OPERATING MANUAL

MIXER HEAD

MODEL NUMBERS

750-0210, 750-0220

750-0230, 750-0240

AND

MIXER CONTROLLER

MODEL NUMBER 750-0202

A heavy-duty modular mixing system with a detachable controllerto

accommodate a wide variety of small batch mixing applications.

Barnant Company

28W092 Commercial Ave .

Barrington, Illinois U.S.A.60010-2392

(847) 381-7050

(847) 381-7053 (Fax)

800-637-3739

www.barnant.com

e-mail:barnant@barnant.com

A-1299-0483

Edition 04

I

SO

REGISTERED

9001

SAFETY PRECAUTIONS

DANGERS:

W ARNINGS:

Highv ol ta gesexistandareaccessibleintheController.

Return the unit to your dealer for servicing.

Do not operate mixer s wher e e xplosi ve v apor s or

flammable materials exist. Death or serious injury

could result. Check NEC and local codes before

installing.

Never clean the Contr oll er or Mixer Head while power

is applied to the system.

Use only those mixer shafts that are properlysized for

the Mixer Head being used. Refer to Mixer Head

specificationsf orthe propershaftdiameterorr angeto

be used. Sizes other than those specified can cause

injury to personnel or damage to equipment.

Disconnect the AC power input line cord before

connecting the drive motor cable.

Exerci se extreme care when adjusting mixer height

and/or position to avoid personal injury. Never make

these adjustments while the mixer shaft is rotating.

Never insert or remove the mixer shaft/impeller while

the mixer shaft is rotating.

Check that all cords are clear of any moving parts and

not subject to splashes or spills.

Be sure the SPEED control is fully countercl oc kwi se

beforethePOWERswit chisplacedintheFWD or REV

positions.

Usecarewhensettingtheoperatingspeedofthemixer.

Operationat highspeedsinsmallmixingvesselscould

result in hazardous splashi ng on the operator and

equipment.

When running at full speed and load at higher ambient

temperatures,the Mixer Head may get very hot to the

touch.

Use of mixing shafts and impellers larger than those

recommended could result in poor product

performanceand shortened service life.

Mixer shafts must be inserted into high speed

through-shaftmixersatleast3 in(7.6cm) andthecollet

hand-tightened firmly to ensure adequate shaft

retention. Keep mixer shafts as short as possib l e to

reduce resonant vibrations caused by shaft flexing at

higher speeds.

The Mixer Head is to be used only for mixing. It is not

intended for any other purpose.

–2–

INTRODUCTION

The heavy-duty modular mixing system cov ered in this manual consists of

four different Mixer Heads and a Controller.

The following chart cross-references the model number, operating speed

range and torque rating of the Mixer Heads.

MIXER HEAD MAXIMUM

MODEL NO. SPEED RANGE TORQUE

(r/min) (oz-in) (kg•cm)

