Page 1

WORKSHOP MANUAL

PARK

2008 - 201ˀ

Page 2

TABLE OF CONTENTS

1 - General instructions

2 - Chassis and body

3 - Steering

4 - Hydraulic system

5 - Belts

6 - Control Wires

7 - Electrical System

All brands, names, logos and trademarks mentioned belong to their respective owners.

© by STIGA - No use of the illustrations or duplication, reproduction or translation, even partial, of the texts in this

document may be made without explicit authorisation.

Page 3

WORKSHOP MANUAL

PARK

1 General instructions

Contents in this chapter

Chapter

1 - General instructions

EDITION

2018

Page

1

1.1 Introduction ...................................... 2

1.1.1 Responsibility declaration .............. 2

1.1.2 How this manual is used ................ 2

1.1.3 Abbreviations ................................. 2

1.2 Safety Precautions ........................... 2

1.2.1 Symbols and warnings .................. 3

1.2.2 Warm parts .................................... 3

1.2.3 Moving parts .................................. 3

1.2.4 Lifting and blocking up ................... 3

1.2.5 Cleanliness .................................... 3

1.2.6 Tightening torque ........................... 3

1.2.7 Sharp edges .................................. 3

1.2.8 Replacement parts ........................ 3

1.2.9 Inspection ...................................... 3

1.3 Unpacking and assembly ................ 4

1.3.1 Unpacking ..................................... 4

1.3.2 Battery ........................................... 5

1.3.3 Final checks .................................. 6

1.4 Service .............................................. 7

1.4.1 Service times ................................. 7

1.4.2 First Service .................................. 8

1.4.3 Intermediate Service ..................... 8

1.4.4 Basic Service ................................ 9

1.4.5 Description of service points ....... 10

1.5 Transmission .................................. 14

1.5.1 Transmission oil and filter change

interval .................................................. 14

1.6 Technical specifications ................14

1.6.1 General tightening torque ............. 14

1.7 Instructions for use ........................ 14

General

This Workshop Manual covers all Park – Park Pro models from 2008. The Park 120-220

have a separate workshop manual. The Park Pro models from 2015 with steering cylinder

have a separate workshop manual.

This Manual do not cover repair instructions for the engines. Regarding engines, contact

the respective representative in the actual country.

This Manual and its specifications are valid for machines in their original design. In case of

modified or changed machine, i.e. the engine is replaced, the manual accordance is limited.

The manual is divided in the following chapters:

Chapter 1 is this chapter

Chapter 2 Chassis

Chapter 3 Steering

Chapter 4 Hydraulic system

Chapter 5 Belts

Chapter 6 Control Wires

Chapter 7 Electrical system

Page 4

1.1

WORKSHOP MANUAL

PARK

Introduction

Chapter

1 - General instructions

EDITION

2018

Page

2

1.1.1

In spite of the great care we have taken there may be errors in this publication.

The author cannot be made liable for incorrect or missing information.

STIGA reserves the right to regularly change product specifications without prior notice.

All the information in this book is based on the information available at the time of

production. Illustrations and photographs may be arranged schematically, which implies

that one picture may cover several models and therefore not correspond exactly with all

models.

1.1.2

To make this manual easy to understand we have divided the machine into its main

systems and components. These parts are now the different chapters in the book.

Each chapter is divided up into sections.

There is a quick-guide on the cover of this book, which refers to the different chapters. In

each chapter there is a detailed table of contents so that you can easily and quickly find

what you are looking for.

Always check that you are reading the right chapter for your particular machine before

starting the repair work.

1.1.3

Responsibility declaration

How this manual is used

Abbreviations

The following abbreviations are used in this manual:

HST Hydrostatic Transmission PTO Power Take Off

1.2

Safety Precautions

This manual has been written primarily for trained mechanics working in a well-equipped

workshop.

A basic knowledge of repairs, tools and repair instructions is, however, always a

prerequisite for first-rate results.

A qualified mechanic should always be consulted if the owner does not have sufficient

knowledge to carry out repairs.

During the warranty period all service must be carried out by an Authorised Workshop for

the warranty to be valid.

The following basic points should be observed if the machine is to function perfectly:

•

Follow the service schedule.

•

Be on the alert for sudden vibrations or abnormal noise to avoid major breakdowns.

•

Always use Genuine Spare Parts

•

Follow the descriptions in this manual carefully. Do not take any short cuts.

Page 5

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

Page

3

1.2.1

Symbols and general warnings

Warning!

This symbol indicates a risk of

personal injury or damage if the

instructions are not followed.

Note!

This text indicates a risk of damage to

the material or risk of unnecessarily

complicated work if the instructions

are not followed.

1.2.2

Please observe that engine and exhaust

system picks up a lot of heat during use.

This applies above all to the silencer of

machines equipped with catalytic

converter.

To avoid injuries, allow the machine to cool

before any kind of repairs are made to or

near parts of the engine or exhaust

system.

1.2.3

The machines are all equipped with v-belt

transmissions. Always stop the engine and

remove the starter key before inspections

or repairs are carried out.

Always use extreme caution when testing

systems with moving parts to avoid

injuries.

Always use Genuine Spare Parts during

service work.

1.2.4

Warm parts

Moving parts

Lifting and blocking up

1.2.5

Clean the machine before starting repairs.

Dirt that penetrates into sensitive

components can seriously influence the

service life of the machine.

1.2.6

Unless otherwise stated the tightening

torque in the tables in the section

Technical specifications must be used for

the different sizes of screws. This does not

refer to self-tapping screws, which are

mainly used for the assembly of body

parts.

1.2.7

Watch out for sharp edges, especially

when working with the mower deck. The

blades can be very sharp. Always wear

gloves when working with the blades.

1.2.8

Always use Genuine Spare Parts during

service work.

1.2.9

Each part dismantled in conjunction with

service work must be inspected.

Examine for: wear, cracks, out of

roundness, straightness, dents,

discolouring, abnormal noise and

jamming.

Cleanliness

Tightening torque

Sharp edges

Replacement parts

Inspection

Before work under the machine, always

make sure that lifting devices and jackstands are approved for the weight.

Work safe!

Page 6

WORKSHOP MANUAL

PARK

1 - General instructions

1.3 Unpacking and assembly

Every STIGA Park has undergone an extensive

control programme before delivery. The

machines are delivered as completely

assembled as possible.

Thanks to this the assembly on delivery is rapid

and easy.

The correct and careful assembly of the

machine on delivery is a simple way of ensuring

satisfied customers!

Note!

The machine shall remain placed on the

pallet during the unpacking and

assembly.

1.3.1 Unpacking

Chapter

EDITION

2018

Page

4

Open up the crate and release the part as

follows:

1. Check the air pressure in the tyres. The

pressure is designated on the floor mat.

The air pressure in the tyres is of critical

importance for the performance and

handling of the machine. The correct air

pressure for mowing is 0.6 bar (9 psi) in the

front tyres, and 0.4 bar (6 psi) in the rear

tyres.

When using heavy accessories, e.g. snow

thrower, it may be necessary to increase the

pressure somewhat. However, the

maximum permitted pressure is always

0.8 bar (12 psi).

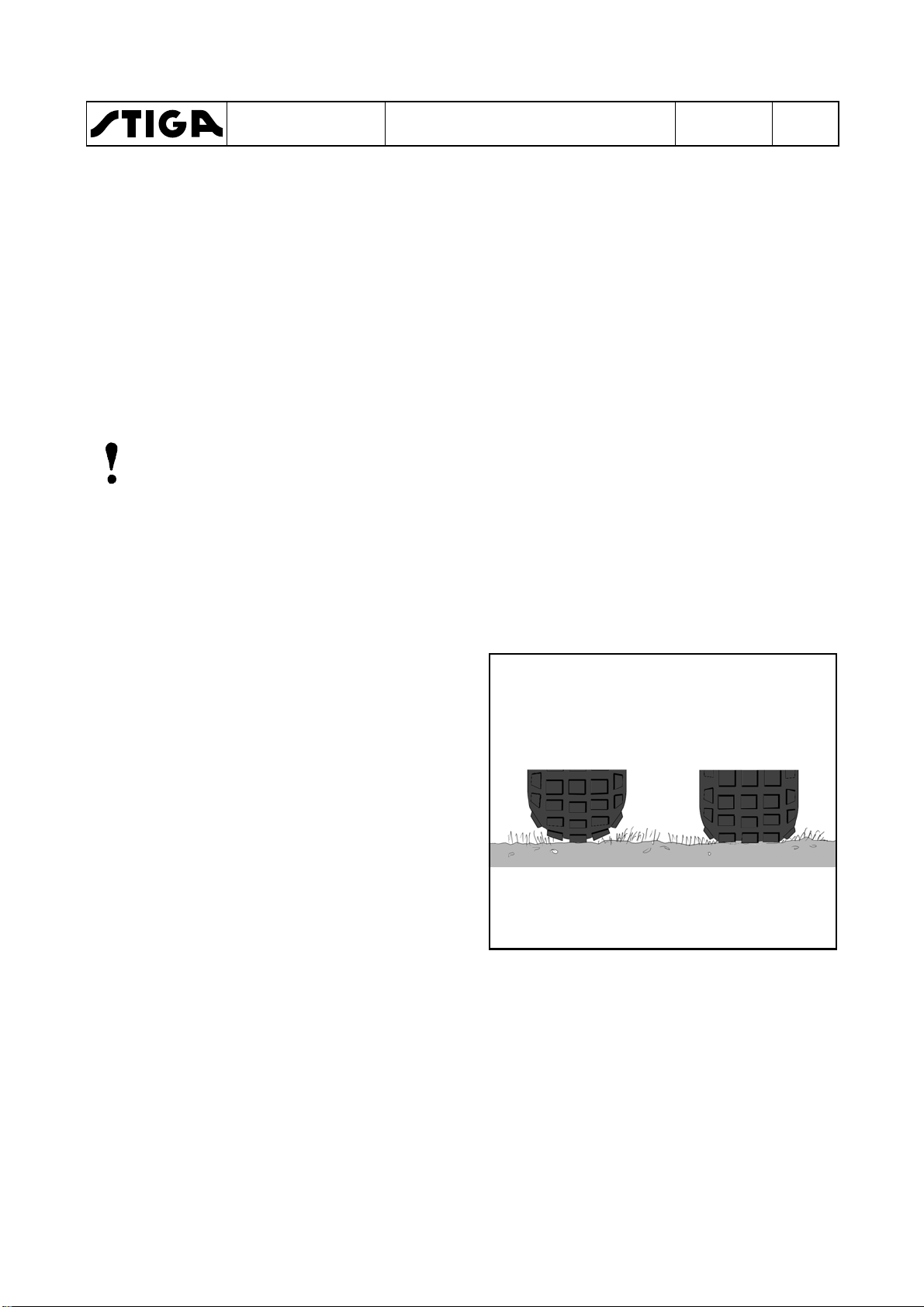

Too high pressure Correct pressure

Too high pressure in the tyres leads to that

the machine drives poor due to:

•

A small surface in contact to the ground.

•

Hard tyre = less flexibility = self cleaning characteristic deteriorate.

2. Remove the following parts from the

package and put them on the floor.

•

The battery (some models).

•

The steering wheel.

•

The plastic bag, containing owners manuals,

information media and assembly screws.

Page 7

WORKSHOP MANUAL

PARK

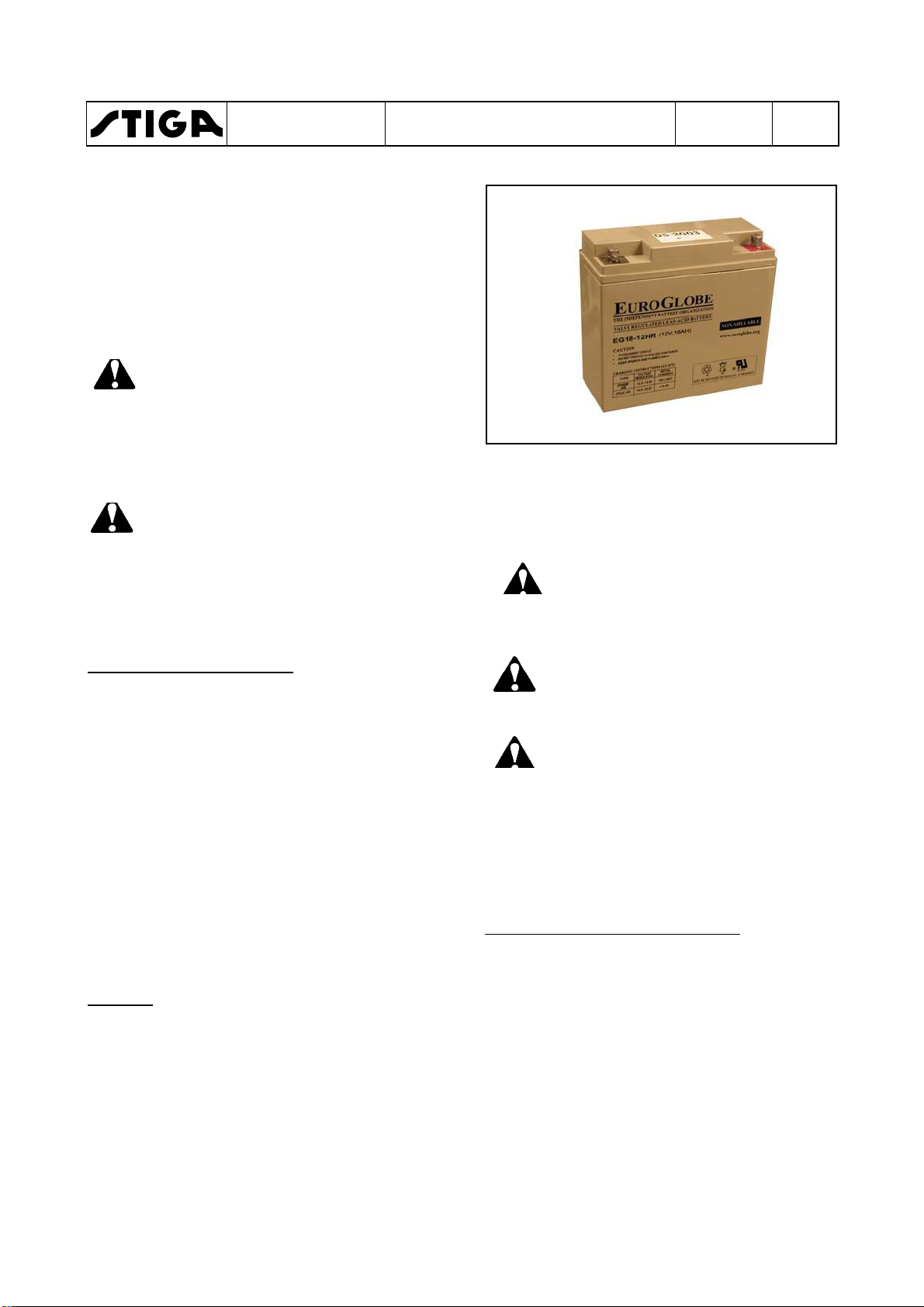

1.3.2

The battery is a valve regulated battery.

