Page 1

OPERATING MANUAL

Cole-Parmer

®

Stir-Pak®

Mixer Head Model Numbers

50007-10, 50007-15, 50007-20, 50007-25

50007-30, 50007-35, 50007-40, 50007-45

&

Mixer Controller Model Numbers 50007-00, 50007-05

Cole-Parmer® ServoDyne™

Mixer Head Model Numbers

50008-10, 50008-20, 50008-30, 50008-40

&

Mixer Controller Model Number 50008-00

Cole-Parmer

625 East Bunker Court

Vernon Hills, Illinois U.S.A. 60061-1844

Toll Free: 800-323-4340

Phone: 847-549-7600

Fax: 847-247-2929

www.coleparmer.com

E-mail: techinfo@coleparmer.com

-- 1 --

Version 11Nov08 Rev1

Page 2

SAFETY PRECAUTIONS

• High voltages exist and are accessible in the controller.

Contact Cole-Parmer for servicing.

• Do not operate mixers where explosive vapors or flammable

materials exist. Death or serious injury could result. Check

NEC and local codes before installing.

• Never clean the controller or mixer head while power is

applied to the system.

• Use only those mixer shafts that are properly sized for the

mixer head being used. Refer to mixer head specifications for

the proper shaft diameter or range to be used. Sizes other than

those specified can cause injury to personnel or damage to

equipment.

• Disconnect the AC power input line cord before connecting the

mixer head cable.

• Exercise extreme care when adjusting mixer height and/or

position to avoid personal injury. Never make these

adjustments while the mixer shaft is rotating.

• Never insert or remove the mixer shaft/impeller while the mixer

shaft is rotating.

• Be sure speed control is fully counterclockwise before the

POWER switch is placed in the FWD or REV positions. (5000700 and 50007-05 Controller)

• Check that all cords are clear of any moving parts and not

subject to splashes or spills.

• Use care when setting the operating speed of the mixer.

Operation at high speeds in small mixing vessels could result

in hazardous splashing on the operator and equipment.

• When running at full speed and load at higher ambient

temperatures, the mixer head may get very hot to the touch.

• Use of mixing shafts and impellers larger than those

recommended could result in poor product performance and

shortened service life.

• Mixer shafts must be inserted into high-speed through-shaft

mixers at least 3 inches (8 mm) and the collet hand-tightened

firmly to ensure adequate shaft retention. Keep mixer shafts as

short as possible to reduce resonant vibrations caused by the

shaft flexing at higher speeds.

• The mixer head is to be used only for mixing. It is not intended

for any other purpose.

-- 2 --

Page 3

INTRODUCTION

The Stir-Pak 50007-series heavy-duty modular mixing system covered in this manual consists of eight different

mixer heads and two analog controllers for 115VAC and 230VAC operation.

The ServoDyne 50008-series digital modular mixing system consists of four different mixer heads and a

precision digital controller for 115VAC operation.

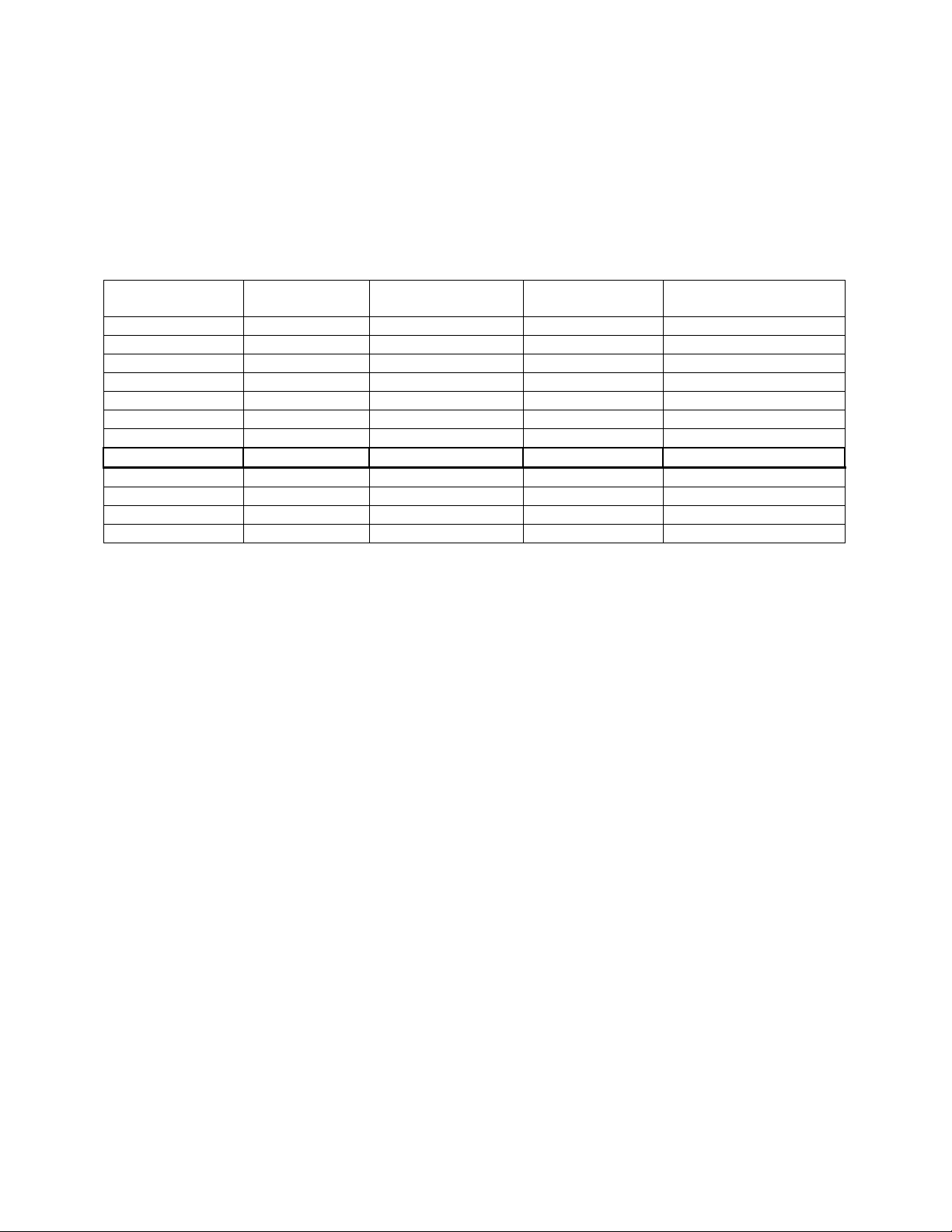

The following chart cross-references the model number, operating speed range and torque rating of the mixer

heads and the compatible controller.

