STIHL HT 102, 103, 132, 133

Instruction Manual

Notice d’emploi

G Instruction Manual

1 - 37

F Notice d’emploi

38 - 80

Contents

English

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 2

Using the Unit 8

Cutting Attachment 10

Mounting the Bar and Chain 10

Tensioning the Chain 11

Checking Chain Tension 12

Original Instruction ManualPrinted on chlorine-free paper

Adjusting the Throttle Cable 12

Fitting the Clip 12

Fuel 13

Fueling 14

Chain Lubricant 15

Filling Chain Oil Tank 15

Checking Chain Lubrication 17

Adjusting the Telescoping Shaft 17

Fitting the Harness 18

Backpack Carrying System 18

Starting / Stopping the Engine 20

Operating Instructions 22

Taking Care of the Guide Bar 23

Replacing the Air Filter 23

Printing inks contain vegetable oils, paper can be recycled.

Engine Management 24

Adjusting the Carburetor 24

Spark Arresting Screen in Muffler 24

Spark Plug 25

Storing the Machine 26

Checking and Replacing the Chain

Sprocket 26

Maintaining and Sharpening the

Saw Chain 27

Maintenance and Care 30

Main Parts 32

Specifications 34

Maintenance and Repairs 35

Disposal 35

STIHL Limited Emission Control

Warranty Statement 36

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

It has been built using modern

production techniques and

comprehensive quality assurance.

Every effort has been made to ensure

your satisfaction and trouble-free use of

the product.

Please contact your dealer or our sales

company if you have any queries

concerning this product.

Your

Dr. Nikolas Stihl

© ANDREAS STIHL AG & Co. KG, 2020

0458-435-8221-A. VA2.H20.

0000007471_003_GB

HT 102, HT 103, HT 132, HT 133

This instruction manual is protected by copyright. All rights reserved, especially the rights to reproduce, translate and process

with electronic systems.

1

English

Guide to Using this Manual

Pictograms

The meanings of the pictograms

attached to the machine are explained in

this manual.

Depending on the model concerned, the

following pictograms may be attached to

your machine.

Fuel tank; fuel mixture of

gasoline and engine oil

Chain oil tank; chain oil

Direction of chain rotation

Operate manual fuel

pump

Manual fuel pump

Symbols in text

WARNING

Warning where there is a risk of an

accident or personal injury or serious

damage to property.

NOTICE

Caution where there is a risk of

damaging the machine or its individual

components.

Engineering improvements

STIHL's philosophy is to continually

improve all of its products. For this

reason we may modify the design,

engineering and appearance of our

products periodically.

Therefore, some changes, modifications

and improvements may not be covered

in this manual.

Safety Precautions and

Working Techniques

Special safety precau

tions must be observed

when working with the

pole pruner because it

operates at a very high

chain speed, has very

sharp cutters and a long

reach.

It is important you read

and understand the User

Manual before commis

sioning and keep it in a

safe place for future ref

erence. Non-compliance

with the User Manual

may cause serious or

even fatal injury.

Observe all applicable local safety

regulations, e.g. by trade organizations,

social insurance institutions, labor safety

authorities etc.

If you have never used a power tool

before: Have your dealer or other

experienced user show you how to

operate your machine – or attend a

special course to learn how to operate it.

Minors are not allowed to work with the

power tool – except adolescents above

16 years of age who are instructed

under supervision.

Children, animals and bystanders must

remain at a distance.

When not using the machine, it must be

laid down in such a way that it does not

endanger anyone. Ensure that the

machine cannot be used without

authorization.

-

-

-

2

HT 102, HT 103, HT 132, HT 133

English

275BA009 KN

The user is responsible for accidents or

risks involving third parties or their

property.

Do not lend or rent your power tool

without the User Manual. Be sure that

anyone using it understands the

information contained in this manual.

The use of machines that emit noise

may be limited to certain hours of the

day as specified by national and/or

regional or local regulations.

Anyone operating the machine must be

well rested, in good physical health and

in good mental condition.

If you have any condition that might be

aggravated by strenuous work, check

with your doctor before operating a

machine.

If you have a pacemaker: The ignition

system of your machine produces an

electromagnetic field of very low

intensity. This field may interfere with

some pacemakers. STIHL recommends

that persons with pacemakers consult

their physician and the pacemaker

manufacturer to reduce any health risk.

Anyone who has consumed alcohol or

drugs or medicines affecting their ability

to react must not operate a power tool.

Use your pole pruner for limbing only

(removing or pruning branches). Saw

wood and wooden objects only.

The machine must not be used for any

other purposes – risk of accidents!

Only use guide bars, saw chains, chain

sprockets and accessories that are

explicitly approved for this power tool

model by STIHL or are technically

identical. If you have any questions in

this respect, consult your dealer. Use

only high quality parts and accessories.

In order to avoid the risk of accidents

and damage to the machine.

STIHL recommends the use of STIHL

original tools, guide bars, saw chains,

chain sprockets and accessories. They

are specifically designed to match the

product and meet your performance

requirements.

Never attempt to modify your power tool

in any way since this may increase the

risk of personal injury. STIHL excludes

all liability for personal injury and

damage to property caused while using

unauthorized attachments.

Do not use a high-pressure washer to

clean the power tool. The solid jet of

water may damage parts of the unit.

Clothing and equipment

Wear proper protective clothing and

equipment.

Clothing must be sturdy

but allow complete free

-

dom of movement. Wear

close-fitting clothes such

as a boiler suit, not a

loose jacket.

Do not wear clothing which could

become trapped in wood, brush or

moving parts of the machine. Do not

wear a scarf, necktie or jewelry. Tie up

and confine long hair above your

shoulders.

Wear cut protection

safety boots with non-slip

soles and steel toe caps.

WARNING

To reduce the risk of eye

injuries, wear close-fit

-

ting safety glasses in

accordance with Euro

-

pean Standard EN 166.

Make sure the safety

glasses are a snug fit.

Wear "personal" sound protection, e.g.

ear defenders.

Wear a safety hard hat where there is a

danger of head injuries from falling

objects.

Wear sturdy protective

gloves made of a resist

-

ant material (e. g.

leather).

STIHL can supply a comprehensive

range of personal protective equipment.

Transporting the machine

Always stop the engine.

