Page 1

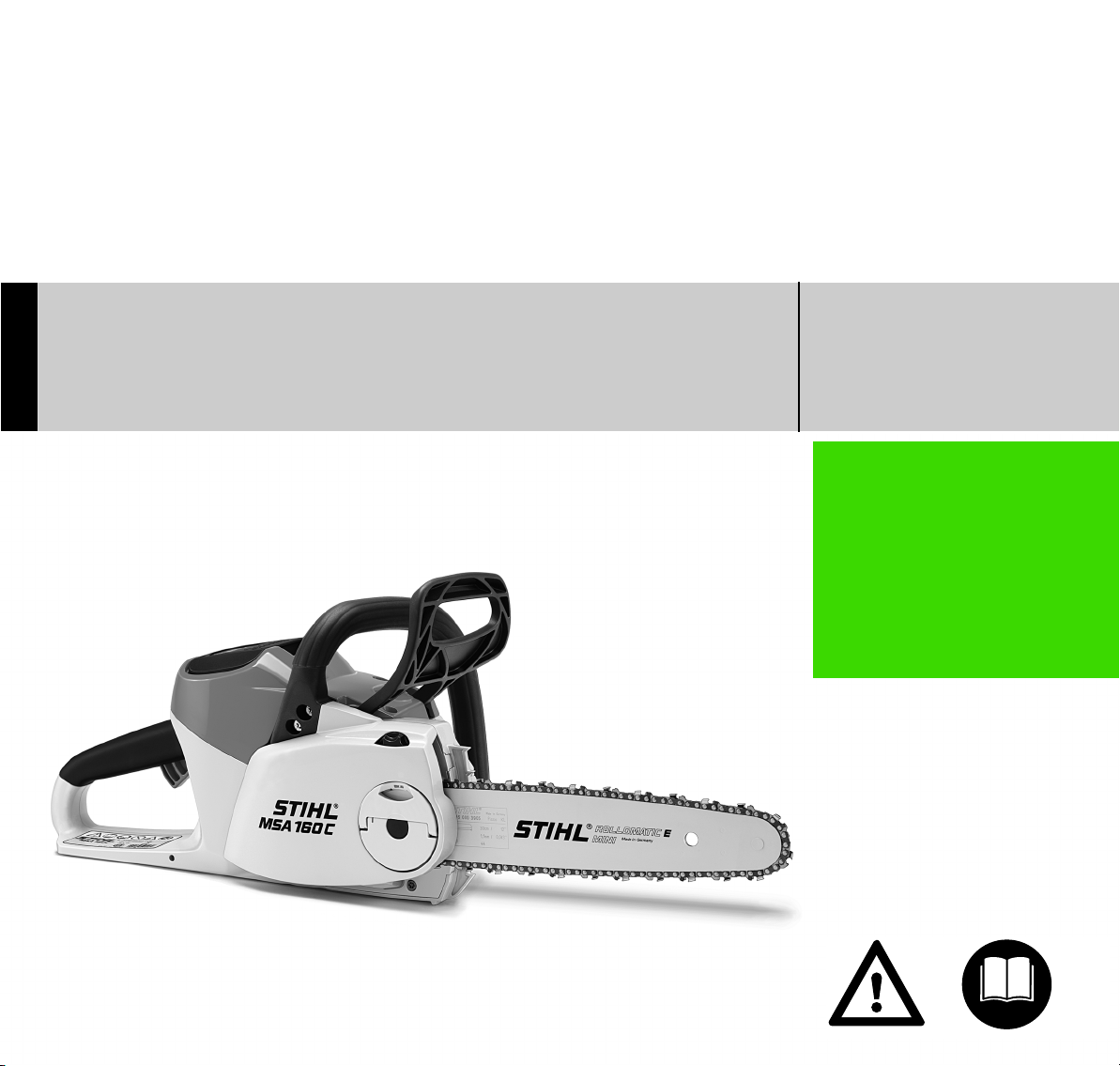

STIHL MSA 160 C

{

Instruction Manual

Manual de instrucciones

Warning!

To reduce the risk of kickback injury use

STIHL reduced kickback bar and STIHL PM3

(1/4“ Picco) chain depending on sprocket pitch

or other available low kickback components.

Advertencia!

Para reducir el riesgo de lesionarse como

resultado de un culatazo, utilice la barra de

contragolpe reducido y la cadena PM3 (Picco

de 1/4 pulg) de STIHL, dependiendo de la

rueda dentada usada y de otros componentes

reductores de contragolpe.

Read and follow all safety precautions in

Instruction Manual – improper use can cause

serious or fatal injury.

Lea y siga todas las precauciones de

seguridad dadas en el manual de

instrucciones – el uso incorrecto puede causar

lesiones graves o mortales.

Page 2

Instruction Manual

1 - 56

Manual de

instrucciones

57 - 117

Page 3

Contents

English

Guide to Using this Manual 2

Safety Precautions for Chain Saw

Users 2

Safety Precautions and Working

Techniques 4

Description of Operation 23

Cutting Attachment 23

Mounting the Bar and Chain (quick

chain tensioner) 23

Original Instruction ManualPrinted on chlorine-free paper

Tensioning the Saw Chain (quick

chain tensioner) 25

Checking Chain Tension 25

Chain Lubricant 26

Filling Chain Oil Tank 26

Checking Chain Lubrication 28

Coasting Brake 28

Chain Brake 28

Connecting Charger to Power

Supply 29

Charging the Battery 29

Light Emitting Diodes (LED) on

Battery 30

Light Emitting Diodes (LED) on

Printing inks contain vegetable oils, paper can be recycled.

Charger 32

Switching On 33

Switching Off 34

Operating Instructions 34

Taking Care of the Guide Bar 35

Storing the Machine 36

Checking and Replacing the Chain

Sprocket 36

Maintaining and Sharpening the

Saw Chain 37

Maintenance and Care 41

Main Parts 43

Specifications 45

Special Accessories 46

Ordering Spare Parts 47

Troubleshooting 48

Maintenance and Repairs 50

Battery Recycling 50

Disposal 50

Trademarks 51

Addresses 52

General Power Tool Safety

Warnings 53

Allow only persons who fully understand

this manual to operate your chain saw.

To receive maximum performance and

satisfaction from your STIHL chain saw,

it is important that you read, understand

and follow the safety precautions and

the operating and maintenance

instructions in chapter "Safety

Precautions and Working Techniques"

before using your chain saw. For further

information you can go to

www.stihlusa.com.

Contact your STIHL dealer or the STIHL

distributor for your area if you do not

understand any of the instructions in this

manual.

Warning!

Because a chain saw is a high-speed

wood-cutting tool, some special safety

precautions must be observed as with

any other power saw to reduce the risk

of personal injury. Careless or improper

use may cause serious or even fatal

injury.

{

© ANDREAS STIHL AG & Co. KG, 2011

0458-701-8621-A. M8.D11.FST.

0000004001_002_GB

MSA 160 C

1

Page 4

English

Guide to Using this Manual

Pictograms

The meanings of the pictograms

attached to or embossed on the

machine are explained in this manual.

Depending on the model concerned, the

following pictograms may be on your

machine.

Chain oil tank; chain oil

Direction of chain rotation

Tension the chain

Symbols in Text

Many operating and safety instructions

are supported by illustrations.

The individual steps or procedures

described in the manual may be marked

in different ways:

N A bullet marks a step or procedure.

A description of a step or procedure that

refers directly to an illustration may

contain item numbers that appear in the

illustration. Example:

N Loosen the screw (1).

N Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols and signal words described

below:

Danger!

Indicates an imminent risk of severe or

fatal injury.

Warning!

Indicates a hazardous situation which, if

not avoided, could result in severe or

fatal injury.

Caution!

Indicates a risk of property damage,

including damage to the machine or its

individual components.

Engineering Improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. Therefore,

some changes, modifications and

improvements may not be covered in

this manual. If the operating

characteristics or the appearance of

your machine differs from those

described in this manual, please contact

your STIHL dealer for assistance.

Safety Precautions for

Chain Saw Users

Warning!

When using cordless electric chain

saws, basic safety precautions should

always be followed to reduce the risk of

fire, electric shock and personal injury,

including the following:

READ ALL INSTRUCTIONS

1. Keep Work Area Clean –

Cluttered areas invite injuries. Do

not start cutting until you have a

clear work area, secure footing and

a planned retreat path from the

falling tree.

2. Consider Work Area Environment –

Use extreme caution when cutting

small size brush and saplings

because the slender material may

catch the saw chain and be whipped

toward you or pull you off balance.

Do not operate chain saw in a tree

unless specifically trained to do so.

When cutting a limb that is under

tension be alert for spring back so

that you will not be struck when the

tension in the wood fibers is

released. Don’t expose chain saw to

rain. Don’t use chain saw in damp or

wet locations. Do not use chain saw

in presence of flammable liquids or

gases.

3. Guard Against Electric Shock –

Prevent body contact with grounded

surfaces. For example: metal pipes,

wire fences.

2

MSA 160 C

Page 5

English

4. Keep Children Away –

Do not let bystanders contact chain

saw. All bystanders should be kept

away from work area.

5. Store Idle Chain Saw Indoors –

When not in use, chain saws should

be stored indoors in a dry, and high

or locked-up place with battery

removed and chain brake engaged

(front hand guard on ƒ – out of

reach of children). When storing

saw, use a scabbard or carrying

case.

6. Don’t Force Chain Saw –

It will do the job better and safer at

the rate for which it was designed.

7. Use Right Tool –

Cut wood only.

Don’t use chain saw for purpose not

intended – for example – don’t use

chain saw for cutting plastic,

masonry, non-wood building

materials.

8. Dress Properly –

Do not wear loose clothing or

jewelry. They can be caught in

moving parts. Use of heavy-duty,

nonslip gloves and substantial

footwear is recommended when

working outdoors. Wear protective

hair covering to contain long hair.

9. Use Safety Glasses –

Also use safety footwear; snug

fitting clothing; protective gloves;

hearing and head protection.

10. Carrying Saw –

Carry the chain saw by the front

handle with the saw stopped, finger

off the trigger switch, the guide bar

and saw chain to the rear. Do not

carry chain saw with battery

plugged in.

11. Maintain Chain Saw With Care –

Inspect chain saw periodically and if

damaged, have repaired by

authorized service facility. Keep

chain sharp and chain saw clean for

better and safer performance.

Follow instructions for lubricating

and changing accessories. Keep

handles dry, clean, and free from oil

and grease.

12. Switch Off Chain Saw –

Remove battery and move front

hand guard to ƒ when chain saw is

not in use, before servicing and

when changing accessories and

attachments, such as saw chain or

guard.

13. Stay Alert –

Watch what you are doing. Use

common sense. Do not operate

chain saw when you are tired. Keep

all parts of the body away from the

saw chain when the motor is

operating. Before you start the saw,

make sure the saw chain is not

contacting anything.

14. Check Damaged Parts –

Before further use of the chain saw,

a guard or other part that is

damaged or not functioning properly

should be carefully checked to

determine that it will operate

properly and perform its intended

function. Check for alignment of

moving parts, binding of moving

parts, breakage of parts, mounting,

and any other condition that may

affect its operation. A guard or other

part that is damaged should be

properly repaired or replaced by

your STIHL servicing dealer unless

indicated elsewhere in this manual.

Have damaged or non functioning

switches replaced by your STIHL

servicing dealer. Do not use chain

saw if switch does not turn it on and

off. Do not operate a chain saw that

is damaged, improperly adjusted, or

is not completely and securely

assembled. Be sure that the saw

chain stops moving when the trigger

switch is released.

15. Replacement Parts –

When servicing, use only identical

STIHL replacement parts

Warning!

Kickback may occur when the nose or

tip of the guide bar touches an object, or

when the wood closes in and pinches

the saw chain in the cut. Tip contact in

some cases may cause a lightning fast

reverse reaction, kicking the guide bar

up and back towards the operator.

Pinching the saw chain along the top of

the guide bar may push the guide bar

rapidly back towards the operator.

Either of these reactions may cause you

to lose control of the saw which could

result in serious personal injury.

The following precautions should be

followed to minimize kickback:

MSA 160 C

3

Page 6

English

1. Grip Saw Firmly –

Hold the chain saw firmly with both

hands when the motor is running.

Use a firm grip with thumbs and

fingers encircling the chain saw

handles.

2. Do not overreach.

3. Keep proper footing and balance at

all times.

4. Don’t let the nose of the guide bar

contact a log, branch, ground or

other obstruction.

5. Do not cut above shoulder height.

6. Use devices such as low kickback

chain, guide bar tip guards, chain

brakes and special guide bars that

reduce the risks associated with

kickback.

7. Only use replacement bars and

chains specified by the naufacturer

or the equivalent.

SAVE THESE INSTRUCTIONS

Safety Precautions and

Working Techniques

Because a chain saw is a

high-speed, fast-cutting

power tool, special safety

precautions must be

observed to reduce the

risk of personal injury.

It is important that you

read, fully understand

and observe the preceding and following safety

precautions and warnings. Read the instruction

manual and the safety

instructions periodically.

Careless or improper use

may cause serious or

fatal injury.

Warning!

Reactive forces, including kickback, can

be dangerous. Pay special attention to

the section on reactive forces.

Have your STIHL dealer show you how

to operate your power tool. All safety

precautions that are generally observed

when working with an axe or a hand saw

also apply to the operation of chain

saws. Observe all applicable federal,

state and local safety regulations,

standards and ordinances.

The use of noise emitting power tools

may be restricted to certain times by

national, state or local regulations.

Warning!

Do not lend or rent your power tool without the instruction manual. Be sure that

anyone using it understands the information contained in this manual.

Warning!

The use of this machine may be hazardous.The saw chain has many sharp

cutters. If the cutters contact your flesh,

they will cut you, even if the chain is not

moving.

Use your chain saw only for cutting

wooden objects.

Warning!

Do not use it for other purposes, since

misuse may result in personal injury or

property damage, including damage to

the machine.

Warning!

Minors should never be allowed to use

this power tool. Bystanders, especially

children, and animals should not be

allowed in the area where it is in use.

Warning!

To reduce the risk of injury to bystanders and damage to property, never let

your power tool run unattended. When it

is not in use (e.g. during a work break),

shut it off and make sure that unauthorized persons do not use it. To do this,

move the front hand guard to

remove the battery from the power tool.

ƒ and

4

MSA 160 C

Page 7

English

Most of these safety precautions and

warnings apply to the use of all STIHL

chain saws. Different models may have

different parts and controls. See the

appropriate section of your instruction

manual for a description of the controls

and the function of the parts of your

model.

Always switch off the motor, move front

hand guard to ƒ and remove the battery

before transporting, storing or carrying

out any work on the power tool. This

avoids the risk of the motor starting

unintentionally.

STIHL recommends the use of original

STIHL replacement parts. They are

specifically designed to match your

model and meet your performance

requirements.

Safe use of a chain saw involves

1 the operator

2 the power tool

3 the use of the power tool.

THE OPERATOR

Physical Condition

You must be in good physical condition

and mental health and not under the

influence of any substance (drugs,

alcohol, etc.) which might impair vision,

dexterity or judgment. Do not operate

this machine when you are fatigued.

Warning!

Be alert – if you get tired, take a break.

Tiredness may result in loss of control.

Working with any power tool can be

strenuous. If you have any condition

that might be aggravated by strenuous

work, check with your doctor before

operating this machine.

Warning!

Prolonged use of a power tool (or other

machines) exposing the operator to

vibrations may produce whitefinger disease (Raynaud's phenomenon) or

carpal tunnel syndrome.

These conditions reduce the hand's

ability to feel and regulate temperature,

produce numbness and burning

sensations and may cause nerve and

circulation damage and tissue necrosis.

All factors which contribute to

whitefinger disease are not known, but

cold weather, smoking and diseases or

physical conditions that affect blood

vessels and blood transport, as well as

high vibration levels and long periods of

exposure to vibration are mentioned as

factors in the development of whitefinger

disease. In order to reduce the risk of

whitefinger disease and carpal tunnel

syndrome, please note the following:

– Wear gloves and keep your hands

warm.

– Keep the saw chain sharp and the

saw well maintained. A dull chain

will increase cutting time, and

pressing a dull chain through wood

will increase the vibrations

transmitted to your hands. A power

tool with loose components will tend

to have higher vibration levels.

– Maintain a firm grip at all times, but

do not squeeze the handles with

constant, excessive pressure. Take

frequent breaks.

