Page 1

OPERATION AND INSTALLATION

FUNCIONAMIENTO E INSTALACIÓN

MODE D’EMPLOI ET INSTALLATION

.ĉ®êļ¼ŒùźÐļ¼®ŷ|Œ¼ļä¼|Œ¼ļŷêŒä¼ù¼Œļê|÷şĤä¼|ŒêĉÖ¼ù¼ă¼ĉŒ

|ù¼ĉŒ|®Ēļ®¼|Öş||Ïş¼ÖĒêĉ®êļ¼ŒĒĒĉ|ù¼ĉŒ|®Ēļ¼ù½ŒļêĒ®¼ļ¼Ïş¼ļſĒ

ä|şÏϼé¼|şä|şÏÏ|Ö¼êĉ®êļ¼Œ|Ŷ¼½ù½ă¼ĉŒ®¼ä|şÏÏ|Ö¼½ù¼Œļêış¼|şŹêùê|êļ¼

» SB 300 E

» SB 400 E

Conforms to ANSI/UL Std. 174

Certified to CAN/CSA Std. C22.2 No. 110-94

Conforme a ANSI/UL Std. 174

Certificación con CAN/CSA Std. C22.2 No. 110-94

Conforme à la norme ANSI/UL Std. 174

Certifié à la norme CAN/CSA Std. C22.2 No. 110-94

Tested and certified by WQA to NSF/ANSI372

for lead free compliance.

Probado y certificado por WQA NSF/ANSI 372 para

el cumplimiento de las regulaciones sin plomo.

Testé et certifié par WQA à la NSF/ANSI 372 pour

une utilisation sans plomb.

Page 2

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information ____________________________________3

