Page 1

TABLE TENNIS TABLE

MODEL NO.

T8612

O W N E R ' S M A N U A L

1. Read this manual carefully before starting assembly. Read each step completely before beginning

each step.

2. Some smaller parts may be shipped inside larger parts. Check inside all parts and cartons

before assembling or ordering parts.

3. To make assembly easier, use the Hardware Identifier on page 9 to identify and sort all

fasteners. Check all cartons for kits. All hardware may not be located in one kit.

4. Do not tighten hardware until instructed to do so. If hardware is tightened too soon, mounting holes

may not align and parts may not easily fit together. Leave locknuts slightly loose until you are instructed to

tighten them.

5. Tools required for assembly: Phillips Screwdriver, 3/8 Wrench, and Two 7/16 Wrenches (adjustable

wrenches may be substituted for the wrenches).

Please Do Not Return This Product To The Store!

Contact Escalade® Sports customer service department at:

Phone: 1-866-873-3528 Toll – Free !

Fax: 1-866-873-3533 Toll – Free !

E-mail: tabletennis@escaladesports.com

Mailing Address (correspondence only):

Escalade Sports

PO Box 889

Evansville, IN 47706

Please visit our World Wide Web site at: www.escaladesports.com

ON-LINE TROUBLE SHOOTING TECHNICAL ASSISTANCE

ON-LINE PARTS REQUESTS FREQUENTLY ASKED QUESTIONS

®

ADDITIONAL ESCALADE

SPORTS PRODUCT INFORMATION

2L-5034-00

Escalade® Sports products may be manufactured and/or licensed under the following patents.

6120397, 5816957, 5769744, 5119741, 4911085, 4717157, D460140, D420563

Additional patents may be pending. One or more of the listed patents and/or pending patents may cover specific product.

2009 Escalade Sports

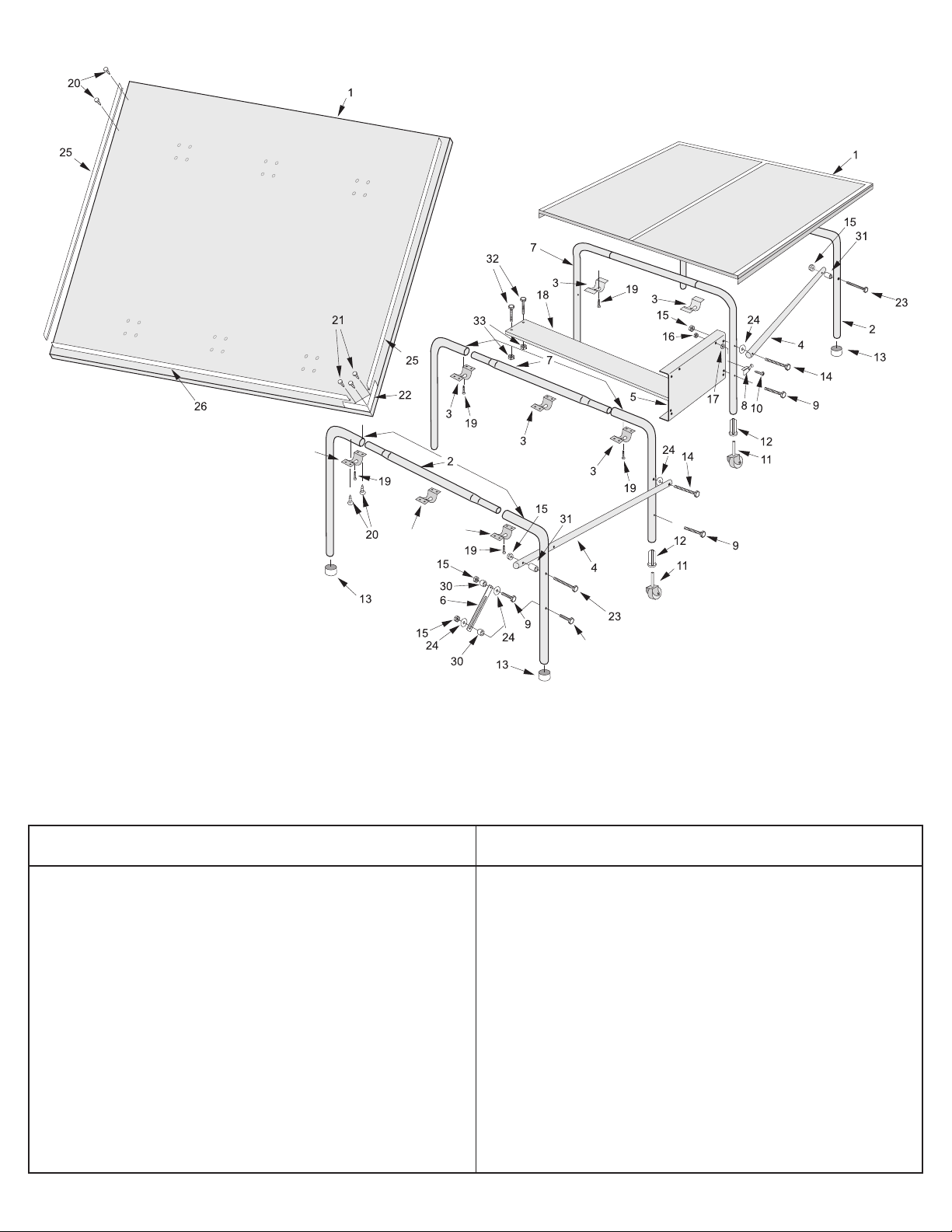

Page 2

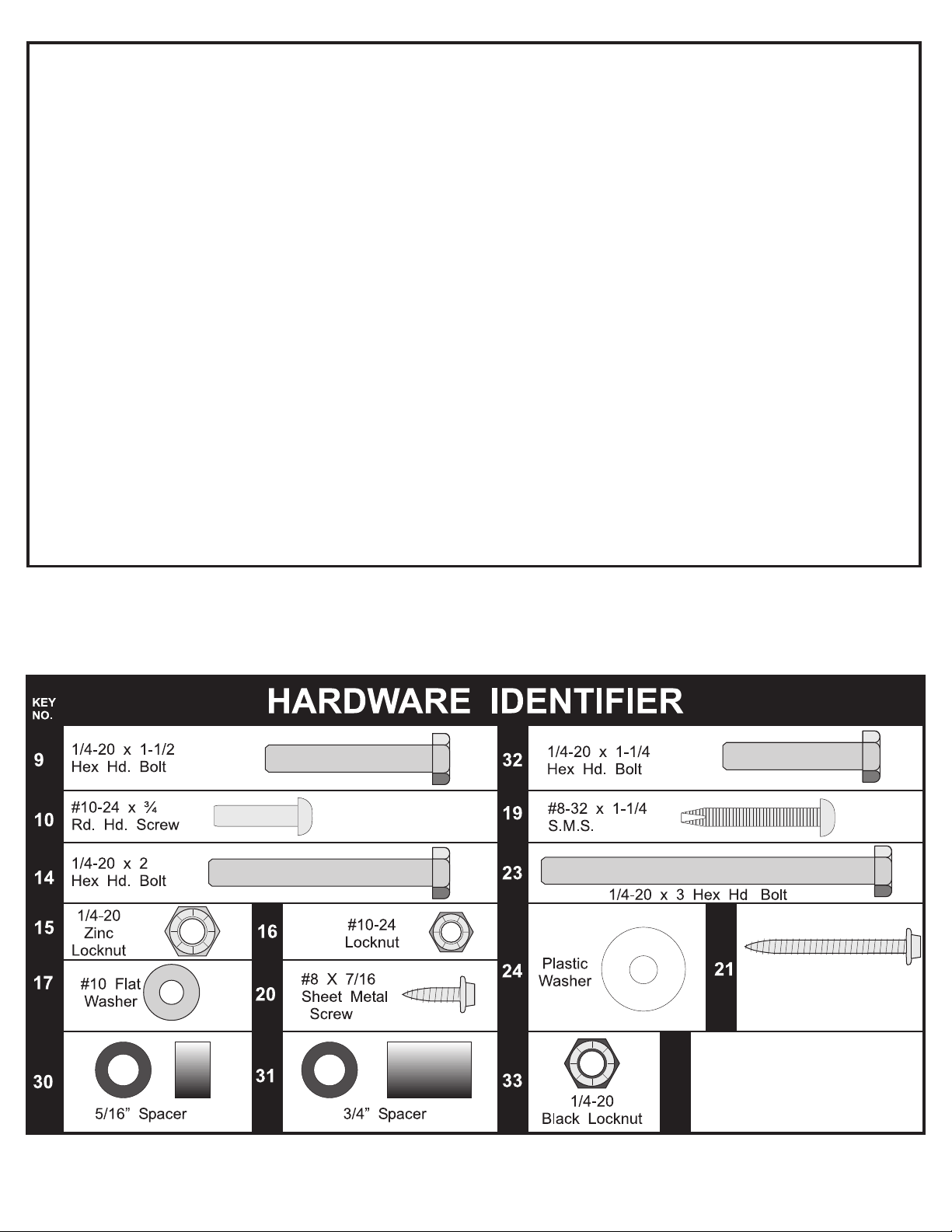

For aid in identifying hardware, see hardware identifier on page 9.

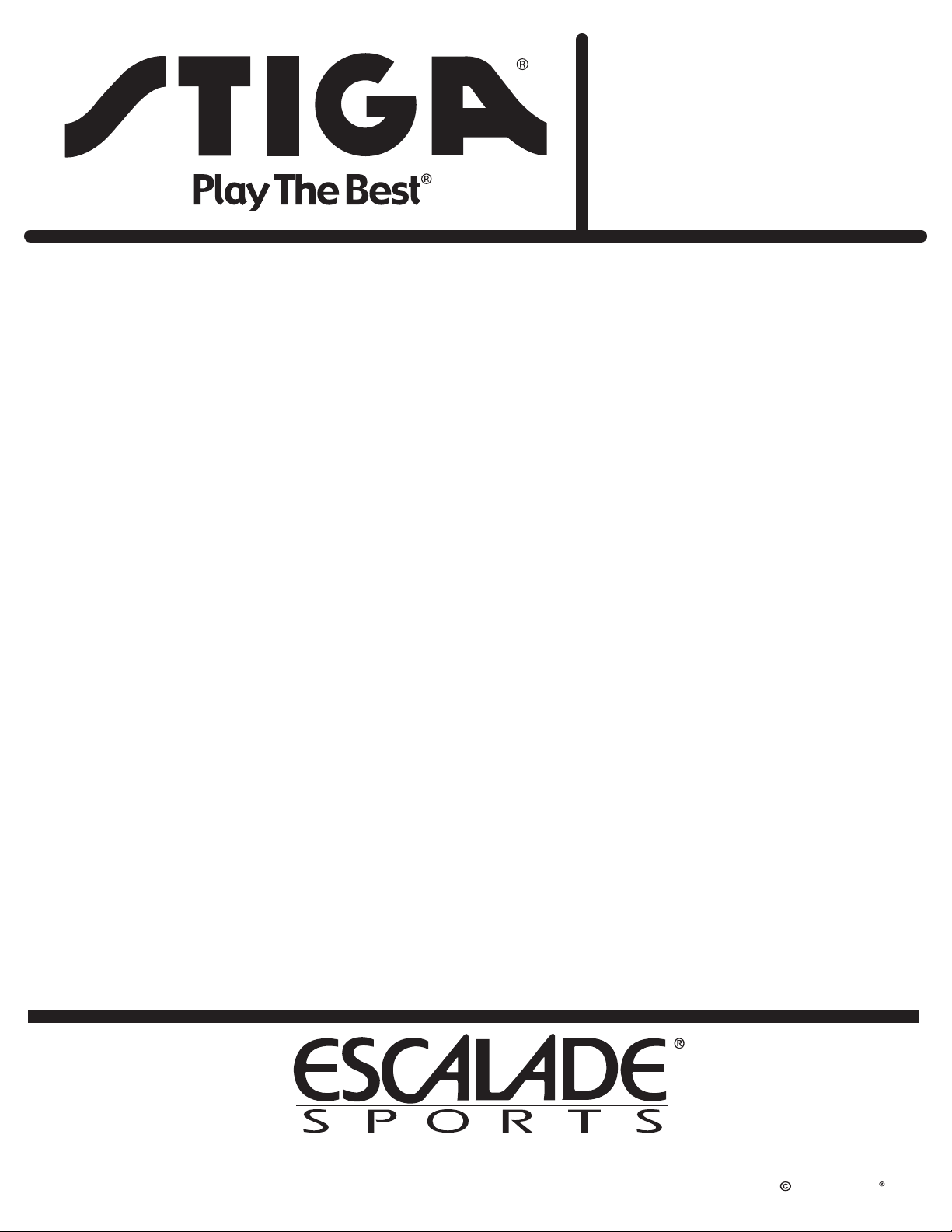

1. Lay table top #1 painted side down, on a smooth, flat

surface. Use the shipping container to protect the

painted surface of the table top.

