Page 1

STIGA PARK

PRO 18

PRO 16

PRESIDENT

CLASSIC

8211-0211-06

Page 2

7. Park Classic-President 11.

8. Park Pro16-Pro18

9. Park President

10. Park Pro16-Pro18

12. Park Classic-President

13. Park Pro16-Pro18

14. Park President

Page 3

15. Park Pro16-Pro18

20. Park Pro16-Pro18

16. Park Pro16-Pro18

17.

19. Park Classic-President

21. Park Classic-President

18.

22. Park Pro16-Pro18

23.

Page 4

27. Park President-Pro16-Pro18

31. Park President

28. Park Classic-President

29. Park Classic

30. Park Classic 34.

32. Park Pro16-Pro18

33. Park Pro16-Pro18

Page 5

24. Park Classic

25. Park President

26. Park Pro16-Pro18

Page 6

9

1

11

10

4

1. Park Classic

3. Park President-Pro16

8

2

9

1

13

2. Park Classic

11

3

7

12

15

2

14

7

19

13

16

6

85

9

4. Park President-Pro16

3

17

18

12

14

15

20

5. Park Pro18

5

6. Park Pro18

11

2

13

3

Page 7

GB

ENGLISH

GENERAL

This symbol indicates WARNING. Personal injury and/or damage to property

may result if the instructions are not

followed carefully.

You must read these instructions for

use and the accompanying pamphlet

"SAFETY INSTRUCTIONS" carefully before starting up the machine.

SYMBOLS

The following symbols are displayed on the machine in order to remind you about the safety precautions and attention necessary when using the

machine.

The symbols mean:

Warning!

Read the instruction book and safety manual before using the machine.

Warning!

Beware of objects being flung out. Keep

spectators away.

Warning!

Always use hearing protectors (earplugs

or muffs).

Warning!

This machine is not designed to be driven

on public roads.

CONTROLS

Items 1 - 20, see figures 1 - 6.

1. IMPLEMENT RAISING LEVER (not

Pro18)

A lever for raising front-mounted accessories to the

transport position.

2. SERVICE BRAKE

A pedal that acts on the machine's braking system.

There are two positions:

1. Pedal released - service brake

not activated.

2. Pedal fully depressed - service

brake fully activated. (PresidentPro: forward drive also released.

Classic:

The engine is provided with automatic governor

control. This means that the engine speed increases

under load. For this reason, you must disengage the

forward drive before braking the machine.

Press both the brake and clutch pedals when you

want to brake or stop the machine. Never brake the

machine without first de-clutching

3. PARKING BRAKE

An inhibitor that can lock the brake pedal in the depressed position.

Depress the brake pedal fully. Move the

brake inhibitor to one side and then release

the brake pedal.

The parking brake is released by pressing the brake

pedal lightly. The spring-loaded inhibitor slides to

one side.

Make sure the parking brake is released when operating the machine.

4. CLUTCH (Classic)

A pedal used for engaging and disengaging the

drive to the mechanical gearbox. Two positions:

1. Pedal released - forward drive

engaged. The machine will move

if a gear is engaged.

2. Pedal depressed - forward

drive released, gearshifting can

be performed.

NOTE! You must never regulate the operating

speed by slipping the clutch. Use a suitable gear instead so that the right speed is obtained.

5. DRIVE PEDAL (President - Pro16 Pro18)

A pedal that activates the variable transmission.

1. Depress the pedal with the ball

of the foot - the machine moves

forwards.

2. No load on the pedal - the machine is stationary.

3. Depress the pedal with the heel

- the machine reverses.

The speed is regulated by the drive pedal. The more

pressure applied, the faster the machine will move.

Page 8

ENGLISH

GB

6. DISENGAGING LEVER (President Pro16 - Pro18)

A lever for disengaging the variable transmission.

Enables the machine to be moved by hand without

the help of the engine. (Note that, on the Pro16Pro18, the lever is on the left-hand side.) There are

two positions:

1. Lever moved back - transmission engaged for normal operation.

2. Lever moved forward - transmission disengaged. The machine can be moved by hand.

To avoid damage to the transmission, do not tow the

machine for any great distance.

7. POWER TAKE OFF - IN (not Pro18)

A lever for engaging the power take-off for driving

front-mounted accessories. There are two positions:

1. Lever in lower position - power take-off

disengaged.

2. Lever in upper position - power take-off

engaged. The lever is locked in this position if a person weighing more than 30 kg

is sitting on the seat.

8. POWER TAKE OFF - OUT (not

Pro18)

A spring-loaded lever for disengaging the power

take-off.

Press the button to disengage the

powertake-off.

9. SEAT SUSPENSION

Rotary control for variable adjustment of the seat

suspension. Adjust to weight of driver.

1. Turning counter-clockwise suspension will become softer.

2. Turning clockwise - suspension will become harder.

If the suspension is tightened too hard it could

mean that the lever for engaging the power takeoff (7) cannot be locked in its upper position.

NOTE! To prevent a deterioration in mobility,

do not over tighten the screw joints in the seat

suspension.

10. GEAR LEVER (Classic)

A lever for selecting one of the five forward gears

in the gearbox (1-2-3-4-5), neutral (N), or reverse

(R).

The clutch pedal must be kept depressed when

changing gear.

NOTE! You must make sure the machine is quite

stationary before changing from reverse to forward

gear or vice versa. If a gear does not engage immediately, release the clutch pedal and depress it

again, and then engage the gear once again. Never

force a gear in.

11. THROTTLE/CHOKE CONTROL

A control for setting the engine speed and to choke

the engine when starting from cold. (The latter

does not apply to Pro16-Pro18, which has a separate choke control - see item 12).

1. Choke - for starting a cold engine.

Choke located in top of groove (does not

apply to Pro16-Pro18).

2. Full throttle - when the machine is in

operation, full throttle should always be

used. Full throttle positioned 1 - 1.5 cm

from the top edge of the groove.

3. Idle.

12. CHOKE CONTROL (Pro16 Pro18)

A pull-type control to choke the engine when starting from cold.

