Page 1

OPERATION AND INSTALLAT ION

Air | water heat pump

» WPL 15 AS

» WPL 15 ACS

» WPL 20 A

» WPL 20 AC

» WPL 25 A

» WPL 25 AS

» WPL 25 AC

» WPL 25 ACS

Page 2

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information �����������������������������������������3

1.1 Safety instructions ����������������������������������������������� 3

1.2 Other symbols in this documentation ����������������������� 4

1.3 Units of measurement ������������������������������������������ 4

1.4 Standardised output data �������������������������������������� 4

2. Safety ���������������������������������������������������������� 4

2.1 Intended use ������������������������������������������������������ 4

2.2 Safety instructions ����������������������������������������������� 4

3. Appliance description ���������������������������������������5

3.1 Properties ��������������������������������������������������������� 5

3.2 Function ����������������������������������������������������������� 5

4. Settings �������������������������������������������������������5

5. Maintenance and care ���������������������������������������6

6. Troubleshooting ����������������������������������������������6

INSTALLATION

7. Safety ���������������������������������������������������������� 7

7.1 General safety instructions ������������������������������������ 7

7.2 Instructions, standards and regulations �������������������� 7

8. Appliance description ���������������������������������������7

8.1 Standard delivery ������������������������������������������������ 7

8.2 Accessories �������������������������������������������������������� 7

9. Preparations �������������������������������������������������� 7

9.1 Sound emissions ������������������������������������������������� 7

9.2 Minimum clearances �������������������������������������������� 8

9.3 Preparation of the installation location ��������������������� 8

9.4 Siting ��������������������������������������������������������������� 8

9.5 Installing supply lines and supply cables ������������������ 10

9.6 WPM heat pump manager ������������������������������������ 10

9.7 Buffer cylinder �������������������������������������������������� 10

9.8 Preparing the electrical installation ������������������������ 11

10. Installation �������������������������������������������������� 11

10.1 Handling ���������������������������������������������������������� 11

10.2 Siting �������������������������������������������������������������� 11

10.3 Heating water connection ������������������������������������� 11

10.4 Flow and return connection ���������������������������������� 12

10.5 Fitting the push-fit connector �������������������������������� 12

10.6 Oxygen diffusion ������������������������������������������������ 13

10.7 Filling the heating system ������������������������������������ 13

10.8 Minimum flow rate ��������������������������������������������� 13

10.9 Setting the flow rate on the heating side ������������������ 13

10.10 Condensate drain ����������������������������������������������� 15

10.11 External second heat generator �����������������������������15

10.12 Safety temperature controller for underfloor heating

system STB-FB �������������������������������������������������� 15

11. Power supply ����������������������������������������������� 15

11.1 Power connection WPL15AS| WPL15ACS ��������������� 17

11.2 Power connection WPL20A| WPL20AC| WPL25A|

WPL25AC �������������������������������������������������������� 17

11.3 Power connection WPL25AS| WPL25ACS ��������������� 18

11.4 Electrical connection of supplementary heating facility 18

12. Commissioning ��������������������������������������������� 20

12.1 Checks before commissioning�������������������������������� 20

12.2 Using the appliance with an external second heat

generator ��������������������������������������������������������� 20

12.3 Settings ����������������������������������������������������������� 20

12.4 Operation and control ����������������������������������������� 21

12.5 Decommissioning ����������������������������������������������� 21

13. Maintenance ������������������������������������������������ 21

14. Troubleshooting �������������������������������������������� 22

14.1 Checking the IWS DIP switch settings ���������������������� 22

14.2 Light emitting diodes (LEDs) ����������������������������������23

14.3 Reset button ����������������������������������������������������� 24

14.4 Resetting the high limit safety cut-out ��������������������� 24

14.5 Fan noise ��������������������������������������������������������� 24

15. Specification ������������������������������������������������ 26

15.1 Dimensions and connections ��������������������������������� 26

15.2 Wiring diagram for WPL15AS| WPL15ACS|

WPL25AS| WPL25ACS (single-phase) ������������������� 28

15.3 Wiring diagram for WPL20A| WPL20AC| WPL25A|

WPL25AC (3-phase) �������������������������������������������30

15.4 Output diagrams WPL15AS| WPL15ACS ���������������� 32

15.5 Output diagrams WPL20A| WPL20AC ��������������������34

15.6 Output diagrams WPL25A| WPL25AC| WPL25AS|

WPL25ACS ������������������������������������������������������ 36

15.7 Data table �������������������������������������������������������� 38

GUARANTEE

ENVIRONMENT AND RECYCLING

2 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 3

SPECIAL INFORMATION | OPERATION

General information

SPECIAL INFORMATION

- The appliance may be used by children aged 8

and up and persons with reduced physical, sensory or mental capabilities or a lack of experience

and know-how provided that they are supervised

or they have been instructed on how to use the

appliance safely and have understood the resulting risks. Children must never play with the appliance. Children must never clean the appliance

or perform user maintenance unless they are

supervised.

- Use a permanent connection to the power supply.

The appliance must be able to be separated from

the power supply by an isolator that disconnects

all poles with at least 3mm contact separation.

- Maintain the minimum clearances to ensure trouble-free operation of the appliance and facilitate

maintenance work.

- Maintenance work, such as checking the electrical safety, must only be carried out by a qualified

contractor.

- We recommend an annual inspection (to establish

the system’s current condition), and maintenance

by a qualified contractor if required (to return the

system to the desired condition).

OPERATION

1. General information

The chapters “Special Information” and “Operation” are intended

for both the user and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

KEYWORD Type of risk

!

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

!

Injury

Electrocution

- Following isolation from the mains supply, parts

of the appliance may remain live for up to 2 minutes since the capacitors still have to discharge

into the inverter.

- Never interrupt the power supply, even outside

the heating period. The system’s active frost protection is not guaranteed if the power supply is

interrupted.

- If the heat pump and frost protection are completely switched off, drain the system on the

water side.

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

injury or death.

WARNING Failure to observe this information may result in serious

injury or death.

CAUTION Failure to observe this information may result in non-seri-

ous or minor injury.

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 3

Page 4

OPERATION

Safety

1.2 Other symbols in this documentation

Note

General information is identified by the symbol shown

on the left.

Read these texts carefully.

Symbol Meaning

!

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

Material losses

(appliance and consequential losses, environmental pollution)

Appliance disposal

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

1.4 Standardised output data

Explanations to determine and interpret the specified standardised

output data.

1.4.1 EN 14511

The output data specifically mentioned in text, diagrams and

technical datasheets has been calculated according to the test

conditions of the standard shown in the heading of this section.

However, there is a deviation from this norm in the output data for

air/water inverter heat pumps at source temperatures of > -7°C

as this concerns partial load values. The associated percentage

weighting in the partial load range can be found in EN14825 and

EHPA quality label regulations.

Generally, the test conditions stated above will not fully meet the

conditions found at the installation site of the system user.

Depending on the chosen test method and the extent to which

this method deviates from the test conditions defined in the first

paragraph of this section, any deviations can have a considerable

impact.

Further factors that have an influence on the test values are the

measuring equipment, the system configuration, the age of the

system and the flow rates.

A confirmation of the specified output data can only be obtained

if the test conducted for this purpose is also performed in accordance with the test conditions defined in the first paragraph

of this section.

2. Safety

2.1 Intended use

Observe the application limits listed in chapter "Specification /

Data table".

This appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a non-domestic environment, e.g. in a small business, as long as it is used

in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 Safety instructions

Observe the following safety instructions and regulations.

- Only qualified contractors should carry out the electrical

work and installation of this appliance.

- The qualified contractor is responsible for adherence to all

currently applicable instructions during installation and

commissioning.

- Operate the appliance only when fully installed and with all

safety equipment fitted.

- Protect the appliance from dust and dirt ingress during

building work.

WARNING Injury

!

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how provided

that they are supervised or they have been instructed

on how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

4 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 5

OPERATION

Appliance description

3. Appliance description

3.1 Properties

The appliance is a heating heat pump for outdoor installation that

operates as an air | water heat pump. Heat is extracted from the

outdoor air at a low temperature level, and is then transferred to

the heating water at a higher temperature. The heating water can

be heated up to a flow temperature of 65°C.

The appliance is equipped with an electric emergency/booster

heater (DHC). If the dual mode point can no longer be maintained

in mono mode operation, the electric emergency/booster heater is activated to safeguard heating operation and the provision

of high DHW temperatures. In such cases, the electric emergency/booster heater is activated in mono energetic operation as a

booster heater.

This appliance has further operational characteristics:

- Suitable for underfloor and radiator heating.

- Preferred for low temperature heating systems.

- Extracts heat from the outdoor air even at –20 °C outside

temperature.

- Corrosion-protected, external casing made from hot-dipped

galvanised sheet steel plus stove-enamelled finish.

- Comprises all components and safety equipment required for

operation.

- Filled with non-combustible safety refrigerant.

Note

For centralised control of the heating system you will

need heat pump manager WPM.

3.2 Function

3.2.1 Heating

Heat is extracted from the outdoor air via the heat exchanger

(evaporator) on the air side. The evaporated refrigerant is compressed by a compressor. Electrical energy is necessary for this

process. At this point, the refrigerant is at a higher temperature

level. A further heat exchanger (condenser) transfers the heat to

the heating circuit. During this process, the refrigerant expands,

and the cycle restarts from the beginning.

At air temperatures below approx. +7 °C, the humidity in the air

condenses as hoarfrost on the evaporator fins. Any hoarfrost is

automatically defrosted. Water created by this process collects in

the defrost pan and is drained off via a hose.

The heat pump automatically reverts to heating mode at the end

of the defrost cycle.

Material losses

!

In dual mode operation, the return water of the second

heat generator can flow through the heat pump. Please

note that the return temperature must be no higher than

60°C.

3.2.2 Cooling

Material losses

!

The heat pump is not suitable for continuous, year-round

cooling.

Observe the application limits (see chapter “Specifi-

cation / Data table”).

Rooms are cooled by reversing the heat pump circuit. Heat is

extracted from the heating water and the evaporator transfers

this heat to the outdoor air.

Area cooling requires the installation of the FEK remote control

unit in a reference room to capture the relative humidity and the

room temperature as part of monitoring the dew point.

Heat pump application limit

The heat pump is switched off if the outside temperature falls

below the selected lower application limit for cooling (parameter

LIMITCOOLING).

4. Settings

The system is operated exclusively by the WPM heat pump manager.

Please observe the heat pump manager operating and instal-

lation instructions.

Material losses

!

In the defrost cycle, the fan is switched off and the heat

pump circuit is reversed. The heat required for defrosting

is drawn from the buffer cylinder. For operation without a

buffer cylinder, observe chapter „Operation / Menu structure / Menu SETTINGS/ STANDARD SETTING / BUFFER

OPERATION“ in the operating and installation instructions

of the WPM. Otherwise the heating water freezes under

unfavourable conditions.