MIXER HEAD CONTROLLER OPERATING

VOLTAGE

50007-10 50007-00 115 VAC, 50/60 Hz 2 to 180 340 (24.5)

50007-20 50007-00 115 VAC, 50/60 Hz 9 to 900 70 (5)

50007-30 50007-00 115 VAC, 50/60 Hz 23 to 2300 45 (3.2)

50007-40 50007-00 115 VAC, 50/60 Hz 60 to 6000 17 (1.2)

50007-15 50007-05 230 VAC, 50 Hz 2 to 180 340 (24.5)

50007-25 50007-05 230 VAC, 50 Hz 9 to 900 70 (5)

50007-35 50007-05 230 VAC, 50 Hz 23 to 2300 45 (3.2)

50007-45 50007-05 230 VAC, 50 Hz 60 to 6000 17 (1.2)

50008-10 50008-00 115 VAC, 50/60 Hz 3 to 180 340 (24.5)

50008-20 50008-00 115 VAC, 50/60 Hz 20 to 900 70 (5)

50008-30 50008-00 115 VAC, 50/60 Hz 60 to 2300 45 (3.2)

50008-40 50008-00 115 VAC 50/60 Hz 150 to 6000 17 (1.2)

SPEED RANGE,

rpm

MAXIMUM TORQUE,

oz-in (kg-cm)

-- 3 --

Page 4

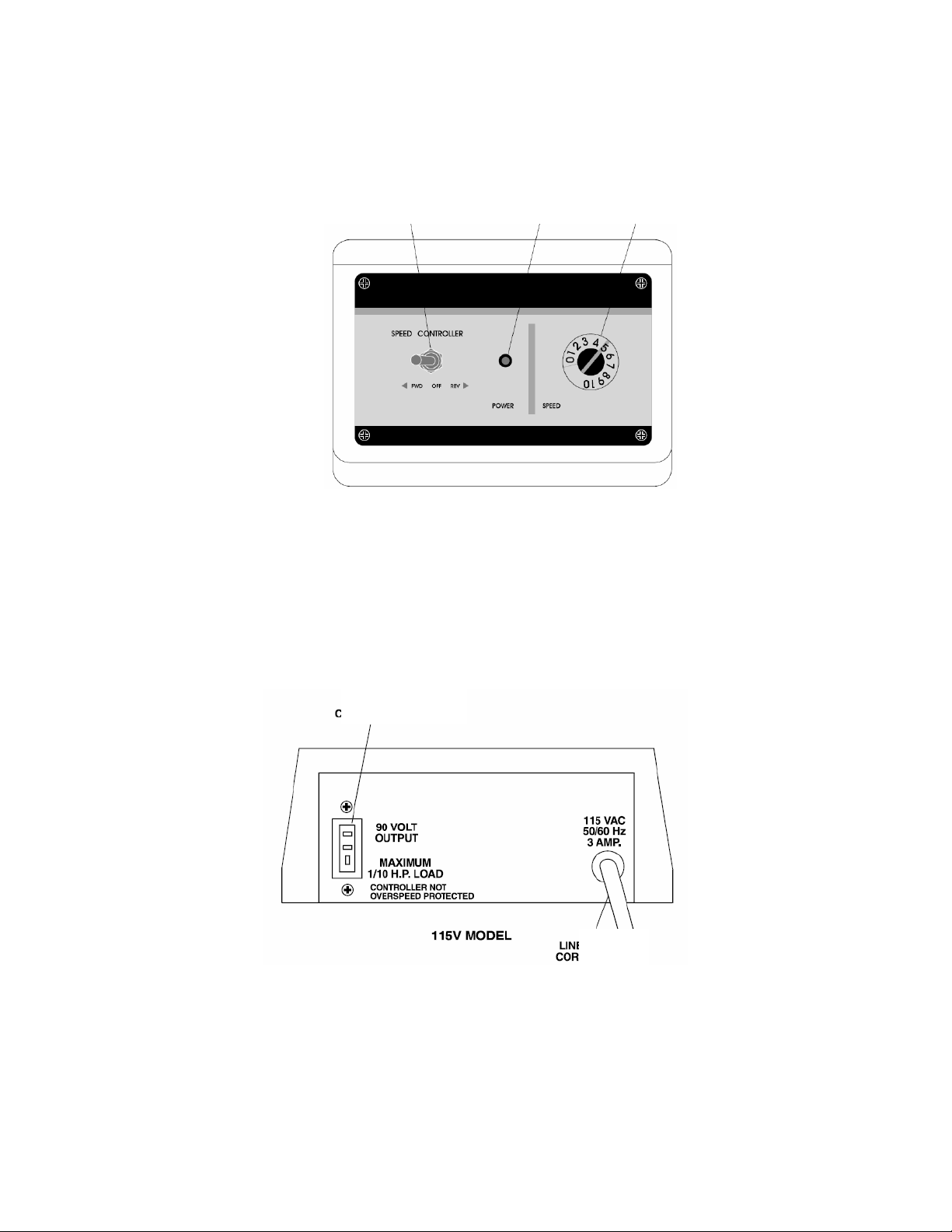

50007-00, -05 STIR-PAK CONTROLLER

The variable-speed controller, Figure 1a and 1b, is used to set the speed of the mixer heads and provides

a 100:1 adjustment range.

