PM6686

Dual step-down controller with adjustable voltages, adjustable LDO

and auxiliary charge pump controller for notebook

Features

■ 5.5 V to 28 V input voltage range

■ Dual fixed OUT1 = 1.5 V/5 V and OUT2 =

1.05 V / 3.3 V outputs or adjustable OUT1 = 0.7

V to 5.5 V and OUT2 = 0.7 V to 2.5 V outputs,

± 1.5% accuracy over valley regulation

■ Low-side MOSFETs' R

current sensing

DS(on)

and programmable current limit

■ Constant ON-time control

■ Frequency selectable

■ Soft-start internally fixed at 2 ms and soft-stop

■ Selectable pulse skipping at light loads

■ Selectable minimum frequency (33 kHz) in

pulse skip mode

■ Independent Power Good and EN signals

■ Latched OVP and UVP

■ Charge pump feedback

■ Fixed 3.3 V/5.0 V, or adjustable output 0.7 V to

4.5 V, ± 1.5% (LDO): 200 mA

■ 3.3 V reference voltage ± 2.0%: 5 mA

■ 2.0 V reference voltage ± 1.0%: 50 µA

Applications

■ Notebook computers

■ Main (3.3 V/5 V), chipset (1.5 V/1.05 V),

DDR1/2/3, graphic cards power supply

■ PDAs, mobile devices, tablet PC or slates

■ 3-4 cells Li+ battery powered devices

Description

PM6686 is a dual step-down controller specifically

designed to provide extremely high efficiency

conversion, with lossless current sensing

technique. The constant on-time architecture

assures fast load transient response and the

embedded voltage feed-forward provides nearly

constant switching frequency operation. Pulse

skipping technique increases efficiency at very

light load. Moreover a minimum switching

frequency of 33 kHz is selectable to avoid audio

noise issues. The PM6686 provides a selectable

switching frequency, allowing three different

values of switching frequencies for the two

switching sections. The output voltages OUT1

and OUT2 can be programmed to regulate

1.5 V/5 V and 1.05 V/3.3 V outputs respectively or

can deliver two adjustable output voltages. An

optional external charge pump can be monitored.

This device embeds a linear regulator that can

provide 3.3 V/5 V or an adjustable voltage from

0.7 V to 4.5 V output. The linear regulator

provides up to 100 mA output current. LDO can

be bypassed with the switching regulator outputs

or with an external power supply (switchover

function).

VFQFPN-32 5 x 5 mm

When in switchover, the LDO output can source

up to 200 mA.

Table 1. Device summary

July 2009 Doc ID 15281 Rev 4 1/50

Order codes Package Packaging

PM6686

Tr ay

VFQFPN-32L 5 x 5 mm

PM6686TR Tape and reel

www.st.com

50

Contents PM6686

Contents

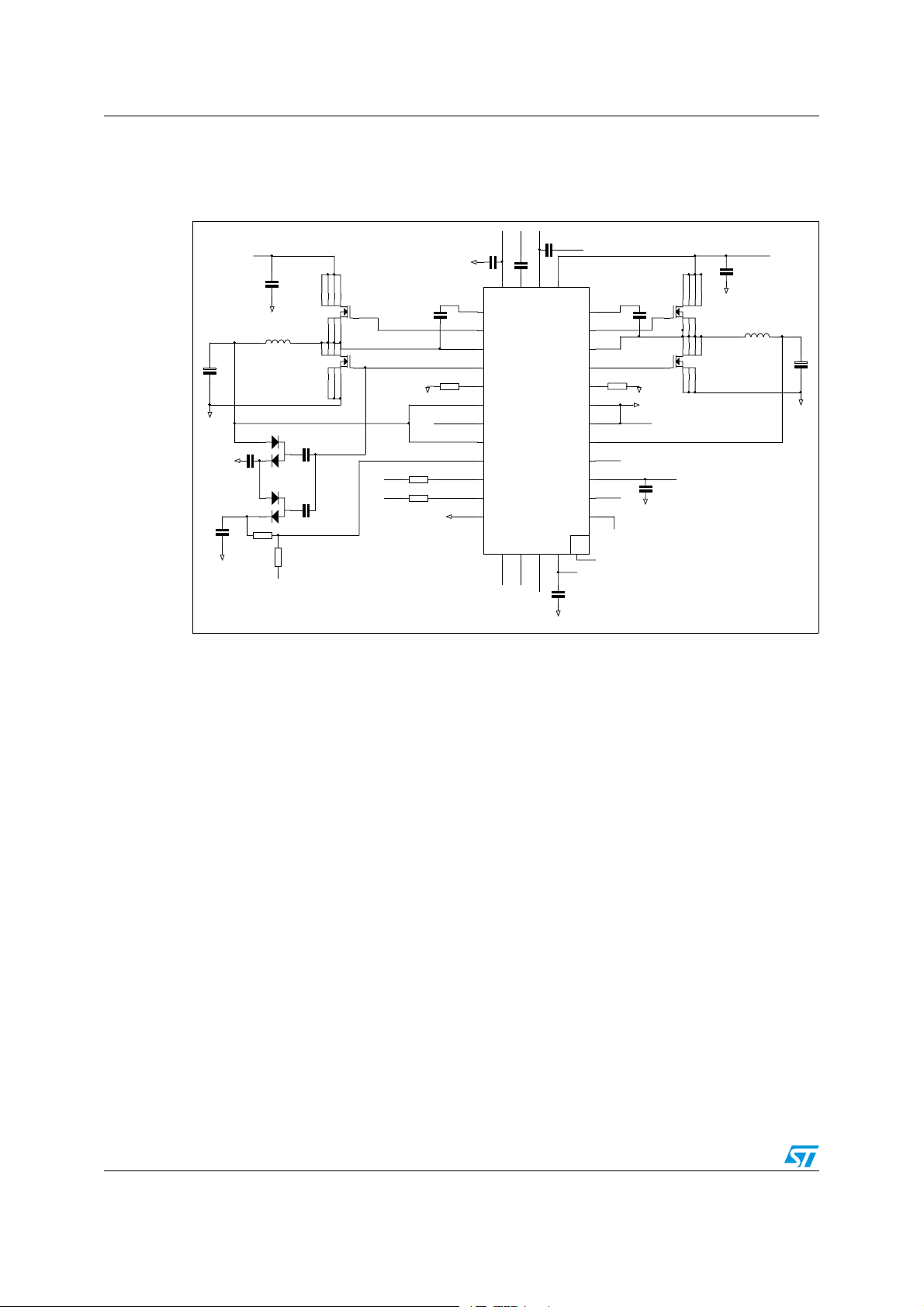

1 Simplified application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

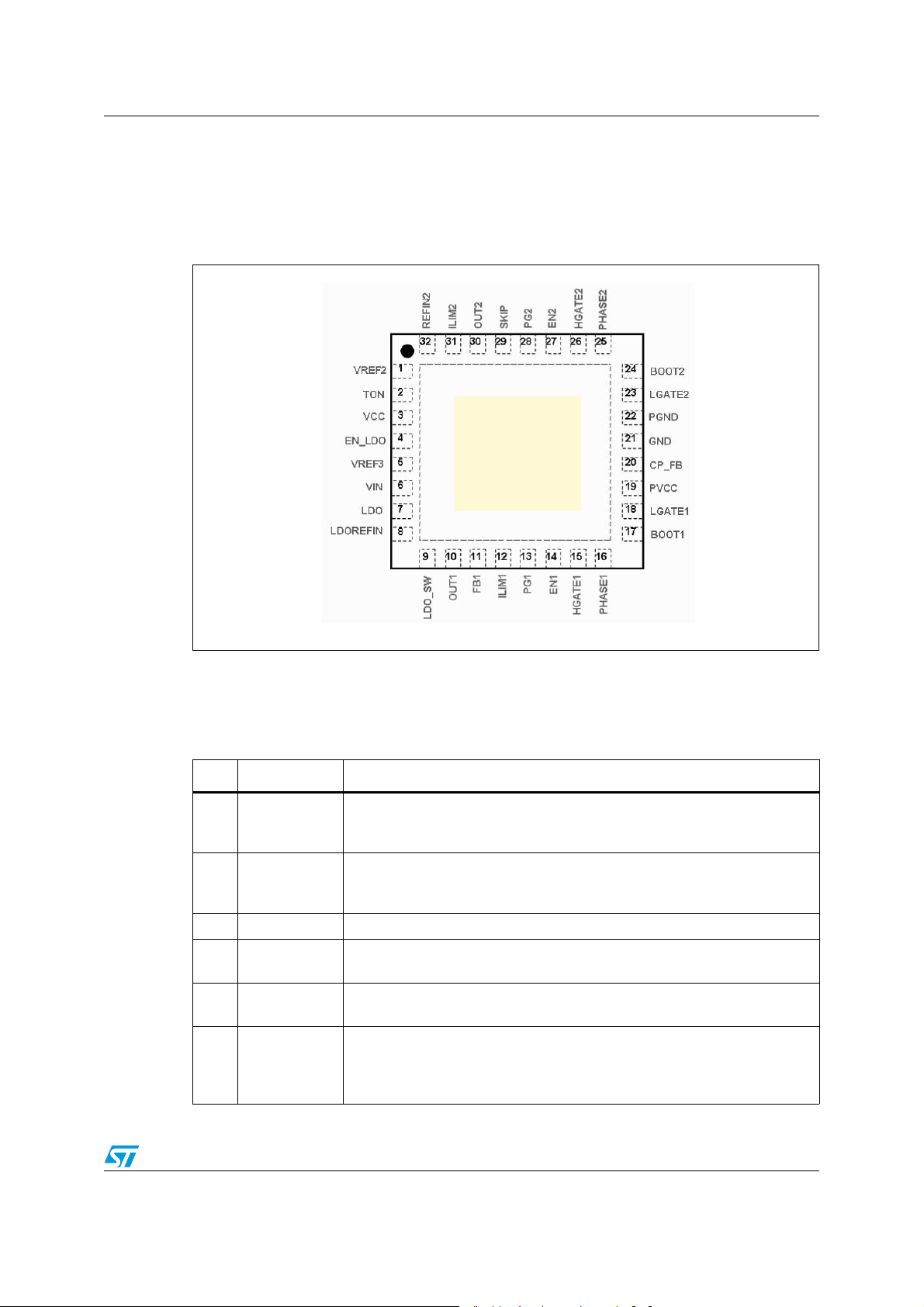

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Typical operating characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Screen shots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.1 Switching sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.1.1 Output voltage set up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.1.2 Constant on time control (COT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.1.3 PWM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.1.4 SKIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.1.5 Non audible SKIP (NA SKIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.1.6 Gate drivers and logic supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.1.7 Current sensing and current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1.8 Soft-start and soft-end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9 Monitoring and protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.2 Undervoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.3 PVCC monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2/50 Doc ID 15281 Rev 4

PM6686 Contents

9.4 Linear regulator section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.5 Charge pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.6 Voltage references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.7 General device fault management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.7.1 Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.1 External components selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.1.1 Inductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.1.2 Input capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.1.3 Output capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.1.4 MOSFET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11 Diode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.1 Freewheeling diode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.2 Charge pump diode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.3 Other important components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.3.1 VIN filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.3.2 PVCC and VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.3.3 VREF2 and VREF3 capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

