Page 1

STIGA PARK

121M

8211-3011-07

Page 2

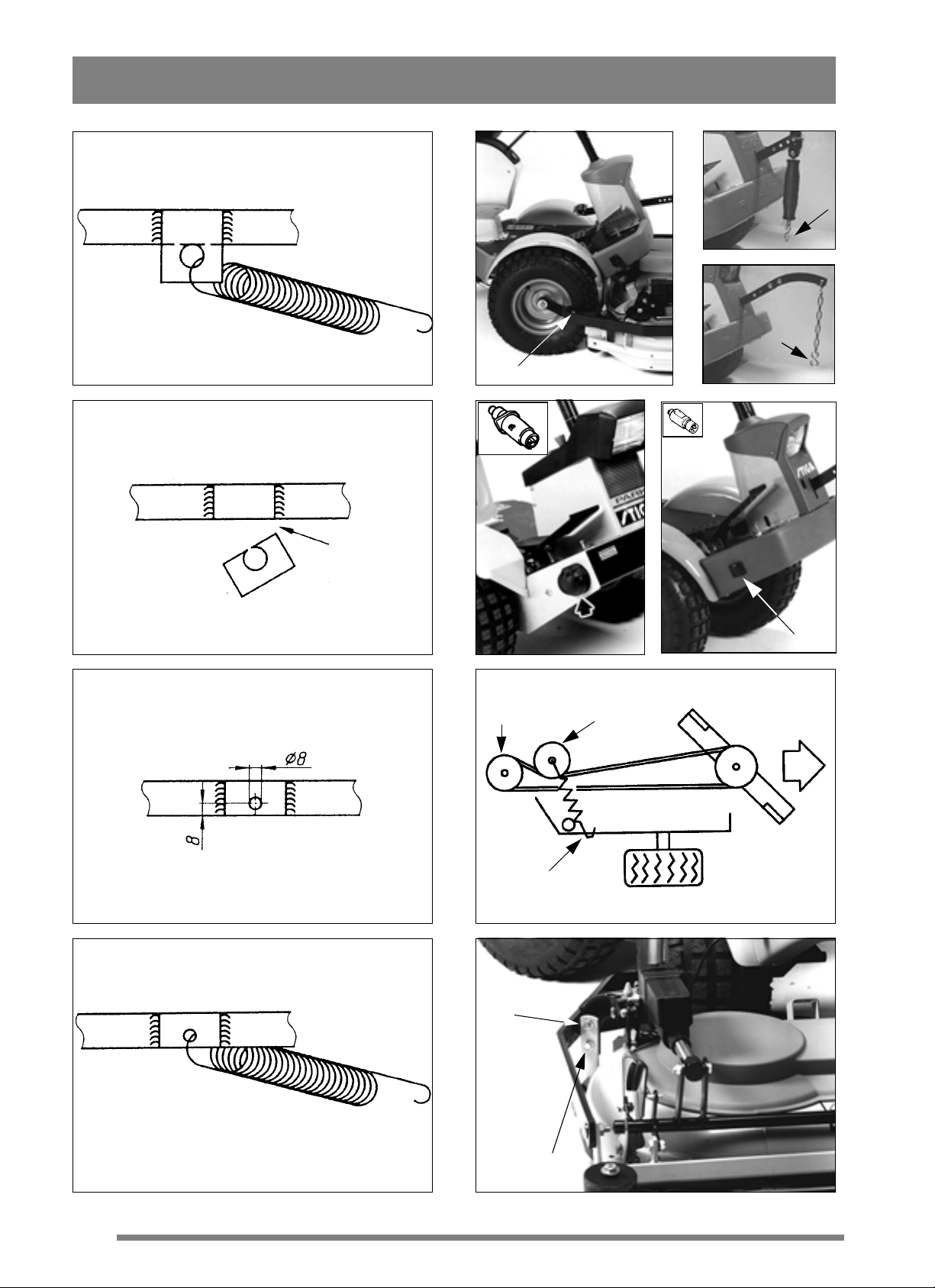

1. Park -1993

5a.

5b.

D

5c. Pro18 - Pro20

2. Park -1993

3. Park -1993

6a. Park -1999

F

H

7.

I

6b. Park 2000-

G

4. Park -1993

2

I

8.

Page 3

J

9.

13.

10.

11.

14.

Z

V

W

15.

Denna produkt, eller delar därav, omfattas av följande

mönsterskydd:

This product, or part of it, is covered by the follow ing

design registration:

Sverige/Sweden 62 435

Tyskland/Germany M97 07 997.9 (pending)

X

Y

12.

3

Page 4

ENGLISH

SYMBOLS

The following symbols are displayed on the machine in order to remind you about the safety precautions and attention necessary when using the

machine.

The symbols mean:

Warning!

Read the instruction book and safety manual before using the machine.

Warning!

Do not put hands or feet under the cover of

the machine when it is running.

Warning!

Beware of objects being flung out. Keep

spectators away.

Warning!

Beforestartinganyrepair work,remove the

spark plug cable from the spark plug.

GB

ASSEMBLY

MOWER DECK

1.Bolt the mower decktothe attachment brackets D

(fig 5a).

2. Then hook the l ower S-hook on to the mower

deck (fig 5b-c).

3. Connect the electrical contact to the outlet on the

side of the machine (applies only to art. no. 13-

2921), (fig. 6).

