Page 1

OPERATION AND INSTALLAT ION

Central ventilation unit with heat recovery

» LWZ70E

Page 2

2 | LWZ70E www.stiebel-eltron.com

CONTENTS | SPECIAL INFORMATION

SPECIAL INFORMATION

OPERATION

1. General information �����������������������������������������3

1.1 Safety instructions ����������������������������������������������� 3

1.2 Other symbols in this documentation ����������������������� 3

1.3 Units of measurement ������������������������������������������ 3

1.4 Standardised output data �������������������������������������� 3

2. Safety ���������������������������������������������������������� 3

2.1 Intended use ������������������������������������������������������ 3

2.2 General safety instructions ������������������������������������ 4

2.3 Test symbols ������������������������������������������������������ 4

3. Appliance description ���������������������������������������4

4. Settings �������������������������������������������������������4

4.1 Remote control ��������������������������������������������������� 4

4.2 User interface on the appliance������������������������������� 4

4.3 Switching the appliance on ������������������������������������ 5

4.4 Switching off the appliance ������������������������������������ 5

4.5 Standard mode ��������������������������������������������������� 6

5. Maintenance, cleaning and care ����������������������������7

5.1 Replacement filter ����������������������������������������������� 7

5.2 Cleaning filters ��������������������������������������������������� 7

6. Troubleshooting ����������������������������������������������8

6.1 Fault analysis ����������������������������������������������������� 8

6.2 Fault code ��������������������������������������������������������� 8

INSTALLATION

7. Safety ���������������������������������������������������������� 9

7.1 General safety instructions ������������������������������������ 9

7.2 Instructions, standards and regulations �������������������� 9

7.3 Operation of the appliance in buildings with

combustion equipment ����������������������������������������� 9

8. Appliance description ������������������������������������� 10

8.1 Standard delivery ����������������������������������������������� 10

8.2 Required accessories ������������������������������������������10

8.3 Further accessories��������������������������������������������� 10

9. Preparations ������������������������������������������������ 10

9.1 Installation site �������������������������������������������������� 10

9.2 Transport ��������������������������������������������������������� 10

10. Installation �������������������������������������������������� 10

10.1 Mounting the appliance ���������������������������������������10

10.2 Connecting the condensate drain ��������������������������� 11

10.3 Connecting air ducts ������������������������������������������� 11

10.4 Power supply ���������������������������������������������������� 12

11. Commissioning ��������������������������������������������� 12

11.1 Initial start-up ��������������������������������������������������� 12

11.2 Shutdown ��������������������������������������������������������12

11.3 Recommissioning ����������������������������������������������� 12

12. Settings ����������������������������������������������������� 13

12.1 Settings menu ��������������������������������������������������� 13

12.2 Read-out menu �������������������������������������������������14

12.3 Service menu ���������������������������������������������������� 15

12.4 Restoring factory settings ������������������������������������� 16

SPECIAL INFORMATION

- The appliance may be used by children aged8

and up and persons with reduced physical, sensory or mental capabilities or a lack of experience

and know-how, provided that they are supervised

or they have been instructed on how to use the

appliance safely and have understood the resulting risks. Children must never play with the appliance. Children must never clean the appliance

or perform user maintenance unless they are

supervised.

- The power cable must only be replaced (for example if damaged) by qualified contractors authorised by the manufacturer.

- Secure the appliance as described in chapter "Installation/ Installation".

13. Maintenance ������������������������������������������������ 16

14. Troubleshooting �������������������������������������������� 18

15. Specification ������������������������������������������������ 19

15.1 Dimensions and connections ��������������������������������� 19

15.2 Standard circuit ������������������������������������������������� 20

15.3 Wiring diagram ������������������������������������������������� 21

15.4 Fan diagram �����������������������������������������������������22

15.5 Data table �������������������������������������������������������� 23

GUARANTEE

ENVIRONMENT AND RECYCLING

Page 3

OPERATION

General information

ENGLISH

www.stiebel-eltron.com LWZ70E | 3

OPERATION

1. General information

The chapters "Special Information" and "Operation" are intended

for both the user and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to any new user where appropriate.

1.1 Safety instructions

1.1.1 Structure of safety instructions

!

KEYWORD Type of risk

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

Injury

Electrocution

Burns

(burns, scalding)

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

injury or death.

WARNING Failure to observe this information may result in serious

injury or death.

CAUTION Failure to observe this information may result in non-seri-

ous or minor injury.

1.2 Other symbols in this documentation

Note

General information is identified by the adjacent symbol.

Read these texts carefully.

Symbol Meaning

Material losses

(appliance damage, consequential losses and environmental pollution)

Symbol Meaning

Appliance disposal

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

1.4 Standardised output data

Explanations to determine and interpret the specified standardised

output data

1.4.1 Standard: DINEN 13141-7

The output data specifically mentioned in text, diagrams and

technical datasheets has been determined in line with the test

conditions described in the standard shown in the heading of

this chapter.

Generally, these standardised test conditions will not fully meet

the conditions found at the installation site of the system user.

Depending on the chosen test method and the extent to which

the selected method deviates from the conditions described in the

standard shown in the heading of this chapter, any deviations can

have a considerable impact. Further factors that have an influence

on the test values are the measuring equipment, the system configuration, the age of the system and the flow rates.

A confirmation of the specified output data can only be obtained

if the conditions applicable to the relevant test match those of the

standard shown in the heading of this chapter.

2. Safety

2.1 Intended use

The appliance is designed as a mechanical ventilation unit with

centralised supply air and extract air routing.

This appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a non-domestic environment, e.g.in a small business, as long as it is used

in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

It is deemed inappropriate to:

- Use extract air loaded with grease, explosive gases, dust or

adhesive aerosols

- Install the unit outdoors

- Connect cooker hoods and dryer exhausts to the ventilation

system.

Never adjust the setting of supply and extract air valves inside the

rooms. These have been set up by a qualified contractor during

commissioning.

!

!

Page 4

OPERATION

Appliance description

4 | LWZ70E www.stiebel-eltron.com

2.2 General safety instructions

!

WARNING Injury

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided

that they are supervised or they have been instructed on

how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

Note

Trouble-free operation of the appliance is only possible

with a closed appliance cover.

2.3 Test symbols

See type plate on the appliance.

3. Appliance description

The appliance draws in outdoor air with a fan. A second fan draws

in extract air from rooms in the home with odour or humidity loads

(kitchen, bathroom and WC). Extract air and outdoor air are routed

through separate ducts. Extract air and outdoor air are filtered

by separate filters.

Both air streams are routed through a cross-countercurrent heat

exchanger. The extract air gives off heat, which is transferred to

the outdoor air. This means that the extracted stale indoor air

heats the fresh clean outdoor air, saving energy and routing fresh

air into the interior.

You can use the user interface to infinitely adjust the air flow rates.

The appliance has a filter service indicator, as well as an optional

filter service indicator at the stage switch.

The control unit has three fan stages. The air flow rate is preset

for each fan stage by the qualified contractor. Constant flow rate

control ensures that the air flow rates of the supply air and extract

air are achieved irrespective of the duct pressure.

Fan stage

Humidity protection ventilation: This fan stage prevents mould

formation using the factory-set air flow rate of 50m³/h. Alternatively, the contractor can set an air flow rate of 0m³/h when

commissioning the appliance. In such a case, no humidity protection is provided.

Fan stage1 should be seen as background ventilation, to be se-

lected when going away for example.

Fan stage2 is recommended for standard ventilation.

Fan stage3 is recommended as intensive ventilation, to temporarily increase the air flow rate for load peaks (e.g. as a party

stage).

Frost protection

On account of the high heat recovery level, low outdoor temperatures result in the extract air being cooled down so severely that

any condensate that is created in the process may freeze. Frost

protection ensures that the extract air side of the heat exchanger

cannot freeze. Depending on the outdoor air temperature and

the pressure drop at the heat exchanger, the balance between

the supply air flow and the extract air flow is disrupted, thus preventing freezing. The supply air fan may also, for short periods,

be switched OFF at very low outdoor temperatures. Preheating

the outdoor air by using an electric preheating coil or by means

of a geothermal heat exchanger, for example, can prevent this

imbalance or can prevent the supply air fan shutting down.

Bypass function

The appliance is equipped with a bypass function. If the conditions

for the bypass function are met, the ventilation air fan is switched

off. This enables warm indoor air to be transported away. Once

the conditions for the bypass function are no longer being met,

the ventilation air fan is switched back on.

The bypass function can be adjusted in the settings menu using

parameters 05, 06 and 07.

Conditions

Bypass function

active

The outside temperature is higher than 10°C and lower

than the room temperature, and the room temperature is

higher than the bypass temperature set in parameter 05.

Bypass function

inactive

The outside temperature is lower than 10°C.

The outside temperature is at least 0.5°C higher than the

room temperature.

The room temperature is lower than the bypass temperature reduced by the bypass hysteresis. The bypass

temperature is set in parameter 05. The bypass hysteresis

is set in parameter 06.

4. Settings

Note

User operations are restricted to switching the appliance

ON and OFF. The basic settings are set by your qualified

contractor when commissioning the appliance.

4.1 Remote control

Observe the operating and installation instructions for the relevant

remote control (see chapter "Appliance description/ Required accessories" or "Appliance description / Other accessories").

