Page 1

STIGA GARDEN

COMBI

MULTICLIP

8211-0202-11

Page 2

H

I

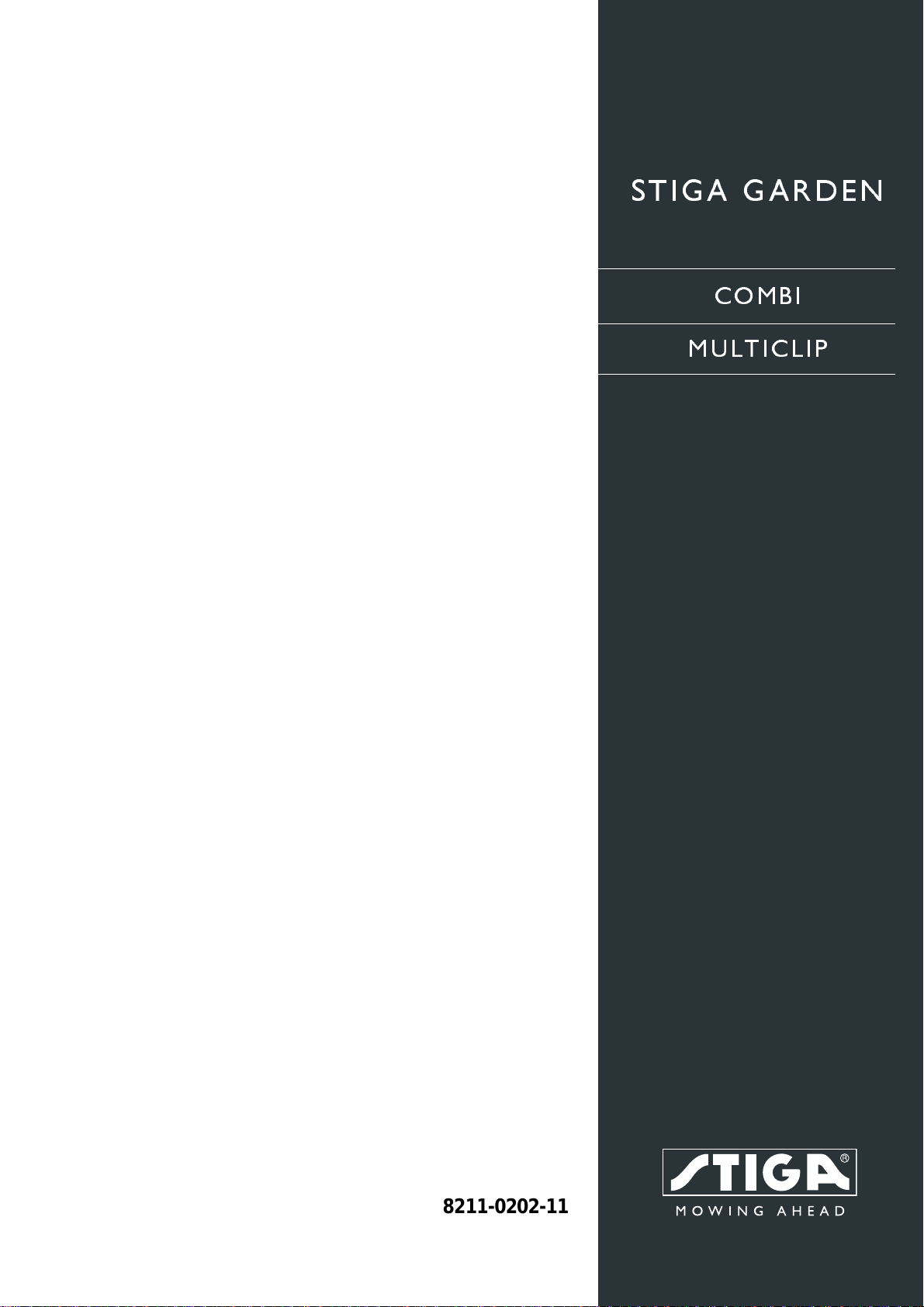

1.

