PV

pulse

CC P Input not filtered

PV

pulse

V

DD_HV

DD_HV

V

DD_HV

DD_HV

= 5.0 V ± 10% — — 500 ns

= 3.3 V ± 10% — — 600

=5.0V ± 10% 2000 — — ns

=3.3V ± 10% 3000 — —

PAD POWER-UP State RESET state DEFAULT state

Table 19. Reset Pad state during power-up and reset

(1)

STANDBY state

PORST Strong pull-down Weak pull-down Weak pull-down Weak pull-up

1. Before SW Configuration. Please refer to the Device Reference Manual, Reset Generation Module (MC_RGM) Functional

Description chapter for the details of the power-up phases.

DS11620 Rev 7 39/153

39

Electrical characteristics SPC584Cx, SPC58ECx

PLL0

PLL1

IRCOSC

XOSC

PLL1_PHI

PLL0_PHI1

PLL0_PHI

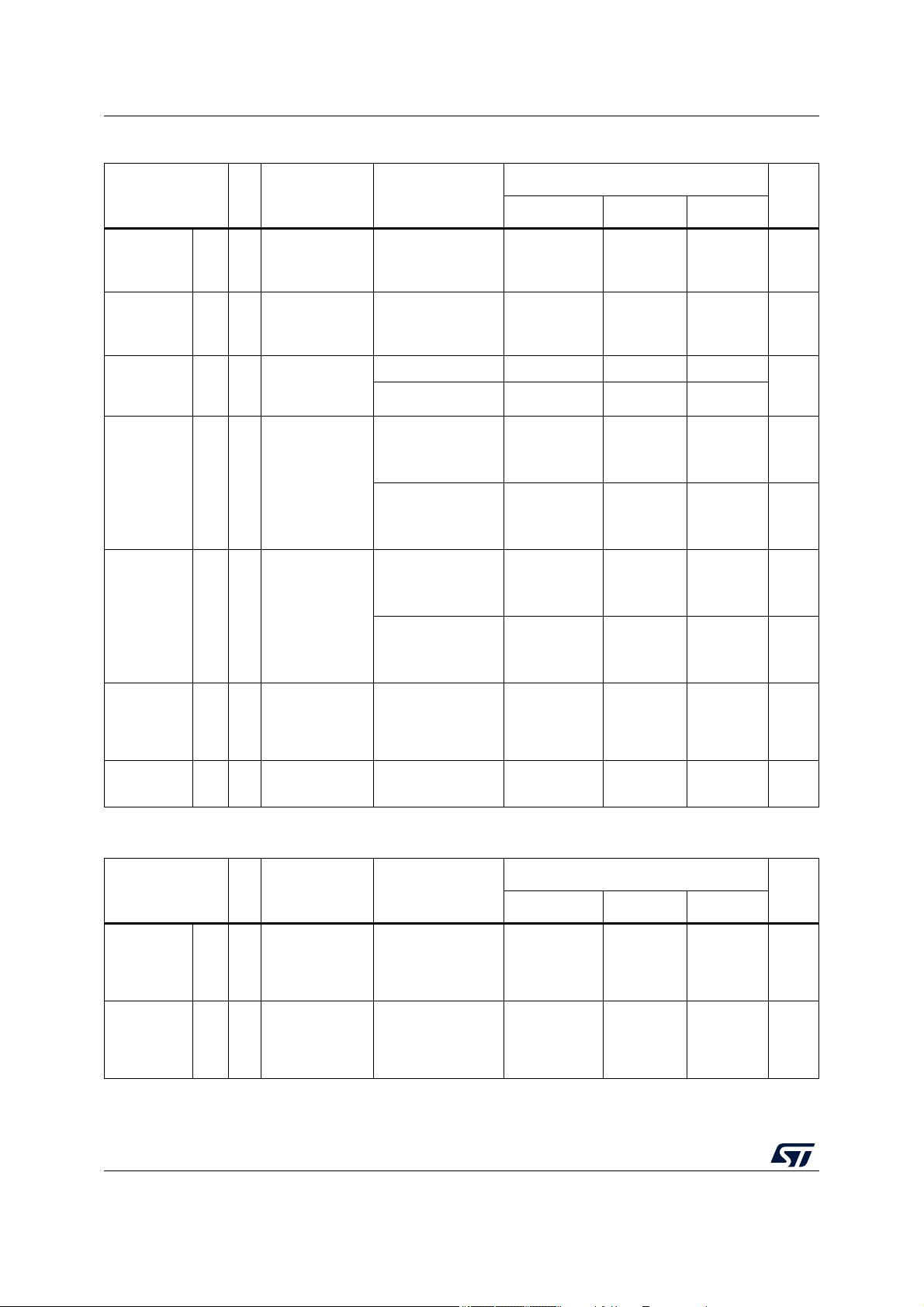

4.10 PLLs

Two phase-locked loop (PLL) modules are implemented to generate system and auxiliary

clocks on the device.

