Page 1

STIGA PARK

PRO 20

PRO 16

ROYAL

PRESIDENT

SENATOR

8211-0276-02

Page 2

20

PARK

19

1.

6

2

4

3

2.

16

5

1

3.

Page 3

PARK

10

7

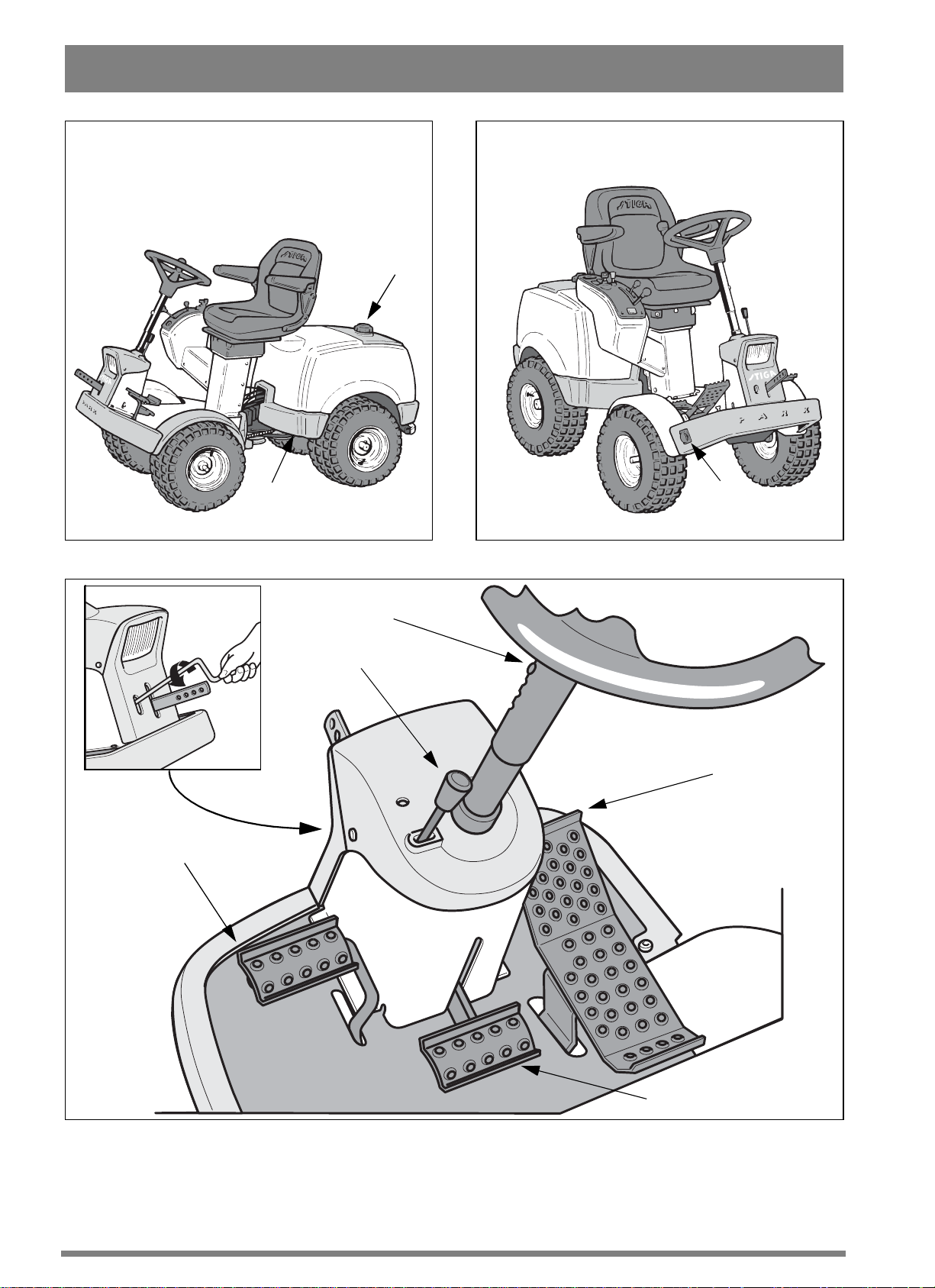

4. Senator 5. President

14

7

11

9

11

8

9

7

13

7

14

14

11

9

11

8

9

15

6. Royal 7. Pro 16

13

14

7

15

8

9

12

16

13

15

14

7

15

8

18

16

9

12

16

8. Pro 18

17

9. Pro 20

Page 4

PARK

1

2

2

1

10.

12.

11.

13. Senator - President

14. Royal

OPEN

16.

15.Pro16-Pro18-Pro20

17. Royal

Page 5

PARK

18. Pro 16 - Pro 18 - Pro 20

20. Royal

19. Senator - President

21.Pro16-Pro18-Pro20

0.75 mm

22. Pro 18 - Pro 20

24. Senator - President

23.

25.Royal-Pro16-Pro18-Pro20

Page 6

PARK

26.

MAX

28.

27.

29a. President - Royal

29b. Pro 16 - Pro 18 - Pro 20

Page 7

GB

GENERAL

This symbol indicates WARNING. Personal injury and/or damage to property

may result if the instr u ctions are not

followed carefully.