V-BELT

1. Set the height adjustment to an intermediate position.

2. Lift the mower deck using the attachment lift.

3. Pull the v-belt over the machine's central belt pulley F (fig 7).

4. Tension the belt using the tension roller G. The

tension roller should be on the left of the belt seen

from the operator's position.

INTRODUCTION

ThismowerdeckcanonlybeusedforParkmachines with a motor output of at least 16 hp.

The mower deck is available in two versions as

standard:

- with mechanical setting of the mowing height

(art. no. 13-2915)

- with factory-fitted, electrical setting of the

mowing height (art. no. 13-2921).

PREPARATIONS

Park models up to 1993:

A modification must be made to the machine to use

the mower deck:

1. Dismantle the return spring for centre steering

(fig 1).

2. Saw off the spring bracket,level with the frame

side member (fig 2).

5a. Park -1999:

Hookthe tension rollerspringH into theflooron the

right hand side (fig 7).

5b. Park 2000- :

Hook the tension roller spring H into the fastener,

just behind the front right wheel (fig 7).

SETTING

For the attachment to mow evenly and cleanly it

needs to be adjusted correctly:

1. Make sure the tyre pressure is correct:

Front: 0.6 bar (9 psi).

Rear: 0.4 bar (6 psi).

2. Place the machine on a flat surface. Loosen the

screws I (fig 8).

3. Adjust the mower deck so that the casing's front

and rear edges are the same height from the floor.

4. Tighten the screws.

USE

3. Drill a new hole (Ø 8 mm), 8 mm from the lower

edge of the frame side member (fig 3).

4. Fit the spring in the new hole (fig 4).

MOWING HEIGHT

The mowing height may vary from 30 to 80 mm:

- art. no. 13-2915 has seventeen fixed mowing

5

Page 5

GB

ENGLISH

height positions

- art. no. 13-2921 has stepless adjustment of the

mowing height.

N.B.Thestatedmowingheightsapplywhenthe

machine is standing on firm ground.

MOWING HINTS

For the best "Multiclip" effect follow this advice:

- mow regularly.

- use full throttle on the engine.

- keep the underside of the mower deck clean.

- use sharp b lades.

- do not mow wet g rass.

- mow twice (using different mowing heights)

if the grass is long.

MAINTENANCE

PREPARATIONS

Unless otherwise stated, all service and maintenancemustbeperformedonamachinethatis

standing still where the engine has been switched

off.

Preventthe machine fromrolling, by always applying the parking brake.

CLEANING

After use the underside of the mower deck should

be hosed down.

If grass cuttings have dried on to the mower deck,

scrape the underside clean.

If necessary touch-up the underside using a suitable paint to prevent corrosion.

DRIVE BELTS

If any of the blades have hit a solid object (e.g. a

stone) the belt tension can change. This means that

the drive belt can, "miss-mesh" which in the long

term can damage the blades.

If necessary adjust the drive belt:

1. Unhook the tension roller spring H (fig 7).

2. Pry off the drive belt from the central belt

pulley F.

3. Dismantle the transmission casing.

4. Loosen t he tension arm K (fig 12).

5. Loosen the bearing box's fixing bolts L (fig 13).

6. Tension the drive belt by pressing the tension

arm b ackwards.

7. Tighten the tension arm's fixing bolts.

Prevent involuntary engine start by always stopping the engine, loosening the

spark plug cable from the sparking

plug and earthing it. Remove the minus

(-) cable from the battery.

MAINTENANCE TIPS

To facilitate cleaning and maintenance of the

mower deck it can be folded up:

1. Set the mowingheight adjustmentto an interme-

diate position (= least tension on the drive belt).

2. Lift up the mower deck using the attachment lift.

3. Unhook the tension roller spring H (fig 7).

4. Pull off the v-belt from the central belt pulley F.

5. Loosen both locking pins J (fig 9).

6. Grip the mower deck's frame (fig 10).

7. Fold up the mower deck until it stands upright

on the rear support plates (fig 11).

8. Tighten the bearing box's fixing bolts.

9. Carry out the same procedurefor the other drive

belt.

When changing the drive belts, make

sure that the outer blades are always at

90° to the centre blade (see fig 14).

If you fit the drive belts incorrectly the blades will

collide as they overlap each other.

Always check the position of the blades after

changing the drive belt or adjusting the tension.

CHANGING BLADES

Use protective gloves to prevent cuts

when changing blades/blade tips.

Make sure the blades are always sharp. This gives

the best mowing results.

Always check the blade(s) after an impact. If the

bladesystem has been damaged the defective parts

must be changed.

6

Page 6

ENGLISH

Always use original spare parts. Using

non-original spare parts can result in

the risk of damage even if they fit in the

machine.

The cutting system consists of three blade bars,

each with two interchangeable blade tips Y (fig

15). Both blade tips should be replaced at the same

time to avoid any imbalance.

Fit the new blade tips. Tighten the screws V and W

fully. Tightening torque: V - 9.8 Nm, W - 24 Nm.

And heavy impact can result in the blade tip being

folded aside.LoosenthelockingnutX andturn the

blade tip back to its correct position. Mount a new

shear bolt V. Tighten the lock nuts X and Z.

SPARE PARTS

STIGA original spare parts and accessories are

constructed exclusively for STIGA machines.

Note that non original spare parts and accessories

have not been checked or approved by S TIGA.

GB

Usage of such parts and accessories can

influence the machines operability and

safety. STIGA cannot be held responsible for injuries caused by these products.

STIGA reservesthe right to modify the product without

prior notice.

7

Loading...

Loading...