Page 1

STIGA VILLA

ROYAL

PRESIDENT

SENATOR

COMFORT

MASTER

8211-0288-01

Page 2

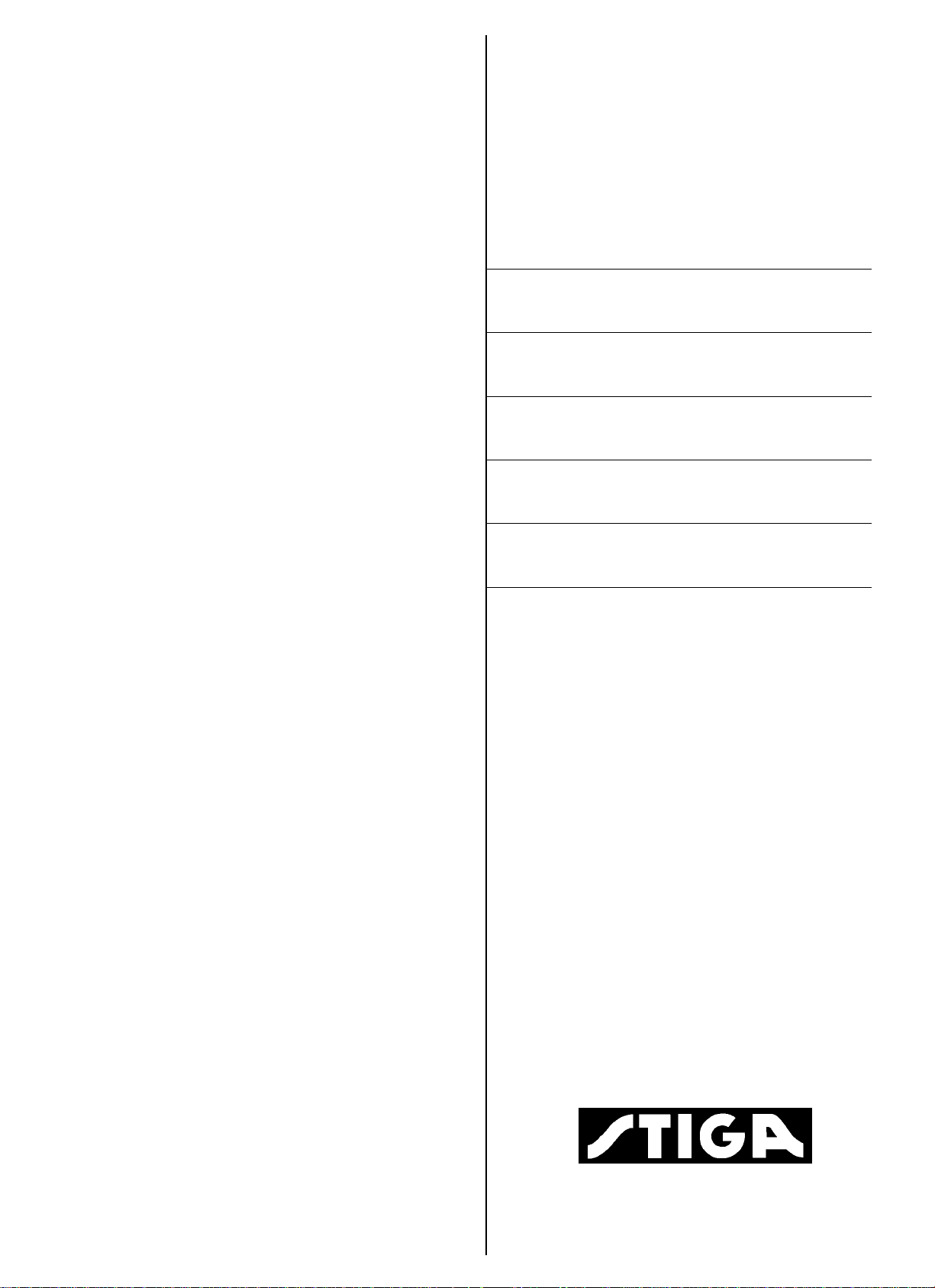

VILLA

V-R-REGL

1.