1. Control fully pulled out - choke valve in

carburettor closed. For starting cold engine.

2. Control pushed in - choke valve open.

For starting warm engine and when operating the machine.

Never operate the machine with the choke pulled

out when the engine is warm.

13. STARTER KEY

An ignition key used for starting and stopping the

engine. There are three positions:

1. Stop position - engine short circuited.

STOP

The key can be be removed.

Page 9

GB

ENGLISH

2. Drive position (without symbol).

3. Start position - the electric starter motor

START

is activated when the key is turned to the

spring-loaded start position. Once the engine has started, allow the key to return to

the drive position.

A spare key is enclosed in the plastic bag that also

includes this "instructions for use". Keep this key

in a safe place.

14. CRUISE CONTROL (Pro16 Pro18)

A switch for activating the cruise control. The

function of the cruise control allows the drive pedal (5) to be locked in the desired position. You do

not need to use the right foot.

1. Depress the drive pedal until the desired

speed is achieved. Then press the rear part

of the switch to activate the cruise control.

The symbol will light up green.

2. Disengage the cruise control by pressing the front part of the switch.

15. LIGHT SWITCH (not Classic)

A pull-type switch for the halogen headlamp. The

headlamp works only when the engine is running there is no load on the battery. There are two positions:

1. Switch pulled out - headlamp "on".

2. Switch pushed in - headlamp "off".

16. POWER TAKE OFF (Pro18)

Circuit-breaker for engaging and disengaging the

electromagnetic power take-off.

1. Press the lower part of the circuit-breaker - the power take-off will be engaged.

The symbol will indicate green.

2. Press the upper part of the circuit-breaker - the power take-off will be disengaged.

17. HOUR METER (Pro18)

Indicates the number of operating hours. Works

only when the engine is running.

18. ELECTRIC LIFTER (Pro18)

Switch (red symbol) for controlling the frontmounted, electric lifter.

1. Press the upper part of the switch - the lifter will

be lowered to the working position.

2. Press the lower part of the switch - the lifter will

be raised to the transport position.

19. EL. CUTTING HEIGHT ADJUSTMENT (Pro18)

The machine has been designed for electrical adjustment of the cutting height (available as an accessory).

A connection plug is located on the right hand side,

in front of the front wheel.

The switch (orange symbol) is used to adjust the

cutting height up or down in continuously variable

positions.

20. REAR RAKE (Pro18)

The machine has been designed for the use of a

rear rake, which can be raised and lowered electrically (available as an accessory).

Connection cables are located at the rear of the machine, under the solenoid.

The switch (blue symbol) is used for raising or

lowering the rear rake.

OPERATING THE MACHINE

AREAS OF USE - PARK

The machine may only be used for the following

tasks using the STIGA accessories stated:

1. Mowing

Using mower deck 13-2922 (100B), 13-2913

(102M), 13-2917 (110S), 13-2915/13-2921

(121M) or flail mower 13-1977.

2. Sweeping

Using brush unit 13-1933 or collector brush

unit 13-1939. Use of dust guard 13-1936 is recommended with the first option.

3. Snow clearance

Using snow blade 13-1916 or snow thrower

13-1948. Snow chains 13-1956 and wheel

weights 13-1982 are recommended.

4. Grass clipping and leaf collection

Using towed collector 13-1978 (30") or

13-1950 (42").

Page 10

ENGLISH

GB

5. Grass and leaf transport

Using dump cart 13-1979 (Standard) or

13-1988 (Maxi).

6. Fertiliser spreading

Using fertiliser spreader 13-1987. Can also be

used for spreading grass seed.

7. Sand spreading

Using sand spreader 13-1975. Can also be used

for spreading salt. Snow chains 13-1956 and

wheel weights 13-1982 are recommended.

8. Weeding on gravel paths

Using front mounted hoe 13-1944 and rear

mounted rake 13-1969.

9. Lawn edge trimming

Using edge trimmer 13-1972.

10.Moss scarification

Using flail mower 13-1977 equipped with

special moss scarifier 13-1986.

The maximum vertical load on the towing hitch

must not exceed 100 N.

The maximum over-run load on the towing hitch

from towed accessories must not exceed 500 N.