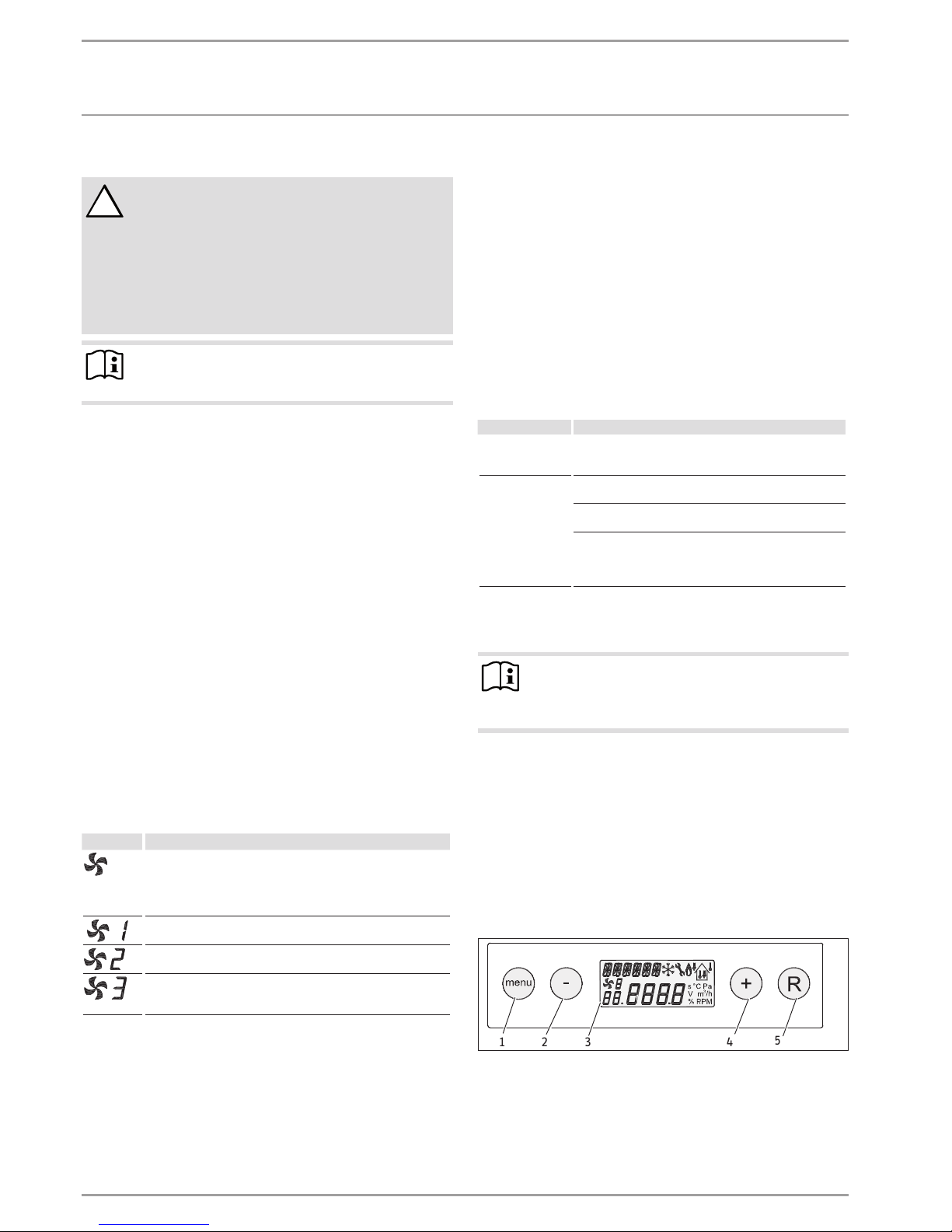

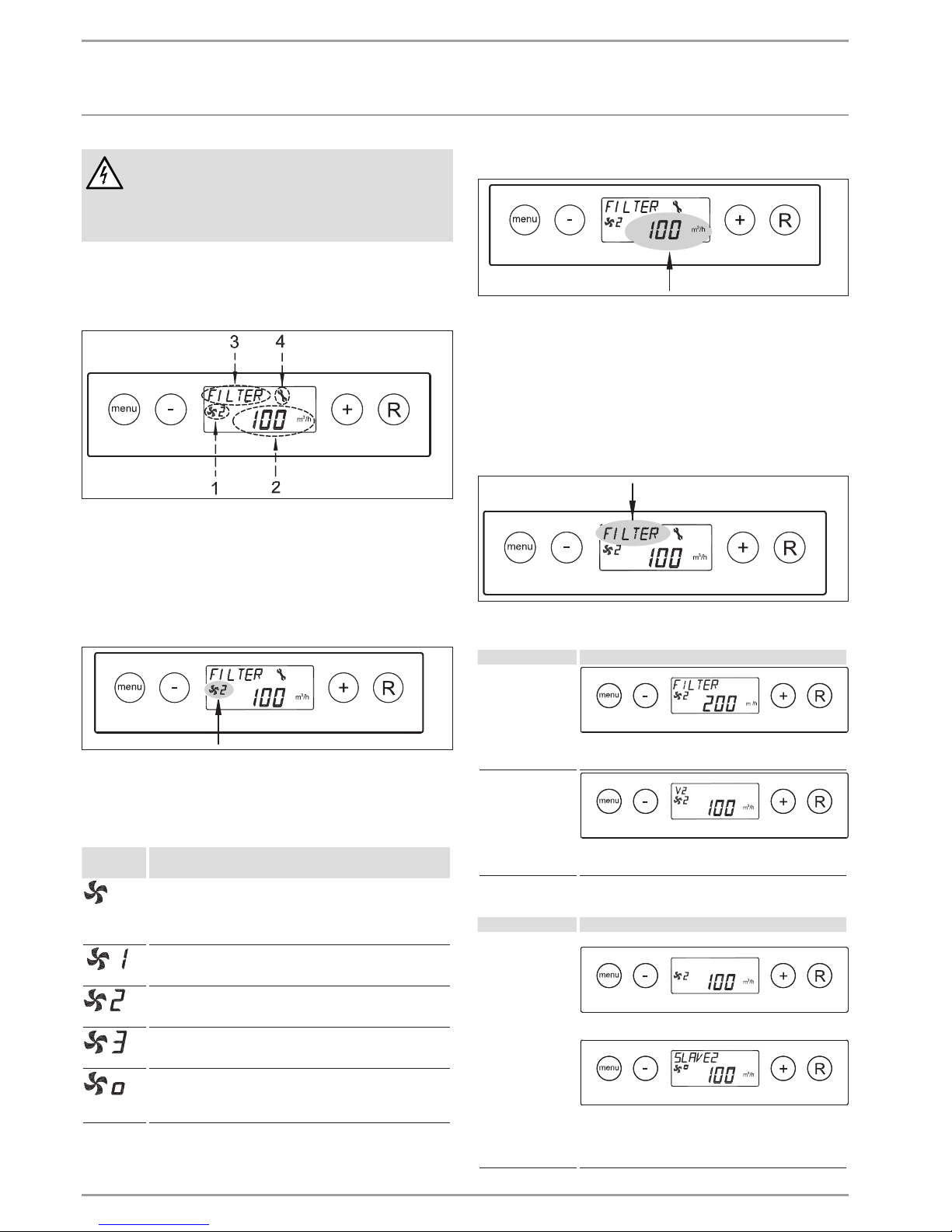

4.2 User interface on the appliance

The appliance has a user interface with display. This enables

air flow rates to be variably adjusted or operating details to be

checked.

