Stir-Pak 50007-10, 50007-15, 50007-20, 50007-25, 50007-30 Instruction Manual

...

OPERATING MANUAL

Cole-Parmer

®

Stir-Pak®

Mixer Head Model Numbers

50007-10, 50007-15, 50007-20, 50007-25

50007-30, 50007-35, 50007-40, 50007-45

&

Mixer Controller Model Numbers 50007-00, 50007-05

Cole-Parmer® ServoDyne™

Mixer Head Model Numbers

50008-10, 50008-20, 50008-30, 50008-40

&

Mixer Controller Model Number 50008-00

Cole-Parmer

625 East Bunker Court

Vernon Hills, Illinois U.S.A. 60061-1844

Toll Free: 800-323-4340

Phone: 847-549-7600

Fax: 847-247-2929

www.coleparmer.com

E-mail: techinfo@coleparmer.com

-- 1 --

Version 11Nov08 Rev1

SAFETY PRECAUTIONS

• High voltages exist and are accessible in the controller.

Contact Cole-Parmer for servicing.

• Do not operate mixers where explosive vapors or flammable

materials exist. Death or serious injury could result. Check

NEC and local codes before installing.

• Never clean the controller or mixer head while power is

applied to the system.

• Use only those mixer shafts that are properly sized for the

mixer head being used. Refer to mixer head specifications for

the proper shaft diameter or range to be used. Sizes other than

those specified can cause injury to personnel or damage to

equipment.

• Disconnect the AC power input line cord before connecting the

mixer head cable.

• Exercise extreme care when adjusting mixer height and/or

position to avoid personal injury. Never make these

adjustments while the mixer shaft is rotating.

• Never insert or remove the mixer shaft/impeller while the mixer

shaft is rotating.

• Be sure speed control is fully counterclockwise before the

POWER switch is placed in the FWD or REV positions. (5000700 and 50007-05 Controller)

• Check that all cords are clear of any moving parts and not

subject to splashes or spills.

• Use care when setting the operating speed of the mixer.

Operation at high speeds in small mixing vessels could result

in hazardous splashing on the operator and equipment.

• When running at full speed and load at higher ambient

temperatures, the mixer head may get very hot to the touch.

• Use of mixing shafts and impellers larger than those

recommended could result in poor product performance and

shortened service life.

• Mixer shafts must be inserted into high-speed through-shaft

mixers at least 3 inches (8 mm) and the collet hand-tightened

firmly to ensure adequate shaft retention. Keep mixer shafts as

short as possible to reduce resonant vibrations caused by the

shaft flexing at higher speeds.

• The mixer head is to be used only for mixing. It is not intended

for any other purpose.

-- 2 --

INTRODUCTION

The Stir-Pak 50007-series heavy-duty modular mixing system covered in this manual consists of eight different

mixer heads and two analog controllers for 115VAC and 230VAC operation.

The ServoDyne 50008-series digital modular mixing system consists of four different mixer heads and a

precision digital controller for 115VAC operation.

