Stiga Park 2WD, Park Compact, Park CH 4WD, Park CH 2WD, Park Pro 4WD Workshop Manual

WORKSHOP MANUAL

PARK

2008 - 201ˀ

TABLE OF CONTENTS

1 - General instructions

2 - Chassis and body

3 - Steering

4 - Hydraulic system

5 - Belts

6 - Control Wires

7 - Electrical System

All brands, names, logos and trademarks mentioned belong to their respective owners.

© by STIGA - No use of the illustrations or duplication, reproduction or translation, even partial, of the texts in this

document may be made without explicit authorisation.

WORKSHOP MANUAL

PARK

1 General instructions

Contents in this chapter

Chapter

1 - General instructions

EDITION

2018

Page

1

1.1 Introduction ...................................... 2

1.1.1 Responsibility declaration .............. 2

1.1.2 How this manual is used ................ 2

1.1.3 Abbreviations ................................. 2

1.2 Safety Precautions ........................... 2

1.2.1 Symbols and warnings .................. 3

1.2.2 Warm parts .................................... 3

1.2.3 Moving parts .................................. 3

1.2.4 Lifting and blocking up ................... 3

1.2.5 Cleanliness .................................... 3

1.2.6 Tightening torque ........................... 3

1.2.7 Sharp edges .................................. 3

1.2.8 Replacement parts ........................ 3

1.2.9 Inspection ...................................... 3

1.3 Unpacking and assembly ................ 4

1.3.1 Unpacking ..................................... 4

1.3.2 Battery ........................................... 5

1.3.3 Final checks .................................. 6

1.4 Service .............................................. 7

1.4.1 Service times ................................. 7

1.4.2 First Service .................................. 8

1.4.3 Intermediate Service ..................... 8

1.4.4 Basic Service ................................ 9

1.4.5 Description of service points ....... 10

1.5 Transmission .................................. 14

1.5.1 Transmission oil and filter change

interval .................................................. 14

1.6 Technical specifications ................14

1.6.1 General tightening torque ............. 14

1.7 Instructions for use ........................ 14

General

This Workshop Manual covers all Park – Park Pro models from 2008. The Park 120-220

have a separate workshop manual. The Park Pro models from 2015 with steering cylinder

have a separate workshop manual.

This Manual do not cover repair instructions for the engines. Regarding engines, contact

the respective representative in the actual country.

This Manual and its specifications are valid for machines in their original design. In case of

modified or changed machine, i.e. the engine is replaced, the manual accordance is limited.

The manual is divided in the following chapters:

Chapter 1 is this chapter

Chapter 2 Chassis

Chapter 3 Steering

Chapter 4 Hydraulic system

Chapter 5 Belts

Chapter 6 Control Wires

Chapter 7 Electrical system

1.1

WORKSHOP MANUAL

PARK

Introduction

Chapter

1 - General instructions

EDITION

2018

Page

2

1.1.1

In spite of the great care we have taken there may be errors in this publication.

The author cannot be made liable for incorrect or missing information.

STIGA reserves the right to regularly change product specifications without prior notice.

All the information in this book is based on the information available at the time of

production. Illustrations and photographs may be arranged schematically, which implies

that one picture may cover several models and therefore not correspond exactly with all

models.

1.1.2

To make this manual easy to understand we have divided the machine into its main

systems and components. These parts are now the different chapters in the book.

Each chapter is divided up into sections.

There is a quick-guide on the cover of this book, which refers to the different chapters. In

each chapter there is a detailed table of contents so that you can easily and quickly find

what you are looking for.

Always check that you are reading the right chapter for your particular machine before

starting the repair work.

1.1.3

Responsibility declaration

How this manual is used

Abbreviations

The following abbreviations are used in this manual:

HST Hydrostatic Transmission PTO Power Take Off

1.2

Safety Precautions

This manual has been written primarily for trained mechanics working in a well-equipped

workshop.

A basic knowledge of repairs, tools and repair instructions is, however, always a

prerequisite for first-rate results.

A qualified mechanic should always be consulted if the owner does not have sufficient

knowledge to carry out repairs.

During the warranty period all service must be carried out by an Authorised Workshop for

the warranty to be valid.

The following basic points should be observed if the machine is to function perfectly:

•

Follow the service schedule.

•

Be on the alert for sudden vibrations or abnormal noise to avoid major breakdowns.

•

Always use Genuine Spare Parts

•

Follow the descriptions in this manual carefully. Do not take any short cuts.

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

Page

3

1.2.1

Symbols and general warnings

Warning!

This symbol indicates a risk of

personal injury or damage if the

instructions are not followed.

Note!

This text indicates a risk of damage to

the material or risk of unnecessarily

complicated work if the instructions

are not followed.

1.2.2

Please observe that engine and exhaust

system picks up a lot of heat during use.

This applies above all to the silencer of

machines equipped with catalytic

converter.

To avoid injuries, allow the machine to cool

before any kind of repairs are made to or

near parts of the engine or exhaust

system.

1.2.3

The machines are all equipped with v-belt

transmissions. Always stop the engine and

remove the starter key before inspections

or repairs are carried out.

Always use extreme caution when testing

systems with moving parts to avoid

injuries.

Always use Genuine Spare Parts during

service work.

1.2.4

Warm parts

Moving parts

Lifting and blocking up

1.2.5

Clean the machine before starting repairs.

Dirt that penetrates into sensitive

components can seriously influence the

service life of the machine.

1.2.6

Unless otherwise stated the tightening

torque in the tables in the section

Technical specifications must be used for

the different sizes of screws. This does not

refer to self-tapping screws, which are

mainly used for the assembly of body

parts.

1.2.7

Watch out for sharp edges, especially

when working with the mower deck. The

blades can be very sharp. Always wear

gloves when working with the blades.

1.2.8

Always use Genuine Spare Parts during

service work.

1.2.9

Each part dismantled in conjunction with

service work must be inspected.

Examine for: wear, cracks, out of

roundness, straightness, dents,

discolouring, abnormal noise and

jamming.

Cleanliness

Tightening torque

Sharp edges

Replacement parts

Inspection

Before work under the machine, always

make sure that lifting devices and jackstands are approved for the weight.

Work safe!

WORKSHOP MANUAL

PARK

1 - General instructions

1.3 Unpacking and assembly

Every STIGA Park has undergone an extensive

control programme before delivery. The

machines are delivered as completely

assembled as possible.

Thanks to this the assembly on delivery is rapid

and easy.

The correct and careful assembly of the

machine on delivery is a simple way of ensuring

satisfied customers!

Note!

The machine shall remain placed on the

pallet during the unpacking and

assembly.

1.3.1 Unpacking

Chapter

EDITION

2018

Page

4

Open up the crate and release the part as

follows:

1. Check the air pressure in the tyres. The

pressure is designated on the floor mat.

The air pressure in the tyres is of critical

importance for the performance and

handling of the machine. The correct air

pressure for mowing is 0.6 bar (9 psi) in the

front tyres, and 0.4 bar (6 psi) in the rear

tyres.

When using heavy accessories, e.g. snow

thrower, it may be necessary to increase the

pressure somewhat. However, the

maximum permitted pressure is always

0.8 bar (12 psi).

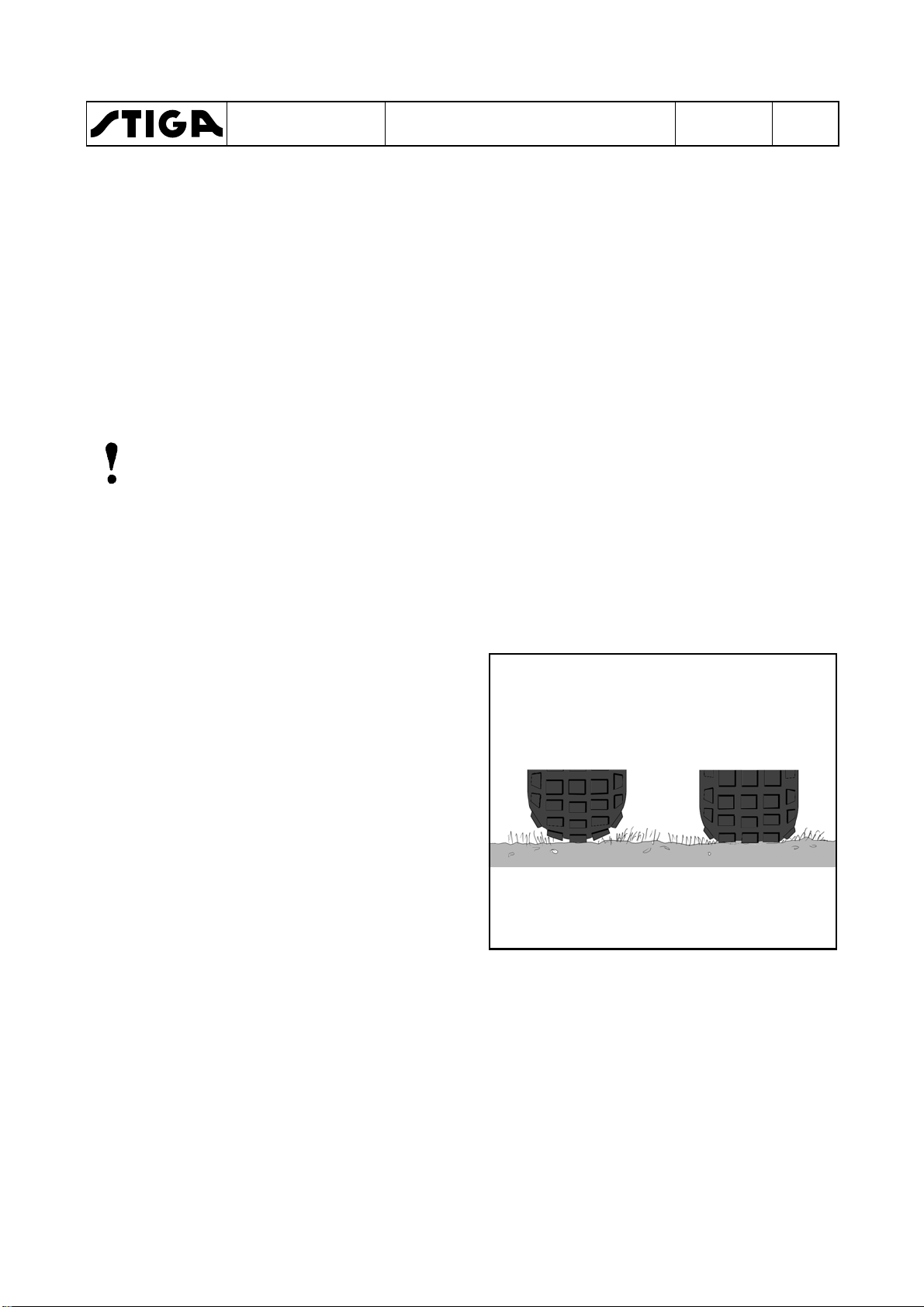

Too high pressure Correct pressure

Too high pressure in the tyres leads to that

the machine drives poor due to:

•

A small surface in contact to the ground.