2

3

1.

2A

7

6

2a. Master - Senator - Comfort

1

2B

1

4

6

5

8

2b. President - Royal

8

5

9

3. President - Royal

Page 3

VILLA

2

5

3

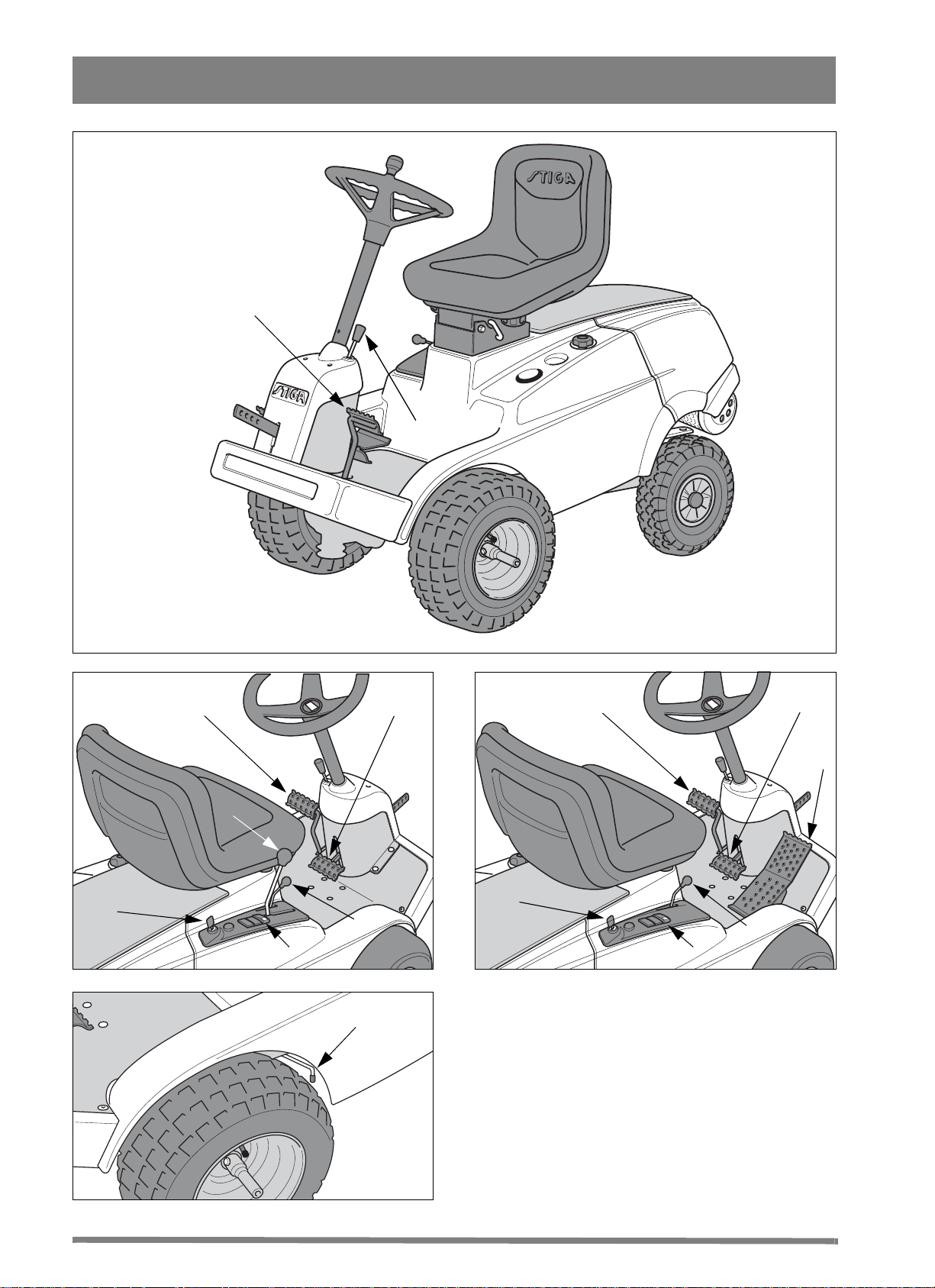

4.