11.3.4 LDO output capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

11.3.5 Bootstrap circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

12 PCB design guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

13 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Doc ID 15281 Rev 4 3/50

List of figures PM6686

List of figures

Figure 1. Simplified application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Pin connection (through top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Efficiency vs load OUT1 = 5 V, TON = VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 4. Efficiency vs load OUT2 = 3.3 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 5. Efficiency vs load OUT1 = 1.5 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. Efficiency vs load OUT2 = 1.05 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. Load regulationOUT1 = 5 V, TON = VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 8. Load regulationOUT2 = 3.3 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. Load regulation OUT1 = 1.5 V, TON = VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. Load regulation OUT2 = 1.05 V, TON = VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11. Switching frequency vs load OUT1 = 5 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 12. Switching frequency vs load OUT2 = 3.3 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 13. Section 1 line regulation OUT1 = 5 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 14. Section 2 line regulation OUT2 = 3.3 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 15. Section 1 line regulation OUT1 = 1,5 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 16. Section 2 line regulation OUT2 = 1,05 V, TON = VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 17. Stand-by mode input battery current vs input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 18. Shut-down mode input battery current vs input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 19. PWM no load input currents vs input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 20. SKIP no load input currents vs input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 21. NA SKIP no load input currents vs input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 22. VREF3 load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 23. VREF2 load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 24. LDO = 3,3 V load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 25. LDO = 5 V load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 26. OUT1 soft-start no load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 27. OUT2 soft-start no load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 28. OUT1 soft-start 8 A constant current load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 29. OUT2 soft-start loaded 8 A constant current load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 30. OUT1 soft-end, no load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 31. OUT2 soft-end, no load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 32. OUT1 soft-start, EN2 = VREF2 no loads applied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 33. OUT2 soft-start, EN1=VREF2 no loads applied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 34. soft-end, EN2 = VREF2 no loads applied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 35. soft-end, EN1=VREF2 no loads applied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 36. Load transient 0-5 A 2 A/µs OUT1 = 5 V PWM mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 37. Load transient 0-5 A 2 A/µs OUT1 = 5 V SKIP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 38. Load transient 0-5 A 2 A/ µs OUT1 = 1,5 V PWM mode . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 39. Load transient 0-5 A 2 A/ µs OUT1 = 1,5 V SKIP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 40. Load transient 0-5 A 2 A/µs OUT2 = 3.3 V PWM mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 41. Load transient 0-5 A 2 A/µs OUT2 = 3.3 V SKIP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 42. Load transient 0-5 A 2 A/ µs OUT2 = 1,05 V PWM mode . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 43. Load transient 0-5 A 2 A/ µs OUT2 = 1,05 V SKIP mode . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 44. Functional block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 45. Resistor divider to configure the output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 46. Constant on time block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 47. Inductor current and output voltage in PWM mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 48. Inductor current and output voltage in SKIP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4/50 Doc ID 15281 Rev 4

PM6686 List of figures

Figure 49. Inductor current and output voltage in NA SKIP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 50. Internal supply diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 51. Current waveforms in current limit conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 52. Current limit circuit block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 53. VOUT2 behavior if EN2 is connected to VREF2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 54. Charge pump application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 55. VIN pin filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 56. VCC and PVCC filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 57. Bootstrap circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 58. Current paths, ground connection and driver traces layout . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 59. Package dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Doc ID 15281 Rev 4 5/50

Simplified application schematic PM6686

1 Simplified application schematic

Figure 1. Simplified application schematic

62%&

06##

62%&2%&

3'.$

"//4

('!4%

0(!3%

,'!4%

),)-

/54

&"

,$/?37

#0?&"

0'

0'

3+)0

3'.$

06##

0-

%.

2%&

6##

6).

5

6).

6##

62%&

%.

4/.

"//4

('!4%

0(!3%

,'!4%

),)-

0'.$

'.$

/54

2%&).

,$/2%&) .

%.?,$/

62%&

2%&

3'.$

6##

,$/

3'.$

62%&

0!$

3'.$

0'.$

0'.$

3'.$

06##

0'.$

0'.$

0'.$

6).

0'.$

0'.$

0'.$

3'.$

6##

6##

3'.$

0'.$

3'.$

0'.$

3'.$

!-V

6/50 Doc ID 15281 Rev 4

PM6686 Pin settings

2 Pin settings

2.1 Connections

Figure 2. Pin connection (through top view)

0-

2.2 Pin descriptions

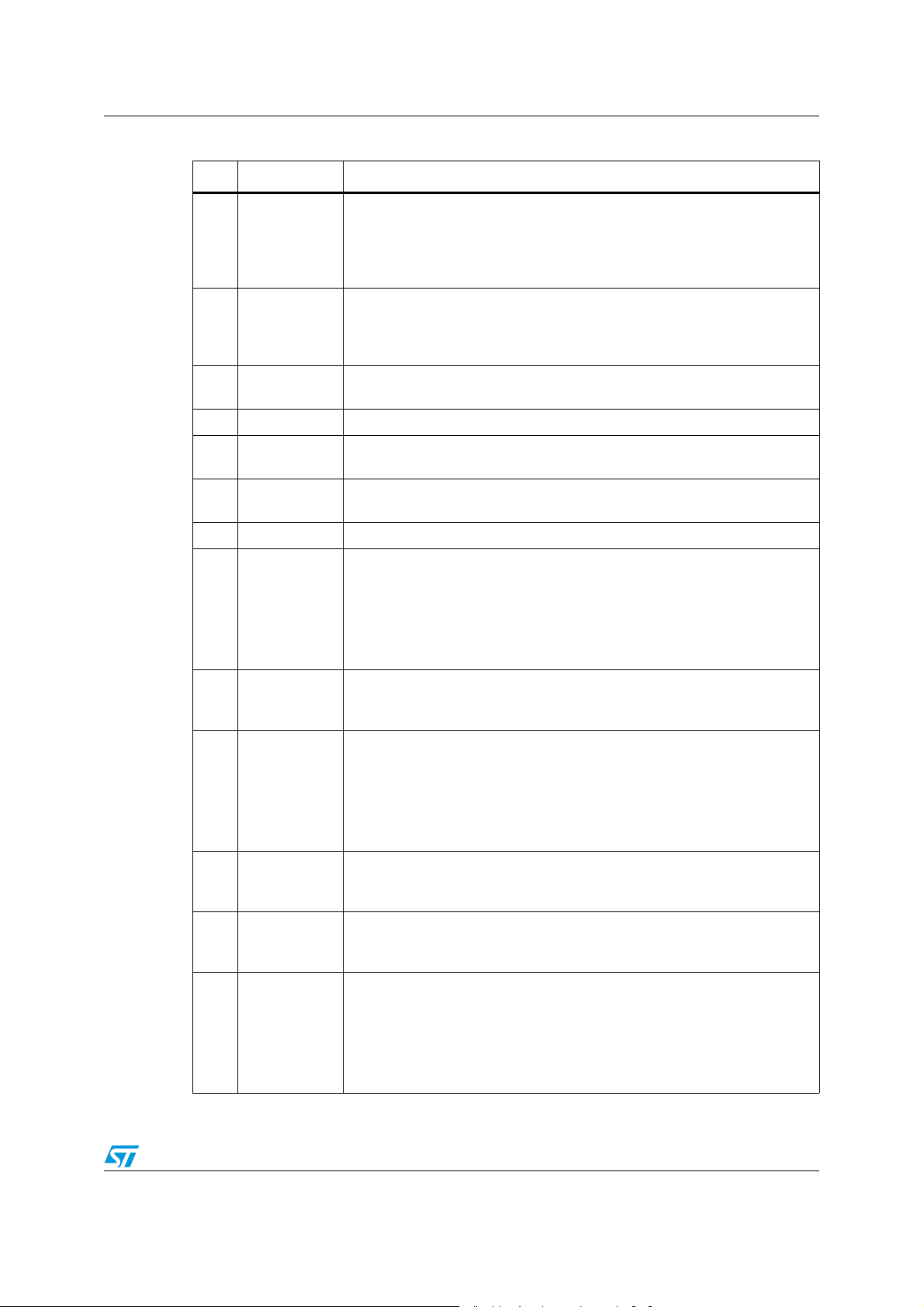

Table 2. Pin descriptions

N° Pin Function

1VREF2

2TON

3 VCC Controller supply voltage input. Bypass to GND with a 1 μF capacitor.

4EN_LDO

5VREF3

6VIN

!-V

Internal 2 V high accuracy voltage reference. It can deliver 50 μA. Loading

VREF2 can affect FB and output accuracy. Bypass to GND with a 100 nF

capacitor.

Frequency selection pin. It provides a selectable switching frequency,

allowing three different values of switching frequencies for the switching

sections.

Enable input for the linear regulator. The LDO is enabled if

EN_LDO is > 1.6 V and is disabled if EN_LDO < 1 V.

Internal 3.3 V high accuracy voltage reference. It can deliver 5 mA if

bypassed to GND with a 10 nF capacitor. If not used, it can be left floating.

Device supply voltage pin. VIN is used in the on-time generators of the two

switching controllers. VIN is also used to power the linear regulator when the

switchover function is not active. Connect VIN to the battery input and

bypass with a 1 µF capacitor.

Doc ID 15281 Rev 4 7/50

Pin settings PM6686

Table 2. Pin descriptions (continued)

N° Pin Function

Linear regulator output. It can provide up to 100 mA peak current. The LDO

regulates at 5 V If LDOREFIN is connected to GND. When the LDO is set at

5 V and LDO_SW is within 5 V switchover threshold, the internal regulator

shuts down and the LDO output pin is connected to LDO_SW through a

7LDO

8 LDOREFIN

9LDO_SW

10 OUT1

0.8 Ω switch. The LDO regulates at 3.3 V if LDOREFIN is connected to

VCC. When the LDO is set at 3.3 V and LDO_SW is within 3.3 V switchover

threshold, the internal regulator shuts down and the LDO output pin is

connected to LDO_SW through a 1.1 Ω switch. Bypass LDO output to GND

with a minimum of 4.7 µF ceramic capacitor.

Feedback of the adjustable linear regulator. Connect LDOREFIN to GND for

fixed 5 V operation. Connect LDOREFIN to VCC for fixed 3.3 V operation.

LDOREFIN can be used to program LDO output voltage from 0.7 V to 4.5 V:

LDO output is two times the voltage of LDOREFIN. The switchover function

is disabled in adjustable mode.

Source of the switchover connection. LDO_SW is the switchover source

voltage for the LDO when LDOREFIN is connected to GND or VCC.

Connect LDO_SW to 5 V if LDOREFIN is tied to GND. Connect LDO_SW to

3.3 V if LDOREFIN is tied to VCC.

Output voltage sense for the switching section 1.This pin must be directly

connected to the output voltage of the switching section. It provides also the

feedback for the switching section 1 when FB1 is tied to GND/VCC.

Feedback input for the switching section 1:

– If this pin is connected to GND, OUT1 operates at 5 V

11 FB1

– If this pin is connected to VCC, OUT1 operates at 1.5 V

– This pin is connected to a resistive voltage-divider from OUT1 to GND to

adjust the output voltage from 0.7 V to 5.5 V.

12 ILIM1

Positive current sense input for the switching section 1. It is possible to set a

threshold voltage that is compared with 1/10

th

of the GND-PHASE1 drop

during the off time.

Power Good output signal for the section 1. This pin is an open drain output

13 PG1

and It is pulled down when the output of the switching section 1 is out of

+/- 10% of its nominal value.

Enable input for the switching section 1.

– If EN1 < 0.8 V the switching section OUT1 is turned off and all faults are

14 EN1

cleared.

– If EN1 > 2.4 V the switching section OUT1 is turned on.

– If EN1 is connected to VREF2, the switching section OUT1 turns on after

the switching section OUT2 reaches regulation.

15 HGATE1 High-side gate driver output for section 1.

16 PHASE1

17 BOOT1

Switch node connection and return path for the high-side driver for the

section 1.It is also used as positive and negative current sense input.

Bootstrap capacitor connection for the switching section 1. It supplies the

high-side gate driver.

18 LGATE1 Low-side gate driver output for the section 1.

19 PVCC

5 V low-side gate drivers supply voltage input. Bypass to PGND with a 1 μF

capacitor.

8/50 Doc ID 15281 Rev 4

PM6686 Pin settings

Table 2. Pin descriptions (continued)

N° Pin Function

The CP_FB is used to monitor the optional external 14 V charge pump.

Connect a resistive voltage-divider from 14 V charge pump output to GND. If

20 CP_FB

21 GND

22 PGND

23 LGATE2 Low-side gate driver output for the section 2.

24 BOOT2

25 PHASE2

26 HGATE2 High-side gate driver output for section 2.

27 EN2

28 PG2

29 SKIP

30 OUT2

31 ILIM2

32 REFIN2

CP_FB drops below the threshold voltage, the device performs a no audible

skip cycle. This charges the charge pump output (driven by LGATE1). Leave

CP_FB floating if the charge pump feedback is not needed.

Signal ground reference for internal logic circuitry and LDO. It must be

connected to the signal ground plan of the power supply and to the exposed

pad. The signal ground plan and the power ground plan must be connected

together in one point near the PGND pin.

Power ground. This pin must be connected to the power ground plan of the

power supply.

Bootstrap capacitor connection for the switching section 2. It supplies the

high-side gate driver.

Switch node connection and return path for the high-side driver for the

section 2. It is also used as positive and negative current sense input.

Enable input for the switching section 2.