D0000044898

1 2 3 4

5

1 Menu key

2 Minus key

3 LCD

4 Plus key

5 R key

You can access and change settings using the four keys (menu,

plus, minus, R).

Page 5

OPERATION

Settings

ENGLISH

www.stiebel-eltron.com LWZ70E | 5

When the mains power is switched on, all available symbols are

displayed for two seconds. The backlight is also switched on for

60 seconds.

If one of the keys is pressed, the display is illuminated for 30

seconds.

If no keys are pressed and/or if no blocking fault occurs, standard

mode is displayed.

When the menu key is pressed, you can use the plus or minus key

to choose between three different sub-menus:

- Settings menu (SET)

- Read-out menu (READ)

- Service menu (SERV)

With the R key, you can exit any selected menu and return to

standard mode.

To switch on the display backlight without changing anything in

the menu, press the R key briefly (less than 5 seconds).

Button Key function

Menu Open menu; open sub-menu; enable parameter for value change;

confirm value change

- Scroll; adjust value; switch appliance on or off from standard mode

(press and hold down for 5 seconds)

+ Scroll; adjust value

R One step back in the menu; reset adjusted value; filter reset (press

and hold down for 5 seconds); delete fault history

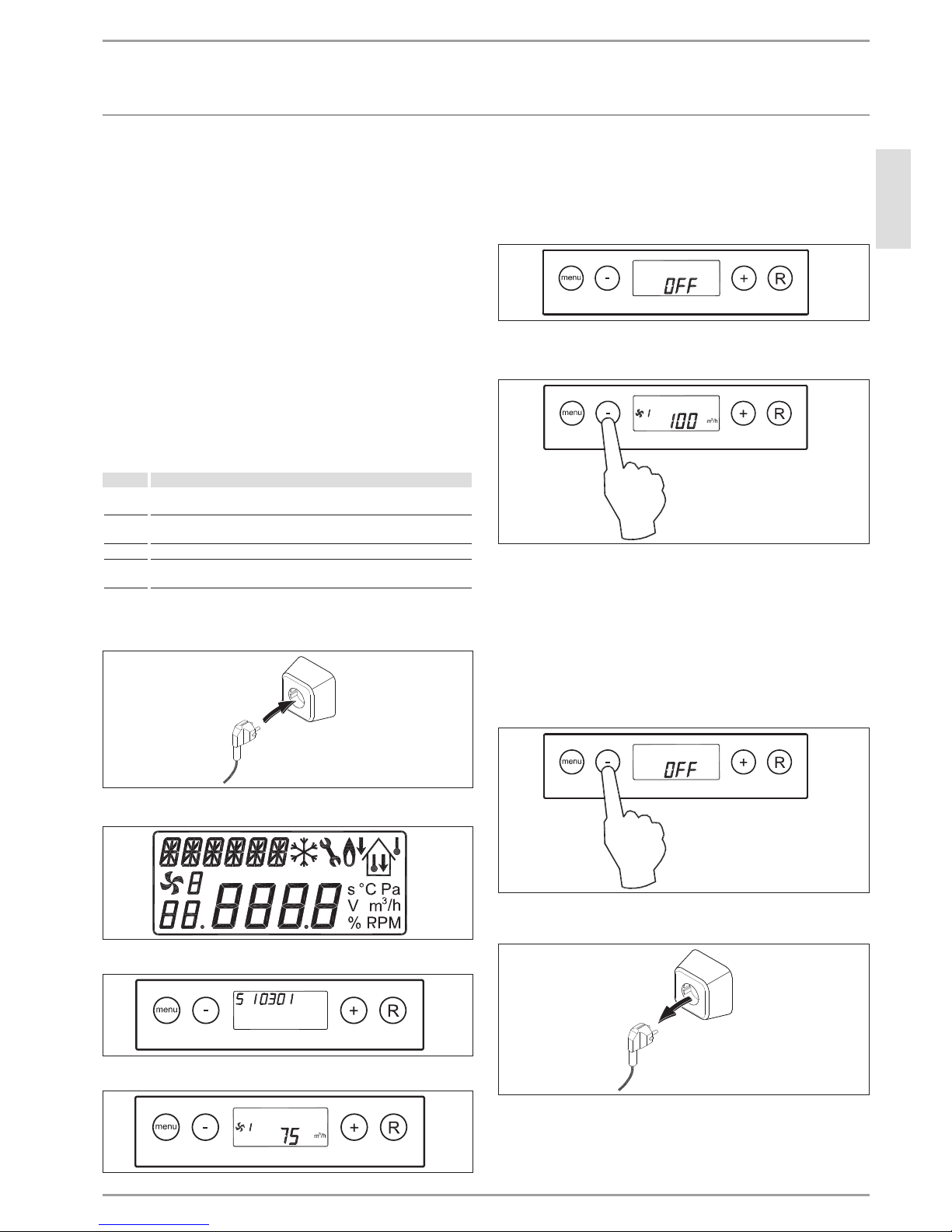

4.3 Switching the appliance on

26�04�15�0009

Plug the appliance into a standard socket.