5.

G

-

+

2.

D

3. 7.

G

C

6.

4.

8.

Page 3

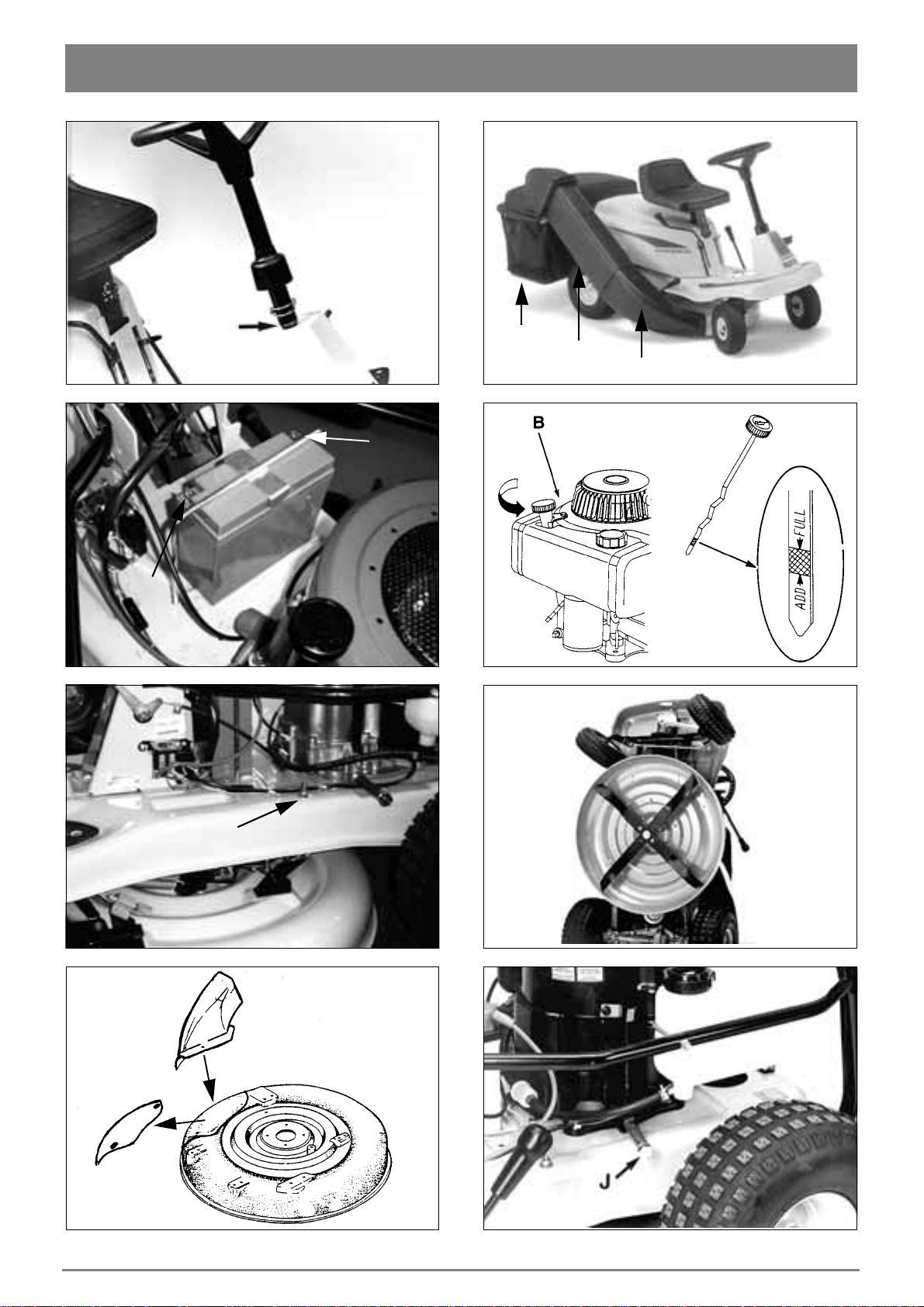

9.