2. Assemble the two “L” tubes and the center tubes that

make up the “U” Support and the “U” Leg. Align on

Table Top as shown in Figure 1. Note: “U” Leg is

larger and wider than the U Support. The Uleg should be installed on the end of the table

half with the end rail mounting holes.

3. Put plastic caps #13 on the end of U-leg #2.

Figure 1

13

Plastic

Cap

End Rail

Mounting

Holes

2

U-Leg

7

U-support

13

Plastic

Cap

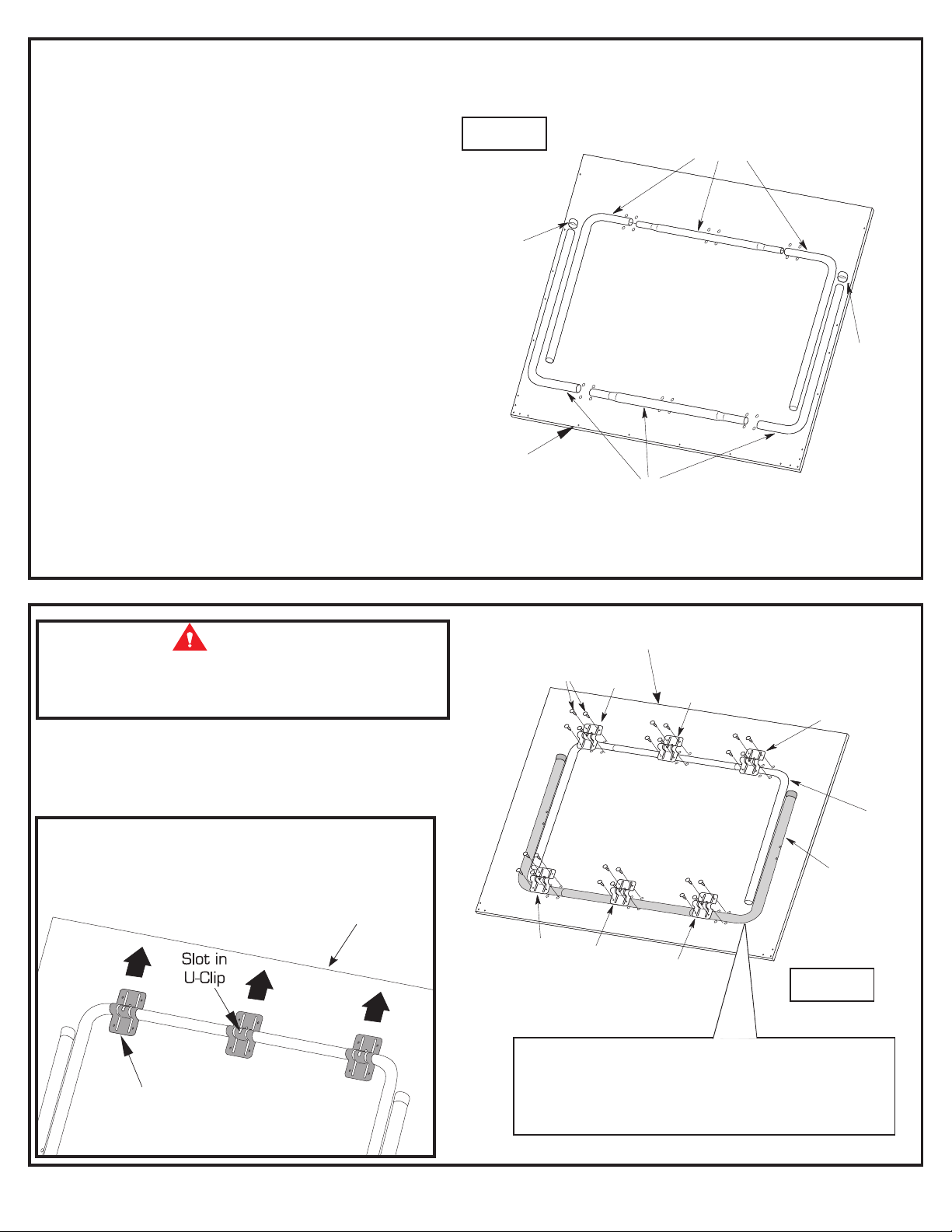

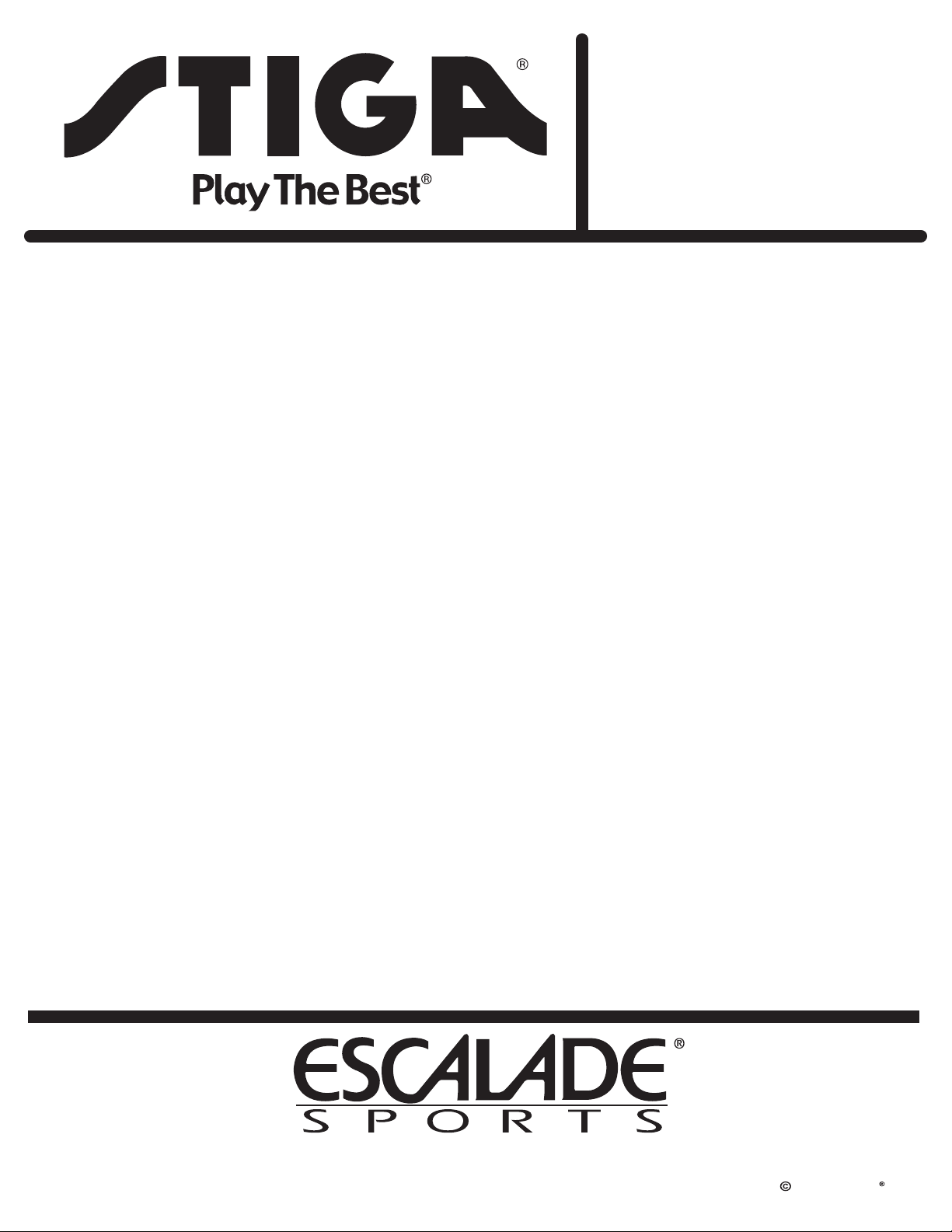

CA UTION :

WHEN ASSEMBLING TABLE, IT IS EXTREMELY IMPORTANT THAT THE UCLIPS (#34) AND (#3) BE TURNED AS SHOWN HERE. IF U-CLIPS ARE

TURNED INCORRECTLY, YOU WILL DO IRREPARABLE DAMAGE TO YOUR

TABLE WHEN YOU ATTEMPT TO OPEN IT TO THE PLAYING POSITION.

4. Align the holes in the Large U-clips #34 and the U-clips #3

with pilot holes in table top assembly and secure with twenty

four screws #20 as shown.

IMPORTANT:

Be sure that slot in the three U-clips #34 and the three

U-clips #3 all face the same direction (toward the

middle of the table with the U-support) as shown.

This end is the

middle of the table

3

This end is the

middle of the table

20

34

3

34

34

All screws shown

are (#20) sheet

metal screws.

3

3

2

U-Leg

7

U-support

Figure 2

IMPORTANT: U-Leg is wider than U-support.

Make sure they are assembled exactly as

shown. If not, there will be a large gap between

table halves and table will not operate properly!

