Stir-Pak 750-0210, 750-0220, 750-0230, 750-0240 Instruction Manual

OPERATING MANUAL

MIXER HEAD

MODEL NUMBERS

750-0210, 750-0220

750-0230, 750-0240

AND

MIXER CONTROLLER

MODEL NUMBER 750-0202

A heavy-duty modular mixing system with a detachable controllerto

accommodate a wide variety of small batch mixing applications.

Barnant Company

28W092 Commercial Ave .

Barrington, Illinois U.S.A.60010-2392

(847) 381-7050

(847) 381-7053 (Fax)

800-637-3739

www.barnant.com

e-mail:barnant@barnant.com

A-1299-0483

Edition 04

I

SO

REGISTERED

9001

SAFETY PRECAUTIONS

DANGERS:

W ARNINGS:

Highv ol ta gesexistandareaccessibleintheController.

Return the unit to your dealer for servicing.

Do not operate mixer s wher e e xplosi ve v apor s or

flammable materials exist. Death or serious injury

could result. Check NEC and local codes before

installing.

Never clean the Contr oll er or Mixer Head while power

is applied to the system.

Use only those mixer shafts that are properlysized for

the Mixer Head being used. Refer to Mixer Head

specificationsf orthe propershaftdiameterorr angeto

be used. Sizes other than those specified can cause

injury to personnel or damage to equipment.

Disconnect the AC power input line cord before

connecting the drive motor cable.

Exerci se extreme care when adjusting mixer height

and/or position to avoid personal injury. Never make

these adjustments while the mixer shaft is rotating.

Never insert or remove the mixer shaft/impeller while

the mixer shaft is rotating.

Check that all cords are clear of any moving parts and

not subject to splashes or spills.

Be sure the SPEED control is fully countercl oc kwi se

beforethePOWERswit chisplacedintheFWD or REV

positions.

Usecarewhensettingtheoperatingspeedofthemixer.

Operationat highspeedsinsmallmixingvesselscould

result in hazardous splashi ng on the operator and

equipment.

When running at full speed and load at higher ambient

temperatures,the Mixer Head may get very hot to the

touch.

Use of mixing shafts and impellers larger than those

recommended could result in poor product

performanceand shortened service life.

Mixer shafts must be inserted into high speed

through-shaftmixersatleast3 in(7.6cm) andthecollet

hand-tightened firmly to ensure adequate shaft

retention. Keep mixer shafts as short as possib l e to

reduce resonant vibrations caused by shaft flexing at

higher speeds.

The Mixer Head is to be used only for mixing. It is not

intended for any other purpose.

–2–

INTRODUCTION

The heavy-duty modular mixing system cov ered in this manual consists of

four different Mixer Heads and a Controller.

The following chart cross-references the model number, operating speed

range and torque rating of the Mixer Heads.

MIXER HEAD MAXIMUM

MODEL NO. SPEED RANGE TORQUE

(r/min) (oz-in) (kg•cm)

750-0210 2–180 340 24.5

750-0220 9–900 70 5.0

750-0230 23–2300 45 3.2

750-0240 60–6000 17 1.2

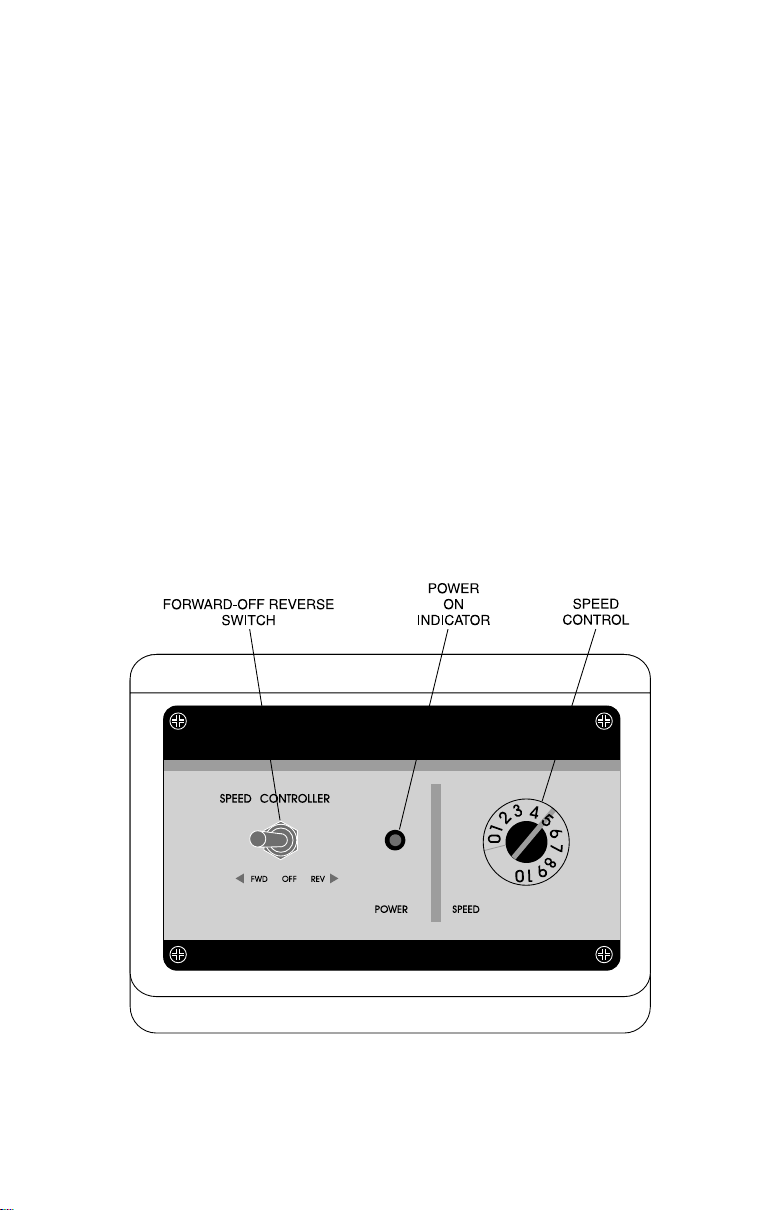

The variablespeed Controller,Figure1andFigure2, is used to set the speed

of the Mixer Heads and provides a 100:1 adjustment range. Mixer Head

Models750-0230and750-0240 are used formixinglowerviscosityfluidsand

have a 0.375 in collet and through-shaft design that accepts 0.375 in mixer

shafts.Models750-0210and 750-0220provideahightorqueoutputatspeeds

up to 180 r/min for mixing higher viscosity fluids and have a JACOBS

chuck that accepts stirring shafts from 5/16 in to 3/8 in.

®

-type

Figure 1 Readouts and Controls

–3–

Loading...

Loading...