Stihl STIHL FSA 90 R STIHL FSA 90 R (en / fr) [en, fr]

STIHL FSA 90 R

Instruction Manual

Notice d’emploi

G Instruction Manual

1 - 31

F Notice d’emploi

32 - 65

Contents

English

Guide to Using this Manual 2

Safety Precautions 2

Reactive Forces 8

Working Techniques 8

Approved Combinations of Cutting

Attachment, Deflector, Handle and

Harness 10

Mounting the Loop Handle 11

Mounting the Deflector 12

Original Instruction ManualPrinted on chlorine-free paper

Mounting the Cutting Attachment 13

Connecting Charger to Power

Supply 15

Charging the Battery 16

LEDs on Battery 17

LED on Charger 18

Fitting the Harness 19

Balancing the Machine 19

Switching On 20

Switching Off 22

Storing the Machine 22

Maintaining the Mowing Head 23

Sharpening Metal Cutting Blades 24

Printing inks contain vegetable oils, paper can be recycled.

Maintenance and Care 25

Main Parts 26

Specifications 27

Troubleshooting 29

Maintenance and Repairs 31

Battery Recycling 31

Disposal 31

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

It has been built using modern

production techniques and

comprehensive quality assurance.

Every effort has been made to ensure

your satisfaction and trouble-free use of

the product.

Please contact your dealer or our sales

company if you have any queries

concerning this product.

Your

Dr. Nikolas Stihl

© ANDREAS STIHL AG & Co. KG, 2022

0458-709-8221-B. VA2.B22.

0000007009_009_GB

FSA 90 R

This instruction manual is protected by copyright. All rights reserved, especially the rights to reproduce, translate and process

with electronic systems.

1

English

Guide to Using this Manual

This instruction manual covers a

STIHL cordless trimmer which is also

referred to as the power tool or machine

in the descriptions.

Pictograms

The meanings of the pictograms

attached to the machine are explained in

this manual.

Depending on the model concerned, the

following pictograms may be attached to

your machine.

Preset trigger travel

(infinitely variable)

Unlock

Lock

Symbols in text

WARNING

Warning where there is a risk of an

accident or personal injury or serious

damage to property.

NOTICE

Caution where there is a risk of

damaging the machine or its individual

components.

Engineering improvements

STIHL's philosophy is to continually

improve all of its products. For this

reason we may modify the design,

engineering and appearance of our

products periodically.

Therefore, some changes, modifications

and improvements may not be covered

in this manual.

Safety Precautions

Some special safety precautions have to be

observed when working

with this power tool

because of the very high

speed of the cutting

attachment.

It is important that you

read the instruction manual before first use and

keep it in a safe place for

future reference. Nonobservance of the safety

precautions may result in

serious or even fatal

injury.

General

WARNING

– Minors should never be allowed to

operate this power tool. Watch

children to be sure that they do not

play with the power tool.

– This power tool may be operated

only by persons who have been

instructed in its use and proper

handling.

– This power tool may not be used by

persons who are not able to operate

it safely due to limited physical,

sensory or mental ability.

2

FSA 90 R

English

– Lend or rent your power tool only

together with this instruction manual

and only to persons who are familiar

with this model and its operation.

– Remove the battery before

performing any work on the power

tool, e.g. cleaning, maintenance,

replacing parts.

If you have not used this model before:

Have your dealer or a trained expert

show you how to operate it properly and

safely.

Observe all applicable local safety

regulations, standards and ordinances.

The use of noise emitting power tools

may be restricted to certain times by

national or local regulations.

Keep bystanders, especially children,

and animals away from the work area.

The user is responsible for avoiding

injury to third parties or damage to their

property.

To operate this power tool you must be

rested, in good physical condition and

mental health.

If you have any condition that might be

aggravated by strenuous work, check

with your doctor before operating a

power tool.

Do not operate the power tool if you are

under the influence of any substance

(drugs, alcohol) which might impair

vision, dexterity or judgment.

Remove the battery from

the power tool:

– before carrying out inspections,

adjustments or cleaning work

– before working on the cutting

attachment

– before leaving the machine

unattended

– before transporting

– before storing

– before performing repairs and

maintenance work

– in the event of danger or in an

emergency

This avoids the risk of the motor starting

unintentionally.

Intended Use

Use your power tool only as specified for

the cutting attachment mounted, see

"Working Techniques".

Do not use your power tool for any other

purpose – risk of accidents.

Never attempt to modify your power tool

in any way since this may increase the

risk of personal injury. STIHL excludes

all liability for personal injury and

damage to property caused while using

unauthorized attachments.

Clothing and Equipment

Wear proper protective clothing and

equipment.

Clothing must be sturdy

but allow complete freedom of movement. Wear

snug-fitting clothing, an

overall and jacket combination, do not wear a

work coat.

Avoid clothing that could get caught on

branches or brush or moving parts of the

machine. Do not wear a scarf, necktie or

jewelry. Tie up and confine long hair

(e.g. with a hair net, cap, hard hat, etc.).

Wear steel-toed safety

boots with non-slip soles.

Sturdy shoes with non-slip soles may be

worn as an alternative only when using

mowing heads.

WARNING

To reduce the risk of eye

injuries, wear close-fitting safety glasses in

accordance with European Standard EN 166.

Make sure the safety

glasses are a comfortable and snug fit.

Wear a face shield. A face shield alone

does not provide adequate eye

protection.

Wear a safety hard hat where there is a

danger of head injuries from falling

objects.

FSA 90 R

3

English

Wear heavy-duty work

gloves made of durable

material (e.g. leather).

STIHL offers a comprehensive range of

personal protective clothing and

equipment.

Transporting

Before transporting – even for short

distances – always switch off the

machine, move the retaining latch to ƒ

and remove the battery. This avoids the

risk of the motor starting unintentionally.

Carry the unit horizontally and properly

balanced by the drive tube.

To reduce the risk of cut injuries, fit

transport guard on a metal cutting

attachment, even when carrying the tool

for short distances.

Transporting by vehicle: Properly secure

the power tool to prevent turnover and

damage.

Cleaning

Clean plastic surfaces with a cloth. Do

not use aggressive detergents. They

may damage the plastic.

Always clean dust and dirt off the power

tool – do not use any grease solvents for

this purpose.

Clean the cooling slots if necessary.

Keep the battery guides free from

foreign matter – clean as necessary.

Do not use a pressure washer to clean

the unit. The solid jet of water may

damage parts of the unit.

Do not spray the power tool with water.

Do not spray the cutting attachment or

deflector with water or immerse them in

water as this may damage the drive

motor and electronic control unit in the

motor housing.

Accessories

Only use cutting attachments and

accessories that are explicitly approved

for this power tool by STIHL or are

technically identical. If you have any

questions in this respect, consult a

servicing dealer. Use only high quality

tools and accessories in order to avoid

the risk of accidents and damage to the

unit.

STIHL recommends the use of genuine

STIHL tools and accessories. They are

specifically designed to match the

product and meet your performance

requirements.

Drive

Battery

Follow the supplement sheet or User

Manual for the STIHL rechargeable

battery and keep them in a safe place.

For further safety instructions, see

www.stihl.com/safety-data-sheets

Battery charger

Observe the supplement sheet for the

STIHL charger and keep in a safe place.