26�04�15�0011

All display symbols are shown for two seconds.

26�04�15�0029

The software version is displayed for two seconds.

D0000044916

The appliance then runs according to the stage switch setting. If

no stage switch is connected, the appliance always runs in fan

stage1.

Switching on via software

26�04�15�0032

If the appliance has been switched off via software, "OFF" is displayed.

5 s

26�04�15�0031

Switch on the appliance by pressing the minusbutton for 5

seconds.

4.4 Switching off the appliance

Switching off via software

Press and hold down the minus button for 5 seconds to

switch off the appliance.

The display shows "OFF".

5s

26�04�15�0048

Interrupting the power supply

26�04�15�0010

The display is now blank.

Page 6

OPERATION

Settings

6 | LWZ70E www.stiebel-eltron.com

WARNING Electrocution

Before working on the appliance, always isolate the

appliance from the power supply by first switching the

appliance off via the software and then unplugging it

from the mains.

4.5 Standard mode

In standard mode, the display shows up to four different pieces of

information (operating modes and values) simultaneously.

D0000044913

1 Indication of the fan stage, indication of connected

appliances

2 Indication of the air flow rate

3 Message text, e.g. filter status text, triggering of external

switching contact, etc.

4 Fault symbol

4.5.1 Fan stage

D0000044914

A fan symbol is displayed when the supply air fan and the extract

air fan rotate. The fan symbol is not visible when the fans are at

a standstill.

The number after the fan symbol indicates the fan stage.

Fan stage

indicator

Description

The supply air and extract air fans generate an air flow rate of

50m³/h or stop. This depends on the setting of parameter 01.

This fan stage cannot be enabled with a 3-stage switch. This fan

stage prevents mould formation using the factory-set air flow

rate of 50m³/h.

The supply air and extract air fans rotate according to stage1

of the stage switch. The air flow rate depends on the parameter

02 setting.

The supply air and extract air fans rotate according to stage 2

of the stage switch. The air flow rate depends on the parameter

03 setting.

The supply air and extract air fans rotate according to stage 3

of the stage switch. The air flow rate depends on the parameter

04 setting.

A number of appliances of this type have been connected. The

supply air and extract air fans rotate according to the fan stage

selected at the master appliance. If the appliance is connected

in a cascade, the slave number of the appliance is displayed.

4.5.2 Indication of the air flow rate

D0000044915

The selected air flow rate of the supply air and extract air fans is

displayed.

If the air flow rates of the supply air and extract air fans differ,

e.g. when an external switching contact is used, the highest air

flow rate is always displayed.

If you switch the appliance off using the programming unit, the

text "OFF" appears.

4.5.3 Message texts in standard mode

D0000044921

At this point on the display, a message text may appear. The message text "FILTER" always takes priority over other message texts.

Message text Description

FILTER

If FILTE R is displayed, the filter must be cleaned or replaced.

V1 or V2

If V1 or V2 is displayed, one of the 0-10V inputs is enabled.

Only when using connection X1:

Message text Description

Slave 1, Slave 2, etc.

Master appliance:

Slave appliance:

With connected appliances, the message tex t indicates

which appliance is the "Slave 1" to "Slave 9". The default

display for fan operation is indicated on the master

appliance.

Page 7

OPERATION

Maintenance, cleaning and care

ENGLISH

www.stiebel-eltron.com LWZ70E | 7

5. Maintenance, cleaning and care

Maintenance by the user is limited to filter cleaning or replacement

required at certain intervals.

5.1 Replacement filter

Produc t designation

Part number Description

FMSLWZ 70 222446 Filter mat G3;

10pce per packing unit

FMSF7-2 70 227660 Fine f ilter F7;

2pce per packing unit

5.2 Cleaning filters

Filters must be cleaned when "FILT ER" is displayed.

D0000044917

Replace filters annually.

Never operate the appliance without filters.

Cleaning or replacing filters

> 5 s

D0000041945

Press and hold down the minus button for 5 seconds to

switch off the appliance.

Remove the filter flaps.

D0000041946

1

2

1 Extract air filter

2 Supply air filter

Extract the supply air and extract air filters. Make a note of

how the filters were fitted.

26�04� 15�0015

Clean the filters, e.g. with a vacuum cleaner.

D0000041947

Push the cleaned or new filter into the appliance.

> 5 s

D0000041948

Assemble the two filter flaps.

Switch on the appliance by pressing the minusbutton for 5

seconds.

5s

1

2 3

D0000044937

After cleaning or replacing the filters, hold down the R key

for 5 seconds to reset the filter display.

Page 8

OPERATION

Troubleshooting

8 | LWZ70E www.stiebel-eltron.com

To confirm that the filters have been reset, the text "FILT ER" will

flash briefly. Even if the message "FILTER" has not yet been displayed, you can reset the filter message. The counter is then reset

to zero.

Once the filter has been reset, the text "FILT ER" disappears and

standard mode is displayed again.