Always fit the chain scabbard – even

when you carry the power tool for short

distances.

HT 102, HT 103, HT 132, HT 133

3

English

Carry the power tool properly balanced

by the shaft. Do not touch hot parts of

the machine, especially the surface of

the muffler – Risk of burns!

By vehicle: When transporting in a

vehicle, properly secure your machine to

prevent turnover, damage and fuel

spillage.

Refueling

Gasoline is highly flam

mable – keep away from

fire or flame – do not spill

any fuel – no smoking.

Always shut off the engine before

refueling.

Do not fuel a hot engine – fuel may spill

and cause a fire.

Open the fuel cap carefully to allow any

pressure build-up in the tank to release

slowly and avoid fuel spillage.

Only refuel the machine in a well

ventilated place. If fuel has been spilled,

immediately clean the machine – do not

allow your clothes to be splashed with

fuel. If that happens, change your

clothes at once.

After fueling, tighten

down the screw-type fuel

cap as securely as

possible.

This helps reduce the risk of unit

vibrations causing an incorrectly

tightened fuel cap to loosen or come off

and spill quantities of fuel.

-

Check for leaks. Do not start the engine

if there is a fuel leak – serious or fatal

burns could result!

Before starting

Check that your power tool is properly

assembled and in good condition – refer

to appropriate chapters in the User

Manual.

– Check the fuel system for leaks,

especially the visible parts, e. g.,

fuel cap, hose connections, manual

fuel pump (only in machines with a

manual fuel pump). In case of

leakage and damage, do not start

the engine – risk of fire! Have the

machine serviced by a dealer

before using it

– Correctly mounted guide bar

– Correctly tensioned saw chain

– The stop switch must be easy to

push

– Check the choke lever, throttle

trigger and throttle trigger lockout

for smooth action - throttle trigger

must return automatically to idle

position. The choke lever must

spring back from the g and <

positions to the run position F when

the throttle trigger lockout and

throttle trigger are squeezed

– Check that the spark plug boot is

secure – a loose boot may cause

sparking that could ignite

combustible fumes and cause a fire!

– Never attempt to modify the controls

or safety devices

– Keep the handles dry and clean –

free from oil and dirt – this is

important for safe control of the

machine

– Adjust the harness to suit your

height and reach. Observe the

chapter "Fitting the Harness"

To reduce the risk of personal injury, do

not operate your power tool if it is

damaged or not properly assembled!

If you use a harness: Practice setting

down the machine quickly by removing

the harness or by unhooking the

machine as you would in an emergency.

To avoid damage, do not throw the

machine to the ground when practicing.

Starting the engine

Start the engine at least 3 meters from

the fueling spot, outdoors only.

Place the power tool on level ground in

an open area. Make sure you have good

balance and secure footing. Hold the

power tool securely. The chain must be

clear of the ground and all other

obstructions because it may begin to run

when the engine starts.

Your power tool is designed to be

operated by one person only. Do not

allow other persons within a radius of

15 m of your own position – even when

starting the power tool – Risk of injury!

Start the engine as described in the user

manual.

The saw chain continues running for a

short period when you release the

throttle trigger – flywheel effect!

4

HT 102, HT 103, HT 132, HT 133

English

390BA026 KN

15m (50ft)

15m (50ft)

Check engine idling speed: The saw

chain must not move when the engine is

idling – with the throttle trigger released.

Keep easily flammable materials (e.g.

wood chips, bark, dry grass, fuel) away

from the hot exhaust gas flow and the

hot muffler surface – Risk of fire!

Holding and guiding the machine

Always hold the power tool firmly with

both hands – right hand on the control

handle, left hand on the drive tube –

even if you are left-handed. Wrap your

thumbs firmly around the control handle

and shaft.

Machines with telescopic shaft: Extend

the telescopic shaft only as far as the

working height.

While working

Make sure you always have good

balance and secure footing.

In the event of impending danger or in

an emergency, switch off the engine

immediately by pressing the stop switch.

This power tool is not

insulated. Keep at least

15 m away from electric

power lines – Danger of

fatal electric shock!

Do not allow other persons within a

radius of 15 m of your own position due

to falling branches and ejected wood

particles – Risk of injury!

This distance must also be maintained in

relation to objects (vehicles, window

panes) – risk of property damage!

Keep the bar nose at least 15 m away

from electric power lines . Electric

current may also arc over from highvoltage cables at greater distance. Have

the power switched off before starting

work in the immediate vicinity of power

lines.

Switch off the engine before changing

the saw chain – Risk of injury!

Ensure that the engine idling speed is

correct. The saw chain must not move

when the throttle trigger has been

released.

It the saw chain continues moving, have

the machine repaired by your specialist

dealer. Check and correct the idle speed

setting at regular intervals.

Never leave a running machine

unattended.

Take special care in slippery, wet

conditions, in snow and on slopes,

uneven ground, etc. – Risk of slipping!

Watch out for obstacles: tree stumps,

roots – risk of tripping or stumbling!

When working at heights:

– Always use a lift bucket

– Never use the machine while

standing on a ladder or in a tree

– Never work on an insecure support

– Never use the machine with just one

hand

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

Take breaks when you start getting tired

or feeling fatigue – risk of accidents!

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Proceed with caution, do not put

others in danger.

HT 102, HT 103, HT 132, HT 133

5

English

246BA030 KN

246BA032 KN

As soon as the engine is

running, the power

machine generates toxic

exhaust gas. These

gases may be odorless

and invisible and may

contain unburned hydro

-

carbons and benzene.

Never run the engine

indoors or in poorly venti

lated locations, even if

your model is equipped

with a catalytic converter.

To reduce the risk of serious or fatal

injury from breathing toxic fumes,

ensure proper ventilation when working

in trenches, hollows or other confined

locations.

Stop work immediately if you start

suffering from nausea, headaches,

impaired vision (e.g. your field of vision

gets smaller), impaired hearing,

dizziness, or impaired concentration –

these symptoms may possibly be the

result of too-high exhaust gas

concentration – Risk of accidents!

Operate your power tool so that it

produces a minimum of noise and

emissions – do not run the engine

unnecessarily, accelerate the engine

only when working.

To reduce the risk of fire, do not smoke

while operating or standing near your

power tool. Combustible fuel vapor may

escape from the fuel system.