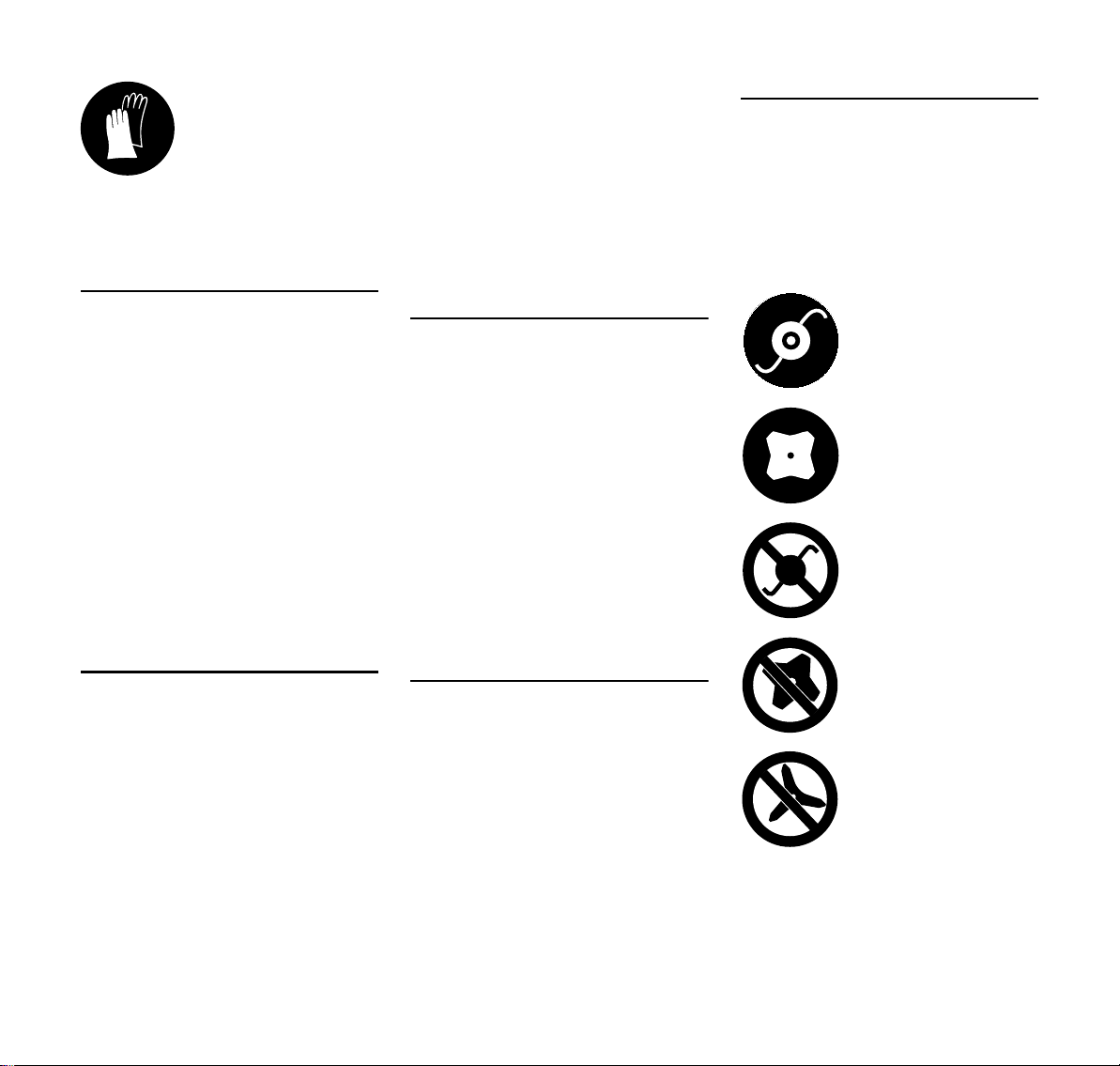

Symbols on Deflectors

An arrow on the deflector shows the

correct direction of rotation of the cutting

attachments.

Some of the following symbols are

applied to the outside of the deflector to

indicate the approved combination of

cutting attachment and deflector.

Deflector may be used

with mowing heads.

Deflector may be used

with grass cutting blades.

Deflector must not be

used with mowing heads.

Deflector must not be

used with grass cutting

blades.

Deflector must not be

used with brush knives.

4

FSA 90 R

English

Deflector must not be

used with circular saw

blades.

Cutting Attachments

To reduce the risk

of injury from

thrown objects,

never operate the

power tool without

the proper deflector for the type of

cutting attachment

being used.

The deflector on this power tool cannot

protect the operator from all objects

thrown by the cutting attachment

(stones, glass, wire, etc.). Such objects

may ricochet and then hit the operator.

Check the cutting attachment at regular

short intervals during operation or

immediately if there is a noticeable

change in cutting behavior:

– Switch off the motor, move the

retaining latch to ƒ and wait for the

cutting attachment to come to a

standstill, remove the battery.

– Check condition and tightness, look

for cracks.

To replace the cutting attachment,

switch off the power tool, move the

retaining latch to ƒ and remove the

battery. This avoids the risk of injury

from the motor starting unintentionally.

Never continue using or attempt to

repair damaged or cracked cutting

attachments.

This may cause parts of the cutting

attachment to come off and hit the

operator or bystanders at high speed

and result in serious or fatal injuries.

Using Mowing Heads

Use only the deflector with properly

mounted line limiting blade to ensure the

mowing lines are automatically trimmed

to the approved length.

Before adjusting nylon line on manually

adjustable mowing heads, switch off the

machine, set retaining latch to ƒ and

remove the battery. This avoids the risk

of injury from the motor starting

unintentionally.

WARNING

To reduce the risk of serious injury,

never use wire or metal-reinforced line in

place of the nylon line.

Using Metal Cutting Attachments

STIHL recommends the use of original

STIHL metal cutting attachments. They

are specifically designed to match your

model and meet your performance

requirements.

Metal cutting attachments rotate at very

high speed. The forces that occur act on

the machine, the attachment and the

material being cut.

Sharpen metal cutting attachments

regularly as specified.

Check sharpness. Replace or sharpen

dull metal cutting attachments

immediately.

Unevenly sharpened metal cutting

attachments cause out-of-balance

which can impose extremely high loads

on the machine and increase the risk of

breakage.

Dull or improperly sharpened cutting

edges can put a higher load on the metal

cutting attachment and increase the risk

of injury from cracked or broken parts.

Inspect metal cutting attachments for

cracks or warping after every contact

with hard objects (e.g. stones, rocks,

pieces of metal). To reduce the risk of

injury, remove burrs and other visible

build-ups of material (use a file) because

they may become detached and be

thrown at high speed during operation.

Do not continue using or attempt to

repair damaged or cracked metal cutting

attachments by welding, straightening or

modifying the shape (out of balance).

If a rotating metal cutting attachment

makes contact with a rock or other solid

object there is a risk of sparking which

may cause easily combustible material

to catch fire under certain

circumstances. Dry plants and scrub are

also easily combustible, especially in hot

and dry weather conditions. If there is a

risk of fire, do not use metal cutting

attachments near combustible

materials, dry plants or scrub. Always

contact your local forest authority for

information on a possible fire risk.

To reduce the above-mentioned risks

when using a metal cutting attachment,

never use a metal cutting attachment

with a diameter larger than specified. It

must not be too heavy. It must be

manufactured from materials of

adequate quality and its geometry must

be correct (shape, thickness).

FSA 90 R

5

English

15m (50ft)

To reduce the risk of injury, a metal

cutting attachment not manufactured by

STIHL must not be heavier, thicker,

have a different shape or a diameter

larger than the largest metal cutting

attachment approved by STIHL for this

power tool model.

Before Starting Work

Check that your power tool is properly

assembled and in good condition – refer

to appropriate chapters in the instruction

manual.

– The trigger and trigger lockout must

move freely and spring back to the

idle position when they are

released.

– Use only an approved combination

of cutting attachment, deflector and

handle. All parts must be

assembled properly and securely.

– Check that the cutting attachment is

properly and securely mounted and

in good condition.

– Check protective devices (e.g.

deflector for cutting attachment,

rider plate) for damage or wear.

Always replace damaged parts. Do

not operate your machine with a

damaged deflector or worn rider

plate (lettering and arrows no longer

legible).

– Never attempt to modify the controls

or safety devices in any way.

– Keep the handles dry and clean –

free from oil and dirt – for safe

control of the power tool.

– Check contacts in battery

compartment for foreign matter.

6

– Fit the battery correctly – it must

engage audibly.

– Never use defective or deformed

batteries.

To reduce the risk of accidents, do not

operate the unit if it is not properly

assembled and in good condition.

Switching On

Before switching on your power tool,

make sure the cutting attachment is not

touching the ground or any other object.

To reduce the risk of injury, avoid

contact with the cutting attachment.

Note that the cutting

attachment continues to

run for a short period

after the power tool is

switched off – flywheel

effect.

During Operation

In case of imminent danger or in an

emergency, switch off the motor

immediately, move retaining latch to ƒ

and remove the battery.

This power tool may be used in the rain

and wet. Dry off your power tool after

finishing work.

Do not leave the power tool outdoors in

the rain.

Take special care in slippery conditions

(ice, wet ground, snow), on slopes or

uneven ground.

Watch out for obstacles: Roots and tree

stumps which could cause you to trip or

stumble.

Inspect the work area:

Stones, pieces of metal

or other solid objects may

be thrown more than 15

meters and cause personal injury or damage

the cutting attachment

and property (e.g. parked

vehicles, windows).

The cutting attachment may catch and

fling objects a great distance and cause

injury - therefore, do not allow any other

persons within a radius of 15 meters of

your own position. To reduce the risk of

damage to property, also maintain this

distance from other objects (vehicles,

windows). Even maintaining a distance

of 15 meters or more cannot exclude the

potential danger.

To reduce the risk of accidents, take a

break in good time to avoid tiredness or

exhaustion.

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Stay alert so as not to endanger

others.

Special care must be taken when

working in difficult, over-grown terrain.

The dust that occurs during operation

may be harmful to health. If dust levels

are very high, wear a suitable respirator.

FSA 90 R

English

0208BA006 KN

Clean grass and plant residue off the

cutting attachment mounting at regular

intervals – remove any build up of

material from the cutting attachment and

deflector.

Before leaving the power tool

unattended: Always switch off the power

tool, set the retaining latch to ƒ and

remove the battery.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting Work". Make sure the

safety devices are working properly. Do

not continue operating your power tool if

it is damaged. In case of doubt, consult

your servicing dealer.

Always hold the power tool firmly with

both hands on the handles.

Make sure you always have good

balance and secure footing.

Models with loop handle

Right hand on control handle, left hand

on loop handle, even if you are lefthanded.

After Finishing Work

Switch off the power tool, move retaining

latch to ƒ and remove the battery.

Storing

When the power tool is not in use, store

it so that it does not endanger others.

Secure it against unauthorized use.

Store the machine in a dry, locked

location with the retaining latch on ƒ

and the battery removed.

Vibrations

This power tool minimizes the vibrations

transmitted to the operator's hands.

However, the operator should seek

medical advice in the event of suspected

circulatory problems in the hands (e.g.

tingling sensation in the fingers).

Maintenance and Repairs

Always move the retaining latch to ƒ

and remove the battery before carrying

out any repairs or maintenance work on

the power tool. This avoids the risk of the

motor starting unintentionally.

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in the instruction manual.

Have all other work performed by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

Only use high-quality replacement parts

in order to avoid the risk of accidents

and damage to the unit. If you have any

questions in this respect, consult a

servicing dealer.

STIHL recommends the use of genuine

STIHL replacement parts. They are

specifically designed to match your

model and meet your performance

requirements.

Never attempt to modify your power tool

in any way since this will increase the

risk of personal injury.

Check the electrical contacts and ensure

that the insulation of the connecting

cords and plug of the charger show no

sign of aging (brittleness).

Electrical components, e.g. connecting

cord of charger, may only be repaired or

replaced by a qualified electrician.

Check tightness of mounting screws on

safety devices and the cutting

attachment and retighten if necessary.

