Page 1

Contents

English

Guide to Using this Manual .............. 2

Safety Precautions ........................... 3

Using the Saw .................................. 9

Mounting the Bar and Chain ........... 17

Tensioning the Saw Chain .............. 18

Checking Chain Tension ................. 18

Fuel ................................................ 19

BA_SE_153_002_01_06.fm Printed on chlorine-free paper.

Fueling ............................................ 20

Chain Lubricant .............................. 21

Filling Chain Oil Tank ...................... 22

Checking Chain Lubrication ........... 22

Chain Brake .................................... 23

Information Before You Start .......... 24

Starting / Stopping the Engine ........ 24

Operating Instructions .................... 27

Oil Quantity Control

Taking Care of Guide Bar ............... 29

Cleaning the Air Filter ..................... 29

Adjusting the Carburetor ................ 30

Checking the Spark Plug ................ 32

Spark Arresting Screen

in Muffler* ....................................... 33

Replacing Starter Rope

and Rewind Spring ......................... 34

Storing the Machine ........................ 36

Checking and Replacing

Printing inks contain vegetable oils; paper can be recycled.

Chain Sprocket ............................... 36

Maintaining and Sharpening

Saw Chain ...................................... 38

* ...................... 28

Maintenance Chart ......................... 42

Minimize Wear and

Avoid Damage ................................ 44

Main Parts and Controls ................. 45

Specifications ................................. 46

Special Accessories ....................... 46

Ordering Spare Parts ..................... 47

Maintenance and Repairs .............. 47

Manufacturer's declaration

of conformity ................................... 48

Quality Certification ........................ 48

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

This machine has been built using

modern production techniques and

comprehensive quality assurance.

Every effort has been made to ensure

your satisfaction and troublefree use

of the machine.

Please contact your dealer or our

sales company if you have any

queries concerning your machine.

Hans Peter Stihl

* see "Guide to Using this Manual"

STIHl

© ANDREAS STIHL AG & Co. KG, 2004

0458 215 0121. M3. E4. MET. Printed in Brazil

1MS 380

Page 2

English

Guide to Using this Manual

Pictograms

All the pictograms attached to the

machine are shown and explained in

this manual.

The operating and handling instructions

are supported by illustrations.

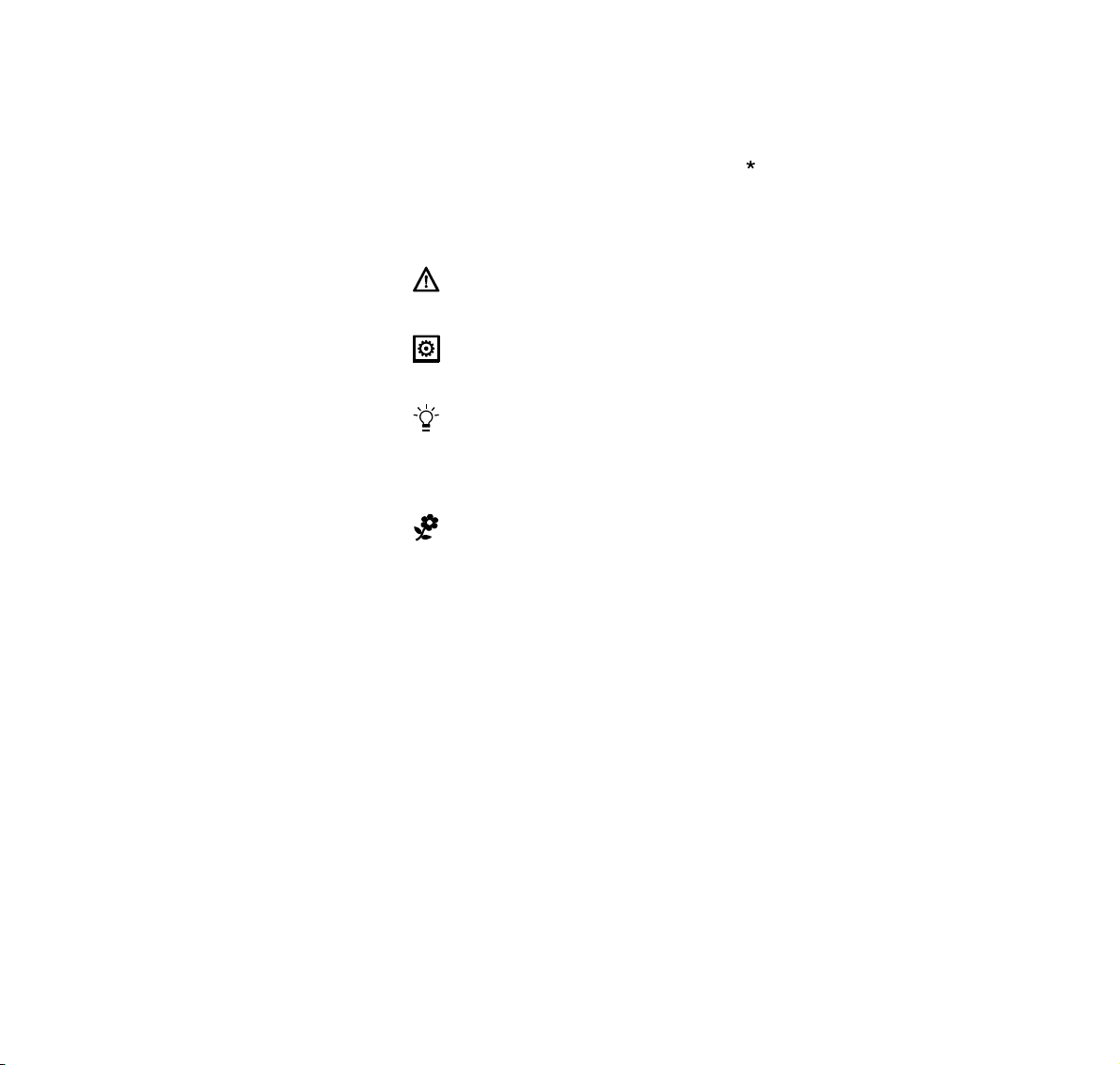

Symbols in text

The individual steps or procedures

described in the manual may be marked

in different ways:

: A bullit marks a step or procedure

without direct reference to an

illustration.

A description of a step or procedure that

refers directly to an illustration may

contain item numbers that appear in the

illustration.

Example:

Loosen the screw (1)

Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols described below:

Warning where there is a risk of an

accident or personal injury or

serious damage to property.

Caution where there is a risk of

damaging the machine or its

individual components.

Note or hint which is not essential

for using the machine, but may

improve the operator’s understanding of the situation and result

in better use of the machine.

Note or hint on correct procedure in

order to avoid damage to the

environment.

Equipment and features

This instruction manual may refer to

several models with different

features. Components that are not

installed on all models and related

applications are marked with an

asterisk (*). Such components may

be available as special accessories

from your STIHL dealer.

Engineering improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. If the

operating characteristics or the

appearance of your machine differ from

those described in this manual, please

contact your STIHL dealer for

assistance.

Therefore some changes, modifications

and improvements may not be covered

in this manual.

2

MS 380

Page 3

Safety Precautions

English

Because a chainsaw is a

high-speed wood-cutting

tool some special safety

precautions must be

observed in addition to

those that generally apply when working

with an axe or hand saw.

It is important that you

read and understand the

owner's manual before

using your chainsaw for

the first time. Non-

observance of the

following safety precautions may cause

serious or even fatal injury.

Always observe local safety regulations,

standards and ordinances.

If you have never used this chainsaw

model before:

Have your STIHL dealer or other

experienced user show you how to

operate your chainsaw or attend a

special course of training in chainsaw

operation.

Minors should never be allowed to use a

chainsaw.

Children, bystanders and animals

should not be allowed in the area where

a chainsaw is in use.

The chainsaw user is responsible for

accidents or risks involving third parties

or their property.

Do not lend or rent your chainsaw

without the owner's manual. Be sure that

anyone using your saw understands the

information contained in this manual.

You must be in good physical condition

and mental health and not under the

influence of any substance (drugs,

alcohol) which might impair vision,

dexterity or judgment.

If you have a pacemaker: The ignition

system of this power tool produces a

very weak electromagnetic field. It is not

possible to exclude the risk of it

interfering with some types of

pacemakers. To avoid health problems,

STIHL recommends that you ask your

doctor and the pacemaker manufacturer

for advice.

STIHL recommends only guide bars,

saw chains and chain sprockets

supplied by STIHL and explicitly

approved for your chainsaw model by

STIHL (see specifications and sales

documentation).

The characteristics of these components

are specifically designed to match your

chainsaw model and meet your

performance requirements (cutting

capacity, vibration, kickback behavior).

Only use attachments supplied by

STIHL or explicitly approved for your

chainsaw model by STIHL. Other

attachments must not be used because

of the increased risk of accidents and

negative effects on the chainsaw.

Never attempt to modify your chainsaw

in any way since this can be extremely

dangerous and result in serious or fatal

injury. STIHL cannot accept any liability

for personal injury or damage to property

caused by modifications to the

chainsaw, using attachments not

approved by STIHL or non-approved

guide bars and saw chains.

3MS 380

Page 4

English

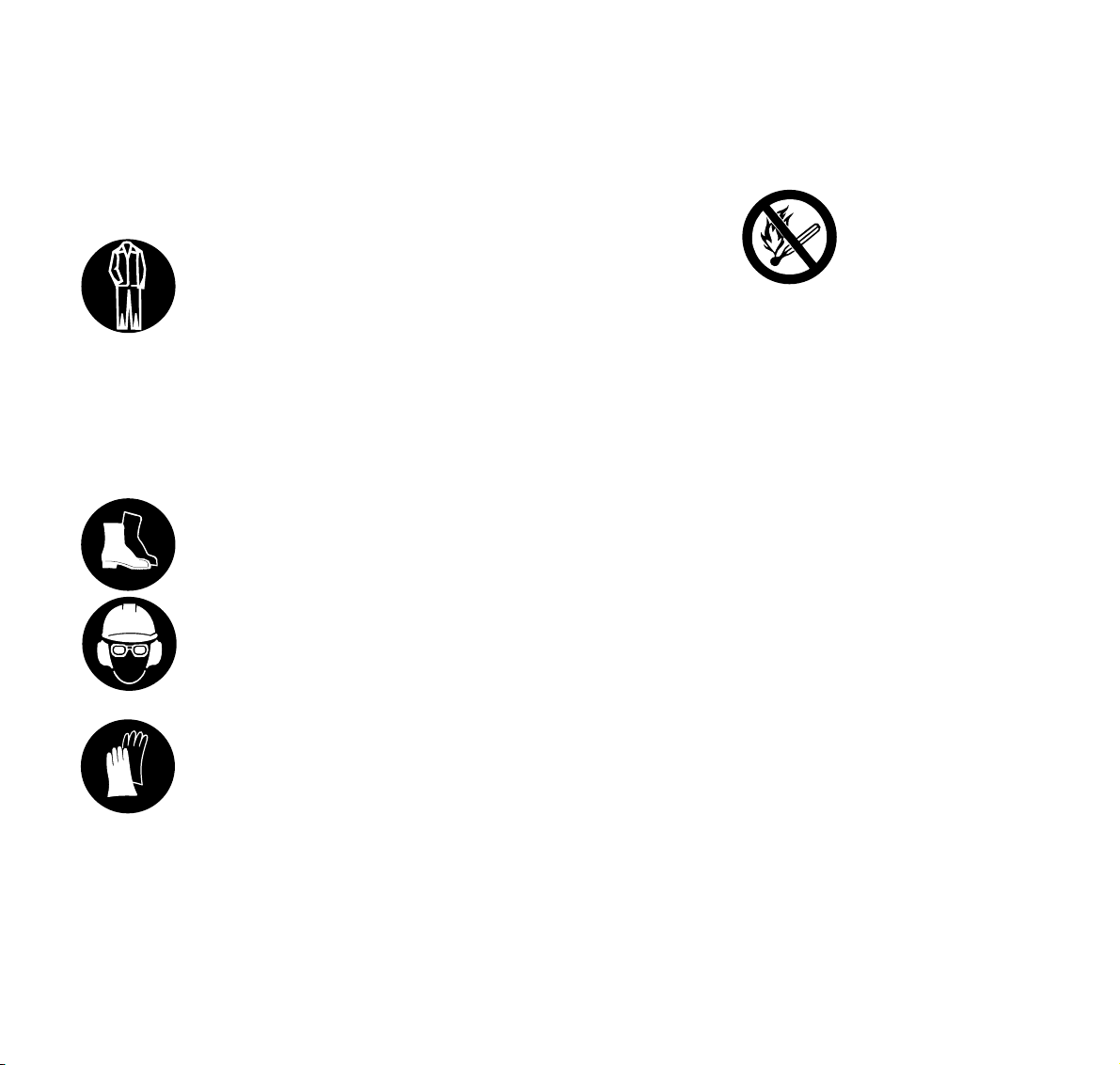

Clothing and Equipment

Wear proper protective clothing and

equipment.