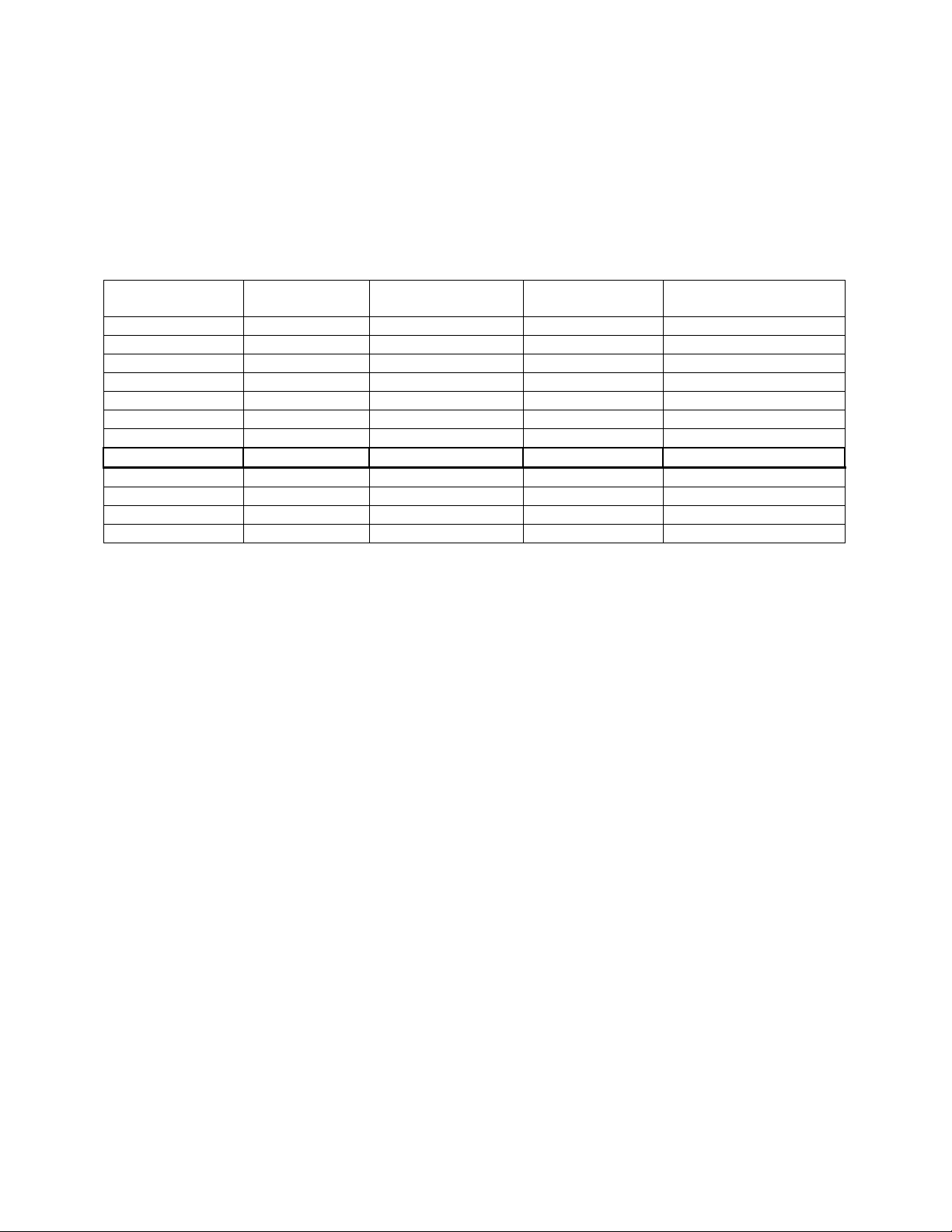

The following chart cross-references the model number, operating speed range and torque rating of the mixer

heads and the compatible controller.

MIXER HEAD CONTROLLER OPERATING

VOLTAGE

50007-10 50007-00 115 VAC, 50/60 Hz 2 to 180 340 (24.5)

50007-20 50007-00 115 VAC, 50/60 Hz 9 to 900 70 (5)

50007-30 50007-00 115 VAC, 50/60 Hz 23 to 2300 45 (3.2)

50007-40 50007-00 115 VAC, 50/60 Hz 60 to 6000 17 (1.2)

50007-15 50007-05 230 VAC, 50 Hz 2 to 180 340 (24.5)

50007-25 50007-05 230 VAC, 50 Hz 9 to 900 70 (5)

50007-35 50007-05 230 VAC, 50 Hz 23 to 2300 45 (3.2)

50007-45 50007-05 230 VAC, 50 Hz 60 to 6000 17 (1.2)

50008-10 50008-00 115 VAC, 50/60 Hz 3 to 180 340 (24.5)

50008-20 50008-00 115 VAC, 50/60 Hz 20 to 900 70 (5)

50008-30 50008-00 115 VAC, 50/60 Hz 60 to 2300 45 (3.2)

50008-40 50008-00 115 VAC 50/60 Hz 150 to 6000 17 (1.2)

SPEED RANGE,

rpm

MAXIMUM TORQUE,

oz-in (kg-cm)