FSA 90 R

7

English

002BA135 KN

1

3988BA000 KN

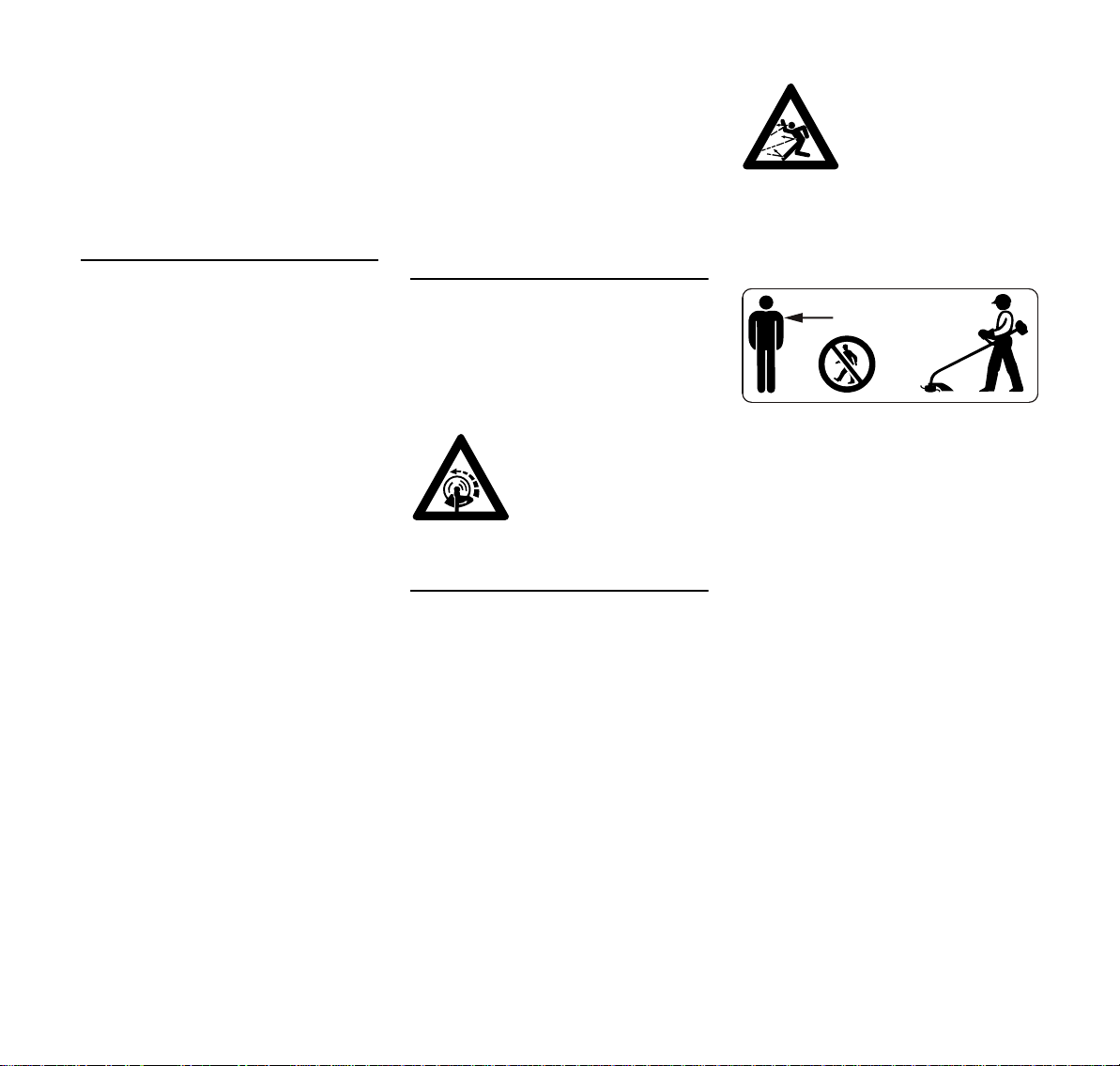

Reactive Forces

Risk of Kickout (Blade Thrust) with Metal

Cutting Attachments

WARNING

When using metal cutting attachments there is

a risk of kickout when the

rotating blade comes into

contact with a solid object

such as a tree trunk,

branch, tree stump, rock

or similar. The machine is

thrown to the right or to

the rear – opposite to the

attachment's direction of

rotation.

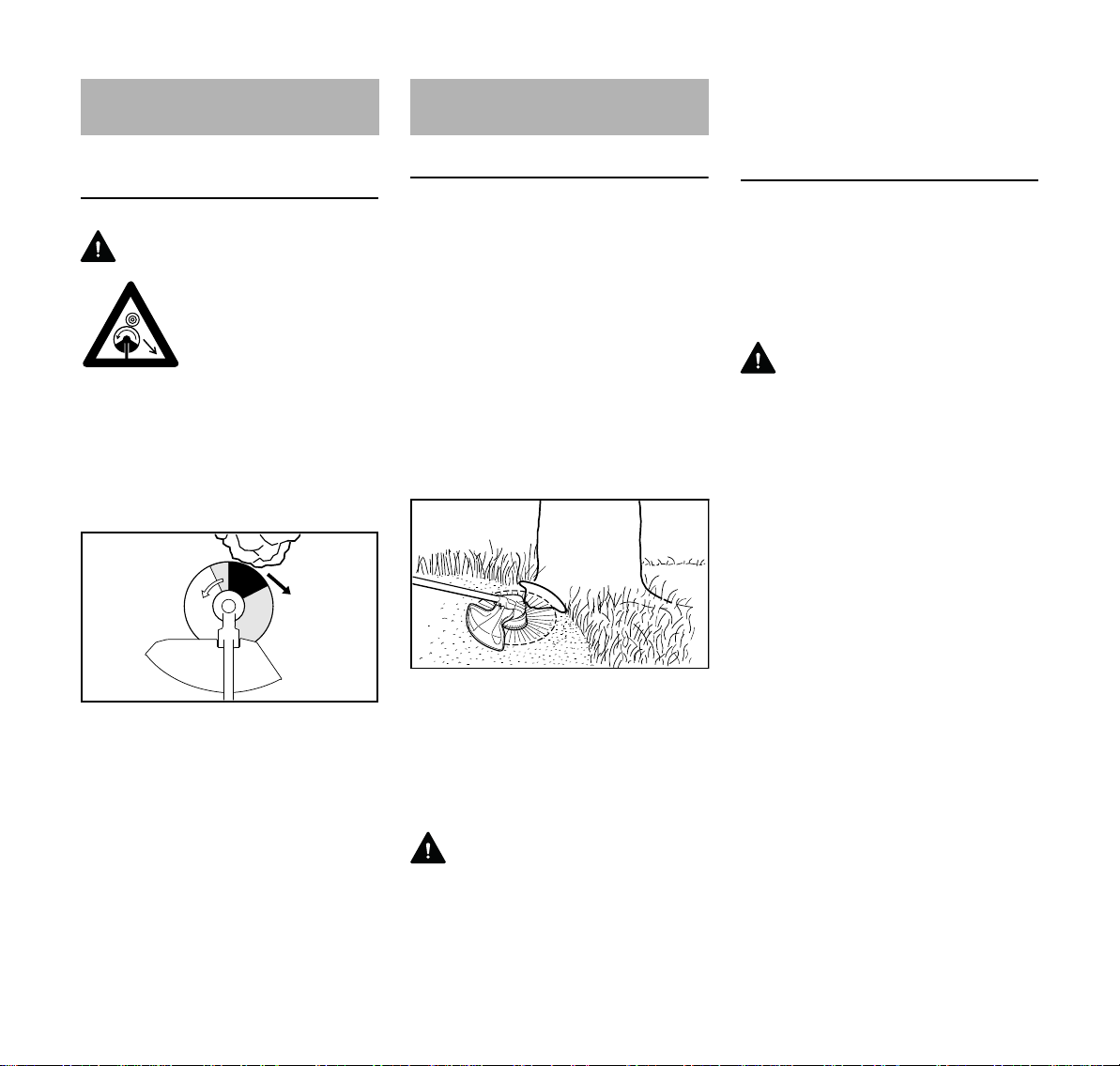

Working Techniques

Mowing Head with Nylon Line

Nylon line mowing heads are suitable for

lawn edging and trimming small to

medium areas and around obstacles.

The working technique is described

below, see "Mowing".

The mowing head comes with an

instruction leaflet. Refill the mowing

head with nylon line as described in the

instruction leaflet.

Working with Bump Guard

The bump guard is available as a special

accessory.

come to a standstill before adjusting the

bump guard – do not adjust it with your

foot.

Grass Cutting Blade

Grass cutting blades are suitable for

cutting tough grass, weeds. fern,

stinging nettles and reed. They are

robust and can be used for mowing large

areas. The working technique is

described below, see "Mowing".

WARNING

Improper use may damage the grass

cutting blade – risk of injury from thrown

parts.

Resharpen the grass cutting blade

according to instructions when it has

dulled noticeably.

The risk of kickout is greatest when the

black area of the rotating cutting

attachment comes into contact with a

solid object.