The controller ensures accurate, dependable motor speed (mixing) control, with “soft-start” and smooth, gradual

adjustment to the speed setting. Constant speed with a 100:1 adjustment range is maintained electronically via

automatic compensation for changes in load torque demands at both high and low speeds. Built-in motor current

compensation minimizes speed drift with changes in load. Motor current limiting protects the system in case of a

locked rotor condition. Output circuit protection protects against inadvertent output shorting. Mixer rotation is

reversible.

FORWARD-OFF-

REVERSE SWITCH

Figure 1a: Display and Controls

MOTOR

CONNECTOR

POWER ON

INDICATOR

SPEED

CONTROL

LINE

CORD

Figure 1b: Controller Rear Panel (115VAC model shown)

-- 4 --

Page 5

50008-00 SERVODYNE CONTROLLER/DISPLAY FUNCTIONS

p

p

Four-digit LED display

shows selected mixing

time, mixing time

remaining, rpm, and

torque values.

Displays last

countdown setting.

Starts counting

down when you

press the START

key.

Displays the last

mixer shaft speed.

Displays current torque

value (in-oz for 115VAC

model; cm-kg for 230VAC

model) and high and low

torque limits. Mixer

automatically stops when

preset limits are reached.

Zeroes the torque

when impeller is

running in free air or

in a reference fluid.

Figure 2a: Controller Functions

LEDs indicate the

function being displayed

(time, rpm, or torque). A

flashing time or torque

light and audible alarm

indicate that a limit

condition has been

reached.

Increases value of

parameter.

Decreases value

arameter.

of

Press at any time

mixer.

to sto

Starts mixer.

Stops when countdown

power entry

IN-RS-232C

IN-Connect cable

from host computer.

OUT-RS-232C

OUT-Connect cable

to next mixer.

IEC 320

POWER SWITCH

retained in memory.

MIXER HEAD PLUG

RECEPTACLE

Multi-pin plug enables

microprocessor to identify

connected mixer head

and properly control

speed and torque.

Figure 2b: Controller Rear Panel

All settings are

FUSE

T3.15A (115VAC)

T1.6A (230VAC)

-- 5 --

Page 6

INSTALLATION AND SETUP PROCEDURES

The mixer heads are equipped with an adjustable-tilt mounting assembly. The mounting assembly is designed

to be attached to an optional mixer support stand or tank clamp. Components supplied as part of the mixer

package include the following:

• Mixer head with 6-ft cable

• Precision controller with 6-ft line cord

• 3-jawed chuck on high-torque mixers

• ⅜-inch collet on high-speed mixers

• Adjustable-tilt mounting assembly with support rod

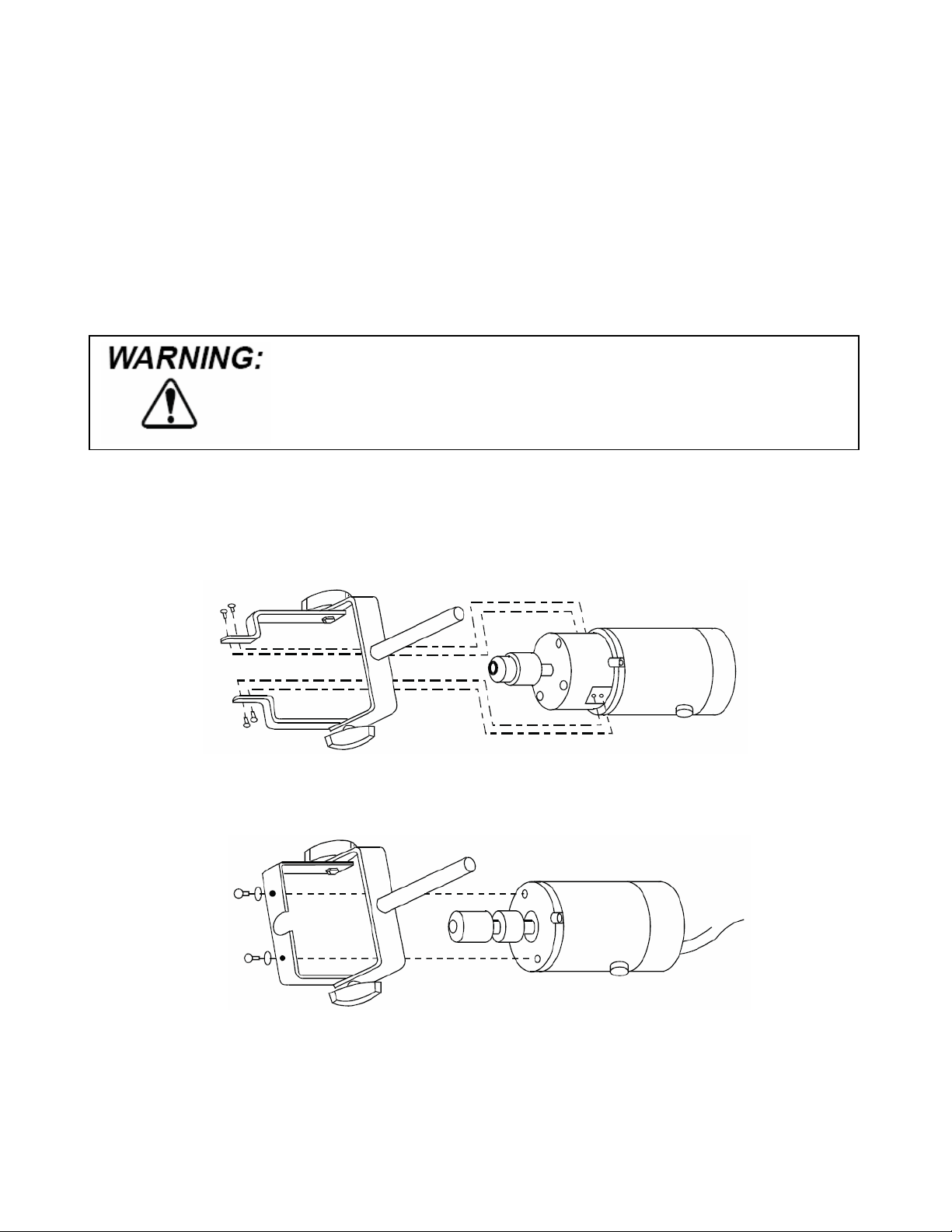

Installation of Adjustable-Tilt Mounting

• Never insert or remove the mixer shaft/impeller while the mixer

shaft is rotating.