ENGLISH

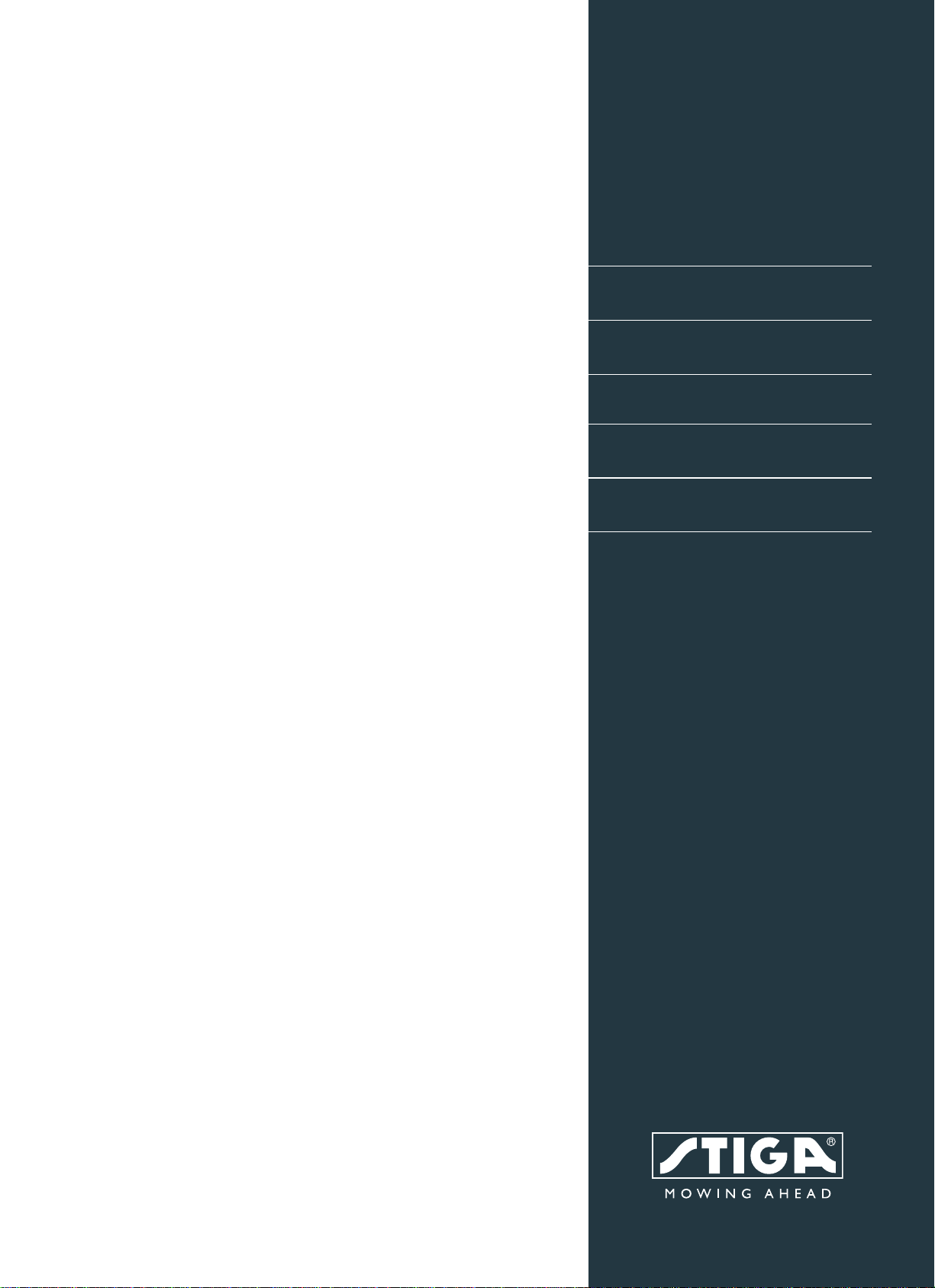

1. IMPLEMENT LIFTER

A pedal for raising front-mounted accessories to

the transport position.

To liftup theaccessory,pressthe pedaldownas far

as it will go. Then release the pedal, the implement

lifter is now locked in the lift position.

Youmustreadthese instructionsfor use

and the accompanying pamphlet

“SAFETY INSTRUCTIONS” carefully, before starting up the machine.

SYMBOLS

The following symbols are displayed on the machine in order to remind you about the safety precautions and attention necessary when using the

machine.

The symbols mean:

Warning!

Read the instruction bookand safety manual before using the machine.

Warning!

Beware of objects being flung out. Keep

spectators away.

Warning!

Always use hearing protectors.

Warning!

This machine is not designed to b e driven

on public roads.

To lower the accessory, press the pedal down so

that the lock is released.Lower the implement lifter to the working position by slowly lifting your

foot from the pedal.

2. LIFT HELP (Pro18 - Pro20)

The implementlifter is complementedwith adjustable lifthelp in the form of a gas spring.This facilitates lifting heavy accessories.

Under the engine casing, on the top of the rear

bumper, there is a setting crank.

Use this to increase/decrease the lift help.

Screw anti-clockwise to increase the

lift help if heavy accessories are being used.

Screw clockwise to decrease the lift

help if lighter accessories are being

used.

3A. SERVICE BRAKE/CLUTCH

(Senator)

A pedal that combines both service brake and

clutch. Three positions:

Warning!

The machine, equipped with original accessories, must not be driven in any direction on slopes with a gradient greater than

10º.

Warning!

Clamp risk. Keep hands and feet well

away from the articulated steering joint.

Warning!

Riskfor burn injuries. Do not touchthe silencer/catalytic converter.

CONTROLS AND

INSTRUMENTS

Items 1 - 20, see figures 1 - 9

8

1. Pedalreleased– forward drive

engaged. The machine will

move if a gear is engaged. Service brake not activated.

2. Pedal depressed halfway –

forward drive disengaged, gear

shifting can be performed. Service brake not activated.

3. Pedal fully depressed – forward drive disengaged. Service

brake fully activated.