750-0210 2–180 340 24.5

750-0220 9–900 70 5.0

750-0230 23–2300 45 3.2

750-0240 60–6000 17 1.2

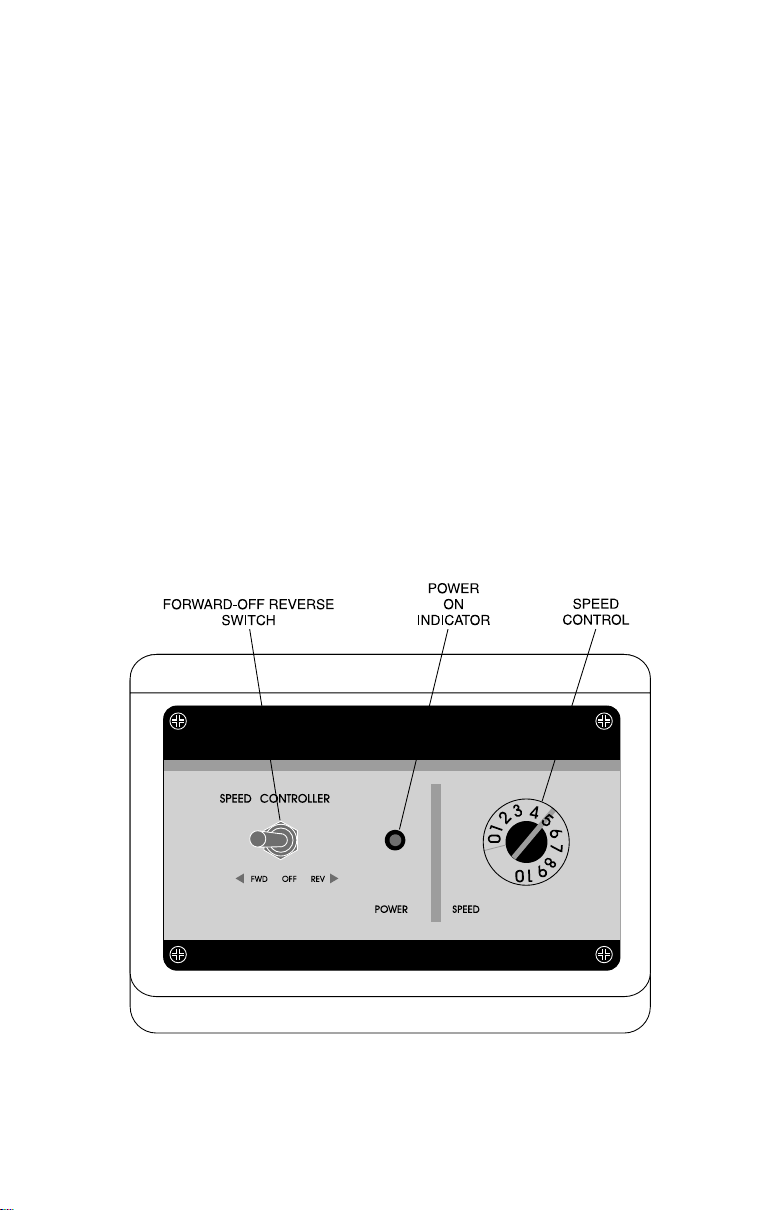

The variablespeed Controller,Figure1andFigure2, is used to set the speed

of the Mixer Heads and provides a 100:1 adjustment range. Mixer Head

Models750-0230and750-0240 are used formixinglowerviscosityfluidsand

have a 0.375 in collet and through-shaft design that accepts 0.375 in mixer

shafts.Models750-0210and 750-0220provideahightorqueoutputatspeeds

up to 180 r/min for mixing higher viscosity fluids and have a JACOBS

chuck that accepts stirring shafts from 5/16 in to 3/8 in.

®

-type

Figure 1 Readouts and Controls

–3–

DESCRIPTION

The heavy-duty modular mixing system has been designed toaccommodate

a wide variety of small batch mixing applications.Its modular design allows

the user to select from four different Mixer Heads — from low speed/high

torque heads (model 750-0210 and 750-0220) for high viscosity applications

to high speed/low torque heads (750-0230 and 750-0240) for blending and

shearing applications.

Models 750-0210 and 750-0220 high-torque mix ers use a JACOBS-type

chuck and accept shafts from 5/16 in to 3/8 in. The in-line shaft rotates at

speeds from 2 to 900 r/min depending on the model.

Models 750-0230 and 750-0240 high-speed mixersuse a 0.375 in collet and

have a through shaft design that accepts stirring shafts up to 0.375 in in

diameter. The through-shaft design provides quick depth adjustment of the

mixerb lade .These mixersoperateatspeeds from23to6000r/mindepending

on the model.

The Controller ensures accurate, dependable motor speed (mixing) control,

with“softstart”andsmoothgradualadjustment to thespeedsetting.Constant

speed with a 100:1 adjustment range is maintained electronically via

automatic compensation for changes in load torque demands — at both high

and low speeds. Built-in motor current compensation minimizes speed drift

with changes in load. Motor current limiting protects the system in case of a

locked rotor condition.Output circuit protection protects against inadvertent

output shorting.

Themotorisatotallyenclosed,non-ventedpermanent-magnetdirect-current

motor.Models750-0210and750-0220 are ratedat1/15hp.Models750-0230

and 750-0240 are rated at 1/10 hp.Mixer rotation is reversible.

Figure 2 Controller Rear Panel

–4–

INSTALLATION AND SETUP PROCEDURE

TheMixerHeadsareequippedwithanadjustabletiltmountingassembly.The

mounting assembly is designed to be attached to an optional mixer support

stand, or tank clamp. Components supplied as part of the mixer package

include the following:

• Mixer Head with 6-ft cable

• Controller with 6-ft line cord

• JACOBS-type chuck on high-torque mixers

• 0.375 in collet on high-speed mixers

• Adjustable tilt mounting assembly with support rod

Installation of Adjustable Tilt Mounting

Perf orm the following steps.