•

Hard tyre = less flexibility = self cleaning characteristic deteriorate.

2. Remove the following parts from the

package and put them on the floor.

•

The battery (some models).

•

The steering wheel.

•

The plastic bag, containing owners manuals,

information media and assembly screws.

WORKSHOP MANUAL

PARK

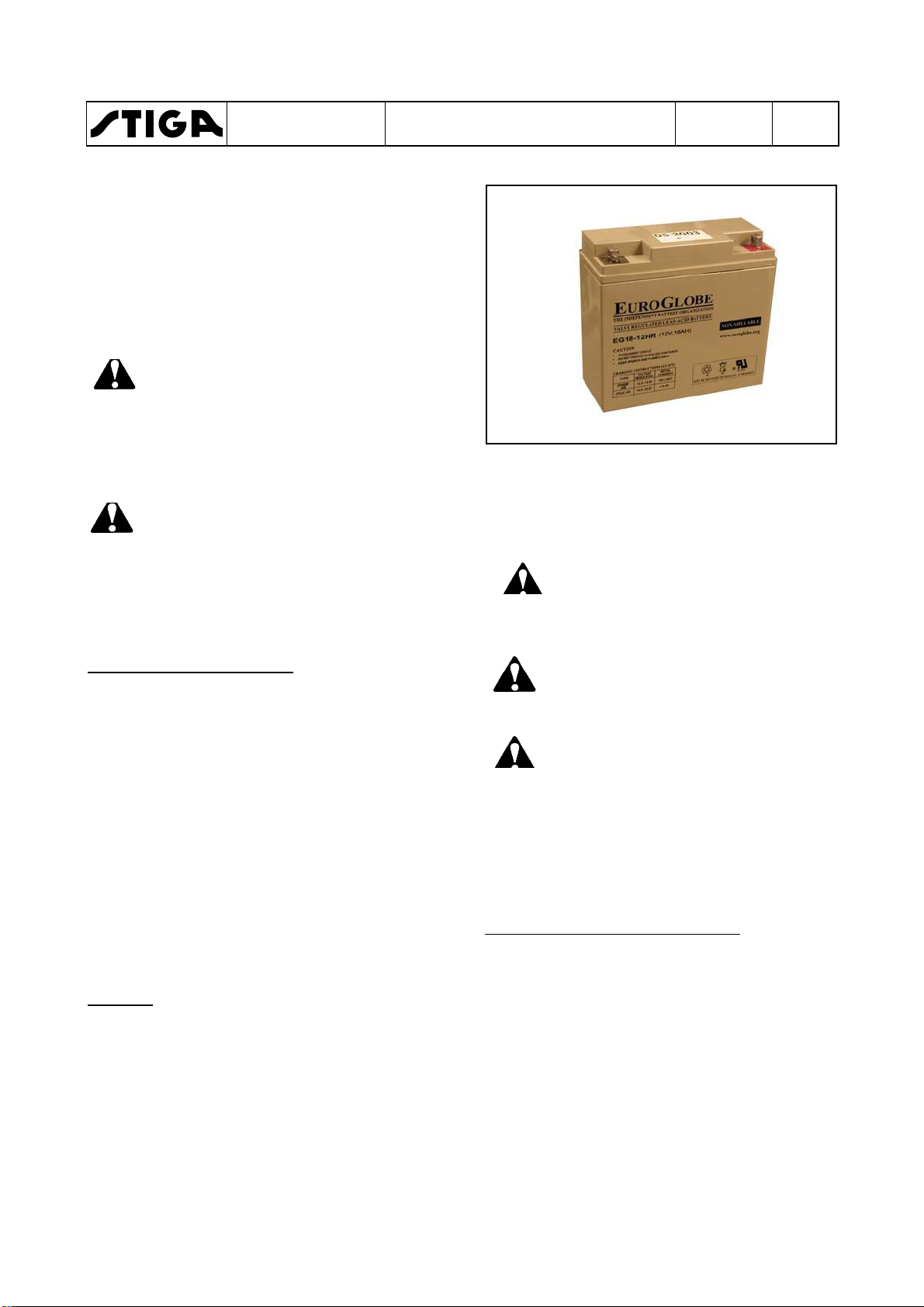

1.3.2

The battery is a valve regulated battery.

Load and assemble the battery, following the

instructions below.

The battery needs limited maintenance. Is has

no electrolyte levels or plugs.

Charging with the engine

The battery can be charged using the engine’s

generator as follows:

1. Install the battery in the machine as shown

2. Place the machine outdoors or install an

3. Start the engine according to the

4. Allow the engine to run continuously for 45

5. Stop the engine. The battery will now be

Storage

Battery

Warning!

Do not wear rings, metallic bracelet,

chain round the neck or similar metal

objects when working with the

battery. It can cause short-circuit,

burns and fire.

Warning!

The battery must be fully charged be-

fore being used for the first time. The

battery must always be stored fully

charged. If the battery is stored while

discharged, serious damage will occur.

below.

extraction device for the exhaust fumes.

instructions in the user guide.

minutes.

fully charged.

1 - General instructions

Chapter

A

EDITION

2018

Page

5

If the cables are disconnected/

connected in the wrong order,

there is a risk of a short-circuit

and damage to the battery.

If the cables are interchanged,

the generator and the battery

will be damaged.

Charging using battery charger

When charging using a battery charger, a

battery charger with constant voltage

must be used.

The engine must never be driven

with the battery disconnected.

There is a risk of serious damage to the generator and the

electrical system.

The battery voltage is not allowed to drop under

12,5 V during storage.

Make sure that the battery voltage always is

more than 12,5 during storage. If not, the

battery will be destroyed.

Ordering number: 1136-0602-01.

The battery can be damaged if a standard

type battery charger is used.

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

Page

6

1.3.3

Final checks

Removing from pallet

All the above measures shall have been done with the machine standing on the pallet.

Now, loosen the remaining straps and roll off the machine from the pallet.

Fit and adjust accessories.

Test driving

Warning!

Do not drive without a work equipment (mover deck) attached. Risk for

turning over.

Drive the machine for a few minutes. Test all the functions. Pay special attention to the

safety functions. If the machine is to be delivered with mower deck or other accessories,

fit these before test driving the machine.

HST oil

Check the oil level in the HST’s expansion tank after test driving, and top up if

necessary.

Engine oil

Check the oil level in the engine and top up if necessary.

Steering chain / Steering wire

Check that the steering chain / steering wire is sufficiently taut. Adjust if necessary.

Miscellaneous

Give the machine a general inspection.

•

Is the machine clean?

•

Is there any oil leakage?

•

Abnormal noise or rattle?

Receipt

By filling in the guarantee certificate you guarantee that the delivery service has been

correctly conducted.

Remember to make sure that the customer receives all the documentation when the

machine is collected / delivered.

Service

Shall be performed

First service

Within 5 hours of running

Intermediate service

After the first 50 hours of running and then 50 hours after/before

Basic service

Every 100 hours or every year, which first occur.

Service

Shall be performed

First service

Within 5 hours of running

Intermediate service

After the first 100 hours of running and then 100 hours after/before

Basic service

Every 200 hours or every year, which first occur.

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

1.4 Service

Every new machine is delivered with a service book. This service book is part of the

active post-market programme and shall be kept in a safe place during the entire

lifetime of the machine. Hand over the service book if the machine is sold in 2:nd

hand.

Service should generally be carried out at least every 50 operating hours (exception

of the first service), although in accordance with the conditions below.

There are three different grades of service events. Every service event consists of a

number of service points as described in the following paragraphs. Every service

point has a number which refer to a describing text after the schedules.

The grades of service events are:

•

First service

•

Intermediate service

•

Basic service

Some service points do not coincide with the scheduled service intervals, but shall

be performed in connection with a scheduled service when possible. E.g. some items

shall be performed at every second service and some also between two services.

These service points are described with procedure and interval in the respective

“Instruction for use”.

Page

7

Typical service points wich not coincide with scheduled service intervals are:

•

Cleaning/changing air filter in some engines.

•

Change of oil in some engines.

•

Valve adjustments for some engines.

•

Change of transmission oil in 4 WD machines.

•

Change of spark plug in some engines.

1.4.1

Service times

Petrol driven machines

every basic service.

Diesel driven machines

every basic service.

Number

Service point

1

Safety check.

2

Tyres, air pressure.

3

Engine oil and filter, see “Engine - Transmission” at

page 14.

4

5

Belt transmissions, check.

6

Steering adjustment.

7

Battery check.

21

Number

Service point

1

Safety check.

2

Tyres, air pressure.

3

Engine oil and filter, see “Engine - Transmission” at

4

6

Steering adjustment.

9

10

Air filter catalytic converter, cleaning.

11

Cooling fins, clean.

12

Lubrication

WORKSHOP MANUAL

PARK

Chapter

1 - General instructions

EDITION

2018

Page

8

1.4.2

First Service

This service is very important to safeguard the continuing function of the machine.

The first service includes the service points as per the table below.

Oil level in HST, see “Engine - Transmission” at

page 14.

Test driving.

1.4.3 Intermediate Service

The intermediate service is not as extensive as the Basic Service and can therefore be

conducted by the customer, or by an authorised Service Workshop. Regardless of who

conducts the service, it must be documented in the service book..

page 14.

Oil level in HST, see “Engine - Transmission” at

page 14.

Air filter, cleaning.

Note!Ɩ¿»É»ÂºÈ¿Ì»Ä÷¹¾¿Ä»ÉƓ

Check/tighten engine support screwsupport screws every 100 hours.

Number

Service item

1

Safety check

2

Tires, air pressure

3

4

Oil level in HST, see “Engine - Transmission” at

page 14.

5

Belt transmissions, check

6

Steering adjustment

7

Battery check

8

Air filter for engine, see “Engine - Transmission” at

page 14.

9

Air filter catalytic converter, see “Engine -

(Valid for machines with catalytic converter only)

10

Cooling fins, clean

11

Spark plug, check/replace

13

Transmission, check

14

Speed check

15

Bearing boxes, check**

16

Exhaust system, check*

17

Electrical system, check*

18

19

Blades, check**

20

Power take-off, check

21

Control check

22

Valve play***

23

Test driving

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

1.4.4 Basic service

The Basic Service must always be conducted by an authorized Service Workshop,

and documented with a stamp in the service book.

Engine oil and filter, see “Engine - Transmission” at

page 14.

Page

9

Transmission” at page 14.

Mower deck, check**

*) See also “Safety check”.

