Page 1

1034, 036, 036 QS

© 2001 Andreas Stihl AG & Co., Waiblingen

Contents

1 Introduction 2

2 Safety Precautions 3

3 Specifications 4

3.1 Engine 4

3.2 Fuel System 4

3.3 Ignition System 5

3.4 Cutting Attachment 5

3.5 Tightening Torques 6

3.6 Special Accessories 7

3.6.1 For User 7

3.6.2 For Service 7

4 Clutch, Chain Drive,

Chain Brake and

Chain Tensioner 8

4.1 Clutch Drum and Chain

Sprocket 8

4.2 Replacing the

Chain Catcher 9

4.3 Clutch 9

4.4 Chain Brake (034, 036)10

4.4.1 Removing 10

4.4.2 Installing 11

4.5 Chain Brake (036 QS) 12

4.5.1 Removing 12

4.5.2 Installing 14

4.5.3 Checking Play 15

4.5.4 Adjusting Play 16

4.5.5 Checking Operation of

Chain Brake 17

4.6 Chain Tensioner 17

4.7 Bar Mounting Studs 18

5Engine 19

5.1 Removing and

Installing Muffler 19

5.2 Exposing the Cylinder 20

5.3 Cylinder and Piston 20

5.3.1 Removing 20

5.3.2 Installing 21

5.4 Piston Rings 24

5.5 Crankcase 24

5.5.1 Removing the

Crankshaft 24

5.5.2 Installing the

Crankshaft 26

5.6 Crankcase Leakage

Test 31

5.6.1 Preparations 31

5.6.2 Pressure Test 32

5.6.3 Vacuum Test 33

5.7 Replacing the Oil

Seals 33

6 Ignition System 34

6.1 Ignition Lead/

Spark Plug Boot 34

6.2 Short Circuit Wire/

Ground Wire 35

6.3 STOP Contact 37

6.4 Flywheel 38

6.4.1 Removing 38

6.4.2 Installing 38

6.5 Ignition Module 39

6.5.1 Removing and

Installing 39

6.5.2 Ignition Timing 40

7 Rewind Starter 40

7.1 Routine

Maintenance 40

7.2 Rope Rotor, Pawls,

Starter Rope,

Rope Guide Bush 40

7.3 Rewind Spring 41

7.3.1 Replacing the Rewind

Spring (034) 41

7.3.2 Replacing the Rewind

Spring (036, 036 QS) 41

7.4 Tensioning the Rewind

Spring 42

8 AV Handle System 42

8.1 Repair 42

9Master Control 43

9.1 Construction and

Function 43

9.2 Throttle Trigger/Interlock

Lever (034, 036) 44

9.3 Throttle Trigger/Interlock

Lever/Switch Lever

(036 QS) 45

9.4 Switch Shaft 46

10 Electric Handle Heating

System (034, 036) 47

10.1 Troubleshooting 47

10.1.1 Troubleshooting Chart 49

10.1.2 Test Connections and

Test Values 50

10.2 Heater Switch 51

10.3 Heating Element

in Rear Handle 51

10.4 Heating Element in

Front Handle 53

10.5 Generator 54

10.5.1 Removing 54

10.5.2 Installing 55

11 Chain Lubrication 55

11.1 Pickup Body 55

11.2 Suction Hose 56

11.3 Vent Valve 56

11.4 Removing and

Installing the Oil Pump 57

11.5 Servicing the Oil Pump 58

12 Fuel System 59

12.1 Air Filter 59

12.2 Leakage Testing the

Carburetor 60

12.3 Removing and Installing

the Carburetor 61

12.4 Servicing the

Carburetor 62

12.5 Adjusting the

Carburetor 66

12.6 Tank Vent 67

12.7 Fuel Filter and Fuel

Hose 68

12.8 Tank Hous ing 69

12.8.1 Removing and

Installing 69

13 Special Servicing

Tools and Aids 71

13.1 Special Servicing

Tools 71

13.2 Servicing Aids 72

Page 2

2 034, 036, 036 QS

This service manual contains

detailed descriptions of all the repair

and servicing procedures specific to

this series of chain saws.

There are separate handbooks for

servicing procedures on

standardized parts and assemblies

that are installed in several STIHL

power tool models. Reference is

made to these handbooks in the

appropriate chapters of this manual

You should make use of the

illustrated parts lists while carrying

out repair work. They show the

installed positions of the individual

components and assemblies.

Refer to the latest edition of the

relevant parts list to check the part

numbers or any replacement parts.

Parts lists on microfiche and CDROM are always more up to date

than printed lists.

A fault on the machine may have

several causes. To help locat e the

fault, consult the troubleshooting

charts for all assemblies in the

"Standard Repairs, Troubleshooting" handbook.

Refer to the "Technical Info rmation"

bulletins for engineering changes

which have been introduced since

publication of this service manual.

Technical information bulletins also

supplement the parts list until a

revised edition is issued.

The special servicing tools

mentioned in the descriptions are

listed in the last chapter of this

manual.

Use the part numbers to identify the

tools in the "STIHL Special Tools"

manual.

The manual lists all special

servicing tools currently available

from STIHL.

Symbols are included in the text and

pictures for greater clarity.

The meanings are as follows:

In the descriptions:

= Action to be taken as

shown in the illustration

(above the text)

– = Action to be taken that is

not shown in the illustration

(above the text)

= Situation applies from

serial number

= Situation applies up to

serial number

In the illustrations:

Pointer

Direction of movement

Service manuals and all technical

Information bulletins are intended

exclusively for the use of STIHL

servicing dealers. They must not be

passed to third parties.

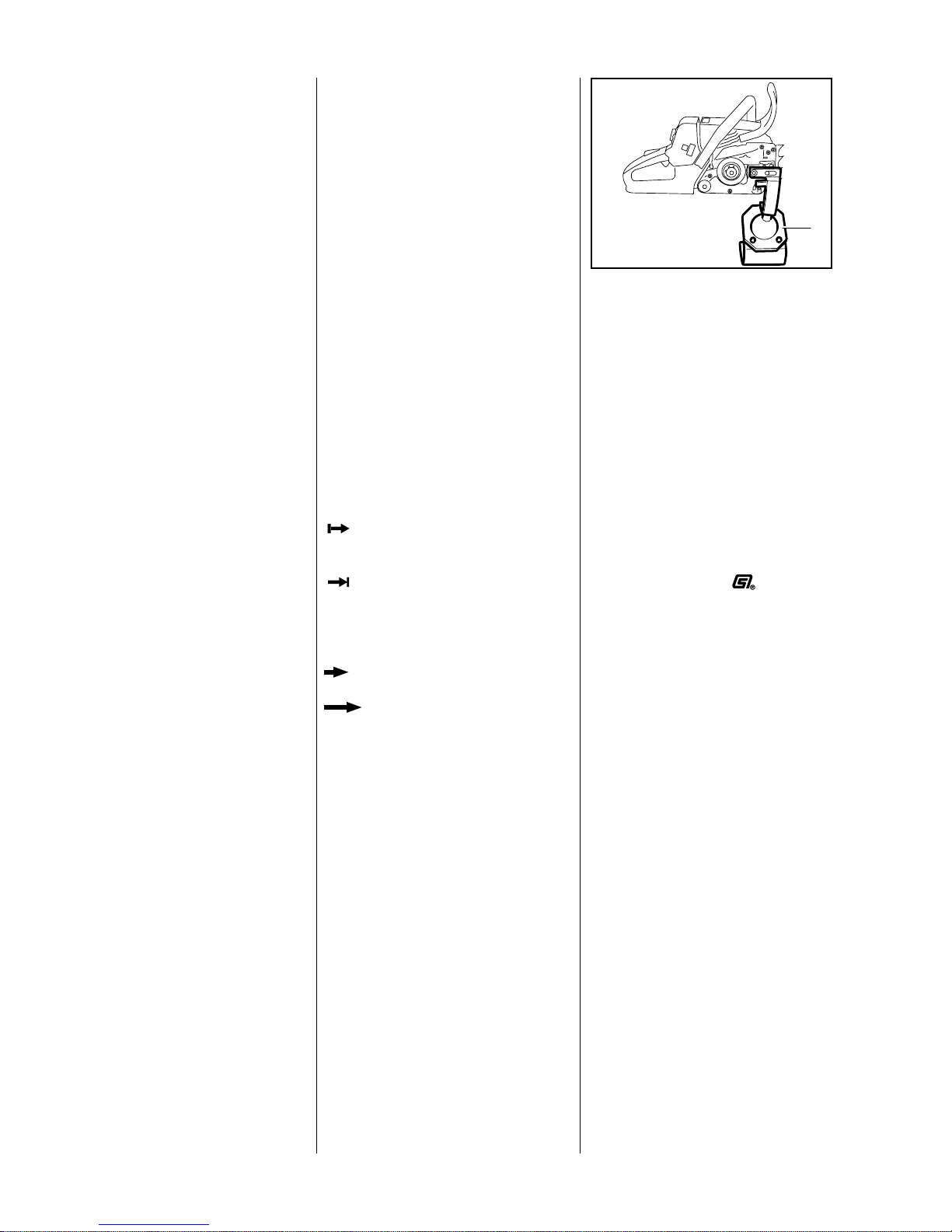

Servicing and repairs are made

considerably easier if the

powerhead is mounted on assembly

stand (1) 5910 890 3100. Remove

the chain sprocket cover, bar and

chain first.

The powerhead can then be

swivelled to the best position for the

VA

138RA001

1

ongoing repair. This leaves both

hands free.

Always use original STIHL

replacement parts.

They can be identified by the

STIHL part number,

the

67,+logo and the

STIHL parts symbol

This symbol may appear alone on

small parts.

1 Introduction

Page 3

3034, 036, 036 QS

If the engine is started up in the

course of repairs or maintenance

work, observe all local and countryspecific safety regulations as well

as the safety precautions and

warnings in the owner’s manual.

Gasoline is an extremely flammable

fuel and can be explosive in certain

conditions.

Improper handling may result in

burns or other serious injuries.

Warning!

Do not smoke or bring any fire,

flame or other source of heat near

the fuel. All work with fuel must be

performed outdoors only. Spilled

fuel must be wiped away

immediately.

2 Safety Precautions

Page 4

4 034, 036, 036 QS

3 Specifications

3.1 Engine

STIHL single cylinder two-stroke engine with special impregnated cylinder bore

034 036, 036 QS

Displacement:

Bore:

Stroke:

Compression ratio:

Engine power to ISO 8893:

Max. torque:

Max. permissible engine speed with

bar and chain:

Mean idle speed:

Crankshaft:

Main bearings:

Crankshaft journal diameter:

Big end bearing:

Piston pin diameter:

Small end bearing:

Connecting rod length:

Rewind starter:

Starter rope:

Clutch:

Diameter:

Clutch engages at:

Crankcase leakage test

at gauge pressure:

under vacuum:

56.5 cm

3

46 mm

34 mm

9.5:1

3.0 kW (4.1 bhp)

at 9,500 rpm

3.5 Nm

at 6,500 rpm

13,000 rpm

2,700 rpm

Two-part, drop forged

Two deep-groove ball bearings

14.4 mm

Needle cage

10 mm

Needle cage

58 mm

Pawl engagement with automatic

starter rope rewind mechanism

3.5 mm dia., 960 mm

Centrifugal clutch without linings

76 mm

approx. 3,500 rpm

0.5 bar

0.5 bar

61.5 cm

3

48 mm

34 mm

9.5:1

3.4 kW (4.6 bhp)

at 9,500 rpm

3.7 Nm

at 6,500 rpm

13,000 rpm

2,700 rpm

Two-part, drop forged

Two deep-groove ball bearings

14.4 mm

Needle cage

10 mm

Needle cage

58 mm

Pawl engagement with automatic

starter rope rewind mechanism

3.5 mm dia., 960 mm

Centrifugal clutch without linings

76 mm

approx. 3,500 rpm

0.5 bar

0.5 bar

3.2 Fuel System 034, 036, 036 QS

Carburetor:

Standard setting

High speed screw H:

Low speed screw L:

Idle setting:

Carburetor leakage test

at gauge pressure:

Fuel tank capacity:

Fuel mixture:

Mix ratio:

Air filter:

All positon diaphragm carburetor

with integral fuel pump

approx. 1 turn open

approx. 1 turn open

(starting with screws firmly against

their seats)

0.4 bar

625 cm

3

Regular brand-name gasoline and

brand-name two-stroke engine oil

50:1 with STIHL two-stroke engine

oil

25:1 with other brand-name twostroke, air-cooled engine oils

Large area, bisectional box filter

with wire mesh

Page 5

5034, 036, 036 QS

3.3 Ignition System

Type:

Air gap:

Spark plug (suppressed):

Electrode gap:

Spark plug thread:

Thread length:

Heat range:

034, 036, 036 QS

Transistorized magneto ignition

(breakerless)

0.2 - 0.3 mm

Bosch WSR 6 F

0.5 mm

M14x1.25

9.5 mm

200

3.4 Cutting Attachment

Guide bars:

Cutting lengths:

Oilomatic chain:

Chain sprockets:

Chain speed:

Chain lubrication:

Oil delivery rate:

Oil tank capacity:

STlHL Rollomatic S bars with nose

sprocket.

STlHL Duromatic bars with stellitetipped nose.

Both types with corrosion-resistant

finish and induction hardened rails.

Rollomatic 37, 40, 45 and 50 cm

Duromatic 37, 40, 45 and 50 cm

9.32 mm (3/8") Rapid-Micro,

Rapid-Super

(Options: 8.25 mm (0.325")

Rapid-Micro, Rapid-Super,

Topic-Micro and Topic-Super)

7-tooth, 3/8" rim sprocket

20.7 m/s at 9,500 rpm (with 7-toot h,

3/8" sprocket)

Fully automatic, speed-controlled

reciprocating oil pump; no oil feed

at idle speed. Additional manual oil

flow control

Adjustable 5.5 - 15.5 cm

3

/min

at 10,000 rpm

320 cm

3

Page 6

6 034, 036, 036 QS

3.5 Tightening Torques

DG and P (Plastoform) screws are used in polymer and lightmetal components. These screws form a

permanent thread when they are installed for the first time. They can be removed and installed as often as

necessary without impairing the strength of the screwed assembly, providing the specified tightening torque is

observed.

For this reason it is essential to use a torque wrench.