5.

4

95

6.

7. Master - Senator - Comfort - President

8. Royal

N

OPEN

N

9.

N

N

10. Master - Senator - Comfort - President

11. Royal

Page 4

VILLA

5

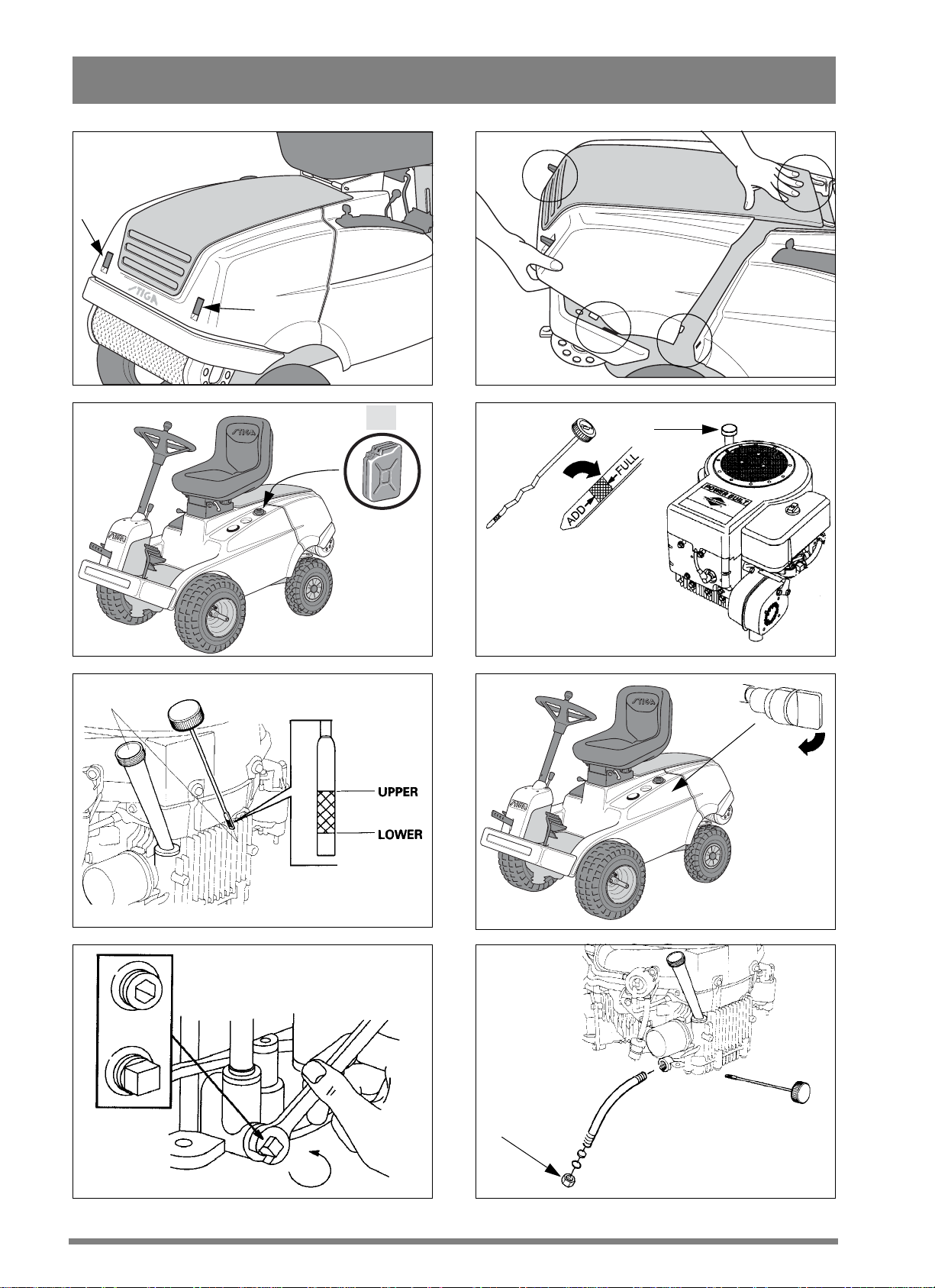

12. Master - Senator - Comfort - President

0.75 mm

14.

UPPER

LOWER

13. Royal

15. Master - Senator - Comfort - President

850ml

8

16.

18.

17.

Page 5

GB

ENGLISH

GENERAL

This symbol means WARNING. Personalinjuryand/ordamage toproperty

can occur if the instructions are not followed carefully.

You must read these operating instructions and the enclosed pamphlet

“SAFETYINSTRUCTIONS”carefully

before starting the machine.

SYMBOLS

The following symbols are displayed on the machine to remind you of the care and attention required when using the machine.

The symbols mean:

Warning!

Read the instruction book and safety manual before using the machine.

Warning!

Beware of objects being flung out. Keep

spectators away.

Warning!

Always u se hearing protectors.

To liftup the accessory, pressdown the pedalas far

as it goes. Release the pedal and the accessory lifter will now be locked in the lift position.

To lower the accessory, press the pedal to release

the lock. Lower the accessorylifter to wo rking position by slowly lifting your foot from the pedal.

2A. SERVICE BRAKE/CLUTCH

(Master - Senator - Comfort)

Pedal which combines both the service brake and

clutch. Three positions:

1.Pedal released– forwarddrive

engaged. The machine starts to

move if a gear is engaged. The

service brake is not activated.

2.Pedal pressedhalfwaydown–

front drive disengaged, it is not

possible to change gear . The

service brake is not activated.

3. Pedal pressed fully down –

front drive disengagedThe service brake is fully activated.

NOTE! Do not regulate the speed by slipping the