Dust (e.g. sawdust), fumes and smoke,

generated while using the machine, may

be hazardous to health. Wear a dust

mask in case of dust formation.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting". Check in particular

that the fuel system has no leaks and the

safety equipment is fully operative.

Never use a power tool that is no longer

-

safe to operate. In case of doubt, contact

a dealer.

If you use a harness, ensure that the

exhaust gas flow is diverted away from

your body – Risk of fire!

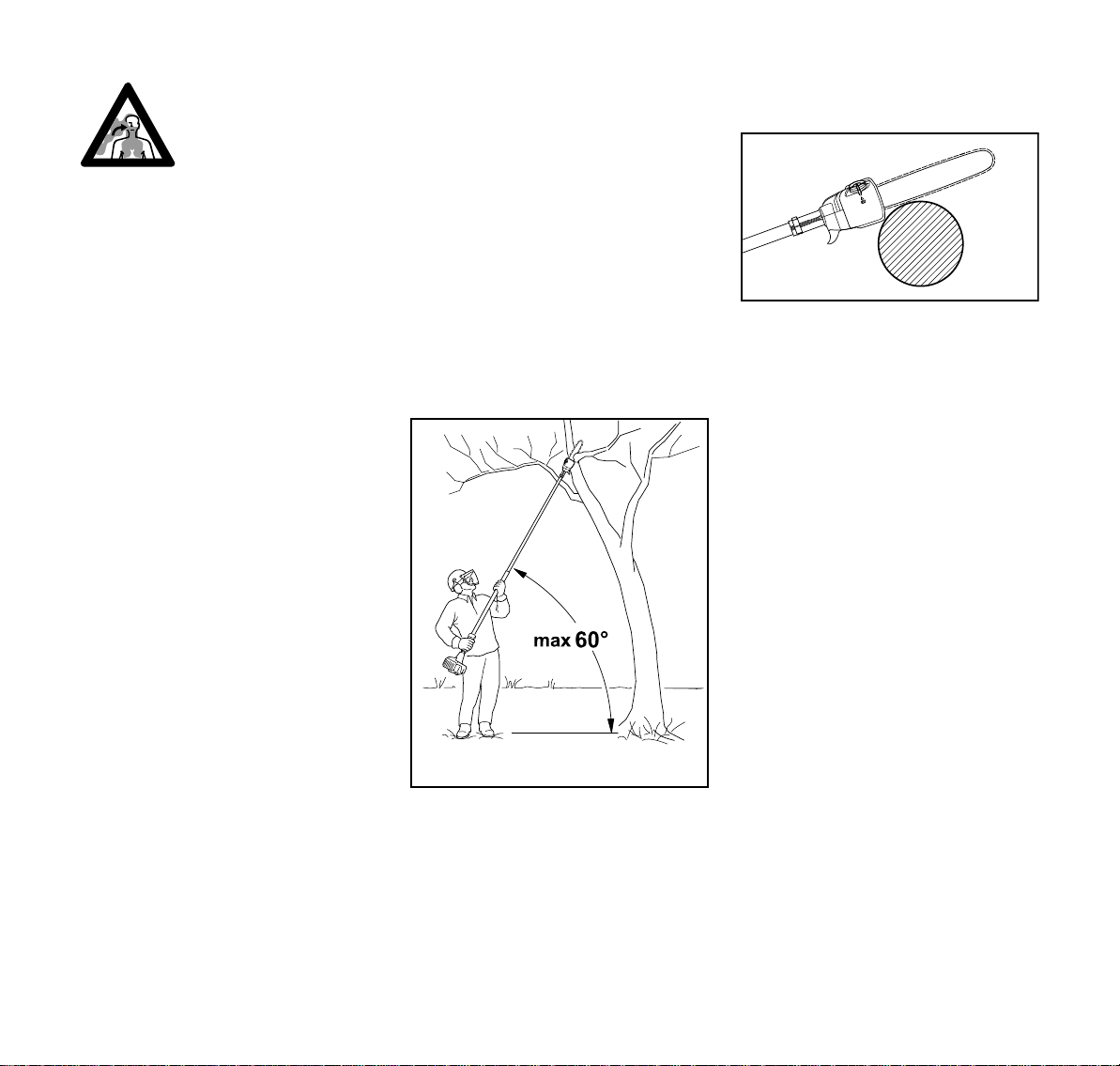

Limbing

Hold the pole pruner at an angle. Do not

stand directly underneath the limb being

cut. Do not exceed an angle of 60° from

the horizontal. Watch for falling wood.

Keep the work area clear – remove

interfering limbs and brush.

Before sawing branches, establish an

escape route and remove all obstacles.

When performing the separating cut,

position the bar against the branch near

the hook. This will prevent the power tool

from making jolting movements when

you start the separating cut.

Start the cut with the saw chain at full

throttle.

Always cut with a correctly sharpened,

properly tensioned saw chain – the

depth gauge setting must not be too

large.

Do not operate your power tool in the

starting throttle position – engine speed

cannot be controlled in this position.

Perform cross-cut from the top

downward to avoid the chain pinching in

the cut.

If branches are thick or heavy, make a

relief cut – see "Using the Pole Pruner".

Exercise extreme caution when sawing

branches under tension – Risk of injury!

Always make a relieving cut on the

compression side first and then perform

the bucking cut at the tension side.

Be careful when cutting splintered wood

– Risk of injury from ejected pieces of

wood!

6

HT 102, HT 103, HT 132, HT 133

English

If working on a slope, always stand uphill

or to the side of the branch which is to be

sawn. Watch out for rolling branches.

Note when reaching the end of a cut that

the power tool is no longer supported by

the guide bar in the cut. The user must

bear the weight of the machine – risk of

loss of control!

Always pull the power tool out of the cut

with the saw chain running.

Use the power tool for limbing and

pruning only, not for felling – Risk of

accidents!

Keep the saw chain away from any

foreign objects: Stones, nails, etc. may

be ejected and damage the saw chain.

If a rotating saw chain hits a stone or

another hard object, sparks may be

generated which may ignite easily

flammable materials under certain

conditions. Also dried-out plants and

brushwood are combustible, above all in

hot and dry weather. If there is a risk of

fire, do not use your pole pruner near

easily flammable materials, dry plants or

scrub. It is mandatory that you ask the

responsible forestry office about the

current fire hazard.