Fastener Thread size For component Torque

Nm

Remarks

Pan head screw M4x8 Chain tensioner cover plate 3.0

M7x12.5 Starter post to fan housing 12.0 1)

Screw M8x22 Brake band/crankcase

(036 QS II) 10.0 2)

Self-tapping screw B3.9x13 Brake cable retainer/tank housing (036 QS II) 1.5

Collar screw M8x21.5 Guide bar 23.0 2)

Spline screw IS-M4x12 Cover, chain brake/crankcase 3.0

M10x1 Decompression valve (036, 036 QS) 14.0

Spline screw M3.5x12 Generator (W version) 2.0 3)

Spline screw IS-P6x21.5 Front handle/tank housing, top right

(W version) 7.0 3)

Spline screw IS-P6x19 Front ha nd le /ta nk housing, bottom

(W version) 7.0 3)

Spline screw IS-P6x32,5 Front handle/tank housing, top right, polymer 5.0 3)

Spline screw IS-P6x21,5 Front handle/tank housing, bottom, polymer 5.0 3)

Spline screw IS-P4x19 Handle mo ldin g 1.6

Screw assembly M5x30 Hand guard, left 7.0 2)

Spline screw IS-P6x19 Chain catcher 2.8

Spline screw IS-M5x12 Spiked bumber 7.5

Spline screw IS-M5x20 Crankcase 9.0

Spline screw IS-M5x20 Fan housing/crankcase 7.0

M12x1 L Carrier 50.0

Screw HL6x18.5 Annular buffer to rear left/right of tank housing 5.0

Spline screw IS-P6x19 Annular buffer to front right of tank housing 5.0

Spline screw IS-M5x6 Muffler, upper/lower casing 6.5 2)

Spline screw IS-M5x25 Muffler/crankcase 10.0 2)

Spline screw IS-M5x16 Muffler/cylinder (036, 036 QS) 10.0 2)

Spline screw IS-M5x25 Muffler/crankcase (034) 10.0 4)

Spline screw IS-M5x20 Muffler/cylinder (034) 10.0 4)

Spline screw IS-M5x22 Muffler/cylinder (034/Z version) 10.0 4)

Slotted nut M5 Shroud 3.3

Slotted nut M5 Air filter 2.0

M8x1 Flywheel 33.0 6)

Setscrew M5x8.5 Setscrew, l/h side of cylinder 1.4 5)

Setscrew M5x8.5 Setscrew, r/h side of cylinder 1.4

Page 7

7034, 036, 036 QS

Hexagon nut M5 Carburetor (initial) 2.0

Hexagon nut M5 Carburetor (final) 3.5

Spline screw IS-M5x20 Cylinder/crankcase (036, 036 QS) 11.5

Spline screw IS-M5x20 Cylinder/crankcase (034) 10.5

M14x1.25 Spark plug 25.0

Spline screw IS-M5x20 Ignition module (with washer) 8.0 2)

Spline screw IS-M4x12 Oil pump/crankcase 3.5

1) Micro-encapsulated

2) Threadlocking method: medium strength adhesive (e.g . LOCTITE 243)

3) Threadlocking method: high strength adhesive (e.g. LOCTITE 649)

4) Threadlocking method: high strength adhesive up to 250 °C (e.g. LOCTITE 272)

5) Threadlocking method: high strength adhesive (e.g. LOCTITE 270)

6) Degrease taper with cleaning agent (e.g. Somentor 33)

Use the following procedure when refitting a DG or P screw in an existing thread:

– Place the screw in the hole and rotate it counterclockwise until it drops down slightly.

– Tighten the screw clockwise to the specified torque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread

and weaken the assembly.

Note:

Power screwdriver settings for polymer:

– Plastoform screws max. 600 rpm

– DG screws max. 500 rpm

3.6 Special Accessories

3.6.1 For User

3.6.2 For Service

Intake air preheating kit

Intake air preheating kit

.325", 8-tooth rim sprocket kit

.325", 7-tooth rim sprocket kit

3/8", 7-tooth rim sprocket kit

3/8", 7-tooth spur sprocket

.325", 7-tooth spur sprocket

Gasket set

Carburetor parts kit

Gasket panel

034, 036, 036 QS

1125 007 1035 (036)

1125 007 1004 (034/034S)

1125 007 1000

1125 007 1001

1125 007 1002

1125 640 2000

1125 640 2005

1125 007 1050

1128 007 1065

0457 281 0604

Fastener Thread size For component Torque

Nm

Remarks

Page 8

8 034, 036, 036 QS

Troubleshooting chart - see

"Standard Repairs, Troubleshooting" handbook.

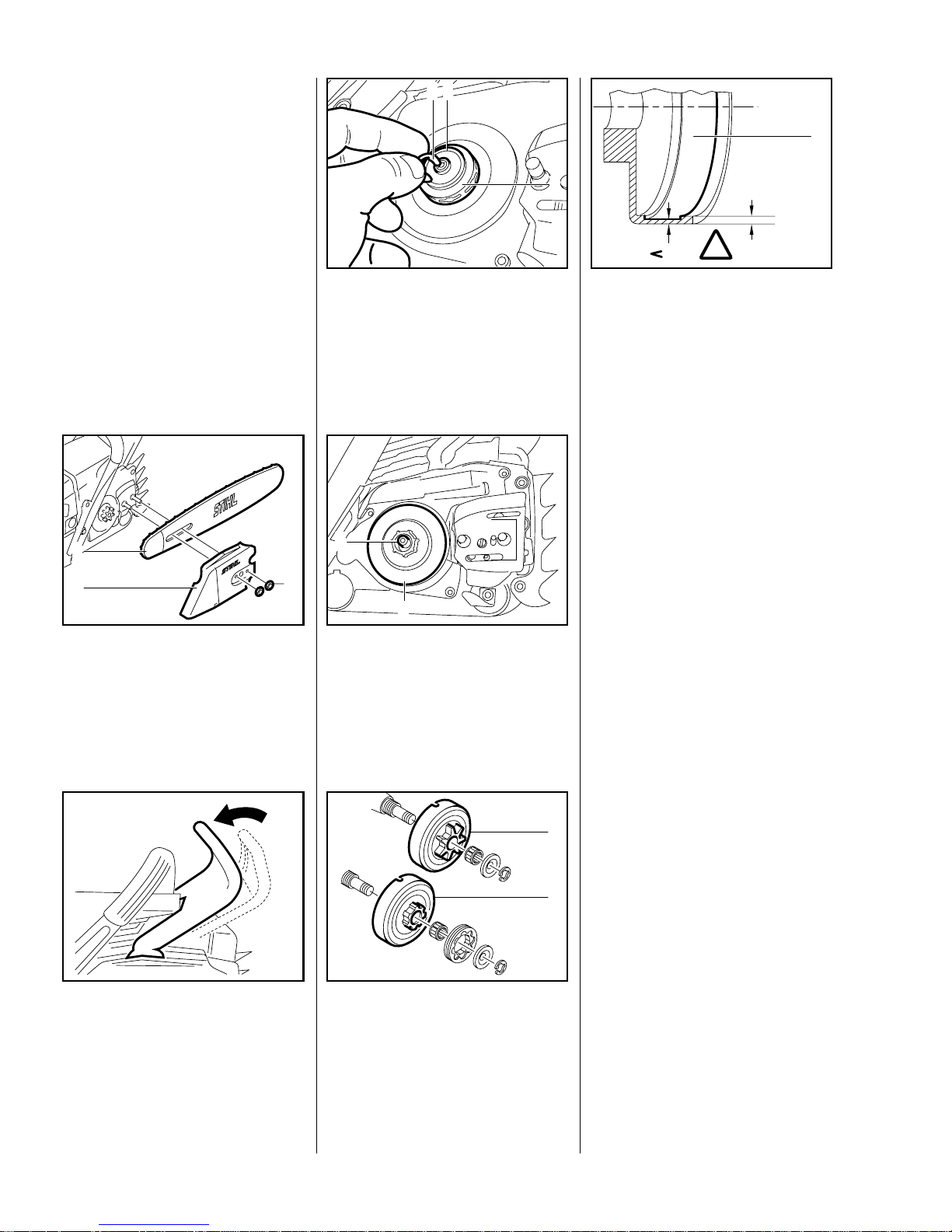

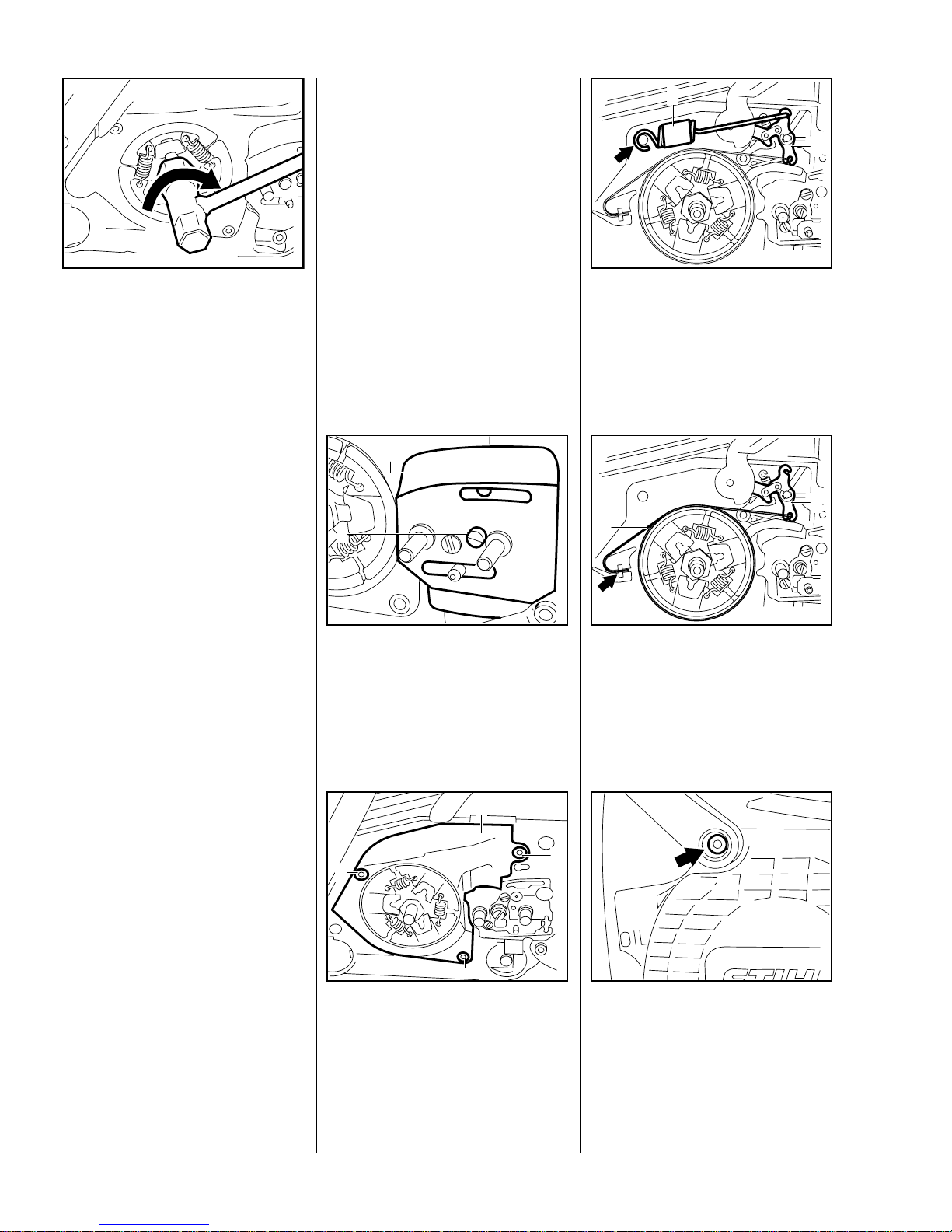

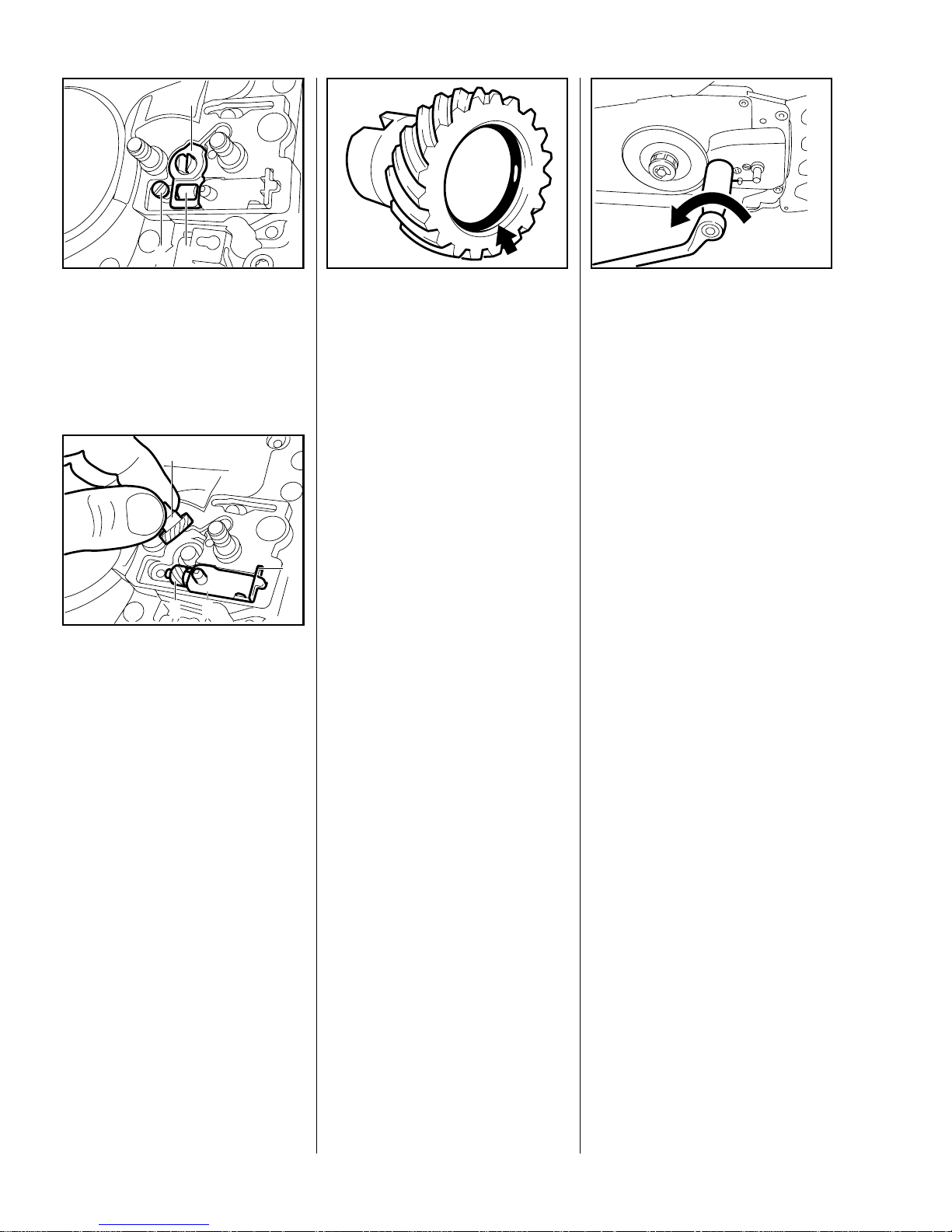

Unscrew nuts (1) from chain

sprocket cover (2). Remove the

sprocket cover , bar and chain (3).

VA

138RA002

1

2

3

Disengage the chain brake by

pulling the hand guard toward the

front handle.

VA

143RA004

Remove the E-clip (1) and

washer (2). If a rim sprocket (3)

is fitted, pull it off.

VA

148RA061

3

21

036 QS

Disengage the additional brake

by pressing down the throttle

trigger and interlock lever.

Remove the clutch drum (1) and

needle cage (2).

VA

148RA062

1

2

034, 036

Pull off the chain sprocket (1) or

clutch drum (2).

– Take out the needle cage.

VA

138RA003

1

2

Inspect the clutch drum (1).

There should be no scores or

signs of excessive wear.

Important:

If there are signs of serious wear on

the inside diameter of the clutch

drum (1), check the remaining wall

VA

148RA101

80%

100%

1

!

thickness. If it is less than about

80% of the original thickness, fit a

new clutch drum.

Note:

Clean stub of crankshaft. Wash

needle cage, examine it for damage

and replace if necessary. Lubricate

needle cage with STIHL multipurpose grease - see 13.2.

Reassemble in the reverse

sequence - start by fitting the ne edle

cage on the crankshaft stub.