WARNING: Never insert or remove the mixer shaft/

impeller while the mixer shaft is rotating.

1. Attach Mixer Head to adjustable tilt mounting assembly as follows:

a. For models 750-0210 and 750-0220, attachmounting assemblywith

four screws and lockwashers.(See Figure 3.)

Figure 3 750-0210 and 750-0220 Mixer Mounting

b. For models 750-0230 and 750-0240, attachmounting assemblywith

two screws and lockwashers.(See Figure 4.)

–5–

Figure 4 750-0230 and 750-0240 Mixer Mounting

Note: Themixerisnowready to be attached to a support stand or toatank

clamp (not supplied). Recommended stands, tank clamps and a

double (rod) clamp are available through your dealer.Part numbers

are listed in ACCESSORIES.

Installation Using a Support Stand

1. Set up support stand in accordance with the manufacturer’sinstructions.

2. Attach a double (rod) clamp to the vertical rod on the support stand and

tighten clamp screw. (See Figure 5.)

3. Slide rod of adjustabletiltmountingassemblyintoclampandsecurewith

clampscrew.

4. Selectanimpellerandshaftf ortherequir edoperati onandinstal lasf ol lows:

a. Place impeller on shaft and tighten set screw.

b. For high-torque mixers, slide the shaft of the stirring device into the

JACOBS-chuck and tighten chuck with key supplied.

c. For high-speed models, slide the shaft through the collet and

hand-tighten collet.

5. Place support stand legs around vessel.Tiltangle is adjustable from 0 to

30 degrees.

WARNINGS: Exercise extreme care when adjusting mixer

height and/or position to avoid personal

injury. Never make these adjustments while

the mixer shaft is rotating.

Mixer shafts must be inserted into high speed

through-shaftmixersatleast3in(7.6cm)and the

collet hand-tightened firmly to ensure adequate

shaft retention. Keep mixer shafts as short as

possibletoreduceresonantvibrationscausedby

shaft flexing at higher speeds.

–6–

c. Place Controller on platform and proceed to step 9.

8. To install the pivot mount, proceed as follows:

a. Remove the two cap nuts from the mounting studs on bottom of

Controller.

b. Position pivot mount bracket over two studs, re-install two cap nuts

and tighten.

c. Attach a double (rod) clamp to the vertical support rod on the stand

and position so that pivot mount bracket will be clear of Mixer Head.

d. Slidethemountingrodofthepivotmountbrack etintothedouble(rod)

clamp and tighten clamp.

e. Adjust position of Controller by first loosening knob on piv ot mount

bracket, adjusting position and then retightening knob.

WARNING: Check that all cords are clear of any moving

parts and not subject to splashes or spills.

9. Connect the 6-ft.cable between the MixerHead and the Controller rear

panel.

10. Check that the SPEED control is set fully counterclockwise (0) and that

the FWD-OFF-REV switchis in the OFF position.

11. Connect the 6-foot line cord from the Controller to a 90–130V AC 50 or

60 Hz 3-wire grounded power source.

WARNING: Be sure the SPEED control is fully

counterclockwisebeforethePOWERswitchis

placed in the FWD or REV positions.

The Mixer is now ready to operate.

Installation using a Tank Clamp

The Tank Clamp is attached to the side of a tank and supports both the Mixer

Head and the Controller.(See Figure 6.)

1. Position the tank clamp over the edge of the tank with large knob to the

outside of tank.

2. Allow clamp to rest on edge of tank for added stability, and tighten knob.

3. PositionMixerHeadovermaterialtobe mixedandinsert mixermounting

shaft into upper hole in tank clamp.Tighten locking knob securely .

4. Select an impeller and shaft f or the required operation and install as

follows:

–8–

MIXER

HEAD

TANK

CLAMP

CONTROLLER

PLATFORM

Figure 6 Typical Mixer Setup Using a Tank Clamp

a. Place impeller on shaft and tighten set screw.

b. For high-torque mixers, slide the 5/16 in to 3/8 in shaft of the stirring

device into the JACOBS-chuck and tighten chuck.

c. Forhigh-speedmodels,slidethe0.375in shaft through thecolletand

tighten collet. Be sure only 0.0375 in (±0.0005) shafts are used.See

your dealer for obtaining proper shaft size.Referto ACCESSORIES

for part numbers.

DANGER: Do not operate mixers where explosive vapors or

flammable materials exist. Death or serious injury

could result. Check NEC and local codes before

installing.