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 5

Page 6

OPERATION

Maintenance and care

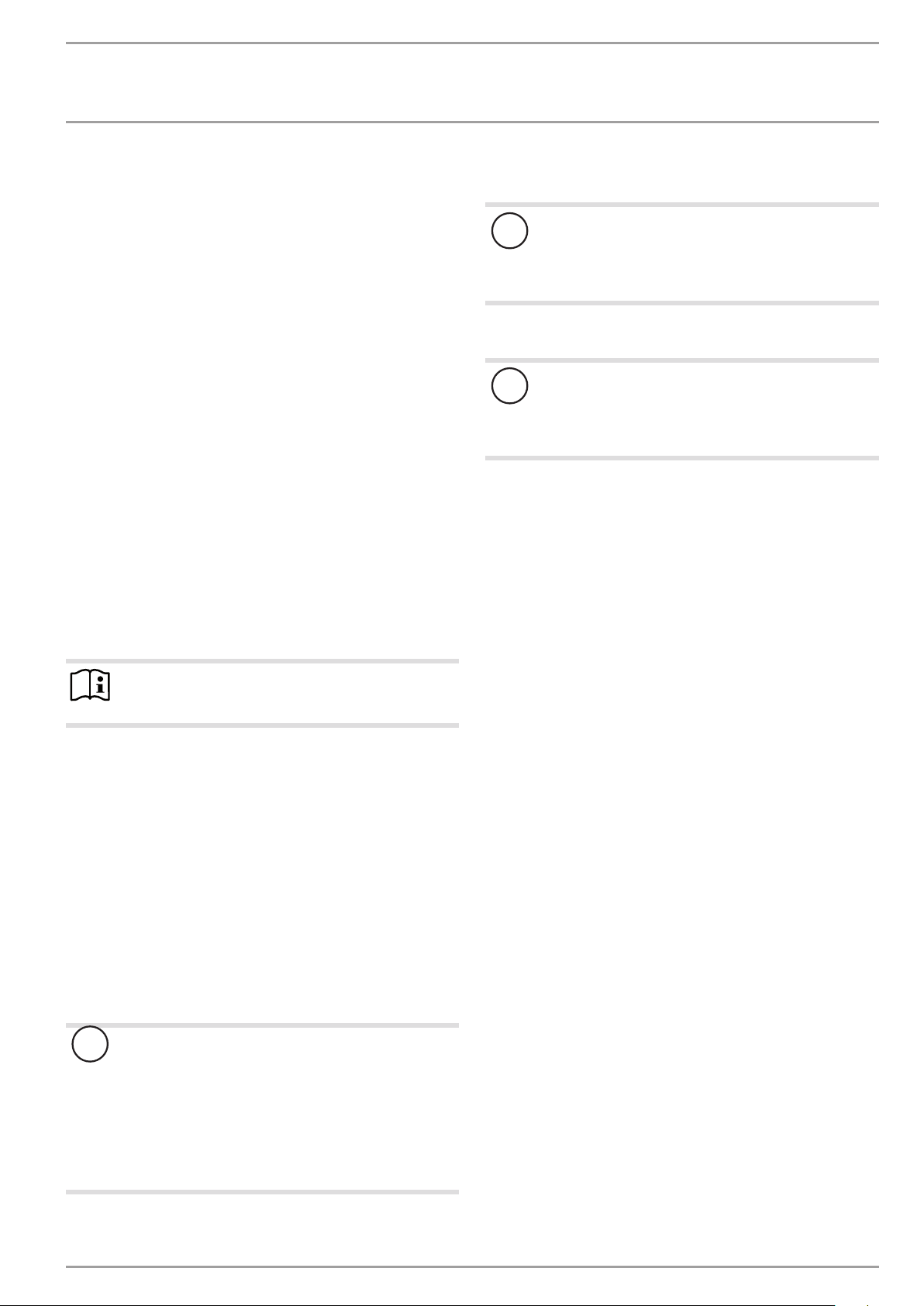

5. Maintenance and care

Material losses

!

Maintenance work, such as checking the electrical safety,

must only be carried out by a qualified contractor.

A damp cloth is sufficient for cleaning all plastic and sheet metal

parts. Never use abrasive or corrosive cleaning agents.

Regularly check the condensate drain (visual inspection). Remove

contamination and blockages immediately (see chapter "Installation/ Condensate drain").

1.

2.

1

1 Inspection port

6. Troubleshooting

Fault Cause Remedy

There is no hot

water or the heating system stays

cold.

The external unit

leaks water.

This can cause the

humidity in the

outdoor air to accumulate as dew or

frost on the cooled

heat pump casing

Note

Even when the condensate is draining away correctly,

expect water to drip from the appliance onto the floor.

If you cannot remedy the fault, notify your qualified contractor.

To facilitate and speed up your enquiry, please provide the serial

number from the type plate. The type plate is located at the front

top, on the right or left hand side of the casing.

D0000037831

Sample type plate

No power at the appliance.

The condensate drain may be

blocked.

The heat pump is drawing

heat from the outdoor air to

heat the building. This can

cause the humidity in the

outdoor air to accumulate as

dew or frost on the cooled

heat pump casing. This is not

a defect.

Check the fuses/MCBs in

your fuse box/distribution

panel. Replace the fuses/

reset the MCBs if required.

Notify your qualified contractor if the fuses/MCBs

blow/trip again.

Clean the condensate drain

as described in „Maintenance and care“.

Material losses

!

Keep the air discharge and intake apertures free from

snow and leaves.

We recommend an annual inspection (to establish the current condition of the system), and maintenance by a qualified contractor if

required (to return the system to its original condition).

Protect the appliance from dust and dirt ingress during building

work.

Montageanweisung beachten! Dichtheit geprüft!

1 Number on the type plate

Made in Germany

*xxxxxxxxxxxxxxxxxx*

1

26�03�01�1736

6 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 7

INSTALLATION

Safety

INSTALLATION

7. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free function and operational reliability only

if original accessories and spare parts intended for the appliance

are used.

7.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

8. Appliance description

The appliance offers frost protection for the connection lines. The

integral frost protection circuit starts the circulation pump in the

heat pump circuit automatically at a condenser temperature of

8 °C, and thereby ensures circulation in all water-carrying sections. If the temperature inside the buffer cylinder drops, the heat

pump starts automatically no later than when the temperature

falls below +5°C.

8.1 Standard delivery

The following are delivered with the appliance:

- Wiring diagram

9. Preparations

The appliance is designed for siting in front of a wall. Observe the

minimum clearances. If the appliance is installed in an open space

or on a roof, protect the air intake side. Do this by erecting a wall

to shield it against the wind.

9.1 Sound emissions

The appliance is louder on the air intake and air discharge sides

than on the two enclosed sides. Observe the following information

when selecting the installation location.

Note

For details regarding the sound power level, see chapter

"Specification / Data table".

- Lawn areas and shrubs help reduce the spread of noise.

- Sound propagation can also be reduced by installing closely

spaced palisade fencing around the appliance.

Ensure that the air intake direction is the same as the main

wind direction.

Air should not be blown out against the wind.

Never direct the air intake or discharge towards noise-sensi-

tive rooms of the house, e.g. bedrooms.

Avoid installation on large, echoing floor areas, e.g. tiled

floors.

Avoid installation between reflective building walls. Reflect-

ing building walls can increase the sound level.

Maintain the minimum clearances to ensure trouble-free op-

eration of the appliance and facilitate maintenance work.

8.2 Accessories

8.2.1 Required accessories

- Heat pump manager in wall mounting enclosure, WPM

8.2.2 Further accessories

- Remote control for heating systems FEK

- Remote control for heating systems FE7

- Ribbon heater HZB-1

- Ribbon heater HZB-2

- Safety temperature controller for underfloor heating system

STB-FB

- T-support SK-WPL

- Wall mounting support WK 2

- Mounting bracket MK 1

- Connection set AS-WP 1

- Connection set AS-WP 2

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 7

Page 8

INSTALLATION

750

Preparations

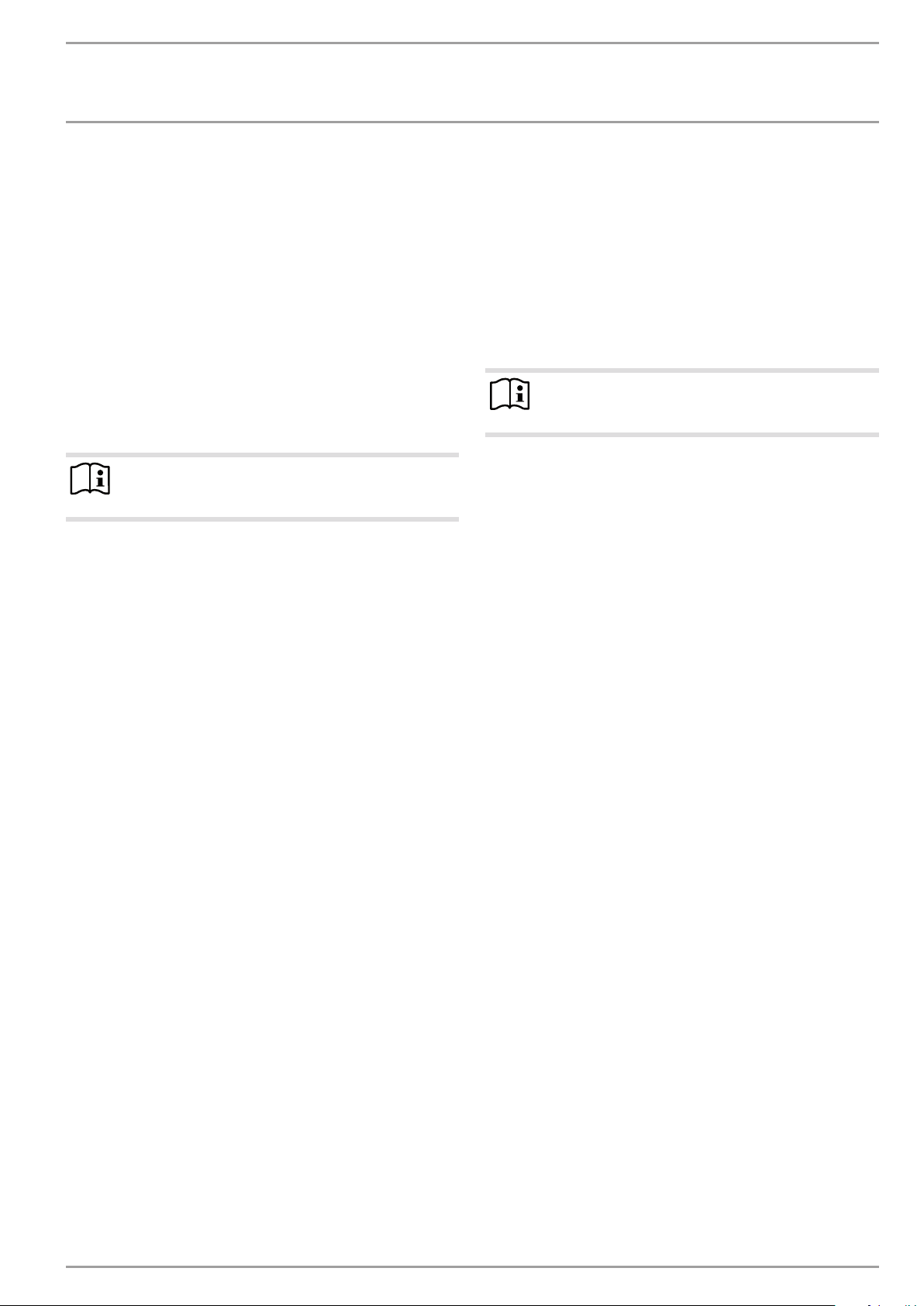

9.2 Minimum clearances

≥1000

≥800

≥300

≥500

9.4 Siting

Note

If the condensate drain hose is not laid with frost protection or is exposed to severe weather conditions, installation of a ribbon heater is recommended both with the

plinth and the wall mounting support.