4 Clutch, Chain Drive,

Chain Brake and

Chain Tensioner

4.1 Clutch Drum and Chain Sprocket

Page 9

9034, 036, 036 QS

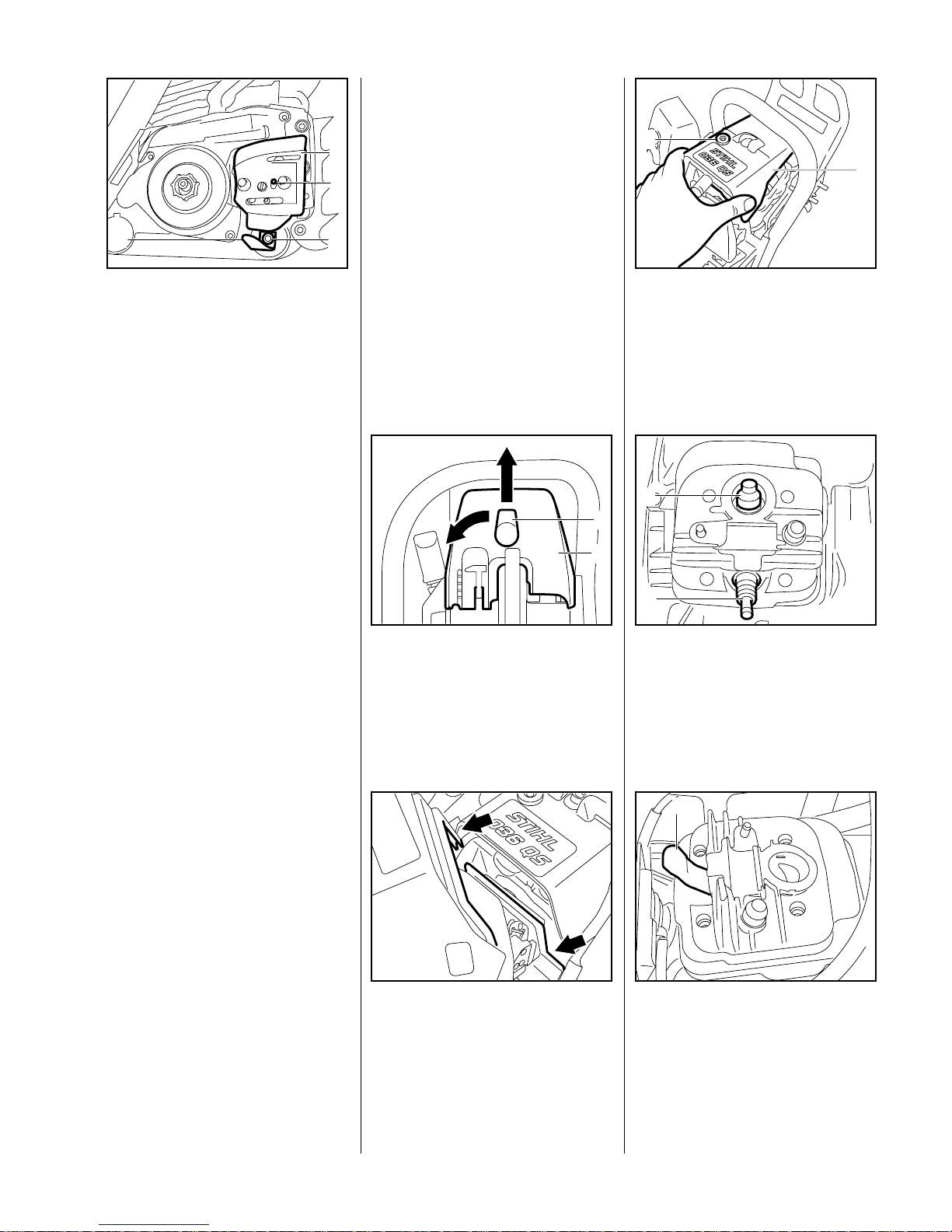

– Remove chain sprocket cover -

see 4.1.

Take out screw (1 ) an d re m ove

the inner side plate (2).

Take out screw (3 ) an d re m ove

the chain catcher (4).

VA

148RA063

2

1

3

4

Reassemble in the reverse

sequence.

Troubleshooting chart - see

"Standard Repairs, Troubleshooting" handbook.

– Remove clutch drum/chain

sprocket - see 4.1.

Release twist lock (1) on

carburetor box cover (2) and lift

cover off vertically.

VA

148RA064

1

2

Note:

When reassembling, check

correct position of groove and

guide.

VA

148RA065

Unscrew the slotted nut (1).

– Pull boot off the spark plug.

Remove the shroud (2).

VA

148RA066

2

1

On powerheads with a

decompression valve (1), remove

the cover and unscrew the

decompression valve.

Unscrew the spark plug (2).

VA

148RA067

1

2

Push the locking strip (1)

0000 893 5903 into the cylinder

so that the words "OBEN - TOP"

face upward.

VA

148RA069

1

4.2 Replacing the

Chain Catcher

4.3 Clutch

Page 10

10 034, 036, 036 QS

Unscrew the clutch clockwise

from the crankshaft (left-hand

thread).

On 036, 036 QS:

Remove cover washer from the

crankshaft stub.

VA

148RA068

– Disassemble and reassemble the

clutch - see "Standard Repairs,

Troubleshooting" handbook.

– Reassemble in the reverse

sequence.

Note:

Observe tightening torque for clutch

(see "Tightening Torques").

Troubleshooting chart - see

"Standard Repairs, Tro ubleshooting" handbook.

– Remove the chain sprocket cover

and cutting attachment - see 4.1.

– Remove the clutch drum/chain

sprocket - see 4.1

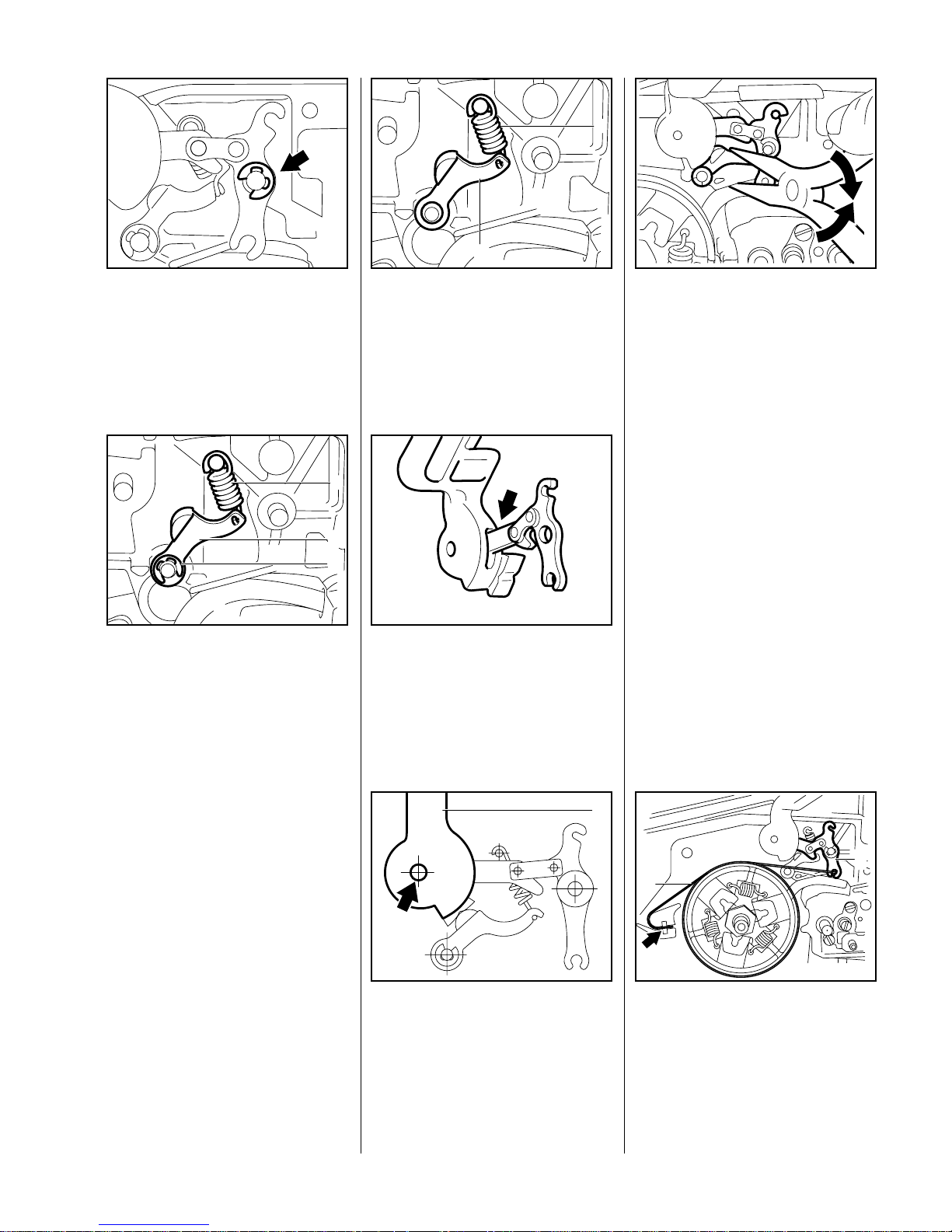

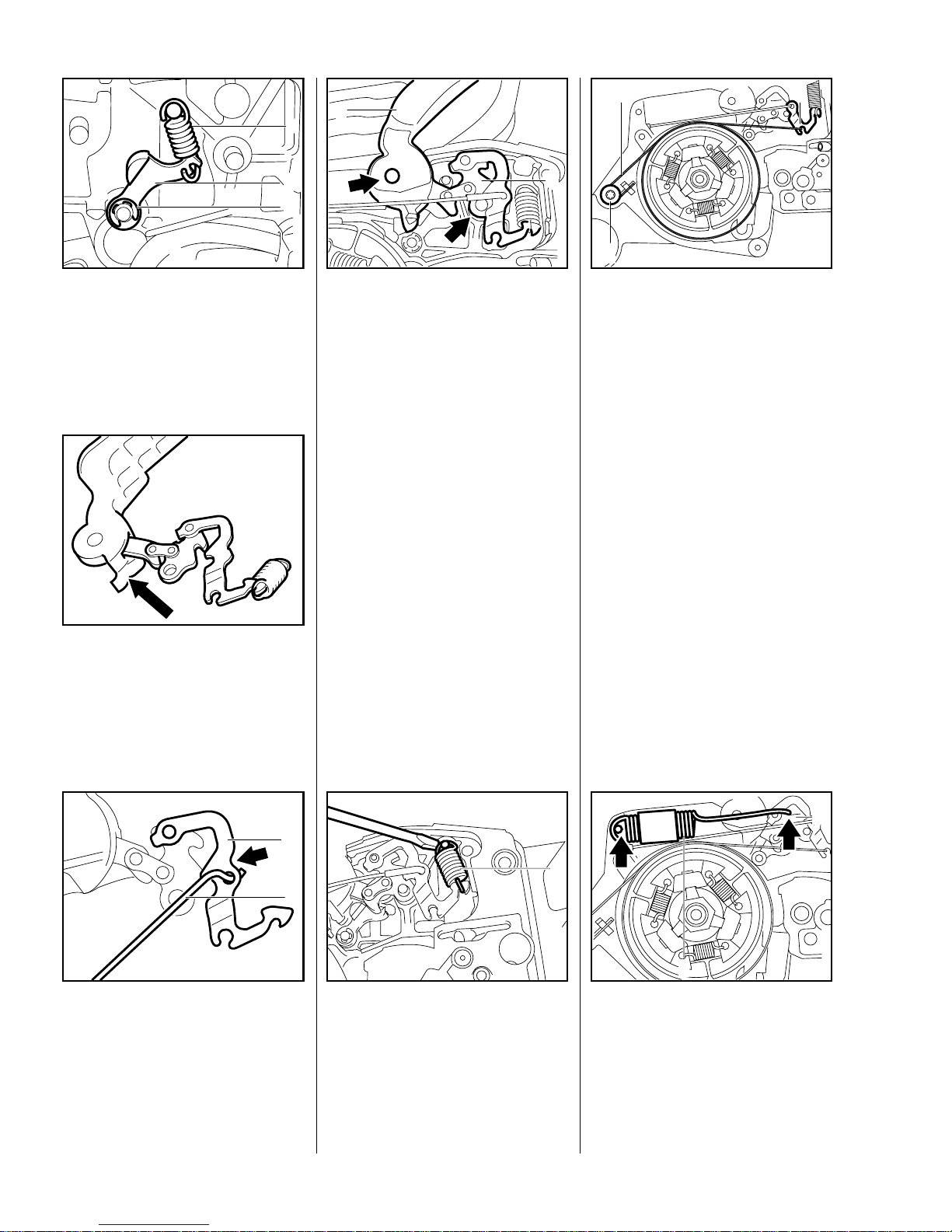

Remove mounting screw (1 ) from

inner side plate (2) and lift side

plate away.

– Engage the chain brake by

pushing the hand guard away

from the front handle.

VA

138RA004

1

2

Remove mounting screws (1)

from cover (2) and lift the cover

away.

VA

138RA005

1

1

1

2

Carefully pry the brake spring (1)

off the anchor pin and disconnect

it from the lever (2).

VA

138RA006

1

2

Ease the brake band (1) out of

its seat in the crankcase and

disconnect it from the lever (2).

VA

138RA007

1

2

Remove screw with captive

washer from the hand guard.

Note:

When installing, tighten down the

screw with captive washer firmly

(see "Tightening Torques").

VA

138RA008

4.4 Chain Brake (034, 036)

4.4.1 Removing

Page 11

11034, 036, 036 QS

Remove the E-clip from the pivot

pin.

– Pull the hand guard and lever

from the pivot pins.

VA

138RA009

– Pull the lever out of the hand

guard.

Remove the E-clip (3) from pivot

pin of lever (2) and detach the

spring (1).

Remove the cam lever and

VA

138RA010

1

2

3

spring.

– Clean all disassembled parts in

white spirit. Replace any worn or

damaged parts.

Fit the cam lever (2) and

spring (1).

– Fit the E-clip.

VA

1

2

138RA011

Insert lever in th e side of the hand

guard so that short arm of lever

points up.

Note:

Check correct installed position of

lever.

VA

138RA012

Position the hand guard (1)

against the pivot pin and fit the

other side of the hand guard over

the fan housing.

VA

138RA013

1

Press the cam lever slightly

downward and push the hand

guard and lever onto the pivot

pins.

– Secure lever with E-clip.

– Insert hand guard mounting

VA

138RA014

screw with captive washer at fan

side and tighten down firmly (see

"Tightening Torques")

Important:

Coat all sliding and bearing points

with STIHL multipurpose grease,

see 13.2, or (better) with

molybdenum grease (e.g.

Molykote), see 13.2.

Do not lubricate the brake band.

First att ach the brake band (1) to

the lever (2) and then push it into

the crankcase recess (arrow).