– If EN2 < 0.8 V the switching section OUT2 is turned off and all faults are

cleared.

– If EN2 > 2.4 V the switching section OUT2 is turned on.

If EN2 is connected to VREF2, the switching section OUT2 turns on after

the switching section OUT1 reaches regulation.

Power Good output signal for the section 2. This pin is an open drain output

and It is pulled down when the output of the switching section 2 is out of

+ 14% / - 10% of its nominal value.

Pulse skipping mode control input.

– If the pin is connected to VCC the PWM mode is enabled.

– If the pin is connected to GND, the pulse skip mode is enabled.

– If the pin is connected to VREF2 (or floating) the pulse skip mode is

enabled but and the switching frequency is kept higher than 33 kHz (No-

audible pulse skip mode).

Output voltage sense for the switching section 2.This pin must be directly

connected to the output voltage of the switching section. It provides also the

feedback for the switching section 2 when REFIN2 is tied to VREF3/VCC.

Positive current sense input for the switching section 2. It is possible to set a

threshold voltage that is compared with 1/10

th

of the GND-PHASE2 drop

during the off time.

Feedback input for the switching section 2:

– If this pin is connected to VCC, OUT2 operates at 3.3 V

– If this pin is connected to VREF3, OUT2 operates at 1.05 V

– If this pin is connected to an external reference from 0.7 V to 2.5 V, OUT2

works in tracking with this reference. Bypass REFIN2 to GND with a 100

nF capacitor.

Doc ID 15281 Rev 4 9/50

Electrical data PM6686

3 Electrical data

3.1 Maximum rating

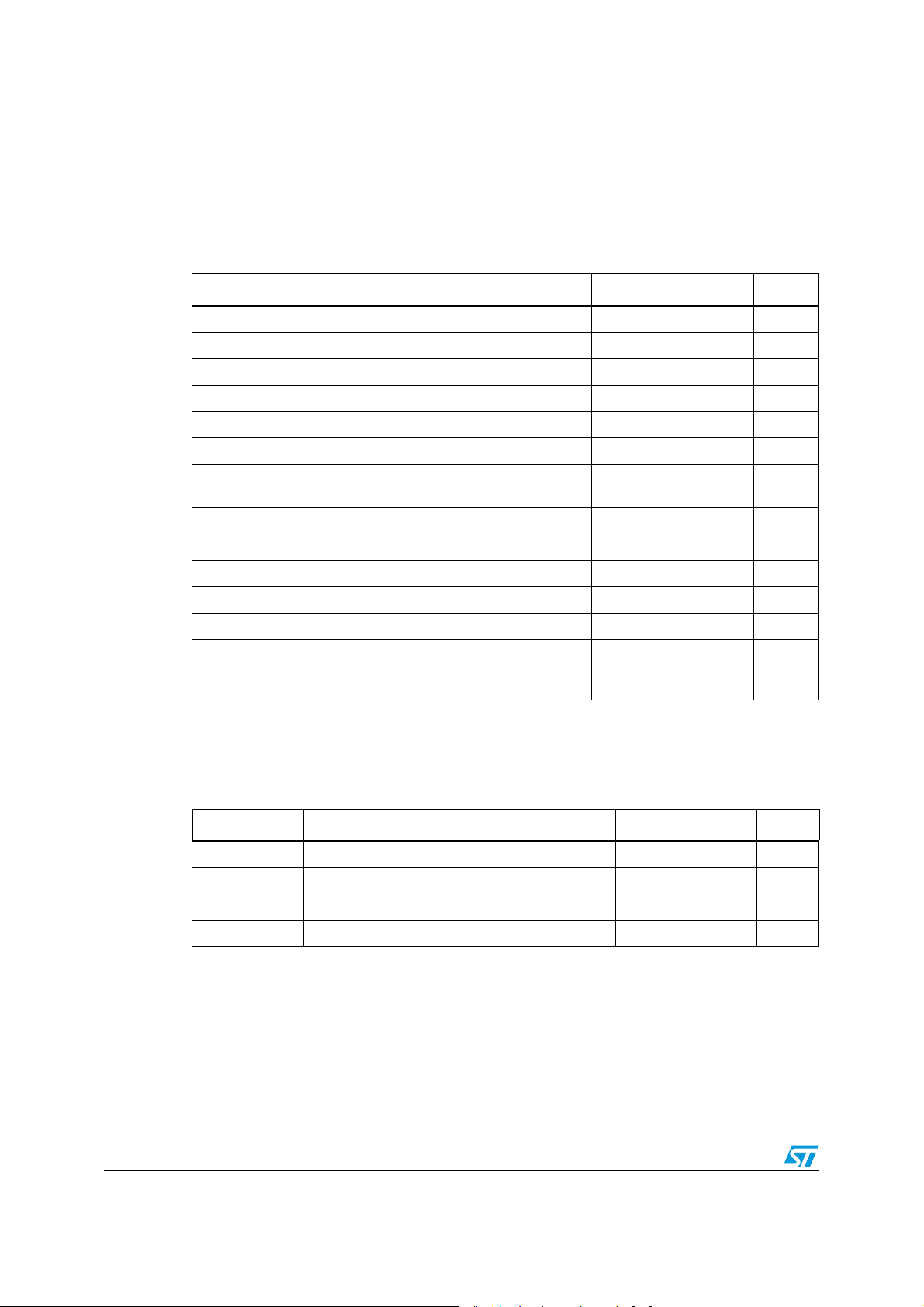

Table 3. Absolute maximum ratings

Parameter Value Unit

VIN to PGND -0.3 to 38 V

PHASEx to PGND -0.3 to 38 V

BOOTx to PHASEx -0.3 to 6 V

PVCC to PGND -0.3 to 6 V

HGATEx to PHASEx -0.3 to BOOTx +0.3 V

LGATEx, CP_FB to PGND -0.3 to PVCC +0.3 V

VCC, ENx, SKIP, PGx, LDO, REFIN2, OUTx, VREF3,

LDOREFIN, LDO_SW, TON to GND

FB1, ILIMx to GND -0.3 to VCC+0.3 V

EN_LDO to GND -0.3 to 7 V

-0.3 to 6 V

VREF2 to GND -0.3 to VREF3+0.3 V

PGND to GND -0.3 to +0.3 V

Power dissipation at T

Maximum withstanding voltage range test condition: CDF-AECQ100-002- “human body model” acceptance criteria: “normal

performance”

3.2 Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

T

J

T

STG

Operating ambient temperature range -40 to 85 °C

T

A

Thermal resistance junction to ambient 35 °C/W

Junction operating temperature range -40 to 125 °C

Storage temperature range -50 to 150 °C

= 25 °C 2 W

A

±1250 V

10/50 Doc ID 15281 Rev 4

PM6686 Recommended operating conditions

4 Recommended operating conditions

Table 5. Recommended operating conditions

Val ue

Symbol Parameter

Min Typ Max

VIN Input voltage range, LDO = 5 V in regulation 5.5 - 28 V

VCC VCC operative voltage range 4.5 - 5.5 V

REFIN2

REFIN2 voltage range with OUT2 in

adjustable mode, VIN = 5.5 V to 28 V

0.7 - 2.5 V

OUT1 OUT1 output voltage range 0.70 - 5.50 V

ILIM ILIM voltage range 0.2 - 2 V

Unit

LDOREFIN

LDO DC output current

(switchover function

enabled)

LDO DC output current

(switchover function

disabled)

LDOREFIN setting with LDO = 2 x LDOREFIN

(adjustable mode)

VIN = 5.5 V to 28 V, LDO_SW = 5 V,

LDOREFIN = GND

VIN = 5.5 V to 28 V, LDO_SW = 3.3 V,

LDOREFIN = VCC

VIN = 5.5 V to 28 V, LDO_SW = 0 V,

LDOREFIN = GND, VCC

0.35 - 2.25 V

- 200 mA

- 100 mA

- 100 mA

Doc ID 15281 Rev 4 11/50

Electrical characteristics PM6686

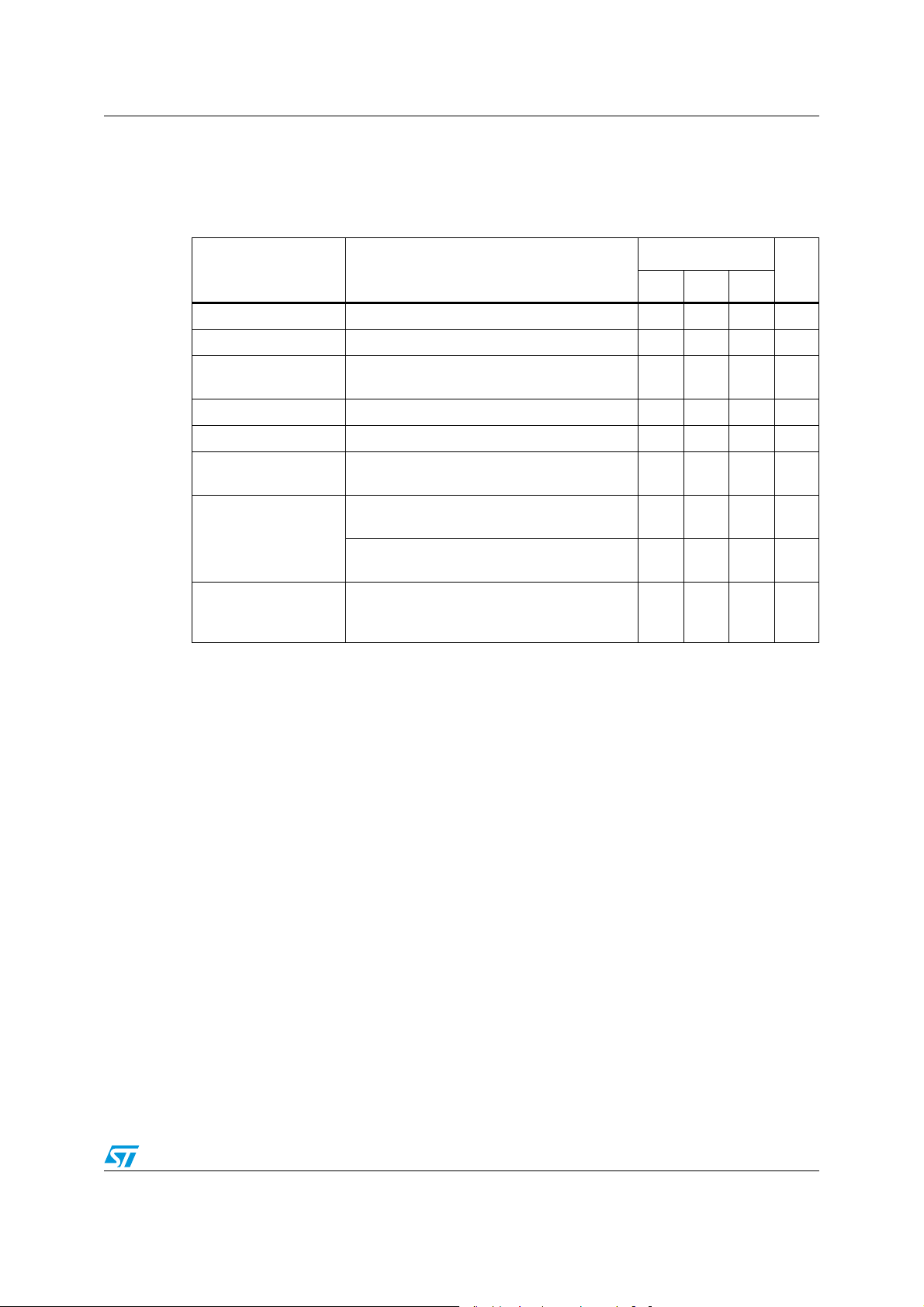

5 Electrical characteristics

VIN = 12 V, no load on LDO, OUT1, OUT2, VREF3, and VREF2. EN2 = EN1 = VCC,

LDO_SW = 5 V, PVCC = 5 V, EN_LDO = 5 V, T

Table 6. Electrical characteristics

Symbol Parameter Test condition Min Typ Max Unit

Switching controller output accuracy

= 25 °C unless otherwise specified)