Before you leave the machine: Shut the

engine off.

Vibrations

Prolonged use of the power tool may

result in vibration-induced circulation

problems in the hands (whitefinger

disease).

No general recommendation can be

given for the length of usage because it

depends on several factors.

The period of usage is prolonged by:

– Hand protection (wearing warm

gloves)

– Work breaks

The period of usage is shortened by:

– Any personal tendency to suffer

from poor circulation (symptoms:

frequently cold fingers, tingling

sensations).

– Low outside temperatures.

– The force with which the handles

are held (a tight grip restricts

circulation).

Continual and regular users should

monitor closely the condition of their

hands and fingers. If any of the above

symptoms appear (e.g. tingling

sensation in fingers), seek medical

advice.

Maintenance and Repairs

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in the instruction manual.

Have all other work performed by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

Only use high-quality replacement parts

in order to avoid the risk of accidents

and damage to the machine. If you have

any questions in this respect, consult a

servicing dealer.

STIHL recommends the use of genuine

STIHL replacement parts. They are

specifically designed to match your

model and meet your performance

requirements.

To reduce the risk of injury from

unintentional engine startup, always

shut off the engine and disconnect the

spark plug boot before performing any

repairs, maintenance or cleaning work. –

Exception: Carburetor and idle speed

adjustments.

Do not turn the engine over on the

starter with the spark plug boot or spark

plug removed since there is otherwise a

risk of fire from uncontained sparking.

To reduce the risk of fire, do not service

or store your machine near open flames.

Check the fuel filler cap for leaks at

regular intervals.

Use only a spark plug of the type

approved by STIHL and make sure it is

in good condition – see "Specifications".

Inspect the ignition lead (insulation in

good condition, secure connection).

Check the condition of the muffler.

To reduce the risk of fire, do not operate

your machine if the muffler is damaged

or missing – there is also a risk of

hearing damage.

Do not touch a hot muffler since burn

injury will result.

Shut off the engine

– before checking chain tension.

– before retensioning the chain.

– before replacing the chain.

– before rectifying problems.

HT 102, HT 103, HT 132, HT 133

7

English

246BA030 KN

Observe sharpening instructions – keep

the chain and guide bar in good

condition at all times for safe and correct

handling of the machine. The chain must

be properly sharpened, tensioned and

well lubricated.

Always change the chain, guide bar and

sprocket in good time.

Store fuel and chain lubricant in properly

labeled, safety-type canisters only.

When handling gasoline, avoid direct

contact with the skin and avoid inhaling

fuel vapor – health risk.

Maintenance, replacement, or repair of

the emission control devices and

systems may be performed by any

nonroad engine repair establishment or

individual. However, if you make a

warranty claim for a component which

has not been serviced or maintained

properly, STIHL may deny coverage.

For any maintenance please refer to the

maintenance chart and to the warranty

statement near the end of the instruction

manual.

Using the Unit

Preparations

N Wear suitable protective clothing,

observe safety precautions.

N Adjust telescoping shaft to the

required length (HT 103, HT 133

only).

N Start the engine.

N Put on the shoulder strap.

Cutting Sequence

To allow branches to free fall, always cut

the lower branches first. Prune heavy

branches (large diameter) in several

controllable pieces.

WARNING

Never stand directly underneath the

branch you are cutting – be wary of

falling branches. Note that a branch may

spring back at you after it hits the ground

– risk of injury.

HT 102, HT 132

Always hold the shaft with your left hand

in the area of the handle hose.

The shaft should always be held at an

angle of 60° or less.

The least tiring working position is a tool

angle of 60°.

Any lesser angle may be used to suit the

situation.

Disposal

Do not throw cuttings into the garbage

can – they can be composted.

Working Techniques

Hold the control handle with your right

hand, and the shaft with your left hand.

Your left arm should be extended to the

most comfortable position.

8

HT 102, HT 103, HT 132, HT 133

English

246BA032 KN

2

1

246BA033 KN

3

4

A

390BA024 KN

0000-GXX-1568-A0

0000-GXX-1569-A0

Cross-cut

To avoid pinching the bar in the cut,

position the cutting attachment with the

housing against the branch and then

perform the cross-cut from the top

downwards.

Relieving cut

N To do this, apply the cutting

attachment and pull it across the

bottom of the branch in an arc as far

as the bar nose.

N Perform the cross cut (2) – position

the bar with the housing against the

branch.

Flush-cutting thick branches

Cutting above obstacles

The machine's long reach makes it

possible to prune branches that are

overhanging obstacles, such as rivers or

lakes. The tool angle in this case

depends on the position of the branch.

Cutting from a lift bucket

To avoid tearing the bark on thick

branches, always start by performing a

relieving cut (1) on the underside of the

branch.

HT 102, HT 103, HT 132, HT 133

If branch diameter is more than

10 cm (4 in), first

N perform undercut (3) and then

cross-cut at a distance of about

20 cm/8 in (A) from the final cut.

Then carry out the flush-cut (4),

starting with a relieving cut and

finishing with a cross-cut.

The machine's long reach enables

cutting to be performed next to the trunk

without the risk of the lift bucket

damaging other branches. The tool

angle in this case depends on the

position of the branch.

9

English

001BA248 KN

1

2

3

a

001BA244 KN

246BA021 KN

1

2

246BA022-A1

Cutting Attachment

A cutting attachment consists of the saw

chain, guide bar and chain sprocket.

The cutting attachment that comes

standard is designed to exactly match

the pole pruner.

– The pitch (t) of the saw chain (1),

chain sprocket and the nose

sprocket of the Rollomatic guide bar

must match.

– The drive link gauge (2) of the saw

chain (1) must match the groove

width of the guide bar (3).

If non-matching components are used,

the cutting attachment may be damaged

beyond repair after a short period of

operation.

Chain Scabbard

The scope of supply includes a bar

scabbard that matches the cutting

attachment.

If guide bars of different lengths are

mounted to the pole pruner, always use

a chain scabbard of the correct length

which covers the complete guide bar.

The length of the matching guide bars is

marked on the side of the chain

scabbard.