2. Safety _____________________________________________________3

2.1 Intended use _________________________________________________3

2.2 Incorrect use _________________________________________________ 3

2.3 General safety instructions _______________________________3

2.4 Heat exchanger loop _______________________________________ 3

2.5 Test symbols _________________________________________________3

3. Register your product __________________________________4

4. Appliance description __________________________________4

4.1 Heating the DHW tank _____________________________________4

5. Using the electric heating element ____________________4

6. Maintenance and care __________________________________4

6.1 Temperature / pressure relief valve _____________________5

6.2 Decalcification _______________________________________________ 5

6.3 Replacement of the sacrificial anode ___________________ 5

7. Plumbing troubleshooting _____________________________5

7.1 Notifying a qualified contractor _________________________5

7.2 Safety label __________________________________________________6

8. Safety _____________________________________________________6

8.1 General safety instructions _______________________________6

8.2 Instructions, standards and regulations _______________6

9. Preparations _____________________________________________6

9.1 Transport _____________________________________________________6

9.2 Storage ________________________________________________________ 7

9.3 Delivery configuration _____________________________________7

9.4 Installation site ______________________________________________7

9.5 Siting the appliance ________________________________________7

10. Installation _______________________________________________8

10.1 Water connection ___________________________________________8

10.2 Heating connection _________________________________________9

10.3 Power supply ________________________________________________ 9

11. Commissioning ________________________________________ 10

11.1 Commissioning ____________________________________________ 10

11.2 Recommissioning _________________________________________ 10

12. Shutting down _________________________________________ 10

13. Electrical Troubleshooting ___________________________ 10

13.1 Resetting the high limit safety cut-out _______________ 11

14. Maintenance and cleaning ___________________________ 11

14.1 Removing the heating element cover _________________ 11

14.2 Draining the tank _________________________________________ 11

14.3 Descaling the electric element _________________________ 11

14.4 Valves _______________________________________________________ 11

14.5 Replacing the electric element cover _________________ 11

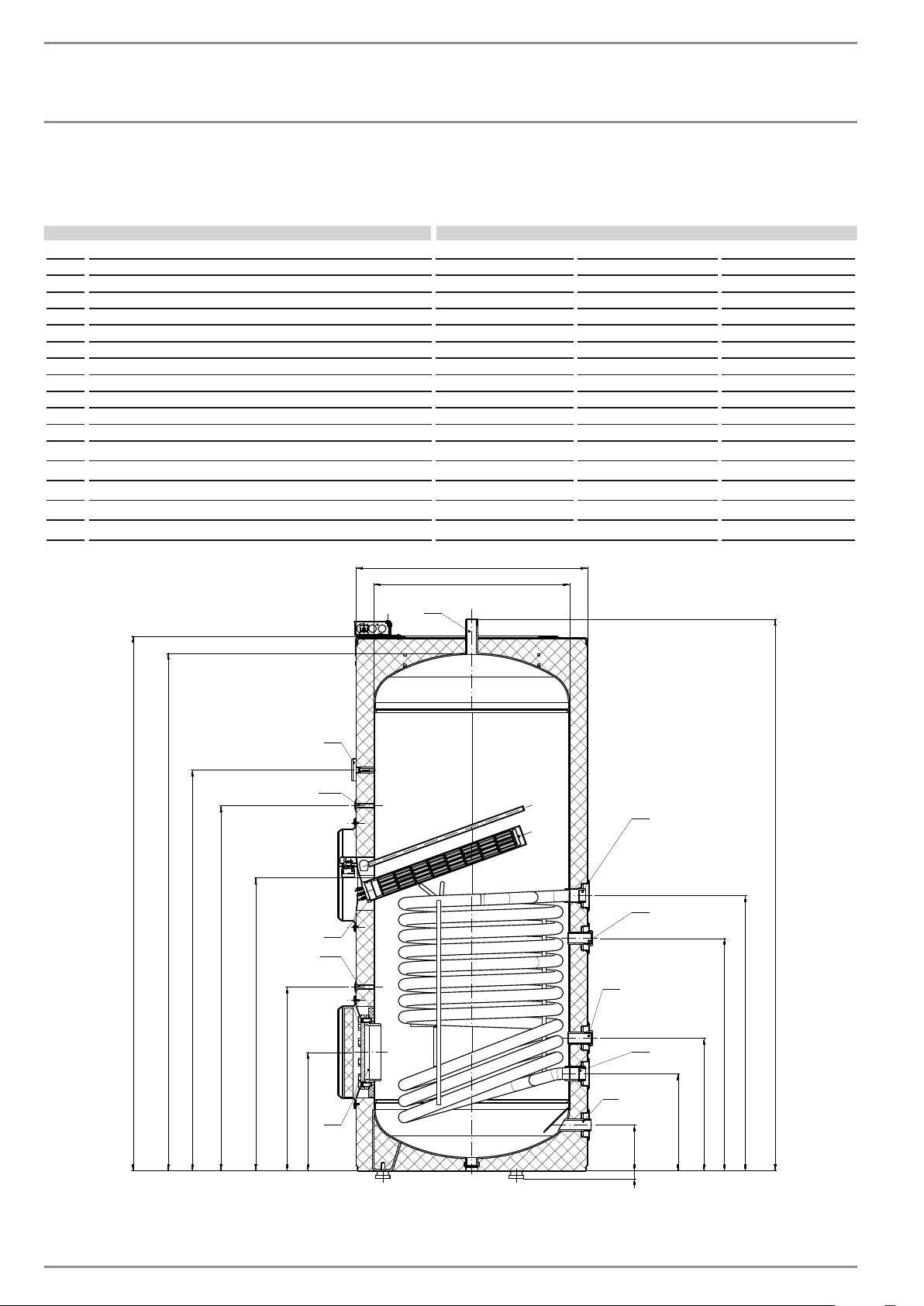

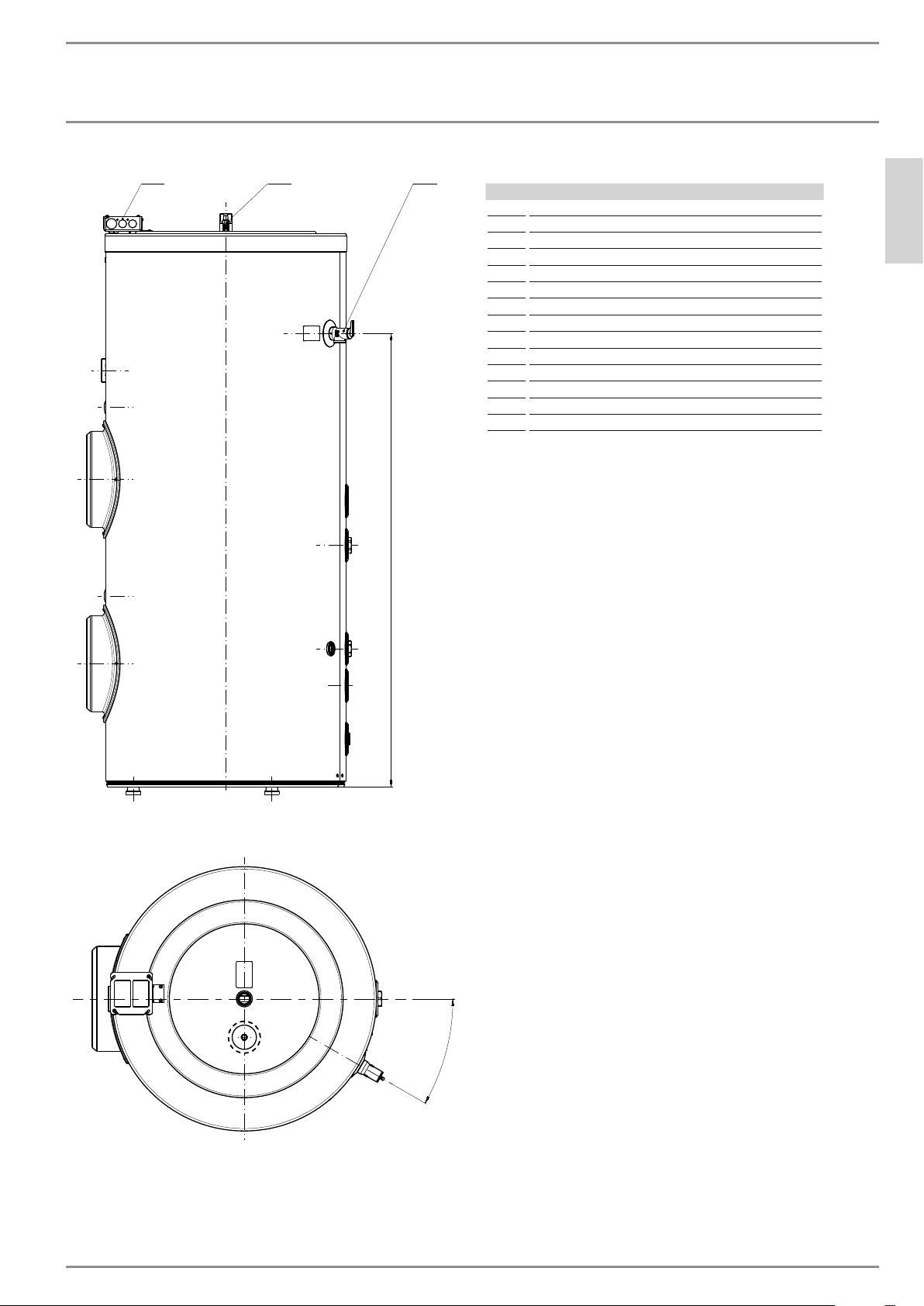

15. Specifications __________________________________________ 12

15.1 Dimensions _________________________________________________ 12

15.2 Features ____________________________________________________ 13

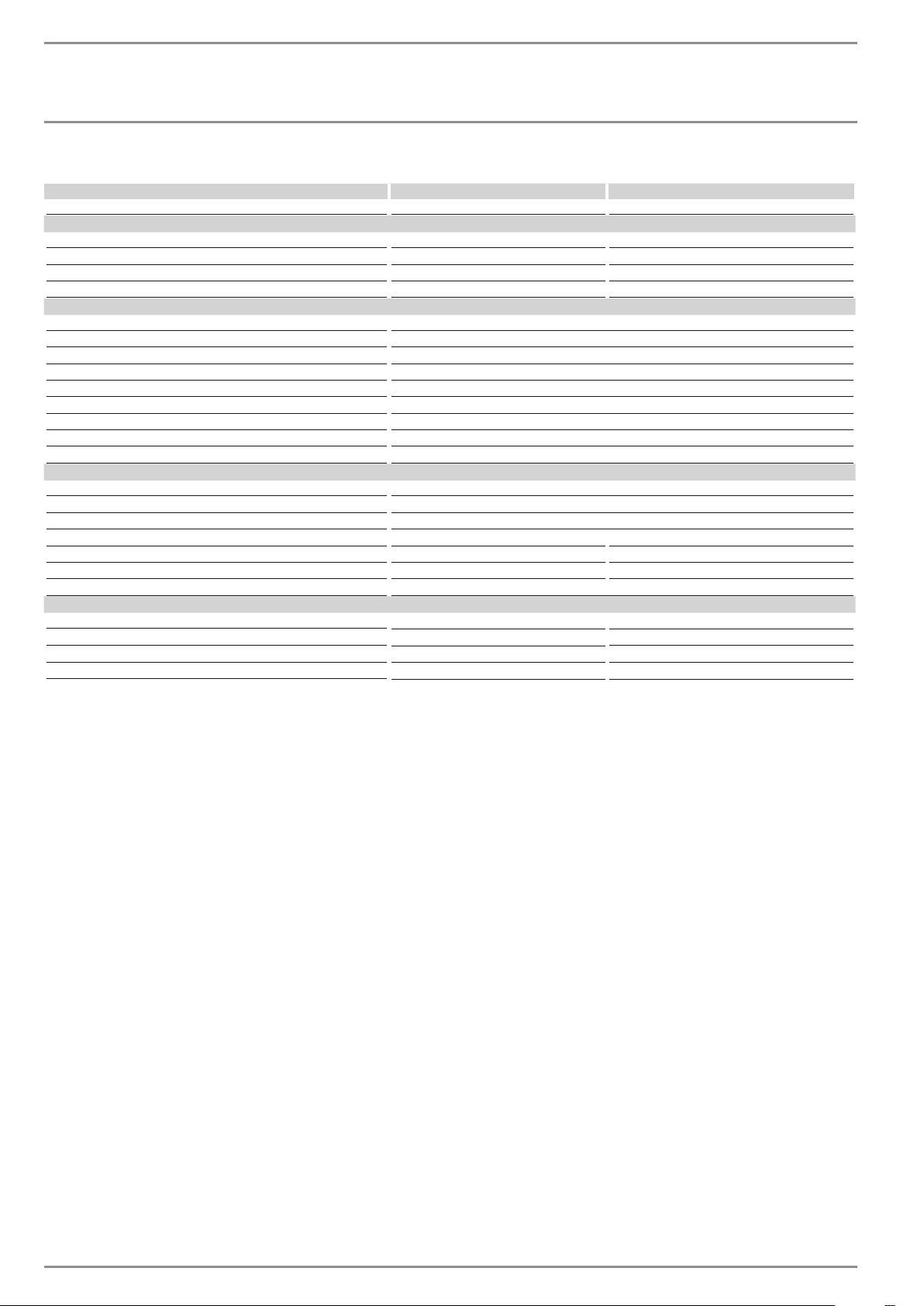

15.3 Data table ___________________________________________________14

15.4 Spare parts_________________________________________________ 15

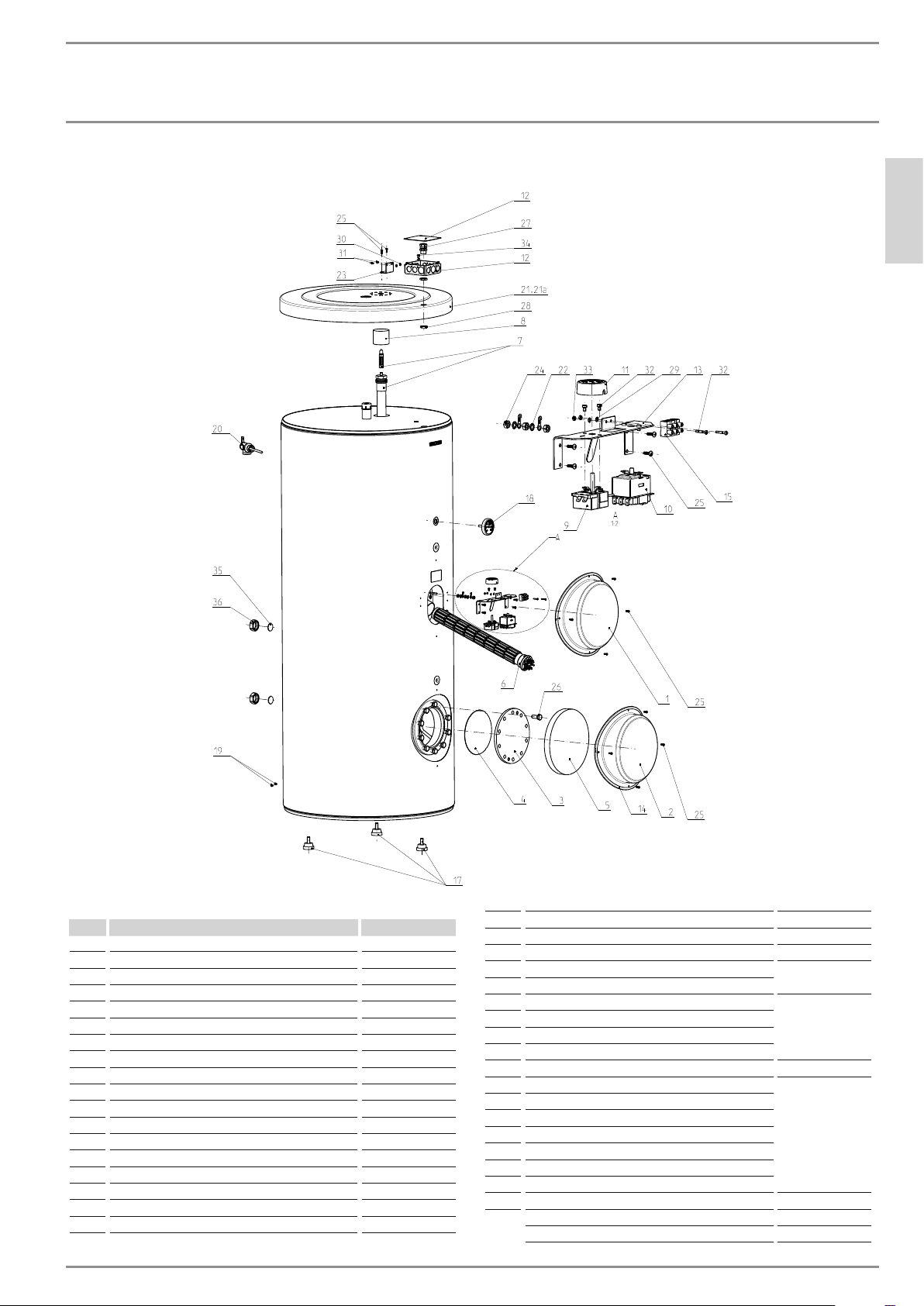

15.5 Spare parts list ____________________________________________ 15

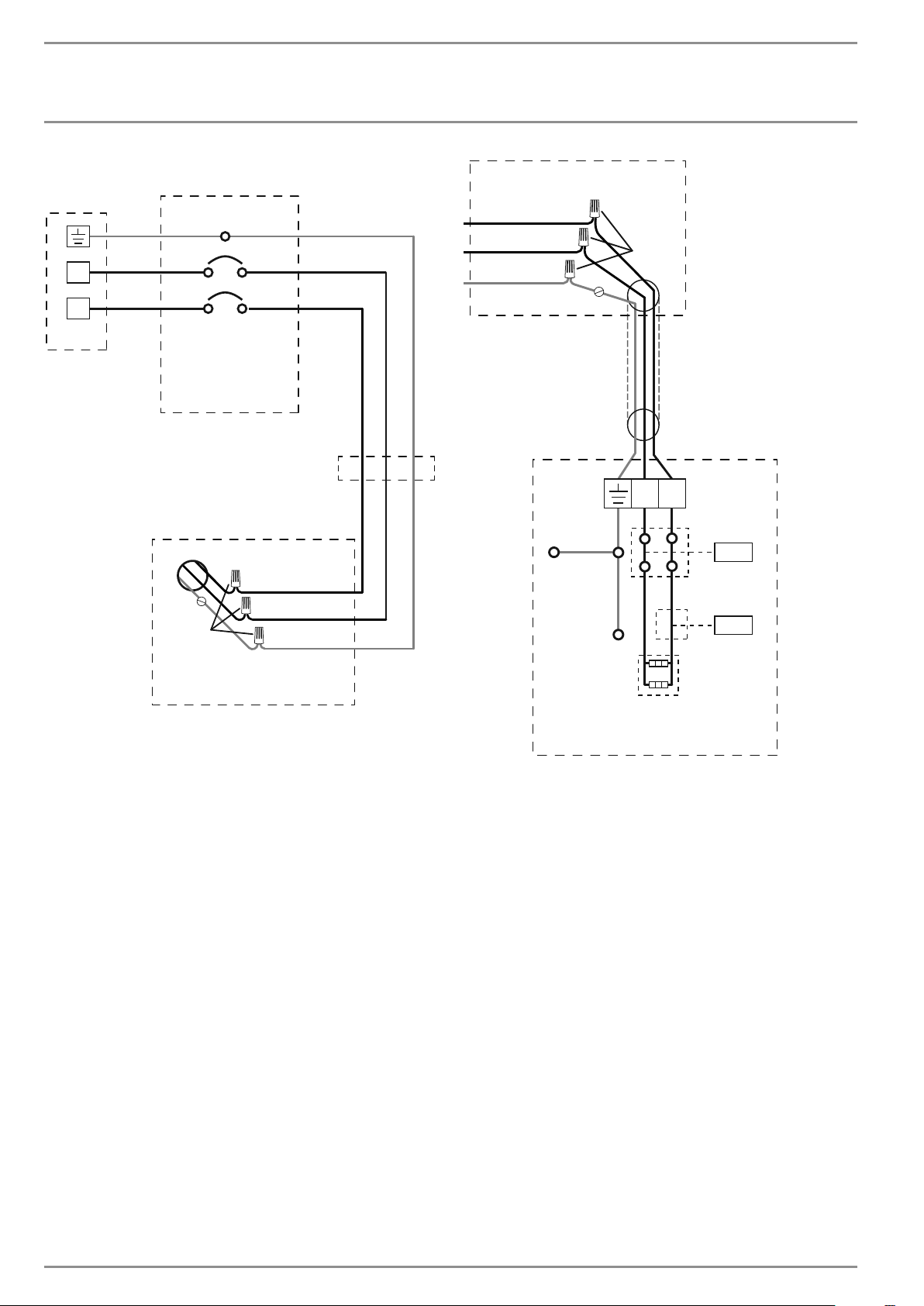

15.6 Wiring diagram _________________________________________________ 16

16. Environment and Recycling _______________________________ 16

17. Warranty ____________________________________________________ 17

SPECIAL INFORMATION

- Observe all applicable national and regional regulations and instructions during installation.

- The appliance is not approved for outdoor

installation.

- If the appliance is permanently connected to the

power supply, ensure that the appliance can be

separated from the power supply by an isolator

that disconnects all poles with at least 1/8˝/4 mm

contact gap. Contactors, disconnect switches or

circuit breakers can be used for this.

- Observe the safety regulation to prevent contact

with dangerous ‘live’ currents.

- The appliance is pressurized. During the heat-up

process, expansion water will drip from the safety

valve.

- Regularly activate the safety valve to prevent

it from becoming blocked, e.g. by limescale

deposits.

- Install a type-tested safety valve in the cold water

supply line.

- The maximum pressure in the cold water supply

line must be at least 20% below the response

pressure the safety valve. If the maximum pressure in the cold water supply line is higher, install

a pressure reducing valve.

- Size the drain so that water can drain off unimpeded when the safety valve is fully opened.

- Fit the discharge pipe of the safety valve with a

constant downward slope and in a room without

risk of frost.

- The safety valve discharge aperture must remain

open to atmosphere.

- Never set the heat exchanger loop pressure

greater than the potable (domestic) water supply

pressure. If potable water pressure is too low, a

booster pump may be needed to assure that it exceeds the required heat exchanger loop pressure.

2 |SB 300-400 E www.stiebel-eltron-usa.com

Page 3

OPERATION

General information

OPERATION

1. General information

The chapters “Special information” and "Operation" are intended

for appliance users and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

2. Safety

2.1 Intended use

The appliance is intended for DHW heating within the application

limits. See 15.3, “Data table”, pg. 14.

The appliance is intended for domestic use, i.e. it can be used

safely by untrained persons. The appliance can also be used in a

non-domestic environment, e.g. in a small business, as long as it

is used in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

WARNING Scalding

The water in the DHW tank can be heated to temperatures in excess of 149 °F (65 °C). T here is a risk of scalding

at outlet temperatures in excess of 110 °F (43 °C).

f Ensure you do not come into contact with the water

when discharged.

