Page 1

Introduction

UM2271

User manual

Discovery kit with STM32L4R9AI MCU

The 32L4R9IDISCOVERY kit is a complete demonstration and development platform for the

STMicroelectronics Arm

Leveraging the innovative ultra-low power oriented features, 640

graphics performance (Chrom-ART Accelerator™) and DSI controller offered by the

STM32L4R9AI, the 32L4R9IDISCOVERY kit enables users to easily prototype applications

with state-of-the-art energy efficiency, as well as providing stunning audio and graphics

rendering with direct support for an AMOLED DSI round display. For even more userfriendliness, the on-board ST-LINK/V2-1 debugger provides out-of-the-box programming

and debugging capabilities.

The STM32L4R9AI microcontroller features four I2Cs, five USARTs, one ULP UART, three

SPIs, two SAIs, one SDIO, one USB 2.0 full-speed OTG, two CANs, one FMC parallel

synchronous interface, one 12-bit ADC, one 12-bit DAC, two ULP analog comparators, two

op amps, one 2 data-lane DSI display, one digital filter for sigma delta modulator and SWP

interface, two Octo-SPI interfaces, 8- to 14-bit camera interface, one touch sensing

controller interface, JTAG and SWD debugging support.

This Discovery board offers everything required for users to get started quickly and develop

applications easily.The hardware features on the board help to evaluate the following

peripherals: USB OTG FS, microSD™ card, 8-bit camera interface, 16-Mbit PSRAM, PMOD

and STMod+ connectors, IDD measurement, full-duplex I2S with an audio codec and stereo

headset jack including an analog microphone, DFSDM with a pair of MEMS digital

microphones on board, 512-Mbit Octo-SPI Flash memory device, I2C extension connector,

1.2" AMOLED display using a one data-lane DSI interface with a capacitive touch panel.

The Arduino™ compatible connectors expand the functionality with a wide choice of

specialized shields. The integrated ST-LINK/V2-1 provides an embedded in-circuit

debugger and programmer for the STM32 MCU.

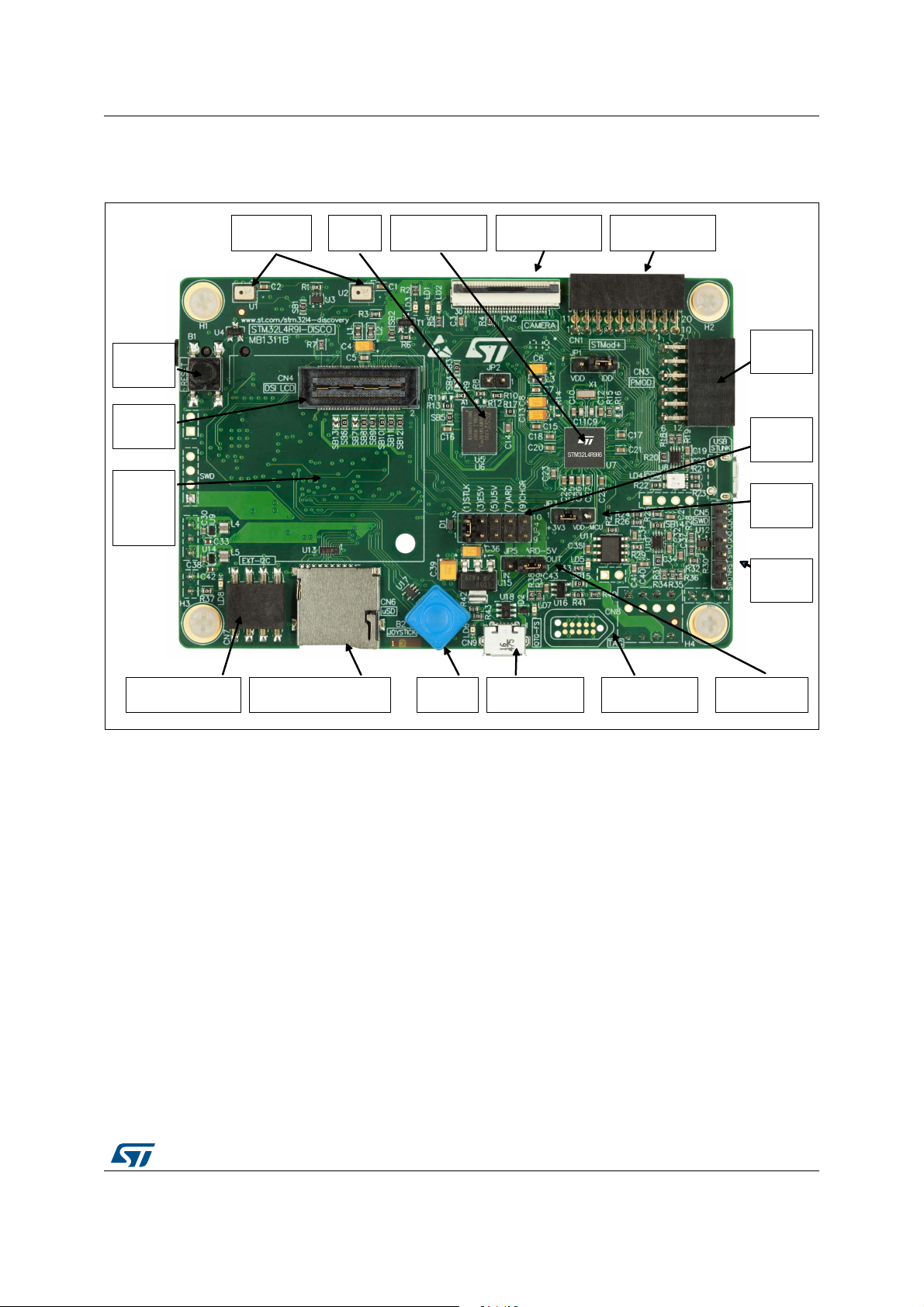

Figure 1. 32L4R9IDISCOVERY top view Figure 2. 32L4R9IDISCOVERY bottom view

®

Cortex®-M4 core-based STM32L4R9AI microcontroller.

Kbytes of embedded RAM,

Pictures are not contractual

October 2017 DocID030906 Rev 2 1/78

www.st.com

1

Page 2

Contents UM2271

Contents

1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Product marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Development toolchains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Demonstration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Technology partners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Bootloader limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9 AMOLED display limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10 Hardware layout and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10.1 32L4R9IDISCOVERY layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

10.2 32L4R9IDISCOVERY mechanical drawing . . . . . . . . . . . . . . . . . . . . . . . 15

10.3 Embedded ST_LINK/V2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10.3.1 Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10.3.2 ST-LINK/V2-1 firmware upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10.4 Low-power consumption status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10.5 TAG and SWD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.6 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.6.1 Power supply sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.6.2 MCU power supply options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10.6.3 Supplying 32L4R9IDISCOVERY through ST-LINK/V2-1 USB . . . . . . . . 21

10.6.4 Measurement of MCU current consumption . . . . . . . . . . . . . . . . . . . . . 22

10.6.5 Program or debug when power supply not from ST-LINK/V2-1 . . . . . . . 23

10.7 Clock sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.8 Reset Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2/78 DocID030906 Rev 2

Page 3

UM2271 Contents

10.9 Boot configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10.10 Audio codec . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10.11 DFSDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10.12 PSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.13 USB OTG FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.13.1 32L4R9IDISCOVERY as USB device . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.13.2 32L4R9IDISCOVERY as USB host . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.14 Octo-SPI Flash memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.15 Virtual COM port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.16 Buttons and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11.1 Arduino connectors CN10, CN11, CN16 and CN17 . . . . . . . . . . . . . . . . . 28

11.2 DSI display, backlight and touch panel connector CN4 . . . . . . . . . . . . . . 30

11.2.1 DSI AMOLED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11.2.2 Backlight and OLED power supplies generation . . . . . . . . . . . . . . . . . . 32

11.2.3 Touch panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11.3 USB OTG FS connector CN9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

11.4 ST-LINK/V2-1 USB Micro-B connector CN13 . . . . . . . . . . . . . . . . . . . . . 33

11.5 microSD card connector CN6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11.6 STMod+ connector CN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11.7 PMOD connector CN3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.8 Camera module connector CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.9 TAG connector CN8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11.10 SWD header CN5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11.11 EXT_I2C connector CN7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.12 Stereo headset and headphone jack CN12 . . . . . . . . . . . . . . . . . . . . . . . 41

Appendix A GPIO assignment and sharing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Appendix B Solder bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Appendix C STMod+ GPIO sharing and multiplexing . . . . . . . . . . . . . . . . . . . . . 52

Appendix D Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

DocID030906 Rev 2 3/78

4

Page 4

Contents UM2271

Appendix E Fanout board (MB1280) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

E.1 MikroElektronika mikroBUS™ compatible connector

(Fanout CN10 / CN11). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

E.2 ESP-01 Wi-Fi

®

board compatible connector. . . . . . . . . . . . . . . . . . . . . . . 72

E.3 Compatible connectors for the Grove boards . . . . . . . . . . . . . . . . . . . . . . 72

E.3.1 Compatible connector for I2C Grove boards (Fanout CN3) . . . . . . . . . . 72

E.3.2 Compatible connector for UART Grove boards (Fanout CN2) . . . . . . . . 73

Appendix F Federal Communications Commission (FCC) and Industry Canada

(IC) Compliance74

F.1 FCC Compliance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

F.1.1 Part 15.19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

F.1.2 Part 15.105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

F.1.3 Part 15.21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

F.2 IC Compliance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

F.2.1 Compliance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

F.2.2 Déclaration de conformité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Appendix G CISPR32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

