Page 1

Edition Manual Chapter Page

2005-05-04 Workshop Manual, Stiga Park 1 General instructions 1

Workshop

manual

Primo

2008

Page 2

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 1

1 General instructions

Contents in this chapter

General

This Workshop Manual is intended for Stiga Primo model 2008.

This Manual do not cover repair instructions for the motor. Regarding the motor, see the

motor manual.

This Manual and its specifications are valid for machines in their original design. In case of

modified or changed machine, i.e. the motor is replaced, the manual accordance is limited.

The manual is divided in the following chapters:

Chapter 1 is this chapter

Chapter 2 Chassis

Chapter 3 Steering

Chapter 4 Belts

Chapter 5 Electrical system

Chapter 5 Cutting deck

1.4 Unpacking and assembly......... 5

1.4.1 Unpacking.............................. 5

1.4.2 Battery ................................... 6

1.4.3 Assembly............................... 7

1.4.4 Final checks........................... 9

1.4.5 General tightening torque...... 10

1.5 Instructions for use .................. 10

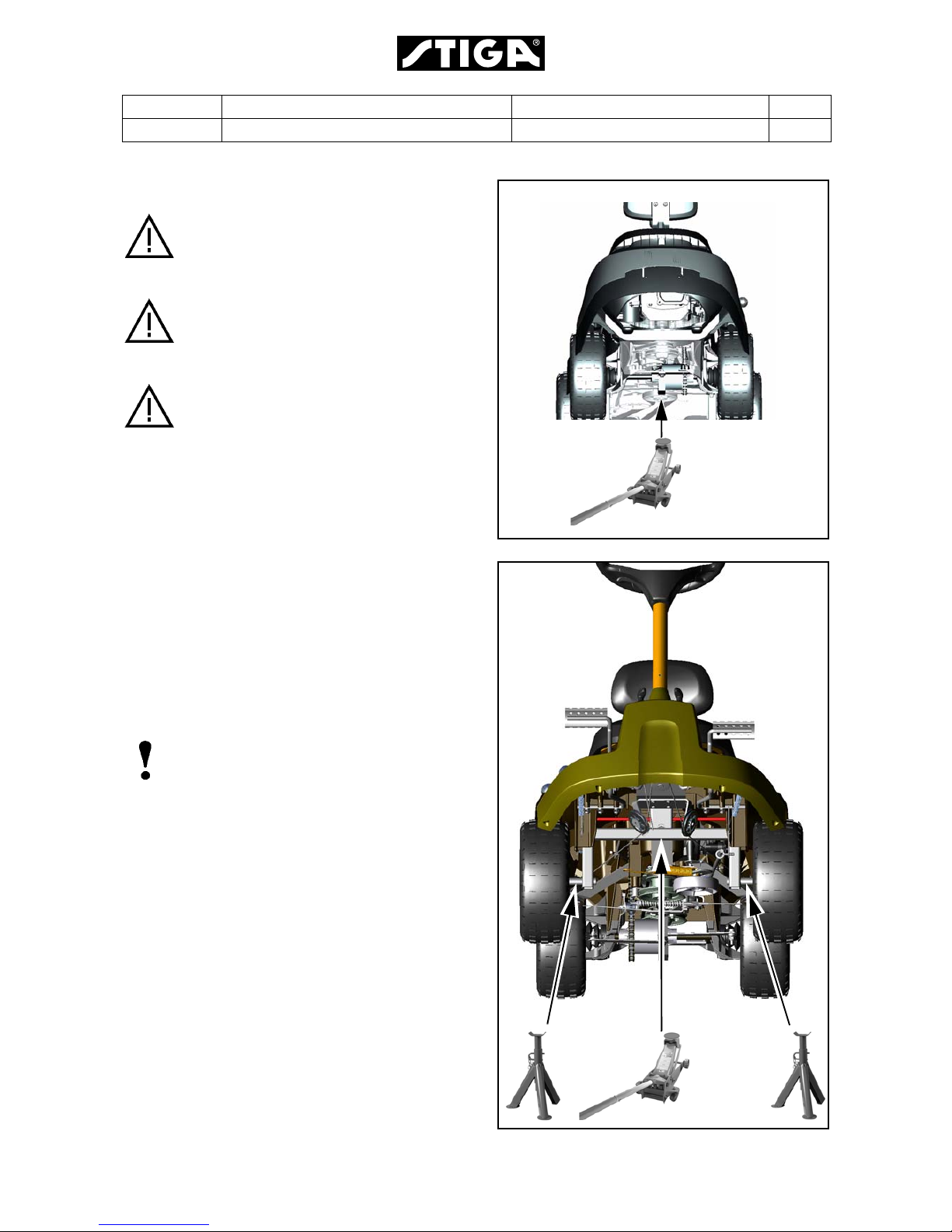

1.6 Raising....................................... 11

1.6.1 Raising back.......................... 11

1.6.2 Raising front........................... 11

1.7 Turning upsidedown................. 12

1.7.1 Preparing............................... 12

1.7.2 Draining the petrol ................. 12

1.7.3 Seat with its plate................... 12

1.7.4 Motor hood............................. 13

1.7.5 Motor oil................................. 13

1.7.6 Petrol tank.............................. 13

1.7.7 Turning................................... 13

1.7.8 Restoring the machine on its

wheels.................................... 13

1.1 Introduction................................2

1.1.1 Responsibility declaration.......2

1.1.2 How this manual is used ........2

1.2 Safety Precautions ....................2

1.2.1 Before service or maintenance2

1.2.2 Symbols and general

warnings.................................3

1.2.3 Warm parts.............................3

1.2.4 Moving parts...........................3

1.2.5 Lifting and blocking up............3

1.2.6 Cleanliness.............................3

1.2.7 Tightening torque ...................3

1.2.8 Sharp edges...........................3

1.2.9 Replacement parts.................3

1.2.10 Inspection.............................3

1.3 Guarantee...................................4

1.3.1 Guarantee period ...................4

1.3.2 Exeptions................................4

1.3.3 Conditions for validity of the

warranties...............................4

Page 3

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 2

1.1 Introduction

1.1.1 Responsibility declaration

In spite of the great care we have taken there may be errors in this publication.

The author cannot be made liable for incorrect or missing information.

GGP SE reserves the right to regularly change product specifications without prior notice.

All the information in this book is based on the information available at the time of

production. Illustrations and photographs may be arranged schematically, which implies

that one picture may cover several models and therefore not correspond exactly with all

models.

1.1.2 How this manual is used

To make this manual easy to understand we have divided the machine into its main

systems and components. These parts are now the different chapters in the book.

Each chapter is divided up into sections.

There is a quick-guide on the cover of this book, which refers to the different chapters. In

each chapter there is a detailed table of contents so that you can easily and quickly find

what you are looking for.

1.2 Safety Precautions

This manual has been written primarily for trained mechanics working in a well-equipped

workshop. Nevertheless, the manual contains such detailed information that it can also be

of use to owners who wish to carry out simple service and repairs on their machine.

A basic knowledge of repairs, tools and repair instructions is, however, always a

prerequisite for first-rate results.

A qualified mechanic should always be consulted if the owner does not have sufficient

knowledge to carry out repairs.

During the warranty period all service must be carried out by an Authorised Workshop for

the warranty to be valid.

The following basic points should be observed if the machine is to function perfectly:

• Follow the service schedule.

• Be on the alert for sudden vibrations or abnormal noise to avoid major breakdowns.

• Always use Genuine Spare Parts

• Follow the descriptions in this manual carefully. Do not take any short cuts.

1.2.1 Before service or maintenance

Before service or maintenance is carried out, the mesures below shall be performed:

• Prevent the machine from rolling by always applying the parking brake.

• Prevent unintentional starting of the engine by removing the ignition key.

• All service and all maintenance must be carried out on a stationary machine with the

engine switched off.

Page 4

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 3

1.2.2 Symbols and general

warnings

Warning!

This symbol indicates a risk of

personal injury or damage if the

instructions are not followed.

Note!

This text indicates a risk of damage to

the material or risk of unnecessarily

complicated work if the instructions

are not followed.

1.2.3 Warm parts

Please observe that engine and exhaust

system picks up a lot of heat during use.

T o avoid injuries, allow the machine to cool

before any kind of repairs are made to or

near parts of the engine or exhaust

system.

1.2.4 Moving parts

The machines are all equipped with v-belt

transmissions. Always stop the engine and

remove the starter key before inspections

or repairs are carried out.

Always use extreme caution when testing

systems with moving parts to avoid

injuries.

Always use Genuine Spare Parts during

service work.

1.2.5 Lifting and blocking up

Before work under the machine, always

make sure that lifting devices and jackstands are approved for the weight.

Work safe!

1.2.6 Cleanliness

Clean the machine before starting repairs.

Dirt that penetrates into sensitive

components can seriously influence the

service life of the machine.

1.2.7 Tightening torque

Unless otherwise stated the tightening

torque in the tables in the section

Technical specifications must be used for

the different sizes of screws. This does not

refer to self-tapping screws, which are

mainly used for the assembly of body

parts.

1.2.8 Sharp edges

Watch out for sharp edges, especially

when working with the mower deck. The

blades can be very sharp. Always wear

gloves when working with the blades.

1.2.9 Replacement parts

Always use Genuine Spare Parts during

service work.

1.2.10 Inspection

Each part dismantled in conjunction with

service work must be inspected.

Examine for: wear, cracks, out of

roundness, straightness, dents,

discolouring, abnormal noise and

jamming.

Page 5

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 4

1.3 Guarantee

1.3.1 Guarantee period

For consumer use: two years from date of

purchase.

1.3.2 Exeptions

The extended warranty does not cover

damage due to the following:

• Neglect by users to acquaint themselves

with accompanying documentation.

• Carelessness.

• Incorrect and non-permitted use or

assembly.

• The use of non-genuine spare parts.

• The use of accessories not supplied or

approved by the manufacturer.

Neither does the warranty cover:

• Wearing components such as blades,

belts, wheels,battery and cables.

• Normal wear.

• Engine and transmission. These are cov-

ered by the respective manufacturer’s

warranties, with separate terms and conditions.

The purchaser is covered by the national

laws of each country. The rights to which

the purchaser is entitled with the support of

these laws are not restricted by this

warranty.