Perform the following steps:

1. Attach mixer head to adjustable-tilt mounting assembly as follows:

a. For Stir-Pak models 50007-10, -15, -20, -25 and ServoDyne models 50008-10, -20, attach mounting

assembly with four screws and lock washers. (See Figure 3a)

Figure 3a: 50007-10, -15, -20, -25 and 50008-10, -20 mixer head mounting

b. For Sir-Pak models 50007-30, -35, -40, -45 and ServoDyne models 50008-30, -40, attach mounting

assembly with two screws and lock washers. (See Figure 3b)

Figure 3b: 50007-30, -35, -40, -45 and 50008-30, -40 mixer head mounting

Note: The mixer is now ready to be attached to a support stand or to a tank clamp (not supplied).

Recommended stands, tank clamps, and a double (rod) clamp are available through ColeParmer. Part numbers are listed in the ACCESSORIES section.

-- 6 --

Page 7

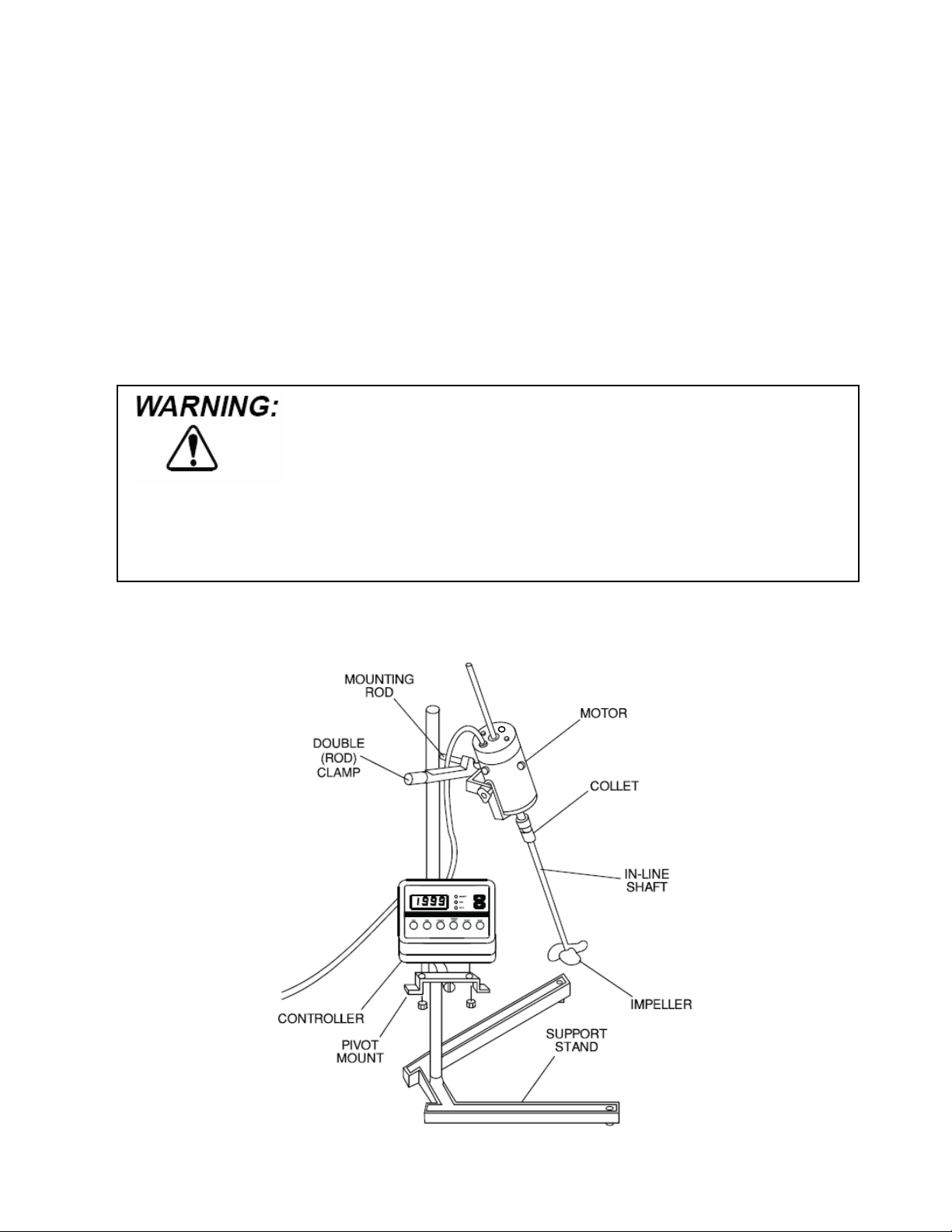

Installation Using a Support Stand

1. Set up support stand in accordance with the manufacturer’s instructions.

2. Attach a double (rod) clamp to the vertical rod on the support stand and tighten clamp screw. (See

Figure 4)

3. Slide rod of adjustable-tilt mounting assembly into clamp and secure with clamp screw.

4. Select an impeller and shaft for the required operation and install as follows:

a. Place impeller on shaft and tighten set screw.

b. For high-torque mixers head, slide the shaft of the stirring device into the three-

jawed chuck and tighten chuck.

c. For high-speed mixer head, slide the shaft through the collet at least 3 inches and hand-tighten

collet.