Clothing must be sturdy

and snug-fitting, but allow

complete freedom of

movement. Wear overalls

with a cut-retardant inlay -

a STlHL safety coverall is

recommended.

Do not wear loose-fitting garments,

scarves, jewelry or anything that could

restrict movement or become entangled

with the saw, wood or brush. Confine

long hair (e.g. with a hair net).

Wear steel-toed safety

boots with non-slip soles.

Wear a safety hard hat

to protect your head.

Wear safety glasses and

sound barriers, i.e. ear

plugs or ear muffs.

Transporting the Chainsaw

Always engage the chain brake and fit

the chain guard (scabbard) before

carrying the saw short distances.

Also stop the engine before carrying the

saw longer distances (more than about

50 m).

Always carry the saw by the front handle

– with the hot muffler away from your

body – the guide bar must point to the

rear. To avoid serious burn injuries,

avoid touching hot parts of the machine,

especially the surface of the muffler.

Transporting by vehicle: When

transporting in a vehicle, properly secure

your saw to prevent turnover, fuel

spillage and damage.

When your saw is not in use, put it down

in a safe place so that it does not

endanger anybody.

Fueling

Gasoline is an

extremely flammable

fuel. Keep clear of naked

flames and fire. Do not

spill any fuel.

Stop the engine before refueling.

Do not refuel while the engine is still hot

since fuel may overflow and catch fire.

In order to reduce risk of burns or other

personal injury from escaping gas vapor

and fumes, unscrew the fuel cap

carefully to allow any pressure build-up

in the tank to release slowly.

Fuel your chainsaw in a well-ventilated

area, outdoors only. If you spill fuel, wipe

the saw immediately – if fuel gets on

your clothing, change immediately.

Wear heavy-duty, non-

slip gloves, preferably

made of chrome leather.

STIHL offers a comprehensive range of

personal protection equipment

4

MS 380

Page 5

English

The saw comes standard with either a

screw-type or bayonet-type fuel filler

cap.

After fueling, tighten down

the screw-type fuel filler

cap as securely as

possible.

Insert the fuel filler cap

with hinged grip (bayonet

type) correctly in the

opening, turn it clockwise

as far as stop and fold the

grip down.

This helps reduce the risk of unit

vibrations causing an improperly

tightened fuel cap to loosen or come off

and spill quantities of fuel.

To reduce the risk of serious or fatal

burn injuries, check for fuel leakage. If

fuel leakage is found, do not start or run

the engine until leak is fixed.

Before Starting

Check that saw is properly assembled

and in good condition - refer to

appropriate chapters in the owner’s

manual:

– Check operation of chain brake.

– Correctly mounted guide bar.

– Correctly tensioned chain.

– Smooth action of throttle trigger and

throttle trigger interlock – throttle

trigger must return automatically to

idle position.

– Master control/stop switch must

move easily to STOP or $

– Check that spark plug boot is secure

– a loose boot may cause arcing

that could ignite combustible fumes

and cause a fire.

– Never attempt to modify the controls

or safety devices

– Keep the handles dry and clean –

free from oil and pitch – for safe

control.

To reduce risk of personal injury, do not

operate your saw if it is damaged or not

properly assembled.

Starting the Engine

Start the engine at least 3 meters from

the fueling spot, outdoors only.

Your chain saw is a one-person saw. Do

not allow other persons near the running

chainsaw. Start and operate your saw

without assistance.

To reduce risk of chain rotation and

personal injury, lock the chain with the

chain brake before starting.

Do not drop start the chainsaw.

The correct starting procedure is

described in your owner's manual.

During Operation

In the event of impending danger or in

an emergency, switch off the engine

immediately by moving the Master

Control/stop switch to $ or d.

When the engine is running:

Note that the chain continues to rotate

for a short period after your let go of the

throttle trigger.

5MS 380

Page 6

English

Take special care in slippery conditions

– damp, snow, ice, on slopes, uneven

ground and freshly debarked logs.

Avoid stumbling on stumps, roots, rocks

or in ditches.

Take special care to maintain good

footing at all times.

Do not work alone – keep within calling

distance of others in case help is

needed.

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

If you get tired, take a break in good

time.

To reduce risk of fire, keep hot exhaust

gases and hot muffler away from easily

combustible materials (e.g. wood chips,

bark, dry grass, fuel).

Your chainsaw produces

toxic exhaust fumes as

soon as the engine is

running. These fumes

may be colorless and

odorless. Never run the

engine indoors or in poorly ventilated

locations, even if your model is equipped

with a catalytic converter.

To reduce the risk of serious or fatal

injury from breathing toxic fumes,

ensure proper ventilation when working

in trenches, hollows or other confined

locations.

The dusts (e.g. sawdust) produced

during cutting may be dangerous to

health. If the work area is very dusty,

wear a respirator.

To reduce risk of fire, do

not smoke while

operating or standing

near your chainsaw. Note

that combustible fuel

vapor may escape from

the fuel system.

If your chainsaw is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing cutting work.

Check the fuel system for leaks and

make sure the safety devices are

working properly. Do not continue

operating your saw if it is damaged. In

case of doubt, have the saw checked by

your STIHL servicing dealer.

Make sure the chain does not rotate

while the engine is idling. If necessary,

adjust idle speed properly. If the chain

still rotates, have the saw checked by

your STIHL dealer.