1.3.3 Conditions for validity of the

warranties

The fully completed warranty card must be

sent to Stiga´s subsidiary or distributor.

Page 6

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 5

1.4 Unpacking and assembly

Every Stiga machine has undergone an

extensive control programme before delivery.

The machines are delivered as completely

assembled as possible.

Thanks to this the assembly on delivery is rapid

and easy.

The correct and careful assembly of the

machine on delivery is a simple way of ensuring

satisfied customers!

Note!

The machine shall remain placed on the

pallet during the unpacking and

assembly.

1.4.1 Unpacking

Open up the crate and release the part as

follows:

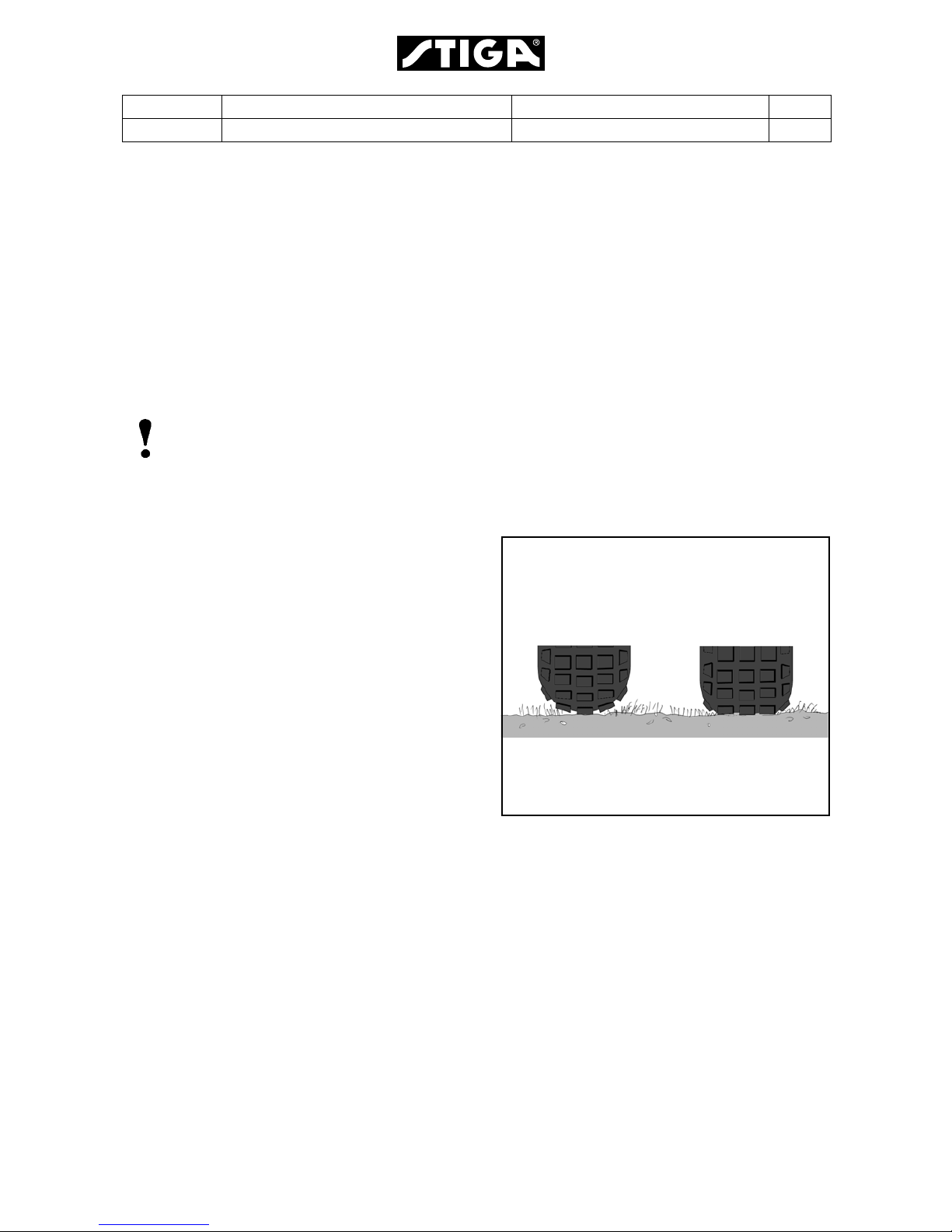

1. Check the air pressure in the tyres. The

pressure is designated on the floor mat.

The air pressure in the tyres is of critical

importance for the performance and

handling of the machine. The correct air

pressure for mowing is:

Front: 1,2 bar (17 psi)

Rear: 1,2 bar (17 psi)

Too high pressure in the tyres leads to that

the machine drives poor due to:

• A small surface in contact to the ground.

• Hard tyre = less flexibility = self cleaning characteristic deteriorate.

2. Remove the following parts from the

package and put them on the floor.

• The steering wheel.

• The backrest.

• The plastic bag, containing owners manuals,

and assembly screws.

Too high pressure Correct pressure

Page 7

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 6

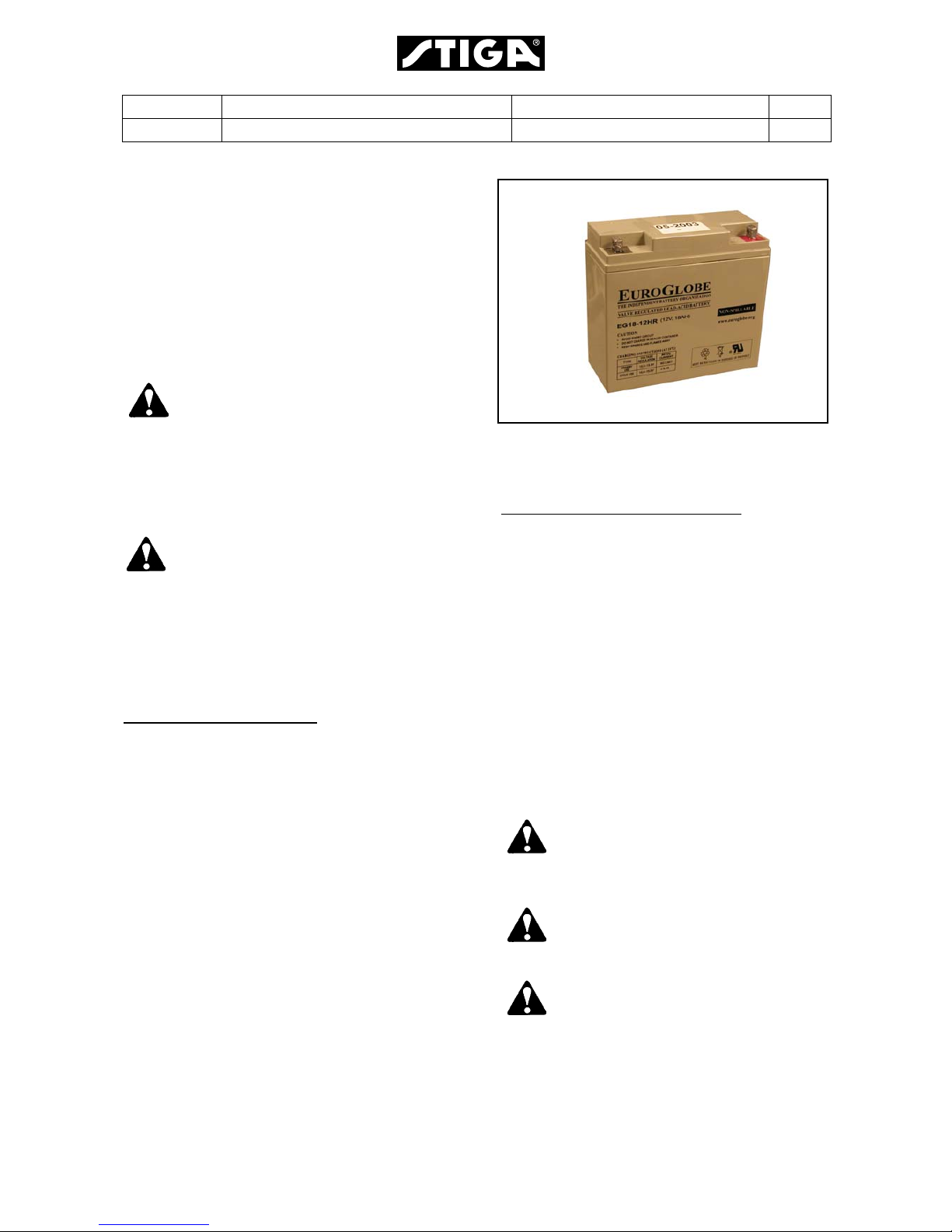

1.4.2 Battery

The battery is a valve regulated type.

Valve regulated battery

This battery needs limited maintenance. It has

no electrolyte levels or plugs.

Warning!

Do not wear rings, metallic bracelet,

chain round the neck or similar metal

objects when working with the

battery. It can cause short-circuit,

burns and fire.

Warning!

The battery must be fully charged

before being used for the first time.

The battery must always be stored

fully charged. If the battery is stored

while discharged, serious damage will

occur.

Charging with the engine

The battery can be charged using the engine’s

generator as follows:

1. Install the battery in the machine as shown

below.

2. Place the machine outdoors or install an

extraction device for the exhaust fumes.

3. Start the engine according to the

instructions in the user guide.

4. Allow the engine to run continuously for 45

minutes.

5. Stop the engine. The battery is now fully

charged.

Charging using battery charger

When charging using a battery charger, a

battery charger with constant voltage must

be used.

The battery can be damaged if a standard

type battery charger is used.

Installation of battery

Connect first the red cable to plus (+) and

then the black cable to minus (-).

If the cables are disconnected/

connected in the wrong order ,

there is a risk of a short-circuit

and damage to the battery.

If the cables are interchanged,

the generator and the battery

will be damaged.

The engine must never be driven

with the battery disconnected.

There is a risk of serious

damage to the generator and the

electrical system.

Page 8

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 7

1.4.3 Assembly

The assembly procedure shall take place in a

clean, well illuminated and dry place.