WARNING Burns

Touching hot components can lead to burns.

When working on hot components, always wear protective working clothing and safety gloves.

The pipework connected to the DHW outlet of the appliance can reach temperatures in excess of 149 °F (65 °C).

CAUTION

!

Install temperature and pressure protective equipment

required by local codes and no less than a combination temperature and pressure relief valve certified by a

nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or

materials, as meeting the requirements for Relief Valves

and Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22. T his value must be marked with a

maximum set pressure not to exceed the marked maximum working pressure of the water heater. Install the

valve into an opening provided and marked for this purpose in the water heater, and orient it or provide tubing

so that any discharge from the valve exits only within 6

inches above, or at any distance below, the structural

floor, and does not contact any live electrical part.

ENGLISH

2.2 Incorrect use

The following are not permitted:

- Heating liquids other than potable water

- Operating the appliance with an empty DHW tank

- Operating the appliance outside the application limits (See

15.3, “Data table”, pg. 14)

- Interrupting the power supply

2.3 General safety instructions

Only qualified contractors should carry out the electrical work and

installation of this appliance. Qualified contractors are responsible

for adherence to all applicable regulations.

Operate the appliance only when fully installed and with all safety

equipment fitted.

WARNING

Contact with live components presents a threat to life.

Damage to the electric insulation or to individual components may result in a threat to life.

f If there is damage to the insulation, disconnect the

power supply and arrange a repair.

All work on the electrical installation must be carried

out by a qualified contractor.

Caution

!

Only operate the appliance when the DHW tank has been

filled.

Caution

!

Keep the appliance installation room free from air contaminated with oil or salt and corrosive or explosive substances.

2.4 Heat exchanger loop

The SB E tanks have an indirectly fired heat exchanger loop. This

may be used in a variety of scenarios which include boiler loops,

geothermal systems, radiant floor loops, etc. Since the interior

of the heat exchanger is uncoated carbon steel, they must be

configured in a closed loop.

Use only a mixture of inhibited propylene glycol and de-ionized

water. The percentage of the glycol in the mixture depends upon

the climate. Some areas require that the propylene glycol be

GRAS, which is a food grade liquid (Heat exchanger type SW,

AWWA Fluid Class II - see MSDS for handling instructions).

2.5 Test symbols

See 7.1.1, “Sample type plate”, pg. 5.

www.stiebel-eltron-usa.com SB 300-400 E | 3

Page 4

OPERATION

Register your product

3. Register your product

NOTE:

You must register this product within 90 days of purchase on our web site in order to activate any standard

warranty or to be eligible for the extended warranty.

Go to our website at: www.stiebel-eltron-usa.com and

click on “Register Your Product.”

Before beginning the registration process, we suggest that you

gather the necessary information as follows:

Model, Example: SB 300 E (from the label that is on the side of

the unit)

Number listed after “Nr.”

Place of Purchase

Purchase Date

First & Last Name

Email address

Physical Address

Phone Number

If you have any questions concerning the registration process or

warranty options, please contact Stiebel Eltron USA directly at

800.582.8423.

If either of the last two heating methods require a temperature

sensor, 2 ports are provided on the opposite side of the tank from

the auxiliary and heat exchanger connections.

5. Using the electric heating element

A 3 kW electric heating element comes standard with this product.

The element has a built-in temperature probe that detects the tank

water temperature.

The appliance’s 3 kW electric resistance heating element is factory

preset at 125 °F (52 °C). The setpoint of the heating element can

be changed easily. A knob is located under the heating element

and can change the level of comfort to meet the needs of the user.

The heating element can be either unplugged during a period of

disuse or removed entirely.

For convenience, the heating element can be removed from the

tank without draining it.

Thermostat knob

Setpoint notch

4. Appliance description

The appliance is designed for indoor installation. The appliance

is equipped to heat water through a number of different heating

methods.

There are three ways that this unit can heat water:

- 3 kW electric resistance heating element

- Indirect heat via internal coil heat exchanger

- Indirect heat via auxiliary inlet/outlet ports

The entire heater and hot water system must be filled with water

and have adequate air ventilation. If used, please refer to the solar

collectors and the boilers installation instructions.

4.1 Heating the DHW tank

The first method of heating is by the 3 kW electric resistance heating element. This is the appliances most basic mode of operation.

An integral temperature sensor detects the thermal energy content

of the amount of heat in the DHW tank. The water in the DHW

tank is heated if the amount of heat is lower than that required to

achieve the set temperature.

The second method of heating is by the internal coil heat exchanger. This heat exchanger is designed to have a heat transfer

fluid circulate through it from an indirect heater. This indirect

heater can be a closed loop solar thermal system, boiler or other

traditional appliance that generates heat and transfers it through

a corrosion inhibited heat transfer fluid.

The third method of heating is by auxiliary ports located on the

side of the unit. These auxiliary ports offer direct access to the

domestic water in the tank. A flat plate heat exchanger should be

used to exchange heat between an indirect heater and the water

in the tank.

6. Maintenance and care

Routine care and maintenance extends the life expectancy and

operating safety of the hot water storage unit. The outer casing

should be cleaned with a slightly damp cloth and commercially

available neutral cleaning agent. This should be done on a regular

basis.

WARNING

Never spray the appliance with water.

Never spray water into the appliance.

WARNING Injury

!

Maintenance work, such as checking the electrical safety, must only be carried out by a qualified contractor.

4 |SB 300-400 E www.stiebel-eltron-usa.com

Page 5

OPERATION

Plumbing troubleshooting

Appliance compo-

Care and maintenance tips

nents

Casing Use a damp cloth to clean the casing sections. Never

use abrasive or corrosive cleaning agents.

DHW tank

The DHW tank is equipped with a sacrificial anode

and wear indicator to safeguard it against corrosion.

The wear indicator should be checked regularly. Otherwise there is a risk of corrosion.

Electric resistance

heater

Check the condition of the electric resistance heater.

This will extend the expected life of the element.

6.1 Temperature / pressure relief valve

WARNING: The T&P relief valve is designed to relieve

!

built up pressure in the water heater. Fluid may be

discharged at high temperature and/or pressure. Scalding hot

water injuries can occur.

The proper function of the Temperature / Pressure (T&P) relief

valve is required to prevent damage to the hot water storage unit.

The T&P valve needs to be open during cold-water filling of the

unit. When water flows from the relief line at full stream, the tank

is filled, and the T&P valve can be returned to its normal position.

6.2 Decalcification

With hard tap water, a deposit of scale will form on the inside of

the storage unit. Based on professional experience, it is necessary

to decalcify with commercially available solvents at timely intervals. Follow the manufacturers instructions for solvent use. The

hot water storage unit needs to be emptied to do this process. The

clean-out port cover must be removed and sediments on the tank

bottom must be flushed.

6.3 Replacement of the sacrificial anode

Depending on the composition of the tap water, an inspection of

the sacrificial anode at timely intervals is recommended. With

heavy wear, an original equipment replacement anode must be

installed to protect the inner container from corrosion. An inspection should be performed at least once per year.

7. Plumbing troubleshooting

Problem Cause Remedy

Inadequate

water pressure

Hot water flow

inadequate

Hot water

storage tank not

being heated

Faucet flow rate

inadequate

Hot water supply exhausted

too quickly

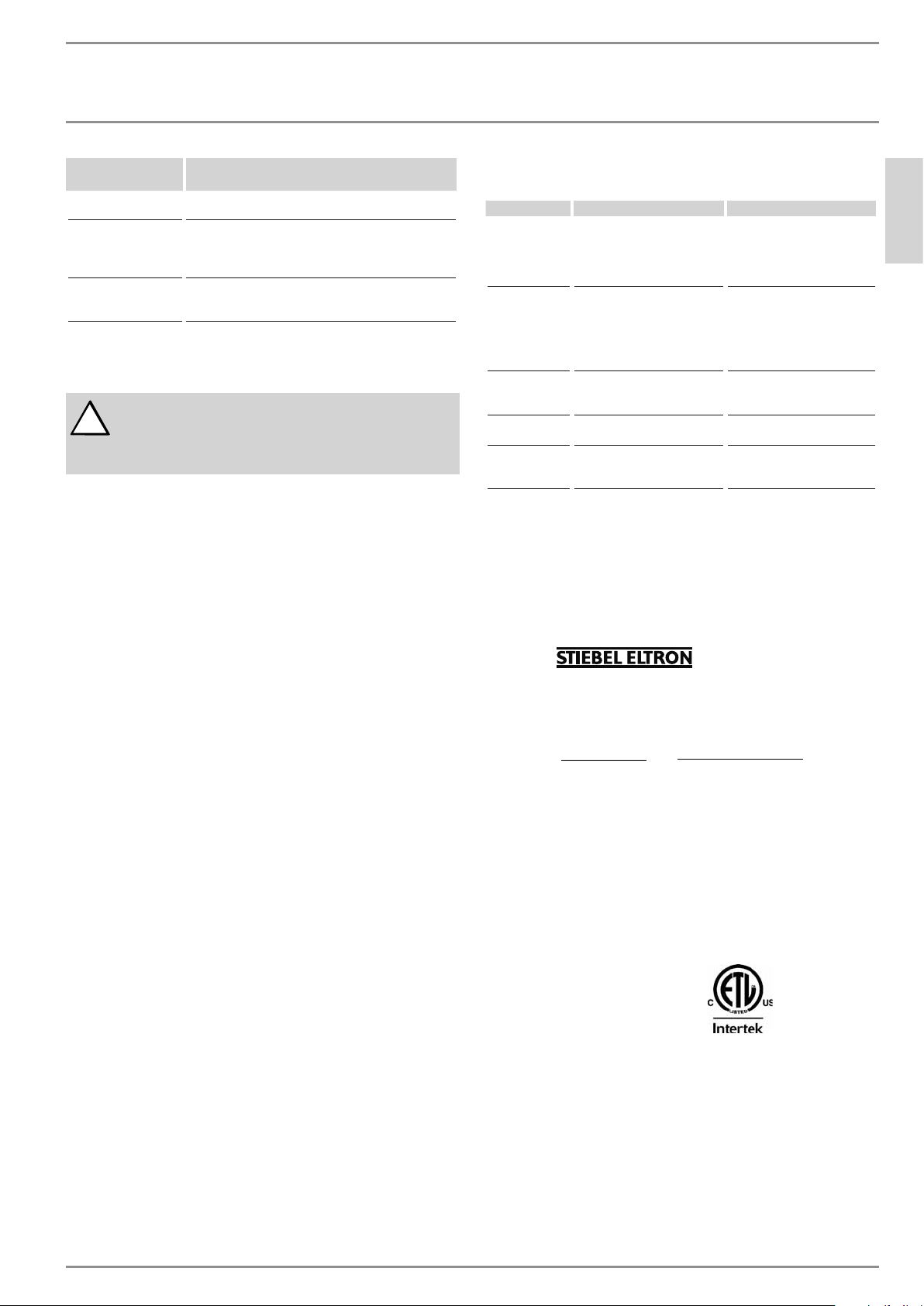

7.1

If you cannot remedy a failure, notify your qualified contractor. To

facilitate and speed up your request, provide the serial number

from the type plate (000000-0000-00000). The type plate can be

found on the left, above the "DHW outlet" connection.

7.1.1 Sample type plate

Shut-off valve is not completely open.

OR

Cold or hot water line is ob-

Open shut-off valve. Clean or

replace pipes.

structed.

Indirect boiler setpoint tem-

perature is too low.

Recommended 176–185 °F

(80–85 °C).

OR

Heat exchanger is calcified.

Program selection at the

heater control is not properly

Set boiler to recommended

temperature

OR

Clean heat exchanger.

Select and set program per

instructions.

selected.

Aerator at the extraction

Unscrew aerator and clean.

point is blocked.

Flow rate is too high. Rec-

ommended 2.6–3.9 gpm

Restrict spigot valve rate.

(9.8–14.7 l/min).