clutch. Use a suitable gear instead to obtain the

right speed.

Warning!

This machine is not intended to be driven

on public roads.

Warning!

The machine, equipped with original accessories, must not be driven in any direction onslopeswith a gradient ofmore than

10°.

Warning!

Risk for burn injuries. Do not touchthe silencer.

CONTROLS AND

INSTRUMENTS

Items 1 - 9, see figures 1 - 3.

1. ACCESSORY LIFTER

Pedal for lifting front-mounted accessories to

transport position.

2B. SERVICE BRAKE

(President - Royal)

Pedal which activates the machine’s brake system.

Three positions:

1.Pedal released– forwarddrive

not engaged.

2. Pedal pressed halfway– front

drive disengaged The service

brake is not activated.

3. Pedal pressed fully down –

front drive disengagedThe service brake is fully activated.

3. PARKING BRAKE

Inhibitor to lock the brake pedal in depressed position.

Press down the brake pedal fully. Move

the inhibitor to the right and then release

the brake pedal.

The parking brake is released by pressing the brake

pedal.The spring-loaded inhibitorslides to oneside.

5

Page 6

ENGLISH

GB

Make sure that the parking brake is released when

driving.

4. DRIVE PEDAL (President - Royal)

Pedal which activates the variable transmission.

1. Press down the pedal with the

ball of your foot – the machine

moves forwards.

2. No pressure on pedal – the

machine is stationary.

3.Press downthe pedalwithyour

heel – the machine reverses.

The speed is regulated with the drive pedal. The

more pressure applied on the pedal, th e faster the

machine goes.

5. THROTTLE/CHOKE CONTROL

Control for setting the engine speed and to choke

the engine for cold start.

1. Choke – for starting a cold engine. The

choke is located in the top of the groove.