VA

138RA007

1

2

4.4.2 Installing

Page 12

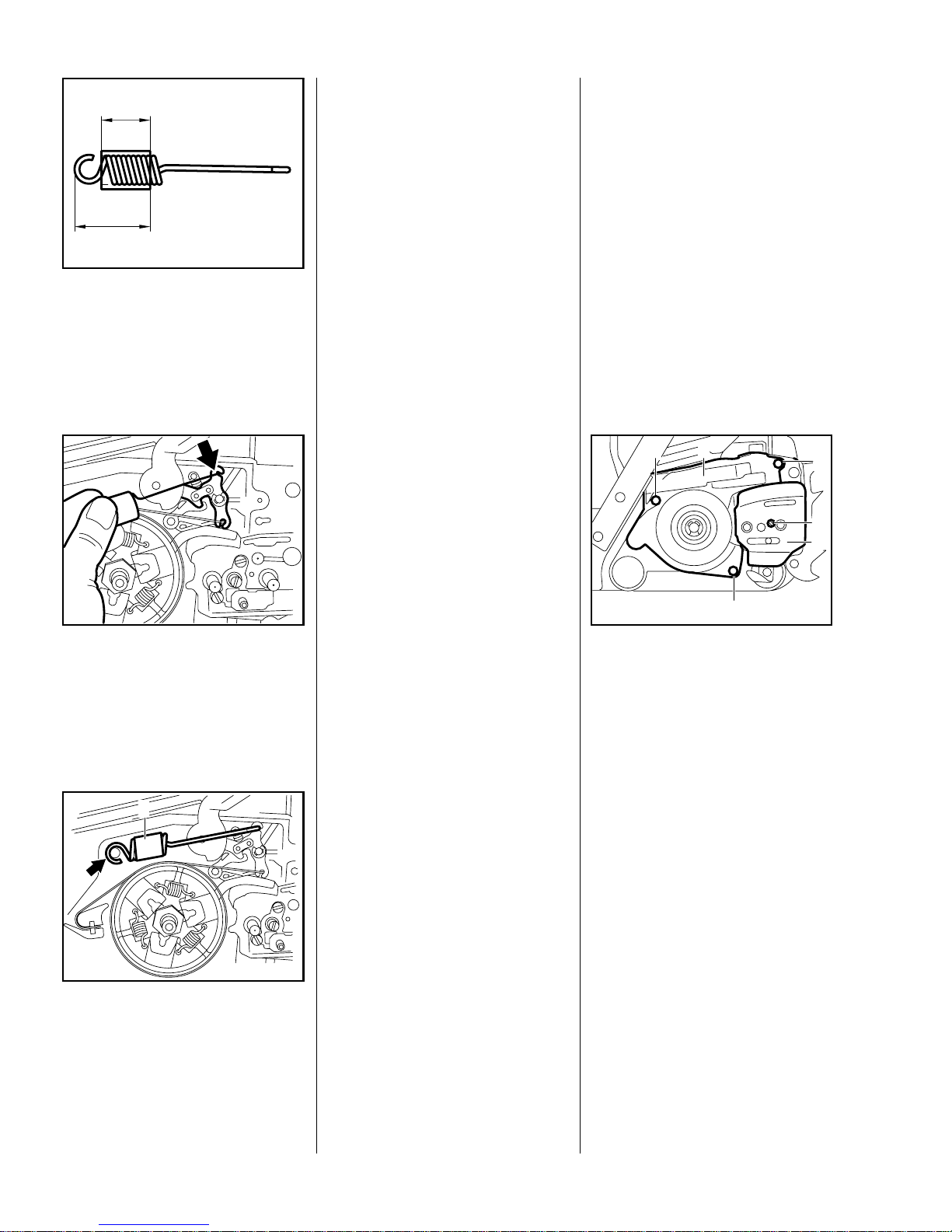

12 034, 036, 036 QS

Check that protective tube is

correctly positioned:

a = 20 mm

b = 33 mm

b

a

VA

138RA016

Hook the brake sp ring to the

lever.

VA

138RA017

Use the assembly tool

1117 890 090 0 to at tach the

brake spring (1) to the anchor pin.

– Fit cover over the chain brake.

VA

138RA015

1

– Fit the inner side plate - see 4.1.

– Install the clutch drum/chain

sprocket - see 4.1.

– Fit the cutting attachment and

chain sprocket cover - see 4.1.

Troubleshooting chart - see

"Standard Repairs, Troubleshooting" handbook.

– Remove the chain sprocket cover

and cutting attachment - see 4.1.

– Remove clutch drum/chain

sprocket - see 4.1.

Remove mounting screw (1) from

inner side plate (2) and lift side

plate away.

Remove mounting screws (3)

from cover (4) and lift the cover

away.

VA

148RA070

4

2

3

3

3

1

– Engage the chain brake by

pushing the hand guard away

from the front handle.

4.5 Chain Brake (036 QS)

4.5.1 Removing

Page 13

13034, 036, 036 QS

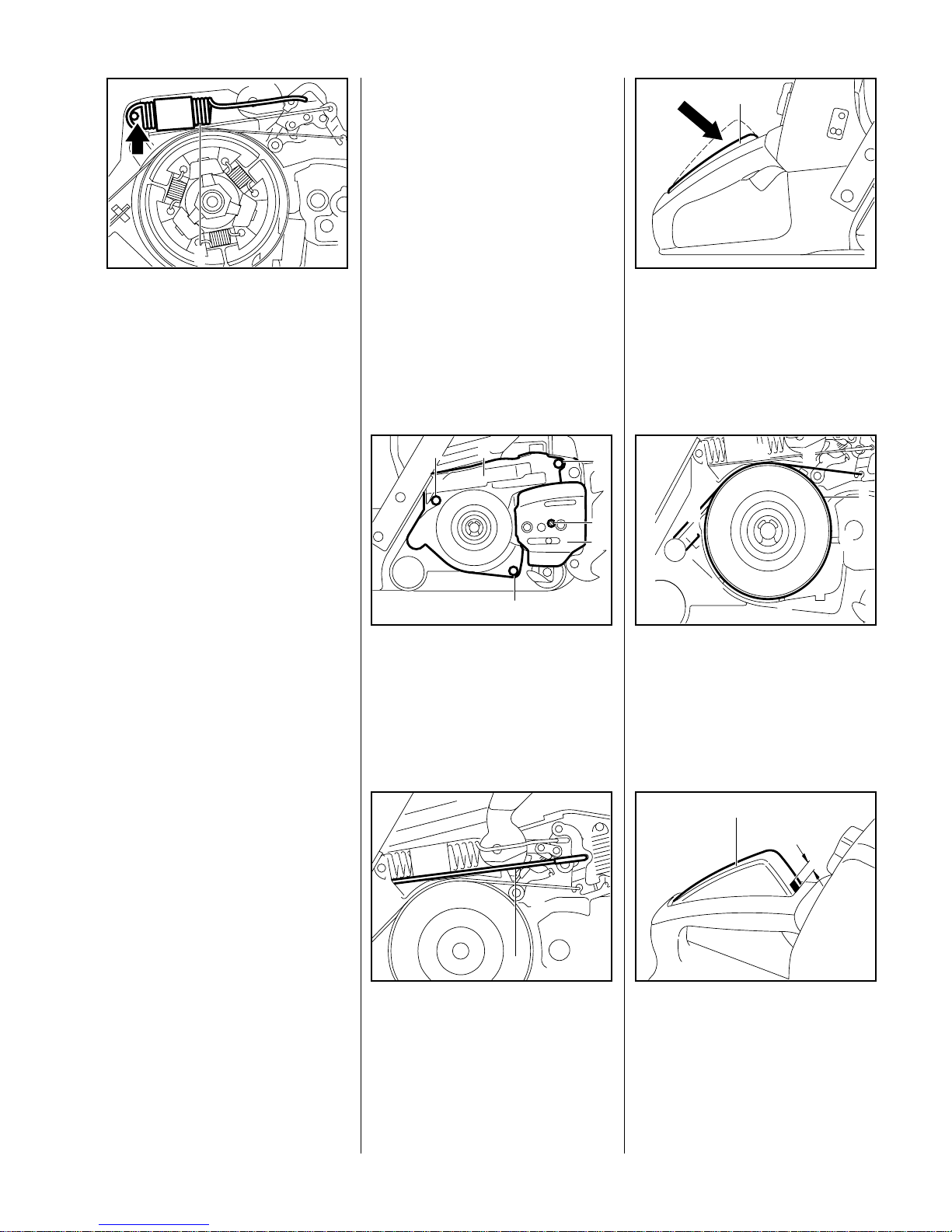

Carefully pry the brake spring (1)

off the anchor pin and disconnect

it from the lever (2).

VA

148RA071

1

2

Remove the screw (1).

Ease the brake band ( 2) out of

its seat in the crankcase and

disconnect it from the lever (3).

3

2

1

VA

148RA072

Remove screw with captive

washer from the hand guard.

Note:

When installing, tighten down the

screw with captive washer firmly

(see "Tightening Torques").

VA

138RA008

Carefully pry spring (1) off the

pivot pin.

VA

148RA073

1

Pull the hand guard (2) and brake

lever (1) off the pivot pins.

VA

148RA074

2

1

Disconnect brake cable ( 1) from

the brake lever (2).

– Take the brake lever out of the

hand guard.

VA

148RA075

2

1

Disconnect spring (1) from

lever (2).

Pry the E-clip (3) off the pivot pin

and remove the lever with spring.

Clean all disassembled parts in

VA

148RA076

1

2

3

white spirit. Replace any worn or

damaged parts.

Page 14

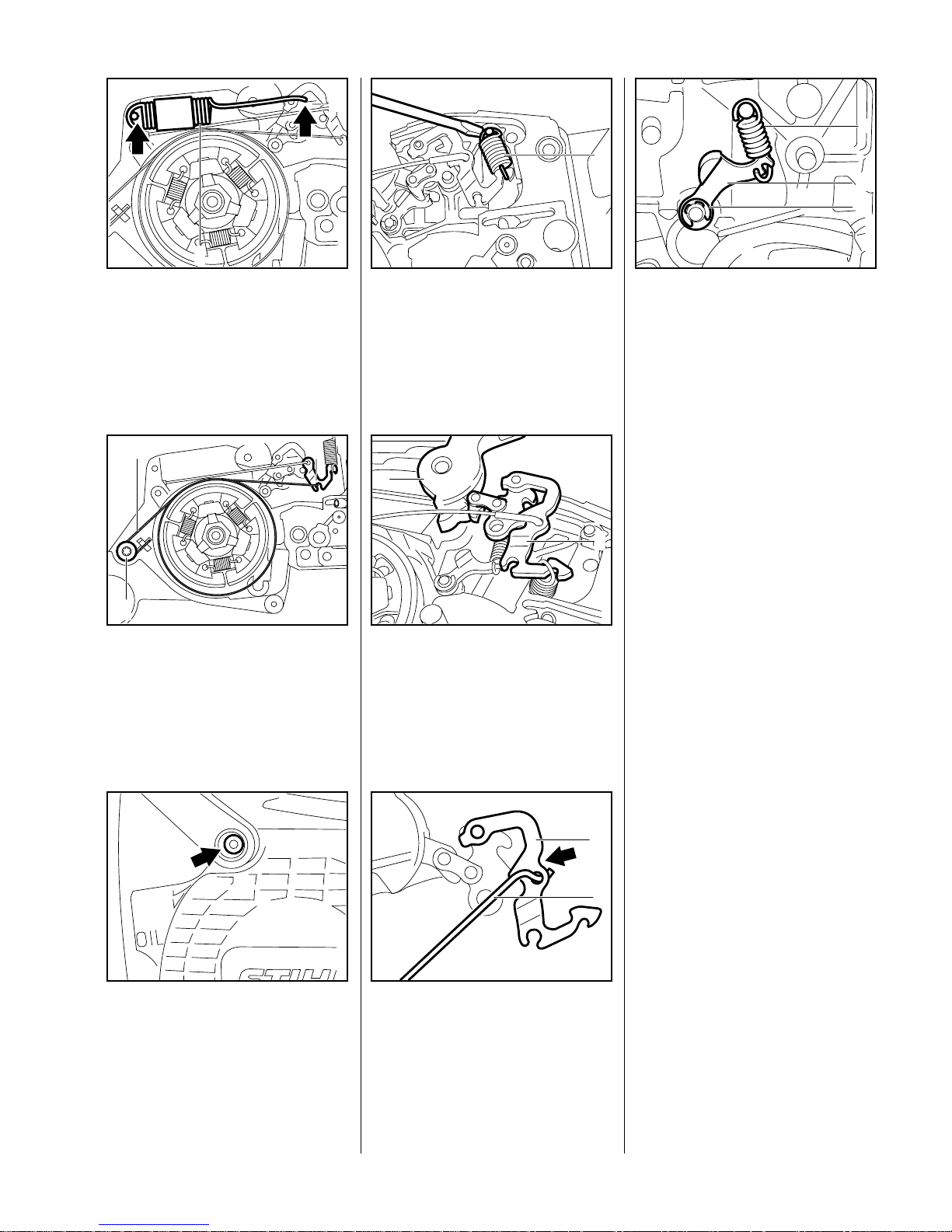

14 034, 036, 036 QS

Fit the lever (2) and spring (1).

Fit the E-clip (3).

VA

148RA076

1

2

3

Insert lever in the side of the hand

guard as shown.

VA

148RA077

Attach brake cable (1) to hole

(arrow) in brake lever (2).

VA

148RA075

2

1

Position the hand guard (1)

against the pivot pin and fit the

other side of the hand guard over

the fan housing.

Press the lever (1) slightly

downward and push the hand

guard and brake lever (2) onto

VA

148RA078

1

2

the pivot pins.

– Insert screw with captive washer

for hand guard and tighten down

firmly (see "Tightening Torques").

Important:

Coat all sliding and bearing points

with STIHL multipurpose grease,

see 13.2, or (better) with

molybdenum grease (e.g.

Molykote), see 13.2.

Do not lubricate the brake band.

Attach spring (1) to the pivot pin.

VA

148RA073

1

First att ach the brake band (2) to

the brake lever (3) and then pu sh

it into the slot in the crankcase.

Install screw (1) with LOCTITE

243 and tighten down firmly (see

"Tightening Torques")

3

2

1

VA

148RA072

Hook the brake spring (1) to the

brake lever (2).

VA

148RA071

1

2

4.5.2 Installing

Page 15

15034, 036, 036 QS

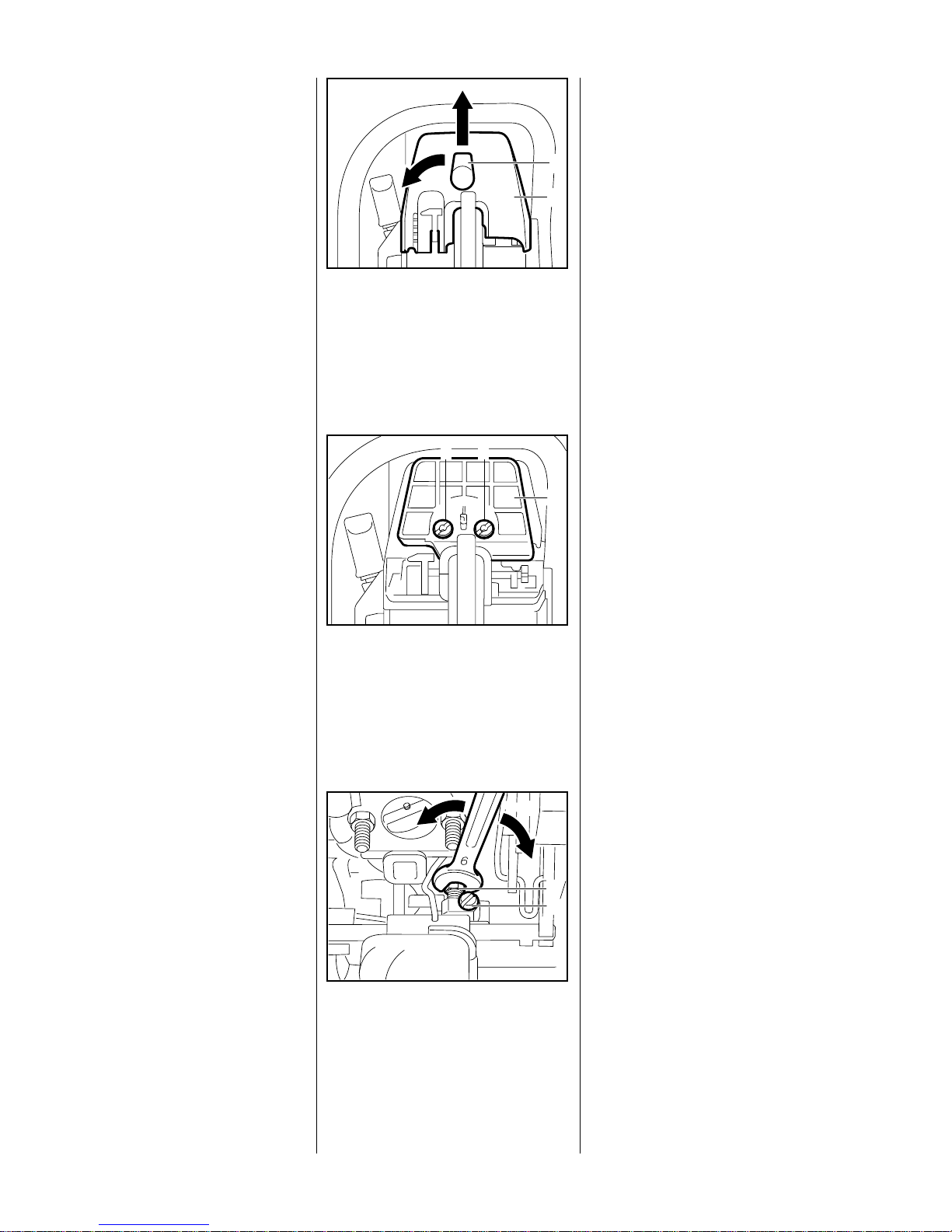

Use the assembly tool

1117 890 090 0 to at tach the

brake spring (1) to the anchor pin.