Load and assemble the battery, following the

instructions below.

The battery needs limited maintenance. Is has

no electrolyte levels or plugs.

Charging with the engine

The battery can be charged using the engine’s

generator as follows:

1. Install the battery in the machine as shown

2. Place the machine outdoors or install an

3. Start the engine according to the

4. Allow the engine to run continuously for 45

5. Stop the engine. The battery will now be

Storage

Battery

Warning!

Do not wear rings, metallic bracelet,

chain round the neck or similar metal

objects when working with the

battery. It can cause short-circuit,

burns and fire.

Warning!

The battery must be fully charged be-

fore being used for the first time. The

battery must always be stored fully

charged. If the battery is stored while

discharged, serious damage will occur.

below.

extraction device for the exhaust fumes.

instructions in the user guide.

minutes.

fully charged.

1 - General instructions

Chapter

A

EDITION

2018

Page

5

If the cables are disconnected/

connected in the wrong order,

there is a risk of a short-circuit

and damage to the battery.

If the cables are interchanged,

the generator and the battery

will be damaged.

Charging using battery charger

When charging using a battery charger, a

battery charger with constant voltage

must be used.

The engine must never be driven

with the battery disconnected.

There is a risk of serious damage to the generator and the

electrical system.

The battery voltage is not allowed to drop under

12,5 V during storage.

Make sure that the battery voltage always is

more than 12,5 during storage. If not, the

battery will be destroyed.

Ordering number: 1136-0602-01.

The battery can be damaged if a standard

type battery charger is used.

Page 8

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

Page

6

1.3.3

Final checks

Removing from pallet

All the above measures shall have been done with the machine standing on the pallet.

Now, loosen the remaining straps and roll off the machine from the pallet.

Fit and adjust accessories.

Test driving

Warning!

Do not drive without a work equipment (mover deck) attached. Risk for

turning over.

Drive the machine for a few minutes. Test all the functions. Pay special attention to the

safety functions. If the machine is to be delivered with mower deck or other accessories,

fit these before test driving the machine.

HST oil

Check the oil level in the HST’s expansion tank after test driving, and top up if

necessary.

Engine oil

Check the oil level in the engine and top up if necessary.

Steering chain / Steering wire

Check that the steering chain / steering wire is sufficiently taut. Adjust if necessary.

Miscellaneous

Give the machine a general inspection.

•

Is the machine clean?

•

Is there any oil leakage?

•

Abnormal noise or rattle?

Receipt

By filling in the guarantee certificate you guarantee that the delivery service has been

correctly conducted.

Remember to make sure that the customer receives all the documentation when the

machine is collected / delivered.

Page 9

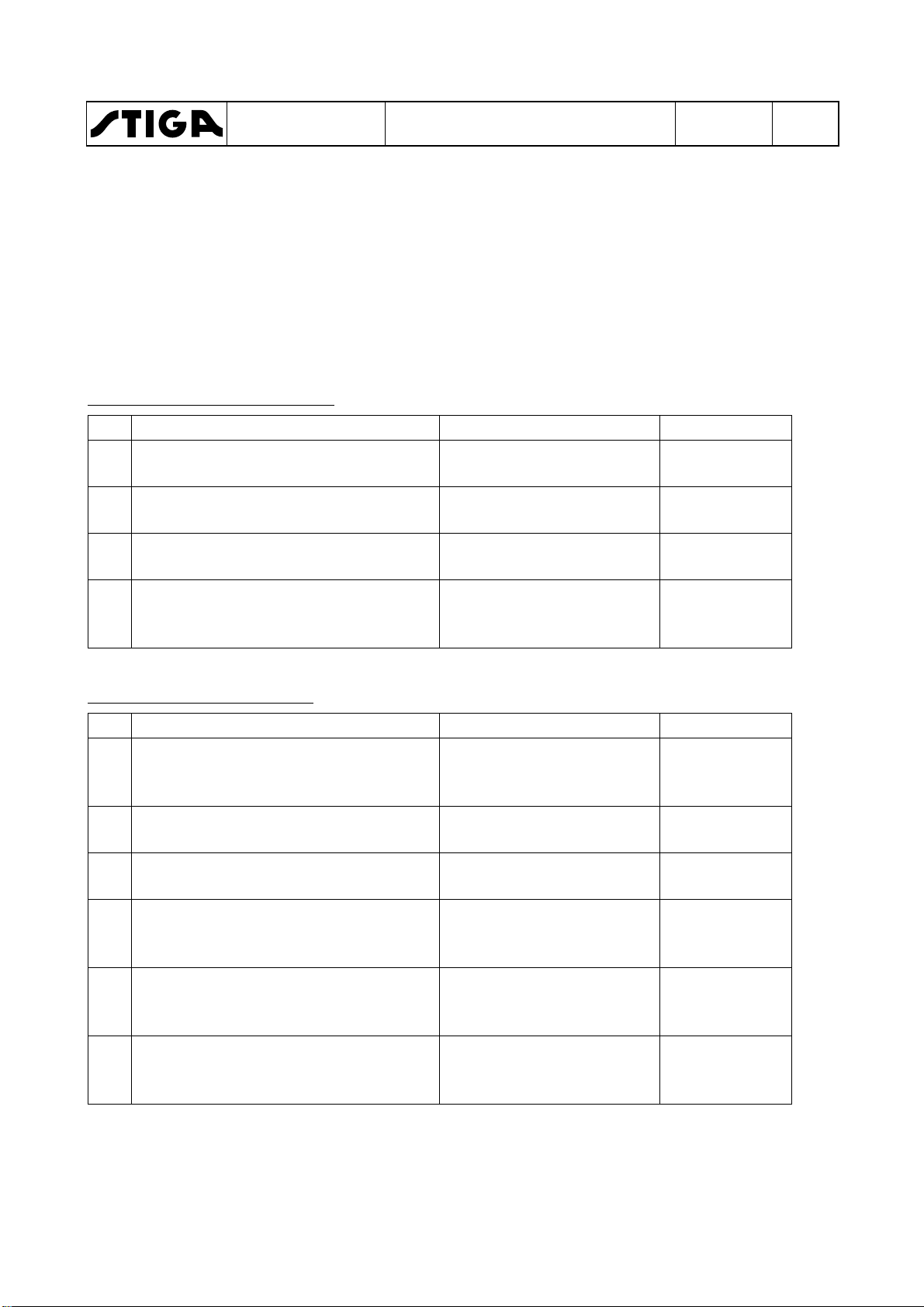

Service

Shall be performed

First service

Within 5 hours of running

Intermediate service

After the first 50 hours of running and then 50 hours after/before

Basic service

Every 100 hours or every year, which first occur.

Service

Shall be performed

First service

Within 5 hours of running

Intermediate service

After the first 100 hours of running and then 100 hours after/before

Basic service

Every 200 hours or every year, which first occur.

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

1.4 Service

Every new machine is delivered with a service book. This service book is part of the

active post-market programme and shall be kept in a safe place during the entire

lifetime of the machine. Hand over the service book if the machine is sold in 2:nd

hand.

Service should generally be carried out at least every 50 operating hours (exception

of the first service), although in accordance with the conditions below.

There are three different grades of service events. Every service event consists of a

number of service points as described in the following paragraphs. Every service

point has a number which refer to a describing text after the schedules.

The grades of service events are:

•

First service

•

Intermediate service

•

Basic service

Some service points do not coincide with the scheduled service intervals, but shall

be performed in connection with a scheduled service when possible. E.g. some items

shall be performed at every second service and some also between two services.

These service points are described with procedure and interval in the respective

“Instruction for use”.

Page

7

Typical service points wich not coincide with scheduled service intervals are:

•

Cleaning/changing air filter in some engines.

•

Change of oil in some engines.

•

Valve adjustments for some engines.

•

Change of transmission oil in 4 WD machines.

•

Change of spark plug in some engines.

1.4.1

Service times

Petrol driven machines

every basic service.

Diesel driven machines

every basic service.

Page 10

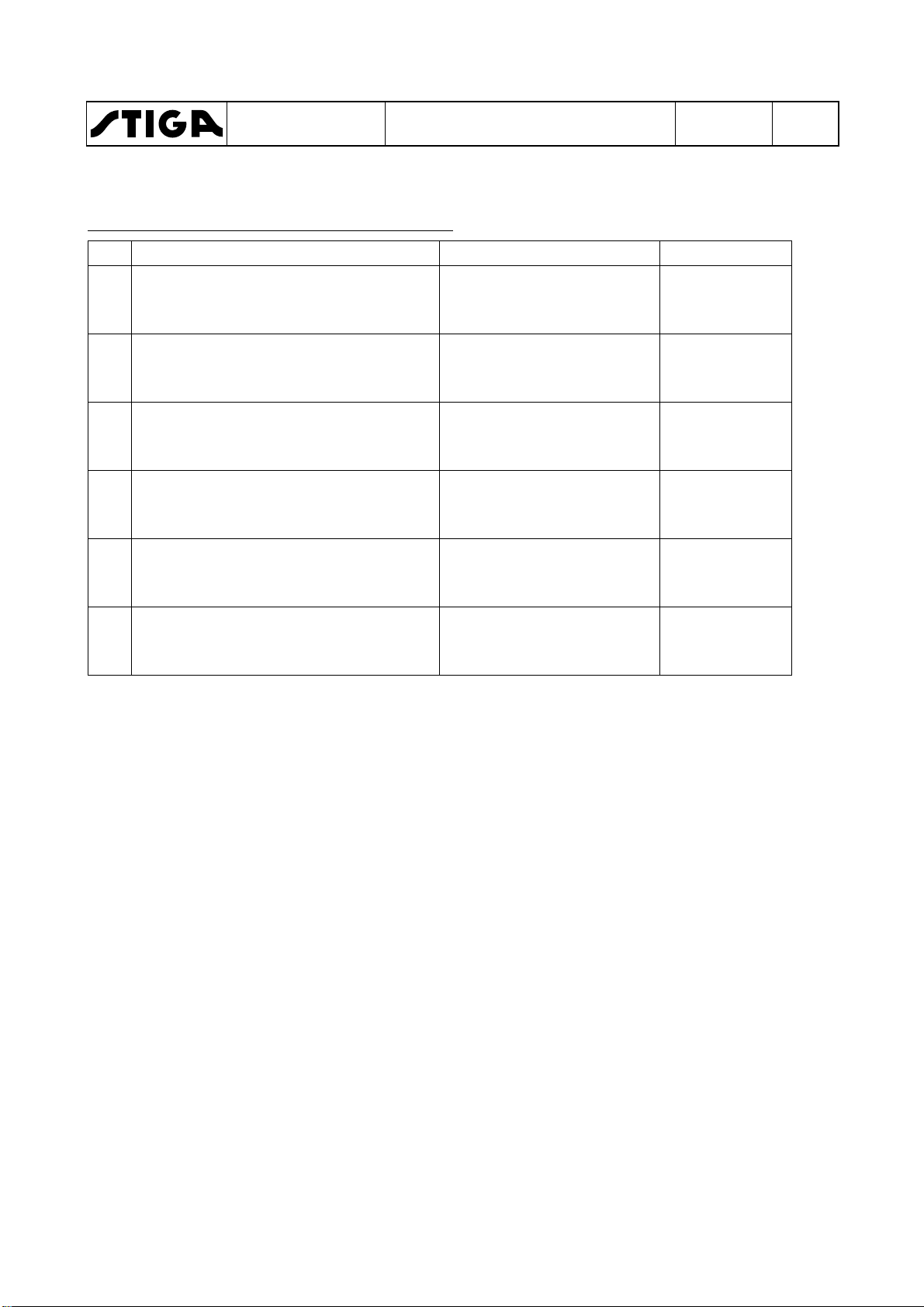

Number

Service point

1

Safety check.

2

Tyres, air pressure.

3

Engine oil and filter, see “Engine - Transmission” at

page 14.

4

5

Belt transmissions, check.

6

Steering adjustment.

7

Battery check.

21

Number

Service point

1

Safety check.

2

Tyres, air pressure.

3

Engine oil and filter, see “Engine - Transmission” at

4

6

Steering adjustment.

9

10

Air filter catalytic converter, cleaning.

11

Cooling fins, clean.

12

Lubrication

WORKSHOP MANUAL

PARK

Chapter

1 - General instructions

EDITION

2018

Page

8

1.4.2

First Service

This service is very important to safeguard the continuing function of the machine.

The first service includes the service points as per the table below.

Oil level in HST, see “Engine - Transmission” at

page 14.

Test driving.

1.4.3 Intermediate Service

The intermediate service is not as extensive as the Basic Service and can therefore be

conducted by the customer, or by an authorised Service Workshop. Regardless of who

conducts the service, it must be documented in the service book..

page 14.

Oil level in HST, see “Engine - Transmission” at

page 14.

Air filter, cleaning.

Note!Ɩ¿»É»ÂºÈ¿Ì»Ä÷¹¾¿Ä»ÉƓ

Check/tighten engine support screwsupport screws every 100 hours.

Page 11

Number

Service item

1

Safety check

2

Tires, air pressure

3

4

Oil level in HST, see “Engine - Transmission” at

page 14.

5

Belt transmissions, check

6

Steering adjustment

7

Battery check

8

Air filter for engine, see “Engine - Transmission” at

page 14.

9

Air filter catalytic converter, see “Engine -

(Valid for machines with catalytic converter only)

10

Cooling fins, clean

11

Spark plug, check/replace

13

Transmission, check

14

Speed check

15

Bearing boxes, check**

16

Exhaust system, check*

17

Electrical system, check*

18

19

Blades, check**

20

Power take-off, check

21

Control check

22

Valve play***

23

Test driving

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

1.4.4 Basic service

The Basic Service must always be conducted by an authorized Service Workshop,

and documented with a stamp in the service book.

Engine oil and filter, see “Engine - Transmission” at

page 14.

Page

9

Transmission” at page 14.

Mower deck, check**

*) See also “Safety check”.

**) See also the mover deck manual.

***) See the engine manual.

Note!Ɩ¿»É»ÂºÈ¿Ì»Ä÷¹¾¿Ä»ÉƓ

Check/tighten engine support screwsupport screws every 100 hours.