NOTE! You must never regulate the operating

speed by slipping the clutch. Use a suitable gear instead, so that the right speed is obtained.

3B. SERVICE BRAKE (President Royal - Pro16 - Pro18 - Pro 20)

A pedal that acts upon the machine’s braking sys-

Page 8

ENGLISH

GB

tem. There are 3 positions:

1. Pedal released – service brake

not activated.

2. Pedal depressed halfway –

forward drive disengaged. Service brake not activated.

3. Pedal fully depressed – forward drive disengaged. Service

brake fully activated.

4. PARKING BRAKE

An inhibitor that can lock the brake pedal in the depressed position.

Depress the brake pedal fully. Move the

inhibitor to the right and then release the

brake pedal.

The parking brake isre leased by pressingthebrake

pedal. The spring-loaded inhibitor slides to one

side.

Make sure that the parking brake is released when

operating the machine.

7. THROTTLE/CHOKE CO NTRO L

A control for setting the engine speed and to choke

the engine when starting from cold (the latter does

not apply to Royal-Pro16-Pro18-Pro20 whic h

have separate choke control – see item 8).

1. Choke – for starting a cold engine. The

chokeis located in topof groove (doesnot

apply to Royal- Pro16-Pro18-Pro20).

2. Full throttle – when the machine is in

operation, full throttle should always be

used.

3. Idle running.

8. CHOKE CONTROL (Royal - Pro16 Pro18 - Pro20)

A pull-type control to choke the engine when starting from cold.

1. Control fully pulled out – choke valve

in carburettor closed. For starting cold engine.

5. DRIVE PEDAL (President - Royal Pro16 - Pro18 - Pro20)

A pedal that activates the variable transmission.

1. Depress the pedal with the

ball of your foot – the machine

moves forwards.

2. No load on the pedal – the machine is stationary.

3. Depress the pedal with your

heel – the machine reverses.

The drive pedal regulates the speed. The more

pressure applied, the faster the machine will move.

6. ADJUSTABLE STEERING WHEEL

(President - R oyal - Pro16 - Pro18 Pro20)

The steering wheel can be adjusted vertically in 5

positions. Press in the inhibitor on the steering column and raise or lower the steering wheel to the

desired position.

Do not adjust the steeri ng wheel during operation.

2. Control pushed in – choke valve open.

For starting warm engine and when operating the machine.

Never operate the machine with the choke

pulled out when the engine is warm.

9. IGNITION LOCK/SPOTLIGHT

Ignition lock used for starting/stopping the engine.

Also includes switch for spotlight (Senator does

not have a spotlight). Four positions:

1. Stop position – the engine is shortcircuited. The key can be removed.

2. Operating position – spotlight activated.

3. Operating position – spotlight not activated.

4. Start position – the electric start motor

isactivatedwhenthekeyisturnedtothe

spring-loaded start position. Once the engine has started, let the key return to operating position 3.

T o turn on the spotlight, turn the key to position 2.

NOTE! If the key is turned from the stop posi-

9

Page 9

GB

ENGLISH

tion to operating position 2, the spotlight is activated. Th is uses up battery power. Do not leave

the machine with the key in position 2 (applies

to Pro16-Pro18-Pro20).

10. GEAR LEVER (Senator)

A lever for selecting one of the five forward gears

in the gearbox (1-2-3-4-5), neutral (N) or reverse

(R).

The clutch pedal must be kept pressed in when

changing gear.

NOTE! You must make sure the machine is quite

stationary before changing from reverse toforward

gear or vice versa. If a gear does not engage immediately,release theclutch pedal andthen press it in

once again, then engage the gear once again. Never

force a gear in.

11. POWER TAKE-OFF (Senator President - Royal - Pro16)

A lever for engaging and disengaging the power

take-off for driving front-mounted accessories.

There are two positions:

1. Lever in forward position – power takeoff disengaged.

2. Lever in backward position - power

take-off engaged.

tion.

2. Backward position– the differential inhibitor is engaged. For normal operation.

Works for both forward and reverse drive.

The differential lever is of greatest use when the

rear wheels are unevenly loaded. For example,

when driving across a slope, where the upper rear

wheel is not as loaded, as wheel as when turning

sharp corners where the inner rear wheel bears a

lesser load.

When drivingduringthe winter onslippery surfaces, the drive capacity is improved if snow chains

are not used.

When the differential inhibitor is engaged, the

steering is heavy. Avoid turning the steering

wheel!

14. HOUR METER (President - R oyal

-Pro16-Pro18-Pro20)

Indicates the number of working hours. Only

works when the engine is running.

15.CRUISECONTROL(Royal- Pro16

-Pro18-Pro20)

A switch for activating the cruise control. The

function of the cruise control allows the drive pedal (5) to be locked in the desired position. You do

not need to use your right foot.

12. POWER TAKE-OFF (Pro18 Pro20)

Switch for engaging/disengaging the electromagnetic power take-off for driving front-mounted accessories. There are two positions:

1. Press the front part of the switch – the

power take-off is engaged. The symbol

lights up.

2. Press the rear part of the switch – the

power take-off is disengaged.

13. DIFFERENTIAL INHIBITOR

(Pro16 - Pro18 - Pro20)

Lever for engaging the differential inhibitor. This

improves the towing capacity by locking the rear

wheels so that both wheels drive simultaneously.

There are two positions:

1. Forward position – the differential inhibitor is not engaged. For normal opera-

1. Press down the drive pedal until the desired speed is obtained. Then press the

front part of the switch to activate the

cruise control. The symbol will light up.

2. Disengage the cruise control by pressing the rear part of the switch.

16.CUTTING HEIGHT ADJUSTMENT

(Pro16 - Pro18 - Pro20)

The machine is equipped with a control for using

the mower deck with electrical cutting height adjustment (available as an accessory).