6

MS 380

Page 7

English

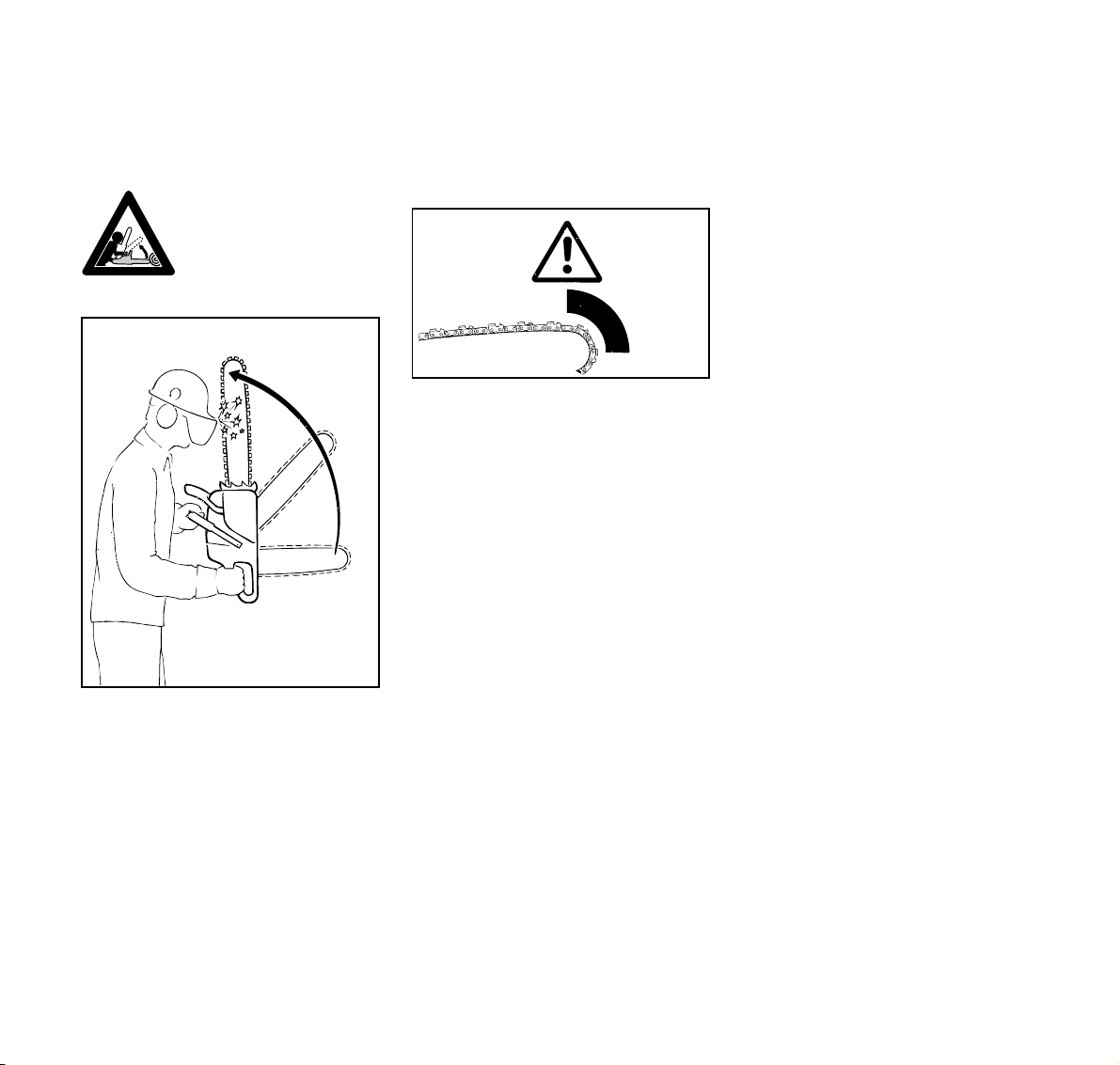

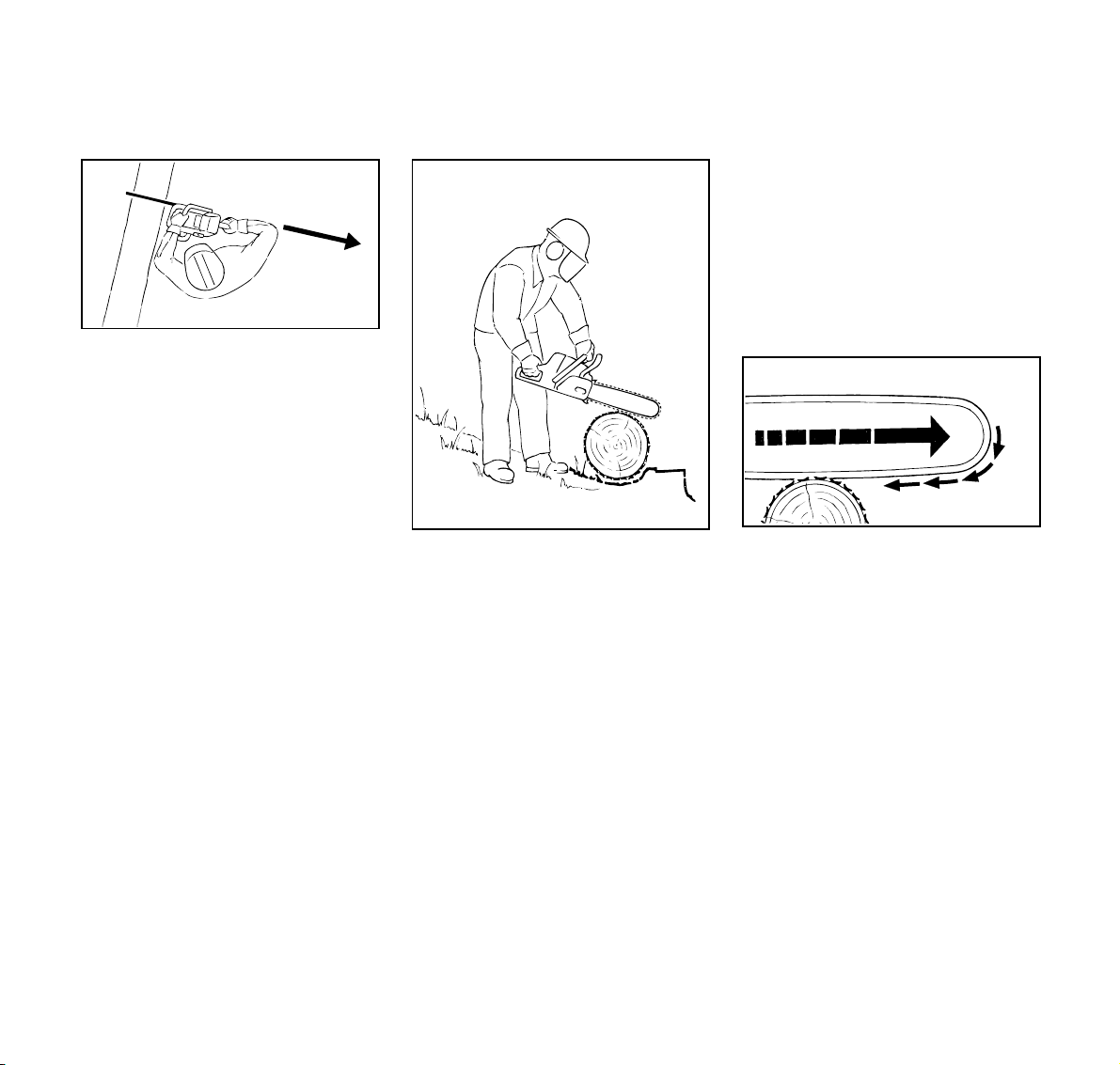

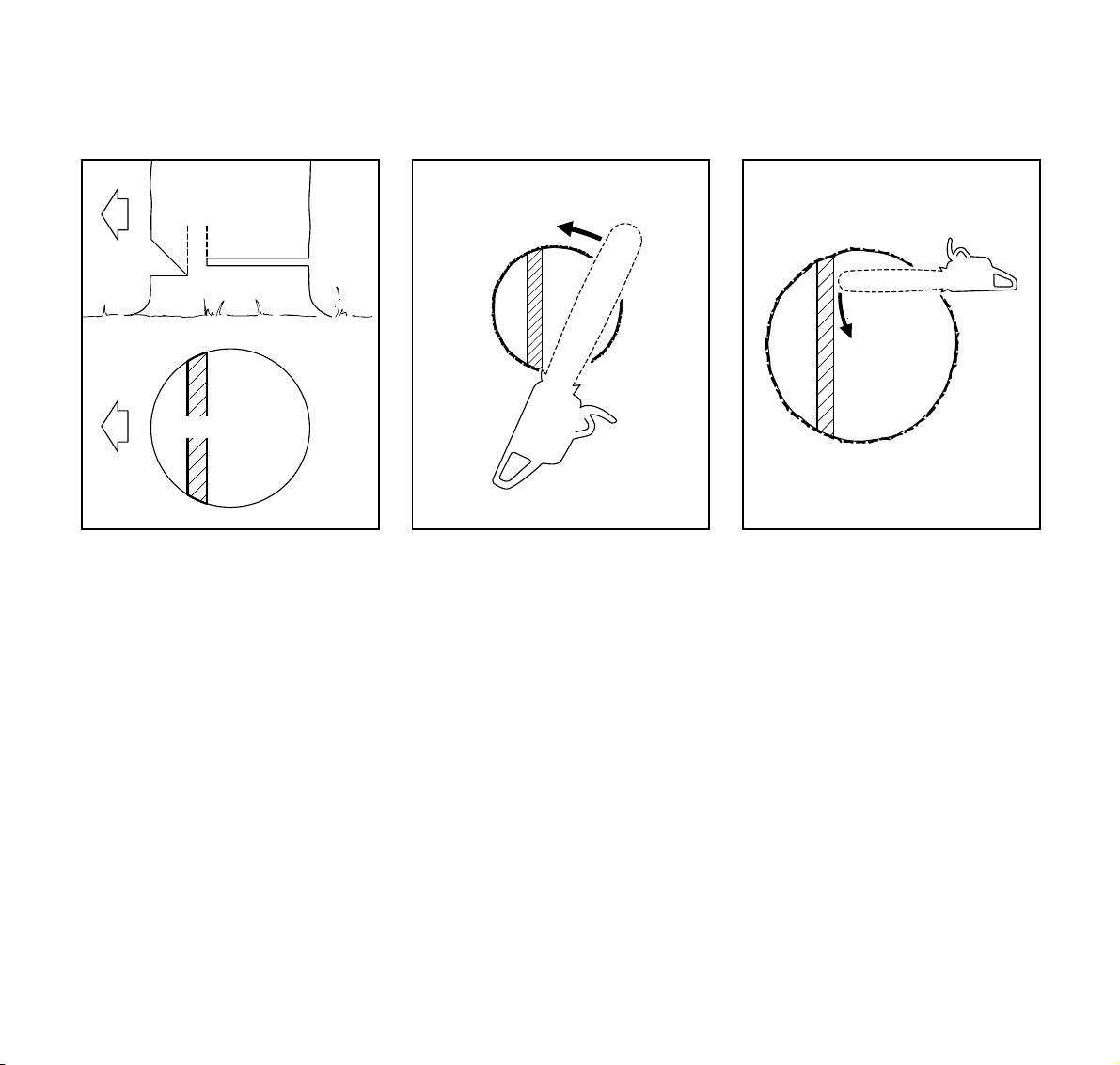

Dangers of kickback

Kickback can result

in serious or fatal

injury.

Kickback causes the the saw to be

suddenly thrown up and back in an

uncontrolled arc towards the operator.

Kickback may occur in the following

situations

– when the upper quadrant of the bar

nose unintentionally contacts wood

or another solid object, e.g. another

limb during limbing,

– when the chain at the nose of the

guide bar is pinched in the cut.

Quickstop chain brake

This device reduces the risk of injury in

certain situations – it cannot prevent

kickback. If activated, the brake stops

the saw chain within a fraction of a

001BA036 KN

second – for a description of this device

refer to "Chain Brake" chapter in this

manual.

To reduce the risk of kickback

– Work cautiously using proper

cutting techniques.

– Hold the chainsaw firmly with both

hands and maintain a secure grip.

– Always cut at full throttle.

– Be aware of the location of the guide

bar nose at all times.

– Do not cut with the bar nose.

001BA093 LÄ

– Take special care with small, tough

limbs, they may catch the chain.

– Never cut several limbs at once.

– Do not overreach.

– Never cut above shoulder height.

7MS 380

Page 8

English

– Do not attempt plunge cuts if you

are not experience in this cutting

technique.

– Be wary of position of log and forces

that may cause the cut to close and

pinch the chain.

– Always cut with a correctly

sharpened, properly tensioned

chain – the depth gauge setting

must not be too large.

Use reduced kickback chain and a guide

bar with a narrow radius nose.

Vibrations

Prolonged use of the unit may result in

vibration-induced circulation problems in

the hands (whitefinger disease).

No general recommendation can be

given for the length of usage because it

depends on several factors.

The period of usage is prolonged by:

– Hand protection (wearing warm

gloves)

–breaks

The period of usage is shortened by:

– Any personal tendency to suffer

from poor circulation (symptoms:

frequently cold fingers, itching).

– Low outside temperatures.

– Gripping force (a tight grip hinders

circulation).

Continual and regular users should

monitor closely the condition of their

hands and fingers. If any of the above

symptoms appear, seek medical advice.

Maintenance and Repairs

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in your owner's manual.

Have all other worked performed by your

STIHL dealer. Only use genuine STlHL

replacement parts. Never modify your

machine in any way as this could result

in serious injury.

Always shut off the engine

– before checking chain tension.

– before retensioning the chain.

– before replacing the chain.

– before rectifying problems.

Check the chain catcher –

and replace it if damaged.

Observe sharpening instructions

for safe and correct handling of saw

chain and guide bar.

Keep the chain in good condition at all

times. It must be properly sharpened,

tensioned and well lubricated.

8

MS 380

Page 9

Using the Saw

English

Always change the chain, guide bar and

sprocket in good time.

Check condition of clutch drum

periodically.

Check the fuel tank for leaks at short

regular intervals.

Do not touch a hot muffler. Check

condition of muffler at regular intervals to

reduce the risk of fires and damage to

hearing. Do not operate your machine if

the muffler is damaged or missing.

Use only a spark plug of the type

approved by STIHL and make sure it is

in good condition (see chapter

“Specifications”). Inspect ignition lead

(insulation in good condition, secure

connection).

To reduce the risk of fire and burn injury

as a result of sparking outside the

cylinder, move the stop switch to STOP

before turning the engine over on the

starter with the spark plug boot removed

or the spark plug unscrewed.

Store fuel and chain lubricant in properly

labelled, safety-type canisters only. Take

care when handling gasoline. Avoid

direct contact with the skin and avoid

inhaling fuel vapour.

To reduce the risk of injury, shut down

your chainsaw immediately in the event

of a chain brake malfunction.

Take the saw to your STIHL dealer. Do

not use your chainsaw until the fault has

been fixed (see chapter “Chain Brake”).

Cutting

Use your saw for cutting wood or

wooden objects only.

Do not operate your chainsaw with the

starting throttle lock engaged. Engine

speed cannot be controlled with the

throttle trigger in this position.

Work calmly and carefully – in daylight

conditions and only when visibility is

good – ensure you do not endanger

others – stay alert at all times.

Use the shortest possible guide bar: The

chain, guide bar and chain sprocket

must match each other and your saw.

001BA087 LÄ

Always hold your saw firmly with both

hands - right hand on the rear handle,

even if you are left-handed. To ensure

safe control, wrap your fingers tightly

around the front handle and control

handle.

9MS 380

Page 10

English

Run the engine at full throttle, engage

the spiked bumper firmly in the wood

and then start cutting.

Never work without the spiked bumper –

the saw may pull you forwards and off

balance.

Position the saw so that your body is

clear of the cutting attachment.

Always pull the saw out of the cut with

the chain running.

Use your saw for cutting only. It is not

designed for prying or shoveling away

limbs, roots or other objects.

Do not underbuck freely hanging limbs.

Take special care when cutting

shattered wood – sharp slivers of wood

may be caught and flung in your

direction.

Make sure your saw does not touch any

foreign materials:

Stones, nails, etc. may be flung off,

damage the saw chain or cause the saw

to kick back unexpectedly.

001BA082 KN

If on a slope, stand on the uphill side or

to one side of the log. Watch out for

rolling logs.

When working at heights:

– Always use a lift bucket.

– Never work on a ladder.

– Never work in a tree.

– Never work on any insecure

support.

– Do not work above shoulder height.

– Never operate the saw with one

hand.

A = Pull-in

001BA033 KN

Pull-in occurs when the chain on the

bottom of the bar is suddenly pinched,

caught or encounters a foreign object in

the wood. The reaction of the chain pulls

the saw forward. Always hold the

spiked bumper securely against the

tree or limb.