**) See also the mover deck manual.

***) See the engine manual.

Note!Ɩ¿»É»ÂºÈ¿Ì»Ä÷¹¾¿Ä»ÉƓ

Check/tighten engine support screwsupport screws every 100 hours.

Test

Status

Action

Result

1 Brake pedal not pressed.

Turn the key and make a

Engine shall

2 Brake pedal pressed.

Turn the key and make a

Engine shall

3 Engine running.

Operator rises from the

Engine shall

4 Engine running.

Disconnect cable from the

Engine shall

stop after a few

Test

Status

Action

Result

1 Operator not sitting in seat.

Turn the key and make a

Engine shall

2 Brake pedal not pressed.

Turn the key and make a

Engine shall

3 Brake pedal pressed.

Turn the key and make a

Engine shall

4 Engine running.

Operator rises from the

PTO magnetic

5 Cruise control activated.

Operator rises from the

Cruise control

6 Engine running.

Disconnect cable from the

Engine shall

stop after a few

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

1.4.5 Description of service points

1. Safety check

Check the safety functions. It is often appropriate to do this check in conjunction with

test driving. The following items shall be checked at all machines:

•

No leakage on fuel lines and connections.

•

No mechanical damages to the electrical cables. All insulation intact.

•

The muffler shall be undamaged and its screws tightened. No exhaust leakage in

connections.

Machines with mechanic PTO

Page

10

PTO not activated.

PTO activated.

PTO activated.

Machines with electric PTO

Brake pedal pressed.

PTO not activated

PTO not activated.

PTO magnetic clutch activated.

start attempt.

start attempt.

seat.

shut off valve.

start attempt.

start attempt.

start attempt.

not start.

not start.

stop.

minutes.

not start.

not start.

not start.

PTO magnetic clutch activated.

(If applicable)

seat.

seat.

shut off valve.

clutch shall

disengage.

shall

disengage

minutes.

Test

Status

Action

Result

1 Operator not sitting in seat.

Turn the key and make a

Engine shall

2 Brake pedal not pressed.

Turn the key and make a

Engine shall

3 Brake pedal pressed.

Turn the key and make a

Engine shall

4 Engine running.

Operator rises from the

PTO magnetic

5 Hydraulic lift in neutral position.

Attempt to engage the

PTO magnetic

6 Engine running.

Disconnect cable from the

Engine shall

stop after a few

WORKSHOP MANUAL

PARK

Machines with electric PTO and hydraulic lift

Chapter

1 - General instructions

EDITION

2018

Page

11

Brake pedal pressed.

PTO not activated

PTO magnetic clutch not activated.

PTO magnetic clutch activated.

PTO magnetic clutch activated.

start attempt.

start attempt.

start attempt.

seat.

PTO magnetic clutch.

shut off valve.

not start.

not start.

not start.

clutch shall

disengage.

clutch shall not

engage.

minutes.

2 Tyres, air pressure

WORKSHOP MANUAL

PARK

Chapter

1 - General instructions

11 Spark plug

EDITION

2018

Page

12

Check the air pressure. Adjust if necessary.

The recommended air presure is

designated at the floor mat.

3 Engine oil and oil filter

See the “Instructions for use”, delivered

with the machine or “Instructions for use” at

page 31. See also the engine manufacturer

manual.

4 Oil, HST

See section 4 or the “Instructions for use”,

delivered with the machine.

5 Belt transmissions, check

Check the condition of all the belts and belt

tensioners.

6 Steering, adjustment

See section 3.

7 Battery, check

Valid for dry charged batteries only.

Check the acid level. Top up with distilled

water if necessary. See page 6-7.

8 Engine air filter

See the “Instructions for use”, delivered

with the machine. See also the engine

manufacturer manual.

9 Catalytic converter air filter

See the “Instructions for use”, delivered

with the machine. See also the engine

manufacturer manual.

10 Cooling fins

Remove protective covers from the engine

and cleans between cooling fins. Use a

brush and compressed air. See also the

engine manufacturer manual.

Remove the spark plug (not valid for Pro

Diesel) and clean it or replace if necessary.

See also the engine manufacturer manual.

12 Lubrication

Lubricate the articulation point (4 nipples)

and all moving parts such as wires and

levers. See also the instruction manual,

delivered with the machine.

13 Transmission

Listen for abnormal noise.

Manual models: Check that the drive

function works properly at all gears. Adjust

if required.

14 Speed check

Check that the speed corresponds to the

specified value. See pages 18-22.

15 Bearing boxes

Listen for abnormal noise from the

bearings. Check that there are no wear,

play or seizure.

16 Exhaust system

Check that there are no cracks, leakage or

other damages. Check the attachment

devices. See also the engine

manufacturer manual.

17 Electrical system

Check that there are no damaged cables,

contacts or other devices. Check that all

cables are properly secured to the chassis

and with cable holders. Check that there is

no friction between cables and chassis,

which can result in cable damage and

short circuit.

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

Page

13

18 Mower deck

Warning!

The blades are sharp. Always

wear gloves when working with

the blades to avoid injury.

Check if there are collision damages or

wear at the deck body and painting. Align,

repair and touch up the painting as

required.

Check the tightening of the bearing boxes

screws and tighten.

Rotate the blades and check the the shafts

are correct, not bent, no abnormal bearing

noise and no plays.

Check the belts and their tensions, see

section 4.

Check that the lifting mechanism moves

evenly, not jammed and no play and that it

locks in desired position.

Check the electrical function of the

electrikal mower lifter (if applicable).

Check the plastic guide bar between the

blades. Replace if required.

19 Blades

Warning!

The blades are sharp. Always

wear gloves when working with

the blades to avoid injury.

Check that the blades are sharp. Sharpen

as reqiured.

20 Power take-off (PTO)

Check that the magnetic clutch (if

applicable) engage the work equipment

rotation in the desired time and that it not

slips during normal load. Replace the

clutch if necessary.

Check that the power take-off belt (if

applicable) engage the work equipment

rotation in the desired time and that it not

slips during normal load. Adjust if

necessary. See section 4.

Check that the power take-off brake (if

applicable) brakes the rotation movement

in the desired time. Adjust if necessary.

See section 4.

21 Control check

Check that all controls function properly,

that there are no jammings or excessive

plays. Adjust if nesaccary. See section 5.

22 Valve play

See the engine manual regarding

procedure and interval.

23 Test driving

Drive the machine during a few minutes

and make the following attentions in

different speeds and turnings in right and

left. Check that all functions work evenly

and proper and without any abnormal

noise.

•

Brake function

•

Clutch function

•

Power take-off

•

Steering

Check that there are no abnormal

vibrations.

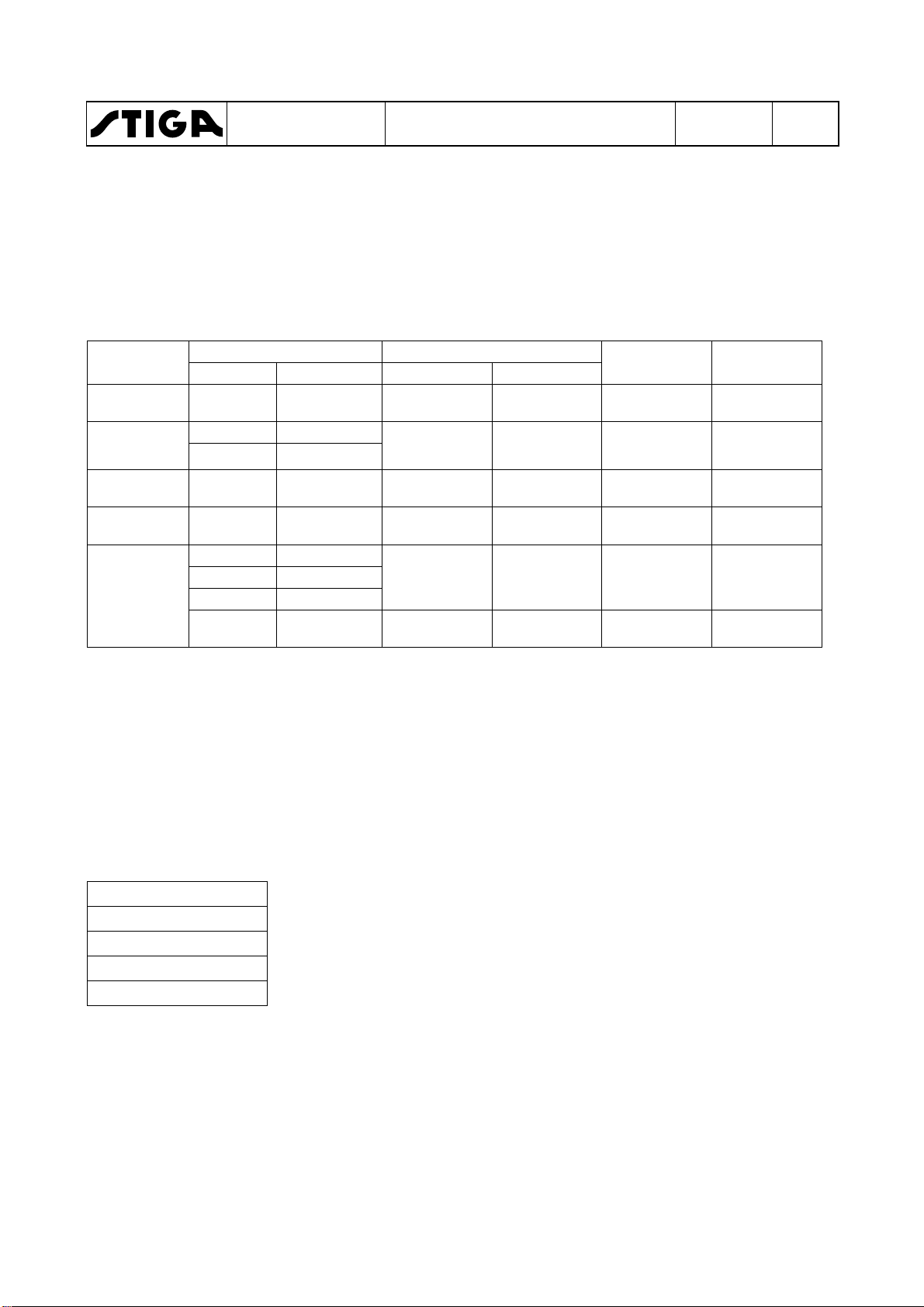

Machine

Transmission

Oil and filter change interval

Oil volume

Oil grade

Description

Number

1:st time

Thereafter

Park 2WD

K46

1137-0123-01

Park Compact

Park CH 2WD

Park CH 4WD

Park Pro 4WD

KTM10G

1134-5701-01

KTM10F

1134-5702-01

KTM-13

118475000/0

5 h

200 h

4,7 Liter

5W-50

Thread

Torque

M5

5,7 Nm

M6

9,8 Nm

M8

24 Nm

M10

47 Nm

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

1.5 Transmission

1.5.1 Transmission oil and filter change interval

Below is listed oil and filter data for the transmissions.