13.

10.

14.

N

M

11. 15.

12.

16.

Page 4

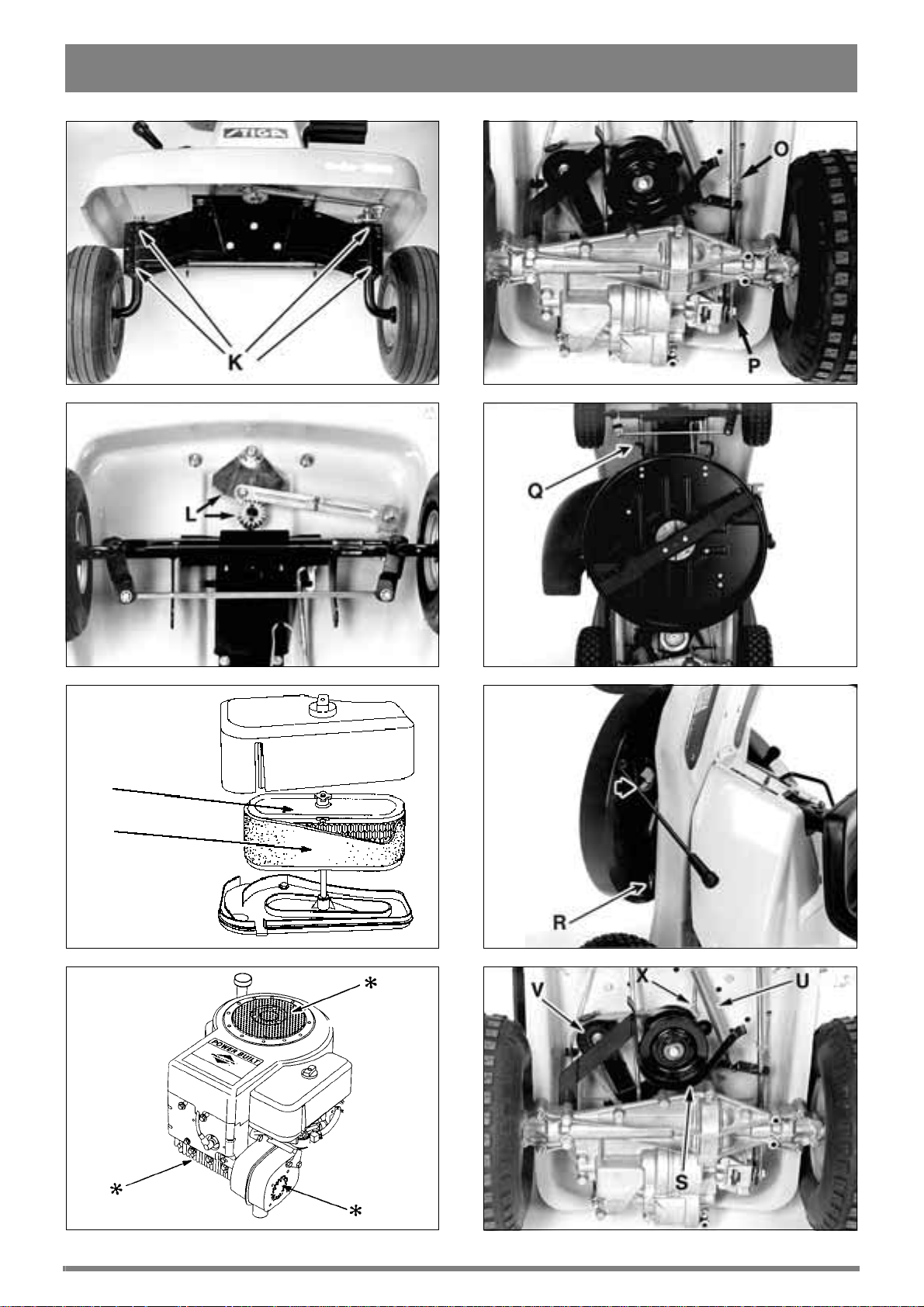

17.