5. Place support stand legs around vessel. Tilt angle is adjustable from 0 to 30 degrees.

6. Position the height of the mixer head by moving the clamp up or down on the support stand or, on highspeed models, by loosening the collet and positioning the shaft.

• Exercise extreme care when adjusting mixer head height and/or

position to avoid personal injury. Never make these

adjustments while the mixer shaft is rotating.

• Mixer shafts must be inserted into high-speed through-shaft

mixers at least 3 inches and the collet hand-tightened firmly to

ensure adequate shaft retention. Keep mixer shafts as short as

possible to reduce resonant vibrations caused by shaft flexing

at higher speeds.

-- 7 --

Page 8

Figure 4: Typical mixer setup using a support stand and pivot mount (ServoDyne system shown)

Note: The controller can be placed on any flat surface within 6 feet of the mixer head or can be

mounted on a support platform (not supplied) or a pivot mount (not supplied). Refer to the

ACCESSORIES section for part numbers.

To attach the support platform proceed with step 7. To attach the pivot mount proceed with step

8. If controller is placed elsewhere proceed with step 9.

7. To install the support platform proceed as follows:

a. Attach a double (rod) clamp to the vertical support rod and position so that platform will be clear

of mixer head.

b. Slide the mounting rod of the support platform into the double (rod) clamp and tighten clamp.

c. Place controller on platform and proceed to step 9.

8. To install the pivot mount proceed as follows:

a. Remove the two cap nuts from the mounting studs on bottom of controller (see Figure 4).

b. Position pivot mount bracket over two studs, reinstall two cap nuts and tighten.

c. Attach a double (rod) clamp to the vertical support rod on the stand and position so that pivot

mount bracket will be clear of mixer head.

d. Slide the mounting rod of the pivot mount bracket into the double (rod) clamp and tighten clamp.

e. Adjust position of controller by first loosening knob on pivot mount bracket, adjust position and

then retighten knob.

9. Connect the 6-foot cable between the mixer head and the controller rear panel.

10. Check that the controller is not powered.

a. For Stir-Pak controller, ensure that the FWD-OFF-REV switch is in the OFF position.

b. For the ServoDyne controller, check that the rear panel ON-OFF switch is in the OFF position.

11. Connect the 6-ft line cord from the controller to the appropriate 3-wire, grounded power source.

• Check that all cords are clear of any moving parts and not

subject to splashes or spills.

• Be sure the SPEED control is fully counterclockwise before

the POWER switch is placed in the FWD or REV positions

12. Place the red safety switch on the top of the mixer head in the On ‘1’ position.

(Stir-Pak models only).

The mixer is now ready to operate.

-- 8 --

Page 9

Installation Using a Tank Clamp

The tank clamp is attached to the side of a tank and supports both the mixer head and the controller (see Figure

5).

1. Position the tank clamp over the edge of the tank with large knob to the outside of tank.

2. Allow clamp to rest on edge of tank for added stability and tighten knob.

3. Position mixer head over material to be mixed and insert mixer mounting shaft into upper hole in tank

clamp, tighten locking knob securely.

4. Select an impeller and shaft for the required operation and install as follows:

a. Place impeller on shaft and tighten set screw.

b. For high-torque mixer head, slide the 5/16 inch to 3/8 inch shaft of the stirring device into the

keyless chuck and tighten.

c. For high-speed mixer head, slide the 0.375 inch mixer shaft through the collet and tighten collet.

Be sure only 0.375 (+/-0.0005) inch shafts are used. Contact Cole-Parmer or your dealer for

obtaining the proper shaft size. Refer to the ACCESSORIES section for the part numbers.

• Exercise extreme care when adjusting mixer head height

and/or position to avoid personal injury. Never make these

adjustments while the mixer shaft is rotating.

• Mixer shafts must be inserted into high speed through-

shaft mixers at least 3 inches and the collet hand-tightened

firmly to ensure adequate shaft retention. Keep mixer

shafts as short as possible to reduce resonant vibrations

caused by the shaft flexing at higher speeds.

• Do not operate mixers where explosive vapors or

flammable materials exist. Death or serious injury could

result. Check NEC and local codes before installing.

-- 9 --

Page 10

Figure 5: Typical mixer setup using a tank clamp (ServoDyne controller shown)

5. Position the height of the mixer head on high-speed models by loosening the collet and positioning the

shaft.

Note: The controller can be placed on any flat surface within 6 feet of the mixer head and can be

mounted on a support platform (not supplied) or a pivot mount (not supplied). Refer to

ACCESSORIES for part numbers. To attach the support platform, proceed with step 6. To

attach the pivot mount, proceed with step 7. If controller is placed elsewhere, proceed with

step 8.

6. To install the support platform proceed as follows:

a. Slide the mounting rod of the support platform into the lower hole on the tank clamp and tighten

clamp.

b. Place controller on platform and proceed to step 8.

7. To install the pivot mount proceed as follows:

a. Remove the two cap nuts from the mounting studs on bottom of controller.

b. Position pivot mount bracket over two studs, reinstall two cap nuts and tighten.

c. Slide the mounting rod of the pivot mount bracket into the lower hole on the tank clamp and

tighten clamp.

d. Adjust position of controller by first loosening knob on pivot mount bracket, adjusting position

and then retighten knob.

8. Connect the 6-foot cable between the mixer head and the controller rear panel.

9. Check that the rear panel ON-OFF switch is in the OFF position.

-- 10 --

Page 11

10. Connect the 6-ft line cord from the controller to the appropriate power source, either a 90-130VAC

50/60Hz 3-wire, grounded power source or a 200-260VAC 50/60Hz 3-wire, grounded power

source.

11. Place the red safety switch on the top of the mixer head in the On ‘1’ position.

The mixer is now ready to operate.