Mounting the Bar and Chain

Removing the Chain Sprocket Cover

N Unscrew the nut and remove the

chain sprocket cover.

N Turn the screw (1) clockwise until

the tensioner slide (2) butts against

the right end of the housing slot.

10

HT 102, HT 103, HT 132, HT 133

English

390BA003 KN

1

246BA024 KN

Fitting the Chain

WARNING

Wear work gloves to protect your hands

from the sharp cutters.

N Fit the chain – start at the bar nose.

1

5

3

4

N Fit the guide bar over the screw (3)

and engage peg of tensioner slide in

the hole (4) – place the chain over

the sprocket (5) at the same time.

N Turn the tensioning screw (1)

counterclockwise until there is very

little chain sag on the underside of

the bar – and the drive link tangs are

engaged in the bar groove.

N Refit the sprocket cover and screw

on the nut fingertight.

N Go to chapter on "Tensioning the

Saw Chain".

Tensioning the Chain

246BA023 A1

Re-tensioning during cutting work:

N Shut off the engine.

N Loosen the nut.

N Hold the bar nose up.

N Use a screwdriver to turn the

tensioning screw (1)

counterclockwise until the chain fits

snugly against the underside of the

bar.

N While still holding the bar nose up,

tighten down the nut firmly.

N Go to "Checking Chain Tension".

A new chain has to be re-tensioned

more often than one that has been in

use for some time.

N Check chain tension frequently –

see chapter on "Operating

Instructions".

HT 102, HT 103, HT 132, HT 133

11

English

246BA025 KN

002BA655 KN

0000-GXX-1672-A0

Checking Chain Tension

N Shut off the engine.

N Wear work gloves to protect your

hands.

N The chain must fit snugly against

the underside of the bar and it must

still be possible to pull the chain

along the bar by hand.

N If necessary, re-tension the chain.

A new chain has to be re-tensioned

more often than one that has been in

use for some time.

N Check chain tension frequently –

see chapter on "Operating

Instructions".

Adjusting the Throttle Cable

It may be necessary to correct the

adjustment of the throttle cable after

assembling the machine or after a

prolonged period of operation.

Adjust the throttle cable only when the

unit is completely and properly

assembled.

N Set the throttle trigger to the full

throttle position.

N Carefully rotate the screw in the

throttle trigger in the direction of the

arrow until you feel initial resistance.

Then rotate it another half turn in the

same direction.

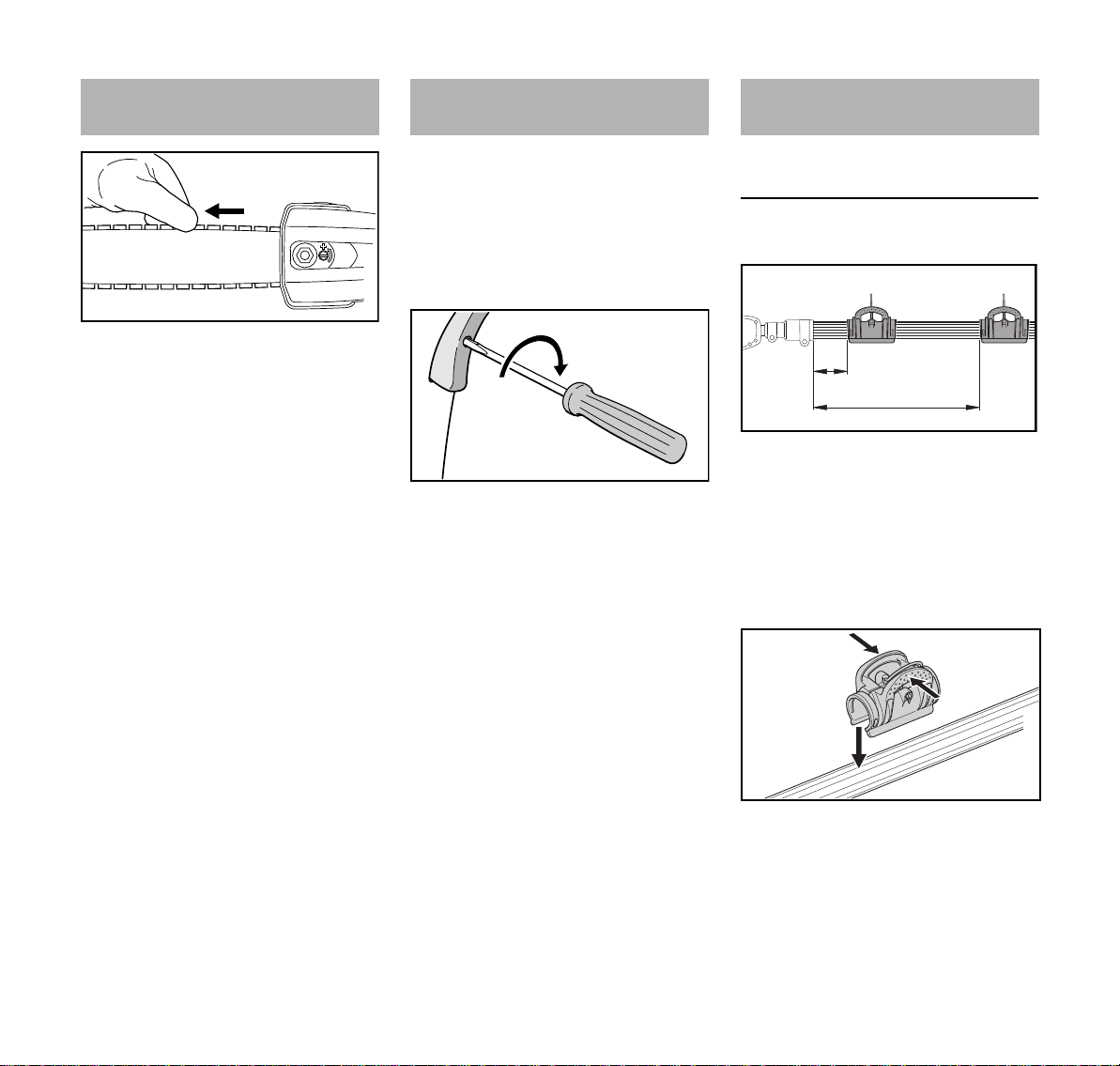

Fitting the Clip

Clip-On Carrying Ring (only versions

with telescoping shaft)

Position of carrying ring

A

B

0000-GXX-1673-A0

Depending on the shaft length, the

following positions are recommended:

– Telescoping shaft compressed,

distance A = 15 cm (6 in)

– Telescoping shaft fully extended,

distance B = 50 cm (20 in)

Fitting the clip-on carrying ring

12

N Squeeze the ends (arrows) together

and push carrying ring onto the

shaft.