8

The bump guard (1)

– limits the cutting range of the

mowing line

– reduces the risk of the rotating

mowing line causing damage (e.g.

tree bark)

WARNING

The mowing head may continue to

rotate briefly after you switch off your

power tool – wait for the mowing head to

FSA 90 R

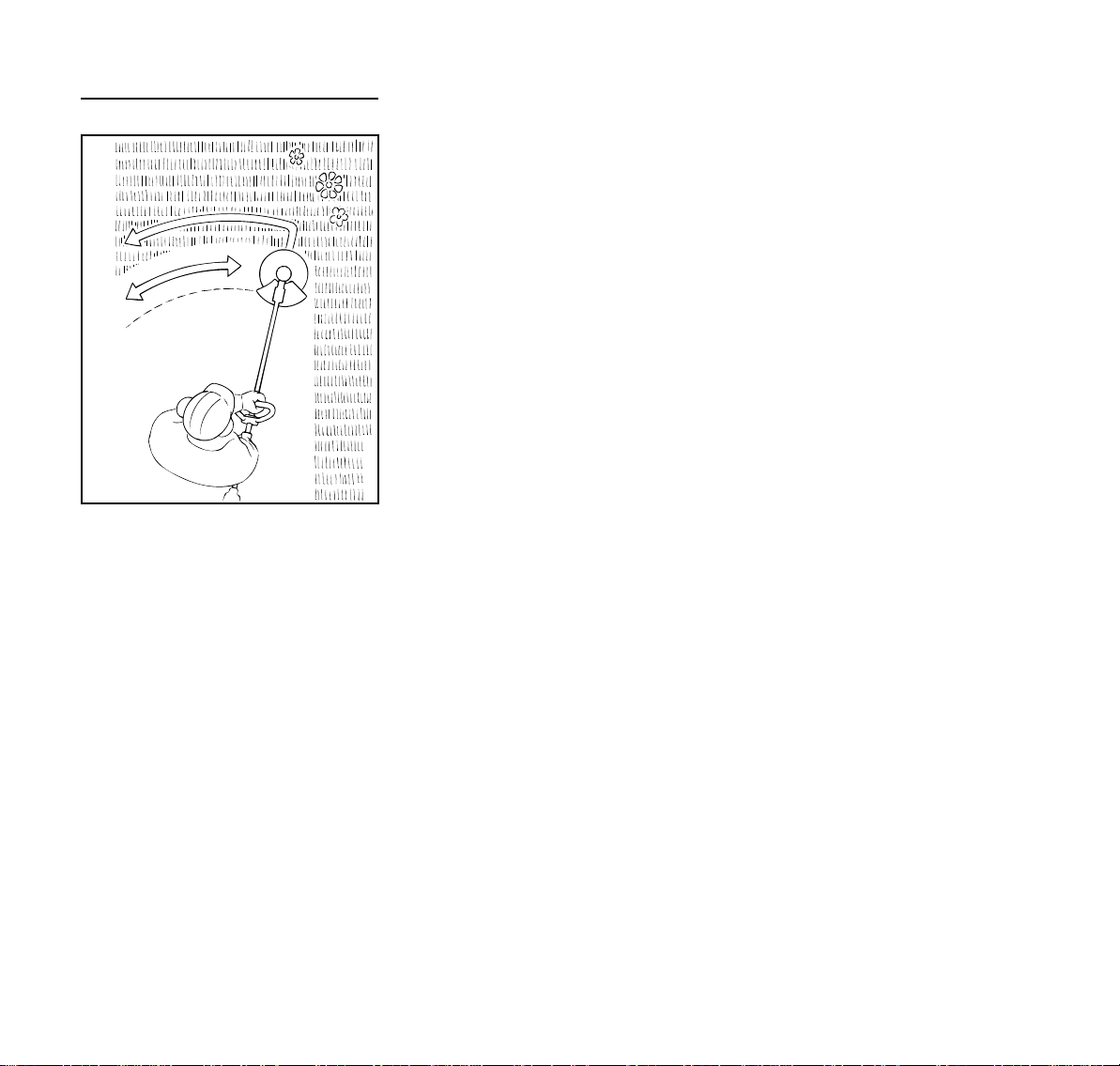

Mowing

002BA341 KN

N Hold your trimmer with both hands –

right hand on the control handle.

N Stand upright – hold the power tool

in a relaxed position.

N Make sure the cutting attachment is

not touching the ground or any other

objects.

N Swing the trimmer back and forth in

an arc.

N The cutting height is determined by

the distance of the mowing line from

the lawn surface.

N Avoid contact with fences, walls,

rocks, etc. since it will result in a

higher rate of wear.

Do not throw cuttings in the garbage

can. They can be composted.

English

FSA 90 R

9

English

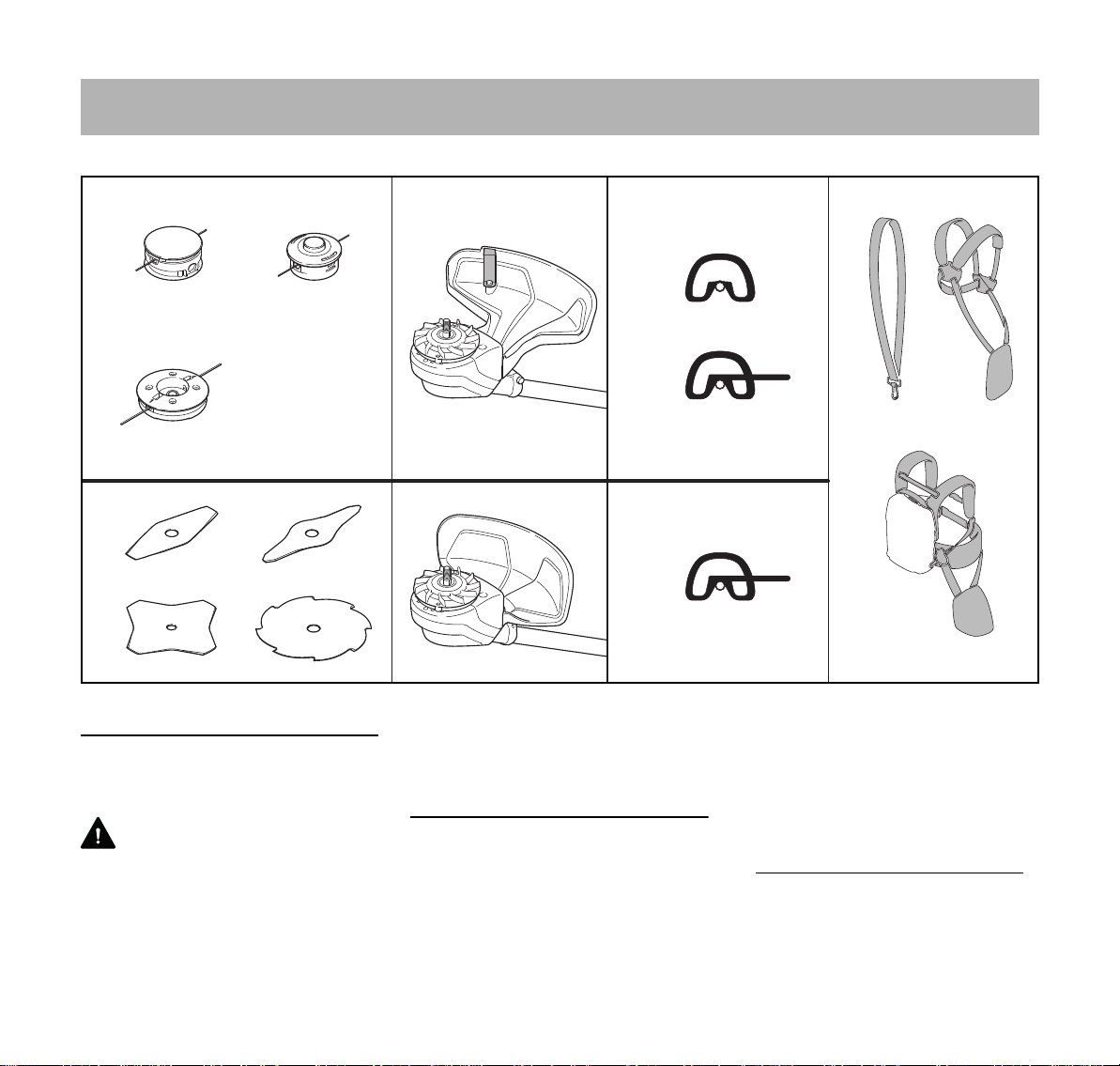

Approved Combinations of Cutting Attachment, Deflector, Handle and Harness

Cutting attachment Deflector Handle Carrying strap

1

2

3

4

6

Permissible combinations

Choose the correct combination from

the table depending on the cutting tool!

WARNING

For safety reasons only the cutting

attachments, deflector, handle and

harness versions within one line of the

table may be combined with one

5

7

8

9

another. No other combinations are

permitted because of the risk of

accidents.