A

001BA037 KN

10

MS 380

Page 11

English

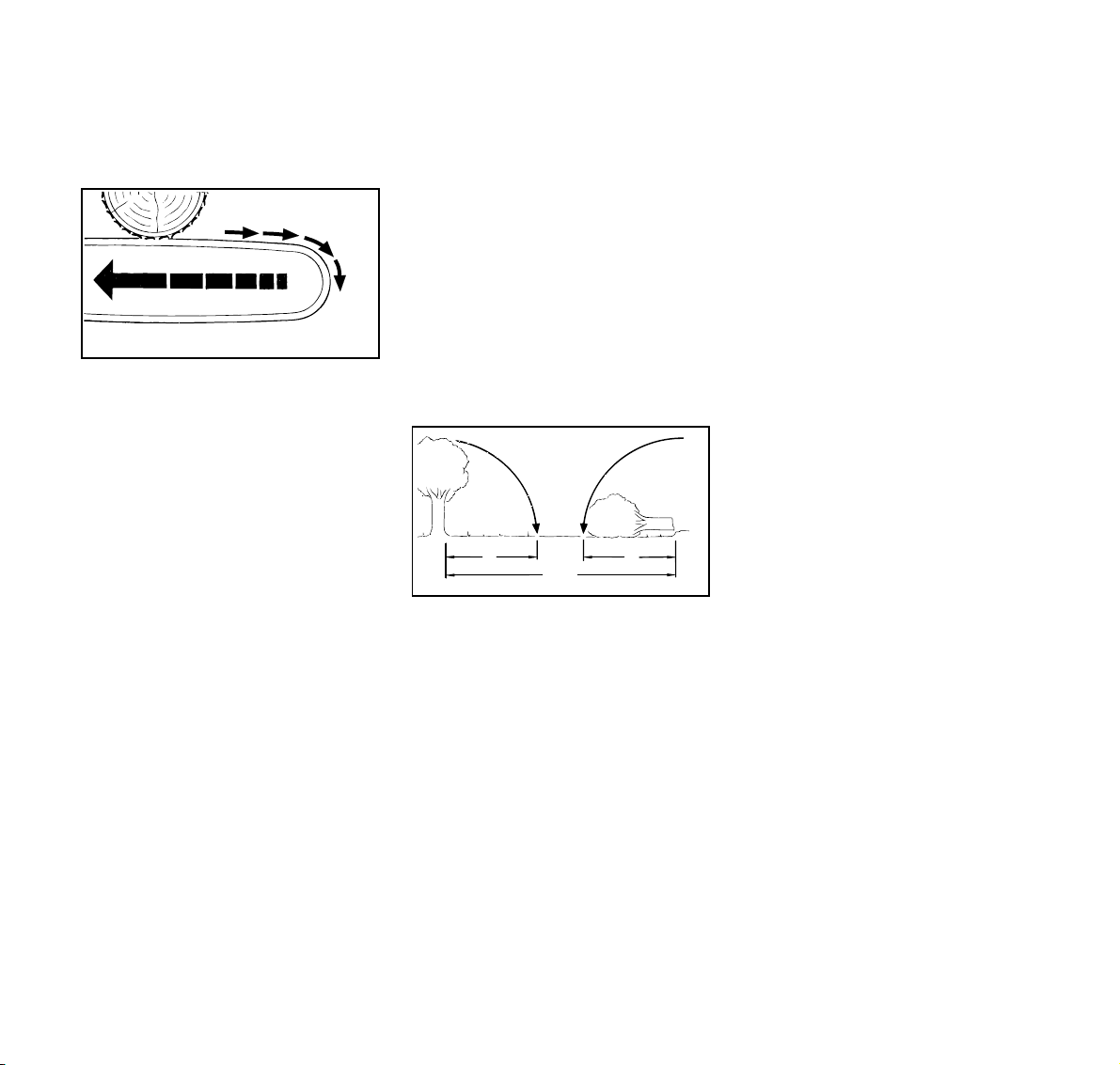

B = Pushback

B

Pushback occurs when the chain on the

top of the bar is suddenly pinched,

caught or encounters a foreign object in

the wood. The reaction of the chain

drives the saw straight back toward the

operator.

Felling and limbing

Do not attempt felling or limbing unless

you have been trained in the necessary

techniques.

Observe local regulations on felling

techniques.

Bystanders must not be allowed in the

felling area – other than helpers.

001BA038 KN

Make sure no-one is endangered by the

falling tree – the noise of your engine

may drown any warning calls.

1

1 1

Maintain a distance of at least 21/2 tree

lengths from next felling site.

/

2

1

/

2

2

Determine direction of fall and

escape paths

Select a clearing into which the tree can

fall.

Pay special attention to the following

points:

– The natural lean of the tree.

– Any unusually heavy limb structure,

damage to tree.

– The wind direction and speed – do

not fell in high winds.

– Direction of slope.

– Neighboring trees.

– Snow load.

– Check the general condition of the

tree. Take particular care with dry or

damaged trees (decayed or rotted).

001BA088 LÄ

11MS 380

Page 12

English

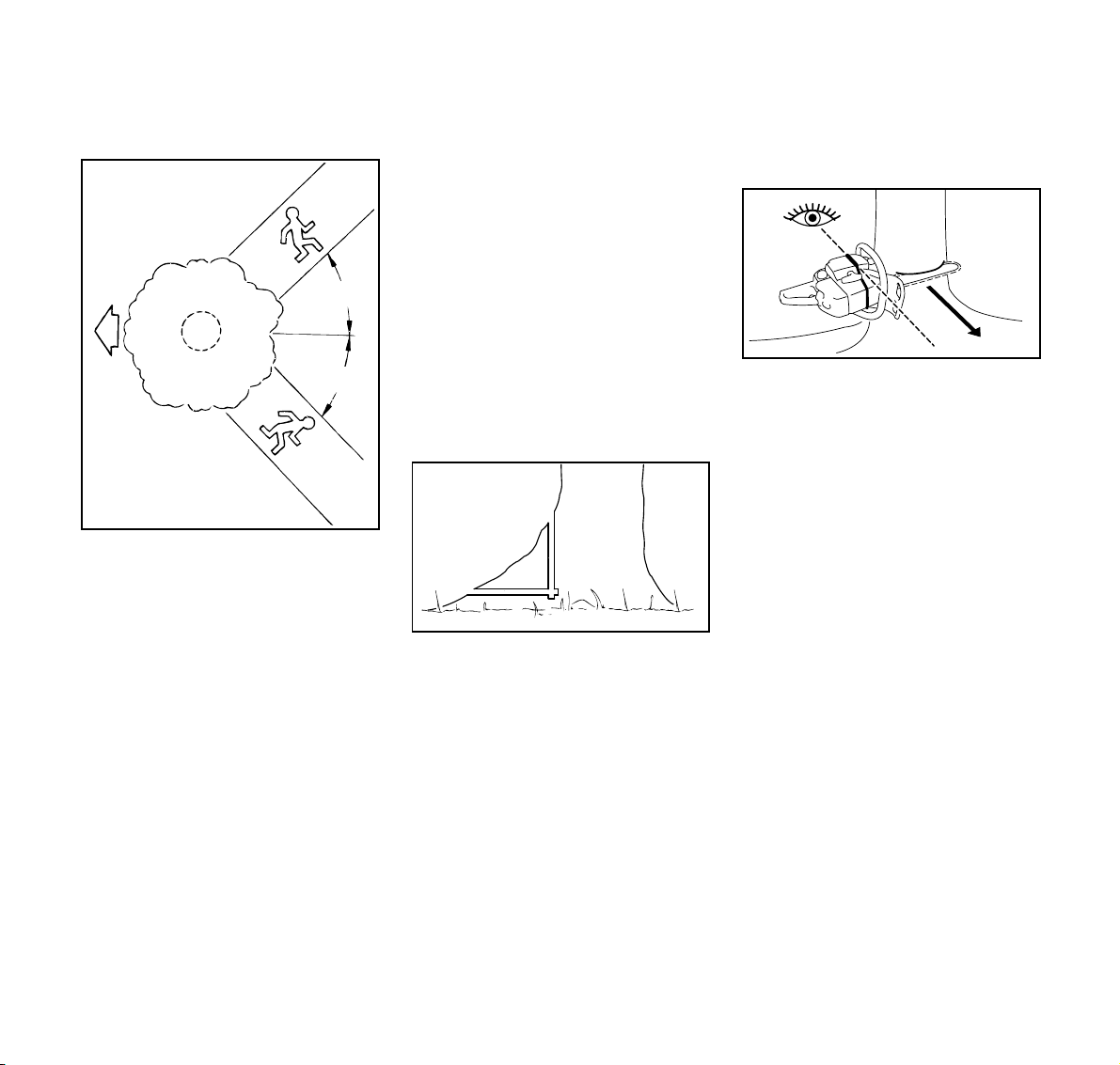

B

45°

A

45°

B

A = Direction of fall

B = Escape paths

– Establish paths of escape for

everyone concerned – opposite to

direction of fall at about 45°.

– Remove all obstacles from escape

paths.

– Place all tools and equipment a safe

distance away from the tree, but not

on the escape paths.

– Always keep to the side of the falling

tree. When the tree starts to fall,

withdraw the bar, shut off the engine

and walk away on the preplanned

escape path.

– On steep slopes, prepare escape

paths parallel to the slope.

– Watch out for falling limbs and pay

attention to crown.

Preparing work area at base of tree

– First clear the tree base and work

area from interfering limbs and

brush – safe footing for all persons

concerned.

– Clean lower portion of tree base

with an axe. Sand, stones and other

foreign objects will dull the saw

chain.

001BA040 KN

– Remove large buttress roots: Make

vertical cut first, then horizontal –

but only if tree is in sound condition.

Making felling notch

When making the felling notch, make

use of the gunning sight on the shroud

and fan housing to check the planned

direction of fall.

Position your saw so that the gunning

sight points in exactly in the direction

you want the tree to fall.

There are several permissible ways of

making the horizontal and angled cuts –

observe country-specific regulations on

felling techniques.

001BA146 KN

STIHL recommends the following

sequence:

001BA153 KN

12

MS 380

Page 13

English

C

C

C = Felling notch determines the

direction of fall

: Make the horizontal cut – check the

direction of fall with the gunning

sight.

: Make top cut at an angle of about

45°.

: Check the felling notch and correct it

if necessary.

Important points:

– Felling notch at a right angle to

planned direction of fall.

– As close as possible to the ground.

1

– Cut to a depth of about

the trunk diameter.

