STIH)

STIHL Series 4149 Powerhead

FS 94

KM 94

SP 92, SP 92 T

2014-10

Contents

RA_593_00_01_03

1. Introduction and

Safety Precautions 2

1.1 Introduction 2

1.2 Safety Precautions 3

2. Specifications 4

2.1 Engine 4

2.2 Fuel System 4

2.3 Ignition System 4

2.4 Tightening Torques 5

3. Troubleshooting 7

3.1 Clutch 7

3.2 Rewind Starter 8

3.3 Ignition System 10

3.4 Carburetor 11

3.5 11

3.6 Engine 15

4. Clutch 16

4.1 Clutch Drum 16

4.2 Clutch 17

5. Engine 19

5.1 Muffler / Spark

Arresting Screen 19

5.2 Leakage Test 20

5.2.1 Preparations 21

5.2.2 Vacuum Test 21

5.2.3 Pressure Test 22

5.3 Oil Seals 22

5.4 Shroud 24

5.4.1 Air guide shroud 25

5.5 Cylinder 26

5.6 Crankshaft 29

5.6.1 Bearings /

Crankcase 32

5.7 Piston 34

5.8 Piston Rings 35

6. Ignition System 36

6.1 Ignition Timing 36

6.2 Install new

ignition module 36

6.3 Testing the

Ignition Module 38

6.3.1 Testing

Ignition Module

with STIHL MDG 1 38

6.4 Spark Plug Boot /

Ignition Lead 38

6.5 Flywheel 39

6.6 Short Circuit Wire 40

6.6.1 Testing 40

6.6.2 Short Circuit Wire

on Engine

– Removing and

Installing 41

6.6.3 Short Circuit Wire and

Contact Springs

on Control Handle

– Removing and

Installing 42

6.6.4 Ground Wire 44

6.6.5 Contact Springs 44

6.7 Ignition System

Troubleshooting 45

7. Rewind Starter 48

7.1 General 48

7.2 Rewind Starter 48

7.3 Pawl / Carrier 49

7.4 ErgoStart /

Rope Rotor 50

7.5 Starter Rope / Grip 51

7.6 Tensioning

the Rewind Spring 52

7.7 Replacing

the Rewind Spring 53

8. AV Elements 55

8.1 Rubber Element 55

9. Control Levers 57

9.1 Control Handle

on Drive Tube

Removing and

Installing 57

9.2 Control Handle for

Bike Handle

Removing and

Installing 58

9.3 Throttle Trigger /

Lockout Lever 59

9.4 Stop switch lever

(momentary contact

switch): 62

9.5 Adjusting Wheel 63

9.6 Adjusting the

Throttle Cable 65

10. Fuel System 67

10.1 Air filter 67

10.2 Filter Housing 67

10.3 Carburetor 68

10.3.1 Leakage Test 70

10.4 Servicing the

Carburetor 71

10.4.1 Metering Diaphragm 71

10.4.2 Inlet Needle 72

10.4.3 Pump Diaphragm 73

10.4.4 Control Valve 74

10.4.5 Adjusting Screws 75

10.5 Adjusting the

Carburetor 76

10.5.1 Basic Setting 76

10.5.2 Adjustments by User 78

10.6 Spacer Flange 79

10.7 Tank Vent 80

10.7.1 Testing 80

10.7.2 Removing and

Installing 81

10.8 Fuel Intake 82

10.8.1 Pickup Body 82

10.8.2 Fuel Hose

on Carburetor 82

10.8.3 Fuel Suction Hose

in Fuel Tank 83

10.8.4 Fuel Hose / Fuel

Return Hose and

Manual Fuel Pump 84

10.9 Fuel Tank 86

10.9.1 Fuel Tank

Removing and

Installing 86

10.9.2 Fuel tank

Replacing 87

10.9.3 Tank Guard (FS 94) 89

11. Special Servicing

Tools 90

12. Servicing Aids 92

q

© ANDREAS STIHL AG & Co. KG, 2014

1Series 4149 Powerhead

1. Introduction and Safety Precautions

1.1 Introduction

This service manual contains

detailed descriptions of all the repair

and servicing procedures specific to

this power tool.

You should make use of the

illustrated parts lists while carrying

out repair work. They show the

installed positions of the individual

components and assemblies.

Refer to the latest edition of the

relevant parts list to check the part

numbers of any replacement parts.

A malfunction on the machine may

have several causes. To help locate

the problem, consult the chapter on

"Troubleshooting" and the

"STIHL Service Training System"

for all assemblies.

Refer to the “Technical Information”

bulletins for engineering changes

which have been introduced since

publication of this service manual.

Technical information bulletins also

supplement the parts list until a

revised edition is issued.

The special tools mentioned in the

descriptions are listed in the chapter

on "Special Servicing Tools" in this

manual. Use the part numbers to

identify the tools in the

"STIHL Special Tools" manual. The

manual lists all special servicing

tools currently available from

STIHL.

Symbols are included in the text and

pictures for greater clarity.

The meanings are as follows:

In the descriptions:

N Action to be taken as shown in

the illustration above the text

– Action to be taken that is not

shown in the illustration above

the text

In the illustrations:

A Pointer

a Direction of movement

@ 4.2 =Reference to another

chapter, i.e. chapter 4.2

in this example.

Always use original STIHL

replacement parts.

They can be identified by the STIHL

part number,

the { logo and the

STIHL parts symbol K

This symbol may appear alone on

small parts.

Storing and disposing of oils

and fuels

Collect fuel or lubricating oil in a

clean container and dispose of it

properly in accordance with local

environmental regulations.

Service manuals and all technical

information bulletins are intended

exclusively for the use of properly

equipped repair shops. They must

not be passed to third parties.

2 Series 4149 Powerhead

1.2 Safety Precautions

If the machine is started up in the

course of repairs or maintenance

work, observe all local and countryspecific safety regulations as well

as the safety precautions and

warnings in the instruction manual.

Gasoline is an extremely flammable

fuel and can be explosive in certain

conditions.

Do not smoke or bring any fire,

flame or other source of heat near

the fuel. All work with fuel must be

performed outdoors only. Spilled

fuel must be wiped away

immediately.

Always perform leakage test after

working on the fuel system and the

engine.

Exercise extreme caution while

carrying out maintenance and repair

work on the ignition system. The

high voltages which occur can

cause serious or fatal accidents.

The chapter on tightening torques

lists all machine components that

have to be tightened to a specific

torque or coated with threadlocking

adhesive. The specifications must

be maintained when tightening

down screws, nuts and other

fasteners in all the procedures

described in this service manual.

Fuel system – hose barb

connectors

Pull off or push on fuel hoses in line

with the connector, preferably by

hand, to ensure the tightness of the

fuel system.

Avoid damaging the hose barb

– do not use sharp-edged pliers,

screwdrivers, etc.

Do not cut open fuel hoses with a

knife or similar tool.

Do not re-use fuel hoses after

removal. Always install new hoses

– fuel hoses can be overstretched

during removal.

Always wear suitable protective

gloves for operations in which

components are heated for

assembly or disassembly. Hot

grease can cause burn injuries. The

lubricants in the components can

become very hot.

Improper handling may result in

burns or other serious injuries.

Always replace damaged parts.

Check disassembled parts for wear

or damage before re-installing –

replace as necessary.

Run the machine only with the

shroud mounted in position – there

is otherwise a risk of injury from the

fanwheel and a risk of engine

damage due to overheating.

Install new fuel hoses either dry or

with the aid of STIHL press fluid,

b 12.

Other press fluids are not approved

and may result in damage to the fuel

hoses.

Coat the ends of the hoses and the

connectors with STIHL press fluid

and then push the new hoses on to

the hose barbs, b 12.

3Series 4149 Powerhead

2. Specifications

2.1 Engine

SP 92, SP 92 T FS 94, KM 94

Displacement: 21.4 cm

3

24.1 cm

3

Bore: 33.0 mm 35.0 mm

Stroke: 25.0 mm 25.0 mm

Engine power to ISO 8893: 0.75 kW (1.0 bhp)

at 8,500 rpm

0.9 kW (1.2 bhp)

at 8,500 rpm

Max. torque

at engine speed (rated): 1 Nm / 5,000 rpm 1.3 Nm / 5,000 rpm

Cut-off speed (rated): 9,800 rpm

1)

9,800 rpm

1)

Idle speed (rated): 2,800 rpm 2,800 rpm

Clutch: Centrifugal clutch without linings Centrifugal clutch without linings

Clutch engages at (rated): 3,850 rpm 3,850 rpm

Crankcase leakage test

at gauge pressure: 0.5 bar 0.5 bar

under vacuum: 0.5 bar 0.5 bar

2.2 Fuel System

Carburetor leakage test at gauge

pressure: 0.8 bar 0.8 bar

Operation of tank vent at gauge

pressure: 0.5 bar 0.5 bar

Fuel: as specified in instruction manual as specified in instruction manual

2.3 Ignition System

Air gap between ignition module and

fanwheel: 0.30 (+ 0.15/- 0.20) mm 0.30 (+ 0.15/- 0.20) mm

Spark plug (resistor type): NGK CMR 6 H

BOSCH USR 4 AC

NGK CMR 6 H

BOSCH USR 4 AC

Electrode gap: 0.5 mm 0.5 mm

1) The engine reaches its maximum RPM and maximum power after the break-in period (5 to 10 tank fillings) –

do not make any changes to the high speed screw (H) during the break-in period.

4 Series 4149 Powerhead

2.4 Tightening Torques

DG and P (Plastoform) screws are used in polymer and light metal components. These screws form a

permanent thread when they are installed for the first time. They can be removed and installed as often as

necessary without impairing the strength of the screwed assembly, providing the specified tightening torque is

observed.

For this reason it is essential to use a torque wrench.

Use the following procedure when refitting a DG or P screw in an existing thread:

Insert the screw in the hole and rotate it counterclockwise until it drops down slightly and engages in the existing

thread. Tighten the screw clockwise to the specified torque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread

and weaken the assembly.

Micro-encapsulated screws and screws coated with threadlocking adhesive:

Before re-installing, clean both threads (screw tap into female thread by hand and then blow out with

compressed air; clean male thread with brush), coat micro-encapsulated screws with medium-strength Loctite

242 or 243, and screws previously coated with threadlocking adhesive with Loctite (see list of screws below).

Power screwdriver setting for polymer: P and DG screws max. 500 rpm.

Do not use an impact wrench for releasing or tightening screws.

Do not mix up screws with and without binding heads.