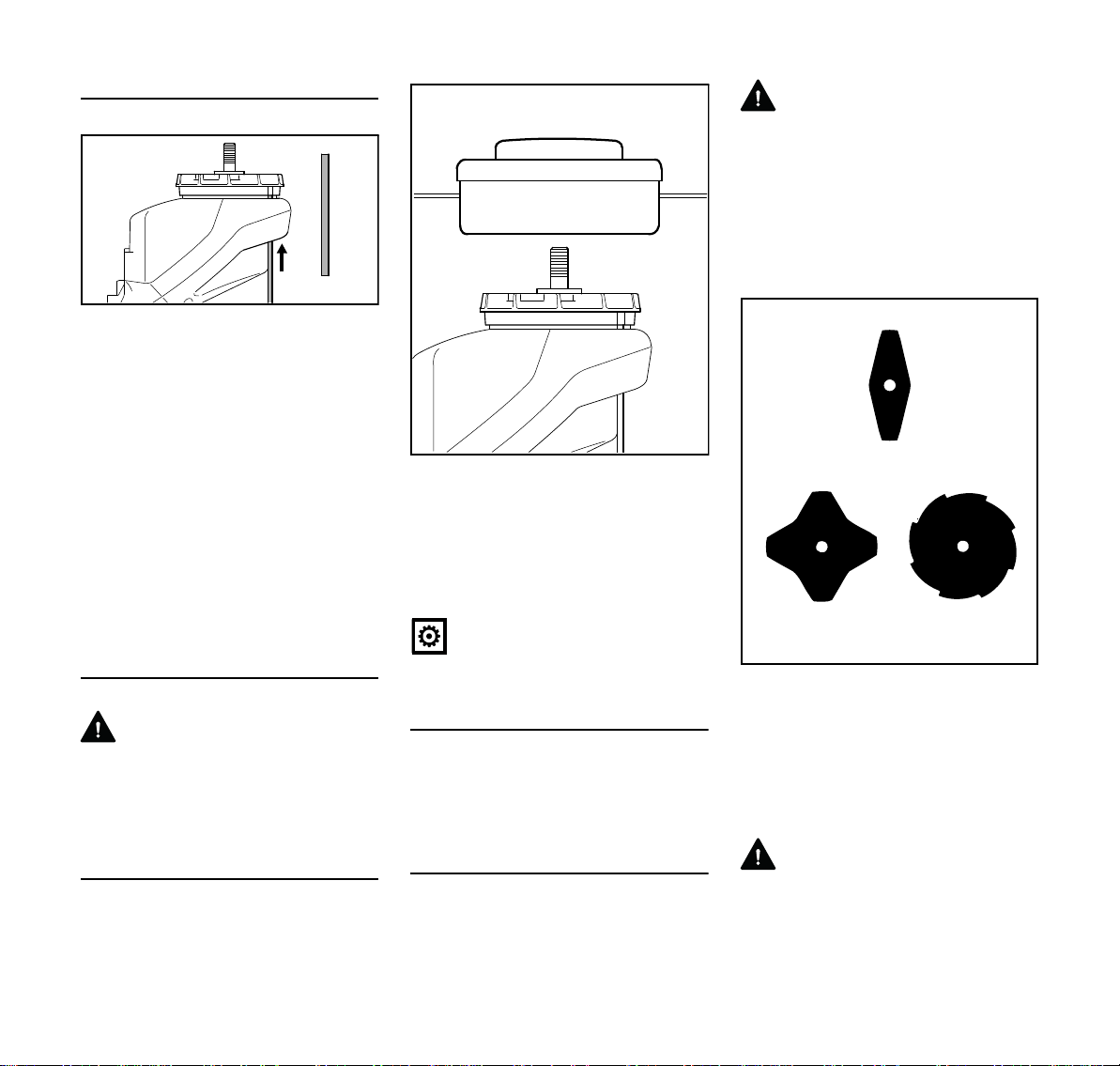

Cutting attachments

Mowing heads

1 STIHL SuperCut 20-2

2 STIHL AutoCut 25-2

3 STIHL DuroCut 20-2

1)

1)

1)

10

11

11

13

14

12

15

12

16

Metal cutting tools

4 Grass cutting blade 230-2

(230 mm dia.)

1)

Operate the mowing head only with

2.4 mm diameter (0.095 in) round,

quiet mowing line

0000-GXX-0408-A1

10

FSA 90 R

English

3988BA034 KN

2

1

1

3988BA030 KN

2

5

4

3

6

7

3988BA007 KN

5 Grass cutting blade 260-2

(260 mm dia.)

6 Grass cutting blade 230-4

(230 mm dia.)

7 Grass cutting blade 230-8

(230 mm dia.)

WARNING

Grass cutting blades of materials other

than metal must not be used.

Deflectors

8 Deflector with line limiting blade

9 Deflector without line limiting blade

Handles

10 Loop handle

11 Loop handle with

12 Barrier bar

Shoulder straps

13 Shoulder strap can be used

14 Full harness can be used

15 Harness for Type AR battery may

be used together with

16 padding (special accessory)

See chapter "Fitting the Harness"

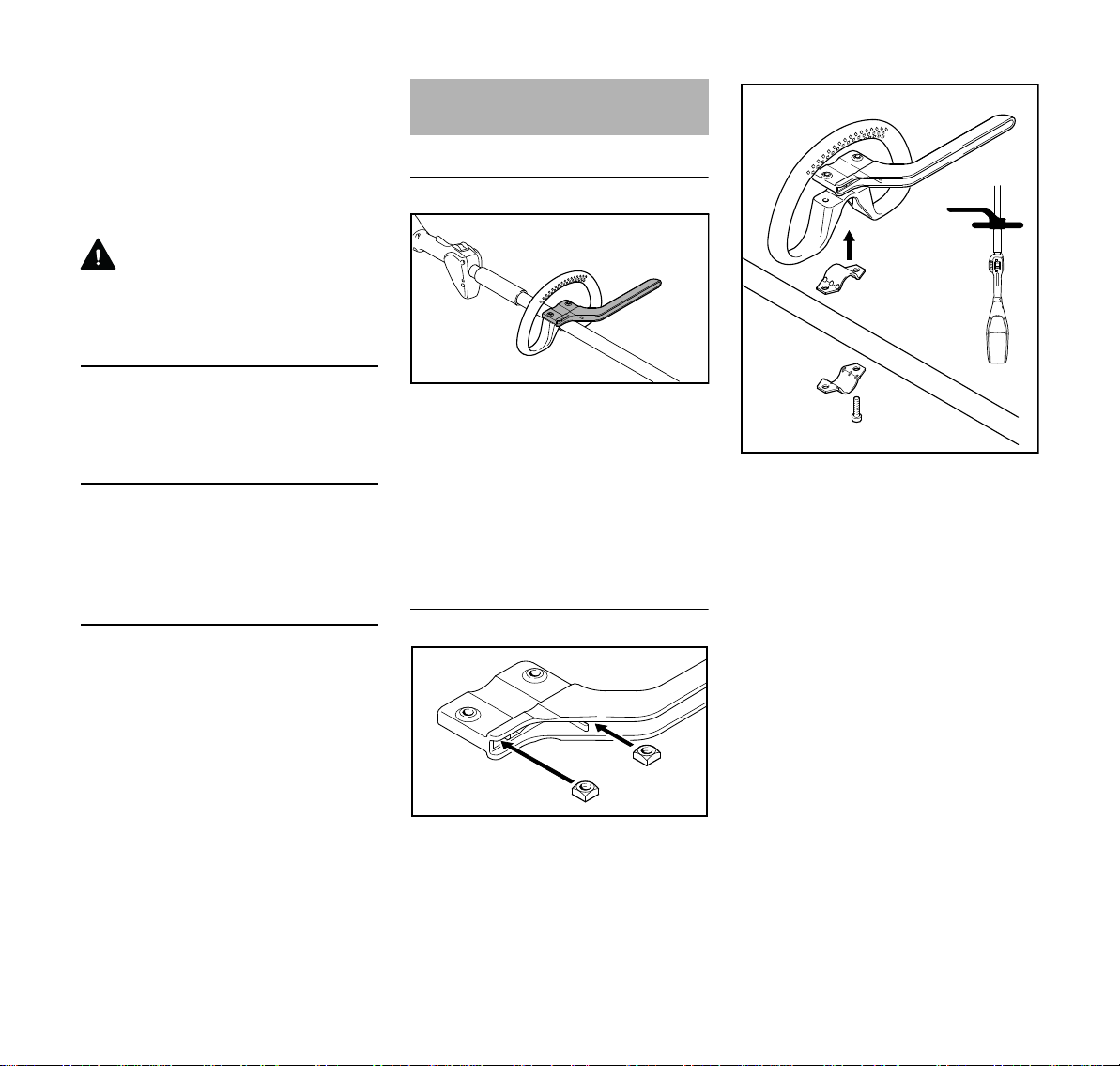

Mounting the Loop Handle

Using the Barrier Bar

A barrier bar may have to be mounted to

suit the cutting attachment you intend to

use – see "Approved Combinations of

Cutting Attachment, Deflector, Handle

and Harness".

The barrier bar comes standard with the

machine or is available as a special

accessory.

Mounting Loop Handle with Barrier Bar

N Place the clamp (3) in the loop

handle (4) and position them both

against the shaft (5).

N Position the clamp (6) against the

shaft.

N Place the barrier bar (2) in position

as shown.

N Line up the holes.

N Insert the screws (7) in the holes

and screw them into the barrier

bar (2) as far as stop.

N Go to "Adjusting and Securing the

Loop Handle".

FSA 90 R

N Fit the square nuts (1) in the barrier

bar (2); the holes must line up.

11

English

7

8

5

4

1

6

1

3

8

7

3988BA001 KN

4

A

3988BA029 KN

1

3988BA008 KN

2

3988BA009 KN

Mounting the Loop Handle without

Barrier Bar

N Place the clamp (3) in the loop

handle (4) and position them both

against the shaft (5).

N Position the clamp (6) against the

shaft.

N Line up the holes.

N Fit washers (8) on the screws (7)

and insert the screws in the holes.

Fit the square nuts (1) and screw

them down as far as stop.

N Go to "Adjusting and Securing the

Loop Handle".

Adjusting and Securing the Loop Handle

The loop handle can be adjusted to suit

the height and reach of the operator and

the application by changing

distance (A).

Distance A when using mowing heads:

Max. 30 cm (12 in)

Distance A when using metal cutting

attachments: Max. 25 cm (10 in)

N Slide the handle to the required

position.

N Line up the loop handle (4).

N Tighten down the screws until the

loop handle can no longer be

rotated on the shaft. If no barrier bar

is fitted – lock the nuts if necessary.

