Page 1

Motosega - MANUALE DI ISTRUZIONI

ATTENZIONE: prima di utilizzare la macchina, leggere attentamente

il presente libretto.

Chain-saw - OPERATOR’S MANUAL

WARNING: read thoroughly the instruction booklet before using this

machine.

Scie à chaîne - MANUEL D’UTILISATION

ATTENTION: lire attentivement le manuel avant d'utiliser cette

machine.

Motorsäge - GEBRAUCHSANWEISUNG

ACHTUNG: vor Inbetriebnahme des Geräts die Gebrauchsanleitung

aufmerksam lesen.

Motosierra - MANUAL DE INSTRUCCIONES

CUIDADO: antes de utilizar esta máquina, lea atentamente el manual

de instrucciones.

Kettingzaag - GEBRUIKERSHANDLEIDING

LET OP: Voordat u de deze machine gaat gebruiken dient u eerst

deze handleiding aandachtig door te lezen.

Motosserra - MANUAL DE INSTRUÇÕES

ATENCAO! Antes de usar a moto-roçadeira, ler com atenção este

manual de instruções.

∞Ï˘ÛÔÚ›ÔÓÔ - ∂°Ã∂πƒπ¢π√ √¢∏°πø¡

¶ЪФЫФ¯‹: ЪИУ ¯ЪЛЫИМФФИ‹ЫВЩВ ЩФ МЛ¯¿УЛМ·, ‰И·‚¿ЫЩВ ЪФЫВОЩИО¿

ЩФ ·ЪfiУ ВБ¯ВИЪ›‰ИФ.

Motorlu testere - KULLANIM KILAVUZU

D‹KKAT! Makineyi kullanmadan önce talimatlar içeren kılavuzu dikkatle

okuyun.

Spalinowa piła łańcuchowa - INSTRUKCJE OBSŁUGI

UWAGA: Przed użyciem urządzenia przeczytaj uważnie niniejszą

instrukcję.

Motorna verižna žaga - PRIROČNIK ZA UPORABU

POZOR: Preden uporabite stroj, pazljivo preberite priročnik

z navodili.

иЛО‡ ·ВМБЛМУПУЪУМ‡fl ˆВФМ‡fl - кмKйЗйСлнЗй ий щKлигмДнДсаа

ЗзаеДзаЦ: иВК‰В ˜ВП ФУО¸БУ‚‡Ъ¸Тfl У·УЫ‰У‚‡МЛВП,

‚МЛП‡ЪВО¸МУ ФУ˜ЪЛЪВ БЪУ ЫНУ‚У‰ТЪ‚У ФУ БНТФОЫ‡Ъ‡ˆЛЛ.

Motorna pila - PRIRUČNIK ZA UPORABO

POZOR: Prije nego pristupite uporabi stroja, pažljivo pročitajte

upute.

FR

EN

IT

NL

DE

ES

PT

EL

TR

SL

PL

RU

HR

Page 2

ITALIANO ......................................

ENGLISH ......................................

FRANÇAIS ....................................

DEUTSCH ....................................

ESPAÑOL .....................................

NEDERLANDS...............................

PORTUGUÊS.................................

∂§§∏¡π∫∞ ...................................

TÜRKÇE .......................................

POLSKI..........................................

SLOVENSKI...................................

кмллдав ....................................

HRVATSKI......................................

HR

RU

SL

PL

TR

EL

PT

NL

ES

DE

FR

EN

IT

i

Page 3

ii

7 8

9

1

1

2

2

3 4

4

5

13

5 6

1

2 2

3

4

1

3

4

10 11

Page 4

iii

12

13

17

20

1

2

2

2

3

3

START

STOP

1

14

2

3 4

1

16

1

45°

45°

2

18 19

15

Page 5

iv

21

24

26

< 0,5 mm

22

23

1

2

2

2a

1a

25

> 5 mm

0,5 mm

B A

Page 6

EN

INTRODUCTION 1

Dear Customer,

thank you for choosing one of our products. We hope that you will be completely satisfied with this

machine and that it fully meets your expectations. This manual has been compiled in order to provide

you with all the information you need to get acquainted with the machine and use it safely and efficiently. Don’t forget that it is an integral part of the machine, so keep it handy so that it can be consulted when necessary, and pass it on to a further user if you resell or loan the machine.

Your new machine has been designed and manufactured in pursuance with current regulations, and is

safe and reliable if used in compliance with the instructions provided in this manual (proper use). Using

the machine in any other way, or non-compliance with the safety specifications relative to use, maintenance and repair is considered "improper use" which will invalidate the warranty, relieve the manufacturer from all liabilities, and the user will consequently be liable for all and any damage or injury to

himself or others.

Since improvements are periodically made to our products, you may find slight differences between

your machine and the descriptions contained in this manual. Certain modifications can be made to the

machine without prior warning and without the obligation to update the manual, although the essential safety and function characteristics will remain unaltered. In case of any doubts, please contact your

dealer. And now enjoy your work!