Fastener Thread size For component Torque

Remarks

Nm

Screw M 5x12 Cover / shroud 5.0 1), 2)

Screw D 5x24 Rewind starter / shroud / cylinder 6.0 1), 2)

Screw D 5x24 Rewind starter / tank housing / crankcase 6.0 1), 2)

Screw P 4x16 Control handle molding, outer / inner 1.3 1), 2)

Screw M 5x12 Control handle clamp/shaft 5.0 1), 2)

Screw P 4x10 Control handle, throttle set wheel / lever /

1.3

inner handle molding

Screw M 5x12 Filter cover / filter housing 5.0

Nut M 5 Filter housing / carburetor 3.5

Screw D 5x12 Sleeve, anti-vibration / drive tube 5)

Screw M 5x20 Sleeve, anti-vibration clamp screw 5.5 1), 2)

Screw M 6x25 Clutch / flywheel 12.0

Screw D 5x24 Crankcase / cylinder 8.0 1), 2)

Screw D 5x24 Crankcase, flywheel side / crankcase, starter

8.0 1), 2)

side

Screw D 5x24 Fan housing / shroud / crankcase 6.0 1), 2)

Screw D 5x24 Fan housing / crankcase 6.0 1). 2)

Carrier M 8x1 Carrier / crankshaft 17,0

Screw D 5x20 Muffler / cylinder 8,0 1). 2)

Nut M 6 Flywheel / crankshaft 12.0 4)

Nut M 8 Flywheel / crankshaft 16.0 4)

5Series 4149 Powerhead

Fastener Thread size For component Torque

Remarks

Nm

Screw D 5x12 Carburetor / throttle cable 3.0

M 10x1 Spark plug / cylinder 12.0

Screw D 4x20 Ignition module / cylinder 4.0 1), 2)

Screw D 5x28 Spacer flange / cylinder 7.0 1), 2)

Remarks:

1) Screws with binding head

2) Waxed screws

3) Micro-encapsulated screws

4) Degrease crankshaft / flywheel and mount oil-free

5) Tighten down until head is seated

6 Series 4149 Powerhead

3. Troubleshooting

3.1 Clutch

Condition Cause Remedy

Working tool stops under full load Clutch shoes badly worn Install new clutch

Clutch drum badly worn Install new clutch drum

Working tool runs when engine

Engine idle speed too high Readjust with idle speed screw LA

is idling

Clutch spring stretched Replace the clutch spring or install

new clutch

Clutch spring broken Replace the clutch spring

Loud noises Clutch spring stretched Replace clutch spring

Clutch drum bearing damaged Replace fan housing

Clutch screws loose Tighten down screws, replace

clutch if necessary and check

tapped holes in flywheel, replace

flywheel if necessary

Clutch shoes worn Install new clutch

7Series 4149 Powerhead

3.2 Rewind Starter

Condition Cause Remedy

Starter rope broken Rope pulled out too vigorously as

far as stop or constantly over the

edge

Normal wear Install new starter rope

Starter rope does not rewind Rewind spring very dirty or

corroded

Insufficient spring tension Check rewind spring and increase

Rewind spring broken Install new rewind spring

Starter rope cannot be pulled out

Spring overtensioned Check rewind spring and reduce

far enough

Starter rope can be pulled out

almost without resistance

Pegs on pawls broken or pawls

worn

(crankshaft does not turn)

Install new starter rope

Clean or replace rewind spring

tension

tension

Replace pawls

Pawl springs fatigued Fit new springs and check pawls,

replace if necessary

Springs not installed correctly Install springs correctly

Lugs on carrier worn Fit new carrier, check pawls and

replace if necessary

Spring loop in ErgoStart spring

housing not attached to carrier

Attach ErgoStart spring loop to

carrier

8 Series 4149 Powerhead

Condition Cause Remedy

Starter rope is difficult to pull or

rewinds very slowly

Starter mechanism is very dirty Thoroughly clean complete starter

mechanism

ErgoStart spring in rope rotor

fatigued

Replace ErgoStart spring, check

carrier and rope rotor, replace if

necessary

At very low outside temperatures:

Lubricating oil on rewind spring

becomes viscous (spring windings

stick together) or moisture has got

onto the rewind spring (spring

windings frozen together)

Coat rewind spring with a small

amount of standard solvent-based

degreasant (containing no

chlorinated or halogenated

hydrocarbons), then pull rope

carefully several times until normal

action is restored

9Series 4149 Powerhead

3.3 Ignition System

Exercise extreme caution while

carrying out maintenance and

repair work on the ignition system.

The high voltages which occur can

cause serious or fatal accidents.

Condition Cause Remedy

Engine runs roughly, misfires,

temporary loss of power

Spark plug boot is loose Press boot firmly onto spark plug

and fit new spring if necessary

Spark plug sooted, smeared with oil Clean the spark plug or replace if

necessary.

If sooting keeps recurring, check air

filter

Fuel/oil mixture

Use correct mixture of fuel and oil

– too much oil

Incorrect air gap between ignition

Set air gap correctly

module and flywheel

Flywheel cracked or

Install new flywheel

damaged or pole shoes have

turned blue

Ignition timing wrong, flywheel out

Install new flywheel

of adjustment

– key in flywheel has sheared off

Weak magnetization in flywheel Install new flywheel

Irregular spark Check operation of lever for stop

function (stop switch) / contact

spring and ignition module.

Damaged insulation or break in

ignition lead or short circuit. Check

ignition lead/module, replace

ignition module if necessary. Check

operation of spark plug, clean or

replace spark plug if necessary.

10 Series 4149 Powerhead

3.4 Carburetor

Condition Cause Remedy

Carburetor floods; engine stalls Inlet needle not sealing

– foreign matter in valve seat or

Remove and clean the inlet needle,

clean the carburetor

cone

Inlet needle worn Fit new inlet needle

Inlet control lever sticking on

spindle

Helical spring not located on nipple

of inlet control lever

Perforated disc on metering

Check the inlet control lever and

replace if necessary

Remove the inlet control lever and

refit it correctly

Fit new metering diaphragm

diaphragm is deformed and

presses constantly against the inlet

control lever

Metered diaphragm deformed Fit new metering diaphragm

Poor acceleration Setting of low speed screw too lean Check basic carburetor setting,

correct if necessary

3.5

Setting of high speed screw too

lean

Check basic carburetor setting,

correct if necessary

Inlet needle sticking to valve seat Remove inlet needle, clean and

refit

Metering diaphragm gasket leaking Fit new diaphragm gasket

Metering diaphragm damaged or

Fit new metering diaphragm

shrunk

Tank vent faulty Fit new tank vent

Leak in fuel hose from tank to

carburetor

Seal connections or install new fuel

hose

11Series 4149 Powerhead

Condition Cause Remedy

Engine loses power during

acceleration

Engine will not idle, idle speed too

high

Jet on the

Clean the carburetor

low speed screw L dirty –

insufficient volume of fuel, engine

running too lean

Fuel strainer dirty Clean fuel strainer and carburetor

Control valve opened too wide by

idle speed screw (LA)

Reset idle speed screw (LA)

correctly

Oil seals / crankcase leaking Seal oil seals / crankcase, replace if

necessary

Cylinder gasket leaking Perform leakage test, inspect

sealing faces and replace cylinder

gasket if necessary

Gaskets on spacer flange and

carburetor leaking, or crack in

spacer flange

Spring in control valve broken or

fatigued – throttle lever is not

Perform leakage test, replace

gaskets and spacer flange if

necessary

Install new control valve, check and

replace carburetor if necessary

returned to original position

Engine stops while idling Setting of low speed screw (L) too

rich or too lean

Setting of idle speed screw LA

incorrect – control valve completely

closed

Control valve lever does not locate

against

idle speed screw LA

– control valve completely closed

Tank vent faulty Fit new tank vent

Leak in fuel hose from tank to

carburetor

Reset low speed screw (L)

correctly

Reset idle speed screw (LA)

correctly

Open the throttle wide, the control

valve lever returns to its original

position and locates against the idle

speed screw (LA), replace control

valve if necessary

Install a new fuel suction hose.

12 Series 4149 Powerhead

Condition Cause Remedy

Working tool runs when engine is

idling

Engine speed drops quickly under

load – low power

Engine idle speed too high Readjust idle speed screw

LA (counterclockwise)

Clutch spring stretched or fatigued Replace the clutch spring or install

new clutch

Clutch spring hooks broken Replace the clutch spring

Air filter dirty Clean or replace fleece filter;

replace paper filter

Control valve not opened fully Check the throttle cable and re-

adjust if necessary.

Leak in fuel hose from tank to

carburetor

Setting of high speed screw (H) too

rich

Seal connections or install new fuel

hose

Check basic carburetor setting,

correct if necessary

Tank vent faulty Fit new tank vent

Fuel pickup body dirty Fit new pickup body

Fuel strainer dirty Clean fuel strainer in carburetor,

replace if necessary

Main jet bores or ports blocked Clean the carburetor

Pump diaphragm damaged or

Fit new pump diaphragm

fatigued

Ignition timing wrong, flywheel out

Install new flywheel

of adjustment

– key in flywheel has sheared off

13Series 4149 Powerhead

Condition Cause Remedy

Engine running extremely rich, has

no power and a very low maximum

speed

Cold start device of control valve

sticking or does not return to

original position

Check and clean the control valve

or replace if necessary

Engine does not start No spark Replace spark plug, check ignition

module/control unit, replace if

necessary

Starter rope not pulled vigorously

enough

– fuel mixture too rich (flooded)

Remove and dry off the spark plug,

pull starter rope several times to

clear combustion chamber, refit

and tighten down the spark plug,

repeat starting procedure

Jet on the

low speed screw L blocked

Clean the carburetor or replace if

necessary

– no fuel feed

Jet on the

Install new carburetor

low speed screw L broken – engine

stalls

14 Series 4149 Powerhead

3.6 Engine

Always check and, if necessary,

repair the following parts before

looking for faults on the engine:

- Air filter

- Fuel system

- Carburetor

- Ignition system

Condition Cause Remedy

Engine does not start easily, stalls

Oil seals in engine damaged Install new oil seals

at idle speed, but operates normally

at full throttle

Crankcase leaking or damaged

(cracks)

Engine does not deliver full power

Piston rings worn or broken Install new piston rings

or runs erratically

Muffler carbonized Clean the muffler (inlet and

Air filter dirty Clean or replace fleece filter;

Fuel hose kinked or torn Fit new hose or position it free from

Engine overheating Insufficient cylinder cooling.

Air inlets in fan housing or air slots

in shroud blocked.

Cylinder cooling fins heavily soiled.