/5 to 1/3 of

001BA143 KN

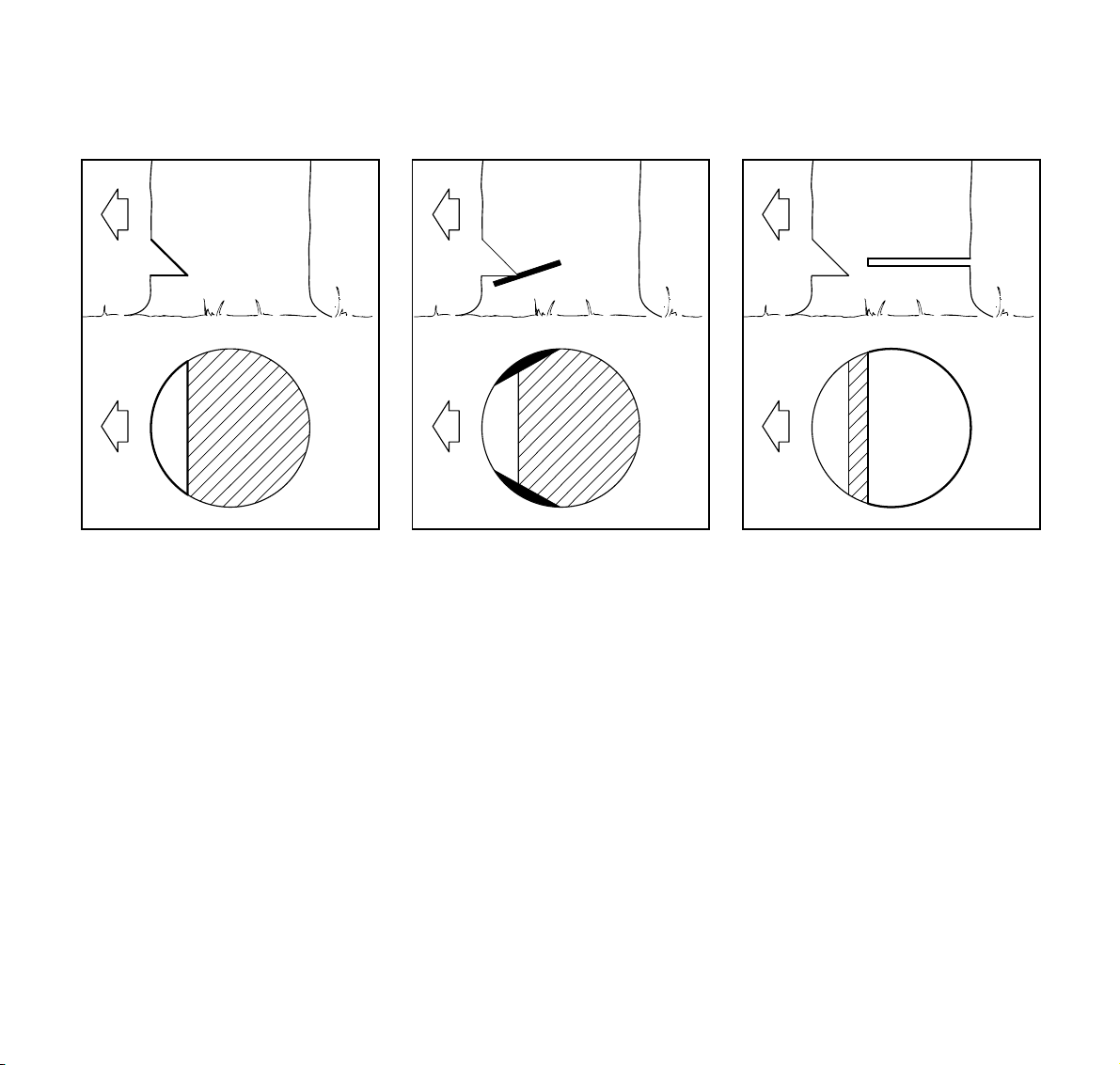

Sapwood cuts

Sapwood cuts help prevent long-fibered

wood splintering when the tree falls.

Apply the cuts at both sides of the trunk

at the same height as the bottom of the

felling notch, to a depth of about

the trunk diameter. On large diameter

trees, cut to no more than the width of

the guide bar.

Do not use sapwood cuts on diseased

trees.

1

/10 of

D

001BA150 KN

Felling cut

Shout a warning before starting the

felling cut.

– Make the felling cut (D) slightly

higher than bottom of felling notch.

– Cut horizontally.

– Leave approx.

uncut. This is the hinge.

1

/10 of tree diameter

D

001BA144 KN

13MS 380

Page 14

English

E

1

E

Drive wedges into the felling cut in good

time – use only wooden, aluminum or

plastic wedges – never steel, which can

damage the chain and cause kickback.

– The hinge (E) helps control the

falling tree.

– Do not cut through the hinge – you

could lose control of the direction of

fall – this could result in an accident.

14

001BA145 KN

– If the trunk is rotten, leave a wider

hinge.

Shout a warning immediately before the

tree falls.

Small diameter trees:

simple fan cut

Apply the spiked bumper behind the

hinge – pivot the saw around this point –

only as far as the hinge. The spiked

bumper rolls against the trunk.

001BA147 KN

Large diameter trees:

sectioning method

If the diameter is greater than the length

of the guide bar, use the sectioning

method.

Use the spiked bumper as a pivot –

avoid repositioning the saw more than

necessary.

First cut (1):

Nose of guide bar should enter wood

just behind the hinge – hold the saw

horizontally and swing it as far as

possible.

001BA148 KN

MS 380

Page 15

English

2

3

When repositioning for the next cut (2),

keep the guide bar fully engaged in the

kerf to keep felling cut straight – apply

the spiked bumper.

Last cut (3):

Apply the spiked bumper as for the

simple fan cut.

Do not cut through the hinge!

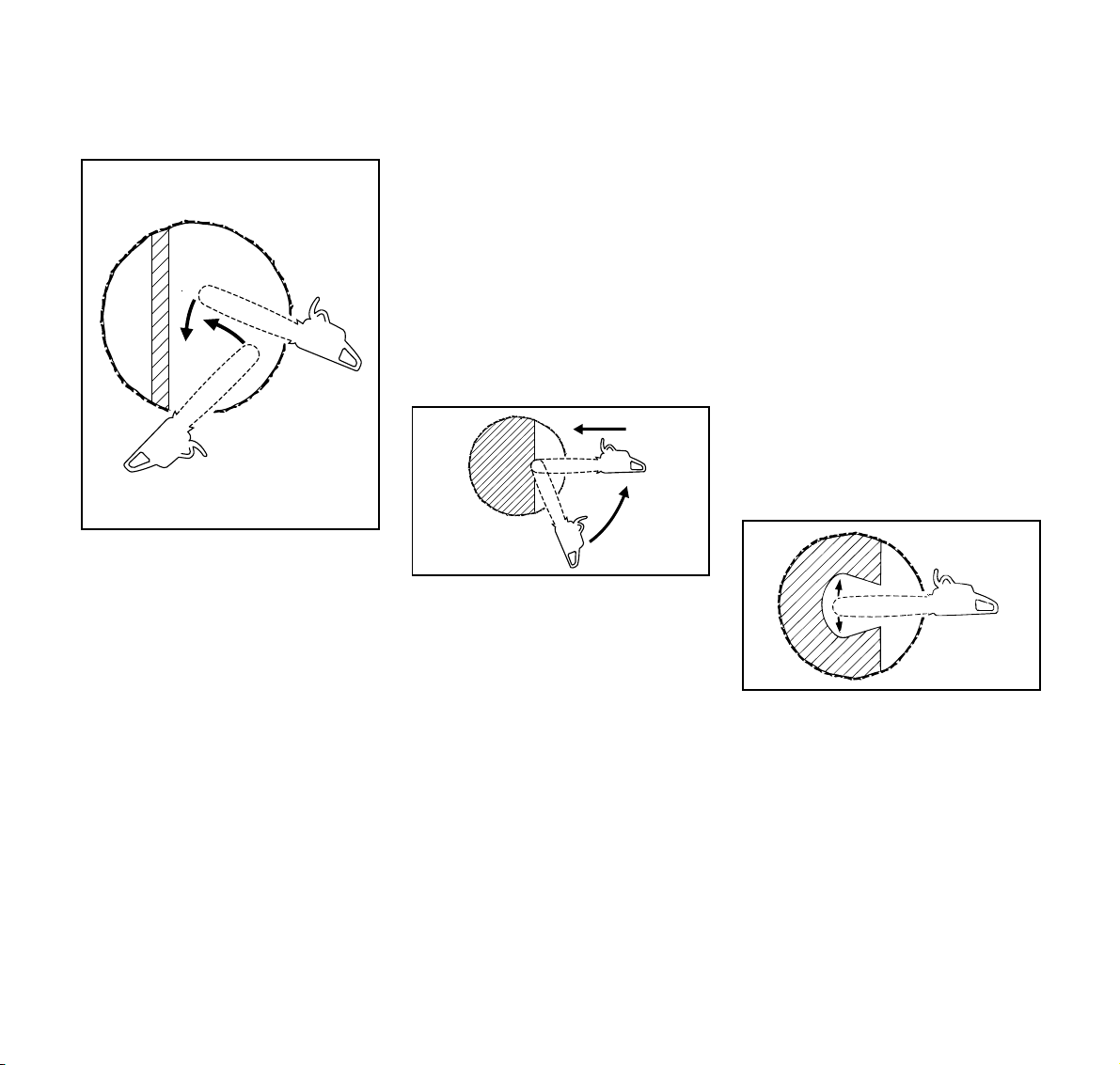

Plunge-cutting

Do not attempt plunge-cutting unless

you are experienced in this cutting

technique.

– Use a low kickback chain and be

extremely cautious.

– For heartwood cut.

– For felling leaners.

– For relieving cuts during bucking.

– For DIY projects.

001BA149 KN

5

4

Begin cut by applying lower portion of

the guide bar nose (4) – do not use

upper portion because of risk of

kickback. Cut until depth of kerf is twice

the width of the guide bar.

Swing saw slowly (5) into plunge-cutting

position. Take care because of the risk

of kickback or pushback.

Heartwood cut

Perform heartwood cut

– if tree diameter is more than twice

the length of the guide bar.

– if a large portion of heartwood

remains uncut on large diameter

trees.

– on trees that are difficult to fell (oak,

beech), to prevent heartwood

splintering and maintain planned

direction of fall.

6

– on soft deciduous trees to relieve

tension in lying log and prevent

slivers in the center of the hinge

being torn out of the log.

001BA154 KN

001BA089 LÄ

: Begin plunge cut by inserting the

bar in the felling notch and then

enlarge the cut to both sides.

Make the plunge cut (6) very carefully.

Danger of pushback.

15MS 380

Page 16

English

Exercise extreme caution

– with leaners

– with trees that have fallen

unfavorably between other trees

and are under strain

– when working in blowdown areas.

Do not work with the chainsaw in such

circumstances. Use block and tackle,

cable winch or tractor.

Pull out exposed and cleared logs.

Select clear area for cutting.

Dry or damaged trees (decayed or

rotted) represent a considerable danger

that is difficult or almost impossible to

assess. Use aids such as block and

tackle, cable winch or tractor

When felling in the vicinity of roads,

railways, power lines, etc.

Take extra precautions. If necessary,

inform the police, utility company or

railway authority

Limbing

– Use a low kickback chain.

– Work with the saw supported

wherever possible.

– Do not stand on the log while

limbing.

– Do not work with the bar nose.

– Watch for limbs which are under

tension.

– Never attempt to cut several limbs

at once.

When cutting small logs

– Use a sturdy and stable support –

sawhorse.

– Never hold the log with your leg or

foot.

– Never allow another person to hold

the log or help in any other way.

Lying or standing logs under tension

1

2

001BA151 KN

2

1

001BA152 KN

Always start relieving cut (1) at the

compression side, then perform the

bucking cut (2) at the tension side – the

saw will otherwise pinch or kick back.

If not otherwise possible, make the

bucking cut from the bottom upwards

(underbuck) – be wary of pushback.

16

Lying logs must not touch the ground at

the point where the cut is made –

this will damage the chain.

MS 380

Page 17

Mounting the Bar and Chain

English

1

a

t = a : 2

You can run chains of different pitches

on this chainsaw – depending on the

chain sprocket (see “Specifications”):

The chain pitch (1) must match the pitch

of the sprocket and the guide bar (for

Rollomatic). The drive link gauge (2)

must match the bar groove width (3).

The pitch is marked on the chain

sprocket and guide bar in inches

(e.g. 3/8 or .325). The groove width

is marked on the guide bar in

millimeters (e.g. 1.6).

If non-matching components of the

wrong pitch or drive link gauge are

run together on the same machine

they may be damaged beyond

repair after a short period of

operation.

2

3

001BA105 KN

: Unscrew the nuts and take off the

chain sprocket cover.

4

5

: Turn screw (4) counterclockwise

until the tensioner slide (5) butts

against left end of housing slot.

143BA034 KN

: Disengage the chain brake: Pull

hand guard (6) toward front handle.

001BA107 KN

Wear work gloves to protect your

hands from the sharp cutters.

: Fit the chain – start at the bar nose.