GENERAL

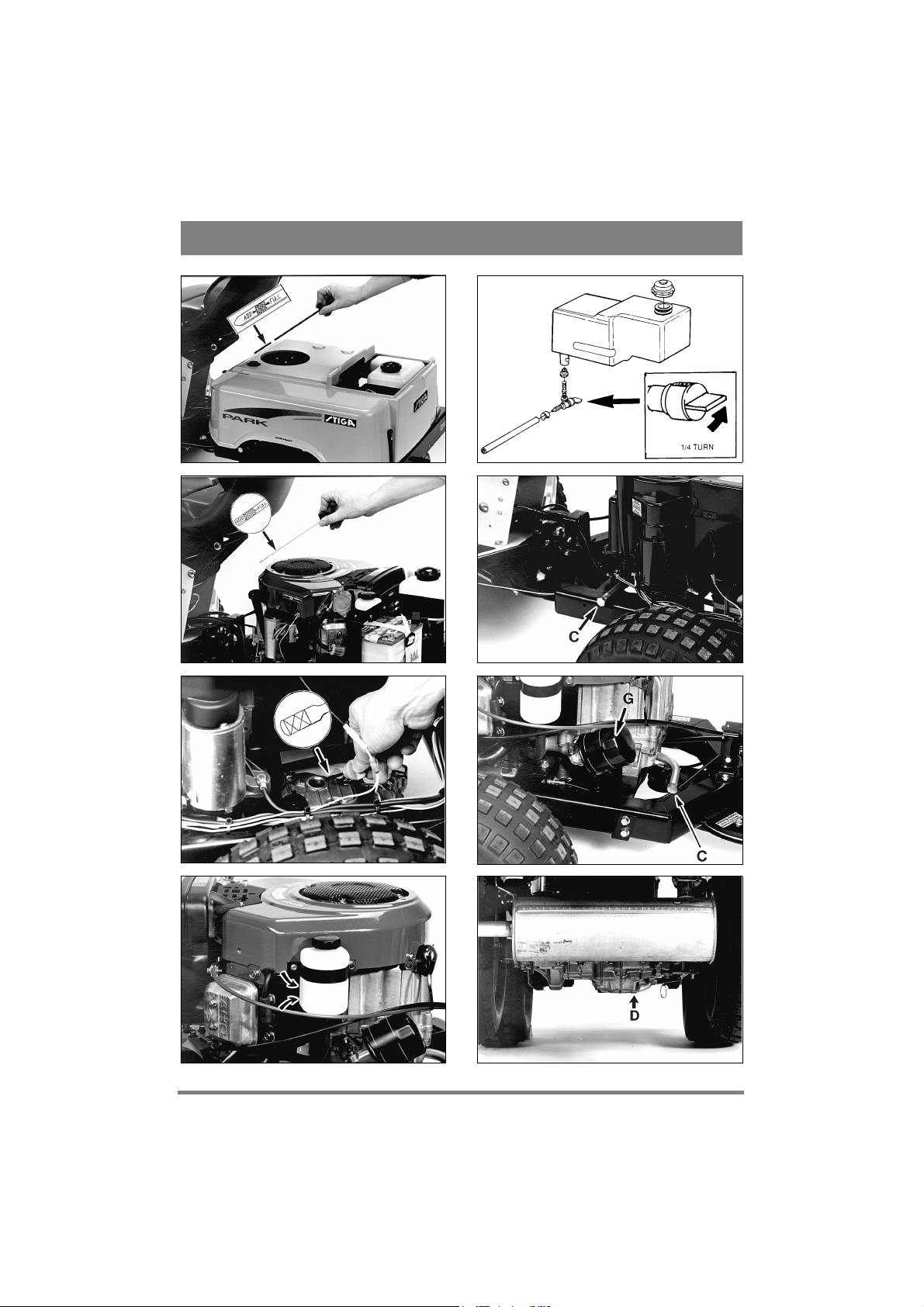

You can fill with fuel and check the oil level in the

engine by removing the engine cover. You do this

by lifting it upwards and backwards (fig 34).

NOTE that, to check the oil level on the Pro16Pro18 models, you must remove the entire engine

casing.

Do not use the machine without first fitting the engine casing, otherwise there

is a risk of burn injuries or crushing accidents.

FILLING THE FUEL TANK

Always use lead-free petrol. Never use

oil-mixed petrol.

NOTE! Bear in mind that petrol is a perishable, do

not purchase more petrol than can be used within

30 days.

Petrol is highly inflammable. Always

store petrol in containers that are made

specially for this purpose.

Fill or top up with petrol only outdoors,

and never smoke when filling or topping up. Fill with petrol before starting

the motor. Never remove the filler cap

or fill with petrol while the motor is

running or still warm.

CHECK THE ENGINE OIL LEVEL

On delivery the crankcase is filled with SAE 30

oil.

Check the oil level every time before using to

ensure it is correct. The machine should be

standing on level ground.

Wipe clean round the oil dipstick, remove

it and wipe off. Push down the dipstick

fully and screw it in.

Then unscrew it and pull it up again. Read off the

oil level. Top up with oil to the “FULL” mark if the

level comes below it (fig 7 - 8).

CHECKING THE TRANSMISSION

OIL LEVEL (President- Pro16 Pro18)

The transmission is filled with SAE 20W-50 oil

when the machine is delivered from the factory,

Check the oil level every time before using to

ensure it is correct. The machine should be

standing on level ground.

President:

Unscrew the oil dipstick (fig 9). Read off the oil

level. It should be within the xx markings.

Pro16-Pro18:

Read off the oil level in the reservoir (fig 10). It

should be between the MAX and MIN marks.

If necessary, top up with SAE 20W-50 oil.

It is important that you observe cleanness when handling oil for the transmission. There must not be any particles of

dirt in the system as dirt can easily

cause total failure of the transmission.

SAFETY SYSTEM

This machine is equipped with a safety system that

consists of:

- a switch on the gear box (only Classic)

- a switch at the brake pedal

- a switch in the seat mounting

- a switch at the power take-off engagement

Page 11

GB

ENGLISH

lever (only US and Canada)

In order to start the machine the following are necessary:

- gear lever in neutral (only Classic)

- brake pedal depressed

- driver sitting on seat

- power take-off engagement lever at lowest

setting (i.e. power take-off disengaged)

Always check the operation of the safety system before using the machine!

Check in the following way:

- start the engine, sit on the seat, select a gear,

lift your weight off the seat - the engine must

stop (applies to Classic)

- start the engine, sit on the seat, press the drive

pedal so that the machine starts to move, release

the drive pedal - the machine must stop (applies

to President)

- start the engine, sit on the seat, press the drive

pedal so that the machine starts to move, engage

the cruise control, lift your weight off the seat the machine must stop (applies to Pro16 Pro18)

- start the engine, sit on the seat, press the drive

pedal so that the machine starts to move, engage

the cruise control, press the brake pedal - the

machine must stop (applies to Pro16 - Pro18)

- start the engine, sit on the seat, engage the

power take-off, lift your weight off the seat - the

power take-off must be disengaged (all models)

Do not use the machine if the safety system does not work! Take the machine to

a service agent for inspection.

STARTING ENGINE

1. Open the fuel cock (fig 11).

2. Make sure that the sparking plug cable is prop-

erly in place.

3. Check to make sure the power take-off is en-

gaged.

4a. Classic:

Put the gear lever in neutral.

4b. President-Pro16-Pro18:

Do not keep your foot on the drive pedal.

5a. Classic-President:

Starting cold engine - put the throttle control in the

choke position. Starting warm engine - put the

throttle control at full throttle (1 - 1.5 cm below the

choke position).

5b. Pro16-Pro18:

Put the throttle control at full throttle. Starting cold

engine - pull the choke control out fully. Starting

warm engine - do not touch the choke control.

