Page 1

STIGA PARK

121 M

8211-3011-09

Page 2

1. Park -1993

5a.

D

5b.

2. Park -1993

3. Park -1993

6a. Park -1999

F

H

7.

I

6b. Park 2000-

G

4. Park -1993

2

I

8.

Page 3

J

9.

13.

10.

11.

14.

Z

X

Y

V

W

15.

Denna produkt, eller delar därav,omfattas av följande

mönsterskydd:

This product, or part of it, is covered by the following

design registration:

Sverige/Sweden 62 435

Tyskland/Germany M97 07 997.9 (pending)

12.

3

Page 4

4

Page 5

ENGLISH

GB

SYMBOLS

The following symbols can be found on the

machine to remind you of the care and attention

that are required during use.

The symbols mean:

Warning!

Read the instruction manual and the safety

manual before using the machine.

Warning!

Do not insert your hands or feet under the

cover when the machine is in operation.

Warning!

Watch out for discarded objects. Keep

onlookers away.

Warning!

Before starting repair work, remove the

spark plug cable from the spark plug.

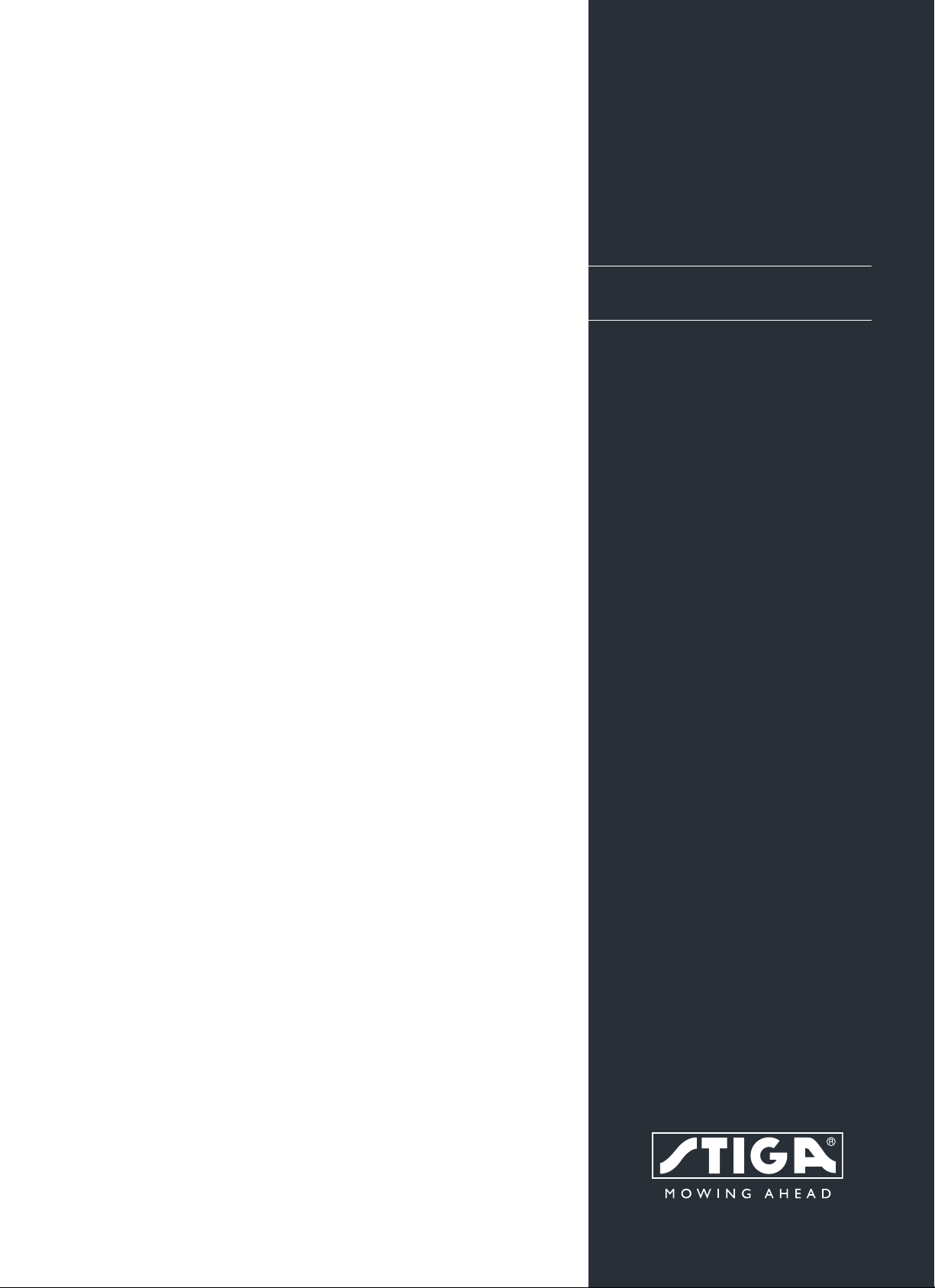

4. Install the spring in the new hole (fig. 4).

INSTALLATION

CUTTING DECK

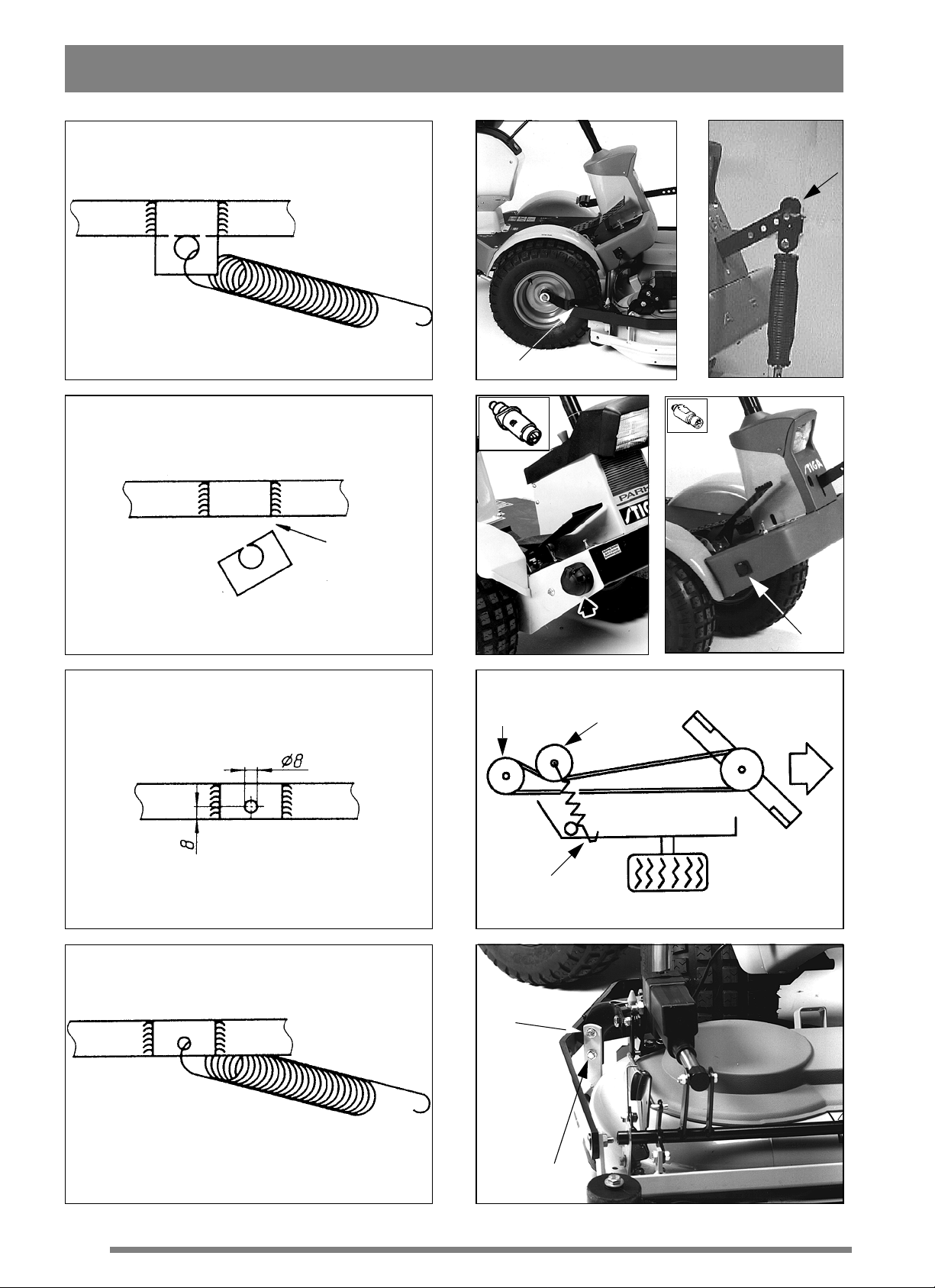

1. Screw the cutting deck into the deck mounts D

(fig. 5a).