Notifying a qualified contractor

Made in EU

Hecho en EU

Fabriqué en EU

SB 300 E

M-NO.: 234110

S-NO.:

Technical data

Datos técnicos

Données techniques

Volume:

Volumen:

Volume:

293 l / 77.4 gal

Supply:

Alimentación:

Alimentation:

220-240 V AC, 60 Hz

SINGLE PHASE L-L ONLY

Power:

Potencia:

Puissance:

3 kW / 10,239 BTU/h

Max. pressure:

Presión máxima:

Pression max:

1 MPa / 145 PSI

Testing pressure:

Presión de prueba:

Pression d'essai:

1.5 MPa / 217 PSI

Standby loss:

Pérdida de calor:

Pertes en mode de veille:

2.8 kWh/24h

Heat exchanger

Intercambiador de calor

Échangeur de chaleur

Max. pressure:

Presión máxima:

Pression max.:

1 MPa / 145 PSI

Heating surface:

Superficie de calefacción:

Surface de chauffe:

2

1.5 m

Volume:

Volumen:

Volume:

Max. temp.:

Temperatura máxima:

Temp. max.:

/ 16.1 ft

9.5 l / 2.37 gal

95 °C / 203 °F

4010487

Conforms to UL STD. 174

Certified to CAN/CSA STD. C22.2 No.110-94

2

315277-38053

ENGLISH

www.stiebel-eltron-usa.com SB 300-400 E | 5

Page 6

INSTALLATION

Safety

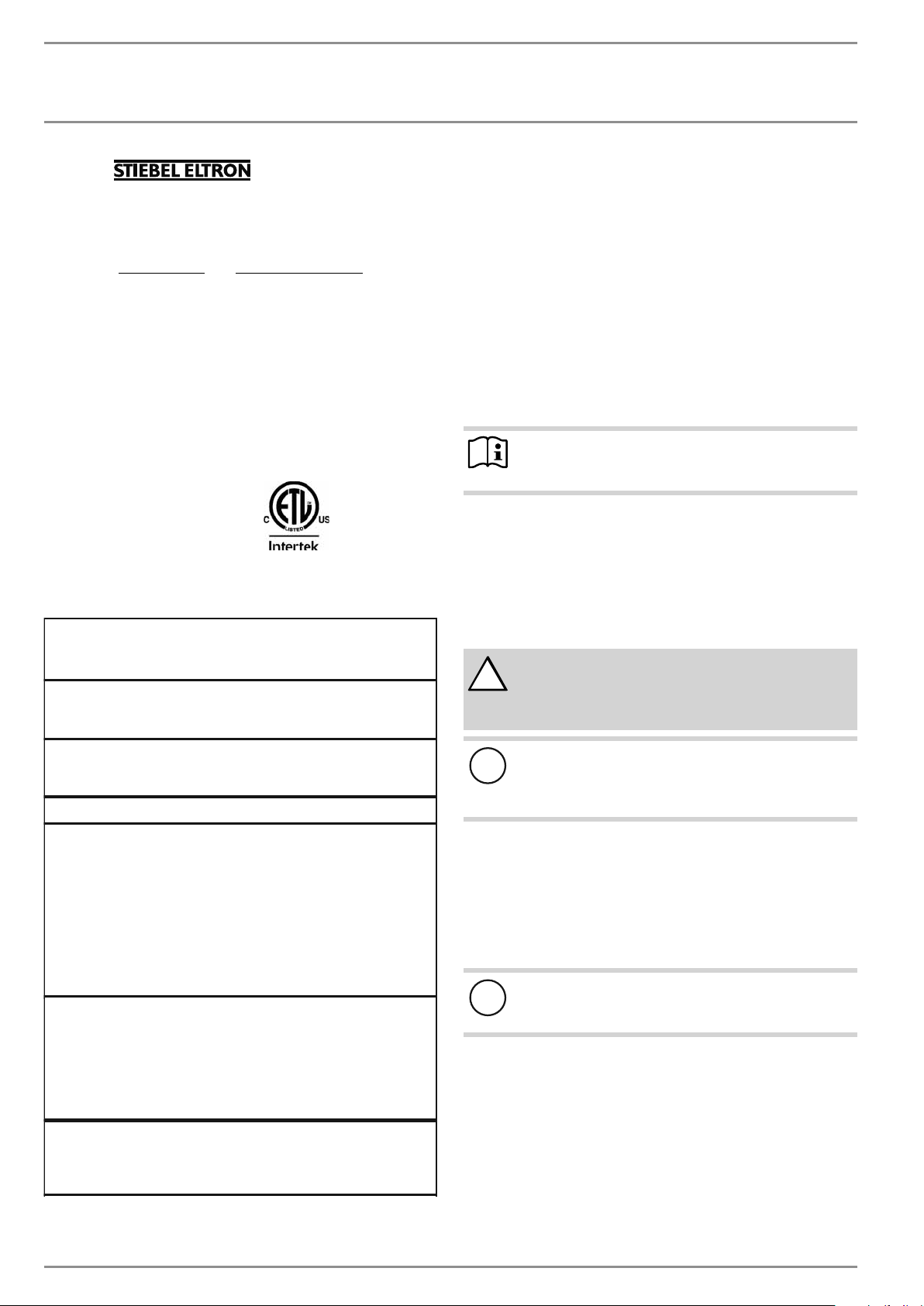

M-NO.: 234111

S-NO.:

Technical data

Datos técnicos

Données techniques

Volume:

Volumen:

Volume:

413 l / 109.1 gal

Supply:

Alimentación:

Alimentation:

220-240 V AC, 60 Hz

SINGLE PHASE L-L ONLY

Power:

Potencia:

Puissance:

3 kW / 10,239 BTU/h

Max. pressure:

Presión máxima:

Pression max:

1 MPa / 145 PSI

Testing pressure:

Presión de prueba:

Pression d'essai:

1.5 MPa / 217 PSI

Standby loss:

Pérdida de calor:

Pertes en mode de veille:

3.0 kWh/24h

SB 400 E

Made in EU

Hecho en EU

Fabriqué en EU

Heat exchanger

Intercambiador de calor

Échangeur de chaleur

Max. pressure:

Presión máxima:

Pression max.:

1 MPa / 145 PSI

Heating surface:

Superficie de calefacción:

Surface de chauffe:

Volume:

Volumen:

Volume:

Max. temp.:

Temperatura máxima:

Temp. max.:

Conforms to UL STD. 174

Certified to CAN/CSA STD. C22.2 No.110-94

2

1.92 m

/ 20.6 ft

11.1 l / 2.9 gal

95 °C / 203 °F

4010487

2

315298-38054

INSTALLATION

8. Safety

Only a qualified contractor should carry out the installation, commissioning, maintenance and repair of the appliance.

8.1 General safety instructions

To prevent the necessity of a warranty claim, use only original accessories and spare parts. If you need spare parts, call

800.582.8423.

8.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

Take note of the appliance type plate and See 15, “Specifications”,

pg. 12.

7.2 Safety label

CAUTION

To reduce the risk of electric shock or fire use only on a utility supply

having a maximum 250 volt, three wire system.

CAUTION

Risk of Electric Shock. Connect branch circuit equipment grounding

means to water heater. For detailed information, refer to instructions.

CAUTION

Risk of Electric Shock and Fire Hazard. Do not connect to supply

by extension cord.

FOR INSTALLED RATING SEE ELEMENT MARKING

Install temperature and pressure protective equipment required by

local codes, but not less than a combination temperature and

pressure relief valve certified as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22, by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed equipment

or materials. The valve must be oriented, provided with tubing, or

otherwise installed so that discharge can exit only within 6 inches

(15 cm) above, or at any distance below, the structural floor, and

cannot contact any live electrical part.

CAUTION

If the water heater is retrofitted with supplemental heating

equipment, you must adjust both the thermostat controlling the

supplemental heat source (located in the water piping) and the

thermostat on the water heater (behind the access panel) to the

same temperature. Failure to adjust both thermostats to the same

temperature can cause loss of proper temperature control.

When a supplemental heat source is connected to the

appliance, a provision must be made to limit the heat

source temperature not to exceed that of the water heater

thermostat setting.

9. Preparations

9.1 Transport

CAUTION Injury

!

f Take note of the weight of the appliance.

f Use suitable transport aids (e.g. a hand truck) and

enough personnel for transportation.

Caution

!

The appliance is top heavy.

f Make sure the unit is not tilted.

f Only set the appliance down on an even base.

Do not unpack the appliance until it has arrived in the final installation room.

Leave the appliance in its packaging and on the pallet. This enables

horizontal transport and provides places to rest during transport.

Vehicular transport

Caution

!

The appliance must generally be stored and transported

vertically.

f Observe the information on the packaging.

Safety label on the appliance

6 |SB 300-400 E www.stiebel-eltron-usa.com

Page 7

INSTALLATION

Preparations

1

1 Recessed grips

Transport from vehicle to installation room

The cardboard box has reinforced recessed grips along the top of

the appliance. You can use these recessed grips, as well as the

pallet at the lower end, to carry the appliance into the installation

room. Take note of the weight of the appliance and ensure a sufficient number of personnel is available for handling the appliance.

9.2 Storage

If it is necessary to store the appliance for a prolonged period

before installation, observe the following information:

- Only store the appliance in a vertical position. Never store

the appliance horizontally.

- Store the appliance in a location that is dry and largely

dust-free.

- Protect the appliance from coming into contact with corrosive

substances.

- The floor of the installation room must be level and have sufficient load bearing capacity. Take note of the weight of the

appliance with a full DHW tank (See 15.3, “Data table”, pg.

14). A floor with insufficient weight capacity is in danger of

collapse. If the appliance is not evenly balanced, there may

be a risk of appliance damage.

- Always leave sufficient distance to provide access for installation, maintenance and cleaning. Observe the required minimum clearances (See 9.5, “Siting the appliance”, pg. 7).

- Ensure that the operation of other equipment in the installation room is not impaired.

- To reduce the required plumbed tube length, install the unit

very close to the point.

D0000034797

The following installation locations are not permissible, due to

risk of appliance damage:

- Locations where the air is contaminated with oil or salt

- Saline environments

- Areas in proximity to high frequency machines

- Places where the air contains ammonia (e.g.sewage works)

- Places where the air contains chlorine (e.g.swimming pools)

- Generally places where the air is strongly contaminated, e.g.

due to dust, or contains aggressive substances

9.5 Siting the appliance

f Carefully undo the cardboard packaging at the clips.

1

ENGLISH

9.3 Delivery configuration

The hot water storage tank arrives with the following equipment:

-Storage unit

- Welded steel plain-ended pipe heat exchanger

- Hot water corrosion protection with special enamel coating

- Three immersion sleeves for housing of temperature probes

- Magnesium sacrificial anode

-Circulation port

- Two auxiliary heating ports

- Attached flange inspection cover

- PU foam insulation 2 in. thick

- Steel outer cover

9.4 Installation site

The appliance is not approved for outdoor installation except for

garages.

Further requirements regarding the installation room and appliance positioning, to prevent appliance damage:

- The installation location must be free from flammable, highly

combustible gases and substances, as well as high levels of

dust.

- The installation room must be free from the risk of frost.

D0000034797

1 Cardboard packaging clips

The appliance is secured to the pallet with metal brackets and

screws. The metal brackets are hooked on to the feet underneath

the floor plate of the appliance.