Assemble the machine as follows:

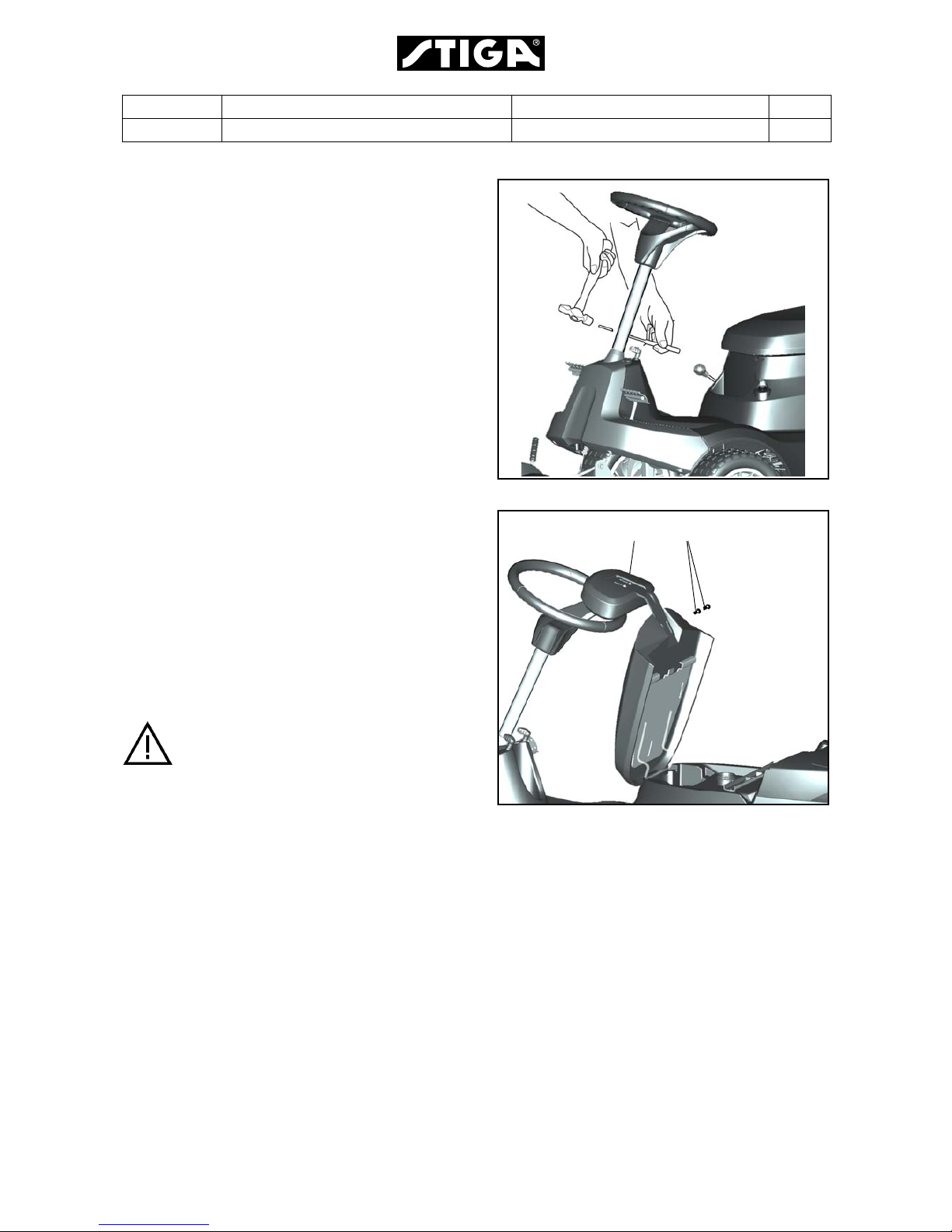

Steering wheel

Install the steering wheel as follows:

1. Install the steering column jacket on the

steering column using a drift or similar so

that the holes in the steering column jacket

and steering column align with each other.

2. Tap in the supplied tension pin from the

other side using a hammer.

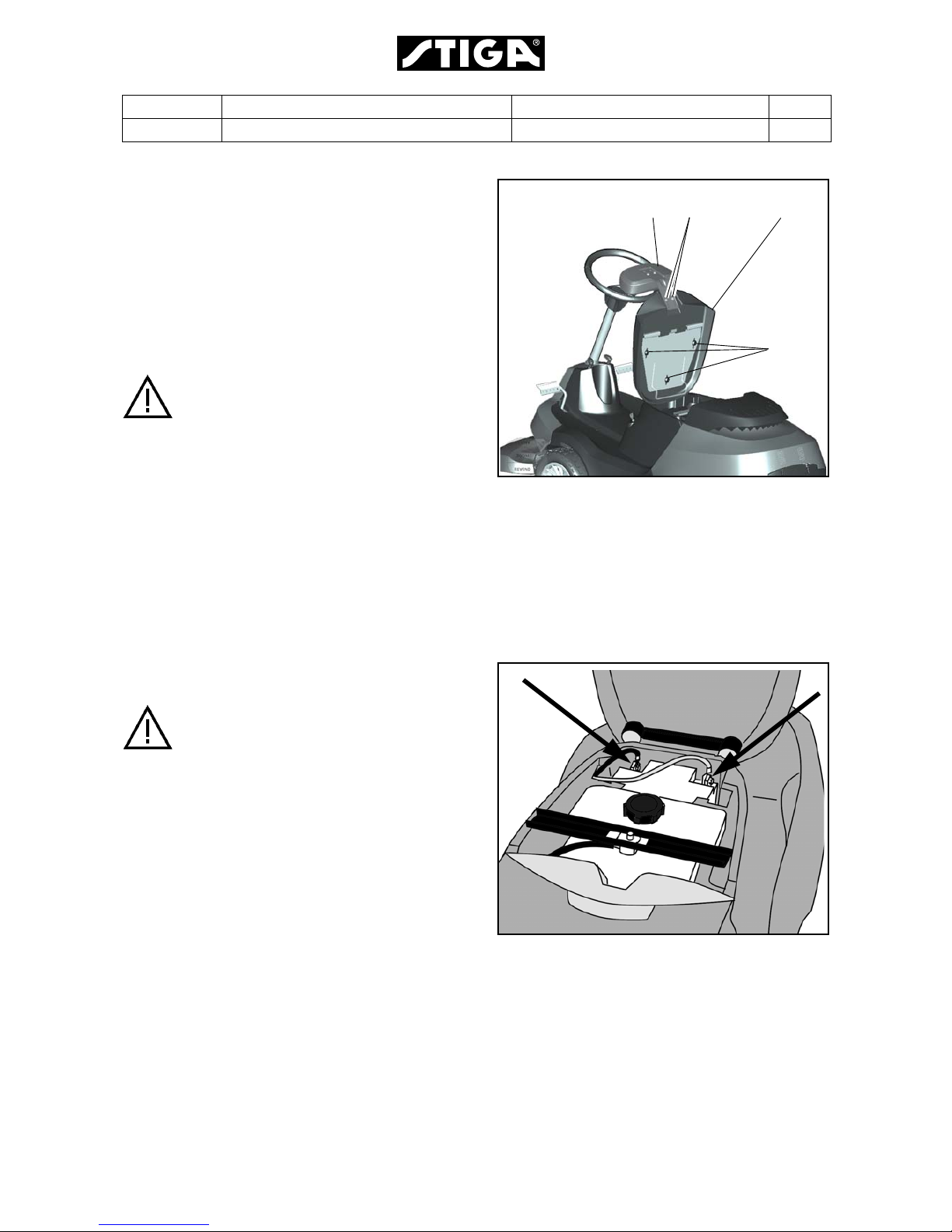

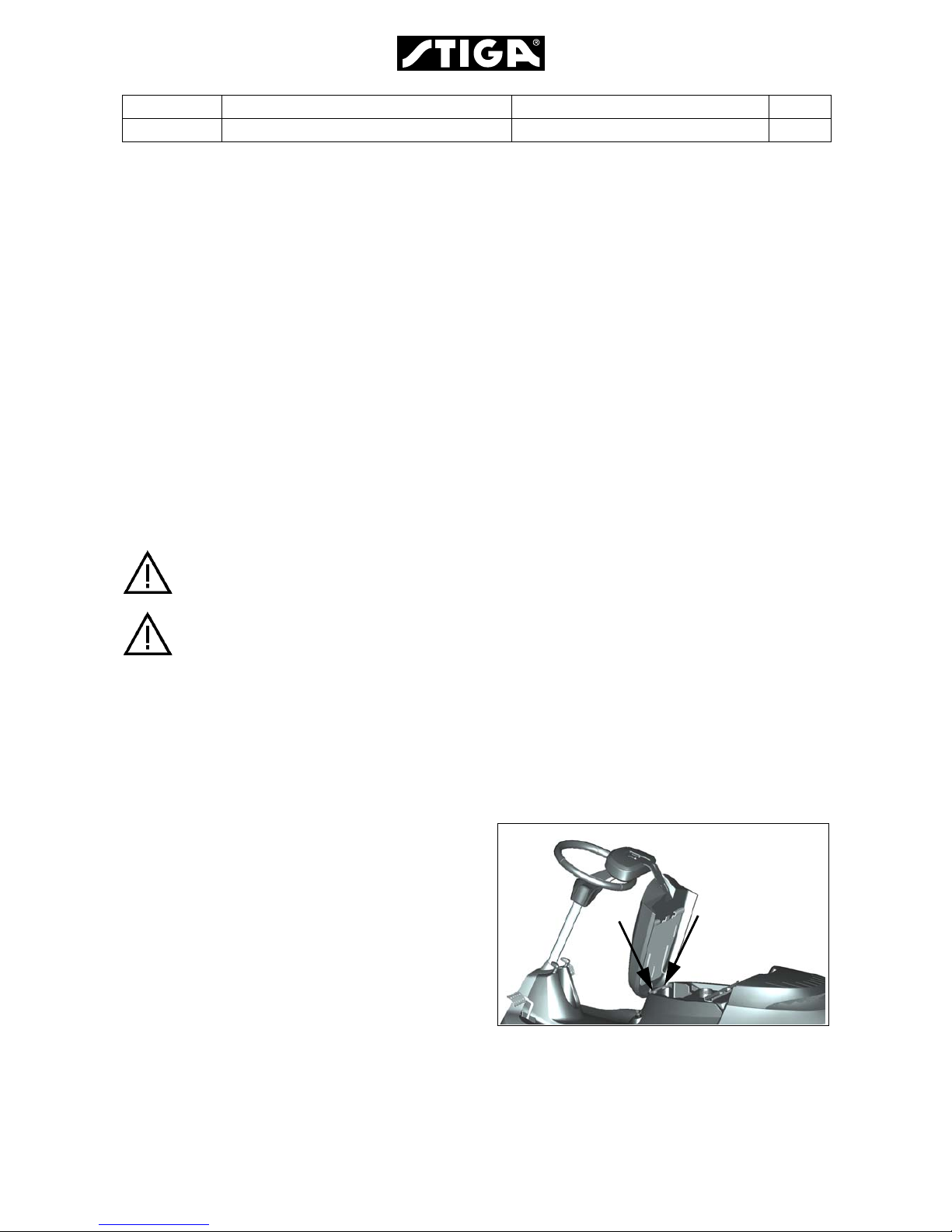

Backrest

Install the backrest as follows:

1. Fold the seat up towards the steering wheel.

2. Install the backrest with the screws (O)

without tightening.

