HSE 61, 71, 81

Instruction Manual2 - 18

English

Contents

1 Guide to Using this Manual.........................2

2 Safety Precautions and Working Techni‐

ques............................................................ 2

3 Using the Unit............................................. 7

4 Connecting to Power Supply.......................8

5 Switching On...............................................9

6 Switching Off...............................................9

7 Rotating Handle........................................ 10

8 Storing the Machine.................................. 10

9 Sharpening Instructions............................ 10

10 Maintenance and Care..............................11

11 Minimize Wear and Avoid Damage...........12

12 Main Parts.................................................12

13 Specifications............................................13

14 Maintenance and Repairs......................... 14

15 Disposal.................................................... 14

16 EC Declaration of Conformity................... 15

17 UKCA Declaration of Conformity.............. 15

18 General Power Tool Safety Warnings.......16

Dear Customer,

Thank you for choosing a quality engineered

STIHL product.

It has been built using modern production techni‐

ques and comprehensive quality assurance.

Every effort has been made to ensure your satis‐

faction and trouble-free use of the product.

Please contact your dealer or our sales company

if you have any queries concerning this product.

Your

Dr. Nikolas Stihl

1 Guide to Using this Manual

1.1 Pictograms

All the pictograms attached to the machine are

shown and explained in this manual.

1.2 Symbols in text

WARNING

Warning where there is a risk of an accident or

personal injury or serious damage to property.

NOTICE

Caution where there is a risk of damaging the

machine or its individual components.

1.3 Engineering improvements

STIHL's philosophy is to continually improve all

of its products. For this reason we may modify

the design, engineering and appearance of our

products periodically.

Therefore, some changes, modifications and

improvements may not be covered in this man‐

ual.

2 Safety Precautions and

Working Techniques

Special safety precautions must be

observed when working with this

power tool because it has very sharp

cutting blades and is powered by

electricity.

It is important that you read and

understand the User Manual before

commissioning and keep it in a safe

place for future reference. Non-com‐

pliance with the User Manual could

lead to serious or even fatal injury.

Note the national safety regulations issued, e.g.

by the employers' liability insurance association,

social security institutions, occupational safety

and health authorities or other organizations.

If you have never used a power tool before:

Have your dealer or other experienced user

show you how to operate your machine – or

attend a special course to learn how to operate

it.

Minors are not allowed to work with the power

tool – except adolescents above 16 years of age

who are instructed under supervision.

Children, animals and bystanders must remain at

a distance.

When not using the machine, it must be laid

down in such a way that it does not endanger

anyone. Ensure that the machine cannot be

used without authorization.

Original Instruction Manual

0000000907_027_GB

Printed on chlorine-free paper

Printing inks contain vegetable oils, paper can be recycled.

© ANDREAS STIHL AG & Co. KG 2022

0458-279-0121-E. VA1.B22.

2 0458-279-0121-E

2 Safety Precautions and Working Techniques English

The user is responsible for accidents or risks

involving third parties or their property.

Do not lend or rent your power tool without the

User Manual. Be sure that anyone using it under‐

stands the information contained in this manual.

Persons who are not able to operate the power

tool safely due to limited physical, sensory or

mental ability may work with it only under super‐

vision or after being appropriately instructed by a

responsible person.

The use of machines that emit noise may be limi‐

ted to certain hours of the day as specified by

national and/or regional or local regulations.

Anyone operating the machine must be well res‐

ted, in good physical health and in good mental

condition.

If you have any condition that might be aggrava‐

ted by strenuous work, check with your doctor

before operating a machine.

Anyone who has consumed alcohol or drugs or

medicines affecting their ability to react must not

operate a power tool.

Use the machine only for cutting hedges, shrubs,

bushes, scrub and the like.

Other uses are not permitted and may lead to

accidents or damage to the machine.

Always disconnect the machine from the mains

power supply before starting any work on the

machine – risk of accident!

Never jerk the power cord to disconnect it from

the wall outlet. To unplug, grasp the plug, not the

cord.

Unsuitable extension cords may be dangerous.

When using extension cords, ensure that the

minimum conductor cross-sections are main‐

tained (refer to the chapter entitled "Connecting

the machine to the power supply").

The connector and coupling of the extension

cord must be waterproof or routed in such a way

that they cannot come into contact with water.

Only use cutting blades and accessories that are

explicitly approved for this power tool by STIHL

or are technically identical. If you have any ques‐

tions in this respect, consult your dealer. Use

only high quality parts and accessories. in order

to avoid the risk of accidents and damage to the

machine.

STIHL recommends the use of original STIHL

tools and accessories. They are specifically

0458-279-0121-E 3

designed to match the product and meet your

performance requirements.

Never attempt to modify your power tool in any

way since this may increase the risk of personal

injury. STIHL excludes all liability for personal

injury and damage to property caused while

using unauthorized attachments.

Do not use a high-pressure washer to clean the

power tool. The solid jet of water may damage

parts of the unit.

Do not spray the power tool with water.

2.1 Clothing and equipment

Wear proper protective clothing and equipment.

Clothing must be sturdy but allow

complete freedom of movement.

Wear close-fitting clothes such as a

boiler suit, not a loose jacket.

Do not wear clothing which could become trap‐

ped in wood, brush or moving parts of the

machine. Do not wear a scarf, necktie or jewelry.

Tie up and confine long hair above your should‐

ers.

Wear sturdy shoes with non-slip

soles.

2.1.1 Safety Glasses, Hearing Protection

WARNING

To reduce the risk of eye injuries,

wear close-fitting safety glasses in

accordance with European Standard

EN 166. Make sure the safety

glasses are a snug fit.