www.stiebel-eltron-usa.com SB 300-400 E | 7

Page 8

INSTALLATION

Installation

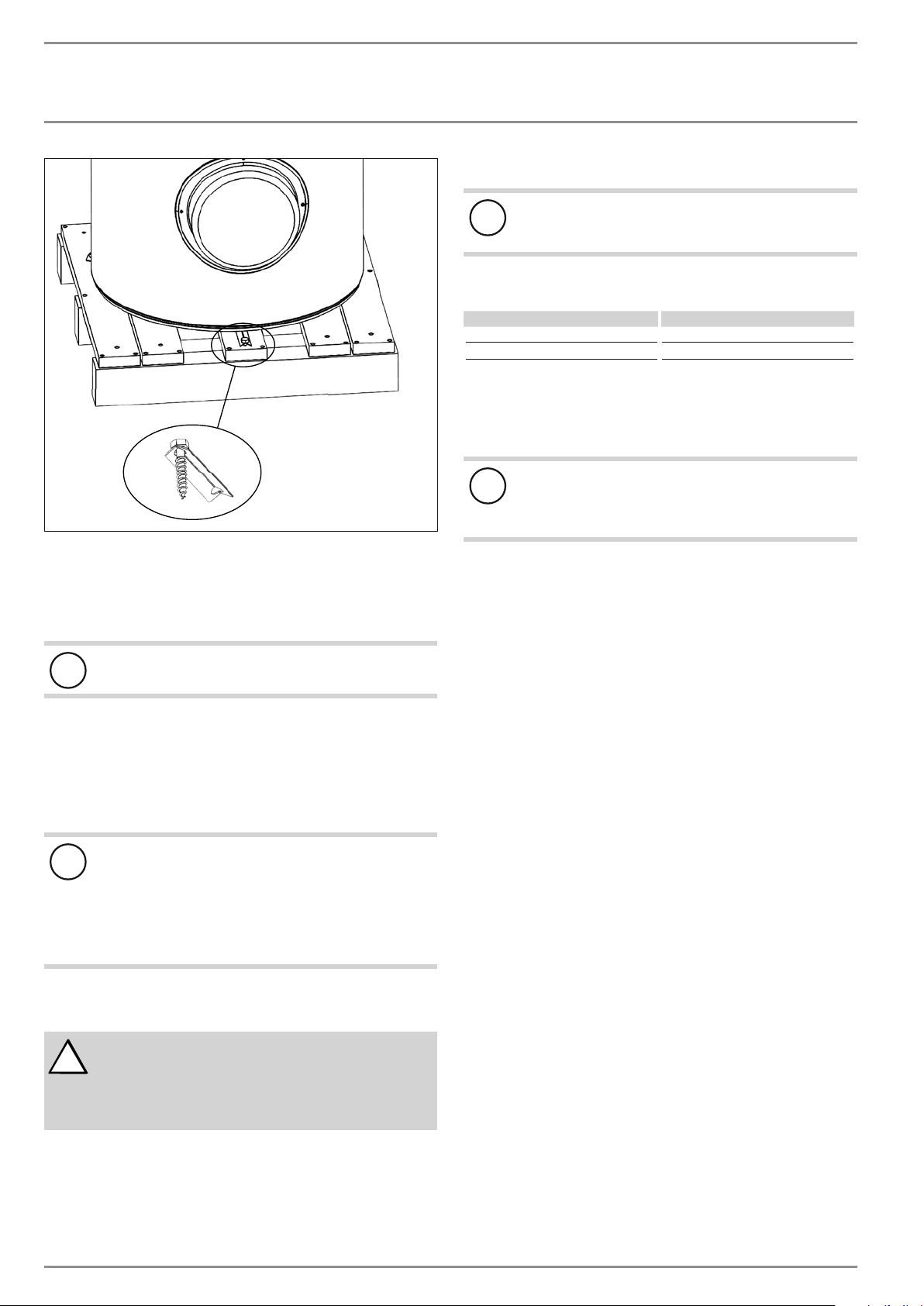

1 Metal bracket fixing screw

f Remove the fixing screw of the metal bracket from the pallet.

f Tilt the appliance to the side for each foot. Screw out the

adjustable tank foot, remove the brackets, and screw in the

adjustable tank foot.

Caution

!

Take note of the appliance's weight and top-heaviness.

f Slightly tip the appliance and carefully roll the appliance off

the pallet.

f Bring the appliance in its final location.

Minimum clearances

f Maintain the minimum clearances.

Caution

!

The appliance must be straightened vertically to avoid

appliance damage.

The feet under the floor plate of the appliance are

height-adjustable.

f Level the appliance horizontally using the height-ad-

justable feet.

10. Installation

WARNING Injury

!

Incorrect installation can lead to serious personal injury.

Before any work, ensure sufficient clearances for the

installation.

Handle sharp-edged components carefully.

10.1 Water connection

Caution

!

Carry out all water connection and installation work in

accordance with local plumbing regulations.

The following material combinations are approved for metal pipework installations:

Cold water inlet DHW outlet

Copper pipe Copper pipe

Steel pipe Steel pipe or copper pipe

f Thoroughly flush the pipework before connecting the ap-

pliance. Foreign bodies, such as welding pearls, rust, sand

or sealant can impair the operational reliability of the

appliance.

Caution

!

To protect the stubs against corrosion the water tube connection must be made with flat gaskets. The use of hemp

on stub threads is not permissible.

Safety valve

The appliance is a sealed unvented DHW tank. Provide the

appliance with a pressure relief valve.

f Install a type-tested safety valve in the T&P port on the side

of the unit. The response pressure of the safety valve must be

below or equal to the permissible operating pressure of the

DHW tank.

The safety valve protects the appliance against unacceptable excess pressure.

f Ensure that the expansion water escaping from the safety

valve can drip into a drain, e.g. a tank or sink.

Ensure the drain cannot be shut off.

f Size the drain in a way that water can drain off unimpeded

when the safety valve is fully opened.

f Ensure that the discharge pipe of the safety valve is open to

atmosphere.

f Fit the discharge pipe of the safety valve with a constant

downward slope and in a room free from the risk of frost.

Pressure reducing valve

The maximum pressure in the cold water supply line must be at

least 20% below the response pressure the safety valve. If the

maximum pressure in the cold water supply line is higher, install

a pressure reducing valve.

Drain valve

f Install a suitable drain valve at the lowest point in the cold

water inlet line.

8 |SB 300-400 E www.stiebel-eltron-usa.com

Page 9

INSTALLATION

Installation

DHW circulation

The heat losses incurred in the DHW circulation line and the electrical power consumption of the circulation pump reduce the efficiency of the system. The cooled water in the circulation line mixes

with the tank content. Where possible, avoid installing a DHW

circulation line. Where that is not possible, the DHW circulation

pump must be controlled thermally or by time switch.

Thermal insulation

f Insulate the DHW line against heat loss in accordance with

locally applicable regulations.

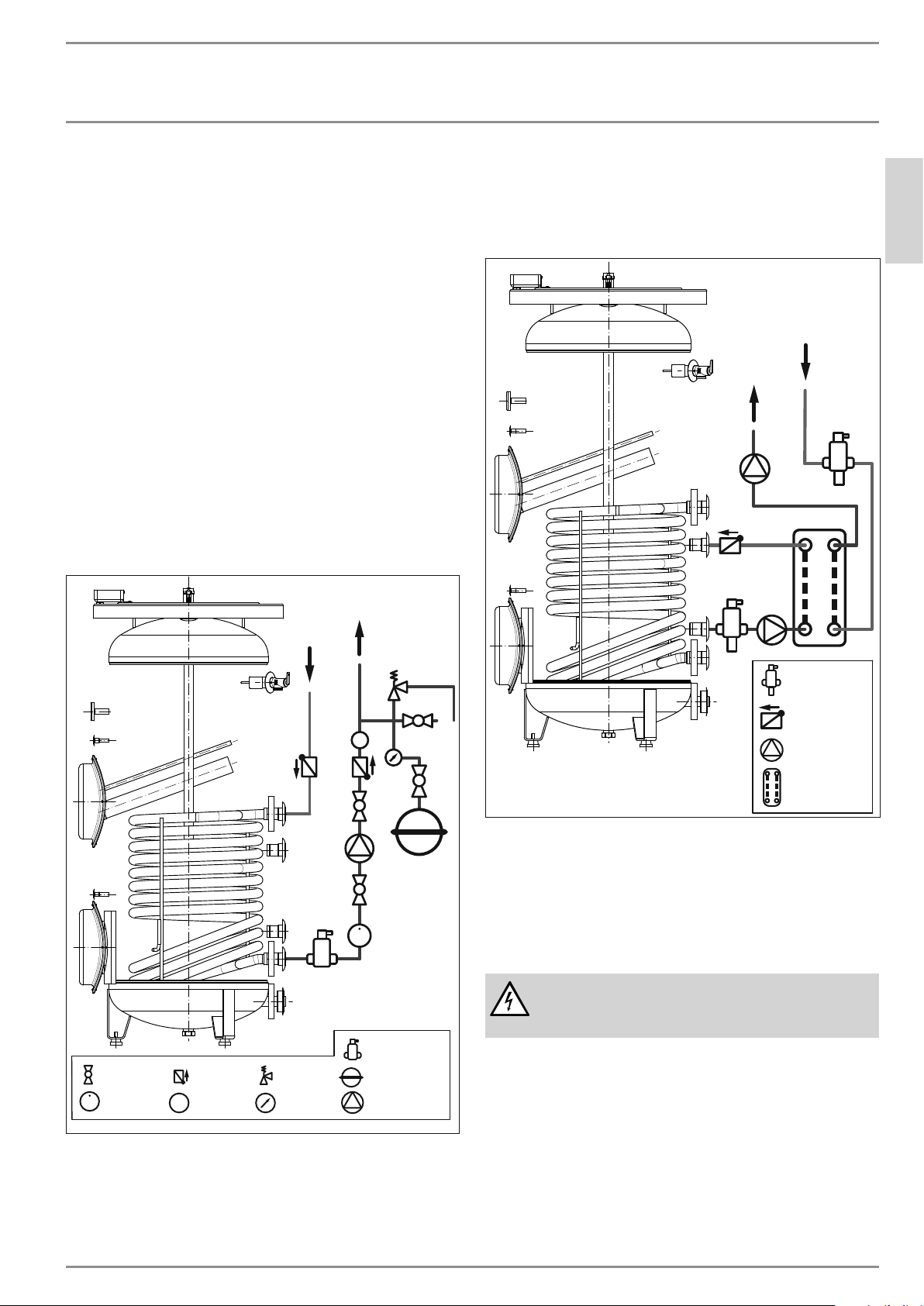

10.2 Heating connection

The heating system can be configured in a variety of ways. The

methods described here are for the most common installation

method. For more questions on installation and configuration of

the heating system, contact Stiebel Eltron.

10.2.1 Connecting to the internal coil heat exchanger

The internal coil heat exchanger connections are 1˝ NPT female.

A common use of this coil is for closed-loop solar thermal applications, like in the below image.

To solar

10.2.2 Connecting to the auxiliary ports

The auxiliary ports can be used to add another heating source,

or to supply heat stored in the tank to another location. If the

auxiliary ports are unused for heating, they can be used for a

DHW recirculation loop.

From aux.

heat source

To aux.

heat source

ENGLISH

From solar

V

Ball valve

Flow meter

Check valve

Temp. gauge

T

T&P valve

Pres. gauge

A few necessary features of this system include:

- Corrosion inhibiting propylene glycol

- Air separator/eliminator

- Circulation pump

T

V

Air separator

Expansion tank

Circulation pump

Air/dirt separator

Check valve

Circulation pump

Flat-plate HX

It is necessary for both sides of the heat exchanger to have circulation pumps and air/dirt separators. A check valve is also recommended to prevent thermosiphoning.

Consult your local plumbing code for requirements regarding heat

exchanger properties (double wall, brazed, stainless steel, etc.)

10.3 Power supply

WARNING

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

If the appliance is permanently connected to the power supply,

ensure that the appliance can be separated from the power supply by an isolator that disconnects double terminal with at least

3mm contact gap. Contactors, mains isolators or fuses can be

used for this.

Disconnect the appliance from the power supply before carrying

out work on the control panel. Prevent the power supply from

being switched on while you are working on the system.

Ensure the appliance is earthed according to locally applicable

requirements.

www.stiebel-eltron-usa.com SB 300-400 E | 9

Page 10

INSTALLATION

Commissioning

10.3.1 Installing the power cable

Caution

!

Never connect the appliance to the power supply before

the DHW tank is filled.

The power to this appliance is delivered with a power cable with

a mains plug.

f Use minimum 14/2 (with ground) AWG copper wire for in-

stallation. For long wire lengths, you may need to increase

the gauge size. Always install in accordance with all national

and local electrical codes.

f Unit shall be connected to a 15 A dual pole breaker.

f Using the 14/2 wire (or larger if the code calls for it), connect

the 14/2 wire to the 3 wires in the junction box as shown.

f Use the proper strain relief grommet where the wire enters

the junction box.

See 15.6, “Wiring diagram”, pg. 16.

11. Commissioning

11.1 Commissioning

Caution

!

Never connect the appliance to the power supply before

the DHW tank is filled.

11.1.1 Filling the DHW tank

Fill the DHW tank and vent the pipework by following the procedure below:

f Close the drain valve.

f Open all DHW tap points and the shut-off valve in the cold

water supply.

f Close the DHW tap points as soon as water starts to emerge

from them.

11.1.2 Appliance handover

f Explain the appliance function to users and familiarize them

with its operation.

f Make users aware of potential dangers, especially the risk of

scalding.

f Make users aware of critical environmental factors and re-

quirements concerning the installation location.

f Inform users that water may drip from the safety valve

during the heating operation.

f Hand over these operating and installation instructions to

users for safe-keeping.

12. Shutting down

Caution

!

If the appliance is disconnected from the power supply,

it is no longer protected against frost.

f Only disconnect the appliance from the power sup-

ply for longer periods if you are also draining the

DHW tank.

If there is no usage of hot water for a long period of time, always

drain the DHW tank. See 14.2, “Draining the tank”, pg. 11.

The appliance can only be switched off by interrupting the power

supply.

f Pull the mains plug from the socket or disconnect the appli-

ance from the mains in the fuse box.

13. Electrical Troubleshooting

WARNING Risk of Electric Shock

Prior to all work on the appliance, isolate it from the

power supply.