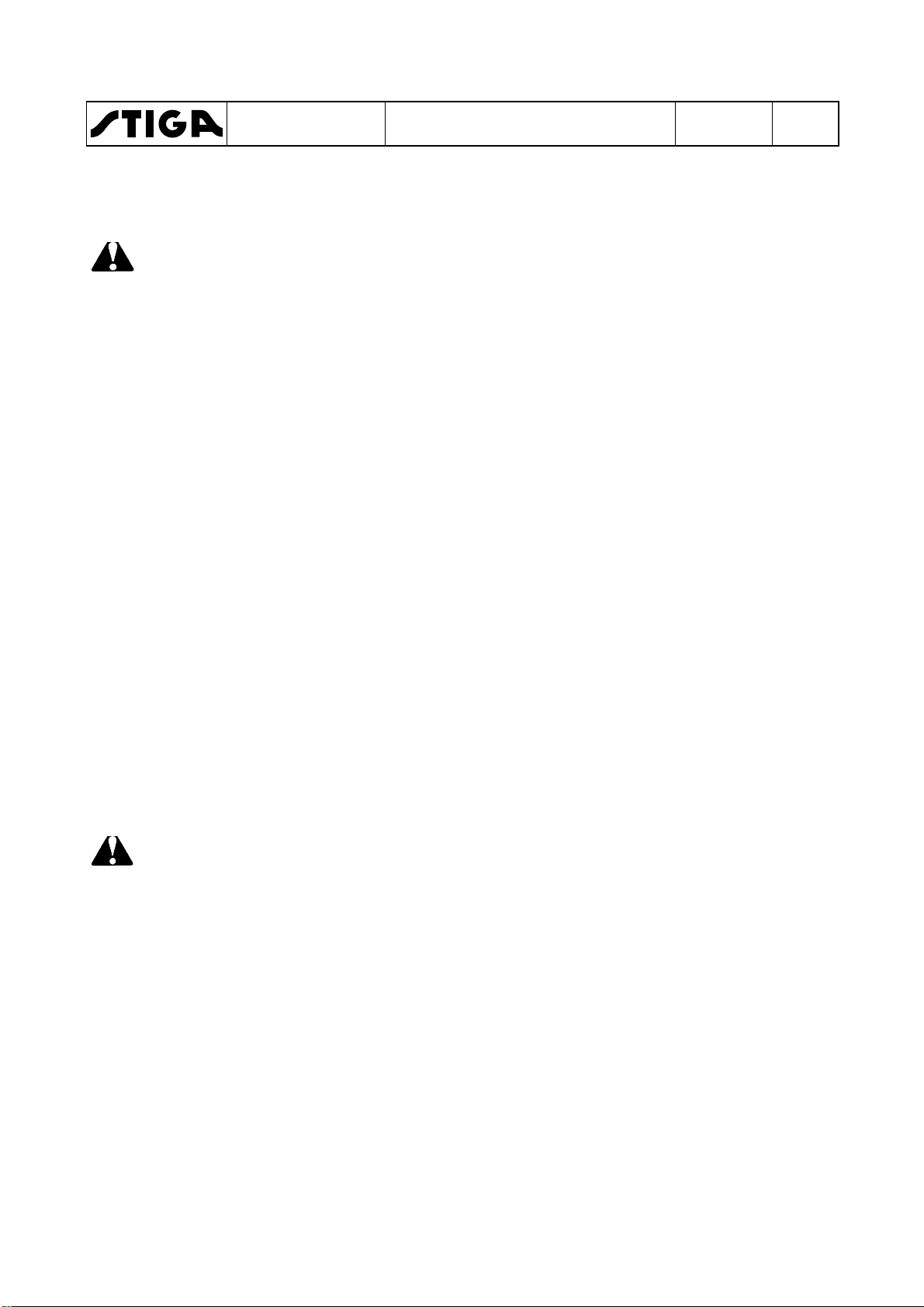

Page 12

Test

Status

Action

Result

1 Brake pedal not pressed.

Turn the key and make a

Engine shall

2 Brake pedal pressed.

Turn the key and make a

Engine shall

3 Engine running.

Operator rises from the

Engine shall

4 Engine running.

Disconnect cable from the

Engine shall

stop after a few

Test

Status

Action

Result

1 Operator not sitting in seat.

Turn the key and make a

Engine shall

2 Brake pedal not pressed.

Turn the key and make a

Engine shall

3 Brake pedal pressed.

Turn the key and make a

Engine shall

4 Engine running.

Operator rises from the

PTO magnetic

5 Cruise control activated.

Operator rises from the

Cruise control

6 Engine running.

Disconnect cable from the

Engine shall

stop after a few

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

1.4.5 Description of service points

1. Safety check

Check the safety functions. It is often appropriate to do this check in conjunction with

test driving. The following items shall be checked at all machines:

•

No leakage on fuel lines and connections.

•

No mechanical damages to the electrical cables. All insulation intact.

•

The muffler shall be undamaged and its screws tightened. No exhaust leakage in

connections.

Machines with mechanic PTO

Page

10

PTO not activated.

PTO activated.

PTO activated.

Machines with electric PTO

Brake pedal pressed.

PTO not activated

PTO not activated.

PTO magnetic clutch activated.

start attempt.

start attempt.

seat.

shut off valve.

start attempt.

start attempt.

start attempt.

not start.

not start.

stop.

minutes.

not start.

not start.

not start.

PTO magnetic clutch activated.

(If applicable)

seat.

seat.

shut off valve.

clutch shall

disengage.

shall

disengage

minutes.

Page 13

Test

Status

Action

Result

1 Operator not sitting in seat.

Turn the key and make a

Engine shall

2 Brake pedal not pressed.

Turn the key and make a

Engine shall

3 Brake pedal pressed.

Turn the key and make a

Engine shall

4 Engine running.

Operator rises from the

PTO magnetic

5 Hydraulic lift in neutral position.

Attempt to engage the

PTO magnetic

6 Engine running.

Disconnect cable from the

Engine shall

stop after a few

WORKSHOP MANUAL

PARK

Machines with electric PTO and hydraulic lift

Chapter

1 - General instructions

EDITION

2018

Page

11

Brake pedal pressed.

PTO not activated

PTO magnetic clutch not activated.

PTO magnetic clutch activated.

PTO magnetic clutch activated.

start attempt.

start attempt.

start attempt.

seat.

PTO magnetic clutch.

shut off valve.

not start.

not start.

not start.

clutch shall

disengage.

clutch shall not

engage.

minutes.

Page 14

2 Tyres, air pressure

WORKSHOP MANUAL

PARK

Chapter

1 - General instructions

11 Spark plug

EDITION

2018

Page

12

Check the air pressure. Adjust if necessary.

The recommended air presure is

designated at the floor mat.

3 Engine oil and oil filter

See the “Instructions for use”, delivered

with the machine or “Instructions for use” at

page 31. See also the engine manufacturer

manual.

4 Oil, HST

See section 4 or the “Instructions for use”,

delivered with the machine.

5 Belt transmissions, check

Check the condition of all the belts and belt

tensioners.

6 Steering, adjustment

See section 3.

7 Battery, check

Valid for dry charged batteries only.

Check the acid level. Top up with distilled

water if necessary. See page 6-7.

8 Engine air filter

See the “Instructions for use”, delivered

with the machine. See also the engine

manufacturer manual.

9 Catalytic converter air filter

See the “Instructions for use”, delivered

with the machine. See also the engine

manufacturer manual.

10 Cooling fins

Remove protective covers from the engine

and cleans between cooling fins. Use a

brush and compressed air. See also the

engine manufacturer manual.

Remove the spark plug (not valid for Pro

Diesel) and clean it or replace if necessary.

See also the engine manufacturer manual.

12 Lubrication

Lubricate the articulation point (4 nipples)

and all moving parts such as wires and

levers. See also the instruction manual,

delivered with the machine.

13 Transmission

Listen for abnormal noise.

Manual models: Check that the drive

function works properly at all gears. Adjust

if required.

14 Speed check

Check that the speed corresponds to the

specified value. See pages 18-22.

15 Bearing boxes

Listen for abnormal noise from the

bearings. Check that there are no wear,

play or seizure.

16 Exhaust system

Check that there are no cracks, leakage or

other damages. Check the attachment

devices. See also the engine

manufacturer manual.

17 Electrical system

Check that there are no damaged cables,

contacts or other devices. Check that all

cables are properly secured to the chassis

and with cable holders. Check that there is

no friction between cables and chassis,

which can result in cable damage and

short circuit.

Page 15

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

EDITION

2018

Page

13

18 Mower deck

Warning!

The blades are sharp. Always

wear gloves when working with

the blades to avoid injury.

Check if there are collision damages or

wear at the deck body and painting. Align,

repair and touch up the painting as

required.

Check the tightening of the bearing boxes

screws and tighten.

Rotate the blades and check the the shafts

are correct, not bent, no abnormal bearing

noise and no plays.

Check the belts and their tensions, see

section 4.

Check that the lifting mechanism moves

evenly, not jammed and no play and that it

locks in desired position.

Check the electrical function of the

electrikal mower lifter (if applicable).

Check the plastic guide bar between the

blades. Replace if required.

19 Blades

Warning!

The blades are sharp. Always

wear gloves when working with

the blades to avoid injury.

Check that the blades are sharp. Sharpen

as reqiured.

20 Power take-off (PTO)

Check that the magnetic clutch (if

applicable) engage the work equipment

rotation in the desired time and that it not

slips during normal load. Replace the

clutch if necessary.

Check that the power take-off belt (if

applicable) engage the work equipment

rotation in the desired time and that it not

slips during normal load. Adjust if

necessary. See section 4.

Check that the power take-off brake (if

applicable) brakes the rotation movement

in the desired time. Adjust if necessary.

See section 4.

21 Control check

Check that all controls function properly,

that there are no jammings or excessive

plays. Adjust if nesaccary. See section 5.

22 Valve play

See the engine manual regarding

procedure and interval.

23 Test driving

Drive the machine during a few minutes

and make the following attentions in

different speeds and turnings in right and

left. Check that all functions work evenly

and proper and without any abnormal

noise.

•

Brake function

•

Clutch function

•

Power take-off

•

Steering

Check that there are no abnormal

vibrations.

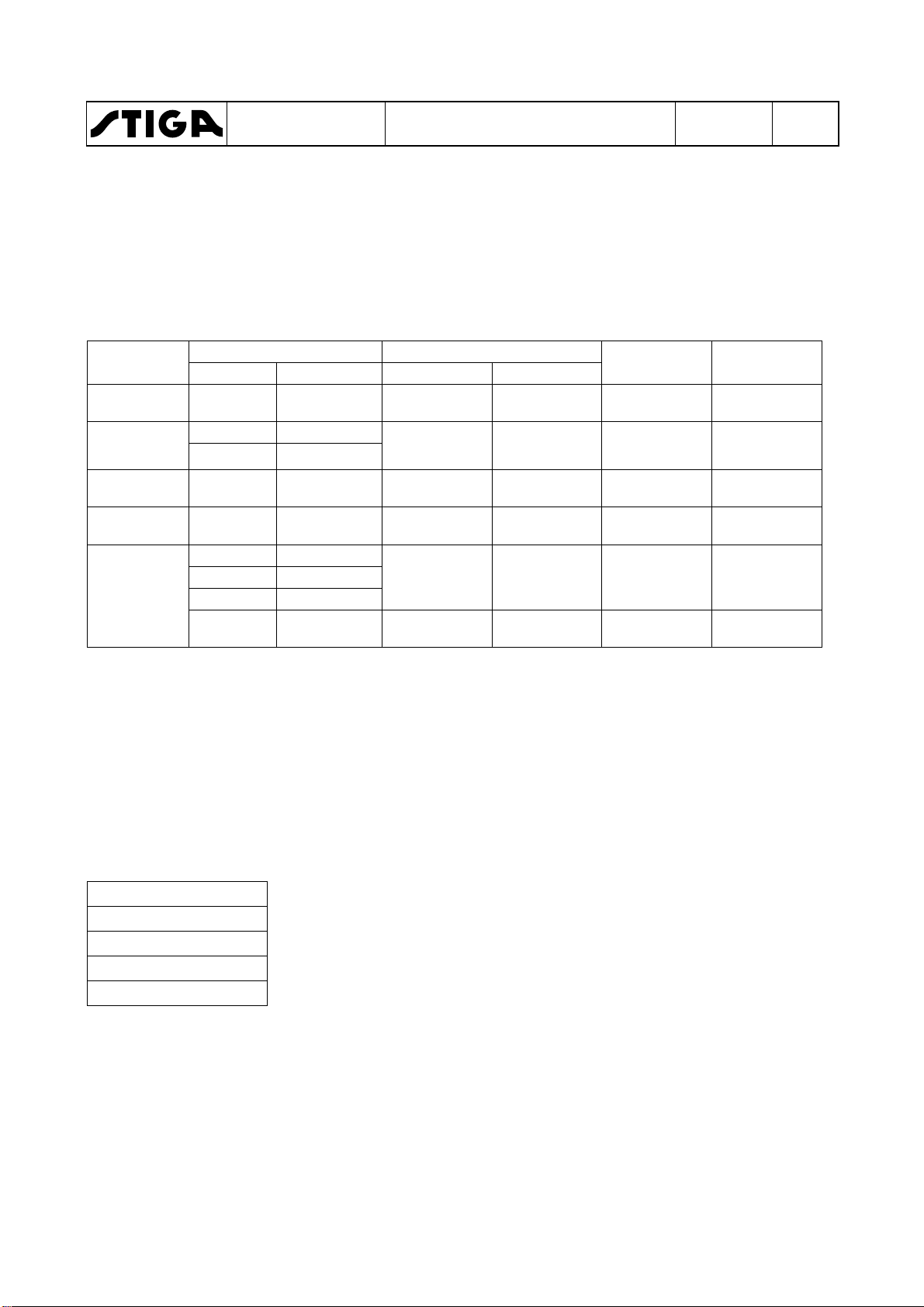

Page 16

Machine

Transmission

Oil and filter change interval

Oil volume

Oil grade

Description

Number

1:st time

Thereafter

Park 2WD

K46

1137-0123-01

Park Compact

Park CH 2WD

Park CH 4WD

Park Pro 4WD

KTM10G

1134-5701-01

KTM10F

1134-5702-01

KTM-13

118475000/0

5 h

200 h

4,7 Liter

5W-50

Thread

Torque

M5

5,7 Nm

M6

9,8 Nm

M8

24 Nm

M10

47 Nm

WORKSHOP MANUAL

PARK

1 - General instructions

Chapter

1.5 Transmission

1.5.1 Transmission oil and filter change interval

Below is listed oil and filter data for the transmissions.

-

and CH 4WD

without servo

with servo

with servo

K574G 1137-0124-01 5 h 200 h 3,5 Liter

KTM10M 1134-6029-01

K57-V 1137-0126-01

K574F

KTM10M

KPL 10ALP 1134-5700-01 5 h 200 h 4,2 Liter

1137-0125-01

1134-6029-01

-

-

1,3 Liter

3,6 Liter

EDITION

2018

SAE 10W-30

(20W-50)

Synthetic oil

5W-50

Synthetic oil

5W-50

Synthetic oil

5W-50

Synthetic oil

5W-50

Page

14

1.6 Technical specifications

1.6.1 General tightening torque

Unless otherwise stated, the following

tightening torque are applicable for screws and

nuts on the machine:

Tightening torques

1.7 Instructions for use

Synthetic oil

Some procedures, e.g. changing engine oil,

engine filter etc., are refered to the owner´s

manual, delivered with the actual machine.

The owner´s manual can also be downloaded

from STIGA´s homepage. Go to www.STIGA.com

and click further to your actual language and

heading.