All the above-mentioned precautions do

not guarantee that you will not sustain

whitefinger disease or carpal tunnel

syndrome. Therefore, continual and

regular users should closely monitor the

condition of their hands and fingers. If

any of the above symptoms appear,

seek medical advice immediately.

Warning!

According to STIHL’s current knowledge, the electric motor of this unit

should not interfere with a pacemaker.

When in doubt, however, persons with a

pacemaker should consult their physician and the pacemaker manufacturer

before operating this tool.

Proper Clothing

Warning!

To reduce the risk of injury, the operator

should wear proper protective apparel.

MSA 160 C

5

Page 8

English

Clothing must be sturdy

and snug-fitting, but allow

complete freedom of

movement. Wear long

pants made of heavy

material to help protect

your legs from contact

with branches or brush.

To reduce the risk of cut

injuries, wear pants or

chaps that contain pads

of cut retardant material.

Avoid loose-fitting jackets, scarfs, neckties,

jewelry, flared or cuffed

pants, unconfined long

hair or anything that

could become caught on

branches, brush or the

moving parts of the unit.

Secure hair so it is above

shoulder level.

Good footing is very

important. Wear sturdy

boots with nonslip soles.

Steel-toed safety boots

are recommended. Never

wear sandals, flip-flops or

go barefoot.

Warning!

To reduce the risk of

injury to your eyes never

operate your power tool

unless wearing goggles

or properly fitted protec-

tive glasses with

adequate top and side protection complying with ANSI Z87.1 (or your

applicable national standard). To

reduce the risk of injury to your face

STIHL recommends that you also wear

a face shield or face screen over your

goggles or protective glasses.

Wear an approved safety hard hat to

reduce the risk of injury to your head

when there is a danger of head injuries.

Chain saw noise may damage your

hearing. Wear sound barriers (ear plugs

or ear mufflers) to protect your hearing.

Continual and regular users should

have their hearing checked regularly.

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

Always wear gloves

when handling the

machine and the cutting

tool. Heavy-duty, nonslip

gloves improve your grip

and help to protect your

hands.

THE POWER TOOL

For illustrations and definitions of the

power tool parts see the chapter on

"Main Parts."

Warning!

Never modify this power tool in any way.

Only attachments supplied by STIHL or

expressly approved by STIHL for use

with the specific STIHL model are

authorized. Although certain unauthorized attachments are useable with

STIHL power tools, their use may, in

fact, be extremely dangerous.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting Work." Make sure the

safety devices are working properly. Do

not continue operating your power tool if

it is damaged. In case of doubt, have the

machine checked by your STIHL

servicing dealer.

Battery

Warning!

Risk of fire, explosion

and/or burns, including

chemical burns. Do not

disassemble, crush,

heat above 212 °F

(100 °C), expose to fire

or incinerate. Never expose the battery

to microwaves or high pressures.

Do not place the battery on or near fires,

stoves or in other high-temperature

locations. Do not place the battery in

direct sunlight or store it inside a vehicle

in hot weather. Doing so may cause the

battery to generate heat, rupture or

6

MSA 160 C

Page 9

English

ignite. Using the batteries in this manner

may also result in a loss of performance

and a shortened life expectancy.

In case of fire: Stay clear of any vapors

or gases generated, taking wind

direction into account. If possible without

danger, remove battery from the vicinity

of the fire. In principle, cooling the

battery or extinguishing the fire with

water is possible. It is preferable to

extinguish the fire with a multipurpose

dry chemical fire extinguisher. As for any

fire, evacuate the area and fight the fire

from a safe distance. Once the fire has

been extinguished, the area should be

monitored (fire watch) in case of a flareup, until the battery has cooled

sufficiently. Restrict access to the area

until completion of clean-up. Do not

touch the burnt battery or any spilled

liquids. Use inert absorbent to absorb

spilled liquids.

Use and store the battery only within a

temperature range from

14 °F (-10 °C) and no

more than 122 °F

(+ 50 °C). Protect the battery from direct sunlight.

Warning!

Use STIHL batteries only with STIHL

power tools and charge them only with

STIHL chargers. Replace battery with

STIHL AP battery only. Use only original

STIHL rechargeable batteries.

Charge the battery before use.

Protect from rain – do not

immerse in fluids.

Warning!

Do not open, drop, hit or damage battery. Never insert objects into the

battery's cooling slots, since they may

damage the battery. The battery contains safety features and devices which,

if damaged, may cause the battery to

generate heat, rupture or ignite. Never

use or charge a defective, damaged,

cracked or deformed battery.

Immediately discontinue use of the

battery if, while using, charging or

storing, it emits an unusual smell, feels

hot or appears abnormal in any other

way.

Warning!

Fluid may leak from the battery if it is

damaged or is not used properly – avoid

contact with the skin! Leaking battery

fluid can cause skin irritation and chemical burns. In the event of accidental

contact, immediately rinse thoroughly

with mild soap and water. If fluid gets

into your eye(s), do not rub your eye(s)

but rinse water over the open eye(s) for

15 minutes at least. Also seek medical

attention immediately.

Warning!

Never bridge (short circuit) the battery

terminals with metallic objects, since

this may damage the battery and possibly cause a fire. Keep a battery that is

not in use away from metal objects (e.g.

nails, coins, jewelry). Do not use metal

containers for transporting batteries.

Store the battery out of reach of children

in a cool and dry area away from direct

sunlight and excess heat or cold (14 °F

– 122 °F (-10 °C – +50 °C)).

Charger

Use only original STIHL chargers.

Use only for charging geometrically

matching STIHL type AP batteries with a

maximum capacity of 10 Ah and a

maximum voltage of 42 V.

Never charge defective, leaking or

deformed batteries.

Connect the charger only to a power

supply with the voltage and frequency

specified on the rating plate. Always

connect the charger to a properly

installed wall outlet.

Never use a charger with damaged

housing, damaged power supply cord or

damaged plug. Do not operate the

charger if it has received a sharp blow,

been dropped or otherwise damaged in

any way.

Do not open or dissassemble charger –

no user serviceable parts inside.

Store charger out of the reach of

children.

MSA 160 C

7

Page 10

English

Protect the charger from

rain and dampness. Keep

charger dry.

Use and store charger

only indoors in dry rooms.

Operate charger at temperatures

between 41 °F (5 °C) and 104 °F

(40 °C).

Allow the charger to cool down normally

– do not cover it.

Never bridge the contacts of the charger

with metallic objects (e.g. nails, coins,

jewelry) – short circuit. The charger may

be damaged by a short circuit.

In the event of smoke or fire in the

charger, disconnect it from outlet

immediately.

Warning!

To reduce the risk of electric shock or

short circuit, do not insert any objects

into the charger's cooling slots.

Warning!

The charger heats up during the charging process. Do not operate on an easily

combustible surface (e.g. paper, texiles)

or in an easily combustible environment

– risk of fire.

Warning!

Do not operate in a hazardous location,

i.e. in a location where there are combustible liquids (fumes), vapors or

dusts. Chargers can produce sparks,

which may ignite the dust or vapors –

risk of explosion.

Check the charger's

power supply cord and

plug regularly for damage. If the power supply

cord or plug is damaged,

immediately disconnect

the plug from the wall

outlet to avoid the risk of

electric shock.

Never jerk the power supply cord to

disconnect it from the wall outlet. To

unplug, grasp the plug, not the cord.

Have a damaged power supply cord

repaired by an experienced electrician.

Do not use the power supply cord for

any other purpose, e.g. for carrying or

hanging up the charger.

Never use power supply cords that do

not comply with regulations.

Make sure the power supply cord is

located and/or marked so that it will not

be stepped on, tripped over, come in

contact with sharp edges or moving

parts or otherwise be subjected to

damage or stress.

An extension cord should not be used

unless absolutely necessary. If an

extension cord must be used, plug the

charger into a properly wired 16 gauge

(AWG 16) or heavier gauge extension

cord with blades that are the same

number, size and shapes as the blades

on the charger.

To reduce the risk of electric shock:

– Always connect the unit to a

properly installed wall outlet.

– Make sure the insulation of the

power supply cord and plug is in

good condition.

Unplug the power supply cord from the

outlet when charger is not in use.

Never store the battery in the charger.

THE USE OF THE POWER TOOL

Transporting the Power Tool

Warning!

To reduce the risk of injury from saw

chain contact, never carry or transport

your power tool with the saw chain moving. Always fully release the trigger

switch and make sure the chain has

stopped moving before putting the saw

down or carrying it. Always engage the

chain brake when taking more than a

few steps.

Warning!

Always switch off the motor, and fit the

chain guard (scabbard) over the chain

and guide bar, move front hand guard to

ƒ and remove the battery - even when

you carry the unit for short distances.

When transporting it in a vehicle, properly secure it to prevent turnover, chain

oil spillage and damage.

8

MSA 160 C

Page 11

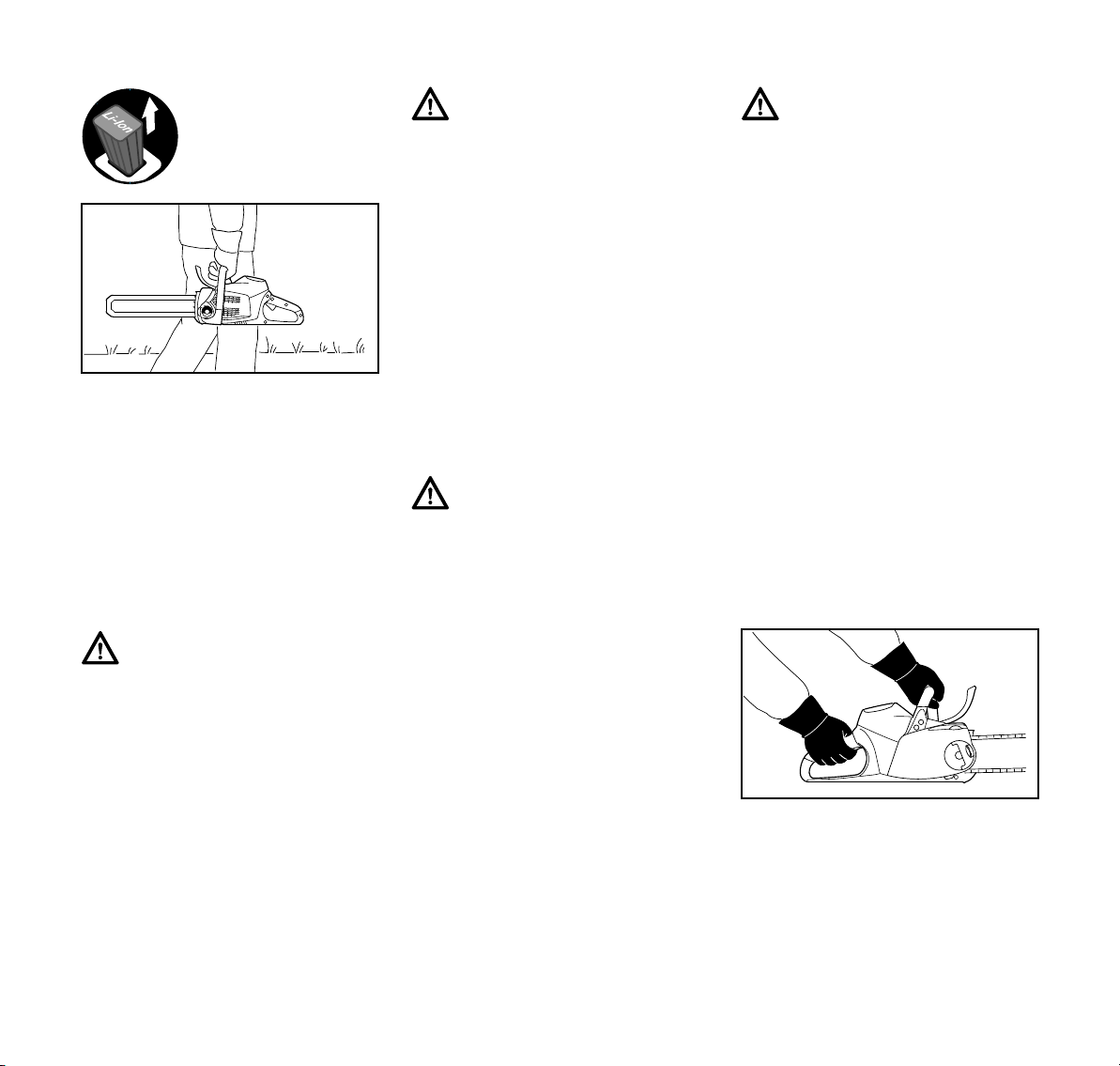

Remove the battery from

3999BA024 KN

3999BA000 KN

the power tool. This

avoids the risk of the

motor starting

unintentionally.

It may be carried only in a horizontal

position. Grip the front handle in a

manner that the machine is balanced

horizontally. Keep the cutting

attachment behind you.

Before Starting Work

Take off the chain guard (scabbard) and

inspect the saw for proper condition and

operation. (See the maintenance chart

near the end of the instruction manual.)

Warning!

Always check your power tool for proper

condition and operation before starting,

particularly the trigger switch, trigger

switch lockout, front hand guard and

cutting tool. The trigger switch and the

trigger switch lockout must move freely

and always spring back to the idle position. Ensure that the trigger switch will

not engage when the trigger switch lockout is not pressed. Never attempt to

modify the controls or safety devices.

Warning!

Never operate your power tool if it is

damaged, improperly adjusted or maintained, or not completely or securely

assembled.

For proper assembly of the bar and

chain follow the procedure described in

the chapter "Mounting the Bar and

Chain" of your instruction manual.

STIHL Oilomatic chain, guide bar and

sprocket must match each other in

gauge and pitch. Before replacing any

bar and chain, see the chapter entitled

"Specifications" in the instruction

manual and the section "Kickback" and

the "ANSI B175.1-2000 chain saw

kickback standard" below.

Warning!

Proper tension of the chain is extremely

important. In order to avoid improper

setting, the tensioning procedure must

be followed as described in your manual. Always make sure the hexagonal

nut(s) for the sprocket cover is (are)

tightened securely after tensioning the

chain in order to secure the bar. Never

start the saw with the sprocket cover

loose. Check chain tension once more

after having tightened the nut(s) and

thereafter at regular intervals (whenever

the saw is shut off). If the chain

becomes loose while cutting, switch off

the motor, remove the battery and then

tighten. Never try to adjust the chain

while the motor is running!

English

Warning!

After adjusting a chain, start the saw, let

the motor run for a while, then switch

motor off and recheck chain tension.

Proper chain tension is very important at

all times.

Keep the handles clean and dry at all

times; it is particularly important to keep

them free of moisture, pitch, oil, grease

or resin in order for you to maintain a firm

grip and properly control your power

tool.

Check contacts in battery compartment

for foreign matter. Keep clean.

Fit the battery correctly – it must engage

audibly.

For specific starting instructions, see the

appropriate section of your instruction

manual.