-

and CH 4WD

without servo

with servo

with servo

K574G 1137-0124-01 5 h 200 h 3,5 Liter

KTM10M 1134-6029-01

K57-V 1137-0126-01

K574F

KTM10M

KPL 10ALP 1134-5700-01 5 h 200 h 4,2 Liter

1137-0125-01

1134-6029-01

-

-

1,3 Liter

3,6 Liter

EDITION

2018

SAE 10W-30

(20W-50)

Synthetic oil

5W-50

Synthetic oil

5W-50

Synthetic oil

5W-50

Synthetic oil

5W-50

Page

14

1.6 Technical specifications

1.6.1 General tightening torque

Unless otherwise stated, the following

tightening torque are applicable for screws and

nuts on the machine:

Tightening torques

1.7 Instructions for use

Synthetic oil

Some procedures, e.g. changing engine oil,

engine filter etc., are refered to the owner´s

manual, delivered with the actual machine.

The owner´s manual can also be downloaded

from STIGA´s homepage. Go to www.STIGA.com

and click further to your actual language and

heading.

WORKSHOP MANUAL

PARK

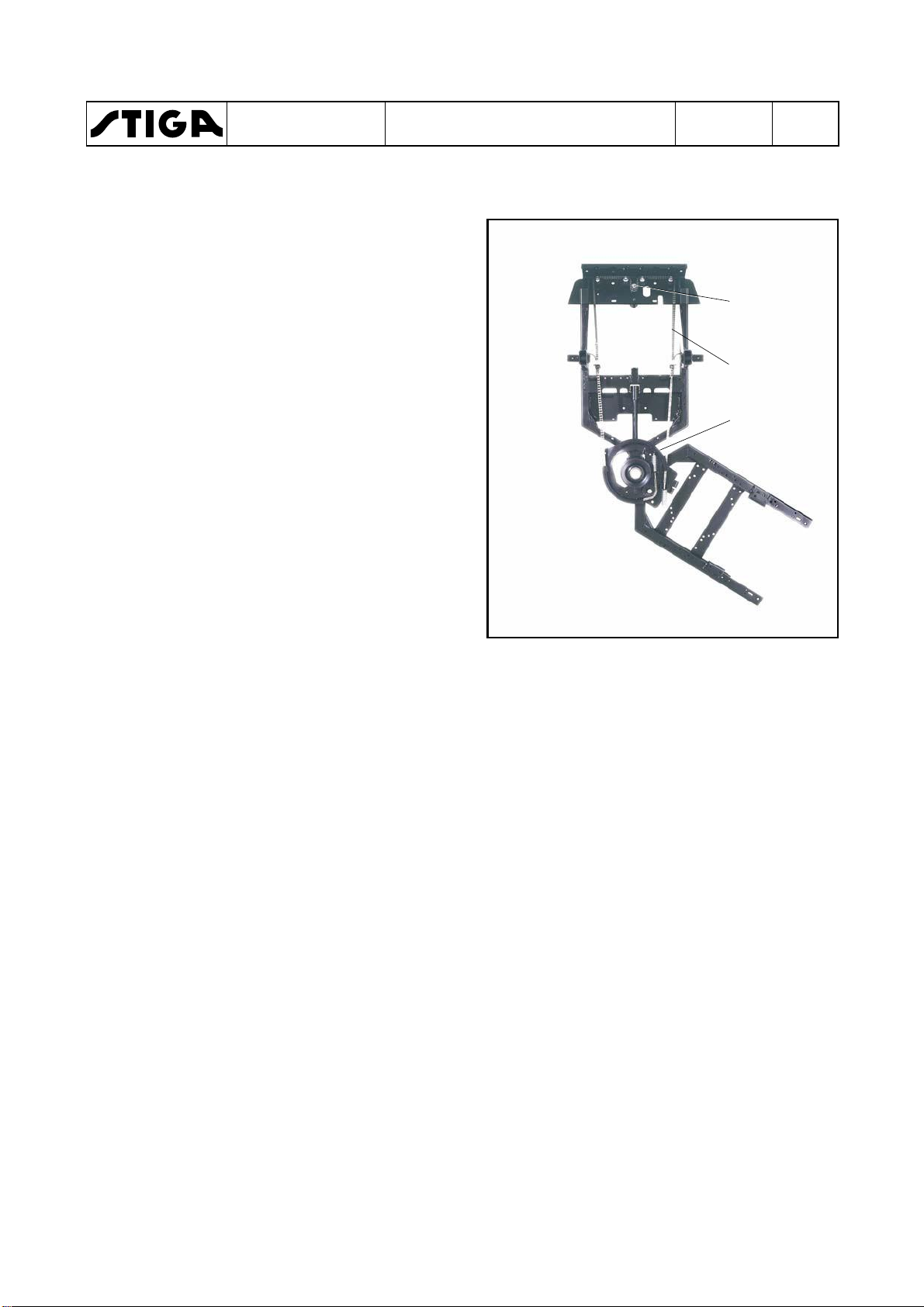

2 - Chassis and body

Chapter

EDITION

2018

2 Chassis and body

Contents in this chapter

2.1 Rear wheel ........................................ 2

2.1.1 Assembly ....................................... 2

2.2 Lubrication chassis .......................... 3

2.3 Hydraulic pump ................................ 4

2.3.1 Dismantling .................................... 4

2.3.2 Assembly ....................................... 6

General

To facilitate the driving, handling of work equipment and to make it comfortable for the

driver, the machines are equipped with a various number of aid equipments. These

equipments are mainly the same for all the machines covered by this manual, but in some

cases configurated in different ways. Where divergences occour between the machines,

particular instructions are given for each particular equipment.

Page

1

This chapter gives a brief description of the equipments and describes their repair and

replacements.

2.1

WORKSHOP MANUAL

PARK

Rear wheel

Chapter

2 - Chassis and body

EDITION

2018

Page

2

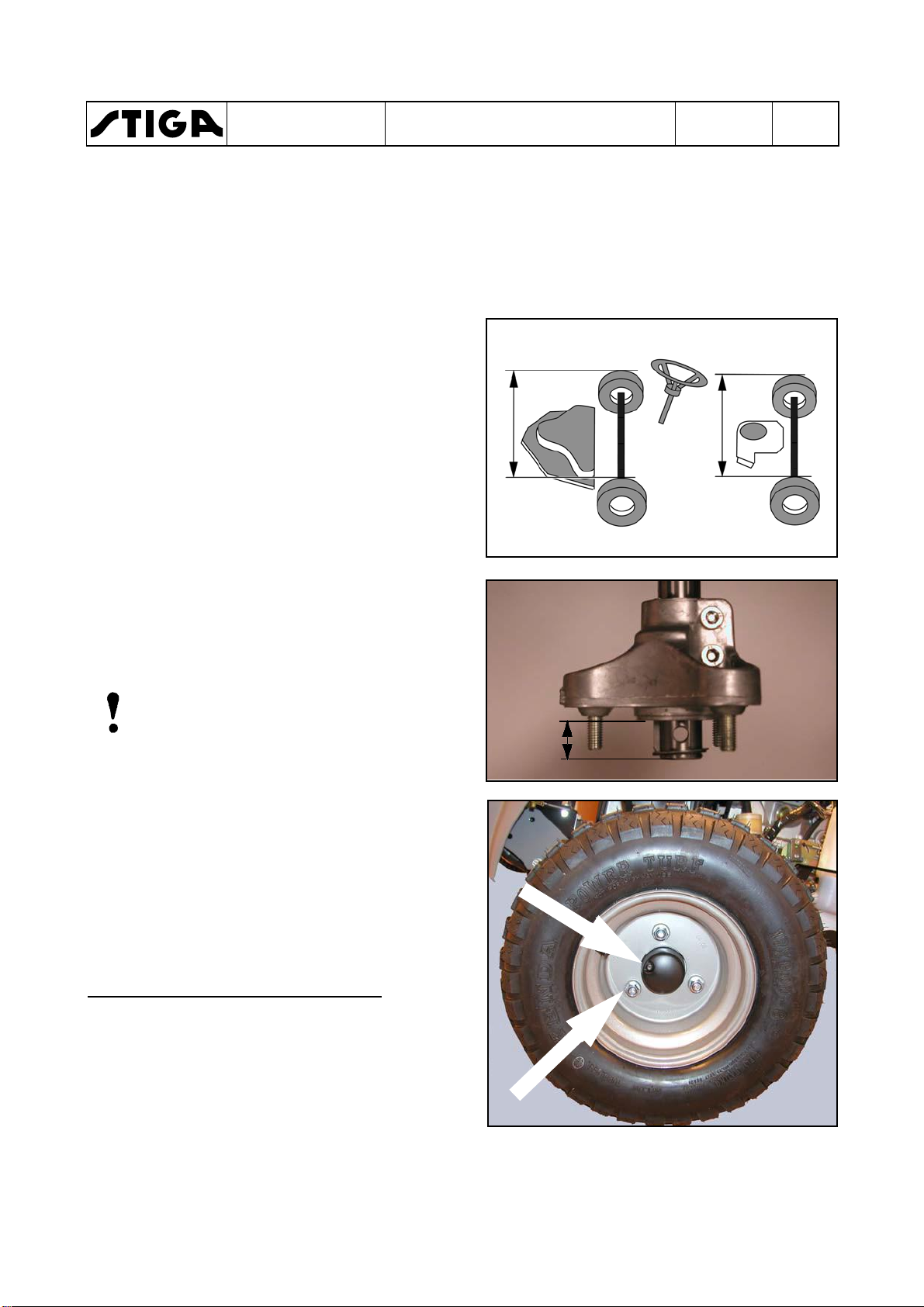

2.1.1

1. Push the hub on the shaft until it rests

2. Assemble the washer and the circlip onto the

3. Check the key and assemble it in the groove,

4. Assemble the rear wheel without tightening

5. Measure the distance (X) between the front

Assembly

against the transmission body.

shaft. The washer shall rest against the

circlip.

against the washer.

the nuts.

wheels and adjust the rear hubs until the

distance between the rear wheels is the

same (X).

Pull out the hubs until the measure (Y) is the

same at the both sides.

Note!

If the measures between the wheels front

and rear not is the same, the machine will

be hard to steer.

X

X

Y

6. Tighten the two allen screws, using a 8 mm

allen key.

The tightening shall be performed in two

steps. Tighten first to 18 Nm and then, finally

to a torque of 24 Nm.

7. Assemble the rear wheel and the protecting

cover.

Asembly when tyre chains are used

To give place for the tyre chains, the distance X

can be increased. If necessary until the hub

rests against the washer.