CONTENTS

1. Identification of the main components ........................................ 2

2. Symbols........................................................................................ 3

3. Safety requirements ..................................................................... 4

4. Machine assembly........................................................................ 6

5. Preparing to work......................................................................... 7

6. How to start - Use – Stop the engine .......................................... 8

7. Using the machine ..................................................................... 10

8. Maintenance and storage........................................................... 12

9. Identification of faults................................................................. 15

Page 7

EN

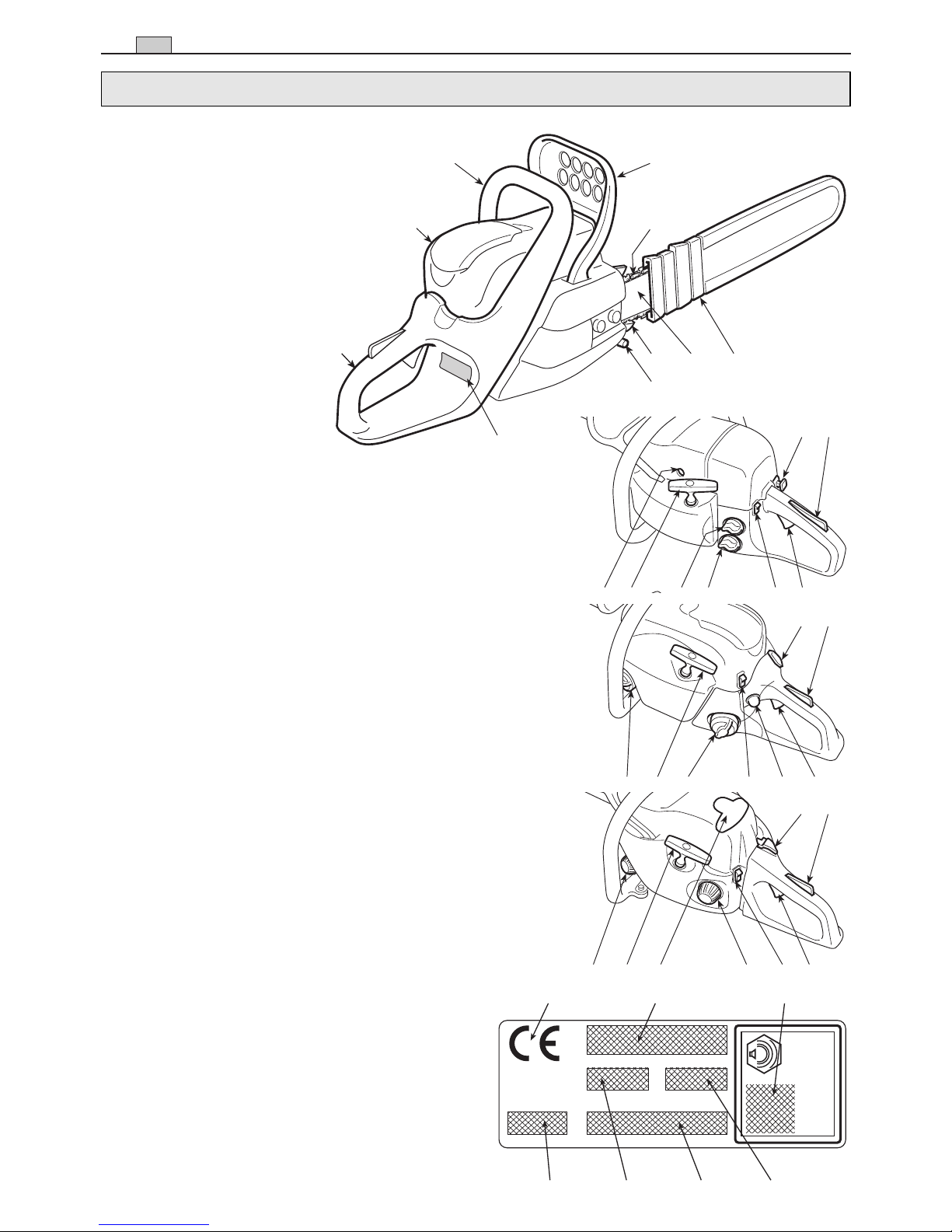

MAIN COMPONENTS

1. Power unit

2. Spiked bumper

3. Front hand guard

4. Front handgrip

5. Rear handgrip

6. Chain catcher

7. Bar

8. Chain

9. Bar cover

10. Identification plate

CONTROLS AND REFUELLING

11. Engine stop switch

12. Throttle trigger

13. Throttle trigger lockout

14. Starter

15. Choke (if present)

16. Primer (if present)

17. Decompression valve (if present)

21. Fuel tank cap

22. Chain oil tank cap

2

IDENTIFICATION OF MAIN COMPONENTS

1. IDENTIFICATION OF MAIN COMPONENTS

IDENTIFICATION PLATE

10.1) Conformity marking in accordance with

Directive 98/37/EC

10.2) Name and address of the manufacturer

10.3) Acoustic output level LWA in accordance

with directive 2000/14/EC

10.4) Manufacturer’s model of reference

10.5) Machine model

10.6) Serial number

10.7) Year of manufacture

10.1

L

WA

dB

10.2

10.6 10.4

10.5

10.7

10.3

P 45(x) - P 46(x)

P 50(x) - P 51(x)

P 36(x) - P 37(x)

P 39(x) - P 41(x)

P 43(x) - P 44(x)

P 47(x) - P 48(x)

15 13

22 21 11 1214 16

15 13

21 22 11 1217 14

15 13

22 16 121114 21

1

2

8

34

5

6

7 9

10

5

Page 8

EN

1) Warning! Danger. The failure to use this

machine correctly can be hazardous for oneself

and others.

2) Beware of kickback! Kickback is the rapid

and uncontrollable backward motion of the

chain-saw in the direction of the operator.

Always work in complete safety. Use chains with

safety links that limit kickback.

3) Never hold the machine with one hand! Hold

the machine fast with both hands to control the

machine and reduce the risk of kickback.

11) Fuel tank

12) Chain oil tank and oil flow adjuster

13) Carburettor adjustments

L= low speed mixture adjuster

H= high speed mixture adjuster

T - IDLE - MIN = idle speed adjuster

14) Choke

15) Primer

16) Chain brake (the white arrow shows the

direction in which the brake is released)

17) Direction in which the chain is mounted.

4) Read the instruction manual before using the

machine.

5) If you are using the machine every day in normal conditions, you can be exposed to a noise

level of 85 dB (A) or higher. Wear earmuffs or

earplugs and a protective helmet.

6) Wear gloves and protective footwear!

SYMBOLS 3

EXPLANATORY SYMBOLS ON THE MACHINE (if present)

2. SYMBOLS

5

1 2 3

4 6

11

12

13

14

15

16

17

Page 9

EN

A) TRAINING

1) Read the instructions carefully. Become

acquainted with the controls and the proper use

of the machine. Learn how to stop the engine

quickly.

2) Only use the machine for the purpose for

which it was designed, that is for “felling, buck-

ing and delimbing trees with dimensions suitable for the length of the bar” or wooden

objects with the same characteristics. Any other

use may be dangerous and damage the

machine.

3) Never allow children or persons unfamiliar

with these instructions to use the machine. Local

regulations may restrict the age of the operator.

4) The machine must never be used by more

than one person.

5) Never use the machine:

– when people, especially children or pets are in

the vicinity;

–f the user is tired or unwell, or has taken med-

icine, drugs, alcohol or any substances which

may slow his reflexes and compromise his

judgement;

– if the user is not capable of holding the

machine firmly with two hands and/or remaining standing on the ground whilst working.

6) Remember that the operator or user is

responsible for accidents or hazards occurring

to other people or their property.

B) PREPARATION

1) Always wear adequate clothing which

does not hamper movements when using the

machine.

– Always wear slim-fitting protective clothing,

fitted with shear-proof protection devices.