18.

5

2

3

6

1

7

3

3.19.

4

Page 5

GB

ENGLISH

GENERAL

This symbol indicates WARNI NG. Personalinjuryand/ordamagetoproperty

may result if the instructionsare not

followed carefully.

SYMBOLS

The following symbols can be found on the machine to remind you of the care and attention that

are required during use:

The symbols mean:

Warning!

Readthe instruction manual and the safety

manual before using the machine.

Warning!

Do not insert your hands or feet under the

cover when the machine is in operation.

1 Shim washer 16 x 38 x 1.0

2 Locking nut

2 Wing nut

2 Washer 8.4 x 24 x 2.0

1 Battery mount

STEERING WHEEL

Install the wheel on the steering column with the

enclosed pin and push on the steering column

sleeve.

The shim washers in theaccessories bag should be

installed between the lower and upper steering column jacket to compensate for any axial play: 0, 1

or 2 washers may be necessary (fig. 1).

BATTERY

The battery is a valve-regulated battery with 12 V

nominal voltage. T he battery is maintenance-free

insofar as you don’t have to check or top up the

electrolyte level.

Warning!

Watch out for discarded objects. Keep onlookers away.

Warning!

Before starting repair work, remove the

spark plug cable from the spark plug.

Warning!

Use hearing protectors.

Warning!

This machineis not designed to be driven

on public roads.

INSTALLATION

To avoid injury and damage to people

andproperty,trynot to startthe engine

before all the measures under “ASSEMBLY“ have been carried out.

On delivery, the battery is in the accessories box.

The battery must be fully charged before being used f or the first time. The

battery should always be stored fully

charged. If the battery is stored for

longer than 10 days without being

charged, it can be damaged.

If the machine is not going to be used for an extended period (more than 1 month), the battery

shouldbe charged, disconnected and then storedin

a cool, safe place. Charge the battery completely

before reinstalling.

The battery can be charged in two ways:

1. Viaabattery charger (recommended). Thismust

be a charger with constant voltage. The battery

can be damaged if a standard type battery

charger (for acid batteries) is used.

Stigarecommendsbatterychargerwithitemno.

1136-0602-01 which may be ordered by an authorised dealer.

ACCESSORIES BAG

A plastic bag is enclosed with the machine containing:

No. Designation Dimension

1 Spark plug sleeve

1 Torsion pin for ditto

1 Shim washer 16 x 38 x 0.5

2. You can also allow the engine to charge the battery. In this case it is very important, above all

when starting the machine for the firsttime and

when it has not been used for a long time, to allow the engine to run continuously for at least

45 minutes.

Page 6

ENGLISH

GB

Do not short circuit the battery’s terminals. Sparks occur which can result in

fire. Do not wear metal jewellery which

can come into contactwith the battery

terminals.

In the event of damage to the battery

casing, cover, terminals or interference

to the strip covering the valves, the battery should be replaced.

If the battery terminals are coated with oxide, they

shouldbecleaned. Clean the battery terminals with

awirebrushandgreasethem.

Position the battery in the appropriate place under

the engine casing and thread over the battery

mount in accordance with fig. 2. Press down the

mount into the appropriate holes.Place the locking

nuts in the wing nuts. Thread the washers onto the

battery mount’s legs from below and secure with

the wing nuts so that the battery is securely mounted. Connect the battery cables.

NOTE! Toavoid damage to theengine andthe battery, the positive battery cable (+) should always

be connected to the battery first.

Do not run the engine when the battery is disconnected.

4. Install the battery cables.

GRASS COLLECTOR (Accessory)

Assemble the grass collector according to the separate assembly instructions suppliedwiththe grass

collector.

The ejector tube G may only be used together

with the complete grass collector.

When using the grass collector, all components

which make up the collector must be installed on

the machine (fig. 5).

Never use the machine without the collection sackH and the long ejectortube

beinginstalled. There isa riskof stones

and other objects being thrown out, injuringpeople and animals ordamaging

property .