• Check that all cords are clear of any moving parts and

not subject to splashes or spills.

• Be sure the SPEED control is fully counterclockwise

before the POWER switch is placed in the FWD or REV

positions (Stir-Pak models only).

• Always wear appropriate eye protection when mixing

any kind of fluid.

• Avoid wearing loose clothing that may be caught by a

rotating mixer shaft.

• Use care when setting the operating speed of the

mixer. Operation at high speeds in small mixing

vessels could result in hazardous splashing on the

operator and equipment.

• Be sure the SPEED control is fully counterclockwise

before the POWER switch is placed in the FWD or REV

positions (Stir-Pak models only).

-- 11 --

Page 12

50007-00, -05 STIR-PAK CONTROLLER OPERATION

FWD-OFF-REV Switch

In the FWD position, the shaft will rotate in a

counterclockwise direction when viewed from

the impeller.

The center or OFF position removes power from

both the controller and mixer head.

In the REV position, the shaft will rotate in a

clockwise direction when viewed from the

impeller.

POWER Indicator

The green LED indicator illuminates whenever

the FWD-OFF-REV switch is in either the FWD

or REV position.

SPEED Control

The SPEED control precisely sets the output speed of the shaft. The controller has a range of 100:1

depending on the model; shaft speed can be as low as 2RPM or as high as 6000RPM.

Slowly adjust the SPEED Control from the 0 position to a setting that provides the desired mixing speed.

Always return the speed control to the 0 position when mixing is complete.

FORWARD-OFF-REVERSE

SWITCH

• To stop the mixer head in an emergency, place the FWD-

OFF-REV switch in the OFF position or remove the power

plug.

POWER ON

INDICATOR

LIGHT

SPEED

CONTROL

• Be sure the SPEED control is fully counterclockwise before

the POWER switch is placed in the FWD or REV positions.

• Use care when setting the operating speed of the mixer.

Operation at high speeds in small mixing vessels could

result in hazardous splashing on the operator and

equipment.

• When running at full speed and load at higher ambient

temperatures, the mixer head may get very hot to the touch.

• Never insert or remove the mixer shaft/impeller while the

mixer shaft is rotating.

Note: With new mixing heads, allow approximately 20 minutes run-in time to allow warm-up drift to

become minimal.

-- 12 --

Page 13

50008-00 SERVODYNE CONTROLLER OPERATION

Power On

An EEPROM permits storage of all previously set parameters including speed, torque, time and

calibration constant. Turning the rear-panel mounted ON/OFF switch to the “ON” position

energizes the display without running the motor. The display will come up in the last mode

operated. Depressing the START button causes the mixer motor shaft to rotate at the previously

programmed speed. Depressing the STOP button stops the motor. Changing Display Modes

(TIME, RPM, TORQUE) is accomplished by pressing the desired mode button once. Additional

operation of the mode button advances operation to the set mode.

Set Run Time

The use of the TIME button in conjunction with the INC/DEC buttons permits entry of a desired

mixing time. Pressing the TIME button once when already in the time display mode causes the

left (minutes) digit to flash, pressing the TIME button once again causes the right two (seconds)

digits to flash. During this period the time can be set with the INC/DEC buttons. Pressing the

TIME button a third time starts the countdown provided the motor is running; otherwise the display

shows the set time. Maximum programmable time is 99 minutes 59 seconds. A “0” programmed

time results in continuous motor operation.

Set Motor Speed

Depressing the RPM button when in the RPM mode causes the display to flash and read the set

motor speed. Use of the INC/DEC buttons changes the desired speed.

Set Motor Torque Limit

The TORQUE limit feature provides for the setting of both HI and LO torque limits. Depressing

the TORQUE button when in the TORQUE mode causes the first digit of the display to read either

on “H” or “L” (for High or Low limit) and the last three digits to flash and read the set limit.

Pressing the INC/DEC buttons changes the set torque limit.

Pressing the Torque button once again while the digits are flashing causes the H or L to flash

while the set limit digits stop flashing. It is now that the High or Low limit can be selected by

pressing either the INC/DEC buttons. Pressing any button other than INC/DEC buttons returns

the display to actual torque. If the motor is running while the torque limit is being modified, the

previously programmed limit will be in effect until the torque limit mode is exited; then the new limit

will take over.

Regardless of the set torque limit, there is always a maximum torque limit check to guard

against motor overheating. If this limit is exceeded, the motor stops, the alarm sounds, the

display flashes “HI” and the in-oz LED flashes. Pressing any key causes the display to return to

what was previously displayed before the alarm. The error must be corrected or the over-limit

warning will sound again when the motor is restarted.

The TORQUE ZERO button is used to zero the torque display so that the actual torque necessary

to mix something can be read directly on the display. To use this feature, the TORQUE ZERO

button is pressed while the mixer head shaft is running in free air; the display will zero. The mixer

shaft is then placed into the solution being mixed, the reading on the display will now indicate the

torque necessary to mix the solution. This number can now be used to determine the proper shut

off or torque limit when mixing several batches of the same consistency.

When the TORQUE ZERO button is operated, the maximum torque limit that can be set is

adjusted so that the absolute torque does not exceed the continuous torque of the mixer head

being used.

Example: The operator has set a high torque limit of 50 oz-in for a motor rated for 65. The motor

is then running with an actual torque reading of 30 oz-in. When the TORQUE ZERO button is

pressed, the maximum torque that can be set would be 35 (65-30). Since the set limit of 50 is

above this, it will automatically be changed to 35. The operator will see this when the set mode is

entered, which will prevent a setting over 35.

An audible alarm will sound and the LED that corresponds to the limit that has been reached will

flash when either the preset time or the torque limit is reached. Both the LED and alarm will cycle

on and off until turned off by pressing any button other than the INC/DEC buttons.

-- 13 --

Page 14

• Never insert or remove the mixer shaft/impeller while the

mixer shaft is rotating.