Seal crankcase, replace if

necessary

exhaust), replace if necessary

replace paper filter

kinks

Thoroughly clean all cooling air

openings and the cylinder fins

15Series 4149 Powerhead

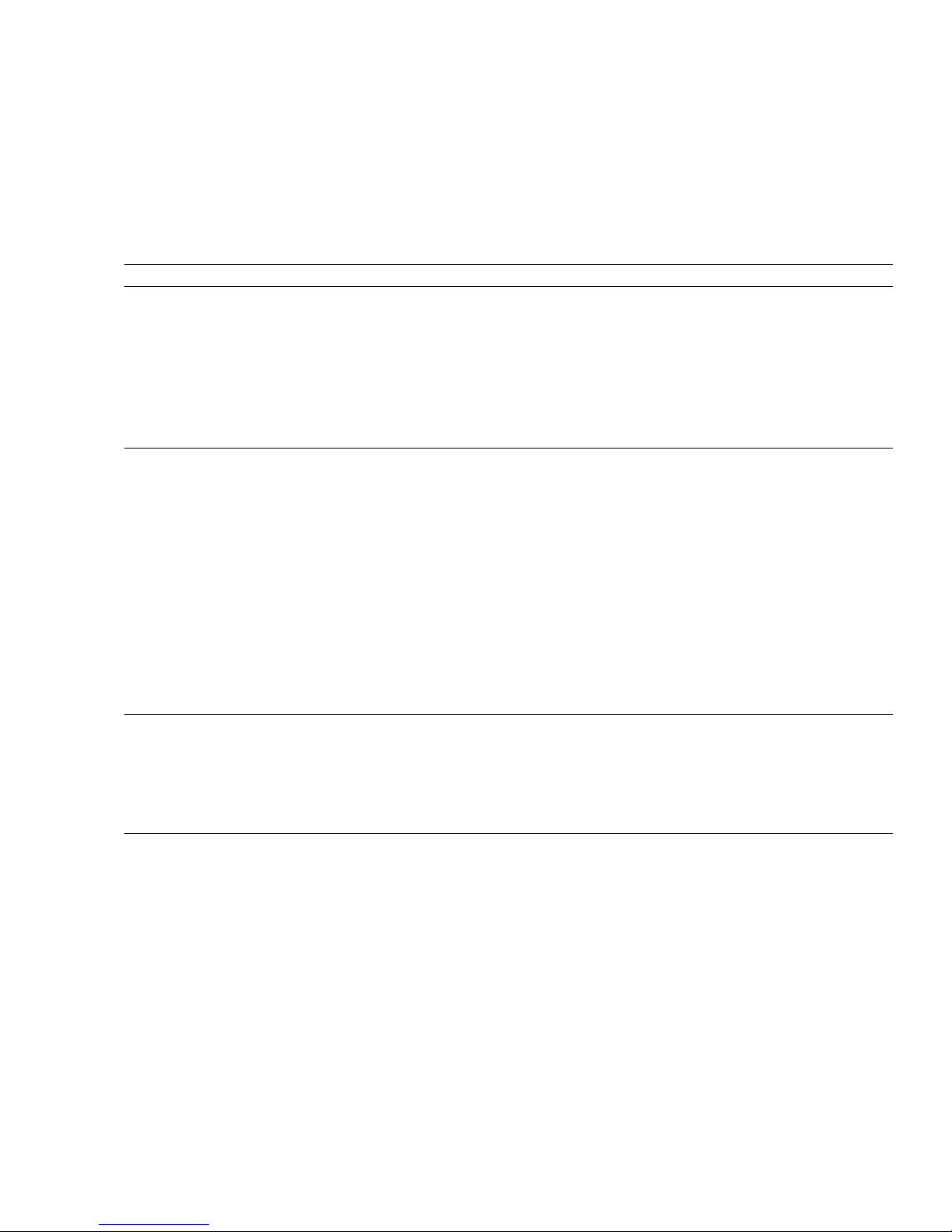

4. Clutch

4.1 Clutch Drum

– Troubleshooting, b 3.1

– Remove the rewind starter,

b 7.2

– Remove the shroud, b 5.4

– Remove the drive tube, b 9.1

2

1

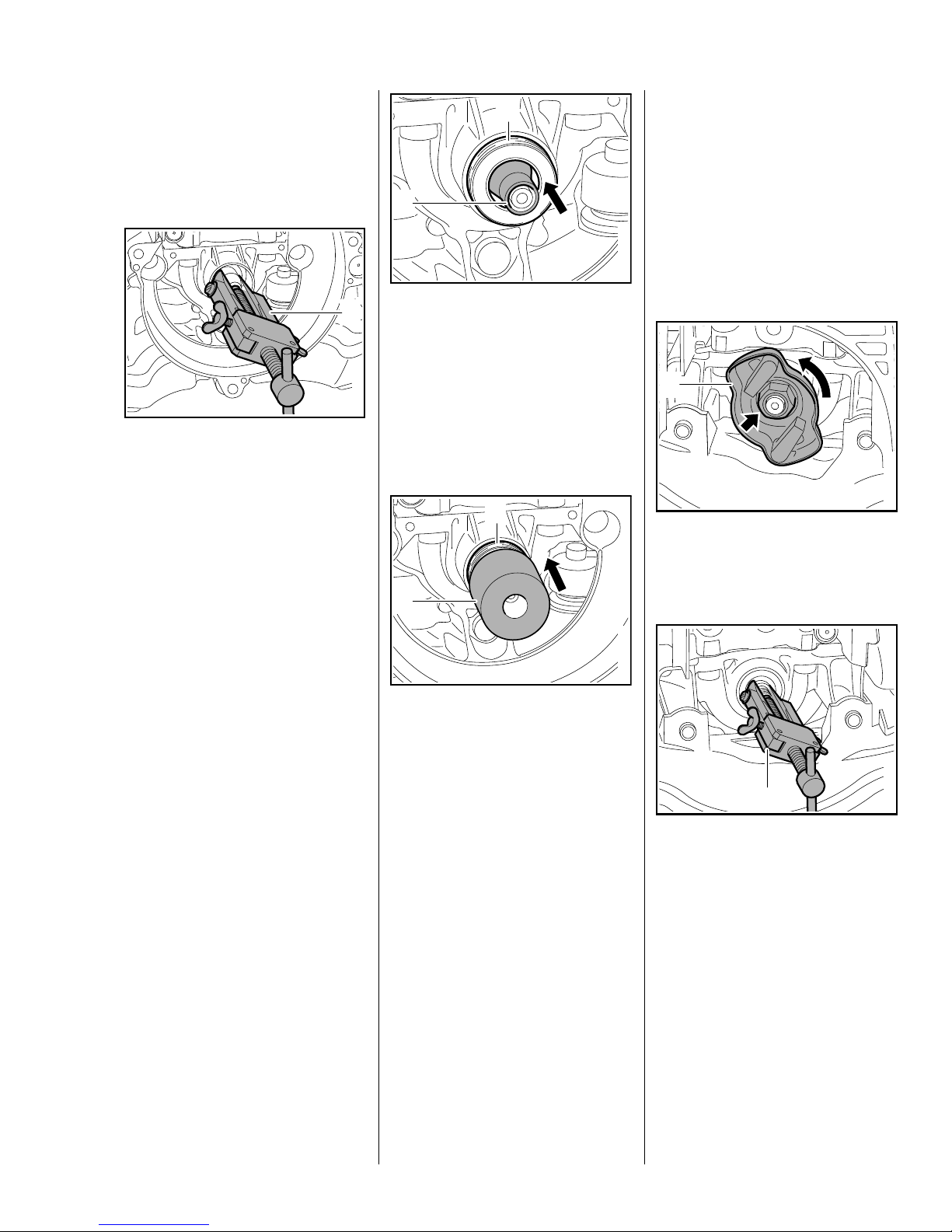

: Take out the screw (1) and

remove the fan housing (2)

– the two upper screws have

already been removed.

3

1

2

: Place the fan housing (1) on

ring (2) 5910 893 7008 – this

ensures the fan housing (1) is

upright and securely supported.

: Position the ring (2) so that it

engages the projecting clutch

drum.

: Use suitable press arbor (3) to

remove the clutch drum.

7022RA000 TG0208RA001 TG

Installing

1

0208RA002 TG

2

– Heat inner race of ball bearing to

about 120°C (250°F).

: Position clutch drum (1) on ball

bearing (2) and push it home as

far as stop.

This operation must be carried out

quickly because the clutch drum

absorbs heat and begins to expand.

1

0208RA003 TG

– Remove the sleeve and rubber

element, b 8.1

1

: Remove the retaining ring (1).

100%

80%

– Inspect the clutch drum (1) for

signs of wear.

If there are signs of serious wear on

the inside diameter of the clutch

drum (1), check the remaining wall

thickness. If it is less than about

80% of the original thickness, install

a new clutch drum.

If square socket is worn or the stub

damage, install a new clutch drum.

– Inspect the ball bearing and

replace if necessary.

1

0208RA396 TG

If it is not possible the heat the inner

bearing race, use a bench press to

install the cold clutch drum.

– Support the other side of the fan

housing with a suitable tube on

the inner race of the ball bearing.

: Position clutch drum (1) on ball

bearing (2) and press it home as

far as stop.

2

0208RA004 TG

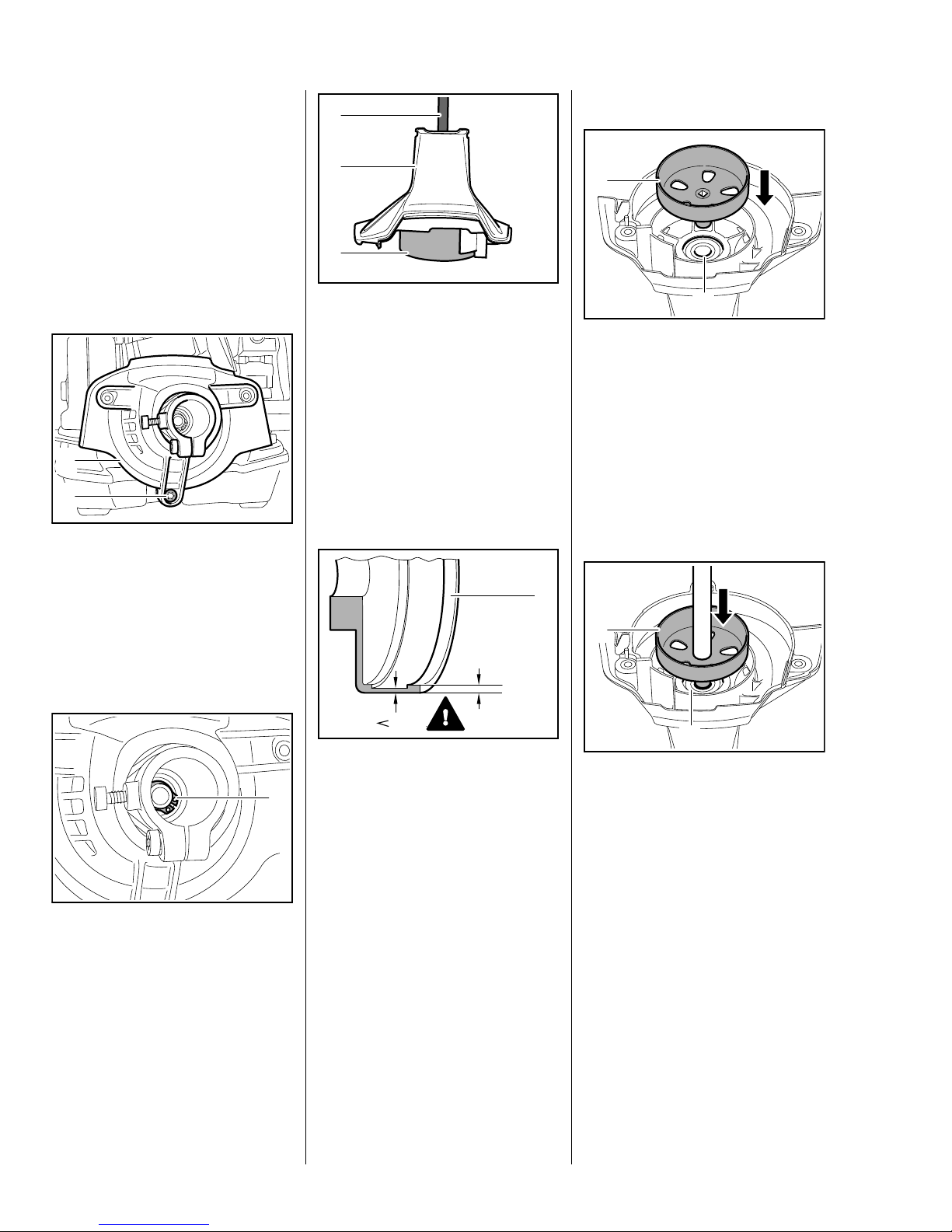

16 Series 4149 Powerhead

– Install the drive tube, b 9.1

4.2 Clutch

1

: Install circlip (1) at the other side.

– Remove the sleeve and rubber

element, b 8.1

3

1

4

2

4

– Fit the shroud, b 5.4

1

0208RA001 TG

2

: Fit screws (1), then tighten down

screw (2) and screws (1) firmly.