Theswitchisusedtoadjustthecutting

height in continuou sly variable positions.

The contact used for connecting the mower deck is

mounted on the right side, in front of the front tyre

(fig. 2).

17. REAR RAKE (Pro 20)

The machine has been designed for electrical ad-

10

Page 10

ENGLISH

GB

justmentof a rear rake (available as an accessory).

Theswitchisusedtoraiseandlowerthe

rear rake.

Connection cables for the rake are located to the

rear of the machine, to the left on the top of the

bumper (Pro16 and Pro18 are prepared for a rear

rake).

18. SAND SPREADER (Pro20)

The machine has been designed for electrical adjustment of a sand spreader (available as an accessory).

Theswitchisusedtostartandstopthe

12V

A connection contact for the sand spreader is located to the rear of the machine, to the left on the top

of the bumper (Pro16 and Pro18 are prepared for a

sand spreader).

spreader.

19. DISENGAGING LEVER (President - Royal - Pro16 - Pro18 - Pro20)

A lever for disengaging the variable transmission.

Enables the machine to be moved by hand without

the help of the engine. There are two positions:

1. Lever moved back – transmission engaged for normal operation.

2. Lever moved forward – transmission disengaged. The machine can be moved by hand.

1. Mowing

Using mower deck 13-2927 (107M), 13-2917

(110S), 13-2915/13-2921 (121M) or flail mower 13-1977.

2. Sweeping

Using brush unit 13-1933 or collector brush

unit 13-1939. Use of dust guard 13-1936 is recommended with the first option.

3. Snow clearanc e

Usingsnow blade13-1916 or snowthrower 13-

1948. Snow chains 13-1956 (16”)/13-0902

(17”) and wheel weights 13-1982 are recommended.

4. Grass clipping and leaf collection

Using towed collector 13-1978 (30”) or 131950 (42”).

5. Grass and leaf transport

Using dump cart 13-1979 (Standard), 13-1988

(Maxi) or 13-1992 (Combi).

6. Sand spreading

Using sand spreader 13-1975. Can also be used

for spreading salt. Snow chains 13-1956 (16”)/

13-0902 (17”) and wheel weights 13-1982 are

recommended.

7. Weeding on gravel paths

Using front mounted hoe 13-1944 and rearmounted rake 13-1969.

8. Lawn edge trimming

To avoid damage to the transmission, do not tow

the machine for any great distance.

20. FUEL GAUGE/FUEL CAP

Fuel cap with built-infuel gaugethat indicates how much fuel there is in the fuel

tank. (applies to Royal-Pro16-Pro18Pro20)

Senator and President have a fuel cap without a

fuel gauge.

The fuel tank has a capacity of 11.5 l.

AREAS OF USE

Themachinemayonlybeusedforthefollowing

tasks using the STIGA accessories stated.

Using edge trimmer 13-0905.

9. Moss scarification

Using moss scarifier 13-1984.

The maximum vertical load on the towing hitch

must not exceed 100 N.

The maximum over-run load on the towing hitch

from towed accessories must not exceed 500 N.

NOTE! Before using a trailer – contact your insurance company.

NOTE! This machine is not intended to be driven

on public roads.