J

OUT2 Output voltage

OUT1 Output voltage

FB1

Feedback accuracy with

OUT1 in adjustable mode

REFIN2 Accuracy referred to REFIN2

Current limit and zero crossing comparator

ILIM ILIM bias current T

Positive current limit threshold

Zero crossing current

threshold

VIN = 5.5 V to 28 V, REFIN2 = VCC,

SKIP = VCC

VIN = 5.5 V to 28 V,

REFIN2 = VREF3, SKIP = VCC

VIN = 5.5 V to 28 V, FB1 = VCC,

SKIP = VCC

VIN = 5.5 V to 28 V, FB1 = GND,

SKIP = VCC

3.25 3.330 3.397 V

1.038 1.05 1.062 V

1.482 1.500 1.518 V

4.975 5.050 5.125 V

VIN = 5.5 V to 28 V, SKIP = VCC 0.693 0.700 0.707 V

REFIN2 = 0.7 V to 2.5 V,

SKIP = VCC

= +25 °C. 4.5 5 5.5 µA

A

-1 1 %

Adjustable, VILIM = 0.5 V, GND-PHASE 35 50 65 mV

Adjustable, VILIM = 1 V or VCC, GNDPHASE

85 100 115 mV

Adjustable, VILIM = 2 V, GND-PHASE 180 200 220 mV

SKIP = GND, VREF2, or OPEN, GNDPHASE

-1 +11 mV

Switching frequency

OUT1 = 5.125 V

On-time pulse width

OUT2 = 3.368 V TON = GND 0.477 0.561 0.655

Minimum Off-time 350 472

No-audible skip mode

operating frequency

SKIP = VREF2(or OPEN) 25 33 kHz

Soft-start and soft-end

Soft-start ramp time 2 4 ms

12/50 Doc ID 15281 Rev 4

TON = GND or

VREF2

0.908 1.068 1.228

TON = VCC 1.815 2.135 2.455

TON = VCC or

VREF2

0.796 0.936 1.076

µs

PM6686 Electrical characteristics

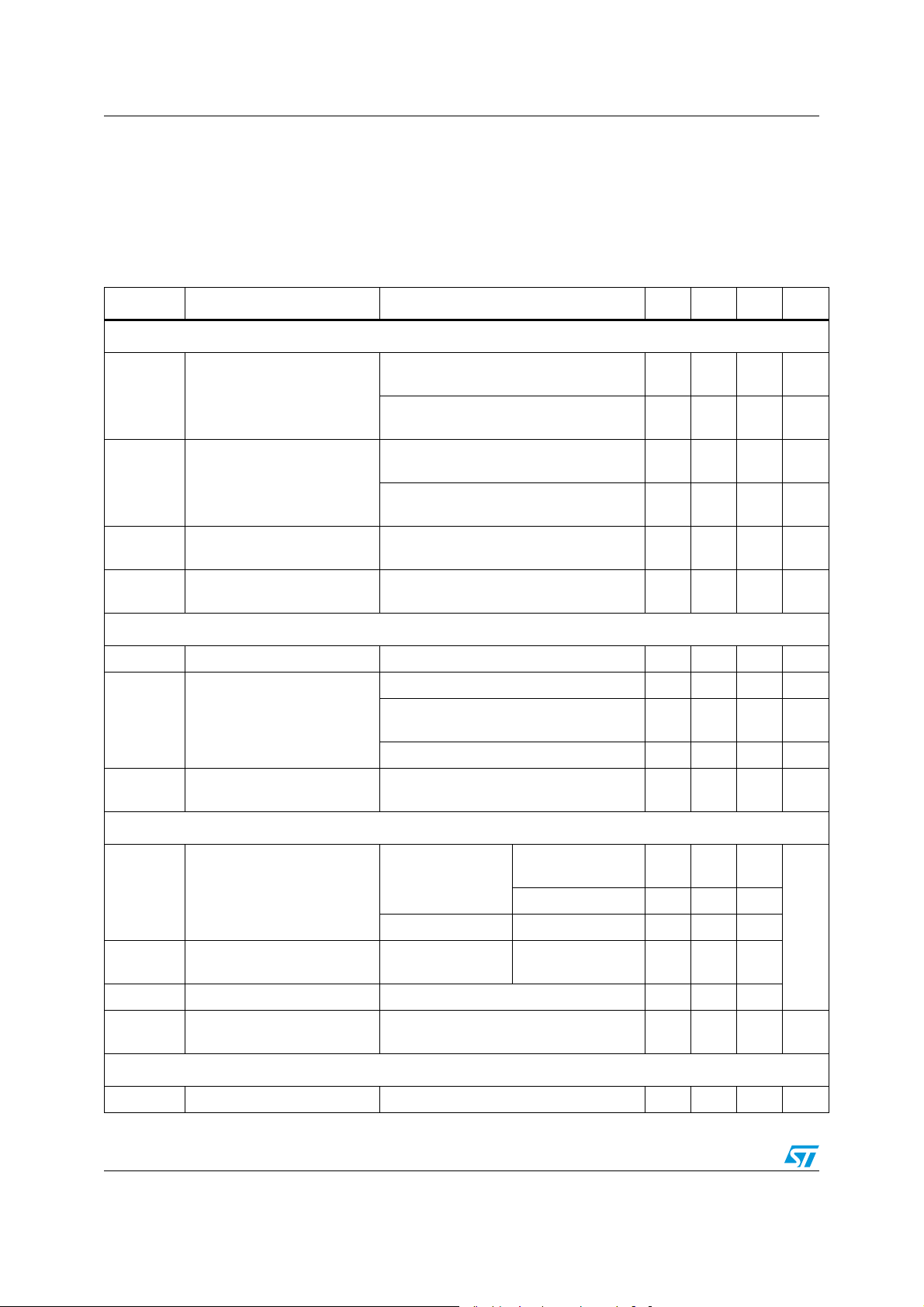

Table 6. Electrical characteristics (continued)

Symbol Parameter Test condition Min Typ Max Unit

Linear regulator and reference

LDO LDO output voltage

LDO_SW = GND, 5.5 V < VIN < 28 V,

LDOREFIN < 0.3 V, 0 < ILDO < 100 mA

LDO_SW = GND, 5.5 V < VIN < 28 V,

LDOREFIN = VREF3,

4.925 5.000 5.075 V

3.250 3.300 3.350 V

0 < ILDO < 100 mA

LDO accuracy in adjustable

mode

LDO short circuit current

(linear regulator enabled)

LDO_SW LDO_SW switch on threshold

LDO_SW LDO_SW hysteresis

VIN = 5.5 V to 28 V, LDOREFIN = 0.35 V

to 2.25 V, no load

-2.5 +2.5 %

LDO = 4.3 V, LDO_SW = GND 260 320 380 mA

LDO = 5 V, rising edge of LDO_SW,

LDOREFIN = GND

LDO = 5 V, falling edge of LDO_SW,

LDOREFIN = GND

4.64 4.75 4.84 V

200 400 mV

LDO = 5 V, rising edge of LDO_SW,

LDO_SW switch resistance

LDOREFIN = GND,

0.81 1.275 Ω

output current = 200 mA

VREF3 output voltage No load 3.235 3.300 3.365 V

VREF3

VREF3 current limit VREF3 = GND 22 30 mA

VREF2 VREF2 output voltage No load 1.980 2.000 2.02 V

VREF2 load regulation 0 < Load < 50 μA6mV

VREF2 sink current VREF2 > 2.030 V 10 µA

Fault management

VIN shutdown current EN1 and EN2 low, EN_LDO low 49 70 µA

VIN standby current

Operating power consumption

(VCC and VIN pins

consumption)

EN1 and EN2 low, EN_LDO high,

LDOREFIN = GND

Switching regulators on,

FB1 = SKIP = GND, REFIN2 = VCC,

LDOREFIN = GND,

OUT1 = LDO_SW = 5.3V, OUT2 = 3.5 V

132 180 µA

4,3 6,5 mW

Rising edge of PVCC 4.33 V

PVCC UVLO threshold

Falling edge of PVCC 4 V

Referred to FB1 nominal regulation point +11 %

Overvoltage trip threshold

Referred to REFIN2 nominal regulation

point. worst case:REFIN2 = 0.7 V

+14 %

PG threshold Lower threshold -13 -10 -7 %

PG low voltage ISink = 4 mA 159 235 405 mV

PG leakage current PG = 5 V 1 µA

Doc ID 15281 Rev 4 13/50

Electrical characteristics PM6686

Table 6. Electrical characteristics (continued)

Symbol Parameter Test condition Min Typ Max Unit

Output undervoltage

shutdown threshold

Inputs and outputs

FB1 FB1 logic level

REFIN2 REFIN2 logic level

LDOREFIN LDOREFIN logic level

SKIP SKIP logic level

TON TON logic level

EN1,2 EN level

Referred to FB1, REFIN2 nominal

regulation point

67 70 73 %

fixed OUT1 = 5 V 0.528 V

fixed OUT1 = 1.5 V 4.1 V

fixed OUT2 = 1.05 V, VCC = 5 V

fixed OUT 2= 3.3 V, VCC = 5 V

VREF3

VCC-

0.838

fixed LDO = 5 V 0.4 V

fixed LDO = 3.3 V 2.43 V

Pulse skip mode 0.8 V

No audible skip mode (VREF2 or floating)

VREF2 V

PWM mode 2.4 V

Low level 0.8 V

Middle level

VREF2

High level 2.4 V

Switching regulators off level 0.8 V

Delay start level

VREF2 V

Switching regulators on level 2.4 V

V

V

V

EN_LDO EN_LDO level

Input leakage current FB1 = 0.7 V -1 +1 µA

Internal bootstrap diode

Diode forward voltage PVCC = -BOOT, Idiode = 10 mA 0.2 V

Diode Leakage current BOOT= 30 V, PHASE = 28 V, PVCC = 5 V 500 nA

High-side and low-side gate drivers

HGATE driver on-resistance

LGATE driver on-resistance

Linear regulator off level 0.905 1.00 1.050 V

Linear regulator on level 1.500 1.6 1.650 V

REFIN2 = 2.5 V 12

HGATEx high state (pull-up)

Isource = 100 mA

HGATEx low state (pull-down)

Isink = 100 mA

LGATEx high state (pull-up)

Isource = 100 mA

LGATEx low state (pull-down)