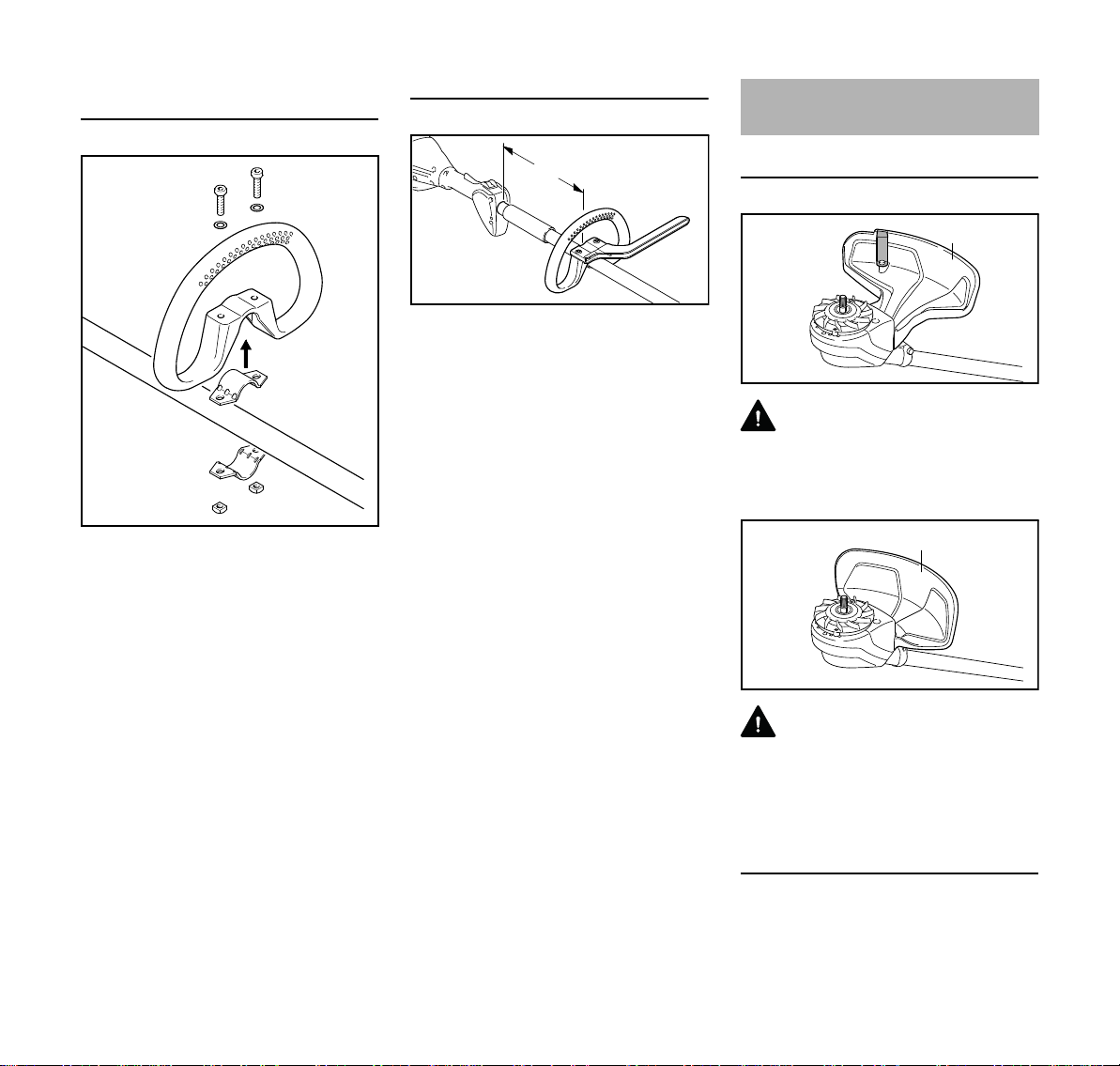

Mounting the Deflector

Use the Right Deflector

WARNING

Deflector (1) is approved for mowing

heads only and must therefore be

mounted before fitting a mowing head

WARNING

Deflector (2) is approved for grass

cutting blades only and must therefore

be mounted before fitting a grass cutting

blade.

12

Mounting the Deflector

Deflectors (1 and 2) are both mounted to

the motor housing in the same way.

FSA 90 R

English

3

3988BA010 KN

4

3988BA028 KN

2

3988BA011 KN

1

2

3988BA012 KN

3

5

3988BA013 KN

4

N Position the deflector against the

motor housing.

N Push hooks (3) on deflector into the

recesses in the motor housing.

N Insert the screw (4) and tighten it

down firmly.

Mounting the Cutting

Attachment

Placing Power Tool on the Ground

N Move the retaining latch to ƒ and

remove the battery.

N Position your power tool so that the

cutting attachment mounting face is

pointing up.

Mounting the Fanwheel

The machine comes standard with a

fanwheel.

Mounting Hardware for Cutting

Attachments

The mounting hardware supplied

depends on the cutting attachment that

comes as original equipment with the

new machine.

Machine supplied without mounting

hardware

Only mowing heads may be used which

mount directly to the shaft (2).

Machine supplied with mounting

hardware

Mowing heads and metal cutting

attachments may be mounted.

FSA 90 R

N Push the fanwheel (1) onto the

shaft (2).

NOTICE

The fanwheel is necessary for mounting

cutting attachments.

Depending on the cutting attachment, it

may be necessary to use the nut (3),

rider plate (4) and thrust washer (5).

These parts are included in a kit

supplied with the machine and are also

available as special accessories.

13

English

7

6

2

3988BA014 KN

6

2

3988BA015 KN

1

3

2

681BA050 KN

Blocking the Shaft

The output shaft (2) must be blocked

with the stop pin (6) to mount or remove

cutting attachments. The stop pin is

included with the machine and is

available as a special accessory.

N Push the stop pin (6) into the

hole (7) in the motor housing.

N Rotate the shaft, nut or cutting

attachment to line up the hole in the

fanwheel (1) with the stop pin (6).

N Push the stop pin (6) home until its

end is level with the blades on the

fanwheel (1).

The shaft is now blocked.

Mounting the Cutting Attachment

WARNING

Use a deflector that matches the cutting

attachment – see "Mounting the

Deflector".

Fitting Mowing Head with Screw

Mounting

Keep the instruction leaflet for the

mowing head in a safe place.

N Screw the mowing head

counterclockwise on to the shaft (2)

as far as stop.

N Blocking the shaft

N Tighten down the mowing head

firmly.

NOTICE

Remove the tool used to block the shaft.

Remove the mowing head.

N Block the shaft.

N Unscrew the mowing head

clockwise.

Mounting the Metal Cutting Attachment

Keep the leaflet and packaging of the

metal cutting attachment in a safe place.

WARNING

Wear protective gloves to reduce the

risk of direct contact with the sharp

cutting edges.

Mount only one metal cutting

attachment.

Check direction of rotation of cutting

attachment

The cutting edges of the grass cutting

blades (1) and (2) may point in either

direction – these cutting attachments

must be turned over regularly to reduce

one-sided wear.

Cutting edges of grass cutting blade (3)

must point clockwise.

WARNING

Direction of rotation is indicated by an

arrow on the inside of the deflector.

14

FSA 90 R

English

6

4

5

7

8

9

3988BA016 KN

3901BA015 KN

2

1

1

3901BA019 KN

N Place the cutting attachment (4) on

the fanwheel (5).

WARNING

Collar (see arrow) must engage the

cutting attachment's mounting hole.

Securing the cutting attachment

N Fit the thrust washer (6) – convex

side must face up.

N Fit the rider plate (7).

N Block the shaft (8).

N Screw the mounting nut (9) on to the

shaft counterclockwise and tighten

it down firmly.

WARNING

If the mounting nut has become too

loose, fit a new one.

FSA 90 R

NOTICE

Remove the tool used to block the shaft.

Removing the Metal Cutting Attachment

WARNING

Wear protective gloves to reduce the

risk of direct contact with the sharp

cutting edges.

N Block the shaft.

N Unscrew the mounting nut

clockwise.

N Take the cutting attachment and its

mounting hardware off the

fanwheel (5) – but do not remove

the fanwheel.