– Fit cover over the chain brake -

see 4.5.1.

– Fit inner side plate - see 4.5.1.

VA

148RA098

1

– Install the clutch drum/chain

sprocket - see 4.1.

– Fit the cutting attachment and

chain sprocket cover - see 4.1.

– Pull hand guard toward front

handle.

– Unscrew nut from chain sprocket

cover and remove the cover - see

4.1.

– Remove the cutting att a chment -

see 4.1.

Take out screw (1) and remove

the side plate (2).

Take out screws (3) an d re m ove

the cover (4).

VA

148RA070

4

2

3

3

3

1

The brake cable (1) must hang

loosely in the crankcase when

the brake is disengaged.

VA

148RA079

1

Press down interlock lever (1) all

the way and hold it in that

position.

VA

148RA080

1

The brake band (1) must locate

without any play against the

points (A) in the crankcase.

VA

148RA081

A

A

A

A

A

1

A

Let go of the interlock lever (1).

Check free travel by slowly

squeezing the interlock lever (1).

Play must be within the mark (B)

at the front end of the interlock

lever.

VA

148RA082

1

B

4.5.3 Checking Play

Page 16

16 034, 036, 036 QS

The brake lever must not move. If

it does, adjust play - see 4.5.4

Reassemble in the reverse

sequence.

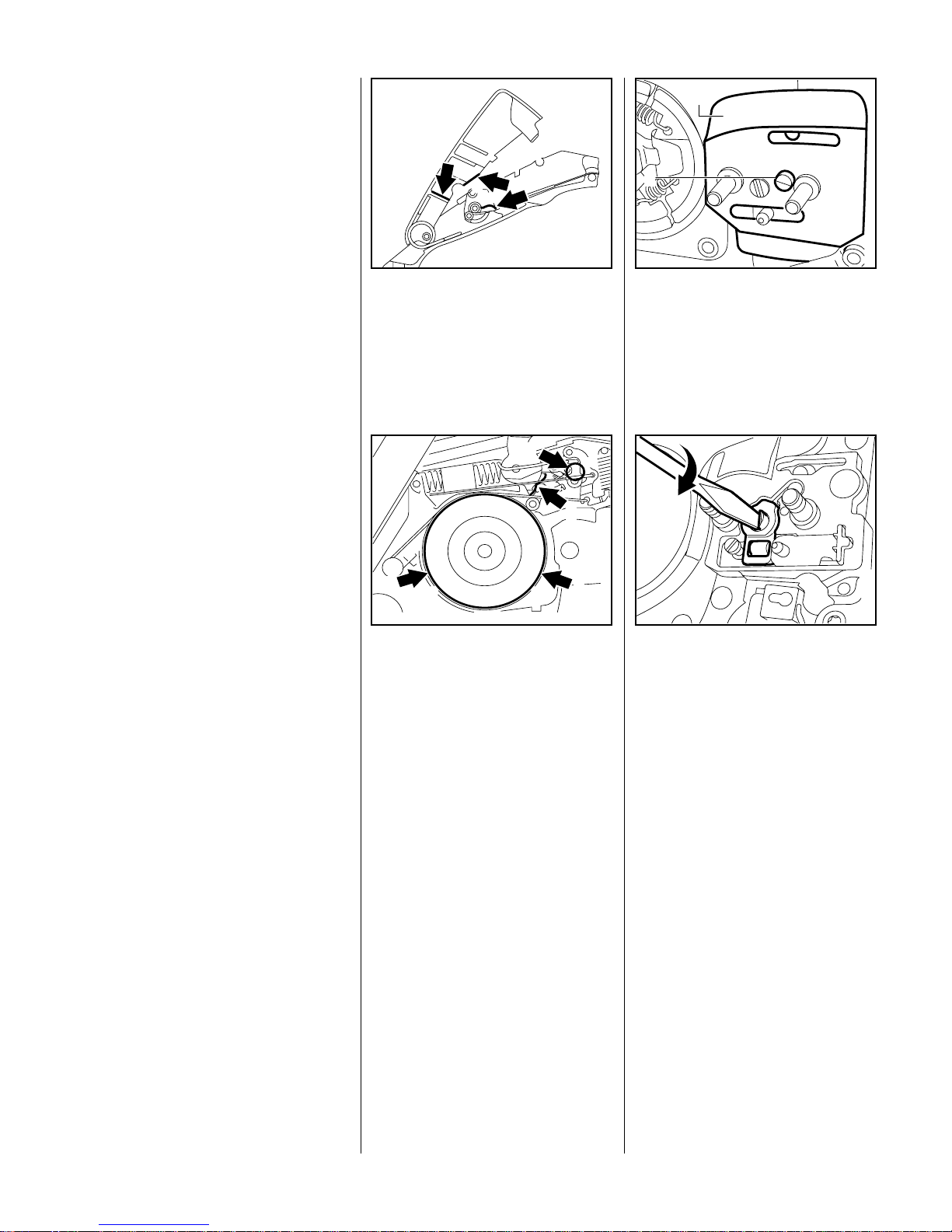

Open twist lock (1) and lift away

the carburetor box cover (2)

vertically.

VA

148RA064

1

2

Release and unscrew slotted

nuts (1).

Remove the air filter (2).

VA

148RA084

2

11

Loosen the self-tapping

screw (1).

Use a 6mm open-end wrench to

adjust play with nut (2).

VA

148RA085

1

2

Turn wrench to right to reduce

play.

Turn wrench to left to increase

play.

Lock the setting with se lf-tapping

screw (1).

Reassemble in the reverse

sequence.

4.5.4 Adjusting Play

Page 17

17034, 036, 036 QS

Check operation of the chain brake

with the bar and chain mounted.

Note:

When starting the machine observe

local safety regulations and the

safety precautions in the owner’s

manual.

– With the engine running, open

the throttle wide.

– Release the rear handle.

The chain must come to a standstill

in less than one second.

If the brake does not operate

properly, service the sliding and

bearing points shown in the

illustrations as follows:

If lightly contaminated:

– Clean all parts with a brush and

white spirit.

If heavily contaminated or

clogged with resin:

– Remove the parts concerned and

clean in white spirit or a resin

solvent.

– Replace worn or damaged parts.

– Before re-installing parts, the

machine recesses and seats.

Lubricate bearing points with

Mobilplex grease (see 13.2).

VA

148RA047

Lubricate these points (1) with

Mobilplex grease (see 13.2).

Coat outside diam eter of clutch

drum (2) with chain oil.

Note:

If a biological chain oil is preferred,

VA

148RA048

1

1

2

2

STIHL recommends the use of

rapidly biodegradable STIHL

Bioplus.

To guarantee t roublefree oper ation,

use only original STIHL replacement parts as per the latest parts

list.

– Remove chain sprocket cover

and cutting attachment - see 4.1.

Remove mounting scre w (1) from

inner side plate (2) and lift side

plate away.

VA

138RA004

1

2

Use a screwdriver to turn the spur

gear clockwise until tensioner

slide butts against the thrust pad.

Note:

Older machines are equipped wi th

a front chain tensioner - see 5.5.2.

148RA086

VA

4.5.5 Checking Operation of Chain Brake 4.6 Chain Tensioner

Page 18

18 034, 036, 036 QS

Take out the cover plate

mounting screw (1).

Remove the cover plate (2) with

retainer (3) from the spur gear.

148RA087

VA

3

1 2

Pull out the spur gear (1).

Take out the tensio ne r slid e (3 )

with adjusting screw (4) and

thrust pad (2).

– Inspect the teeth on the spur gear

and adjusting screw, remove

VA

4 3

1

2

148RA088

thrust pad if necessary.

– Take the adjusting screw out of

the tensioner slide and replace

the parts.

Install in the reverse sequence.

Check that O-ring is fit ted in spur

gear.

– Lubricate O-ring with a little oil

before fitting the spur gear.

Note:

Coat teeth of adjusting screw and

VA

138RA018

spur gear with grease, see 13.2,

before refitting.

The adjusting screw and spur gear

must be replaced as a matching

pair.

– Remove chain sprocket cover

and cutting attachment - see 4.1.

Push stud puller 5910 893 0501

over the collar stud as far as it will

go. Use a 15 mm wrench to

unscrew the collar stud counterclockwise.

VA

138RA019

– Before installing, coat thread of

collar stud with LOCTITE - see

13.2.

– Install and tighten down t he collar

studs (see "Tightening Torques").

4.7 Bar Mounting Studs

Page 19

19034, 036, 036 QS

Always check and, if necessary,

repair the fuel system, carburetor,

air filter and ignition system before

looking for faults on the engine.

Troubleshooting chart - see

"Standard Repairs, Troubleshooting" handbook.

(034)

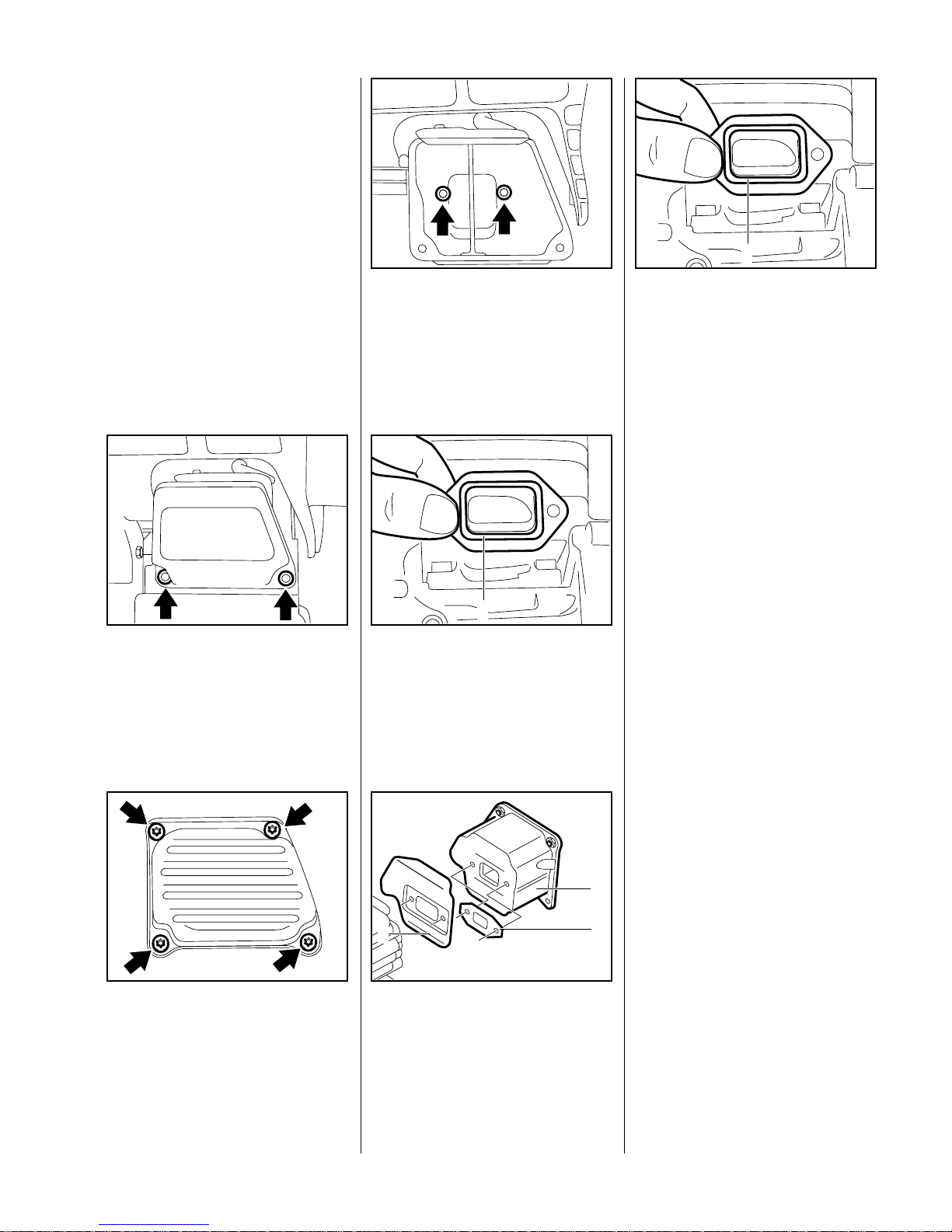

Take out the screws and remove

the upper casing.

VA

138 RA 219

(036, 036 QS)

Take out screws and remove the

upper casing.

VA

138 RA 220

Take out the screws and remove

the lower casing.

VA

138 RA 020

(034)

Remove exhaust gasket (1) and

flange.

VA

138RA021

1

(036, 036 QS)

Remove heat shield (1) and

gasket (2) from the upper

casing (3).

VA

138RA022

1

3

2

Install new gasket (1) so that its

bead points toward the muffler.

Note:

If the bores of the lower casing are

not reinforced, fit washers under the

heads of the mounting screws.

VA

138RA021

1

– Coat threads of mounting screws

with LOCTITE - see 13.2.

– Insert and tighten down the

mounting screws firmly (see

"Tightening Torques").

5Engine

5.1 Removing and Installing Muffler

Page 20

20 034, 036, 036 QS

Always check and, if necessary,

repair the fuel system, carburetor,

air filter and ignition system before

looking for faults on the engine.

Troubleshooting chart - see

"Standard Repairs, Troubleshooting" handbook.

– Drain the fuel and oil tanks.

– Remove the air filter - see 12.1

– Remove the carburetor - see 12.3

Pull the washer (1) off the studs

and remove the sleeve (2) from

the manifold.

– Remove the shroud, spark plug

and, if fitted, the decompression

valve - see 4.3.

VA

138RA023

1

2

– Remove the muffler - see 5.1

Reassemble in the reverse

sequence.