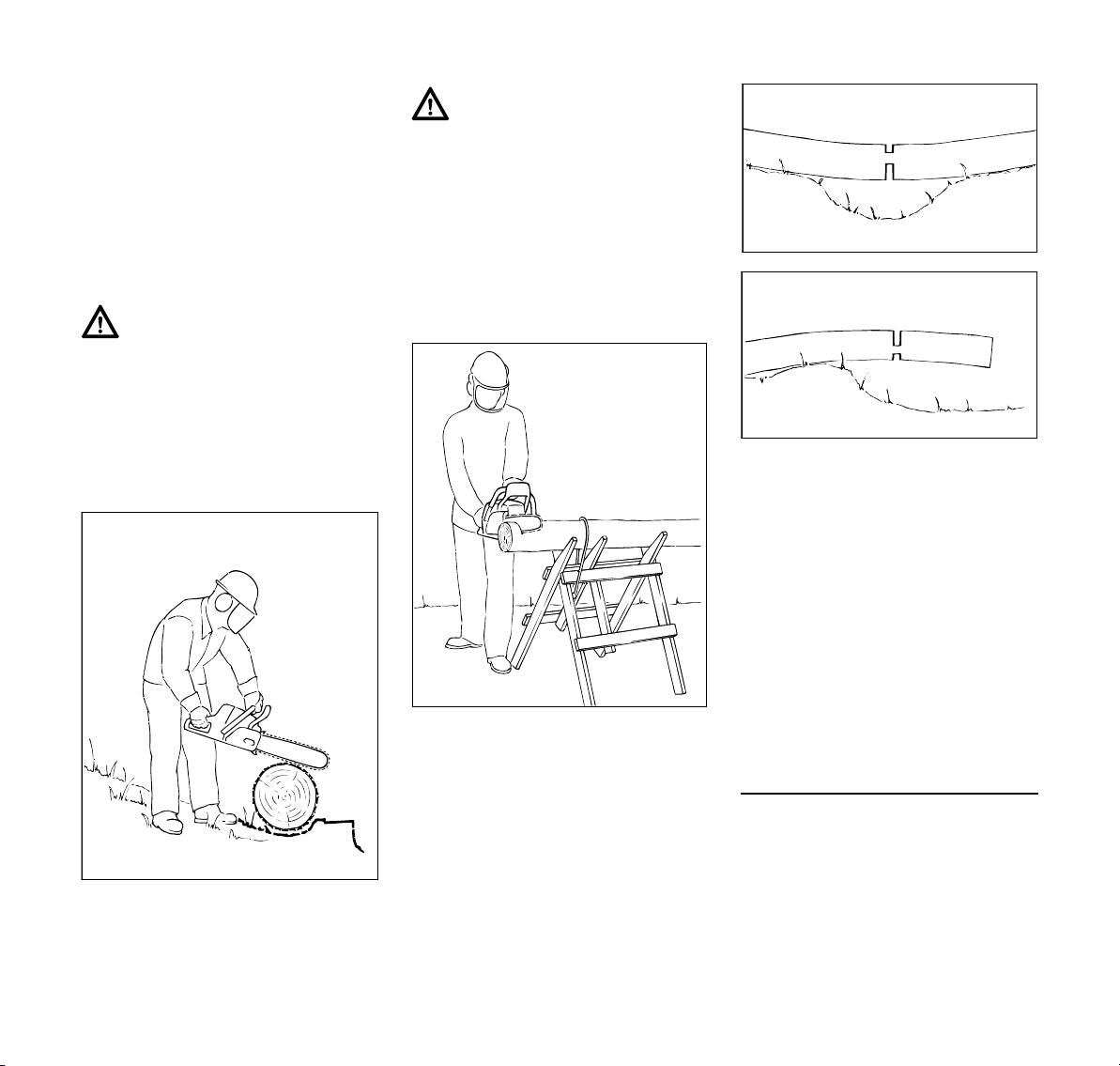

During Operation

Holding and Controlling the Power

Tool

Always hold the unit firmly with both

hands on the handles while you are

working. Wrap your fingers and thumbs

around the handles.

Your right hand should grip the rear

handle. This also applies to left-handers.

With your hands in this position, you can

MSA 160 C

9

Page 12

English

001BA031 KN

001BA082 KN

best oppose and absorb the push, pull

and kickback forces of your saw without

losing control (see section on reactive

forces).

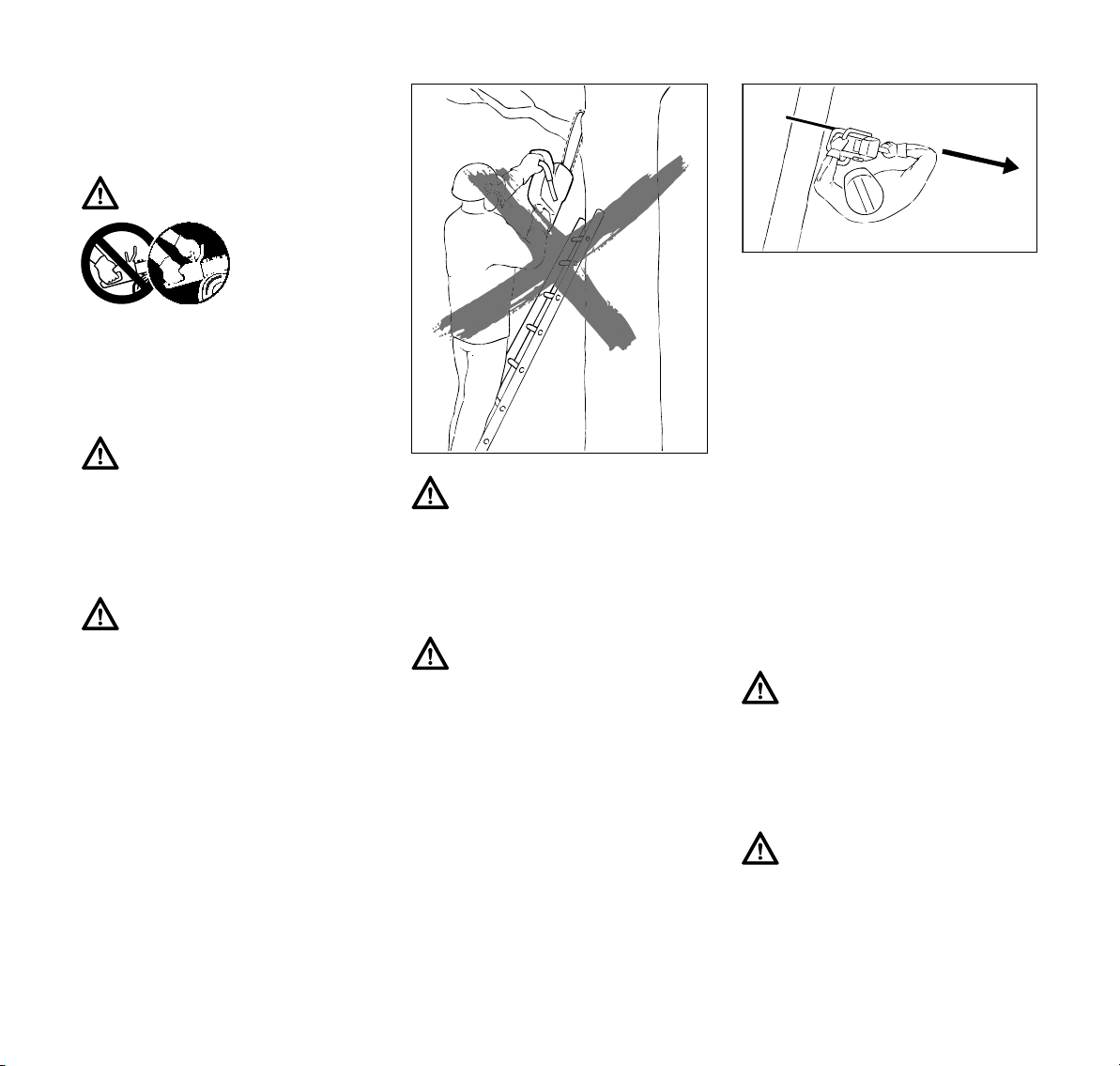

Warning!

To reduce the risk

of serious or fatal

injury to the operator or bystanders

from loss of control, never use the saw with one hand. It

is more difficult for you to control reactive forces and to prevent the bar and

chain from skating or bouncing along

the limb or log.

Warning!

To reduce the risk of cut injuries, keep

hands and feet away from the saw

chain. Never touch a moving saw chain

with your hand or any other part of your

body.

Warning!

Keep proper footing and balance at all

times. Special care must be taken in

slippery conditions (wet ground, snow)

and in difficult, overgrown terrain. Watch

for hidden obstacles such as tree

stumps, roots, rocks, holes and ditches

to avoid stumbling. There is increased

danger of slipping on freshly debarked

logs. For better footing, clear away

fallen branches, scrub and cuttings. Be

extremely cautious when working on

slopes or uneven ground.

Warning!

To reduce the risk of injury from loss of

control, never work on a ladder or any

other insecure support. Never hold the

machine above shoulder height. Do not

overreach.

Warning!

Never work in a tree unless you have

received specific, professional training

for such work, are properly secured

(such as tackle and harness system or a

lift bucket), have both hands free for

operating the chain saw in a cramped

environment and have taken proper precautions to avoid injury from falling

limbs or branches.

Position the chain saw in such a way

that your body is clear of the cutting

attachment whenever the motor is

running. Stand to the left of cut while

bucking.

Never put pressure on the saw when

reaching the end of a cut. The pressure

may cause the bar and rotating chain to

pop out of the cut or kerf, go out of

control and strike the operator or some

other object. If the rotating chain strikes

some other object, a reactive force may

cause the moving chain to strike the

operator.

Working Conditions

Operate your power tool only under

good visibility and daylight conditions

only. Work carefully.

Warning!

Your chain saw is a one-person

machine. Do not allow other persons in

the general work area, even when starting. Stop the motor immediately if you

are approached.

Warning!

Even though bystanders should be kept

away from the running saw, never work

alone. Keep within calling distance of

others in case help is needed.

10

MSA 160 C

Page 13

English

Warning!

Be sure that the guide bar and chain are

clear of you and all other obstructions

and objects, including the ground. If the

upper quadrant of the tip of the bar

touches any object, it may cause kickback to occur (see section on reactive

forces). Never attempt to start the chain

saw when the guide bar is in a cut or

kerf.

Warning!

Use of this product (including sharpening the saw chain) can generate dust,

mist and fumes containing chemicals

that are known to cause respiratory

problems, cancer, birth defects, or other

reproductive harm. If you are unfamiliar

with the risks associated with the particular dust, mist or fume at issue, consult

your employer, governmental agencies

such as OSHA and NIOSH and other

sources on hazardous materials. California and some other authorities, for

instance, have published lists of substances known to cause cancer,

reproductive toxicity, etc.

Warning!

Inhalation of certain dusts, especially

organic dusts such as mold or pollen,

can cause susceptible persons to have

an allergic or asthmatic reaction. Substantial or repeated inhalation of dust

and other airborne contaminants, in particular those with a smaller particle size,

may cause respiratory or other illnesses. This includes wood dust,

especially from hardwoods, but also

from some softwoods such as Western

Red Cedar. Control dust (such as saw

dust), mists (such as oil mist from chain

lubrication) and fumes at the source

where possible. Use good work practices, such as always cutting with a

properly sharpened chain (which produces wood chips rather than fine dust)

and operating the unit so that the wind

or operating process directs any dust

raised by the power tool away from the

operator. Follow the recommendations

of EPA / OSHA / NIOSH and occupational and trade associations with

respect to dust ("particulate matter").

When the inhalation of dust cannot be

substantially controlled, i.e., kept at or

near the ambient (background) level,

the operator and any bystanders should

wear a respirator approved by NIOSH /

MSHA for the type of dust encountered.

Warning!

Breathing asbestos dust is dangerous

and can cause severe or fatal injury,

respiratory illness or cancer. The use

and disposal of asbestos-containing

products have been strictly regulated by

OSHA and the Environmental Protection Agency. If you have any reason to

believe that you might be cutting asbestos, immediately contact your employer

or a local OSHA representative.

Operating Instructions

In the event of an emergency, switch off

the motor immediately, move the front

hand guard to

ƒ and remove the

battery.

Warning!

The saw chain continues to move for a

short period after the trigger switch is

fully released.

Warning!

Your chain saw is equipped with a chain

catcher. It is designed to reduce the risk

of personal injury in the event of a

thrown or broken chain. From time to

time, the catcher may be damaged or

removed. To reduce the risk of personal

injury, do not operate a chain saw with a

damaged or missing chain catcher.

MSA 160 C

Warning!

Your saw is not designed for prying or

shoveling away limbs, roots or other

objects. Such use could damage the

cutting attachment.

11

Page 14

English

001BA093 LÄ

001BA035 KN

Warning!

When sawing, make sure that the saw

chain does not touch any foreign materials such as rocks, fences, nails and the

like. Such objects may be flung off,

damage the saw chain or cause the saw

to kickback.

Check the cutting attachment at regular

short intervals during operation, or

immediately if there is a noticeable

change in cutting behavior:

– Switch off the motor.

– Move front hand guard to ƒ.

– Remove the battery.

– Check condition and tightness, look

for cracks.

The drive motor is not

waterproof. Never work

with the power tool in the

rain or in wet or very

damp locations.

Do not leave the machine outdoors in

the rain.

Danger!

Do not rely on the tool’s

insulation against electric

shock. To reduce the risk

of electrocution, never

operate this power tool in

the vicinity of any wires or

cables (power, etc.) which may be carrying electric current.

Reactive Forces Including Kickback

Warning!

Reactive forces may occur any time the

chain is rotating. Reactive forces can

cause serious personal injury.

The powerful force used to cut wood can

be reversed and work against the

operator. If the rotating chain is suddenly

stopped by contact with any solid object

such as a log or branch or is pinched, the

reactive forces may occur instantly.

These reactive forces may result in loss

of control, which, in turn, may cause

serious or fatal injury. An understanding

of the causes of these reactive forces

may help you avoid the element of

surprise and loss of control. Sudden

surprise contributes to accidents.

The most common reactive forces are:

– kickback,

– pushback,

– pull-in.