Wear "personal" sound protection, e.g. ear

defenders.

Wear sturdy protective gloves made

of a resistant material (e. g. leather).

STIHL can supply a comprehensive range of per‐

sonal protective equipment.

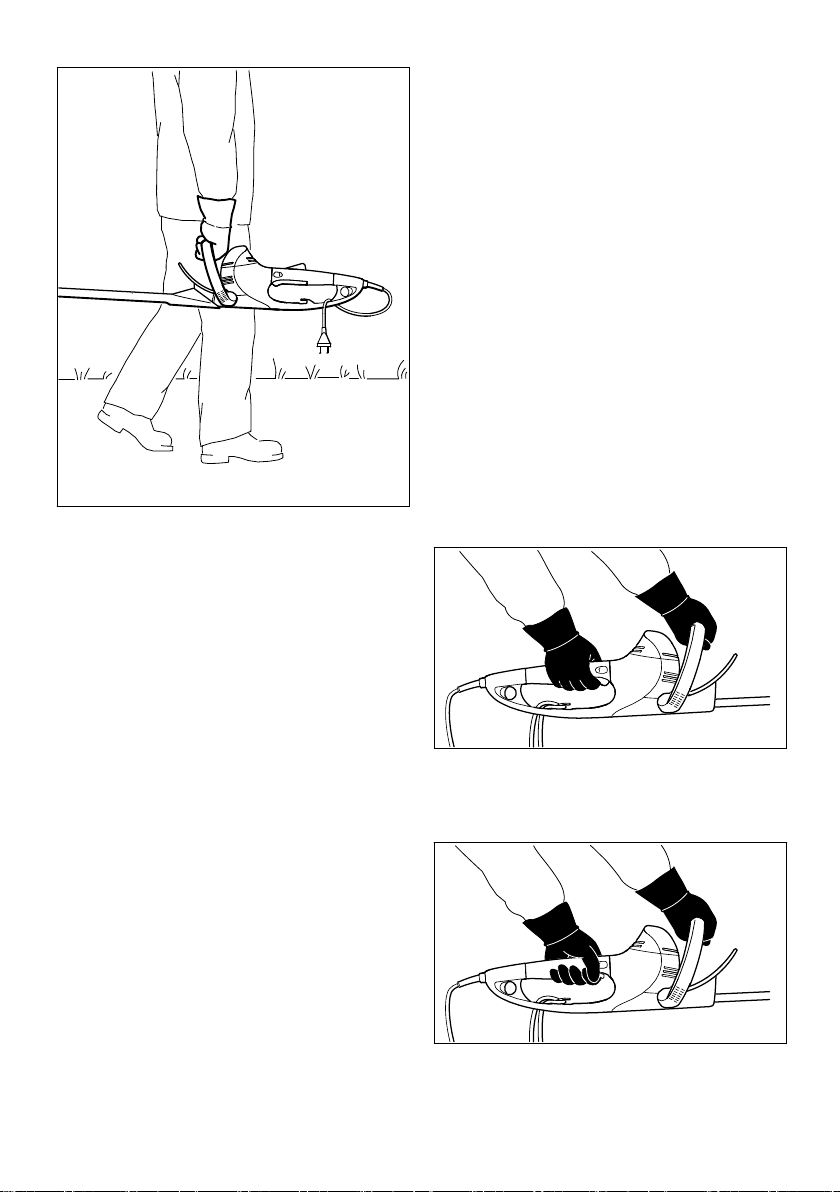

2.2 Transporting the machine

Always switch off the power tool, unplug it from

the power supply and fit the blade scabbard –

even when carrying the unit short distances.

279BA016 KN

279BA017 KN

279BA018 KN

English 2 Safety Precautions and Working Techniques

Never attempt to modify the controls or safety

–

devices

Keep the handles dry and clean – free from oil

–

and dirt – this is important for safe control of

the machine

To reduce the risk of personal injury, do not

operate your power tool if it is damaged or not

properly assembled!

To reduce the risk of electric shock:

Always connect the engine analyzer to a prop‐

–

erly installed wall outlet.

Any extension cords used must comply with

–

the specifications for the particular application

Check that the insulation of the power cord,

–

extension cord, plug and coupling is in good

condition

2.4 Holding and guiding the machine

Always hold the unit firmly with both hands on

the handles. Wrap your fingers and thumbs

around the handles.

Carry the power tool by the handle – cutting

2.4.1 Right-handed users

blades behind you.

Transporting by vehicle: Properly secure the

power tool to prevent tipping over and damage.

2.3 Before Starting Work

Check that your power tool is properly assem‐

bled and in good condition – refer to appropriate

chapters in the User Manual:

Voltage and frequency of the machine (see

–

rating plate) and the voltage and frequency of

your power supply must be the same.

Examine the connecting cord, power plug and

–

extension cord for damage. Damaged cords,

couplings and plugs or connecting cords that

do not comply with the regulations must not be

used

Extension cord sockets must be splash-proof

–

To reduce the risk of stumbling, position and

–

signpost the connecting cord so that it cannot

be damaged or endanger others

Trigger switch lockout, trigger, switch lever

–

and auxiliary switch must move freely and

return to the idle position when they are

released.

Cutting blades must be properly tightened and

–

in safe operating condition (clean, sharp, not

bent or warped), correctly mounted and thor‐

oughly sprayed with STIHL resin solvent (lubri‐

cant)

Check cutter guard (if fitted) for damage

–

4 0458-279-0121-E

Right hand on the control handle and left hand

on the loop handle.