15/17 mm box spanner

WORKSHOP MANUAL

PARK

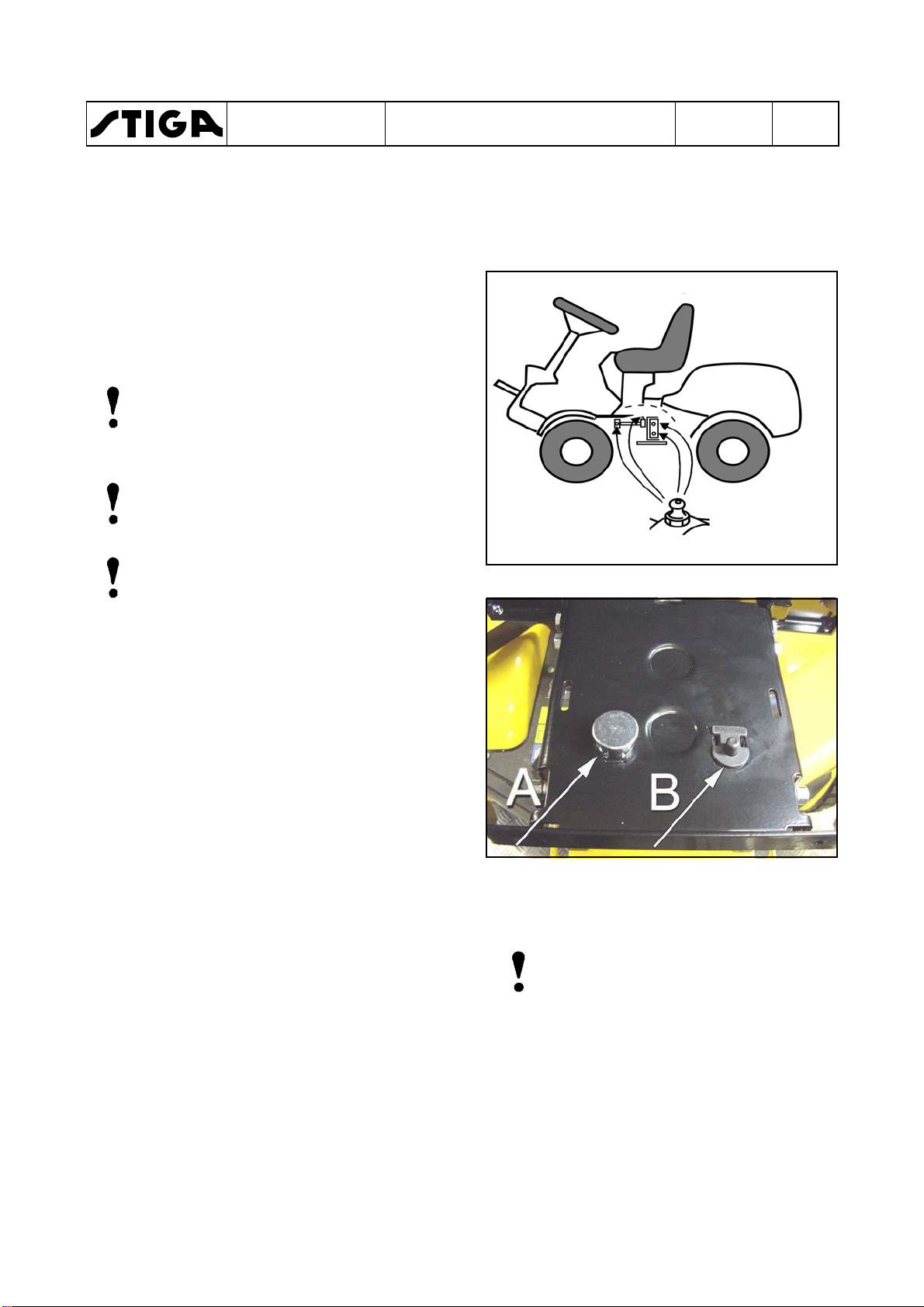

2.2

Lubrication chassis

The bearing for the articulation must be

lubricated in accordance with the service

schedule. Other moving parts are lubricated

once per season, although at least every 50

operating hours.

Note!

Lubrication is equally important for a

machine that is only used for a few hours

per year.

Note!

The lubricant provides not only

protection from wear but also from rust.

Note!

The machine should always be

lubricated before prolonged storage.

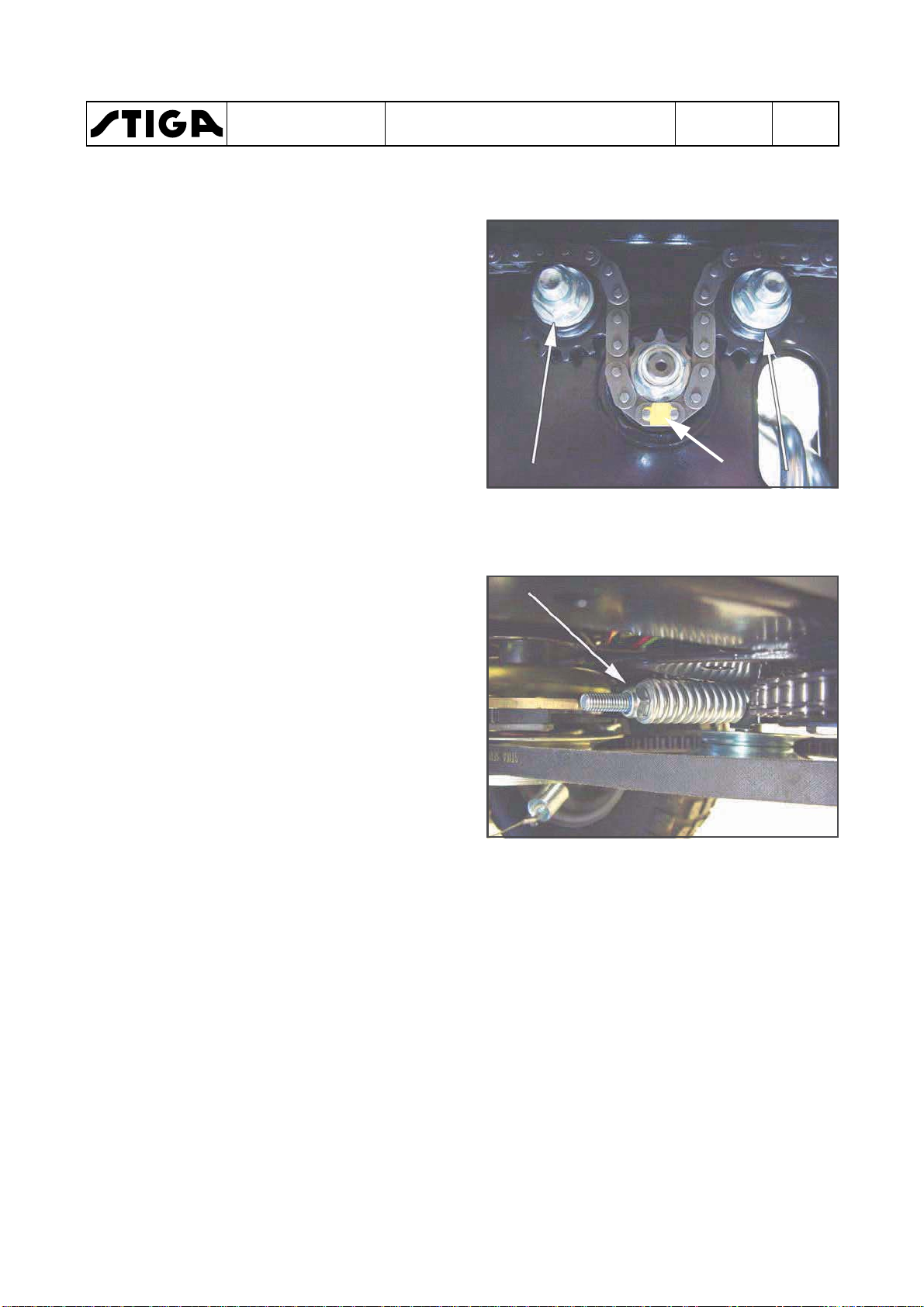

The bearing for the articulation has four grease

nipples which must be lubricated with universal

grease.

The steering chain must be lubricated with

chain spray two or three times per season.

If the chains are heavily fouled: dismantle the

chains and wash them.

Refit and lubricate them.

The pressure pin (A) in the seat suspension

must be lubricated to avoid problems with the

safety circuit.

Plastic bearings, e.g. the brake pedal bearing,

hydrogear pedal bearing and steering-column

bearing, must be lubricated with grease or

lubricating spray.

Drop a little engine oil or lubricating spray in the

ends of the control wires two or three times a

year.

Chapter

2 - Chassis and body

Note!

Wires on machines used in

freezing conditions should not be

lubricated with engine oil since

this can lead to the control cables

seizing in the cold.

The wires on such machines

should be lubricated with a

fluent, strongly penetrating

lubricant, e.g. 5-56 or WD40.