2. Attach the lift spring to the implement lifter (fig.

5b).

3. Install the lifting cylinder in the front lifting arm

by inserting the accompanying spacer in the hole

on the lifting cylinder and threading on two

washers, one on either side.Secure with screw and

nut (only applies to item no. 13-2921).

4. Connect the electrical contact to the socket on

the side of the machine (only applies to item no.

13-2921), (fig. 6).

V-BELT

1. Set the cutting height setting to an intermediate

position.

INTRODUCTION

ThiscuttingdeckmayonlybeusedwithPark

machines with a motor performance of at least 16

hp.

The cutting deck is available as standard in two

versions:

- with mechanical setting of the cutting height

(item no. 13-2915).

- with factory-fitted, electrical setting

of the cutting height (item no. 13-2921).

PREPARATIONS

Park, year models up to and including 1993:

In order for the deck to be used, the machine has to

be modified:

1. Remove the return spring for the articulated

joint

(fig. 1).

2. Saw off the spring mount flush with the frame

side member

(fig. 2).

2. Force the V-belt onto the machine’s centre

pulley F (fig. 7).

3. T ension the belt with belt idler G. The belt idler

should be on the left of the belt viewed from the

driver’s position.

4. Park -1999:

Hook the belt idler spring H in the floor on the

right side (fig. 7).

SETTING

In order forthe deckto cutevenly and attractively,

it has to be correctly adjusted:

1. Make sure the airpressurein the tyres is correct:

Front: 0.6 bar (9 psi).

Rear: 0.4 bar (6 psi).

2. Place the machine on a level floor.Undo screws

I (fig. 8).

3. Adjust the deck so that the front and rear edge of

the cover are the same height above the floor.

4. Tighten the screws.

3. Drill a new hole (Ø 8 mm), 8 mm from the lower

edge of the frame side member (fig. 3).