Page 17

WORKSHOP MANUAL

PARK

2 - Chassis and body

Chapter

EDITION

2018

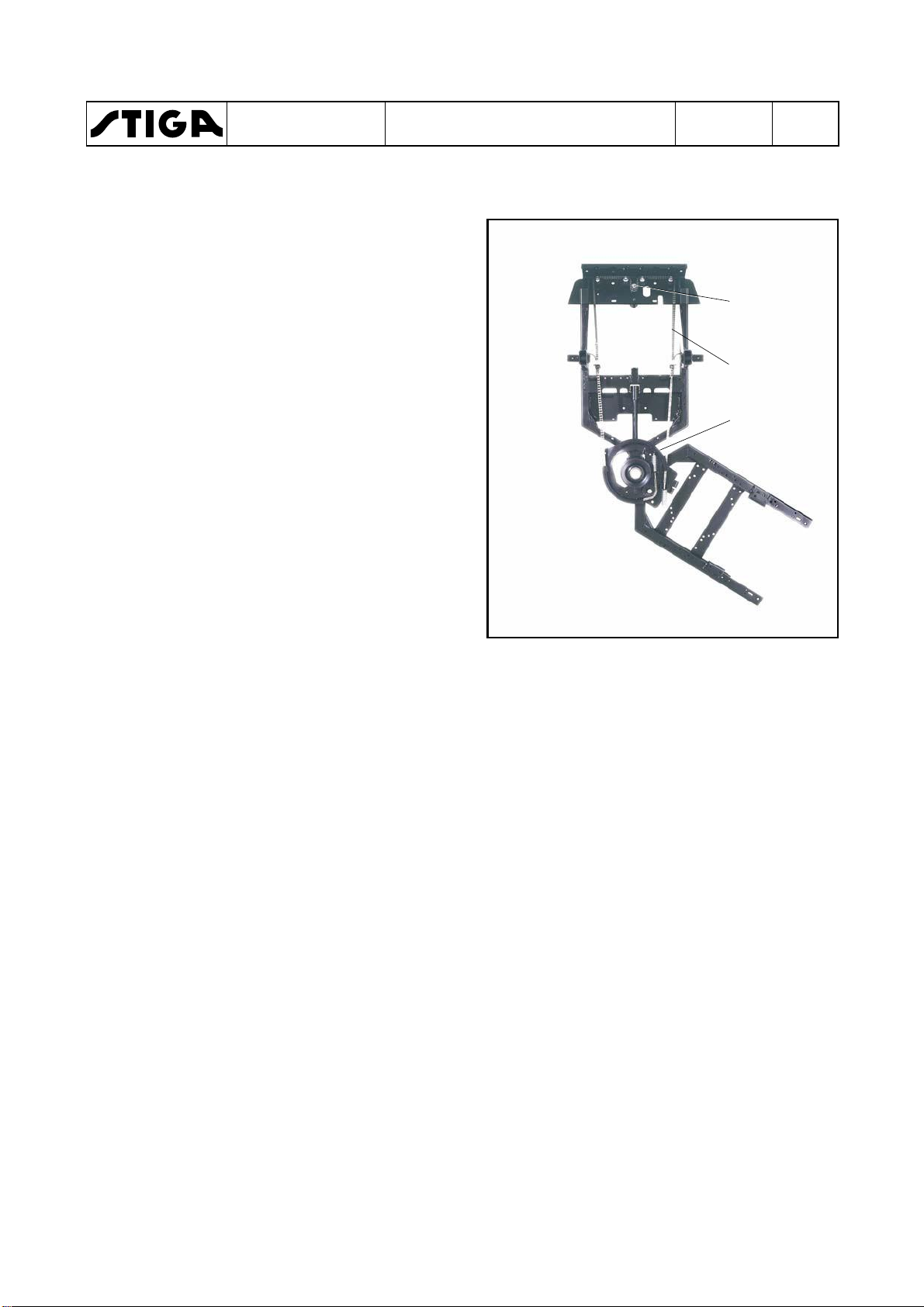

2 Chassis and body

Contents in this chapter

2.1 Rear wheel ........................................ 2

2.1.1 Assembly ....................................... 2

2.2 Lubrication chassis .......................... 3

2.3 Hydraulic pump ................................ 4

2.3.1 Dismantling .................................... 4

2.3.2 Assembly ....................................... 6

General

To facilitate the driving, handling of work equipment and to make it comfortable for the

driver, the machines are equipped with a various number of aid equipments. These

equipments are mainly the same for all the machines covered by this manual, but in some

cases configurated in different ways. Where divergences occour between the machines,

particular instructions are given for each particular equipment.

Page

1

This chapter gives a brief description of the equipments and describes their repair and

replacements.

Page 18

2.1

WORKSHOP MANUAL

PARK

Rear wheel

Chapter

2 - Chassis and body

EDITION

2018

Page

2

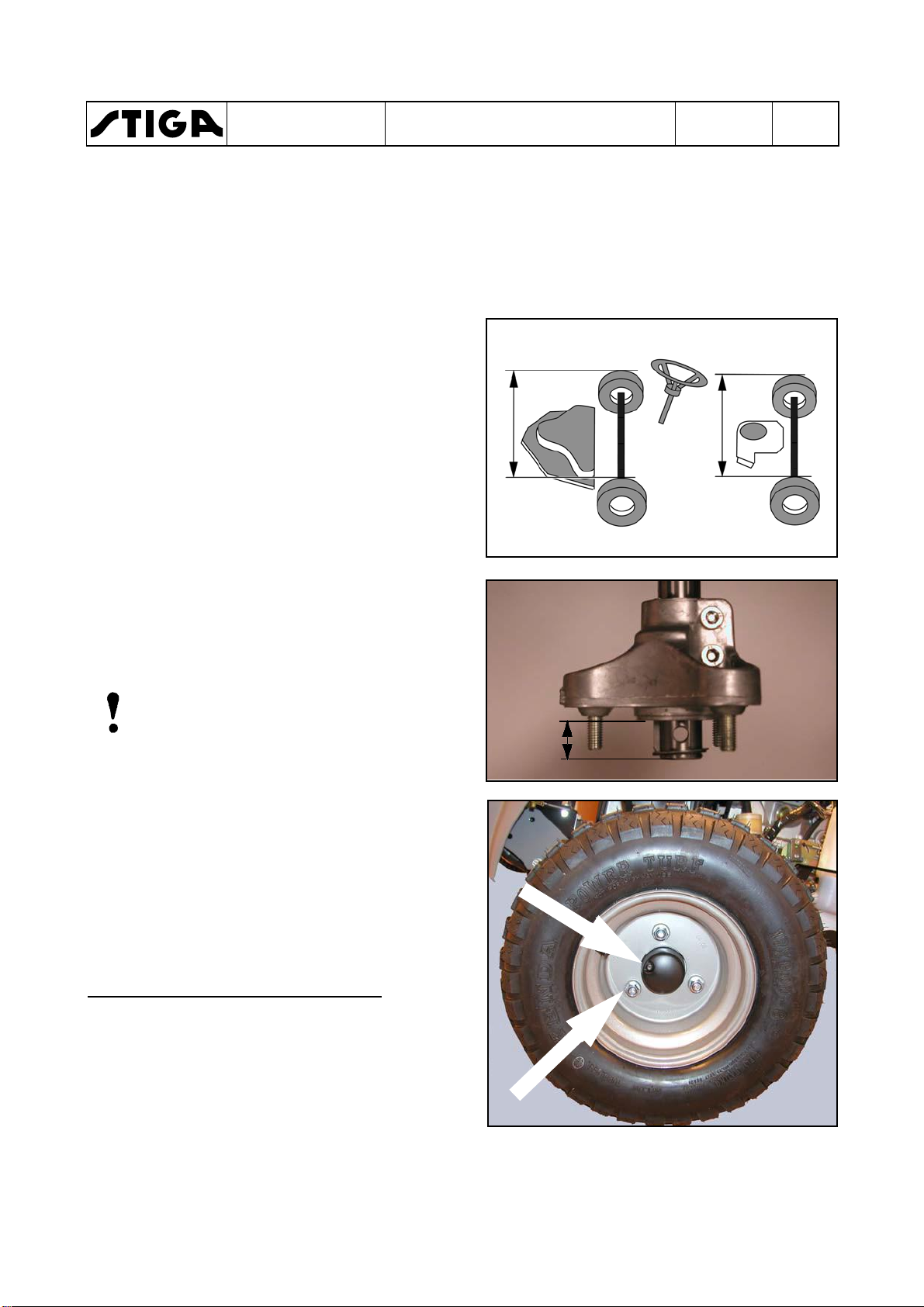

2.1.1

1. Push the hub on the shaft until it rests

2. Assemble the washer and the circlip onto the

3. Check the key and assemble it in the groove,

4. Assemble the rear wheel without tightening

5. Measure the distance (X) between the front

Assembly

against the transmission body.

shaft. The washer shall rest against the

circlip.

against the washer.

the nuts.

wheels and adjust the rear hubs until the

distance between the rear wheels is the

same (X).

Pull out the hubs until the measure (Y) is the

same at the both sides.

Note!

If the measures between the wheels front

and rear not is the same, the machine will

be hard to steer.

X

X

Y

6. Tighten the two allen screws, using a 8 mm

allen key.

The tightening shall be performed in two

steps. Tighten first to 18 Nm and then, finally

to a torque of 24 Nm.

7. Assemble the rear wheel and the protecting

cover.

Asembly when tyre chains are used

To give place for the tyre chains, the distance X

can be increased. If necessary until the hub

rests against the washer.