2

Page 3

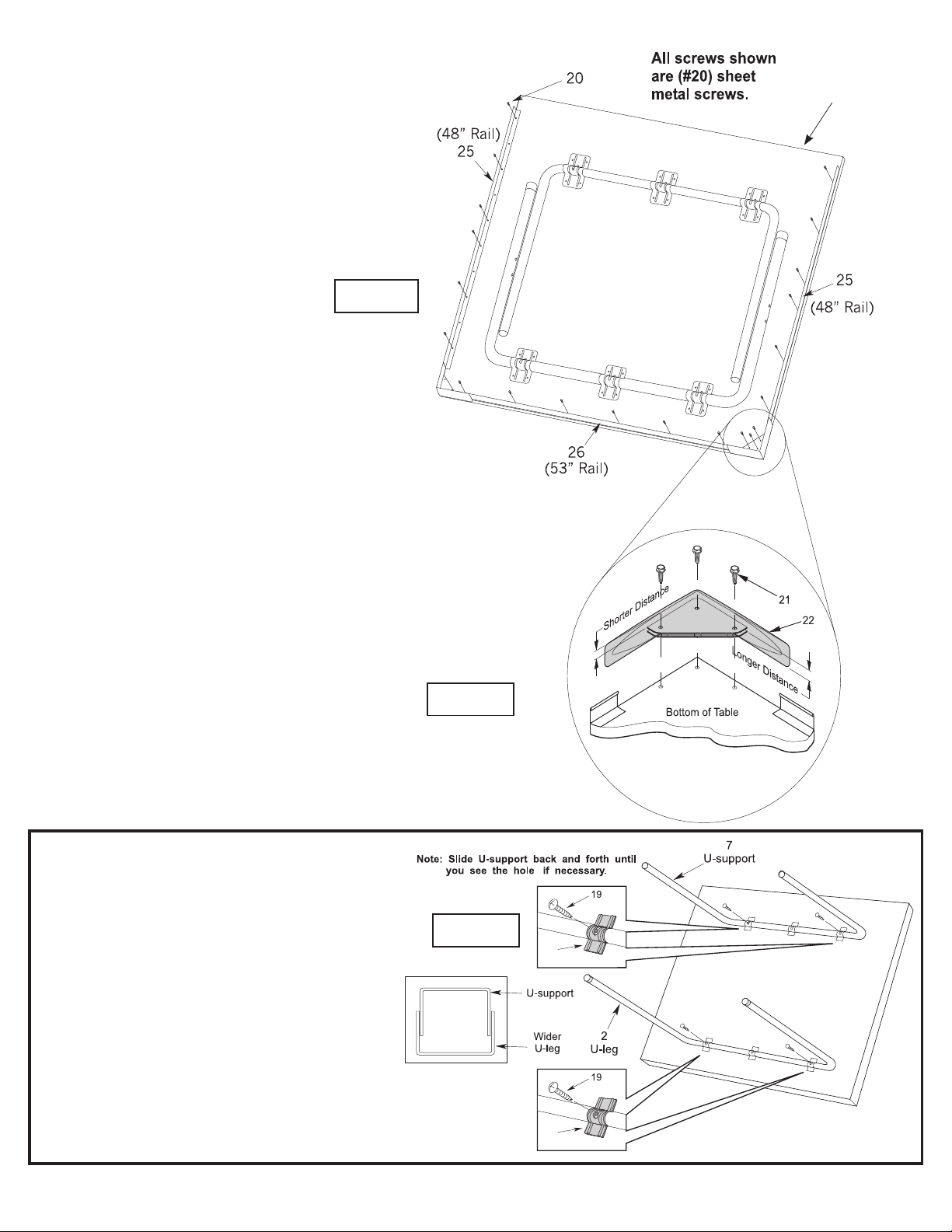

5. Lay out rails #25 and 26, as shown in Figure 3, around edges

of table top.

6. Line up holes in rails with pilot holes in top and secure using

eighteen screws #20. See Figure 3.

Figure 3

This end is the

middle of the table

7. Lay Corner Caps #22 on table as shown in Figure 4. If Corner

Cap sticks above table top surface of table, flip over so shorter

distance is against edge. Secure to bottom of table with three

screws #21.

Figure 4

8. Rotate U-support #7 until you see the screw hole in

the slot of U-clip #3. Slide U-support #7 side to side

if necessary.

9. Insert screw #19 through slot in U-clip #3 and into

U-support #7. Thread it all the way into U-support

#7 until it touches the back of the tube. There should

be about 3/8 inch of screw #19 left sticking out. Repeat for U Leg #2 and U-clip #34.

Figure 5

3

34

3

Page 4

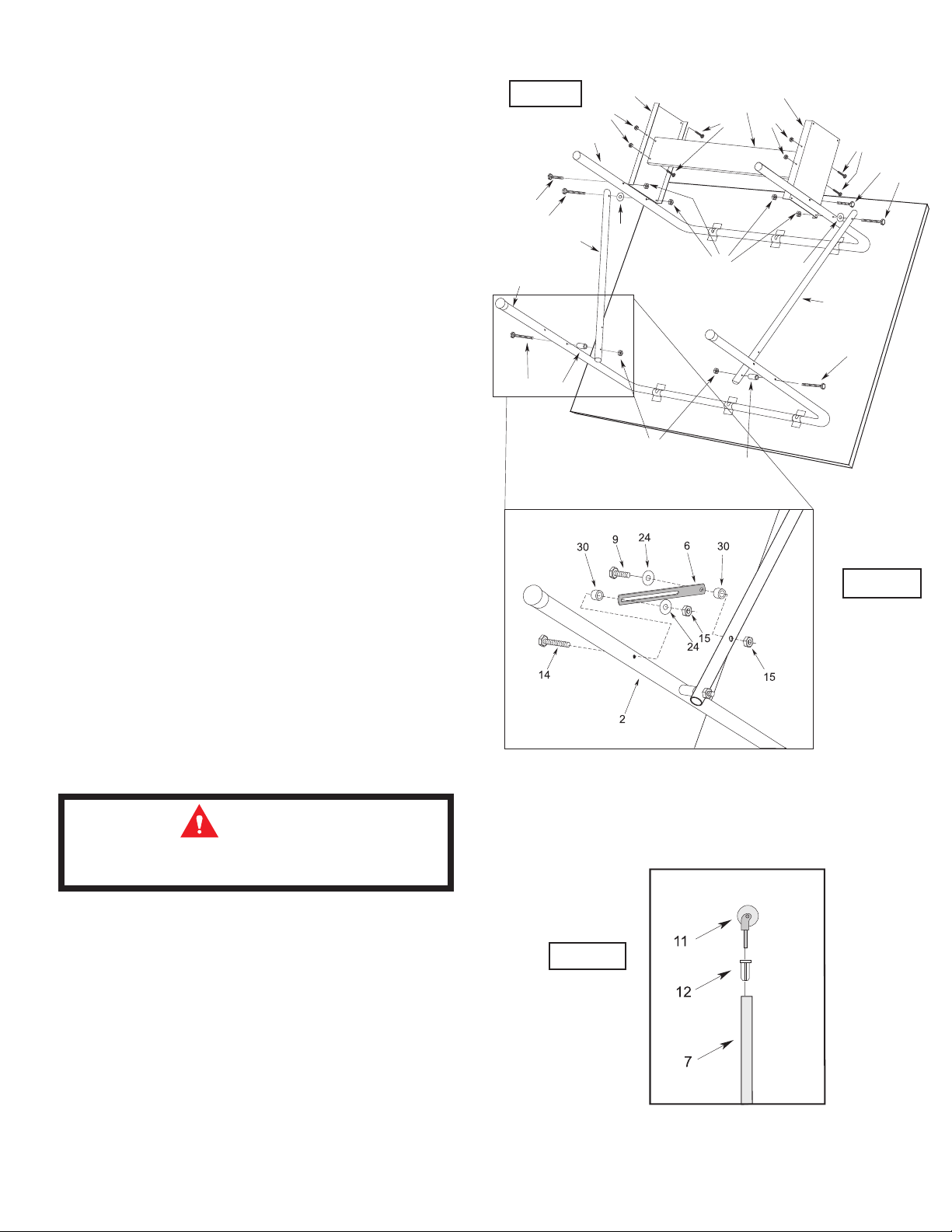

10. Attach end of linkages #4 with two holes to INSIDE of U-leg #2 as

shown in Figure 6. Secure through end hole with screws #23, locknuts

#15 and plastic spacers #31. Tighten hardware snug enough to keep

table stable but do not overtighten. Tubes must pivot freely.

11. On one side of the table attach slotted end of safety strap #6 to INSIDE

of U-Leg #2 using one bolt #14, one spacer #30, one washer #24,

and one hex nut #15. Tighten hardware until snug but do not overtighten.

Tubes must pivot freely. See Figure 7.

12. Attach other end of safety strap #6 to OUTSIDE of linkage #4 using

one bolt #9, one washer #24, one spacer #30, and one hex nut #15.

Important! Do NOT put other safety strap #6 on this table half. It will

be installed on other table half later.

13. Attach other end of linkages #4 to OUTSIDE of U-support #7 with

bolts #14 and plastic washers #24. Then slide name panel #5 onto

the same bolts #14 on the INSIDE of U-support #7. Secure with lock -

nuts #15. Tighten hardware until snug but do not overtighten. Tubes

must pivot freely.

14. Attach bottom of name panel #5 to U-supports #7. Secure with hex

bolts #9 and locknuts #15. Tighten nuts but be careful not to crush

tubes. See Figure 6.

Figure 6

9

14

2

23

31

5

33

7

24

4

15

32

15

18

31

33

5

32

9

14

24

4

23

Attach bottom board # 18 to name panels #5, as shown in Figure 6,

15.

using four bolts #32 and four hex nuts #33.

Gently tap caster sockets #12 into U-support #7 until flange on sock -

16.

ets touches the edge of the tube. DO NOT HIT CASTER SOCKET

DIRECTLY WITH A HAMMER! SET A PIECE OF WOOD

ON CASTER SOCKET AND HIT PIECE OF WOOD TO

DRIVE CASTER SOCKET INTO U-SUPPORT.

Insert casters #11 into caster sockets #12.

17.

CAUTION :

AT LEAST TWO ADULTS ARE NEEDED

TO MOVE TABLE HALF!

18. Prepare an area for the assembly of the second table top half. If neces-

sary, move the first table top half aside with the aid of a helper. Be sure

to place it in a location where it won't be disturbed or damaged. If

setting on its side, be sure to place the bottom edge no less than 12

inches away form the wall. Also be sure to place carpet or pieces of the

shipping carton down to protect table top edges. If floor is not carpeted, brace table top half with a heavy object to keep it from sliding.