Isink = 100 mA

1.8

1.3 1.9

1.3

0.6 0.8

Ω

14/50 Doc ID 15281 Rev 4

PM6686 Typical operating characteristics

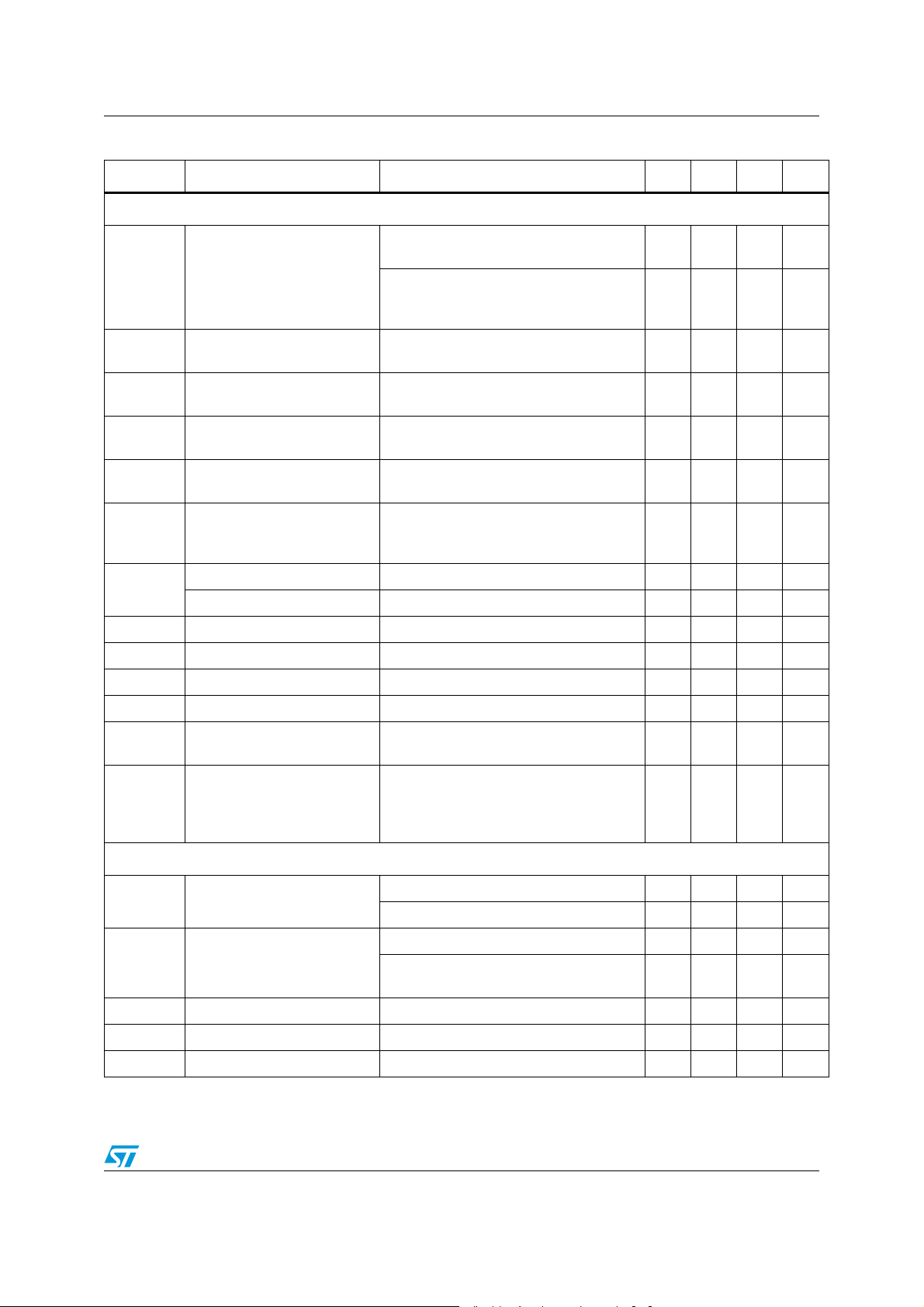

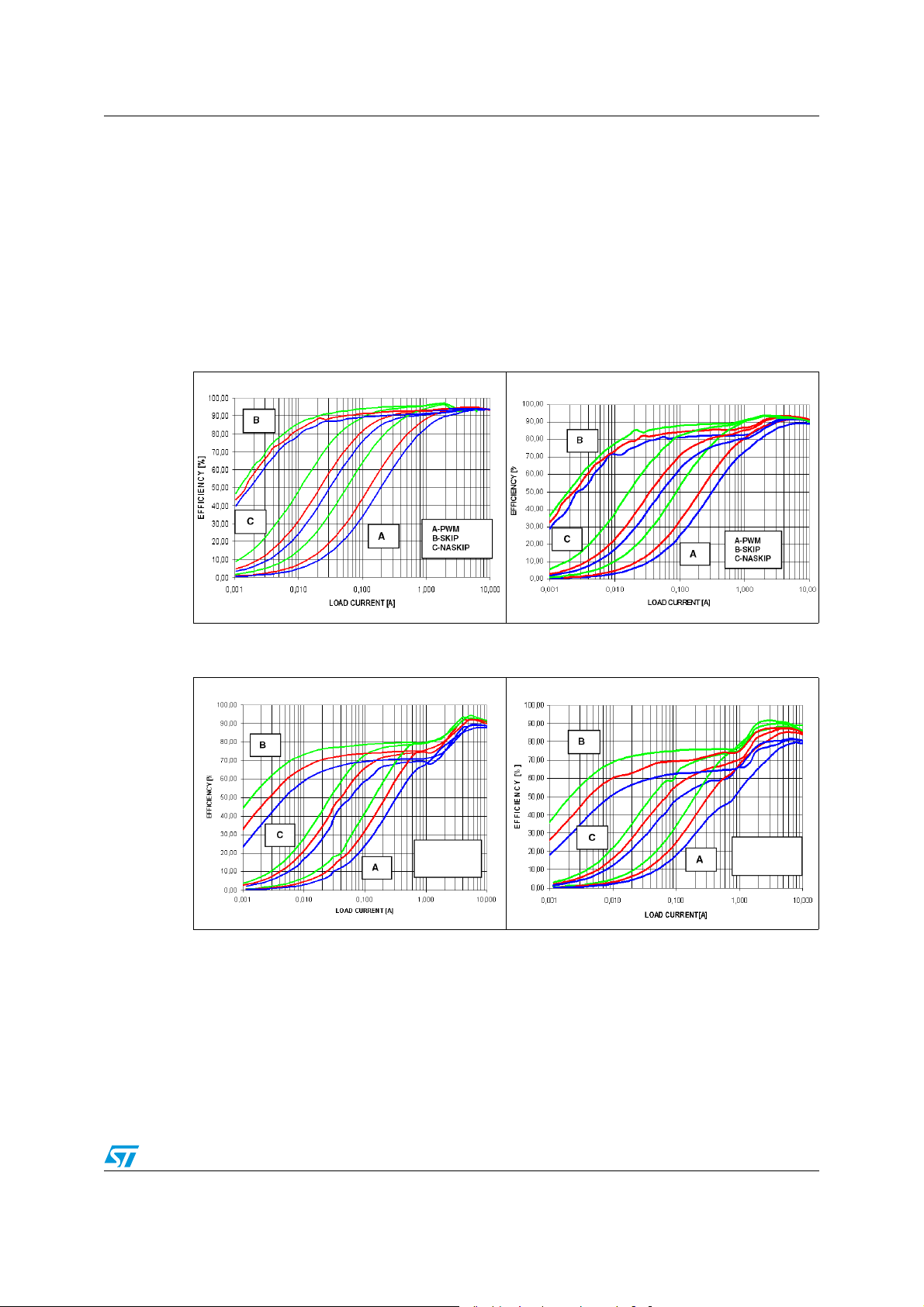

6 Typical operating characteristics

(TON = VCC (200 / 300 kHz), SKIP = GND (skip mode), LDOREFIN = SGND (LDO = 5 V),

LDO_SW = OUT1, PVCC connected to LDO, V

load unless specified). Measures performed on the demonstration kit (PM6686_SYSTEM

and PM6686_CHIPSET)

Efficiency traces: Green: VIN = 7 V, red: VIN = 12 V, blue: VIN = 19 V.

= 12 V, EN1-EN2-EN_LDO are high, no

IN

Figure 3. Efficiency vs load

OUT1 = 5 V, T

= VCC

ON

Figure 5. Efficiency vs load

OUT1 = 1.5 V, T

ON

= VCC

Figure 4. Efficiency vs load

OUT2 = 3.3 V, TON = VCC

Figure 6. Efficiency vs load

OUT2 = 1.05 V, TON = VCC

A-PWM

B-SKIP

A-NASKIP

A-PWM

B-SKIP

A-NASKIP

Doc ID 15281 Rev 4 15/50

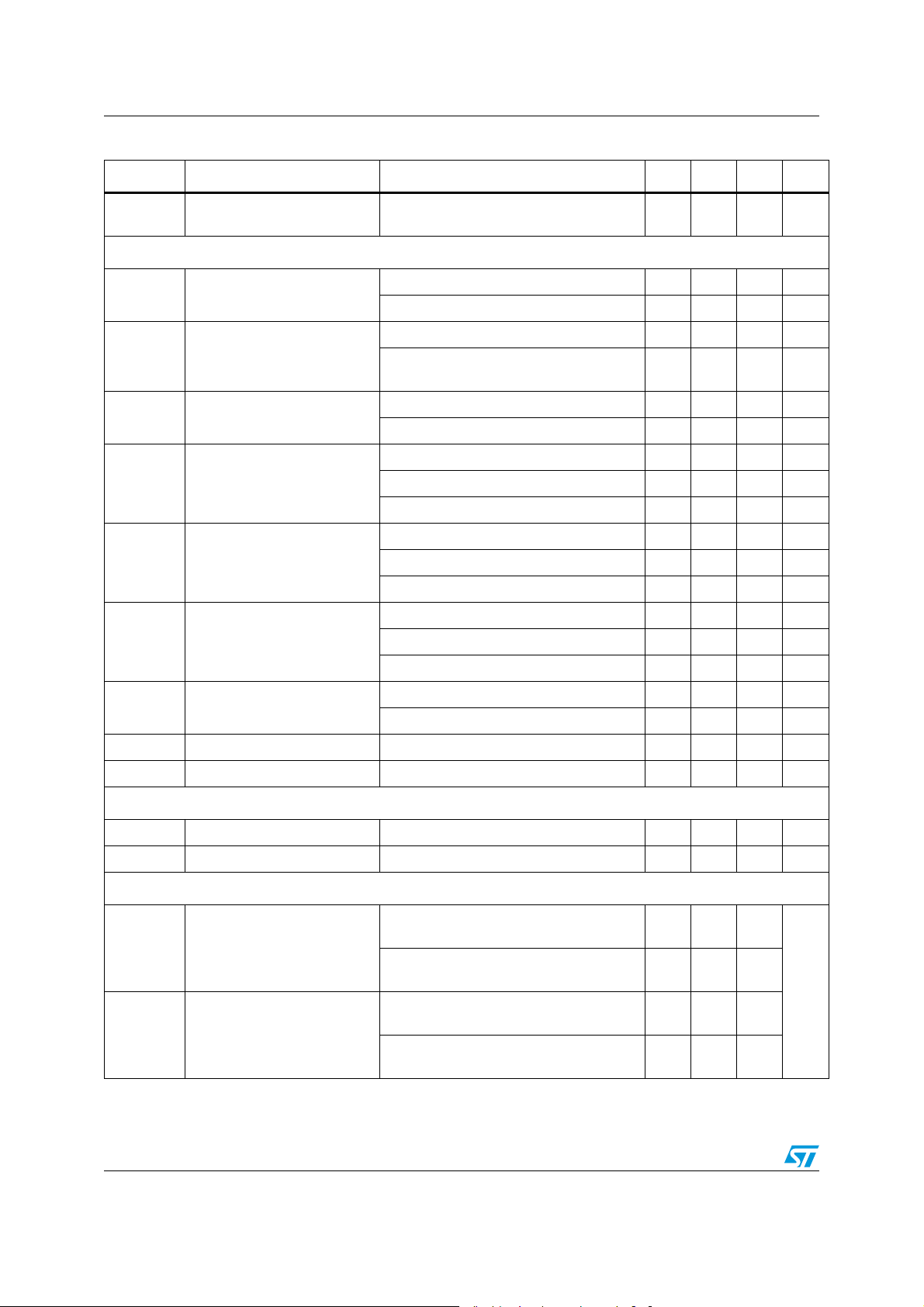

Typical operating characteristics PM6686

Figure 7. Load regulation

OUT1 = 5 V, T

= VCC

ON

Figure 9. Load regulation

OUT1 = 1.5 V, T

= VCC

ON

Figure 8. Load regulation

OUT2 = 3.3 V, T

Figure 10. Load regulation

OUT2 = 1.05 V, TON = VCC

ON

= VCC

Figure 11. Switching frequency vs load

OUT1 = 5 V, T

16/50 Doc ID 15281 Rev 4

= VCC

ON

Figure 12. Switching frequency vs load

OUT2 = 3.3 V, TON = VCC

PM6686 Typical operating characteristics

Figure 13. Section 1 line regulation

OUT1 = 5 V, T

= VCC

ON

Figure 15. Section 1 line regulation

OUT1 = 1,5 V, T

ON

= VCC

Figure 14. Section 2 line regulation

OUT2 = 3.3 V, TON = VCC

Figure 16. Section 2 line regulation

OUT2 = 1,05 V, TON = VCC

Figure 17. Stand-by mode input battery

current vs input voltage

Figure 18. Shut-down mode input

battery current vs input

voltage

EN1=EN2=GND

FN_LDO=GND

Doc ID 15281 Rev 4 17/50

Typical operating characteristics PM6686

Figure 19. PWM no load input currents

vs input voltage

Figure 21. NA SKIP no load input

currents vs input voltage

Figure 20. SKIP no load input currents

vs input voltage

Figure 22. VREF3 load regulation

Figure 23. VREF2 load regulation Figure 24. LDO = 3.3 V load regulation

18/50 Doc ID 15281 Rev 4

PM6686 Typical operating characteristics

Figure 25. LDO = 5 V load regulation

6.1 Screen shots

Typical operating characteristic (T

= VCC (200 / 300 kHz), SKIP = GND (skip mode),

ON

FB1 = GND (OUT1 = 5 V), REFIN2 = VCC (OUT2 = 3.3 V), LDOREFIN = SGND

(LDO = 5 V), CP_FB = floating, LDO_SW = OUT1, PVCC connected to LDO, VIN = 12 V,

EN1-EN2-EN_LDO are high, no load unless specified)