-- 3 --

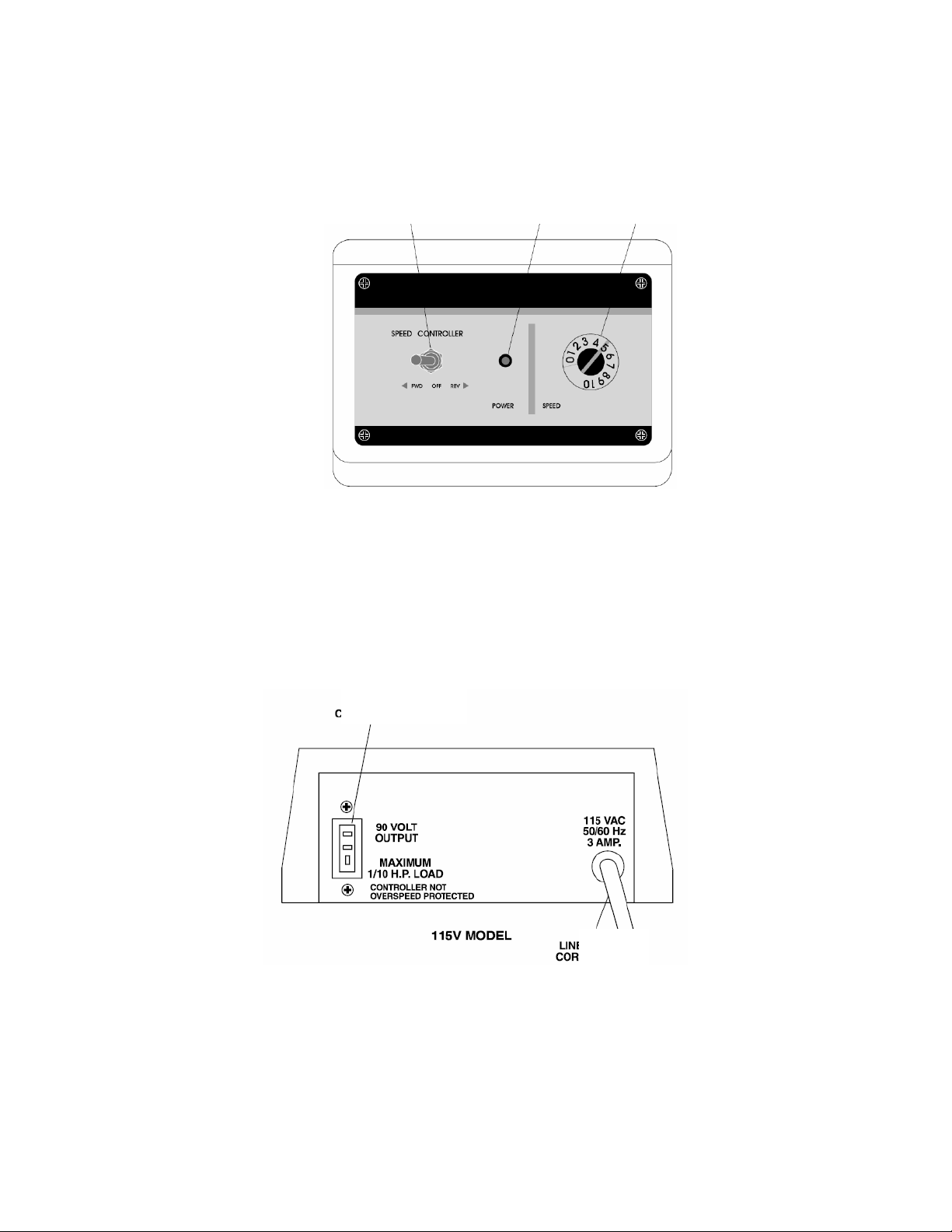

50007-00, -05 STIR-PAK CONTROLLER

The variable-speed controller, Figure 1a and 1b, is used to set the speed of the mixer heads and provides

a 100:1 adjustment range.