Figure 7

Figure 8

4

Page 5

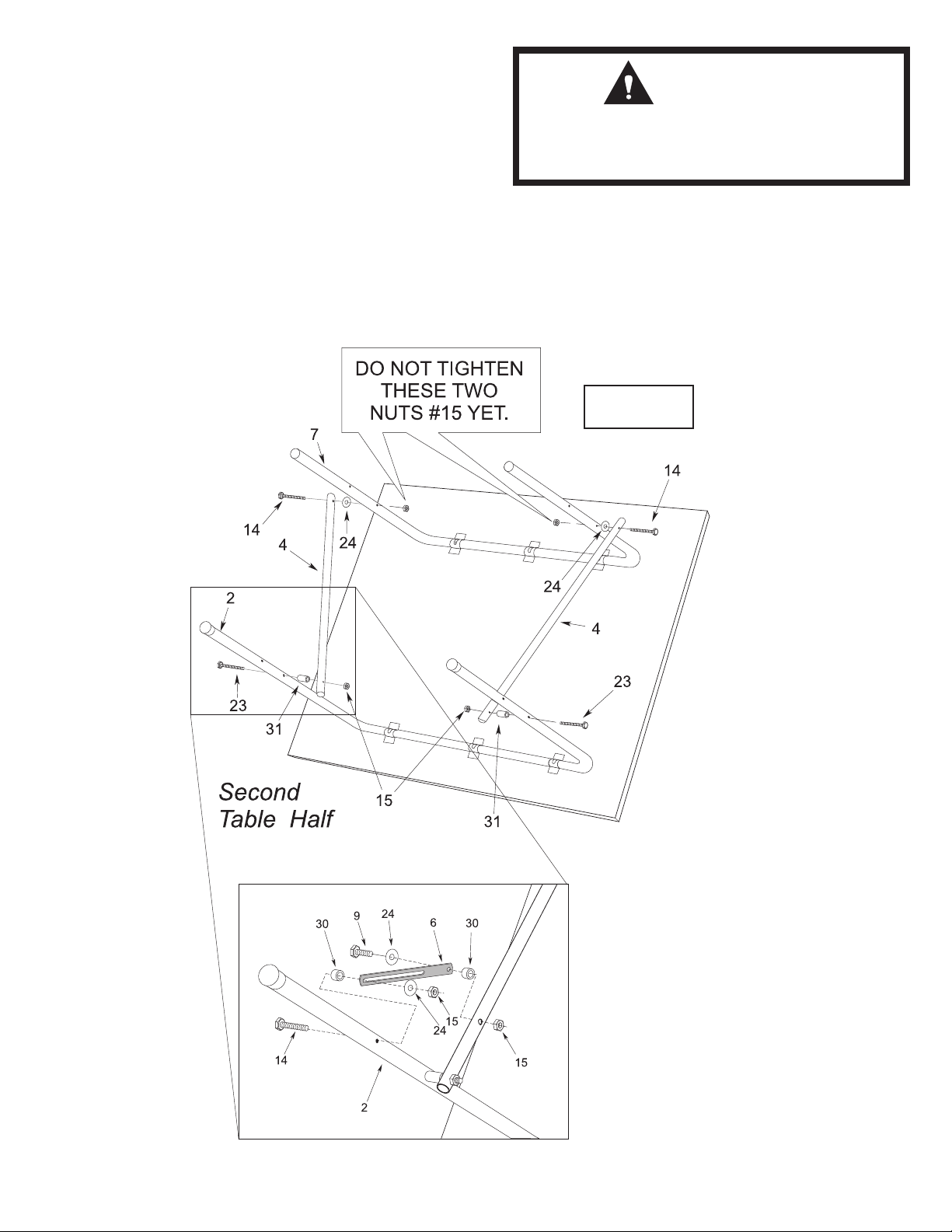

19. Repeat steps 1 through 12 on second table half.

20. Gently tap caster sockets #12 into U-support #7 on second table

half until flange on sockets touches the edge of the tube. DO NOT

HIT CASTER SOCKETS TOO HARD WITH A HAMMER. Casters could break if hit too hard.

21. Insert casters #11 into caster sockets #12 on second table half.

22. Attach linkages #4 to the OUTSIDE of U-support #7 on second

table half. Use screws #14, plastic washers #24 and hex nuts #15.

NOTE: Tighten locknuts #15 finger tight only. They will be

removed when the two table top halves are connected.

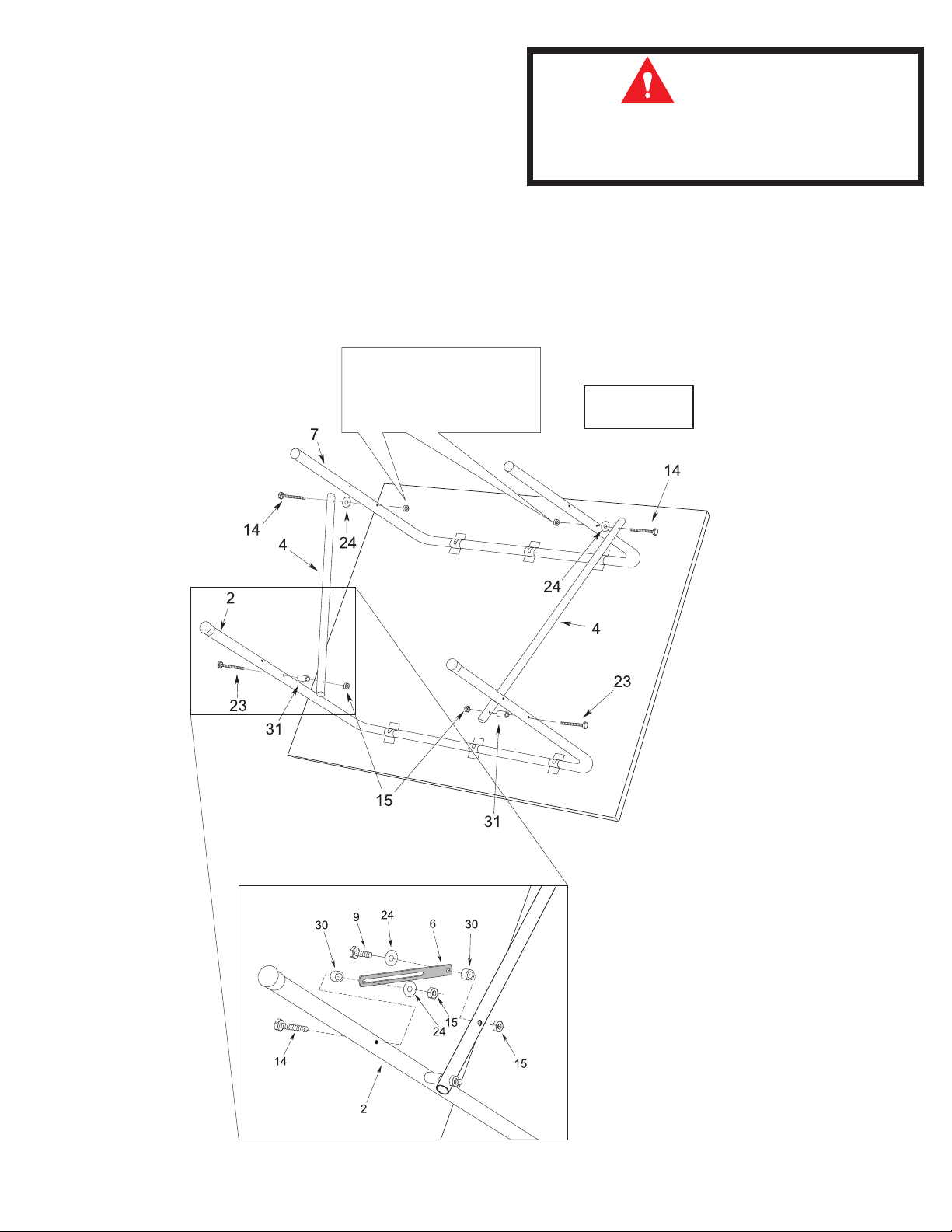

CAUTION:

AT LEAST TWO ADULTS ARE NEEDED TO

COMPLETE THE REMAINDER OF THE

ASSEMBLY!

Figure 9

5

Page 6

Figure 10

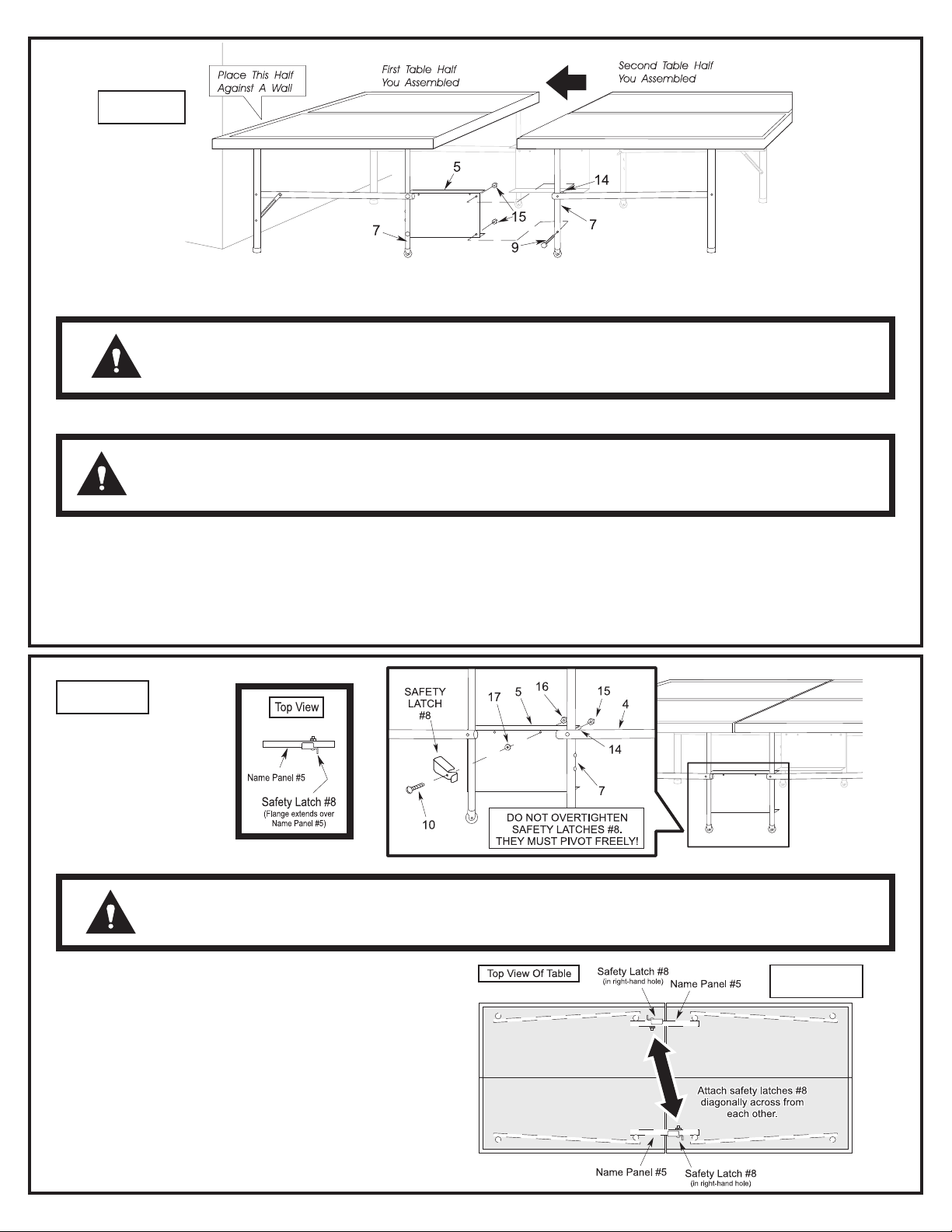

23. Make sure the legs on the first table top half (the half with the name panel #5) are open. With one person on each side of the table, lift and set

table half on its legs. Place table against a wall as shown above to help stabilize table top half while second half is being attached. Be sure there

is enough room to connect second half.

BE SURE THE FIRST TABLE HALF YOU ASSEMBLED (WITH NAME PANELS #5

CAUTION:

24. Place a hex bolt #9 and a locknuts #15 on floor next to caster wheels (on both sides of the table half) so they will be handy for the next step.

CAUTION:

25. With a person on both sides of the second table half, slide the second table half against the first table half. Remove locknuts #15 from screws

#14 on second table half where U-support #7 and linkages #4 join. Align holes in name panels #5 (on first table half) with holes in Usupports (on second table half). Secure second table half to top hole in name panel #5 using hex bolt #14 installed earlier and locknuts just

removed. Secure second table half to bottom hole in name panel #5 with the two hex bolts #9 and locknuts #15 you placed on the floor

earlier. Tighten locknuts snug but do not overtighten. These joints must pivot. At this point go back and tighten hex bolts #9.

ATTACHED) IS STABLE AND AGAINST A WALL. DO NOT LEAVE TABLE HALF

STANDING UNATTENDED.

UNTIL THE TABLE HALVES ARE CONNECTED THEY WILL NOT STAND ON THEIR

OWN. IT IS RECOMMENDED TO HAVE THREE PEOPLE TO CONNECT TABLE

HALVES. TWO TO STABILIZE TABLE AND ONE TO BOLT TABLE TOGETHER.