15/17 mm box spanner

Page 19

WORKSHOP MANUAL

PARK

2.2

Lubrication chassis

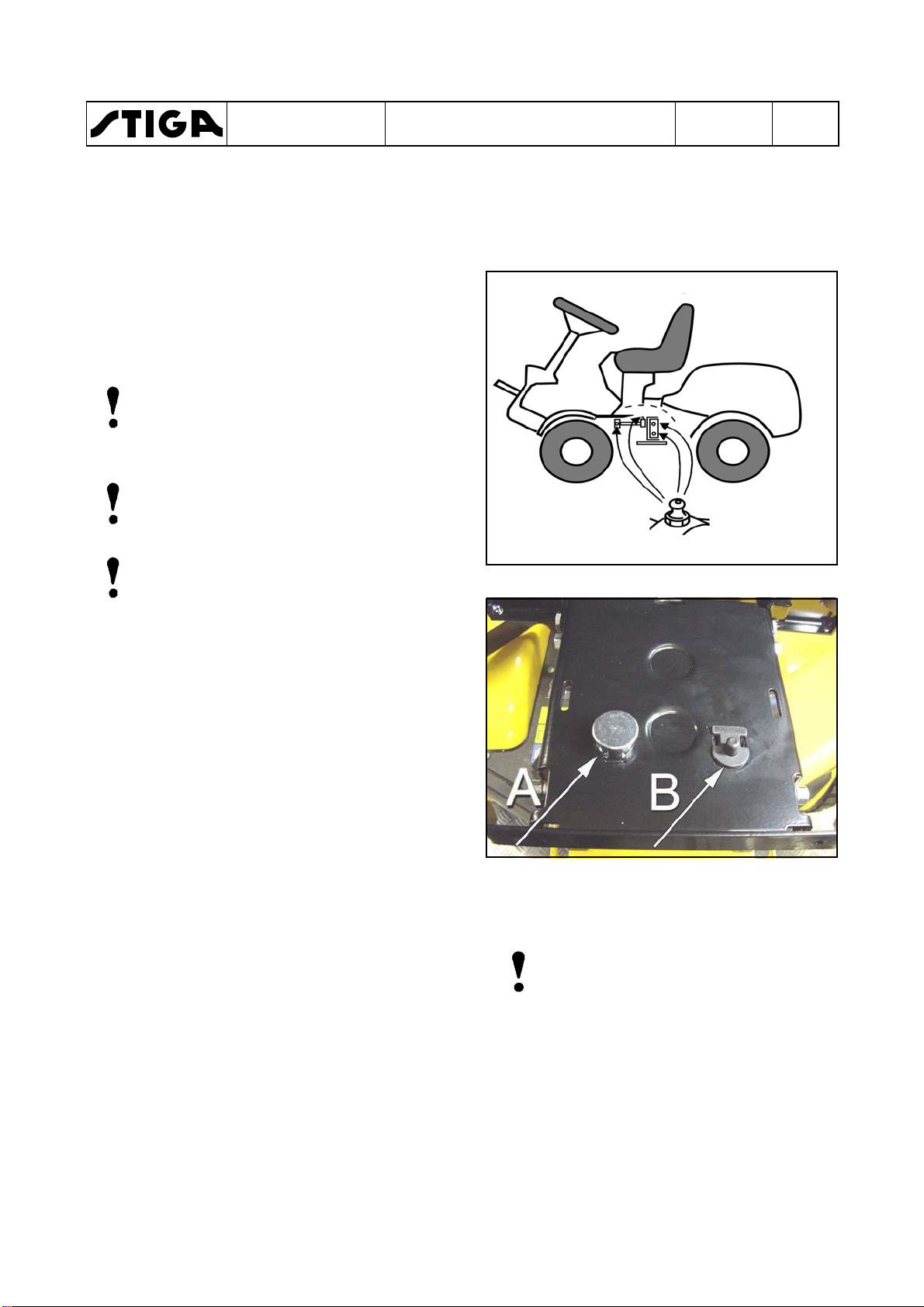

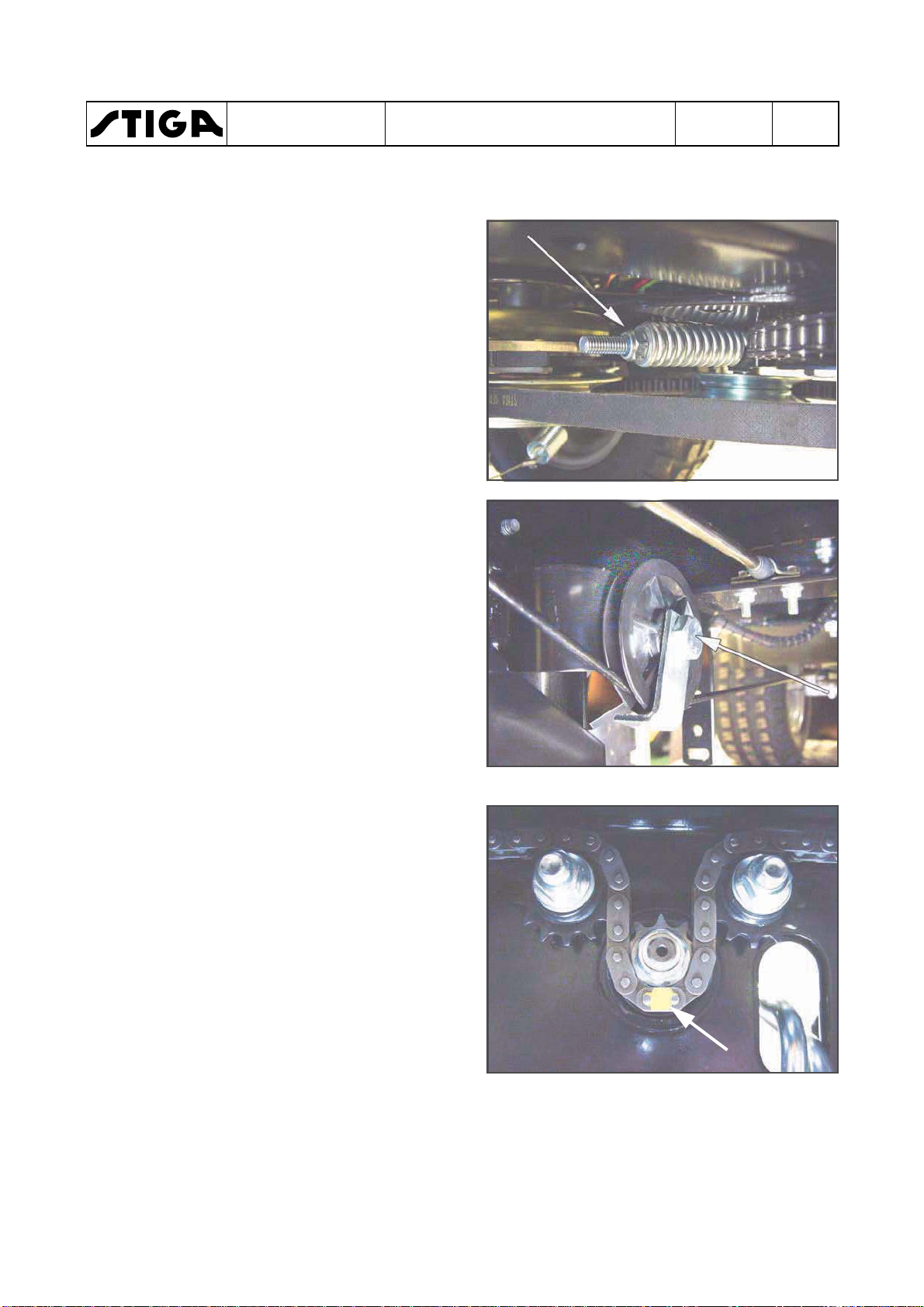

The bearing for the articulation must be

lubricated in accordance with the service

schedule. Other moving parts are lubricated

once per season, although at least every 50

operating hours.

Note!

Lubrication is equally important for a

machine that is only used for a few hours

per year.

Note!

The lubricant provides not only

protection from wear but also from rust.

Note!

The machine should always be

lubricated before prolonged storage.

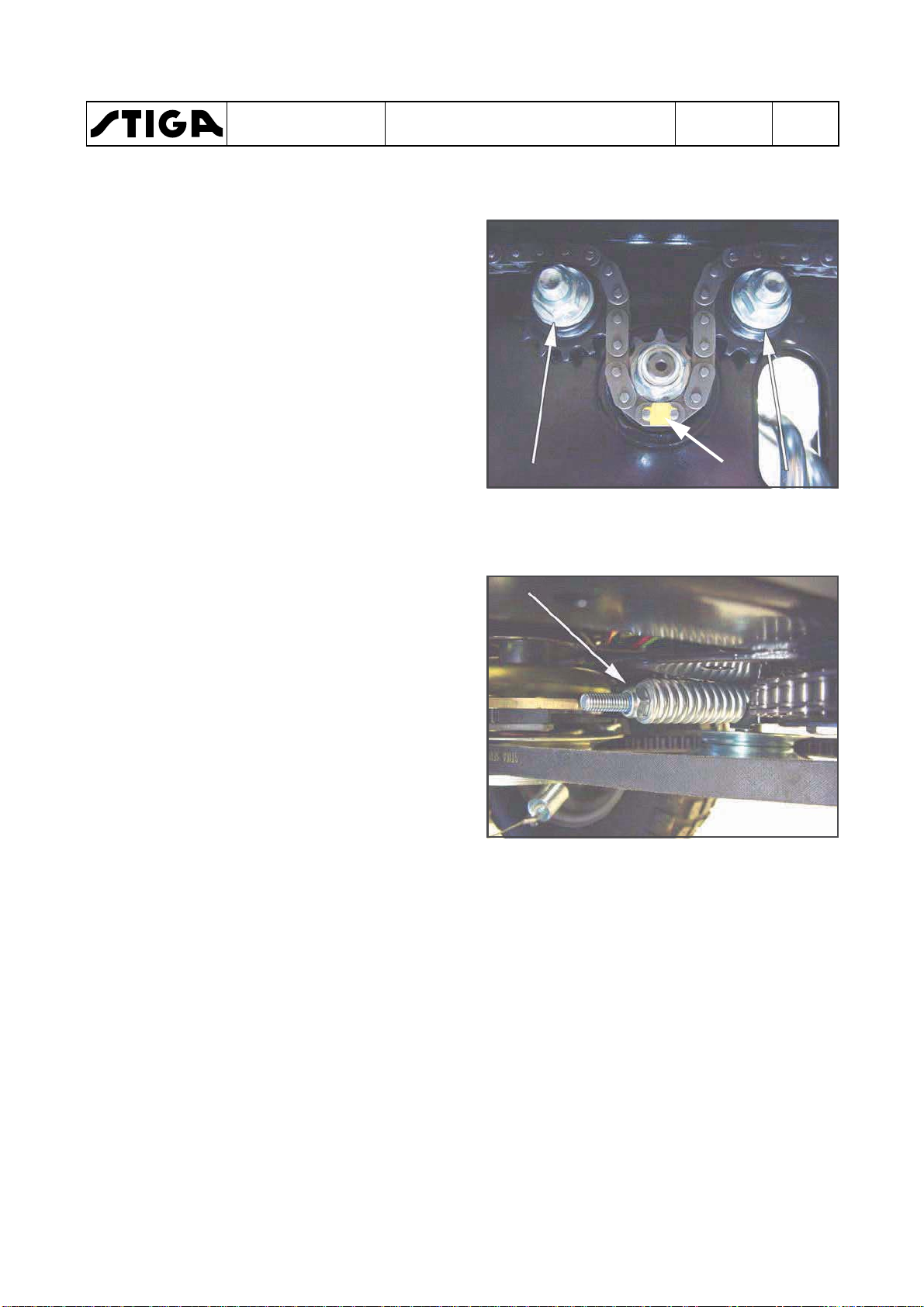

The bearing for the articulation has four grease

nipples which must be lubricated with universal

grease.

The steering chain must be lubricated with

chain spray two or three times per season.

If the chains are heavily fouled: dismantle the

chains and wash them.

Refit and lubricate them.

The pressure pin (A) in the seat suspension

must be lubricated to avoid problems with the

safety circuit.

Plastic bearings, e.g. the brake pedal bearing,

hydrogear pedal bearing and steering-column

bearing, must be lubricated with grease or

lubricating spray.

Drop a little engine oil or lubricating spray in the

ends of the control wires two or three times a

year.

Chapter

2 - Chassis and body

Note!

Wires on machines used in

freezing conditions should not be

lubricated with engine oil since

this can lead to the control cables

seizing in the cold.

The wires on such machines

should be lubricated with a

fluent, strongly penetrating

lubricant, e.g. 5-56 or WD40.

EDITION

2018

Page

3

Page 20

WORKSHOP MANUAL

PARK

2.3

Hydraulic pump

This section will describe the replacement

procedure for the external hydraulic pump in

4WD Park machines.

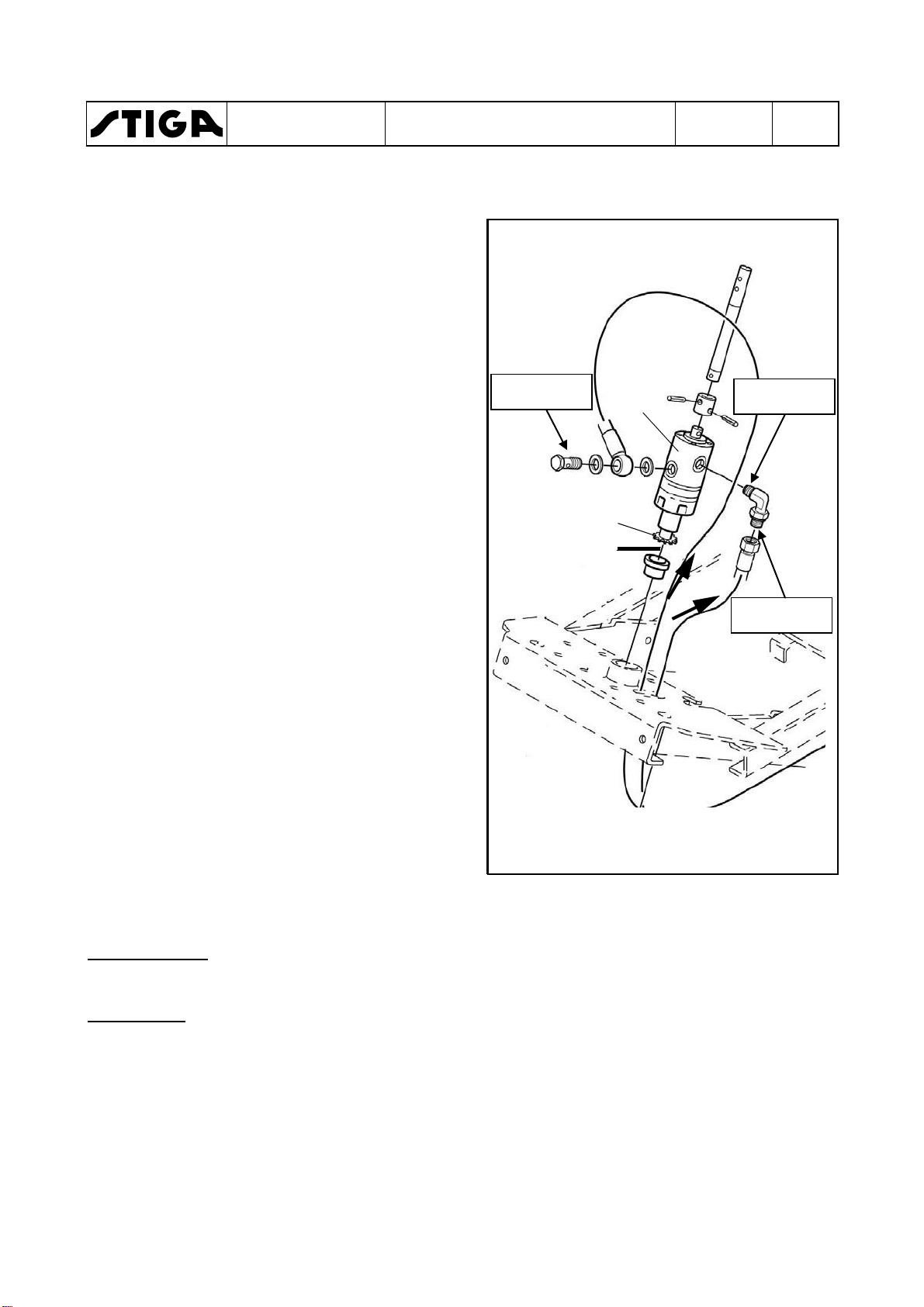

2.3.1

Dismantling

1. Remove the battery. See the owners

manual.

2. Block up the machine. Use a lifting table or

highjack and yokes.

3. Activate the parking brake.

4. Discharge the oil in the hydraulic system.

See the owners manual.

Chapter

2 - Chassis and body

EDITION

2018

Page

4

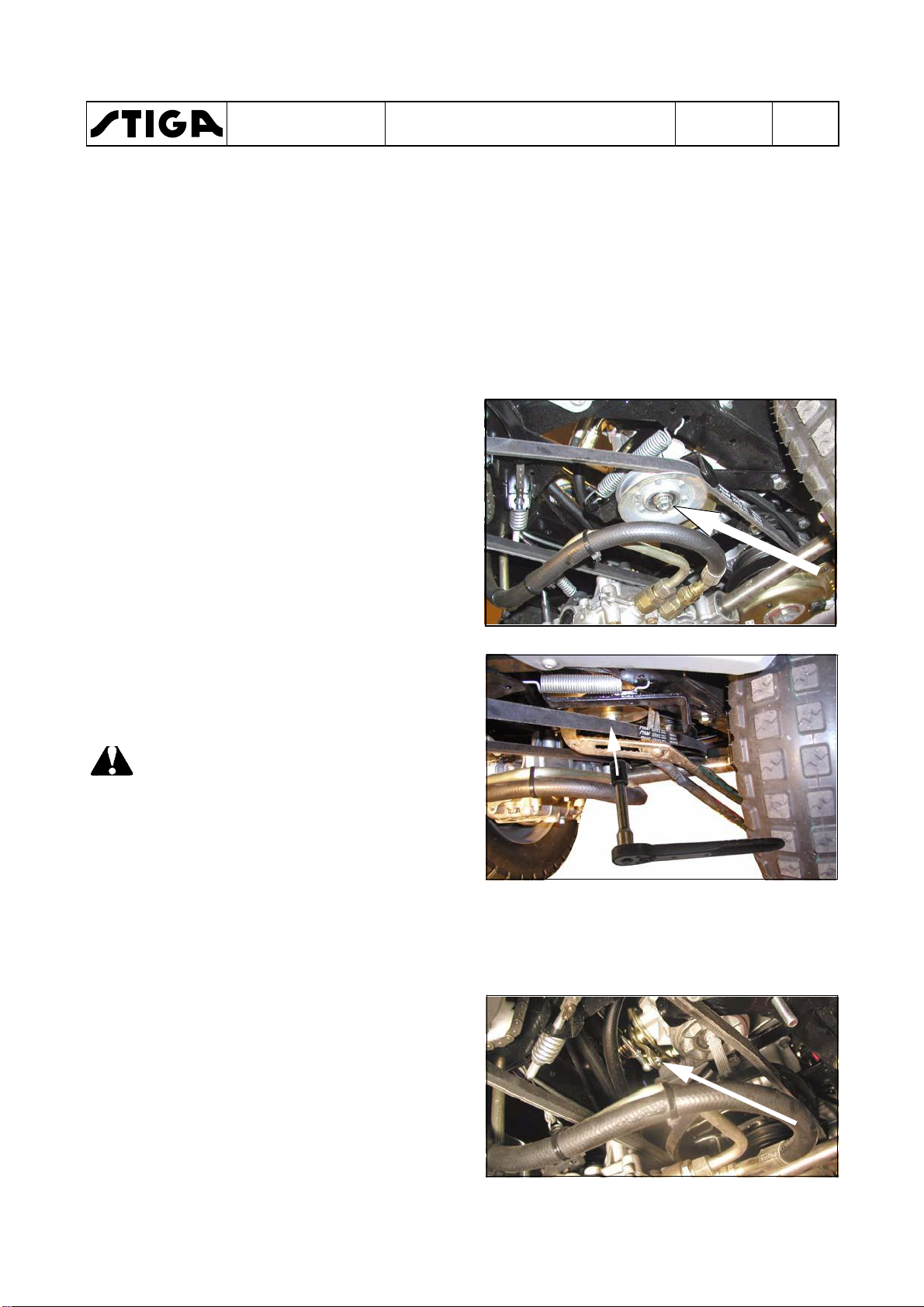

5. Remove the tension pulley by using a 15 mm

and a 17 mm spanner. See the figure.