G.1 Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4/78 DocID030906 Rev 2

Page 5

UM2271 List of tables

List of tables

Table 1. Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 2. JP10: VDD_STL setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 3. SW1 switch setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 4. 32L4R9IDISCOVERY power sources configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5. JP4: power source selector setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 6. JP5: ARD 5 V input/output voltage selection setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 7. JP7: VDD setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 8. JP1: IDD_MCU measurement setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 9. JP3: VDDA and VDDUSB, settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 10. Boot modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 11. LD1 and LD2 details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 12. Buttons and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 13. Arduino compatible connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 14. JP3, VDDA and VDDUSB, settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 15. DSI display connector CN4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 16. USB OTG FS Micro-AB connector CN9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 17. USB Micro-B connector CN13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 18. microSD connector CN6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 19. STMod+ connector CN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 20. Quad SPDT switch configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 21. PMOD connector CN3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 22. Camera module connector CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 23. TAG connector CN8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 24. SWD header CN5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 25. EXT_I2C connector CN7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 26. I2C1 addresses (on board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 27. Audio jack connector CN12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 28. 32L4R9IDISCOVERY GPIO assignment and sharing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 29. MFX_V3 GPIO assignment (LQFP48) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 30. 32L4R9IDISCOVERY solder bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 31. STMod+ GPIO sharing and multiplexing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 32. SPDT quad switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 33. Description of the mikroBUS connectors (CN11 and CN10) . . . . . . . . . . . . . . . . . . . . . . . 72

Table 34. Description of the ESP-01 Wi-Fi board connector pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 35. Description of the I2C Grove board connector pins (CN3) . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 36. Description of the UART Grove board connector pins (CN2) . . . . . . . . . . . . . . . . . . . . . . . 73

Table 37. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

DocID030906 Rev 2 5/78

5

Page 6

List of figures UM2271

List of figures

Figure 1. 32L4R9IDISCOVERY top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. 32L4R9IDISCOVERY bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 3. Hardware block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 4. 32L4R9IDISCOVERY top side layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 5. 32L4R9IDISCOVERY bottom side layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 6. 32L4R9IDISCOVERY mechanical drawing (top view, in mm) . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. 32L4R9IDISCOVERY mechanical drawing (bottom view, in mm) . . . . . . . . . . . . . . . . . . . 16

Figure 8. How to update driver software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9. JP4 default configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10. DSI display connector CN4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 11. USB OTG FS Micro-AB connector CN9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 12. USB Micro-B connector CN13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 13. microSD connector CN6 (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 14. STMod+ connector CN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 15. PMOD connector CN3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 16. Camera module connector CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 17. TAG connector CN8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 18. EXT_I2C connector CN7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 19. Stereo headset with microphone jack CN12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 20. 32L4R9IDISCOVERY board interconnections (MB1311C) . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 21. 32L4R9IDISCOVERY power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 22. 32L4R9IDISCOVERY Arduino Uno V3 connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 23. 32L4R9IDISCOVERY ST-LINK/V2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 24. 32L4R9IDISCOVERY Octo-SPI Flash memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 25. 32L4R9IDISCOVERY peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 26. 32L4R9IDISCOVERY USB OTG FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 27. 32L4R9IDISCOVERY Round DSI display interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 28. 32L4R9IDISCOVERY IDD measurement and Multi Function eXpander . . . . . . . . . . . . . . 63

Figure 29. 32L4R9IDISCOVERY microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 30. 32L4R9IDISCOVERY PSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 31. 32L4R9IDISCOVERY camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 32. 32L4R9IDISCOVERY STMOD+ interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 33. 32L4R9IDISCOVERY Audio and DFSDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 34. Round DSI display board (MB1314) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 35. Fanout board (MB1280) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 36. STMod+ Fanout module plugged into CN1 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6/78 DocID030906 Rev 2

Page 7

UM2271 Features

1 Features

• STM32L4R9AI Arm-based microcontroller with 2-Mbyte Flash memory and 640-Kbyte

RAM in UFBGA169 package

• 1.2" 390x390 pixel AMOLED round display panel with 16 million colors depth, MIPI

interface and capacitive touch panel

• USB OTG FS

• On-board current measurement

• SAI audio codec

• ST-MEMS digital microphones

• 16-Mbit asynchronous PSRAM

• 512-Mbit Octo-SPI Flash

• 2 user LEDs

• 1 reset push-button

• 4-direction joystick with selection button

• Board connectors:

– 8-bit camera

– USB OTG FS with Micro-AB

– Stereo headset jack including analog microphone input

– microSD card

• Board expansion connectors:

– Arduino Uno V3

–STMod+

–PMOD

– EXT_I2C

• Flexible power-supply options:

–ST-LINK USB V

• On-board ST-LINK/V2-1 debugger/programmer with USB

re-enumeration capability: mass storage, virtual COM port and debug port

• Comprehensive free software libraries and examples available with the STM32Cube

package

• Support of a wide choice of integrated development environments (IDEs), including

IAR™, Keil

®

and GCC-based IDEs

or external sources

BUS

®

DSI

2 Product marking

Evaluation tools marked as “ES” or “E” are not yet qualified and are therefore not ready to

be used as reference design or in production. Any consequences arising from such usage

DocID030906 Rev 2 7/78

77

Page 8

System requirements UM2271

will not be at ST’s charge. In no event will ST be liable for any customer usage of these

engineering sample tools as reference designs or in production.

‘E’ or ‘ES’ marking examples of location:

• on the targeted STM32 that is soldered on the board (for illustration of STM32 marking,

refer to the section ‘Package information’ of the STM32 datasheet at www.st.com).

• next to the evaluation tool ordering part number, that is stuck or silkscreen printed on

the board

This board features a specific STM32 device version which allows the operation of any

stack or library. This STM32 device shows a "U" marking option at the end of the standard

part number and is not available for sales.

3 System requirements

• Windows® OS (7, 8 and 10), Linux® 64-bit or macOS

• USB Type-A to Micro-B cable

4 Development toolchains

• Keil MDK-ARM

• IAR EWARM

• GCC-based IDEs including free SW4STM32 from AC6

(a)

(a)

5 Demonstration software

The demonstration software, included in the STM32Cube package corresponding to the onboard MCU, is preloaded in the STM32 Flash memory for easy demonstration of the device

peripherals in standalone mode. The latest versions of the demonstration source code and

associated documentation can be downloaded from the www.st.com/stm32l4-discovery web

page.

®

6 Ordering information

To order the 32L4R9IDISCOVERY kit, refer to Table 1.

a. On Windows only

8/78 DocID030906 Rev 2

Page 9

UM2271 Technology partners

Order code Target STM32

STM32L4R9I-DISCO STM32L4R9AII6

Table 1. Ordering information

7 Technology partners

MACRONIX:

512-Mbit Octo-SPI NOR Flash memory device, part number MX25LM51245GXDI00

GOVISIONOX OPTOELECTRONICS:

1.2 inch 390x390 AMOLED display, part number G1120TB103GF-001

DocID030906 Rev 2 9/78

77

Page 10

Bootloader limitations UM2271

8 Bootloader limitations

Boot from system Flash memory results in executing bootloader code stored in the system

Flash memory protected against writing and erasing. This allows in-system programming

(ISP), that is, flashing the STM32 user Flash memory. It also allows writing data into RAM.

The data come in via one of communication interfaces such as USART, SPI, I2C bus, USB

or CAN.

Bootloader version is identified by reading the bootloader ID at the address 0x1FFF6FFE.

Its value is 0x91 for bootloader V9.1 and 0x92 for V9.2.

The STM32L4R9AII6 part soldered on the 32L4R9IDISCOVERY main board is marked with

a date code corresponding to its date of manufacturing. STM32L4R9AII6 parts with a date

code prior or equal to week 37 of 2017 are fitted with bootloader V9.1 affected by the

limitations to be worked around, as described hereunder. Parts with the date code starting

from week 38 of 2017 contain bootloader V9.2 in which the limitations no longer exist.

To locate the visual date code information on the STM32L4R9II6 package, refer to its

datasheet (DS12023) available at www.st.com, section Package Information. Date code

related portion of the package marking takes Y WW format, where Y is the last digit of the

year and WW is the week. For example, a part manufactured in week 38 of 2017 bares the

date code 7 38.

There is also another mean to identify the need for workaround: before opening the blister of

the Discovery Kit, just check the back side of the blister. At the bottom left side, if the

reference number is equal or higher than 32L4R9IDISCO/ 02-0, it means the bootloader

version is V9.2 and there is no need to apply workaround. Any other inferior number like 010 will need the workaround.

Bootloader ID for the bootloader V9.1 is 0x91.

The following limitation exists in the bootloader V9.1:

Some user Flash memory data get corrupted when written via SPI interface

Description:

During bootloader SPI Write Flash operation, some random 64-bits (2 double-words) may

be left blank at 0xFF

Workarounds:

WA1: add a delay between sending Write command and its ACK request. Its duration

should be the duration of the 256-Byte Flash write time.

WA2: read back after each write operation (256 bytes or at end of user code flashing) and in

case of error start write again.

WA3: Using bootloader, load a patch code in RAM to write in Flash memory through same

Write Memory write protocol as bootloader (code provided by ST). The patch code is

available for download from www.st.com website with a readme.txt file containing usage

instructions.