– Always wear a helmet, protective gloves, eye-

goggles, a half-mask respirator and safety

anti-shear boots with non-slip soles.

– Always wear ear and hearing protection

devices.

– Never wear scarves, shirts, necklaces, or any

hanging or flapping accessory that could

catch in the machine or in any objects or

materials in the work area

–Tie your hair back if it is long.

2) WARNING: DANGER! Fuel is highly flam-

mable:

– keep the fuel in containers which have been

specifically manufactured and homologated

for such use;

– never smoke when handling fuel;

– slowly open the fuel tank to allow the pressure

inside to decrease gradually;

– top up the tank with fuel in the open air, using

a funnel;

– add fuel before starting the engine. Never

remove the fuel tank cap or add fuel while

the engine is running or when the engine is

hot;

– if you have spilt some fuel, do not attempt to

start the engine but move the machine away

from the area of spillage and avoid creating

any source of ignition until the fuel has evaporated and fuel vapours have dissipated;

– immediately clean up all traces of fuel spilt on

the machine or on the ground;

– never start the machine in the same place you

refilled it with fuel;

– make sure your clothing does not come into

contact with the fuel, on the contrary, change

your clothes before starting the engine;

– always put the tank and fuel container caps

back on and tighten well.

4) Replace faulty or damaged silencers.

5) Before using the machine, check its gener-

al condition and in particular:

– the throttle trigger and the safety lever must

move freely, they must not need forcing and

should return automatically and rapidly back

to the neutral position;

– the throttle trigger must remain locked until

the safety lever is pressed;

– the engine stop switch must easily move from

one position to the other;

– the electric cables and in particular the spark

plug cable must be in perfect condition to

avoid the generation of any sparks, and the

cap must be correctly fitted on the spark plug;

– the machine handgrips and protection devices

must be clean and dry and well fastened to

the machine;

– the chain brake must be in perfect working

order;

– the bar and the chain must be fitted correctly;

– the chain must be tensioned correctly.

6) Before starting your work, make sure that all

the protection devices are correctly fitted.

C) OPERATION

1) Do not operate the engine in a confined

space where dangerous carbon monoxide

fumes can collect.

2) Work only in daylight or good artificial light.

3) Take on a firm and well-balanced position:

– where possible, avoid working on wet, slip-

pery ground or in any case on uneven or steep

ground that does not guarantee stability for

the operator;

– avoid using unstable ladders or platforms;

– do not work with the machine above your

shoulders;

– never run, but walk carefully paying attention

4

SAFETY REQUIREMENTS

3. SAFETY REQUIREMENTS

Page 10

to the lay of the land and any eventual obstacles.

– avoid working alone or in an isolated place, in

case you have to find help after an accident.

4) Make sure the machine is securely locked

when you start the engine:

– start the motor in an area at least 3 metres

from where you refuelled;

– check that there are no persons in the vicinity

of the machine;

– do not direct the silencer and therefore the

exhaust fumes towards inflammable materials.

– watch out for flying debris caused by the

movement of the chain, especially when it hits

obstacles or foreign objects.

5) Do not change the engine tuning and do

not rev the engine excessively at maximum

speed.

6) Do not strain the machine too much and do

not use a small chain-saw for heavy-duty sawing. If you use the right machine, you will reduce

the risk of hazards and improve the quality of

your work.

7) Check that when the machine is running idle,

there is no movement of the chain and, after

pressing the throttle trigger, the engine quickly

returns to minimum speed.

8) Take care not to hit the bar hard against foreign objects or flying debris caused by the

movement of the chain.

9) Stop the engine:

– whenever you leave the machine unattended;

– before refuelling.

10) Stop the engine and disconnect the spark

plug cable:

– before cleaning, checking or working on the

machine;

– after striking a foreign object. Inspect the

machine for any damage and make repairs

before restarting it again;

– if the machine starts to vibrate abnormally:

find and remove the cause of the vibration

immediately;

– when the machine is not in use.

D) MAINTENANCE AND STORAGE

1) Keep all nuts, bolts and screws tightly fastened to be sure the equipment is in safe working condition. Routine maintenance is essen-

tial for safety and for maintaining a high performance level.

2) Do not store the machine with fuel in the tank

in an area where the fuel vapours could reach an

open flame, a spark or a strong heat source.

3) Allow the engine to cool before storing in any

enclosure.

4) To reduce fire hazards, keep the engine,

exhaust silencer and fuel storage area free from

sawdust, branches, leaves, or excessive grease;

never leave containers with the cut debris inside

the storage area.

5) Se il serbatoio deve essere svuotato, effettuare questa operazione all’aperto e a motore

freddo.

6) If the fuel tank has to be emptied, this

should be done outdoors once the engine has

cooled down.

7) Make sure the chain is well sharpened. Any

work on the chain and bar require specific experience and special tools. For safety purposes, we

recommend you contact your dealer to ensure

work is done correctly.

8) For safety reasons, never use the machine

with worn or damaged parts. Damaged parts

are to be replaced and never repaired. Only

use original spare parts. Parts that are not of

the same quality can seriously damage the

equipment and compromise safety.

9) Before putting the machine away, check you

have removed wrenches or tools used for maintenance.

10) Store the machine out of the reach of children!

E) TRANSPORTATION AND HANDLING

1) Whenever the machine is to be handled or

transported you must:

– turn off the engine, wait for the chain to stop

and disconnect the spark plug cap;

– mount the bar cover;

– only hold the machine using the handgrips

and position the bar in the opposite direction

to that used during operation.

2) When using a vehicle to transport the

machine, position it so that it can cause no danger to persons and fasten it firmly in place to

avoid it from tipping over, which may cause

damage or fuel spillage.

F) HOW TO READ THE MANUAL

Certain paragraphs in the manual contain particularly significant information and are marked

with various levels of highlighting with the following meaning:

or

These give details or further

information on what has already been indicated,

and aim to prevent both damage to the machine,

and the machine from causing damage..

Non-observance will result

in the risk of injury to oneself or others.

Non-observance will result

in the risk of serious injury or death to oneself

or others.

!

DANGER!

!

WARNING!

IMPORTANT

NOTE

SAFETY REQUIREMENTS 5

EN

Page 11

The machine is supplied with

the bar and chain dismantled and the oil and fuel

tanks empty.

Always wear heavy-duty

gloves when handling the bar and chain.

Mount the bar and chain very carefully so as

not to impair the safety and efficiency of the

machine. If in doubt, contact your dealer.