6. Use a large polygrip and hold the pump

pulley in a securely grip. Fit the polygrip

around the belt, not direct to the pylley.

Back off the pulley nut with a 17 mm sleeve.

See the figure.

Warning!

Be carefully not to damage the

plastic fan during the removal.

7. Remove the following parts from the pump

shaft:

•

Nut

•

Washer

•

Pulley

•

Distance sleeve

•

Fan

•

Distance sleeve

8. Remove the speed control cable from the

hydraulic pump by backing off the nut. Use a

8 mm spanner. See the figure.

9. Back off the circlip from the release lever rod

and disconnect the rod from the lever.

Page 21

40 Nm

78 Nm

78 Nm

40 Nm

B

40 Nm

A

78 Nm

WORKSHOP MANUAL

PARK

10. Place a collecting tray under the pump for

collecting residual oil from the pump and

hoses.

Warning!

Do not spill any oil on the drive belts

during the disconnection of hoses

and tubes.

Warning!

Keep clean when handling hydraulic

parts. Dirt in the oil will cause

malfunctions and breakdowns.

11. Disconnect all hoses and tubes from the

hydraulic pump. Always use two spanners,

one to hold the respective connection in the

pump and one to loosen the nut. See the

figure.

Chapter

2 - Chassis and body

EDITION

2018

Page

5

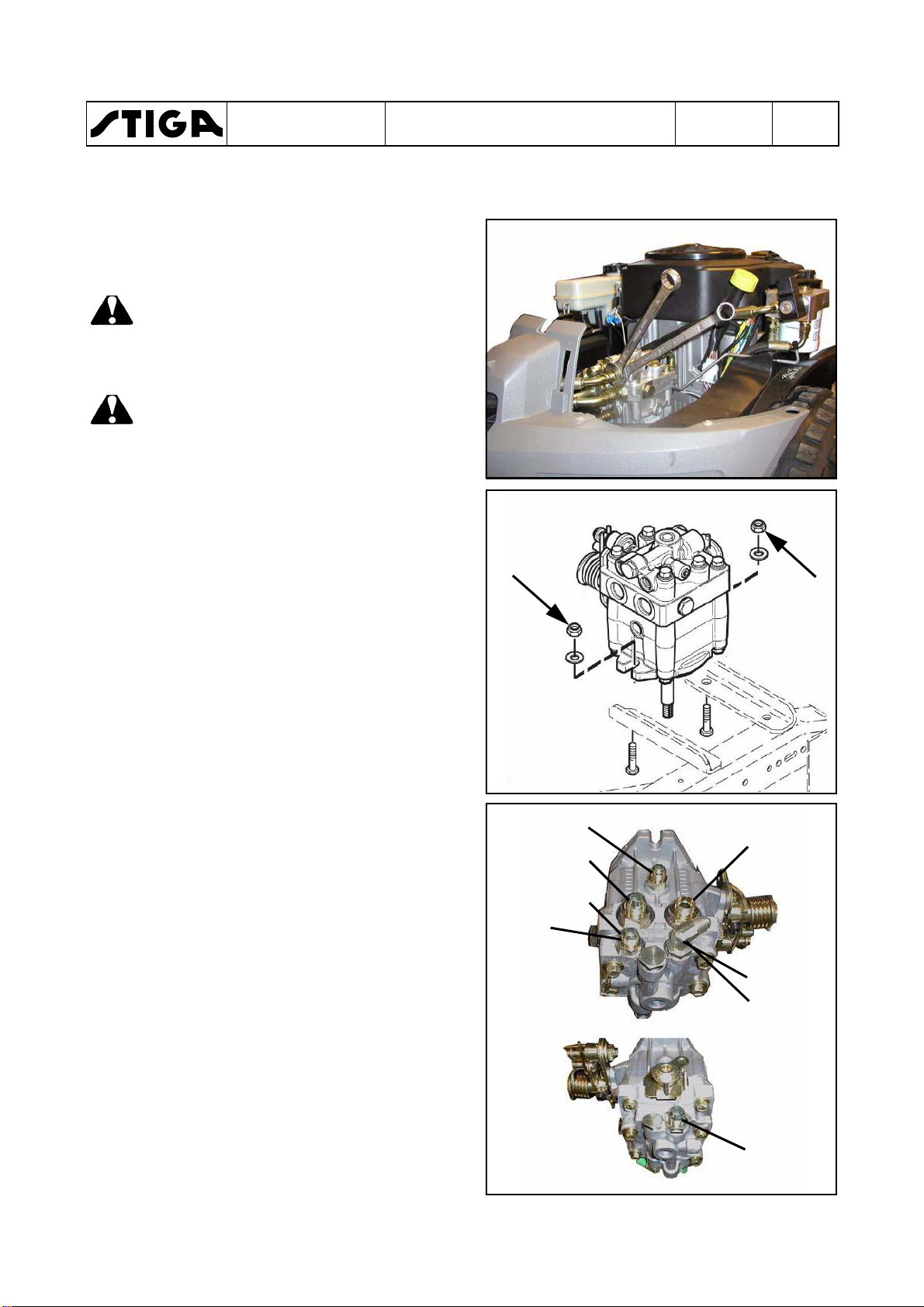

12. Remove the pump from the chassis by

unscrewing the two M10 mounting nuts and

screws. Use two 17 mm spanners. See the

figure.

13. Place and fasten the pump in a table vice.

Loosen the adapters from the pump.

14. Screw out the adapters and insert them in

the corresponding places in the new pump

one at a time. Check or replace the O-rings.

3. Place and fasten the new pump in a table

vice. Tighten the adapters to torques

according to the figures.

When tightening the angle adapter (A),

adjust it to 45° according to the horizontal

line. Use one 14 mm and one 19 mm

spanner.

If a metal tube shall be fitted to the adapters

A and B (machines without external

hydraulics), the connection nuts shall be

tightened with 41 Nm.

Page 22

WORKSHOP MANUAL

PARK

2 - Chassis and body

Chapter

EDITION

2018

Page

6

2.3.2

Assembly

Warning!

Keep clean when handling hydraulic

parts. Dirt in the oil will cause

malfunctions and breakdowns.

Warning!

Be carefully not to damage the

plastic fan during the assembly.

Assemble all parts in the reverse order.

Note!

One distance sleeve (C) at each side of

the fan.

Note!

The tension pulley (D) shall be fitted with

the prolonged part of the sleeve

upwards. See both figures.

C

C

D

Adjust the speed cable. See section 6.

When all parts are fitted and all actual

tightening torques are applied, fill new oil and

bleed the hydraulic system. See the owners

manual.

Up

D

Page 23

WORKSHOP MANUAL

PARK

3 Steering

Contents in this chapter

3.1 Description ....................................... 2

3.1.1 Mechanical system ........................ 2

3.1.2 Hydraulic assisted system ............. 2

3.2 Steering wires ................................... 4

3.2.1 Replacement ................................ 4

3.2.2 Adjustment .................................... 5

3.2.3 Steering chains .............................. 5

General

Chapter

3 - Steering

EDITION

2018

Page

1

3.3 Bearings, steering shaft .................. 7

3.3.1 Replacement of sliding bearings

and ball bearings .................................... 7

3.3.2 Replacement of upper ball bearing

(with steering booster) ............................ 8

3.3.3 Trouble shooting ............................ 9

The articulation steered machines are equipped with either a common mechanical system

or a hydraulic assisted steering system. Both systems work with wires or chains,

depending on the model. The hydraulic assisted system gets its power from the variable

hydraulic transmission at the rear shaft.

This chapter contains a brief description of the function and describes repair, replacements

and adjustments of stressed parts of the steering system.

Page 24

3.1

WORKSHOP MANUAL

PARK

Description

Chapter

3 - Steering

EDITION

2018

Page

2

3.1.1

The sprocket (A) is directly coupled to the

stering wheel on the same shaft. A chain (and

wires) (B) is engaged with the sprocket and

connected to the steering disc (C) on the rear

frame. Thus, the rear frame is forced into actual

angles, related to the front frame when the

driver turns the steering wheel.

3.1.2

Below is given a brief description about how the

steering torque converter works and its

connection to the valves. For a complete

description, see section 4 “Hydraulic system”.

Section 4 describes how the lifting cylinder

works together with the steering torque

converter. It also describes the pressure

division between the two systems and

adjustments.

The power assisted steering is a hydraulic

auxiliary system. The main components are the

torque converter and the oil pump in the

hydrogear.

Mechanical system

Hydraulic assisted system

A

B

C

As opposed to standard power steering (e.g. in

a car), this power assisted steering has a

limited capacity. This implies that in certain

circumstances it has what may be experienced

as negative characteristics.

At low engine speed, or in situations where

extra steering power is required, the steering

may be considered to be somewhat jerky.

The machine should always be in motion when

the steering is used. Avoid turning the steering

wheel when the machine is standing completely

still and the accessory is in lowered working

position.

The machine can be steered even when the

engine is switched off. Nevertheless, it may

require more force than normal to steer the

Page 25

Md D

A

Ms

Mh

Md+Mh=Ms

35-42 Nm

35-42 Nm

30-37 Nm

WORKSHOP MANUAL

PARK

machine. This is particularly noticeable during

cold weather.

Mainly, the hydraulic assisted system works

similar to the mechanical system. The different

is a torque booster (D), atttached to the steering

shaft between the steering wheel and the

sprocket (A).

A oil flow from the HST is flowing through the

torque booster via a filter.

As the driver turns the steering wheel, there

occour a pressure drop over the torque booster.

The pressure drop, multiplied with the flow,

gives a moment (Ma), which is added to the

moment from the driver (Md) and applied on the

sprocket (A) as a moment (Ms).

Chapter

3 - Steering

EDITION

2018

Page

3

The following items are shown in the figure:

A Sprocket of driving the steering chain.

D Torque booster.

Mh Steering power (moment) from the

hydraulic transmision.

Md Hand power (moment) from the driver.

Ms The sum of Ma and Md as steering power

(moment on sprocket A).

Hydraul connections

The hydraul lines have two alternative

connections:

•

Pressure plate with O-rings around the tubes.

•

Banjo fitting.

Pressure plate

Always mount new O-rings when assembling.

Banjo fitting

The connection have no gaskets.

Always tighten the nipples with the correct

tightening when assembling. See the figure.

Page 26

WORKSHOP MANUAL

PARK

3.2 Steering wires

3.2.1 Replacement

1. Loosen the nuts on the steering wire. Brace

with a spanner so that the wire does not

rotate.

2. Loosen the screws that hold the pulley so

that the wire can be taken out between the

pulley and the wire retainer.

Chapter

3 - Steering

EDITION

2018

Page

4

3. Unhook the chain at the front chain sprockets.

It can sometimes be easier to get the chain

off by slightly unscrewing the screws that

hold the chain sprockets.

4. Measure up the middle link (mark A) on the

new chain and mark it.

5. Place the chain on the chain sprockets.

Make sure that the wheel is straight and that

the marked middle link is placed on the middle of the chain sprocket.

6. Place the wire in the pulley and tighten the

screws to the wire retainers.

7. Fit the washer and nut on the threaded rear

ends of the steering wire.

A

Page 27

WORKSHOP MANUAL

PARK

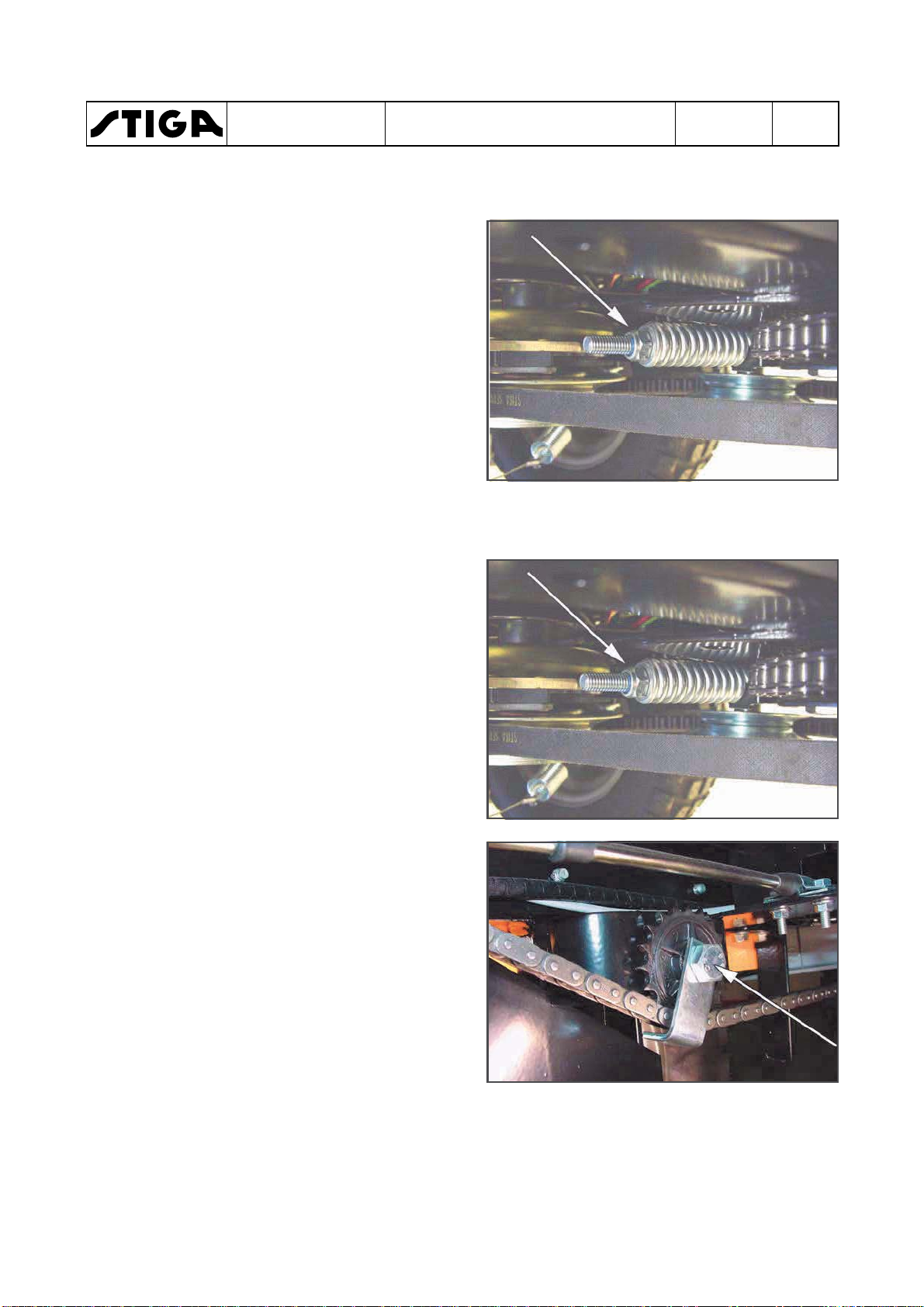

3.2.2 Adjustment

1. Tension the wire nuts equally on both sides

so that the wheel is straight when the

machine is straight.