– Preparations - see 5.2

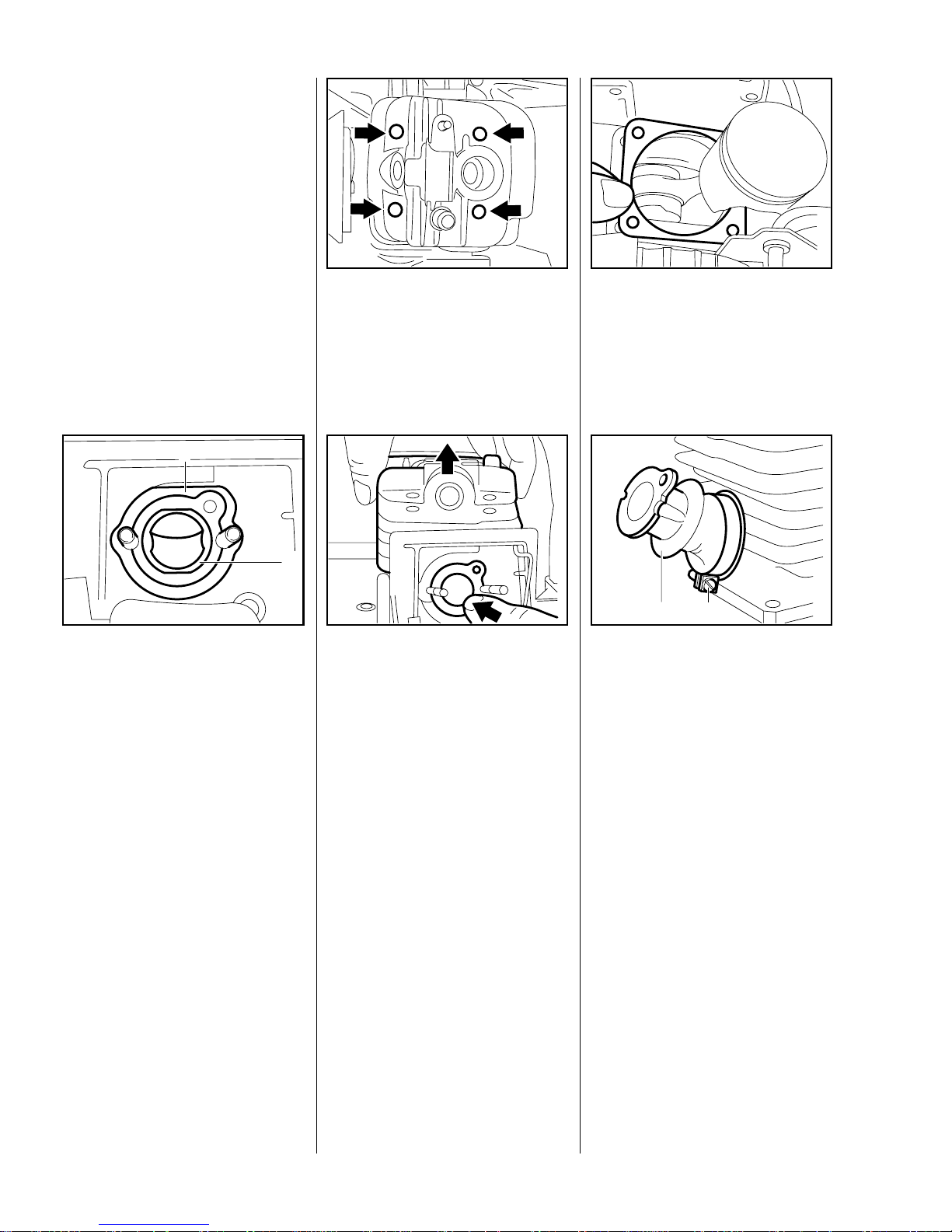

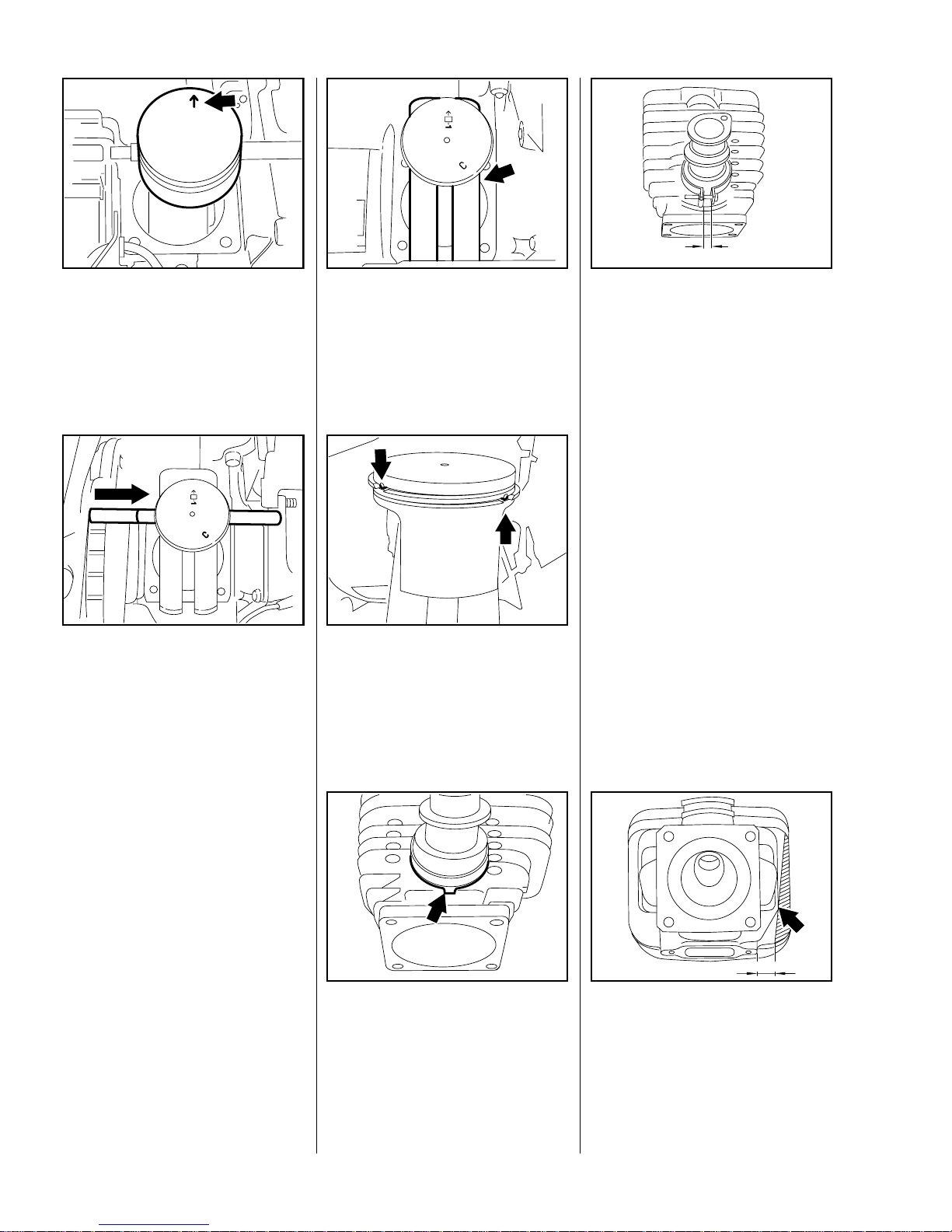

Take out the four cylinder base

screws.

VA

148RA089

Pull the cylinder off the piston

and, at the same time, push the

manifold through the tank

housing opening.

Caution:

Do not use pointed or sharp-edged

tools for this job.

VA

138RA024

Remove the cylinder gasket.

VA

138RA025

Release the hose clamp (1) on

the manifold (2). Pull the manifold

off the intake port.

– Inspect the cylinder and replace it

if necessary.

Note:

VA

138RA026

12

If a new cylinder has to be installed,

always fit the matching piston. New

cylinders are only supplied

complete with piston for this reason.

5.2 Exposing the Cylinder 5.3 Cylinder and Piston

5.3.1 Removing

Page 21

21034, 036, 036 QS

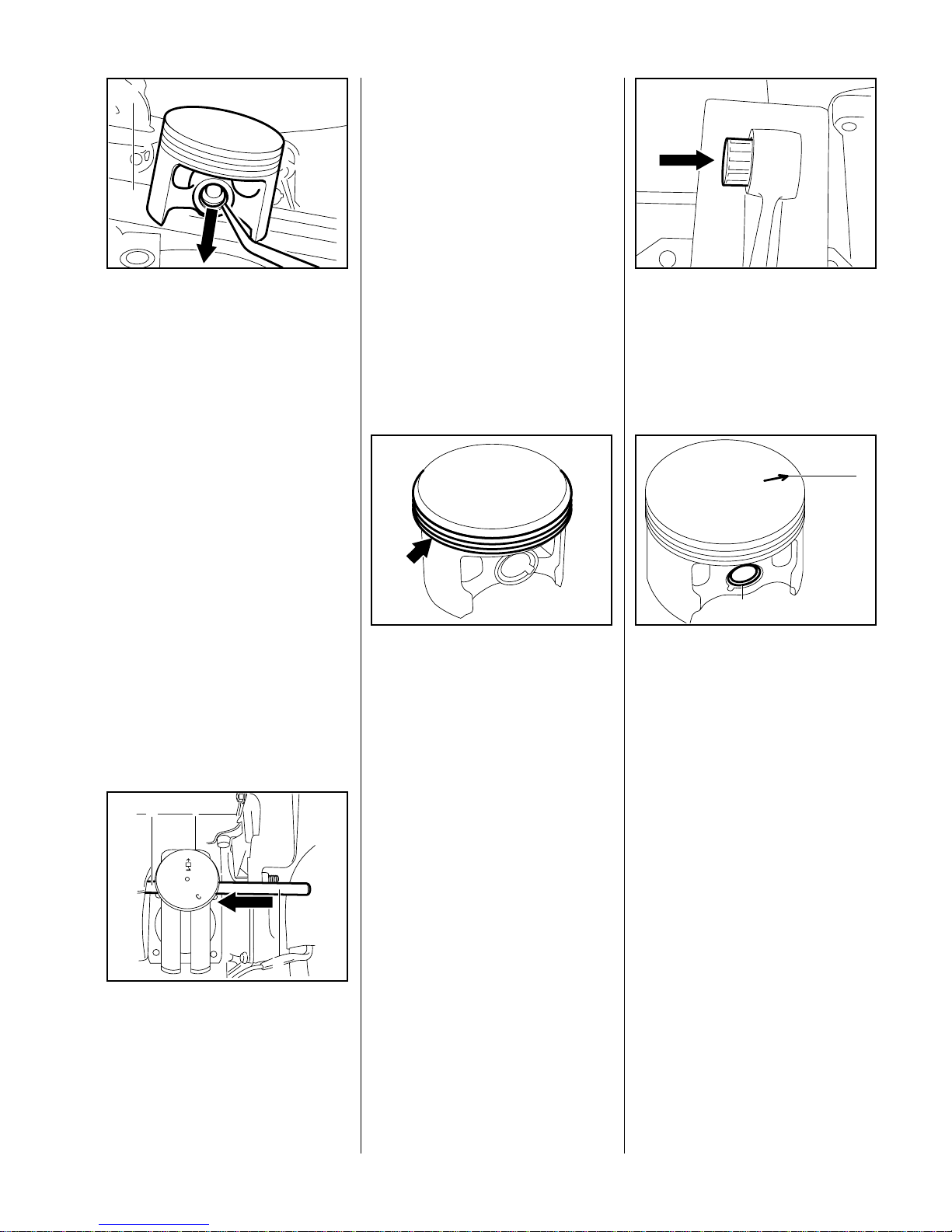

Important:

Before removing the piston, decide

whether or not the crankshaft has to

be removed as well.

To remove the flywheel and

clutch, block the crankshaft by

sliding the wooden assembly

VA

138RA027

1

block (1) 1 108 893 4800 between

the piston and crankcase.

Use a scriber or similar tool to

ease the hookless snap rings out

of the grooves in the piston.

Use the assembly drift (2)

1 1 10 893 4700 to push the pist on

pin (1) out of the piston.

Note:

– If the piston pin is stuck, tap the

end of the drift lightly with a

hammer if necessary.

VA

138RA028

1

2

Important: Hold the piston

steady during this process to

ensure that no jolts are

transmitted to the connecting rod.

– Remove piston and take the

needle cage out of the

connecting rod.

Inspect piston r ings and replace if

necessary - see 5.4.

VA

138RA029

– Thoroughly clean the gasket

seating surface on the cylinder.

Lubricate the need le cage with oil

and fit it in the small end.

VA

138RA030

Install a snap ring in the front

piston boss (2), i.e. the piston

boss facing you when the arrow

(1) on the piston head is pointing

to the right.

Note:

Use installing tool 5510 890 2210 to

VA

138RA031

1

2

fit the snap ring - see "S tandard

Repairs, Troubleshooting"

handbook.

– Heat the piston on an electric

heating plate to about 60°C.

5.3.2 Installing

Page 22

22 034, 036, 036 QS

Slip the piston over the

connecting rod so that arrow on

piston crown points to exhaust

port.

VA

138RA032

– Push the assembly drift

1110 893 4700, sma ll dia m et er

first from the clutch side, through

the piston and small end (needle

cage) and line up the piston.

Fit piston pin on the end of the

assembly drift and push it into the

VA

138RA033

piston.

– Use installing tool 5910 890 2210

to fit the snap ring - see "S tandard

Repairs, Troubleshooting"

handbook.

– Fit new cylinder gasket on the

crankcase.

– Lubricate piston and piston rings

with oil.

Slide the wooden assembly

block between the piston and

crankcase.

Rest the piston on the wooden

assembly block.

VA

138RA034

Position the piston rings so that

the radii at the ring gap meet at

the fixing pin in the piston groove

when the rings are compressed.

VA

138RA035

Push the manifold on to the

intake port so that its tab lines up

with the rib on the cylinder.

VA

138RA036

Slide the hose clamp on to the

manifold. The screw head must

point to the right.

The screw on the hose clamp

must be below the manifold and

at a right angle to the cylinder

axis.

a

VA

138RA037

Tighten the screw until the gap

"a" between the two ends of the

hose clamp is 3.5 to 4.5 mm.

Note:

If a new cylinder is installed in an

older machine, it is necessary to

shorten the seventh cylinder fin.

Use the edge of the eighth fin as a

guide for the modification (see

arrow in illustration).

VA

138RA038

7

8

10mm

Page 23

23034, 036, 036 QS

– Coat thread of setscrew in

cylinder with LOCTITE - see

13.2.

– Insert setscrew and t ighten down

firmly (see "Tightening Torques").

– Lubricate the inside of the

cylinder with oil and line it up so

that it is positioned as it will be in

the installed condition.

Use the clamping strap

0000 89 32600 to compress the

rings around the piston. Check

VA

138 RA 039

correct installed position of rings

once again.

Note:

T o make cylinder inst allation easier ,

apply clamping strap so that it is just

below the piston crown.

Slide the cylinder over the piston.

– Remove the wooden assembly

block and clamping strap.

VA

138 RA 040

Wind a piece of string (about

15 cm long) around the back of

the manifold flange, press the

manifold down and pass the ends

of the string through the intake

opening.

VA

138RA041

Pull the ends of the string

outward. The manifold flange is

pulled through the tank housing

intake opening without damaging

the manifold.

VA

138RA042

– Carefully line up the cylinder and

gasket.