HT 102, HT 103, HT 132, HT 133

English

Fuel

This engine is certified to operate on

unleaded gasoline and the STIHL twostroke engine oil at a mix ratio of 50:1.

Your engine requires a mixture of highquality gasoline and two-stroke air

cooled engine oil.

Use mid-grade unleaded gasoline with a

minimum octane rating of 89 ((R+M)/2)

and no more than 10% ethanol content.

Fuel with an octane rating below 89 may

increase engine temperatures. This, in

turn, increases the risk of piston seizure

and damage to the engine.

The chemical composition of the fuel is

also important. Some fuel additives not

only detrimentally affect elastomers

(carburetor diaphragms, oil seals, fuel

lines, etc.), but magnesium castings and

catalytic converters as well. This could

cause running problems or damage the

engine. For this reason STIHL

recommends that you use only quality

unleaded gasoline!

Gasoline with an ethanol content of

more than 10% can cause running

problems and major damage in engines

and should not be used.

For further details, see

www.STIHLusa.com/ethanol

The ethanol content in gasoline affects

engine speed – it may be necessary to

readjust the carburetor if you use fuels

with various ethanol contents.

WARNING

To reduce the risk of personal injury

from loss of control and / or contact with

the running cutting tool, do not use your

unit with incorrect idle adjustment. At

correct idle speed, the cutting tool

should not move.

If your power tool´s idle speed is

incorrectly adjusted, have your

authorized STIHL servicing dealer

check your machine and make the

proper adjustments and repairs.

The idle speed and maximum speed of

the engine change if you switch from a

fuel with a certain ethanol content to

another fuel with a much higher or lower

ethanol content.

This problem can be avoided by always

using fuel with the same ethanol

content.

To ensure the maximum performance of

your STIHL engine, use a high quality 2cycle engine oil, such as STIHL 2-cycle

engine oils. STIHL 2-cycle engine oils

are specially designed for STIHL

engines. To help your engine run

cleaner and reduce harmful carbon

deposits, STIHL recommends using

STIHL HP Ultra 2-cycle engine oil, or

use an equivalent high quality 2-cycle

engine oil.

To meet the requirements of EPA and

CARB we recommend to use STIHL HP

Ultra oil or equivalent.

Do not use NMMA or TCW rated (twostroke water cooled) mix oils or other

mix oils that state they are for use in both

water cooled and air cooled engines

(e.g., outboard motors, snowmobiles,

chain saws, mopeds, etc.).

Take care when handling gasoline.

Avoid direct contact with the skin and

avoid inhaling fuel vapor. When filling at

the pump, first remove the container

from your vehicle and place the

container on the ground before filling. To

reduce the risk of sparks from static

discharge and resulting fire and/or

explosion, do not fill fuel containers that

are sitting in or on a vehicle or trailer.

The container should be kept tightly

closed in order to limit the amount of

moisture that gets into the mixture.

The machine’s fuel tank should be

cleaned as necessary.

STIHL MotoMix

STIHL recommends the use of STIHL

MotoMix. STIHL MotoMix has a high

octane rating and ensures that you

always use the right gasoline/oil mix

ratio.

STIHL MotoMix uses STIHL HP Ultra

two-stroke engine oil suited for high

performance engines.

For further details, see

www.STIHLusa.com/ethanol

Fuel mix ages

If not using STIHL MotoMix, only mix

sufficient fuel for a few days of work, not

to exceed 30 days of storage. Store in

approved fuel-containers only. When

mixing, pour oil into the container first,

and then add gasoline. Close the

container and shake it vigorously by

hand to ensure proper mix of oil and

gasoline.

HT 102, HT 103, HT 132, HT 133

13

English

0000-GXX-0476-A0

002BA447 KN

002BA448 KN

Gasoline Oil (STIHL 50:1 or equiva

lent high-quality oils)

Liters Liters (ml)

10.02(20)

5 0.10 (100)

10 0.20 (200)

20 0.40 (400)

US gal. US fl.oz.

12.6

2 1/2 6.4

5 12.8

Dispose of empty mixing-oil containers

only at authorized disposal locations.

-

Fueling

Preparations

N Before fueling, clean the filler cap

and the area around it to ensure that

no dirt falls into the tank.

N Position the machine so that the

tank cap faces up.

Opening the Tank Cap

Filling Up with Fuel

Take care not to spill fuel while fueling

and do not overfill the tank.

STIHL recommends you use the STIHL

filler nozzle for fuel (special accessory).

N Fill up with fuel.

Closing the Tank Cap

N Place the cap in the opening.

N Turn the cap clockwise as far as

stop and tighten it down as firmly as

possible by hand.

14

N Turn the cap counterclockwise until

it can be removed from the tank

opening.

N Remove the tank cap.

HT 102, HT 103, HT 132, HT 133

English

246BA026 KN

0000,GXX-0135-A0 KN

0000-GXX-0136-A0

0000-GXX-0137-A0 KN

Chain Lubricant Filling Chain Oil Tank

For automatic and reliable lubrication of

the chain and guide bar – use only an

environmentally compatible quality

chain and bar lubricant. Rapidly

biodegradable STIHL BioPlus is

recommended.

NOTICE

Biological chain oil must be resistant to

aging (e.g. STIHL BioPlus), since it will

otherwise quickly turn to resin. This

results in hard deposits that are difficult

to remove, especially in the area of the

chain drive and chain. It may even cause

the oil pump to seize.

The service life of the chain and guide

bar depends on the quality of the

lubricant. It is therefore essential to use

only a specially formulated chain

lubricant.

WARNING

Do not use waste oil. Renewed contact

with waste oil can cause skin cancer.

Moreover, waste oil is environmentally

harmful.