2.4.2 Left-handed users

Left hand on the control handle and right hand

on the loop handle.

2 Safety Precautions and Working Techniques English

Make sure you always have a secure footing and

hold the machine so that the cutting blades are

always facing away from your body.

2.5 While working

In case of imminent danger or in an emergency,

switch off the motor immediately – release the

trigger or switch lever or trigger or auxiliary

switch.

Ensure that there are no other people within the

working area.

Watch the cutting blades at all times – do not cut

areas of the hedge that you cannot see.

Be extremely careful when cutting tall hedges,

check the other side of the hedge before starting

work.

The drive motor is not waterproof. To

reduce the risk of a short circuit or

electrocution, never work with the

power tool in the rain or in wet or very

damp locations.

Do not leave the power tool outdoors in the rain.

Your power tool is equipped with a system

designed to quickly stop the cutting blades – they

come to an immediate standstill as soon as you

release the trigger switch or the switch lever, or

the auxiliary switch.

Check this function at regular, frequent intervals.

Do not operate the machine if the cutting blades

continue to run after switching off – risk of injury!

Contact a dealer.

Take special care in slippery conditions – damp,

snow, ice, on slopes or uneven ground!

Clear away fallen branches, scrub and cuttings.

Watch out for obstacles such as tree stumps,

roots – risk of tripping or stumbling!

2.5.1 When working at heights:

Always use a lift bucket

–

Never use the machine while standing on a

–

ladder or in a tree

never work in an insecure standing position

–

Be particularly alert and cautious when wearing

hearing protection because your ability to hear

warnings (shouts, alarms, etc.) is restricted.

Take breaks when you start getting tired or feel‐

ing fatigue – risk of accidents!

Work calmly and carefully – in daylight conditions

and only when visibility is good. Proceed with

caution, do not put others in danger.

The gear head becomes hot during operation.

reduce the risk of burn injury, do not touch the

gear housing!

If the machine is subjected to unusually high

loads for which it was not designed (e.g., heavy

impact or a fall), always check that it is in good

condition before continuing work - refer also to

the chapter "Before starting work". Make sure the

safety devices are working properly. Never use a

power tool that is no longer safe to operate. In

case of doubt, contact a dealer.

Inspect the hedge and work area to avoid dam‐

aging the cutting blades:

Remove stones, rocks, pieces of metal and

–

other solid objects

When working close to the ground, make sure

–

that no sand, grit or stones get between the

cutting blades

Take particular care when cutting hedges next

–

to or against wire fences

Do not touch electric power lines – never cut

through electric power lines – risk of electrocu‐

tion!

Do not touch the cutting blades.while

the engine is running. If the cutting

blades become jammed by thick

branches or other obstructions,

switch off immediately and disconnect

the plug from the power supply before

attempting to free the blades.

If the hedge is very dusty or dirty, spray the cut‐

ting blades with STIHL resin solvent from time to

time during cutting. This will significantly reduce

blade friction, the aggressive effects of sap and

the build-up of dirt particles.

The dust that occurs during operation may be

harmful to health. Wear a dust mask in case of

dust formation.

If the power cord is damaged, imme‐

diately disconnect the plug from the

wall outlet to avoid the risk of electric

shock.

Never jerk the power cord to disconnect it from

the wall outlet. To unplug, grasp the plug, not the

cord.

Avoid damage to the power supply cord. Do not

drive over it, pinch or tug it.

Position the connecting and extension cords cor‐

rectly:

Do not chafe on edges, pointed or sharp

–

objects

don't trap or squeeze the cord in or under

–

doors or windows

To

0458-279-0121-E 5

English 2 Safety Precautions and Working Techniques

If cords are twisted – unplug the power tool

–

and straighten them out

Always avoid contact with the cutting attach‐

–

ment

always completely unfurl the connecting cord

–

from the cable reel to avoid risk of fire due to

overheating

Before leaving the power tool unattended: Switch

it off and disconnect the plug from the power

supply.

Check the cutting blades at regular short inter‐

vals during operation or immediately if there is a

noticeable change in cutting behavior:

Switch off the motor; wait until the cutting

–

blades have come to a standstill; unplug the

power cord

Check the condition and firm seat, watch out

–

for fine cracks

Ensure that the cutting blades are sharp

–

To replace the cutting blades, switch off the

machine and unplug the power cord. Risk of

injury from the motor starting unintentionally!

Always clean plant residue, chips, leaves and

excess lubricant off the motor – risk of fire!

2.6 After finishing work

Always clean dust and dirt off the machine – do

not use any grease solvents for this purpose.

Spray the cutting blades with STIHL resin sol‐

vent. Run the motor briefly so that the solvent is

evenly distributed.

2.7 Vibrations

Prolonged use of the power tool may result in

vibration-induced circulation problems in the

hands (whitefinger disease).

No general recommendation can be given for the

length of usage because it depends on several

factors.

The period of usage is prolonged by:

Hand protection (wearing warm gloves)

–

Work breaks

–

The period of usage is shortened by:

Any personal tendency to suffer from poor cir‐

–

culation (symptoms: frequently cold fingers,

tingling sensations).

Low outside temperatures.

–

The force with which the handles are held (a

–

tight grip restricts circulation).

Continual and regular users should monitor

closely the condition of their hands and fingers. If

any of the above symptoms appear (e.g. tingling

sensation in fingers), seek medical advice.

2.8 Maintenance and Repairs

Always switch off the machine and disconnect

the plug from the power supply before carrying

out any maintenance work to reduce the risk of

injury from the motor starting unintentionally.