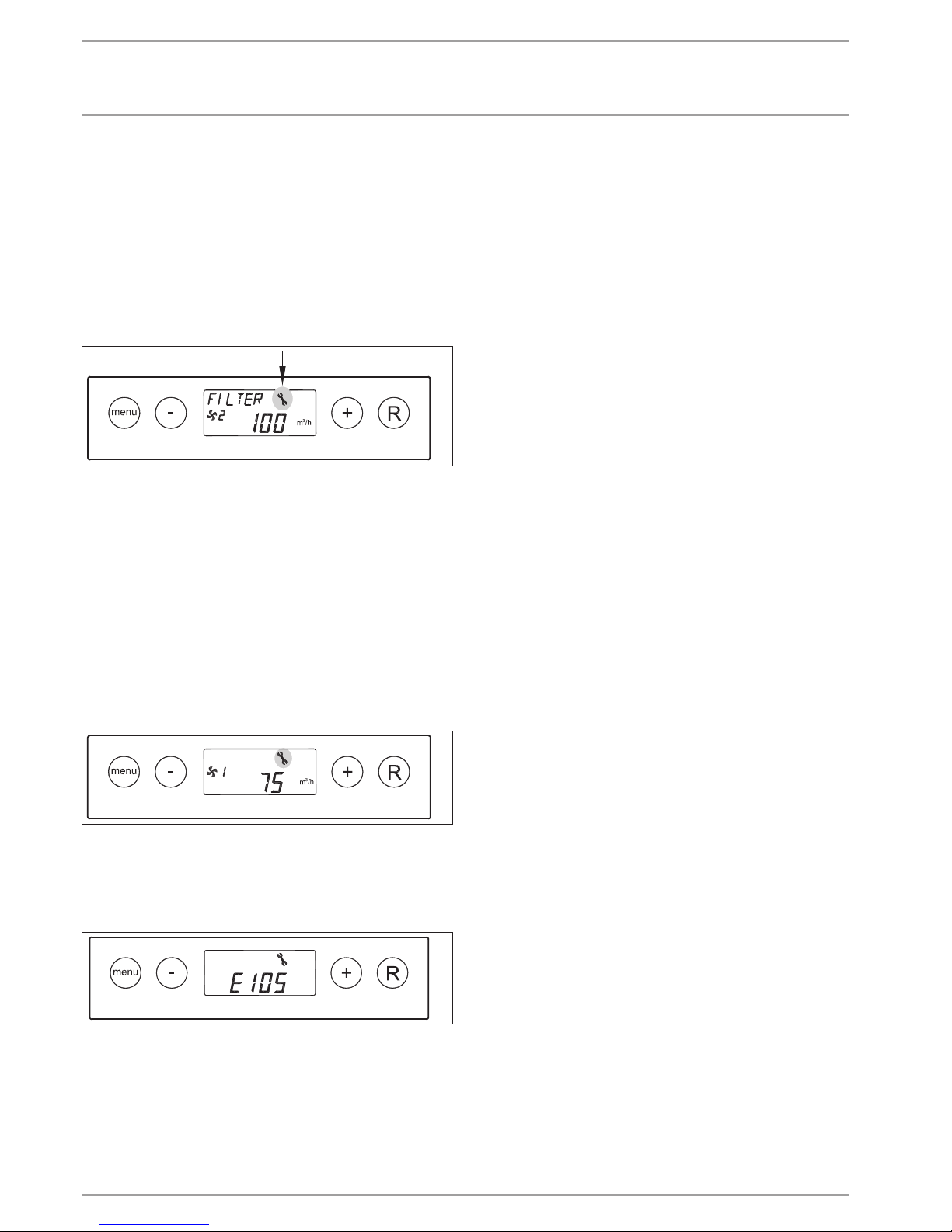

6. Troubleshooting

6.1 Fault analysis

D0000044931

If the appliance detects a fault, a flashing fault symbol (spanner)

is displayed, possibly together with a fault code. The appliance

differentiates between a fault, where the appliance continues to

operate with limited functionality, and a blocking fault, where both

fans are stopped. In the event of a blocking fault, the settings and

read-out menus are also switched off and access is restricted to

the service menu.

The appliance remains in this fault condition until the problem has

been resolved. The appliance then resets itself (auto reset) and

standard mode is displayed again.

6.2 Fault code

Non-blocking fault

D0000044923

If the appliance detects a non-blocking fault code, it continues to

operate with limited functionality. Non-blocking faults are displayed with the fault symbol (spanner).

Blocking fault

D0000036353

If the appliance detects a blocking fault code, it stops. The permanently illuminated display shows the fault symbol (spanner)

together with a fault code.

Notify a qualified contractor, who can correct the fault.

A blocking fault cannot be resolved by briefly disconnecting the

appliance from the power supply. The fault itself must first be

rectified.

If you cannot remedy the fault, notify your qualified contractor.

To facilitate and speed up your request, provide the number from

the type plate (000000-0000-000000). The type plate is located on

the appliance cover.

Page 9

ENGLISH

www.stiebel-eltron.com LWZ70E | 9

INSTALLATION

Safety

INSTALLATION

7. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free function and operational reliability only

if original accessories and spare parts intended for the appliance

are used.

7.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

7.3 Operation of the appliance in buildings with

combustion equipment

If the building contains combustion equipment (tiled stoves, fireplaces, etc.), the responsible flue gas inspector must be consulted

in the planning phase. The flue gas inspector assesses whether all

statutory regulations are being observed. Here, a differentiation

is made between balanced and open flue combustion equipment.

For simultaneous operation of combustion equipment and a mechanical ventilation system, we recommend choosing approved

room sealed combustion equipment (in Germany, DIBt approval).

7.3.1 Room sealed combustion equipment

In conjunction with room sealed combustion equipment, no additional precautions are generally required. Assessment is carried

out by the flue gas inspector.

7.3.2 Open flue combustion equipment

!

WARNING INJURY

If open flue combustion equipment is operated with the

mechanical ventilation system, tested safety equipment

must be installed. The combustion equipment must also

have a separate combustion air supply.