11

Page 11

GB

ENGLISH

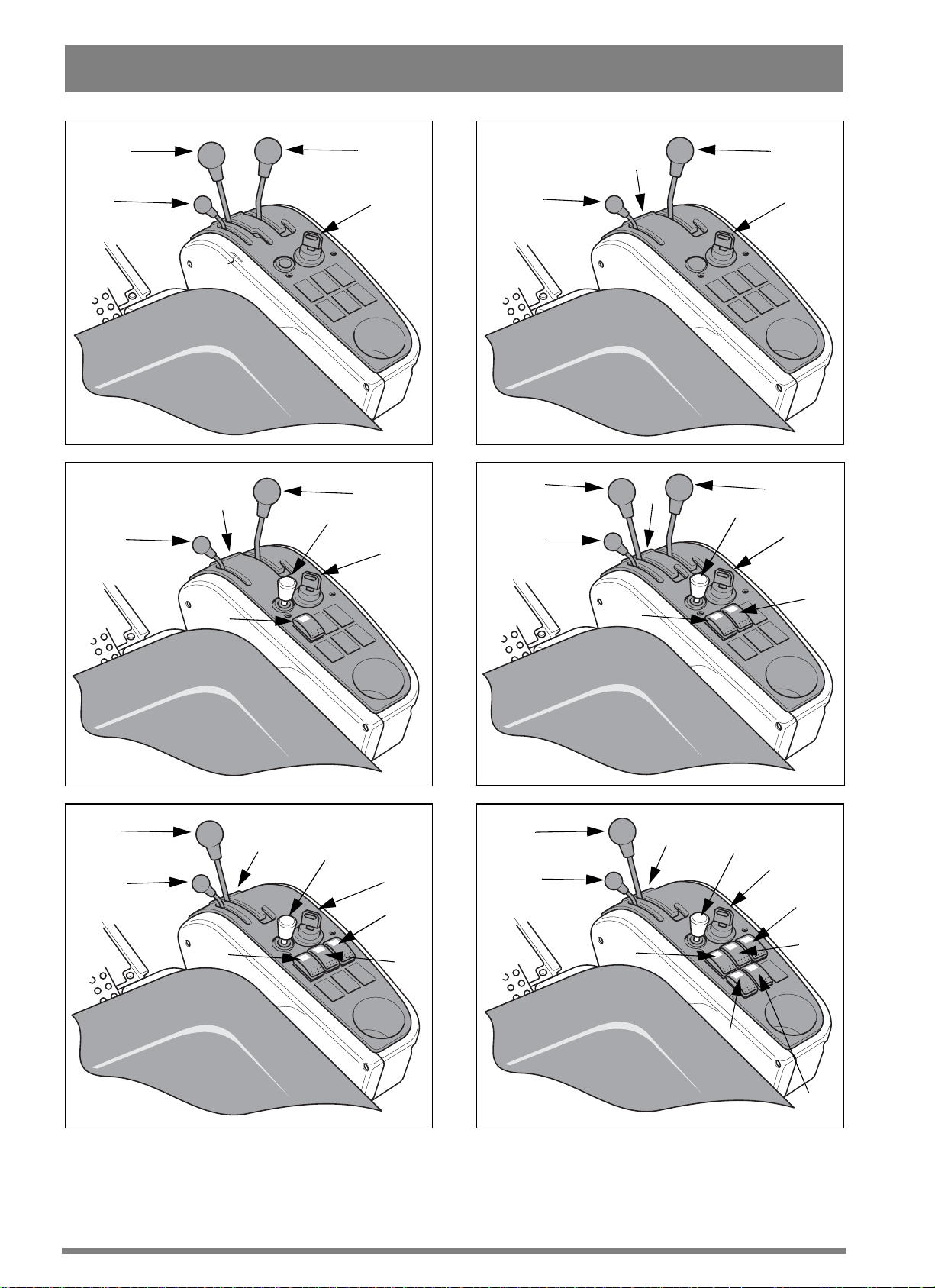

START AND OPERATING

ENGINE CASING

To inspect a nd maintain the engine and battery, remove the engine casing as follows:

1. Unscrew the fuel cap/fuel gauge.

2. Carefully lift off the engine casing (fig. 10).

Assembly:

1. Make sure that the front part of the casing fits

into the track in the U-shaped attachment on the

machine (fig. 11).

2. Place the casing over the lip on each side

(fig. 11).

3. Make sure that the pins on the back edge of the

casing go down into the respective holes (fig. 12).

4. Finally, screw in the fuel cap/fuel gauge.

Do not use the machine without first fitting the engine casing, otherwise there

is a risk of burn injuries or crushing accidents.

FILLING THE FUEL TANK

Always use lead-free petrol . Never use oil-mixed

petrol.

NOTE! Bearin mind that petrol is a p erishable; do

not purchase more petrol than can be used within

thirty days.

Environmentally friendly petrol can be used. This

type of petrol has a composition that is less hazardous for people and nature.

CHECKING THE ENGINE OIL LEVEL

On d elivery, the crankcase is filled with SAE 30

oil.

Check the oil level every time before using to

ensurethat it is correct. The machineshould be

standing on level ground.

Wipe clean round the oil dipstick, remove

it and wipe off. Push down the dipstick

fully and screw it back in.

Then unscrew it and pull it up again. Read off the

oil level. Top up with oil to the “FULL” mark, if

the level comes below it (figs. 13 - 15).

CHECKING THE TRANSMISSION

OILLEVEL(President-Royal-Pro16

-Pro18-Pro20)

The transmission is filled with S AE 10W-40 oil

when the machine is delivered from the factory,

Check the oil level every time before using to

ensure it is correct. The machine should be

standing on level ground.

Read off the oil level in the reservoir (fig. 29). It

should be between the MAX and MIN marks.If

necessary,top up with SAE 10W-40(20W-50) oil.

SAFETY SYSTEM

Thismachine is equippedwith a safetysystem that

consists of:

- a switch on the gearbox (only Senator).

- a switch at the brake pedal.

- a switch in the seat mounting (Senator, President) or the seat bracket (other models).

- a switch at the power take-off engagement.

Petrol is highly inflammable. Always

store petrolin containers that aremade

especially for this purpose.

Onlyfill or top up with petroloutdoors,

and never smoke when filling or topping up. Fill w ith petrol before starting

theengine.Neverremovethefillercap

or fill with petrol while the engine is

running or still warm.

Never completely fill the fuel tank. Leave an empty space (= at least the entire filler tube plus 1 - 2

cm at the top of the tank) to allow the petrol to expand when it warms up without overflowing (fig.

28).

12

In order to start the machine, the following are necessary:

- gear lever in neutral (only Senator).

- brake pedal pressed down.

- driver sitting on seat.

- power take-off engagement lever at lowest setting (i.e. power take-off disengaged).

Always check the operation of the safety system before using the machine!

With the engine operating and the driver sitting on

the seat, check in the following way:

- select a gear, lift your weight off the seat – the

engine must stop (applies to Senator).

- press the drive pedal so that the machine starts

Page 12

ENGLISH

GB

to move, release the drive pedal – the machine

must stop (applies to President, Royal, Pro16,

Pro18, Pro20).

- press the drive pedal so that the machine starts

to move, engage the cruise control, lift your

weight off the seat – the machine must stop (applies to Royal, Pro16, Pro18, Pro20).

- press the drive pedal so that the machine starts

to move, engage the cruise control, press the

brakepedal – the machine must stop(applies to

Royal, Pro16, Pro18, Pro20).

- engage the power take-off, lift your weight off

the seat – the engine must stop (applies to Senator, President, Royal, Pro16).

- engage the power take-off, lift your weight off

the seat, the power take-off must be disengaged

(applies to Pro18, Pro20).

Do not use the machine if the safety system does not work! Take the machine to

a service agent for inspection!

STARTING ENGINE

1. Open the fuel cock (fig. 16).

2. Make sure that the sparking plug cable is prop-

erly in place.

in gradually if it has been used.