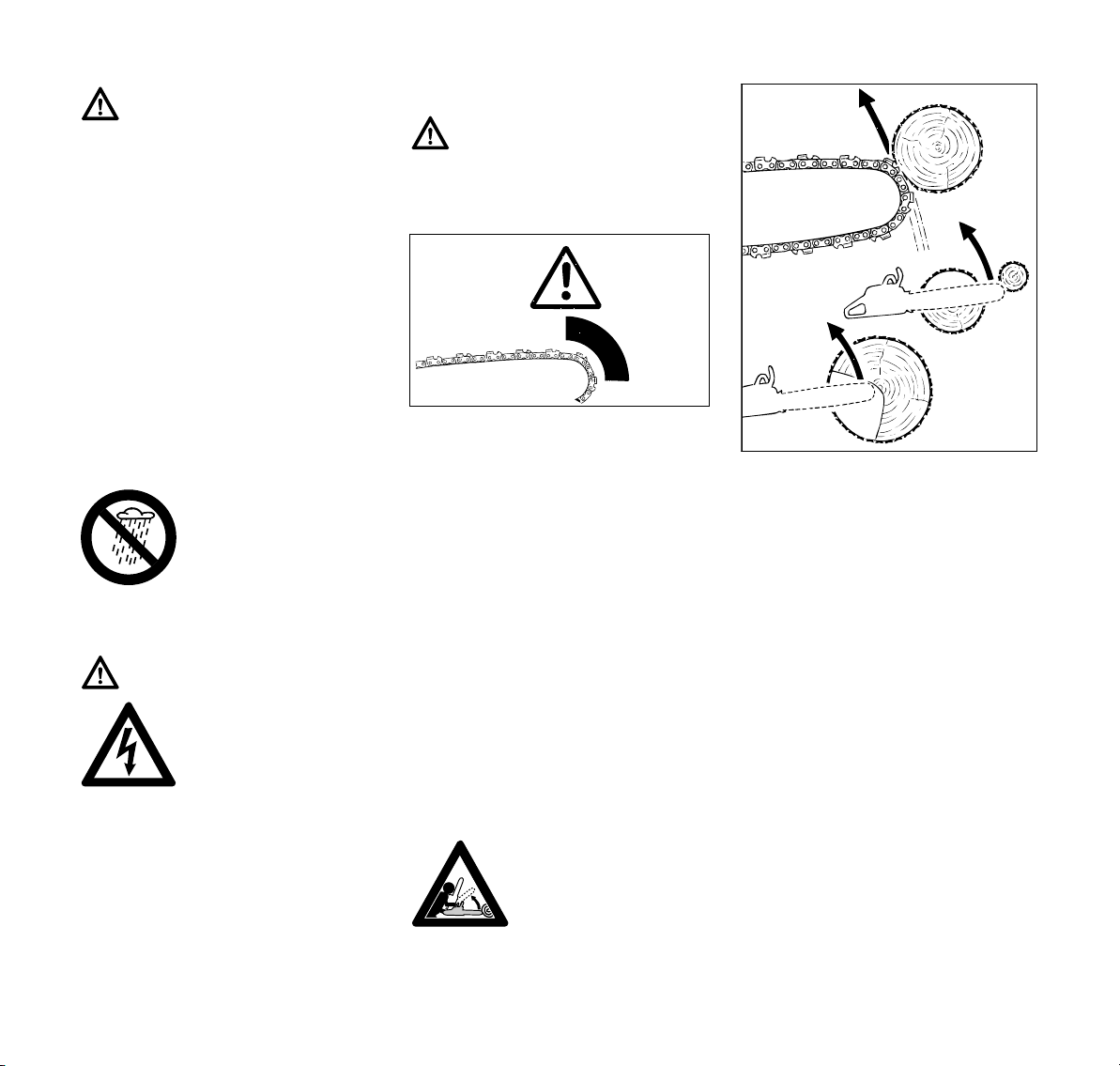

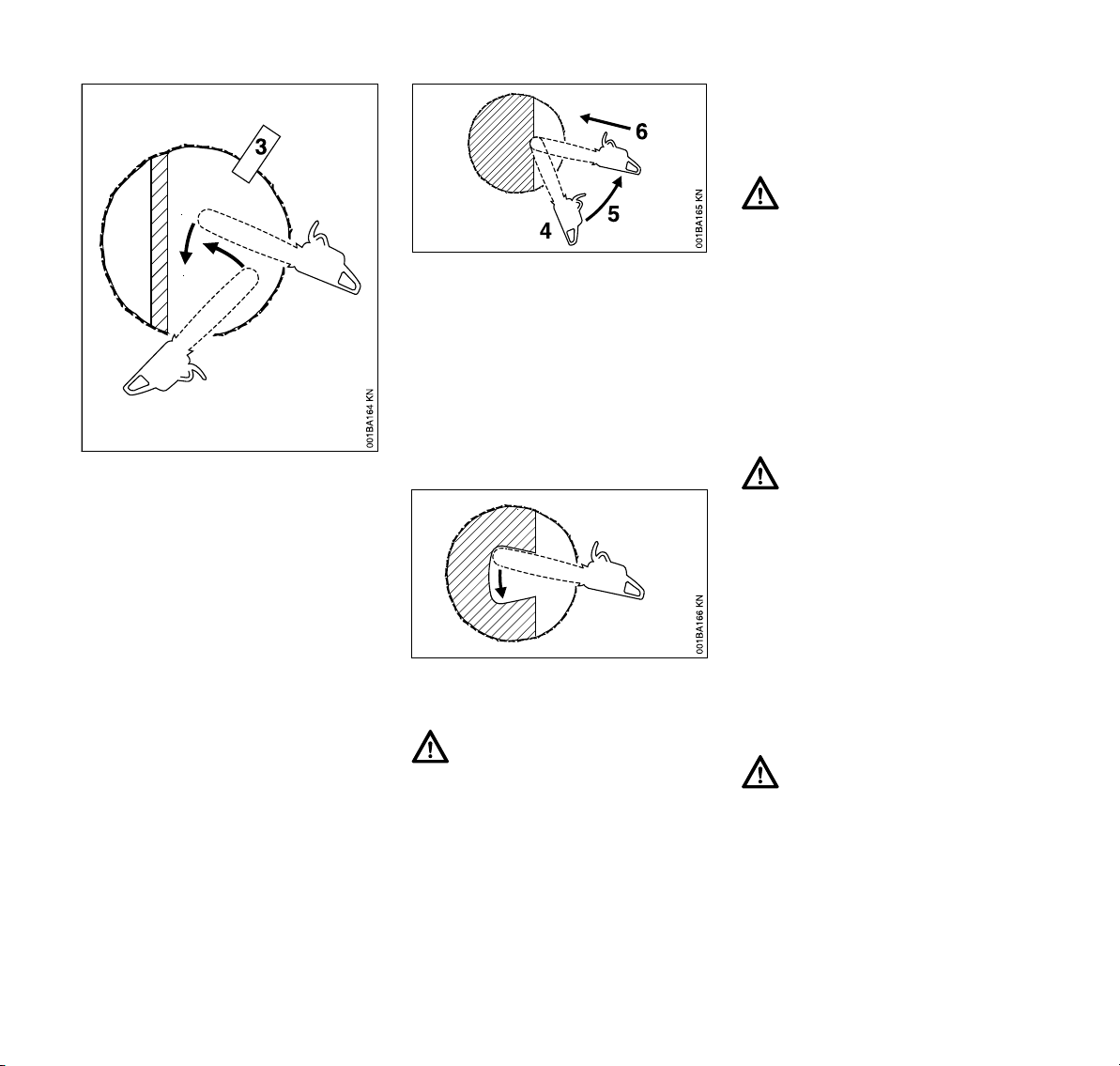

Kickback

Kickback may occur

when the moving saw

chain near the upper

quadrant of the bar nose

contacts a solid object or

is pinched.

The reaction of the cutting force of the

chain causes a rotational force on the

chain saw in the direction opposite to the

chain movement. This may fling the bar

up and back in a lightning fast reaction in

an uncontrolled arc mainly in the plane

of the bar. Under some cutting

circumstances the bar moves toward the

operator, who may suffer severe or fatal

injury.

Kickback may occur, for example, when

the chain near the upper quadrant of the

bar nose contacts the wood or is

pinched during limbing or when it is

incorrectly used to begin a plunge or

boring cut.

The greater the force of the kickback

reaction, the more difficult it becomes for

the operator to control the saw. Many

factors influence the occurrence and

force of the kickback reaction. These

include chain speed, the speed at which

12

MSA 160 C

Page 15

English

001BA174 KN

the bar and chain contact the object, the

angle of contact, the condition of the

chain and other factors.

The type of bar and saw chain you use

is an important factor in the occurrence

and force of the kickback reaction. Some

STIHL bar and chain types are designed

to reduce kickback forces. STIHL

recommends the use of reduced

kickback bars and low kickback chains.

ANSI B175.1-2000 Chain Saw

Kickback Standard

§ 5.11 of ANSI standard B175.1-2000,

sets certain performance and design

criteria related to chain saw kickback,

which has been adopted for electric

chain saws in UL 1662 in § 30.

To comply with kickback § 30 of

UL 1662, electric chain saws

– must, in their original condition,

meet a 45° computer derived

kickback angle when equipped with

certain cutting attachments,

– and must be equipped with at least

two devices to reduce the risk of

kickback injury, such as a chain

brake, low kickback chain, reduced

kickback bar, etc.

The computer derived angles for electric

saws are measured by applying a

computer program to test results from

the kickback test machine.

Warning!

The computer derived angles of § 5.11

of ANSI B175.1-2000 may bear no relationship to actual kickback bar rotation

angles that may occur in real life cutting

situations.

In addition, features designed to reduce

kickback injuries may lose some of their

effectiveness when they are no longer in

their original condition, especially if they

have been improperly maintained.

Compliance with § 5.11 of ANSI

B175.1-2000 does not automatically

mean that in a real life kickback the bar

and chain will rotate at most 45°.

Warning!

In order for powerheads to comply with

the computed kickback angle requirements of § 30 of UL 1662 / § 5.11 of

ANSI B175.1-2000 use only the following cutting attachments:

– bar and chain combinations listed

as complying in the "Specifications"

section of the instruction manual or

– other replacement bar and chain

combinations marked in

accordance with the standard for

use on the powerhead or

– replacement chain designated "low

kickback saw chain.''

See the section on "Low kickback saw

chain and reduced kickback bars."

Devices for Reducing the Risk of

Kickback Injury

STIHL recommends the use of the

STIHL Quickstop chain brake on your

powerhead with green labeled reduced

kickback bars and low kickback chains.

Warning!

To reduce the risk of injury, never use a

saw if the chain brake does not function

properly. Take the saw to your local

STIHL servicing dealer. Do not use the

saw until the problem has been rectified.

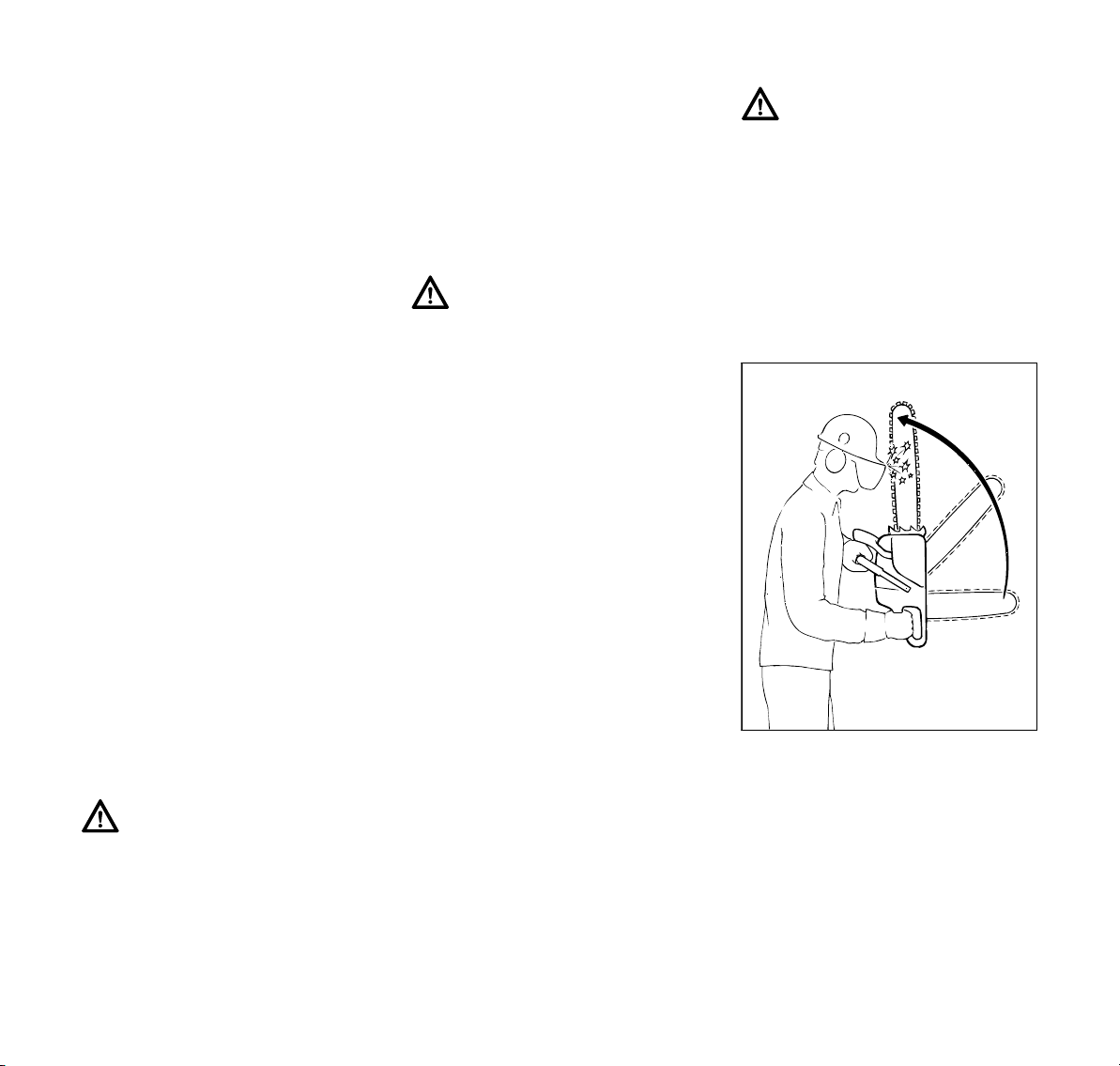

STIHL Quickstop Chain Brake

STIHL has developed a chain stopping

system designed to reduce the risk of

injury in certain kickback situations. It is

called a Quickstop chain brake.

When a kickback occurs, the guide bar

may rotate around the front handle. If the

cutting position is such that the

operator’s left hand is gripping the front

handle behind the hand guard, and if the

left hand rotates around the front handle

and makes a sufficiently forceful contact

with the front hand guard, which is the

Quickstop activating lever, this contact

will activate a properly maintained

Quickstop chain brake.

MSA 160 C

13

Page 16

English

All STIHL chain saws are now equipped

with a Quickstop chain brake that can be

activated by inertia. If the forces of an

occurring kickback are sufficiently high,

the hand guard is accelerated toward

the bar nose even without hand contact.

See the chapter entitled "Chain Brake"

of your instruction manual.

Warning!

Never operate your chain saw without a

front hand guard. In a kickback situation

this guard helps protect your left hand

and other parts of your body. In addition,

removal of the hand guard on a saw

equipped with a Quickstop chain brake

will deactivate the chain brake.

Warning!

No Quickstop or other chain brake

device prevents kickback. These

devices are designed to reduce the risk

of kickback injury, if activated, in certain

kickback situations. In order for the

Quickstop to reduce the risk of kickback

injury, it must be properly maintained

and in good working order. See the

chapter of your instruction manual entitled "Chain Brake" and the section

"Maintenance, Repair and Storing" at

the end of these Safety Precautions. In

addition, there must be enough distance

between the bar and the operator to

ensure that the Quickstop has sufficient

time to activate and stop the chain

before potential contact with the

operator.

Warning!

An improperly maintained chain brake

may increase the time needed to stop

the chain after activation, or may not

activate at all.

Low Kickback Saw Chain and

Reduced Kickback Bars

STIHL offers a variety of bars and

chains. STIHL reduced kickback bars

and low kickback chains are designed to

reduce the risk of kickback injury. Other

chains are designed to obtain higher

cutting efficiency or sharpening ease but

may result in higher kickback tendency.

STIHL has developed a color code

system to help you identify the STIHL

reduced kickback bars and low kickback

chains. Cutting attachments with green

warning decals or green labels on the

packaging are designed to reduce the

risk of kickback injury. The matching of

green decaled powerheads with green

labeled bars and green labeled chains

gives compliance with the computed

kickback angle requirements of § 30 of

UL 1662 / ANSI B175.1-2000 when the

products are in their original condition.

Products with yellow decals or labels are

for users with extraordinary cutting

needs and experience and specialized

training for dealing with kickback.

STIHL recommends the use of its

green labeled reduced kickback bars,

green labeled low kickback chains

and a STIHL Quickstop chain brake

for both experienced and

inexperienced chain saw users.

Please ask your STIHL dealer to

properly match your powerhead with the

appropriate bar/chain combination to

reduce the risk of kickback injury. Green

labeled bars and chains are

recommended for all powerheads. See

your "STIHL Bar and Chain Information"

leaflet for details.

Warning!

Use of other, non-listed bar/chain combinations may increase kickback forces

and increase the risk of kickback injury.

New bar/chain combinations may be

developed after publication of this literature, which will, in combination with

certain electric chain saws, comply with

§ 30 of UL 1662 / § 5.11 of ANSI

B175.1-2000. Check with your STIHL

dealer for such combinations.

Warning!

Reduced kickback bars and low kickback chains do not prevent kickback,

but they are designed to reduce the risk

of kickback injury. They are available

from your STIHL dealer.

Warning!

Even if your saw is equipped with a

Quickstop, a reduced kickback bar

and/or low kickback chain, this does not

eliminate the risk of injury by kickback.

Therefore, always observe all safety

precautions to avoid kickback

situations.

Low Kickback Chain

Some types of saw chains have

specially designed components to

reduce the force of nose contact

kickback. STIHL has developed low

kickback chains for your powerhead.

14

MSA 160 C

Page 17

English

001BA037 KN

A

"Low kickback saw chain" is a chain

which has met the kickback

performance requirements of § 5.11.2.4

of ANSI B175.1-2000 (GasolinePowered Chain Saws–Safety

Requirements) when tested in its

original condition on a selected

representative sample of chain saws

below 3.8 cubic inches (62 cm³)

displacement specified in ANSI

B175.1-2000.

Warning!

There are potential powerhead and bar

combinations with which low kickback

saw chains can be used which have not

been specifically certified to comply with

the 45° computer derived kickback

angle of § 5.11 of ANSI B175.1-2000.

Some low kickback chains have not

been tested with all powerhead and bar

combinations.

Warning!

A dull or improperly sharpened chain

may reduce or negate the effects of the

design features intended to reduce kickback energy. Improper lowering or

sharpening of the depth gauges or

shaping of the cutters may increase the

chance and the potential energy of a

kickback. Always cut with a properly

sharpened chain.

Reduced Kickback Bars

STIHL green labeled reduced kickback

bars are designed to reduce the risk of

kickback injury when used with STIHL

green labeled low kickback chains.

Warning!

When used with other, more aggressive

chains, these bars may be less effective

in reducing kickback.

Warning!

For a properly balanced saw and in

order to comply with § 5.12.1 of ANSI

B175.1-2000, use only bar lengths listed

in the specifications chapter of the

instruction manual for your chain saw

powerhead.

Bow Guides

Warning!

Do not mount a bow guide on any

STIHL chain saw. Any chain saw

equipped with a bow guide is potentially

very dangerous. The risk of kickback is

increased with a bow guide because of

the increased kickback contact area.