With open flue combustion equipment, a differentiation must be

made between alternate and simultaneous operation of the ventilation system and combustion equipment.

Alternate operation

Operation on alternate sides means that, when the combustion

equipment is commissioned, the mechanical ventilation system is

switched off and/or cannot be started.

Simultaneous operation

!

WARNING INJURY

To prevent any flue gas escaping into the installation

room, it is necessary to ensure that sufficient combustion

air is supplied or that the negative pressure in room

where the stove is installed is not greater than 4 Pa.

Tested safety equipment must be installed to monitor the

chimney draught (differential pressure monitoring) and

to switch off the ventilation unit in the event of a fault.

Connect the safety equipment according to the chapter "Installation/ Electrical connection/ Connecting safety equipment for

stove/fireplace operation".

The equipment for differential pressure monitoring should fulfil

the following requirements:

- Monitoring of the differential pressure between the connection piece to the chimney and the room where the combustion equipment is installed.

- Possibility of matching the shutdown value for the differential

pressure to the minimum draught requirement for the combustion equipment.

- Floating contact to switch off ventilation.

- Optional connection of a temperature capturing device so

that differential pressure monitoring is only enabled when

the combustion equipment is in operation and so that unwanted shutdowns due to environmental influences can be

avoided.

Note

Differential pressure switches that use the pressure

differential between the outdoor air pressure and the

pressure in the room where the combustion equipment

is sited as a response criterion are not suitable.

The mechanical ventilation system is switched off when the safety

equipment responds.

Note

The maximum available external pressure (see chapter

"Specification/ Data table") must not be exceeded.

Page 10

10 | LWZ70E www.stiebel-eltron.com

INSTALLATION

Appliance description

8. Appliance description

8.1 Standard delivery

The following are delivered with the appliance:

- Wall mounting bracket set (2mounting brackets, 3protective caps, 1rubber strip, 2rubber rings, 1 set of installation

instructions)

- PVC condensate drain (1x1.5” threaded plastic nut, 1 sealing

ring, 1 PVC glued joint)

- Approx. 90 cm long cable for connecting a remote control

8.2 Required accessories

- Hardwired remote control used to control the air flow rates

preset in three stages. Our range of accessories includes remote control units with additional functions.

8.3 Further accessories

- Preheater coil

- You can obtain ventilation pipes, extract air and supply air

valves and similar accessories from us.

9. Preparations

9.1 Installation site

The appliance can be mounted on the wall with the wall mounting

bracket set supplied.

!

Material losses

For vibration-free mounting, a solid wall with a minimum

mass of 200kg/m2 is required. A plaster board or metal

framed wall is inadequate. Additional measures such as

a double skin or additional supports would be needed

in such cases.

Ensure the equipment is level after installation.

The installation site must have an adequate condensate drain with

stench trap and a fall for the condensate.

The installation site must be free from the risk of frost.

Minimum clearances

≥300

≥300

D0000041883

9.2 Transport

To protect the appliance against damage, you should transport it

to the installation room inside its original packaging.

10. Installation

10.1 Mounting the appliance

10 mm

26�04� 15�0078

Undo the two top crosshead screws on the back of the

appliance.

Secure one of the two rails to the appliance with screws.

!

Material losses

Check whether the wall can bear the weight of the

appliance.

Use appropriate rawl plugs and screws suitable for

the wall structure to attach the rail.

Mount the second rail on the wall as a retainer. To avoid

sound transmission, place the washers supplied between the

wall and the rail.

Affix the spacers supplied to the back of the appliance.

Page 11

ENGLISH

www.stiebel-eltron.com LWZ70E | 11

INSTALLATION

Installation

26�04� 15�0079

Place the rubber strips supplied on the rail mounted on the

wall. The rubber strip helps provide sound insulation.

Fit the appliance so that the two rails interlock.

10.2 Connecting the condensate drain

!

Material losses

Never kink the hose, to ensure the condensate drains

perfectly. The fall must be at least 10%. Ensure the device

is level after installation.

> 60

D0000041960

The condensate drain is routed through the floor plate. The condensate must drain away via the domestic sewer system.

Secure the condensate drain connector supplied along with

the gasket and union nut to the condensate drain located underneath the appliance.

You can fit the condensate drain pipe (bent if required) to this

condensate drain connector with a glued joint.

Before connecting the condensate drain to the appliance,

pour water into the siphon to create a stench trap.

The condensate drain pipe must terminate below the water level

in the siphon. The condensate drain pipe must be immersed in

the water in the siphon by at least 60 mm.

10.3 Connecting air ducts

During installation, ensure that no metal swarf enters the

ductwork. However, should this still occur, you must remove this

material, otherwise the fans may be damaged.

External wall ducts

Supply outdoor air from a location where contamination (dust,

soot, odours, flue gas, exhaust air) is as low as possible.

When installing external wall ducts, prevent any short circuit between the air intake and the air discharge.

Silencers

Install a silencer in both the supply air and extract air ducts. We

recommend installing additional silencers if required to avoid

sound transmission.

If a room with a high noise level must be ventilated, install additional silencers upstream of this room to reduce sound transmission to adjacent rooms.

Aspects such as carried voices and impact sound must also be

taken into consideration in the case of ducts embedded in concrete. Carried voices should be avoided by designing the duct

with separate branches to the extract air and supply air valves.

If required, insulate the supply air ducts, e.g. if they are outside

the insulated wall panel.

Overflow apertures

In living rooms and bedrooms, air is only blown in. Air is only

extracted from rooms where odours and moisture are generated.