10/78 DocID030906 Rev 2

Page 11

UM2271 AMOLED display limitation

9 AMOLED display limitation

Warning: Permanent image sticking may occur if AMOLED displays

same image for an extended period of time.

10 Hardware layout and configuration

32L4R9IDISCOVERY board is designed around the STM32L4R9AI (169 ball UFBGA

package DSI version). The hardware block diagram

between STM32L4R9AI and peripherals (PSRAM, Octo-SPI Flash, DSI color display, USB

OTG connector, USART, audio, camera connector, STMod+ and PMOD connectors, IDD

measurement, joystick, microSD card, I

embedded ST-LINK).

board. Mechanical drawing for 32L4R9IDISCOVERY and round DSI display boards is

described in

Figure 6.

Figure 4 and Figure 5 help the user to locate these features on the

2

C extension connector, Arduino Uno shields and

Figure 3 illustrates the connection

DocID030906 Rev 2 11/78

77

Page 12

Hardware layout and configuration UM2271

06Y9

*3,2

)0&

6:'

2FWR63,0B3

6'00&

3:5

86$57

63,

,&

86$57

'6,

'&0,

')6'0

57&+6(

,&

/38$57

6$,

27*

$5'FRQQHFWRU

302'

670RG

5HVHWEXWWRQ

-R\VWLFN

567Q*3,2

670/5$,

6(/

6(/

0ELW

DV\QFKURQRXV

365$0

99

SRZHUVXSSO\

67/,1.9

.+]FU\VWDO

0+]FU\VWDO

0ELW2FWR63,

)ODVKPHPRU\

7$*FRQQHFWRU

6:'FRQQHFWRU

0(0V

PLFURSKRQHV

8VHU/('

(;7B,&

FRQQHFWRU

0);9,''

PHDVXUHPHQW

/&'WRXFKSDQHO

'6,9FRQQHFWRU

8VHU/('

$XGLRFRGHF

DPSOLILHU

6WHUHRMDFNZLWK

PLFURSKRQH

&DPHUD

FRQQHFWRU

PLFUR6'

86%27*

FRQQHFWRU

Figure 3. Hardware block diagram

12/78 DocID030906 Rev 2

Page 13

UM2271 Hardware layout and configuration

06Y9

88

0LFURSKRQHV

8

365$08670/5$,,

&1

&DPHUDFRQQHFWRU

&1

670RGFRQQHFWRU

&1

302'

FRQQHFWRU

-3

3RZHU

KHDGHU

-3

9''$B

9''86%

&1

6:'

FRQQHFWRU

-3

$5'B,1287

&1

7$*FRQQHFWRU

&1

(;7B,&FRQQHFWRU

&1

PLFUR6'FDUGFRQQHFWRU

%

-R\VWLFN

&1

86%27*)6

%

5HVHW

&1

'6,9

FRQQHFWRU

0%

'6,

GLVSOD\

ERDUG

SODFH

10.1 32L4R9IDISCOVERY layout

Figure 4. 32L4R9IDISCOVERY top side layout

DocID030906 Rev 2 13/78

77

Page 14

Hardware layout and configuration UM2271

06Y9

&1&1$UGXLQRFRQQHFWRUV

&1

$XGLR

MDFN

8

$XGLR

FRGHF

-3

9''

-3

9

SRZHU

/('

8

2FWR63,

)ODVK

PHPRU\

&1

86%

67/,1.

8

67/,1.

0&8

-3

966B67/.

6:6ZLWFK &1&1$UGXLQRFRQQHFWRUV 80);H[SDQGHU

Figure 5. 32L4R9IDISCOVERY bottom side layout

14/78 DocID030906 Rev 2

Page 15

UM2271 Hardware layout and configuration

10.2 32L4R9IDISCOVERY mechanical drawing

Figure 6. 32L4R9IDISCOVERY mechanical drawing (top view, in mm)

Legend:

= Indicates the mounting hole between the 32L4R9IDISCOVERY board (at the top of Figure 6) and

the round DSI display board (at the bottom of Figure 6)

DocID030906 Rev 2 15/78

77

Page 16

Hardware layout and configuration UM2271

Figure 7. 32L4R9IDISCOVERY mechanical drawing (bottom view, in mm)

Plastic spacer height = 13 mm, overall height = 26 mm ± 1 mm

10.3 Embedded ST_LINK/V2-1

The ST-LINK/V2-1 programming and debugging tool is integrated on the

32L4R9IDISCOVERY board. Compared to ST-LINK/V2, the changes are listed below:

• new features supported on ST-LINK/V2-1:

– USB software re-enumeration

– Virtual Com port interface on USB

– Mass storage interface on USB

– USB power management request for more than 100 mA power on USB

• features no more supported on ST-LINK/V2-1:

–SWIM interface

– Application voltage lower than 3 V

For general information concerning the debugging and programming features that are

common to both versions V2 and V2-1, refer to ST-LINK/V2 in-circuit

debugger/programmer.

16/78 DocID030906 Rev 2

Page 17

UM2271 Hardware layout and configuration

10.3.1 Drivers

Before connecting the 32L4R9IDISCOVERY to a Windows (7, 8, 10) PC via USB, a driver

for ST-LINK/V2-1 must be installed. It is available on the www.st.com website.

If 32L4R9IDISCOVERY is connected to the PC before the driver is installed, some

interfaces of the board may be declared as ‘Unknown’ in the PC device manager. In this

case the user must install the driver files, and update the driver of the connected device

from the device manager as shown on

Note: Prefer using the ‘USB Composite Device’ handle for a full recovery.

Figure 8. How to update driver software

Figure 8: How to update driver software

10.3.2 ST-LINK/V2-1 firmware upgrade

The ST-LINK/V2-1 embeds a firmware upgrade mechanism for in-situ upgrade through the

USB port. As the firmware may evolve during the life time of the ST-LINK/V2-1 product

(such as new functionality, bug fixes or support for new microcontroller families), it is

recommended to visit www.st.com before starting to use the 32L4R9IDISCOVERY and

periodically, in order to stay up-to-date with the latest firmware version.

10.4 Low-power consumption status

There is a way to make the board get into very low power consumption status in which the

current on +5

1. The connections between ST-LINK/V2-1 and MCU must be disconnected by micro

switch SW1 manually (see

ARD-5V IN position. Remove JP10. Then, connect an external 5 V power supply on

CN16 pin 5 5V and on GND.

2. Peripherals (including display, CTP and PSRAM) are powered off by MOSFET which is

controlled by MFX_GPIO8 / MFX_aGPIO2 (put them as input floating), and by setting

V can be below 20 uA. How to get into the low power mode:

Tabl e 3 below). Set JP4 on (7) ARD position, and put JP5 in

DocID030906 Rev 2 17/78

77

Page 18

Hardware layout and configuration UM2271

21

21

all peripherals related I/Os to inactive level (input pull-down or input is good option

according to I/Os).

3. Disconnect JP9 to remove +5 V from LD8 power LED, disconnect JP10 (or put it in 2-3

position), power off OCTOSPI (remove SB23/SB24) and configure related I/Os as input

pull down.

4. Peripherals can be setup by FW to reach power down mode. All I/Os must be

configured in non-consuming states. Set MFX_V3 to sleep mode, get SD card out of its

socket slot. Set the Audio Codec in power down.

10.5 TAG and SWD

One TAG interface footprint CN8 is reserved on 32L4R9IDISCOVERY and is usable to

debug and program the on-board MCU.

Note: Micro switch SW1 must be put in Off position. R24 and R31 must be disconnected.

The SWD 6-pin header CN5 added on 32L4R9IDISCOVERY, connected to on board STLINK MCU, is usable to debug and program an external MCU.

VDD from the external board is 1.8 V or 3.3 V, thanks to the on board voltage converter.