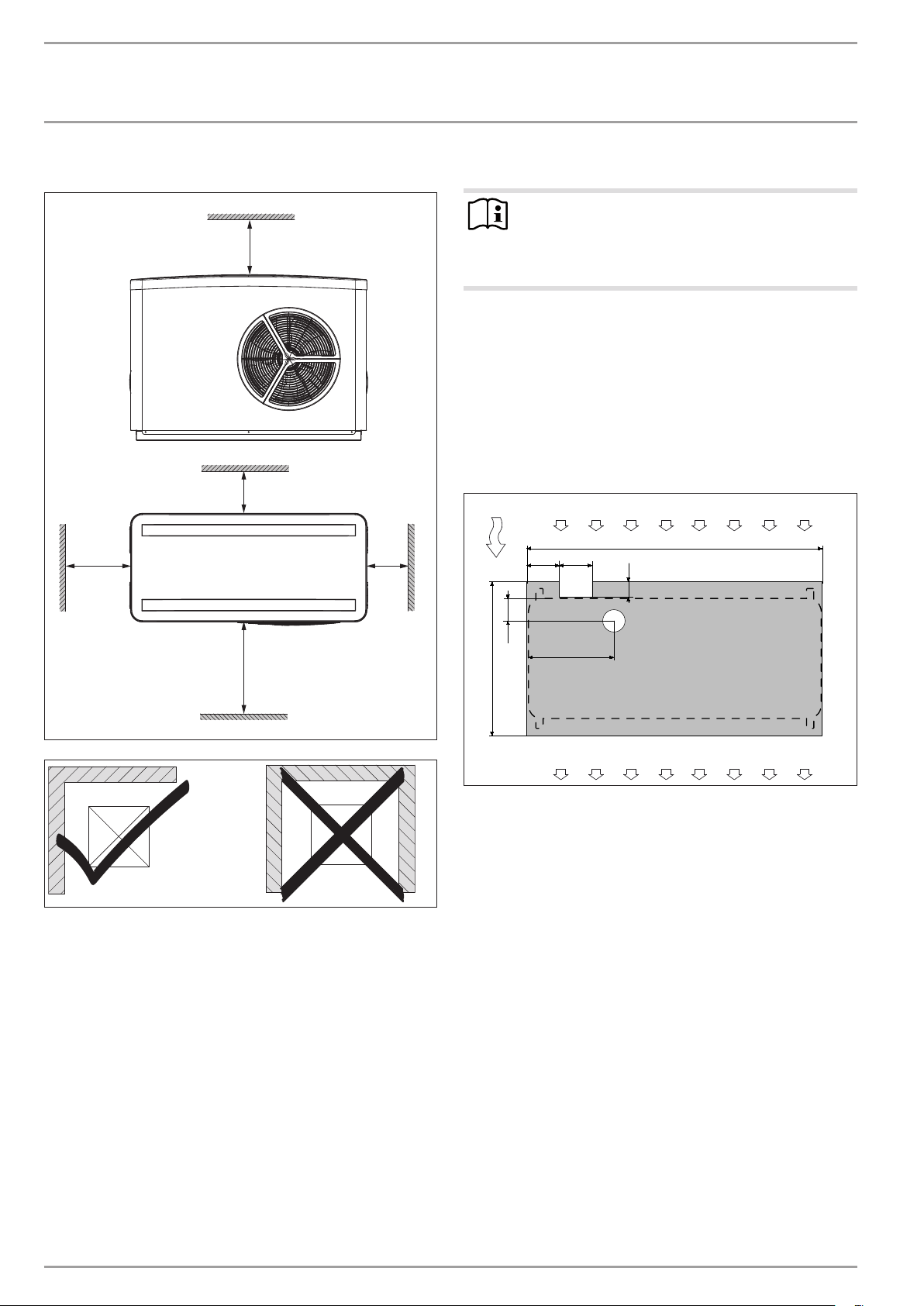

9.4.1 Example: Pipe routing above ground or mounting

bracket MK 1

- The substrate must be horizontal, level, solid and permanent.

Ensure the entire appliance frame is in full contact with the

substrate. Uneven substrates can increase noise emissions.

If the supply lines are run downwards through the ground, they

must be laid in a recess (space) in the foundation.

WPL15AS| WPL15ACS

1

3

200

140

4

1300

75

≥2000

Do not install the appliance in a recess. Two sides of the ap-

pliance must remain exposed.

9.3 Preparation of the installation location

Observe chapter “Sound emissions”.

Ensure that the appliance is accessible from all sides.

5

100

D000002829991�00�00�0036

410

2

1 Air intake

2 Air discharge

3 Main wind direction

4 Supply line recess

5 Condensate drain recess (minimum diameter 70mm)

Ensure that the foundations offer the necessary recess.

D0000034133

8 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 9

INSTALLATION

750

6

1

Preparations

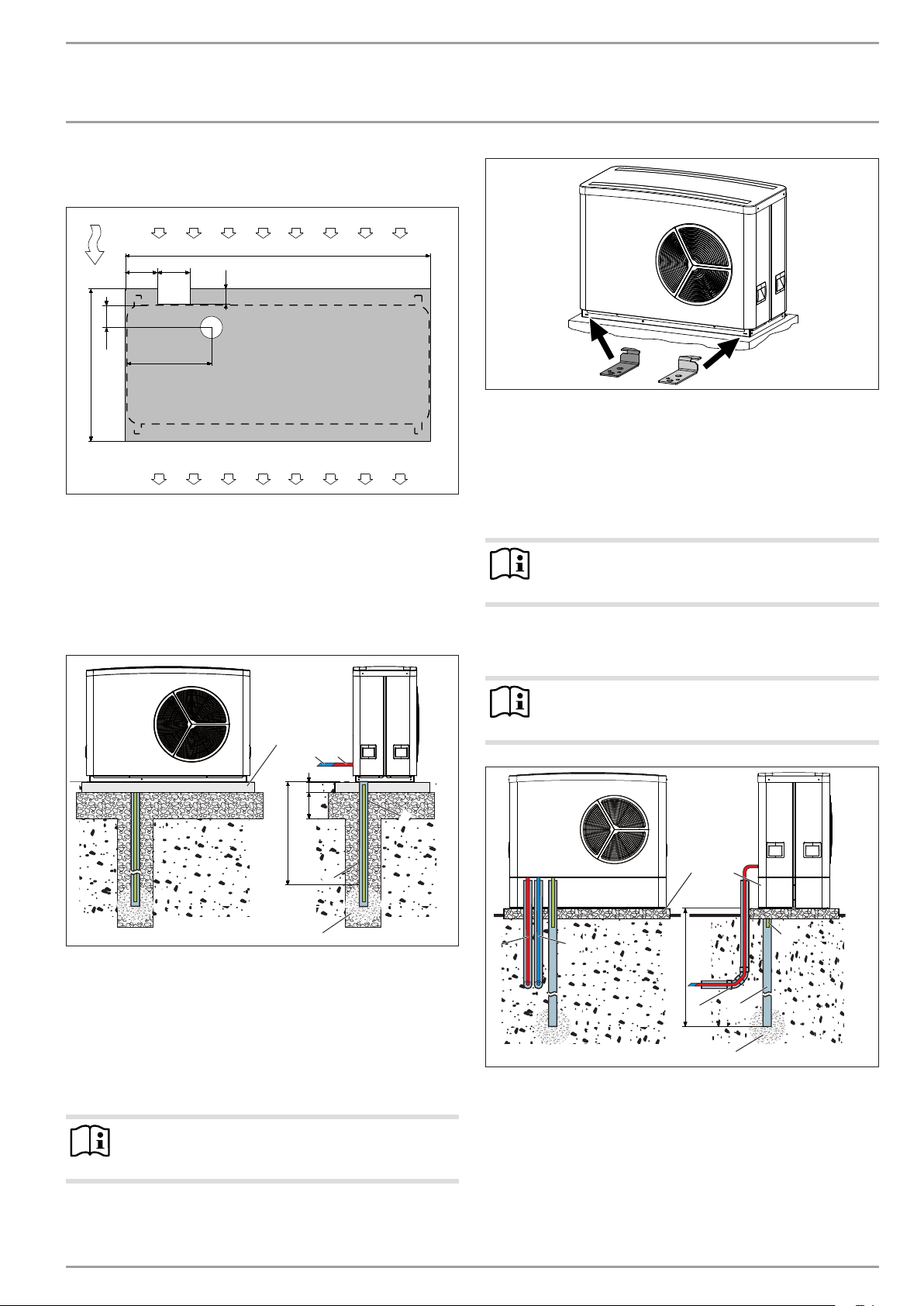

WPL20A| WPL20AC| WPL25A| WPL25AS| WPL25AC|

WPL25ACS

1

3

200

140

4

5

100

410

1 Air intake

2 Air discharge

3 Main wind direction

4 Supply line recess

5 Condensate drain recess (minimum diameter 70mm)

Ensure that the foundations offer the necessary recess.

1500

75

2

Hook two brackets respectively into the lateral slots on the

front and back. Ensure you are using the correct brackets for

the left and right hand slots respectively.

Position the brackets so that the groove on the bracket is

D0000028298

hooked into the appliance.

Secure the appliance to the foundations using the brackets

and suitable rawl plugs and screws.

Note

Do not use the screws with which the appliance was

secured to the transport pallet.

D0000064201

Example: Laying pipes above ground

Example: Mounting bracket MK 1 (only WPL15AS |

WPL15ACS)

Note

The mounting bracket cannot be used in combination

with the connection sets (AS-WP1 and AS-WP2).

4

5

1

2

A

7

3

8

A 100

B 300

C Depth of frost line

1 Heating flow

5

2

1

AB

3

C

4

D0000028297

2 Heating return

3 Condensate drain

4 Condensate drain pipe

5 Foundation

6 Gravel bed

A Depth of frost line

1 Heating flow

6

D0000060818

2 Heating return

Note

The transport brackets can be used to secure the appliance to the foundations.