Low kickback chains will not significantly reduce the risk of kickback injury

when used on a bow guide.

To Avoid Kickback

The best protection from personal injury

that may result from kickback is to avoid

kickback situations:

1. Hold the chain saw firmly with both

hands and maintain a secure grip.

Don’t let go.

2. Be aware of the location of the guide

bar nose at all times.

3. Never let the nose of the guide bar

contact any object. Do not cut limbs

with the nose of the guide bar. Be

especially careful near wire fences

and when cutting small, tough

limbs, small size brush and saplings

which may easily catch the chain.

4. Do not overreach.

5. Do not cut above shoulder height.

6. Begin cutting and continue at full

speed.

7. Cut only one log at a time.

8. Use extreme caution when

reentering a previous cut.

9. Do not attempt to plunge cut if you

are not experienced with these

cutting techniques.

10. Be alert for shifting of the log or

other forces that may cause the cut

to close and pinch the chain.

11. Maintain saw chain properly. Cut

with a correctly sharpened, properly

tensioned chain at all times.

12. Stand to the side of the cutting path

of the chain saw.

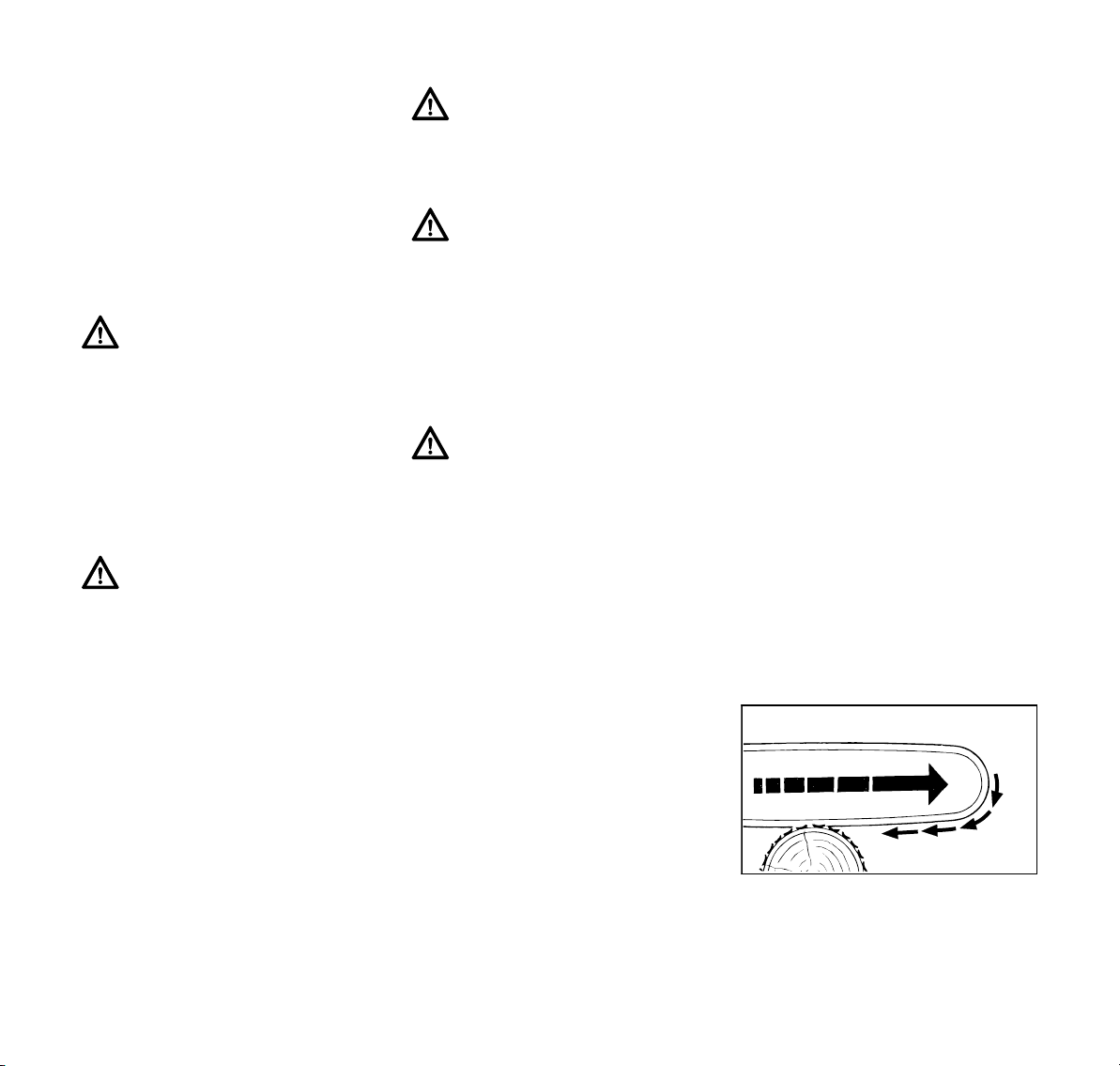

A = Pull-in

Pull-in occurs when the chain on the

bottom of the bar is suddenly stopped

when it is pinched, caught or encounters

MSA 160 C

15

Page 18

English

001BA038 KN

B

a foreign object in the wood. The

reaction of the chain pulls the saw

forward and may cause the operator to

lose control.

Pull-in frequently occurs when the

bumper spike of the saw is not held

securely against the tree or limb and

when the chain is not rotating at full

speed before it contacts the wood.

Warning!

Use extreme caution when cutting small

size brush and saplings which may easily catch the chain, be whipped toward

you or pull you off balance.

To Avoid Pull-in

1. Always start a cut with the chain

rotating at full speed and the

bumper spike in contact with the

wood.

2. The risk of pull-in may also be

reduced by using wedges to open

the kerf or cut.

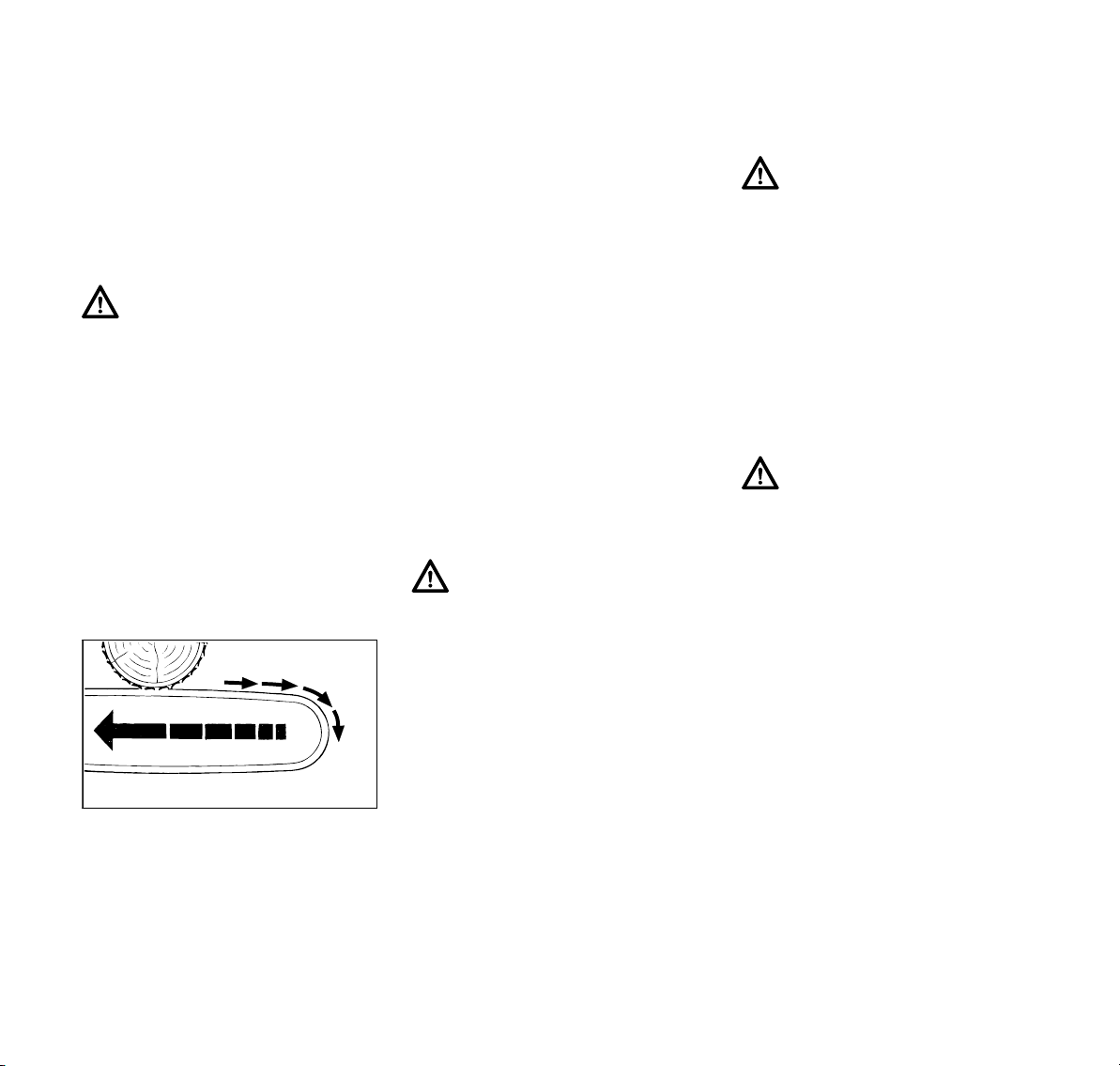

B = Pushback

Pushback occurs when the chain on the

top of the bar is suddenly stopped when

it is pinched, caught or encounters a

foreign object in the wood. The reaction

of the chain may drive the saw rapidly

straight back toward the operator and

may cause loss of saw control.

Pushback frequently occurs when the

top of the bar is used for cutting.

To Avoid Pushback

1. Be alert to forces or situations that

may cause material to pinch the top

of the chain.

2. Do not cut more than one log at a

time.

3. Do not twist the saw when

withdrawing the bar from a plunge

cut or underbuck cut because the

chain can pinch.

Cutting Techniques

These general instructions apply to all

chain saws. As stated above, however,

STIHL recommends against the use of

your cordless electric chain saw for

cutting trees, logs or branches having a

diameter of more than 8 inches.

Warning!

For cutting larger trees, logs or

branches, a more powerful, faster

and/or steady cut may be necessary to

reduce the risk of binding, stalling or a

change in conditions during a longer

cutting time that could lead to a loss of

control of the object being cut and serious personal injury.

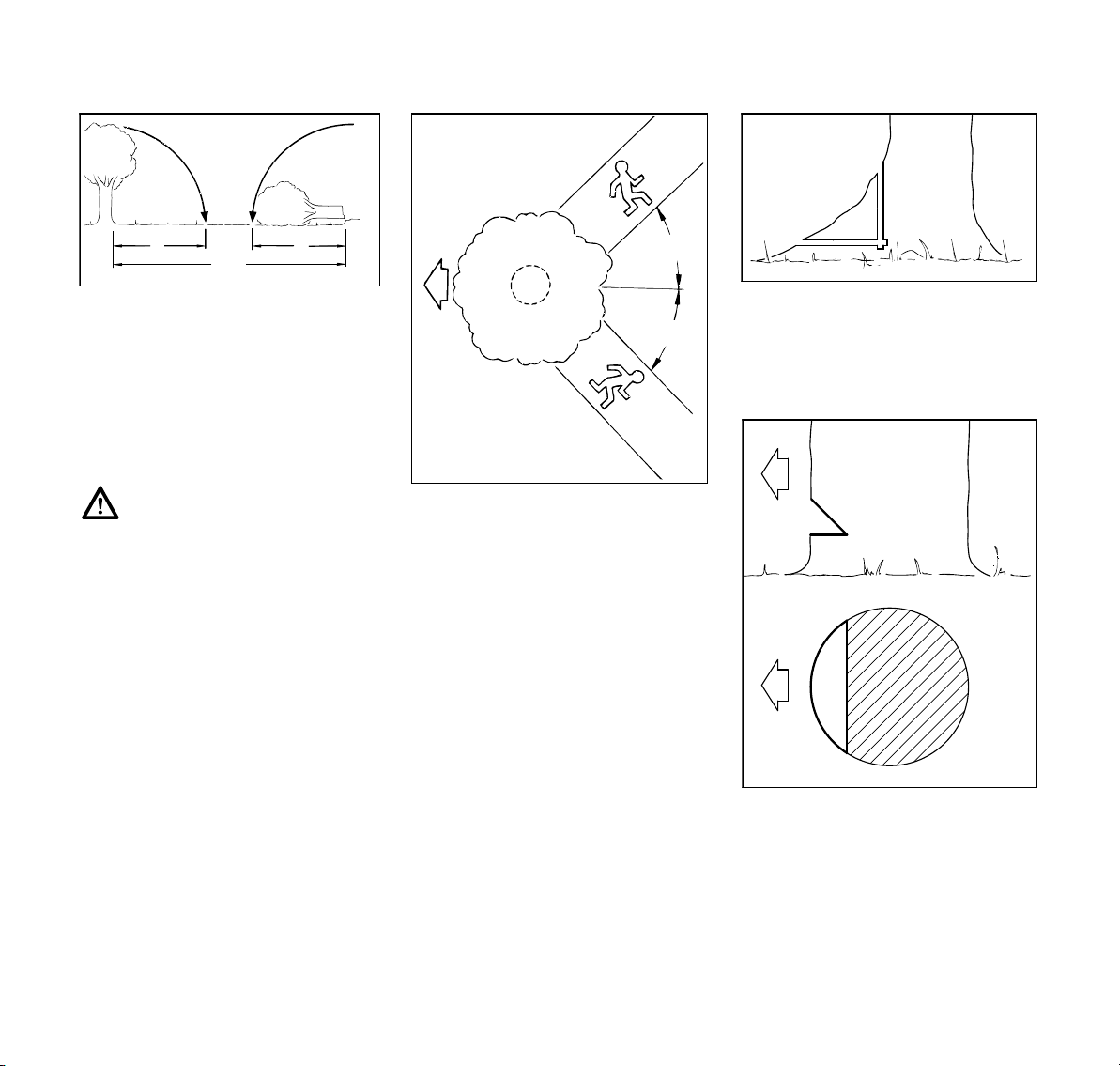

Felling

Felling is cutting down a tree.

The cordless chain saw is of only limited

suitability for felling and limbing.

If, however, a tree is to be felled and

limbed with a cordless chain saw, it is

imperative to observe the following

instructions.

Before felling a tree, consider carefully

all conditions which may affect the

direction of fall.

Warning!

There are a number of factors that may

affect and change the intended direction

of fall, e.g. wind direction and speed,

lean of tree, surrounding trees and

obstacles, sloping ground, one-sided

limb structure, wood structure, decay,

snow load, etc. To reduce the risk of

severe or fatal injury to yourself or others, look for these conditions prior to

beginning the cut, and be alert for a

change in direction while the tree is

falling.

Warning!

Always observe the general condition of

the tree. Inexperienced users should

never attempt to cut trees that are

decayed or rotted inside or that are

leaning or otherwise under tension.

There is an increased risk that such

trees could snap or split while being cut

and cause serious or fatal injury to the

operator or bystanders. Also look for

broken or dead branches which could

vibrate loose and fall on the operator.

When felling on a slope, the operator

should stand on the uphill side if

possible.

16

MSA 160 C

Page 19

English

001BA088 LÄ

2

/

1

2

1 1

/

1

2

B

001BA040 KN

A

45°

45°

B

001BA146 KN

001BA143 KN

C

C

Felling Instructions

When felling, maintain a distance of at

least 2 1/2 tree lengths from the nearest

person.

When felling in the vicinity of roads,

railways and power lines, etc., take extra

precautions. Inform the police, utility

company or railway authority before

beginning to cut.

Warning!

The noise of your chain saw may drown

any warning call.

Escape Path

First clear the tree base and work area

from interfering limbs and brush and

clean its lower portion with an ax.

Then, establish two paths of escape (B)

and remove all obstacles. These paths

should be generally opposite to the

planned direction of the fall of the tree

(A) and about at a 45° angle. Place all

tools and equipment a safe distance

away from the tree, but not on the

escape paths.

Buttress Roots

If the tree has large buttress roots, cut

into the largest buttress vertically first

(horizontally next) and remove the

resulting piece.