9. When starting from cold, do not make the machine work under load immediately, but let the engine run for some minutes first. This will allow the

oiltowarmup.

When in use, always operate the engine at full

throttle.

STOPPING

Disengage the power take-off and apply the parking brake.

Allowthe engineto idle1 - 2 mins.Stopthe engine

by turning off the ignition key.

Shut off the petrol cock. This is particularly important if the machine is to be transported on a trailer

for example.

If the machine is left unattended, removethelead fromthesparkplug.Also

removethestarterkey.

The engine may be very warm immediatelyafteritis shut off. Do nottouchthe

silencer, cylinder or cooling flanges as it

can cause burns and injury.

3. Check to make sure that the power take-off is

disengaged.

4a. Senator:

Put the gear lever in neutral

4b. President-Royal-Pro16-Pro18-Pro20:

Do not keep your foot on the drive pedal.

5a. Senator-President:

Starting cold engine – put the throttle control in the

choke position. Starting warm engine – put the

throttle control at full throttle (approx. 1 cm behind

the choke position).

5b. Royal-Pro16-Pro18-Pro20:

Putthethrottlecontrolatfullthrottle.Startingcold

engine – pull the choke control out fully. Starting

warm engine – do not touch the choke control.

6. Depress the brake pedal fully.

7. Turn the starter key and start the engine.

8a. Senator-President:

Once the engine has started, move the throttlecontrol gradually to full throttle if the choke has been

used.

8b. Royal-Pro16-Pro18-Pro20:

Once theenginehasstarted, push the choke control

CATALYTIC CONVERTER (Pro18 Pro20)

The catalytic converter gets very hot during operation. The heat remains for a long time after the engine has been stopped. Be aware of fire risk.

Do not park in close proximity to inflammable objects. Do not c over the

machine until the catalytic converter

has cooled down.

STEERING AID (Pro20)

Built-in function in order to facilitate steering. The

operator only has to turn the steering wheel gently.

An hydraulic torque amplifier creates the remaining force.

As opposed to a normal servo steering (e.g. in a

car), the steering aid has a limited capacity. This

meansthatithas somecharacteristics thatmightbe

considered negative:

- at a low engine rpm or in situations where extra

steering force is needed,steeringcan be considered to be “jumpy”.

- the machine should always be moving when the

steering is used. Avoid turning the steering

13

Page 13

GB

ENGLISH

wheel when the machine stands completely still

and the accessoryis in the lowered working position.

The steering is adapted in order to produce better

results at a normal worki ng speed.

Even when the engine is not running, the steering

works. However, it is harder to turn in this case, if

the machine is to be manoeuvred manually.

OPERATING

Make sure that there is the correct quantity of oil in

the engine when driving on slopes (oil level on

“FULL”).

Be careful when driving on slopes. No

sudden starting or stopping when moving up or down a slope. Never drive

across a slope. Move from the top and

down, and from down to the top.

The machine, equipped with original

accessories must not be driven on slopes

greater than 10º in any direction.

Reduce the spe e d on slopes and when

moving the machine in sharp turns to

prevent the mach i ne from tipping over

or that you lose control over the machine.

Do not turn the steering wheel to full

lock when driving intop gearandatfull

throttle, as the machine can easily topple over.

Keep hands and feet well away from articulated steeringjointandseatbracket

to avoid having them squeezed. Never

operatethemachinewithouttheengine

casing.

SERVICE AND MAINTENANCE

SERVICE PROGRAM

In order to keep the machine in good condition, as

regards reliability and operational safety as well as

from an environmental perspective, STIGA’s service program should be followed.

The contents of this program can be found in the

attached service log.

work is performed by trained personnel and with

original spare parts.

At every service, the service log should be

stamped. A “fully stamped” service log is a valuable document that improves the machine’s secondhand value.

PREPARATIONS

Unless otherwise stated, all service and maintenance must be performed on a machine that is

standing still where the engine is not running.

Prevent the machine from rolling, by always applying the parking brake.

Prevent involuntary engine start by always stopping the engine, loosening the

spark plug cable from the spark ing

plug and earthing it. Remove the minus

(-) cable from the battery.

CLEANING

To reduce the risk of fire, keep the engine silencer/catalytic converter, battery and fuel tank free from grass,

leaves and oil.

To reduce the risk of fire, regularly

check the machine for oil and/or fuel

leakage.

When washingthe machine with water underhigh

pressure, do not point the jet directly at the transmission.

Do not point jets of water directly at the engine,

use a brush or compressed air in order to clean it.

CHANGING ENGINE OIL

Change the oil for the first time after 8 hours running (Senator and President after 5 hours), and

then after every 50 hours running or once a year.

Change oil when the engine is warm.

Always use a good grade of oil (service grade SF,

SG or SH).

Change the oil more often (after 25 hours of running or at least once a season) if the engine has to

operate under demanding conditions or if the ambient temperature is high.

We recommend that an authorised workshop carries out every service. This guarantees that the

14

Page 14

ENGLISH

GB

The engine oil may be very warm if it is

drained off directly after the engine is

shut off. Therefore, allow the engine to

cool a few minutes before draining the

oil.

1. Oil drain pipe (metal):

Unscrew the oil drain plug a t the end of the pipe.

Let the oil run out into a collection vessel. Then

take the oil to a recycling station. Do not allow

oil to get on the V-belts.

2. Screw up the oil drain plug. Make sure that the

fibre gasket and the O-ring inside the plug are not

damaged and that they are in the correct place.

3. Remove the dipstick and fill up with new oil.

Oil capacity:

Senator, President – 1.4 l

Royal – 1.9 l (including oil filter)

Pro16, Pro18, Pro20 - 1.7 l (including oil filter)

Oil type summertime (> 4º C): SAE-30

(SAE 10W-30 can also be used. However, oil consumption may increase somewhat if 10W/30 is

used. Therefore, check the oil level more regularly

if you use this type of oil).