6

001BA108 KN

143BA003 KN

17MS 380

Page 18

English

9

: Fit the guide bar over the studs (7) –

cutting edges on top of bar must

point to right – and engage the

peg of the tensioner slide in locating

hole (8) – place the chain over

sprocket (9) at the same time.

: Now turn tensioning screw (10)

clockwise until there is very little

chain sag on the underside of the

bar – and the drive link tangs are

located in the bar groove.

: Refit the sprocket cover –

and screw on the nuts only fingertight.

: Go to “Tensioning the Saw Chain”.

7

7

10

8

Tensioning the Saw Chain

1

001BA109 KN

Retensioning during cutting work:

: Shut off the engine first –

and then loosen the nuts.

: Hold the bar nose up and use

screwdriver to turn tensioning screw

(1) clockwise until chain fits snugly

against the underside of the bar.

: While still holding the bar nose up,

tighten down the nuts firmly.

: Go to chapter “Checking Chain

Tension”.

A new chain has to be retensioned more

often than one that has been in use for

some time.

: Check chain tension frequently –

see chapter "Operating

Instructions".

Checking Chain Tension

133BA024 KN

: Shut off the engine.

: Wear work gloves.

: Chain must fit snugly against the

underside of the bar – and, with the

chain brake disengaged, it must still

be possible to pull the chain along

the bar by hand.

: If necessary, retension the chain.

A new chain has to be retensioned more

often than one that has been in use for

some time.

Check chain tension frequently – see

"Operating Instructions".

143BA007 KN

18

MS 380

Page 19

Fuel

English

Your engine requires a mixture of

gasoline and engine oil.

The quality of these constituents and the

mix ratio have a decisive influence on

the function and service life of the

engine.

Unsuitable fuels or lubricants or mix

ratios other than those specified

may result in serious damage to the

engine (piston seizure, rapid rate of

wear, etc.).

Gasoline

Use only high-quality mid-grade

gasoline with a minimum octane rating

of 90. If the octane rating of the midgrade gasoline in your area is lower, use

premium fuel – leaded or unleaded.

For health and environmental

reasons, you should give

preference to unleaded gasoline.

If your machine is equipped with a

catalytic converter, you must use

unleaded gasoline.

A few tankfuls of leaded gasoline

will greatly reduce the efficiency of

the catalytic converter.

Engine Oil

Use only quality two-stroke engine oil.

We recommend STIHL two-stroke

engine oil since it is specially

formulated for use in STlHL engines

and guarantees a long engine life.

Use only STIHL 50:1 two-stroke

engine oil for the fuel mix in models with

a catalytic converter.

If no STIHL two-stroke engine oil is

available, use only quality two-stroke oil

designed for use in air cooled engines.

Do not use oils designed for water

cooled engines or engines with a

separate lubricating system (e.g.

conventional four-stroke engines).

Poor quality gasoline or engine oil

may damage the engine, sealing

rings, hoses and the fuel tank.

Mixing Fuel

1

2

MIX

Avoid direct skin contact with

gasoline and avoid inhaling

gasoline vapor.

: Use a canister approved for storing

fuel. Pour oil (1) into the canister

first, then add gasoline (2) and mix

thoroughly.

Mix Ratio

STIHL 50:1 two-stroke engine oil:

50 parts gasoline to 1 part oil

Other high-quality two-stroke engine

oils:

25 parts gasoline to 1 part oil

000BA042 KN

19MS 380

Page 20

English

Fueling

Examples

Gasoline

Liters Liters (cc) Liters (cc)

STIHL

engine oil

50:1

Other

high-quality

TC oils

25:1

1 0.02 (20) 0.04 (40)

5 0.10 (100) 0.20 (200)

10 0.20 (200) 0.40 (400)

15 0.30 (300) 0.60 (600)

20 0.40 (400) 0.80 (800)

25 0.50 (500) 1.00 (1000)

Storing Fuel

Fuel mix ages:

Only mix sufficient fuel for a few months

work. Store in approved safety-type fuel

canisters in a dry and safe location.

: Thoroughly shake the mixture in the

canister before fueling your

machine.

Pressure may build up in the

canister – open it carefully.

: Clean the fuel tank and canister

from time to time.

Dispose of remaining fuel and

cleaning fluid properly in

accordance with local regulations

and environment requirements.

: Before fueling, clean the filler cap

and the area around it to ensure that

no dirt falls into the tank.

: Position the machine so that the

filler cap is facing up.

Take care not to spill fuel while fueling

and do not overfill the tank. The STIHL

filler nozzle* is recommended for this

purpose and also helps you avoid

inhaling fuel vapor.

Opening the cap

001BA159 KN

001BA160 KN

: Raise the grip until it is upright.

001BA161 KN

: Turn the cap counterclockwise

(approx. a quarter turn).

: Remove the filler cap.

20

* see “Guide to Using this Manual“

MS 380

Page 21

Chain Lubricant

English

Closing the cap

: Fit the cap - grip upright -marks

must line up.

: Turn the cap clockwise as far as

stop (approx. a quarter turn).

: Fold the grip flush with the top of the

cap.

If the grip does not lie completely flush

with the cap and the detent on the grip

does not engage the recess in the filler

neck, the cap is not properly seated and

tightened and you must repeat the

above steps.

001BA162 KN001BA163 KN

Change the fuel pickup body once

every year

: Drain the fuel tank.

: Use a hook to pull the fuel pickup

body out of the tank and take it off

the hose.

: Push the new pickup body into the

hose.

: Place the pickup body in the tank.

For automatic and reliable

lubrication of the chain and guide

bar – use only an environmentally

compatible quality chain and bar

lubricant. Rapidly biodegradable

STIHL Bioplus is recommended.

Biological chain oil must be resistant

to aging (e.g. STIHL Bioplus) since

it will otherwise quickly turn to resin.

This results in hard deposits that are

difficult to remove, especially in the

area of the chain drive, clutch and

chain. It may even cause the oil

pump to seize.

The service life of the chain and guide

bar depends on the quality of the

lubricant. It is therefore essential to use

165BA003 KN

only a specially formulated chain

lubricant.

21MS 380

Page 22

English

If special chain lubricant is not available,

you may - in an emergency - use an HD

single grade or multigrade engine oil

with a viscosity that suits the prevailing

outside temperature.

Do not use waste oil!

Medical studies have shown that

renewed contact with waste oil can

cause skin cancer. Moreover, waste

is environmentally harmfull!

Waste oil does not have the

necessary lubricating properties

and is unsuitable for chain

lubrication.

Filling Chain Oil Tank

: Thoroughly clean the oil filler cap

and the area round it to ensure that

no dirt falls into the tank.

: Remove the filler cap.

: Refill the chain oil tank every time

you refuel.

: Close the filler cap.

There must still be a small amount of oil

in the oil tank when the fuel tank is

empty.

If the oil tank is still partly full, the reason

may be a problem in the oil supply

system: Check chain lubrication, clean

the oilways, contact your STlHL dealer

for assistance if necessary.

Checking Chain Lubrication

001BA158 KN

143BA024 KN

The saw chain must always throw off a

small amount of oil.

Never operate your saw without

chain lubrication. If the chain runs

dry, the whole cutting attachment

will be irretrievably damaged within

a very short time.

Always check chain lubrication and

oil level in tank before starting work.

Every new chain has to be broken in for

about 2 to 3 minutes.

After breaking in chain, check chain

tension and adjust if necessary – see

“Checking Chain Tension”.

22

MS 380

Page 23

Chain Brake

Locking chain with chain brake

– in an emergency

– when starting

– at idling speed

The chain is stopped and locked when

the hand guard is pushed toward the bar

nose by the left hand –

or when brake is activated by inertia in

certain kickback situations.

143BA011 KN

Releasing the chain brake

: Pull the hand guard back toward the

front handle.

Always disengage chain brake

before accelerating engine and

before starting cutting work. The

only exception to this rule is when

you check operation of the chain

brake.

High revs with the chain brake

engaged (chain locked) will quickly

damage the powerhead and chain

drive (clutch, chain brake).

The chain brake is also activated by

the inertia of the front hand guard

if the kickback force of the saw is high

enough:

The hand guard is accelerated toward

the bar nose – even if your left hand is

not behind the hand guard, e.g. during

felling cut.

The chain brake will operate only if the

hand guard has not been modified in any

way.

Check operation of chain brake

Before starting work:

Run engine at idle speed, engage the

chain brake (push hand guard toward

143BA012 KN

bar nose). Accelerate up to full throttle

for no more than 3 seconds – the chain

must not rotate. The hand guard must be

free from dirt and move freely.

English

23MS 380

Page 24

English

Chain brake maintenance

The chain brake is subject to normal

wear. It is necessary to have it serviced

and maintained regularly by trained

personnel, such as your STIHL servicing

dealer, at the following intervals:

Full-time professional

users: every 3

months

Semi-professional

users (in agriculture

and construction): every 6

months

Hobby and

occasional users: every 12

months

Information Before You Start

1

2

3

4

The four positions of the

Master Control lever

1 = Engine off –

ignition is switched off

2 = Normal run position –

engine runs or can fire

To move the Master Control lever from 2

to 3 or 4, press down the throttle trigger

interlock and squeeze throttle trigger at

the same time.

3 = Warm start – this position is used to

start a warm engine. The Master

Control lever moves to the normal

run position as soon as the throttle

trigger is squeezed.

4 = Cold start – this position is used to

start a cold engine.

Starting / Stopping the Engine

1

215BA001 KN

: Observe safety precautions – see

chapter on "Safety Precautions".

: Push hand guard (1) forward:

The chain is now locked.

Press down trigger interlock (2) and

squeeze throttle trigger (3) at the

same time.

Set the Master Control to:

Position 4 if engine is cold.

Position 5 if engine is warm

(also use position 5 if the engine has

been running but is still cold)

5

4

2

3

215BA002 KN

24

MS 380

Page 25

English

: Place your saw on the ground.

: Make sure you have a firm footing –

check that chain is not touching any

object or the ground.

Bystanders must be well clear of the

general work area of the saw.

: Hold the saw firmly on the ground

with your left hand on the front

handle – your thumb should be

under the handlebar.

: Put your right foot into the rear

handle and press down.

143BA018 KN

Alternative method of starting:

: Hold the rear handle tightly between

your legs, just above the knees.

: Hold the front handle firmly with

your left hand – your thumb should

be under the handlebar.

143BA019 KN

: Pull the starter grip slowly with your

right hand until you feel it engage –

then give the grip a brisk strong pull

and push down the front handle at

the same time.

Do not pull out the starter rope all

the way – it might otherwise break.

: Do not let the starter grip snap back

– guide it slowly and vertically into

the housing so that the starter rope

can rewind properly.

If the engine is new, pull the starter

several times to prime the fuel system.

143BA020 KN

25MS 380

Page 26

English

At very low outside temperatures:

: Allow engine to warm up at part

throttle.

9

5

7

8

When engine begins to fire:

: Move Master Control lever (7) to

position 5 and continue cranking.

: As soon as engine runs,

immediately blip the throttle trigger

(8) – the Master Control lever (7) will

move to the run position 9 and the

engine will settle down to idling

speed.

.

As the chain brake is still engaged,

the engine must be returned to

idling speed immediately – or the

engine and chain brake might

otherwise be damaged.

215BA003 KN

: Pull the hand guard back toward

the front handle:=

The chain brake is now disengaged

– your saw is ready for operation.

Always disengage the chain brake

before accelerating the engine.

High revs with the chain brake

engaged (chain locked) will quickly

damage the powerhead and chain

drive (clutch, chain brake).

: Observe safety precautions.

: Always check operation of chain

lubrication before starting work.

To shut down the engine:

: Move Master Control lever to c

If fuel tank has been run until dry

and then refueled:

: Pull starter rope several times until

fuel system is primed.

: Now start the engine.