2. Full throttle – when the machine is in

operation, full throttle should always be

used.

3. Idling.

6. IGNITION LOCK

The clutch pedal must be depressed when changing gear.

NOTE! Make sure that the machine is standing

completely still before changing from reverse to

forward gear, or vice versa. If a gear does not engageimmediately,releasethe clutchand thenpress

it in again. Engage the gear again. Never force a

gear in!

8. POWER TAKE-OFF

Switch for engaging and disengaging the electromagneticpower take-offfordrivingfront-mounted

accessories. Two positions:

1.Press inthe rightside of the switch –the

power take-off engages. The symbol

lights up.

2. Press in the left part of the switch – the

power take-off disengages.

9. DISENGAGING LEVER

(President - Royal)

Lever for disengaging the variable transmission.

Enablesthemachinetobemovedbyhandwithout

using the engine. Two positions:

1. Lever pressed in – the transmission is engaged for normal

use.

2. Lever pulled out – the transmission is disengaged. The machine can be moved by hand.

Ignitionlock used tostart andstop the engine.Four

positions:

1. Stop position – the engine is shortcircuited. The key can be removed.

2/3. Operating position.

4. Start position – the electric start motor

is activated when the key is turned to the

spring-loaded start position. Once the engine has started, let the key return to operating position 2/3.

7. GEAR LEVER (Master - Senator Comfort)

Leverfor selectingone of fiveforwardgears in the

gearbox (1-2-3-4-5), neutral (N), or reverse (R).

The machine must not be towed long distances or

at high speed. This can damage the transmission.

AREAS OF USE

The machine must only be used for the following

tasks with the indicated STIGA original accessories:

1. Mowing

With mower deck 13-2929 (92M) or 13-2930

(107M).

2. Grass clippings and leaves collection

With towed collector 13-1978 (30") or 13-1950

(42").

3. Grass and leaves transport

With dump cart 13-1979 (Standard), 13-1988

(Maxi) or 13-1992 (Combi).

6

Page 7

GB

ENGLISH

The towing unit must only be loaded with a vertical force of max. 100 N.

The pulling force on the tow unit from towed accessories must be max. 500 N.

NOTE! Before using a trailer – contact your insurance company.

NOTE! This machine is not intended to be driven

on public roads.

STARTING AND OPERATING

ENGINE CASING

The engine casing must be removed to inspect and

maintain the engine and battery. Removing:

1. Lift up the two catches on the rear edge (fig. 4).

2. First pull the engine casing backwards slightly.

Then lift it off.

Fitting:

1. Tilt the seat forward.

2. Align th e casing’s top front pegs to the recesses

in the front of the engine casing (fig. 5). Do not

push the pegs in yet (see item 4 below).

3. Place the casing’s bottom pegs in the groove in

the shock absorber.

4. Guide in the two side pegs in the groove in the

front engine casing. Now pressforward the

complete casing.

5. Finally, push down the two catches.

Themachinemust notused without the

engine casing fitted. Risk for burn injuries and pinch injuries.

FILLING THE FUEL TANK

Always use clean unleaded petrol. Never use oilmixed 2-stroke petrol (fig. 6).

NOTE! Bear inmind that standard unleaded petrol

is perishable.Never purchase more than what you

can use within 30 days.

Environmentally-friendly petrol is a good choice

ofpetrol. This typeof petrolhasa composition that

is less hazardous for people and nature.

Petrol is highly inflammable. Store petrol in specially made containers for this

purpose.

Only fill up with petrol outdoors, and

never smoke when filling. Fill up with

petrolbefore startingthe engine.Never

remove the filler cap or fill up with petrol when the engine is running or still

warm.

Never completelyfill the fuel tank. Leave anempty space (= at least the entire filler tube plus 1 - 2

cm at the top of the tank) to allow the petrol to expand when it warms up without overflowing.

CHECKING THE OIL LEVEL

(Master - Senator - Comfort - President)

On delivery ,the crankcase is filled with SAE 30 oil.