3. Set the backrest to the desired position.

4. Tighten the screws. Tightening torque: 2024 Nm.

If the screws are tightened more than

24 Nm, the seat will be damaged.

N O

Page 9

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 8

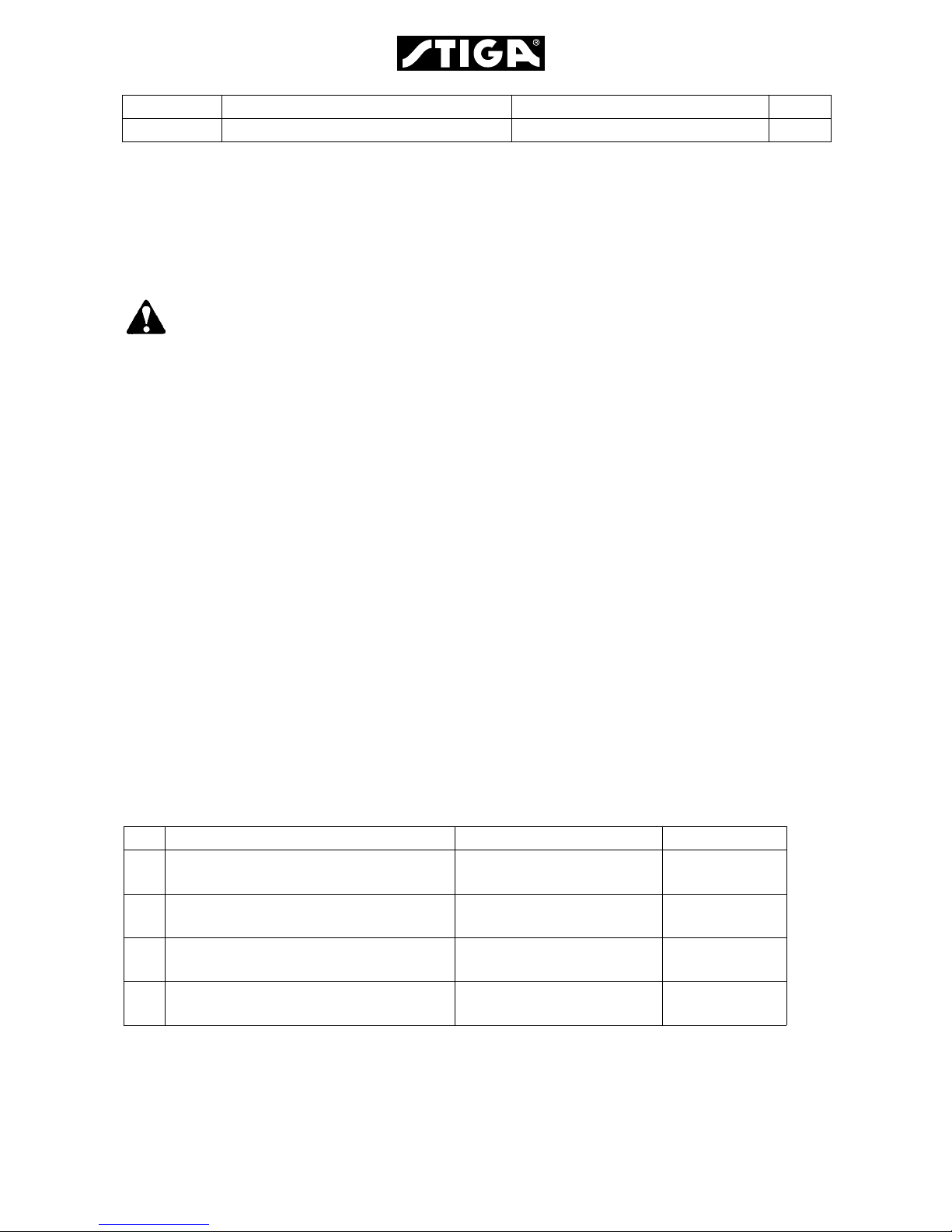

Seat

Adjust the seat backwards/forwards to a

comfortable driving position.

The seat can be folded and adjusted front-rear.

To adjust the seat, slacken of f the three screws

(P), set the seat to the desired position and

tighten the screws.

Tightening torque: 20-24 Nm.

If the screws are tightened more than

24 Nm, the seat will be damaged.

The seat is equipped with a safety switch that is

connected to the machine’s safety system. This

means that certain dangerous activities are not

possible when there is nobody sitting on the

seat.

Backrest

The backrest can be adjusted laterally and

vertically . T o adjust the backrest, slacken off the

screws (O), set the backrest to the desired

position and tighten the screws. Tightening

torque: 20-24 Nm.

If the screws are tightened more than

24 Nm, the seat will be damaged.

Battery

Fold the seat up and install the battery leads.

See also“1.4.2”.

Engine oil

Check the oil level in the engine and top up if

necessary.

A

P

ON

Page 10

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 9

1.4.4 Final checks

The final check consists of test driving and

safety check as described below.

Test driving

Warning!

Do not drive without the mover deck

attached. Risk for turning over.

Drive the machine for a few minutes. Test all

the functions. Pay special attention to the

safety functions. The mower deck must be

fitted before test driving the machine.

Listen to abnormal noise or rattle during the test

driving.

Safety check

Check the safety functions. It is often

appropriate to do this check in conjunction with

test driving. The following items shall be

checked at all machines:

• No leakage on fuel lines and connections.

• No mechanical damages to the electrical

cables. All insulation intact.

• The muffler shall be undamaged and its

screws tightened. No exhaust leakage in connections.

The electrical check items are listed in the

tables below.

Test Status Action Result

1 PTO activated.

No gear activated.

Turn the key and make a

start attempt.

Motor shall not

start.

2 PTO not activated.

A gear is activated.

Turn the key and make a

start attempt.

Motor shall not

start.

3 Motor running.

PTO activated.

Operator rises from the

seat.

Motor shall

stop.

4 Motor running.

A gear activated.

Operator rises from the

seat.

Motor shall

stop.

Page 11

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 10

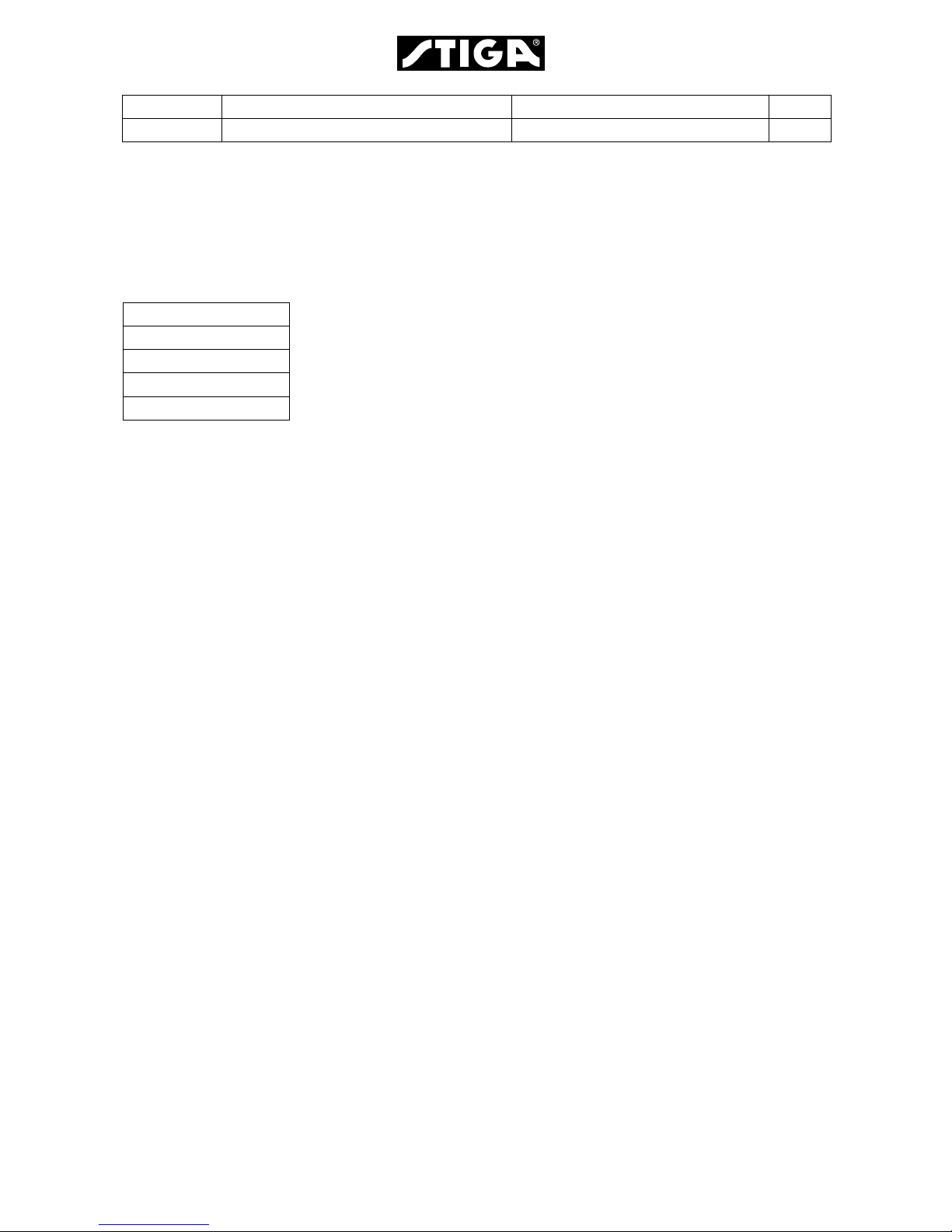

1.4.5 General tightening torque

Unless otherwise stated, the following

tightening torque are applicable for screws and

nuts on the machine:

1.5 Instructions for use

Some procedures, e.g. changing motor oil,

motor filter etc., are refered to the instruction for

use, delivered with the machine.