– Fit cylinder base screws and

torque down firmly in a diagonal

pattern (see "Tightening

Torques").

Important:

It is essential to observe the

specified tightening torque as the

screws might otherwise work loose.

Assemble all other parts in the

reverse sequence. Always install

new gaskets.

Page 24

24 034, 036, 036 QS

– Remove the piston - see 5.3.1.

– Remove rings from piston.

Use a piece of old piston ring to

scrape the grooves clean.

Warning:

VA

138RA043

Do not install 1.2 mm rings in

pistons with 1.5 mm grooves.

Install the new piston rings in the

grooves so that the radii at the

ends of the rings face upward.

– Install the piston - see 5.3.2.

VA

138RA044

– Remove the chain brake - see 4.4

and 4.5.

– Remove the oil pump - see 11.4

– Remove the flywheel - see 6.4.1

– Remove the ignition module - see

VA

138RA045

6.5.1

– On machines with handle and/or

carburetor heating, remove the

generator - see 10.5.1.

– Remove the cylinder and piston -

see 5.3.1.

– Remove the tank housing - see

12.8.1.

– Remove the spiked bumper.

Use a 5 mm drift or other suitable

tool to drive out the two dowel

pins from the clutch side.

Unscrew the five mounting

screws which join the two halves

of the crankcase.

VA

138RA046

Use a screwdriver to rotate the

spur gear clockwise until the

tensioner slide butts against the

thrust pad.

Note:

Use service tools

AS 5910 007 2205 and

148RA086

VA

ZS 5910 007 2200 to remove and

install the crankshaft. Follow the

instructions supplied with the tools.

– Back off spindle on service tool

AS all the way.

Slip service tool

AS 5910 007 2205 over the two

collar studs, fit the hexagon nuts

(for sprocket cover) and tighten

them down by hand.

VA

138RA047

5.4 Piston Rings 5.5 Crankcase

5.5.1 Removing the Crankshaft

Page 25

25034, 036, 036 QS

Turn the spindle of the service

tool clockwise until the crankshaft

is pressed out of the ball bearing.

The two halves of the crankcase

separate during this process.

VA

138RA048

Fit thrust sleeve 1107 894 1000

from clutch puller 1107 890 4500

to protect the crankshaft thread

during the following operation.

VA

138RA049

Fit service tool

ZS 5910 007 2200 aga inst the

outside of the crankcase.

VA

138RA050

Note:

The tool’s drilled plate must locate

flat against the crankcase.

With the crankcase horizontal

(cylinder flange upright), rotate

service tool until the number 7 on

the plate is at the bottom.

Secure the service tool to the

crankcase with M5x72 mounting

screws 9022 341 1190. Insert the

screws in the holes marked "7"

and tighten them down against

the drilled plate.

– Turn spindle counterclockwise

VA

138RA051

(left-hand thread) until it locates

against the crankshaft.

– Use a 19 mm wrench to continue

turning the spindle and push the

crankshaft out of its bear ing seat.

The crankshaft (1), connecting

rod (2) and needle bearing form

an inseparable unit. This means

that the crankshaft must always

be replaced as a complete unit in

the event of damage to any one

of these parts.

VA

138RA052

1

2

– When fitting a replacement

crankshaft, always install new oil

seals and ball bearings.

– Remove the gasket from the

crankcase sealing face.

Use a screwdriver to pry the oil

seal out of the ball bearing at t he

clutch side.

VA

138RA053

Page 26

26 034, 036, 036 QS

Use press arbor 1118 893 7200

to press the ball bearing out of its

seat.

VA

138RA054

Use a screwdriver or similar tool

to knock the oil seal out of its seat

at the ignition side.

VA

138RA055

From outs ide the crankcase, use

arbor 1 120 893 7200 to pre ss the

ball bearing inwards and out of its

seat.

VA

138RA056

– Pull the oil suction hose out of

crankcase.

– Inspect both halves of the

crankcase for cracks and replace

if necessary.

Note:

Always install new gaskets and

ball bearings when replacing the

crankcase. The crankcase must be

replaced as a complete unit even if

only one half is damaged.

All other parts which are still

serviceable can be transferred to

the new crankcase after the new

bearings have been fitted

(crankcase has to be heated).

Use the stud puller 5910 893 0501

to remove and install the bar

mounting studs - see 4.7.

– If the original crankcase is used

again, remove all the gasket

residue and clean the mating

surfaces.

Note:

Clean the mating surfaces

thoroughly to ensure a perfect seal.

Note:

A new front chain tensioner is

supplied with replacement

crankcases.

1 Tensioner slide

2 Adjusting screw

3 Thrust pad

VA

138RA058

1 5

2

3

4

4 Cover plate

5 Pan head screw

– Stamp the machine’s serial

number on the crankcase with

2.5 mm figure stamps.

– Check that dowel pin is in

position. If necessary, drive

dowel pin into new crankcase.

5.5.2 Installing th e Crankshaft

Page 27

27034, 036, 036 QS

See illustrated parts list for correct

installed sequence and positions of

crankcase components.

Pull the plastic plug out of the oil

pump.

VA

138RA059

Position the oil pump ag ainst the

crankcase. Insert and tighten

down the mounting screws.

– Before heating the crankcase,

remove all rubber and polymer

VA

138RA060

components, such as oil suction

and delivery hoses, grommets,

annular buffers and levers - see

8.1 and 11.4.

– Inspect condition of all parts and

replace as necessary.

– Heat area of bearing seat on

clutch side of crankcase to

approx. 120°C.

Place ball bearing in posit ion and

press it in until it locates against

the oil pump.

Note:

The ball bearing can be fitted by

hand if the crankcase is heated as

specified. This operation must be

VA

138RA061

carried out very quickly because the

bearing absorbs heat immediately

and begins to expand.

– Remove the oil pump and refit the

plastic plug.

Push the two annular buffers,

tapered end first, into position so

that the groove (1) engages over

the housing rib.

VA

138RA062

1

Push the oil suction hose into the

crankcase bore.

VA

138RA063

Use a blunt tool to push the oil

suction hose into the bore so that

its tab locates in the bottom right

recess.

VA

138RA064

Page 28

28 034, 036, 036 QS

Fit the lever (1) over the pivot pin,

secure it with the E-clip and

attach the spring (2).

Install the chain tensioner (3) -

see 4.6

VA

138RA065

1

2

3

– Heat area of bearing seat on

ignition side of crankcase to

approx. 120°C.

Use press arbor 1118 893 7200

to install the ball bearing (open

side up).

VA

138RA066

Important:

the ball bearing is closed at one

side. The open side must be on the

inside of the crankcase to

guarantee proper lubrication.

Note:

The ball bearing can be fitted by

hand if the crankcase is heated as

specified. This operation must be

carried out very quickly because the

bearing absorbs heat immediately

and begins to expand.

Push annular buffer into

crankcase bore, from outside,

until its groove (1) engages the

inner rib.

VA

138RA067

1

Extend the spindle of service tool

ZS (2) 5910 007 2200 fully and

then screw the threaded sleeve

(1) 5910 893 2420 onto the

spindle as far as it will go.

VA

148RA093

21

Lubricate short crankshaft stub

with oil and position it in the

bearing from inside the ignition

side of the crankcase.

VA

148RA090

Important:

The original crankshaft must not be

installed in model 034S.

Apply threaded sleeve (1) to

thread (2) on crankshaft stub.

VA

148RA091

1 2

Hold the service tool and

crankshaft steady and continue

turning the spindle clockwise until

the service tool butts against the

crankcase.

VA

148RA092

Page 29

29034, 036, 036 QS

T urn the spindle clockwise to pull

in the crankshaft until it locates

against the ball bearing.

Important:

The connecting rod must point

toward the cylinder flange while the

crankshaft is being installed.

VA

138RA069

– Remove service tool ZS: First

release the spindle counterclockwise and then unscrew the

service tool ZS, also counterclockwise.

– Screw the spindle fully into

service tool AS 5910 007 2205 in

the clockwise direction.

Screw threaded sleeve (2)

5910 893 2409 onto the spindle

of service tool AS (1) as far as it

will go (left-hand thread)

– Lubricate crankshaft stub at

clutch side with oil.

VA

138RA070

2

1

– Fit crankcase gasket.

– Push the clutch side of the

crankcase over the crankshaft

stub as far as it will go.

To prevent the crankcase

and gasket twisting, fit M5x72

screws (1) (from service tool

ZS 5910 007 2200) in two

crankcase holes).

VA

138RA071

1

2

1

3

– Push threaded sleeve over the

crankshaft stub.

– Hold the crankshaft steady

and rotate the spindle counterclockwise to screw the threaded

sleeve onto the crankshaft.

Release the crankshaf t. Hold the

service tool (2) steady and

continue turning the spindle until

the tool locates against the guide

bar mounting face.

Fit the two hexagon nuts (3) on

the bar mounting studs and

screw them down finger-tight.

Turn the spindle counterclock-

wise until the crankshaft locates

against the ball bearing.

VA

138RA072

Page 30

30 034, 036, 036 QS

– Unscrew the hexagon nuts.

Unscrew the spindle clockwise

and take away the service tool.

– Take out the two M5x72 screws.

Drive home the two dowel pins.

VA

138RA073

Fit the five crankcase mounting

screws and tighten them down

alternately in a diagonal pattern

(see "Tightening Torques").

VA

138RA046

Trim away any excess gasket

material in the area of the

cylinder mounting face.

VA

138RA074

If the crankshaft does not turn

freely, it is sufficient to tap the

end of the stub with a plastic

mallet to relieve axial stresses.

VA

138RA075

Before installing oil seal, coat

cavity between dust and sealing

lips with grease - see 13.2.

VA

138RA076

Fit the installing sleeve (1)

1118 893 4602 over the clutch

end of the crankshaft.

Slip the oil seal (2), open side

facing the crankcase, over the

installing sleeve.

VA

138RA077

2

1

Press home the oil seal with

press sleeve (1) 1118 893 2401.

– Remove the installing sleeve.

VA

138RA078

1

Page 31

31034, 036, 036 QS

– Slide the oil seal, open side

facing the crankcase, over the

ignition end of the crankshaft.

Use press sleeve 1121 893 2400

to press home oil seal until sleeve

butts against the crankcase.

VA

138RA079

Important:

It is essential to observe the correct

installed depth of the oil seal to

achieve a proper seal. Always use

the press sleeve for this operation.

– Reassemble all other part s in the

reverse sequence.

Defective oil seals and gaskets or

cracks in castings are the usual

causes of leaks. Such faults allow

supplementary air to enter the

engine and thus upset the fuel-air

mixture.

This makes adjustment of the

prescribed idle speed difficult, if not

impossible.

Moreover, the transition from idle

speed to part or full throttle is not

smooth.

The crankcase can be checked

thoroughly for leaks with the

carburetor and crankcase tester

1106 850 2905 and the vacuum

pump 0000 850 3501.

– Remove the shroud from the

cylinder - see 4.3.

– T ake out the muf fler upper casing

mounting screws and remove the

upper casing - see 5.1.

Loosen the muffler lower casing

mounting screws about half way.

VA

138 RA 020

Fit sealing plate 0000 855 8106,

from above and narrow end first,

between the muffler lower casing

and cylinder exhaust port.

Note:

The sealing plate must completely

fill the space between the two

VA

138RA080

5.6 Crankcase Leakage Test 5.6.1 Preparatio n s

Page 32

32 034, 036, 036 QS

mounting screws. Push the narrow

end of the sealing plate home so

that it is just below the lower casing.

– Retighten the mounting screws

moderately.

– Remove the carburetor - see 12.3

– Set the piston to top dead center

(T.D.C.). This can be checked

through the inlet port.

– Remove screw 1128 855 9000

from test flange 1128 850 4200.

Fit the test flange (1), numbe r "1"

facing up and flat side first, on the

carburetor studs.

While fitting th e test flange, make

VA

148RA051

2

2

1

sure the impulse opening on the

manifold flange is properly

sealed (see arrow).

Fit the two hexagon nuts (2) and

tighten them down moderately.

– Preparations - see 5.6.1.

– Check tightness of spark plug

before starting leakage test.

– If decompression valve is fitted,

make sure it is tight and closed.

Connect pressure hose (1) of

tester 1 106 850 2905 to nipple on

test flange (2).

VA

148RA052

1

2

Close the vent screw (1) on the

rubber bulb.

VA

143RA046

1

– Pump air into the crankcase with

rubber bulb until the gauge

indicates a pressure of 0.5 bar . If

this pressure remains constant

for at least 20 seconds, the

crankcase is airtight.

– However, if the pressure drops,

the leak must be located and th e

faulty part replaced. Then repeat

the pressure test.

Note:

To find the leak, coat the suspe ct

area with oil and pressurize the

crankcase. Bubbles will appear if a

leak exists.

– Open the vent screw and

disconnect the hose.

– A pressure must always be

followed by a vacuum test - see

5.6.3.

– After finishing the tests,

reassemble all parts in the

reverse sequence.

Note:

Coat the mounting screws for the

upper and lower muffler casings

with LOCTITE. Insert and tighten

down the screws (see "Tightening

Torques").

5.6.2 Pressure Test

Page 33

33034, 036, 036 QS

Oil seals tend to fail when subjected

to a vacuum, i.e. the sealing lip lifts

away from the crankshaft during the

piston’s induction stroke because

there is no internal counterpressure.

An additional test can be carried out

with vacuum pump 0000 850 3501

to detect this kind of fault.

Connect suction hose of vacuum

pump 0000 850 3501 (1) to nipple

of test flange (2).

VA

148RA052

1

2

Close the vent screw (1) on the

pump.

Operate lever (2) until pressure

gauge (3) indicates a vacuum of

0.5 bar.

VA

232RA037

1

2

3

Note:

If the vacuum reading remains

constant, or rises to no more than

0.3 bar within 20 seconds, it can be

assumed that the oil seals are in

good condition. However, if the

pressure continues to rise (reduced

vacuum in the crankcase), the oil

seals must be replaced, even if no

leaks were detected in the pressure

test.

– After finishing the test,

reassemble all parts in the

reverse sequence.

Note:

Coat the mounting screws for the

upper and lower muffler casings

with LOCTITE. Insert and tighten

down the screws (see "Tightening

Torques").

It is not necessary to disassemble

the complete crankcase to replace

the oil seals.

– Remove the flywheel - see 6.4.1.

– Remove the Woodruff key from

the crankshaft stub.

On machines with handle or

carburetor heating system, take

out the generator mounting

screws, lift the generator away

and put it to one side.

– Remove the clutch - see 4.3.

VA

138RA084

– Remove the brake band - see

4.4.1 and 4.5.1.

– Remove the oil pump - see 11.4.

– Fit No. 3.1 jaws 000 893 3706 in

the universal oil seal puller

5910 890 4400.

5.6.3 Vacuum Test 5.7 Replacing the Oil Seals

Page 34

34 034, 036, 036 QS

Apply the puller at the clut ch side

and rotate the spindle clockwise

to pull the oil seal out of the

crankcase.

VA

138RA083

Apply the puller at the ignition

side and rotate the spindle

clockwise to pull the oil seal

out of the crankcase.

Important:

When using the puller, make sure it

does not damage the crankcase

VA

138RA085

surface or the ball bearing cages.

Install the oil seals as described

under 5.5.2.

– Install the generato r - see 10 .5.2 .

– Reassemble all other parts in the

reverse sequence.

Exercise extreme caution when

carrying out maintenance and repair

work on the ignition system. The

high voltages which occur can

cause serious or even fatal

accidents.

Troubleshooting on the ignition

system should always begin at the

spark plug - see "S tandard Rep airs,

Troubleshooting" handbook.