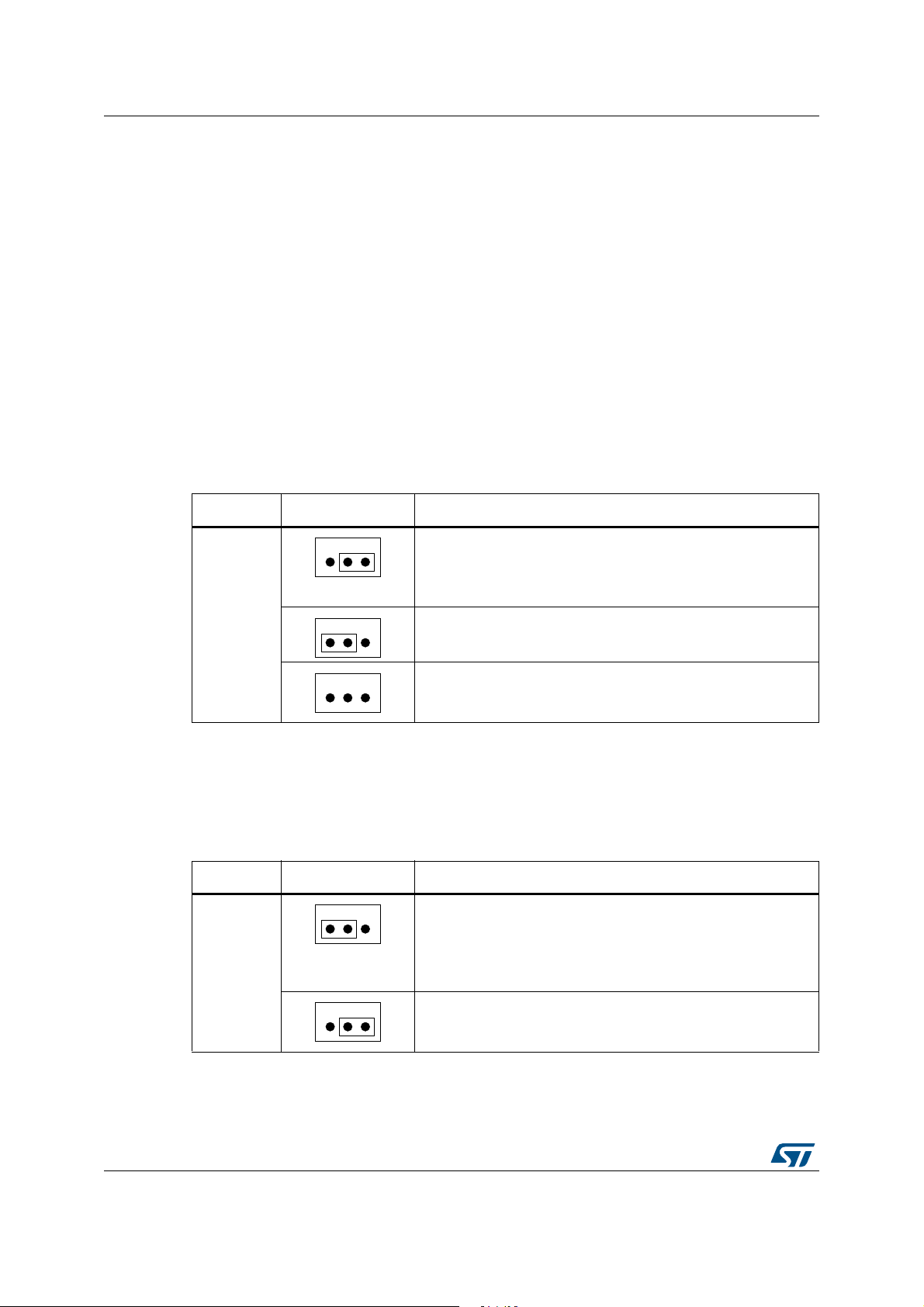

Table 2. JP10: VDD_STL setting

Jumper Setting Description

Default setting.

VDD_STL gets power from 32L4R9IDISCOVERY. ST-LINK is

JP10

then usable to program the on-board MCU.

VDD_STL gets power from external through CN5. ST-LINK is

then usable to program an external MCU.

SW1 is accessible on bottom side of 32L4R9IDISCOVERY. By default, SW1 is in On

position. To put micro switch in Off position, just push away the switch from ON position as

shown in

Tabl e 3.

Table 3. SW1 switch setting

Switch Setting Description

Default setting.

SW1 switch is On.

SW1

SW1 is Off.

18/78 DocID030906 Rev 2

Page 19

UM2271 Hardware layout and configuration

06Y9

10.6 Power supply

10.6.1 Power supply sources

32L4R9IDISCOVERY is designed to be powered by +5 V DC power supply. It is possible to

configure the 32L4R9IDISCOVERY to use any of the sources listed in

By default, the JP4 header must have a jumper on (1) STLK and SW1 is placed in ON

position. Any JP4 position different from (1) STLK requires SW1 to be placed in OFF

position (see

Tabl e 3).

Table 4. 32L4R9IDISCOVERY power sources configuration

Tabl e 4.

JP4 configuration

(function)

(1) STLK (USB_STLINK) CN5 (VBUS) 5 V 500 mA

(3) E5V (ARDUINO) CN16 (VIN) 6 V - 9 V => 5 V

(5) U5V (USB_OTG_FS) CN8 (VBUS) 5 V 500 mA

(7) ARD (ARDUINO) CN16 (ARD-5V)

(9) CHGR (USB_STLINK) CN5 (VBUS) 5 V

1. ARD-5V is a power output pin to Arduino connector CN16 (default) or a power input pin from Arduino

connector CN16, according to JP5 setting. See Table 6 below.

Power source

connector (pin name)

(1)

Voltage Available current

Arduino Uno V3 shield

dependent

5 V

Arduino Uno V3 shield

dependent

Power supply

dependent

Note: 32L4R9IDISCOVERY must be powered by a power-supply unit or by an auxiliary equipment

complying with the standard EN-60950-1: 2006+A11/2009, and must be safety extra low

voltage (SELV) with limited power capability.

Figure 9 shows a physical description of the 10-pin header JP4 default configuration.

Figure 9. JP4 default configuration

Detailed description of all JP4 possible configurations are listed below and in Ta b le 5:

• STLK: 5 V from the ST-LINK/V2-1 USB connector CN13 with 500 mA current limitation.

Power mechanism of supplying the board by STLINK/V2-1 is explained Section 10.6.3.

DocID030906 Rev 2 19/78

77

Page 20

Hardware layout and configuration UM2271

67/.

(9

89 $5' &+*5

67/.

(9

89 $5' &+*5

67/.

(9

89 $5' &+*5

67/.

(9

89 $5' &+*5

67/.

(9

89 $5' &+*5

A jumper must be placed in location STLK of JP4, connecting pins 1 and 2. The green

LED LD8 is lit on to confirm presence of 5 V voltage.

• E5V: 5 V from the 6 V to 9 V DC from VIN pin of Arduino compatible connector CN16

(the U15 regulator is converting VIN into a 5 V voltage). The VIN input voltage is limited

to 9 V to keep temperature of the regulator U15 within its thermal safe area. A jumper

must be placed connecting pins 3 and 4 of JP4. The green LED LD8 is lit on to confirm

presence of 5 V voltage. SW1 must be placed in OFF position.

• U5V: 5 V from the 5 V DC of USB OTG FS user connector CN9. A jumper must be

placed in location USB of JP4, connecting pins 5 and 6.The green LED LD8 is lit on to

confirm presence of 5 V voltage. SW1 must be placed in OFF position.

• ARD: 5 V from the 5 V of Arduino compatible connector CN16. A jumper must be

placed in location ARD of JP4, connecting pins 7 and 8. The green LED LD8 is lit on to

confirm presence of 5 V voltage and at t the same time, pins 2 and 3 of JP5 must be

connected to get 5 V power from Arduino. SW1 must be placed in OFF position. In

case the main board provides 5 V to Arduino compatible connector CN16, which is the

default configuration, pins 1 and 2 of JP5 must be connected (see Tabl e 6 ).

• CHGR: 5 V from 5 V DC power charger connected to USB STLINK (CN13). In this

case, if 32L4R9IDISCOVERY is powered by an external USB charger, then the debug

on CN13 is not available. When CHGR input is chosen, it is not recommended to

connect a PC on USB STLINK, because the 500 mA limitation is no more effective and

this may damage the PC. A jumper must be placed in location CHGR of JP4,

connecting pins 9 and 10. The green LED LD8 is lit on to confirm presence of 5 V

voltage. SW1 must be placed in OFF position.

Table 5. JP4: power source selector setting

Jumper Setting Description

Default setting.

32L4R9IDISCOVERY is supplied though CN13 Micro-B

ST-LINK/V2-1 connector.

32L4R9IDISCOVERY is supplied though Arduino connector

CN16 (VIN).

JP4

32L4R9IDISCOVERY is supplied though USB OTG FS

connector CN9.

32L4R9IDISCOVERY powers ARDUINO or is supplied by

ARDUINO, according to JP5 setting in Tab l e 6 below.

32L4R9IDISCOVERY is supplied though CN13 Micro-B STLINK/V2-1 connector. In that case, the SB36 solder bridge must

be soldered.

20/78 DocID030906 Rev 2

Page 21

UM2271 Hardware layout and configuration

Table 6. JP5: ARD 5 V input/output voltage selection setting

Jumper Setting Description

Default setting.

32L4R9IDISCOVERY supplies 5 V to Arduino connector CN16.

JP5

32L4R9IDISCOVERY is supplied by 5 V from Arduino connector

CN16.

10.6.2 MCU power supply options

32L4R9IDISCOVERY offers possibility to supply the MCU under 1.8 V or 3.3 V. The JP7

jumper must be placed on +3V3 to supply the MCU with 3.3

jumper can be placed on +1V8 of JP7 to supply the MCU with 1.8

pins

2 and 3 (see Table 7).

Functions listed below are not compatible with the +1V8 setting of JP7:

• OCTOSPI

• PSRAM

• ARDUINO Uno Revision 3

• CAMERA

• microSD card

• ADC measurements (except if JP3 is set at +3V3, or except if VREF+ configuration is

changed)

• USB OTG FS (except if JP3 is set at +3V3)

Table 7. JP7: VDD setting

SW1 must be placed in OFF position.

V, connecting pins 1 and 2. The

V, connecting

Jumper Setting Description

Default setting.

VDD is powered from +3V3 regulator.

JP7

VDD is powered from +1V8 regulator.

10.6.3 Supplying 32L4R9IDISCOVERY through ST-LINK/V2-1 USB

To power the board through ST-LINK/V2-1, the USB host (a PC) must be connected with the

32L4R9IDISCOVERY standard Micro-B USB receptacle, via a USB cable. This event starts

the USB enumeration procedure. In its initial phase, the current supply capability of the USB

host port is limited to 100

32L4R9IDISCOVERY draws power at that time. If the solder bridge SB36 is open (default

setting), the U11 ST890 power switch is set to Off position, which isolates the remainder of

the board from the power source. In the next phase of the enumeration procedure, the host

PC informs the ST-LINK/V2-1 facility of its capability to supply up to 500

answer is positive, the ST-LINK/V2-1 sets the U11 ST890 switch to On position to supply

power to the remainder of the board. If the PC USB port is not capable of supplying up to

500

mA, another power source must be used like VIN pin of connector CN16.

mA. It is enough because only ST-LINK/V2-1 part of

mA current. If the

DocID030906 Rev 2 21/78

77

Page 22

Hardware layout and configuration UM2271

The ST890 power switch protects the host USB port against current demand exceeding

625

mA, in case a short circuit occurs on the board (the red LED fault LD5 lights on).