The instruction of use is written in 16 languages

and divided in two parts. The first part always

contains the languages SV, FI, DA, NO, DE,

EN, FR and N.

Tightening torques

Thread Torque

M5 5 Nm

M6 9 Nm

M8 22 Nm

M10 45 Nm

Page 12

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 11

1.6 Raising

Jacks must only be placed in the

designated area. Placing the jack in

other locations will damage the

machine.

The machine must only be raised on

hard, stable and horizontal surfaces.

Otherwise there is a risk of the

machine dropping.

The machine must never be loaded

with further weight when it is raised.

Nobody must sit on the machine when

it is raised.

1.6.1 Raising back

For certain maintenance work, the rear part of

the machine must be raised slightly so that the

required rear wheel can be removed. Raise the

machine as follows:

1. Position the machine on a hard, stable and

horizontal surface.

2. Raise the machine using a jack, see the fig.

1.6.2 Raising front

Note!

To raise the machine at the front, the

cutting deck must be removed.

Raise the machine at the front as follows:

1. Place the machine on a flat, solid and

horisontal ground.

2. Disassemble the cutting deck. See chapter 6.

3. Raise the machine with help of a jack and

apply the yokes according to the figure.

For location of jack and yokes, see the figure.

1

1

2

2

Page 13

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 12

1.7 Turning upsidedown

Some service measures are facilitated by

turning the machine upsidedown on a work

bench.

1.7.1 Preparing

Before the machine is turned, the following

items must be disassembled:

• Cutting deck, see chapter 6

• Draining the petrol

• Seat with its plate

• Motor hood

• Motor oil

• Petrol tank

1.7.2 Draining the petrol

Petrol is highly inflammable. Always

store fuel in containers that are made

especially for this purpose.

Only handle petrol outdoors, and

never smoke during petrol handling.

Never handle petrol together with a

warm or running engine.

1. Place the machine outdoors.

2. Drain the petrol tank by loosening the hose

at the fuel cock. Close the hose and insert it

in a suitable container until the tank is

empty.

3. Start the engine and let it run until it the

carburettor is empty and the engine stops.

1.7.3 Seat with its plate

1. Fold up the seat and remove the screws

(A).

2. Lift up and remove the seat with the seat

plate.

A

A

Page 14

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 1 General 13

1.7.4 Motor hood

1. Open the motor hood.

2. Person 1 holds the hood on one side and

person 2 holds the other side and removes

the screws (B).

3. Lift carefully up the hood and place it on a

soft surface.

1.7.5 Motor oil

Drain the motor oil. See the owners manual.

1.7.6 Petrol tank

Loosen the screws holding the crossbar (C)

and remove the crossbar.

Loosen the screw (D) holding the tank and

battery cage and remove the tank and battery

cage with battery.

1.7.7 Turning

Prepare a work bench to place the machine on.

Two persons lif t the machine, one person at the

rear and one at the front.

Lift and turn the machine 180°. Place it carefully

on the work bench.

1.7.8 Restoring the machine on its

wheels

To restore the machine on its wheels, perform

the instructions above in the opposite order.

BB

CD

Page 15

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 2 Chassis and Body 1

2 Chassis and body

Contents in this chapter

General

To facilita te the driving, handling of work equipment and to make it comfortable for the

driver, the machines are equipped with a various number of aid equipments.

This chapter gives a brief description of the equipments and describes their repair and

replacements.

This chapter also contains information about how to repair the plastic chassis including

material and threads.

2.3 Lubrication chassis .................... 4

2.3.1 Drive chain............................... 4

2.3.2 Steering cable.......................... 4

2.3.3 Tensioning arms, movable joints5

2.3.4 Throttle cable........................... 5

2.3.5 Bearings................................... 5

2.1 Repair of the chassis...................2

2.1.1 Repair of cracks........................2

2.1.2 Repair of threads......................2

2.2 Wheel............................................3

2.2.1 Adjusting the drive chain (U) ....3

Page 16

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 2 Chassis and Body 2

2.1 Repair of the chassis

There are two types of chassis repair:

• Repair of cracks i.e. after interferences etc.

• Repair of threads.

2.1.1 Repair of cracks

Consult the dealer for detailed information.

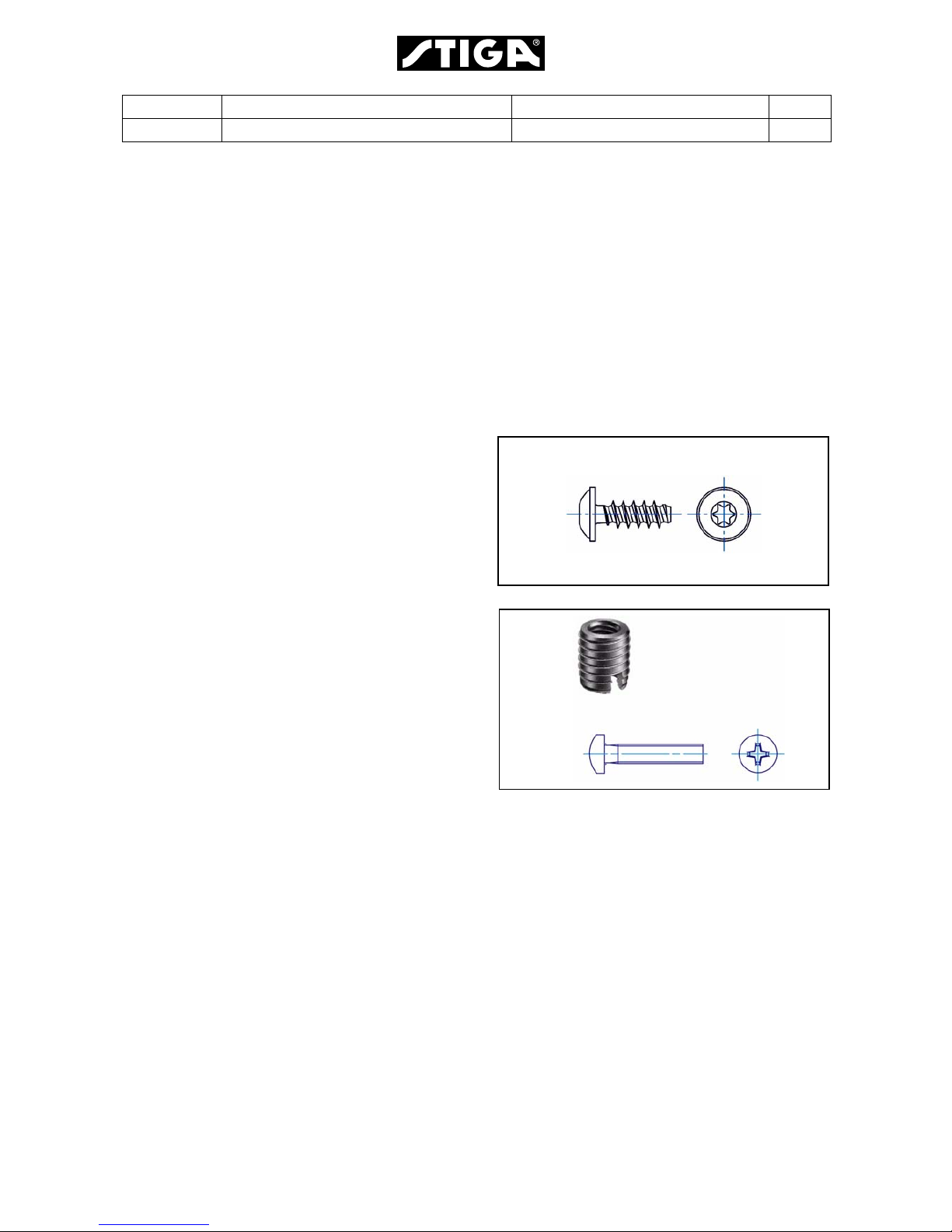

2.1.2 Repair of threads

A number of screws are threaded direct into the

chassis. The screws used are shown in the

figure to the right.

Threads for those screws can be repaired as

follows:

1. Order a repair kit for threads. See the spare

parts list.

2. Drill out the defect thread in the chassis with

a 7 mm drill.

3. Screw the thread adapter (A) from the repair

kit into the hole with the recess first. The

recess is intendet to cut the thread in the

plastic material.

The thread adapter is screwed in with a

screw in its internal thread.

4. Use a csrew M5x25 (B) from the repair kit

and fit the actual item.