EDITION

2018

Page

3

WORKSHOP MANUAL

PARK

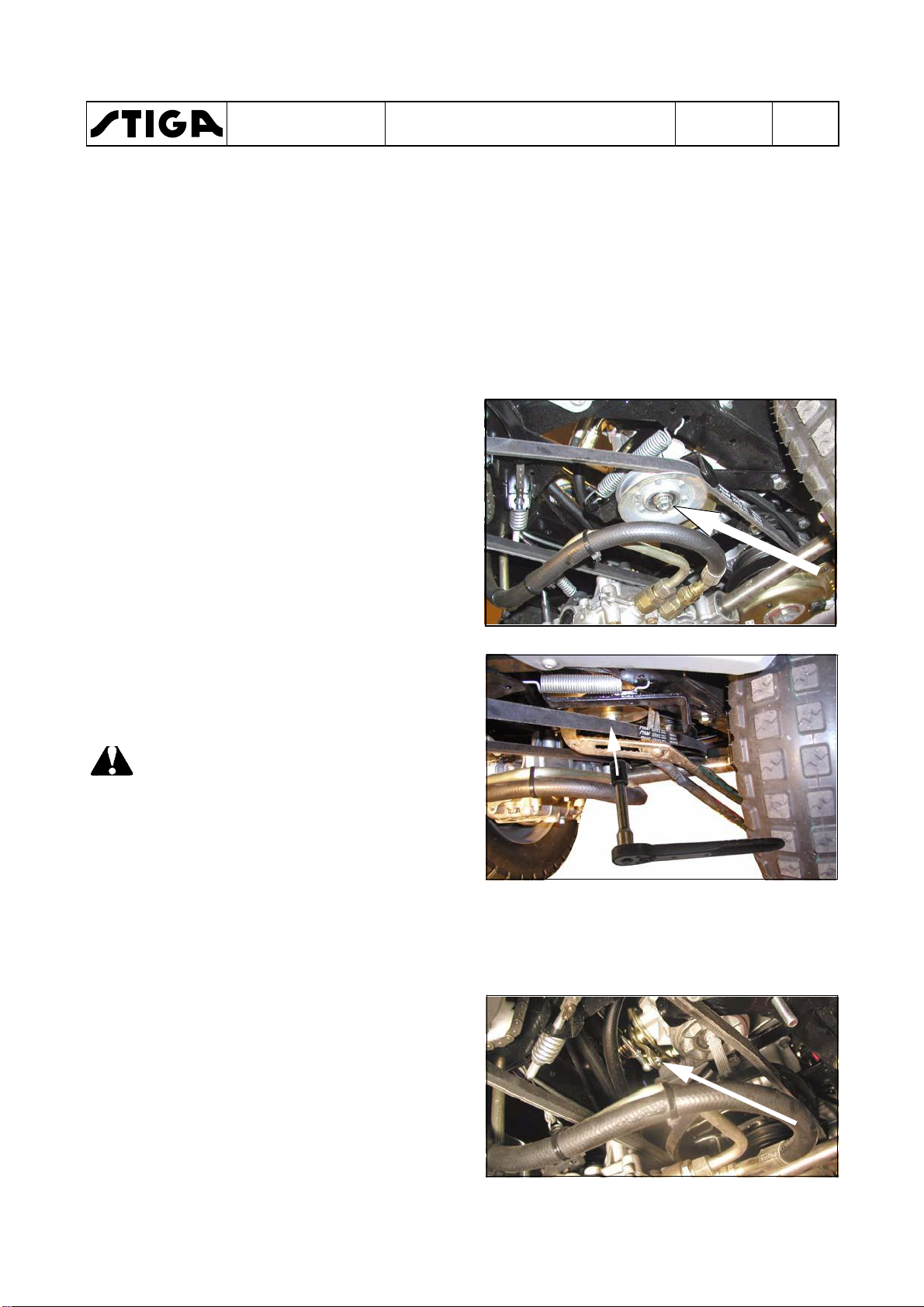

2.3

Hydraulic pump

This section will describe the replacement

procedure for the external hydraulic pump in

4WD Park machines.

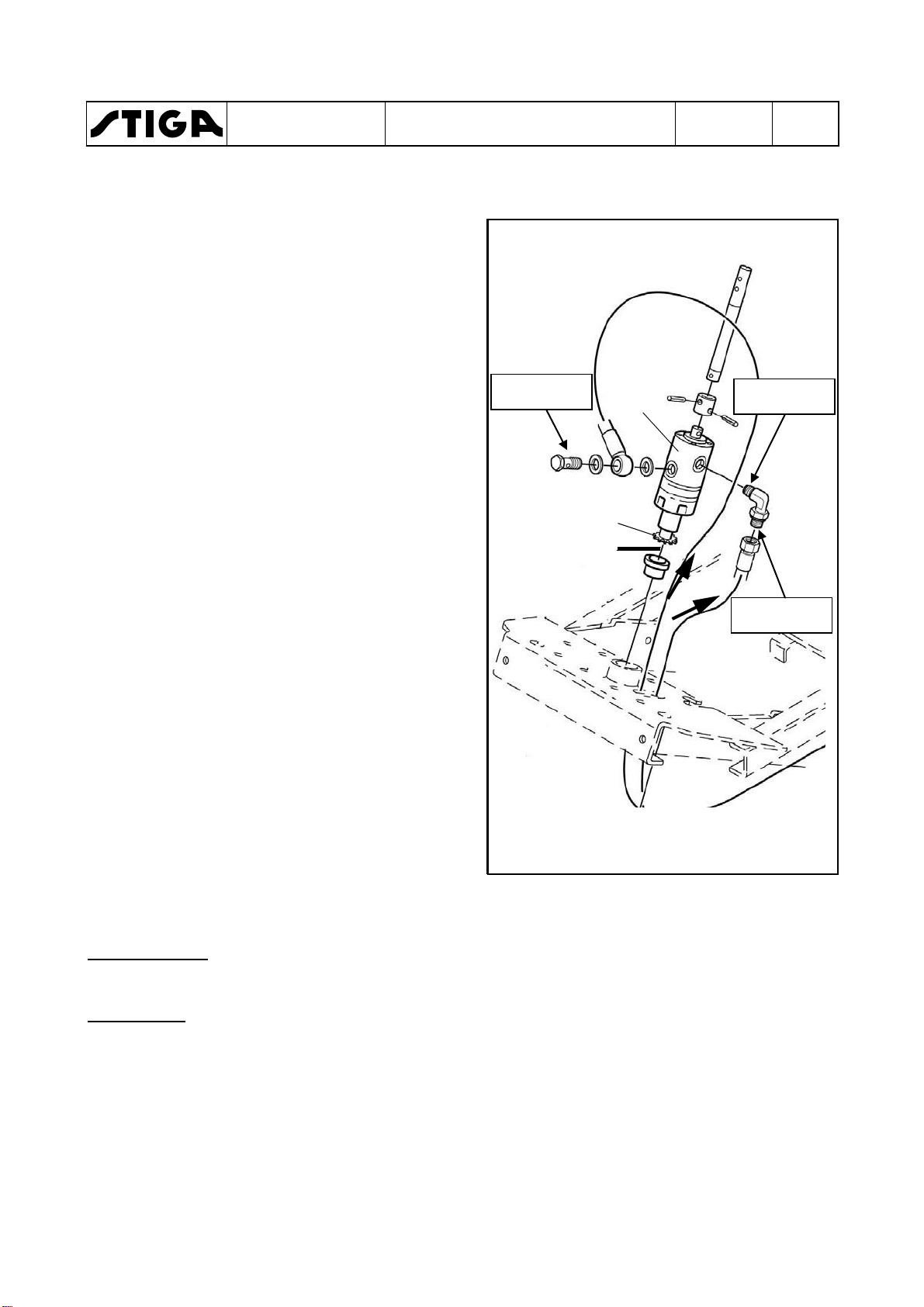

2.3.1

Dismantling

1. Remove the battery. See the owners

manual.

2. Block up the machine. Use a lifting table or

highjack and yokes.

3. Activate the parking brake.

4. Discharge the oil in the hydraulic system.

See the owners manual.

Chapter

2 - Chassis and body

EDITION

2018

Page

4

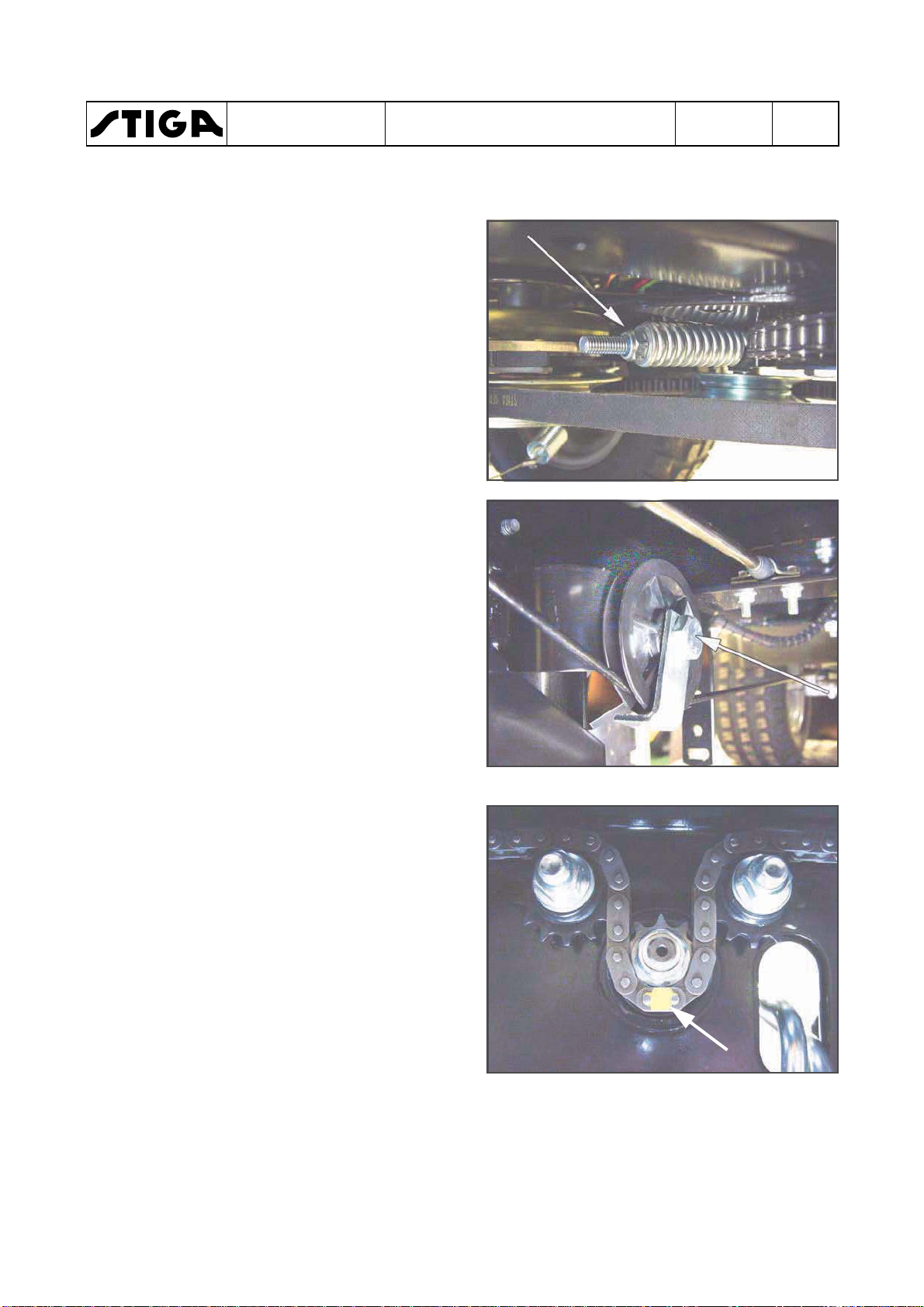

5. Remove the tension pulley by using a 15 mm

and a 17 mm spanner. See the figure.

6. Use a large polygrip and hold the pump

pulley in a securely grip. Fit the polygrip

around the belt, not direct to the pylley.

Back off the pulley nut with a 17 mm sleeve.

See the figure.

Warning!

Be carefully not to damage the

plastic fan during the removal.

7. Remove the following parts from the pump

shaft:

•

Nut

•

Washer

•

Pulley

•

Distance sleeve

•

Fan

•

Distance sleeve

8. Remove the speed control cable from the

hydraulic pump by backing off the nut. Use a

8 mm spanner. See the figure.

9. Back off the circlip from the release lever rod

and disconnect the rod from the lever.