Brace with a spanner so that the wire does

not twist.

2. Turn the wheels fully out in both directions.

Check that the chain does not go into the

pulley and that the wire does not go into the

chain sprocket.

3. Test drive. Check the tension of the wire

after test driving.

Chapter

3 - Steering

EDITION

2018

Page

5

3.2.3 Steering chains

1. Loosen the nuts on the steering chain.

2. Loosen the screws that hold the chain

sprockets so that the chain can be taken out

between the chain sprocket and wire

retainer.

3. Unhook the chain at the front chain

sprockets.

It can be easier to get the chain off by slightly

unscrewing the screws that hold the chain

sprockets.

Page 28

WORKSHOP MANUAL

PARK

4. Measure up the middle link (A) on the new

chain and mark it.

5. Place the chain on the chain sprockets.

Make sure that the wheel is straight and that

the marked middle link (A) is placed on the

middle of the chain sprocket.

6. Place the wire on the chain sprockets and

tighten the screws to the wire retainers.

7. Fit the washer and nut on the threaded rear

ends of the steering chain.

8. Adjust as described below.

Chapter

3 - Steering

EDITION

2018

A

Page

6

Adjustment

1. Tension the nuts equally on both sides so

that the wheel is straight when the machine

is straight.

2. Turn the wheels fully out in both directions.

Check that there is no abnormal noise or

abnormal resistance.

3. Test drive. Check the tension of the chain

after test driving.

Page 29

WORKSHOP MANUAL

PARK

3.3 Bearings, steering shaft

The steering shaft bearings are configurated in

one of the following three ways:

• Two sliding bearings of the composite type.

• Two sealed ball bearings.

• One sealed ball bearing (upper) and one ball

bearing in the torque booster (lower).

3.3.1 Replacement of sliding bearings

and ball bearings

1. Remove the chain from the lower sprocket.

See previous sections.

2. Tap out the spring pin that holds the steering

wheel. Remove the steering wheel.

Chapter

3 - Steering

EDITION

2018

Page

7

3. Pull up the parking brake knob, remove the

upper cover and the lamp section.

4. Remove the to screws, holding the steering

column and remove the steering column (A).

5. Tap out the bearings with a long drift, bar or

similar.

6. Tap in the new bearings with a rubber mallet.

A

7. Reassemble in the reverse order and adjust

the chain/wire. See previous sections.

Page 30

WORKSHOP MANUAL

PARK

3.3.2 Replacement of upper ball bear-

ing (with steering booster)

1. Tap out the spring pin that holds the steering

wheel. Remove the steering wheel.

2. Pull up the parking brake knob, remove the

upper cover and the lamp section.

Note!

Do not forget the washer (G).

The correct number of shims must be

used to avoid tensions in the steering

column.

3. Remove the split pin from the hydraulic lift

bolt (A) and push out the bolt.

4. Remove the spring (B).

Chapter

3 - Steering

A

EDITION

2018

Page

8

5. Remove the four nuts (C) from the underside and the screw (E), holding the steering

console (F) and lift out the steering console

with its four screws.

6. Remove the three M8-screws (I) from the

lower steering tube (D) and pull up the

steering tube with the washer (G).

7. Press or knock out the ball bearing (H) from

the steering tube and assemble a new bearing with help of a rubber mallet.

8. The assembling is performed in the reverse

order.

Note!

Do not forget the washer (G).

The correct number of shims must be used

to avoid tensions in the steering column.

C

D

E

B

F

G

H

I

Page 31

WORKSHOP MANUAL

PARK

3.3.3 Trouble shooting

One prerequisite for the function of the power

assisted steering is the play in the steering. This

play must always spring back to the starting position when the wheel is released.

T est by slowly turning the wheel in one direction

when the engine is switched off. At first there is

a slight resistance, which increases when the

machine begins to turn. Release the wheel. It

should now return to the middle position.

The wheel should spring back approx. 10-20

mm when the wheel is released after turning.

However, the machine will not

“drive straight forward” after turning in the same

way as a car.

automatically

Chapter

3 - Steering

EDITION

2018

Page

9

If the machine always turns in the same direction as soon as the engine is started, there is

probably a fault in the torque converter.

Another conceivable fault can be that the bearing in the steering column tube is jamming, so

that the steering wheel cannot automatically return to the neutral position.

Note!

If the steering does not function this does

not mean that there is always a fault in the

torque converter. Faults can also occur in

more simple mechanical parts such as

chains and gear wheels.

Page 32

WORKSHOP MANUAL

PARK

4 Hydraulic system

Contents in this chapter

Chapter

4 - Hydraulic system

EDITION

2018

Page

1

4.1 Safety ................................................. 2

4.2 Configuration .................................... 2

4.2.1 Hydraulic diagram (Version 2019 -

with lift) ................................................... 5

4.2.2 Hydraulic diagram (Version 2019 -

without lift) .............................................. 6

4.3 Hydraulic pump integrated in the

rear axle drive ....................................... 7

4.3.1 Physical description ....................... 7

4.3.2 Functional description ................... 8

4.4 Separate hydraulic pump for the

power transmission .............................11

4.4.1 Physical description ..................... 11

4.4.2 Functional description ................. 12

4.5 Hydraulic assisted steering and im-

plement lifter ......................................... 15

4.5.1 Physical description ..................... 15

4.5.2 Functional description ................. 16

4.6 Hydraulic assisted steering .......... 21

4.6.1 Physical description ..................... 21

4.6.2 Functional description ................. 21

4.7 Trouble shooting ............................. 22

4.7.1 Drive system ................................ 22

4.8 External hydraulic .......................... 24

4.9 Change of trans oil, 4WD ............... 27

4.9.1 Transmission with external pump . 27

4.9.2 Transmission with the hydraulic

pump in the rear axle drive ................... 30

General

The four wheel drive Park machines are equipped with hydraulic power transmission. I.e.

the engine drives an hydraulic pump, which pumps oil through the rear and front axle

drives. There are two main configurations; separate hydraulic pump and the hydraulic

pump integrated in the rear axle drive.

The front axle and rear axle are connected in series, which means that the front wheels

and rear wheels are forced to rotate at the same speed. To make turning easier, both axles

are equipped with a differential.

Some of the machines, both 2WD and 4WD, are also equipped with hydraulic assisted

steering and implement lifter.

Front-mounted implements are powered via drive belts.

This chapter contains a description of the hydraulic system, trouble shooting to isolate

faults and information about adjustments and corrective measures.

Since the steering torque converter and lifting cylinder belong to the respective chapter

(2 and 3), these components are described in detail in these chapters.

Page 33

Hydraulic

pump

See

Separate

hydraulic

pump See

See

See

Hydraulic

implement

fter

See

13-6002-XX

Mountfield 4140H

X

X

13-6003-XX

Mountfield 4155H

X

X

13-6004-XX

Mountfield 4155H 4WD

X X

13-6100-XX

Park Silent

X

X

13-6101-19

Park Compact 13

Manual gear 5-speed

13-6102-XX

Park Compact 14

X

X

13-6103-XX

Park Compact 16

X

X

13-6104-XX

Park Compact 16 4WD

X X

13-6105-99

Mountfield XK 13

Manual gear 5-speed

13-6106-99

Mountfield XK 16

X

X

13-6107-99

Mountfield XK 16 4WD

X X

13-6109-XX

Park Compact 14

X

X

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

2

4.1

Safety

Hydraulic oil under pressure can be very dangerous if hoses, lines or other

distribution parts are leaking. To avoid personal injuríes, always wear protection

gloves and protection goggles during works with the hydraulic system.

Before starting the motor, place the machine outdoors or install an extraction device

for the exhaust fumes. Otherwise the personel will be poisoned.

Cleanliness is mandatory at all works with the hydraulic system. Foreign substances

and contaminations will jeopardize the function and reliability of the system. Always

protect and close openings of hoses, lines and connections when replacing components.

4.2

Configuration

The machines are equipped with systems according to the table below:

Art.

Number

Machine

Castelgarden XK 140 HD

Béal Master MBF 13,5

Mountfield 4135H

Castelgarden XK 160 HD

Béal Master MBF 15,5

Mountfield 4155H

Castelgarden XK4 160 HD

Béal Master MBF 15,5

Mountfield 4155H 4WD

5

drive

drive

Wheel

2

drive

Wheel

4

axle

rear

the

in

page

at

"4.3"

8

page

at

"4.4"

4WD

steering,

Hydraulic

11

page

at

""

2WD

steering,

Hydraulic

18

page

at

"4.6"

11

page

at

""

li

Page 34

Hydraulic

pump

See

Separate

hydraulic

pump See

See

Hydraulic

implement

lifter

13-6111-61

OKAY Mcut 98-10/155 K4WD

X X

13-6116-XX

Castelgarden XK 140 HD

X

X

13-6141-XX

Park Unlimited 14

X

X

13-6142-XX

Park Unlimited Plus

X

X

13-6144-XX

Park Silent

X

X

13-6175-26

Park Power 4WD

X X

13-6176-16

Park Champion

X

X

13-6177-XX

Park Prestige 4WD

X X

13-6178-15

Park Residence 4WD

X X

X

13-6178-16

Park Residence 4WD

X X

X

13-6179-04

Park Ranger

X

X

X

13-6179-05

Park Ranger Svan

X

X

X

13-6179-06

Park Ranger Svan

X

X

X

13-6180-XX

Park Diesel

X

X

13-6181-34

Park Diesel 4WD

X X

X

X

13-6182-14

Park Comfort

X

X

13-6182-15

Park Comfort

X

X

13-6183-14

Park Royal

X

X

13-6184-XX

Park President 14

X

X

13-6185-XX

Park Prestige 4WD

X X

13-6189-XX

Park Excellent 16

X

X

13-6193-XX

Park Ranger

X

X

X

13-6195-14

Park Fairway 18

X

X

13-6196-25

Park Power 4WD

X X

13-6197-XX

Castelgarden XKH4 165 HD

X X

13-6198-55

75 Years ltd version

X

X

13-6199-15

Park Residence 4WD

X X

X

13-6241-XX

Park Pro 16 4WD

X

X

13-6241-XX

Park Pro Svan 4WD

X

X X

X

13-6242-64

Park Pro Bivoj 4WD

X

X

13-6244-XX

Park Pro 20 4WD

X

X X

X

13-6246-XX

Park Pro 25 4WD

X

X X

X

Art.

Number

WORKSHOP MANUAL

PARK

Machine

Chapter

4 - Hydraulic system

5

drive

drive

Wheel

2

drive

Wheel

4

axle

rear

the

in

page

at

"4.3"

8

page

at

"4.4"

4WD

steering,

Hydraulic

11

page

at

""

See

EDITION

2018

2WD

steering,

Hydraulic

18

page

at

"4.6"

Page

3

11

page

at

""

See

Page 35

Hydraulic

pump

See

Separate

hydraulic

pump See

See

Hydraulic

implement

lifter

13-6269-XX

Park Pro 18 4WD

X

X X

X

13-6270-XX

Park Pro 21 4WD

X

X X

X

13-6271-XX

Park Pro 16 4WD

X

X X

13-6272-XX

Park Pro Svan 4WD

X

X X

X

13-6273-XX

Park Pro 20 4WD

X

X X

X

13-6274-16

Park Pro 23 4WD

X

X X

X

13-6275-16

Park Pro Silver

X

X

13-6276-XX

Park Pro 25 4WD

X

X X

X

13-6310-XX

Park Excellent 16, 620 W

X

X

13-6311-XX

Park Plus

X

X

13-6312-XX

Park Royal 4WD

X X

X

13-6313-11

Park Excellent

X

X

13-6314-11

Park Plus Unlimited

X

X

13-6317-32

Park 740 PWX

X X

X

13-6318-31

Park 520 DP

X

X

X

13-6319-31

Park 520 DPX

X X

X

13-6320-11

Park 520 Anniversary

X

X

X

13-6372-11

Park Power 16 4WD

X X

13-6373-XX

Park 740 WX, Park Ro. 4WD

X X

X

13-6374-11

Park Champion 4WD

X X

X

13-6375-11

Park Power 4WD

X X

13-6377-11

Park Prestige 4WD

X X

13-6378-XX

Park Residence 4WD

X X

X

13-6379-XX

Park Ranger Svan

X

X

X

13-6380-XX

Park 620 PW

X

X

X

13-6381-XX

Park 540 LPX

X X

X

13-6384-11

Park 123

X

X

13-6384-12

Park 420 LM

X

X

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

4

Art.

Number

Machine

drive

Wheel

2

drive

Wheel

4

drive

axle

rear

the

in

5

page

at

"4.3"

8

page

at

"4.4"

4WD

steering,

Hydraulic

11

page

at

""

See

2WD

steering,

Hydraulic

18

page

at

"4.6"

11

page

at

""

See

The power transmission and the hydraulic assisted steering and implement lifter work with

the same oil, but in two separate parallel systems. Therefore, the descriptions are divided

in the following headings:

The following sections will explane the physical arrangement of the hydraulic components

and give a functional description.

Page 36

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

4.2.1 Hydraulic diagram (Version 2019 - with lift)

EDITION

2018

Page

5

Page 37

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

4.2.2 Hydraulic diagram (Version 2019 - without lift)

EDITION

2018

Page

6

Page 38

4 11

12

6

10 9 8 7 2

3

5

B

1

A

13

4.3

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Hydraulic pump integrated in the rear axle drive

Page

7

4.3.1

A. Rear axle drive.

1.

2.

3.

4.

5.

6.

Physical description

The parts 1-3 and 5-8 below are built

in the rear axle drive.

Charge pump, 35-45 bar.

Main pump.

Pressure limit valve for the charge

pressure.

Oil container.

Oil filter.

Connection to the external hydraulics

(steering converter and implement

lifter).

B. Front axle drive. The parts 9 and 10

below are built in the front axle drive.

9.

Hydraulic motor, front axle.

10.

By-pass valve, front axle.

11.

Leak flow line.

12.

Main flow line.

13.

Main flow line.

Colour - Pressure

Red is the feeding pressure to the

main pump and to the external

hudraulics.

7.

Hydraulic motor, rear axle.

8.

By-pass valve, rear axle.

Dark red is the working pressure

to the hydraulic motors.

Blue is the atmospheric pressure

in the oil container and housings.

Light blue is below the

atmospheric pressure (pump

suction side).

Page 39

Driving forward - Integrated pump

11

4

12

6

10

8

9 7

2

3

5 B

1

A

13

Driving backward - Integrated pump

4 11

12 6

10

9 8 7

2

3

5 B 1 A

13

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

8

4.3.2

Functional description

Driving

The oil flows when driving forwards respectively backwards are showh in the diagrams

below.