– Install the rewind starter, b 7.2

7022RA001 TG

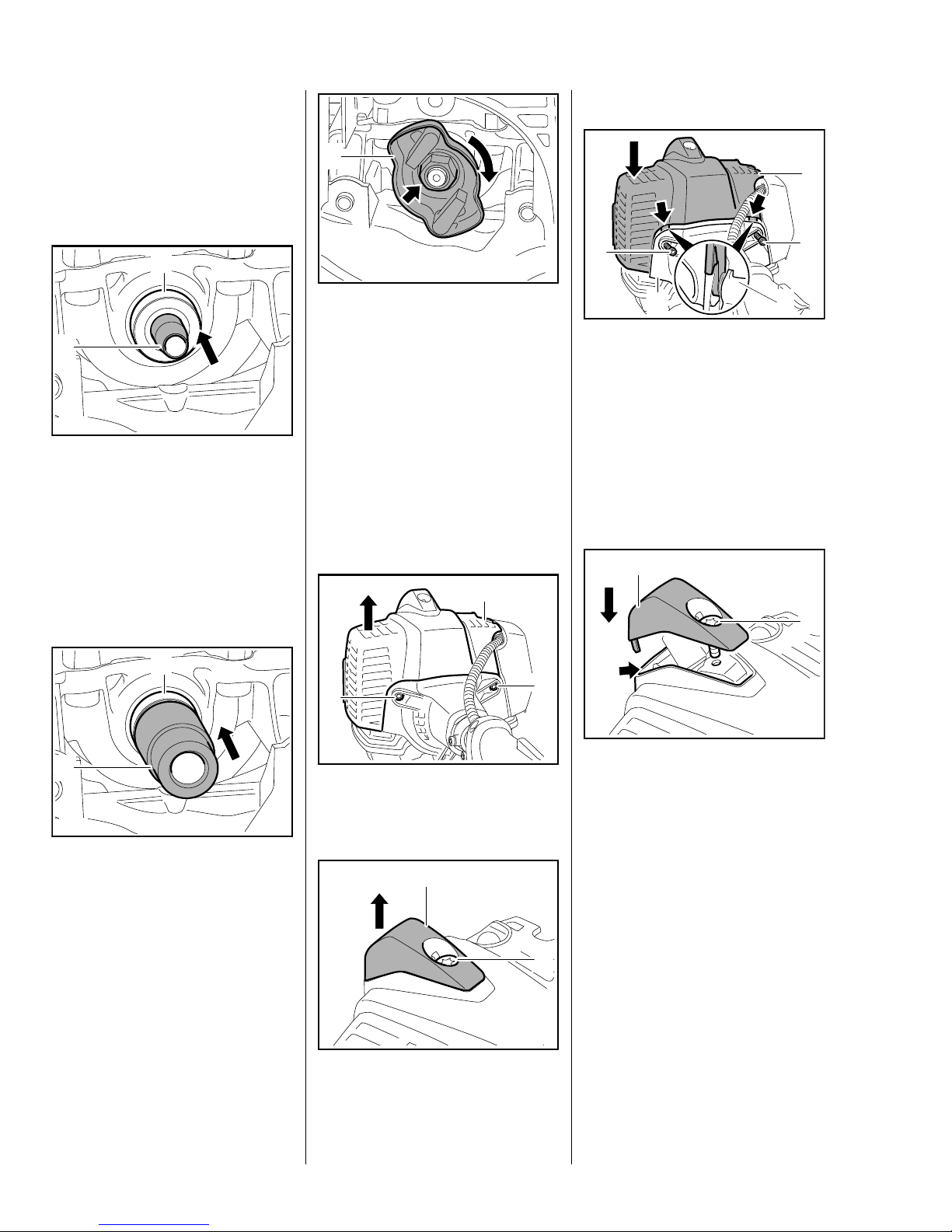

– Remove the fan housing, b 4.1

1

0208RA007 TG

: Pull boot (1) off the spark plug.

– Unscrew the spark plug.

1

1

7022RA066 TG

1

: Fit the fan housing (1) with clutch

drum (2) over the clutch (3) and

line it up so that the pins (4)

engage the holes (arrows) in the

crankcase.

1

: Tighten the screw (1) until the fan

housing is seated

– the upper screws are not fitted

and secured until the shroud is

installed – do not finally tighten

screw (1) yet.

: The throttle cable (1) must not be

under tension.

7022RA002 TG

7022RA067 TG

0208RA008 TG

: Insert locking strip (1)

0000 893 5904 in the cylinder.

17Series 4149 Powerhead

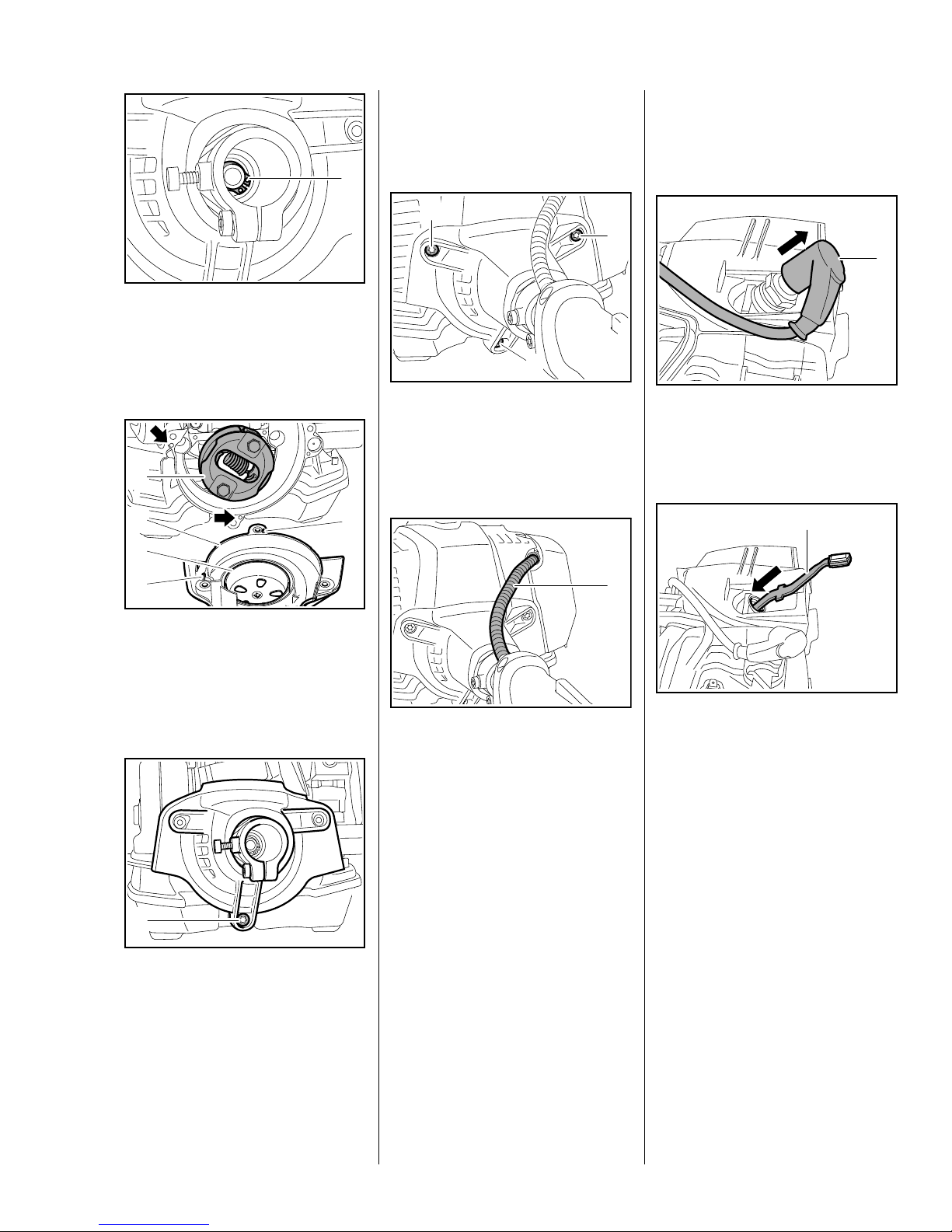

Assembling

1

1

1

1

0208RA017 TG

0208RA013 TG

: The locking strip (1)

0000 893 5904 must butt against

the cylinder wall (arrow)

– as shown in the illustration.

Disassembling

1

2

1

: Take out the screws (1).

: Remove the clutch (2) with cover

washers.

1

2

: Fold the clutch shoes (1) and

unhook the spring (2).

Position the clutch shoes (1) so that

the markings (arrows) are visible.

The spring (2) must be hooked into

the back of the clutch shoes (1).

– Reassemble the clutch shoes in

the reverse sequence.

0208RA009 TG

2

3

1

4

: Fit the washers (1) over the

sleeves.

: Position the clutch (2) so that the

marks (arrows) face up.

: Push clutch (2) onto sleeves (3)

of lower cover washer (4).

: Fit upper cover washer (1) so that

0208RA011 TG

the recesses (arrows) face up

and the holes are in alignment.

Installing

2

1

3

: Position clutch (1) with cover

washers on tapped holes

3

1

(arrows) in flywheel (2).

: Insert and tighten down the

screws (3) firmly.

0208RA012 TG

– Remove the locking strip from the

cylinder.

– Install the fan housing, b 4.1

– Reassemble all other parts in the

reverse sequence.

3

7022RA003 TG

0208RA010 TG

– Remove the upper cover washer.

: Pull the clutch (1) off the lower

cover washer.