40 Nm

78 Nm

78 Nm

40 Nm

B

40 Nm

A

78 Nm

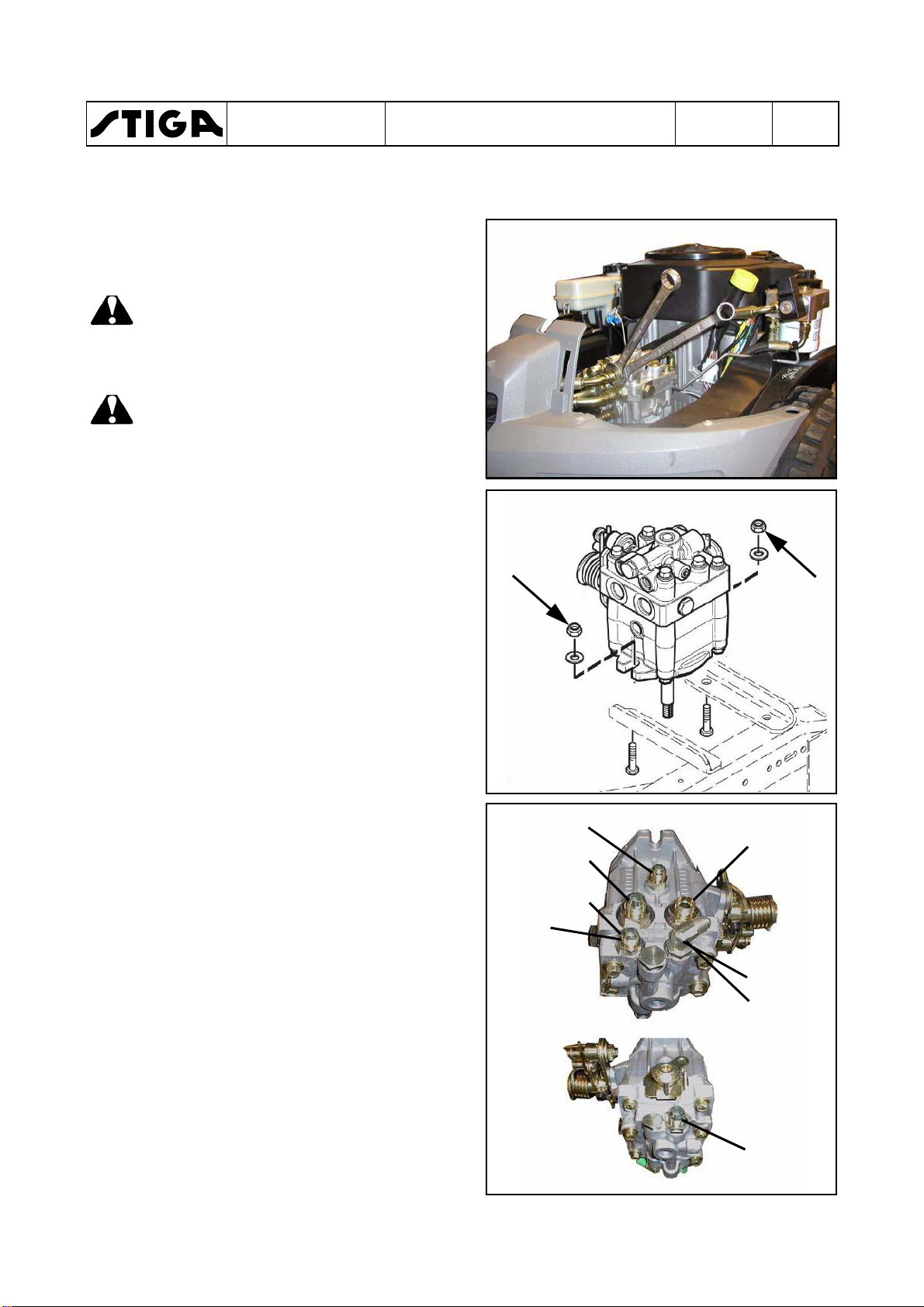

WORKSHOP MANUAL

PARK

10. Place a collecting tray under the pump for

collecting residual oil from the pump and

hoses.

Warning!

Do not spill any oil on the drive belts

during the disconnection of hoses

and tubes.

Warning!

Keep clean when handling hydraulic

parts. Dirt in the oil will cause

malfunctions and breakdowns.

11. Disconnect all hoses and tubes from the

hydraulic pump. Always use two spanners,

one to hold the respective connection in the

pump and one to loosen the nut. See the

figure.

Chapter

2 - Chassis and body

EDITION

2018

Page

5

12. Remove the pump from the chassis by

unscrewing the two M10 mounting nuts and

screws. Use two 17 mm spanners. See the

figure.

13. Place and fasten the pump in a table vice.

Loosen the adapters from the pump.

14. Screw out the adapters and insert them in

the corresponding places in the new pump

one at a time. Check or replace the O-rings.

3. Place and fasten the new pump in a table

vice. Tighten the adapters to torques

according to the figures.

When tightening the angle adapter (A),

adjust it to 45° according to the horizontal

line. Use one 14 mm and one 19 mm

spanner.

If a metal tube shall be fitted to the adapters

A and B (machines without external

hydraulics), the connection nuts shall be

tightened with 41 Nm.

WORKSHOP MANUAL

PARK

2 - Chassis and body

Chapter

EDITION

2018

Page

6

2.3.2

Assembly

Warning!

Keep clean when handling hydraulic

parts. Dirt in the oil will cause

malfunctions and breakdowns.

Warning!

Be carefully not to damage the

plastic fan during the assembly.

Assemble all parts in the reverse order.

Note!

One distance sleeve (C) at each side of

the fan.

Note!

The tension pulley (D) shall be fitted with

the prolonged part of the sleeve

upwards. See both figures.

C

C

D

Adjust the speed cable. See section 6.

When all parts are fitted and all actual

tightening torques are applied, fill new oil and

bleed the hydraulic system. See the owners

manual.

Up

D

WORKSHOP MANUAL

PARK

3 Steering

Contents in this chapter

3.1 Description ....................................... 2

3.1.1 Mechanical system ........................ 2

3.1.2 Hydraulic assisted system ............. 2

3.2 Steering wires ................................... 4

3.2.1 Replacement ................................ 4

3.2.2 Adjustment .................................... 5

3.2.3 Steering chains .............................. 5

General

Chapter

3 - Steering

EDITION

2018

Page

1

3.3 Bearings, steering shaft .................. 7

3.3.1 Replacement of sliding bearings

and ball bearings .................................... 7

3.3.2 Replacement of upper ball bearing

(with steering booster) ............................ 8

3.3.3 Trouble shooting ............................ 9

The articulation steered machines are equipped with either a common mechanical system

or a hydraulic assisted steering system. Both systems work with wires or chains,

depending on the model. The hydraulic assisted system gets its power from the variable

hydraulic transmission at the rear shaft.

This chapter contains a brief description of the function and describes repair, replacements

and adjustments of stressed parts of the steering system.

3.1

WORKSHOP MANUAL

PARK

Description

Chapter

3 - Steering

EDITION

2018

Page

2

3.1.1

The sprocket (A) is directly coupled to the

stering wheel on the same shaft. A chain (and

wires) (B) is engaged with the sprocket and

connected to the steering disc (C) on the rear

frame. Thus, the rear frame is forced into actual

angles, related to the front frame when the

driver turns the steering wheel.

3.1.2

Below is given a brief description about how the

steering torque converter works and its

connection to the valves. For a complete

description, see section 4 “Hydraulic system”.

Section 4 describes how the lifting cylinder

works together with the steering torque

converter. It also describes the pressure

division between the two systems and

adjustments.

The power assisted steering is a hydraulic

auxiliary system. The main components are the

torque converter and the oil pump in the

hydrogear.

Mechanical system

Hydraulic assisted system

A

B

C

As opposed to standard power steering (e.g. in

a car), this power assisted steering has a

limited capacity. This implies that in certain

circumstances it has what may be experienced

as negative characteristics.

At low engine speed, or in situations where

extra steering power is required, the steering

may be considered to be somewhat jerky.

The machine should always be in motion when

the steering is used. Avoid turning the steering

wheel when the machine is standing completely

still and the accessory is in lowered working

position.

The machine can be steered even when the

engine is switched off. Nevertheless, it may

require more force than normal to steer the

Md D

A

Ms

Mh

Md+Mh=Ms

35-42 Nm

35-42 Nm

30-37 Nm

WORKSHOP MANUAL

PARK

machine. This is particularly noticeable during

cold weather.

Mainly, the hydraulic assisted system works

similar to the mechanical system. The different

is a torque booster (D), atttached to the steering

shaft between the steering wheel and the

sprocket (A).

A oil flow from the HST is flowing through the

torque booster via a filter.

As the driver turns the steering wheel, there

occour a pressure drop over the torque booster.

The pressure drop, multiplied with the flow,

gives a moment (Ma), which is added to the

moment from the driver (Md) and applied on the

sprocket (A) as a moment (Ms).

Chapter

3 - Steering

EDITION

2018

Page

3

The following items are shown in the figure:

A Sprocket of driving the steering chain.

D Torque booster.

Mh Steering power (moment) from the

hydraulic transmision.

Md Hand power (moment) from the driver.

Ms The sum of Ma and Md as steering power

(moment on sprocket A).

Hydraul connections

The hydraul lines have two alternative

connections:

•

Pressure plate with O-rings around the tubes.

•

Banjo fitting.

Pressure plate

Always mount new O-rings when assembling.

Banjo fitting

The connection have no gaskets.

Always tighten the nipples with the correct

tightening when assembling. See the figure.

WORKSHOP MANUAL

PARK

3.2 Steering wires

3.2.1 Replacement

1. Loosen the nuts on the steering wire. Brace

with a spanner so that the wire does not

rotate.

2. Loosen the screws that hold the pulley so

that the wire can be taken out between the

pulley and the wire retainer.

Chapter

3 - Steering

EDITION

2018

Page

4

3. Unhook the chain at the front chain sprockets.

It can sometimes be easier to get the chain

off by slightly unscrewing the screws that

hold the chain sprockets.

4. Measure up the middle link (mark A) on the

new chain and mark it.

5. Place the chain on the chain sprockets.

Make sure that the wheel is straight and that

the marked middle link is placed on the middle of the chain sprocket.

6. Place the wire in the pulley and tighten the

screws to the wire retainers.

7. Fit the washer and nut on the threaded rear

ends of the steering wire.