Figure 11

INSTALL SAFETY LATCHES #8 AS SHOWN ABOVE FOR PROPER USE OF

CAUTION:

26. Choose a name panel #5 on either side of the table and install

one safety latch #8 into the right-hand hole on that name panel

as shown in Figures 11 & 12. Use one screw #10 one washer

#17 and one hex nut #16. NOTE: Flange on safety latch

must extend over top of name panel as shown in Figure

11. Safety latch must pivot freely.

27. Go to the other side of the table and install the second safety latch

into the right-hand hole on the other name panel #5. NOTE:

Safety latches must be attached diagonally across

from each other. (See Figure 12)

TABLE! DO NOT SKIP THIS STEP! DO NOT OPERATE TABLE UNTIL SAFETY

LATCHES ARE INSTALLED AND ASSEMBLY IS COMPLETE!

Figure 12

6

Page 7

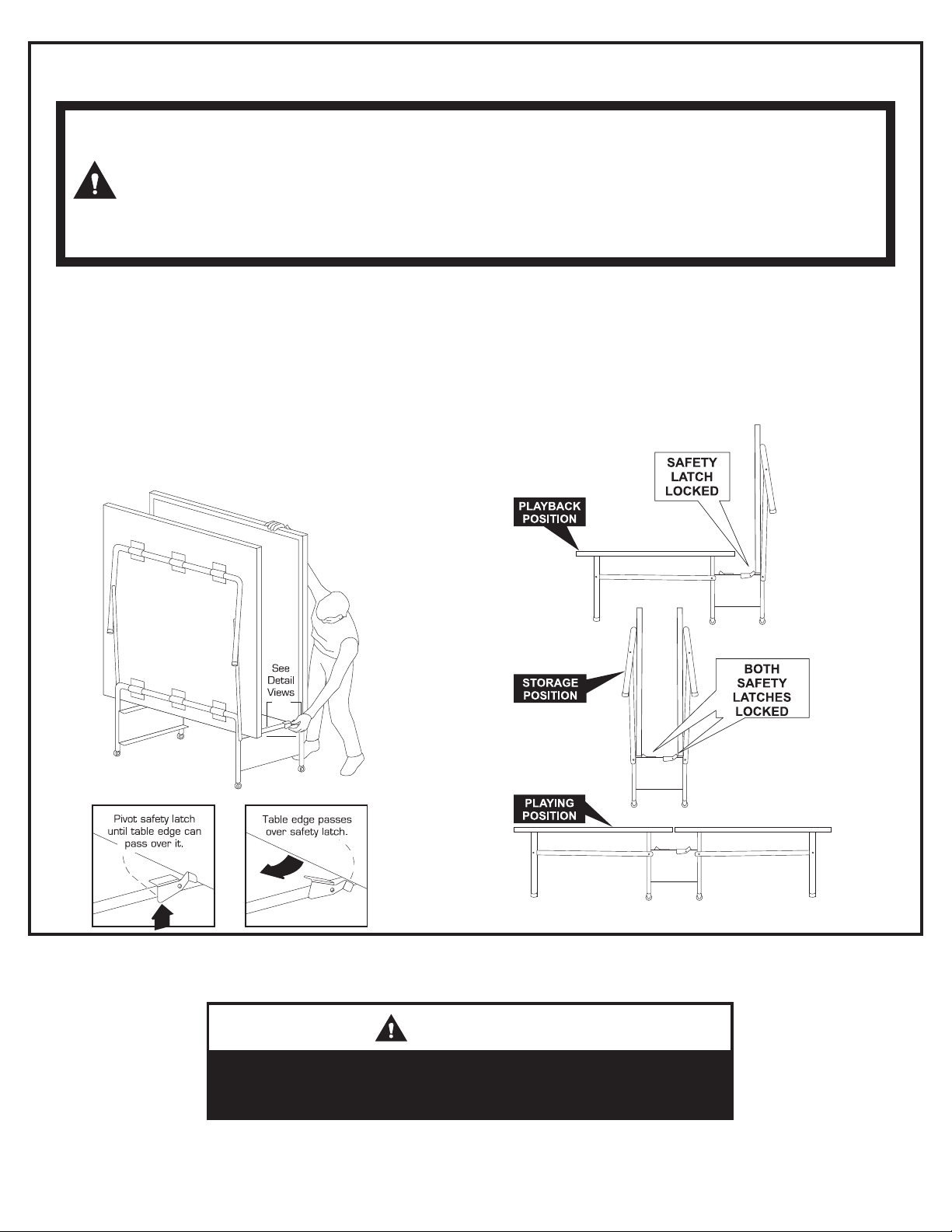

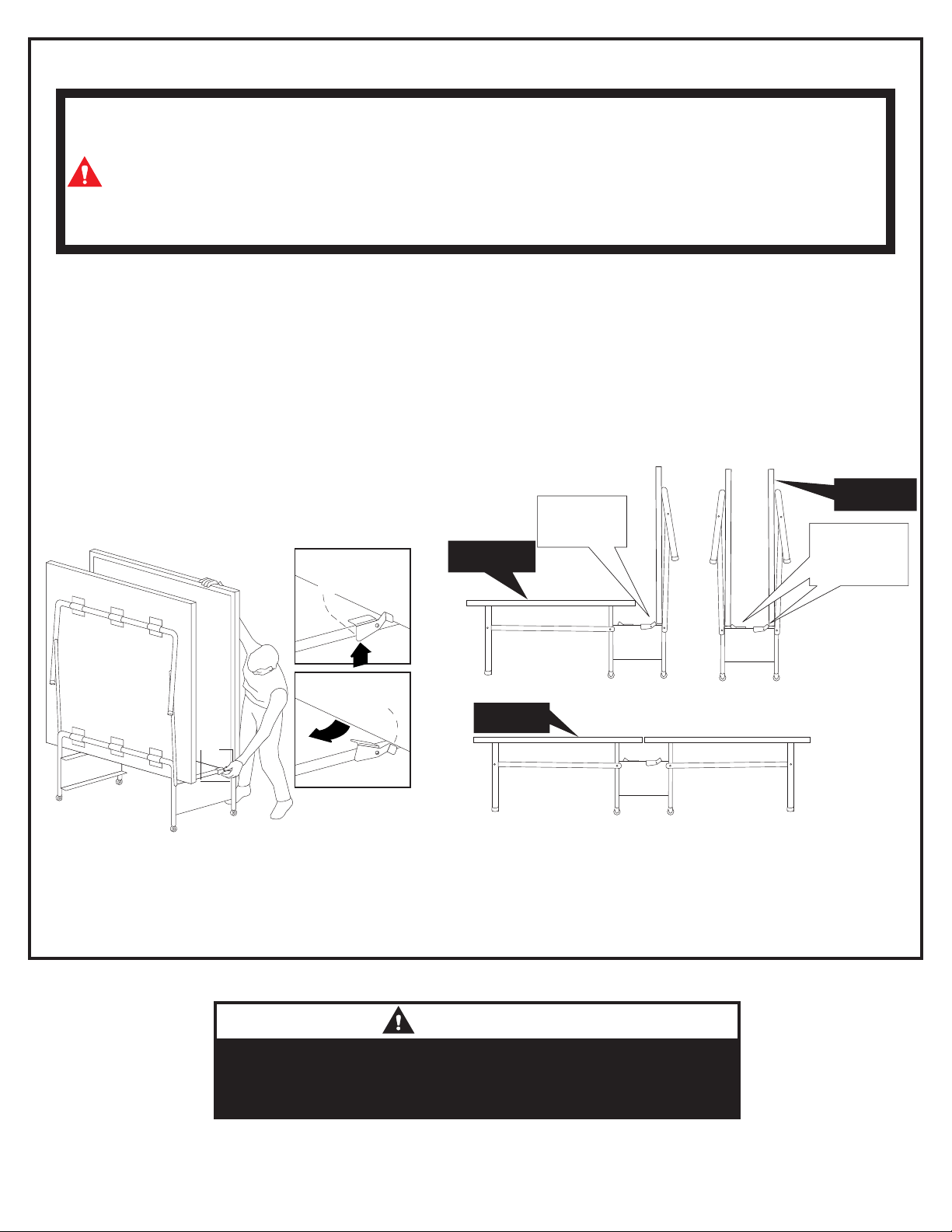

OPENING AND CLOSING INSTRUCTIONS

READ OPERATING INSTRUCTIONS CAREFULLY BEFORE OPERATING TABLE! DO

NOT ALLOW CHILDREN TO OPEN TABLE! DO NOT CLIMB, STAND OR JUMP ON

CAUTION:

TABLE! SERIOUS OR FATAL INJURY MAY RESULT! THIS IS NOT A TOY! TABLE IS

TO BE OPENED OR CLOSED BY ADULTS ONLY! FAILURE TO COMPLY WITH

OPENING AND CLOSING INSTRUCTIONS COULD RESULT IN PERSONAL INJURY

OR PROPERTY DAMAGE.

TO OPEN:

1. Pull both legs away from table slightly.

2. Stand behind the table near the safety latch.

3. Hold table half with one hand and pivot safety latch enough to

allow the edge of the table half to pass over it.

4. While keeping an eye on the safety latch, pivot table half until it

moves past the safety latch. Once edge of table has passed over

safety latch, stop pivoting table half.

5. With both hands on the table half, center yourself along the table

half and lower the table half to the floor.

6. Repeat for the other table half.

TO CLOSE:

1. Lift table half upward and inward to vertical position.

2. Check to be sure that table half is locked in the safety latch.

3. Repeat for the other table half.

CAUTION

THIS IS A GAME TABLE. DO NOT SIT, STAND, LEAN, WALK OR JUMP

ON TABLE! FAILURE TO COMPLY WITH THIS CAUTION COULD

RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

7

7

Page 8

90 DAY LIMITED WARRANTY

This consumer warranty extends to the original consumer purchase of any ESCALADE SPORTS Product

®

(hereinafter referred as the "Product").

WARRANTY DURATION: This Product is warranted to the original consumer purchase of a period of ninety (90) days from the original

purchase.

WARRANTY COVERAGE: ESCALADE SPORTS warrants to the original Consumer Purchaser that any Product of its manufacture is free from

defects in material and workmanship when used for the intended purpose under normal use and conditions. THIS WARRANTY IS VOID IF THE

PRODUCT HAS BEEN DAMAGED BY ACCIDENT, UNREASONABLE USE, NEGLIGENCE, IMPROPER SERVICE, FAILURE TO FOLLOW

INSTRUCTIONS PROVIDED WITH THE PRODUCT OR OTHER CAUSES NOT ARISING OUT OF DEFECTS IN MATERIAL AND

WORKMANSHIP.

WARRANTY PERFORMANCE: During the above ninety (90) day warranty period, ESCALADE SPORTS shall repair or replace with a

comparable model, and Product, or component thereof, which may prove defective under normal use and proper care, and which our

examination shall disclose to our satisfaction to be thus defective, please contact our Warranty Dept.

1-866-873-3528 / Warranty Dept.

Or Write us at:

Escalade® Sports, Inc. - P.O. Box 889, Evansville, IN 47706 - Attn: Warranty Dept.

Or E-mail us at:

customerservice@escaladesports.com

Other than shipping requirements no charge will be made for such repair or replacement of in-warranty Products. ESCALADE®

SPORTS strongly recommends that the Product is insured for value prior to mailing.

WARRANTY DISCLAIMERS: ANY IMPLIED WARRANTIES ARISING OUT OF THIS SALE, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO

THE ABOVE NINETY (90) DAY WARRANTY PERIOD. ESCALADE® SPORTS SHALL NOT BE LIABLE FOR LOSS OF USE OF THE

PRODUCT OR OTHER CONSEQUENTIAL OR INCIDENTAL COSTS, EXPENSES OR DAMAGES INCURRED BY THE

CONSUMER OF ANY OTHER USE.

Some states do not allow the exclusion or limitation of implied warranties or consequential or incidental damages, so the above

limitations or exclusions may not apply to you.