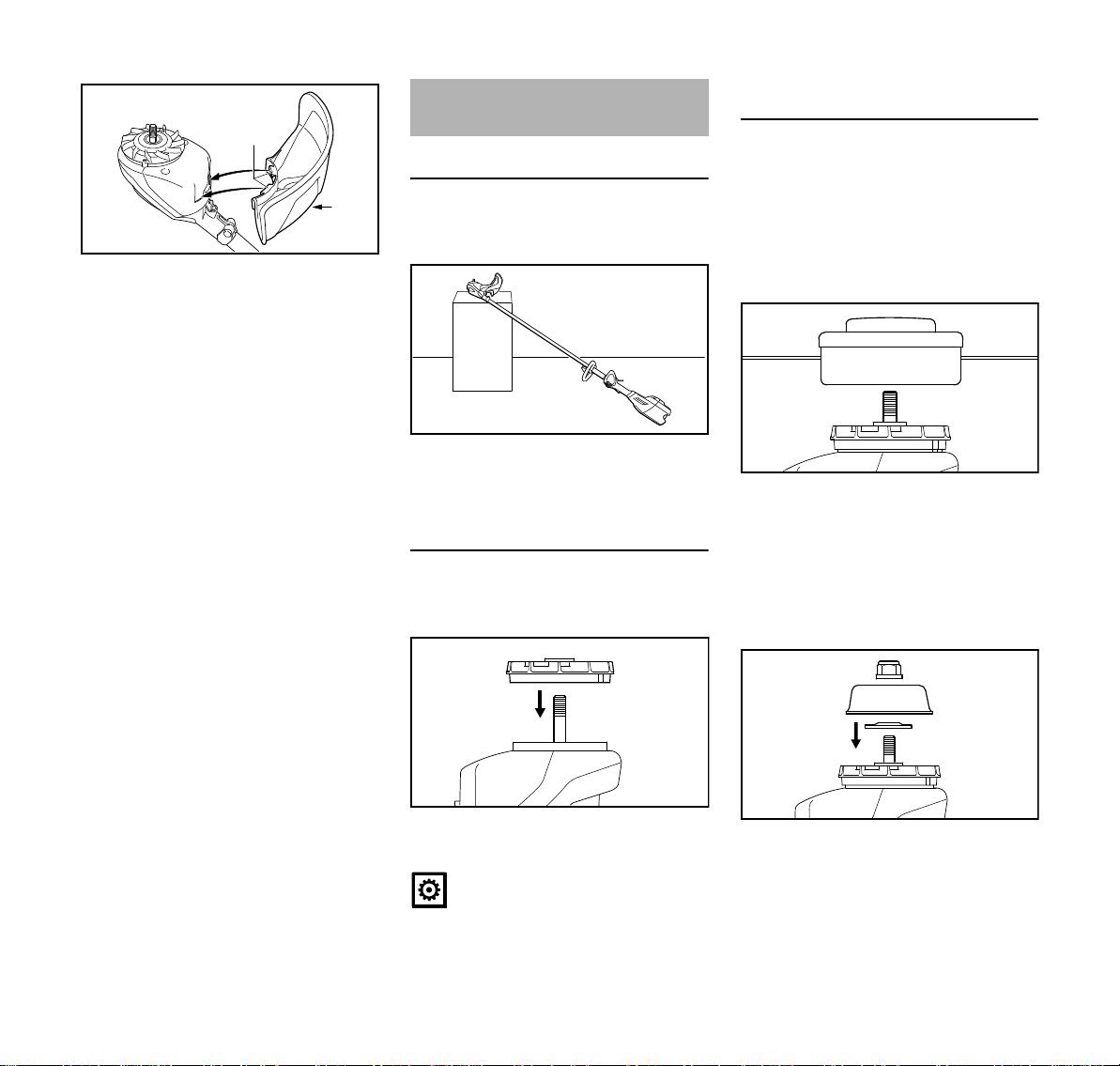

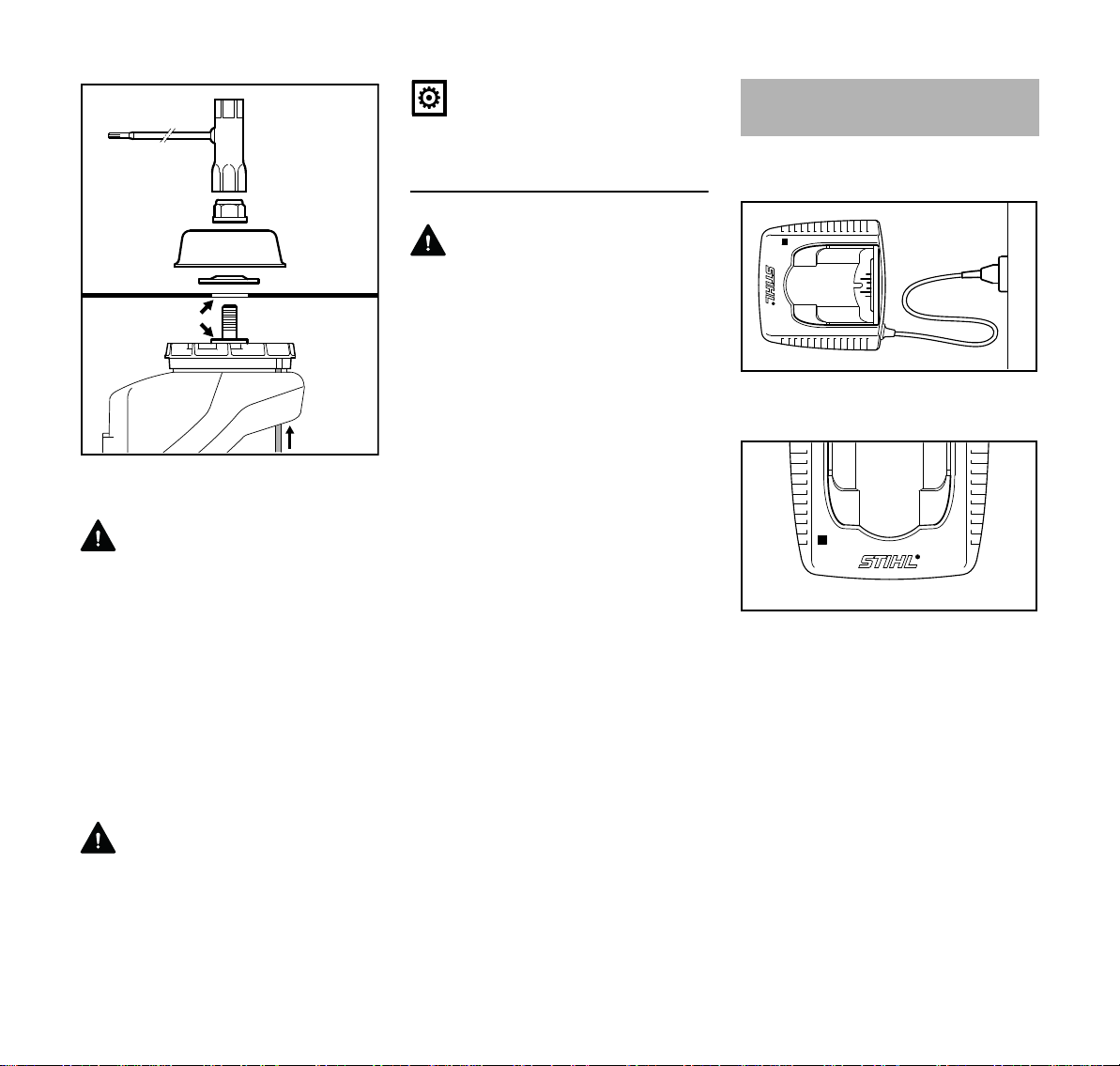

Connecting Charger to

Power Supply

Power supply (mains) voltage and

operating voltage must be the same.

N Insert the plug (1) in the wall

outlet (2).

A self test is performed after the charger

is connected to the power supply. During

this process, the light emitting diode (1)

on the charger lights up green for about

1 second, then red and goes off again.

15

English

2

3901BA009 KN

4

3901BA014 KN

3

Charging the Battery

A factory-new battery is not fully

charged.

Recommendation: Fully charge the

battery before using it for the first time.

N Connect the charger to the power

supply – mains voltage and

operating voltage of the charger

must be the same – see

"Connecting Charger to Power

Supply".

Operate the charger only in enclosed

and dry rooms at ambient temperatures

between +5°C to +40°C (+41°F to

+104°F)

Only charge dry batteries. Allow a damp

battery to dry before charging.

N Push the battery (1) into the

charger (2) until noticeable

resistance is felt – then push it as far

as stop.

The LED (3) on the charger comes on

when the battery is inserted – see "LED

on Charger"

Charging begins as soon as the

LEDs (4) on the battery glow green –

see "LEDs on Battery".

The charge time is dependent on a

number of factors, including battery

condition, ambient temperature, etc.,

and may therefore vary from the times

specified.

The battery heats up during operation in

the power tool. If a hot battery is inserted

in the charger, it may be necessary to

cool it down before charging. The

charging process begins only after the

battery has cooled down. The time

required for cooling may prolong the

charge time.

The battery and charger heat up during

the charging process.

AL 300, AL 500 Chargers

AL 100 Charger

The AL 100 charger has no fan and

waits for the battery to cool down before

starting the charging process. The

battery is cooled by heat transfer to the

ambient air.

End of Charge

The charger switches itself off

automatically when the battery is fully

charged:

– LEDs on the battery go off.

– The LED on the charger goes off.

– The charger's fan is switched off (if

charger is so equipped)

Remove the fully charged battery from

the charger.