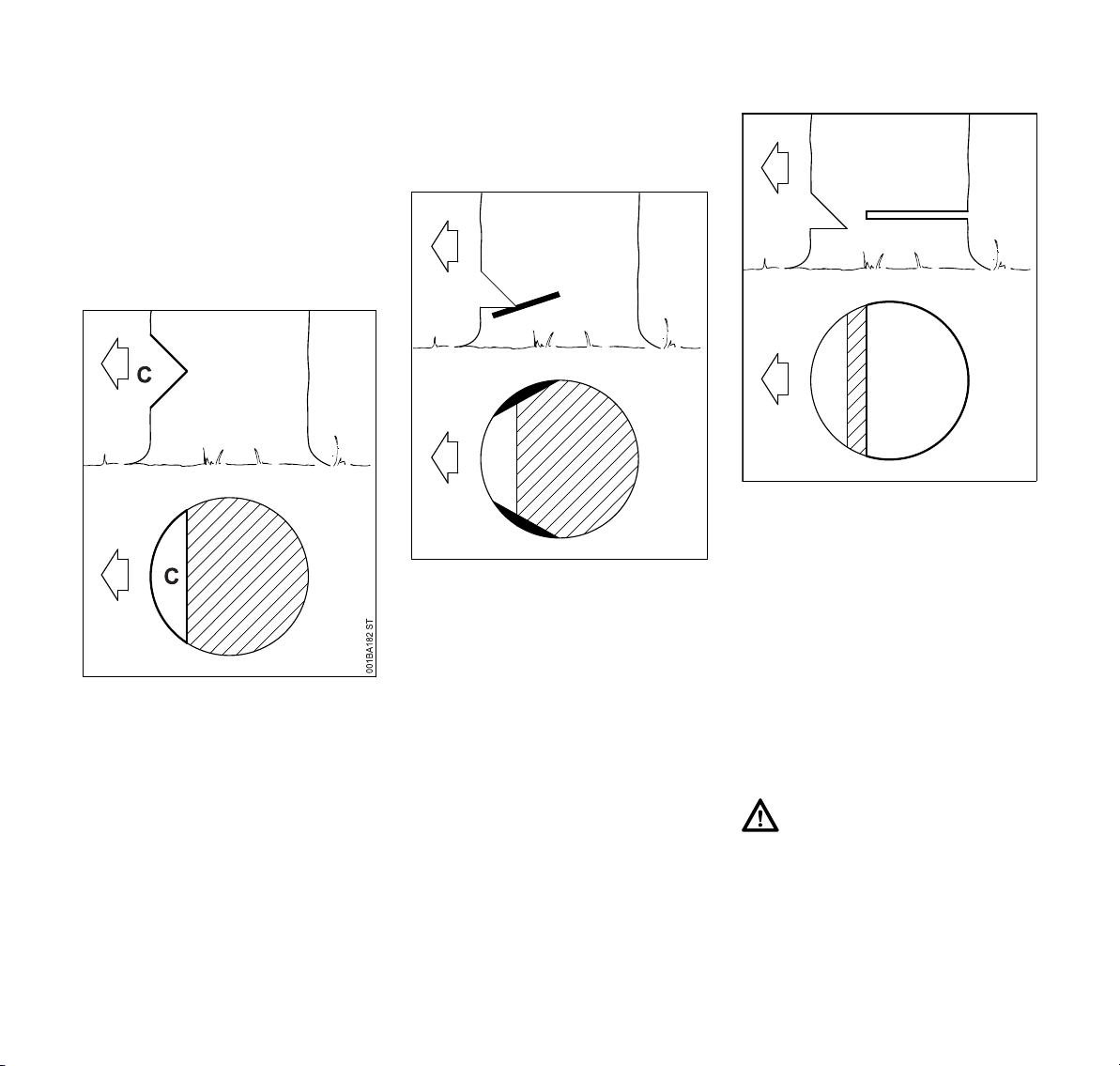

Conventional Cut

MSA 160 C

Felling notch (C) – determines the

direction of the fall

For a conventional cut:

17

Page 20

English

001BA150 KN

001BA144 KN

D

D

N Properly place felling notch

perpendicular to the line of fall,

close to the ground.

N Cut down at approx. 45° angle to a

depth of about 1/5 to 1/4 of the trunk

diameter.

N Make second cut horizontal.

N Remove resulting 45° piece.

Open-face Technique

Felling notch (C) – determines the

direction of the fall

For an open-face cut:

N Properly place felling notch

perpendicular to the line of fall,

close to the ground.

N Cut down at approx. 50° angle to a

depth of approx.1/5 to 1/4 of the

trunk diameter.

N Make second cut from below at

approx. 40 degree angle.

N Remove resulting 90° piece.

Making Sapwood Cuts

N For medium sized or larger trees

make cuts at both sides of the trunk,

at same height as subsequent

felling cut.

N Cut to no more than width of guide

bar.

This is especially important in softwood

in summer – it helps prevent sapwood

splintering when the tree falls.

D =Felling Cut

Conventional and open-face technique:

N Begin 1 to 2 inches (2,5 to 5 cm)

higher than center of felling notch.

N Cut horizontally toward the felling

notch.

N Leave approx.1/10 of diameter

uncut. This is the hinge.

N Do not cut through the hinge – you

could lose control of the direction of

the fall.

Drive wedges into the felling cut where

necessary to control the fall.

Warning!

If the tip of the bar contacts a wedge, it

may cause kickback. Wedges should be

of wood or plastic – never steel, which

can damage the chain.

18

MSA 160 C

Page 21

English

001BA145 KN

E

E

001BA147 KN

001BA148 KN

1

E = Hinge

N Helps control the falling tree.

N Do not cut through the hinge – you

could lose control of the direction of

the fall.

Felling Cut for Small Diameter Trees:

Simple Fan Cut

Engage the bumper spikes of the chain

saw directly behind the location of the

intended hinge and pivot the saw around

this point only as far as the hinge. The

bumper spike rolls against the trunk.

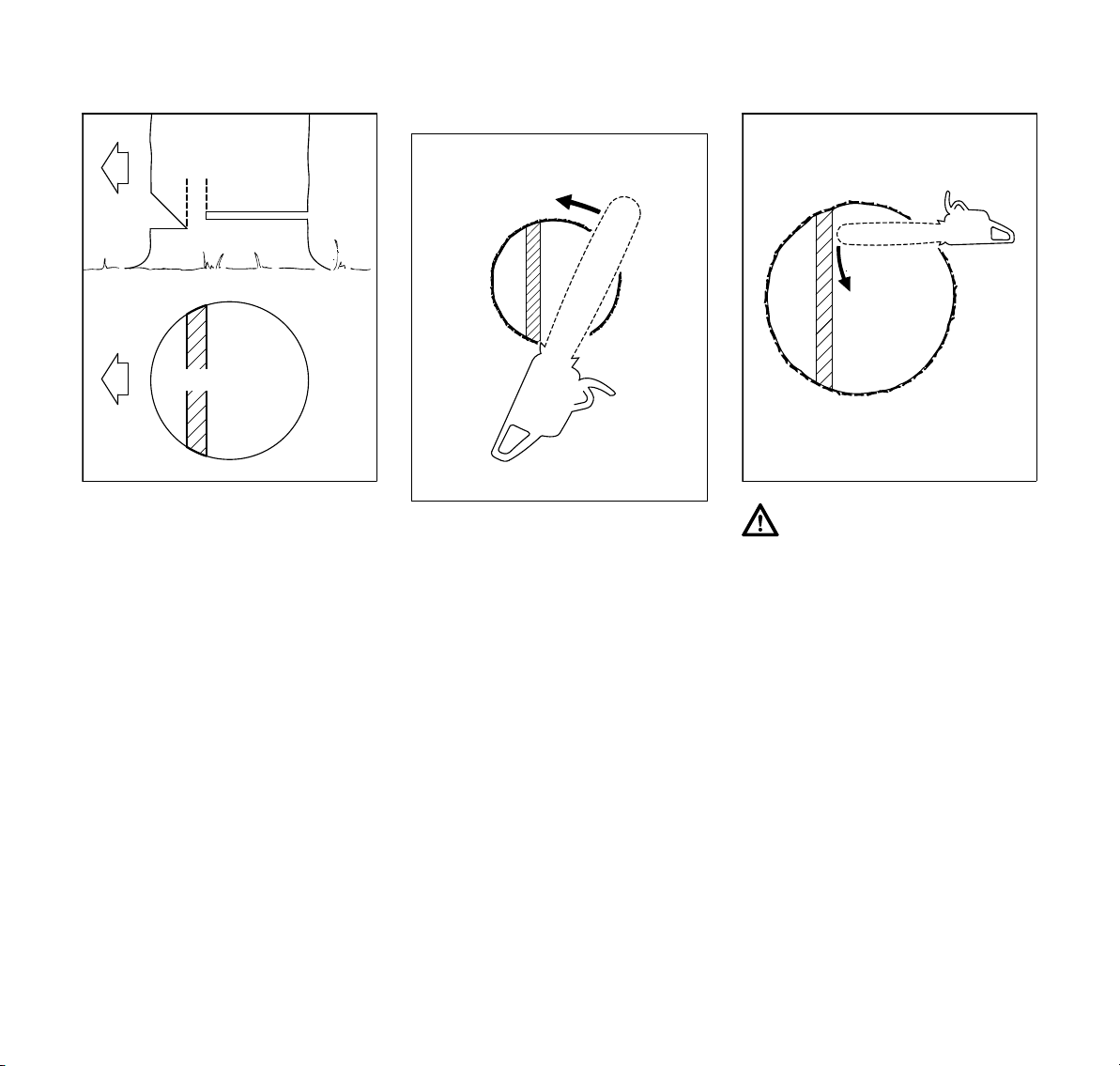

Felling Cut for Large Diameter Trees

Warning!

Felling a tree that has a diameter

greater than the length of the guide bar

requires use of either the sectioning felling cut or plunge-cut method. These

methods are extremely dangerous

because they involve the use of the

nose of the guide bar and can result in

kickback. Only properly trained professionals should attempt these

techniques.

Sectioning Method

For the sectioning method make the first

part of the felling cut with the guide bar

fanning in toward the hinge. Then, using

the bumper spike as a pivot, reposition

the saw for the next cut.

MSA 160 C

19

Page 22

English

4

2

Avoid repositioning the saw more than

necessary. When repositioning for the

next cut, keep the guide bar fully

engaged in the kerf to keep the felling

cut straight. If the saw begins to pinch,

insert a wedge to open the cut. On the

last cut, do not cut the hinge.

Plunge-cut Method

Timber having a diameter more than

twice the length of the guide bar requires

the use of the plunge-cut method before

making the felling cut.

First, cut a large, wide felling notch.

Make a plunge cut in the center of the

notch.

The plunge cut is made with the guide

bar nose. Begin the plunge cut by

applying the lower portion of the guide

bar nose to the tree at an angle. Cut until

the depth of the kerf is about the same

as the width of the guide bar. Next, align

the saw in the direction in which the

recess is to be cut.

With the saw at full speed, insert the

guide bar in the trunk.

Enlarge the plunge cut as shown in the

illustration.

Warning!

There is an extreme danger of kickback at this point. Extra caution must

be taken to maintain control of the

saw. To make the felling cut, follow

the sectioning method described

previously.

If you are inexperienced with a chain

saw, plunge-cutting should not be

attempted. Seek the help of a

professional.

Warning!

In order to reduce the risk of personal

injury, never stand directly behind the

tree when it is about to fall, since part of

the trunk may split and come back

toward the operator (barber-chairing),

or the tree may jump backwards off the

stump. Always keep to the side of the

falling tree. When the tree starts to fall,

withdraw the bar, switch off the motor

and walk away on the preplanned

escape path. Watch out for falling limbs.

Warning!

Be extremely careful with partially fallen

trees which are poorly supported. When

the tree hangs or for some other reason

does not fall completely, set the saw

aside and pull the tree down with a

cable winch, block and tackle or tractor.

If you try to cut it down with your saw,

you may be injured.

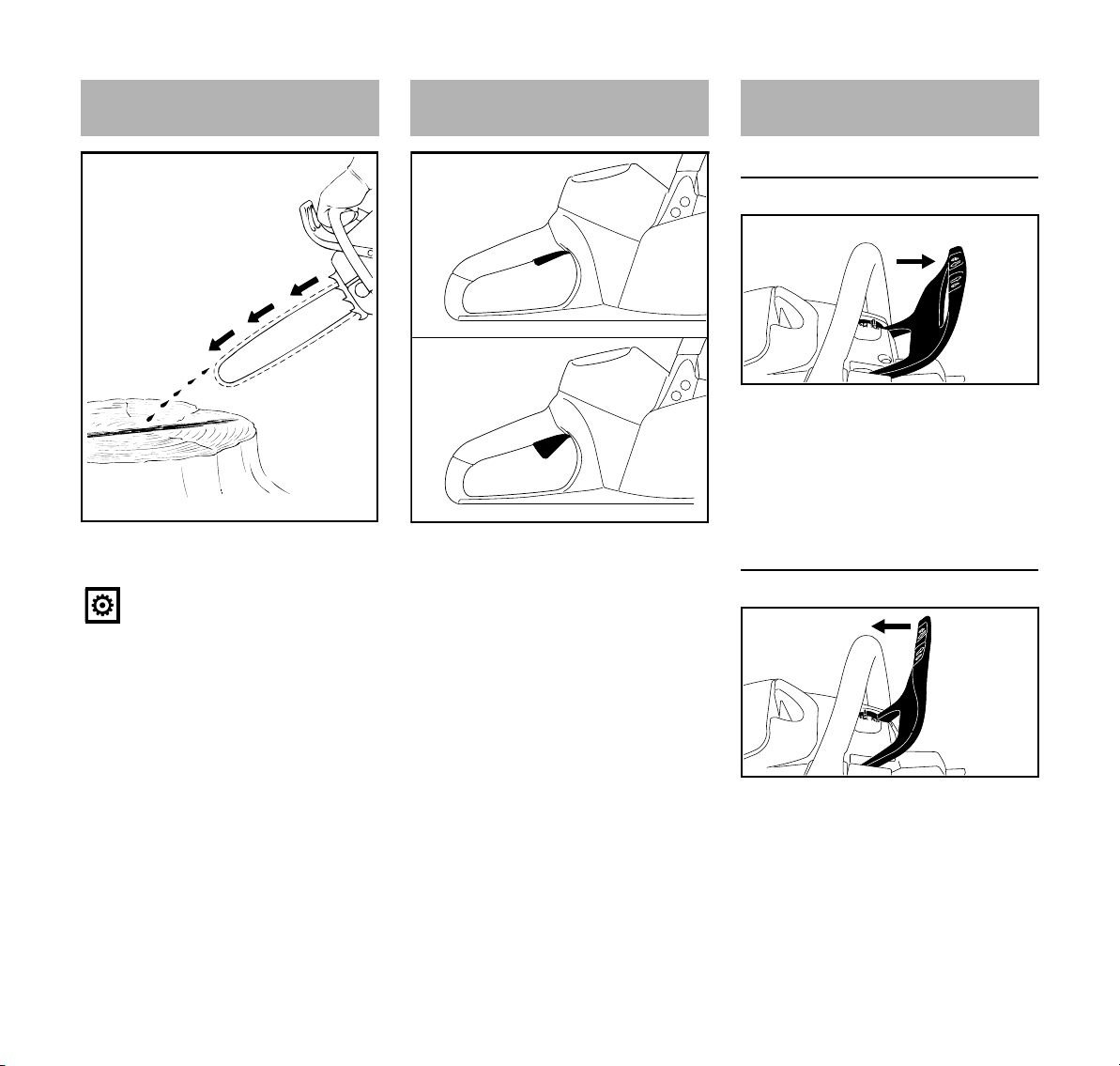

Limbing

Limbing is removing the branches from a

fallen tree.

Warning!

There is an extreme danger of kickback

during the limbing operation. Do not

work with the nose of the bar. Be

extremely cautious and avoid contacting the log or other limbs with the nose

of the guide bar.

20

MSA 160 C

Page 23

Do not stand on a log while limbing it –

001BA033 KN

001BA051 LÄ

1

001BA151 KN

2

1

001BA152 KN

2

you may slip or the log may roll.

Start limbing by leaving the lower limbs

to support the log off the ground. When

underbucking freely hanging limbs, a

pinch may result or the limb may fall,

causing loss of control. If a pinch occurs,

switch off the motor, move front hand

guard to ƒ, remove the battery and

remove the saw by lifting the limb.