Warning for the rotating blade. Never

put your hand or foot in the ejector

opening.

CONTROLS

Items 1 - 7, see figures 18 - 19.

TYRE PRESSURE

Check the air pressure in the tyres. Correct air

pressure:

Front: 1.7 bar (24 psi)

Rear: 0.6 bar (9 psi)

CUTTING DECK

The deck’sparallel alignment with the surface can

beadjusted with nutsD at the reardeck suspension

mounts (fig. 3).

Multiclip (Garden Multiclip - Garden Combi):

The unit is installed on the machine on delivery.

Collector (Garden Combi):

Theunitis installedon the machine on deliverybut

must be completed with ejector tubes.

1. Disconnect the battery cables.

2. Remove the cover C (fig. 4).

3. Install the ejector tube G (fig. 4). Use the same

screws and nuts as were used for the cover.

Under no circumstances may the lawnmowerbestartedifthecoverhasnot

been replaced with the ejector tube.

1. HEIGHT SETTING LEVER

Lever for setting the height of the cutting deck

above the ground.

Release the lever by pushing it inwards.

Then move it up or down to the desired

position.

The lever has fivepositions, giving cutting heights

from 35 to 75 mm.

2. BLADE ENGAG ING LEVER

Lever for engaging the drive for the cutting deck.

There are two positions:

1. Lever in the forward position – the

blade rotates.

2. Lever in t he rear position – the blade

does not rotate. Theblade brake is activated.

3. SERVICE BRAKE/CLUTCH

A pedal that combines both service brake and

clutch. There are 3 positions:

Page 7

GB

ENGLISH

1. Pedal released – forward

drive engaged. The machine

will move if a gear is engaged.

Service brake not activated.

2. Pedal depressed halfway –

forward drivedisengaged, gear

shifting can be performed.

Service brake not activated.

3. Pedal fully depressed – forward drive disengaged. Service

brake fully activated.

4. PARKING BRAKE

An inhibitor that can lock thebrake pedal inthe depressed position.

Depress the brake pedal fully. Move the

brake inhibitor to theside and thenrelease

the brake pedal.

The parking brake is released by gently pressing

the brake pedal. The spring-loaded inhibitor slides

to one side.

once again. Engage the gear once again. Never

forceagearin.

7. STARTER KEY

Ignition lock used for starting/stopping the engine.

There are 3 positions:

STOP

START-

1. Stop position – the engine is shortcircuited. The key can be removed.

2. Operating position (no symbol).

3. Start position – the electric start motor

is activated when the key is turned to the

spring-loaded start position. Once the engine has started, let the key return to operating position.

USING THE MOWER

AREAS OF USE

The machine may only be used for the following

tasks using the genuine STIGA accessories stated.

Make sure that the parking brake is released when

operating the machine.

5. THROTTLE/CHOKE CONTROL

A control forsettingthe engine speedand to choke

the engine when starting from cold

Idling.

Full throttle – when the machine is in operation, full throttle should always be

used. Full throttle located1 - 1.5 cm from

the bottom edge of the groove.

Choke – for starting a cold engine. The

choke is located in the bottom of the

groove.

6. GEAR LEVER

A lever for selecting one of the five forward gears

in the gearbox (1 - 2 - 3 - 4 - 5), neutral (N) or reverse (R).

The clutch pedal (on the left-hand side of the machine) must be depressed when changing gear.

1. Mowing

With the cutting deck mounted originally.

2. Grass clipping and leaf collection

Using towed collector 13-1978 (30“).

3. Grass and leaf transport

Using dump cart 13-1979 (Standard) or combi

cart 13-1992 (plastic).

The maximum vertical load on the towing hitch

must not exceed 100 N.

The maximum over-run load on the towing hitch

from towed accessories must not exceed 500 N.

NOTE! Before using a trailer, contact your insurance company.

NOTE! This machine is not intended to be driven

on public roads.

BEFORE STARTING

Youmustreadtheseinstructionsforuse

and the accompanying pamphlet

“SAFETY INSTRUCTIONS“ carefully, before starting up the machine.