18 Series 4149 Powerhead

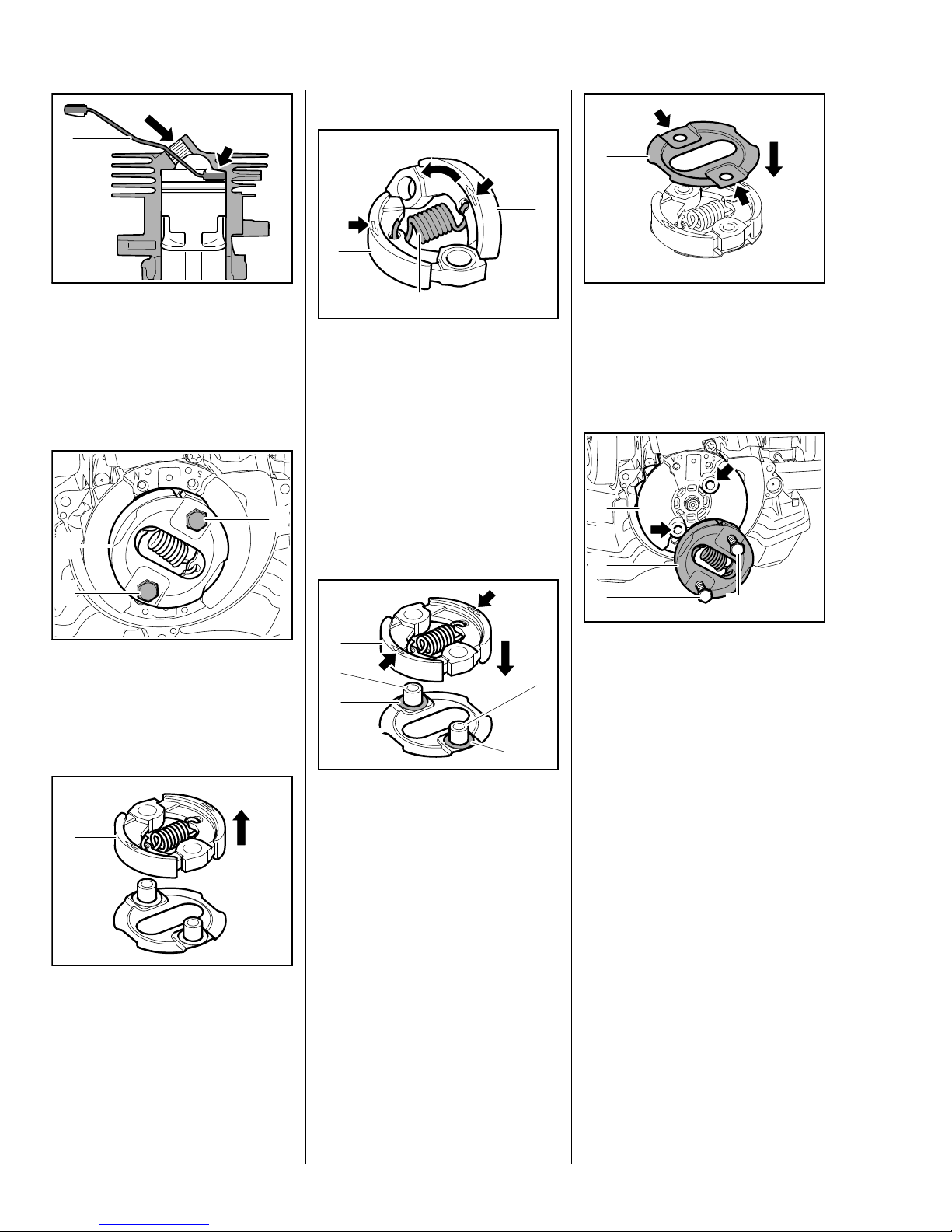

5. Engine

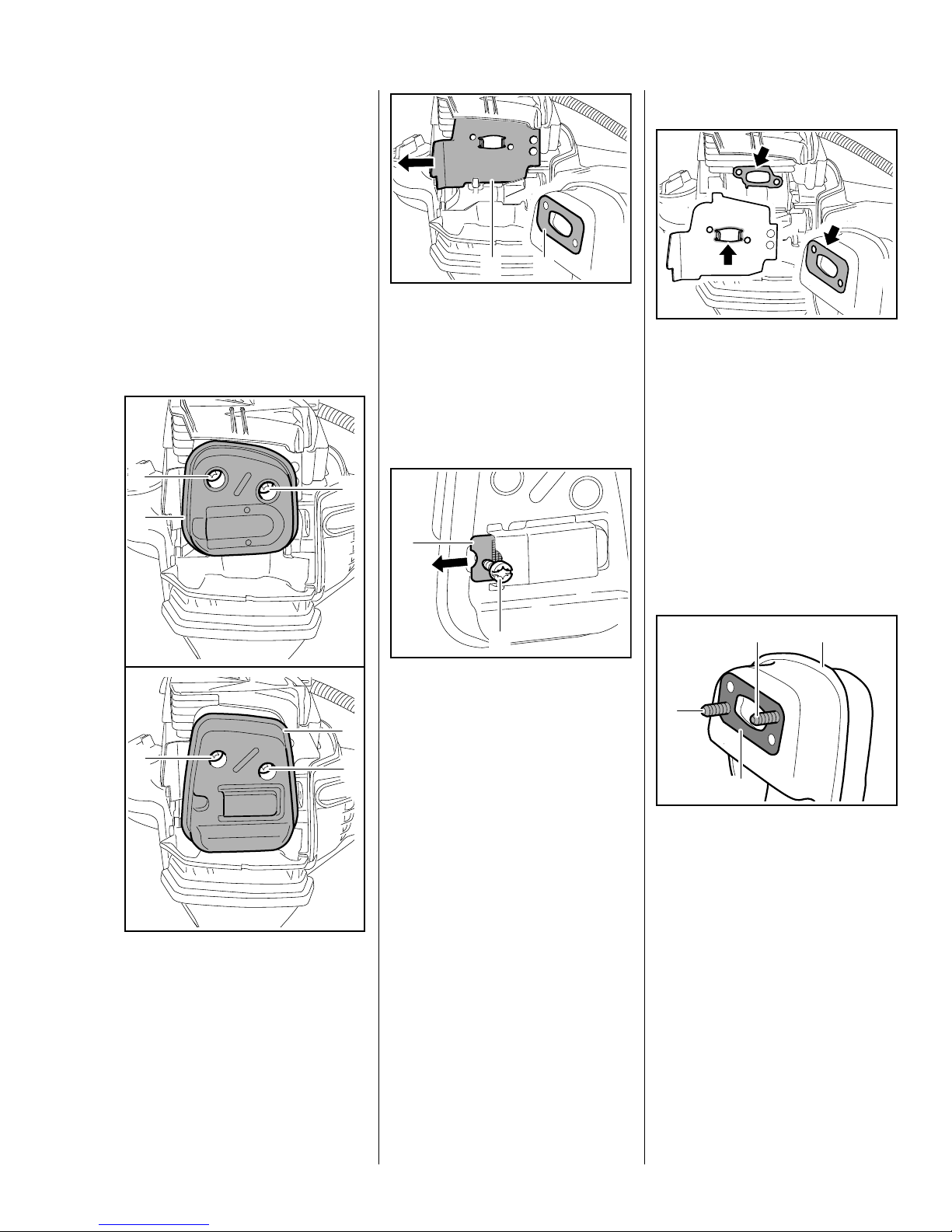

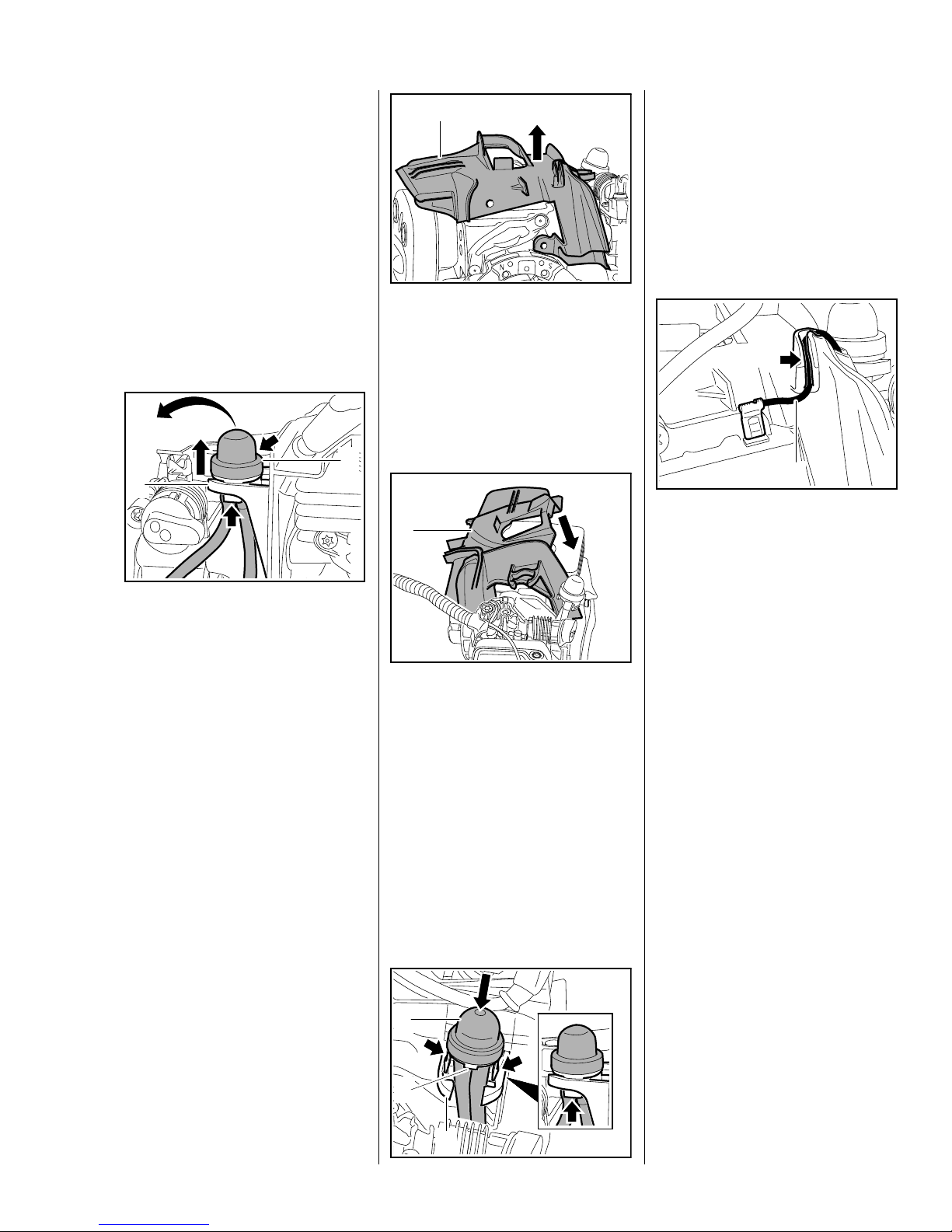

5.1 Muffler / Spark Arresting

Screen

Always check and, if necessary,

repair the fuel system, carburetor,

air filter and ignition system before

looking for faults on the engine.

– Troubleshooting, b 3

– Remove the shroud, b 5.4

Before removing the muffler, set the

piston to top dead center to ensure

that no dirt falls into the cylinder.

1

1

2

12

: Remove the muffler gasket (1)

and pull out the heat shield (2)

sideways – always install a new

muffler gasket.

Spark arresting screen

(if fitted)

2

Installing

7022RA005 TG

7022RA006 TG

– Cover the exhaust port. Remove

any dirt from around the cylinder

and exhaust port.

: Check and clean the sealing

faces (arrows) on the exhaust

port, heat shield and muffler,

remove any gasket residue –

make sure there is no gasket

residue or dirt in the exhaust port.

Always replace components with

damaged sealing faces.

2

1

: Take out the screws (1).

: Remove the muffler (2), check it

and replace if necessary.

1

1

: Take out the screw (1) and pull

out the spark arresting

screen (2).

– Clean the spark arresting screen

or replace if necessary.

– Reassemble in the reverse

sequence.

7022RA004 TG

1

7022RA073 TG

3

1

2

: Insert the screws (1).

: Fit new muffler gasket (2) over

the screws (1) and against the

muffler (3).