Warning!

Be extremely cautious when cutting

limbs or logs under tension (spring

poles). The limbs or logs could spring

back toward the operator and cause

loss of control of the saw and severe or

fatal injury to the operator.

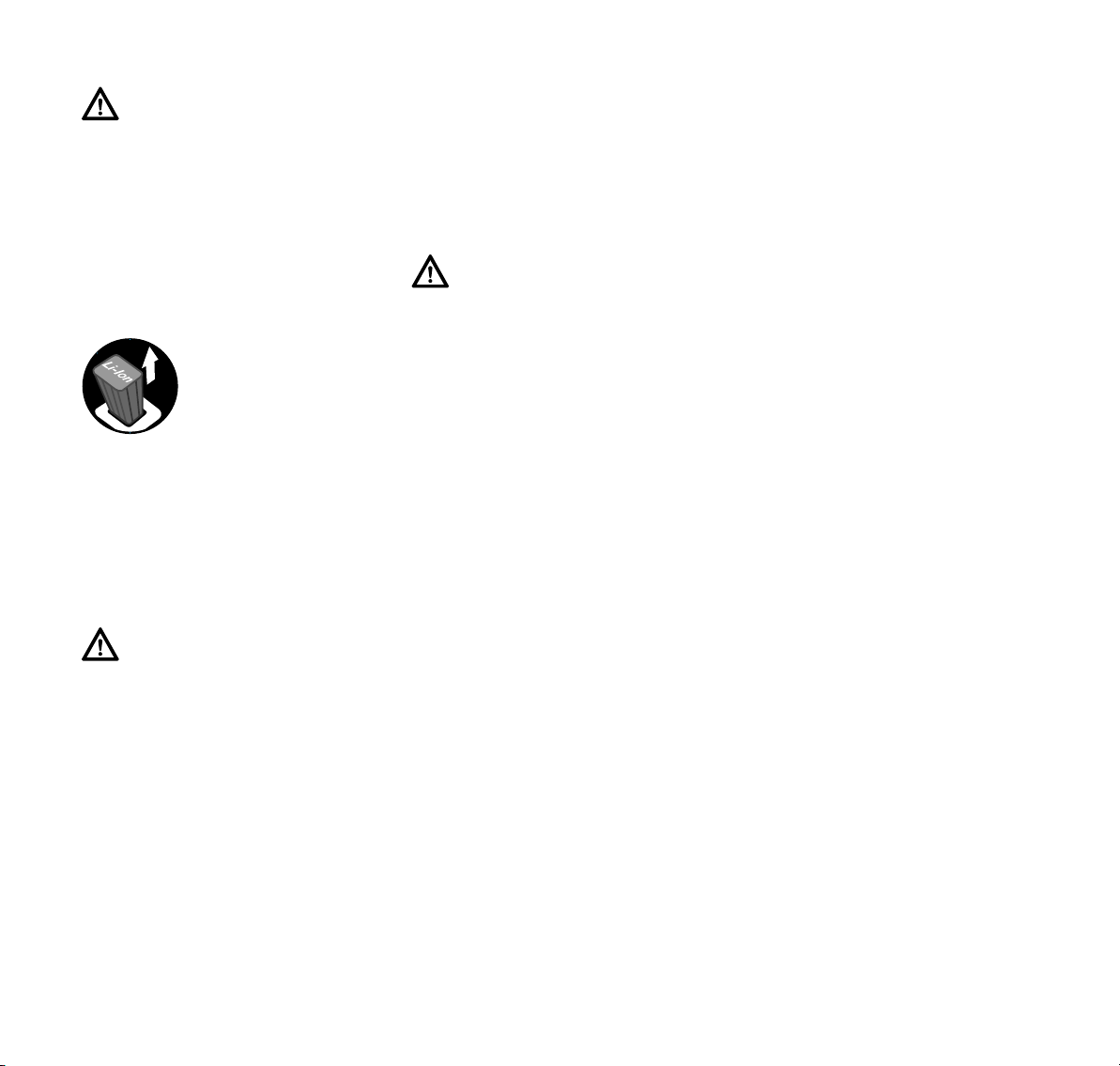

Bucking

Bucking is cutting a log into sections.

Warning!

When bucking, do not stand on the log.

Make sure the log will not roll downhill. If

on a slope, stand on the uphill side of

the log. Watch out for rolling logs.

Cut only one log at a time.

Shattered wood should be cut very

carefully. Sharp slivers of wood may be

caught and flung in the direction of the

operator of the saw.

When cutting small logs, place log

through "V" – shaped supports on top of

a sawhorse. Never permit another

person to hold the log. Never hold the

log with your leg or foot.

English

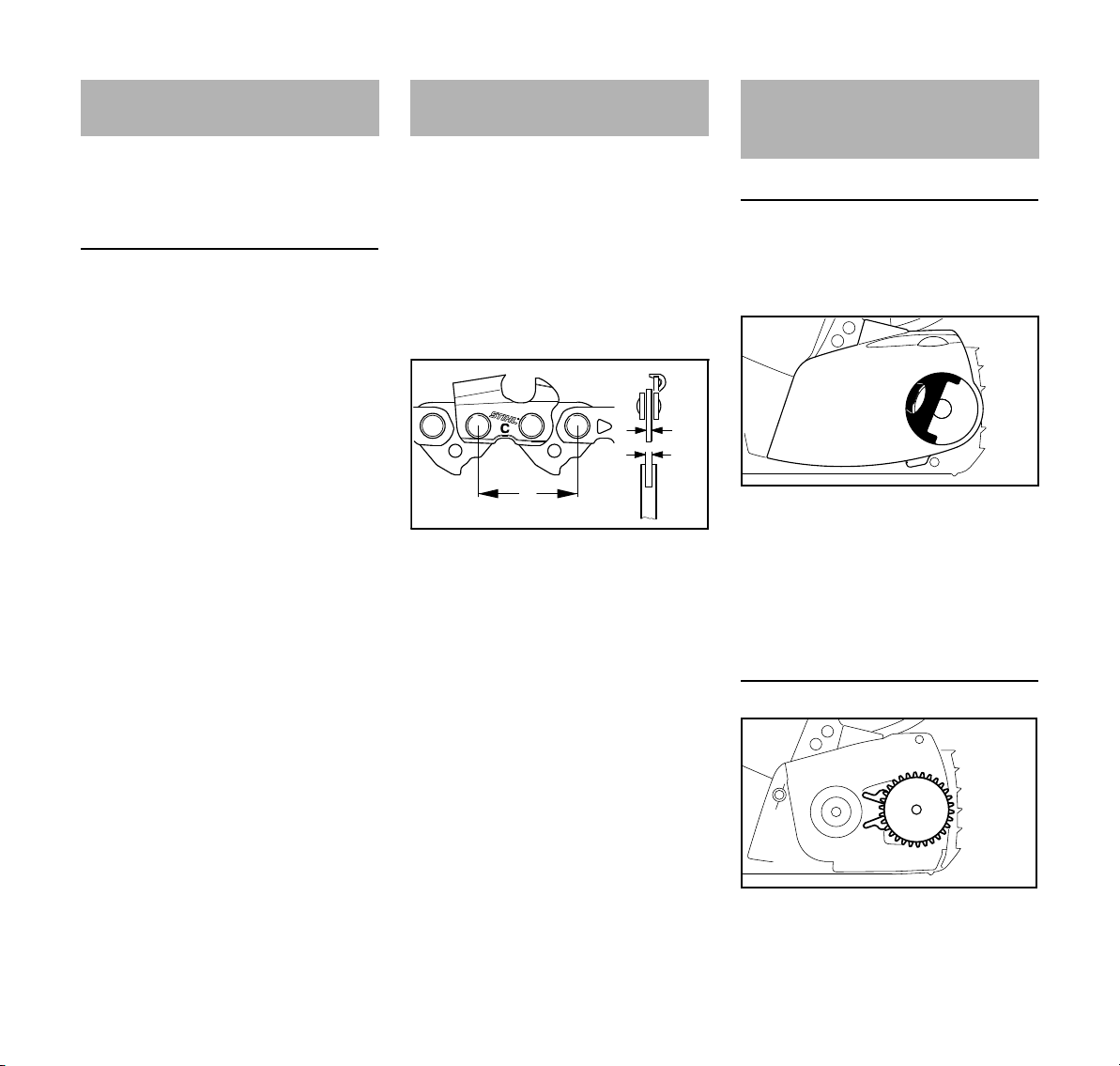

Logs under strain:

Risk of pinching! Always start relieving

cut (1) at compression side.Then make

bucking cut (2) at tension side. If the saw

pinches, stop the motor and remove it

from the log.

Only properly trained professionals

should work in an area where the logs,

limbs and roots are tangled. Working in

"blow down" areas is extremely

hazardous. Drag the logs into a clear

area before cutting. Pull out exposed

and cleared logs first.

MAINTENANCE, REPAIR AND

STORING

If you make a warranty claim for a

component which has not been

serviced or maintained properly or if

nonapproved replacement parts were

used, STIHL may deny coverage.

MSA 160 C

21

Page 24

English

Warning!

Use only identical STIHL replacement

parts for maintenance and repair. Use of

non-STIHL parts may cause serious or

fatal injury.

Strictly follow the maintenance and

repair instructions in the appropriate

section of your instruction manual.

Please also refer to the maintenance

chart in this manual.

Always switch off the

motor, move front hand

guard to ƒ, remove the

battery from the power

tool and make sure that

the cutting tool is stopped

before carrying out any

maintenance or repair

work, such as replacing

the cutting attachment, or

cleaning the power tool.

This avoids the risk of the

motor starting

unintentionally.

Warning!

Do not attempt any maintenance or

repair work not described in your

instruction manual. Have such work performed by your STIHL servicing dealer

only.

Wear gloves when handling or

performing maintenance on saw chains.

Keep the chain, bar and sprocket clean;

replace worn sprockets or chains. Keep

the chain sharp. You can spot a dull

chain when easy-to-cut wood becomes

hard to cut and burn marks appear on

the wood. Keep the chain at proper

tension.

Always replace the chain, guide bar and

sprocket as necessary.

Tighten all nuts, bolts and screws after

each use.

Warning!

In order for the chain brake on your

STIHL chain saw to properly perform its

function of reducing the risk of kickback

and other injuries, it must be properly

maintained. Like an automobile brake, a

chain saw chain brake incurs wear each

time it is engaged.

The amount of wear will vary depending

upon usage, conditions under which the

saw is used and other factors. Excessive

wear will reduce the effectiveness of the

chain brake and can render it

inoperable.

For the proper and effective operation of

the chain brake, the brake band and

chain sprocket drum must be kept free of

dirt, grease and other foreign matter

which may reduce friction of the band on

the drum.

For these reasons, each STIHL chain

saw should be returned to trained

personnel such as your STIHL servicing

dealer for periodic inspection and

servicing of the brake system according

to the following schedule:

Heavy usage – every three months,

Moderate usage – twice a year,

Occasional usage – annually.

The chain saw should also be returned

immediately for maintenance whenever

the brake system cannot be thoroughly

cleaned or there is a change in its

operating characteristics.

Regularly check the electrical contacts

and ensure that the insulation of the

power cord and plug of the charger is in

good condition and shows no sign of

aging (brittleness).

Electrical components, e.g. power cord

of charger, may only be repaired or

replaced by a qualified electrician.

Keep the battery guides free from

foreign matter – clean as necessary.

Do not spray the machine with water.

Do not clean your machine with a

pressure washer. The solid jet of water

may damage parts of the machine.

Clean plastic components with a cloth.

Do not use aggressive detergents. They

may damage the plastic.

Store chain saw in a dry, locked location

with the front hand guard on ƒ, the

battery removed and out of reach of

children (see chapter "Storing the

Machine" in the instruction manual).

22

MSA 160 C

Page 25

English

001BA191 KN

1

2

3

a

t = a : 2

1

3999BA001 KN

3

2

1

3999BA029 KN

Description of Operation Cutting Attachment

The power tool is operated with a

rechargeable battery. Use only STIHL

chargers to recharge the battery.

Data exchange

The power tool, battery and charger

communicate with each other. The

charger charges the battery and the

battery supplies the necessary power

only if data exchange functions properly.

For this reason you should operate your

power tool only with the approved STIHL

batteries and STIHL chargers.

STIHL is the only manufacturer in the

industry to produce its own chain saws,

guide bars, saw chains and chain

sprockets.

A cutting attachment consists of the saw

chain, guide bar and chain sprocket.

The cutting attachment that comes

standard is designed to exactly match

the chain saw.

– The pitch (t) of the saw chain (1),

chain sprocket and the nose

sprocket of the Rollomatic guide bar

must match.

– The drive link gauge (2) of the saw

chain (1) must match the groove

width of the guide bar (3).

If non-matching components are used,

the cutting attachment may be damaged

beyond repair after a short period of

operation.

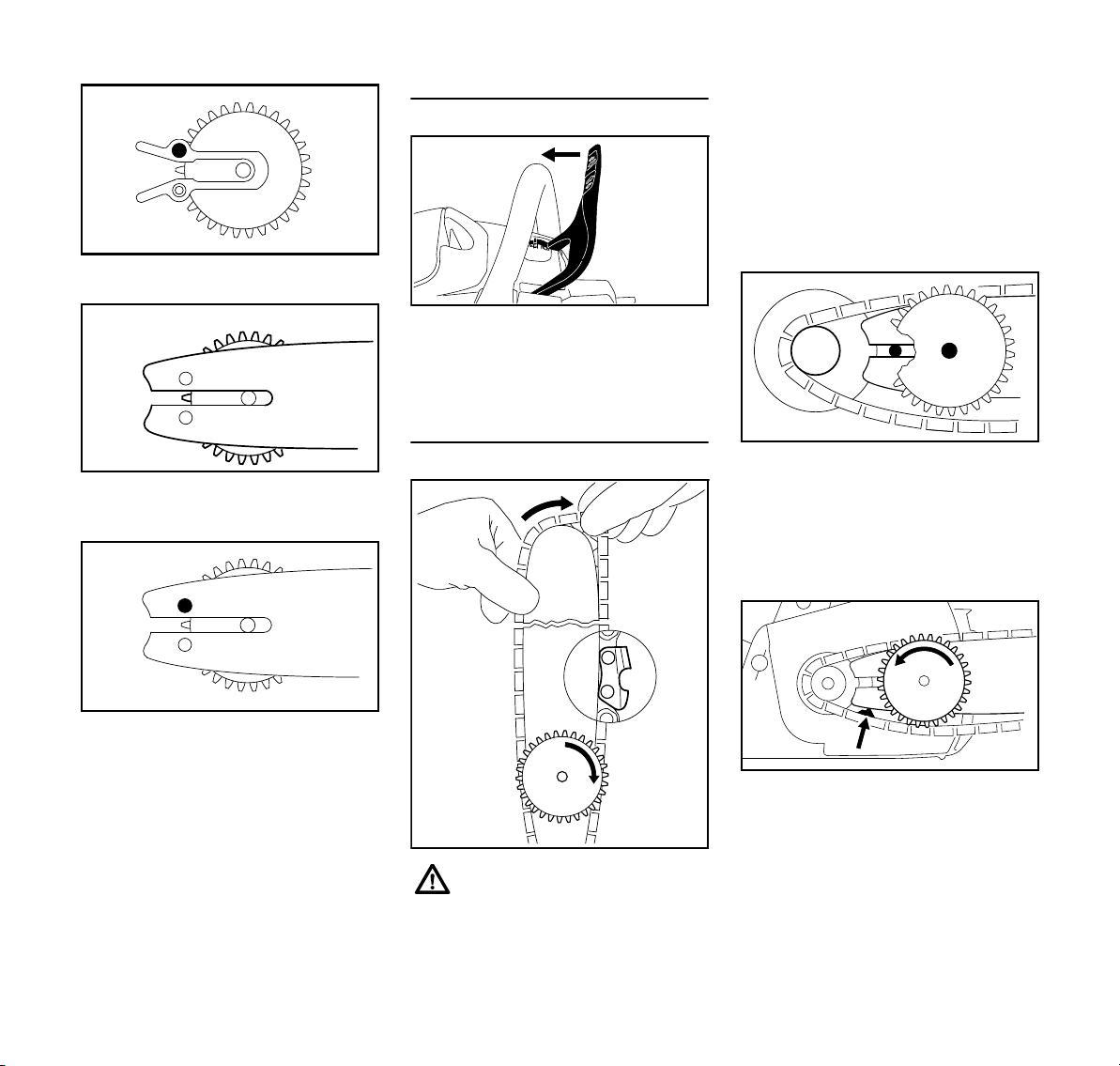

Mounting the Bar and

Chain (quick chain

tensioner)