32L4R9IDISCOVERY can also be supplied by STLINK USB power source with no

enumeration, such as a USB charger. In this particular case, the SB36 solder bridge must

be closed. ST-LINK/V2-1 turns the ST890 power switch On regardless of enumeration

procedure result and passes the power unconditionally to the board. The green LED LD8

lights on whenever the whole board is powered.

10.6.4 Measurement of MCU current consumption

Jumper JP1 allows the consumption of STM32L4R9AI to be measured directly by a built-in

MCU current ammeter circuit (MFX_V3, able to measure from 60

removing the jumper and replace it by an external ammeter (see

To measure the MCU consumption in standby or shutdown modes, MFX_V3 needs to run

software. To wake up MCU from these modes, it is necessary to press the Reset button B1,

or to wait a few seconds.

Jumper Setting Description

JP1

Table 8. JP1: IDD_MCU measurement setting

Default setting.

A module on the board is designed to measure from 60 nA to

50 mA by using several MOSFET, and switching automatically

depending on the read value.

STM32L4R9AI is powered by VDD. MCU current measurement

is not possible

No jumper on JP1: an ammeter can be connected on

pins 2 and 3 to measure STM32L4R9AI current (if there is no

ammeter, STM32L4R9AI is not powered).

nA to 50 mA) or by

Table 8).

VDDA and VDDUSB power inputs from STM32L4R9AI can be connected to two different

power sources, +3V3 or VDD_MCU. These power inputs may be included or not in the IDD

current measurement of VDD_MCU, depending on the JP3 jumper configurations described

in

Tabl e 9.

Jumper Setting Description

JP3

22/78 DocID030906 Rev 2

Table 9. JP3: VDDA and VDDUSB, settings

Default setting.

VDDA and VDDUSB power pins of STM32L4R9AI are supplied

with +3V3. the IDD measurement does not include their current

consumption. USB OTG FS is functional even if JP7 is set on

+1V8.

VDDA and VDDUSB power pins of STM32L4R9AI are supplied

with VDD_MCU. The IDD measurement includes their current

consumption.

Page 23

UM2271 Hardware layout and configuration

10.6.5 Program or debug when power supply not from ST-LINK/V2-1

Before connecting the USB cable from ST-LINK/V2-1 CN13 to the PC, it is mandatory to

power the board using the user USB OTG FS connector CN9 or the VIN pin of Arduino

connector CN16. Proceeding this way ensures that the enumeration succeeds thanks to the

external power source.

The following power-sequence procedure must be respected:

1. Put a jumper in JP4 at location U5V to use power from user USB CN9 or at location

E5V to use power from VIN of Arduino connector CN16.

2. Connect the corresponding external power source.

3. Check the green LED LD8 is turned On.

4. Connect the PC to ST-LINK/V2-1 USB connector CN13.

If this order is not respected, the board may be powered by VBUS first from ST-LINK, and

the following risks may be encountered:

• If more than 500 mA current is needed by the board, PC may be damaged or current is

limited by PC. As a consequence the board is not powered correctly.

• 500 mA is requested at the enumeration, so there is a risk that the request is rejected

and enumeration does not succeed if PC cannot provide such current.

10.7 Clock sources

Two clock sources are used by STM32L4R9AI: one on LSE input and another on HSE input.

LSE clock source

The available clock source is X1, 32 kHz crystal for the STM32L4R9AI embedded RTC.

HSE clock source

The second clock source available by default is X2, 16 MHz crystal for the STM32L4R9AI

HSE system clock.

Note that another HSE clocking option is available on PCB: MCO output from STLINK MCU

to STM32L4R9AI HSE input. Please refer to

10.8 Reset Source

The general reset of 32L4R9IDISCOVERY is active low. The reset sources are listed below:

• Reset button B1

• Embedded ST-LINK/V2-1, SW1 micro-switch set to On (default setting)

• Arduino compatible connector CN16 pin 3

The general reset is connected to following peripheral reset functions:

• STM32L4R9AI MCU reset

• Octo-SPI Flash reset

• MFX_V3 reset

• Camera reset

Appendix B: Solder bridges.

DocID030906 Rev 2 23/78

77

Page 24

Hardware layout and configuration UM2271

10.9 Boot configuration

After reset, STM32L4R9AI boots from one of the three different embedded memory

locations, depending on BOOT0 and BOOT1 bits:

• Boot from the main Flash memory (MCU internal Flash). This is the default

configuration.

• Boot from the system memory ISP (in-system programming).

• Boot from the SRAM1.

On 32L4R9IDISCOVERY board, the boot configuration of the MCU is controlled by the

BOOT0 signal on PH3 pin.

BOOT0 is by default grounded through the R15 pull-down resistor.

It is possible to set BOOT0 high by removing resistor R15 and populating resistor R16 with

a 10K resistor.

Please check below Tab l e 10 for other boot modes.

Table 10. Boot modes

nBOOT1

FLASH_OPTR[23]

XX01

XX01

X1X0

0X11

00X0

1X11

10X0

nBOOT0

FLASH_OPTR[27]

10.10 Audio codec

A Cirrus codec CS42L51-CNZ U26 connected to the SAI1 interface of STM32L4R9AI offers

possibility to connect a stereo headphone or headset with a mono analog microphone.

BOOT0 pin

PH3

nSWBOOT0

FLASH_OPTR[26]

Boot Memory Space Alias

Main Flash memory is selected

as boot area

System memory is selected as

boot area

Main Flash memory is selected

as boot area

Embedded SRAM1 is selected

as boot area

Embedded SRAM1 is selected

as boot area

System memory is selected as

boot area

System memory is selected as

boot area

The I²C-bus addresses of CS42L51-CNZ are 0x95 and 0x94.

10.11 DFSDM

Two ST-MEMS MP34DT01TR digital microphones U1 and U2 are available on

32L4R9IDISCOVERY. The two microphones are located at a distance of 21

other. They are connected to the STM32 DFSDM by the PC2 port, generating the clock, and

24/78 DocID030906 Rev 2

mm from each

Page 25

UM2271 Hardware layout and configuration

by PB12 port, collecting the PDM interleaved data. These microphones are powered by

MIC_VDD (PH2 of STM32L4R9AI).

The two DFSDM interface signals (clock and data), are also accessible on the STMod+

connector CN1. Before using STMod+, the user must follow the recommendations below:

• If STMod+ pin 17 is used, SB1 (DOUT) must be disconnected first.

• If STMod+ pins 18 or 20 are used, MIC_VDD GPIO (PH2) must be activated at high

level first.

10.12 PSRAM

Two PSRAM footprints are supported on the design, both connected to STM32L4R9AI FMC

interface:

• A 16-Mbit asynchronous PSRAM (U5), using up to A19 address, is soldered by default.

Reference is IS66WV1M16EBLL-55BLI.

• A 32-Mbit synchronous PSRAM (U6), using up to A20 address, may be used.

Reference is IS66WVC2M16ECLL-7010BLI.

By default, this PSRAM (U6) is exclusive with CAMERA function (due to DCMI_D4

function multiplexed with A20 of MCU). In case CAMERA is used at the same time than

PSRAM, it is possible to change two solder bridges to deactivate A20 on PSRAM (tied

to high, usable density 16 Mbits) and DCMI_D4 is used for CAMERA.

Note: Limitation: the two PSRAM are not compatible with JP7 setting at +1V8.

See Appendix B: Solder bridges for possible PSRAM configuration change.

10.13 USB OTG FS

32L4R9IDISCOVERY supports USB OTG FS (full-speed) communication via the USB

Micro-AB connector (CN9) and USB power switch (U16) connected to VBUS. The board

can be powered by this USB connection at 5

A green LED LD6 is lit in one of the following cases:

• Power switch (U16) is On and 32L4R9IDISCOVERY works as a USB host

• VBUS is powered by another USB host when 32L4R9IDISCOVERY works as a USB

device.

The red LED LD7 is lit when over-current occurs.

10.13.1 32L4R9IDISCOVERY as USB device

When the board works as a USB device, it can be powered by the 5 V DC VBUS of this USB

OTG FS connection (jumper JP4 pins 5 and 6 must be connected in position U5V). The

green LEDs LD6 VBUS and LD8 PWR are lit on to confirm the 5

V DC with 625 mA current limitation.

V presence.

DocID030906 Rev 2 25/78

77

Page 26

Hardware layout and configuration UM2271

10.13.2 32L4R9IDISCOVERY as USB host

When the board works as a USB host, it supplies the 5 V to the USB peripheral using one of

the following sources:

• ST-LINK/V2-1 USB Micro-B connector CN13 (jumper put in STLK location of JP4)

• an external 5 V source connected to pin 5 of the Arduino connector CN16 (jumper put

in ARD location of JP4)

• an external source between 7 V and 11 V, connected to VIN pin of Arduino connector

CN16 (jumper put in E5V location of JP4)

The green LED LD8 is lit on to confirm the presence of the 5 V source.

The power switch STMPS2141STR is controlled by the port MFX_GPIO13 to deliver the 5 V

power to the USB device connected to the USB connector CN9. When MFX_GPIO13 is

pulled down to ground, the power switch is closed, and the green LED LD6 confirms the 5

presence for the USB device. The red LED LD7 FAULT is lit when an over-current occurs.