7022RA007 TG

19Series 4149 Powerhead

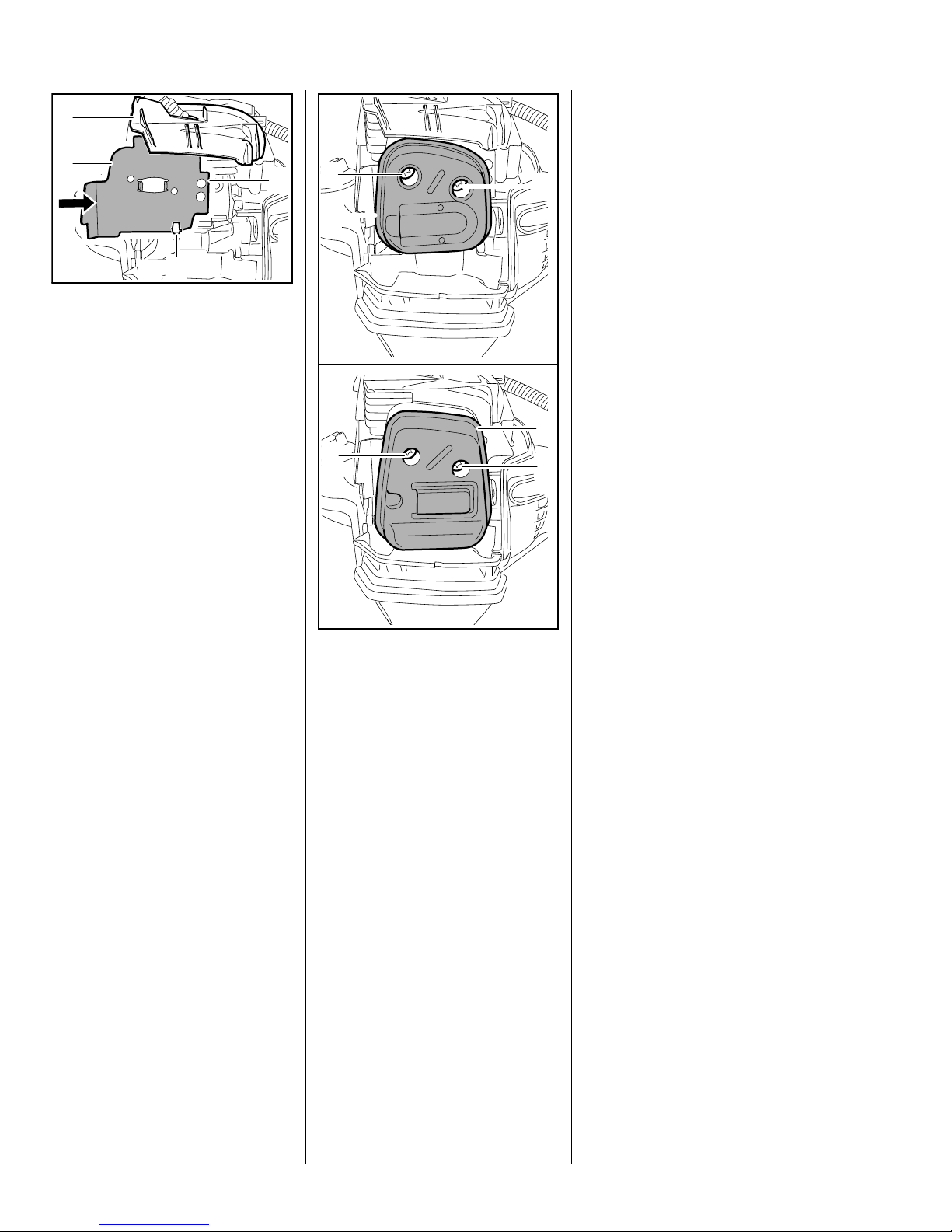

5.2 Leakage Test

3

Defective oil seals and gaskets or

1

2

2

1

cracks in castings are the usual

causes of leaks. Such faults allow

2

supplementary air to enter the

engine and upset the fuel-air

mixture.

4

: Push the upper edge of the heat

shield (1), tab (2) first, between

the wall of the air guide

shroud (3) and cylinder and its

lower edge between the hook (4)

and the cylinder.

: Push the heat shield (1) home

until its holes line up with the

holes in the cylinder.

7022RA007 TG

2

: Carefully fit the muffler (1) in

position and insert the screws (2)

– do not tighten down yet.

This makes adjustment of the

prescribed idle speed difficult, if not

impossible.

Moreover, the transition from idle

speed to part or full throttle is not

smooth.

Always perform the vacuum test

first and then the pressure test.

1

The engine can be checked

2

thoroughly for leaks under vacuum

and pressure with the pump

0000 850 1300.

7022RA009 TG

: Check that gasket and heat

shield are properly positioned.

: Insert and tighten down the

screws (2) firmly.

– Reassemble all other parts in the

reverse sequence.

20 Series 4149 Powerhead

5.2.1 Preparations

1

– Remove the shroud, b 5.4

1

– Pull off the boot and unscrew the

spark plug.

– Set the piston to top dead center.

This can be checked through the

spark plug hole.

: Fit the spark plug (1) and tighten

it down firmly.

– Remove the heat shield and

gasket, fit muffler in position and

insert screws, b 5.1

2

7022RA010 TG

2

: Fit the sealing plate (1)

0000 855 8106 between the

cylinder exhaust port and muffler.

1

2

Make sure the gasket (1) is in place.

1

1

3

2

2

: Line up the flange (1)

5910 850 4200 and fit it over the

studs (2).

7022RA011 TG

: Fit the nuts (3) and tighten them

down firmly.

2

0208RA028 TG

3

7022RA218 TG

: Tighten the screws (2)

moderately.

The sealing plate must completely

fill the space between the two

screws.

– Remove carburetor with fuel

hoses still attached and put it to

one side, b 10.3

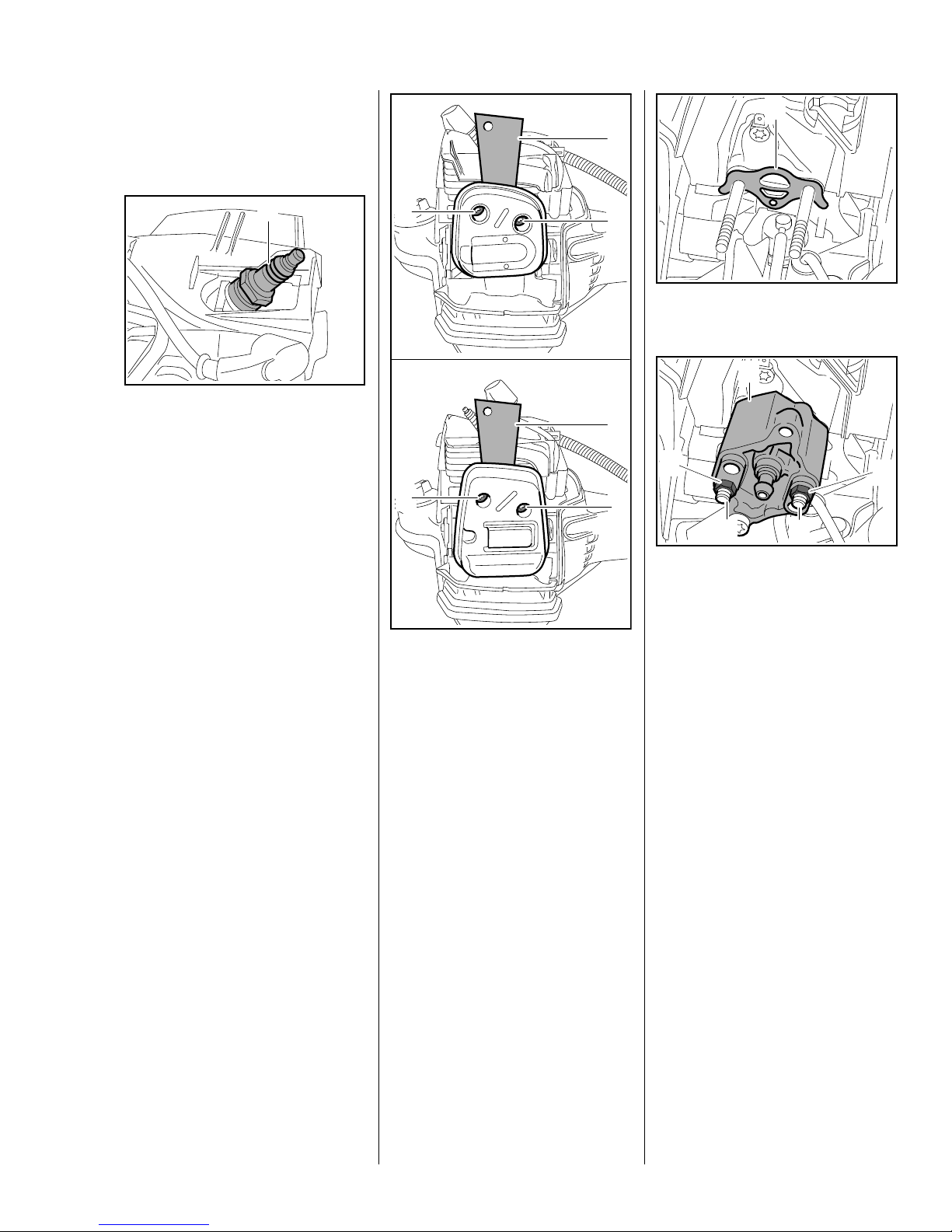

5.2.2 Vacuum Test

Oil seals tend to fail when subjected

to a vacuum, i.e. the sealing lip lifts

away from the crankshaft during the

piston's induction stroke because

there is no internal counterpressure.

A test can be carried out with pump

0000 850 1300 to detect this kind of

fault.

21Series 4149 Powerhead

2

4

3

5.2.3 Pressure Test

– Install the gasket, heat shield and

muffler, b 5.1

Carry out the same preparations as

for the vacuum test, b 5.2.2

– Reassemble all other parts in the

reverse sequence.

1

: Connect hose (1) of pump

0000 850 1300 to the nipple

(arrow).

: Push ring (2) to the left

– vacuum test.

: Operate the lever (3) until the

pressure gauge (4) indicates a

vacuum of 0.5 bar.

If the vacuum reading remains

constant, or rises to no more than

0.3 bar within 20 seconds, it can be

assumed that the oil seals are in

good condition.

If the pressure continues to rise

(reduced vacuum in engine), the oil

seals must be replaced, b 5.3.

31

7022RA220 TG

: Push ring (1) to the right

– pressure test.

: Operate the lever (2) until the

pressure gauge (3) indicates a

pressure of 0.5 bar. If this

pressure remains constant for at

least 20 seconds, the engine is

airtight.

– If the pressure drops, the leak

must be located and the faulty

part replaced.

