Page 1

STIGA PARK

110 S

8211-3009-06

Page 2

1.

2.

F

G

H

3.

4.

Page 3

SYMBOLS

ENGLISH

3. Slide in the attachment'sfixing arms into the machine's attachment brackets.

GB

The following symbols are displayed on the machine in order to remind you about the safety precautions and attention necessary when using the

machine.

The symbols mean:

Warning!

Read the instructionbook and safetymanual before using the machine.

Warning!

Do not put hands or feet under the cover of

the machine when it is running.

Warning!

Bewareof objects being flung out. Keep

spectators away.

Beforestartingany repair work,remove the

spark plug cable from the spark plug.

4. Setthe v-belt onthe machine's central belt pulley

F(fig3).

5. The tension roller G should rest on the left-hand

side of the v-belt, seen from the driver's seat (fig 3).

6. Now pull the mower deck forwards so that the

holes in the fixing arms correspond with the holes

on the attachment brackets.

7. Insertthe screws and tighten.

8a. Park -1999:

Hook the tension roller spring H into the floor on

the right-hand side (fig 3).

8b. Park 2000Hook the tension roller spring H into the fastener,

just behind the front right wheel (fig 3).

9. Lift up the mower deck and hook the chain into

the attachment lifter.

Whenchangingthe v-beltor dismantlingthemower

deck follow the above procedures in the reverse order.

PREPARATION

If this clipping unit is used with the Park model,

the number of revolutions per minute should be reduced slightly in order to comply with the current

regulations for approved noise levels:

- Senator and President models: reduce to 3,000

rpm

- Royal, Pro 16, Pro 18 and Pro 20 models: reduce to 3,200 rpm

Thisadjustment torpmshould onlybe made bythe

retaileror atanauthorised workshop,i.e. bypeople

who have the correct skills and equipment.