The machine can be assembled in different ways, depending on the bar fastening system and the chain tensioning mechanism.

Before fitting the bar, make sure the chain brake

is not engaged; this is done by pulling the front

hand guard right back towards the body of the

machine.

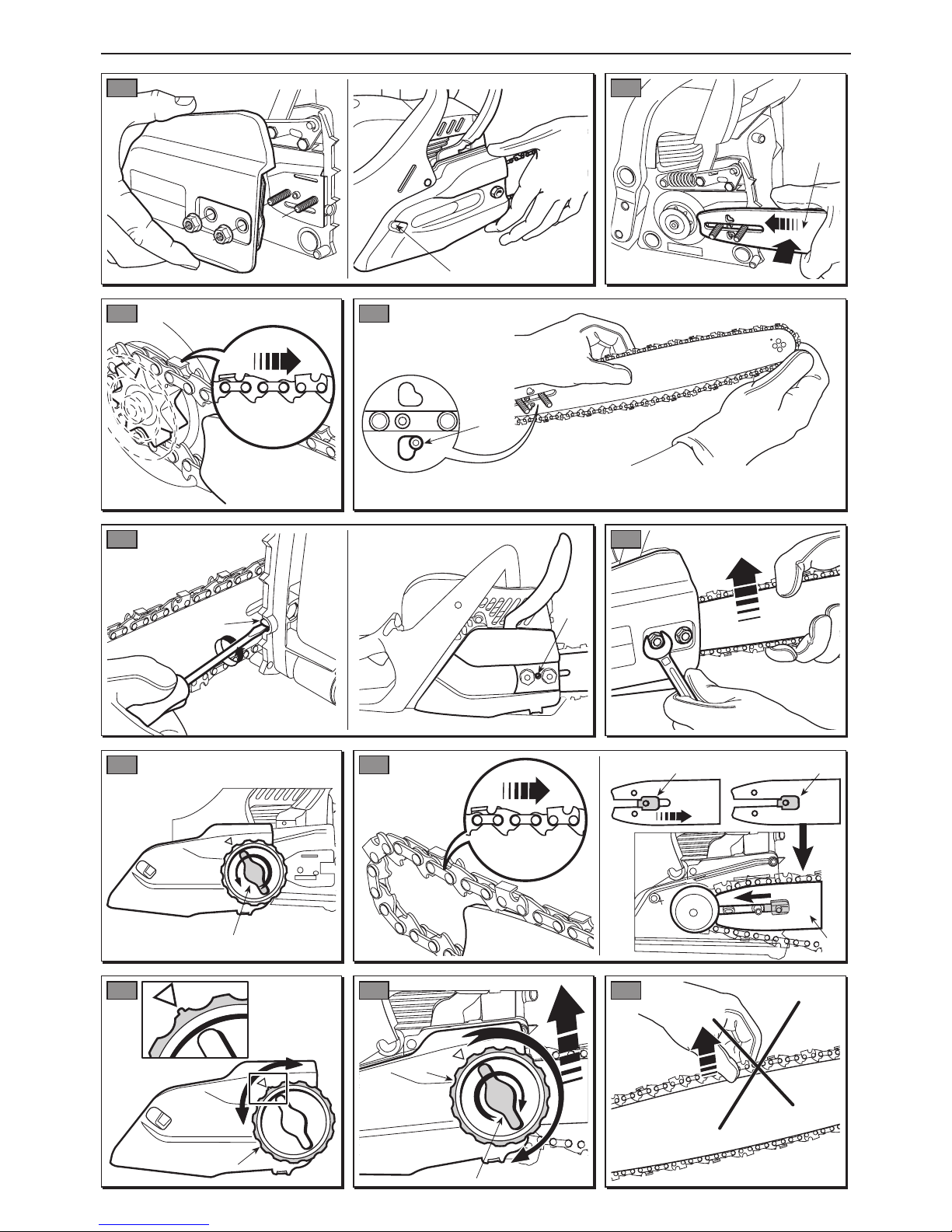

1a. MACHINES WITH STANDARD CHAIN

TENSION ADJUSTER

– Unscrew the nuts and remove the clutch cover

to get to the drive sprocket and point where

the bar is to be fitted (Fig. 1).

– Mount the bar (2) by inserting the stud bolts in

the groove and push it towards the back of the

machine body (Fig. 2).

– Mount the chain in the right direction around

the drive sprocket and along the bar rail (Fig.

3). If the tip of the bar has a nose sprocket,

make sure the drive links fit correctly in the

sprocket rims.

– Check that the chain tension adjuster pin (3) is

fitted properly in the hole on the bar (Fig. 4); if

it isn’t, turn the chain tension adjuster screw

(4) using a screwdriver until the pin is completely inserted (Fig. 5).

– Fit the guard back on without tightening the

nuts.

In models P 36(x) - P 37(x) - P 39(x) - P

41(x)

, check that the pin (1 - Fig.1) is inserted

correctly.

NOTE

!

WARNING!

IMPORTANT

–Turn the chain tension adjuster screw (4) to

adjust the chain tension (Fig. 5).

Models P

44(x) and P 48(x)

have another tension

adjuster between the guard nuts (5 - Fig. 5).

– Raise the bar and tighten the guard nuts

securely using the wrench (Fig. 6).

1b. MACHINES WITH “Q-TENS” QUICK

CHAIN TENSION ADJUSTER

– Unscrew the knob (1) and remove the clutch

cover to get to the drive sprocket and the

point where the bar is fitted (Fig. 7).

– Push the chain tension adjuster lock on the

bar (2) forwards as far as it goes (Fig. 8).

– Mount the chain in the right direction on the

bar (Fig. 8). If the tip of the bar has a nose

sprocket, make sure the drive links are correctly inserted in the sprocket rims.

– Insert the bar (3) and wind the chain around

the drive sprocket (Fig. 8).

– Rotate the outer ring (4) on the cover to line up

its pointer with the one on the guard (Fig. 9).

– Fit the cover back on by screwing the knob (1)

but not tight (Fig. 10).

–Tighten the chain by rotating the outer ring (4)

clockwise (Fig. 10).

– Raise the bar and tighten the knob (1) secure-

ly (Fig. 10).

2. CHECKS AFTER MOUNTING THE BAR

AND THE CHAIN

– Check the chain tension. The tension is cor-

rect when the drive links do not slip out of the

chain guides if you hold the chain in the middle of the bar (Fig. 1).