2

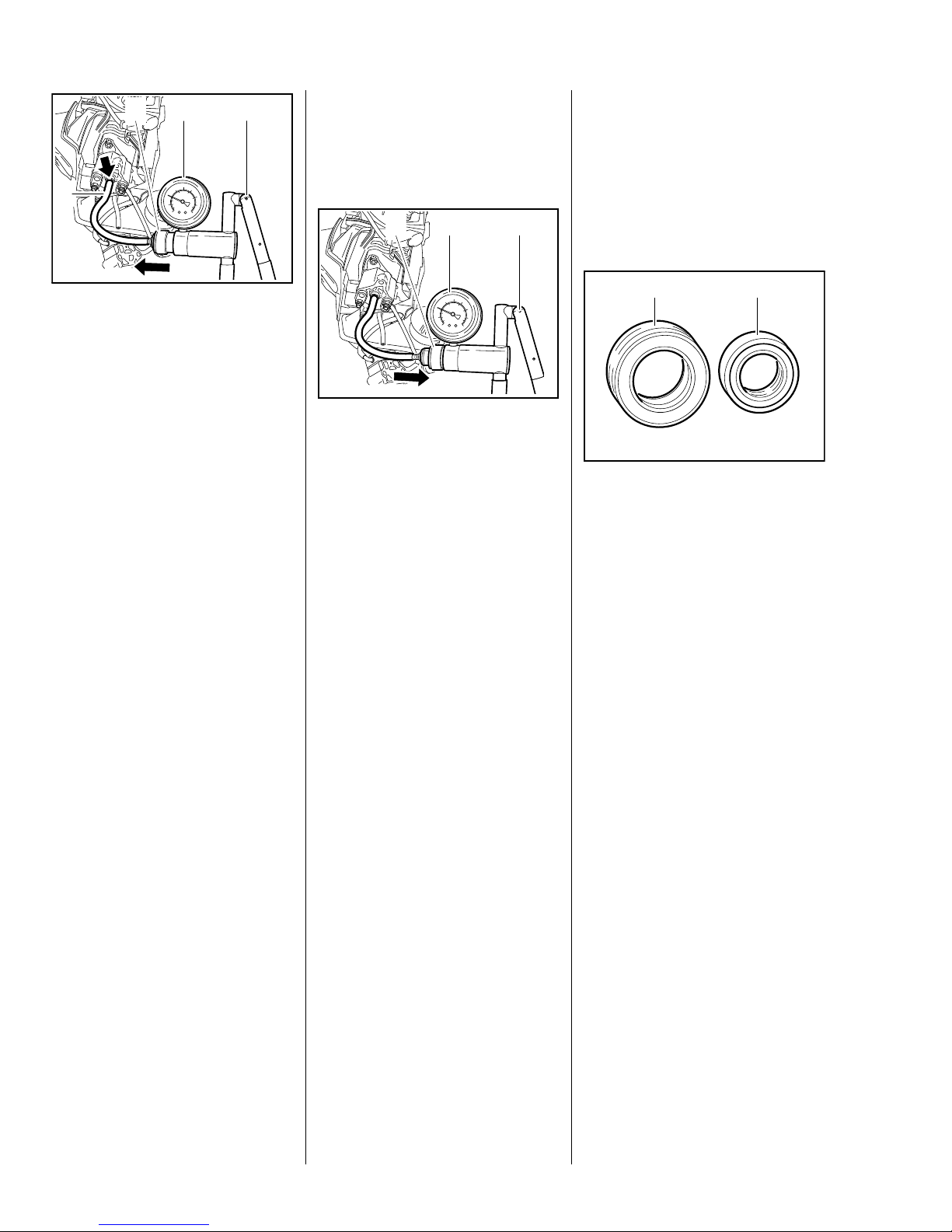

5.3 Oil Seals

1 2

7022RA219 TG

5904RA044 TG

When replacing oil seals, note that

the 12x22x5 oil seal (1) must be

installed at the ignition side and the

10x20x4 oil seal (2) at the starter

side.

It is not necessary to disassemble

the engine to replace the oil seals.

– After finishing the test, push the

ring to the right to vent the pump.

– Continue with pressure test,

b 5.2.3

To find the leak, coat the suspect

area with soapy water and

pressurize the engine again.

Bubbles will appear if a leak exists.

– After finishing the test, push the

ring to the left to vent the pump –

disconnect the hose.

– Remove the flange

5910 850 4200 from the intake

manifold.

– Install the carburetor, b 10.3

– Remove the muffler and the

sealing plate 0000 855 8106.

22 Series 4149 Powerhead

Ignition Side

– Remove the clutch, b 4.2

2

reverse sequence.

– Reassemble all other parts in the

– Remove the flywheel, b 6.5

1

Take care not to damage the

crankshaft stub.

– Free off the oil seal in its seat by

tapping it with a suitable tube or a

punch.

: Apply puller (1) 5910 890 4400

with No. 6 jaws 0000 893 3711.

1

: Fit the installing sleeve (1)

4149 893 4600.

: Slip the oil seal (2), sealing lip

facing the crankcase, over the

installing sleeve.

0208RA018 TG

– Remove the installing sleeve.

2

1

Starter Side

– Remove the rewind starter,

b 7.2

– Block the piston, b 4.2

0208RA141 TG

1

: Use hexagon (arrow) to loosen

and unscrew carrier (1)

counterclockwise.

0208RA073 TG

– Clamp the puller arms.

– Pull out the oil seal.

Installing

– Clean the sealing face, b 12

– Lubricate sealing lips of new oil

seal with grease, b 12

To avoid the risk of engine damage,

only use press sleeve (1)

4149 893 2400 to install the oil seal.

: Fit the press sleeve (1)

4149 893 2400 with the smaller

diameter (22 mm) facing the

crankcase and press home the oil

seal (2).

The seating face must be flat and

free from burrs.

– Degrease the crankshaft taper,

b 12

0208RA142 TG

1

Take care not to damage the

crankshaft stub.

– Free off the oil seal in its seat by

tapping it with a suitable tube or a

punch.

: Apply puller (1) 5910 890 4400

with No. 3.1 jaws 0000 893 3706.

– Clamp the puller arms and pull

out the oil seal.

0208RA143 TG

23Series 4149 Powerhead

Installing

– Clean the sealing face.

– Lubricate sealing lips of new oil

seal with grease, b 12

Installing

1

1

2

1

: Fit the installing sleeve (1)

1146 893 4600.

: Slip the oil seal (2), sealing lip

facing the crankcase, over the

installing sleeve.

– Remove the installing sleeve.

2

: Use hexagon (arrow) to screw

carrier (1) into place clockwise,

then tighten it down firmly.

– Reassemble all other parts in the

reverse sequence.

0208RA144 TG

5.4 Shroud

– Remove the rewind starter,

b 7.2

2

1

4

0208RA146 TG

3 2

: Fit the shroud (1) so that the tabs

(arrows) engage between the

crankcase (2) and fan

housing (3).

: Insert and tighten down the

screws (4) firmly.

– Install the rewind starter, b 7.2

1

1

4

0208RA034 TG

2

1

: Fit the press sleeve (1)

4149 893 2400 with the larger

diameter (25 mm) facing the

crankcase and press home the oil

seal (2).

The seating face must be flat and

free from burrs.

: Take out the screws (1) and

remove the shroud (2).

0208RA145 TG

2

: Take out the screw (1) and

remove the cover (2).

0208RA032 TG0208RA033 TG

: Push tab of cover (1) into

opening in shroud and fit cover in

position.

: Insert and tighten down the

screw (2) firmly.

1

0208RA035 TG

24 Series 4149 Powerhead

5.4.1 Air guide shroud

– Remove the drive tube, b 9.1

1

so that the lug (2) points towards

the carburetor.

: Line up the manual fuel pump (1)

– Remove the shroud, b 5.4

– Remove the fan housing, b 4.1

– Remove the ignition module,

b 6.2

– Pull short circuit wire out of guide

in air guide shroud.

2

1

: Squeeze locking tabs (arrows)

under the retainer (1) together

and push out the manual fuel

pump (2).

: Remove the manual fuel

pump (2) with fuel hoses still

attached and put it to one side.

– Unscrew the spark plug.

: Lift the air guide shroud (1) at the

starter side and remove it over

the cylinder.

Installing

1

0208RA054 TG

: Position the air guide shroud (1)

at a slight angle and lower it in the

direction of the starter side.

: Push the manual fuel pump (1)

into the retainer (3) on the air

guide shroud until the locking

tabs (arrows) snap into place

below the retainer (3).

7022RA012 TG

1

: Starting at the flag terminal, push

the short circuit wire (1) into the

guide (arrow) so that it fits snugly

– if necessary, also push the

wires on the throttle cable

retainer fully into the guide.

– Reassemble all other parts in the

7022RA013 TG

reverse sequence.

0208RA155 TG

: Line up the air guide shroud (1)

so that it locates on the cylinder

and spacer flange and lines up

with the holes in the cylinder.

– Fit the spark plug and tighten it

down firmly.