A

WORKSHOP MANUAL

PARK

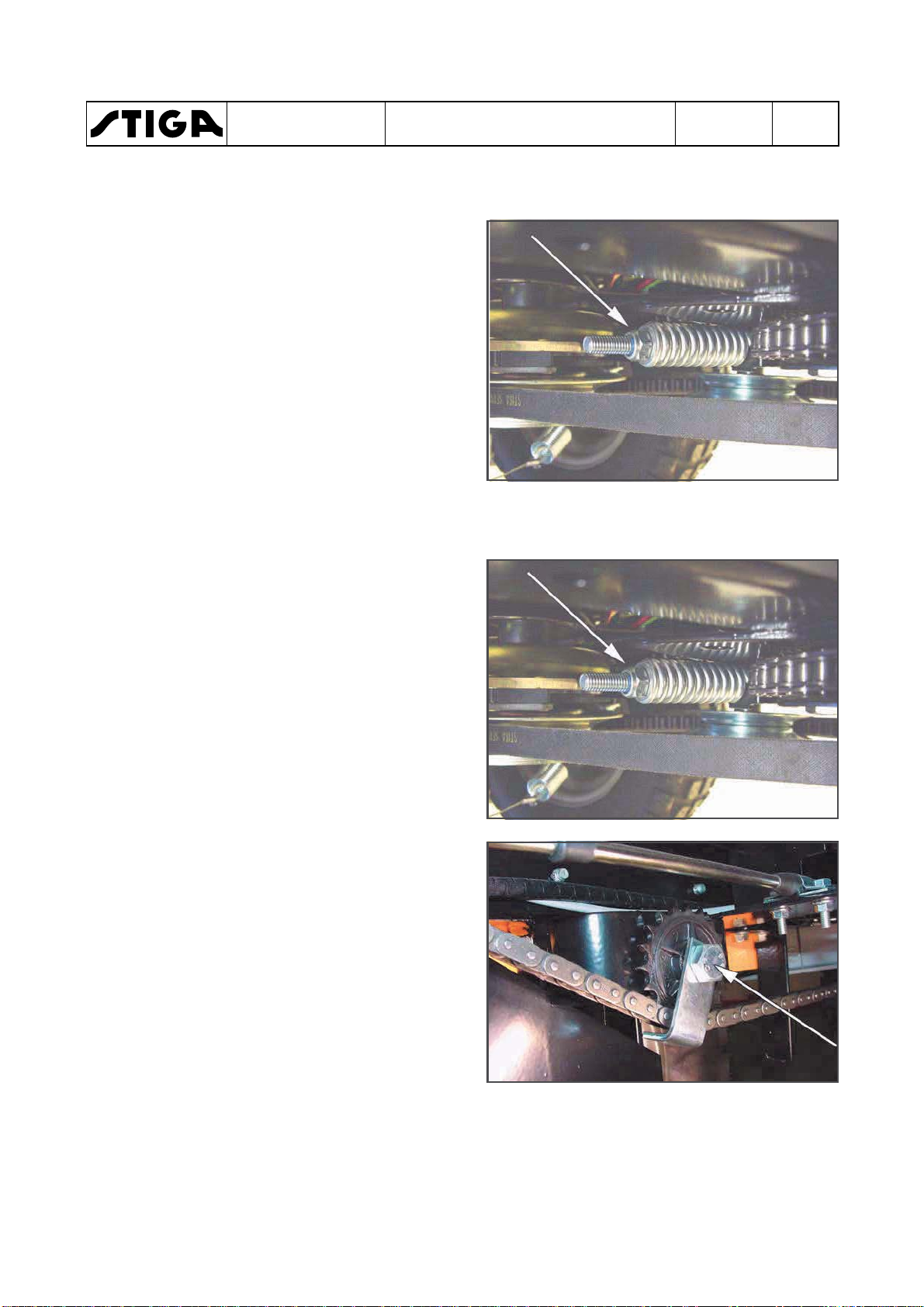

3.2.2 Adjustment

1. Tension the wire nuts equally on both sides

so that the wheel is straight when the

machine is straight.

Brace with a spanner so that the wire does

not twist.

2. Turn the wheels fully out in both directions.

Check that the chain does not go into the

pulley and that the wire does not go into the

chain sprocket.

3. Test drive. Check the tension of the wire

after test driving.

Chapter

3 - Steering

EDITION

2018

Page

5

3.2.3 Steering chains

1. Loosen the nuts on the steering chain.

2. Loosen the screws that hold the chain

sprockets so that the chain can be taken out

between the chain sprocket and wire

retainer.

3. Unhook the chain at the front chain

sprockets.

It can be easier to get the chain off by slightly

unscrewing the screws that hold the chain

sprockets.

WORKSHOP MANUAL

PARK

4. Measure up the middle link (A) on the new

chain and mark it.

5. Place the chain on the chain sprockets.

Make sure that the wheel is straight and that

the marked middle link (A) is placed on the

middle of the chain sprocket.

6. Place the wire on the chain sprockets and

tighten the screws to the wire retainers.

7. Fit the washer and nut on the threaded rear

ends of the steering chain.

8. Adjust as described below.

Chapter

3 - Steering

EDITION

2018

A

Page

6

Adjustment

1. Tension the nuts equally on both sides so

that the wheel is straight when the machine

is straight.

2. Turn the wheels fully out in both directions.

Check that there is no abnormal noise or

abnormal resistance.

3. Test drive. Check the tension of the chain

after test driving.

WORKSHOP MANUAL

PARK

3.3 Bearings, steering shaft

The steering shaft bearings are configurated in

one of the following three ways:

• Two sliding bearings of the composite type.

• Two sealed ball bearings.

• One sealed ball bearing (upper) and one ball

bearing in the torque booster (lower).

3.3.1 Replacement of sliding bearings

and ball bearings

1. Remove the chain from the lower sprocket.

See previous sections.

2. Tap out the spring pin that holds the steering

wheel. Remove the steering wheel.

Chapter

3 - Steering

EDITION

2018

Page

7

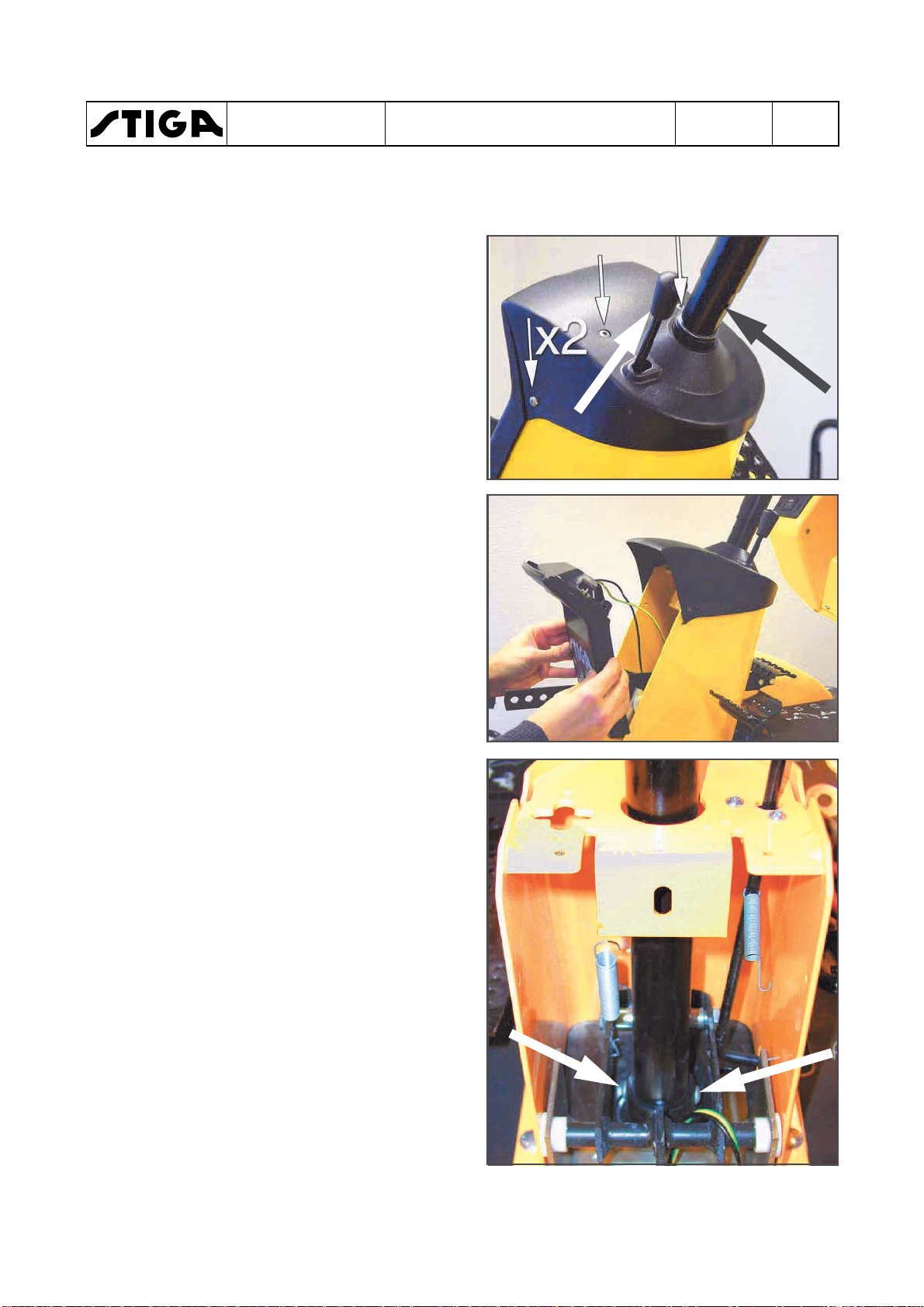

3. Pull up the parking brake knob, remove the

upper cover and the lamp section.

4. Remove the to screws, holding the steering

column and remove the steering column (A).

5. Tap out the bearings with a long drift, bar or

similar.

6. Tap in the new bearings with a rubber mallet.

A

7. Reassemble in the reverse order and adjust

the chain/wire. See previous sections.

WORKSHOP MANUAL

PARK

3.3.2 Replacement of upper ball bear-

ing (with steering booster)

1. Tap out the spring pin that holds the steering

wheel. Remove the steering wheel.

2. Pull up the parking brake knob, remove the

upper cover and the lamp section.

Note!

Do not forget the washer (G).

The correct number of shims must be

used to avoid tensions in the steering

column.

3. Remove the split pin from the hydraulic lift

bolt (A) and push out the bolt.

4. Remove the spring (B).

Chapter

3 - Steering

A

EDITION

2018

Page

8

5. Remove the four nuts (C) from the underside and the screw (E), holding the steering

console (F) and lift out the steering console

with its four screws.

6. Remove the three M8-screws (I) from the

lower steering tube (D) and pull up the

steering tube with the washer (G).

7. Press or knock out the ball bearing (H) from

the steering tube and assemble a new bearing with help of a rubber mallet.

8. The assembling is performed in the reverse

order.

Note!

Do not forget the washer (G).

The correct number of shims must be used

to avoid tensions in the steering column.

C

D

E

B

F

G

H

I

Loading...

Loading...