Figure 26. OUT1 soft-start no load Figure 27. OUT2 soft-start no load

Doc ID 15281 Rev 4 19/50

Typical operating characteristics PM6686

Figure 28. OUT1 soft-start 8 A constant

Figure 30. OUT1 soft-end, no load Figure 31. OUT2 soft-end, no load

current load

Figure 29. OUT2 soft-start loaded 8 A

constant current load

Figure 32. OUT1 soft-start, EN2 = VREF2

20/50 Doc ID 15281 Rev 4

no loads applied

Figure 33. OUT2 soft-start, EN1=VREF2

no loads applied

PM6686 Typical operating characteristics

Figure 34. Soft-end, EN2 = VREF2 no

loads applied

Figure 36. Load transient 0-5 A 2 A/µs

OUT1 = 5 V PWM mode

Figure 35. Soft-end, EN1=VREF2 no

loads applied

Figure 37. Load transient 0-5 A 2 A/µs

OUT1 = 5 V SKIP mode

Figure 38. Load transient 0-5 A 2 A/ µs

OUT1 = 1.5 V PWM mode

Figure 39. Load transient 0-5 A 2 A/ µs

OUT1 = 1.5 V SKIP mode

Doc ID 15281 Rev 4 21/50

Typical operating characteristics PM6686

Figure 40. Load transient 0-5 A 2 A/µs

OUT2 = 3.3 V PWM mode

Figure 42. Load transient 0-5 A 2 A/ µs

OUT2 = 1.05 V PWM mode

Figure 41. Load transient 0-5 A 2 A/µs

OUT2 = 3.3 V SKIP mode

Figure 43. Load transient 0-5 A 2 A/ µs

OUT2 = 1.05 V SKIP mode

22/50 Doc ID 15281 Rev 4

PM6686 Block diagram

7 Block diagram

Figure 44. Functional block diagram

LD OR EFI N

LDO

LD O_ SW

CP_FB

BOOT1

HGAT E1

PHASE1

OU T1

UVLO

VREF3

+

-

VREF3 VREF2

VIN

VREF2

ADJ.

LIN EAR

REGUL ATOR

LDO EN INT

SWITCHOVER

+

THRE SH OLD

-

PVC C PVCC

LEVEL

SHIFTER

SM PS1

CONTROLLER

SMPS2

CONTROLLER

PVCC

LEV EL

SHIFTE R

PVCC

PVCC

VCC

ILIM1

ILIM2

BOOT2

HSIDE2

PHASE2

OU T2

LGA TE2

LGATE1

FB1

PG1

EN1

EN2

STARTUP

CONTROLLER

LDO EN INT

THER MAL

CONTROLLER

REFIN2

PG2

EN _LDO

TON SKIP

Doc ID 15281 Rev 4 23/50

Device description PM6686

8 Device description

The PM6686 is a dual step down controller dedicated to provide logic voltages for notebook

computers. It offers several operating configurations: it combines two synchronous buck

controllers, an internal linear regulator (LDO), two voltage references and a charge pump

controller.

Each buck controller is based on constant on time (COT) architecture. This type of control

offers a very fast load transient response with a minimum external components count.

The two switching sections (SMPS) generate two output voltages OUT1 and OUT2 that

regulate adjustable voltages. A fixed output voltage configuration can also be selected,

reducing further the external components count because no external resistor divider is

needed.

In fixed mode, OUT1 provides 5 V or 1.5 V; in adjustable mode OUT1 can regulate an output

voltage between 0.7 V and 5.5 V. In fixed mode, OUT2 provides 3.3 V or 1.05 V, in

adjustable mode OUT2 can regulate an output between 0.7 V to 2.5 V by tracking an

external reference.

The switching frequencies of both switching controllers can be adjusted to 200 kHz/300 kHz,

400 kHz/300 kHz or 400 kHz/500 kHz respectively. To maximize the efficiency at light loads

a pulse skipping mode can be selected. Moreover a pulse skipping mode with a minimum

switching frequency of 33 kHz (non audible skip operation mode) can be selected to avoid

audible noise issue. The linear regulator can provide a fixed (5 V or 3.3 V) or an adjustable

output voltage. In order to reduce the power consumption the internal LDO can be turned off

and the LDO output can be supplied with an external voltage applied at LDO_SW pin

(switch-over function).

The PM6686 supplies two voltage references: 3.3 V and 2 V. The charge pump controller

can be programmed to regulate a 14 V output. The switching sections and the LDO have

independent enable signals. Moreover the switching sections have a selectable power up

sequence and a turn off management.

The device is protected against overvoltage, undervoltage and over temperature. Two

independent Power Good signals monitor the output voltage range of each switching

sections.

8.1 Switching sections

8.1.1 Output voltage set up

The switching sections can be configured in several ways.

OUT1 output voltage is configured with FB1 pin. If FB1 pin is tied to GND the PM6686

regulates 5 V while if FB1 is connected to VCC the controller set OUT1 at 1.5 V. Using an

external resistor divider the output can be adjusted following this equation:

Equation 1

1R

⎛

V7,0V

1OUT

⎜

⎝

⎞

+⋅= 1

⎟

2R

⎠

24/50 Doc ID 15281 Rev 4

PM6686 Device description

Figure 45. Resistor divider to configure the output voltage

VOUT

CO UT

L

R1

PHASE

FB1

R2

Where R1, R2 are the resistors of the FB1 pin divider, as shown in Figure 2.

OUT2 output voltage is programmed with REFIN2 pin. Fixed output voltage is selected

connecting REFIN2 to VREF3 (OUT2 = 1.05 V) or to VCC (OUT2 = 3.3 V).

When the REFIN2 voltage is between 0.7 V and 2.5 V, OUT2 output voltage tracks REFIN2

voltage. When REFIN2 is lower than 0.5 V the section is turned OFF.

Table 7. Switching output voltages configuration

Output control pin

Control pin

connected to

Operation mode Output voltage

GND Fixed 5 V

VCC Fixed 1.5 V

OUT1 FB1

Resistor divider Adj

1R

⎛

V7.0V

1OUT

⎜

⎝

⎞

+⋅= 1

⎟

2R

⎠

VCC Fixed 3.3 V

OUT2 REFIN2

VREF3 Fixed 1.05 V

Ext source Tracking =REFIN2

Doc ID 15281 Rev 4 25/50

Device description PM6686

8.1.2 Constant on time control (COT)

PM6686 implements a pseudo-fixed frequency algorithm using the COT architecture. The

two sections are completely independent with separated switching controllers (SMPS).

The COT architecture bases its algorithm on the output ripple derived across the output

capacitor's ESR. The controller has an internal on time (T

output voltage valley: when VOUT reaches the regulation value a new T

duration is given by the following equation:

Equation 2

V

OUT

KT ⋅=

ON

V

IN

) generator triggered on the

ON

starts. The TON

ON

Where TON is the on time duration, K is a constant, V

is the sensed output voltage and

OUT

VIN is the input voltage.

The duty cycle in a buck converter is:

Equation 3

T

ON

T

SW

V

OUT

D

==

V

IN

The switching frequency in continuous current mode (CCM) is:

Equation 4

V

OUT

f

SW

D

T

ON

V

IN

==

V

OUT

⋅

K

V

1

=

K

IN

The switching frequency is theoretically constant, but in a real application it depends on

parasitic voltage drops that occur during the charging path (high-side switch resistance,

inductor resistance (DCR)) and discharging path (low-side switch resistance, DCR). As a

result the switching frequency increases as a function of the load current. The following

table shows the switching frequencies that can be selected through TON pin:

Table 8. Frequency configurations

SMPS 1 SMPS 2

TON

Frequency K Frequency K

VCC 200 kHz 5 µs 300 kHz 3.33 µs

VREF2 or open 400 kHz 2.5 µs 300 kHz 3.33 µs

26/50 Doc ID 15281 Rev 4

GND 400 kHz 2.5 µs 500 kHz 2 µs

PM6686 Device description

The COT architecture uses a minimum off-time (T

OFFMIN

) to allow inductor valley current

sense on the synchronous switch and to allow the charge of the bootstrap capacitor. A

minimum on-time is also introduced to assure the start-up sequence.

An adaptive anti-cross conduction algorithm avoids current paths between V

and GND

IN

during switching transition.

The PM6686 has three different operation modes selectable with SKIP pin: forced PWM

(PWM), pulse SKIP (SKIP) and non audible pulse SKIP (NA SKIP). The following

paragraphs explain in details the different features of these operation modes.

Table 9. Operative mode configurations

Control pin

SKIP

Control pin

connected to

Operation mode

VCC PWM

GND SKIP

VREF2 or floating NA SKIP

Figure 46. Constant on time block diagram

Toff min

BOOT

ILIM

OU T

VIN

1/10

PHA SE

Vol tag e

Reference

+

-

0,8V

-

+

PWM

Comparator

+

-

Z.C.

Comparator

-

SE T

Q

S

Q

R

CLR

Ton

ge ne ra tor

Level

Shifter

SE T

Q

S

Q

R

CLR

-

+

HS Driver

0,25V

-

-

+

-

PVCC

LS Driver

HGATE

PH ASE

0,5V

LGATE

PG ND

Doc ID 15281 Rev 4 27/50

Device description PM6686

f

t

8.1.3 PWM

PWM implements the continuous current mode (CCM). During TON, the high-side MOSFET

is turned on and the inductor current starts increasing. When the Ton is elapsed the highside MOSFET is turned off and after a dead time during which neither MOSFET conducts,

the low-side MOSFET turns on. The inductor current decreases until these three conditions

are verified:

● Output voltage reaches the regulation voltage

● Inductor current is below the current limit

● T

OFFMIN

When these conditions are satisfied a new T

PWM operation mode has a quasi-constant switching frequency, avoiding any audible noise

issue and the continuous current mode assures better load transitions despite of a lower

efficiency at light loads.

Figure 47. Inductor current and output voltage in PWM mode

Inductor

current

is elapsed

ON

starts.

Output

voltage

Vreg

Ton Tof

28/50 Doc ID 15281 Rev 4

PM6686 Device description

T

T

8.1.4 SKIP

To improve the efficiency at light load the PM6686 implements pulse skip operation mode.

When SKIP pin is tied to GND the inductor current is sensed and if it is equal to zero the

synchronous MOSFET is turned off. As a consequence the output capacitor is left floating

and the discharge depends only on the current sourced by the load. The new T

when the output reaches the voltage regulation. As a consequence at light load conditions

the switching frequency decreases improving the total efficiency of the converter. Working in

discontinuous current mode, the switching and the conduction losses are decreased

skipping some cycles.

If the output load is high enough to make the system work in CCM, skip mode is

automatically changed in PWM mode.

Figure 48. Inductor current and output voltage in SKIP mode

Inductor

current

Output

ON

starts

Vreg

ON

OFF

8.1.5 Non audible SKIP (NA SKIP)

To avoid audio noise the NA SKIP operation mode can be selected, connecting SKIP pin to

VREF2 or leaving it floating. In this condition if a new cycle doesn't start within 30

from the previous one the PM6686 turns on the low-side MOSFET to discharge the output

capacitor. The inductor current goes negative until the output reaches the voltage regulation

voltage allowing a new cycle to begin. If the switching frequency is above 33 kHz the device

works in SKIP mode.

This operation mode is useful to avoid audio noise but it lowers the efficiency at light loads if

it is compared to the SKIP mode.

μs typ.

Doc ID 15281 Rev 4 29/50

Device description PM6686

T

T

T

⋅⋅=

Figure 49. Inductor current and output voltage in NA SKIP mode

Inductor

cu rren t

Ou tput

Vreg

MA X

TON

OFF

IDLE

8.1.6 Gate drivers and logic supply

The integrated high-current drivers allow the use of different power MOSFET.

high-side driver is supplied with a bootstrap circuit with an integrated bootstrap diode. The

BOOT and the PHASE pins work respectively as supply and return rails for the HS driver.

The PVCC pin is the input for the supply of the low-side driver and PGND is the pin used as

return rail.

The PM6686 implements an anti-cross conduction protection which prevents high-side and

low-side MOSFET from being on at the same time.