LEGAL REMEDIES: This warranty gives you specific legal rights and you may also have other rights which may vary from state to state.

8

Page 9

CARE AND MAINTENANCE

You have purchased a quality product that will give you years of enjoyment. By following these simple maintenance steps, you will add to the life of

your new table.

THE TABLE TOP

The top (playing surface) of your table is made of particle board. Like all products made of wood, it can be affected by atmospheric changes in both

temperature and humidity. This may cause a slight sag or distortion as the top expands or contracts. This is normal and should not cause concern

as it does not detract from the play or utility value of the table. After assembly of the table, you can minimize the effects of temperature and humidity

changes by storing the table in the folded up position in a dry area when table is not in use.

STORAGE OF YOUR TABLE

This table must be stored indoors to prevent damage to the playing surface. Dampness and extreme temperature changes can cause the wood to

warp, swell, crack or blister. When your table is not in use, it should be folded up in a dry area. Due to the nature of particle board, table top may

bow. Damp and humid conditions will amplify this. This is normal and will not affect playability of table.

CLEANING YOUR TABLE

To clean your table use a soft, damp (NOT WET) cloth only. To prevent damage to your table's playing surface, DO NOT USE ANY CHEMICALS,

ABRASIVE OR CLEANING PRODUCTS on your table's playing surface.

MAINTENANCE OF YOUR TABLE

Be sure to oil all moving parts of your table including the pivot points. This will insure the safety and ease of use of your table.

This table must be kept indoors to prevent damage to the playing surface. Dampness and extreme temperature changes which occur on patios or

similar areas can cause wood to warp, swell, crack or blister.

UNLEVEL FLOORS

If table does not seem level, it is probably due to uneven or unlevel floors. Set the table in its PLAYING POSITION and move table several inches in

different directions to find the best location for the table. If the floor is extremely unlevel, table may not play or operate properly. If table is high in

the center, shim up under the outer U-legs.

#8 X 1 7/16

Sheet Metal Screw

NOT USED

9

Page 10

34

34

34

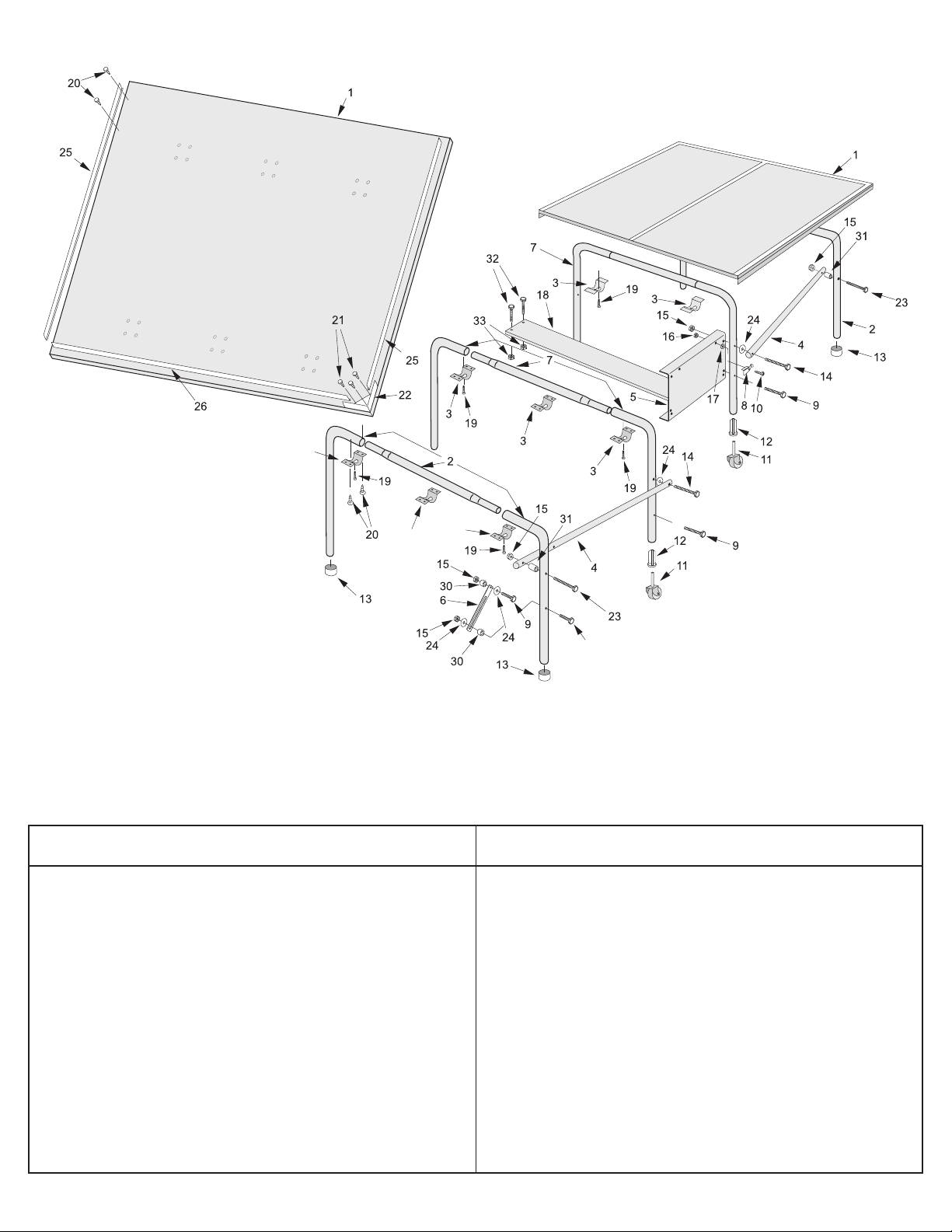

PRODUCT PARTS LIST - T8612

Key # Part# Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

4A-6597-06

8S-6640-00

2S-6387-02

8S-6605-00

2S-6422-17

2S-6428-01

8S-6606-00

2S-6264-02

WB-1094-00

1B-4049-01

2Q-6084-00

3M-6115-00

3M-6447-00

WB-1110-00

2B-4047-98

WB-1007-99

2N-0214-99

Table Top

U-Leg - 1 1/4" Diameter

1” U-Clip

Linkage

Name Panel- STIGA

Safety Strap

U-Support

Safety Latch

1/4-20 x 1 1/2 Hex Head Bolt

#10-24 x 3/4 Phillips Round Hd. Screw

2" Caster

Caster Socket

Leg Cap

1/4-20 x 2 Hex Head Bolt

1/4-20 Locknut

#10-24 Locknut

#10 Flat Washer

2

2

6

4

2

2

2

2

6

2

4

4

4

6

16

2

2

14

Key # Part# Description Qty.

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

2W-6269-02

1B-4089-00

1B-6451-00

1B-6951-00

3M-4149-01

1B-5012-00

2B-6087-00

2S-4616-01

2S-4615-01

5A-6700-00

2L-5034-00

7B-6257-00

7B-6256-00

1B-6475-00

2B-6149-00

2S-6319-03

Wood Bottom Board

#8-32 x 1 1/4” Sheet Metal Screw

#8 x 7/16 Sheet Metal Screw

#8 x 1 7/16 Hex/Phil Hd. SMS

Corner Cap - Yellow

1/4-20 x 3” Hex Head Bolt

Plastic washer

1 1/2" Side Rail-Black

1 1/2” End Rail-Black

Net & Posts Kit

Owners Manual - T8612

Not Used

5/16" Spacer

3/4" Spacer

1/4-20 X 1-1/4 Hex Head Bolt

1/4-20 Black Locknut

1 1/4" U-Clip

1

8

85

12

4

4

8

4

2

1

1

4

4

4

4

6

10

2L-5034-00

Page 11

MESA

NÚMERO DE MODELÓ

DE TENIS

T8612

M A N U A L D E L U S A R I O

1. Lea este manual cuidadosamente antes de empezar a ensamblar. Lea completamente cada uno de los

pasos antes de empezar cada paso.

2. Algunas partes pequeñas pueden ser empacadas dentro de las partes grandes. Verifique en el interior

de todas las partes y cartones antes de ensamblar o solicitar partes.

3. Para que el ensamblado le sea más fácil, utilice la lista de partes de la página 9 para la identificación y

clasificación de las partes y sus componentes. Busque los juegos de tornillos en todos los cartones.

Todos los tornillos y sus componentes no se encuentren en un sólo juego.

4. No ajuste las partes hasta que las instrucciones se lo indiquen. Si las partes se ajustan antes de lo indicado,

es posible que los orificios no queden alineados, resultando que las partes queden fuera de su lugar y fácilmente no

coincidan. Deje las tuercas de seguridad levemente flojas hasta que las instrucciones le indiquen ajustarlas.

5. Herramientas necesarias: Desarmador Phillips, una llave de 3/8” y dos llaves de 7/16” (Puede utilizar una llave

ajustable en vez de llaves).

Por favor no devuelva este producto a la tienda!

Contacte al departamento de servicio al cliente de Escalade® Sports:

Teléfono: 1-866-873-3528 ¡Sin costo alguno!

Fax: 1-866-873-3533 ¡Sin costo alguno!

E-mail: tabletennis@escaladesports.com

Apartado postal (sólo para correspondencia):

Escalade Sports

PO Box 889

Evansville, IN 47706

Visite nuestra página Web internacional: www.escaladesports.com

SOLUCIÓN DE PROBLEMAS POR INTERNET ASISTENCIA TÉCNICA

PEDIDO DE PARTES POR INTERNET PREGUNTAS FRECUENTES

MÁS INFORMACIÓN SOBRE PRODUCTOS DE ESCALADE® SPORTS

2L-5034-00

Los productos Escalade® Sports se pueden fabricar y/o producir bajo las siguientes patentes.

6120397, 5816957, 5769744, 5119741, 4911085, 4717157, D460140, D420563

Puede haber patentes en trámite. Una o más patentes mencionadas y/o en trámite pueden cubrir productos específicos.

2009 Escalade Sports

Page 12

Para que se ayude a la identificación de las partes y de los tornillos. Vea la lista de las partes en la página 9.

1.

Coloque sobre una superficie plana y lisa con

el tablero #1

la cara pintada hacia abajo. Use la caja en donde venia la

mesa para proteger la pintura de la superficie de la mesa.

Ensamble los dos tubos en “L” y los dos tubos del centro que

2.

harán el soporte en “U” y la pata en “U”. Alinéelos sobre el

tablero como está mostrado en la Figura 1. Nota: La

pata en “U” es más grande y más ancha que el

soporte en “U”. La pata en “U” deberá ser instalada

del lado extremo de la mitad de la mesa y del lado

del los orificios del riel.

Ponga las Tapaderas de plástico #13 en la parte de abajo

3.

de las patas en “U” #2.

Figura 1

13

Tapadera

de

plástico

Orificios para

montar el riel

1

Tablero

2

Pata en U

7

Soporte en U

13

Tapadera de

plástico

ADVERTENCIA:

CUANDO ENSAMBLE LA MESA, ES EXTREMADAMENTE IMPORTANTE QUE

TODAS LAS ABRAZADERAS EN “U” #3 & #34 ESTÉN PUESTAS COMO

ESTÁN MOSTRADAS EN LA FIGURA DE ABAJO. SI LAS ABRAZADERAS EN

“U” ESTÁN COLOCADAS INCORRECTAMENTE, USTED LE OCASIONARA

DAÑOS IRREPARABLES A SU MESA CUANDO TRATE DE ABRIRLA EN LA

POSICIÓN DE JUEGO.

4.