5

Page 6

GB

USE

ENGLISH

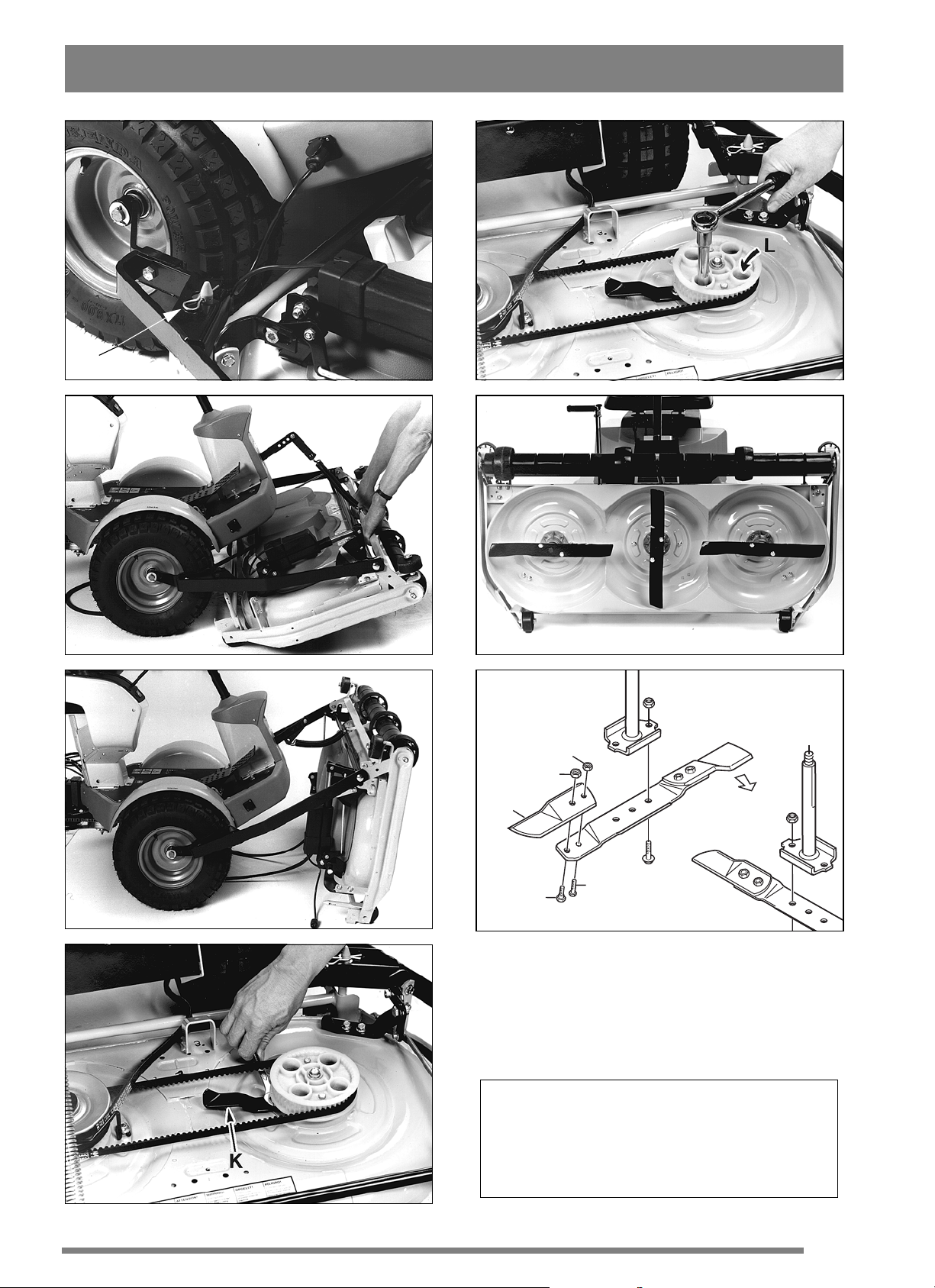

6. Fold up the deck until it is upright on the rear

support plates (fig. 11).

CUTTING HEIGHT

The cutting height can be varied from30to80 mm.

- item no. 13-2915 has seventeen fixed positions

for cutting height.

- item no. 13-2921 has continuously variable

adjustment of cutting height.

Note: Stated cutting heights apply when the

machine is on a firm surface.

CUTTING TIPS

For optimum ‘Multiclip effect’, follow these tips:

- cut frequently.

- run the motor at full revs.

- keep the underside of the cutting deck clean.

- use sharp blades.

- do not cut wet grass.

- cut twice (with different cutting heights) if

the grass is long.

MAINTENANCE

CLEANING

After each use, the underside of the cutting deck

should be rinsed off.

If the grass has dried solid, scrape clean the

underside.

If necessary, paint the underside to prevent

corrosion.

POSITIVE DRIVE BELTS

If one of the blades has struck a solid object (e.g. a

stone), the b elt tension may be altered. This can

lead to the positive drive belt ‘over-meshing’

which, in the long term, can damage the blades.

Adjust the belt tension if necessary:

1. Secure the tensioning arm on the hook.

2. Force the belt off the centre pulley F.

3. Dismantle the transmission cover.

4. Undo tensioning arm K (fig. 12).

PREPARATIONS

Unless otherwise stated, all service and

maintenance must be carried out on a stationary

machine when the motor is not running.

Prevent the machine from rolling by

always applying the parking brake.

Prevent unintentional starting of the

motor by always stopping the motor,

disconnecting the spark plug c able

from the spark plug and earthing it.

Disconnect the negative cable from the

battery.

MAINTENANCE TIPS

To make cleaning and maintenance easier, the

cutting deck can be folded up:

1. Set the cutting height setting to an intermediate

position (= drive belt minimum tension).

2. Secure the tensioning arm on the hook.

5. Undo the bearing box’s mounting screws L (fig.

13).

6. Tension the positive drive belt by pressing the

tensioning arm backwards.