For more details please refer to Section 10.6: Power supply.

V

10.14 Octo-SPI Flash memory

A 512-Mbit Octo-SPI user Flash memory (MX25LM51245GXDI00 from MACRONIX) is

connected to OCTOSPIM_P2 interface of STM32L4R9AI. By default, OCTOSPI_RESET of

Flash memory has been connected to the general reset of 32L4R9IDISCOVERY.

See Appendix B: Solder bridges for possible Octo-SPI Flash configuration change.

Note: Limitation: the Octo-SPI Flash memory is not compatible with JP7 setting at +1V8.

10.15 Virtual COM port

The serial interface USART2 is directly available as a virtual COM port of the PC, connected

to the ST-LINK/V2-1 USB connector CN13. The virtual COM port settings are configured as

follow: 115200

bps, 8-bit data, no parity, one stop bit, no flow control.

10.16 Buttons and LEDs

The blue button B2 is a four-directions joystick with a selection mode when pressed in the

center. The logic state is high when one of the five-position switch (left, right, up, down,

selection) is pressed. The center position (Select function) is connected to a wake-up pin of

the microcontroller PC13. The other four directions are mapped on MFX GPIOs.

The black button B1 near the display is the Reset button. It is used to reset the board and

can wake-up MCU from standby and shutdown IDD measurement modes.

Two user LEDs located near the camera connector CN2 are available for the user (see

Figure 4): LD1, LD2, from left to right, with orange and green color respectively. To light on a

LED, a low logic state 0 must be written in the corresponding GPIO.

• LD1 (orange) is managed by MFX function

• LD2 (green) is managed by STM32L4R9AI main MCU

26/78 DocID030906 Rev 2

Page 27

UM2271 Hardware layout and configuration

Table 11. LD1 and LD2 details

LED MCU port control color

LD1 PB0 (MFX_GPIO0 from MFX) Orange

LD2 PH4 (from main MCU) Green

Other LEDs are present on the 32L4R9IDISCOVERY. Find below a summary list of all

buttons and LEDs, with their description.

Reference Color Function Comment

B1 black RESET For MCU, OCTO-SPI Flash, MFX_V3, CAMERA

B2 blue

LD1 orange USER1 MFX_GPIO0, PB0

LD2 green USER2 PH4

Table 12. Buttons and LEDs

SELECT with Wake-up alternate function, PC13

UP MFX_GPIO1, PB1

DOWN MFX_GPIO2, PB2

RIGHT MFX_GPIO3, PB3

LEFT MFX_GPIO4, PB4

LD3 green ARDUINO PB13

LD4 red/green ST-LINK COM Green during communication

LD5 red ST-LINK USB FAULT Current higher than 625 mA

LD6 green VBUS USB OTG FS Status also available on PA9

LD7 red USB OTG FS OVCR Overcurrent detection, also on MFX_GPIO14, PB14

LD8 green 5V POWER -

DocID030906 Rev 2 27/78

77

Page 28

Connectors UM2271

11 Connectors

11.1 Arduino connectors CN10, CN11, CN16 and CN17

CN10, CN11, CN16 and CN17 are female connectors compatible with Arduino Uno

Revision 3 standard. Most of shields designed for Arduino can fit to 32L4R9IDISCOVERY

board.

Left connectors Right connectors

Table 13. Arduino compatible connectors

CN No.

CN16

Power

Pin

No.

1 - - E5V test SPI2_SCK PB13 D13 6

2 IOREF - VDD SPI2_MISO PB14 D12 5

3 NRST NRST Reset

43V3 -

5 5V - 5Vinput/output TIM8_CH1N PH13 D9 2

6 GND - Ground - PH15 D8 1

7 GND - Ground -

8VIN -

1 A0 PA7 ADC1_IN12 TIM5_CH2 PA1 D5 6

Pin

Name

MCU

Pin

-

- TIM3_CH1 PB4 D6 7

Function Function

I2C3_SCL PG7 D15 10

I2C3_SDA PG8 D14 9

AVD D - AVDD 8

Ground - GND 7

TIM3_CH2,

SPI2_MOSI

3V3output

(note 1)

+6V to +9V

power input

(note 2)

TIM5_CH4,

SPI2_NSS

-

-PA4D78

MCU

Pin

PB15 D11 4

PI0 D10 3

Pin

Name

Pin

No.

CN No.

CN10

Digital

2 A1 PC4 ADC1_IN13 - PG6 D4 5

3 A2 PC3 ADC1_IN4 TIM15_CH2 PF10 D3 4

4 A3 PB0 ADC1_IN15 - PG11 D2 3

CN17

Analog

5A4

PA0 or

PG8

(note 3)

PA5 or

6A5

28/78 DocID030906 Rev 2

PG7

(note 3)

ADC1_IN5

or

I2C3_SDA

(note 3)

ADC1_IN10

or

I2C3_SCL

(note 3)

LPUART1_TX PC1 D1 2

LPUART1_RX PC0 D0 1

CN11

Digital

Page 29

UM2271 Connectors

1. The 3V3 on ARD connector PIN4 is not a power input for 32L4R9IDISCOVERY board, to simplify power architecture.

2. The external voltage applied to pin VIN should be in the range 6 to 9V at 25°C ambient temperature. If a higher voltage is

applied on the regulator U15, it may overheat and could be damaged.

3. By default, pin 5 and pin 6 of CN17 connector are connected to ADC MCU input ports PA0 and PA5 respectively, thanks to

configuration of solder bridges: SB33 and SB35 closed, SB32 and SB34 opened. In case it is necessary to connect I2C

interface signals on pins 5 and 6 of CN17 instead of ADC inputs, open SB33 and SB35, and close SB32 and SB34.

VREF+, the voltage reference used by the internal DAC and ADC of STM32L4R9AI, has

three different power sourcing capabilities:

• from STM32L4R9AI MCU Internal buffer generation (Default). VREFBUF internal ADC

/ DAC voltage reference is set to 2.5V by default.

• from an external Arduino shield, connected to connector CN10. In that case, SB27

needs to be connected to bring AVDD on VREF+, a 100nF is necessary on C48 and

VREFBUF needs to be de-activated.

• from a VDDA power supply generated on 32L4R9IDISCOVERY board. VDDA is also

connected to VDDUSB of STM32L4R9AI. In that case, mounting a 0 ohm resistor on

R14 is necessary. VREFBUF needs to be de-activated. A jumper JP3 also needs to be

set as below description.

Jumper Setting Description

Table 14. JP3, VDDA and VDDUSB, settings

Default setting.

JP3

Jumper on PIN1/2, VDDA get power from +3V3

VDDA

Setting

Jumper on PIN2/3, VDDA get power form VDD_MCU

(See warning below)

Warning: When VDDA=VDD_MCU and if VDD_MCU=1.8 V (check JP7

setting), there will be huge leakage current and a risk of

damaging MCU I/Os in case 3.3 V logic level is connected to

ADC input I/Os of STM32L4R9AI. Also, ADC measurements

will not be functional in default configuration

Caution: The I/Os of STM32 microcontroller are 3V3 compatible instead of 5 V for Arduino Uno.

Note: Limitation: the Arduino Uno Revision 3 is not compatible with JP7 setting at +1V8.

See Appendix B: Solder bridges for possible Arduino configuration change.

DocID030906 Rev 2 29/78

77

Page 30

Connectors UM2271

06Y9

ϭ

Ϯ

ϲϬ

ϱϵ

11.2 DSI display, backlight and touch panel connector CN4

All the necessary signals to interface with round DSI display board are available through the

DSI V3 connector CN4.

Figure 10. DSI display connector CN4

Function GPIO port Signal name

General ground - GND 1 2 NC - -

Differential DSI

clock

Differential DSI

clock

General ground - GND 7 8 DSI_D2_P -

Differential DSI

data 0

General ground - GND 13 14 DSI_D3_P -

Differential DSI

data 1

- DSI_CK_P 3 4 TOUCH_INT MFX_GPIO9

- DSI_CK_N 5 6 GND -

- DSI_D0_P 9 10 DSI_D2_N -

-DSI_D0_N1112GND -

- DSI_D1_P 15 16 DSI_D3_N -

-DSI_D1_N1718GND -

General ground - GND 19 20 NC - -

Power output - +5v 21 22 SPI_CS PH14

Table 15. DSI display connector CN4

CN6 pin

number

Signal name GPIO port Function

Touch panel

interrupt

General

ground

reference

Not

connected

Not

connected

General

ground

Not

connected

Not

connected

General

ground

SPI chip

select

30/78 DocID030906 Rev 2

Page 31

UM2271 Connectors

Table 15. DSI display connector CN4 (continued)

Function GPIO port Signal name

Power output - +5v 23 24 SPI2_SCK PB13 SPI clock

- - NC 25 26 SPI2_MOSIp PB15 SPI data

SM3321 ground - BLGND 27 28 SPI_DCX PB14

SM3321 ground - BLGND 29 30 NC - -

- - NC 31 32 RESERVED - -

- - NC 33 34 NC - -

- - NC 35 36 3V3 -

- - NC 37 38 VDDIO -

- - NC 39 40 I2C1_SDA PG13

- - NC 41 42 NC - -

DSI_SWIRE

control output

- - NC 45 46 NC - -

- - NC 47 48 NC - -

DSI tearing

effect input

PA8 DSI_SWIRE 43 44 I2C1_SCL PB6

PF11 TE 49 50 NC - -

CN6 pin

number

Signal name GPIO port Function

SPI

data/control

3V3 voltage

reference

IOVDD

reference

Touch panel

I2C data

Touch panel

I2C clock

- - NC 51 52 NC - -

DSI Backlight

control output

- - NC 55 56 NC - -

DSI and Touch

panel Reset

output

- - NC 59 60 1V8 -

General ground - GND 61 62 GND -

General ground - GND 63 64 GND -

PB1 DSI_BL_CTRL 53 54 NC - -

MFX_

GPIO10

DSI_RESET 57 58 NC - -

See Appendix B: Solder bridges for possible DSI display configuration change.