117

146

Page 40

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

9

The engine drives the charge pump (1) and the main pump (2) with a constant speed. The

charge pump is feeding the main pump. The oil, fed into the main pump during operation, is

a replacement for the leak oil from the front and rear axle drives (A and B).

The charge pump sucs its oil from the rear axle drive volume and through the lter (5). The

rear axle drive is supplied with oil from the oil container (4).

The oil ow and the ow direction through the main pump (2) - front hydraulic motor (9)

- rear hydraulic motor (7) is controlled by the speed pedal, mechanical connected to the

main pump (2) in the rear axle drive (A). The main pump pressure is depending on the

power requirements at the wheel axles and is limited by the engine power.

The motors are connected in serie with the front motor (9) rst, when driving forwards.

This means, due to the leakage in the front motor, that the machine under normal conditions drives on the front wheels only. When the front wheels begin to slip (rotate with 1-4%

higher speed than the rear wheels) also the rear wheels start to drive and the slipping is

avoided.

This fact is not noticed by the operator, since the machine is driven with its four wheels

after demand.

Dynamic balancing valve.

The hydraulic circuit is equipped with a dynamic balancing valve for the correct balancing

of the circuit. When the machine is stationary, the dynamic balancing valve is open and allows the hydraulic steering to rotate smoothly.

While when the machine starts to move forward, the dynamic balancing valve closes automatically, the front drive axle starts to transmit and then a few moments later, the rear drive

axle also starts to transmit. The rotation of the hydraulic steering remains uid.

The time that passes between the engagement of the front axle and the rear axle is not

normally perceived by the user.

Page 41

WORKSHOP MANUAL

PARK

Chapter

EDITION

4 - Hydraulic system

The dynamic balancing valve

has a standard calibration of

0.15mm, this can be adjusted

in the +/- 0.05 range compared to the standard calibration.

With a dynamic balancing

valve set to 0.10mm, the

valve closing time will be

reduced.

With a dynamic balancing valve set to

0.20mm, the valve closing time will be

increased.

2018

Page

10

By-pass valves

The axle drives are equipped with by-pass valves. Each by-pass valve is connected to their

clutch release lever

. When the by-pass valve (10) is open, it allows oil to ow into the motor

housing and the pressure drop

over the motor is such neutralized. The bypass valve is intended to make it possible to

push the machine without heavy resistance from the axle drive.

The front by-pass valve is equipped with a mechanic interlock which always resets the valve, if

previously opened, at driving attempts forwards

An attempted to drive the machine forwards with

the rear by-pass valve (8) closed and the front

by-pass valve (10) open will result in an powerful oil ow into the front axle drive housing. Since

the leak ow line (11) not are dimensioned for this

ow and the main ow line (13) is blocked, it will

result in a hazardous pressure rise in the front

axle drive housing. This pressure rise forces the

oil to presses out through the sealings and can

cause damages.

8. Rear clutch release lever, connected

to the rear bypass valve.

10. Front clutch release lever, connected

to the front bypass valve.

Page 42

4 11 5

11

11

12

6 13

B 3

A

9

8

C

2

7 1 3 12

WORKSHOP MANUAL

PARK

4.4

Separate hydraulic pump for the power transmission

4 - Hydraulic system

Chapter

EDITION

2018

Page

11

4.4.1

Physical description

A. Rear axle drive with its hydraulic

motor (7).

B. Front axle drive with its hydraulic

motor (9).

C. Hydraulic pump. The parts 1-3 and 8

below are built in the hydraulic pump.

1.

Charge pump, 35-45 bar.

2.

Main pump.

3.

Pressure limit valve for the charge

pressure.

4.

Oil container.

13

8.

By-pass valve in the main pump (C).

9.

Hydraulic motor in the

front axle drive (B).

11.

Leak flow lines.

12.

Main flow lines.

13.

B-pass valve (only used when oil

change)

Colour - Pressure

Red is the feeding pressure to the

main pump and to the external

hudraulics.

5.

Oil filter.

6.

Connection to the external hydraulics

Dark red is the working pressure

to the hydraulic motors.

(steering converter and implement

lifter).

Blue is the atmospheric pressure

in the oil container and housings.

7.

Hydraulic motor in the

rear axle drive (A).

Light blue is below the

atmospheric pressure (pump

suction side).

Page 43

Driving forward - Separate pump

4 11 5

11

11

12

6

13 B 3

A 13 9

8

C

2

7 1 12

Driving backward - Separate pump

4

11

5

11

11

12 6

13 B 3

13

9 9

8

C 2

7 2

1 12

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

12

4.4.2

Functional description

Driving

The oil flows when driving forwards respectively backwards are showh in the diagrams

below.

Page 44

WORKSHOP MANUAL

PARK

The charge pump (1) and the main pump (2) are integrated into one unit, the hydraulic

pump (C) which is located separat in front of the engine.

The engine drives the the hydraulic pump (C) with a constant speed. The charge pump (1)

is feeding the main pump (2) with 35-45 bar. The oil, fed into the main pump during

operation, is a replacement for the leak oil from the front and rear axle drives (A and B) and

the main pump (2).

The charge pump sucs its oil from the oil container (4) and through the filter (5).

The oil flow and the flow direction through the main pump (2) - front hydraulic motor (9) rear hydraulic motor (7) is controlled by the speed pedal, mechanical connected to the

main pump (2). The main pump pressure is depending on the power requirements at the

wheel axles and is limited by the engine power.

The hydraulic motors and the hydraulic pump have a small oil leakage (1-4%), which

increases with increased power requirement (increased pressure). The leakage oil is

collected inside the unit housings an forwarded back to the oil tank through the leak flow

lines.

4 - Hydraulic system

Chapter

EDITION

2018

Page

13

The motors are connected in serie with the rear hydraulic motor (7) first, when driving

forwards. This means, due to the leakage in the rear motor, that the machine under normal

conditions drives on the rear wheels only. When the rear wheels begin to slip (rotate with

1-4% higher speed than the front wheels) also the front wheels start to drive and the

slipping is avoided. This fact is not noticed by the operator, since the machine is driven with

its four wheels after demand.

By-pass valve

The main pump (2) is equipped with a bypass valve (8), connected to its clutch

release lever. When the by-pass valve is

open, the main pump is disconnected from

the oil circuit by an open passage out into

the housing.

The pressure drop over the pump is such

neutralized and the oil can flush free in the

system. See the figure.

The by-pass valve is intended to make it

possible to push the machine without heavy

resistance from the main pump.

8

8

2

Page 45

figures.

With external hydraulic

6

6 5 2 7

4

3

1

Without external hydraulic

6

6

5

2

1.5-2.5 bar

7

4

35

3

1

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Charge pump

The charge pump has two tasks:

•

To feed the external hydraulic with 35-45 bar.

•

To feed the main pump with its initial pressure, 1,5-2,5 bar.

External hydraulic

The charge pump (1) sucks oil from the oil

container (5).

When the external hydraulics are in use, the

pressure in the out line (3) is limited to 35-45

bar by the pressure valve (4).

Without external hydraulic

The connections for the external hydraulics are

connected to each other. Compare the two

Chapter

EDITION

2018

Page

14

The charge pump (1) sucs oil from the oil

container (5).

The pressure valve (4) has no function because

the pressure valve (7) is set to a much lower

pressure (see below).

Feeding the main pump

The line (2) feeds oil to the main pump

respective suction lines (depending on driving

forwards or backwards) through the respective

back valves (6). The pressure in the line (2) is

limited to 1,5-2,5 bar by the pressure valve (7).

-45 bar

7

4

Page 46

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

4.5

Hydraulic assisted steering and implement lifter

This section is valid for 4WD machines with steering chain.

EDITION

2018

Page

15

4.5.1

This section explanes the physical arrangement of the hydraulic components and the

different maximal pressures in the system.

Physical description

A. The dashed box indicates parts (1-4)

which are builtin the rear axle drive or

arranged separat in front of the

engine.

B. Hand operated valve unit with the

built in parts 6-10.

1.

Charge pump.

2.

Main pump. This pump belongs to the

driving system and supplies the oil

pressure/flow.

3.

Pressure limit valve.

A

9.

Slide with 4 different hole patterns for

the resp. functions. Illustrated in

normal status.

10.

Hand lever, connected to the slide.

11.

Double acting lifting cylinder.

Red lines indicate the maximum total

pressure from the HST when the torque

converter (5) works.

Yellow lines indicate the maximum

pressure to the lifting cylinder when it lifts

the implement.

4.

Oil container.

5.

Steering torque converter.

Blue lines indicate return oil with low

pressure (>1 bar).

6.

Pressure limit valve.

7.

Pressure adjustment screw.

8.

Non-return valve.

Page 47

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

16

4.5.2

Functional description

Normal condition

Operation state:

•

Motor is running in full speed.

•

The steering wheel is not actuated.

•

The implement lifter is not activated.

The loading pump (1) is forcing oil through the steering converter (5), and the open valve

(9).

The oil flow is indicated with arrows in the figure below. Since neither of the two items are

working, the resistance can be ignored and the pressure is very low (<1 bar).

In the normal condition, the lifting cylinder (11) is locked in its set position, because no oil

can flow out or in since the oil lines are shut by the slide (9).

Page 48

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

17

Steering wheel actuated

Operation state:

•

Motor is running in full speed.

•

The steering wheel is actuated.

•

The implement lifter is not activated.

The loading pump (1) is forcing oil through the steering converter (5), and the open valve

(9).

The oil flow is indicated with arrows in the figure below. Since the steering converter (5) is

working, a pressure drop will be built up over it.

The pressure drop =

the pressure in the red line - the pressure after the steering converter (5)

The pressure drop is depending on the steering power needed and is limited of the built in

valve (3).

Page 49

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

Raising

Operation state:

•

Motor is running in full speed.

•

The steering wheel is actuated or not.

•

The implement lifter is activated upwards.

The operator has actuated the hand lever (10) to its raising position (rear position), which

moves the slide (9) to change the hole pattern between the connections in the valve. The

hole pattern is adapted for the raising procedure. Oil forces through the non-return valve

(8), through the slide (9) and presses out the piston in hydraulic cylinder (11).

When the piston in cylinder (11) is fully extended and the hand lever still is activated, the

oil will flow only through the valve (6) and a noice will be heard from the valve.

When the hand lever is released, valve (9) will reurn to its neutral position and the system

switches over to its normal state. The piston in the hydraulic cylinder (11) is then locked in

its actual position.

18

Page 50

WORKSHOP MANUAL

PARK

4 - Hydraulic system

Chapter

EDITION

2018

Page

Lowering

Operation state:

•

Motor is running in full speed.

•

The steering wheel is actuated or not.

•

The implement lifter lever is activated upwards.

The operator has actuated the hand lever (10) to its lowering position (one step forwards),

which moves the slide (9) to change the hole pattern between the connections in the valve.

The hole pattern is adapted for the lowering procedure (crossed in the figure below). Oil

forces through the non-return valve (8), through the slide (9) and presses back the piston

into the hydraulic cylinder (11).

In this arrangement, the implement is forced down, irrespective its weight.

When the piston in cylinder (11) has reached its bottom position and the hand lever still is

activated, the oil will flow only through the valve (6) and a noice will be heard from the valve.

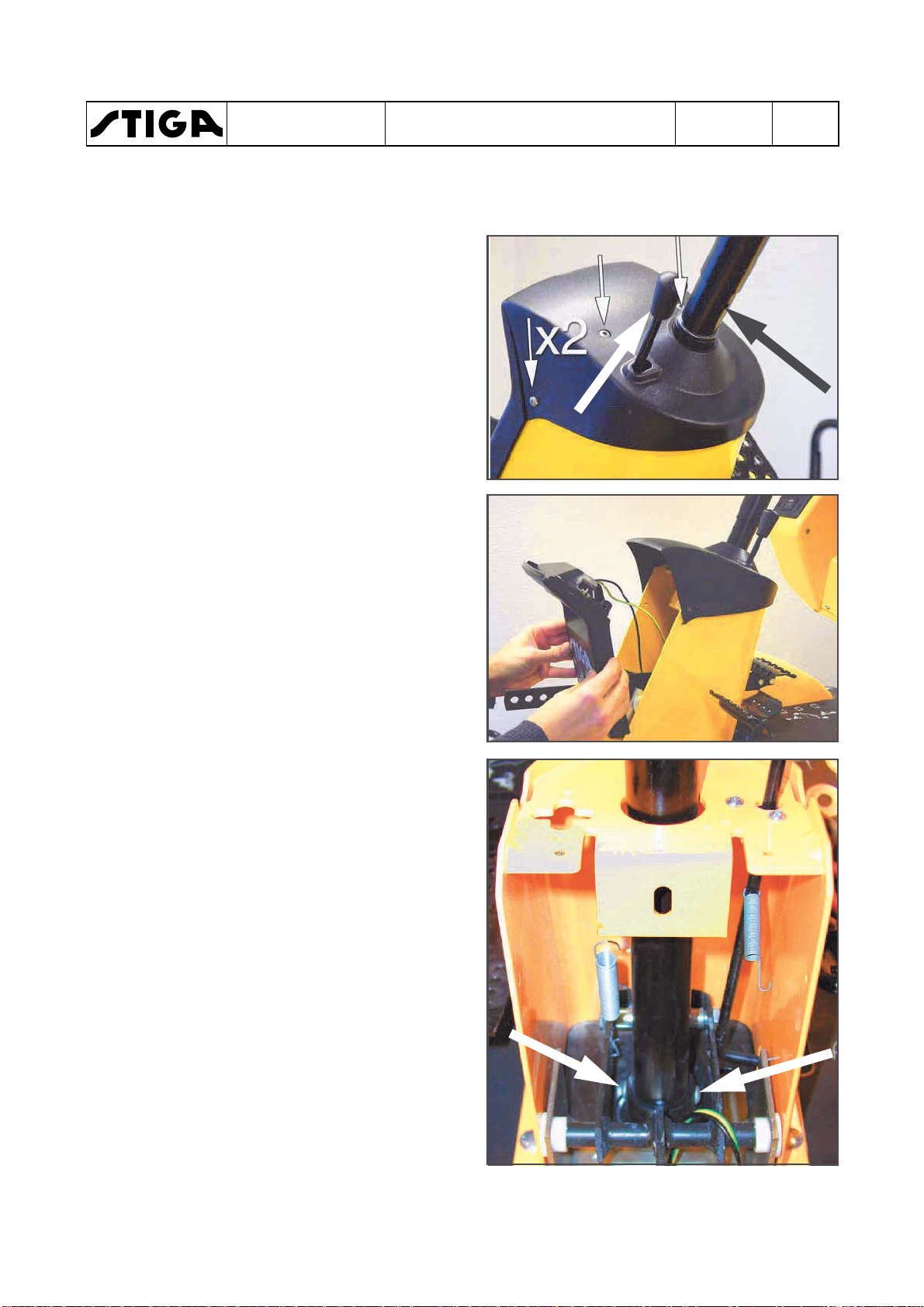

When the hand lever is released, valve (9) will reurn to its normal position and the system