ASSEMBLY

MOWER DECK

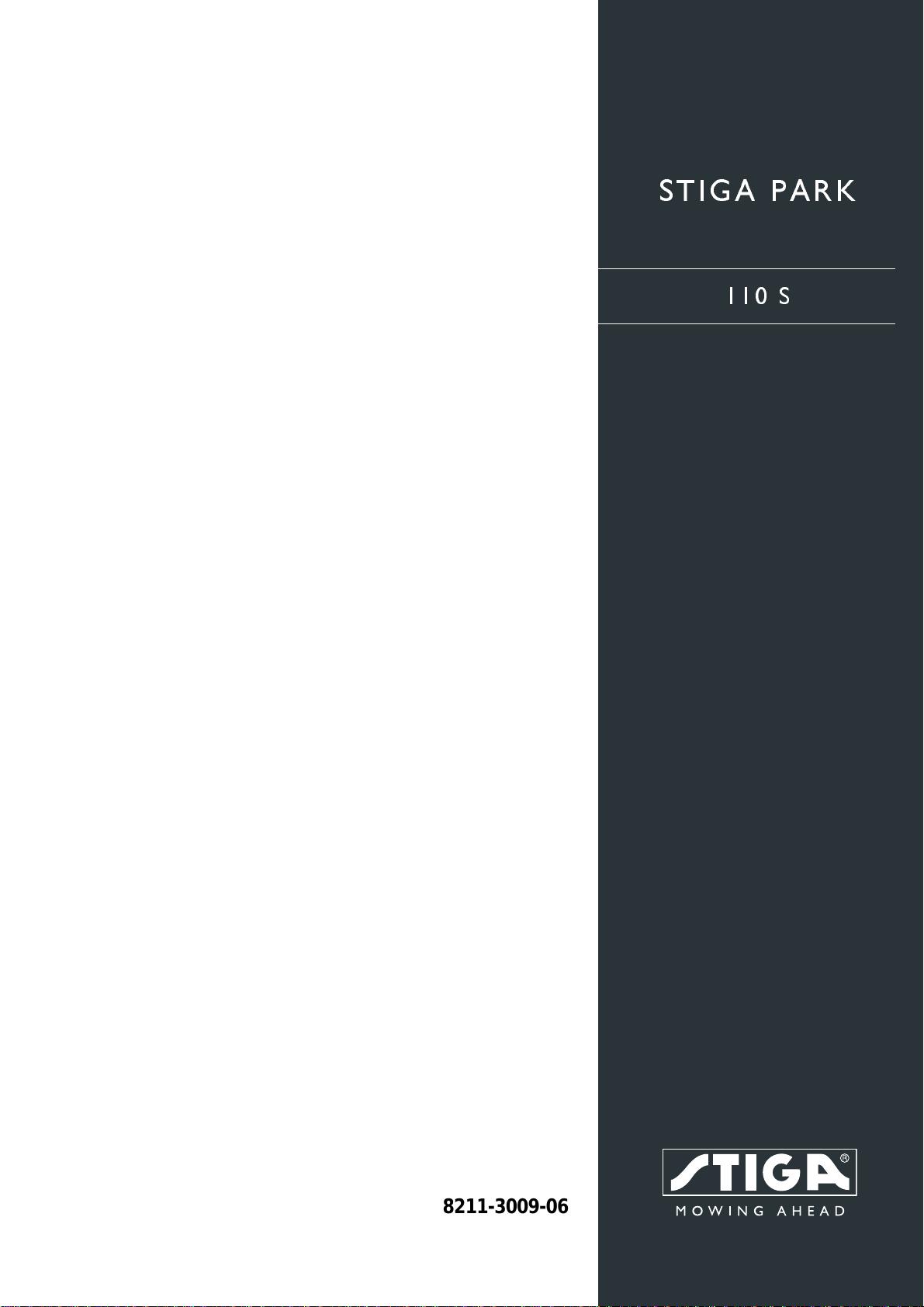

1. Fit the support wheels and the deflector as show

in figure 1.

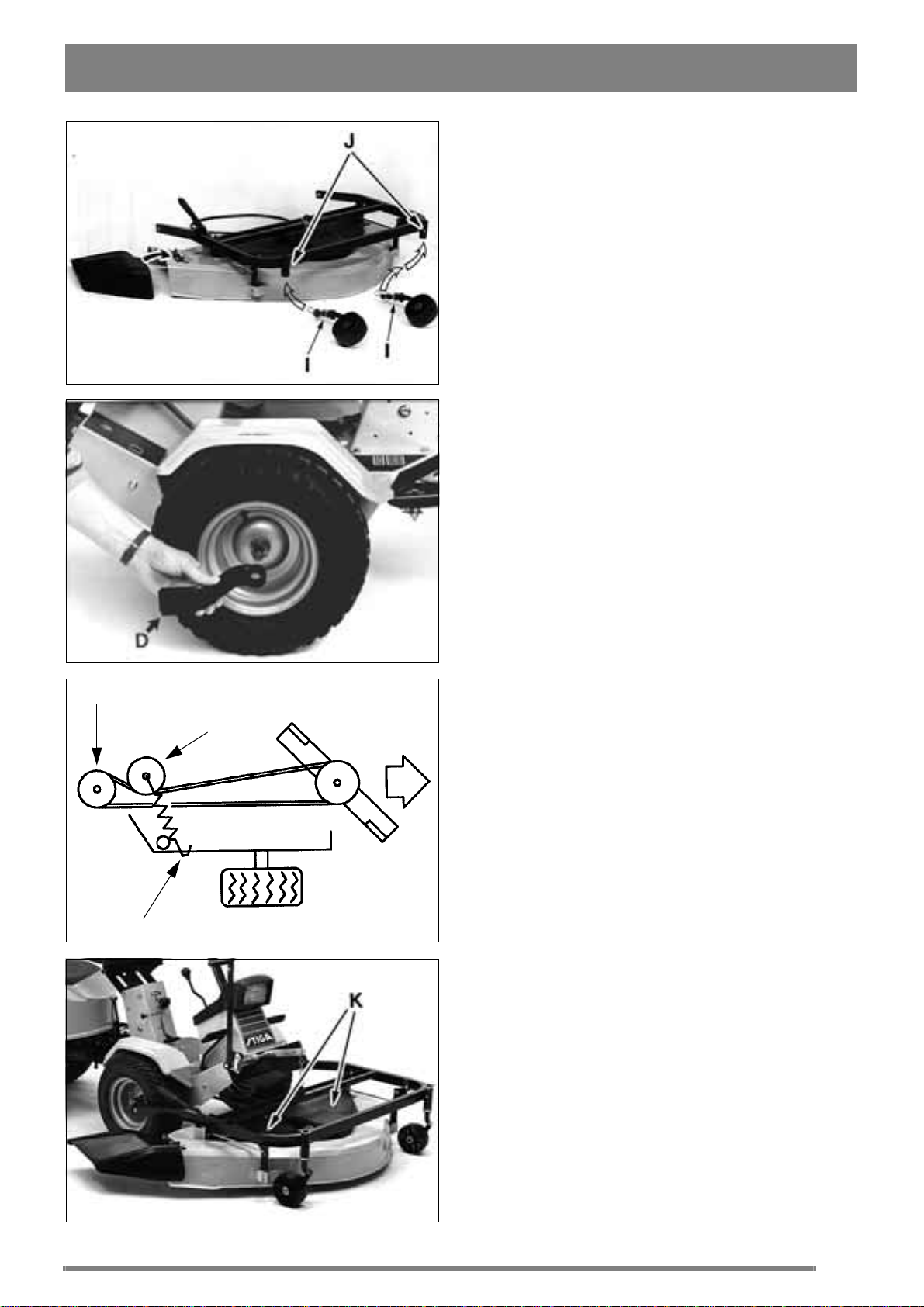

2. Fit the attachment brackets D on the front axle

studsby usingthe washers and lockingclips (fig 2).