A

B

Page 17

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 2 Chassis and Body 3

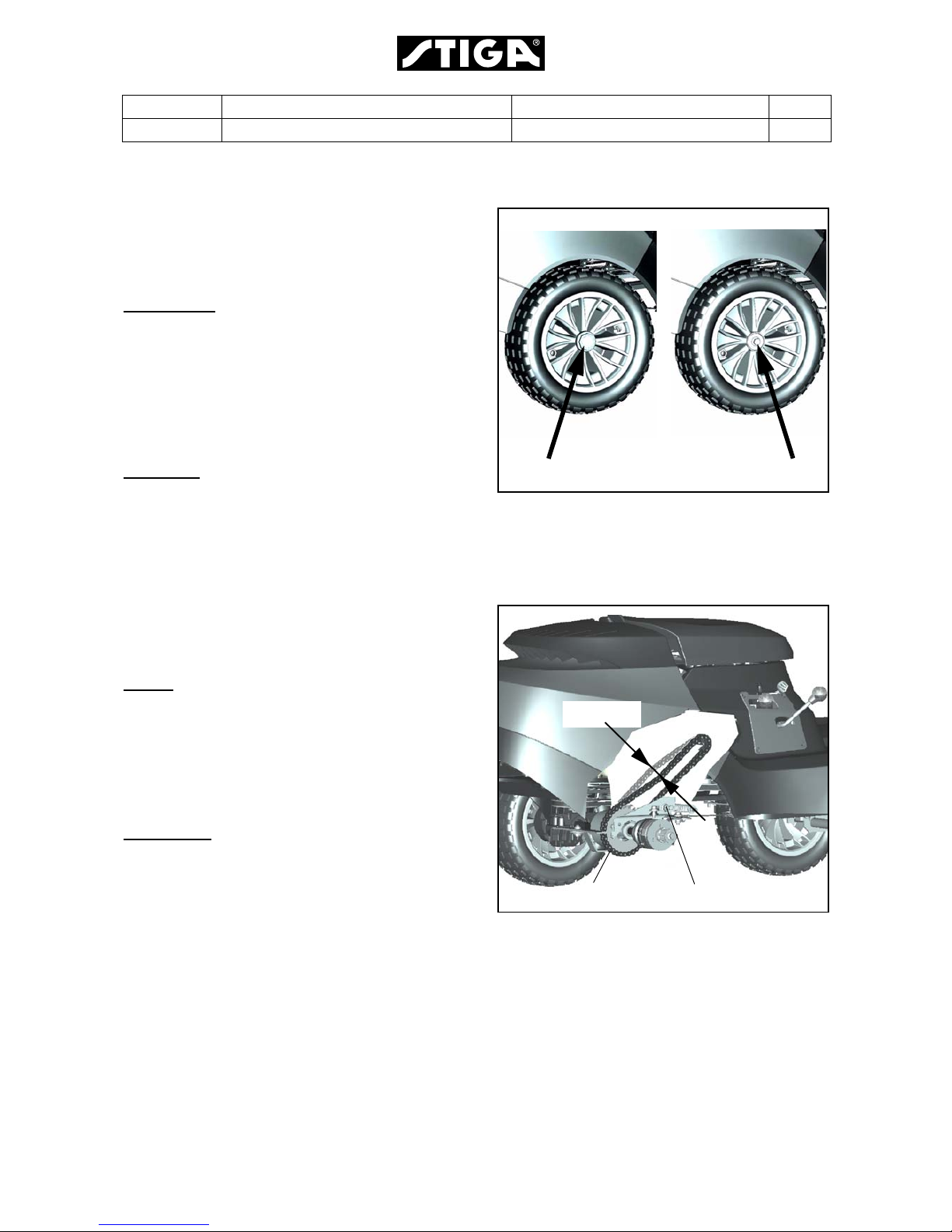

2.2 Wheel

For certain maintenance work, it is necessary

to remove a rear wheel.

Dismantling:

1. Raise the machine according to chapter 1.

2. Remove the cover disc (A).

3. Use a 17 mm wrench and remove the screw

(B) with disc.

4. Pull the wheel from the axle.

Assembly:

1. Slide the wheel onto the axle.

2. Install the screw (B) with disc.

3. Tighten the screw to 40-45 Nm.

2.2.1 Adjusting the drive chain (U)

Check/adjust the belt tension each season as

follows:

Check:

1. Raise the machine and remove the righthand rear wheel. See 6.4.

2. The chain (15:U) must have 5-10 mm of

play.

Any required adjustment, see blow.

Adjustment

:

Adjust the play by moving the tensioner wheel

as follows:

1. Slacken off the nut (15:T) and set the

tensioner wheel to the desired position.

2. Tighten the nut and check the play. Adjust

again if required.

3. Tighten the nut to 40-45 Nm when

adjustment has been completed.

AB

5-10 mm

T

U

Page 18

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 2 Chassis and Body 4

2.3 Adjustments

2.4 Brake - Clutch

General

Pedal has the following functions:

•Clutch

• Service brake

• Parking brake

The pedal has three positions:

1. Pedal released – forward drive engaged.

The machine will move if a gear is engaged.

Service brake not activated.

2. Pedal depressed halfway – forward drive

disengaged, gear shifting can be performed.

Service brake not activated.

3. Pedal fully depressed – forward drive

disengaged. Service brake fully activated.

Also see “Parking brake” below.

4. Pedal fully depressed and locked – Parking

brake.

Adjustment

The adjustment is performed in 2 steps:

Step 1

The pedal shall have a play of 10-20 mm at the

top.

Adjust this play by inserting the cotter pin in a

suitable hole in the brake rod.

Note!

Check that the pedal return spring (A) is

in place. If not, the play cannot be felt.

10-20 mm

A

Page 19

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 2 Chassis and Body 5

Step 2

Adjust the brake to act according to the

description under “General” at the previous

page.

The adjustment is performed at the center nut

at the gearbox brake lever.

• Turn the nut CW to increase the braking

effect.

• Turn CCW to decrease the braking effect

Page 20

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 2 Chassis and Body 6

2.5 Lubrication chassis

All lubrication points according to the table

below must be lubricated after every 25

operating hours as well as after each clean.

2.5.1 Drive chain

Lubricate the drive chain (U) using chain spray

as follows. Use universal type chain spray.

1. Trestle up the machine’s right-hand rear

wheel so that it can rotate freely.

2. Brush the chain clean using a wire brush.

3. Rotate the rear wheel by hand and at the

same time spray the chain so that it is fully

lubricated.

4. Lower the machine.

2.5.2 Steering cable

Lubricate the steering cable using chain spray

as below. Use universal type chain spray.

1. Brush the chain clean using a wire brush.

2. Turn the steering wheel and at the same

time spray the cable so that it is fully

lubricated.

Item Chapter / Section

Drive chain 2.3.1

Steering cable 2.3.2

Tensioning arms

and moving joints

2.3.3

Throttle cable 2.3.4

U

Page 21

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 2 Chassis and Body 7

2.5.3 Tensioning arms, movable joints

Lubricate the bearing points using an oil can at

the same time as activating the respective

control.

Preferably carried out by two people.

Activate the controls:

• Steering

• Clutch, brake

• Raise the cutting deck

• Engaging the cutting deck.

• Setting the cutting height

2.5.4 Throttle cable

Lubricate the cable ends using an oil can at the

same time as activating the respective control.

2.5.5 Bearings

Shafts and attachments pivoted in the plastic

chassie shall be lubricated with universal

grease.

Page 22

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 3 Steering 1

3 Steering

Contents in this chapter

General

The machine is equipped with a mechanical steering system, working with a wire.

This chapter contains a brief description of the function and describes repair , replacements

and adjustments of stressed parts of the steering system.

3.1 Steering wire..............................2

3.1.1 Description .............................2

3.1.2 Dismantling.............................2

3.1.3 Assembly................................3

3.1.4 Steering pulleys......................5

Page 23

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 3 Steering 2

3.1 Steering wire

3.1.1 Description

The steering power from the steering wheel is

transmitted to the rear wheels by a wire as

follows:

• The roller (A) is turned by the steering wheel

and mowes the wire (B).

• The wire is pulling the lever (C), which affects

the wheels by the rods (D)

3.1.2 Dismantling

Note!

Observe how the wire is located above/

under rods, arms etc. This observation is

helpful at the installation of the new wire.

1. Remove the four steering pulleys (E). Use a

15 mm and a 17 mm wrench.

2. Remove the nut (F), holding the wire end.

Use a 13 mm wrench and a pliers to hold the

wire end.

3. Remove the spring

4. Unwind the wire from the steering roller and

unhook it from the rear attachment.

5. Remove the wire from the machine.

A

B

C

D

E E

E

E

F

Page 24

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 3 Steering 3

3.1.3 Assembly

1. Hook on the wire to the rear steering lever.

2. Mount the 2 pulleys (E) with the wire at the

right side of the machine.

Note!

Locate the wire as observed during the

dismantling.

Check that the wire not interface with

frame parts, rods, levers etc.

Lubricate the pulleys and mount them

according to the figure.

See “3.1.4 Steering pulleys”.

3. Turn the steering wheel until the wire rivet

hole in the steering roller is facing forwards.

4. Wind up the wire on the steering roller.

Keep the right part of the wire stretched by

blocking or holding the rear wheels.

St art winding at position (A), wind 1,25 turns

and push in the rivet (B) into the hole in the

steering roller.

5. Continue to wind up the wire another 1,25

turns.

EE

AB

Page 25

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 3 Steering 4

6. Fit the threaded wire to the rear steering

lever.

Note!

Locate the wire as observed during the

dismantling.

Check that the wire not interface with

frame parts, rods, levers etc.

Mount the following parts:

• Spring (G)

• Nut (F). To facilitate the mounting of the

remaining steering pulleys, screw on the

nut a few turns only.

6. Mount the two pulleys at the left part of the

machine together with the wire.

See “3.1.4 Steering pulleys”.

7.Tighten the nut (F) and compress the spring

until its length is 108 mm. Hold the wire with

a pliers.

8. Turn the wheels fully out in both directions.

Check that there is no abnormal noise or

abnormal resistance.

FG

E E

108 mm

Page 26

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 3 Steering 5

3.1.4 Steering pulleys

Every singel steering pulley consists of the

following parts:

A.Screw

B.Washer

C.Bushing

D.Steering pulley

E.Part of the frame

F.Nut

Assembly instructions:

• Check the wear, specially of the steering pulley, and replace defective parts.

• Apply a thin layer of machine oil to the bushing (C).

A

B

C

D

E

F

Page 27

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 4 Belts 1

4 Belts

Contents in this chapter

General

All mechanical power, delivered by the motor, is conducted to the different power

consuments by a belt system. The maximum tension of each belt is regulated by a spring

loaded belt tensioner.

This chapter gives a brief description of the belt system and describes replacements of

belts and adjustments of their tensions.

This chapter is valid for the actual machines where the actual system occur.

4.1 Description.................................2

4.2 Belt theory..................................3

4.2.1 Why it is so important to use

original belts from the

retail dealer?...........................3

4.3 Replacement of belts................5

4.3.1 Disassembly of belt C ............5

4.3.2 Inspection and measures.......6

4.3.3 Assembly of belt C.................7

4.3.4 Adjustmen of PTO brake........7

Page 28

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 4 Belts 2

4.1 Description

Belt A

Belt A belongs to the work equipment and is

connected to the machine pulley (double)

(3). The belt is tensioned by the tension

pulley (2) which is mounted on a spring

loaded lever.