Service the machine regularly. Do not attempt

any maintenance or repair work not described in

the instruction manual. Have all other work per‐

formed by a servicing dealer.

STIHL recommends that you have servicing and

repair work carried out exclusively by an author‐

ized STIHL servicing dealer. STIHL dealers are

regularly given the opportunity to attend training

courses and are supplied with the necessary

technical information.

Only use high-quality replacement parts in order

to avoid the risk of accidents and damage to the

machine. If you have any questions in this

respect, consult a servicing dealer.

STIHL recommends the use of genuine STIHL

replacement parts. They are specifically

designed to match your machine model and

meet your performance requirements.

Never attempt to modify your power tool in any

way since this will increase the risk of personal

injury.

Regularly check that the insulation of the power

cord and plug is in good condition and shows no

sign of ageing (brittleness).

Electrical components, e.g. power cord, may only

be repaired or replaced by a qualified electrician.

Clean plastic components with a cloth. Do not

use aggressive detergents. They may damage

the plastic.

Do not spray the machine with water.

Check tightness of mounting screws on safety

devices and the cutting attachment and retighten

if necessary.

Clean cooling air inlets in motor housing as nec‐

essary.

Store the machine is a safe and dry place.

6 0458-279-0121-E

279BA029 KN

279BA030 KN

279BA007 KN

3 Using the Unit English

3 Using the Unit

3.1 Cutting Season

Observe country-specific or municipal rules and

regulations for cutting hedges.

Do not use your power tool during other people's

rest periods.

3.2 Preparations

Use lopping shears or a chain saw to cut out

thick branches first.

3.3 Cutting Sequence

Cut the sides of the hedge first, then the top.

If a radical cut is necessary, cut a little at a time

in several stages.

3.4 Rotating handle

Your hedge trimmer is equipped with a rotating

handle to enhance user comfort – see chapter on

“Rotating Handle”.

3.5 Disposal

Do not throw cuttings into the garbage can – they

can be composted.

3.6 Working Technique

3.6.1 Vertical cut

Swing the cutting blade from the bottom upwards

in an arc – lower the nose of the blade, move

along the hedge and then swing the blade up

again in an arc.

Any working position above head height is tiring.

To minimize the risk of accidents, work in such

positions for short periods only.

3.6.2 Horizontal cut

Hold the cutting blade at an angle of 0° to 10° as

you swing the hedge trimmer horizontally, using

both sides of the blade.

Swing the cutting blade in an arc towards the

outside of the hedge so that the cuttings are

swept to the ground.

If the hedge is wide, cut it in several passes –

one hand on the front switch lever – one hand on

the control handle.

0458-279-0121-E 7

279BA008 KN

21

279BA005 KN

4

3

5

279BA019 KN

English 4 Connecting to Power Supply

To extend your reach, hold the control handle

with one hand and operate the auxiliary switch at

the rear of the control handle with the other

hand.

4 Connecting to Power Sup‐

ply

The voltage and frequency of the machine (see

rating plate) must match the voltage and fre‐

quency of the power connection.

The minimum fuse protection of the power con‐

nection must comply with the specifications – see

"Specifications".

The machine must be connected to the power

supply via an earth-leakage circuit breaker to dis‐

connect the power supply if the differential cur‐

rent to earth exceeds 30 mA.

The power connection must correspond to

IEC 60364 and relevant national regulations.

4.1 Extension cord

The design of the extension cord must at least

fulfill the same features as the connecting cord

on the machine. Observe the design marking

(type designation) on the connecting cord.

The cores in the cord must have the following

minimum cross-section depending on the mains

voltage and cord length.

Cord length Minimum cross-section

220 V – 240 V:

Up to 20 m

20 m to 50 m

100 V – 127 V:

Up to 10 m

10 m to 30 m

2

1.5 mm

2.5 mm

AWG 14 / 2.0 mm

AWG 12 / 3.5 mm

2

2

2

► Insert the plug (1) into the extension cord cou‐

pling (2).

4.2 Strain Relief

The strain relief (cord retainer) protects the con‐

necting cord against damage.

8 0458-279-0121-E

► Make a loop (3) in the extension cord.

► Pass the loop (3) through the opening (4).

2

3

1

279BA020 KN

279BA021 KN

2

3

4

2

1

279BA022 KN

279BA023 KN

1

3

279BA009 KN

5 Switching On English

► Slip the loop (3) over the hook (5) and pull it

tight.

► Connect the extension cord plug to a properly

installed wall outlet.

5 Switching On

► Make sure you have a secure and balanced

footing.

► Stand upright – hold the power tool in a

relaxed position.

► Make sure the cutting attachment is not touch‐

ing the ground or any other objects.

► Hold the unit with both hands – one hand on

the control handle – one hand on the loop han‐

dle.

► Push the switch lever (1) against the loop han‐

dle and hold it there.

► Push down the trigger switch lockout (2),

depress the trigger switch (3) and hold them in

that position.

The machine is designed for two-hand operation,

i.e. it will run only when the operator’s hands are

on the switch lever (1) and trigger switch (3).

5.1 To extend reach

► Push down the trigger switch lockout (2),

depress the trigger switch (3) and hold them in

that position.

The machine is designed for two-hand operation,

i.e. it will run only when the operator’s hands are

on the auxiliary switch (4) and trigger switch (3).

6 Switching Off

► Release the trigger switch (1) and the switch

lever (2).

Extended reach position:

► Release the trigger switch (1) and auxiliary

switch (3).

HSE 61, 71

► Hold the power tool with both hands – one

hand on the control handle – one hand on the

auxiliary switch at the rear end of the control

handle.