Check the oil level every time before using to

ensure that it is correct.Themachine should be

standing on level ground.

Wipeclean round the oil dipstick. Release

it and pull out. Wipe,push down fully and

screw it back in.

Unscrew it and pull out again. Check the oil level.

Top up with oil to the “FULL” mark if the oil level

is below this (fig. 7).

CHECKING THE OIL LEVEL (Royal)

On delivery, the crankcase is filled with SAE oil

10W-40.

Check the oil level every time before using to

ensure that it is correct.Themachine should be

standing on level ground.

Wipeclean round the oil dipstick. Release

it and pull out. Wipe,push down fully

without screwing it back in.

Pull out again and check the oil level. Top up with

oil tothe “FULL” mark iftheoil level is below this

(fig. 8).

SAFETY SYSTEM

This machine is equipped with a safety system that

consists of:

- a switch at the gear lever (only Master, Senator,

Comfort).

- a switch at the brake pedal (only President,

Royal).

- a switch in the seat mounting (all).

In orderto start the machine, the following are necessary:

7

Page 8

ENGLISH

GB

- gear lever in neutral (only Master, Senator,

Comfort).

- brake pedal pressed down.

- driver sitting on the seat.

Always check the operation of the safety system before using the machine!

With the engine running and the driver sitting on

the seat, check as follows:

- select a gear, and lift your weight off the seat –

the engine should stop (only Master, Senator,

Comfort).

- press the drive pedal so that themachinestarts to

move, and then release the drive pedal – the machine should stop (applies to President, Royal).

- engage the power take-off, lift your weight off

the seat – the power take-off should disengage

The machine must not be used if the

safety system does not work! Take the

machine to a service agent for inspection.

STARTING

1. Open the fuel cock (fig. 9).

2. Check that the spark plug cable is in place.

STOPPING

Disengage the power take-off. Apply the parking

brake.

Allow the engine to idle for 1 - 2 minutes. Stop the

engine by turning off the starter key.

Shut off the fuel cock. This is p articularly important if the machine is to be transported on a trailer

for example.

If the machine is left unattended, remove the leadfrom the spark plug. Remove also the starter key.

The enginecanbevery hot immediately

aftertheengine isstopped.Do not touch

the silencer, cylinder or cooling flanges

to avoid burn injuries.

OPERATING TIPS

Make sure that there isthecorrect quantity ofoilin the

engine when driving on slopes (oil level at “FULL ”).

Be careful when driving on slopes. No

sudden starting or stopping when moving up or down a slope. Never drive

across a slope. Drive from the top and

down, or from the bottom and up.

3. Check that the power take-off is disengaged.

4a. Master - Senator - Comfort:

Put the gear lever in neutral.

4b. President - Royal:

Do not keep your foot on the drive pedal.

5. Starting cold engine – put the throttle control in

the choke position. Starting warm engine – put the

throttlecontrolatfull throttle(approx.1cm behind

the choke position).

6. Press down the brake pedal fully.

7. Turn the starter key and start the engine.

8. Once the engine has started, move the throttle

control gradually to full throttle if the choke has

been used.

9. When starting a cold engine let the engine run

for a few minutes before using the machine. This

allows the oil to warm up.

When in use, always run the engine at full throttle.

When going down slopes greater than

20º the rear wheels can lift from the

ground. However, the mower deck prevents the machine from tipping over

forwards.

The machine, equipped with original

accessories, must not be driven in any

direction on slopes with a gradient of

more than 10°.

Reduce speed on slopes and when making sharp turns to prevent the machine

fromtippingover, andtomake sureyou

do not loose control of the machine.

Do not turn the steering wh eel to full

lockwhendrivingin topgearand at full

throttle. The machine can tip over.

Keep hands and fingersaway from the

seat mounting. Risk of pinch injuries.

Never operate the machine without the

engine casing.

Never drive with the mower deck engaged and lifted up. This will damage

the drive belt to the unit.