6. Depress the brake pedal fully.

7. Turn the starter key and start the engine.

8a. Classic-President:

Once the engine has started, move the throttle control gradually to full throttle if the choke has been

used.

8b. Pro16-Pro18:

Once the engine has started, push the choke control

in gradually if it has been used.

9. When starting from cold do not make the machine work under load immediately, but let the motor run for some minutes first. This will allow the

oil to warm up.

STOPPING

Disengage the power take-off and apply the parking brake.

Allow the engine to idle for 1 - 2 minutes. Stop the

engine by switching off the ignition key.

Shut off the petrol cock. This is particularly important if the machine is to be transported on a trailer,

for example.

If the machine is left unattended to, remove the lead from the spark plug. Also

remove the starter key.

The engine may be very warm immediately after it is shut off. Do not touch the

silencer, cylinder or cooling flanges as it

can cause burns and injury.

Machines with catalytic converters:

The catalytic converter gets very hot during operation. The heat remains for a long time after the engine has been stopped.

Avoid risk of fire:

- do not park in close proximity to inflammable

objects.

- do not cover the machine until the catalytic converter has cooled down.

OPERATING

Make sure that there is the correct quantity of oil in

the engine when driving on slopes (oil level on

Page 12

ENGLISH

GB

“FULL”).

Be careful when driving on slopes. No

sudden starting or stopping when moving up or down a slope. Never drive

across a slope. Move from the top and

down, and from down to the top.

The machine, equipped with original

accessories, must not be driven on

slopes greater than 10° in any direction.

Reduce the speed on slopes and when

moving the machine in sharp bend-like

patterns to prevent the machine from

turning over or you losing control over

the machine.

NOTE! Before using a trailer, contact your insurance company.

NOTE! This machine is not designed to be driven

on public roads.

Do not turn the steering wheel to full

lock when driving in top gear and with

full throttle as the machine can easily

topple over.

Keep hands and feet well away from the

articulated steering joint and seat

bracket to avoid having them squeezed.

Never operate the machine without the

engine casing.

When in operation always run the engine at full

throttle.

MAINTENANCE

No service should be carried out on the

machine unless:

- the engine has been stopped

- the ignition key has been removed

- the spark plug cable has been removed

from the sparking plug

- the parking brake is applied

- the power take-off is disengaged

CLEANING

To reduce the risk of fire:

- keep the engine, silencer, battery and

fuel tank free from grass, leaves and oil.

- regularly check the machine for oil

and/or fuel leakage.

NOTE! When washing the machine with water un-

der high pressure, do not point the jet directly at the

transmission.

CHANGING ENGINE OIL

Classic-President:

Change the oil for the first time after 5 hours running and then after every 50 hours running or once

a year. Change oil when the engine is warm.

Always use a good grade of oil (service grade SE,

SF or SG).

Pro16-Pro18:

Change the oil for the first time after 8 hours running and then after every 50 hours of running or

once a month. Change oil when the engine is

warm.

Always use a good grade of oil (service grade SE,

SF or SG).

Classic-President-Pro16-Pro18:

Change the oil after every 25 hours of running, or

once a week if the motor has to operate under demanding conditions or if the ambient temperature

is high.

The engine oil may be very warm if it is

drained off directly after the engine is

shut off. Therefore, allow the engine to

cool a few minutes before draining the

oil.

1. Screw out the oil drain plug C (fig 12 - 13). Let

the oil run out into a collection vessel. Do not allow oil to get on the v-belts.

2. Screw in the plug again.

3. Remove the dipstick and fill up with new oil.

Oil Capacity:

Classic - 1,4 litres

President - 1,4 litres

Pro16, Pro18 - 1,4 litres, when the oil filter is not

replaced. 1,7 litres, when the filter is replaced.

Oil type summer: SAE-30

(SAE 10W-30 can also be used. However, oil consumption may increase somewhat if 10W-30 is

used. Therefore check the oil level more regularly

if you use this type of oil).

Oil type winter: SAE 5W-30

(if this oil is not available, use SAE 10W-30).

Use oil without any additives.

Do not fill too much oil as this can result in overheating of the engine.

Page 13

GB

ENGLISH

Check the oil every time when topping up. The

level should come up to the “FULL” mark.

CHANGING THE TRANSMISSION

OIL (President - Pro16 - Pro18)

Change the oil the first time after 50 hours of operation, and then after every 250 hours or operation

or once a season.

Use a good grade of SAE 20W-50 oil (service

grade SE, SF or SG).

Total amount of oil:

President - 1.6 litres

Pro16, Pro18 - 3.3 litres

NOTE that the design of the transmission permits only about 80% of the total amount of oil

to run out when the oil is changed.

After filling the transmission with oil, the oil

which is left in the transmission mixes with the

new oil.

You should, therefore, not pour in too much oil

when you change the oil. Check the oil level several times while filling.

It is important that you observe cleanness when handling oil for the transmission. There must not be any particles of

dirt in the system as dirt can easily

cause total failure of the transmission.