NOTICE

A full chain oil tank is sufficient for only

half a tankful of fuel. Check the oil level

regularly during cutting work. Never

allow the oil tank to run dry.

Preparations

N Thoroughly clean the tank cap and

the area around it to ensure that no

dirt falls into the tank.

N Position the machine so that the

tank cap faces up.

Opening

N Raise grip to vertical position.

N Turn the cap counterclockwise

(about a quarter turn).

NOTICE

Waste oil does not have the necessary

lubricating properties and is unsuitable

for chain lubrication.

HT 102, HT 103, HT 132, HT 133

Marks on tank cap and oil tank must line

up.

15

English

0000-GXX-0138-A0 KN

0000-GXX-0137-A0 KN

0000-GXX-0139-A0 KN

0000-GXX-0140-A0 KN

0000-GXX-0141-A0 KN

0000-GX-0142 A0 KN

N Remove the tank cap.

Filling Up with Chain Oil

N Fill the tank with chain oil.

Take care not to spill chain oil while

refilling and do not overfill the tank.

STIHL recommends you use the STIHL

filler nozzle for chain oil (special

accessory).

Closing

Grip must be vertical:

N Fit the cap – marks on tank cap and

oil tank must line up.

N Press the cap down as far as stop.

N While holding the cap depressed,

turn it clockwise until it engages in

position.

The marks on the cap and oil tank are

then in alignment.

N Fold the grip down.

Tank cap is locked.

If the oil level in the tank does not go

down, the reason may be a problem in

the oil supply system: Check chain

lubrication, clean the oilways, contact

your dealer for assistance if necessary.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer.

If the tank cap cannot be locked in the oil

tank opening

Bottom of cap is twisted in relation to

top.

N Remove the cap from the oil tank

and check it from above.

16

HT 102, HT 103, HT 132, HT 133

English

002BA584 KN

1

0000-GXX-0136-A0

246BA027 KN

Left: Bottom of cap is twisted –

inner mark (1) in line with

outer mark.

Right: Bottom of cap in correct posi

tion – inner mark is under the

grip. It is not in line with the

outer mark.

N Place the cap on the opening and

rotate it counterclockwise until it

engages the filler neck.

N Continue rotating the cap

counterclockwise (about a quarter

turn) – this causes the bottom of the

cap to be turned to the correct

position.

N Turn the cap clockwise and lock it in

position – see section on "Closing".

Checking Chain Lubrication

-

The saw chain must always throw off a

small amount of oil.

NOTICE

Never operate your machine without

chain lubrication. If the chain runs dry,

the whole cutting attachment will be

irretrievably damaged within a very short

time. Always check chain lubrication and

the oil level in the tank before starting

work.

Every new chain has to be broken in for

about 2 to 3 minutes.

After breaking in the chain, check chain

tension and adjust if necessary – see

"Checking Chain Tension".

Adjusting the Telescoping

Shaft

WARNING

Always shut off the engine and fit the

chain guard

0000-GXX-1566-A0

N Loosen the clamp nut half a turn

counterclockwise.

N Adjust shaft to the required length.

N Tighten down the clamp nut firmly.

HT 102, HT 103, HT 132, HT 133

17

English

2

1

0000-GXX-1663-A0

2

1

0000-GXX-1664-A0

2

1

0000-GXX-1571-A0

Fitting the Harness

The type and style of the shoulder strap

depend on the market.

Shoulder strap (HT 102, HT 132)

N Put on the shoulder strap (1).

N Adjust the length of the strap.

N With the power tool attached, the

carabiner (2) must be at about the

same height as your right hip.

Shoulder strap (HT 103, HT 133)

N Put on the shoulder strap (1).

N Adjust the length of the strap.

N With the power tool attached, the

carabiner (2) must be at about the

same height as your right hip.

Backpack Carrying System

Only versions with rigid shaft

N Put the backpack carrying

system (1) on your back and adjust

it as described in the instruction

leaflet provided.

N Attach the carabiner (2) to the

machine's carrying ring.

N Attach the pole pruner to the

carrying strap when cutting.

18

HT 102, HT 103, HT 132, HT 133

English

Only versions with telescoping shaft

1

4

5

3

5

4

2

3

N Adjust the hip belt (3), both shoulder

straps (4) and the carrying strap (5).

0000-GXX-1572-A0

N Put the backpack carrying

system (1) on your back and adjust

it as described in the instruction

leaflet provided.

N Attach the carabiner (1) to the

carrying ring (2) on the shaft.

N Attach the pole pruner to the

carrying strap when cutting.

3

N Adjust the hip belt (3), both shoulder

0000-GXX-1573-A1

straps (4) and the carrying strap (5).

N Squeeze the clip together to move it

up or down the shaft.

0000-GXX-1574-A0

0000-GXX-1575-A0

HT 102, HT 103, HT 132, HT 133

19

English

2

1

3

0000-GXX-0477-A0

0000-GXX-0478-A0

0000-GXX-1576-A0

Starting / Stopping the

Engine

Controls

1 Throttle trigger lockout

2 Throttle trigger

3 Stop switch with Run and Stop

positions. Depress the stop switch

(…) to switch off the ignition – see

"Function of stop switch and ignition

system".

Function of stop switch and ignition

system

The ignition is switched off and the

engine stopped when the stop switch is

pressed. The stop switch returns

automatically to the Run position when it

is released: The ignition is switched on

again after the engine stops – the engine

is then ready to start.

Starting the Engine

N Press the manual fuel pump

bulb (9) at least five times – even if

the bulb is already filled with fuel.

N Press in the choke knob (8) and turn

it to the position that suits the engine

temperature:

g if the engine is cold

< for warm start – also use this posi

tion if the engine has been running

but is still cold.

-

Cranking

N Remove the chain scabbard. Check

that the chain is not touching the

ground or any other obstacles.

N Place the unit on the ground: It must

rest securely on the engine support

and the hook. If necessary, rest the

hook on a raised support (e.g. a

branch, mound or something

similar).

WARNING

Check that nobody is standing within the

working range of the pruner.

N Make sure you have a safe and

secure footing.

N Hold the unit with your left hand on

the fan housing and press it down

firmly – your thumb should be under

the fan housing.

NOTICE

Do not stand or kneel on the drive tube.

N Hold the starter grip with your right

hand.