The AL 300 and AL 500 chargers are

equipped with a battery cooling fan

16

FSA 90 R

English

1

3901BA010 KN

3901BA018 KN

80 - 100 %

60 - 80 %

40 - 60 %

20 - 40 %

0 - 20 %

1

3901BA010 KN

3901BA016 KN

80 - 100 %

60 - 80 %

40 - 60 %

20 - 40 %

0 - 20 %

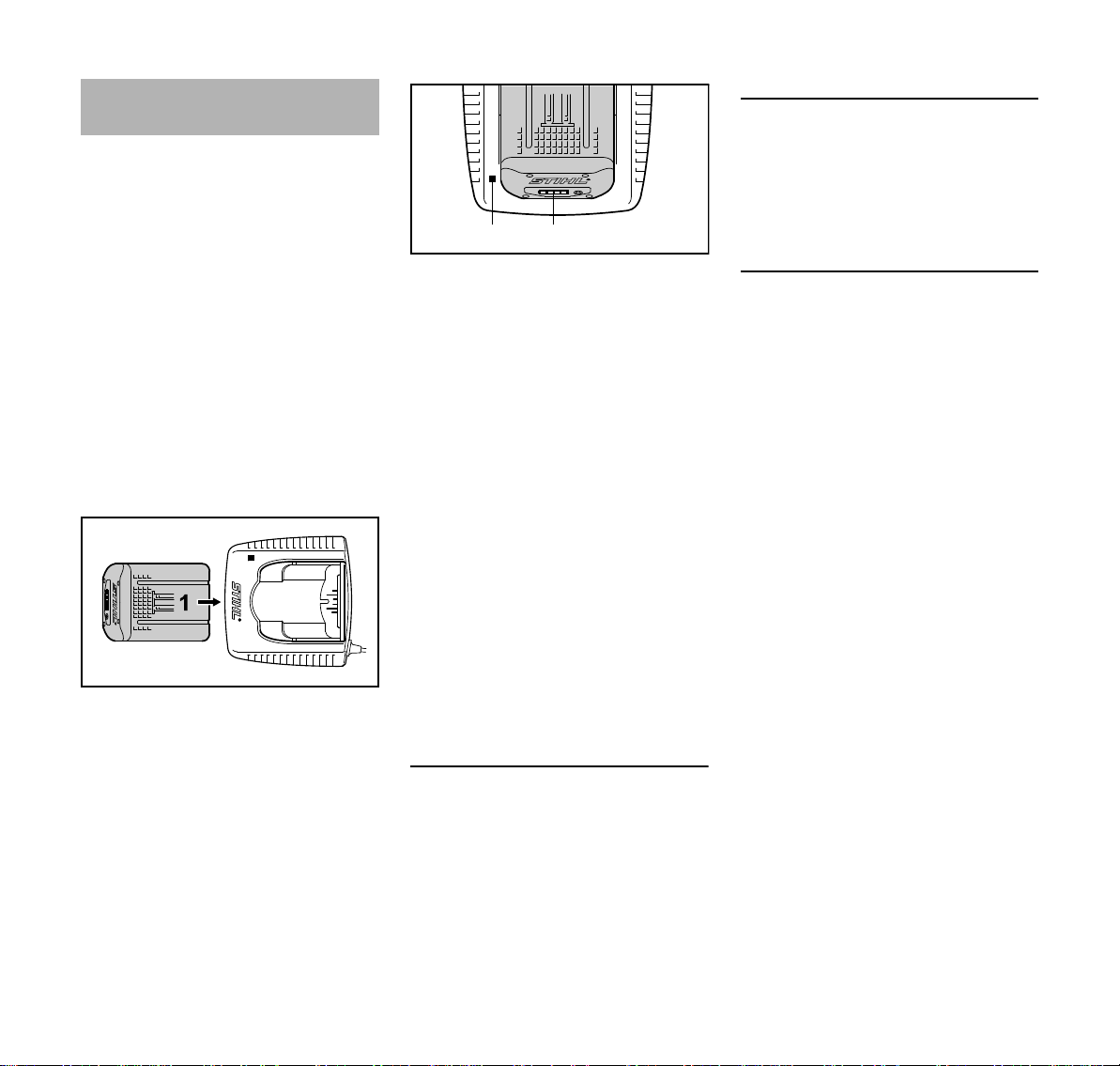

LEDs on Battery

Four LEDs show the battery's state of

charge and any problems that occur in

the battery or machine.

N Press button (1) to activate the

The LEDs can glow or flash green or

red.

display – the display goes off

automatically after 5 seconds.

LED glows continuously green.

LED flashes green.

LED glows continuously red.

LED flashes red.

During charging

The LEDs glow continuously or flash to

indicate the progress of charge.

A green flashing LED indicates the

capacity that is currently being charged.

The LEDs on the battery go off

automatically when the charge process

is completed.

If the LEDs on the battery flash or glow

red – see "If the red LEDs glow

continuously / flash".

During Operation

N Press button (1) to activate the

display – the display goes off

automatically after 5 seconds.

The green LEDs glow continuously or

flash to indicate the state of charge.

FSA 90 R

If the LEDs on the battery flash or glow

red – see "If the red LEDs glow

continuously / flash".

17

English

3901BA041 KN

A

B

C

D

1

3901BA019 KN

If the red LEDs glow continuously / flash

A 1 LED glows

continuously

Battery is too hot

1) 2)

/cold

red:

B 4 LEDs flash

C 3 LEDs glow

D 3 LEDs flash

1)

red

continuously

red:

red

When charging: Charge process

Malfunction in

battery

Machine is too hot

– allow it to cool

down.

Malfunction in

machine

starts automatically after the battery

has cooled down / warmed up.

2)

During operation: Machine cuts out

– allow battery to cool down; it may

be necessary to take the battery out

of the machine for this purpose.

3)

Electromagnetic problem or fault.

Take the battery out of the machine

LED on Charger

tool and refit it. Switch on the

machine – if the LEDs continue to

flash, the battery is faulty and must

be replaced.

4)

Electromagnetic problem or fault.

Take the battery out of the

machine. Use a blunt tool to

remove dirt from the contacts in the

battery compartment. Refit the

battery. Switch on the machine – if

the light emitting diodes still flash,

the machine is faulty and must be

checked by a servicing dealer –

STIHL recommends an authorized

STIHL servicing dealer.

The LED (1) on the charger may glow

continuously green or flash red.

Green continuous light ...

... indicates the following:

The battery

1)

– is being charged

– is too hot and must cool down

before charging

See also "LEDs on battery".

3)

The green LED on the charger goes off

as soon as the battery is fully charged.

Red flashing light ...

4)

... may indicate the following:

– No electrical contact between

battery and charger – remove and

refit the battery

– Malfunction in battery – see also

"LEDs on Battery".

– Malfunction in charger – have

checked by a servicing dealer.

STIHL recommends an authorized

STIHL servicing dealer.

18

FSA 90 R

English

1

3988BA017 KN

2

1

2

1

2

002BA387 KN

3988BA019 KN

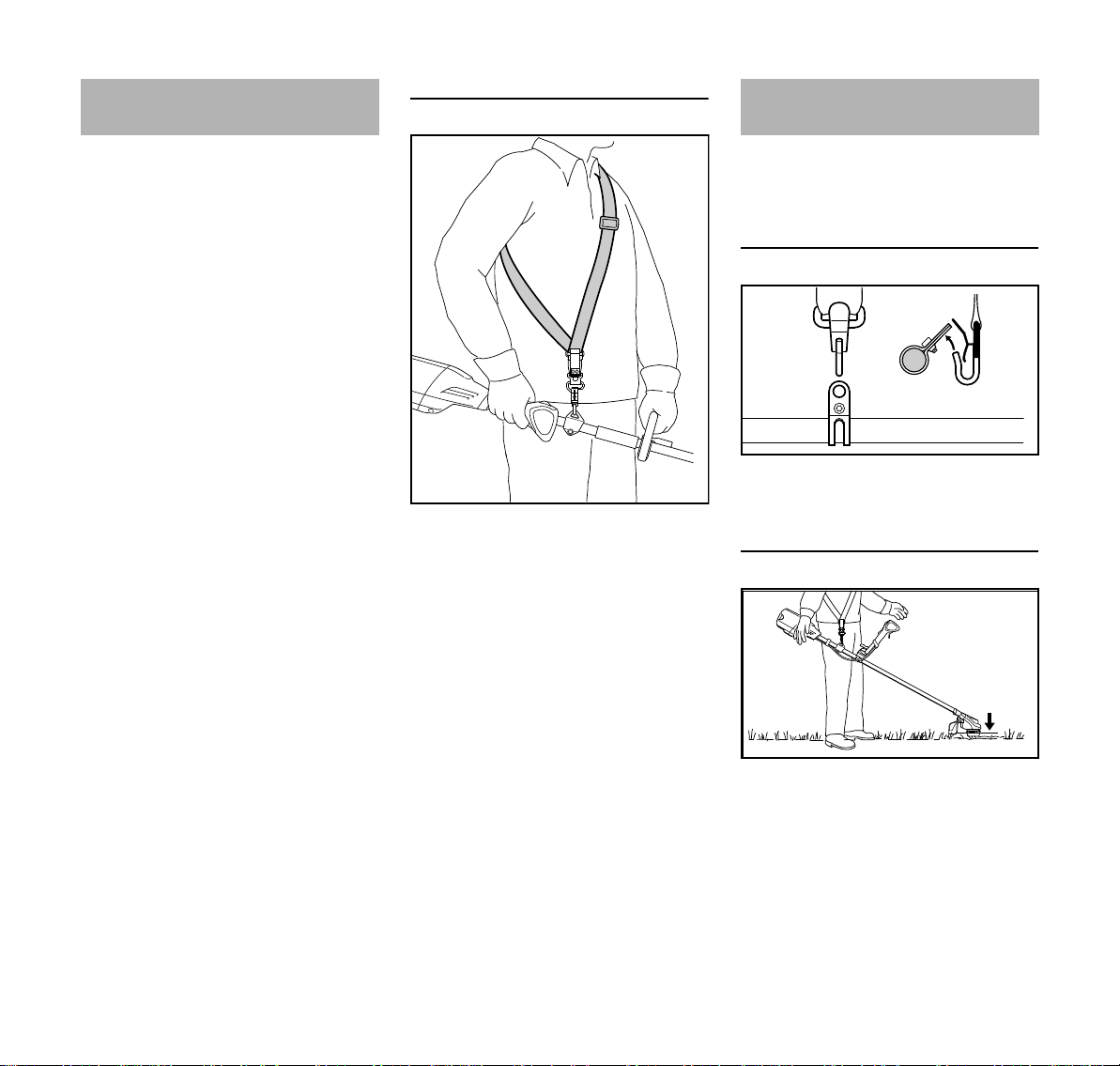

Fitting the Harness

The type and style of the

harness/shoulder strap depend on the

market.

The use of the shoulder strap/harness is

described in the chapter on "Approved

Combinations of Cutting Attachment,

Deflector, Handle and Harness".

Use Type AR batteries only with the

harness provided – do not combine with

other carrying straps (e.g. shoulder

strap, full harness, etc.).

Shoulder Strap

N Put on the shoulder strap (1).

N Adjust the length of the strap so that

the carabiner (2) is about a hand’s

width below your right hip.

N Balance the machine – see

"Balancing the Machine".

Balancing the Machine

The type and style of the harness and

carabiner (spring hook) depend on the

market.

Attaching Machine to Harness

N Attach the carabiner (1) to the

carrying ring (2) on the shaft.

Floating Position

FSA 90 R

N The cutting attachment should just

touch the ground.

The correct floating position is obtained

as follows:

19

Loading...

Loading...