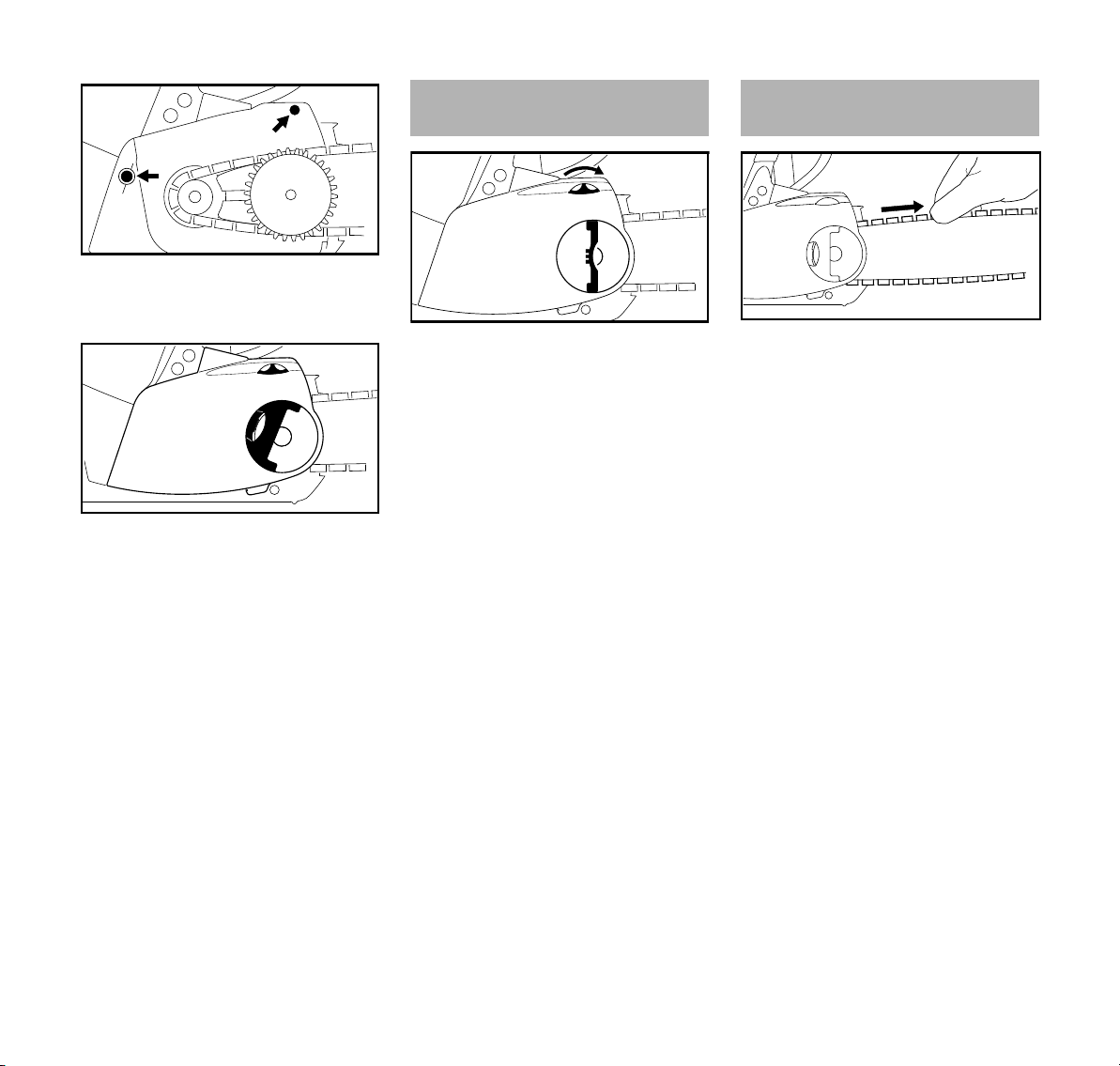

Removing the chain sprocket cover

N Set hand guard to ƒ

N Remove the battery from the

machine

N Swing grip (1) into position (until it

engages)

N Turn the wing nut (2) to the left until

it hangs loosely in the chain

sprocket cover (3)

N Remove chain sprocket cover (3)

Mounting the tensioning gear

N Remove and reverse tensioning

gear (1)

MSA 160 C

23

Page 26

English

2310BA015 KN

2

1

3

2310BA016 KN

2

2310BA017 KN

3999BA010 KN

1

181BA012 KN

2

3

181BA013 KN

3999BA004 KN

N Remove screw (2)

N Position tensioning gear (1) and

guide bar (3) relative to one another

Releasing the chain brake

N Pull hand guard towards the front

handle until it engages audibly and

the hand guard is in the position ‚

– chain brake is released

Fitting the saw chain

N Fit the saw chain – starting at the

nose of the guide bar – pay attention

to the position of the tensioning gear

and the cutting edges

N Turn tensioning gear (1) to the right

as far as possible

N Turn the guide bar so that the

tensioning gear faces the user

N Place the saw chain on the chain

sprocket (2)

N Slide the guide bar over the collar

screw (3); the head of the rear collar

screw must protrude into the oblong

hole

N Insert and tighten screw (2)

24

N Guide the drive link into the bar

groove (arrow) and turn the

tensioning gear to the left as far as

possible

Put on protective gloves – risk of

injury by the sharp cutters

MSA 160 C

Page 27

English

3999BA005 KN

4

5

3999BA006 KN

2

1

3999BA007 KN

3999BA008 KN

N Fit chain sprocket cover, sliding the

guide lugs into the engine housing

openings

When fitting the chain sprocket cover,

the teeth of the adjusting wheel and the

tensioning gear must mesh; if

necessary,

N turn the adjusting wheel (4) a little

until the chain sprocket cover can

be slid completely against the

engine housing

N Swing grip (5) into position (until it

engages)

N Fit wing nut and tighten lightly

N Go to chapter "Tensioning the saw

chain"

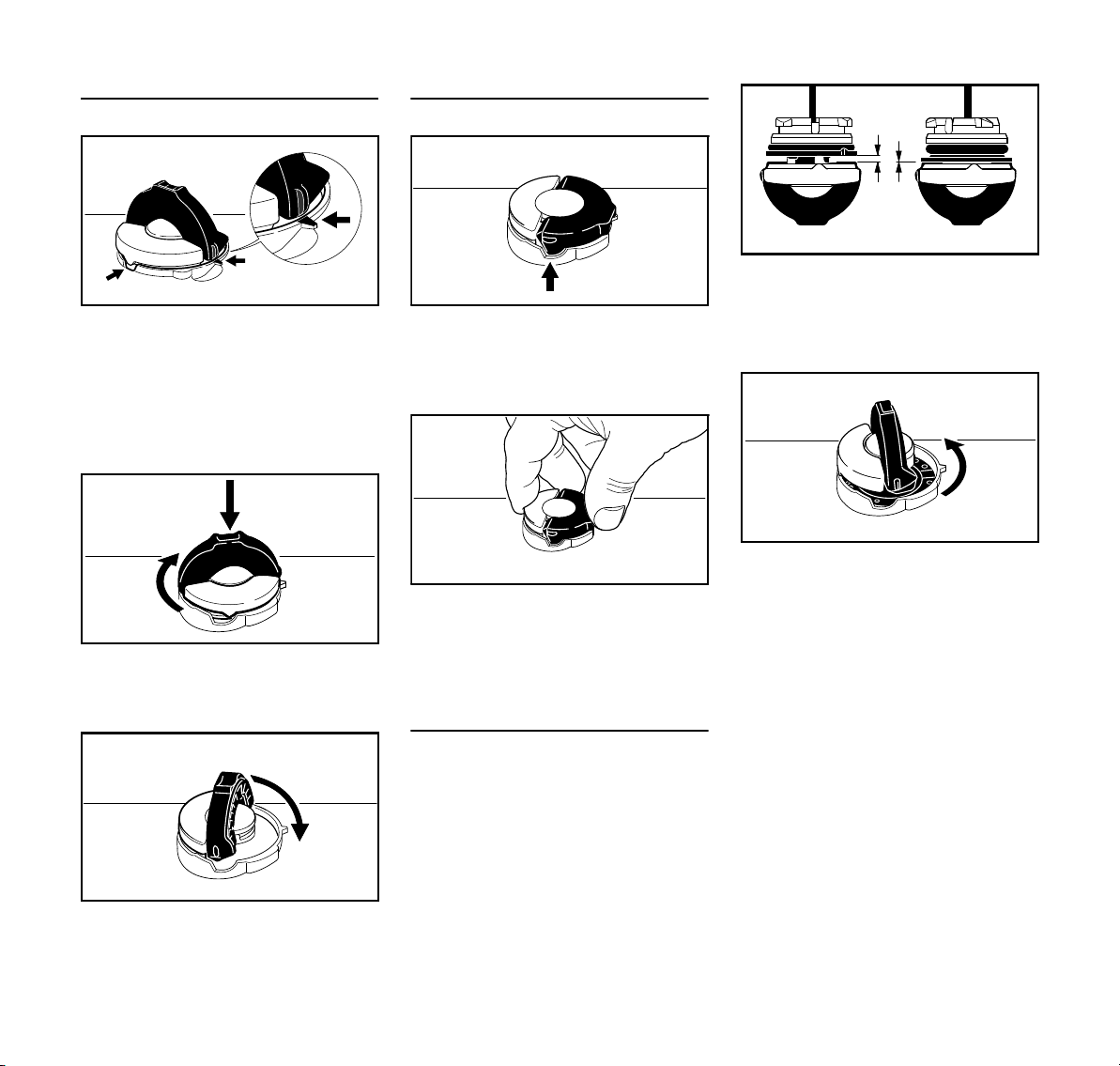

Tensioning the Saw Chain

(quick chain tensioner)

For retensioning during operation:

N Remove the battery from the

machine

N Fold out the wings of the wing nut

and loosen the wing nut

N Turn the adjusting wheel (1) to the

right as far as possible

N Tighten the wing nut (2) by hand

N Fold in the wings of the wing nut

N Next step: Continue with "Check

chain tension"

A new saw chain must be retensioned

more frequently than one that has been

in use already for an extended period!

N Check chain tension frequently –

see "Operating Instructions"

Checking Chain Tension

N Remove the battery from the

machine

N Put on protective gloves

N Pull hand guard towards the front

handle until it engages audibly and

the hand guard is in the position ‚

– chain brake is released

N The saw chain must lie against the

bottom of the bar and it must be

possible to pull it across the guide

bar by hand

N if necessary, retension saw chain

A new saw chain must be retensioned

more frequently than one that has been

in use already for an extended period.

N Check chain tension frequently, see

"Operating Instructions"

MSA 160 C

25

Page 28

English

3999BA011 KN

001BA218 KN

001BA219 KN

001BA224 KN

Chain Lubricant

For automatic and reliable lubrication of

the chain and guide bar – use only a

quality, environmentally compatible

chain and bar lubricant – preferably the

rapidly biodegradable STIHL Bioplus.

Biological chain oil must be

sufficiently resistant to aging

(e. g., STIHL Bioplus). Oil with a

low resistance to aging tends to

turn to resin quickly. This results in

hard deposits that are difficult to

remove, especially in the area of

the chain drive and on the saw

chain – .possibly even causing the

oil pump to seize.

The service life of the chain and guide

bar depends on the quality of the

lubricant – it is therefore essential to use

only a specially formulated chain oil.

Do not use waste oil! Prolonged

and repeated contact with waste

oil can cause skin cancer. It also

harms the environment!

Waste oil does not have the

necessary lubricant properties

and is unsuitable for chain

lubrication.

Filling Chain Oil Tank

N Check oil level before starting work,

while sawing, and each time the

battery is changed

N Refill chain oil at the latest every

second time the battery is changed

If the oil tank is still partly full, the reason

may be a problem in the oil supply

system: Check chain lubrication, clean

the oil passages, contact your servicing

dealer for assistance if necessary.

STIHL recommends that all

maintenance and repairs be carried out

by STIHL servicing dealers

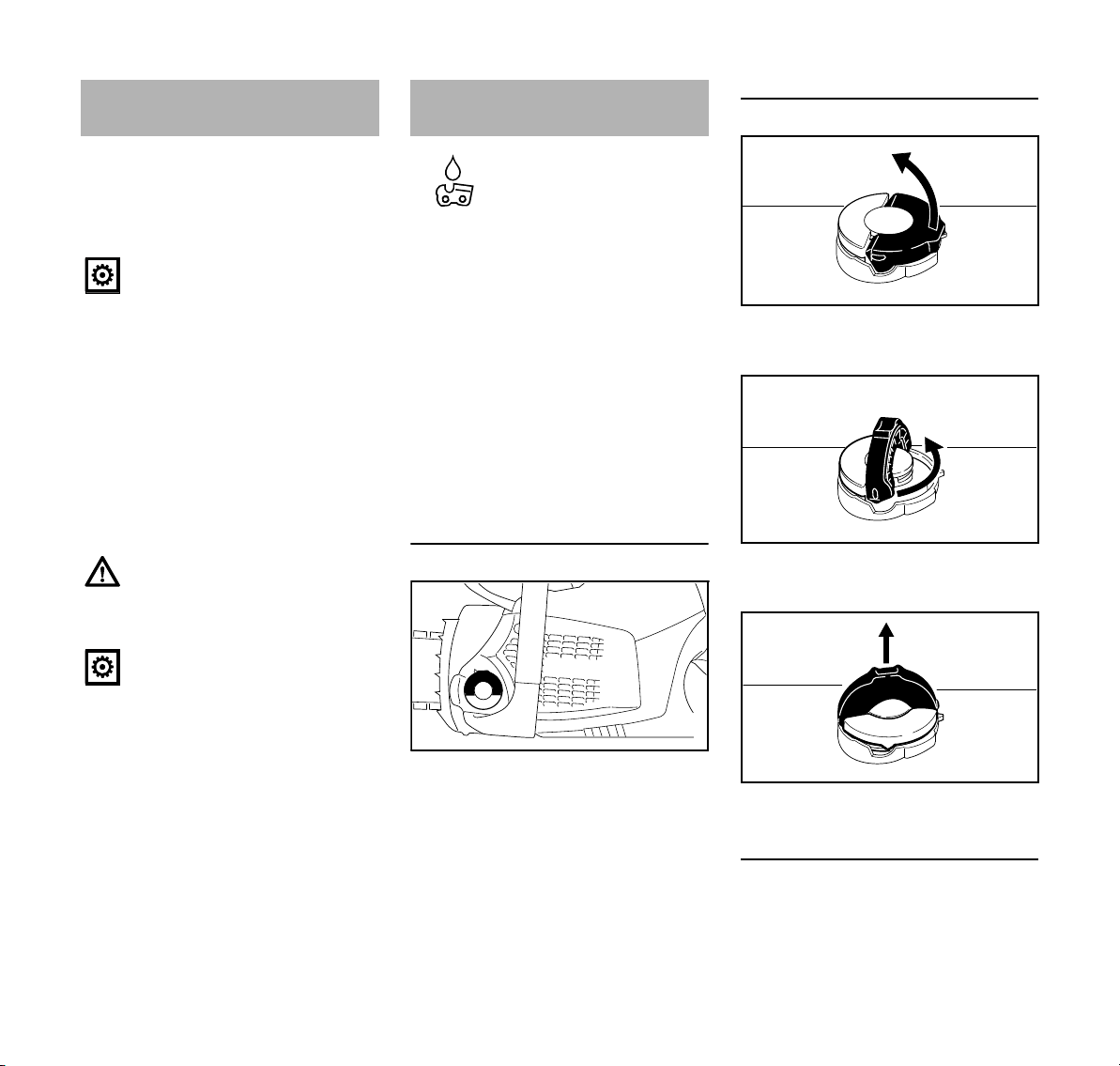

Oil filler cap

Opening

N Raise the grip into an upright

position.

N Turn the cap counterclockwise

(approx. 1/4 turn).

26

N Thoroughly clean the filler cap and

the area around it to ensure that no

dirt falls into the tank

N Always position the machine so that