• When running at full speed and load at higher ambient

temperatures, the mixer head may get very hot to the touch.

-- 14 --

Page 15

Specifications – Mixer Head

Direction of Rotation:

50007 Stir-Pak Series

50008 ServoDyne Series

Speed Range:

50007-10 and 50007-15

50007-20 and 50007-25

50007-30 and 50007-35

50007-40 and 50007-45

50008-10

50008-20

50008-30

50008-40

Torque Output, max:

50007-10, 50007-15, and 50008-10

50007-20, 50007-25, and 50008-20

50007-30, 50007-35, and 50008-30

50007-40, 50007-45, and 50008-40

Mixer Shaft Interface:

50007-10, -15, -20, -25

50008-10, -20

Bi-directional controlled with the FWD-OFF-REV switch

CCW (Viewed from Impeller end)

2 to 180 rpm

9 to 900 rpm

23 to 2300 rpm

60 to 6000 rpm

3 to 180 rpm

20 to 900 rpm

60 to 2300 rpm

150 to 6000 rpm

CONTINUOUS INTERMITTENT

340 in-oz 510 in-oz

70 in-oz 105 in-oz

45 in-oz 65 in-oz

17 in-oz 25 in-oz

3-jawed type chuck with key accepts

5/16 in. to 3/8 in. dia shaft

50007-30, -35, -40, -45

50008-30, -40

Collet accepts 0.375 (± 0.0005) inch

diameter shaft

Input Voltage, max:

50007-10, -20, -30, -40

50008-10, -20, -30, -40

50007-15, -25, -35, -45

90 Volts DC

180 Volts DC

Input Current, max:

50007-30, -40

50008-30, -40

50007-35, -45

50007-10, -20

50008-10, -20

50007-15, -25

2.3 Amps DC

1.2 Amps DC

1.5 Amps DC

0.8 Amps DC

Installation Category:

Installation Category I per IEC 664 (Signal level–parts of equipment)

Construction:

Dimensions (L x dia)

Weight

Enclosure rating

11.5 in. x 3.6 in. (292 x 92 mm)

8 lb (3.5 kg)

IP 24 per IEC 34-5

-- 15 --

Page 16

Environment:

Operating temperature

Storage temperature

Humidity (noncondensing)

Altitude

Degree of pollution

0 to 40°C (32 to 104°F)

Storage: −45 to 65°C (−49 to 149°F)

10% to 90%

Less than 2000 m

Pollution Degree 2 per IEC 664 (Indoor Usage–lab, office)

Chemical Resistance:

Exposed material is painted aluminum, plastic, and vinyl

Compliance:

115VAC CAN/CSA C22.2, No.61010-1 2nd Edition

CAN/CSA-C22.2 No. 61010-2-051-04

ANSI/UL 61010-1 2

UL61010A-051 1

230VAC EN 61010-1

EN 61010-2-051

nd

Edition

st

Edition

-- 16 --

Page 17

Specifications – Controller

Output:

Model Maximum

Voltage, V

50007-00

50007-05

50008-00

90 2.3 207

180 1.2 216

90 2.3 207

Maximum

Current, Amps

Maximum

Power, Watts

Speed regulation:

Model Line Load Drift

50007-00, -05

50008-00

±1% F.S. ±2% F.S. ±10% F.S.

±0.25% F.S. ±0.25% F.S. ±0.25% F.S.

Display

Maximum settable countdown timer

Time accuracy

Four-digit, seven-segment LED

99 minutes, 59 seconds

±1 second

Input:

Model Voltage Maximum

Current, Amps

50007-00

50007-05

50008-00

90 to 130VAC RMS, 50/60 Hz 3 Amps 360 VA

200 to 260VAC RMS, 50 Hz 1.6 Amps 370 VA

90 to 130VAC RMS, 50/60 Hz 2.3 Amps 280 VA

Maximum

Power

Installation Category:

Installation Category II per IEC 664 (Local level – appliances, portable equipment, etc.)

Computer Control:

RS-232-C (Full Duplex)

Construction:

Dimensions (L x W x H)

Weight

Enclosure rating

Environment:

Operating temperature

Storage temperature

Humidity (noncondensing)

Altitude

Degree of pollution

Chemical Resistance:

Exposed material is painted aluminum, plastic, and vinyl

Compliance:

115VAC CAN/CSA C22.2, No.61010-1 2

230VAC EN 61010-1

CAN/CSA-C22.2 No. 61010-2-051-04

ANSI/UL 61010-1 2

UL61010A-051 1

EN 61010-2-051

50007-00, -05 50008-00

7 x 5 x 3½ inches

(178 x 127 x 89 mm)

1.4 lb (0.62 kg) 3 lb (1.4 kg)

IP 22 per IEC 529 IP 22 per IEC 529

0 to 40°C (32 to 104°F)

-45 to 65°C (-49° to 149°F)

10% to 90%

< 2000 m

2 per IEC 664, (indoor usage – lab, office)

nd

Edition

nd

Edition

st

Edition

7¾ x 6½ x 3½ inches

(197 x 165 x 89 mm)

-- 17 --

Page 18

MAINTENANCE AND TROUBLESHOOTING

Maintenance is limited to replacement of motor brushes on the mixer head, replacing the fuse on

the controller, and cleaning the unit. If a fault is detected when troubleshooting and cannot be

corrected by the suggested remedy, contact Cole-Parmer or your dealer for service.

Motor Brush Check/Replacement

Note: Brushes should be checked every 6 months or 1000 operating hours or if erratic operation

occurs. Erratic operation may occur immediately after brush replacement. Allow motor to

run up to an hour to allow brushes to seat.

1. Turn the controller off

a. For the Stir-Pak controllers, place the FWD-OFF-REV switch in the OFF position

b. For the ServoDyne controller, place the rear panel ON-OFF switch in the OFF position.