Caution

!

If you disconnect the appliance from the power supply, it

is no longer protected against frost.

f Only disconnect the appliance from the power sup-

ply for longer periods if you are also draining the

DHW tank.

f For work on the electric heating element, remove the heating

element cover (See 14.1, “Removing the heating element

cover”, pg. 11).

If the unit does not provide hot water, then the heating element

is likely not heating the water.

1 Check that the circuit breaker is in the on position. Reset if

necessary.

2 Inspect the connections inside the junction box. Repair if

necessary.

3 Check the voltage at the junction box connections. The volt-

age should be 240 VAC.

4 Check for proper resistance of the heating element.

f Turn off circuit breaker.

f Disconnect wire nuts on L1 and L2 and separate wires.

f Measure the resistance between the two black wires going

into the conduit of the tank. It should measure 17.6 Ω ±10%.

f If the measurement is off, there may be an internal wiring

problem or a faulty heating element. Call Stiebel Eltron for

technical support.

11.2 Recommissioning

If the appliance is switched off due to an interruption to the power

supply, no specific measures for restarting are required once the

power supply has been restored.

10 |SB 300-400 E www.stiebel-eltron-usa.com

Note

Refit the heating element cover after completing your

work. See 14, “Maintenance and cleaning”, pg. 11).

Page 11

INSTALLATION

Maintenance and cleaning

13.1 Resetting the high limit safety cut-out

The high limit safety cut-out protects the appliance from overheating. The cut-out switches off the electric element when the tank

water temperature exceeds 199–208 °F (93–98 °C).

Once the cause of the failure has been removed, press the reset

button of the high limit safety cut-out on the rod thermostat. To

do so, remove the appliance cover.

Thermal safety

cut-out

14. Maintenance and cleaning

WARNING

Prior to all work on the appliance, isolate it from the

power supply.

14.1 Removing the heating element cover

f Undo the screws that fasten the heating element cover to the

appliance.

f Pull off the cover.

14.2 Draining the tank

WARNING Burns

Hot water may escape when draining the DHW tank.

To drain the DHW tank, e.g. when shutting the appliance down,

proceed as follows:

f Unplug the appliance from the power supply.

f Close the shut-off valve in the cold water supply line.

The DHW tank is drained via the cold water supply line.

f Open the drain valve installed in the cold water supply line

(See 10.1, “Water connection”, pg. 8). If no drain valve

has been installed, undo the cold water supply line at the

"cold water inlet" connection.

f Open one tap in one sink.

Some residual water will remain in the lower section of the DHW

tank.

14.3 Descaling the electric element

Only descale the flange of the electric booster heater after removing it, and never treat the interior of the DHW tank and the

sacrificial anode with descaling agents.

14.4 Valves

Regularly check the system's valves (safety valve, pressure reducing valve, drain valve, vacuum breaker, mixing valve), to ensure the

operational reliability of the appliance. The amount of limescale

deposits depends on the local water quality.

f Check all valves in the system and remove limescale deposits.

f Replace the valves if necessary.

f Check the function of the valves.

f Whether a sand filter is installed.

14.5 Replacing the electric element cover

ENGLISH

Note

Refit the heating element cover after completing your

work.

www.stiebel-eltron-usa.com SB 300-400 E | 11

WARNING

f Reconnect the earth cable to the appliance cover.

f Place cover back in its original position.

f Secure the screws holding the cover onto the appliance.

Page 12

INSTALLATION

ZĤ¼êÐ|ŒêĒĉń

15. Specifications

15.1 Dimensions

Type SB 300 E SB 400 E Connection

A Height of tank with insulation 59.1˝ (1501 mm) 59˝ (1500 mm)

B Height of tank without insulation 57.3˝ (1456 mm) 57˝ (1448 mm)

C Height to thermometer 44.4˝ (1128 mm) 45.1˝ (1145 mm)

D Height to upper temperature sensor sleeve 40.5˝ (1028 mm) 42.7˝ (1085 mm) 9 mm

E Height to electric element opening 32.5˝ (825 mm) 34.9˝ (887 mm)

F Height to lower temperature sensor sleeve 23.4˝ (518 mm) 19.6˝ (498 mm) 9 mm

G Height to clean-out port 13.2˝ (335 mm) 12.4˝ (315 mm) 115 mm

H Height to cold water inlet 5.1˝ (129 mm) 4.3˝ (110 mm) 1˝ NPT male

I Height to heat exchanger lower port 10.8˝ (275 mm) 11˝ (280 mm) 1˝ NPT female

J Height to auxiliary heat source lower port 14.8˝ (375 mm) 15˝ (380 mm) 1˝ NP T male

K Height to auxiliary heat source upper port 25.8˝ (655 mm) 28˝ (710 mm) 1˝ NP T male

L Height to heat exchanger upper port 30.5˝ (775 mm) 32.7˝ (830 mm) 1˝ NPT female

M Height to hot water outlet (overall height) 61.1˝ (1552 mm) 60.8˝ (1544 mm) 1˝ NPT male

N Height to T&P valve port 48.3˝ (1228 mm) 48.3˝ (1228 mm) ¾˝ NPT female

O Tank diameter without 21.7˝ (550 mm) 25.6˝ (650 mm)

P Tank diameter with insulation 25.6˝ (650 mm) 29.5˝ (750 mm)

Q Foot height 0.9–1.3˝ (22–34 mm)

P

O

2

5

10

7

A

B

4

11

C

D

8

9

M

E

6

F

G

3

1

I

H

Q

L

K

J

12 |SB 300-400 E www.stiebel-eltron-usa.com

Page 13

INSTALLATION

ZĤ¼êÐ|ŒêĒĉń

13 14

12

N

15.2 Features

1 Cold water inlet

2 Hot water outlet

3 Clean-out port

4 Electric heating element

5 Analog thermometer

6 Lower heat exchanger port

7 Upper heat exchanger port

8 Lower auxiliary port

9 Upper auxiliary port

10 Upper temperature sensor sleeve

11 Lower temperature sensor sleeve

12 T&P valve port

13 Junction box

14 Anode replacement indicator

ENGLISH

30°

www.stiebel-eltron-usa.com SB 300-400 E | 13

Page 14

INSTALLATION

ZĤ¼êÐ|ŒêĒĉń

15.3 Data table

SB 300 E SB 400 E

234110 234111

Hydraulic data

Nominal capacity 79.3 gal (300 l) 105.6 gal (400 l)

Water volume 77.4 gal (293 l) 109.1 gal (413 l)

Internal coil heat exchanger volume 2.4 gal (9.5 l) 2.9 gal (11.1 l)

Internal coil heat exchanger area 16.1 ft² (1.5 m²) 20.6 ft² (1.9 m²)

Heating element

Heating element voltage 220–240 V

Heating capacity 3.0 kW (10,239 BTU/hr)

Frequency 60 Hz

Rated current 12.5 A

Required circuit breaker 15 A

Heating element type Dome element

Heating element material Ceramic

Temperature control Knob with °F & °C scale under the heating element cover

Set range of thermostat 86–167 °F (30–75 °C)

Miscellaneous

Maximum allowed pressure (tank) 145 psi (10 bar)

Maximum allowed pressure (heat exchanger) 145 psi (10 bar)

Maximum tank temperature 203 °F (95 °C)

Tank heat loss in 24 hours at 149°F / tank temperature 2.8 kWh (9,553 Btu) 3.0 kWh (10,236 Btu)

Empty weight 313 lb (142 kg) 399 lb (181 kg)

Filled weight 1,010 lb (458 kg) 1,334 lb (605 kg)

Type of anode Magnesium with wear indicator

Dimensions

Height

Diameter

Insulation thickness 2 in (50 mm) 2 in (50 mm)

Diameter without insulation

1

61

/ 8 in (1552 mm) 60 13/ 16 in (1544 mm)

9

25

/ 16 in (650 mm)

5

21

/ 8 in (550 mm) 25 9/ 16 in (650 mm)

29 ½ in (750 mm)

14 |SB 300-400 E www.stiebel-eltron-usa.com

Page 15

INSTALLATION

ZĤ¼êÐ|ŒêĒĉń

15.4 Spare parts

ENGLISH

15.5 Spare parts list

Name Part #

Pos.

1 Heating element assembly cover 315268

2 Clean-out port cover 315266

3 Flange plate 082357

4 Flange gasket 168662

5 Foam insulation for clean-out port 299891

6 3 kW heating element 296391

7 Segmented sacrificial anode 1¼˝ 143499

8 Anode sleeve 166375

9 Thermostat 269978

10 Thermal safety cut-out 279006

11 Thermostat knob 315423

12 Junction box 4x4˝ 315357

13 Electric element holder 315269

14 Gasket cap 298307

15 Terminal block 309566

16 Connection cable (not shown) 315272

17 Adjustable tank foot 291975

18 Thermometer, 32–248 °F (0–120 °C) 315265

19 Rivets for outer jacket 298745

20 T&P valve 100 psi (6.9 bar) 315664

21 Top cover for SB 300 E 315264

21a Top cover for SB 400 E 315297

22 Washer for thermostat (DIN 6797-A6.4)

23 Junction box holder 315271

24 Nut for thermostat (I4032-M6)

25 Screw for element holder (DIN7981-M4.2x16)

26 M12 12x30-8.8 ISO4017 bolt

27 Cable gland 298306

28 Junction box nut 315287

29 Washer (125-3.2-140HV-ZN)

30 Nut (I4032-M 4-4-A0E)

31 Screw for thermostat (DIN7985-M4x6)

32 Screw for terminal block (I4075-M3-18)

33 Nut for terminal block (I4032-M3-6)

34 Screw (DIN 7500 CE M5x8-Z-AoE)

35 Threaded cap seal 306211

36 Threaded cap 309113

Cable loop 315273

Insulating bushing 315540

www.stiebel-eltron-usa.com SB 300-400 E | 15

Page 16

INSTALLATION

Environment and Recycling

15.6 Wiring diagram

L2

L1

240 VAC

15 A Dual Pole

Circuit Breaker

Breaker Box

Outlet (Optional)

Wire Nuts

Black

Black

Green/Yellow

SB E Junction Box

Black

Black

Green/Yellow

Anode

Outer Casing

Wire Nuts

Tank

L1L2

Wiring Terminal

Safety Cutout

Thermostat

SB E Junction Box

The above wiring diagram shows the connection between the

circuit breaker and the SB E junction box.

Heating Element

SB E Heating Element

The above wiring diagram shows the internal pre-wired connection of the SB E.

16. Environment and Recycling

We ask you to help protect the environment. After use, dispose

of the various materials in accordance with national and local

regulations.

16 |SB 300-400 E www.stiebel-eltron-usa.com

Page 17

WARRANTY | ENVIRONMENT AND RECYCLING

17. Warranty

DHW SOLAR & INDIRECT STORAGE TANKS

All SB 150 S, SB 200 S, SB 300 E, SB 400 E, SBB 300 S, SBB 400 S, SBB 300 Plus, SBB 400 Plus,

& SBB 600 Plus Models

LIMITED WARRANTY

Subject to the terms and conditions set forth in this limited

lifetime warranty, Stiebel Eltron, Inc. (the “Manufacturer”)

hereby warrants to the original purchaser (the “Owner”) that

each storage tank (the “Tank”) shall be free from defects in the

Manufacturer’s materials or workmanship for a period of:

1. (10 Years) from the date of purchase for single, two-, and

three-family residential installations

2. (5 Years) from the date of purchase for all other

installations

3. (Excluded) sacrificial or electronic anode

As Owner’s sole and exclusive remedy for the above warranty,

Manufacturer shall, at the Manufacturer’s discretion, either

factory repair or replace the defective Tank with a replacement

unit or part(s) with comparable operating features.

Manufacturer’s maximum liability under all circumstances shall

be limited to the Owner’s purchase price for the Tank.

This limited warranty shall be the exclusive warranty made by

the Manufacturer and is made in lieu of all other warranties,

express or implied, whether written or oral, including, but

not limited to warranties of merchantability and fitness for

a particular purpose. Manufacturer shall not be liable for

incidental, consequential or contingent damages or expenses

arising directly or indirectly from any defect in the Tank or the

use of the Tank. Manufacturer shall not be liable for any water

damage or other damage to property of Owner arising, directly

or indirectly, from any defect in the Tank or the use of the Tank.

Manufacturer alone is authorized to make all warranties on

Manufacturer’s behalf and no statement, warranty or guarantee

made by any other party shall be binding on Manufacturer.