Figure 7 depicts the integration of the two PLLs. Refer to device Reference Manual for more

detailed schematic.

Figure 7. PLLs integration

4.10.1 PLL0

Symbol C Parameter Conditions

f

PLL0IN

Δ

PLL0IN

f

INFIN

f

PLL0VCO

f

PLL0PHI0

f

PLL0PHI1

t

PLL0LOCK

|Δ

PLL0PHI0SPJ

(3)

|

Table 20. PLL0 electrical characteristics

Val ue

Unit

Min Typ Max

SR — PLL0 input clock

SR —

PLL0 input clock duty

(1)

cycle

PLL0 PFD (Phase

SR —

Frequency Detector) input

clock frequency

CC P PLL0 VCO frequency — 600 — 1400 MHz

CC D PLL0 output frequency — 4.762 — 400 MHz

CC D PLL0 output clock PHI1 — 20 — 175

CC P PLL0 lock time — — — 100 µs

PLL0_PHI0 single period

CC T

jitter

fPLL0IN = 20 MHz

(resonator)

(1)

f

PLL0PHI0

6-sigma pk-pk

—8—44MHz

—40—60%

—8—20MHz

(2)

MHz

= 400 MHz,

— — 200 ps

40/153 DS11620 Rev 7

SPC584Cx, SPC58ECx Electrical characteristics

Table 20. PLL0 electrical characteristics (continued)

Val ue

Symbol C Parameter Conditions

Min Typ Max

PLL0_PHI1 single period

|Δ

PLL0PHI1SPJ

|

(3)

CC D

jitter

fPLL0IN = 20 MHz

f

PLL0PHI1

= 40 MHz,

6-sigma pk-pk

— — 300

(resonator)

10 periods

accumulated jitter

(80 MHz equivalent

— — ±250 ps

frequency), 6-sigma

pk-pk

Δ

PLL0LTJ

(3)

CC D

PLL0 output long term

(4)

jitter

f

= 20 MHz

PLL0IN

(resonator), VCO

frequency = 800 MHz

16 periods

accumulated jitter

(50 MHz equivalent

frequency), 6-sigma

pk-pk

— — ±300 ps

long term jitter

(< 1 MHz equivalent

frequency), 6-sigma

— — ±500 ps

pk-pk)

I

PLL0

1. PLL0IN clock retrieved directly from either internal RCOSC or external FXOSC clock. Input characteristics are granted

when using internal RCOSC or external oscillator is used in functional mode.

2. If the PLL0_PHI1 is used as an input for PLL1, then the PLL0_PHI1 frequency shall obey the maximum input frequency

limit set for PLL1 (87.5 MHz, according to Table 21).

3. Jitter values reported in this table refer to the internal jitter, and do not include the contribution of the divider and the path to

the output CLKOUT pin.

4. V

noise due to application in the range V

DD_LV

filtered.

CC D PLL0 consumption FINE LOCK state — — 6 mA

= 1.20 V±5%, with frequency below PLL bandwidth (40 kHz) will be

DD_LV

(4)

Unit

ps

DS11620 Rev 7 41/153

42

Electrical characteristics SPC584Cx, SPC58ECx

4.10.2 PLL1

PLL1 is a frequency modulated PLL with Spread Spectrum Clock Generation (SSCG)

support.

Symbol C Parameter Conditions

f

PLL1IN

Δ

PLL1IN

f

INFIN

f

PLL1VCO

f

PLL1PHI0

t

PLL1LOCK

f

PLL1MOD

|δ

PLL1MOD

|Δ

PLL1PHI0SPJ

(4)

SR — PLL1 input clock

SR —

SR —

CC P PLL1 VCO frequency — 600 — 1400 MHz

CC D PLL1 output clock PHI0 — 4.762 — F

CC P PLL1 lock time — — — 50 µs

CC T

|CCT

|

CC T

Table 21. PLL1 electrical characteristics

(1)

PLL1 input clock duty

(1)

cycle

PLL1 PFD (Phase

Frequency Detector)

input clock frequency

PLL1 modulation

frequency

PLL1 modulation depth

(when enabled)

PLL1_PHI0 single period

peak to peak jitter

200 MHz, 6-sigma

— 37.5 — 87.5 MHz

—35—65%

— 37.5 87.5 MHz

— — — 250 kHz

Center spread

(3)

Down spread 0.5 — 4 %

f

PLL1PHI0

=

Value

Unit

Min Typ Max

(2)

SYS

MHz

0.25 — 2 %

——500

(5)

ps

I

PLL1

1. PLL1IN clock retrieved directly from either internal PLL0 or external FXOSC clock. Input characteristics are granted when

using internal PPL0 or external oscillator is used in functional mode.