Note:

The electronic (breakerless) ignition

system basically consists of an

ignition module (1) and flywheel (2)

which requires no outside power

source (battery or dynamo). A

special flywheel (with ring magnet

for the generator) is installed in

VA

138RA086

2 1

models with handle or carburetor

heating system.

– Remove the air filter - see 12.1

– Pull boot off the spark plug.

– Remove the shroud - see 4.3

– Remove the ignition module - see

6.5.1

– Pull the ignition lead out of seat in

crankcase.

Unscrew the ignition lead (1) f rom

high voltage output on ignition

module (2).

– Pull the insulating tube off the

ignition lead.

VA

138RA087

1

2

Use a suitable pair of pliers to grip

the leg spring and pull it out of the

spark plug boot.

VA

138RA088

6 Ignition System 6.1 Ignition Lead/

Spark Plug Boot

Page 35

35034, 036, 036 QS

– Unhook the leg spring from the

ignition lead and slip the spark

plug boot off the lead.

– Coat the end of the ignition lead

and insulating tube (about

20 mm) with oil.

– Fit spark plug boot over the lead.

– Use a suitable pair of pliers to grip

the end of the ignition lead inside

the spark plug boot and pull it out.

Pinch the hook of the leg spring

into the center of the lead, i.e.

about 15 mm from the end of the

lead.

VA

138RA089

Pull the lead back into the boot so

that the leg spring locates

properly inside it.

VA

366RA104

– Use a pointed tool to pierce the

center of the other end of the

ignition lead.

– Slip the insulating tube over the

ignition lead.

– Screw the ignition lead into the

ignition module.

– Push the insulating tube right up

the ignition module’s high volt age

output.

– Install the ignition module - see

6.5.1.

– Push ignition lead into seat in

crankcase.

– Fit the shroud - see 4.3.

– Fit boot on the spark plug.

– Fit the air filter - see 12.1.

Note:

If the insulation of the short circuit

wire (2) is damaged it can cause a

short circuit to ground and upset or

completely interrupt ignition.

To remove the short circuit wire (2)

and ground wire (1), perform the

VA

138RA208

2

1

following operations:

– Remove the fan housing - see

6.4.

– Remove the shroud - see 4.3.

– Remove the air filter - see 12.1.

– Remove the tank vent - see 12.6.

Use a small screwdriver to ease

the connector sleeve of the short

circuit wire (1) out of its seat in the

switch shaft.

VA

138RA090

1

6.2 Short Circuit Wire/

Ground Wire

Page 36

36 034, 036, 036 QS

Pull ground wire connector

sleeve out of contact spring.

VA

138RA092

– On machines with handle or

carburetor heating, disconnect

the pin and socket connectors of

the heating systems - see 10.3.

Pull grommet out of t ank housing.

– Slip grommet off the wires.

VA

138RA211

– Pull the boot off the spark plug

and remove the ignition lead from

its seat in the crankcase.

– Pull the insulating tube through

the cable gland in the crankcase.

Removing the short circuit wire:

Disconnect short circuit wire f rom

ignition module.

– Pull short circuit wire out of

retainer on ignition module.

VA

138RA104

– Pull the short circuit wire through

the insulating tube.

– Install in the reverse sequence.

Note:

A ground wire is installed because

the contact spring in the polymer

tank housing is not connected to

ground on the ignition module.

Removing the ground wire:

Take out the screw (1) and

remove the ground wire (2).

VA

138RA093

2

1

– Pull the ground wire out through

the insulating tube.

– Install the new ground wire in the

reverse sequence. Check that

the insulating tube is properly

located in the crankcase cable

gland.

Important:

Use an ohmmeter to check correct

operation of the ground and short

circuit wires as well as the STOP

contact.

– Set the ohmmeter to measuring

range "Ω x 1".

Clip one of the two test leads to

the contact spring (1).

VA

138RA094

1

Clip the other test lead to the

ground wire terminal.

VA

138RA095

Page 37

37034, 036, 036 QS

– The ohmmeter must now show a

reading of 0 Ω. If no reading is

obtained, check the connection

between the contact spring and

connector sleeve.

Checking short circuit wire and

STOP contact :

– Leave one test lead clipped to the

contact spring.

– On machines with carburetor

heating, pull the thermostatic

switch’s flag connector off the

contact spring.

– Move the Master Control lever

upwards to "STOP".

– Clip other lead to short circuit

wire’s terminal.

– The ohmmeter must again show

a reading of 0 Ω. If no reading is

obtained, check the connection

between the connector sleeve in

the switch shaft’s cam and the

contact spring.

– On machines with carburetor

heating, push the thermostatic

switch’s flag connector onto the

contact spring.

– Remove the air filter - see 12.1

– Remove the tank vent - see 12.6.

The short circuit system is in

order if the short circuit wire

makes contact with the connector

sleeve when the Master Control

VA

138RA096

lever is in the "STOP" position.

Replacing a bent or broken

contact spring:

– T o avoid damaging the fuel hose,

pull it off the carburetor’s elbow

connector.

– On machines with carburetor

heating, pull the thermostatic

switch’s flag connector off the

contact spring.

Pull the ground wire connector

sleeve out of the contact spring.

– Move Master Control lever to

"STOP" position.

VA

138RA092

Squeeze the contact spring so

that is disengages from the

Master Control lever and, at the

same time, use a screwdriver to

pry it out of its seat in the

crankcase.

– Install the new contact spring.

VA

138RA097

– Reconnect the ground wire

connector sleeve.

Important:

– Check operation of the short

circuit wire - see 6.2.

– On machines with carburetor

heating, push the thermostatic

switch’s flag connector onto the

contact spring.

– Fit the tank vent - see 12.6.

– Fit the air filter - see 12.1.

6.3 STOP Contact

Page 38

38 034, 036, 036 QS

Take out mounting screws and

remove the fan housing.

– Rotate the flywheel so that the

magnet poles are opposite the

ignition module.

VA

138RA098

– Use locking strip 0000 893 5903

to block the piston - see 4.3.

Unscrew the flywheel mounting

nut from the crankshaft.

VA

138RA099

Screw puller 1110 890 4500 into

flywheel hub as far as stop.

Hold puller steady with a 24 mm

wrench and use a 17 mm wrench

to screw home the thrust bolt until

the flywheel comes away from its

seat on the crankshaft.

VA

138RA100

– Take off the flywheel.

– Inspect the flywheel. If you find

any damage (e.g. cracks, ,

broken fan blades), fit a new

flywheel.

Important:

If a new flywheel 1125 400 1208 is

installed in a machine with heated

handles

X 31 813 247, the

original front handle must always be

replaced by front handle

1125 790 1702 to take account of

the higher power output.

In addition, the new heating element

1 128 434 5000 must be fit ted in the

rear handle since the heating

elements may otherwise burn out.

The old front handle 1 125 790 1707

and the old heating elements

1125 434 5000 may only be

installed in machines with flywheel

1125 400 1207.

Front handles and heating elements

can be identified with the aid of the

following resistances:

Rear handle heating element:

Old version (1) 0.225...0.275 Ω

New version (2) 0.922...1.1 Ω

Front handle heating element:

Old version 1.44 ...1.76 Ω

New version 6.3 ...7.7 Ω

VA

148RA217

1 2

Check correct position of

Woodruff key.

VA

138RA101

Important:

– Clean the stub of the crankshaft

and the flywheel hub bore with a

standard commercial, solventbased degreasant containing no

chlorinated or halogenated

hydrocarbons - see 13.2.

VA

138RA102

– Fit the flywheel in position.

Fit and tighten down the flywheel

nut (see "Tightening Torques").

Reassemble all other parts in the

reverse sequence.

Observe tightening torques when

refitting the fan housing (see

"Tightening Torques").

6.4 Flywheel

6.4.1 Removing

6.4.2 Installing

Page 39

39034, 036, 036 QS

The ignition module accommodates

all the components required to

control ignition timing.

Ignition module components a nd

connections

1 Ignition lead with insulating tube

VA

138RA103

1

4

3

2

2 High voltage output

3 Ground wire

4 Connector tag for

short circuit wire

Accurate testing of the ignition

module is only possible with special

test equipment. For this reason it is

only necessary to carry out a spark

test in the workshop.

A new ignition module must be

installed if no ignition spark is

obtained (after checking that wiring

and stop switch are in good

condition).

– Remove the fan housing - see

6.4.1

Use a screwdriver to disconnect

the short circuit wire from the

ignition module.

VA

138RA104

Take out the two mounting

screws and lift away the ignition

module.

Note:

If the ignition module is faulty,

unscrew the ignition lead

counterclockwise and transfer it

VA

138RA105

along with the spark plug boot and

cable retainer to the new ignition

module.

– To install the ignition module,

connect short circuit wire to tag

on ignition module and then push

the short circuit wire into the

retainer.

– Place the ignition module in the

crankcase.

– Coat threads of ignition module

mounting screws with LOCTITE -

see 13.2.

– Use lower mounting screw to

connect the ground wire to the

ignition module.

Fit the two screws and tighten

them down moderately.

– Rotate the flywheel until the

magnets are between the two

arms of the ignition module.

Slide the setting gauge

1111 890 6400 or 0.2 mm metal

gauge between the arms of the

ignition module and the flywheel

magnets.

– Press the ignition module against

the flywheel and tighten down the

VA

138RA107

mounting screws (see

"Tightening Torques").

Important:

Tighten the upper screw first.

– Remove the setting gauge and

use a feeler gauge to check the

air gap. It should be 0.2 to

0.3 mm.

– Fit the fan housing - observe

tightening torques (see

"Tightening Torques").

6.5 Ignition Module 6.5.1 Removing and Installing

Page 40

40 034, 036, 036 QS

Ignition timing on electronic

(breakerless) magneto ignition

systems is fixed at 2.5 mm B.T.D.C.

at 8,000 rpm and is not adjustable.

However , in view of the permissible

tolerances in the electronic circuitry ,

it may vary between 1.8 and 2.6 mm

B.T.D.C. at 8,000 rpm.

Since there is no mechanical wear

in these systems, ignition timing

cannot get out of adjustment.

However, an internal fault in the

circuit can alter the switching point

in such a way that a spark test will

still show the system to be in order

although timing is outside the

permissible tolerance. This will

impair engine starting and running

behavior.

Troubleshooting chart - see

"Standard Repairs, Tro ubleshooting" handbook.

If the action of the starter rope

becomes very stiff and the rope

rewinds very slowly or not completely, it can be assumed that the

starter mechanism is in order but

plugged with dirt. At very low

outside temperatures the lubricating oil on the rewind spring may

thicken and cause the spring

windings to stick together . Th is has

a detrimental effect on th e function

of the starter mechanism. In such a

case it is sufficient to apply a few

drops of paraffin (kerosine) to the

rewind spring.

Then carefully pull out the starter

rope several times and allow it to

rewind until its normal smooth

action is restored.

If clogged with dirt or pitch, the

entire starter mechanism, including

the rewind spring, must be removed

and disassembled. Take special

care when removing the spring.

Wash all parts in paraffin/kerosine

or white spirit.

Lubricate the rewind spring and

starter post with STIHL special

lubricant, see 13.2, before inst alling.

– Remove the fan housing - see

6.4.1

Note:

For descriptions on removing and

installing the rope rotor, replacing

the starter rope, p awls or rope guide

bush - see "Standard Repairs,

Troubleshooting" handbook.

Observe tightening torques when

refitting the fan housing (see

"Tightening Torques").

6.5.2 Ignition Timing 7 Rewind Starter

7.1 Routine

Maintenance

7.2 Rope Rotor, Pawls,

Starter Rope,

Rope Guide Bush

Page 41

41034, 036, 036 QS

– Remove the rope rotor - see 7.2.

Use suitable pliers to grip the

anchor loop of the rewind spring

and lift it up.

– Take the sp ring housing and

rewind spring out of the fan

VA

138RA108

housing.

– Remove any remaining bits of

spring from the fan housing.

– Lubricate die rewind spring with

STIHL special lubricant and fit it

with the spring housing (bottom

plate facing up) in the fan

housing.

– Engage the spring loop over the

lug in the fan housing.

Warning:

The rewind spring may pop out and

uncoil during installation. If the

rewind spring has popped out, refit it

in the spring housing as follows:

Position anchor loop about

25 mm from the edge of the

spring housing.

VA

138RA109

Refit the rewind spring in the

spring housing in the counterclockwise direction, starting

outside and working inwards.

– Fit the spring housing in the fan

housing.

VA

138RA110

– Engage the spring loop over the

lug in the fan housing.

– Install the rope rotor - see 7.2.

– Tension the rewind spring - see

7.4.

– Remove the rope rotor - see 7.2.

– Use suitable pliers to grip the

anchor loop of the rewind spring

and pull it out carefully.

Warning:

The rewind spring jumps out of its

seat in the fan housing in this

process.

– Remove any remaining bits of

spring from the fan housing.

– Lubricate the rewind spring with

STIHL special lubricant.

Engage the anchor loop over the

lug in the fan housing and fit the

rewind spring in the fan housing

in the clockwise direction, starting

outside and working inwards.

– Install the rope rotor - see 7.2.

VA

148RA053

– Tension the rewind spring - see

7.4.

7.3 Rewind Spring

7.3.1 Replacing the Rewind Spring (034)

7.3.2 Replacing the

Rewind Spring

(036, 036 QS)

Page 42

42 034, 036, 036 QS

Grip the rope between the guide

bush and rotor, pull it out and

make a loop.

Hold the rope close to the rotor

and use it to turn the rotor about

five full turns clockwise.

138RA112

VA

– Hold the rope rotor steady.

Pull out the rope with the starter

grip and straighten it out.

– Hold the starter grip firmly to keep

the rope tensioned.

– Let go of the rope rotor and

slowly guide the starter grip back

VA

138RA113

so the starter rope can rewind

properly.

Note:

The rewind spring is correctly

tensioned when the starter grip sits

firmly in the rope guide bush without

drooping to one side. If this is not

the case, tension the spring by one

additional turn.

When the starter rope is fully

extended, it must still be possible to

rotate the rope rotor a t least another

half turn before maximum spring

tension is reached. If this is not the

case, pull the rope out, hold the

rope rotor steady and take off one

turn of the rope.

Do not overtension the rewind

spring as this will cause it to

break.

– Fit the fan housing - see 6.4.

The crankcase and tank housing

are connected by vibration damping

rubber buffers. Damaged rubber

buffers (annular buffers) must

always be replaced in sets.

Note:

When replacing annular buffers,

make sure you always install the

latest type.

Annular buffers must be replaced in

sets of the same hardness. Harder

buffers are installed for more

accurate control but reduced

vibration damping, while softer

butters provide better vibration

damping.

T o remove the annular buf fers at the

clutch side:

– Remove the chain sprocket cover

and cutting attachment - see 4.1.

– Remove the chain catcher - see

4.2.

Use a screwdriver to remove the

two plugs from the annular

buffers.

VA

138RA115

7.4 Tensioning the Rewind Spring 8 AV Handle System

8.1 Repair

Page 43

43034, 036, 036 QS

– Take out the annular buffer

mounting screws.

– Use a screwdriver to pry the

annular buffers out of their seats.

To remove the annular buffer at the

ignition side:

– Remove the carburetor box cover

and shroud - see 4.3.

– Remove the fan housing - see

6.4.

Use a screwdriver to ease the

plug (1) out of the annular buffer.

– Take out the annular buffer

mounting screw.

VA

138RA209

1

– Use a screwdriver to pry the

buffer out of its seat.

Note:

The tank housing has to be