– Using a screwdriver, make the chain run along

the guides to check it moves smoothly without

resistance.

6

MACHINE ASSEMBLY

EN

4. MACHINE ASSEMBLY

Page 12

PREPARING TO WORK 7

EN

CHECKING THE MACHINE

Before starting work please:

– check that all the screws on the machine and

the bar are tightly fastened;

– check that the chain is sharp and there are no

signs of any damage;

– check that the air filter is clean;

– check that the protection devices are well fas-

tened and working efficiently;

– check that the handgrips are well fastened;

– check that the chain brake is working effi-

ciently.

PREPARING THE FUEL

This machine is fitted with a two-stroke engine

which requires a mixture of petrol and lubricating

oil.

Using petrol alone will damage the motor and will cause for invalidation of

the warranty.

Only use quality fuels and

oils to maintain high performance and guarantee

the duration of the mechanical parts over time.

• Petrol characteristics

Only use unleaded petrol with a fuel grade of at

least 90 N.O.

Unleaded petrol tends to

create deposits in the container if preserved for

more than 2 months. Always use fresh petrol!

• Oil characteristics

Only use top quality synthetic oil specifically for

two-stroke engines.

Your dealer can provide you with oils which have

been specifically developed for this type of

engine, and which are capable of guaranteeing a

high level of protection.

The use of these oils makes it possible to prepare a 2% mixture, consisting in 1 part oil to 50

parts petrol.

In the event that no specific oil is available, it is

IMPORTANT

IMPORTANT

IMPORTANT

possible to use a mineral lubricating oil for

engines (class FA or FB), where in this case the

mixture must be 4%, i.e. 1 part oil and 25 parts

petrol.

•Preparation and preservation of the fuel

mixture

Petrol and the fuel mixture are highly inflammable!

– Keep the petrol and fuel mixture in homolo-

gated fuel containers, in safe place, away

from any flames or heat sources.

– Never leave the containers within the reach

of children.

– Never smoke whilst preparing the mixture

and avoid inhaling the petrol fumes.

The chart indicates the amount of petrol and oil

to use to prepare the fuel mixture according to

the type of oil used.

To prepare the fuel mixture:

– Place about half the amount of petrol in a

homologated tank

– Add all the oil, according to the chart.

– Add the rest of the petrol.

– Close the top and shake well.

The fuel mixture tends to

age. Do not prepare excessive amounts of the

fuel mixture to avoid deposits from forming.

Keep the petrol and fuel mixture containers separate and easily identifiable to

avoid the mistake of using one in place of the

other.

IMPORTANT

IMPORTANT

!

DANGER!

5. PREPARING TO WORK

Petrol Synthetic oil Mineral oil

2-stroke Class FA - FB

litres litres cm

3

litres cm

3

10,02 2,0 0,04 40

20,04 40 0,08 80

30,06 60 0,12 120

50,10 100 0,20 200

10 0,20 200 0,40 400

Page 13

EN

Periodically clean the petrol

and fuel mixture containers to remove any eventual deposits.

REFUELLING

Never smoke whilst refuelling and avoid inhaling the petrol fumes.

Carefully open the tank top

as pressure could have formed inside.

Before refuelling:

– Shake the fuel mixture container well.

– Place the machine on a flat stable surface,

with the fuel tank cap facing upwards.

– Clean the fuel tank cap and the surrounding

area to avoid any dirt from entering the tank

during refilling.

– Carefully open the fuel tank cap to allow the

pressure inside to decrease gradually. Use a

funnel to refill and avoid filling the tank to the

brim.

Always close the fuel tank

cap firmly.

!

WARNING!

!

WARNING!

!

DANGER!

IMPORTANT

Immediately clean all

traces of fuel which may have dripped on the

machine or the ground and do not start the

engine until the petrol fumes have dissipated.

CHAIN LUBRICANT

Only use oil with SAE 30 viscosity, specifically for lubricating chains. Do not

use oil containing impurities, to avoid clogging

the tank filter and permanently damaging the

oiler.

It is essential that you use good quality oil to

lubricate the cutting parts effectively. Used or

poor quality oil does not guarantee good lubrication and reduces the duration of the chain and

bar.

It is always worth topping up the oil tank completely (using a funnel) every time you refuel.

Since the oil tank capacity is enough to guarantee that the fuel runs out first, you will avoid the

risk of operating the machine without lubricant.

IMPORTANT

!

WARNING!

means starting it after at least 5 minutes from

when it was switched off or after refuelling.

To start the engine (Fig. 12):

1. Check that the chain brake is engaged (with

the front hand guard pushed forward).

2. Set the switch (1) to «START».

3.

If your machine has a decompression

valve

, press it now.

4. Pull out the choke (2).

5.

If your machine has a primer (3), press it 34 times to aid starting.

6. Hold the machine firmly on the ground, with

your hand on the handgrip and your foot in

the rear handgrip, to avoid losing control during starting (Fig. 13).

STARTING THE ENGINE

The engine must be started in an area at least 3 metres from where

you refilled the fuel tank.

Before starting the engine:

– Place the machine firmly on the ground.

–Take off the bar cover.

– Make sure the bar is not touching the ground

or any other object.

• Cold starting

A “cold” start of the engine

NOTE

!

WARNING!

8 PREPARING TO WORK / HOW TO START - USE – STOP THE ENGINE

6. HOW TO START - USE – STOP THE ENGINE

Page 14

EN

HOW TO START - USE – STOP THE ENGINE 9

If the machine is not held

firmly, the force of the engine could cause the

user to lose his balance or direct the bar

towards him or an obstacle.

7. Pull the starter rope slowly for 10 - 15 cm until

you feel some resistance, then tug it hard a

few times until you hear the engine turn over.

To avoid breaking the starter

rope, do not pull the whole length of it or let it

slide along the edge of the cable guide hole.

Release the starter gradually, to avoid letting it fly

back uncontrollably.

8. Pull the starter rope again until the engine

starts as normal.

9. When the engine has started, press the throt-

tle trigger to disconnect the starter and allow

the engine to idle.

Do not let the engine run at

high power with the chain brake engaged, as this

could cause overheating and damage to the

clutch.

10. Let the engine run idle for at least 1 minute

before using the machine.

If the starter rope is pulled

repeatedly with the choke on, it may flood the

engine and make starting difficult.

If you have flooded the engine, remove the spark

plug and gently pull the handle on the starter

rope to eliminate any excess fuel; then dry the

spark plug electrodes and replace it on the

engine.