Oil type winter (< 4º C): SAE 5W-30

(if this oil is not available, use SAE 10W-30).

Use oil without any additives.

Do not fill too much oil as this can result in overheating the engine.

After filling up the oil, start the engine and idle for

30 seconds. Stop the engine. Wait for 30 seconds

and then check the oil level.

Check to see if there is any oil leakage. If necessary,filluptheoiluptothe“FULL”mark.

OIL F ILTER - ENG INE (Royal - Pro16

- Pro18 - Pro20)

Replace the oil filter after every 100 hours of operation or once a season.

Before screwing the new fil ter, oil the filter gasket

with engine oil.

Screw the filter by hand, until the filter gasket

touches the filter attachment. Then tighten ½ to ¾

of a full turn (fig. 17 - 18).

Start the engine and idle to see if any leakage occurs. Switch off the engine, check the oil level. If

necessary, fill up the oil up to the “FULL” mark.

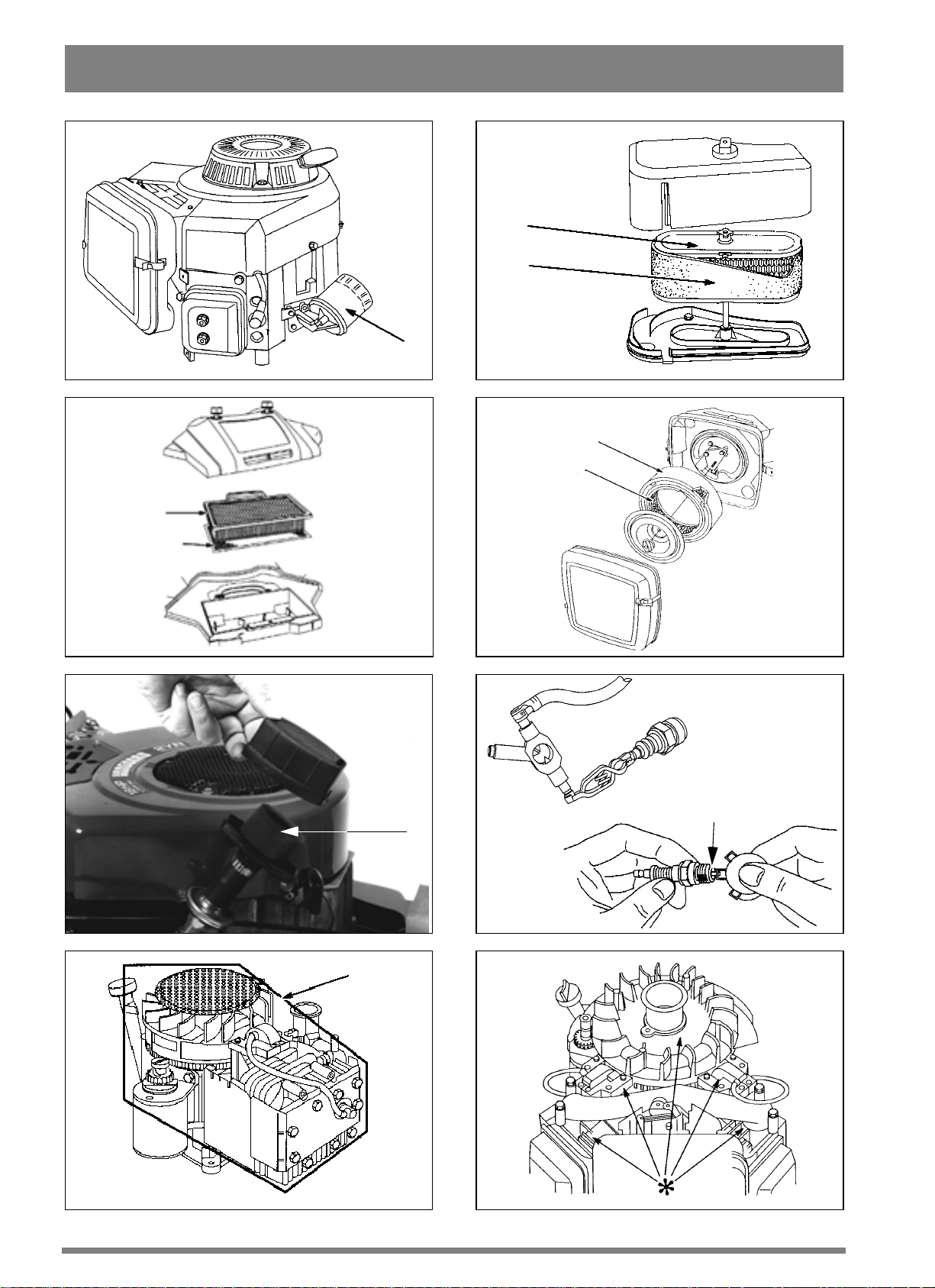

AIRFILTER-ENGINE

Clean the foam pre-filter every 3 months or after

every 25 hours of operation, whichever comes

first.

Clean the paper filter insert once a year or after

every 100 hours of operation, whichever comes

first.

NOTE! The filters should be cleaned more often if

the machine operates on dusty ground.

1. Loosen the wing nut under the fuel tank and

move it backwards (fig. 16). Also loosen the battery to make it easier to get at the air filter (applies

to Pro16-Pro18-Pro20).

2.Remove the protectivecoverof theair filter(fig.

19 - 21).