3 Conduit for supply lines

4 Foundation

5 Mounting support

6 Gravel bed

7 Drainage pipe

8 Condensate drain

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 9

Page 10

INSTALLATION

Preparations

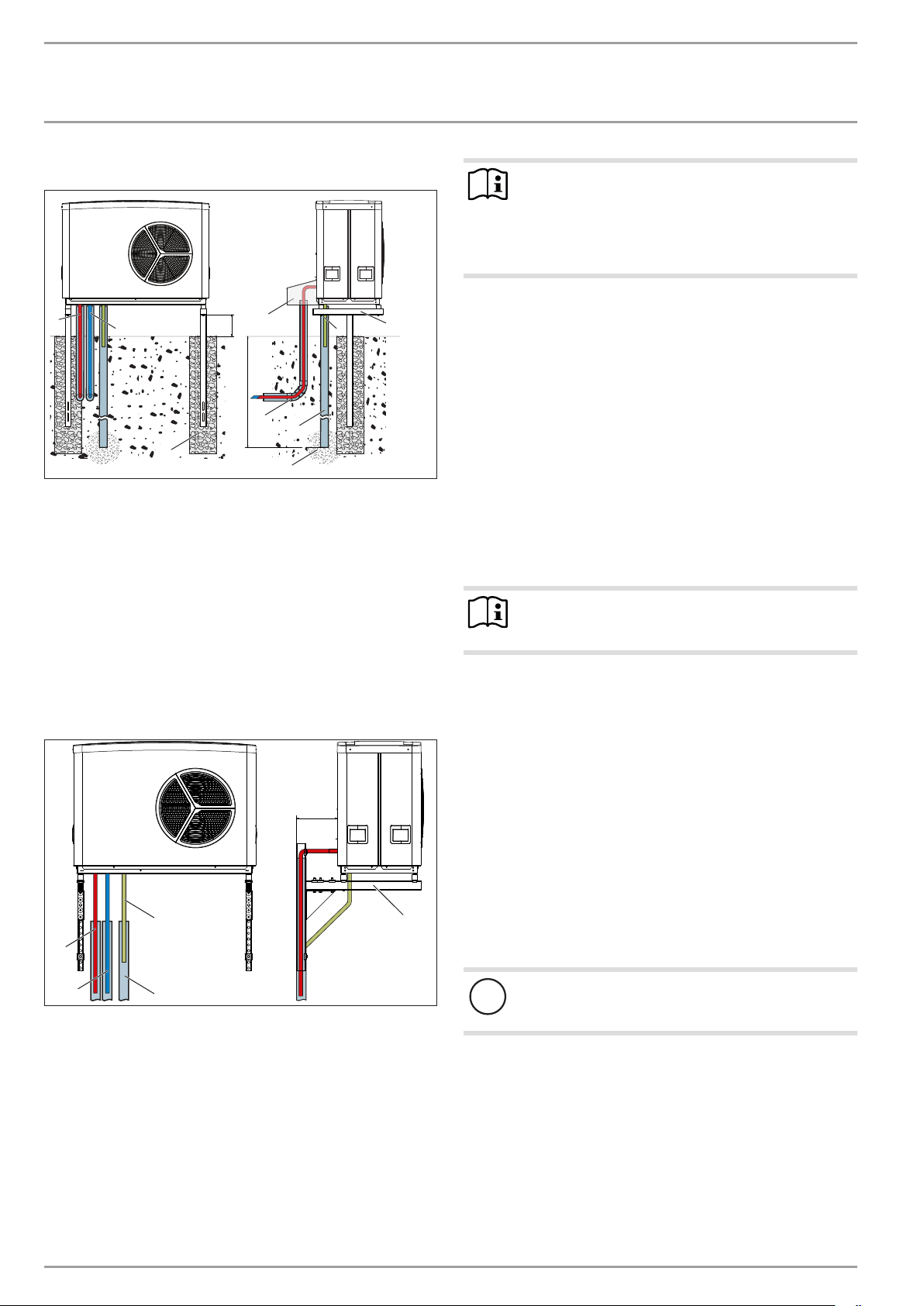

9.4.2 Example: T-support SK-WPL

1

A Depth of frost line

B 300

1 Heating flow

2 Heating return

3 Conduit for supply lines/cables

4 Foundation

5 T-support

6 Gravel bed

7 Drainage pipe

8 Condensate drain

9 Cover

Observe the static limits of the T-support used.

9.4.3 Example: Wall mounting support WK 2

2

4

9

B

A

3

7

6

Note

To prevent disturbance due to structure-borne noise

transmission, never install the wall mounting bracket on

the external walls of living areas or bedrooms.

Install the wall mounting bracket, for example, on a

garage wall.

8

5

9.5 Installing supply lines and supply cables

The supply lines are all electric cables plus the heating flow and

return lines.

Use only weather-resistant cables, e.g. NYY.

Protect the flow and return lines against frost, with sufficient

thermal insulation. Provide the thermal insulation in accordance with applicable regulations.

Also protect all supply lines/cables against humidity, damage

D0000050006

and UV radiation by means of a conduit.

Protect the supply lines and cables routed through the

ground from moisture and damage by routing them through

a conduit.

Protect all pipe fixings and outer wall transitions with an-

ti-vibration insulation.

Note

When routing the condensate hose, observe chapter "Installation / Condensate drain".

9.6 WPM heat pump manager

A WPM heat pump manager is required to operate the appliance.

This controls the entire heating system.

≥300

3

1

2

1 Heating flow

2 Heating return

3 Condensate drain

4 Drainage pipe

5 Wall mounting bracket

Observe the static limits of the wall mounting support used.

4

9.7 Buffer cylinder

A buffer cylinder is recommended to ensure trouble-free appliance

operation.

The buffer cylinder provides hydraulic separation of the volume

flows in the heat pump circuit and heating circuit, and also serves

as an energy source for defrosting.

When operating without a buffer cylinder, observe the de-

5

D0000058719

tails specified in chapter „Minimum flow rate with individual

room controller by means of FEK / FE7 in the case of systems

without buffer cylinder“.

Material losses

!

A buffer cylinder with diffusion-proof insulation is essential for cooling mode.

10 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 11

INSTALLATION

Installation

9.8 Preparing the electrical installation

WARNING Risk of electrocution!

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

WARNING Risk of electrocution!

Use a permanent connection to the power supply. The

appliance must be able to be separated from the power

supply by an isolator that disconnects all poles with at

least 3mm contact separation. This requirement can be

met by contactors, isolators, fuses, etc.

Material losses

!

The specified voltage must match the mains voltage. Observe the type plate.

Material losses

!

Provide separate fuses for the 3 power circuits (for the

appliance, the electric emergency/booster heater and the

control unit).

Lay the relevant pipe cross-sections. Observe the applicable

national and regional regulations.

Fuse protection Assignment Cable cross-section

10. Installation

Note

The device is designed in such a way that it can be positioned and connected without removing the cover or

side panels.

10.1 Handling

Use the recessed grips provided at the sides.

Material losses

!

Protect the appliance against heavy impact during

transport.

Only allow the appliance to be tilted during transport for a short

time to one of its longitudinal sides. The longer the appliance is

tilted, the greater the distribution of refrigerant oil in the system.

Wait approx. 30 minutes before starting the appliance after it has

been tilted.

10.2 Siting

When installing the appliance, observe the air intake

direction.

Position the standard appliance on the prepared substrate.

1x C 20 A

1x C 35 A

3x C 16 A

2x B 16 A

3x B 16 A

1x B 16 A Control 1.5 mm²

The electrical data is provided in the "Specification" chapter. You

require a J-Y (St) 2x2x0.8mm² cable as BUS cable.

Note

The appliance contains an inverter for the variable speed

compressor. In case of a fault inverters can cause DC

residual currents. If RCDs are provided, they have to be

type B AC/DC-sensitive.

A DC residual current can block type A RCDs.

Heat pump

(single phase)

WPL 15 AS

WPL 15 ACS

Heat pump

(single phase)

WPL 25 AS

WPL 25 ACS

Heat pump

(3-phase)

WPL 20 A

WPL 20 AC

WPL 25 A

WPL 25 AC

Electric emergency/booster

heater WPL15AS

WPL15ACS

WPL25AS

WPL25ACS

Electric emergency/booster heater

WPL 20 A

WPL 20 AC

WPL25A

WPL25AC

Make sure that the appliance power supply is dis-

connected from the fuse board/distribution panel.

2.5 mm² for routing above the surface

4.0 mm² for routing through a wall

6.0 mm² for routing through a wall

2.5 mm²

2.5 mm²

2.5 mm²

Note

The appliance can be secured to a foundation with screws

as additional protection against tipping over.

Use the accessories that were in place to secure the

appliance to the transport pallet.

10.3 Heating water connection

The heat pump heating system must be connected by a qualified

contractor in accordance with the water installation drawings,

which are part of the technical guides.

Thoroughly flush the pipework before connecting the heat

pump. Foreign bodies, such as welding beads, rust, sand,

sealant, etc. can impair the operational reliability of the heat

pump.

Connect the heat pump on the heating water side. Check for

tightness.

Ensure the correct connection of the heating flow and return.

To facilitate connection to the heating system, push-fit connectors

are enclosed with the appliance (see chapter "Fitting the push-fit

connectors").

Provide the thermal insulation in accordance with applicable

regulations.

When designing the heating circuit, observe the internal

pressure difference (see chapter "Specification / Data table").

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 11

Page 12

INSTALLATION

Installation

10.4 Flow and return connection

Material losses

!

Insulate the heating flow and return lines for cooling

mode with vapour diffusion-proof material.

Take the position of the heating flow and return from the fol-

lowing figure:

1

2

4

3

1 Heating flow

2 Heating return

3 Drain

4 Ventilation

Connect the heat pump to the heating circuit. Check for

tightness.