► Operate the auxiliary switch (4) and hold it in

that position.

0458-279-0121-E 9

The blades are covered by the blade guard in

the idle position.

279BA024 KN

2

3

1

279BA025 KN

English 7 Rotating Handle

HSE 81

The blades are partly covered by the blade guard

in the idle position.

6.1 Other hints

► During longer work breaks – disconnect the

plug from the power supply.

► When the machine is not in use, shut it off so

that it does not endanger others.

► Secure it against unauthorized use.

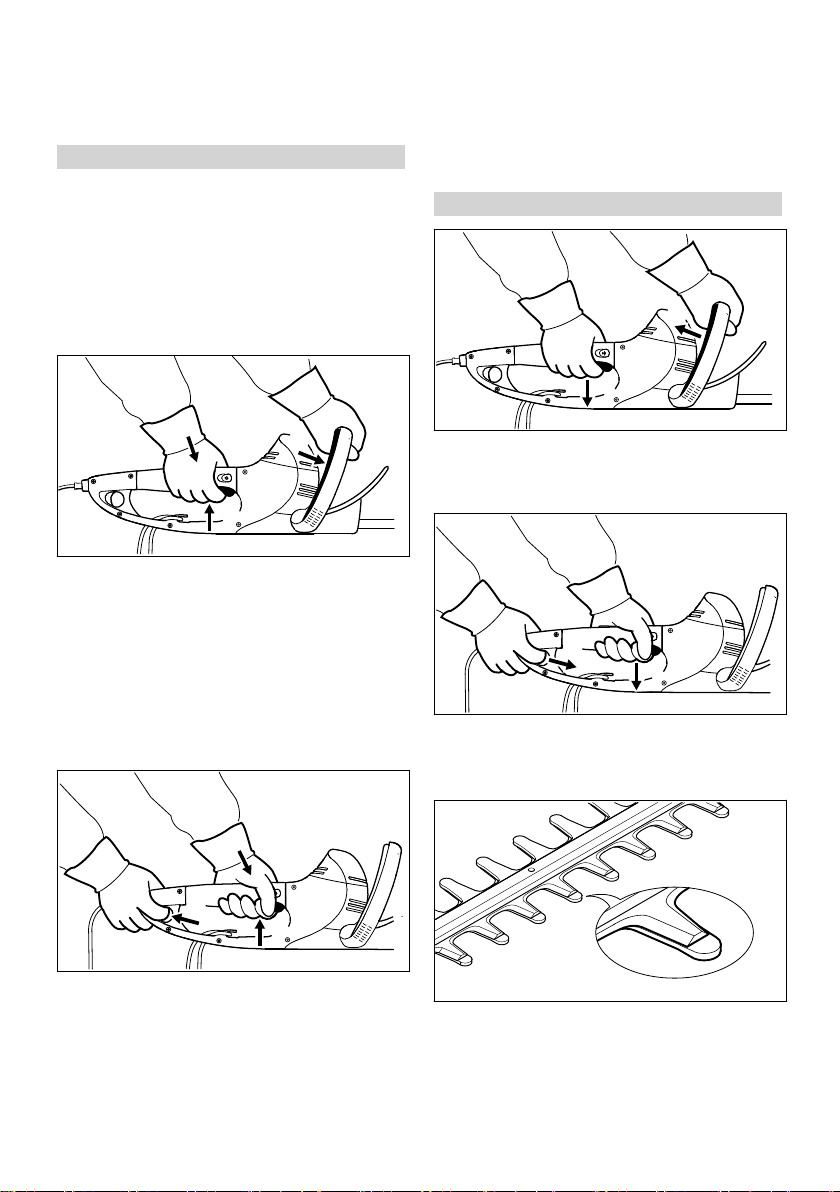

7 Rotating Handle

► Move the two buttons (1) in the direction of the

arrows and hold them there.

► Rotate the handle (2) to the required position.

► Release the two buttons and engage the han‐

dle in position.

The handle (2) cannot be rotated while the trig‐

ger switch (3) is depressed.

8 Storing the Machine

For periods of about 30 days or longer

► Clean cutting blades, check condition and

spray with STIHL resin solvent

► Attach blade scabbard

► Thoroughly clean the machine, especially the

ventilation slots

► Store the machine in a dry and secure loca‐

tion; the blade scabbard can be mounted to

the wall for this purpose. Keep out of the reach

of children and other unauthorized persons

9 Sharpening Instructions

When cutting performance and behavior begin to

deteriorate, i.e. blades frequently snag on

branches: Resharpen the cutting blades.

It is best to have the cutting blades resharpened

by a dealer on a workshop sharpener. STIHL

recommends a STIHL servicing dealer.

It is also possible to use a flat crosscut sharpen‐

ing file. Hold the sharpening file at the prescribed

angle (see "Specifications").

► Only sharpen the cutting edge – do not file

blunt projecting parts of the cutting blade or

the cutting blade guard (see "Main Parts and

Controls")

► Always file towards the cutting edge.

► The file only sharpens on the forward stroke –

lift it off the blade on the backstroke.

► Use a whetstone to remove burr from cutting

edge.

► Remove as little material as possible.

► After sharpening, clean away filing or grinding

dust and then spray the cutting blades with

STIHL resin solvent.

10 0458-279-0121-E

10 Maintenance and Care English

NOTICE

Do not operate your machine with dull or dam‐

aged cutting blades. This may cause overload

and will give unsatisfactory cutting results.

10 Maintenance and Care

The following intervals apply for normal operating con‐

ditions. The specified intervals must be shortened

accordingly when working for longer than normal or

under difficult cutting conditions (extensive dust, etc.).