The controller ensures accurate, dependable motor speed (mixing) control, with “soft-start” and smooth, gradual

adjustment to the speed setting. Constant speed with a 100:1 adjustment range is maintained electronically via

automatic compensation for changes in load torque demands at both high and low speeds. Built-in motor current

compensation minimizes speed drift with changes in load. Motor current limiting protects the system in case of a

locked rotor condition. Output circuit protection protects against inadvertent output shorting. Mixer rotation is

reversible.

FORWARD-OFF-

REVERSE SWITCH

Figure 1a: Display and Controls

MOTOR

CONNECTOR

POWER ON

INDICATOR

SPEED

CONTROL

LINE

CORD

Figure 1b: Controller Rear Panel (115VAC model shown)

-- 4 --

50008-00 SERVODYNE CONTROLLER/DISPLAY FUNCTIONS

p

p

Four-digit LED display

shows selected mixing

time, mixing time

remaining, rpm, and

torque values.

Displays last

countdown setting.

Starts counting

down when you

press the START

key.

Displays the last

mixer shaft speed.

Displays current torque

value (in-oz for 115VAC

model; cm-kg for 230VAC

model) and high and low

torque limits. Mixer

automatically stops when

preset limits are reached.

Zeroes the torque

when impeller is

running in free air or

in a reference fluid.

Figure 2a: Controller Functions

LEDs indicate the

function being displayed

(time, rpm, or torque). A

flashing time or torque

light and audible alarm

indicate that a limit

condition has been

reached.

Increases value of

parameter.

Decreases value

arameter.

of

Press at any time

mixer.

to sto

Starts mixer.

Stops when countdown

power entry

IN-RS-232C

IN-Connect cable

from host computer.

OUT-RS-232C

OUT-Connect cable

to next mixer.

IEC 320

POWER SWITCH

retained in memory.

MIXER HEAD PLUG

RECEPTACLE

Multi-pin plug enables

microprocessor to identify

connected mixer head

and properly control

speed and torque.

Figure 2b: Controller Rear Panel

All settings are

FUSE

T3.15A (115VAC)

T1.6A (230VAC)

-- 5 --

INSTALLATION AND SETUP PROCEDURES

The mixer heads are equipped with an adjustable-tilt mounting assembly. The mounting assembly is designed

to be attached to an optional mixer support stand or tank clamp. Components supplied as part of the mixer

package include the following:

• Mixer head with 6-ft cable

• Precision controller with 6-ft line cord

• 3-jawed chuck on high-torque mixers

• ⅜-inch collet on high-speed mixers

• Adjustable-tilt mounting assembly with support rod

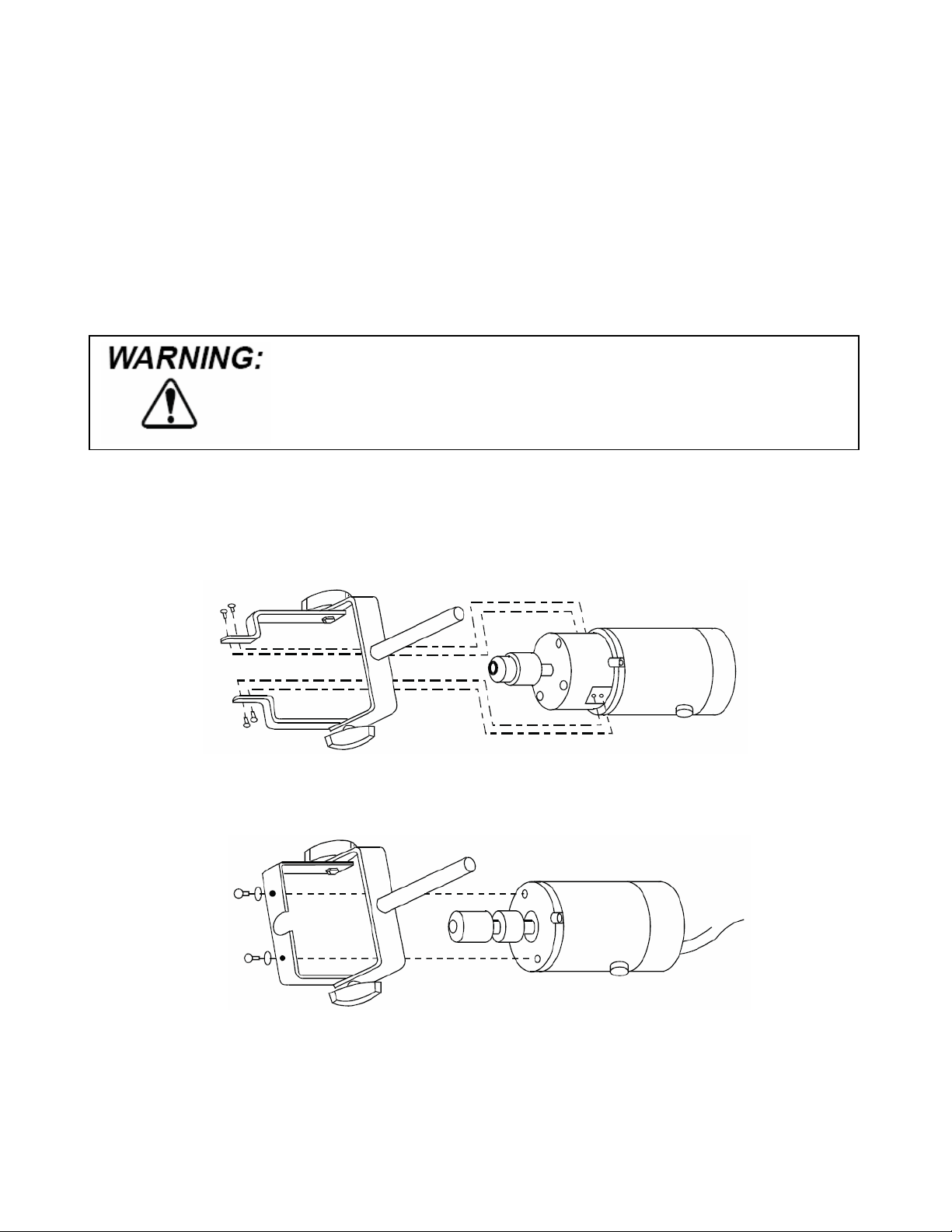

Installation of Adjustable-Tilt Mounting

• Never insert or remove the mixer shaft/impeller while the mixer

shaft is rotating.

Perform the following steps:

1. Attach mixer head to adjustable-tilt mounting assembly as follows:

a. For Stir-Pak models 50007-10, -15, -20, -25 and ServoDyne models 50008-10, -20, attach mounting

assembly with four screws and lock washers. (See Figure 3a)

Figure 3a: 50007-10, -15, -20, -25 and 50008-10, -20 mixer head mounting

b. For Sir-Pak models 50007-30, -35, -40, -45 and ServoDyne models 50008-30, -40, attach mounting

assembly with two screws and lock washers. (See Figure 3b)

Figure 3b: 50007-30, -35, -40, -45 and 50008-30, -40 mixer head mounting

Note: The mixer is now ready to be attached to a support stand or to a tank clamp (not supplied).

Recommended stands, tank clamps, and a double (rod) clamp are available through ColeParmer. Part numbers are listed in the ACCESSORIES section.