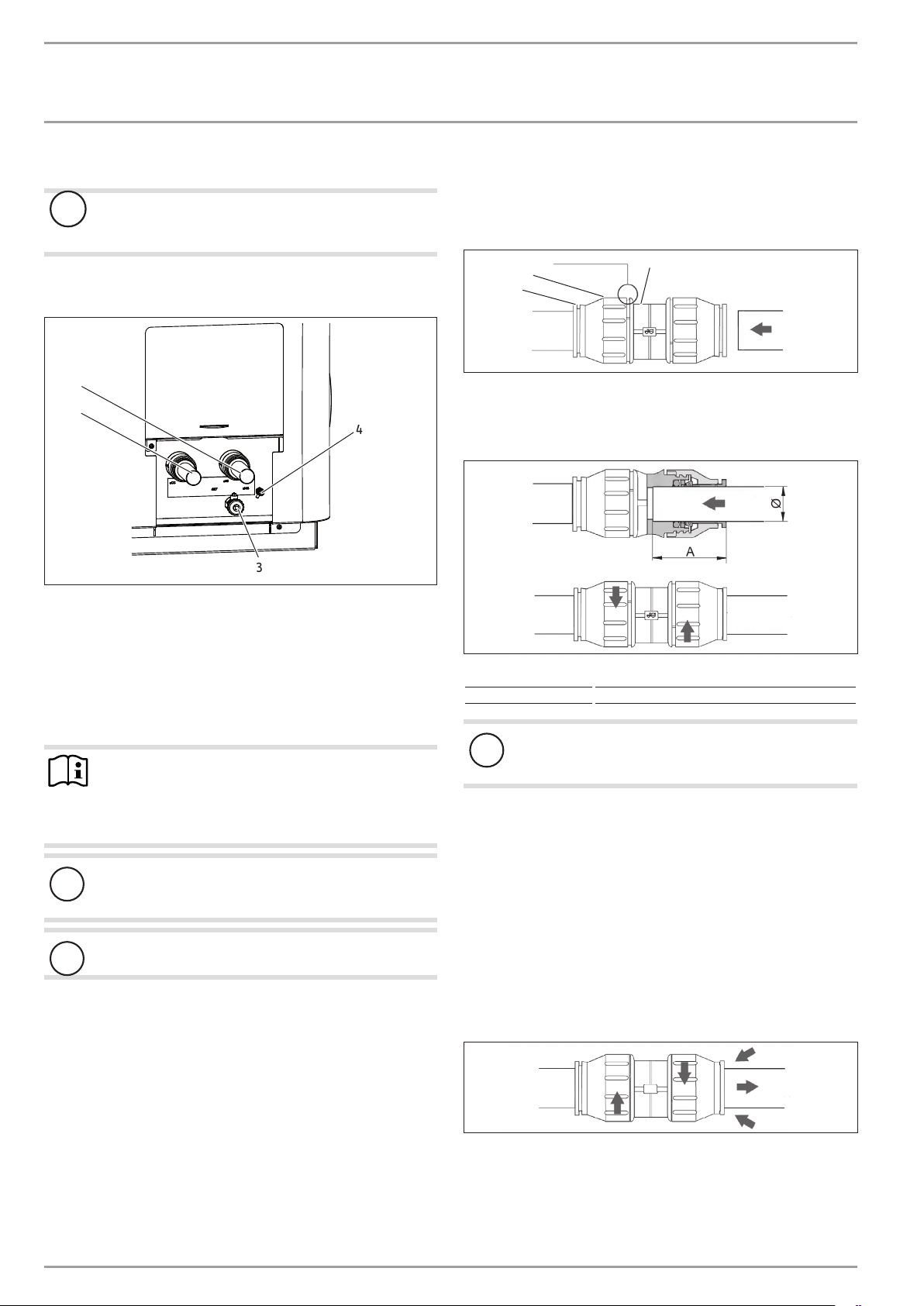

Making the push-fit connection

The connector must be in its relaxed position before the pipe is

inserted. In this position, there is a small gap between the screw

cap and main body.

3

2

1

1 Retainer

2 Screw cap

3 Gap between screw cap and main body

4 Main body

26�03�01�1871

Pipe Ø 28 mm

Depth of insertion A 44 mm

4

26�03�01�0693

26�03�01�0693

10.5 Fitting the push-fit connector

Note

The plastic push-fit connectors are not suitable for installation in the DHW line or the solar circuit.

Only install the push-fit connectors in the heating or

brine circuits.

Material losses

!

Tighten the screw cap of the push-fit connector by hand.

Never use a tool.

Material losses

!

Support sleeves are required when using plastic pipes.

How the push-fit connectors work

The push-fit connectors are equipped with a retainer with stainless steel serrations and an O-ring seal. In addition, the pushfit connectors are equipped with the “twist and lock” function.

Simply turning the screw cap by hand will secure the pipe in the

connector and push the O-ring against the pipe to seal it.

Material losses

!

Pipe ends must be deburred.

Always use a pipe cutter to trim pipes.

Push the pipe through the O-ring into the push-fit connector

until it reaches the prescribed insertion depth.

Tighten the screw cap by hand against main body as far as it

will go. This locks the push-fit connection.

Undoing the push-fit connection

If the push-fit connectors later need to be undone, proceed as

follows:

Turn the screw cap anti-clockwise until there is a narrow gap

of approx. 2mm. Press the retainer back with your fingers

and hold on to it.

Pull out the inserted pipe.

26�03�01�0693

12 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 13

INSTALLATION

Installation

10.6 Oxygen diffusion

Material losses

!

Avoid open heating systems and plastic pipes in underfloor heating systems which are permeable to oxygen.

In underfloor heating systems with plastic pipes that are permeable to oxygen and in open vented heating systems, oxygen

diffusion may lead to corrosion on the steel components of the

heating system (e.g. on the indirect coil of the DHW cylinder, on

buffer cylinders, steel heating elements or steel pipes).

Material losses

!

The products of corrosion (e.g. rusty sludge) can settle in

the heating system components and can result in a lower

output or fault shutdowns due to reduced cross-sections.

10.7 Filling the heating system

Fill the heating system via the drain (see chapter "Specifica-

tion / Dimensions").

10.7.1 Water quality

Before the system is filled, a fill water analysis must be made

available. This may, for example, be requested from the relevant

water supply utility.

To avoid damage as a result of scaling, it may be necessary to

soften or desalinate the fill water. The fill water limits specified

in chapter "Specification / Data table" must always be observed.

Recheck these limits 8-12 weeks after commissioning and as

part of annual system maintenance.

Note

With conductivity of >1000μS/cm, desalination treatment

is recommended in order to avoid corrosion.

Note

If you treat the fill water with inhibitors or additives, the

same limits as for desalination apply.

Note

Suitable appliances for water softening, as well as for

filling and flushing heating systems, can be obtained via

trade suppliers.

10.7.2 Venting the heating system

1

1 Ventilation

Vent the pipework by activating the ventilation.

10.8 Minimum flow rate

For heating operation without buffer cylinder, ensure the minimum flow rate and the availability of defrost energy.

10.9 Setting the flow rate on the heating side

Material losses

!

For operation without a buffer cylinder, it is essential

that the electric emergency/booster heater (DHC) is connected.

The appliance is designed in such a way that no buffer cylinder

is required to provide hydraulic separation of the flow in the heat

pump circuit and the heating circuit in conjunction with panel

heating systems.

We recommend the use of a buffer cylinder for installations with

several heating circuits.

The setting is made in heat pump mode. For this, make the following settings first:

Temporarily remove the fuse from the electric emergency/

booster heater to isolate the emergency/booster heater from

the power supply. Alternatively, switch OFF the second heat

generator.

Operate the appliance in heating mode.

26�03�01�1871

10.9.1 Minimum flow rate with individual room controller by

means of FEK / FE7 in systems without buffer cylinder

For systems without a buffer cylinder, in menu „SETTINGS/ HEATING/ STANDARD SETTING“, set parameter „BUFFER OPERATION“

to „OFF“.

In such cases, one or more heating circuits in the heating system

must be left open. Ensure the minimum flow rate (see „Specification / Data table“) by means of the correspondingly opened heating circuits (see table „Design recommendation for an underfloor

heating system inside the lead room“).

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 13

Page 14

INSTALLATION

Installation

Design recommendation for underfloor heating system inside the lead room:

Material losses

!

A buffer cylinder with diffusion-proof insulation is essential for cooling mode.

Minimum flow

rate

l/h l m² n x m m² n x m

WPL 15 AS 700 16 21 3x70 21 2x70

WPL 15 ACS 700 16 21 3x70 21 2x70

WPL 20 A 1000 29 28 4x70 32 3x70

WPL 20 AC 1000 29 28 4x70 32 3x70

WPL 25 A 1000 29 28 4x70 32 3x70

WPL 25 AS 1000 29 28 4x70 32 3x70

WPL 25 AC 1000 29 28 4x70 32 3x70

WPL 25 ACS 1000 29 28 4x70 32 3x70

Buffer cylinder always

required

WPL 15 AS no 100 200 yes

WPL 15 ACS no 100 200 yes

WPL 20 A no 200 400 yes

WPL 20 AC no 200 400 yes

WPL 25 A no 200 400 yes

WPL 25 AS no 200 400 yes

WPL 25 AC no 200 400 yes

WPL 25 ACS no 200 400 yes

Install the open heating circuit(s) in the lead room (room

where the external programming unit of the heat pump

control unit is installed, such as in the living room). The individual room can then be controlled either with the external

programming unit or directly by adjusting the heating curve

or the room influence.

Fully open the heating circuit(s) in the lead room.

Close all other heating circuits.

If an overflow valve has been installed in the heating system,

fully close this overflow valve in order to determine the minimum flow rate.

In combination with an hydraulic module, cylinder and hydraulic

module or integral cylinder:

Under menu item “COMMISSIONING/ HEATING” set the pa-

rameter “HEATING CIRC PUMP RATE” (heating circuit pump

rate) so that the minimum flow rate required for system op-

Minimum water content of buffer

cylinder or open circuits

Recommended buffer cylinder

volume, underfloor heating

Composite pipework 16 x 2mm

/ rout ing gap 10cm

Lead room

floor area

Number of circuits

Recommended buffer cylinder

volume, radiators

Composite pipework 20x2.25mm /

rout ing gap 15cm

Lead room

floor area

Number of circuits

Activat ing the integral

emergency/booster

heater

10.9.2 Minimum flow rate for systems with buffer cylinder

When using a buffer cylinder, in menu „SETTINGS/ HEATING/

STANDARD SETTING“, set parameter „BUFFER OPERATION“ to

„ON“.

In combination with an hydraulic module, cylinder and hydraulic

module or integral cylinder:

Under menu item “COMMISSIONING/ HEATING” set the pa-

rameter “HEATING CIRC PUMP RATE” so that the nominal

flow rate required for system operation is assured (see chapter “Specification/ Data table”).

If the appliance is operated on its own with a WPM:

Set the buffer charging pump so that the nominal flow rate

required for system operation is assured.

The current flow rate can be called up in the menu „INFO/ HEAT

PUMP INFO/ PROCESS DATA“ under „WP WATER FLOW RATE“.

eration is assured (see chapter “Specification / Data table”).

If the appliance is operated on its own with a WPM:

Set the heating circuit pump so that the minimum flow rate

required to operate the system is safeguarded.

The current flow rate can be called up in the menu „INFO/ HEAT

PUMP INFO/ PROCESS DATA“ under „WP WATER FLOW RATE“.

14 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 15

INSTALLATION

Power supply

10.10 Condensate drain

A condensate drain connector is factory fitted to the defrost pan

to enable any condensate that may form to drain off.

1

1 Condensate drain

If required, you may install a supplementary heating facility inside

the condensate drain pipe on site. We recommend that you install

a supplementary heating facility if the routing of the condensate

hose means it is at risk of frost or is fully exposed to the elements.

If the appliance is mounted on a wall mounting bracket or T-support, a supplementary heating facility must be fitted.

If the appliance is mounted on a wall bracket or T-support,

attach a condensate hose to the condensate drain.

Protect the condensate hose against frost with sufficient

thermal insulation.

11. Power supply

WARNING Electrocution

Before any work, isolate the appliance from the

power supply at the control panel.

Following isolation from the mains supply, parts of the

appliance may remain live for up to 2 minutes since

the capacitors still have to discharge into the inverter.

The connection must only be carried out by a qualified contractor

and in accordance with these instructions.

Permission to connect the appliance may need to be obtained from

your local power supply utility.

Note

Observe the operating and installation instructions for

the WPM heat pump manager.

The terminals are located in the wiring chamber of the appliance.