1.8V voltage

reference

General

ground

General

ground

DocID030906 Rev 2 31/78

77

Page 32

Connectors UM2271

11.2.1 DSI AMOLED display

Warning: Permanent image sticking may occur if AMOLED displays

same image for an extended period of time.

The DSI display is based on a round AMOLED Touch sensitive panel of 1.2 inch and

390x390

Optoelectronics. It displays up to 16M colors. The round DSI display module board

reference is MB1314. The DSI interface of MB1314 is only one data-lane width and a clock

lane, but the 32L4R9IDISCOVERY board supports DSI displays with up to two data-lane

width. The DSI_V3 connector interface also enables the use of dedicated low power modes

of display, thanks to the available SPI2 interface (MB1314 does not use it). It is also possible

to use some of USART3 signals to control a low power mode (SB6 and SB8 are respectively

exclusive with SB13 and SB7).

The DSI_TE signal PF11 is used as an input of the main microcontroller connected to the

display signal TE (tearing effect). DSI_TE signal is used to synchronize the refresh of the

display memory by the microcontroller with the display scan, this to avoid visible artefacts.

DSI_3V3_PWRON signal (MFX_GPIO8, low level active) controls the 3V3 level Power

supplies provided on the DSI_V3 connector interface. DSI_1V8_PWRON signal

(MFX_aGPIO2) controls the 1V8 level Power supplies provided on the DSI_V3 connector

interface. Both shall be used to enable or disable display, TP and PSRAM. They allows to

disconnect those peripherals when doing low power IDD measurement.

pixels. The display module reference is IEG1120TB103GF-001 from Govisionox

DSI_RESET signal (MFX_GPIO10, low level active) controls the reset for the display and

the Touch panel.

An optional DSI_SWIRE signal PA8 offers additional possibility to control the voltage for any

display supply during initialization (not used by MB1314 by default). PA8 is exclusive with

another function from 32L4R9IDISCOVERY board: CAMERA clock Interface (MCO), which

is the default setting.

11.2.2 Backlight and OLED power supplies generation

This function is handled by the Power driver circuit SM3321, included on the MB1314 DSI

display Board. SM3321 is a switching mode boost converter supplied by the 3V3 rail of the

DSI_V3 connector interface. SM3321 is controlled either by the AMOLED driver circuit itself

(default configuration), either by DSI_BL_CTRL (PB1) from main MCU, either from the

DSI_SWIRE (PA8) interface from main MCU. SM3321 provides all necessary voltage

references to AMOLED display.

If used, the signal DSI_BL_CTRL switches on the backlight with a high level. It is possible to

dim the backlight intensity by applying a low frequency PWM signal to DSI_BL_CTRL (1 to

10

kHz typically).

11.2.3 Touch panel

The touch panel is a capacitive touch panel using an I2C interface. The touch panel IC

reference is FT3267, and is located on the MB1314 board. The FT3267 I2C1 default

addresses are 0x71 and 0x70.

32/78 DocID030906 Rev 2

Page 33

UM2271 Connectors

06Y9

Touch panel interrupt output DSI_TOUCH_INT is connected to MFX_GPIO9. It is used as

touch panel detection indication. MFX_GPIO10 resets capacitive touch panel and DSI

display.

11.3 USB OTG FS connector CN9

An USB OTG full speed communication link is available at USB Micro AB receptacle

connector CN9. Micro AB receptacle enables USB Host and USB Device features.

MFX_GPIO13 is used to enable on-board VBUS power when in Host mode.

Figure 11. USB OTG FS Micro-AB connector CN9

Pin number Description Pin number Description

1 VBUS (PA9) 4 ID (PA10)

2DM (PA11) 5GND

3 DP (PA12) - -

Table 16. USB OTG FS Micro-AB connector CN9

11.4 ST-LINK/V2-1 USB Micro-B connector CN13

The USB connector CN13 is used to connect the embedded ST-LINK/V2-1 to the PC.

DocID030906 Rev 2 33/78

77

Page 34

Connectors UM2271

06Y9

Figure 12. USB Micro-B connector CN13

Pin number Description Pin number Description

1 VBUS (power) 4 GND

2 DM 5,6 Shield

3DP --

Table 17. USB Micro-B connector CN13

11.5 microSD card connector CN6

microSD cards with 4 GBytes or more capacity are inserted in the receptacle CN6. Four

data bits of the SDMMC1 interface, CLK and CMD signals of the STM32L4R9AI are used to

communicate with the microSD card at +3V3 only. The card insertion is detected by the

MFX_GPIO5: when a microSD card is inserted, the logic level is 0, otherwise it is 1.

34/78 DocID030906 Rev 2

Page 35

UM2271 Connectors

06Y9

Figure 13. microSD connector CN6 (top view)

Pin

number

1 SDMMC1_D2 (PC10) 6 GND

2 SDMMC1_D3 (PC11) 7 SDMMC1_D0 (PC8)

3 SDMMC1_CMD (PD2) 8 SDMMC1_D1 (PC9)

4 VDD (+3V3) 9 µSD_DETECT (MFX_GPIO5)

5 SDMMC1_CLK (PC12) 10-11-12 GND (casing)

Table 18. microSD connector CN6

Description

Pin

number

Note: Limitation: the microSD is not compatible with JP7 setting at +1V8.

11.6 STMod+ connector CN1

The standard 20-pin STMod+ connector is available on 32L4R9IDISCOVERY board to

increase compatibility with external boards and modules from the Ecosystem of

microcontrollers. By default, it is designed to support an ST dedicated Fanout board which

allows connecting different modules or board extensions from different manufacturers.

Fanout board also embeds a 3V3 regulator and I2C level shifters. Schematics of Fanout

board is available in

Figure 35.: Fanout board (MB1280). For more detailed information,

Description

DocID030906 Rev 2 35/78

77

Page 36

Connectors UM2271

06Y9

)URQWYLHZ

please refer to ST Fanout board user manual and to relevant datasheets of associated

modules.

For details about STMod+ interface, please refer to STMod+ connector interface

specification.

Figure 14. STMod+ connector CN1

Pin

number

Table 19. STMod+ connector CN1

Description

Pin

number

Description

1 SPI2_CS/USART3_CTS (PA6) 11 INT (PC6)

2 SPI2_MOSIp/USART3_TXD (PB15/PB10) 12 RST (PI7)

3 SPI2_MISOp/USART3_RXD (PB14/PB11) 13 ADC (PA4)

4 SPI2_SCK/USART3_RTS (PB13/PA15) 14 PWM (PA5)

5GND15+5V

6 +5V 16 GND

7 I2C3_SCL (PG7) 17 GPIO (PB12)

8 SPI2_MOSIs (PI3) 18 GPIO (PC2)

9 SPI2_MISOs (PI2) 19 GPIO (PC7)

10 I2C3_SDA (PG8) 20 GPIO (PC2)

In order to be able to support selection of SPI or UART functions connection on STMod+ by

software, a quad SPDT switch has been added. It is controlled by two GPIOs from MFX

circuit and enables MCU signal selection for pins 2, 3 and 4. By default, STMod+ connector

is selected, and STMOD+_SEL_0 and STMOD+_SEL_1 of MFX circuit are set to support

one of the STMod+ interface configuration.

Pin number SPI UART / SPI

Table 20. Quad SPDT switch configuration

(1)

UART

STMOD+_SEL_0 (GPIO6 of MFX_V3) 0 1 1

STMOD+_SEL_1 (GPIO7 of MFX_V3) 0 0 1

STMod+ pin 1 (directly connected to PA6) SPI_CS SPI_CS USART3_CTS

STMod+ pin 2 SPI2_MOSIp USART3_TX USART3_TX

36/78 DocID030906 Rev 2

Page 37

UM2271 Connectors

06Y9

)URQWYLHZ

Table 20. Quad SPDT switch configuration (continued)

Pin number SPI UART / SPI

STMod+ pin 3 SPI2_MISOp USART3_RX USART3_RX

STMod+ pin 4 SPI2_SCK SPI2_SCK USART3_RTS

1. UART / SPI defines default configuration for STMOD+_SEL_0 and STMOD+_SEL_1.

(1)

UART

Please, take care that this connector shares many GPIOs with other functions on the Board:

for more detailed information please refer to

Appendix A: GPIO assignment and sharing.

In addition, to have a quick look at STMod+ GPIO sharing and multiplexing, and to get a

quick view on other Alternate functions available on its pins, please refer to

Appendix C:

STMod+ GPIO sharing and multiplexing.

Note: Limitation: The STMod+ interface is not compatible with JP7 setting at +1V8.

Note: Limitation: if STMod+ pin 17 is used, please take care to disconnect SB1 first. If STMod+ pin

18/20 is used, please activate MIC_VDD GPIO (PH2) at high level first.