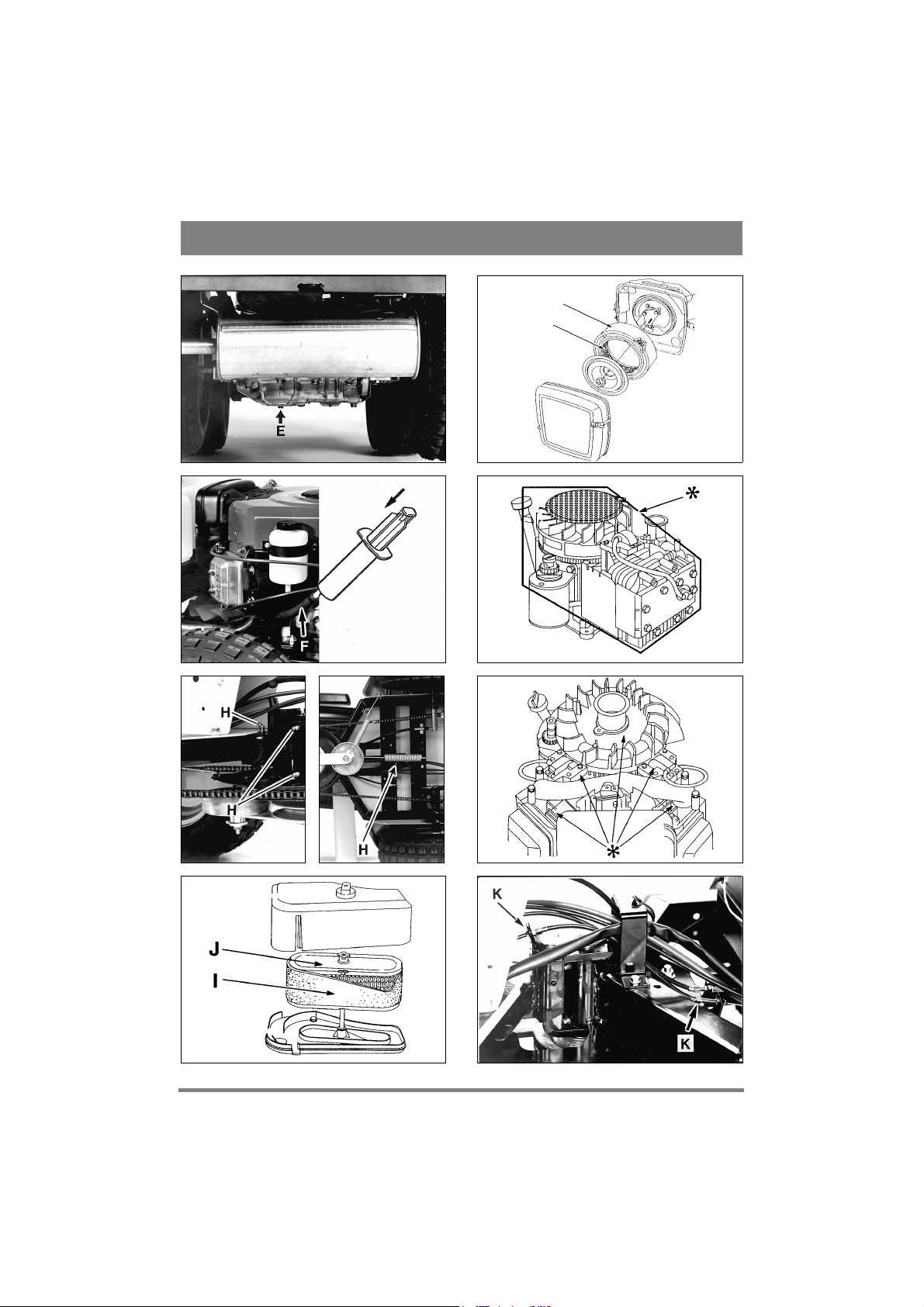

President:

1. Unscrew the oil drain plug D. This is located to

the right as viewed from the rear (figs 14 and 25).

Allow the oil to run out into a collection vessel.

2. Screw the oil drain plug back into place.

3. Remove the oil dipstick and top up with new oil.

Pro16-Pro18:

1. Remove the oil reservoir cover (fig 10).

2. Unscrew the oil drain plug E. This is located to

the left as viewed from the rear (figs 15 and 26).

Allow the oil to run out into a collection vessel.

3. Screw the oil drain plug back into place.

4. Remove hose F from the lower side of the oil

reservoir (fig 16).

5. To facilitate filling up the oil, we recommend

that you use, for example, a pump (figure 16 shows

a STIGA pump, part number 1134-3898-01).

6. Fill the pump with oil. Then insert the nipple

into the hose F and slowly press the oil into the

transmission.

7. Connect the hose to the oil reservoir.

8. Finally, fill the oil reservoir with oil.

AIR BLEEDING (President - Pro16 Pro18)

After filling with oil, it may be necessary to bleed

the transmission.

1. Raise the rear part of the machine to enable the

drive wheels to rotate freely.

2. Start the engine and allow it to idle.

3. Press the drive pedal down forwards and back-

wards alternately.

4. When the drive wheels start to rotate, lower the

machine down onto its wheels.

5. Push the machine backwards while pushing the

front part of the drive pedal down. Then push the

machine forwards while pushing the rear part of

the drive pedal down.

6. When the machine starts to move, put the throt-

tle control at full throttle.

7. Start and stop the machine rapidly until its speed

is normal.

Remarks: Initial bleeding can be made as early as

when filling with oil. While filling, rotate the

transmission's belt pulley by hand.

REPLACING ENGINE OIL FILTER

(Pro16 - Pro18)

Replace the oil filter after every 100 hours of operation.

Before screwing the new filter securely into place,

oil the filter gasket with motor oil.

Screw the filter G securely by hand until the filter

gasket touches the filter attachment. Then tighten

three-quarters of a full turn (fig 13).

Start the engine and run it for 30 seconds. Then

switch off the engine. Check the oil level. If the oil

level is below the “FULL” mark on the dipstick,

top up with oil.

Start the engine and check for any oil leakage.

LUBRICATION

The machine has four grease nipples H which

should be lubricated with universal grease every

Page 14

ENGLISH

GB

25 hours running (fig 17 - 18).

All plastic bearings should be lubricated twice

each season.

Apply universal grease to the steering chain a cou-

ple of times each season. If the steering chain is really dirty, dismantle it, wash it, and then grease it

once more.

Apply a coating of engine oil to the tension arm

joints twice each season.

Apply a few drops of engine oil on both ends of the

throttle control cable a couple of times a season.

Classic:

The transmission is filled with oil (SAE 80W-90)

on delivery from the factory. If it is not opened

(which must only be done by a specialist), no topping up with oil should normally be done.

BATTERY

Check the acid level regularly.

The acid level should be between “UPPER” and

“LOWER” on the battery. When adjusting the level only use distilled water (battery water).

The battery acid is extremely corrosive

and can cause burns and injury to skin

and clothing. Always use rubber gloves,

and glasses (goggles) to protect the eyes.