Weekly

Monthly

Before starting work

If faulty

Annually

If damaged

As required

Complete machine Visual inspection X

At the end of work and/or daily

Clean X

Two-hand control Check function – the cut‐

X

ting blades must quickly

come to a standstill when

the trigger switch or

switch lever, or the trigger

switch, or auxiliary switch

is released

Cool air intake port Visual inspection X

Clean X

Cutting blades Visual inspection X

2)

Clean

1)2)

sharpen

Gear assembly and con‐

necting rod

Have replaced by servic‐

ing dealer

inspection by a specialist

dealer after every 50

hours of operation

Have gearbox topped up

with STIHL gear lubricant

1)

1)

by servicing dealer

Carbon brushes inspection by a specialist

Accessible screws, nuts

dealer after every 100

hours of operation

Have replaced by servic‐

ing dealer

Tighten X

1)

1)

X

X

X

X

1)

X

and bolts

Safety information label replace X

1)

STIHL recommends STIHL dealers

2)

Afterwards spray the blades with STIHL resin solvent

0458-279-0121-E 11

11, 12

14

6

3

2

1

4

5

7

8

9

10

15

13

1

#

15

11

12

279BA026 KN

English 11 Minimize Wear and Avoid Damage

11 Minimize Wear and Avoid

Damage

Observing the instructions in this manual helps

reduce the risk of unnecessary wear and dam‐

age to the power tool.

The power tool must be operated, maintained

and stored with the due care and attention

11.2 Parts Subject to Wear and Tear

Some parts of the power tool are subject to nor‐

mal wear and tear even during regular operation

in accordance with instructions and, depending

on the type and duration of use, have to be

replaced in good time. Among other parts, this

includes:

Cutting blades

–

described in this instruction manual.

The user is responsible for all damage caused by

12 Main Parts

non-observance of the safety precautions, oper‐

ating and maintenance instructions in this man‐

ual. This includes in particular:

Alterations or modifications to the product not

–

approved by STIHL.

Using tools or accessories which are neither

–

approved or suitable for the product or are of a

poor quality.

Using the product for purposes for which it

–

was not designed.

Using the product for sports or competitive

–

events.

Consequential damage caused by continuing

–

to use the product with defective components.

11.1 Maintenance Work

All the operations described in the "Maintenance

Chart" must be performed on a regular basis. If

these maintenance operations cannot be per‐

formed by the owner, they should be performed

by a servicing dealer.

STIHL recommends that you have servicing and

repair work carried out exclusively by an author‐

ized STIHL servicing dealer. STIHL dealers are

regularly given the opportunity to attend training

courses and are supplied with the necessary

technical information.

If these maintenance operations are not carried

out as specified, the user assumes responsibility

for any damage that may occur. Among other

things, this includes:

Damage to the motor due to neglect or defi‐

–

cient maintenance (e.g. not cleaning cooling

air inlets).

Damage due to incorrect electrical connection

–

(voltage, inadequately rated connecting

cords).

Corrosion and other consequential damage

–

resulting from improper storage.

Damage to the product resulting from the use

–

of poor quality replacement parts.

12 0458-279-0121-E

1 Power cord

2 Auxiliary switch

3 Strain relief (cord retainer)

4 Control handle with rotating grip

5 Trigger switch lockout

6 Handle lock

7 Trigger

8 Switch lever

9 Loop handle

10 Hand guard

11 Cutting blades (HSE 61, 71) – see "Specifica‐

tions"

12 Cutting blades (HSE 81) – see "Specifica‐

tions"

13 Blade scabbard

14 Blade guard (HSE 81 only)

15 Tip guard

# Serial number

13 Specifications English

13 Specifications

13.1 Engine

13.1.1 HSE 61

Voltage: 230 - 240 V

Rated current: 2.1 A

Frequency: 50 Hz

Power consumption: 500 W

Fuse: min. 10 A

Insulation:

13.1.2 HSE 71

Voltage: 230 - 240 V

Rated current: 2.6 A

Frequency: 50 Hz

Power consumption: 600 W

Fuse: min. 10 A

Insulation:

13.1.3 HSE 81

Voltage: 230 - 240 V

Rated current: 2.8 A

Frequency: 50 Hz

Power consumption: 650 W

Fuse: min. 10 A

Insulation:

13.2 Cutting Blades

13.2.1 HSE 61

Sharpening angle: 34°

Tooth spacing: 29 mm

Stroke rate: 3,200/min

Cutting length: 500 mm, 600 mm

13.2.2 HSE 71

Sharpening angle: 28°

Tooth spacing: 36 mm

Stroke rate: 2,600/min

Cutting length: 600 mm, 700 mm

13.2.3 HSE 81

Sharpening angle: 45°

Tooth spacing: 36 mm

Stroke rate: 2,600/min

Cutting length: 500 mm, 600 mm,

700 mm

13.3 Weight

13.3.1 HSE 61

500 mm blade: 3.9 kg

500 mm blade1):

600 mm blade: 4.1 kg

13.3.2 HSE 71

600 mm blade: 4.1 kg

500 mm blade1):

II, E

II, E

II, E

4.6 kg

4.8 kg

700 mm blade: 4.2 kg

700 mm blade1):

13.3.3 HSE 81

500 mm blade: 4.1 kg

600 mm blade: 4.2 kg

700 mm blade: 4.4 kg

700 mm blade1): 5.0 kg

4.9 kg

13.4 Sound and Vibration Levels

Sound and vibration levels are determined on

the basis of the operating status at nominal maxi‐

mum speed.