11.7 PMOD connector CN3

The standard 12-pin PMOD connector is available on STM32L4R9I-DISCO Discovery board

to support low frequency, low I/O pin count peripheral modules. The PMOD interface which

has been implemented on STM32L4R9I-DISCO Discovery board is compatible with the

PMOD type 2A & 4A I/O signal assignment convention.

Figure 15. PMOD connector CN3

Pin number Description Pin number Description

1 SPI2_CS/USART3_CTS (PA6) 7 INT (PC6)

2 SPI2_MOSIp/USART3_TXD (PB15/PB10) 8 RESET (PI7)

3 SPI2_MISOp/USART3_RXD (PB14/PB11) 9 NA

4 SPI2_SCK/USART3_RTS (PB13/PA15) 10 NA

5GND 11GND

Table 21. PMOD connector CN3

63V3 123V3

DocID030906 Rev 2 37/78

77

Page 38

Connectors UM2271

06Y9

In order to be able to support selection of SPI or UART functions connection on PMOD by

software, a quad SPDT switch has been added on board. It is controlled by two GPIOs from

MFX_V3 circuit and enables MCU signal choice for pins 2, 3 and 4: refer to

Tabl e 20

STMod+ chapter for switch description details (pin 1, 2, 3 and 4 of PMOD are common with

STMod+).

By default, STMod+ connector is selected, so STMOD+_SEL_0 and STMOD+_SEL_1

needs to be modified to support one of the PMOD interface configuration. Also, PMOD

shares GPIOs with other functions of the Board: for more detailed information please refer

to

Appendix A: GPIO assignment and sharing.

Note: Limitation: the PMOD interface is not compatible with JP7 setting at +1V8.

11.8 Camera module connector CN2

An 8-bit camera module function is supported thanks to the 30-pin dedicated ZIF connector

CN2. The reference of camera module to be used is STM32F4DIS-CAM. This module has

to be connected with caution before powering on the STM32L4R9I-DISCO Discovery board.

The camera module I²C addresses are 0x61 and 0x60. Camera can be used by default, but

one might take care about GPIO sharing and multiplexing with other function, in order to

program the good configuration. For more detailed information please refer to

GPIO assignment and sharing.

Appendix A:

Note: Limitation: the camera is not compatible with JP7 setting at +1V8.

Figure 16. Camera module connector CN2

Pin number Description Pin number Description

1GND 16GND

2 NC 17 DCMI_HSYNC (PA4)

3NC 18NC

4 DCMI_D0 (PC6) 19 DCMI_VSYNC (PI5)

5 DCMI_D1 (PC7) 20 VDD

6 DCMI_D2 (PH11) 21 DCMI_CLK (PA8)

Table 22. Camera module connector CN2

7 DCMI_D3 (PH12) 22 NC

8 DCMI_D4 (PE4) 23 GND

9 DCMI_D5 (PI4) 24 NC

38/78 DocID030906 Rev 2

Page 39

UM2271 Connectors

06Y9

Table 22. Camera module connector CN2 (continued)

Pin number Description Pin number Description

10 DCMI_D6 (PB8) 25 DCMI_PWR_EN (MFX_GPIO12)

11 DCMI_D7 (PI7) 26 DCMI_NRST (NRST from MCU)

12 NC 27 I2C1_SDA (PG13)

13 NC 28 I2C1_SCL (PB6)

14 GND 29 GND

15 DCMI_PIXCK (PH5) 30 VDD

11.9 TAG connector CN8

The TAG connector footprint CN8 is used to connect STM32L4R9AI microcontroller for

programming or debugging the board.

Figure 17. TAG connector CN8

Pin number Description Pin number Description

1 VDD 10 NRST (PH3, RESET#)

2 SWDIO (PA13) 9 NA

3GND 8NA

4 SWCLK (PA14) 7 NA

5GND 6SWO (PB3)

11.10 SWD header CN5

The 6-pin SWD header is used to program or debug an MCU in an external application

board using a dedicated cable connected to it. To use this SWD header interface, pins 2 and

3 of JP10 need to be connected with a jumper. Furthermore, SW1 must be set in OFF

position while R24 and R31 need to be disconnected.

By default, STLINK/V2-1 is used to program or debug on board MCU. Pin1 and 2 of JP10

are connected, SW1 is in ON position, R24 and R31 are connected.

Table 23. TAG connector CN8

DocID030906 Rev 2 39/78

77

Page 40

Connectors UM2271

06Y9

)URQWYLHZ

Table 24. SWD header CN5

Pin number Description Pin number Description

1 VDD 4 SWDIO (PA13)

2 SWCLK (PA14) 5 NRST

3GND 6SWO (PB3)

11.11 EXT_I2C connector CN7

The EXT_I2C connector socket is used to connect external modules to I2C1 interface or to

monitor the I2C1 interface.

Figure 18. EXT_I2C connector CN7

Table 25. EXT_I2C connector CN7

Pin number Description Pin number Description

1 I2C1_SDA (PG13) 5 +3V3

2NC 6NC

3 I2C1_SCL (PB6) 7 GND

4 EXT_RESET (MFX_GPIO11) 8 NC

As I2C1 is available for external use, it is important to note that those following I2C1

applications and addresses are already used on board:

Application

DSI display Touch Panel 0x71/0x70 400 kHz Default I2C address

Audio Codec 0x95/0x94 100 kHz Default I2C address

CAMERA 0x61/0x60 400 kHz For STM32F4DIS-CAM Module

MFX_V3 0x85/0x84 400 kHz Default I2C address

Table 26. I2C1 addresses (on board)

W/R I2C

address

I2C max. speed Comment

Depending on the I2C module plugged into CN7, I2C1 could even be used up to

Fast mode + (1 MHz).

40/78 DocID030906 Rev 2

Page 41

UM2271 Connectors

06Y9

ϯ

Ϯ

ϲ

ϰ

ϱ

ϭ

11.12 Stereo headset and headphone jack CN12

A stereo headphone or a stereo headset with analog microphone is pluggable into the

3.5

mm standard jack socket CN12.

Figure 19. Stereo headset with microphone jack CN12

Pin number Description Stereo headset with microphone pinning

6 OUT_Left SPK_L (33 ohms typ.)

4 OUT_Right SPK_R (33 ohms typ.)

3GND GND

2 IN_Analog Microphone

5NC

1NC

Table 27. Audio jack connector CN12

NA

If a headset is plugged into CN12, the bias of the microphone is driven by the output

MICBIAS1 of the codec and the analog audio enters into the codec by the pin AIN3A.

DocID030906 Rev 2 41/78

77

Page 42

42/78 DocID030906 Rev 2

Appendix A GPIO assignment and sharing

GPIO assignment and sharing UM2271

Table 28. 32L4R9IDISCOVERY GPIO assignment and sharing

Pin GPIO port GPIO primary interface STMod+ interface PMOD interface ARDUINO interface

K3 PA0 - - - ARD_A4 (ADC1_IN5)

M1 PA1 - - - ARD_D5 (TIM5_CH2)

N1 PA2 STLINK_USART2_TX - - -

M2 PA3 STLINK_USART2_RX - - -

N2 PA4

L3 PA5 -

L4 PA6 -

DCMI_HSYNC/DE STMod+_ADC (ADC_1_IN9) - ARD_D7

STMod+_PWM (TIM2_CH1) - ARD_A5 (ADC1_IN10)

STMod+_SPI2_CS //

STMod+_USART3_CTS

(NU)

PMOD_SPI2_CS //

PMOD_USART3_CTS

(NU)

-

M4 PA7 - - - ARD_A0 (ADC1_IN12)

(NU)

//

-- -

E11 PA8

DSI_SWIRE

DCMI_CLK (MC0)

E12 PA9 VBUS - - -

D11 PA10 ID - - -

E13 PA11 DM - - -

D13 PA12 DP - - -

A11 PA13 JTMS/SWDIO - - -

A10 PA14 JTCK/SWCLK - - -

A9 PA15 - STMod+_USART3_RTS

(NU)

(NU)

(NU)

//

--ARD_A3 (ADC1_IN15)

-- -

N4 PB0 DSI_USART3_CK

L5 PB1

DSI_BL_CTRL

DSI_SWIRE

(NU)

PMOD_USART3_RTS

(NU)

N5 PB2 MFX_WAKEUP_OUT - - -

-

Page 43

Table 28. 32L4R9IDISCOVERY GPIO assignment and sharing (continued)

Pin GPIO port GPIO primary interface STMod+ interface PMOD interface ARDUINO interface

A6 PB3 JTDO/TRACESWO - - -

A5 PB4 - - - ARD_D6 (TIM3_CH1)

B5 PB5 SAI1_SD_B - - -

C5 PB6 I2C1_SCL - - -

D5 PB7 PSRAM_NL (ADV) - - -

C4 PB8 DCMI_D6

(NU)

D4 PB9 SAI1_FS_A - - -

N9 PB10

DSI_USART3_TX

(NU)

STMod+_USART3_TX PMOD_USART3_TX -

-- -

UM2271 GPIO assignment and sharing

DocID030906 Rev 2 43/78

H7 PB11 -

N12 PB12

N13 PB13

M12 PB14

L10 PB15

DFSDM_1_DATIN1 STMod+_GPIO

DSI_SPI2_SCK

DSI_SPI_D/CX

DSI_SPI2_MOSI

(NU)

(NU)

(NU)

STMod+_USART3_RX PMOD_USART3_RX -

(NU)

--

STMod+_SPI2_SCK PMOD_SPI2_SCK ARD_D13 (SPI2_SCK)

STMod+_SPI2_MISOp

STMod+_SPI2_MOSIp

(NU)

(NU)

PMOD_SPI2_MISO