Avoid inhaling any acid vapour.

Do not incline the battery too much so

that the battery acid can run out on to

hands or clothing. If this should happen, flush with lots of water.

If the battery terminals are coated with oxide they

should be cleaned. Clean the battery terminals with

a wire brush and grease them.

AIR FILTER

Clean the foam pre-filter I every 3 months or after

every 25 hours of operation, whichever comes

first.

Clean the paper filter insert J once a year or after

every 100 hours of operation, whichever comes

first (fig 19 - 20).

NOTE! The filter should be cleaned more often if

the machine operates on dusty ground.

1. Remove the protective cover of the air filter and

the foam plastic filter.

2. Wash the pre-cleaner in liquid detergent and wa-

ter. Squeeze dry. Pour a little oil on the filter and

squeeze in the oil.

3. Loosen and remove the nut which hold the paper

filter. Lift our the paper filter and thoroughly clean

the air filter housing to prevent dirt from entering

the carburettor.

4. Clean the paper filter as follows: Knock it light-

ly against a flat surface. If the filter is very dirty,

change it.

5. Assemble in the reverse order.

Petroleum-based solvents such as kerosene must

not be used for cleaning the paper filter as these

can destroy the filter.

Do not use compressed air for cleaning the paper

filter. The paper filter must not be oiled.

COOLING AIR INTAKE

The engine is air-cooled. A blocked cooling system can damage the engine. The engine should be

cleaned at least once a year or every 100 hours running.

Remove the fan casing. Clean the cooling fins on

the cylinder, the fan and the rotating protective

grille (fig 21 - 22). Glean more frequently if mowing dry grass.

SPARKING PLUG

An oily and sooty sparking plug with burnt electrodes makes the engine difficult to start.

Clean the plug with a wire brush (do not sandblast) and reset the spark gap to 0.75 mm.

Replace the sparking plug if the electrodes are badly burnt. For replacing a sparking plug, a sparking

plug sleeve AC and torsion pin AD are provided in

the plastic bag containing accessories.

The engine manufacturer recommends:

Classic-President: Champion J19LM.

Pro16-Pro18: Champion RC12YC

CARBURETTOR

The carburettor is positioned at the factory and adjustment should not be necessary.

If the carburettor after all has to be adjusted, contact a service station.

Page 15

GB

ENGLISH

ADJUSTING POWER TAKE - OFF

CABLE (not Pro18)

If the v-belt between the engine belt pulley and

centre belt pulley slips when the power take-off is

engaged, the power take-off cable can be tensioned

by means of the two cable adjusters K (fig 23).

REPLACING THE V - BELTS

You can replace the v-belts while the machine is

standing on its wheels.

Remark: To illustrate how to replace v-belts the

machines are shown here from below and on there

sides (figs 24 - 26).

Always use genuine belts. They will fit properly

and last longest.

V-BELT ENGINE - POWER TAKE-OFF

The power take-off referred to here is the double

belt pulley L which is located in the middle of the

machine and is used to drive the cutter deck/accessory by means of a separate v-belt.

1. Remove the v-belt which runs from the power

take-off to the cutter deck/accessory.

2. Unscrew the tension roller M.

3. Crank off the v-belt from the lower belt groove

N on the engine belt pulley.

4. Remove the v-belt from the upper belt groove on

the power take-off.

5. Replace the v-belt and assemble in the reverse

order.

V-BELT ENGINE - TRANSMISSION

1. Remove the v-belt from between the engine and

power take-off. See above.

2a. Classic:

Keep the left-hand pedal (clutch pedal) pressed

down.

2b. President-Pro16-Pro18:

Keep the left-hand pedal (brake pedal) pressed

down.

3. Classic:

Slacken the belt guides on the transmission belt

pulley and turn them aside.

4. Unscrew the tension roller O.

5. Crank off the v-belt from the transmission belt

pulley. (Pro16-Pro18: Run the v-belt through the

fan.)

6. Remove the v-belt from the upper belt groove N

on the engine belt pulley.

7. Replace the v-belt and assemble in the reverse

order.