143BA012 KN

26

MS 380

Page 27

Operating Instructions

English

If the engine doesn’t start:

If you did not move the Master Control

lever to the "warm start" position quickly

enough after the engine began to fire,

the combustion chamber has flooded.

11

10

7

: Move Master Control (7) to run

position.

: Loosen knob (10) in direction of

arrow.

: Remove carburetor box cover (11).

: Pull off the spark plug boot.

: Unscrew and dry off the spark plug.

: Set the Master Control lever to c

: Press down the trigger interlock

lever – open the throttle wide and

crank the engine several times with

the starter to clear the combustion

chamber.

: Install the spark plug and connect

the spark plug boot (press it down

firmly) – refit carburetor box cover.

: Set Master Control lever to warm

215BA004 KN

start position – even if engine is

cold.

: Now start the engine.

During break-in period

A factory new machine should not be run

at high revs (full throttle off load) for the

first three tank fillings. This avoids

unnecessary high loads during the

break-in period. As all moving parts

have to bed in during the break-in

period, the frictional resistances in the

215BA005 KN

engine are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

Do not make the mixture leaner to

achieve an apparent increase in

power – this could damage the

engine – see “Adjusting

Carburetor”.

Always disengage the chain brake

before opening the throttle. Running

the engine at higher revs with the

chain brake engaged (saw chain at

a standstill) will quickly damage the

engine and chain drive (clutch,

chain brake).

27MS 380

Page 28

English

Oil Quantity Control *

During operation

Check chain tension frequently

A new chain has to be retensioned more

often than one that has been in use for

some time.

Chain cold:

Tension is correct when chain fits snugly

against the underside of the bar and can

still be pulled along the bar by hand.

Retension if necessary – see

“Tensioning the Saw Chain”.

Chain at operating temperature:

The chain stretches and begins to sag.

The drive links must not come out of the

bar groove – the chain may otherwise

jump off the bar.

Retension the chain – see “Tensioning

the Saw Chain”!

Always slacken off the chain after

finishing work. The chain contracts

as it cools down. If it is not

slackened off, it can damage the

crankshaft and bearings.

After long period of full-throttle

operation

Allow engine to run for a short while at

idle speed so that engine heat can be

dissipated by flow of cooling air. This

protects engine-mounted components

(ignition, carburetor) from thermal

overload.

After finishing work

: Slacken off the chain if you have

retensioned it at operating

temperature during cutting work.

The chain contracts as it cools

down. If it is not slackened off, it

could damage the crankshaft and

bearings.

Storing your saw for a short period:

Wait for engine to cool down. To avoid

condensation, fill the fuel tank and keep

the machine in a dry place, well away

from sources of ignition, until you need it

again.

Storing for a long period:

See “Storing the Unit”!

1

001BA157 KN

Different quantities of oil are required for

different bar lengths, types of wood and

cutting techniques.

: Use the adjusting screw (1) (on

underside of machine) to vary the

oil feed rate as required.

: E = Ematic position, medium oil flow

rate - turn adjusting screw to "E"

(Ematic position)

: To increase oil feed – turn adjusting

screw clockwise.

: To reduce oil feed – turn adjusting

screw counter-clockwise.

Your chain must always be wetted

with a film of lubricant.

28

* Special accessory

MS 380

Page 29

English

Taking Care of Guide Bar

2

1

: Turn the bar over –

every time you sharpen the chain

and every time you replace the

chain – this helps avoid one-sided

wear, especially at the nose and

underside of the bar.

: Regularly clean

the oil inlet hole (1),

the oilway (2) and

the bar groove (3).

: Measure groove depth –

with scale on filing gauge* – in area

used most for cutting.

3

3

Chain

type

Picco 3/8" P 5.0 mm

Rapid 1/4" 4.0 mm

Rapid 3/8"; 0.325" 6.0 mm

Rapid 0.404" 7.0 mm

If groove depth is less than specified:

: Replace the guide bar.

The drive link tangs will otherwise

scrape along the bottom of the groove –

the cutters and tie straps will not ride on

the bar rails.

001BA119 KN

Pitch Minimum

groove

depth

Cleaning the Air Filter

3

2

1

215BA006 KN

Dirty air filters reduce engine power,

increase fuel consumption and make

starting more difficult.

If there is a noticeable loss of

engine power

: Move the Master Control lever (1)

to the normal run position.

: Loosen knob (2) in direction of

arrow.

: Remove the carburetor box

cover (3).

: Clean away loose dirt from around

the filter.

* see “Guide to Using this Manual”

29MS 380

Page 30

English

Adjusting the Carburetor

5

4

7

6

: Unscrew the slotted nuts (4).

: Remove the filter (5) and separate

the two halves of the filter.

: Take out the screw (6) in the

carburtetor box cover and remove

the prefilter (7).

: Knock the filter out on the palm of

your hand or blow it clear with

compressed air from the inside

outwards.

In case of stubborn dirt:

: Wash the filter components in

STIHL universal cleaner or a clean,

non-flammable solution (e.g. warm

soapy water) and then dry.

: Always replace a damaged filter.

215BA007 KN

: Reassemble the filter components.

215BA008 KN

: Make sure the choke shutter (8) and

torsion spring are properly seated:

The hook of the torsion spring (9)

must engage the slot (arrow).

: Secure the main filter and prefilter in

position.

: Fit the carburetor box cover.

General Information

Your carburetor comes from the factory

with a standard setting.

This is the optimum setting under the

barometric pressure and climatic

conditions at the factory.

It ensures your machine will deliver

maximum power, be fuel efficient and

operate reliably.

Retuning may be necessary if there is a

change in barometric pressure (weather,

altitude), temperature or humidity.

Adjustment of the high speed screw

changes the power output and

maximum RPM of the engine when it is

running off load.

If the mixture is made too lean

there is a risk of engine damage

due to insufficient lubrication and

overheating.

Do not use a brush to clean the

fleece filter.

30

MS 380

Page 31

English

Standard Setting

(without tachometer)

H

L

: Shut off the engine.

: Check the air filter and clean or

replace it if necessary.

: Carefully screw both adjusting

screws down onto their seats

(clockwise).

: Open high speed screw (H) one full

turn.

: Open the low speed screw (L) one

full turn.

If you do not have a tachometer, do

not set the high speed screw any

leaner by turning it beyond the

standard setting.

Fine Tuning

(with tachometer)

: Check the air filter and clean or

replace it if necessary.

: Check chain tension.

: Start the engine and run until it is

warm.

: Adjust idle speed correctly (chain

215BA010 KN

must not rotate).

: Starting from the standard setting,

use the high speed screw (H) to

adjust the maximum engine speed

with a tachometer to 12,500 rpm

(with bar and properly tensioned

chain).

If the mixture is made too lean

there is a risk of engine damage

due to insufficient lubrication and

overheating.

Adjusting Idle Speed

L

Engine stops while idling

: Open the low speed screw (L) one

full turn.

: Turn the idle speed screw (LA)

clockwise until chain begins to run –

then turn it back one quarter of a

turn.

Chain runs when engine is idling

: Open the low speed screw (L) one

full turn.

: Turn the idle speed screw (LA)

counterclockwise until chain stops

running – then turn screw another

quarter turn in the same direction.

215BA011 KN

31MS 380

Page 32

English

Checking the Spark Plug

Erratic idling behavior, poor

acceleration

(even though the low speed screw is

opened one turn)

Idle setting is too lean.

: Turn the low speed screw (L)

counterclockwise until engine

runs and accelerates smoothly.

It is usually necessary to change the

setting of the idle speed screw (LA)

after every correction to the low speed

screw (L).

If engine is down on power, difficult to

start or runs poorly at idle speed, first

check the spark plug.

: Remove the spark plug –

see "Starting / Stopping the Engine".

: Clean dirty spark plug.

: Check electrode gap (A) and

readjust if necessary – see

"Specifications".

: Rectify the problems which have

caused fouling of spark plug:

– To much oil in fuel mix.

– Dirty air filter.

– Unfavorable running conditions.

: Fit a new spark plug after

about 100 operating hours – or

sooner if the electrodes are badly

eroded.

Install only suppressed spark plugs

of the type approved by STIHL –

see "Specifications".

To reduce the risk of arcing

and fire:

000BA002 KN

1

000BA045 KN

: If the spark plug comes with a

detachable adapter nut (1), screw it

on firmly.

32

MS 380

Page 33

English

Spark Arresting Screen in Muffler*

3

6

7

2

2

1

4

5

3

On all spark plugs:

: Always press the boot (2) firmly on

to the spark plug (3).

: If the engine is down on power,

check the spark arresting screen in

the muffler.

: Wait for the muffler to cool down.

: Take out the screw (1).

: Remove the spark arresting

000BA050 KN

screen (2).

: Clean the spark arresting screen.

If the screen is damaged or heavily

carbonized, fit a new one.

: Take out the screws (3).

: Remove muffler upper casing (4).

3

215BA015 KN

: Remove the screw (5) inside the

upper casing.

: Bend back the retaining tabs (6)

and pull out the spark arresting

screen (7).

: Clean the spark arresting screen.

If the screen is damaged or heavily

carbonized, fit a new one.

: Install the spark arresting screen in

the reverse sequence.

215BA024 KN

* see "Guide to Using this Manual"

33MS 380

Page 34

English

Replacing Starter Rope and Rewind Spring

1

1

1

: Remove the screws (1).

: Lift the fan housing from the

crankcase and pull it away to

sideways.

2

3

4

: Use a screwdriver or suitable pliers

to carefully remove the spring clip

(2) from the starter post.

: Carefully remove the rope rotor with

washer (3) and pawl (4).

The rewind spring may pop out

during this procedure – take care to

avoid injury.

5

215BA012 KN

6

: Use a screwdriver to pry the rope (5)

out of the starter grip.

215BA013 KN

: Remove the remaining rope from

the rotor and grip, making sure the

sleeve is not pushed out of the grip.

: Thread the new rope through the

top of the starter grip and guide

bushing (6).

: Pull the rope through the rotor and

secure it with a simple overhand

knot.

2

3

4

: Coat rope rotor bearing bore with

resin-free oil.

: Slip rotor over the starter post – turn

it back and forth to engage anchor

loop of the rewind spring.

: Fit the pawl (4) in the rope rotor.

: Fit the washer (3) on the starter

215TI014 KN

post.

: Use a screwdriver or suitable pliers

to install the spring clip (2) on the

starter post and engage it on the

pawl’s peg – the spring clip must

point clockwise as shown in the

illustration.

215BA013 KN

34

MS 380

Page 35

English

Tensioning the Rewind Spring

: Make a loop in the unwound starter

rope and use it to turn the rope rotor

seven full revolutions in the

direction of the arrow.

: Hold the rotor steady – pull out and

straighten the twisted rope.

: Release the rope rotor.

: Let go of rope slowly so that it winds

onto the rotor.

The starter grip must locate firmly in the

rope guide bushing. If the grip droops to

one side: Increase spring tension by

adding one more turn.

When the starter rope is fully extended it

must still be possible to rotate the rotor

another half turn. If this is not the case,

the spring is overtensioned and could

break.

Replacing a Broken Rewind

Spring

: Remove the rope rotor.

: Remove the spring housing and

parts of the spring.

The bits of spring might still be

under tension and could fly apart

215BA016 KN

when you take them out of the fan

cover. To reduce risk of injury, wear

eye and face protection and work

gloves.

: Use a screwdriver to carefully

remove the parts of the spring.

: Lubricate the new spring with a few

drops of non-resinous oil.

215BA017 KN

: Fit the new spring housing – bottom

plate must face up – engage outer

spring loop on lug.

: Refit the rope rotor.

: Tension the rewind spring.

: Refit the fan housing and tighten it

down firmly.

: If the spring pops out of the housing

during installation: Refit it in the

counterclockwise direction, starting

outside and working inwards.