For further details on compliance with Vibration

Directive 2002/44/EC, see

www.stihl.com/vib

13.4.1 Sound pressure level Lp according to

EN 60745‑2‑15

HSE 61

500 mm blade: 85 dB(A)

600 mm blade: 85 dB(A)

HSE 71

600 mm blade: 88 dB(A)

700 mm blade: 88 dB(A)

HSE 81

500 mm blade: 88 dB(A)

600 mm blade: 88 dB(A)

700 mm blade: 88 dB(A)

13.4.2 Sound power level Lw according to

EN 60745‑2‑15

HSE 61

500 mm blade: 96 dB(A)

600 mm blade: 96 dB(A)

HSE 71

600 mm blade: 99 dB(A)

700 mm blade: 99 dB(A)

HSE 81

500 mm blade: 99 dB(A)

600 mm blade: 99 dB(A)

700 mm blade: 99 dB(A)

13.4.3 Vibration measurement ahv according

to EN 60745‑2‑15

HSE 61

500 mm blade:

Handle, left:

Handle, right:

HSE 61

600 mm blade:

Handle, left:

5.3 m/s

3.3 m/s

5.3 m/s

2

2

2

1)

Version with 10 meter power supply cord for UK

0458-279-0121-E 13

000BA073 KN

English 14 Maintenance and Repairs

HSE 61

600 mm blade:

Handle, right:

3.3 m/s

2

HSE 71

600 mm blade:

Handle, left:

Handle, right:

3.8 m/s

2.6 m/s

2

2

HSE 71

700 mm blade:

Handle, left:

Handle, right:

3.8 m/s

2.6 m/s

2

2

HSE 81

500 mm blade:

Handle, left:

Handle, right:

3.2 m/s

2.1 m/s

2

2

HSE 81

600 mm blade:

Handle, left:

Handle, right:

3.5 m/s

2.5 m/s

2

2

HSE 81

700 mm blade:

Handle, left:

Handle, right:

3.5 m/s

2.5 m/s

2

2

The K‑factor in accordance with Directive

2006/42/EC is 2.0 dB(A) for the sound pressure

level and sound power level; the K‑factor in

accordance with Directive 2006/42/EC is

2.0 m/s2 for the vibration level.

The vibration values quoted above have been

measured according to a standardized test pro‐

cedure and may be used to compare electric

power tools.

Depending on the type of usage, the vibrations

that actually occur may differ from the values

quoted.

The vibration values quoted may be used for an

initial assessment of the user's exposure to

vibrations.

13.5 REACH

REACH is an EC regulation and stands for the

Registration, Evaluation, Authorization and

Restriction of Chemical substances.

For information on compliance with the REACH

regulation (EC) No. 1907/2006 see

www.stihl.com/reach

14 Maintenance and Repairs

Users of this machine may only carry out the

maintenance and service work described in this

user manual. All other repairs must be carried

out by a servicing dealer.

STIHL recommends that you have servicing and

repair work carried out exclusively by an author‐

ized STIHL servicing dealer. STIHL dealers are

regularly given the opportunity to attend training

courses and are supplied with the necessary

technical information.

When repairing the machine, only use replace‐

ment parts which have been approved by STIHL

for this power tool or are technically identical.

Only use high-quality replacement parts in order

to avoid the risk of accidents and damage to the

machine.

STIHL recommends the use of original STIHL

replacement parts.

Original STIHL parts can be identified by the

STIHL part number, the { logo and the

STIHL parts symbol K (the symbol may appear

alone on small parts).

15 Disposal

Contact the local authorities or your STIHL serv‐

icing dealer for information on disposal.

Improper disposal can be harmful to health and

pollute the environment.

The actual exposure to vibrations has to be eval‐

uated. This process may also take into account

times during which the electric power tool is

switched off and times during which it is switched

on but running without load.

Observe measures to reduce vibration exposure

to protect the user – see section on "Vibrations"

in chapter on "Safety Precautions and Working

Techniques".

► Take STIHL products including packaging to a

suitable collection point for recycling in accord‐

ance with local regulations.

14 0458-279-0121-E

16 EC Declaration of Conformity

► Do not dispose with domestic waste.

16 EC Declaration of Con‐

formity

ANDREAS STIHL AG & Co. KG

Badstr. 115

D-71336 Waiblingen

Germany

declare under our sole responsibility that

Designation: Electric hedge trimmer

Make: STIHL

Series: HSE 61

Serial identification

number:

conforms to the relevant provisions of Directives

2011/65/EU, 2006/42/EC, 2014/30/EU and

2000/14/EC and has been developed and manu‐

factured in compliance with the following stand‐

ards in the versions valid on the date of produc‐

tion:

EN 55014‑1, EN 55014‑2, EN 60745‑1,

EN 60745‑2‑15, EN 61000‑3‑2, EN 61000‑3‑3

The measured and the guaranteed sound power

level have been determined in accordance with

Directive 2000/14/EC, Annex V, and standard

ISO 11094.

Measured sound power level

HSE 61

500 mm blade: 96 dB(A)

600 mm blade: 96 dB(A)

HSE 71

600 mm blade: 99 dB(A)

700 mm blade: 99 dB(A)

HSE 81

500 mm blade: 99 dB(A)

600 mm blade: 99 dB(A)

700 mm blade: 99 dB(A)

Guaranteed sound power level

HSE 61

500 mm blade: 98 dB(A)

600 mm blade: 98 dB(A)

HSE 71

600 mm blade: 101 dB(A)

700 mm blade: 101 dB(A)

HSE 81

500 mm blade: 101 dB(A)

600 mm blade: 101 dB(A)

700 mm blade: 101 dB(A)

Technical documents deposited at:

0458-279-0121-E 15

HSE 71

HSE 81

4812

ANDREAS STIHL AG & Co. KG

Produktzulassung

The year of construction, the country of manufac‐

ture and the machine number are shown on the

machine.