Observe chapter "Preparing the electrical installation".

26�03�01�1868

Use appropriate electrical cables in accordance with local

regulations for all connections.

Access to the wiring chamber

Material losses

!

Ensure the condensate hose is not kinked. Route the hose

with a slope.

After routing the condensate hose, check that the condensate

can drain correctly.

Please also observe the chapter "Electrical connection of sup-

plementary heating facility".

10.11 External second heat generator

For dual mode systems, always connect the heat pump into the

return of the second heat generator (e.g. oil boiler).

10.12 Safety temperature controller for underfloor

heating system STB-FB

Material losses

!

In case of failure, in order to prevent an excessively high

flow temperature in the underfloor heating system, we

generally recommend the use of a safety temperature

controller to limit the system temperature.

D000003535626�03�01�1862

Push the cover upwards.

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 15

Page 16

INSTALLATION

Power supply

Connect the electric emergency/booster heater if you want to

utilise the following appliance functions:

1 2

1 Strain relief

2 Wiring chamber

Route cables and leads through the strain reliefs.

If space behind the appliance is limited, the wiring chamber can

be folded out.

Appliance function

Mono energetic operation

Emergency mode Should the heat pump suffer a fault that prevents its

Heat-up program

(only for underfloor

heating systems)

26�03�01�1865

Pasteurisation

control

Effect of the electric emergency/booster

heater

If the heat pump cannot reach the dual mode point, the

electric emergency/booster heater ensures both the

heating operation and the provision of high DHW temperatures.

continued operation, the heating output will be covered

by the electric emergency/booster heater.

Where return temperatures are <25°C, the electric

emergency/booster heater must provide the necessary

heat for screed drying.

With these low system temperatures, the drying heat

must not be provided by the heat pump, otherwise the

frost protection of the appliance can no longer be guaranteed during the defrost cycle.

When the heat-up program has ended, you can disconnect the electric emergency/booster heater if it is not

required for the appliance operation.

Please note that during the heat-up program, the emergency mode cannot be selected.

The electric emergency/booster heater starts automatically when the pasteurisation control is active in order to

regularly heat the DHW to 60°C to protect it against the

growth of legionella bacteria.

Connect cables according to the following diagram.

Earth the LV lead by inverting the screen over the external

sheath and clamping it under the earth terminal.

Then check the function of the strain relief fittings.

26�03� 01�186326�03�01�1864

16 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 17

INSTALLATION

Power supply

11.1 Power connection WPL15AS| WPL15ACS

4 3215

X2

T

L

H

„+“

BUS

N LL N L N

X5 / DHC X3 / WP X4 / Steuerung

1/N/PE~230/50

C 32A

3,0 kW L N PE

3,2 kW L N PE

6,2 kW L N L N PE

1/N/PE~230/50

C 20A

1 X5 Electr ic emergency/booster heater (DHC)

L, N, L, N, PE

Connected load Terminal allocat ion

3,0 kW L N PE

3,2 kW L N PE

6,2 kW L N L N PE

2 X3 Compressor (inverter)

L, N, PE

3 X4 Control voltage

Power supply: L, N, PE

4 X2 Low voltage (BUS cabl e)

BUS High H

BUS Low L

BUS earth

BUS "+" (is not connected)

5 Earth terminal for screening the LV lead

The tested appliance conforms to IEC 61000-3-12.

The maximum permissible mains impedance is indicated in chapter “Specification / Data table”.

ERR

1/N/PE~230/50

C 16A

LON-

N

11.2 Power connection WPL20A| WPL20AC|

WPL25A| WPL25AC

4 3215

X2

T

L

H

„+“

BUS

D0000037825

1 X5 Electr ic emergency/booster heater (DHC)

L1, L2, L3, N, PE

Connected load Terminal allocat ion

2,6 kW L1 PE

3,0 kW L2 PE

3,2 kW L3 PE

5,6 kW L1 L2 PE

5,8 kW L1 L3 PE

6,2 kW L2 L3 PE

8,8 kW L1 L2 L3 PE

2 X3 Compressor (inverter)

L1, L2, L3, N, PE

3 X4 Control voltage

Power supply: L, N, PE

4 X2 Low voltage (BUS cabl e)

BUS High H

BUS Low L

BUS earth

BUS "+" (is not connected)

5 Earth terminal for screening the LV lead

L2 L3L1 N L2 L3L1 N

3/N/PE~400/50

X5 / DHC X3 / WP X4 / Steuerung

C 16A

2,6 kW L1 N PE

3,0 kW L2 N PE

3,2 kW L3 N PE

5,6 kW L1 L2 N PE

5,8 kW L1 L3 N PE

6,2 kW L2 L3 N PE

8,8 kW L1 L2 L3 N PE

3/N/PE~400/50

C 16A

ERR

1/N/PE~230/50

C 16A

LON-

N

26�03�01�1859

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 17

Page 18

INSTALLATION

Power supply

11.3 Power connection WPL25AS| WPL25ACS

4 3215

X2

T

L

H

„+“

BUS

N LL N L N

X5 / DHC X3 / WP X4 / Steuerung

1/N/PE~230/50

C 32A

3,0 kW L N PE

3,2 kW L N PE

6,2 kW L N L N PE

1/N/PE~230/50

C 36A

1 X5 Electr ic emergency/booster heater (DHC)

L, N, L, N, PE

Connected load Terminal allocat ion

3,0 kW L N PE

3,2 kW L N PE

6,2 kW L N L N PE

2 X3 Compressor (inverter)

L, N, PE

3 X4 Control voltage

Power supply: L, N, PE

4 X2 Low voltage (BUS cabl e)

BUS High H

BUS Low L

BUS earth

BUS "+" (is not connected)

5 Earth terminal for screening the LV lead

LON-

ERR

1/N/PE~230/50

C 16A

N

Closing the wiring chamber

1 Serrated washer

2 Screw

D0000037825

Secure the cover with the screw and serrated washer.

Connect the following components to the heat pump manag-

er in accordance with the technical guides:

- Circulation pump for the heat consumer side

- Outside temperature sensor

- Return sensor (only for operation with buffer cylinder)

11.4 Electrical connection of supplementary heating

facility

If required, you can mount a ribbon heater on the condensate pan

and the condensate hose on site. We recommend that you install

a ribbon heater if the routing of the condensate hose means it is

at risk of frost or is fully exposed to the elements. A ribbon heater

must be fitted if the condensate hose is installed on a wall mounting panel. See also chapter “Electrical connection”.

Access to the wiring chamber

1

2

D0000035356

Remove the cover.

18 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

26�03�01�1544

Page 19

INSTALLATION

Power supply

Closing the wiring chamber

A.

1 Electrical connection for ribbon heater

Power supply: L, N, PE

B.

1

D0000035975

26�03�01�1867

Position the cover on the appliance.

Secure the cover with the four screws.

D0000035976

D0000033168

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 19

Page 20

INSTALLATION

Commissioning

12. Commissioning

A WPM heat pump manager is required to operate the appliance.

All necessary adjustments prior to and during operation are made

on this device.

Only qualified contractors may carry out the adjustments on the

heat pump manager commissioning report, commission the appliance and instruct the owner in its use.

Carry out commissioning in accordance with these installation

instructions and the operating and installation instructions of the

heat pump manager. Our customer service can assist with commissioning, which is a chargeable service.

Where this appliance is intended for commercial use, the rules of

the relevant Health & Safety at Work Act must be observed at commissioning. For further details, check your local authorising body.

12.1 Checks before commissioning

Before commissioning, check the following points.

12.1.1 Heating system

- Have you filled the heating system to the correct pressure,

and opened the quick-action air vent valve?

12.1.2 Temperature sensor

- Have you correctly positioned and connected the outside

temperature sensor and the return temperature sensor (in

conjunction with a buffer cylinder)?

12.1.3 High limit safety cut-out

In ambient temperatures of below -15 °C it is possible that the high

limit safety cut-out of the electrical emergency/booster heater

may trip.

Check whether the high limit safety cut-out has tripped.

1

26�03�01�1872

1 High limit safety cut-out reset button

Reset the high limit safety cut-out by pressing the reset

button.

12.1.4 Power supply

- Have you correctly connected the power supply?

12.2 Using the appliance with an external second

heat generator

The appliance is factory set for Compressor operation with an

electric emergency/booster heater. If the appliance is used in dual

mode with an external second heat generator or as a module with

an additional identical heat pump, you must set the DIP switch

to WP Type 4 (see chapter "Troubleshooting / Checking the IWS

DIP switch settings / Compressor mode with an external second

heat generator").

1

1 Electric emergency/booster heater

Remove the cause of the fault.

12.3 Settings

12.3.1 Heating curve adjustment

The efficiency of a heat pump decreases as the flow temperature

rises. The heating curve should therefore be adjusted with care.

Heating curves that are set too high cause the zone valves and

thermostatic valves to close, which may lead to the minimum flow

rate required for the heating circuit not being achieved.

Observe the WPM operating and installation instructions.

The following steps will help you to adjust the heating curve correctly:

- Fully open thermostatic or zone valves in a lead room (e.g.

26�03�01�1880

26�03�01�1880

living room and bathroom).

We do not recommend installing thermostatic or zone valves

in the lead room. Control the temperature for these rooms

via remote control.

- At different outside temperatures (e.g. –10°C and +10°C),

adjust the heating curve so the required temperature is set in

the lead room.

20 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 21

INSTALLATION

Maintenance

Standard values to begin with:

Parameter Underfloor heating

Heating curve 0.4 0.8

Control response time 25 50

Comfort temperature 21°C 23°C

If the room temperature is not high enough in spring and autumn

(approx. 10 °C outside temperature), raise the „COMFORT TEMPERATURE“ parameter in the heat pump manager menu under

„SETTINGS / HEATING / HEATING CIRCUIT“.

Note

If no remote control is installed, raising the "COMFORT

TEMPERATURE" parameter leads to a parallel offset of

the heating curve.

Increase the „HEATING CURVE“ parameter, if the room temperature is not high enough when outside temperatures are low.

If you raise the „HEATING CURVE“ parameter, adjust the zone valve

or thermostatic valve in the lead room to the required temperature

when outside temperatures are high.

Material losses

!

Never reduce the temperature in the entire building by

closing all zone or thermostatic valves, instead use the

setback programs.

When everything has been implemented correctly, the system

can be heated to its maximum operating temperature and vented

once again.

system

Radiator heating

system

12.4 Operation and control

Material losses

!

Never interrupt the power supply, even outside the heating season. The system's active frost protection is not

guaranteed if the power supply is interrupted.

The system does not have to be switched off in summer. The heat

pump manager has an automatic summer / winter changeover.

12.5 Decommissioning

If the system is to be taken out of use, set the WPM to standby.

This retains the safety functions designed to protect the system

(e.g. frost protection).

Material losses

!

If the heat pump and frost protection are completely

switched off, drain the system on the water side.

13. Maintenance

We recommend that you perform an annual inspection (to establish the current condition of the system), and as required have

maintenance carried out (to return the system to its original condition).