NOTE! You must make sure the machine is quite

stationarybeforechanging from reverse to forward

gear or vice versa. If a gear does notengage immediately,release the clutch pedal and then press it in

SAFETY SYSTEM

This machine is equippedwith a safetysystem that

consists of:

Page 8

ENGLISH

GB

- a switch on the gearbox

- a switch in the seat mount

- a switch at the blade engaging lever

- a replaceable, electronic safety module which

controls the system

In order tostart the machine, the followingare necessary:

- the gear lever in neutral

- driver sitting on seat

- the blade engaging lever in the rear position (=

blade

disengaged)

Always check the operation of the safety system before using the machine!

Check as follows:

- start the engine, sit on the seat, engage a gear,

lift your weight

off the seat – the engine should stop.

- start the engine again, sit on the seat, engage

the blade, lift your weight off the seat – the en-

gine should stop.

Do notuse themachine if the safety systemisnotworking!Takethemachineto

a service workshop for inspection!

FILL UP T HE PETROL TANK

Always use lead-free petrol. You must

never use 2-stroke petrol mixed with oil.

NOTE! Bear in mind that ordinary lead-free petrol

is a perishable; do not purchase more petrol than

can be used within thirty days.

Environmentally friendly petrol can be used, i.e.

alkylate petrol. This type of petrol has a composition that is less harmful for people and nature.

Check theoil level every time before using.The

machine should be standing on level ground.

Removedipstick B and wipe itoff.Slideit

down completely and tighten it.

Then unscrew it and pull it up again. Read off the

oil level. Top up with oil to the “FULL“ mark, if

the oil level comes below it (figs. 11 - 12).

STARTING THE ENGINE

1. Open the fuel cock.

2. Make sure that the sparking plug cable is properly in place.

3. Make sure that the cutting deck is disengaged.

The blade engaging lever should be in its rear position.

4. Put the gear lever in neutral.

5. Starting cold engine – put the throttle control in

the choke position.

Starting warm engine – put the throttle control at

full throttle (1 - 1.5 cm above the choke position).

6. Depress the brake pedal fully.

7. Turn the starter key and start the engine.

8. Once the engine has started, move the throttle

control gradually to full throttle if the choke has

been used.

9. When starting from cold, do not make the machine work under load immediately, but let the engine run for afew minutes first. Thiswill allow the

oil to warm up.

STOPPING

Move the blade engaging lever backwards to the

disengaged position. Apply the parking brake.

Petrol is highly inflammable. Always

storepetrolin containersthat are made

especially for this purpose.

Onlyfill or topupwith petrol outdoors,

and never smoke when filling or topping up. Fill with petrol before starting

the engine. Never remove the filler cap

or fill with petrol while the engine is

running or still warm.

CHECK THE ENG INE’S OIL LEVEL

On delivery, the engine’s crankcase is filled with

SAE 30 oil.

Allow the engine to idle 1 - 2 mins.

Stopthe engine byturning off the starterkey. Then

remove the starter key.

Shut off the petrol cock.

If the machine is left unattended, remove the s park plug cable from the

spark plug.

The engine may be very warm immediatelyafteritis shut off. Donottouchthe

silencer, cylinder or cooling fins. This

can cause burn injuries.

Page 9

GB

ENGLISH

CUTTING TIPS

Before mowing the lawn, take care to remove any

loose stones, toys and other hard objects.

Locate any fixed objects before mowing a lawn

you are unfamiliar with. Loose and/or fixed objects can seriously damage the cutting deck.

Do not cut wet grass ( during or immediately after

rain).

Keep hands and feet away from the rotating blade. Never put your hand or

foot under the blade casing or in the

grass ejector while the engine is running.

MAINTENANCE

No servicing may be carried out on the

engine or cutting deck unless:

-theenginehasstopped.

-the starterkey has been removed.

-the spark plug cablehasbeen removed

from the spark plug.

-the parking brake has been applied.

-the cutting deck is disengaged.

MAINTENANCE TIPS

The machine is designed to stand on its end during

maintenance work (fig. 7).