N Pull the starter grip slowly until you

feel it engage and then give it a brisk

strong pull.

20

HT 102, HT 103, HT 132, HT 133

English

NOTICE

Do not pull out the starter rope all the

way – it might otherwise break.

N Do not let the starter grip snap back.

Guide it slowly back into the housing

so that the starter rope can rewind

properly.

N Continue cranking until the engine

runs.

As soon as the engine runs

N Press down the throttle trigger

lockout and open the throttle – the

choke knob moves to the run

position F. After a cold start, warm

up the engine by opening the

throttle several times.

WARNING

Risk of injury from saw chain running

when the engine is idling. Adjust the

carburetor so that the saw chain does

not run when the engine is idling – see

“Adjusting the Carburetor”.

Your machine is now ready for

operation.

Stopping the Engine

N Depress the stop switch – the

engine stops – release the stop

switch – it springs back to the run

position.

Other Hints on Starting

Engine stalls in cold start position g or

under acceleration.

N Move the choke knob to < and

continue cranking until the engine

runs.

Engine does not start in warm start

position <

N Move the choke knob to g and

continue cranking until the engine

runs.

0000-GXX-1558-A0

If the engine does not start

N Check that all settings are correct.

N Check that there is fuel in the tank

and refuel if necessary.

N Check that the spark plug boot is

properly connected.

N Repeat the starting procedure.

Engine is flooded

N Move the choke knob to F and

continue cranking until the engine

runs.

Fuel tank run until completely dry

N After refueling, press the manual

fuel pump bulb at least five times –

even if the bulb is already filled with

fuel.

N Set the choke knob to suit the

engine temperature.

N Now start the engine.

HT 102, HT 103, HT 132, HT 133

21

English

Operating Instructions

During Break-In Period

A factory-new machine should not be

run at high revs (full throttle off load) for

the first three tank fillings. This avoids

unnecessary high loads during the

break-in period. As all moving parts

have to bed in during the break-in

period, the frictional resistances in the

engine are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

During Operation

NOTICE

Do not make the mixture leaner to

achieve an apparent increase in power –

this could damage the engine – see

"Adjusting the Carburetor".

Check chain tension frequently

A new chain has to be retensioned more

often than one that has been in use for

some time.

Chain cold

Tension is correct when the chain fits

snugly against the underside of the bar

and can still be pulled along the bar by

hand. Retension if necessary – see

"Tensioning the Saw Chain".

Chain at operating temperature

The chain stretches and begins to sag.

The drive links must not come out of the

bar groove – the chain may otherwise

jump off the bar. Retension the chain –

see "Tensioning the Saw Chain".

NOTICE

The chain contracts as it cools down. If it

is not slackened off, it can damage the

gear shaft and bearings.

After long period of full-throttle operation

Allow engine to run for a short while at

idle speed so that engine heat can be

dissipated by the flow of cooling air. This

protects engine-mounted components

(ignition, carburetor) from thermal

overload.

After Finishing Work

N Slacken off the chain if you have

retensioned it at operating

temperature during cutting work.

NOTICE

Always slacken off the chain after

finishing work. The chain contracts as it

cools down. If it is not slackened off, it

can damage the gear shaft and

bearings.

Storing your saw for a short period

Fit the chain scabbard and allow engine

to cool down. To avoid condensation, fill

the fuel tank and keep the machine in a

dry place, well away from sources of

ignition, until you need it again.

Storing for a long period

See chapter on "Storing the Machine"

22

HT 102, HT 103, HT 132, HT 133

English

1

2

3

246BA028 KN

1

1

0000-GXX-0482-A0

2

3

4

Taking Care of the Guide Bar

N Turn the bar over every time you

sharpen the chain and every time

you replace the chain – this helps

avoid one-sided wear, especially at

the nose and underside of the bar.

N Regularly clean the oil inlet hole (1),

the oilway (2) and the bar

groove (3).

N Measure the groove depth – with the

scale on the filing gauge (special

accessory) – in the area used most

for cutting.

The drive link tangs will otherwise

scrape along the bottom of the groove –

the cutters and tie straps will not ride on

the bar rails.

Replacing the Air Filter

Filters have an average life of more than

a year. Do not remove the filter cover or

replace the air filter as long as there is no

noticeable loss of power.

If there is a noticeable loss of engine

power

N Turn the choke knob to g.

N Loosen the screws (1).

N Remove the filter cover (2).

N Clean away loose dirt from around

the filter.

N Remove the filter element (3).

N Replace dirty or damaged filter

element (3).

N Replace any damaged parts.

Installing the Filter Element

Chain type Chain pitch Minimum

groove depth

Picco 1/4" P 4.0 mm

(0.16 in)

If groove depth is less than specified:

N Replace the guide bar.

HT 102, HT 103, HT 132, HT 133

N Install the filter element (3) in the

filter housing and fit the cover.

N Insert the screws (1) and tighten

them down firmly.

23

English

0000-GXX-0495-A0

0000-GXX-0486-A0

4

5

Engine Management Adjusting the Carburetor

Exhaust emissions are controlled by the

design of the engine and components

(e.g. carburation, ignition, timing and

valve or port timing).

The carburetor has been set at the

factory to provide an optimum fuel-air

mixture under most operating

conditions.

Adjusting Idle Speed

Engine stops while idling

N Warm up the engine for about

3 minutes.

N Turn the idle speed screw (LA)

slowly clockwise until the engine

runs smoothly – the saw chain must

not rotate.

Chain rotates when engine is idling

N Turn the idle speed screw (LA)

counterclockwise until the chain

stops running and then turn the

screw another 1/2 to 3/4 turn in the

same direction.

Spark Arresting Screen in

Muffler

N If the engine is down on power,

check the spark arresting screen in

the muffler.

N Wait for the muffler to cool down.

N Take out the screw (4).

N Lift the spark arresting screen (5)

and pull it out.

N Clean the spark arresting

screen (5). If the screen is damaged

or heavily carbonized, install a new

one.

N Refit the spark arresting screen (5).

N Insert the screw (4) and tighten it

down firmly.

24

WARNING

If the chain continues moving when the

engine is idling, have your power tool

checked and repaired by your servicing

dealer.

HT 102, HT 103, HT 132, HT 133

Loading...

Loading...