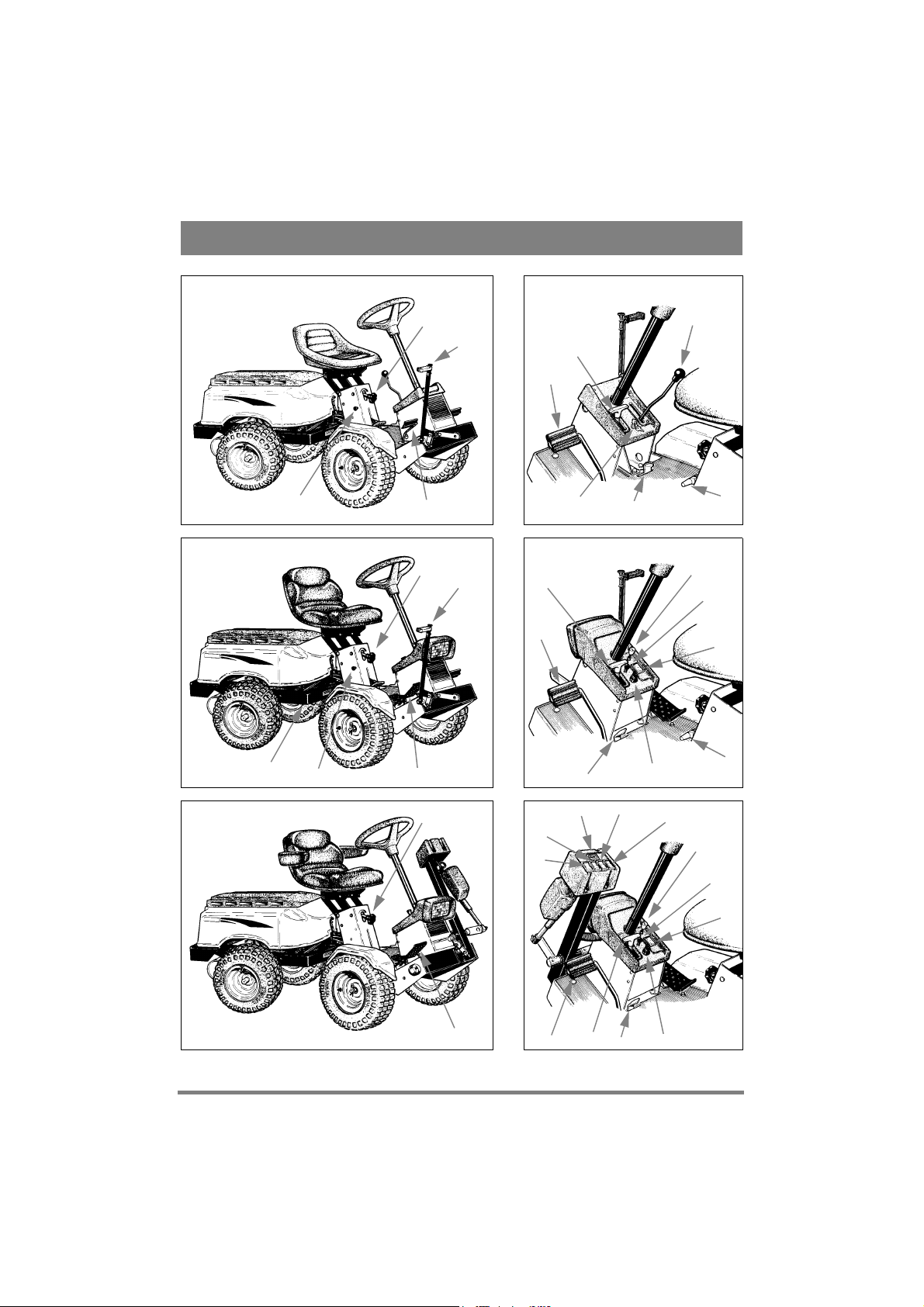

ADJUSTING GEAR POSITIONS

(Classic)

If the gear positions do not agree with the markings on the instrument panel the gear control cable can be adjusted at the elbow links P on the cable (fig 24).

ADJUSTING CLUTCH (Classic)

The clutch cable should be adjusted so that there is

a play of about 10 mm on th clutch pedal. The

clearance is adjusted with the cable adjusters Q on

the clutch cable (fig 24).

ADJUSTING THE DRIVE PEDAL

(President - Pro16 - Pro18)

When the transmission is in neutral (the machine is

stationary) the drive pedal should be adjusted in

such a way that the gap between the front part of

the pedal and the floor plate is 85 - 90 mm, and the

gap between the rear part of the pedal and the floor

plate is 50 - 55 mm (see fig 27).

You can adjust the position of the pedal in both

ends of the cable:

1. Slacken the elbow link R at the drive pedal and/

or at the transmission unit (figs 25 - 26).

2. Adjust the position of the drive pedal by screw-

ing the elbow link out or in on the cable.

3. Then screw the elbow link securely into position

again at the drive pedal/transmission unit.

PEDAL STOP

It is important that the pedal stop is adjusted correctly after the cable is replaced or adjusted. If it is

not, the transmission can be seriously damaged.

1. Screw the pedal stop S down as far as it can go

(fig 27).

2. Then press the front part of the drive pedal until

it resists (= end position of transmission).

3. Then release the front part of the drive pedal by

about 5 mm.

4. Screw the pedal stop up until it touches the low-

Page 16

ENGLISH

GB

er side.

5. Tighten the pedal stop locking nut.

The forward movement of the drive

pedal must not be restricted by the end

position of the transmission, otherwise

serious damage may arise.

6. Then adjust the pedal stop under the rear part of

the drive pedal. The backward movement of the

drive pedal should be about half the forward movement.

STEERING CABLES (Classic President)

After the machine has been in operation for a few

hours the steering cables should be adjusted.

Put the machine in the straight ahead position.

Tension the steering cables by tightening up the

nuts at T. The screws in the ends of the cables

should be held firmly during adjustment. Use an

adjustable wrench or similar for the purpose, inserting it in the key handles in the ends of the

screws (fig 28).

Adjust both cables so that the distance between the

pulley at U and the chain is the same on both sides

of the machine.

Tension the cables until they are no longer slack.

Once adjustment is complete, turn the steering

wheel as far as it will go in either direction. Check

that the chain does not come in contact with the

pulley, and that the cables do not become entangled with the steering pinions.

ADJUSTING STEERING CHAIN

(Pro16 - Pro18)

The steering chain must be adjusted after every 50

hours of use.

Put the machine in a "straight on" position.

Tension the steering chain by tightening the nuts T

(fig 33). Adjust until all play is removed.

Do not over-tighten the steering chain. This will

cause the steering to become heavy and increase

wear on the steering chain.

ADJUSTING THE BRAKE

Do not adjust the brake so hard that it 'locks' when

the brake pedal is not pressed and while the machine is in operation.

Classic:

Adjust the brake cable on the cable adjusters V so

that the brake arm is about 1 mm from the stop

when the brake pedal is in the released position

(figs 24 and 29 - 30).

Slacken the lock nut and screw in the adjusting nut

X (fig 30). Tighten the lock nut.

President:

Adjust the brake cable to allow about 10 mm play

in the brake pedal. Adjust the play by means of the

cable adjusters Y (figs 25 and 31).

After adjustment, make sure the clutch

is always activated before the brake.

If it is not, adjust the separate clutch cable W (fig

25).

Pro16-Pro18:

Adjust the combined brake/clutch cable to allow

about 10 mm play in the brake pedal. Adjust the

play by means of the cable adjusters Y (fig 26).

When adjusting, make sure the cable's

clutch function is always actived before

the brake function.

Then adjust the brake drum with the help of the adjusting nut Z (fig 32).

STIGA reserves the right to make changes in the product

without prior notice.