7. Tighten the tensioning arm’s mounting screw.

8. Tighten the bearing box’s mounting screws.

9. Repeat with the other positive drive belt.

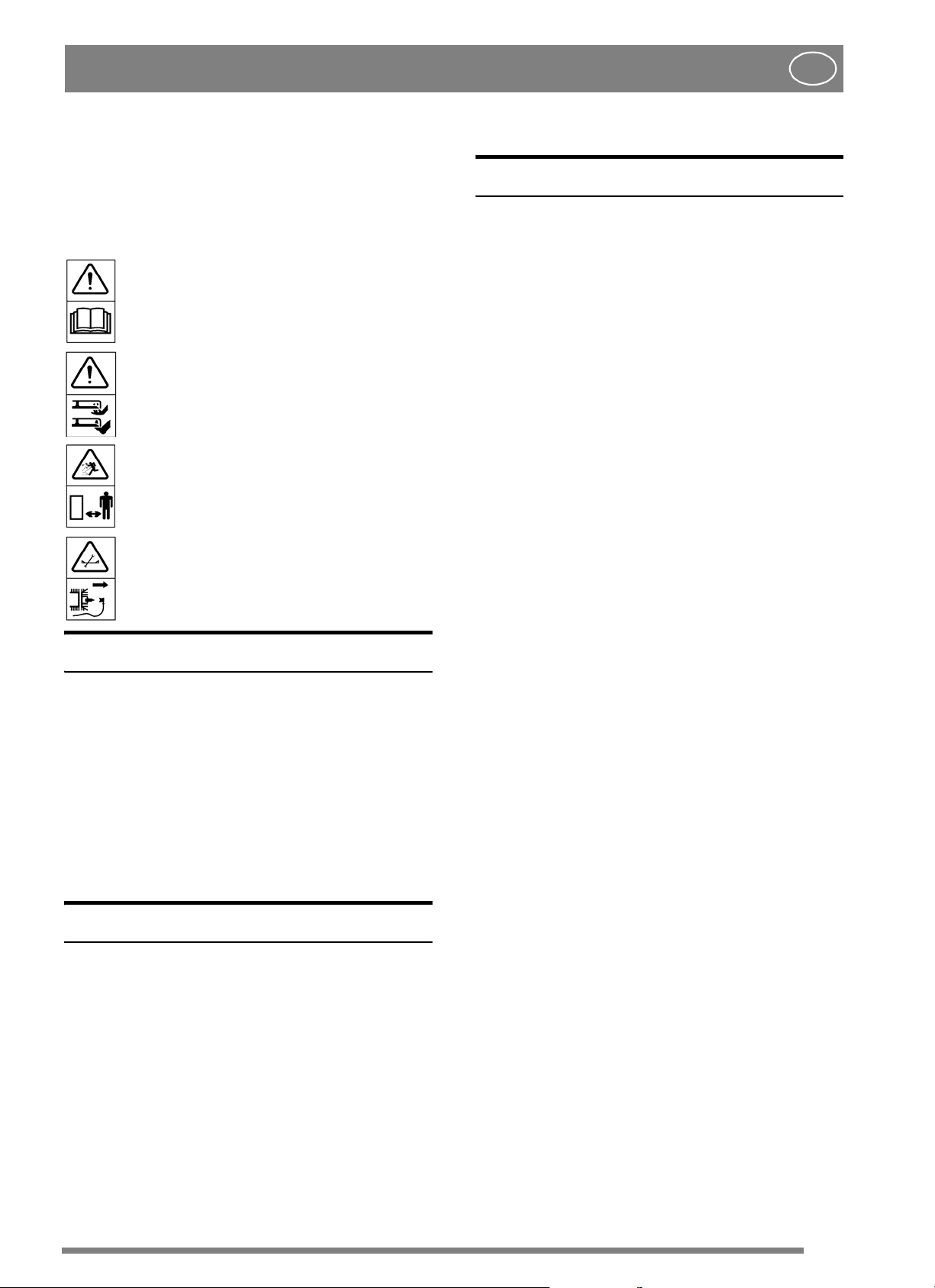

When replacing positive drive belts,

ensure that both the outer blades are

always at right-angles to the central

blade(seefig.14).

If the positive drive belts are incorrectly mounted,

the blades will strike each other because they

overlap.

Always check the position of the blades after

replacing a belt or adjusting belt tension.

REPLACING BLADES

Use protective gloves when changing

blades to avoid cutting yourself.

3. Force the belt off the centre pulley F.

4. Undo both pins J (fig. 9).

5. Grip the deck’s frame (fig. 10).

6

Ensure that the blades are always sharp. This

produces the best cutting results.

Page 7

ENGLISH

Always check the blades after a collision. If the

blade system has been damaged, defective parts

should be replaced.

Always use original spare parts. Nonoriginal spare parts can entail a risk of

injury, even if they fit the machine.

The cutting system comprises three blade

bars with two replaceable blades Y (fig. 15). When

replacing blades, both should be replaced to avoid

imbalance.

Install the new blades. Tighten screws V and W

properly. Tightening torque: V - 9.8 Nm, W - 24

Nm.

In the event of a powerful collision, the blades may

be bent out. Undo the locking nut X and fold back

the blade. Install a new original break bolt V.

Tighten the locking nuts X and Z.

GB

SPARE PARTS

STIGA original spare parts and accessories are

designed specifically for STIGA machines. Please

notethat‘non-original’ spare partsandaccessories

have not been checked or approved by STIGA:

The use of such parts and accessories

can affect the function and safety of the

machine.STIGA accepts no

responsibility for damage or injuries

caused by such products.

STIGA reserves the right to make alterations to the

product without prior notification.

7

Page 8

MOWING AHEAD

BOX 1006 · SE-573 28 TRANÅS

www.stiga.com

Loading...

Loading...