• Hot starting

When hot starting (immediately after stopping

the engine), follow the procedure indicated

above in points 1 -2 -6 - 7 -8.

IMPORTANT

IMPORTANT

IMPORTANT

!

WARNING!

USE OF THE ENGINE (Fig. 14)

The chain speed is regulated by the throttle trigger (1) on the rear handgrip (2).

The throttle trigger only works if the lockout (3) is

pressed at the same time.

The movement is transmitted from the engine to

the chain by a centrifugal mass clutch that prevents the chain from moving when the engine is

running at minimum speed.

Never use the machine if

the chain moves when the engine is running

idle; if this is the case regulate the minimum

rate (see chap.8) and if the problem persists

please contact your dealer.

The correct running speed will be achieved by

pressing the throttle trigger (1) as far as possible.

Avoid using the engine at full

power for the first 6-8 working hours.

STOPPING THE ENGINE (Fig. 14)

To stop the engine:

– Release the throttle trigger (1) and allow the

engine to run idle for a few seconds.

– Set the switch (4) to “STOP”.

When you have reduced

speed to a minimum, it will take a few seconds for the chain to stop.

!

WARNING!

IMPORTANT

!

WARNING!

Page 15

EN

To respect people and the environment:

– Try not to cause any disturbance.

– Scrupulously comply with local regulations

and provisions for the disposal of waste

materials after sawing.

– Scrupulously comply with local regulations

and provisions for the disposal of oils,

petrol, damaged parts or any elements

which have a strong impact on the environment.

Always wear suitable

clothing when using the machine. Your dealer can provide you with all the information on

the most suitable accident-prevention

devices to guarantee your safety.

It takes specific training to

use the machine for felling and delimbing.

CHAIN BRAKE

This machine comes with an automatic brake

that stops the chain when kickback occurs during cutting.

This brake can be operated manually by pushing

the front guard forward. To release the brake,

pull the front guard towards the handgrip until

you hear a click.

Do not use the machine if

the chain brake does not function correctly

and have it inspected by your dealer.

CHECKING THE CHAIN TENSION

The chain tends to stretch gradually as you

work, so you need to check its tension frequently.

Never work with the chain

loose, as it can be hazardous if the chain slips

out of its guides.

CHECKING THE OIL DELIVERY

Never use the machine with-

IMPORTANT

!

WARNING!

!

WARNING!

!

WARNING!

!

WARNING!

out lubrication! The oil tank may get almost

empty every time the fuel runs out. Make sure

you top up the oil tank every time you refuel the

chain-saw.

Make sure the bar and the

chain are in place when you check the oil

delivery.

Start the engine, keep it running at medium

power and check if the chain oil is delivered as

shown in the figure (Fig. 15).

In models P 44(x) and P 48(x), you can adjust

the chain oil flow using a screwdriver on the

adjuster screw (1) of the oiler, which is on the

bottom of the machine (Fig. 15).

DIRECTIONS FOR USE AND CUTTING TECHNIQUES

Before felling or delimbing for the first time, practise sawing logs on the ground or on trestles, so

that you can get familiar with the machine and

the most suitable sawing techniques.

Always hold the machine

with both hands when sawing.

Stop the engine immediately if the chain stops during sawing.

Beware of kickback, which can occur if the

bar contacts an obstacle.

Kickback occurs when the tip of the chain

comes in contact with an object or when the

wood contracts and jams the chain during

sawing.

This contact with the tip of the chain can

cause a rapid backward motion, pushing the

guide bar up and towards the operator. This

also happens when the chain is jammed

along the upper part of the bar. In both cases,

kickback can cause the operator to lose control of the chain-saw, leading to serious consequences.

!

WARNING!

!

WARNING!

!

WARNING!

10 USING THE MACHINE

7. USING THE MACHINE

Page 16

• Delimbing (Fig. 16)

Make sure there is nothing

or nobody in the area where the branches will

fall.

1. Stand opposite the branch you want to cut.

2. Start cutting lower branches followed by the

higher ones.

3. Cut downwards to prevent the bar from get-

ting jammed.

•

Felling (Fig. 17)

When felling on slopes,

always stand uphill from the tree and check

that the felled trunk cannot cause damage if

it rolls down the hill.

1. Decide where the tree should fall – you

should consider the wind, the natural lean of

the tree, the position of the heaviest branches and how easy the work is after felling, etc.

2. Clear the area around the tree and find a sta-

ble place to stand.

3. Plan obstacle-free escape routes at a 45°

angle back and away from the direction of

fall. These routes must allow you reach a safe

area at a distance of about 2.5 times the

length of the tree to be felled

4. On the side of the fall, mark a felling notch

around a third of the trunk’s diameter.

5. Cut the tree on the other side, slightly above

the bottom of the notch, leaving the uncut

wood to act as a “hinge” (1) of approx. 5-10

cm.

6. Reduce the thickness of this hinge without

pulling out the bar, until the tree falls.

7. In particular or unstable conditions, you can

complete felling by inserting wedges (2) on

the opposite side of the fall, and hitting them

with a hammer until the tree falls.

!

WARNING!

!

WARNING!

• Bucking (Fig. 18)

Be careful of where the

branches are lying on the ground, the risk of

them being under tension, the direction the

branch may go during cutting and the risk of

the tree being unstable after the branch has

been cut..

1. Check the direction in which the branch is

attached to the tree

2. First cut on the side where the branch bends

and then finish cutting on the opposite side.

• Sawing logs (Fig. 19)

It is easier to saw a log using the spiked bumper.

1. Dig the spiked bumper into the log and use it

as a pivot. Cut with an arched motion to make

the bar penetrate the wood.

2. Repeat several times if necessary, changing

the point where you plant the spiked bumper.

•

Sawing a log on the ground (Fig. 20)

Cut up to half the diameter, roll the log over and

finishing sawing on the other side.

•

Sawing a raised log (Fig. 21)

1. If you are sawing the overhanging end of a

supported log (A), first cut a third of the diameter from the bottom upwards, then finish

from the top.

2. If you are sawing between two supports (B),

cut a third of the diameter from the top downwards, then finish from the bottom.

END OF OPERATIONS

When you have finished your work:

– Switch off the engine as indicated above

(Chap. 6)..

–Wait for the chain to stop and then mount the

bar cover.

!

WARNING!