The power dissipation of each driver can be calculated as:

Equation 5

Where V

The power dissipated by the drivers can be reduced lowering the sections switching

frequencies and mounting MOSFET with smaller Q

VCC pin is the input voltage rail to supply the internal logic circuit. This pin is connected

internally with a resistor to PVCC. As usual analog supply should be divided by the power

supply with a low pass filter to reduce the noise for the analog supply of the logic. Being the

resistor integrated it is enough to put a decoupling capacitor near VCC pin to realize the

filter with a components count reduction.

is the voltage applied to PVCC pin (+5 V) and fSW is the switching frequency.

PVCC

t

fQVP

swGPVCCDISS

.

G

30/50 Doc ID 15281 Rev 4

PM6686 Device description

Figure 50. Internal supply diagram

8.1.7 Current sensing and current limit

The PM6686 implements a positive valley current limit to protect the application from an

overcurrent fault. Each section has an independent current limit setting. A new switching

cycle can't start until the inductor current is under the positive current limit threshold. Note

that the peak current flowing in the inductor can reach a value greater than the current limit

threshold by an amount equal to the inductor ripple current.

Figure 51. Current waveforms in current limit conditions

The inductor current is sensed during the off time T

across the low-side MOSFET using the R

PGND voltage). The voltage drop is compared to the threshold set with ILIM pin. If ILIM is

connected to a voltage higher than VCC-1V the limit is 100mV. A current of 5 µA is sourced

from the pin ILIM; if a resistor is connected between ILIM and ground the current limit is

given by the voltage at the ILIM pin. The device sets the PHASE voltage threshold at 1/10 of

the ILIM voltage.

by measuring the voltage drop

OFF

as a lossless sensing element (PHASE to

DS(on)

Doc ID 15281 Rev 4 31/50

Device description PM6686

Figure 52. Current limit circuit block diagram

5uA

ILIM

RILIM

+

-

HGATE

9R

R

+-

Ton

Generator

PHASE

LGATE

Table 10. Current limit configuration

Control pin Control pin voltage Threshold SET

= VCC-1 V 100 mV

V

ILIM1

ILIM2

ILIM

0.2 V = V

V

= 5µA * R

ILIM

ILIM

= 2 V

ILIM

V

/10

ILIM

A negative current control is also implemented: the low-side MOSFET is forced off when the

current exceeds the negative limit. This function prevents the excessive negative inductor

current during the PWM operating mode. The threshold is set approximately at the 120% of

the positive current limit.

8.1.8 Soft-start and soft-end

The two sections have independent enable pins, EN1 and EN2. A not programmable softstart procedure takes place when EN pin rises above 2.4 V typ.

To prevent high input inrush currents, the current limit is increased from 25% to 100% with

steps of 25%.

The procedure is not programmable and ends typically in 2.8 ms. The overvoltage protection

is always active while the undervoltage protection is enabled typically 20 ms after the

beginning of the soft-start procedure.

Driving one EN pin below 0.8 V makes the section perform a soft-end: gate driving signals

32/50 Doc ID 15281 Rev 4

are pulled low and the output is discharged through an internal MOSFET with R

28

Ω typ.

A power up sequence for the switching sections can be selected connecting one EN pin to

VREF2.

DS(on)

of

PM6686 Device description

The section with the EN pin connected to VREF2 begins the soft-start only when the other

section is in regulation (its PGOOD is high) and makes a soft-end suddenly when the other

section is turned off.

Figure 53. VOUT2 behavior if EN2 is connected to VREF2

EN1

VOUT 1

PGO OD1

OUT 2

To protect the EN1, EN2, EN_LDO and SKIP pin of the PM6686 an external divider or a

series resistor is required, in order to prevent a large inrush current flowing into the device in

case the voltage spike is exceeding the recommended operating conditions.

Doc ID 15281 Rev 4 33/50

Monitoring and protections PM6686

9 Monitoring and protections

The PM6686 controls its switching output to prevent any damage or uncontrolled working

condition.

The device offers also PGOOD signals to monitor the state of each switching output voltage.

PGOOD is an open drain output: it is pulled low if the output voltage is below the 90% or

above the OVP threshold. of the nominal value.

9.1 Overvoltage protection

PM6686 provides a latched overvoltage protection (OVP). If the output voltage rises above

the +111% typ. for section 1 and above the +116% typ. for the section 2, a latched OVP

protection is activated. The controller tries to pull down the output voltage down to 0 V,

working in PWM. The current is limited by the negative current limit. The low-side MOSFET

is kept on when the output voltage is about 0 V. This management avoids high negative

undervoltage of the output rail that may damage the load.

The protection is latched and this fault is cleared toggling cleared by toggling EN or by

driving PVCC<3.979V and then PVCC>4.025V (PVCC Power On Reset).

9.2 Undervoltage protection

If during regulation the output voltage droops under the 70% of the nominal value, an

undervoltage latched fault is detected. The controller performs a soft-end procedure (see

“soft-start and soft-end” paragraph). The undervoltage fault is cleared by toggling EN or by

driving PVCC<3.979V and then PVCC>4.025V (PVCC power on reset).

9.3 PVCC monitor

The device monitors the driver supply voltage at PVCC pin. The switching sections can start

operating only if the voltage at PVCC pin is above 4,025 V typ. If PVCC falls below 3,979 V

typ., both the switching sections are turned off until the PVCC voltage goes over 4,025 V typ.

Table 11. Faults management summary

Fault Condition Device reaction

Overvoltage

section1

Overvoltage

section 2

Undervoltage V

PVCC

undervoltage

>+111%

V

OUT

>+116%

V

OUT

OUT

PVCC<3,979 V

<70%

Negative current limit protection activated. Low-side MOSFET is turned on when

the output voltage is about 0 V. Latched fault, cleared by toggling EN or by driving

PVCC<3.979V and then PVCC>4.025V (PVCC POR).

Negative current limit protection activated. Low-side MOSFET is turned on when

the output voltage is about 0 V. Latched fault, cleared by toggling EN or by driving

PVCC<3.979V and then PVCC>4.025V (PVCC POR).

The controller performs a soft-end. Latched fault cleared by toggling EN or by

driving PVCC<3.979V and then PVCC>4.025V (PVCC POR).

The controller turns off the switching sections. All faults of switching sections are

cleared. Not latched fault

34/50 Doc ID 15281 Rev 4

PM6686 Monitoring and protections

9.4 Linear regulator section

The PM6686 has an integrated linear regulator (LDO) that can provide an average of

100 mA typ. with a peak current of 270 mA typ. The LDO can be enabled using EN_LDO

pin. If VIN is applied the linear regulator is active even if PVCC is low.

The output voltage can be programmed by LDOREFIN pin. If LDOREFIN pin is tied to

ground (GND) the LDO provides a +5 V output voltage. If it is connected to VREF3 pin the

LDO regulates 3.3 V. If the voltage at the LDOREFIN pin is between 0.35 V and 2.25 V the

LDO generates an output voltage equals to 2xV

LDOREFIN

Table 12. LDO output voltage configuration

LDOREFIN voltage LDO voltage

GND +5 V

VREF3 +3,3 V

0,35 V < V

LDOREFIN

< 2,25 V 2x V

The controller provides a switchover function when LDOREFIN pin is connected to VCC or

GND. If the voltage at LDO_SW pin is high enough, the internal linear regulator is turned off

and the LDO pin is connected with an internal MOSFET to the LDO_SW pin. This feature

decreases the power dissipation of the device.

.

LDOREFIN

When the switchover function is used the maximum current capability is 200 mA if LDO

output is +5 V and 100 mA if the LDO output is +3.3 V.

Table 13. LDO switchover management

V

LDOREFIN

V

BYPLDO_SW

V

LDO

Internal LDO

< 0,35 V > 4,75 V +5 V Disabled 0.81 Ω

< 0,35 V < 4,55 V +5 V Enabled -

> 2.43 V > 3.18 V +3,3 V Disabled 1.12 Ω

> 2.43 V < 3.05 V +3,3 V Enabled -

0,35 V < V

LDOREFIN

< 2,25 V 2x V

LDOREFIN

Enabled -

Switchover

resistance

Doc ID 15281 Rev 4 35/50

Monitoring and protections PM6686

−+=

9.5 Charge pump

The PM6686 can drive an external charge pump circuit whose typical application schematic

is shown in the next figure.

Figure 54. Charge pump application circuit

COU T

Vout

L

D1

D2

D3

C2

CP

C4

D4

C1

C3

PHASE

LGAT E

R1

CP_F B

R2

The charge pump works in 4 phases:

1. LGATE is low. C1 is charged through the D1a diode at OUT1 voltage minus the diode

drop.

2. LGATE is driven high and C1 transfers the charge to C2. C2 voltage is OUT1 voltage

plus the LGATE voltage minus the voltage drops on D1 and D2.

3. LGATE is turned low and C2 shares its charge with C3 thought D3.

4. LGATE becomes high and C3 can charge C4 thought diode D4.

Every diode used to transfer charge introduces a voltage drop that decreases the charge

pump output voltage.

Repeating this cycle several times makes the charge pump output voltage equals to:

Equation 6

V4V2VV

DIODE1LGATE1OUTCP

Where VCP is the charge pump output voltage, V

section 1, V

LGATE1

is the low-side MOSFET gate driving voltage and V

is the output voltage of the switching

OUT1

is the forward

DIODE

voltage droop of the diodes used in the application.

CP_FB pin must be connected to the output of the charge pump with a resistor divider;

when CP_FB pin droops below 2 V typ., OUT1 controller starts a NA SKIP cycle to boost the

voltage of the charge pump.

36/50 Doc ID 15281 Rev 4

PM6686 Monitoring and protections

The minimum voltage of the charge pump is:

Equation 7

FB_CPMIN_CP

Where V

is the minimum voltage of CP_FB pin(2V typ.).

CP_FB

In case the charge pump feedback is not used, leave the CP_FB pin floating or connect the

pin to VCC.

9.6 Voltage references

The PM6686 provides two voltage references.

The device regulates a 3,3 V voltage reference (VREF3) with ±2% accuracy over

temperature. VREF3 can source up to 5 mA. VREF3 voltage is always available if V

applied. The device allows the enabling of the outputs if VREF3 is above 2,8V typ. and turns

off when VREF3 falls under 2,7 V typ.

VREF2 is a + 2 V reference with an accuracy of ±1% over temperature. It can source up to

50 µA typ. and sink up to 10 µA. VREF2is adopted as internal reference; this voltage can be

used as voltage threshold to set configuration pins (e.g. TON, SKIP pins). VREF2 is enabled

when one enable pin (EN1, EN2 or EN_LDO) is pulled high.

9.7 General device fault management

⎛

⎜

⎜

⎝

⎞

R

1

⎟

1VV

+⋅=

⎟

R

2

⎠

is

IN

9.7.1 Thermal protection

If the internal temperature of the device exceeds typically +150 °C, the controller shuts down

immediately all the internal circuitry. Switching sections performs the soft-end management.

Toggling EN, EN LDO or cycling VIN resets the latched fault.

Doc ID 15281 Rev 4 37/50

Application information PM6686

10 Application information

10.1 External components selection

10.1.1 Inductor

Once that switching frequency is defined, inductor selection depends on the desired

inductor ripple current and load transient performance.

Low inductance means great ripple current and could generate great output noise. On the

other hand, low inductor values involve fast load transient response.

A good compromise between the transient response time, the efficiency, the cost and the

size is to choose the inductor value in order to maintain the inductor ripple current

between 20% and 50% of the maximum output current ILOAD (max). The maximum

occurs at the maximum input voltage. With these considerations, the inductor value can be

calculated with the following relationship:

Equation 8

ΔI

L

ΔI

L

VV

L

−

=

Δ×

Where fSW is the switching frequency, VIN is the input voltage, V

and

ΔI

is the selected inductor ripple current.

L

V

OUTIN

OUT

×

V

If

Lsw

IN

is the output voltage

OUT

In order to prevent overtemperature working conditions, inductor must be able to provide an

RMS current greater than the maximum RMS inductor current I

LRMS

:

Equation 9

(max))I(I

LOADLRMS

L

+=

12

2

(max))I(

Δ

2

Where ΔIL(max) is the maximum ripple current:

Equation 10

VV

−

sw

OUTmaxIN

Lf

×

(max)I ×

L

=Δ

V

OUT

V

maxIN

If hard saturation inductors are used, the inductor saturation current should be much greater

than the maximum inductor peak current Ipeak:

Equation 11

Using soft-saturation inductors it’s possible to choose inductors with saturation current limit

nearly to Ipeak.

Below there is a list of some inductor manufacturers.