-- 6 --

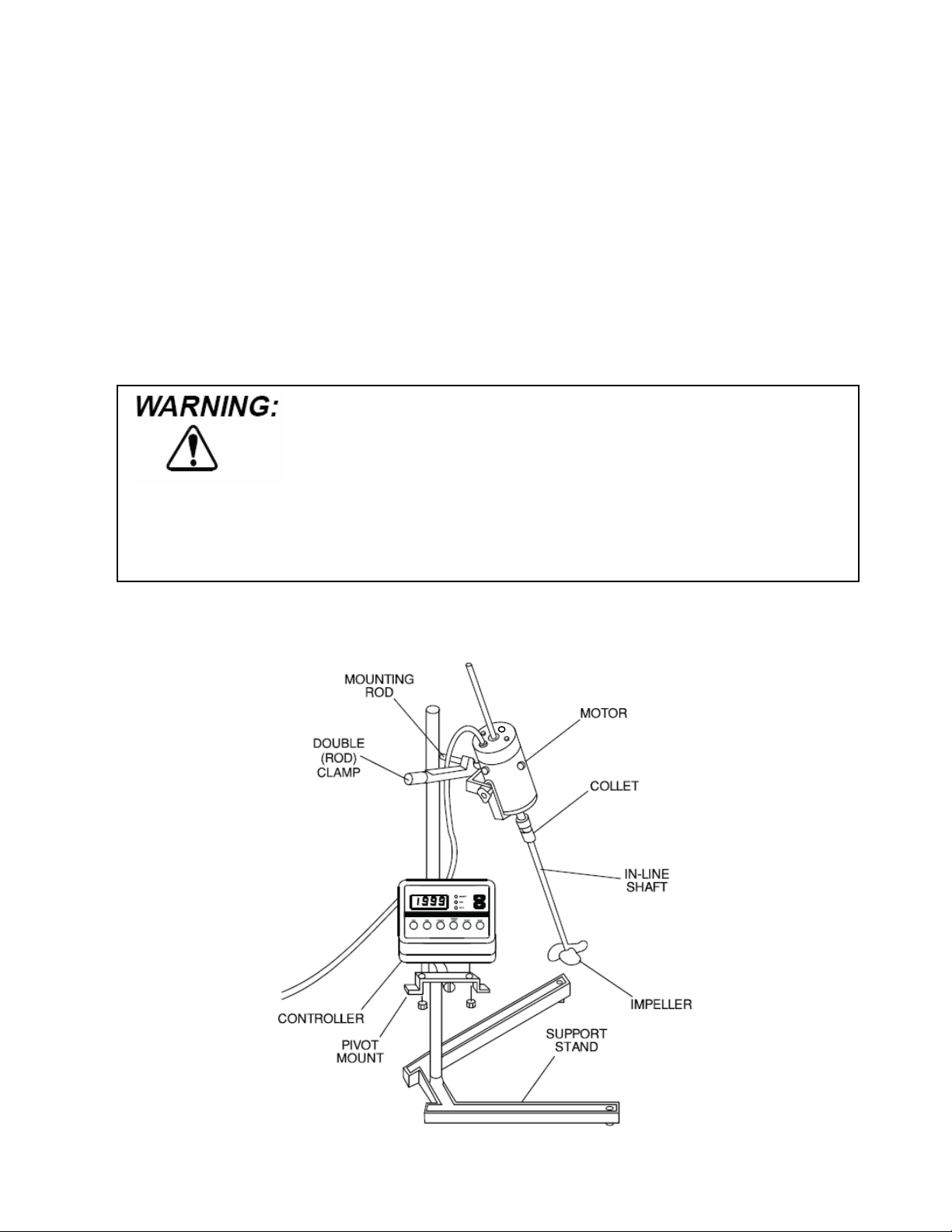

Installation Using a Support Stand

1. Set up support stand in accordance with the manufacturer’s instructions.

2. Attach a double (rod) clamp to the vertical rod on the support stand and tighten clamp screw. (See

Figure 4)

3. Slide rod of adjustable-tilt mounting assembly into clamp and secure with clamp screw.

4. Select an impeller and shaft for the required operation and install as follows:

a. Place impeller on shaft and tighten set screw.

b. For high-torque mixers head, slide the shaft of the stirring device into the three-

jawed chuck and tighten chuck.

c. For high-speed mixer head, slide the shaft through the collet at least 3 inches and hand-tighten

collet.

5. Place support stand legs around vessel. Tilt angle is adjustable from 0 to 30 degrees.

6. Position the height of the mixer head by moving the clamp up or down on the support stand or, on highspeed models, by loosening the collet and positioning the shaft.

• Exercise extreme care when adjusting mixer head height and/or

position to avoid personal injury. Never make these

adjustments while the mixer shaft is rotating.

• Mixer shafts must be inserted into high-speed through-shaft

mixers at least 3 inches and the collet hand-tightened firmly to

ensure adequate shaft retention. Keep mixer shafts as short as

possible to reduce resonant vibrations caused by shaft flexing

at higher speeds.

-- 7 --

Loading...

Loading...