SETTING

1. Check that the tyreshavethe correct air pressure.

Front:0,6 bar (9 psi).

Rear: 0,4 bar (6 psi).

2. To obtain an even cut from the mower deck its

forward and rear edges must be parallel to the

ground.

- Check this by placing the machine on a flat surface.

- If adjustmentis required,adjust usingthe washers

I at the support wheels (fig 1).

Points 1 and 2 must be carried out for the mower

deck to mow evenly.

USE

MOWING HEIGHT

Themowerdeckhas17fixed mowingheights,from

30 mm to 80 mm.

N.B. The stated mowing heights apply when the

machine is standing on firm ground.

Page 4

GB

ENGLISH

MOWING HINTS

For the best effect follow this advice:

- mow regularly

- use full throttle on the engine.

- keep the underside of the mower deck clean.

- use sharp blades.

- do not mow wet grass.

MAINTENANCE

No service work to the engine or mower

deck is to be carried out unless the following action has been taken:

- the engine has been stopped.

- the ignition key has been removed.

- the ignition cable has been removed

from the spark plug.

- the parking brake is engaged.

- the mower deck has been disengaged.

CLEANING

off the v-belt from the central belt pulley.

5. Change thedamagedv-belt. Always use anoriginal v-belt. The tension roller G should rest to the

left of the v-belt as seen from the driver's seat

(fig 3).

6. Fit the screws K (fig 4).

7. Fit the mower deck in the machine's attachment

brackets.

8a. Park -1999:

Hook the tension roller spring H into the floor on

the right-hand side (fig 3).

8b. Park 2000Hook the tension roller spring H into the fastener,

just behind the front right wheel (fig 3).

REPLACEMENT OF THE DRIVE

BELT IN THE MOWER DECK

1. Remove the screws K and remove the transmission casing (fig 4).

Rinse off the underside of the mower deck casing

with a garden hose after using the mower.

If grass has dried onto the casing dismantle the

mower deck and scrape the underside clean.

If necessary, to improve the underside it can be

painted to prevent rust.

Do not spray with high pressure water

against the bearing housings on top of

the mower deck when the transmission

cover isremoved.Otherwisewater may

penetrate the bearings.

LUBRICATION

The attachment's support wheels are fitted with

two grease nipples J (fig 1). Lubricate using a universal grease periodically during the season.

Grease other moving parts too.

REPLACEMENT OF DRIVE BELT

CENTRAL BELT PULLEY - MOWER

DECK

2. Loosenthe spring whichholds the tension roller.

3. Change the v-belt and replace in the reverse order. Always use original v-belts.

BLADES

Use protective gloves to prevent cuts

when changing blades/blade tips.

Make sure the blades are always sharp. This gives

the best cutting results.

SHARPENING

For safety reasons the blades must not be sharpened on an emery wheel. Incorrect sharpening ( =

high temperature) can result in the blades becoming brittle.

When the blades are due to be sharpened, the wet

grindingmethod with awaterstone or grindstoneis

to be used.

Following sharpening, the blades must

be balanced to avoid vibration damage.

1. Unhook the tension roller spring H.

2. Remove the mower deck from the machine.

3. Unscrew the screws K and remove the transmis-

sioncasing(fig4).

4. Slide in the unit towards the machine and pull

CHANGING BLADES

Always useoriginal spare parts whenchangingthe

blades, blade attachments or bolts.

Page 5

ENGLISH

Always use original spare parts. Using

non-original spare parts can result in

the risk of damage even if they fit in the

machine.

When changing the blades, the blades central bolt

should also be replaced. It is provided with a locking device. The blade bolts torque: 65 Nm.

SPARE PARTS

STIGA original spare parts and accessories are

constructed exclusively for STIGA machines.

Note that non original spare parts and accessories

have not been checked or approved by STIGA:

Usage of such parts and accessories can

influence the machines operability and

safety. STIGA cannot be held responsible for injuries caused by these products.

GB

STIGA reserves the right to modify thee productwithout prior notice.

Loading...

Loading...