38/50 Doc ID 15281 Rev 4

LOAD

(max)I

Δ

(max)IIpeak

L

+=

2

PM6686 Application information

Δ×=

Table 14. Inductor manufacturer

Manufacturer Series Inductor value (µH) RMS current (A) Saturation current (A)

COILCRAFT MSS-1048 3,3 7,22 7,6

COILCRAFT MSS-1260 3,3 9,7 7

COILCRAFT MLC-1550 2,5 16,5 11,4

10.1.2 Input capacitor

In a buck topology converter the current that flows into the input capacitor is a pulsed current

with zero average value. The input RMS current of the two switching sections can be roughly

estimated as follows:

Equation 12

Where D1, D2 are the duty cycles and I1, I2 are the maximum load currents of the two

sections.

Input capacitor should be chosen with an RMS rated current higher than the maximum RMS

current given by both sections.

Tantalum capacitors are good in term of low ESR and small size, but they occasionally can

burn out if subjected to very high current during the charge. Ceramic capacitors have

usually a higher RMS current rating with smaller size and they remain the best choice.

Below there is a list of some ceramic capacitor manufacturers.

Table 15. Input capacitor manufacturer

Manufacturer Series Capacitor value (µF) Rated voltage (V)

TAYIO YUDEN UMK325BJ106 KM-T 10 50

TAYIO YUDEN GMK325BJ106MN 10 35

10.1.3 Output capacitor

The selection of the output capacitor is based on the ESR value and on the voltage rating

rather than on the capacitor value Cout.

2

11CinRMS

2

221

)D1(ID)D1(IDI

−××+−××=

2

The output capacitor has to satisfy the output voltage ripple requirements. Lower inductor

value can reduce the size of the choke but increases the inductor current ripp

Since the voltage ripple V

RIPPLEout

is given by:

le ΔIL.

Equation 13

IRV

LoutRIPPLEout

A low ESR capacitor is required to reduce the output voltage ripple. Switching sections can

work correctly even with 15mV output ripple.

Doc ID 15281 Rev 4 39/50

Application information PM6686

Δ

Finally the output capacitor choice deeply impacts on the load transient response. Below

there is a list of some capacitor manufacturers.

Output capacitor manufacturer

Table 16. Input capacitor manufacturer

Manufacturer Series Capacitor value (µF) Rated voltage (V) ESR max (mΩ)

SANYO POSCAP TPB 150 to 330 2.5 to 6.3 35 to 65

SANYO POSCAP TPF 150 to 470 2.5 to 6.3 7 to 15

10.1.4 MOSFET

Logic-level MOSFETs are recommended, since low-side and high-side gate drivers are

powered by PVCC. Their breakdown voltage (VBRDSS) must be higher than the maximum

input voltage.

In notebook applications, power management efficiency is a high level requirement. The

power dissipation on the power switches becomes an important factor in switching

selections. Losses of high-side and low-side MOSFETs depend on their working conditions.

The power dissipation of the high-side MOSFET is given by:

Equation 14

PPP +=

switchingconductionDHighSide

Maximum conduction losses are approximately:

Equation 15

Where R

V

RP ××=

DSonconduction

is the drain-source on resistance of the high-side MOSFET.

DS(on)

OUT

V

LOAD

minIN

2

(max)I

Switching losses are approximately:

Equation 16

Δ

I

L

+×

2

××

ft)

swoff

2

P

switching

Where ton and t

I

=

LOADIN

are the switching times of the turn off and turn off phases of the

off

2

2

L

−×

(max)I(V

××

ft)

(max)I(V

LOADINswon

+

MOSFETs.

As general rule, high-side MOSFETs with low gate charge are recommended, in order to

minimize driver losses.

Below there is a list of possible choices for the high-side MOSFETs.

40/50 Doc ID 15281 Rev 4

PM6686 Application information

=

Table 17. High-side MOSFET manufacturer

Manufacturer Type Gate charge (nC) R

(mΩ) Rated reverse voltage (V)

DS(on)

ST STS12NH3LL 10 8 30

ST STS17NH3LL 18 4 30

The power dissipation of the low-side MOSFET is given by:

Equation 17

PP

conductionDLowSide

Maximum conduction losses occur at the maximum input voltage:

Equation 18

DSonconduction

Choose a synchronous rectifier with low R

⎛

⎜

1RP ×

−×=

⎜

V

⎝

DS(on)

⎞

V

OUT

maxIN

⎟

LOAD

⎟

⎠

2

(max)I

. When high-side MOSFET turns on, the

fast variation of the phase node voltage can bring up even the low-side gate through its

gate-drain capacitance CRSS, causing cross-conduction problems. Choose a low-side

MOSFETs that minimizes the ratio CRSS/CGS (CGS = CISS - CRSS).

Below there is a list of some possible low-side MOSFETs.

Table 18. Low-side MOSFET manufacturer

C

Manufacturer Type R

DS(on)

(mΩ)

C

RSS

GS

ST STS17NF3LL 5.5 0.047 30

ST STS25NH3LL 3.5 0.011 30

Rated reverse voltage

(V)

Dual N-channel MOSFETs can be used in applications with a maximum output current of

about 3 A. Below there is a list of some MOSFETs manufacturers.

Table 19. Dual MOSFET manufacturer

Manufacturer Type R

DS(on)

(mΩ)

Gate charge

(nC)

ST STS8DNH3LL 25 10 30

ST STS4DNF60L 65 32 60

Rated reverse voltage

(V)

Doc ID 15281 Rev 4 41/50

Diode selection PM6686

11 Diode selection

11.1 Freewheeling diode

A rectifier across the low-side MOSFET is recommended. The rectifier works as a voltage

clamp across the synchronous rectifier and reduces the negative inductor swing during the

dead time between turning the high-side MOSFET off and the synchronous rectifier on. It

can increase the efficiency of the switching section, since it reduces the low-side switch

losses. A Schottky diode is suitable for its low forward voltage drop (0.3 V). The diode

reverse voltage must be greater than the maximum input voltage. A minimum recovery

reverse charge is preferable. Below there is a list of some Schottky diode manufacturers.

Table 20. Schottky diode manufacturer

Manufacturer Series

ST STPS1L30M 0.34 30 0.00039

ST STPS1L20M 0.37 20 0.000075

11.2 Charge pump diode

The charge pump capacitors are fed by the current supplied by LGATE1 (output of the lowside driver for the section 1). Dual in package diodes, in series configuration, could be used

to reduce the area occupation.

Table 21. Schottky diode manufacturer

Manufacturer Series

ST BAT54S 0.24 40 0.3

ST BAR43A 0.35 30 0.1

ST BAS69-04 0.35 15 0.01

Forward voltage

(V)

Forward voltage

(V)

Rated reverse

voltage (V)

Rated reverse

voltage (V)

Reverse current

(μA)

Max forward

current (A)

42/50 Doc ID 15281 Rev 4

PM6686 Diode selection

11.3 Other important components

11.3.1 VIN filter

A VIN pin low pass filter is suggested to reduce switching noise. The low pass filter is shown

in the next figure:

Figure 55. VIN pin filter

Typical component value is: C = 1 µF.

11.3.2 PVCC and VCC

PVCC and VCC are connected with an internal resistor (about 10 Ω); this allows reducing

the external components. Connect the +5 V supply rail only to PVCC.

Use a bypass capacitor on PVCC pin. A VCC low pass filter helps to reject switching

commutations noise, this filter can be implemented simply adding a bypass capacitor on

VCC pin.

Figure 56. VCC and PVCC filters

Input

Voltage

VIN

C

C2

PVCC

C1

VC C

Doc ID 15281 Rev 4 43/50

Diode selection PM6686

Typical components values are: C1 = 1 µF and C2 = 1 µF.

11.3.3 VREF2 and VREF3 capacitors

A 10 nF to 100 nF ceramic capacitor on VREF2 pin must be added to ensure noise

rejection. If VREF3 voltage is not used the pin can be left floating, otherwise a 10 nF to 100

nF bypass ceramic capacitor should be mounted.

11.3.4 LDO output capacitors

Bypass the output of the linear regulator with 4,7 µF ceramic capacitor closer to the LDO

pin. In most applicative conditions the ceramic output capacitor can be enough to ensure

stability.

11.3.5 Bootstrap circuit

The external bootstrap circuit is represented in the next figure:

Figure 57. Bootstrap circuit

RBOOT

RBOOT

CBOOT

PHASE

L

The bootstrap circuit capacitor value CBOOT must provide the total gate charge to the highside MOSFET during turn on phase. A typical value is 100 nF.

A resistor RBOOT on the BOOT pin could be added in order to reduce noise when the

phase node rises up, working like a gate resistor for the turn on phase of the high-side

MOSFET. A typical value is R

BOOT

= 1 Ω.

44/50 Doc ID 15281 Rev 4

PM6686 PCB design guidelines

12 PCB design guidelines

The layout is very important in terms of efficiency, stability and noise of the system. It is

possible to refer to the PM6686 demonstration board for a complete layout example.

For good PC board layout follows these guidelines:

● Place on the top side all the power components (inductors, input and output capacitors,

MOSFETs and diodes). Refer them to a power ground plan, PGND. If possible, reserve

a layer to PGND plan. The PGND plan is the same for both the switching sections.

● AC current paths layout is very critical (see Figure 58). The first priority is to minimize

their length. Trace the LS MOSFET connection to PGND plan as short as possible.

Place the synchronous diode D near the LS MOSFET. Connect the LS MOSFET drain

to the switching node with a short trace.

● Place input capacitors near HS MOSFET drain. It is recommended to use the same

input voltage plan for both the switching sections, in order to put together all input

capacitors.

● Place all the sensitive analog signals (feedbacks, voltage references, current sense

paths) on the bottom side of the board or in an inner layer. Isolate them from the power

top side with a signal ground layer, SGND. Connect the SGND and PGND plans only in

one point (a multiple vias connection is preferable to a 0 Ω resistor connection) near the

PGND device pin. Place the device on the top or on the bottom size and connect the

exposed pad and the SGND pins to the SGND plan (see

● As general rule, make the high-side and low-side drivers traces wide and short.

● The high-side driver is powered by the bootstrap circuit. It’s very important to place

capacitor CBOOT as near as possible to the BOOT pin (for example on the layer

opposite to the device). Route HGATE and PHASE traces as near as possible in order

to minimize the area between them.

● The low-side gate driver is powered by PVCC pin. Placing PGND and LGATE pins near

the low-side MOSFETs reduces the length of the traces and the crosstalk noise

between the two sections.

● The linear regulator outputs are referred to SGND as long as the reference voltages

VREF2 and VREF3. Place their output filtering capacitors as near as possible to the

device.

● Place input filtering capacitors near PVCC, VCC and VIN pins.

Figure 58).

Doc ID 15281 Rev 4 45/50

PCB design guidelines PM6686

Figure 58. Current paths, ground connection and driver traces layout

46/50 Doc ID 15281 Rev 4

PM6686 Package mechanical data

13 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK is an ST trademark.

Table 22. VFQFPN 5x5x1.0 mm 32 L pitch 0.50 mechanical data

Databook (mm)

Dim.

Min Typ Max

A0.80.91

A1 0 0.02 0.05

A3 0.2

b 0.18 0.25 0.3

D4.8555.15

D2 See exposed pad variations

E4.8555.15

E2 See exposed pad variations

e0.5

L 0.3 0.4 0.5

ddd 0.05

(2)

(2)

Table 23. Exposed pad variations

(1)(2)

D2

E2

Min Typ Max Min Typ Max

2.90 3.10 3.20 2.90 3.10 3.20

1. VFQFPN stands for thermally enhanced very thin fine pitch quad flat package no lead. Very thin:

A = 1.00 mm max.

2. Dimensions D2 and E2 are not in accordance with JEDEC.

Doc ID 15281 Rev 4 47/50

Package mechanical data PM6686

Figure 59. Package dimensions

48/50 Doc ID 15281 Rev 4

PM6686 Revision history

14 Revision history

Table 24. Document revision history

Date Revision Changes

09-Jan-2009 1 Initial release

26-Feb-2009 2 Updated input voltage range in coverpage

07-May-2009 3 Updated pin 29 description in Table 2 on page 7

23-Jul-2009 4

Updated Table 3 on page 10, Section 8.1.8 on page 32, Section 9.1

on page 34, Section 9.2 on page 34 and Table 11 on page 34

Doc ID 15281 Rev 4 49/50

PM6686

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products