WARNINGS: Exercise extreme care when adjusting mixer

height and/or position to avoid personal injury.

Never make these adjustments while the mixer

shaft is rotating.

Mixer shafts must be inserted into high speed

through-shaft mixers at least 3 in (7.6 cm) and the

collet hand-tightened firmly to ensure adequate

shaft retention. Keep mixer shafts as short as

possible to reduceresonantvibrations caused by

shaft flexing at higher speeds.

–9–

5. PositiontheheightoftheMixer Head onhigh-speedmodelsbyloosening

the collet and positioning the shaft.

Note: The Controller can be placed on any flat surfacewithin 6 ft (1.8 m) of

the Mixer Head and can be mounted on a support platf orm (not

supplied) or a pivot mount (not supplied). Refer to ACCESSORIES

forpartnumbers.Toattachthesupport platform, proceed withstep6.

To attach the pivot plate, proceed with step 7. If Controller is placed

elsewhere, proceed with step 8.

6. To install the support platform, proceed as follows:

a. Slide the mounting rod of the support platform into the lower hole on

the tank clamp and tighten clamp.

b. Place Controller on platform and proceed to step 8.

7. To install the pivot mount, proceed as follows:

a. Remove the two cap nuts from the mounting studs on bottom of

Controller.

b. Position pivot mount bracket over two studs, re-install two cap nuts

and tighten.

c. Slide the mounting rod of the pivot mount bracket into the lower hole

on the tank clamp and tighten clamp.

d. Adjust position of Controller by first loosening knob on pivot mount

bracket, adjusting position and then retightening knob.

8. Connect the 6-foot cablebetweentheMixerHeadandtheControllerrear

panel.

9. Check that the SPEED control is set fully counterclockwise (0) and that

the FWD-OFF-REV switchis in the OFF position.

10. Connect the 6-foot line cord from the Controller to a 90–130V AC 50 or

60 Hz 3-wire grounded power source.

WARNINGS: Check that all cords are clear of any moving

parts and not subject to splashes or spills.

Be sure the SPEED control is fully counter-

clockwisebeforethe POWER switch is placed

in the FWD or REV positions.

The Mixer is now ready to operate.

–10–

OPERATION

Be sure to follow these precautions when using the Mixer Controller System:

Always wear appropriate eye protection when mixing any kind of fluid.

Avoi dwearinglooseclothingthatma ybe caught by arotatingmixershaft.

To stoptheMix erHead inanemergency,placetheFWD/OFF/REV switch

in the OFF position or remove the power plug.

WARNING: Be sure the SPEED control is fully counter-

clockwisebeforethe POWER switchis placed

in the FWD or REV positions.

The FWD position causes the shaft to rotate in a counterclockwise direction

whenviewed from the impeller.TheSPEEDcontrol preciselysetstheoutput

speed of the shaft. The Controller has a range of 100:1 depending on the

model; shaft speed can be as low as 2 r/min or as high as 6000 r/min. The

green LED indicator illuminates whenev er the FWD-OFF-REV switch is in

either the FWD or REV position.

WARNINGS: Use care when settingthe operatingspeed of

the mixer. Operation at high speeds in small

mixing vessels could result in hazardous

splashing on the operator and equipment.

When running at full speedand load at higher

ambienttemperatures,theMixerHeadmayget

very hot to the touch.

Never insert or remove the mixer shaft/

impeller while the mixer shaft is rotating.

Set the SPEED Control to a setting that provides the desired mixing speed.

Allow about 20 minutes run-intime to allow warm-up drift to become minimal.

–11–

Cleaning the Mixer/Controller System

DANGER: NevercleantheControllerorMixerHead while

power is applied to the system.

Keep the Mixer housing and Controller enclosure clean by using a mild

detergent.Never immerse or use excess fluid.

Replacement Parts

Nouser-serviceablepartsare

dealer.

The following parts

Description Part Number

Speed Control Knob B-1083-0035

Motor Brushes (2) 07520-04

Brush Cap (1) A-2542-CR

JACOBS-type Chuck Assembly (-0210 and -0220) B-2857-0012

Chuck Key (-0210 and -0220) A-1377-0002

Collet Nut (-0230 and -0240) A-3535-0012

Pivot Assembly Knob (1) B-1083-0039

Contact your dealer if you have service needs.

are

inside

ofthisinstrument.Referservicing toyour

user replaceable.

–13–

Loading...

Loading...