Page 17

GB

ENGLISH

EC - DECLARATION OF

CONFORMITY

Model: Park

Type: P401

Art. no.: 13-1258, 13-1358, 13-1458, 13-1818,

Serial no.: See machine

Manufact.: STIGA AB, P.O. Box 1006,

Product: Lawn mower with combustion engine

This product complies with the following:

- Electromagnetic Compatibility Directive 89/336/EEC

- Machine Directives 89/392/EEC, 91/386/EEC and

93/44/EEC with particular reference to Annex 1 in

the Directive concerning essential health and safety

requirements in connection with construction and

manufacture.

Place: Tranås, 1th January, 1998

Signature:

13-1442, 13-1443, 13-1446, 13-1448

S-573 28 Tranås, Sweden

Production Manager

Page 18

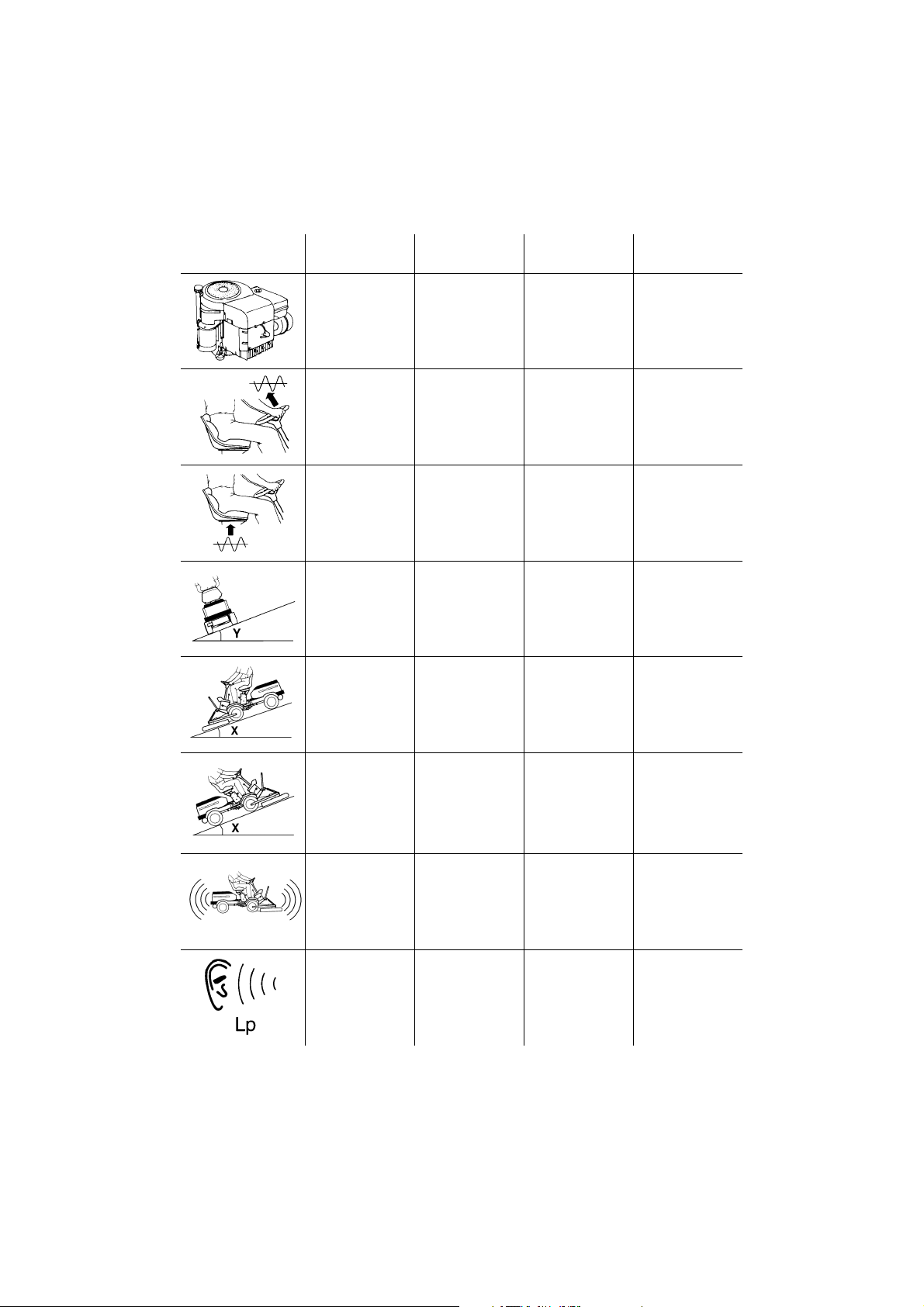

Park

Classic

Park

President

Park

Pro 16

Park

Pro 18

3400 min

9.3 kW

4.5 m/s

< 0.5 m/s

-1

2

2

3400 min

4.5 m/s

< 0.5 m/s

9.3 kW

-1

3400 min

-1

3400 min

11.8 kW

2

2

< 2.5 m/s

< 0.5 m/s

2

2

< 2.5 m/s

< 0.5 m/s

< 10° < 10° < 10° < 10°

< 10° < 10° < 10° < 10°

-1

13.2 kW

2

2

LWA

< 10° < 10° < 10° < 10°

100B: 100 dB(A)

102M: 99 dB(A)

100B: 87 dB(A)

102M: 85 dB(A)

100B: 99 dB(A)

102M: 99 dB(A)

110S: 100 dB(A)

100B: 87 dB(A)

102M: 85 dB(A)

110S: 87 dB(A)

100B: 98 dB(A)

102M: 97 dB(A)

110S: 100 dB(A)

121M: 99 dB(A)

100B: 86 dB(A)

102M: 84 dB(A)

110S: 88 dB(A)

121M: 86 dB(A)

100B: 97 dB(A)

102M: 97 dB(A)

121M: 98 dB(A)

100B: 84 dB(A)

102M: 84 dB(A)

121M: 86 dB(A)

Page 19

MOWING AHEAD

Box 1006 · SE-573 28 TRANÅS

www.stiga.com

Loading...

Loading...