8

Page 9

GB

ENGLISH

SERVICE AND MAINTENANCE

SERVICE PROGRAMME

STIGA’s Service P rogramme should be followed

to keep the machine in good condition in terms of

reliability and operational safety, and from an environmental perspective.

The contents of this programme can be found in

the attached service log.

We recommend that an authorised workshop carries out every service. This guarantees that the

work is carried out by trained personnel and with

original spare parts.

The service log should be stamped at every service. A “fully stam ped” service log is a valuable

document that improves the machine’s secondhand value.

PREPARATIONS

CHANGING THE OIL

(Master - Senator - Comfort - President)

Change the engine oil for the first time after 5

hoursof operation,and thenafter every 50 hours of

operation or once per season.

Change the oil more often, every 25 hours of operation or at least once per season, if the engine has

to operate under very demanding conditions or if

the ambient temperature is high.

Change the oil when the engine is warm. Use a

good grade of oil (service grade SF, S G or SH).

The engine oil may be very hot if it is

drained off directly after switching off

the engine. Forthis reason allow the engine to cool for a few minutes before

draining the oil.

Unscrew the oil drain plug (fig. 10). It is located on

the left side of the engine (machine seen from rear).

Unless oth e rwise stated, all service and maintenance should be performed when the machine is

stationary and with the engine switched off.

Alwaysapply the parking brake to prevent the machine from rolling.

To prevent starting the engine involuntarily, always release the spark plug

lead from the spark plug and earth it.

Remove the minus lead from the battery.

CLEANING

To reduce the risk of fire, keep the engine, silencer/catalytic converter, battery and fuel tank, free fromgrass,

leaves and oil.

To reduce the risk of fire, regularly

check the machine for oil and/or fuel

leakage.

When washing the machine with water underhigh

pressure, do not point the jet directly at the transmission.

Do not point the jet at the engine. Use a brush or

compressed air to clean it.

Let theoil run out into a collectionvessel. Then

take the oil to a recycling station. Avoid spilling

oil on the V-belts.

Screw tight the oil drain plug.

Take out theoil dipstick and fill up with new oil to

the “FULL” mark.

Oil capacity:

Master – 1.1 litre

Senator. Comfort, President – 1.4 litre

Oil type, summertime (> 4° C): SAE -30

(SAE 10W-30 can also be used. The oil consumption may increase somewhat if 10W-30 is used.

Check the oillevel more regularly ifthis type of oil

is used.

Oil type, winter (< 4° C): SAE 5W-30

(if this oil is not available, use SAE 10W-30)

Do not use any additives with the oil.

Do not overfill. This can result in the engine overheating.

CHANGING THE OIL (Royal)

Change the engine oil for the first time after 20

hours of operation (or during the first month), and

then after every 100 hours of operation or every 6

months.

Change the oil when the engine is warm. Use a

good grade of oil (service grade SF, S G or SH).

9

Page 10

ENGLISH

GB

Theengineoilmaybeveryhotifitis

drained off directly after switching off

the engine. For this reason allow the engine to cool for a few minutes before

draining the oil.

Unscrew the oil drain plug in the end of the tube

(fig. 11).

Let the oil run outinto a collection vessel. Then

take the oil to a recycling station. Avoid spilling

oil on the V-belts.

Screw tight the oil drain plug. Make sure that the

fibre gasket and O-ring inside the plug are undamaged and in the correct position.

Take out the oil dipstick and fill up with new oil to

the “FULL” mark.

Oil capacity:

Royal – 0.9 litre (= when changing; total engine

capacity is 1.15 litr e).

Oil type for all seasons: SAE 10W-40.

Fir very low temperatures (< -20° C), u se SAE

5W-30.

Do not use any additives with the oil.

Do not overfill. This can result in the engine overheating.

AIR FILTER - ENGINE

Master-Senator-Comfort-President:

Clean the pre-filter every year or after every 25 operating hours, whichever comes first.

Clean the paper filter every year or every 100 operating hours, whichever comes first.