Check the condensate drain (visual inspection). Remove contaminants and blockages immediately.

Material losses

!

With underfloor heating systems, observe the maximum

permissible temperature for the system.

12.3.2 Other settings

For operation with and without buffer cylinder, observe

chapter „Operation / Menu structure / Menu SETTINGS/

STANDARD SETTING/ BUFFER OPERATION“ in the operating

and installation instructions of the WPM.

When using the heat-up program

If you use the heat-up program, make the following settings on

the WPM:

Initially set parameter „DUAL MODE TEMP HZG“ to 30°C.

Then set parameter „LOWER APP LIMIT HZG“ to 30°C.

Note

After completing the heat-up process, reset the parameters "DUAL MODE TEMP HZG" and "LOWER APP LIMIT HZG"

to their respective standard values or to the respective

system values.

1.

2.

1

1 Inspection port

Material losses

!

Keep the air discharge and intake apertures free from

snow and ice.

Remove any leaves or other foreign bodies from the evaporator

fins periodically.

D0000037831

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 21

Page 22

INSTALLATION

Troubleshooting

14. Troubleshooting

WARNING Electrocution

Before any work, isolate the appliance from the

power supply at the control panel.

Following isolation from the mains supply, parts of the

appliance may remain live for up to 2 minutes since

the capacitors still have to discharge into the inverter.

Note

Please observe the heat pump manager operating and

installation instructions.

If a fault cannot be located during service using the heat pump

manager, open the control panel in emergencies and check the

IWS settings. This check must only be carried out by a qualified

contractor.

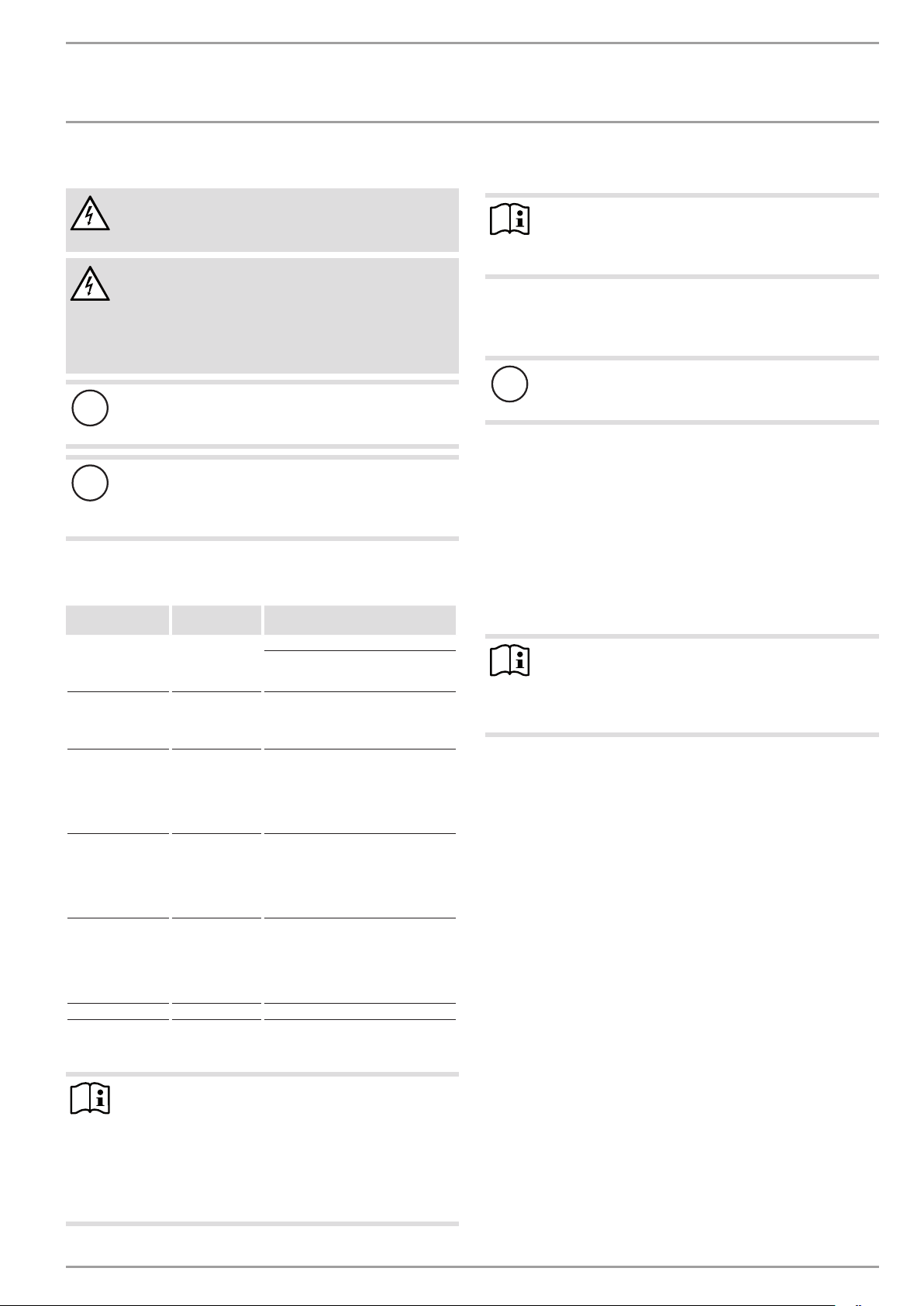

14.1 Checking the IWS DIP switch settings

Carry out the following steps to make the IWS accessible.

1

26�03�01�1870

1 IWS

Lift the cover.

IWS

1

Remove the cover.

Remove the bracket highlighted in grey.

BA

BA

26�03�01�1866

4

1 LEDs

2 DIP switch (WP-Typ)

3 Reset button

4 DIP switch (BA)

DIP switch (WP-Typ)

With the DIP switch ("WP-Typ"), you can select the various heat

pump types on the IWS.

Factory setting

Compressor mode with electric emergency/booster heater

3

WP - Typ

26�03� 01�1869

ON

2

C26�03�01�0921

1 2 3 4

Check whether the DIP switch is set correctly.

22 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

D0000057054

Page 23

INSTALLATION

BA

BA

Troubleshooting

Compressor mode with an external second heat generator

Damage to the appliance and environment

!

In this case, do not connect the electric emergency/booster heater.

If the appliance is operated in dual mode with an external second

heat source, set the DIP switch as follows:

Set the DIP switch as follows.

WP - Typ

ON

1 2 3 4

DIP switch (BA)

Check whether the DIP switch(BA) is set correctly.

Heating operation

BA

14.1.1 Closing the wiring chamber

D0000057055

26�03�01�1867

Position the cover on the appliance.

Secure the cover with the four screws.

Cooling operation

ON

1 2 3 4

ON

1 2 3 4

BA

14.2 Light emitting diodes (LEDs)

D0000057052

D0000051579

1 LEDs

2 Reset button

The following table shows the meaning of the LEDs of the IWS.

LED indicator Meaning

Red LED flashes Single fault. Appliance stops and restarts after 10

Red LED illuminates

Green LED (centre)

flashes

Green LED (centre) illuminates

minutes, and the LED extinguishes.

More than 5 faults within 2 hours run. The appli-

ance is shut down permanently and only restarts

following a reset on the IWS. The internal fault

counter will then be reset. The appliance can be restarted after 10 minutes. The LED extinguishes.

The heat pump is initialising.

The heat pump was initialised successfully and the

connection with the WPM is active.

1

2

26�03�01�0921

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 23

Page 24

INSTALLATION

Troubleshooting

Faults indicated by the red LED:

- High pressure fault

- Low pressure fault

- Other fault and

- Hardware fault on the IWS (see fault list)

14.3 Reset button

If the IWS was not initialised successfully, you can reset the settings with this button.

For this, also observe chapter "Reinitialising the IWS" in the

heat pump manager operating and installation instructions.

14.4 Resetting the high limit safety cut-out

The electric emergency/booster heater stops if the heating water

temperature exceeds 85 °C, for example on account of a low flow

rate.

14.5 Fan noise

The heat pump draws heat from the outdoor air. This causes the

outdoor air to cool down. At outside temperatures of 0°C to 8°C,

the air may be cooled to below freezing point. If under these

conditions precipitation occurs in the form of rain or fog, ice may

form on the air grille, the fan blades or the air routing. If the fan

comes into contact with this ice, noise develops.

How to remedy rhythmically scratching or grinding noises:

Check whether the condensate drain is free from obstruction.

Check whether the design output and temperature are set

correctly. Ice formation is particularly pronounced when

a high heating output is demanded at moderate outside

temperatures.

Carry out a manual defrost, repeatedly if required, until the

fan runs free again. For this, observe the information in the

operating and installation instructions for the WPM.

At outside temperatures above + 1°C, switch the appliance

off for around 1hour or switch it over to emergency mode.

After this, the ice should have melted.

Check whether the appliance is installed in line with the in-

stallation conditions.

If the noises occur frequently, notify customer support.

1 Electric emergency/booster heater

Remove the cause of the fault.

1

1 High limit safety cut-out reset button

Reset the high limit safety cut-out by pressing the reset

button.

Check whether the heating water is being circulated at a suf-

ficient flow rate.

26�03�01�1880126�03�01�1880

26�03�01�1872

24 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 25

INSTALLATION

Troubleshooting

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 25

Page 26

INSTALLATION

100

Specication

15. Specification

15.1 Dimensions and connections

WPL15AS| WPL15ACS

d45

410

70

1160

490

1270

900

WPL 15 AS WPL 15 ACS

e01 Heating flow

Diameter mm 28 28

e02 Heating return

Diameter mm 28 28

d45 Condensate drain Diameter mm 22 22

d47 Drain

g01 Air intake

g02 Air discharge

Type of connection Plug-in connection Plug-in connection

Type of connection Plug-in connection Plug-in connection

g01 g02

157

593

e02

100

e01

176

82

d47

D0000034131

26 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

Page 27

INSTALLATION

1045

100

Specication

WPL20A| WPL20AC| WPL25A| WPL25AS| WPL25AC| WPL25ACS

d45

410

490

1380

1490

g01 g02

157

WPL 20A WPL 20 AC WPL 25 A WPL 25 AS WPL 25 AC WPL 25 ACS

e01 Heating flow

Diameter mm 28 28 28 28 28 28

e02 Heating return

Diameter mm 28 28 28 28 28 28

d45 Condensate

drain

d47 Drain

g01 Air intake

g02 Air discharge

Type of connection Plug-in connection Plug-in connection Plug-in connection Plug-in connection Plug-in connection Plug-in connection

Type of connection Plug-in connection Plug-in connection Plug-in connection Plug-in connection Plug-in connection Plug-in connection

Diameter mm 22 22 22 22 22 22

593

e02

e01

100

176

82

d47

D0000028296

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 27

Page 28

INSTALLATION

3121

F5

11

P1=2600W

AB

K6

U V W

M1

1 3

2 4

K2

X2 Busanschluss WP

Y1

B12

T

B13

T

B9

T

B11

T

V1

M8

M7

M

B2

T

H L T “+”

L

N

M6

M

1~

1 2 3 4 5 6 7

X39

X36

4

3

2

1

X35

6

5

4

3

2

1

X34

Heizungsvorlauf

+12...+18V

GND

ND 4...20mA

HD 4...20mA

MD 4...20mA

Heißgas

7

6

5

4

3

2

1

X30

3

2

1

X37

5

4

3

2

1

X33

5

4

3

2

1

Lüfter Drehz.