Alinee los orificios de las abrazaderas grandes en “U” #34

y las abrazaderas en “U” #3 con los orificios que están de

guía ensamblados en el tablero y atornillelos con los

veinticuatro tornillos #20 como están mostrados.

IMPORTANTE:

Esté seguro que la ranura de todas las tres abrazaderas

“U” #3 y las tres abrazaderas #34 estén de frente en la

misma dirección (hacia la mitad de la mesa con el tubo de

soporte en “U” ) como está mostrado.

Este extremo es

es el centro de la mesa

Este extremo es

es el centro de la mesa

Todos los tornillos

20

34

3

34

mostrados son los (#20)

Tornillos para lamina de

3

34

metal

3

Soporte en U

2

Pata en U

7

Figura 2

IMPORTANTE: La Pata en U es más ancha que el

Soporte en U. Esté seguro de que éstos estén

3

ensamblados exactamente como están mostrados.

De lo contrario quedará un espacio grande entre

las dos mitades de la mesa y la mesa no operará

apropiadamente.

2

Page 13

5.

Coloque los rieles #25 y #26, alrededor de los bordes del

tablero, como están mostrados en la Figura 3.

6.

Alinee los orificios de los rieles con los orificios de guía del

tablero, atornillelos y asegúrelos con los dieciocho tornillos

#20. Ver Figura 3.

(Riel de )48”

25

Todos los tornillos

mostrados son los

(#20) Tornillos para

lamina de metal

Este extremo es

es el centro de la mesa

Figura 3

7.

Coloque los Protectores de Esquina #22 al tablero como están

mostrados en la Figura 4. Si el protector de la esquina

sobresale de la superficie del tablero, volteélo así que la parte

más corta esté en contra del borde. Atornillelos y asegúrelos

por la parte de abajo de la mesa con los tornillos #21.

Figura 4

26

(Riel de )53”

25

(Riel de )48”

at a

t

r

o

c

s

a

i m

c

n

a

s

i

D

Di t

s

a

n

cia ma

s c

o

r

t

a

Abajo de la mesa

8.

Rote el soporte en forma de U #7 hasta que se vean los

orificios a través de las ranuras de las abrazaderas en U

#3 donde iran los tornillos. Descienda el soporte en forma

de U #7 de lado a lado para ver los orificios, si es

necesario, ver Figura 5.

9.

Inserte el tornillo # 19 a través de las ranuras de la

abrazadera en forma de U #3 y dentro del soporte

en forma de U #7. Atornillándolo al soporte en U

hasta que toque el fondo del tubo. El tornillo # 19

debe sobresalir acerca de ⅜ de pulgada. Repita lo

mismo para la pata en “U” #2 y las abrazaderas en

U # 34.

Note: Si es necesario deslice el Soporte en U hacia

adelante y hacia atrás hasta que vea el orificio.

Figura 5

3

Soporte en U

Pata en U

(mas ancha)

34

2

Pata en U

3

Soporte en U

Page 14

10.

Una los extremos de los Tubos Conectores #4 con los dos orificios de

ADENTRO

Atornillelos hasta el final del orificio con los tornillos # 23, las

tuercas de seguridad #15 los separadores de plástico #31

Asegurándose que las tuercas y tornillos estén lo suficientemente

apretadas y seguras para mantener la mesa estable pero no los sobre

apriete. Los tubos deben girar libremente.

11.

En un lado de la mesa una el extremo con la ranura de la correa de

seguridad #6 por de la pata en U #2. usando

uno de los tornillos # 14, un separador #30, una rondana #24, y

una tuerca hexagonal #15. Asegurándose que las tuercas estén

apretadas y seguras. Pero no los sobre apriete. Los tubos deben girar

libremente. Ver Figura 7.

Una el otro extremo de la correa de seguridad #6 a la parte

12.

de del Tubo Conector #4 usando uno de los tornillos # 9,

AFUERA

una rondana #24, un separador #30, y una tuerca hexagonal #15.

Importante: NO coloque la otra correa #6 en esta mitad de la

mesa. Esta sera instalada en la otra mitad de la mesa después.

13.

Una el otro extremo del Tubo Conector #4 a la parte de del

soporte en forma de U #7 con los tornillos # 14 y las rondanas de

plástico #24, luego deslice la Placa #5 sobre los mismos tornillos #

14 por la parte de del soporte en forma de U #7.

Asegúrelos con las tuercas de seguridad #15. Asegurándose que las

tuercas estén apretadas y seguras. Pero no las sobre apriete. Los tubos

deben girar libremente.

14.

Una la parte de abajo de la placa #5 a los soportes en forma de U #7.

Atornillando los tornillos hexagonales # 9, y las tuercas de seguridad #

15. Apriete las tuercas, pero esté seguro de no doblar los tubos. Ver

Figura 6.

15.

Una la Tabla Inferior #18 a las Placas #5, como esta mostrado en la

Figura 6, Use cuatro Tornillos #32 y cuatro Tuercas de Seguridad #33.

de la pata en U #2 como están mostrados en la Figura 6.

de metal DENTRO

de metal

AFUERA

ADENTRO

Figura 6

9

14

2

23

31

5

33

7

24

4

15

32

15

18

31

33

5

32

9

14

24

4

23

Figura 7

Inserte cuidadosamente casquillo de la llanta #12 dentro del soporte

16.

en forma de U #7 hasta que el borde del casquillo toque el borde del

tubo.NO GOLPEE EL CASQUILLO DIRECTAMENTE CON EL

MARTILLO! COLOQUE UN PEDAZO DE MADERA SOBRE EL

CASQUILLO Y GOLPE SOBRE EL PEDAZO DE MADERA PARA

INSERTAR EL CASQUILLO ADENTRO DEL SOPORTE EN FORMA

DE U.

Inserte las llantas #11 adentro del casquillo #12.

17.

ADVERTENCIA:

¡POR LO MENOS SE REQUIERE DE DOS (2)

ADULTOS PARA MOVER LA MITAD DE LA MESA!

18.

Prepare una área para el ensamblado de la Segunda mitad de la mesa.

Si es necesario mueva el primer tablero a un lado con la ayuda de otra

persona. Asegúrese de ponerlo en una lugar donde no estorbe y no se

dañe. Y si se coloca de lado, asegurese de poner el borde inferior a no

menos de 12 pulgadas de distancia de la pared. También esté seguro

de poner un pedazo de alfombra o una colchoneta abajo de los

bordes de la mesa para protegerlos. Si el piso no esta alfombrado

ponga un objeto pesado sosteniendo la mesa para que no se resbale.

Figura 8

4

Page 15

Repita los pasos del 1 al 12 en la segunda mitad de la mesa.

19.

Inserte cuidadosamente el casquillo de la llanta #12 dentro soporte en

20.

forma de U #7 en la Segunda mitad hasta que el borde del casquillo

toque el borde del tubo. NO GOLPEE EL CASQUILLO

DIRECTAMENTE CON EL MARTILLO! PONGA UN PEDAZO DE

MADERA SOBRE EL CASQUILLO Y GOLPE SOBRE EL PEDAZO

DE MADERA PARA INSERTAR EL CASQUILLO ADENTRO DEL

SOPORTE EN FORMA DE U.

Inserte las llantas #11 adentro del casquillo #12 en la segunda mitad

21.

de la mesa.

22.

Una el otro extremo del Tubo Conector #4 a la parte de afuera del

soporte en forma de U #7 a la Segunda mitad de la mesa con los tornillos

# 14, las rondanas de plástico #24 y las tuercas hexagonal #15.

NO APRIETE ESTAS

DOS TUERCAS #15

TODAVIA.

ADVERTENCIA:

¡POR LO MENOS SE REQUIERE DE DOS

(2) ADULTOS PARA MOVER LA MITAD

DE LA MESA!

NOTA: Apriete las tuercas de seguridad #15 con la mano

nadamas. Serán removidas cuando las dos lados de las

mesas esten unidas.

Figura 9

La Segunda Mitad

de la mesa.

5

Page 16

Recargue esta mitad

contra la pared.

La Primera Mitad de

la mesa que

ensamblo.

La Segunda Mitad de

la mesa que

ensamblo.

Figura 10

23.

Esté seguro que las patas de la primera mitad de la mesa (la mitad con la placa #5) estén abiertas. Con una persona en cada lado de la

mesa, levante y ponga la mitad de la mesa sobre sus propias patas. Coloque la mesa contra la pared como está mostrado arriba, para

ayudar a estabilizar la mitad de la mesa mientras que la Segunda mitad esta siendo colocada. Asegúrese que haya suficiente espacio para

colocar la segunda mitad de la mesa.

É

EST SEGURO QUE LA PRIMERA MITAD DE LA MESA QUE USTED ENSAMBLO

ADVERTENCIA:ADVERTENCIA:

(CON LAS PLACAS #5) ESTÉ ESTABLE Y CONTRA LA PARED. NO DEJE LA

MITAD DE LA MESA DESATENDIDA.

Inserte el tornillo hexagonal # 9 y las tuercas de seguridad # 15 sobre el piso a un lado de las llantas (en ambos lados de la mitad de la

24.

mesa) así las tendrá a la mano para el próximo paso.

HASTA QUE LAS DOS MITADES DE LA MESA ESTÉN UNIDAS NO PUEDEN ESTAR

ADVERTENCIA:

PARADAS SOLAS. SE RECOMIENDA QUE TRES (3) PERSONAS PARA UNIR LAS DOS

MITADES DE LA MESA. DOS PERSONAS PARA SOSTENER LA MESA Y UNA

PERSONA PARA ATORNILLAR LOS TORNILLOS A LA MESA.

Con una persona en cada uno de los lados de la Segunda mitad de la mesa, deslice la Segunda mitad o tablero contra de la primera mitad.

25.

Remueva las tuercas de seguridad # 15 de los tornillos # 14 de la Segunda mitad donde el soporte en forma de U #7 y los Tubos Conectores #4

se unen. Alinee los orificios de la Placa #5 los tornillos hexagonal # 14 que fueron instalados anteriormente y las tuercas de seguridad que

removió. Asegure la Segunda mitad de la mesa con el orificio de abajo de la Placa #5 con los dos tornillos hexagonales # 9 y las tuercas de

seguridad # 15 que usted puso en el piso con anterioridad. Asegurándose que las tuercas estén apretadas y seguras. Pero no las sobre apriete.

Estas uniones deben moverse. Hasta este punto regrese y apriete los tornillos hexagonales # 9.

Figura 11

Vista de

Arriba

Placa #5

Pasador de

Seguridad #8

(el borde se extiende sobre

la placa #5)

PASADOR

DE SEGURIDAD

NO SOBRE AJUSTE EL

PASADOR DE SEGURIDAD #8.

DEBE DE GIRAR LIBREMENTE!

INSTALE LOS PASADORES DE SEGURIDAD #8 COMO SE MUESTRA ARRIBA

PARA EL USO APROPIADO DE LA MESA! NO OMITA ESTE PASO! NO USE LA

ADVERTENCIA:

MESA HASTA QUE LOS PASADORES DE SEGURIDAD ESTÉN INSTALADOS Y

HASTA QUE HAYA TERMINADO DE ENSAMBLAR LA MESA.

23.

Escoja la Placa #5 en cualquiera de los lados de la mesa instale

el Pasador de seguridad #8 dentro del lado derecho del orificio

sobre la Placa como está mostrado en las Figuras 11 y 12. Use

uno de los tornillos #10, una rondana #17 y una tuerca

hexagonal #16. NOTA: el borde del pasador de seguridad

debe ir extendido sobre de la placa como está mostrada

en Figura 11. el pasador de seguridad debe moverse

libremente.