Belt B

Belt B is intended to deliver the motor power

to the pulley (double) (3), where it can be

picked up by the work equipment.

Belt B also performs the mechanic PTO

clutch function together with the pulley (5).

Engagement/disengagement of the

mechanic PTO is performed by moving the

pulley (5) to stretch/slacken the belt.

Belt C

Belt C is intended to transmitt the motor

power to the transmission, where it is geared

to a suitable ratio for the drive shaft. The belt

is tensioned by the tension pulley (6) which

together with the belt performs the clutch

function.

The tensioning force is disengaged from the

belt when the parking brake is activated.

Belts:

A. Work equipment belt (belongs to the work

equipment).

B. Work equipment belt.

C.Transmission belt.

Pulleys:

1. Pulley at the work equipment.

2. Tension pulley.

3. Pulley (double).

4. Pulley at the transmission.

5. Tension pulley with PTO clutch function.

6. Tension pulley with clutch function.

7. Drive pulley at the motor shaft.

8. Drive pulley at the motor shaft.

A

B

C

1

2

3

4

5

7

8

6

Page 29

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 4 Belts 3

4.2 Belt theory

4.2.1 Why it is so important to use original belts from the retail dealer?

The table below shows the demands on normal commercial grade belts compared to

demands on original spare parts belts from the retail dealer. The later are designed and

manufactured in close connection between the subcontractor and the rider manufacturer.

The table is intended to display the importance to use the original belts.

Case Commercial

grade belts

Original spare

par ts belts

Remarks

Fitness to pulleys. The belt shall rest

with its angled

sides against the

pulleys. There

must be a space

between belt and

pulley bottom.

The belt shall rest

with its angled

sides against the

pulleys. There must

be a space

between belt and

pulley bottom.

Same demands.

Original belts

guarantee that the belt

fits against the pulleys.

Acceleration. The belt follows

the motor rpm in a

continuous

acceleration up to

full speed.

Some belts shall

engage to the

pulleys with the

motor running in full

speed, which gives

an excessive

generation of heat.

Common belts are

made of natural rubber,

which can resist

temperatures up to 70°

only.

Original belts are made

of chloroprene rubber,

which can resist

temperatures up to 90°

Length Manufactured in

standard lengths

in steps..

Manufactured in

preedefined lengths

to fit between the

pulleys..

The distance between

the pulleys is fix. The

belt tensioner gives the

original belt an optimal

tension.

.

Page 30

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 4 Belts 4

Case Commercial

grade belts

Original spare

par ts belts

Remarks

Floating pulley at

the implement.

Designed to

transmit power

between aligned,

paralell and fixed

pulleys.

The original PTO

belt is designed to

operate, even if the

pulleys are moving

up and down and

are tilting at the

same time

The implement follows

the ground which

involves that its pulley

is constant moving.

To resist the excessive

operating conditions,

the original belts are

made of fibre

reinforced rubber.

Bending in two

directions

Designed to bend

around pulleys in

one direction only

Most of the belts at

the machine have

tension rollers,

actuating from the

outside of the belt.

This means the the

belt has to bend

both inwards and

outwards during the

operation.

All original belts which

operate with tension

rollers actuating from

the outside have

reinforcements. The

reinforcement is

special designed for

the actual case.

Noise Manufactured

without any

special respect to

the actual case.

The original belts

are carefully

selected to give the

lowest noise

increment to the

machine during

operation.

Depending on the

function of the belt, any

of the following belt

types are itemised:

• Wrapped

• Non-friction

• Raw-edge

Page 31

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 4 Belts 5

4.3 Replacement of belts

This section describes the belt changing of belt

C. For changing other belts, see actual parts of

the belt C description.

4.3.1 Disassembly of belt C

The belt C is the uppermost belt and is intended

to conduct the engine power to the gearbox.

The belt is controled by a lever for the clutch

function.

Dismantle the belt as follows:

1. Raise the machine by one of the alternatives

below:

• With a highjack and yokes. See section 1.

• With a lifting table.

2. Set the cutting deck (if mounted) to max

cutting heighth.

3. If the cutting deck is mounted; Pull out the

pulley (H) and take down the belt to unload

the belt tension.

4. If the cutting deck is mounted; Remove the

belt A.

A

C

B

H

A

Page 32

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 4 Belts 6

5. Unhook all springs and note where the

respective spring is attached.

6. Remove the split pin and unhook the rod (R)

at the front.

7. Remove the pulley (5). Use a 15 mm and a

17 mm wrench.

8. T ake of f the belt (B) first from pulley (8), then

thread it around the pulley 3 and finally,

remove it.

9. Remove the pulley (6). Use a 15 mm and a

17 mm wrench.

10.Remove the belt (C) from the pulleys (4) and

(7).

4.3.2 Inspection and measures

1. Check and lubricate all links.

• The links shall move easily and not have

any major play.

• Lubricate all pivot linkages with machine

oil.

2. Check the belts.

• The belt shall rest with its angled sides

against the pulleys. There must be a

space between belt and pulley bottom.

• The belt shall be intact. No loose parts or

cracks.

3. Check all ball bearings with respect to the

following:

• No radial play.

• The sealing shall be intact.

• No abnormal noise when rotating. Shall

rotate evenly without stop tendency.

Replace all defective parts with genuine

spare parts.

3B 5 8R

67C4

Page 33

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 4 Belts 7

4.3.3 Assembly of belt C

Assemble all part in the reverse order.

After the assembly, adjust the PTO brake. See

below.

4.3.4 Adjustmen of PTO brake

Warning!

It is important that the movement of

the tensioning arm is always

stopped by the brake pad, and not

by the engagement rod. If the rod

stops the movement, the braking capacity can be completely lost when

the parts become worn.

1. Remove the rod link and press the brake

shoe hard against the pulley.

Hold the threaded stud above the lever

close to the hole. In this position, 1/4 of the

threaded stud diameter shall overlap the

hole diameter.

2. Adjust the nipple towards + to increase the

brake function.

Adjust the nipple towards - to decrease the

brake function.

.

1/4 Dia.

Page 34

Edition Manual Chapter Page

2008-03-18 Workshop Manual, Stiga Primo 4 Belts 8

3. When 1/4 of the diameters overlap, fit the

nipple in the hole and assemble the nut as

follows:

A. Screw on and tighten the nut moder-

ately.

B. Loosen the nut 1/2 turn.

The nipple shall be movable in the hole.

Warning!

If the nipple is tight in its hole, un-

normal stress will occour to the mechanical parts.

4. When the adjustment is complete, the following items shall be fulfilled:

• Engage the PTO and check that the

brake pad no longer brakes the pulley . If

the brake pad still brakes the belt pulley ,

adjust again.

• Disengage the PTO and check that the

brake works.

If everything is correctly adjusted the

brake should be applied just enough for

the double PTO belt pulley to be turned

round by hand only with extreme force.

Page 35

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 1

5 Electrical System

Contents in this chapter

General

The electrical system has two main duties, to maintain the machine safety and to make the

different functions easy to handle.

The main part of this chapter consists of trouble shooting of the electrical system to isolate

faults and to give information about corrective measures. The electrical system is also

described. There are also given instructions about general repair and replacement

procedures.

5.2.6 The motor can be started with a

gear activated.............................6

5.2.7 The motor does not stop when the

operator leaves the seat and the

mover deck is activated..............7

5.3 Repair and replacements..............8

5.3.1 Connections ...............................8

5.3.2 Circuit diagram...........................9

5.1 Description.....................................2

5.2 Trouble Shooting...........................3

5.2.1 The starter does not rotate......... 4

5.2.2 The starter rotate, but the motor

does not start..............................5

5.2.3 The battery runs repeatedly

empty..........................................5

5.2.4 The motor does not stop............6

5.2.5 The motor can be started with the

mover deck activated .................6

Page 36

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 2

5.1 Description

The electrical components are connected with cables, integrated in a complete insulated

harness. Thus the cables are protected against wear, contaminations and other stresses.

The cables are connected to the actual components with tab or screw connectors and in

some cases with multi-contact connectors.

The electrical system contains several safety circuits. Therefore actual levers and pedals

are provided with micro switches. The micro switches are shown in the figure below. The

signals from the micro switches are used to interlock the actual circuit in case of a forbidden

manoeuvre attempt. Some manual switches and relays have also built in interlocks, related

to the safety system.

To achieve a complete understanding of the electrical system, read also the actual wiring

diagram.

All current consumption circuits except the start circuit are protected by a fuse.

Microswitch at the

Microswitch under the seat

Microswitch at the

gearbox

PTO lever

View from the inside

Page 37

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 3

5.2 Trouble Shooting

Warning!

Do not wear rings, metallic bracelet, chain round the neck or similar metal

objects when working with the electrical system. It can cause short-circuit,

burns and fire.

This section describes the trouble shooting procedures in absence of an electrical function.

It also describes the correction measures in each actual case. When following the trouble

shooting schedules, it is provided that the following states are fulfilled:

• All fuses are checked and, if necessary replaced.

• The battery shall be charged.

• The requirements for the actual measure shall be fulfilled. E.g. if it is advised to perform a

start attempt, the gear shall be in neutral and the power take off shall be in disengaged

position.

When following the trouble shooting shedules, it is in normal cases assumed that

conductors and connectors to conductors are OK. However, in some cases, after a long

period of use or in case of mechanical damages.

Page 38

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 4

5.2.1 The starter does not rotate

Page 39

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 5

5.2.2 The starter rotate, but the motor does not start

5.2.3 The battery runs repeatedly empty

Page 40

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 6

5.2.4 The motor does not stop

5.2.5 The motor can be started with the mover deck activated

5.2.6 The motor can be started with a gear activated

Page 41

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 7

5.2.7 The motor does not stop when the operator leaves the seat and the

mover deck is activated

Page 42

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 8

5.3 Repair and replace-

ments

Warning

Do not wear rings, metallic bracelet,

chain round the neck or similar metal objects when working with the

electrical system. It can cause

short-circuit, burns and fire.

5.3.1 Connections

The machine is equipped with three kinds of

connectors:

• Fixed connectors in plastic holders.