If the engine hasstopped due tothegrass being too

thick: disengage the cutting deck and move the

machine to a cut area before engaging it again.

For optimum ‘Multiclip effect’, follow these tips:

- cut frequently.

- run the engine at full revs.

- keep the underside of the cutting deck clean.

- use sharp blades.

- do not cut wet grass.

- cut twice (with different cutting heights) if

the grass is long.

OPERATION

Makesurethat there is the correctquantityof oil in

the engine when mowing on slopes (oil level on

“FULL“).

Be careful when driving on slopes. No

sudden starting or stopping when movingupordown a slope.Nevercut across

a slope. Move from the top down, and

from the bottom to the top.

The machine, equipped with original

accessories, may notbedriven onslopes

greater than 10º in any direction.

Reduce the speed on slopes and when

making s harp turns to prevent the machine from tipping over or you losing

control of the machine.

Ifthe machine istostandon its end,the

petrol and engine oil must have been

drained out first.

CLEANING

Rinse clean the underside of the cutting deck with

the garden hose.

NOTE! Do not aim the jet directly at the transmission or the air filter.

OIL CHANGE, ENGINE

Change the oil the first time after 5 hours of operation, and subsequently every 50 hours of operation or once a season. Change oil when the engine

is warm.

Always use a good grade of oil (service grade SF,

SG or SH).

The engine oil may bevery warmif itis

drained off directly after the engine is

shut off. Therefore, allow the engine to

cool a few minutes before draining the

oil.

1. Tilt the machine to the left (machine viewed

fromthe rear). Unscrew theoildrainplugJ(fig. 8).

Let the oil run out into a collection vessel. Do not

allow oil to get on the V-belts. Screw in the oil

plug.

2. Remove the dipstick and fill up with new oil.

Oil capacity: 1.4 litres

Oil type, summer: SAE-30

(SAE 10W-30 can also be used. However, oil consumption may increase somewhat if 10W-30 is

used. Therefore, check the oillevel more regularly

if you use this type of oil).

Page 10

ENGLISH

GB

Oil type, winter: SAE 5W-30

(if this oil is not available, use SAE 10W-30).

Use oil without any additives.

Do not fill with too much oil. This can cause the

engine to overheat.

Check t he oil level e ach time after filling. The level should be at “FULL“.

LUBRICATION

The front axle has four lubrication points K

(fig.9).Fillwith grease (useagrease gun) once per

season.

Lubricate the steering pinions L with grease acouple of times per season (fig. 10).

Also lubricate the machine’s other moving parts a

couple of times per season.

AIR FILTER

Important! Never run the engine without the air

cleaner being installed.

Foam filter (pre-filter): Clean every 3 months or

after every 25 hours of operation, whichever

comes first.

Paper filter: Replaceannually or after 100hours of

operation. More often if the machine works under

extremely dusty conditions.

KEEP THE ENGINE CLEAN

The engine is air-cooled. A blocked cooling system can damage the engine.

Clean the cylinder’s cooling fins and air intake of

grass and dirt every 5 hours ordaily (fig.12). This

is particularly important when mowing dry grass.

Also clean around the silencer to avoid fire.

Use compressed airor a brushfor cleaning. Donot

point jets of water directly at the engine.

When cutting dry grass for an extended period of

time, the engine’sinteriorcooling fins may needto

be cleaned. Contact an authorised service station.

SPARK PLUG

Check and clean the spark plug every 100 hoursof

operation.

Clean the spark plug with a wire brush (not sand

blasting) and reset the spark gap to 0.75 mm.

Replace the spark plug if the electrodes are excessively burnt. For replacing a spark plug, a spark

plug sleeve and a torsion pin are provided in the

accessories bag.

The engine manufacturer recommends:

Champion J19LM or similar.

CARBURETTOR

1. Remove the air filter’s protective cover and

foam filter (fig. 11).

2.Washthe pre-filter M inliquid detergentand wa-

ter. Squeeze dry. Pour a little oil on the filter and

squeeze in the oil.