Vaya al otro lado de la mesa e instale el segundo Pasador de

24.

seguridad #8 dentro del lado derecho del orificio sobre la Placa

#5. NOTA: Los Pasadores de seguridad deben ir unidos

diagonalmente cruzados de cada uno. (Ver Figura 12)

Vista de Arriba de la mesa

6

Pasador de Seguridad #8

(en el orificio de lado derecho )

Placa #5

Placa #5

Una los Pasadores de

Una los Pasadores de

Seguridad #8

Seguridad #8

diagonalmente enfrente

diagonalmente enfrente

de si mismo.

de si mismo.

Pasador de Seguridad #8

(en el orificio de lado derecho )

Figura 12

Page 17

INSTRUCIONES PARA ABRIR Y CERRAR LA MESA

¡LEA AS INSTRUCCIONES DE MANEJO ANTES DE MOVER LA MESA! ¡NO

NO DEBEN DE PARARSE, SUBIRSE

ADVERTENCIA!

PERMITA QUE NIÑOS ABRAN LA MESA!

O BRINCAR SOBRE LA MESA

. PUEDEN OCURRIR LESIONES GRAVES O

MORTALES. ¡ESTA MESA NO ES UN JUGUETE! ¡ÚNICAMENTE LOS

ADULTOS DEBEN ABRIR O CERRAR LA MESA. NO CUMPLIR CON LAS

INSTRUCCIONES PARA ABRIR Y CERRAR LA MESA PUEDE RESULTAR EN

LESIONES PERSONALES O DAÑOS MATERIALES.

PARA ABRIR:

1. Jale cuidadosamente ambas patas de la mesa

2. Párese detrás de la mesa cerca de el pasador de seguridad.

3. detenga la mitad de la mesa con una mano y gire el pasador de

seguridad lo suficientemente para permitir que pase sobre la orilla de la

mitad de la mesa.

4. Mientras cuida el pasador de seguridad, gire la mitad de la mesa hasta

que se mueva y pase el pasador de seguridad. Una vez que ha pasado

sobre el pasador de seguridad, pare de girar la mitad de la mesa.

5. Con ambas manos sobre la mitad de la mesa. Desde el centro de la

mitad de la mesa baje la mitad de la mesa a el piso.

6. Repita los mismos pasos para la otra mitad de la mesa.

POSICIÓN PARA

JUGAR SOLO

Vea los

dibujos

detallados

Gire el pasador de

Seguridad hasta que la

orilla de la mesa pueda

pasar sobre el

la orilla de la mesa pasa

sobre el Pasador de

Seguridad.

PARA CERRAR:

1. Levante la mitad de la mesa hacia arriba y hacia el interior y adentro

hasta la posición vertical.

2. Asegúrese que la mitad de la mesa esté asegurada con el pasador de

seguridad.

3. Repita los mismos pasos para la otra mitad de la mesa.

POSICIÓN PARA

PASADORES

ASEGURADO

POSICIÓN DE

JUEGO

GUARDAR

AMBOS

PASADORES

ASEGURADOS

PRECAUCIÓN

ESTA ES UNA MESA DE JUEGO.

BRINCAR SOBRE LA MESA. DE NO CUMPLIR CON LAS

INSTRUCCIONES PARA ABRIR Y CERRAR LA MESA PUEDE RESULTAR

EN LESIONES PERSONALES O DAÑOS MATERIALES.

NO DEBEN DE PARARSE, SUBIRSE O

7

7

Page 18

GARANTÍA LIMITADA POR 90 DÍAS

Esta garantía para consumidores de la compra original de cualquier producto ESCALADE SPORTS (en adelante

es aplicable

®

denominado el "Producto").

DURACIÓN DE LA GARANTÍA: Se garantiza este Producto al comprador original por un período de (90) días a partir de la

fecha de compra.

COBERTURA DE LA GARANTÍA: ESCALADE SPORTS le garantiza al comprador original que cualquier producto de su

fabricación está libre de defectos en los materiales y fabricación cuando se lo utiliza para el propósito establecido, bajo

condiciones normales de uso. ESTA GARANTÍA NO TIENE VALIDEZ SI EL PRODUCTO SE HA DETERIORADO POR

ACCIDENTE, USO INDEBIDO, NEGLIGENCIA, MANTENIMIENTO INCORRECTO, NO SEGUIR LAS INSTRUCCIONES QUE

VIENEN CON EL PRODUCTO U OTRAS CAUSAS NO RELACIONADAS CON DEFECTOS EN LOS MATERIALES O

FABRICACIÓN.

APLICACIÓN DE LA GARANTÍA: Durante el período de garantía de (90) días, ESCALADE SPORTS reparará o reemplazará

con otro similar, todo modelo o Producto o componente que resulte defectuoso bajo condiciones normales de uso y cuidado,

cuando nuestra inspección demuestre que a nuestra satisfacción el mismo realmente es defectuoso; sírvase contactar a nuestro

Departamento de Garantía.

1-866-873-3528 / Departamento de Garantía (Warranty Dept.)

O escríbanos a:

Escalade® Sports, Inc. - P.O. Box 889, Evansville, IN 47706 - Attn: Warranty Dept.

O por correo electrónico a:

tabletennis@escaladesports.com

Fuera de los gastos de envío, no se impondrá cargo alguno por la reparación o reemplazo de los productos en garantía.

ESCALADE® SPORTS recomienda asegurar los Productos por su valor antes del envío.

LIMITACIÓN DE LA GARANTÍA: TODA GARANTÍA ORIGINADA EN ESTA VENTA, INCLUYENDO EN FORMA NO

TAXATIVA, LAS GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN Y APTITUD PARA UN FIN ESPECÍFICO, TENDRÁ VIGENCIA

POR UN PLAZO DE (90) DÍAS. ESCALADE® SPORTS NO SERÁ RESPONSABLE POR LA PÉRDIDA DE USO DEL PRODUCTO U

OTROS COSTOS INCIDENTALES O RELACIONADOS, PERJUICIOS O PERDIDAS GENERADAS POR EL CONSUMIDOR

ANTE CUALQUIER OTRO USO.

Algunos estados no permiten la exclusión o limitación de las garantías implícitas o daños incidentales o conexos, de modo que

las limitaciones que anteceden pueden no ser aplicabes en su caso.

RECURSOS LEGALES: Esta garantía le otorga algunos derechos específicos además de otros derechos que varían según el

estado.

8

Page 19

CUIDADO Y MANTENIMIENTO

Usted ha comprado un producto de calidad que podrá disfrutar muchos años. Si sigue estos simples pasos de mantenimiento, alargará la vida de la mesa.

TABLERO

El tablero (superficie de juego) está construido de aglomerado. Al igual que todos los productos de madera, se puede ver afectado por cambios de

temperatura y humedad causando una leve deformación por expansión o contracción. Esta situación es normal y no resta valor a la mesa ni afecta el

juego. Después de armada, guardar plegada en lugar seco cuando no está en uso para minimizar los efectos de cambios de temperatura y humedad.

GUARDADO DE LA MESA

Se debe guardar la mesa en el interior para prevenir daños en la superficie de juego. La humedad y los cambios buscos de temperatura pueden provocar

alabeo, hinchazón, fisuras o ampollado de la madera. Cuando la mesa no se encuentra en uso, guardar plegada en lugar seco. debido a la naturaleza

del aglomerado, se puede alabear la superficie. La humedad puede aumentar este efecto que es normal y no afecta el uso de la mesa.

LIMPIEZA

Para limpiar la mesa, utilizar un trapo suave y húmedo solamente (NO MOJADO). Para evitar daños en la superficie de juego, NO UTILIZAR AGENTES

QUIMICOS, ABRASIVOS NI PRODUCTOS DE LIMPIEZA sobre el tablero.

MANTENIMIENTO

Lubricar todas las partes movibles, incluyendo los puntos de giro. Esto garantizará la seguridad y facilidad de uso.

Guardar en lugar cerrado para impedir daños en la superficie de juego. La humedad y los cambios bruscos de temperatura que se producen en patios o

áreas similares pueden provocar el alabeo, hinchazón, fisuras o ampollado de la madera.

PISOS DESNIVELADOS

Si la mesa no parece estar nivelada, probablemente se deba a pisos desparejos o desnivelados. Colocar la mesa en POSICION DE JUEGO y moverla

algunas pulgadas en distintas direcciones hasta encontrar una mejor ubicación. Si el piso está extremadamente desnivelado, no se puede utilizar la mesa

adecuadamente. Si el tablero está más alto en el medio, suplementar con una cuña las patas exteriores.

# DE

REFERENCIA

1/4-20 x 1-1/2 Tornillo

de cabeza Hexagonal

Tornillo de Phillips

1/4-20 x 2 Tornillo de

cabeza Hexagonal

Tuerca

de Seguridad

#10

Rondana

Separador de 5/16”

IDENTIFICADOR DE TORNILLOS

1/4-20 x 1-1/4 Tornillo

de cabeza Hexagonal

Tornillo SMS

1/4-20 X 3 Tornillo de Cabeza Hexagonal

Tuerca

de Seguridad

7

Tornillo para

lamina de

metal

Separador de 3/4”

Rondana

de

plástico

Tuerca

de Seguridad

Negra

#8 X 1 7/16

Tornillo para lamina

de metal

NO USADO

9

Page 20

34

# de Ref. # de Parte

4A-6597-06

1

2

8S-6640-00

3

2S-6387-02

4

8S-6605-00

5

2S-6422-17

6

2S-6428-01

7

8S-6606-00

8

2S-6264-02

9

WB-1094-00

10

1B-4049-01

11

2Q-6084-00

12

3M-6115-00

13

3M-6447-00

14

WB-1110-00

15

2B-4047-98

WB-1007-99

16

2N-0214-99

17

34

34

14

LISTA DE PARTES REEMPLAZABLES - T8612

# de Ref. # de Parte

Descripción

Tablero

Pata en U de 1 1/4"

Abrazadera en U -1”

Tubo Conector

Placa- STIGA

Tira de metal de Seguridad

Tubo de Soporte en U

Pasador de Seguridad

1/4-20 x 1 1/2 Tornillo de Cabeza Hexagonal

#10-24 x 3/4 Tornillo de Cabeza Phillips

Llanta - 2"

Casquillo para llanta

Tapadera de plástico

1/4-20 x 2 Tornillo de Cabeza Hexagonal

1/4-20 Tuerca de Seguridad

#10-24 Tuerca de Seguridad

#10 Rondana

Cant.

2

2

6

4

2

2

2

2

6

2

4

4

4

6

16

2

2

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

2W-6269-02

1B-4089-00

1B-6451-00

1B-6951-00

3M-4149-01

1B-5012-00

2B-6087-00

2S-4616-01

2S-4615-01

5A-6700-00

2L-5034-00

7B-6257-00

7B-6256-00

1B-6475-00

2B-6149-00

2S-6319-03

1" Abrazadera en U

#8-32 x 1 1/4” Tornillo para lamina de metal

#8 x 7/16 Tornillo para lamina de metal

#8 x 1 7/16 Tornillo SMS de Cabeza Hexagonal

Protector de Esquinas - Amarillo

1/4-20 x 3” Tornillo de Cabeza Hexagonal

Rondana de plástico

1 1/2” Riel Lateral - Negro

1 1/2” Riel del Extremo - Negro

Red y Postes

Manual del Usario - T8612

NO USADO

5/16" Separador

3/4" Separador

1/4-20 X 1 1/4” Tornillo Hexagonal

1/4-20 Tuerca de Seguridad Negra

Abrazadera en U -1 1/4

Descripción

Cant.

1

8

85

12

4

4

8

4

2

1

1

4

4

4

4

6

10

2L-5034-00

Loading...

Loading...