: Take one turn of rope off the rotor in

such a case.

35MS 380

Page 36

English

Storing the Machine Checking and Replacing

Chain Sprocket

For periods of about 3 months or longer:

: Drain and clean the fuel tank in a

well ventilated area.

: Run engine until carburetor is dry,

this helps prevent the carburetor

diaphragms sticking together.

: Remove the saw chain and guide

bar, clean them and spray with

corrosion inhibiting oil.

: Thoroughly clean the unit,

pay special attention to the cylinder

fins and air filter.

: If you use a biological chain and bar

lubricant, e.g. STIHL BioPlus,

completely fill the chain oil tank.

: Store the unit in a dry and high or

locked location, out of the reach of

children and other unauthorized

persons.

: Remove the chain sprocket cover,

chain and guide bar.

: Disengage the chain brake:

Pull hand guard toward the front

handle.

Replacing the Chain Sprocket

– Replace the chain sprocket after

using two Oilomatic chains.

– Replace sooner if the wear marks

on the sprocket are deeper than

approx. 0.5 mm since this would

reduce the life of the chain. You can

use a reference gauge (Special

Accessories) to check the depth of

the wear marks on sprockets.

It is best to use two chains in

rotation with one sprocket.

Use only original STIHL chain sprockets

to ensure correct operation of the chain

brake.

Rim Sprocket

: Use a screwdriver to remove

the E-clip (1).

: Take off the washer (2).

: Examine the splines on the clutch

001BA121 KN

drum – if wear marks are severe,

install a new clutch drum.

: Replace the rim sprocket (3)

with cavities facing outward.

: Refit the washer and E-clip on the

crankshaft.

36

MS 380

Page 37

English

Spur Sprocket, Clutch Drum

7

5

6

8

4

5

: Use a screwdriver to remove

the E-clip (1).

: Take off the washer (2).

: Use circlip pliers (Special

Accessories) to remove the

circlip (4).

: Take out the screws (5).

: Remove the side plate (6) and

cover (7) with cover washer (8).

2

1

10

12

11

215BA019 KN

: Remove the oil pump drive worm (9)

by rotating it clockwise while pulling

it off the pump shaft.

: Remove the spur sprocket or clutch

drum (10) with sprocket, spur gear

(11) and needle cage (12) from the

crankshaft.

Check serviceability of spur gear

and worm. Replace any worn or

damaged parts.

Install in the reverse sequence:

: Clean the stub of the crankshaft and

needle cage and lubricate with

STlHL grease (Special

Accessories).

: Push the needle cage, spur

9

215BA020 KN

sprocket and clutch drum with spur

gear onto the crankshaft.

: Engage the oil pump drive worm by

rotating it counterclockwise while

pushing it onto the pump shaft.

: Lubricate the worm and spur gear

with STlHL grease (Special

Accessories).

: Fit the cover, cover washer and side

plate, fit screws and tighten down

firmly.

: Install the circlip on the spur

sprocket – each end of the ring must

locate on the top of a tooth.

: Replace the rim sprocket (3)

with cavities facing outward.

: Fit the washer and E-clip on the

crankshaft.

37MS 380

Page 38

English

Maintaining and Sharpening Saw Chain

Correctly sharpened chain

A properly sharpened chain slices

through wood effortlessly and requires

very little feed pressure.

Do not work with a dull or damaged

chain as it will increase the physical

effort required, produce unsatisfactory

results and a higher rate of wear.

: Clean the chain.

Check the chain

:

links and damaged rivets.

: Replace any damaged or worn parts

of the chain and match the new

parts to the shape and size of the

original parts.

It is absolutely essential to comply

with the angles and dimensions

specified below. If the saw chain is

incorrectly sharpened – and in

particular if the depth gauge is set

too low – there is a risk of increased

kickback of the chainsaw, with

resulting risk of injury.

for cracks in the

3/8

3

The chain pitch (e.g.

the depth gauge end of each cutter.

Use only special saw chain

sharpening files. Other files have the

wrong shape and cut.

Select file diameter according to chain

pitch – see table “Sharpening Tools”.

You must observe certain angles when

resharpening the chain cutter.

/8") is marked on

A

B

689BA020 KN

A = Filing angle

B = Side plate angle

Chain type Angle (°)

Rapid-Micro (RM) 30 85

Rapid-Super (RS) 30 60

Picco-Micro (PM/PMN) 30 85

Cutter shapes:

Micro = Semi-chisel

Super = Full chisel

The specified angles A and B are

obtained automatically if the

recommended files or sharpening tools

and correct settings are used.

689BA021 KN

AB

38

MS 380

Page 39

English

Furthermore, the angles must be the

same on all cutters. If angles are

uneven: Chain will run roughly, not in a

straight line, wear quickly and finally

break.

As these requirements can be met only

after sufficient and constant practice:

: Use a file holder*

A file holder must be used for manual

resharpening (see table "Sharpening

Tools"). The correct filing angles are

marked on the file holder.

For checking angles

90°

85°70°

80°

60°

35°

30°

0°

10°

Use a STlHL filing gauge* (see table

"Sharpening Tools"). This is a universal

689BA025 KN

tool for checking the filing and side plate

angles, depth gauge setting and cutter

length. It also cleans the guide bar

groove and oil inlet holes.

File correctly

: Select sharpening tools according

to chain pitch.

: Clamp the bar in a vise if necessary.

: Lock the chain – push hand guard

forward.

: To rotate the chain – pull hand guard

against handle.

: Sharpen chain frequently, take

away as little metal as possible –

two or three strokes of the file are

usually enough.

90°

689BA018 KN

689BA022 KN

689BA043 KN

: Hold the file horizontally (at right

angle to side of guide bar) and file

according to the angles marked on

the file holder. Rest the file holder on

the top plate and depth gauge.

* see “Guide to Using this Manual”

* see “Guide to Using this Manual”

39MS 380

Page 40

English

: Always file from the inside to the

outside of the cutter.

: The file only sharpens on the

forward stroke –

lift the file off the cutter on the

backstroke.

: Avoid touching the tie straps and

drive links with the file.

: Rotate the file at regular intervals

while filing to avoid one-sided wear.

: Use a piece of hardwood to remove

burrs from cutting edge.

: Check angles with the filing gauge.

All cutters must be the same length.

If the cutters are not the same length,

they will have different heights. This

makes the chain run roughly and can

cause it to break.

: Find the shortest cutter and then file

all other cutters back to the same

length. This can be very time

consuming – it is best to have it

done in the workshop on an electric

grinder.

Depth gauge setting

a

The depth gauge determines the height

at which the cutter enters the wood and

thus the thickness of the chip removed.

Specified distance or setting between

depth gauge and cutting edge = a:

This setting may be increased by 0.2mm

(0.008") for cutting softwood in mild

weather season – no frost.

Chain pitch Depth gauge

setting “a“

Inch (mm) mm (inch)

1

/

4

3

/8 PMN (9.32) 0.45 (0.018)

3

/8 PM (9.32) 0.65 (0.026)

0.325 (8.25) 0.65 (0.026)

3

/

8

0.404 (10.26) 0.80 (0.031)

(6.35) 0.65 (0.026)

(9.32) 0.65 (0.026)

Lowering depth gauges

The depth gauge setting is reduced

when the chain is sharpened.

: Use a filing gauge to check the

setting every time you sharpen the

chain.

689BA023 KN

1

689BA047 KN

: Place a filing gauge (1) that

matches the chain pitch on the

chain – if the depth gauge projects

from the filing gauge, the depth

gauge has to be lowered.

40

689BA051 KN

: File down the depth gauge until it is

level with the filing gauge.

MS 380

Page 41

English

On PM1 and RM2 chains the rear

hump of the tie strap (with service

marking) is lowered along with the

depth gauge. The other parts of the

triple-humped tie strap must not be

filed since this may increase the

kickback tendency of the chainsaw.

689BA044 KN

689BA052 KN

: After sharpening, clean the chain

: File the top of the depth gauge

parallel to the stamped service

marking (see arrow) – but do not

lower the highest point of the depth

gauge in this process.

The kickback tendency of the

: Place filing gauge on the chain –

highest point of depth gauge must

be level with the filing gauge.

thoroughly, remove filings or

grinding dust – lubricate the chain

thoroughly.

: Before long out-of-service period,

clean the chain and store it in a

well-oiled condition.

chainsaw is increased if the depth

gauges are too low.

Sharpening Tools (special accessories)

Chain pitch Round file Ø Round file File holder Filing gauge Flat file

1)

Sharpening kit

inch (mm) mm (inch) Part No. Part No. Part No. Part No. Part No.

1

/

4

3

/8 PMN (9.32) 4.0 (5/32) 5605 772 4006 5605 750 4327 0000 893 4000 0814 252 3356 5605 007 1026

3

/8 P (9.32) 4.0 (5/32) 5605 772 4006 5605 750 4327 1110 893 4000 0814 252 3356 5605 007 1027

0.325 (8.25) 4.8 (

3

/

8

(6.35) 4.0 (5/32) 5605 772 4006 5605 750 4327 1110 893 4000 0814 252 3356 5605 007 1027

3

/16) 5605 772 4806 5605 750 4328 1110 893 4000 0814 252 3356 5605 007 1028

(9.32) 5.2 (13/64) 5605 772 5206 5605 750 4329 1110 893 4000 0814 252 3356 5605 007 1029

0.404 (10.26) 5.5 (7/32) 5605 772 5506 5605 750 4330 1106 893 4000 0814 252 3356 5605 007 1030

2)

1) Use triangular file 0811 421 8971 for PM1 and RM2

2) consisting of file holder with round file, flat file and filing gauge

41MS 380

Page 42

English

Maintenance Chart

Please note that the following maintenance intervals apply for normal

operating conditions only. If your daily working time is longer than normal or

cutting conditions are difficult (very dusty work area, resin-rich wood,

tropical wood etc.), shorten the specified intervals accordingly. If you only

use the saw occasionally, extend the intervals accordingly.

Complete machine

Throttle trigger, trigger interlock, Master

Control

Chain brake

Pickup body/filter in fuel tank

Fuel tank Clean

Chain oil tank Clean

Chain lubrication Check

Saw chain

Guide bar

Chain sprocket Check

Air filter

AV elements (rubber buffers, springs)

Cooling inlets Clean

Cylinder fins Clean

1) STIHL dealer

2) see "Chain brake"

Visual inspection (condition, leaks)

Clean

Check operation XX

Check operation

1)2)

Check

Check

Clean, replace filter element

Replace pickup body

Inspect, also check sharpness

Check chain tension

Sharpen

Check (wear, damage)

Clean and turn over

Deburr

Replace

Clean

Replace

Inspect

1)

Replace

before

starting work

after finishing

work or daily

after each

refueling stop

weekly

monthly

every 12 months

if problem

if damaged

as required

XX

X

XX

X

X

XX

XXX

X

X

X

XX

XX

X

X

X

X

XX

X

XX

X

XXX

X

X

XX

42

MS 380

Page 43

Please note that the following maintenance intervals apply for normal

operating conditions only. If your daily working time is longer than normal or

cutting conditions are difficult (very dusty work area, resin-rich wood,

tropical wood etc.), shorten the specified intervals accordingly. If you only

use the saw occasionally, extend the intervals accordingly.

Carburetor

Spark plug Readjust electrode gap

All accessible screws and nuts

(not adjusting screws)

Spark arresting screen* in muffler

Chain catcher

2)

Check idle adjustment – chain must not rotate

Readjust idle

Retighten

Inspect

Clean or replace

Check

Replace

2) Firmly tighten cylinder base screws

of professional saws (3.4 kW or

more) after 10 to 20 hours of

operation

before

starting work

after finishing

work or daily

after each

refueling stop

weekly

XX

X

English

monthly

every 12 months

if problem

if damaged

as required

X

X

X

X

X

X

* see “Guide to Using this Manual“