USING THE MACHINE 11

EN

Page 17

Correct maintenance is essential to maintain the

original efficiency and safety of the machine over

time.

During maintenance operations:

– Remove the spark plug cap.

–Wait until the engine is sufficiently cold.

– Use protective gloves when handling the

bar and chain.

– Keep the bar protection devices on, except

when intervening directly on the bar or the

chain.

– Never dispose of oils, fuel or other polluting

materials in unauthorised places.

CYLINDER AND SILENCER

To reduce fire risks, periodically clean the cylinder flaps with compressed air and clear the

silencer area to get rid of sawdust, branches,

leaves or other debris.

STARTING SYSTEM

To avoid overheating and damage to the engine,

always keep the cooling air vents clean and free

of sawdust and debris.

The starter rope must be replaced as soon as it

shows signs of wear.

CLUTCH UNIT

Keep the clutch bell free of sawdust and debris.

Have your dealer check the greasing of the internal bearing every 30 hours (approx.).

CHAIN BRAKE

Regularly check the efficiency of the chain brake

and the condition of the metal band around the

clutch bell.

Replace this band when the points in contact

with the clutch bell wear down to about half the

thickness of the two ends not subject to rubbing.

!

WARNING!

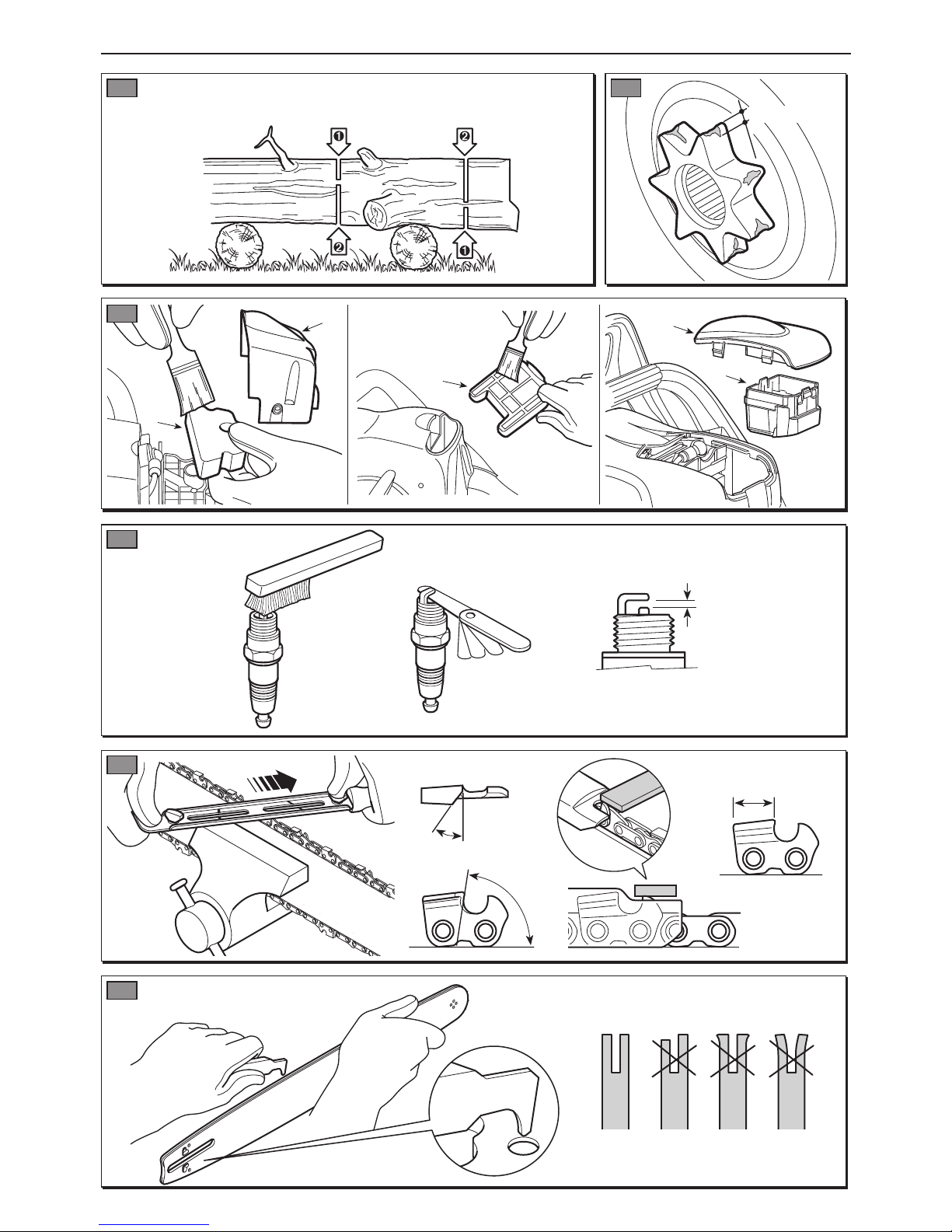

CHAIN SPROCKET (Fig. 22)

Regularly check the condition of the sprocket

and replace it when wear exceeds 0.5 mm.

Do not mount a new chain with a worn sprocket

or vice-versa.

CHAIN CATCHER

This is an important safety device that restrains

the chain if it breaks or degrooves.

Regularly check the condition of the chain

catcher and replace it if it gets damaged.

NUTS AND SCREWS

Periodically check that all the nuts and screws

are securely tightened and the handgrips are

tightly fastened.

CLEANING THE AIR FILTER (Fig. 23)

Cleaning the air filter is

essential to guarantee the efficiency and duration

of the machine. Do not work with a damaged filter or without a filter, as this could permanently

damage the engine.

It must be cleaned after every 8-10 working

hours.

Clean the filter as follows:

– Remove the cover (1) and filter element (2).

– Gently tap the filter element (2) to remove the

dirt and, if necessary, clean it with low pressure compressed air .

The filter element (2) must

never be washed and must be replaced if it is too

dirty or damaged.

– Fit the filter element (2) and the cover (1) back

on.

– In models P43(x) - P44(x) - P47(x) - P48(x),

first attach the filter element (2a) to the cover

IMPORTANT

IMPORTANT

12 MAINTENANCE AND STORAGE

EN

8. MAINTENANCE AND STORAGE

Page 18

(1a) and then fit these assembled parts on the

machine.

CHECKING THE SPARK PLUG (Fig. 24)

Periodically remove and clean the spark plug

using a metal brush to get rid of any deposits.