3. Liftout the paper filterN and clean the air filter

housing carefully to prevent dirt getting into the

carburettor.

4. Clean the paper filter insert as follows:Knock it

lightly against a flat surface. If the filter is very

dirty, change it.

5. Assemble in the reverse order.

Petroleum-based solvents may not be used when

cleaning the paper filter. These solvents can destroy the filter.

Do not use compressed air for cleaning the paper

filter insert. The paper filter insert must not be

oiled.

The carburettor is correctly set at the factory and

no adjustment is normally required.

If the carburettor does need adjustment, contact a

service station.

ADJUSTING CLUTCH/BRAKE

If the drive beltslips(it can stretch slightly when it

becomes worn), there is an adjustment on the gearshift/brake linkage.

Adjustment: Move the locking pin O to the rear

hole (fig. 13).

The brakes are adjusted with nut P on the brake

arm (fig. 13).

Afteradjusting,makesure that the clutch is always

activated before the brake.

REMOVING THE CUTTING DECK

1. Apply the parking brake.

2. Lift the machine and stand it on its end.

Page 11

GB

ENGLISH

Ifthe machine is tostandon its end,the

petrol and engine oil must have been

drained out first.

3. Set the lowest cutting height and remove the

locking pin Q (fig. 14).

4. Remove the two rear locking pins R and the ca-

bles for the switch contact on the deck (fig. 15).

5. Force the belt offthe pulley (bendthe belt guide

S upwards) (fig. 16).

6. Lift off the deck.

REPLACING V-BELT

ENGINE - CUTTING DECK

1. Remove the cutting deck (see above).

2. Remove the belt loop T. Remove the old belt

(fig. 17).

3. Install a new genuine belt in reverse order.

REPLACING V-BELT

ENGINE - TRANSMISSION

1. Apply the parking brake.

2. Lift the machine and stand it on its end.

Ifthe machine is tostandon its end,the

petrol and engine oil must have been

drained out first.

3. Remove the cutting deck (see above).

3. Tighten screw and nut.

Replace the brake lining when it is worn.

BLADE

Ensure that the blade is always sharp. This produces the best cutting results.

SHARPENING

For safety reasons, the blade should not be sharpened on an emery wheel. Incorrect sharpening (=

too high temperature) could cause the blade to become brittle.

Sharpening of the blades must be done by wet

method grinding, using a whetstone or a grindstone.

Once the blade has been sharpened, it

must then be balanced to avoid vibration damage.

REPLACING THE BLADE

When replacing the blade, blade holder and blade

screw – always use genuine spare parts.

Always use original spare parts. Nongenuine spare parts can entail a risk of

injury, even if they fit the machine.

When replacing the blade, the centre bolt should

also be replaced. This is equipped with a lock.

Blade screw tightening torque: 65 Nm.

4. Undo spring U and remove the belt idler V (fig.

16).

5. Disconnect the belt guide X and turn it to one

side.

6. Force the defective belt over the transmission’s

belt pulley. Work from the machine’s upper side.

Use the hole in the base plate.

7. Force the belt over the engine belt pulley. Bend

down the belt guide Sand placethe belt in the lower groove. Bend up the belt guide and remove the

defective belt.

8. Install a new genuine belt in reverse order.

ADJUSTING BLADE BRAKE

1. Set the blade engaging lever in the rear, disen-

gaged position.

2. Undo the blade brake Y and adjust so that it is

lying flush with the belt pulley (fig. 17).

SPARE PARTS

STIGA genuine spare parts and accessories aredesigned specifically for STIGA machines. Please

notethat‘non-genuine’ spare partsandaccessories

have not been checked or approved by STIGA.

The use of such parts and accessories

can affect the function andsafety of the

machine. STIGA accepts no responsibility for damage or injuries caused by

such products.

STIGA reserves the right to make alterations to the product

without prior notification.

Page 12

MOWING AHEAD

Box 1006 · SE-573 28 TRANÅS

www.stiga.com

Loading...

Loading...