• Tab connectors

• Screw connectors

All connectors shall be kept free from

contamination, corrosion and damp.

Fixed connectors in plastic holders

To remove the connectors from the plastic

holder, put a small screwdriver behind the

connector, hold the cable and pull out the

connector.

See the figure.

Tab connectors

To restore tab connectors if bad crimp

forces occur, e.g. after a long time of use,

the connector can be pinched by a pliers.

See the figure.

Page 43

Edition Manual Chapter Page

2008-03-17 Workshop Manual, Stiga Primo 5 Electrical System 9

Screw connectors

When cables shall be connected into screw

connectors, the cable shall be stripped off 5

mm only . No metallic conductor is allowed to

be exposed outside the terminal.

Warning!

Exposed conductors can cause

short-circuit and fire.

5.3.2 Circuit diagram

Page 44

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 1

6 Mower Deck

Contents in this chapter

6.4 Disassembly and assembly....... 5

6.4.1 Disassembly ............................5

6.4.2 Assembly.................................6

6.4.3 Replacing blades.....................7

6.4.4 Synchronising blades...............8

6.4.5 Safety.......................................8

6.4.6 Replacing driving belt ..............9

6.4.7 Replacing timing belt ...............9

6.4.8 Replacements of pulleys and bear-

ing boxes..................................11

6.1 General .........................................2

6.1.1 General tightening torque.........2

6.2 Cutting theory..............................3

6.2.1 Cutting height...........................3

6.3 Original blades.............................4

6.3.1 Why it is so important to use

original blades and blade tips

from the retail dealer?...............4

6. Mover Deck

Page 45

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 2

6.1 General

The decks are equipped with two synchronised rotating blades. The tracks of adjacent

blades are overlapping each other, which means that the synchronization is vit al. All shafts/

pulleys are pivoted in sealed and permanent lubricated bearing boxes.

All decks are provided with a coupling to simplify the cleaning and inspection procedure.

The decks are also provided with an manual adjusting device for the cutting height.

All decks are tested prior to delivery.

This chapter describes repair, replacements and adjustments of stressed parts of the

mower decks.

6.1.1 General tightening torque

Unless otherwise stated, the following tightening torque are applicable for screws and nuts

on the machine:

Tightening torques:

Thread Torque

M5 5 Nm

M6 9 Nm

M8 22 Nm

M10 45 Nm

Page 46

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 3

6.1 Cutting theory

6.1.1 Cutting height

The best cutting results are achieved when the

when the top third of the grass is cut off.

I.e. 2/3 of the length of the grass remains.

If the grass is long and has to be cut

significantly, cut twice using different cutting

heights.

Do not use the lowest cutting heights if the lawn

surface is uneven. This would entail a risk of the

blades being damaged against the surface and

the lawn’s top layer of soil being removed.

1/3

Page 47

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 4

6.2 Original blades

6.2.1 Why it is so important to use original blades and blade tip s from the

retail dealer?

The table below shows the demands on original blades and blade tips, delivered from the

retail dealer.

The table is intended to display the importance to use theoriginal blades and blade tips.

Demand Remarks

No splitting of blade tips. Using steel balls, the manufacturer simulates what can

happen if you drive over foreign objects on the lawn. The

sharpening of the blades may be destroyed, but no parts are

allowed to loosen or fly away.

No splitting of blades. The impact test is the toughes durability test a lawn mower can

be subject to. An iron pipe is placed right into the blades during

operation.

The blade can be deformed but it may not under any

circumstances, come off or split.

This test verifies that blades and other parts fulfil the high

safety requirements.

Optimal balance.

Minimum of noise.

Minimum of vibrations.

Blades and blade tips from the retail dealer have exactly the

same weight.

Blades and blade tips from the retail dealer are optimal

balanced.

This guarantee a minimum of vibration and noise which gives

a maximal durability of the machine.

It also guarantee that the machine corresponds to the

specification according to noise and vibrations.

Optimal cutting result. Blades and blade tips from the retail dealer are optimized in

the application. I.e. the blades are adapted to the shape och

the cover and the number of revolutions to give the best cutting

result.

.

.

.

Page 48

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 5

6.3 Disassembly and assem-

bly

Certain maintenance works are simplified if the

cutting deck is removed from the machine.

6.3.1 Disassembly

Disassemble the cutting deck as follows:

1. Set the highest cutting height.

2. Pull out the tensioning roller (H) and move the

belt down (J) at the side of the tensioning roller

to release the belt tension.

3. Work off the belt from the pulley.

4. Lift the deck and hook off the lifting wire (K).

5. Disassemble the locking screws (L) at both

sides.

H

J

K

L x2

Page 49

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 6

6. Hook off the deck from the front axes and take

it out in the forward direction. See the figure.

6.3.2 Assembly

Install the cutting deck as follows:

1. Hook the deck over the front axles.

2 Install the locking screws (L) on both sides.

3. Set the maximum cutting height.

4. Raise the deck and hook on the lift cable (K).

L x2

K

Page 50

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 7

5. Install the belt (J) onto the pulley.

6. Pull out the belt idler (H) and place it on the

outside of the belt so that the belt tensions.

6.3.3 Replacing blades

Warning!

The blades are sharp. Always wear

gloves when working with the blades

to avoid injury.

Warning!

When replacing, both blades on the

same blade bar must be replaced to

avoid imbalance.

Check that the blades are always sharp. This

produces the best cutting results. The blades

should be replaced once a year.

Always check the blades after a collision. If the

blade system has been damaged, defective

parts should be replaced.

Always use genuine spare parts. Nongenuine spare part s can entail a risk of

injury, even if they fit the machine.

The blades are replaceable. When replacing,

both blades on the same blade bar must be

replaced to avoid imbalance.

Attention!

Note the following when reassembling:

• The blades and blade bar must be installed

as in the figure.

• The blades can be turned 1/3 of a turn in their

mountings. Select positions so that the blades

are offset 90° from each other. See below.

Tightening torque:

• Screws (P) - 45 Nm

• Shear bolts (Q) - 9.8 Nm

In the event of a collision, the shear bolts (Q)

can break and the blades bend back. If this has

happened, install genuine shear bolts and

tighten as above.

H

J

P

PQ

Q

45 Nm

Page 51

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 8

6.3.4 Synchronising blades

The deck has synchronised blades.

If one of the blades has struck a solid object

(e.g. a stone), the synchronisation may be

altered. This entails a risk of the blades

colliding with each other.

Correctly synchronised blades must be offset

90° from each other. See the figure.

Always check synchronisation after a collision.

If the blades are not synchronised, one or more

of the following faults may have occurred in the

cutting deck:

The positive drive belt has slipped on the gear

wheels.

T orque limiting between gear wheels and blade

shaft has deployed. The arrows must be

opposite each other for an intact deck. When

torque limiting has deployed, the arrows are

not opposite each other.

The blade member is incorrectly installed on

the blade shaft. Can be installed in three

different positions. See (R).

6.3.5 Safety

To reduce the risk of accidental injury in the

event of a collision and to protect important

parts in the cutting deck, a force limiter is

integrated as follows.

• Shear bolts between blades and blade bar.

• Torque limiting between gear wheels and

blade shaft.

• Possibility of positive drive belt slipping on

the plastic gear wheels.

R

Page 52

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 9

6.3.6 Replacing driving belt

To replace the drive belt, it is not necessary to

disassemble the deck from the machine.

Replace the driv belt as follows:

1. Remove the deck cover by unscrewing the 3

fastening screws. See the figure.

The fourth screw shall not be removed.

2. Remove the belt guide (A) by unscrewing its

two screws.

3. Loosen the belt from the machine. See previous sections.

4. Fit the new belt and reassemble in the

reverse order. See also previous sections.

6.3.7 Replacing timing belt

To replace the timing belt, disassemble the

deck from the machine.

Replace the timing belt as follows:

1. Disassemble the deck from the machine. See

previous sections.

2. Remove the deck cover by unscrewing the 3

fastening screws. See the figure above.

3. Remove the belt guide (A) by unscrewing its

two screws. See the figure above.

4. Remove the belt pulley from the left shaft by

unscrewing its screw.

A

Page 53

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 10

5. Slacken the belt by loosen the four bearing

box screws a few turns.

6. Work off the timing belt from the pulleys and

fit the new one.

Observe the blades when fitting the new belt.

Correctly synchronised blades must be offset

90° from each other. See the figure.

7. Pretension the timing belt by forcing the loose

bearing box outwards and lock it in this position by tightening the four screws.

Page 54

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 11

8. Check the belt tension.

When pulling out the belt 10 mm, the force

required shall be 30-40 N. See the figure.

9. Loosen the four screws and adjust again if

necessary.

10.Assemble all parts in the reverse order.

6.3.8 Replacements of pulleys and

bearing boxes

Disassembly

1. Disassembly the drive belt and timing belt as

described above.

2. Disassembly the blades as described above.

3. Unscrew the pulley screw at the left shaft and

remove the spacer.

4. Pull up the plastic timing belt pulleys.

Use an extractor if necessary.

5. Disassemble the eight screws and take out

the bearing boxes.

10 mm 30-40 N

Page 55

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 12

Checks

When all parts are disassembled, check the

following items.

All defective parts shall be replaced

Item Check instruction

Bearing

noise

Rotate the shafts in the bearing

boxes and listen for abnormal

noise and feel if any uneven

resistance exists.

If any abnormal noise is heard or

if any uneven resistance exists

shall the bearing box be replaced.

Bearing

play

Force the shafts radially. No radial

play shell exist

Bearing

sealings

Check visually the bearing

sealings. All sealings shall be

intact.

Belts Bend the belts in all directions. No

cracks shall be visible.

Blades The blades shall be sharp. No

cracks are allowed.

Casing The casings shall be intact and

not show up errors any cracks.

Pulleys Check that the arrows coincide at

the timing belt pulleys. See

previous in this chapter.

Painting When the surfaces are completely

dry and clean, touch up the

paintwork. Use durable paint

intended for metal outdoors.

Page 56

Edition Manual Product Page

2008-03-18 Workshop Manual, S tiga Primo 6 Mower Decks 13

Assembly

All parts shall be assembled in the reverse

order.

• Note the following during the assembly:

• Lubricate all links.

• The blades shall be orrectly synchronised.

Fit the parts according to the figure.

Loading...

Loading...