Lüfter +10V

Lüfter 0...10V

Lüfter GND

Heizungsrücklauf

Außenluft

Verdichtereintritt

Verdampferaustritt

GND

Einspritzung

CAN GND

CAN L

CAN H

+12V

Phase 1

Phase 2

Phase 3

Phase 4

+12V

Phase 1

Phase 2

Phase 3

Phase 4

Frostschutz

Verflüssigeraustritt

Fortluft

Ölsumpftemperaturnc0-5V Eingang

GND

A2

(IWS III)

X42

3 2 1

p

P1

Specication

15.2 Wiring diagram for WPL15AS| WPL15ACS| WPL25AS| WPL25ACS (single-phase)

X5 Netz DHC

L N L N

X3 Netz WP

L N

L1 L2

FROM AC

A4

TO DRIVE

L1 L2

X27/7

X23

X27/1

bl

sw

M6

F4

X8

X27/2

X27/8

X4 Netz Steuerung

ON ERR L N

6 5 4 3 2 1

X23

K7

AB

X1

K2

A2 A1

F3

> p

L N PE

3222

12

T >

1

K6

3

1

K7

3

E1

P3=3200W

P2=3000W

A2 Integral heat pump control unit (IWS)

A3 Inverter compressor

B1 Heating flow temperature sensor - KTY

B2 Heating return temperature sensor - KTY

B5 Hot gas temperature sensor - PT1000

B6 Outdoor air temperature sensor - PT1000

B7 Compressor intake temperature sensor - PT1000

B8 Evaporator discharge temperature sensor - PT1000

B9 Frost protection temperature sensor - KTY

B10 Injection temperature sensor - PT1000

B11 Exhaust air temperature sensor - KTY

B12 Condenser outlet temperature sensor - KTY

B13 Oil sump temperature sensor - KT Y

E1 DHC

E2 Oil sump heater

F3 High pressure switch 42 bar

28 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

A3

U V W PE

M

3~

X27/9

X46

N L L’

Y2

sw bl br

E2

F4 Fuse 10 A (fan)

F5 High limit safety cut-out for DHC

K2 Compressor start contactor L

K5 DHC relay

K6 DHC relay

K7 DHC relay

M1 Compressor motor

M6 Fan motor

M7 Electrical expansion valve stepper motor

M8 Electrical injection valve stepper motor

P1 High pressure sensor (42 bar)

P3 Low pressure sensor (16 bar)

P4 Mean pressure sensor (30 bar)

S1 Sinter filter coil

S2 Sinter filter coil

S3 Sinter filter coil

1 2 3

X29

1

2

3

4

5

6

7

8

9

10

11

12

X38

1

2

3

X43

1

2

3

4

X40

1

2

3

4

5

6

X7

X27/2

N

L

K2

nc

ERR

Rohrbegleitheizung

Abtauen

ON

HD

EVU

nc

nc

DHC1

DHC2

Ölsumpfheizung

GND

+5V

H

L

GND

Frequenzeing. 0...5V

+5V 20 mA

nc

nc

+12..+18V

D0000028167

Page 29

INSTALLATION

B12

T

B13

B9

B11

M7

B2

T

M6

X36

X35

X34

X30

X37

X33

3 2 1

P1

Specication

Lüfter Drehz.

Lüfter +10V

Lüfter 0...10V

Lüfter GND

Heizungsrücklauf

Außenluft

Verdichtereintritt

Verdampferaustritt

GND

Einspritzung

CAN GND

CAN L

CAN H

Heizungsvorlauf

+12...+18V

A2

(IWS III)

GND

ND 4...20mA

HD 4...20mA

MD 4...20mA

Heißgas

+12V

Phase 1

Phase 2

Phase 3

Phase 4

+12V

Phase 1

Phase 2

Phase 3

Phase 4

X2 Busanschluss WP

H L T “+”

4

3

2

1

6

5

4

3

2

1

3

2

1

7

6

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

X41

X41

X8 / F4

X6

1 2 3 4

1 2

X9

Frostschutz

Verflüssigeraustritt

Fortluft

Ölsumpftemperaturnc0-5V Eingang

1 2 3 4 5 6 7

X39

GND

X42

M

M

T

T

T

T

M8

V1 Flow sensor

X1 Internal distribution terminal

X2 External BUS terminal

X3 External power terminal

X4 External control terminal

X5 External DHC terminal

X6 4-pole terminal

X7 3-pole terminal

X8 2-pole terminal

X9 2-pole terminal

X23 Power supply earth block

X27 Earth stud

X29 IWS plug 12-pin - control unit

X30 IWS plug 3-pin - BUS

X33 IWS plug 5-pin - electrical expansion valve

X34 IWS plug 7-pin - sensors

3 2 1

p

P4

B5

3 2 1

p

p

T

P3

B1

T

T

B10

B8

T

T

B6

B7

L

M

N

1~

D0000028167

X35 IWS plug 6-pin - temperature sensors

X36 IWS plug 3-pin - fan

X37 IWS plug 5-pin - electrical injection valve

X38 IWS plug 3-pin - oil sump

X39 IWS plug 7-pin - temperature

X40 IWS plug 6-pin - HT special

X41 Link PCB ground

X42 Link PCB ground

X43 IWS plug, 3-pin

X46 Plug-in connector

Y1 Diverter valve - defrost

Y2 Diverter valve (only for WPL ACS)

www.stiebel-eltron.com WPL A | WPL AC | WPL AS | WPL ACS | 29

Page 30

INSTALLATION

K5

3

1

P1=2600W

3121

F5

11

K6

3

1

K7

3

AB

K5

U V W

M1

1 3 5 13

2 4 6 14

K2

S1

1 11

2 22

X2 Busanschluss WP

Y1

B12

T

B13

T

B9

T

B11

T

V1

M8

M7

M

B2

T

H L T “+”

L

N

M6

M

1~

1 2 3 4 5 6 7

X39

X36

4

3

2

1

X35

6

5

4

3

2

1

X34

Heizungsvorlauf

+12...+18V

GND

ND 4...20mA

HD 4...20mA

MD 4...20mA

Heißgas

7

6

5

4

3

2

1

X30

3

2

1

X37

5

4

3

2

1

X33

5

4

3

2

1

Lüfter Drehz.

Lüfter +10V

Lüfter 0...10V

Lüfter GND

Heizungsrücklauf

Außenluft

Verdichtereintritt

Verdampferaustritt

GND

Einspritzung

CAN GND

CAN L

CAN H

+12V

Phase 1

Phase 2

Phase 3

Phase 4

+12V

Phase 1

Phase 2

Phase 3

Phase 4

Frostschutz

Verflüssigeraustritt

Fortluft

Ölsumpftemperaturnc0-5V Eingang

GND

A2

(IWS III)

X42

3 2 1

p

P1

Specication

15.3 Wiring diagram for WPL20A| WPL20AC| WPL25A| WPL25AC (3-phase)

X5 Netz DHC

N L1 L2 L3

X3 Netz WP

L1 L2 L3 N

S3S2

X27/3

X27/7

X23

X27/1

bl

sw

M6

F4

X8

X27/2

X27/8

X4 Netz Steuerung

ON ERR L N

6 5 4 3 2 1

X23

X1

K6

AB

K7

AB

A2 A1

K2

F3

> p

L1 L2 L3 PE

3222

12

T >

1

E1

P3=3200W

P2=3000W

A2 Integral heat pump control unit (IWS)

A3 Inverter compressor

B1 Heating flow temperature sensor - KTY

B2 Heating return temperature sensor - KTY

B5 Hot gas temperature sensor - PT1000

B6 Outdoor air temperature sensor - PT1000

B7 Compressor intake temperature sensor - PT1000

B8 Evaporator discharge temperature sensor - PT1000

B9 Frost protection temperature sensor - KTY

B10 Injection temperature sensor - PT1000

B11 Exhaust air temperature sensor - KTY

B12 Condenser outlet temperature sensor - KTY

B13 Oil sump temperature sensor - KT Y

E1 DHC

E2 Oil sump heater

F3 High pressure switch 42 bar

F4 Fuse 10 A (fan)

30 |WPL A | WPL AC | WPL AS | WPL ACS www.stiebel-eltron.com

A3

U V W PE

M

3~

X27/9

X46

N L L’

Y2

sw bl br

E2

F5 High limit safety cut-out for DHC

K2 Compressor start contactor L

K5 DHC relay

K6 DHC relay

K7 DHC relay

M1 Compressor motor

M6 Fan motor

M7 Electrical expansion valve stepper motor

M8 Electrical injection valve stepper motor

P1 High pressure sensor (42 bar)

P3 Low pressure sensor (16 bar)

P4 Mean pressure sensor (30 bar)

S1 Sinter filter coil

S2 Sinter filter coil

S3 Sinter filter coil

V1 Flow sensor

X1 Internal distribution terminal

1 2 3

X29

1

2

3

4

5

6

7

8

9

10

11

12

X38

1

2

3

X43

1

2

3

4

X40

1

2

3

4

5

6

X7

X27/2

N

L

K2

nc

ERR

Rohrbegleitheizung

Abtauen

ON

HD

EVU

nc

nc

DHC1

DHC2

Ölsumpfheizung

GND

+5V

H

L

GND

Frequenzeing. 0...5V

+5V 20 mA

nc

nc

+12..+18V

D0000028167

Page 31

INSTALLATION

B12

T

B13

B9

B11

M7

B2

T

M6

X36

X35

X34

X30

X37

X33

3 2 1

P1

Specication

Lüfter Drehz.

Lüfter +10V

Lüfter 0...10V

Lüfter GND

Heizungsrücklauf

Außenluft

Verdichtereintritt

Verdampferaustritt

GND

Einspritzung

CAN GND

CAN L

CAN H

Heizungsvorlauf

+12...+18V

A2

(IWS III)

GND

ND 4...20mA

HD 4...20mA

MD 4...20mA

Heißgas

+12V

Phase 1

Phase 2

Phase 3

Phase 4

+12V

Phase 1

Phase 2

Phase 3

Phase 4

X2 Busanschluss WP

H L T “+”

4

3

2

1

6

5

4

3

2

1

3

2

1

7

6

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

X41

X41

X8 / F4

X6

1 2 3 4

1 2

X9

Frostschutz

Verflüssigeraustritt

Fortluft

Ölsumpftemperaturnc0-5V Eingang

1 2 3 4 5 6 7

X39

GND

X42

M

M

T

T

T

T

M8

X2 External BUS terminal

X3 External power terminal

X4 External control terminal

X5 External DHC terminal

X6 4-pole terminal

X7 3-pole terminal

X8 2-pole terminal

X9 2-pole terminal

X23 Power supply earth block