3. Dismantle the paper filter insert and the foam

pre-filter. Make sure that no dirt gets into the carburettor. Clean the air filter housing.

4. Wash the pre-filter in liquid detergent and water.

Squeeze dry. Pour a little oil on the filter and

squeeze in the oil.

5. Clean the paper filter insert as follows: Knock it

lightly against a flat surface. If the filter is very

dirty, change it.

6. Assemble in the reverse order.

Petroleum-based solvents such as kerosene must

not be used for cleaning the paper filter insert as

these can destroy the filter.

Do not use compressed air for cleaning the paper

filter insert. The paper filter insert must not be

oiled.

AIR FILTER - CATALYTIC CONVERTER (Pro18 - Pro20)

Clean the catalytic converter’s air filter every 3

months or after every 25 hours of operation,

whichever comes first.

1. Remove the cover by pressing in the locking

mechanism with a screwdriver, etc. (fig. 22).

2. Remove the foam filter and wash it in liquid de-

tergent and water. Squeeze dry. Pour a little oil on

the filter and squeeze in the oil.

3. Replace the filter and snap the lock into place.

SPARKING PLUG

Only use a Briggs & Stratton sparking tester to

15

Page 15

GB

ENGLISH

check the spark of the sparking plug(s) (fig. 23).

Clean the sparking plug after every 100 hours of

operation or once a season. For replacing a sparking plug, a sparking plug sleeve A and a torsion pin

B are provided in the accessories bag.

The engine manufacturer recommends:

Senator-President: Champion J19LM

Royal-Pro16-Pro18-Pro20: Champion RC12YC

The correct distancebetween the electrodes is 0.75

mm.

COOLING AIR INTAKE - ENGINE

The engine is air-cooled. A blocked cooling system can damage the engine. The engine should be

cleaned at least once a year or every 100 hours of

operation.

Remove the fan casing. Clean the cooling fins on

the cylinder, the fan and the rotating protective

grille (fig. 24 - 25). Clean more frequently if mowing dry grass.

BATTERY

Senator-President-Royal:

Lubricate the steering cables and steering chain

with universal grease a couple of times per season.

Pro16-Pro18-Pro20:

Apply universal grease to the steering chain a couple of times each season.If the steering chains are

really dirty, dismantle them, wash them and then

grease them once more.

Applyuniversalgrease to all the plasticbearings a

couple of times per season.

Apply a coating of engine oil to the tension arm

joints a couple of times each season.

Apply a few drops of engine oil to both ends of the

throttle control cable a couple of times a season.

Senator:

The transmission is filled with oil (SAE 80W-90)

upon delivery from the factory. If it is not opened

(which must only be done by a specia li st), normally no topping up of oil should be carried out.

STEERING CABLES (Senator President - Royal)

Check the acid level regularly.

The acid level should be between “UPPER “ and

“LOWER” on the battery. When adjusting the level, only use distilled water (battery water).

The battery acid is extremely corrosive

and can cause burns and injuries to

skin and clothing. Always use rubber

gloves and glasses (goggles) to protect

the eyes. Avoid inhaling any acid vapour.

Do not incline the battery too much so

that the battery acid can run out on to

hands and clothing. If this should happen, flush with lots of water.

If the batteryterminals are coatedwith oxide, they

shouldbecleaned.Clean thebatteryterminals with

a wire brush and grease them.

LUBRICATION - CHASSIS

The machine’s articulated steering joint has four

grease nipples that should be lubricated with universal grease after every 25 hours of operation

(fig. 26).

Please note that the fourt h grease nipple is not

shown onthepicture. Itislocated ontheunderside,

on the flexible axle’s front bearing.

The steering cables should be adjusted for the first

time after the machine has been in operation for 2

- 3 hours, and then after every 25 hours of opera-

tion.

Put the machine in the straight-ahead position.

Tensionthesteeringcablesbytighteningupthe

nuts that are located on the underside of the articulatedsteeringjoint(fig. 27).Thescrews inthe ends

ofthecablesshouldbeheldfirmlyduringadjustment so that the cables are not twisted. Use an adjustable wrench or similar for this purpose,

inserting it in the key handles in the ends of the

screws. Tension the cables until they are no longer

slack.

Adjust both the nuts the same amount to ensure

that the alignment of the steering wheel is not

changed.

Once the adjustment is complete, turn the steering

wheel as far as it will go in either direction. Check

that the chain does not come into contact with the

pulley, and that the cables do not become entangled with the steering pinions.

Do not tension the steering cables too hard. Otherwise the steering will be heavy and wear and tear

on the cables will increase.

16

Page 16

ENGLISH

STEERING CHAINS (Pro16 - Pro18 Pro20)

Adjust the steering chains after every 50 hours of

operation.

Put the machine in the straight-ahead position.

Tension the steering chains by tightening up the

nuts that are located on the underside of the articulated steering joint (fig. 27). Tension until all play

is removed.

Adjust both the nuts the same amount to ensure

that the alignment of the steering wheel is not

changed.

Do not over-tighten the steering chain. This will

cause the steering to become heavy and will increase wear on the steering chain.

GB

PATENT –

PROTECTION OF DES IGNS

This machine, or parts thereof, is protected by the

following patent and protection of design:

9900627-2 (SE), SE00/00250 (PCT), 9901091-0

(SE), SE00/00577 (PCT), 9901730-3 (SE), SE00/

00895 (PCT), 9401745-6 (SE), SE95/00525

(PCT), 595 7497 (US), 95920332.4 (EPC).

99 1095 (SE), 499 11 740.9 (DE), M1990 000734

(IT), 577 251-253 (FR ), 115325 (US).

STIGA reserves the right to modify the product without giving any prior notice.

17

Loading...

Loading...