– Install the ignition module, b 6.2

1

2

3

0208RA061 TG

25Series 4149 Powerhead

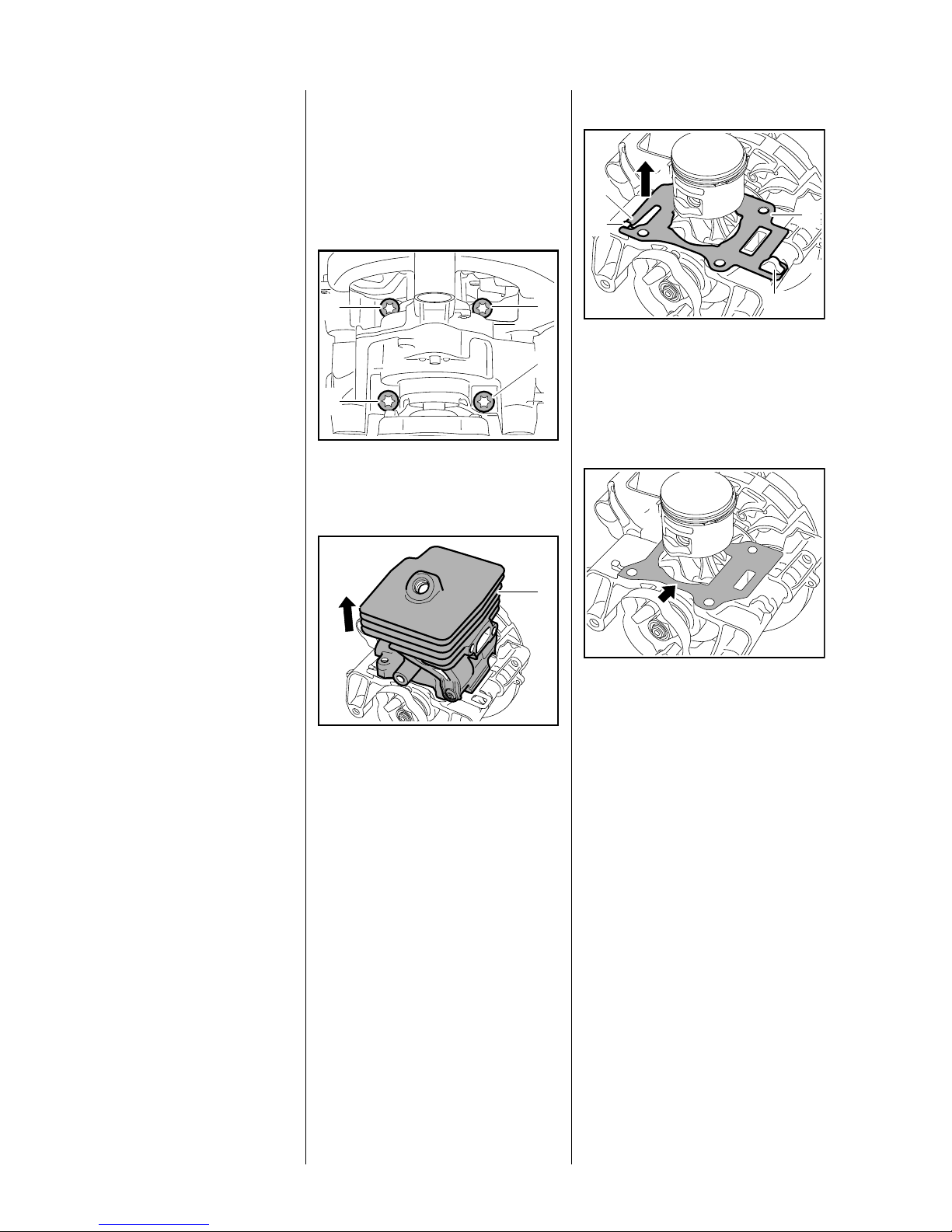

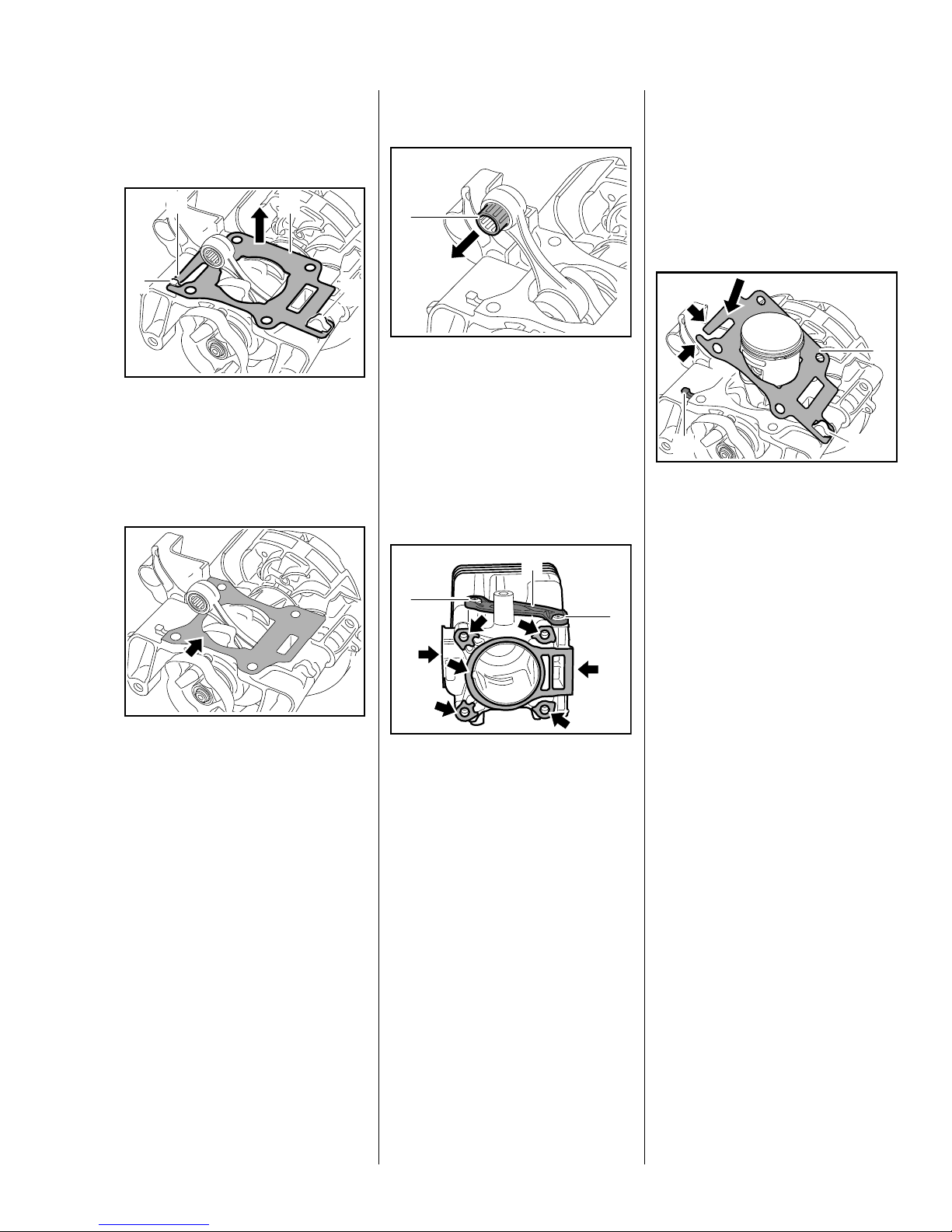

5.5 Cylinder

Before removing the cylinder,

decide whether or not the

crankshaft has to be removed as

well.

Cylinder installed

To remove the clutch, flywheel or

carrier, block the.crankshaft by

inserting the locking strip in the

spark plug hole.

– Remove the ignition module and

air guide shroud, b 6.2

– Remove the muffler, b 5.1

– Remove the fuel tank, b 10.9

1

1

Versions with 0.75 kW engine

2

3

4

1

0208RA335 TG

Cylinder removed

To remove the clutch, flywheel or

carrier, block the crankshaft by

resting the piston on the wooden

assembly block.

All sealing faces must be in perfect

condition. If the sealing faces are

damaged, replace the part

concerned, b 3.6.

– Remove the rewind starter,

b 7.2

– Remove the shroud, b 5.4

– Remove the filter cover, b 10.2

– Remove the throttle cable / short

circuit wire, b 6.6.2

– Remove the drive tube, b 9.1

– Remove the fan housing, b 4.1

1

1

: Remove the screws (1) from the

underside of the crankcase.

1

: Carefully lift the cylinder (1)

away.

: Lift cylinder gasket (1) with

tab (2) over the lug (3), detach it

from the hook (4) and lift it over

the piston – always install a new

cylinder gasket.

0208RA108 TG

: Inspect and clean the sealing

face (arrow) – components with

0208RA109 TG

damaged sealing faces must be

replaced, b 12

0208RA337 TG

– Pull off the boot and unscrew the

spark plug, b 4.2

– Pull off the carburetor and put it to

one side – there is no need to

remover the fuel hoses, b 10.3

– Remove the spacer flange,

b 10.6

26 Series 4149 Powerhead

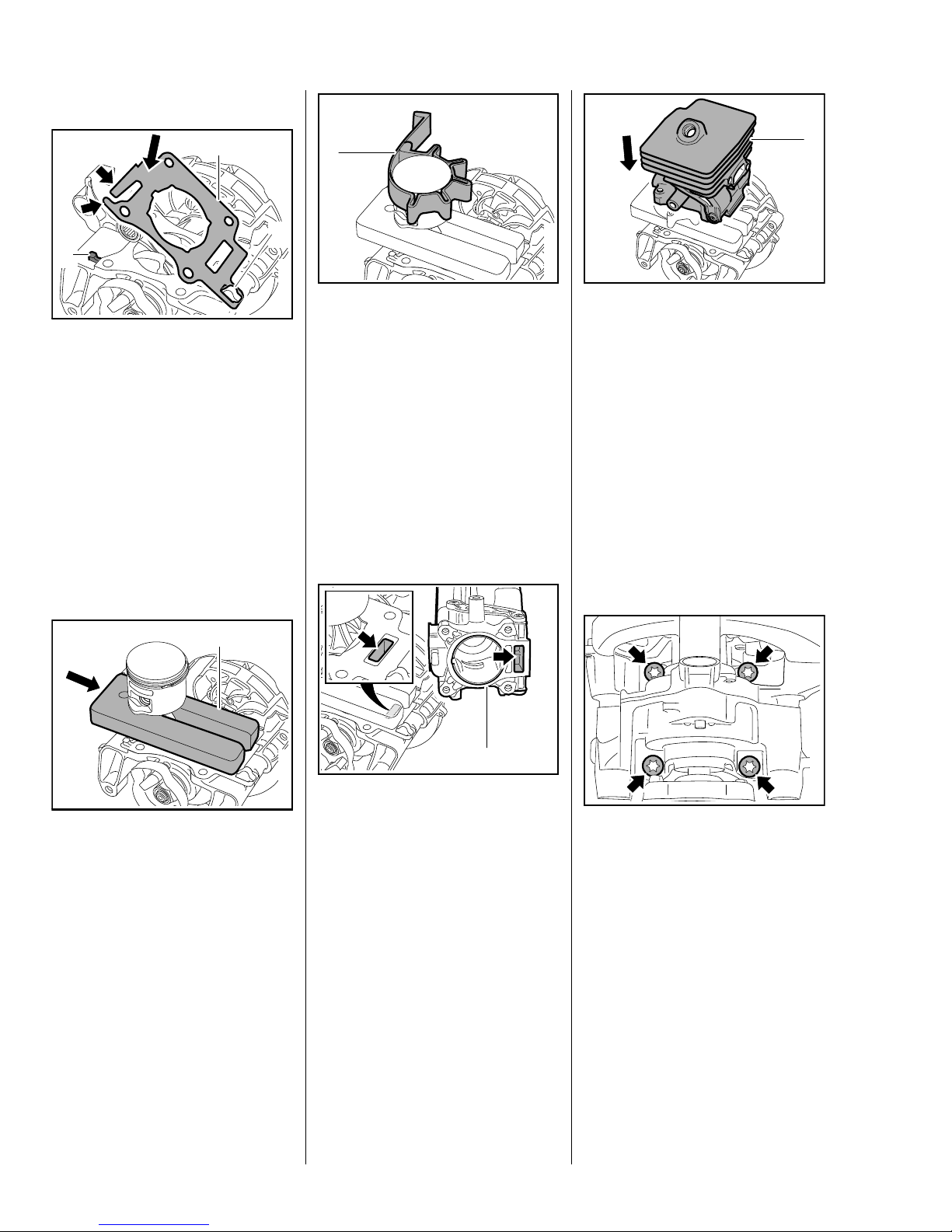

Versions with 0.9 kW engine

– Remove the piston, b 5.7

Versions with replaceable needle

cage

If the piston or the oil seals are

damaged, also inspect the inside of

the cylinder for signs of damage and

install a new cylinder if necessary.

2

1

3

: Lift cylinder gasket (1) with

tab (2) over the lug (3), detach it

from the hook (4) and lift it over

the connecting rod – always

install a new cylinder gasket.

1

4

: Pull out the needle cage (1),

0208RA110 TG

inspect and clean it, replace if

necessary.

– Reassemble in the reverse

sequence.

All models

1

Installing

Versions with 0.75 kW engine

0208RA112 TG

1

3

: Fit the new cylinder gasket (1)

over the piston, attach it to the

hook (2) and place it in position.

2

: Press down tabs (arrows) of new

cylinder gasket (1) until they

locate behind the lug (3).

1

– the cylinder gasket is now held

in position.

2

0208RA338 TG

: Inspect and clean the sealing

face (arrow) – components with

damaged sealing faces must be

replaced, b 12

Versions with fixed needle cage

The needle cage is permanently

connected to the small end and

cannot be replaced separately.

– Inspect and clean the needle

cage, replace crankshaft if

necessary, b 5.6

0208RA111 TG

0208RA113 TG

The screws (1) and cover (2) must

not be removed at either side.

: Inspect and clean the sealing

faces (arrows) and remove any

gasket residue, b 12

Always use a new cylinder gasket

when re-installing the cylinder.

– Inspect the piston and piston

rings and replace if necessary,

b 5.7, b 5.8

27Series 4149 Powerhead

Versions with 0.9 kW engine

0208RA119 TG

1

2

3

: Fit the new cylinder gasket (1)

over the piston, attach it to the

hook (2) and place it in position.

: Press down tabs (arrows) of new

cylinder gasket (1) until they

locate behind the lug (3).

– the cylinder gasket is now held

in position.

– Install the piston, b 5.7

All models

1

– Lubricate the piston, piston rings

0208RA114 TG

and cylinder wall with oil, b 12

– Check correct installed position

of rings, b 5.8

: Use the clamping strap (1)

0000 893 2600 to compress the

rings around the piston.

Apply the clamping strap (1) so that

the piston rings do not project

beyond the cylinder wall.

0208RA116 TG

While sliding the cylinder over the

piston, hold the clamping strap

tightly around the piston so that the

rings do not project

– they might otherwise break.

: Slide the cylinder (1) over the

piston, the clamping strap moves

downwards at the same time.

– Remove the clamping strap and

wooden assembly block.

Make sure the cylinder gasket is

properly seated.

1

0208RA118 TG

1

: Slide the wooden assembly

block (1) 1108 893 4800

between the piston and

crankcase.

Take care not to damage the

cylinder gasket.

: Position the cylinder (1) so that

0208RA115 TG

the rectangular ports (arrows) are

in alignment.

1

0208RA117 TG

– Push cylinder on as far as stop

and hold it steady, then turn

cylinder and crankcase over.

: Fit screws (arrows) in underside

of crankcase and tighten them

down firmly in crosswise pattern.

– Reassemble all other parts in the

reverse sequence.

28 Series 4149 Powerhead

Loading...

Loading...