Royal:

Clean the airfilter (per-filterand paperfilter) every

3 months or afterevery 50 operating hours, whichevercomes first. Changethe paper filter every year

or every 200 operating hours.

All models:

NOTE! Clean both filters more often if the machine is used in dusty conditions.

1. Remove the air filter cover (fig. 12 - 13).

2. Dismantle the paper filter and pre-filter (= foam

plastic filter). Make sure that no dirt gets into the

carburettor. Clean the air filter housing.

4. Clean the paper filter as follows: Tap it lightly

against a flat surface. If the filter is very dirty, r eplace it.

5. Assemble in the reverse order.

Petroleum-based solvents such as kerosene must

notbe used to clean thepaper filter.These solvents

will damage the filter.

Do not use compressed air to clean the paper fi lter.

The paper filter must not be oiled.

SPARK PLUG

Changethe spark plug after every100 hours of operation or every season. In the accessory bag th ere

is a spark plug sleeve A and torsion pin B to

change the spark plug.

The engine manufacturer recommends:

Master - Senator - Comfort - President: Champion

J19LM.

Royal: NGK BPR5ES or DENSO W16EPR-U.

Correct electrode gap: 0.75 mm (fig. 14).

COOLING AIR INTAKE - ENGINE

(Master - Senator - Comfort - President)

The engine is air-cooled. A blocked cooling system can damage the engine. The engine should be

cleaned every 100 hours of operation or at least

once a year.

Remove the fan casing. Clean the cooling fins on

the cylinder, the fan and the rotating protective

grille (fig. 15). Clean more frequently if moving

dry grass.

BATTERY

Check the acid level regularly.

The acid level should lie between the “UPPER”

and “LOWER” markings on the battery (fig. 16).

When adjusting the acid level, only use distilled

water.

The battery acid is extremely corrosive

and can cause burns on the skin and

clothing. Use rubber gloves and protect

youreyes with protective glasses.Avoid

inhaling the acid fumes.

3. Wash the pre-filter inliquiddetergent and water.

Squeeze dry. Pour a little on the filter and squeeze

in the oil.

10

Page 11

GB

Do not tip the battery enough for battery acid to run out onto your hands

and clothing. If this should happen,

flush with lots of water.

ENGLISH

PATENT – PROTECTION OF

DESIGNS

If the battery terminals are coatedwith oxide, they

shouldbe cleaned. Clean the batteryterminals with

a wire brush and grease them.

LUBRICATION - CHASSIS

The machine has three grease nipples on the rear

axle, which should be lubricated with universal

grease after every 25 operating hours (fig. 17).

Lubricate the steeringcables with universal grease

a couple of times per season.

Lubricate the plastic bearings with universal

grease a couple of times per season.

Lubricatethe tension arms joints with engine oil a

couple of times per season.

Drop a little engine oil in both ends of the throttle

control cable a couple of times per season.

Master-Senator-Comfort:

The transmission is filled with oil (SAE 80W-90)

on delivery from the factory. If it is not opened

(which must only be done by aspecialist) it should

not normally need topping up with oil.

This machine, or parts thereof, is protected by the

following patents and protection of designs:

9901091-0 (SE), 9901730-3 (SE), SE00/00577

(PCT), SE00/00895 (PCT), 4.537.581 (US).

00 1080 (SE).

STEERING CABLES

Adjust the steering cables for the first time after 2

– 3 hours of operation, and then after every 25

hours of operation.

Tension the steering cables by tightening up the

nuts (fig. 18). Important! The “screw ends” of the

steering cables should be held firmly during the

adjustment so that the cables are not twisted. Use

an adjustable wrench or the like, inserting it in the

key handles in the ends of the screws.

Tension the cables until they are no longer slack.

Do not tension the cables too hard. This can cause

unnecessary wear on the steering cables a nd pulleys etc.

STIGA reserves the right to modify the product without

giving any prior notice.

11

Loading...

Loading...