Manufacturer shall not be liable for any damage whatsoever

relating to or caused by:

1. any misuse or neglect of the Tank, any accident to the Tank,

any alteration of the Tank, or any other unintended use;

2. acts of God and circumstances over which Manufacturer

has no control;

3. installation of the Tank other than as directed by

Manufacturer and other than in accordance with

applicable building codes;

4. improper installation and/or improper materials used

by any installer and not relating to defects in parts or

workmanship of Manufacturer;

5. failure to maintain the Tank or to operate the Tank in

accordance with the Manufacturer’s specifications;

6. failed components not originally installed by the

Manufacturer as a part of the unit at the time of sale;

7. exposure to freezing conditions;

8. exposure to harmful chemicals, contaminated water,

corrosive fluids or atmosphere, liquids harmful to steel

tubing including improperly applied or maintained heat

transfer fluids.

9. utilizing the tank as an open loop heat exchanger, e.g.,

do not use in drainback systems or continually pass fresh

potable water through the units internal heat exchanger.

10. installing the Tank in a closed system without a properly

sized and installed thermal expansion tank;

11. operating the Tank without the factory installed

sacrificial anode;

12. operating the Tank under fluctuating or excessive water

pressure or in the event the Tank is supplied with nonpotable water for any duration;

13. operating the Tank when it is empty or partially full of

potable water;

14. Installing and operating the Tank outdoors;

15. operating the Tank at temperatures higher than

recommended by Manufacturer;

16. (SB E models) replacing the electric heating element

with a unit not manufactured by Stiebel Eltron or greater

in power than the originally installed element;

17. (SB E models) connecting the Tank to improper voltage

or service;

Should owner wish to return the Tank to manufacturer for

repair or replacement under this warranty, Owner must first

secure written authorization from Manufacturer. Owner shall

demonstrate proof of purchase, including a purchase date, and

shall be responsible for all removal and transportation costs.

If Owner cannot demonstrate a purchase date this warranty

shall be limited to the period beginning from the date of

manufacture stamped on the Tank. Manufacturer reserves

the right to deny warranty coverage upon Manufacturer’s

examination of the Tank. This warranty is restricted to the

Owner and cannot be assigned.

Some States and Provinces do not allow the exclusion or

limitation of certain warranties. In such cases, the limitations

set forth herein may not apply to the Owner. In such cases this

warranty shall be limited to the shortest period and lowest

damage amounts allowed by law. This warranty gives you

specific legal rights and you may also have other rights which

vary from State to State or Province to Province.

Owner shall be responsible for all labor and other charges

incurred in the removal or repair of the Tank in the field. Please

also note that the Tank must be installed in such a manner that

if any leak does occur, the flow of water from any leak will not

damage the area in which it is installed.

ENGLISH

17 West Street

This Warranty is valid for all purchases on or after June 15, 2019.

This Warranty is valid for U.S.A. & Canada only. Warranties

may vary by country. Please consult your local Stiebel Eltron

Representative for the Warranty for your country.

West Hatfield, MA 01088

TOLL FREE 800.582.8423

PHONE 413.247.3380

FAX 413.247.3369

@

stiebel-eltron-usa.com

info

www.stiebel-eltron-usa.com

www.stiebel-eltron-usa.com SB 300-400 E | 17

Page 18

ÍNDICE | FUNCIONAMIENTO

INFORMACIÓN ESPECIAL

FUNCIONAMIENTO

1. Información general __________________________________ 19

2. Seguridad ______________________________________________ 19

2.1 Uso correcto _______________________________________________ 19

2.2 Uso incorrecto _____________________________________________ 19

2.3 Instrucciones generales de seguridad ________________ 19

2.4 Circuito del intercambiador del agua _________________ 19

2.5 Símbolos de prueba ______________________________________ 20

3. Registre su producto _________________________________ 20

4. Descripción del artefacto _____________________________ 20

4.1 Calentamiento del tanque de agua ___________________ 20

5. Uso del calentador eléctrico de refuerzo ___________ 20

6. Cuidado y mantenimiento ____________________________ 21

6.1 Válvula de alivio de temperatura / presión __________ 21

6.2 Descalcificación ___________________________________________ 21

6.3 Reemplazo del ánodo de sacrificio ____________________ 21

7. Resolución de problemas de plomería _____________ 21

7.1 Informar a un técnico calificado _______________________ 22

7.2 Etiqueta de seguridad ___________________________________ 22

8. Seguridad ______________________________________________ 22

8.1 Instrucciones generales de seguridad ________________ 22

8.2 Instrucciones, normas y regulaciones ________________ 23

9. Preparativos ___________________________________________ 23

9.1 Transporte __________________________________________________ 23

9.2 Almacenamiento __________________________________________ 23

9.3 Configuración de la entrega ____________________________ 23

9.4 Lugar de instalación ______________________________________ 23

9.5 Colocación del artefacto _________________________________ 24

10. Instalación _____________________________________________ 25

10.1 Conexión de tuberías ____________________________________ 25

10.2 Conexión de calentamiento _____________________________ 25

10.3 Suministro eléctrico ______________________________________ 26

11. Puesta en marcha _____________________________________ 27

11.1 Puesta en marcha ________________________________________ 27

11.2 Reinicio _____________________________________________________ 27

12. Apagado ________________________________________________ 27

13. Resolución de problemas eléctricos ________________ 27

13.1 Reinicio después del corte de seguridad por

exceso del límite de temperatura _____________________ 28

14. Limpieza y mantenimiento ___________________________ 28

14.1 Remoción de la cubierta del calentador de

refuerzo _____________________________________________________ 28

14.2 Drenaje del tanque _______________________________________ 28

14.3 Limpieza del depósito de cal del calentador

eléctrico de refuerzo _____________________________________ 28

14.4 Válvulas _____________________________________________________ 28

14.5 Remplazo de la cubierta del calentador eléctrico

de refuerzo _________________________________________________ 28

15. Especificaciones _______________________________________ 29

15.1 Dimensiones ______________________________________________ 29

15.2 Características ___________________________________________________ 30

15.3 Tabla de datos ___________________________________________________ 31

15.4 Repuestos ________________________________________________________32

15.5 Lista de repuestos ______________________________________________ 32

15.6 Diagrama de instalación eléctrica

_____________________________________________________________________ 33

16. Medio ambiente y reciclaje _______________________________ 33

INFORMACIÓN

ESPECIAL

- Respete todas las regulaciones e instrucciones nacionales y

regionales pertinentes durante la instalación.

- El artefacto no es apto para instalar en exteriores.

- Si el artefacto está permanentemente conectado al suministro eléctrico, se debe establecer una manera de separarlo de

la red eléctrica mediante un aislante que desconecte todos

los polos con al menos 4 mm (1/8˝) de distancia entre contactos. Para ello, es posible usar contactores, interruptores

de desconexión o disyuntores.

- Respete las regulaciones de seguridad para evitar el contacto

con piezas peligrosas que conduzcan la electricidad.

- El artefacto se encuentra presurizado al expandirse el agua

durante el proceso de calentamiento, parte del agua escapará por la válvula de seguridad.

- Active con regularidad la válvula de seguridad para evitar

que se bloquee, por ejemplo, por depósitos de cal.

- Instale una válvula de seguridad testeada para el tipo específico en la red de suministro de agua fría.

- La presión máxima de la red de suministro de agua fría debe

ser al menos un 20% menor que la presión de respuesta de

la válvula de seguridad. Si la presión máxima de la red de

suministro de agua fría supera la presión de respuesta de

la válvula de seguridad, instale una válvula de reducción de

presión.

- El drenaje debe tener un tamaño suficiente para que el agua

pueda drenar de forma ininterrumpida cuando la válvula de

seguridad está totalmente abierta.

- Instale el tubo de descarga de la válvula de seguridad con

una pendiente descendiente constante y en una habitación

que lo proteja contra la escarcha.

- La abertura de descarga de la válvula de seguridad debe

tener salida al aire libre.

- La presión del circuito del intercambiador de calor nunca

debe fijarse de manera que supere a la presión de la red de

suministro de agua (doméstica) potable. En caso de que la

presión del agua potable sea demasiado baja, es posible que

deba utilizar una bomba de refuerzo a fin de garantizar que

supere la presión requerida del circuito del intercambiador

de calor.

18 |SB 300-400 E www.stiebel-eltron-usa.com

Page 19

FUNCIONAMIENTO

Información general

FUNCIONAMIENTO

1. Información general

Los capítulos “Información especial” y “Funcionamiento” están

destinados a usuarios e instaladores autorizados.

El capítulo “Instalación” está destinado solo a instaladores autorizados.

Nota

Lea estas instrucciones atentamente antes de usar el artefacto y consérvelas para consultas futuras.

Entregue las instrucciones a cualquier nuevo usuario que

las necesite.

2. Seguridad

2.1 Uso correcto

El artefacto está diseñado para el calentamiento del agua doméstica dentro de los límites de aplicación. Véase 15.3, “Tabla de

datos”, pág. 31

El artefacto está diseñado para el uso doméstico, es decir, no hace

falta un entrenamiento especial para utilizarlo con seguridad. El

artefacto también puede usarse en un entorno no doméstico, por

ejemplo una pequeña empresa, con la condición de que se utilice

de la misma manera.

Cualquier otro uso que no esté estipulado se considerará inapropiado. El cumplimiento de estas instrucciones y de las instrucciones de uso de cualquier accesorio también forma parte del uso

correcto del calentador.

2.2 Uso incorrecto

Los siguientes usos no están permitidos:

- Calentar otro líquido que no sea agua potable

- Hacer funcionar el artefacto con el tanque de agua vacío

- Hacer funcionar el artefacto fuera de los límites de aplicación

(Véase 15, “Especificaciones”, pág. 29)

- Interrumpir el suministro de electricidad

2.3 Instrucciones generales de seguridad

Solo los instaladores autorizados deben realizar los trabajos relacionados con la electricidad y la instalación de este artefacto. Los

instaladores autorizados son responsables de cumplir con todas

las regulaciones pertinentes.

Haga funcionar el artefacto solo cuando se haya completado la

instalación y tenga incorporados todos los elementos de seguridad.

ADVERTENCIA

El contacto con partes que conducen electricidad pone

en riesgo la vida. Los daños en el aislante eléctrico o

las piezas individuales pueden poner en riesgo la vida.

f Si existen daños en el aislante, corte el suministro

de electricidad y solicite una reparación.

Todos los trabajos relacionados con la electricidad deben

ser llevados a cabo por un electricista calificado.

ADVERTENCIA Quemaduras por agua caliente

El agua del tanque puede calentarse hasta alcanzar temperaturas que superan los 149 °F (65 °C). Existe el riesgo

de quemaduras por agua caliente cuando la temperatura

del agua que sale supera los 110 °F (43 °C).

f Asegúrese de no entrar en contacto con el agua que

sale durante la descarga.

ADVERTENCIA Quemaduras

El contacto con piezas calientes puede causar quemaduras.

Cuando trabaje cerca de las piezas calientes, utilice

siempre indumentaria de protección y guantes de seguridad.

Las tuberías conectadas a la salida de agua caliente del

artefacto pueden alcanzar temperaturas superiores a

los 149 °F (65 °C).

PRECAUCIÓN

!

Instale equipos de protección de la temperatura y la presión requeridos por los códigos locales y al menos una

válvula combinada de alivio de temperatura y presión

certificada por un laboratorio de pruebas reconocido

a nivel nacional que realice inspecciones periódicas de

la producción de los equipos o materiales enumerados,

cumpliendo con los requisitos para Válvulas de Alivio y

Artefactos de Cierre de Gas Automáticos para Sistemas

de Suministro de Agua Caliente, ANSI Z21.22. Esta válvula debe marcarse con una presión de ajuste máxima

que no supere la presión de trabajo máxima marcada del

calentador de agua. Instale la válvula en una abertura

provista y marcada para este propósito en el calentador

de agua, y oriéntela o instale las tuberías de manera

que cualquier escape de la válvula salga solo a 152 mm

(6 pulgadas) por encima, o a cualquier distancia por debajo del piso estructural, y que no entre en contacto con

ninguna pieza que conduzca electricidad.

Precaución

!

Haga funcionar el artefacto solamente con el tanque de

agua lleno.

Precaución

!

Mantenga el ambiente donde se instaló el artefacto libre

de aire contaminado con aceite o sales, o sustancias corrosivas o explosivas.