Check and reset the correct distance between

the electrodes.

Replace the spark plug and fasten it firmly using

the supplied wrench.

The spark plug must be replaced with one with

the same characteristics whenever the electrodes have burnt or the insulation has worn, and

in any case every 100 working hours.

TUNING THE CARBURETTOR

The carburettor is tuned by the manufacturer to

achieve maximum performance in all situations,

with a minimum emission of toxic gas in compliance with the regulations in force.

When performance is poor, first check that the

chain runs smoothly and the bar rails are not distorted, then contact your dealer to check the

carburetion and the engine.

•

Tuning minimum speed

The minimum speed must

only be tuned if the chain moves when the

engine idles.

Speed is reduced by turning the screw marked

“T” or “MIN - IDLE” anti-clockwise until the chain

stops moving. The engine should continue to run

as normal.

If the engine does not idle smoothly, turn the

screw clockwise to increase the speed.

The chain must not move

when the engine idles; contact your dealer if

you are not able to tune it to your satisfaction.

!

WARNING!

!

WARNING!

SHARPENING THE CHAIN

To ensure that the chainsaw works safely and efficiently, it is essential

that the cutting components are well-sharpened.

Sharpening is necessary when:

• The sawdust looks like dust.

• Cutting becomes more difficult.

• The cut is not straight.

•Vibrations increase.

• Fuel consumption increases.

A specialized centre will sharpen the chain using

the right tools to ensure minimum removal of

material and even sharpness on all the cutting

edges.

If you sharpen the chain yourself, use special

round-section files with the right diameter

depending on the type of chain (see “Chain

Maintenance Table”). You need a certain amount

of skill and experience to avoid damaging the

cutting edges.

Sharpen the chain as follows (Fig. 25):

– Switch off the engine, release the chain brake

and secure the bar with the chain in a vice so

that the chain can run smoothly.

–Tighten the chain if it is loose.

– Mount the file in the guide and then insert it in

the tooth at a constant angle from the cutting

edge.

– Sharpen in a forward motion a few times and

repeat this on all the cutting edges facing the

same way (right or left).

–Turn the bar over in the vice and repeat on all

the other cutting edges.

– Check that the limiter tooth does not stick out

further than the inspection instrument and file

any projecting parts with a flat file, rounding

off the edge.

– After sharpening, remove all traces of filing

and dust and lubricate the chain in an oil bath.

Replace the chain whenever:

– The length of the cutting edges reduces to 5

mm or less;

– There is too much play between the links and

the rivets.

!

WARNING!

MAINTENANCE AND STORAGE 13

EN

Page 19

BAR MAINTENANCE (Fig. 26)

To avoid asymmetrical wear on the bar, make

sure it is turned over periodically.

To keep the bar in perfect working order, proceed as follows:

–grease the bearings on the nose sprocket (if

present) with the syringe;

–clean the bar groove with the scraper;

– clean the lubrication holes;

– with a flat file, remove burr from the edges and

level off the guides.

Replace the bar whenever:

– the groove is not as deep as the height of the

drive links (which must never touch the bot-

tom);

– the inside of the guide is worn enough to

make the chain lean to one side.

EXTRAORDINARY MAINTENANCE

All maintenance operations not foreseen in this

manual must be performed exclusively by your

dealer.

All and any operations performed in unautho-

rised centres or by unqualified persons will totally invalidate the warranty.

STORAGE

After every work stint, clean the machine thoroughly to remove all dust and debris, and repair

or replace any faulty parts.

The machine must be stored in a dry place away

from the elements and with the bar cover correctly fitted.

LONG PERIODS OF DISUSE

If you are not going to use

the machine for a period of more than 2-3

months, we recommend you do a few things

before putting it away. This will make it easier

when you want to use the machine again and will

also prevent permanent damage to the engine.

• Storage

Before putting the machine away:

– Empty the fuel tank.

– Start the engine and run it idle until it comes to

IMPORTANT

14 MAINTENANCE AND STORAGE

EN

Chain maintenance table

The specifications of the chain and the bar homologated for this machine are

shown in the “EC Conformity Statement” provided. Do not use other types of chains or bars for

safety reasons.

The table gives the sharpening data for different types of chains, but this does not mean you

can use different chains from the homologated one.

!

WARNING!

Chain pitch Limiter tooth level (a) File diameter (d)

inches mm inches mm inches mm

3/8 Mini 9.32 0.018 0.45 5/32 4.0

0.325 8.25 0.026 0.65 3/16 4.8

3/8 9.32 0.026 0.65 13/64 5.2

0.404 10.26 0.031 0.80 7/32 5.6

a

d

Page 20

a halt, so that it uses up all the fuel that is left

in the carburettor.

–Wait for the engine to cool down and remove

the spark plug.

– Pour a teaspoon of (new) 2-stroke engine oil

into the spark plug slot.

– Pull the starter rope several times to deliver oil

to the cylinder..

– Replace the spark plug with the piston in the

dead end upper position (visible from the

spark plug slot when the piston is at maximum

stroke).

• Restarting work

When you wish to start using the machine again:

– Remove the spark plug.

– Pull the starter rope a few times to eliminate

excess oil.

– Check the spark plug as described in chapter

“Checking the spark plug”.

–Prepare the machine as indicated in the para-

graph entitled “Preparing for work”.

MAINTENANCE AND STORAGE / TROUBLESHOOTING 15

EN

9. TROUBLESHOOTING

1) The engine will

not start or will not

keep running

2) The engine starts

but is lacking in

power

3) The engine runs

irregularly and lacks

in power when

revved

4) The engine gives

off an excessive

amount of smoke

– Incorrect starting procedure

– Dirty spark plug or incorrect distance

between the electrodes

– Air filter clogged

– Carburetion problems

– Air filter clogged

– Carburetion problems

– Dirty spark plug or incorrect distance

between the electrodes

– Carburetion problems

– Incorrect composition of the fuel

mixture

– Carburetion problems

– Follow the instructions (see chap-

ter 6)

– Check the spark plug (see chapter

8)

– Clean and/or replace the filter (see

chapter 8)

– Contact your dealer

– Clean and/or replace the filter (see

chapter 8)

– Contact your dealer

– Check the spark plug (see chapter

8)

– Contact your dealer

–Prepare the fuel mixture according

to the instructions (see chap. 5)

– Contact your dealer

PROBLEM LIKELY CAUSE SOLUTION

Page 21

16

Page 22

Loading...

Loading...