Done at Waiblingen, 15.07.2021

ANDREAS STIHL AG & Co. KG

pp

Dr. Jürgen Hoffmann

Director Product Certification & Regulatory

Affairs

17 UKCA Declaration of Con‐

formity

ANDREAS STIHL AG & Co. KG

Badstr. 115

D-71336 Waiblingen

Germany

declare under our sole responsibility that

Designation: Electric hedge trim‐

mer

Make: STIHL

Series: HSE 61

HSE 71

HSE 81

Serial identification number: 4812

conforms to the relevant provisions of UK regula‐

tions The Restriction of the Use of Certain Haz‐

ardous Substances in Electrical and Electronic

Equipment Regulations 2012, Supply of Machi‐

nery (Safety) Regulations 2008, Electromagnetic

Compatibility Regulations 2016 and Noise Emis‐

sion in the Environment by Equipment for use

Outdoors Regulations 2001 and has been manu‐

factured in compliance with the following stand‐

ards in the versions valid on the date of produc‐

tion:

EN 55014‑1, EN 55014‑2, EN 60745‑1,

EN 60745‑2‑15, EN 61000‑3‑2, EN 61000‑3‑3

The measured and the guaranteed sound power

level have been determined in accordance with

UK regulation Noise Emission in the Environ‐

ment by Equipment for use Outdoors Regula‐

English

English 18 General Power Tool Safety Warnings

tions 2001, Anhang 8, using the ISO 11094

standard.

Measured sound power level

HSE 61

500 mm blade: 96 dB(A)

600 mm blade: 96 dB(A)

HSE 71

600 mm blade: 99 dB(A)

700 mm blade: 99 dB(A)

HSE 81

500 mm blade: 99 dB(A)

600 mm blade: 99 dB(A)

700 mm blade: 99 dB(A)

Guaranteed sound power level

HSE 61

500 mm blade: 98 dB(A)

600 mm blade: 98 dB(A)

HSE 71

600 mm blade: 101 dB(A)

700 mm blade: 101 dB(A)

HSE 81

500 mm blade: 101 dB(A)

600 mm blade: 101 dB(A)

700 mm blade: 101 dB(A)

Technical documents deposited at:

ANDREAS STIHL AG & Co. KG

The year of construction, the country of manufac‐

ture and the machine number are shown on the

machine.

Done at Waiblingen, 15.07.2021

ANDREAS STIHL AG & Co. KG

pp

Dr. Jürgen Hoffmann

Director Product Certification & Regulatory

Affairs

18 General Power Tool Safety

Warnings

This chapter reproduces the pre-formulated, gen‐

eral safety precautions specified in the EN 60745

European standard for hand-held motor-oper‐

ated electric tools. STIHL is required by law to

print these standardized texts verbatim.

The safety precautions and warnings on avoiding

an electric shock given under "2) Electric Pre‐

cautions" do not apply to STIHL cordless electric

power tools

WARNING

Read all safety warnings and instructions. Failure

to follow the warnings and instructions may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for future ref‐

erence.

The term "power tool" in the warnings refers to

your mains-operated (corded) power tool or bat‐

tery-operated (cordless) power tool.

18.1 1) Work area safety

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

18.2 2) Electrical safety

a)

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed (groun‐

ded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entan‐

gled cords increase the risk of electric shock.

16 0458-279-0121-E

18 General Power Tool Safety Warnings English

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

18.3 3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power

tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better con‐

trol of the power tool in unexpected situa‐

tions.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dustrelated hazards.

18.4 4) Power tool use and care

a)

Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is dan‐

gerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are dan‐

gerous in the hands of untrained users.

e) Maintain power tools. Check for misalign‐

ment or binding of moving parts, breakage of

parts and any other condition that may affect

the power tool's operation. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier

to control.

g) Use the power tool, accessories, tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situa‐

tion.

18.5 5) Service

a)

Have your power tool serviced by a qualified

repair person using only identical replace‐

ment parts. This will ensure that the safety of

the power tool is maintained.

18.6 Hedge Trimmer Safety Warn‐

ings

Keep all parts of the body away from the cut‐

–

ting blades. Do not remove cut material or

hold material to be cut when blades are mov‐

ing. Make sure the switch is off when clearing

jammed material. A moment of inattention

while operating the hedge trimmer may result

in serious personal injury.

Carry the hedge trimmer by the handle with

–

the cutting blades stopped. When transporting

0458-279-0121-E 17

English 18 General Power Tool Safety Warnings

or storing the hedge trimmer always fit the

blade scabbard. Proper handling of the hedge

trimmer will reduce possible personal injury

from the cutting blades.

Always hold your electric power tool by the

–

insulated handles because the cutting blades

may contact hidden electrical wires or your

own power cord. Any blade contact with a live

wire may energize metallic parts of the power

tool and result in an electric shock.

Keep the power cord away from cutting area.

–

During operation the power cord may be hid‐

den in shrubs and can be accidentally severed

by the blade.

18 0458-279-0121-E

18 General Power Tool Safety Warnings English

0458-279-0121-E 19

www.stihl.com

*04582790121E*

0458-279-0121-E

*04582790121E*

0458-279-0121-E

Loading...

Loading...