2. Disconnect the AC line cord from the AC receptacle.

3. Disconnect the mixer head cable from the receptacle on the rear of the controller.

4. Carefully unscrew each brush holder cap. Withdraw the brush and examine it for wear.

Note: Replace both brushes if either brush is less than 0.300 inch (8 mm) long. The

replacement brushes (set of 2) part number is listed under REPLACEMENT PARTS.

5. Insert brushes into brush holder on each side of motor as shown in Figure 6 and screw in brush holder

caps.

6. Reconnect mixer head to rear-panel connector on controller.

7. Reconnect controller to primary power source.

Figure 6: Motor brush orientation

ServoDyne Controller Fuse Replacement

1. Place the power switch in the OFF position.

2. Disconnect the AC power input line cord from the AC receptacle.

3. Remove and check the fuse and replace if defective.

4. Reconnect the AC power input line cord to the AC receptacle.

-- 18 --

Page 19

Cleaning the Mixer/Controller System

Keep the mixer housing and controller enclosure clean with mild detergents. Never immerse nor use

excessive fluid.

Replacement Parts

No user-serviceable parts are inside of this instrument. Refer servicing to Cole-Parmer or your dealer.

The following parts are user-replaceable:

Description For model(s) Part Number

Speed Control Knob

Fuse, T3.15A

Fuse, T1.6, 5x20mm

Motor Brushes (2)

3-Jawed Chuck Assembly

Collet Nut

Pivot Assembly Knob (1)

Cordset–USA (115VAC)

Cordset–European (230VAC)

Cordset–British (230VAC)

Cordset–Swiss (230VAC)

Cordset–Italian (230VAC)

Cordset–NEMA (230VAC)

• Never clean the Controller or Mixer Head while power is

applied to the system.

50007-00, -05 04552-91

50008-00 77500-25

50007-05 77500-11

All 07520-04

50007-10, -15, -20, -25

50008-10, -20

50007-30, -35, -40 ,-45

50008-30, -40

All 04552-99

50001-68

50001-70

50001-72

50001-74

50001-76

50001-78

04552-96

04552-98

Contact Cole-Parmer or your dealer if you have service needs.

-- 19 --

Page 20

Troubleshooting – Stir-Pak

Symptom Cause Remedy

Mixer shaft does not rotate

when controller is switched

to FWD or REV regardless

of SPEED control setting.

POWER indicator does not

glow.

• Disconnected

• Defective fuse

or defective line

cord

1. Check that the unit is plugged

into a live line.

2. For 115VAC unit: Return for

service (fuse is not user

replaceable)

3. For 230VAC unit: Replace fuse

Mixer shaft does not rotate

when controller is switched

to FWD or REV regardless

• Defective mixer

head or

controller

of SPEED control setting.

POWER indicator glows.

Troubleshooting – ServoDyne

The controller microprocessor detects and indicates system faults. The display alternately shows

the error number and a “FAIL” message. The following table summarizes the faults and suggested

corrective action. The system cannot be operated until the fault is corrected.

Error

Code

Err1 No mixer head connection Plug mixer head into controller.

Err2 Invalid mixer head Bad motor cable - return mixer head for repair.

Err3

Err4 Motor speed is excessive Return mixer head and controller for repair.

Err5 No torque information display Return controller for repair.

Err6 Bad PROM check Return controller for repair.

Err7 Motor overload Check mixer for obstructions. Turn off unit to clear error.

Err8 Zero cross failure Return controller for repair.

Err9 Bad EEPROM data Return controller for repair.

Fault Corrective Action

Safety Switch in Off ‘0’

position

No encoder pulses

1. Check mixer cable connections

at rear of the controller - make

sure connector is fully inserted

into the receptacle

2. Check motor brushes (see motor

brush check/replacement for

details)

3. Replace mixer head or controller

with known working unit, if

available, to determine source of

the problem

4. Return for service

5. Check that the red safety switch

on the mixer head in the On ‘1’

position.

Check that the red safety switch on the mixer head in

the On ‘1’ position.

Return mixer head and controller for repair.

“HI” Limit Message

A flashing “HI” limit message will be displayed and the mixer head will stop if the maximum rated torque

of the mixer head is exceeded when the low torque limit mode is being used. To protect the mixer head

motor from overheating, it cannot be restarted until the fault is corrected.

Note: Before contacting Cole-Parmer or your dealer for repair, try to determine whether the fault is in

the controller or mixer head. The best way is to substitute a known good unit, if available, and

recheck.

-- 20 --

Page 21

ACCESSORIES

The accessories listed below, used for mounting the mixer head and controller, are available from ColeParmer or your dealer. Many other accessories such as shafts and impellers are also available.

Contact your dealer for the full line of available accessories.

Part Name Part Number

Tank Clamp 04552-65

Controller Support Platform 04552-75

Pivot Mount Controller Support 04552-70

Support Stand 04552-80

Double (Rod) Clamp 08041-22

Software 07550-74

ServoDyne RS-232-C Interface Cable 07550-64

Satellite Cable 07550-66

Shaft, 12 inches (305 mm) 04552-25

Shaft, 18 inches (457 mm) 04552-35

Shaft, 24 inches (610 mm) 04552-00

Shaft, 30 inches (762 mm) 04552-05

WARRANTY

The manufacturer warrants this product to be free from significant deviations from published

specifications. If repair or adjustment is necessary within the warranty period, the problem will be

corrected at no charge

if it is not due to misuse or abuse on your part as determined by the manufacturer. Repair costs

outside the warranty period, or those resulting from product misuse or abuse, may be invoiced to

you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

To limit charges and delays, contact Cole-Parmer or manufacturer for authorization and shipping

instructions before returning the product, either within or outside of the warranty period. When

returning the product, please state the reason for the return. For your protection, pack the product

carefully and insure it against possible damage or loss. Any damages resulting from improper

packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact Cole-Parmer or your local dealer.

SSMPK027 Rev 1.02

-- 21 --

Loading...

Loading...