ESPAÑOL

2.4 Circuito del intercambiador del agua

Los tanques SB E cuentan con un circuito del intercambiador de

calor a fuego indirecto. Puede utilizarse en diversos entornos que

incluyen circuitos de caldera, sistemas geotérmicos, circuitos de

www.stiebel-eltron-usa.com SB 300-400 E | 19

Page 20

FUNCIONAMIENTO

Registre su producto

piso radiante, etc. Debido a que el interior del intercambiador de

calor es de acero al carbono no revestido, debe configurarse en

un circuito cerrado.

Utilizar únicamente una mezcla de propilenglicol inhibido y agua

desionizada. El porcentaje de glicol en la muestra depende del

ambiente. Algunas áreas requieren que el propilenglicol sea reconocido generalmente como seguro (GRAS), es decir, un líquido

apto para uso alimentario (Intercambiador de calor tipo SW, Líquido Clase II de la Asociación Estadounidense de Obras Hidráulicas

– véase la Hoja de datos sobre la seguridad de los materiales para

conocer las instrucciones de manipulación.

2.5 Símbolos de prueba

Véase 7.1.1, “Ejemplo de placa de identificación”, pág. 22

3. Registre su producto

NOTA:

Debe registrar este producto en un plazo de 90 días

desde la compra a través de nuestra página web para

activar cualquier garantía estándar o para optar a la

ampliación de la garantía. Visite nuestra página web

www.stiebel-eltron-usa.com y haga clic en “Registre

su producto”.

Antes de comenzar el proceso de registro, le sugerimos que recopile la siguiente información que necesitará:

Modelo; ejemplo: SB 300 E (tomado de la etiqueta situada en el

lado de la unidad)

Número que se indica después de “Nr.”

Lugar de compra

Fecha de compra

Nombre y apellido

Dirección de email

Dirección postal

Número de teléfono

Si tiene alguna pregunta en relación con el proceso de registro

o con las opciones de garantía, por favor, póngase en contacto

directamente con Stiebel Eltron USA en el número de teléfono

800.582.8423.

4. Descripción del artefacto

El calentador está diseñado para instalarse en interiores. El artefacto está equipado para calentar agua mediante varios métodos

de calentamiento diferentes.

La unidad puede calentar agua de las siguientes tres maneras:

- Calentador de refuerzo por resistencia eléctrica de 3 kW

- Calor indirecto mediante intercambiador de calor con espiral

interno

- Calor indirecto mediante puertos auxiliares de entrada/salida

Todo el calentador y el sistema de agua caliente deben llenarse

con agua y tener una ventilación de aire adecuada. En caso de

utilizar los colectores solares y las calderas, sírvase consultar las

instrucciones de instalación de los mismos.

4.1 Calentamiento del tanque de agua

El primer método de calentamiento es mediante el calentador de

refuerzo por resistencia eléctrica de 3 kW. Este es el funcionamiento más básico del calentador.

Un sensor de temperatura integral detecta el contenido de energía térmica de la cantidad de calor dentro del tanque de agua. El

agua del tanque se calienta si la cantidad de calor es inferior a la

requerida para alcanzar la temperatura fijada.

El segundo método de calentamiento es mediante el intercambiador de calor con espiral interno. Este intercambiador de calor está

diseñado para que un líquido de transferencia de calor circule a

través de él desde un calentador indirecto. Este calentador indirecto puede consistir en un sistema térmico solar, una caldera u

otro artefacto tradicional de circuito cerrado que genera calor y

lo transfiere a través de un líquido de transferencia de calor con

inhibición de la corrosión.

El tercer método de calentamiento es mediante puertos auxiliares

ubicados del lado de la unidad. Estos puertos auxiliares proporcionan acceso directo al agua doméstica que se encuentra en

el tanque. Debe utilizarse un intercambiador de calor de placa

plana para intercambiar calor entre un calentador indirecto y el

agua del tanque.

Si alguno de los últimos dos métodos de calentamiento requiriese un sensor de temperatura, del lado opuesto del tanque se

proporcionan 2 puertos de las conexiones auxiliares y del intercambiador de calor.

5. Uso del calentador eléctrico de

refuerzo

Este producto viene equipado con un calentador eléctrico de refuerzo de 3 kW. El calentador de refuerzo cuenta con una sonda

de temperatura integrada que detecta la temperatura del agua

del tanque.

El elemento calefactor eléctrico 3 kW viene ajustado de fábrica

a 125 °F (52 °C). El valor de referencia del calentador de refuerzo

puede cambiarse fácilmente. Debajo del calentador de refuerzo,

hay una perilla que puede cambiar el nivel de comodidad para

adaptarse a las necesidades del usuario.

El calentador de refuerzo puede desenchufarse durante un periodo de desuso o puede removerse por completo.

Por comodidad, el calentador de refuerzo puede removerse del

tanque sin drenarlo.

20 |SB 300-400 E www.stiebel-eltron-usa.com

Page 21

FUNCIONAMIENTO

Cuidado y mantenimiento

Perilla del termostato

Muesca del

punto de

referencia

6. Cuidado y mantenimiento

El cuidado y mantenimiento de rutina extienden la vida útil y la

seguridad de funcionamiento de la unidad de almacenamiento

de agua caliente. El exterior debe limpiarse con un trapo un poco

húmedo y con un producto de limpieza neutro disponible en el

mercado. Esto debe hacerse con regularidad.

ADVERTENCIA

Nunca rocíe el artefacto con agua.

Nunca rocíe agua dentro del artefacto.

ADVERTENCIA Lesiones

!

Solo un técnico calificado debe efectuar las tareas de

mantenimiento, como las verificaciones eléctricas de

seguridad.

Componentes del

artefacto

Exterior

Tanque de agua

Calentador por resistencia eléctrica

Consejos para el cuidado y mantenimiento

Use un trapo húmedo para limpiar las secciones exteriores. Nunca use productos de limpieza abrasivos

o corrosivos.

El tanque de agua está equipado con un ánodo de

sacrificio y un indicador de desgaste que protege el

tanque de la corrosión. El indicador de desgaste debe

revisarse con regularidad. De otra manera existe el

riesgo de corrosión.

Verifique el estado del calentador por resistencia

eléctrica. Esto extenderá la vida útil del calentador

de refuerzo.

6.1 Válvula de alivio de temperatura / presión

ADVERTENCIA: La válvula de alivio de temperatura y

!

presión está diseñada para aliviar la presión acumulada en el calentador de agua. El líquido puede descargarse a

una temperatura y/o presión elevadas. Es posible que se produzcan lesiones por quemaduras con agua caliente.

Es necesario hacer funcionar correctamente la válvula de alivio de

temperatura y presión a fin de evitar que la unidad de almacenamiento de agua caliente se dañe. Durante el llenado de la unidad

con agua fría, la válvula de temperatura y presión debe estar

abierta. Cuando el agua fluye a raudales de la línea de alivio, el

tanque se encuentra lleno, y la válvula de temperatura y presión

puede volver a colocarse en su posición normal.

6.2 Descalcificación

Con agua de red dura, se formará un depósito de sarro en el interior de la unidad de almacenamiento. En base a la experiencia

profesional, es necesario descalcificarla con disolventes disponibles en el mercado a intervalos oportunos. Siga las instrucciones

del fabricante para el uso de disolventes. Para realizar este proceso, la unidad de almacenamiento de agua caliente debe vaciarse.

La cubierta del puerto de limpieza debe retirarse y los sedimentos

del fondo del tanque deben enjuagarse.

6.3 Reemplazo del ánodo de sacrificio

Según la composición del agua de red, se recomienda realizar

una inspección del ánodo de sacrificio a intervalos oportunos.

Con el uso intenso, deberá instalarse un ánodo de reemplazo del

equipo original para proteger el envase interior de la corrosión.

Debe llevarse a cabo una inspección al menos una vez por año.

7. Resolución de problemas de

plomería

Problema Causa Solución

Presión de agua

insuficiente

Flujo de

agua caliente

insuficiente

El tanque de

almacenamiento

de agua caliente

no se calienta

Velocidad de

flujo del grifo

insuficiente

El suministro de

agua caliente se

agotó demasiado rápido

La válvula de cierre no está

completamente abierta.

O

La red de suministro de agua

caliente o fría está obstruida.

La temperatura de referencia

de la caldera indirecta es demasiado baja.

Se recomienda una temperatura de 176 a 185 °F (80 a

85 °C).

O

El intercambiador de calor se

encuentra calcificado.

La selección del programa en

el control del calentador no

es adecuada.

El aireador del punto de extracción está bloqueado.

La velocidad de flujo es muy

alta. Se recomienda un volumen de 9.8 a 14.7 litros/

minutos (2.6 a 3.9 gpm).

Abra la válvula de cierre.

Limpie o reemplace las tuberías.

Fije la caldera en la temperatura recomendada.

O

Limpie el intercambiador de

calor.

Seleccione y configure el

programa de acuerdo con las

instrucciones.

Desenrosque el aireador y

límpielo

Restringir la velocidad de la

válvula del grifo.

ESPAÑOL

www.stiebel-eltron-usa.com SB 300-400 E | 21

Page 22

INSTALACIÓN

Seguridad

7.1 Informar a un técnico calificado

Si usted no puede solucionar la falla, informe a un técnico calificado. Para facilitar y agilizar su solicitud, proporcione el número de

serie que se encuentra en la placa de identificación de la unidad

(000000-0000-00000). La placa de identificación se encuentra a

la izquierda, arriba de la conexión de salida de agua caliente

(“DHW outlet”).

7.1.1 Ejemplo de placa de identificación

Made in EU

Hecho en EU

Fabriqué en EU

SB 300 E

M-NO.: 234110

S-NO.:

Technical data

Datos técnicos

Données techniques

Volume:

Volumen:

Volume:

293 l / 77.4 gal

Supply:

Alimentación:

Alimentation:

220-240 V AC, 60 Hz

SINGLE PHASE L-L ONLY

Power:

Potencia:

Puissance:

3 kW / 10,239 BTU/h

Max. pressure:

Presión máxima:

Pression max:

1 MPa / 145 PSI

Testing pressure:

Presión de prueba:

Pression d'essai:

1.5 MPa / 217 PSI

Standby loss:

Pérdida de calor:

Pertes en mode de veille:

2.8 kWh/24h

Heat exchanger

Intercambiador de calor

Échangeur de chaleur

Max. pressure:

Presión máxima:

Pression max.:

1 MPa / 145 PSI

Heating surface:

Superficie de calefacción:

Surface de chauffe:

2

1.5 m

Volume:

Volumen:

Volume:

Max. temp.:

Temperatura máxima:

Temp. max.:

/ 16.1 ft

9.5 l / 2.37 gal

95 °C / 203 °F

4010487

Conforms to UL STD. 174

Certified to CAN/CSA STD. C22.2 No.110-94

Made in EU

Hecho en EU

Fabriqué en EU

2

315277-38053

SB 400 E

M-NO.: 234111

S-NO.:

Technical data

Datos técnicos

Données techniques

Volume:

Volumen:

Volume:

413 l / 109.1 gal

Supply:

Alimentación:

Alimentation:

220-240 V AC, 60 Hz

SINGLE PHASE L-L ONLY

Power:

Potencia:

Puissance:

3 kW / 10,239 BTU/h

Max. pressure:

Presión máxima:

Pression max:

1 MPa / 145 PSI

Testing pressure:

Presión de prueba:

Pression d'essai:

1.5 MPa / 217 PSI

Standby loss:

Pérdida de calor:

Pertes en mode de veille:

3.0 kWh/24h

Heat exchanger

Intercambiador de calor

Échangeur de chaleur

Max. pressure:

Presión máxima:

Pression max.:

1 MPa / 145 PSI

Heating surface:

Superficie de calefacción:

Surface de chauffe:

Volume:

Volumen:

Volume:

Max. temp.:

Temperatura máxima:

Temp. max.:

Conforms to UL STD. 174

Certified to CAN/CSA STD. C22.2 No.110-94

2

/ 20.6 ft

1.92 m

11.1 l / 2.9 gal

95 °C / 203 °F

4010487

2

315298-38054

7.2 Etiqueta de seguridad

CAUTION

To reduce the risk of electric shock or fire use only on a utility supply

having a maximum 250 volt, three wire system.

CAUTION

Risk of Electric Shock. Connect branch circuit equipment grounding

means to water heater. For detailed information, refer to instructions.

CAUTION

Risk of Electric Shock and Fire Hazard. Do not connect to supply

by extension cord.

FOR INSTALLED RATING SEE ELEMENT MARKING

Install temperature and pressure protective equipment required by

local codes, but not less than a combination temperature and

pressure relief valve certified as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22, by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed equipment

or materials. The valve must be oriented, provided with tubing, or

otherwise installed so that discharge can exit only within 6 inches