Ventilation grilles must be installed in internal doors or walls,

or the air gap beneath the door must be increased to ≥ 8 mm to

ensure an unobstructed air flow.

Insulation against condensation

!

Material losses

When warm air meets cold surfaces, condensation can

result.

For outdoor air and exhaust air ducts, use va-

pour-proof thermally insulated pipes.

If you use uninsulated pipes and moulded parts for

this pipework, ensure that they are adequately insulated.

Insulate the supply air and extract air ducts if they

are routed through unheated rooms.

The extract air duct does not require a control valve, because the

necessary air flow rates are controlled by the appliance itself.

Page 12

12 | LWZ70E www.stiebel-eltron.com

INSTALLATION

Commissioning

10.4 Power supply

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

WARNING Electrocution

Before connecting the appliance to the mains power supply, isolate all power cables. Isolation from the mains

power supply must be carried out with a contact separation of at least 3 mm, e.g. by means of omnipolar

isolators.

You can connect the appliance to a standard socket with the plug

fitted to the appliance.

1

2

D0000041968

1

2

3

4

5

1 Power cable

2 Two-pole screw connection (only suitable for low voltage)

3 Modular plug-in connection (RJ12, only suitable for low

voltage)

4 Service connection

5 Entry electrical cables

Connecting safety equipment for stove/fireplace operation so

that the safety equipment can interrupt the power supply

Connect the safety equipment in accordance with the dia-

gram in chapter "Specification/ Standard circuit".

11. Commissioning

11.1 Initial start-up

Setting the air flow rate

Output and energy consumption of the appliance depend on the

pressure drop in the duct system and the resistance of the filters.

Fan stage Air flow rate

m³/h

0

50: Moisture protection ventilation

This fan stage prevents mould formation using the

factory-set air flow rate of 50m³/h.

m³/h must be lower than for stage 2

m³/h must be lower than for stage 3

m³/h 50 - 180

The air flow rate of the higher fan stage is automatically selected

if one of the above conditions is not met.

11.2 Shutdown

Even during longer periods away from home, we recommended

that the equipment should be allowed, via the remote control,

to run at switch position1. If you nevertheless need to take the

appliance out of use for an extended period, switch it off via the

user interface and unplug it from the mains to isolate it from the

power supply.

Clean or replace filters.

11.3 Recommissioning

Check whether filters are fitted in the appliance. Never start

the appliance without filters.

Check whether the condensate drain is damaged or kinked.

Page 13

ENGLISH

www.stiebel-eltron.com LWZ70E | 13

INSTALLATION

Settings

12. Settings

12.1 Settings menu

For optimum appliance function, you can change parameters used

to adapt the appliance to the actual installation. Some parameter

settings such as the air flow rates have been set out in the technical

details appertaining your individual building.

Note

Changes to settings not described may only be made by

agreement with the manufacturer. Incorrect settings may

impair the correct appliance function.

12.1.1 How to set parameters

Press menu in standard mode.

The settings menu is displayed ("SET").

26�04�15�0064

Enabling the settings menu

Press menu again to enable the settings menu.

D0000044922

Selecting parameters

Use the plus or minus key to select the parameter you want

to set.

D0000044924

1 2

1 Parameter number

2 Parameter value

Parameter change

Press menu.

D0000044926

The parameter value starts to flash.

D0000044929

Use plus or minus to change the parameter value.

Discarding a parameter change

If you do not want to save the amended parameter value,

press the R key.

D0000044927

Confirm parameter value

D0000044928

If you do want to save the amended parameter value, press

the R key.

Note

To change other parameters, repeat the steps described

from "Selecting parameters". If you do not want to change

any more parameters, press R. This brings you back to

normal operating mode.

Page 14

14 | LWZ70E www.stiebel-eltron.com

INSTALLATION

Settings

12.1.2 List of parameters in the settings menu

Parameter Description Unit Factory

sett ing

Setting range Step

size

Display text and

symbols

01

Air flow rate of stage

m3/h 50 0

50: Moisture protection ventilation

02 Air flow rate of stage 1 m3/h 75 50- 180 5

03 Air flow rate of stage 2 m3/h 100 50 - 180 5

04 Air flow rate of stage 3 m3/h 150 50-180 5

05 Bypass temperature °C 22 15 - 35 0.5

BYPA SS

06 Bypass hysteresis °C 2 0 - 5 0.5

BY HYS

07 Bypass function 0 0 (Automatic function)

BYPA SS

1 (bypass function permanently inactive)

2 (bypass function permanently active)

08 BUS address 0 0 - 9 (0 = master) BUSADR

09 Introduction of an additional ex-

tract air flow.

OFF This parameter is not relevant for you. As default, this

parameter must remain OFF for this appliance.

CV+WTW

10 Pressure imbalance permissible ON OFF (Air flow rate for supply/extract air the same)

ON (Pressure imbalance permissible)

11 Fixed pressure imbalance m3/h 0 -50 - 50 1

12 Preheating coil connected OFF ON (Preheater coil connected)

OFF (No preheater coil)

13 - 29 no function

30 Humidity sensor OFF OFF (Humidity sensor switched off )

ON (Humidity sensor switched on)

31 Humidity sensor sensitivity 0 2 (sensitive) to -2 (least sensitive)

12.2 Read-out menu

With the read-out menu, you can call up some values for more

detailed information on the function of the appliance. Values and

settings cannot be changed in the read-out menu.

26�04�15�0064

Press menu in standard mode.

The settings menu is displayed ("SET").

26�04� 15�0071

Press plus or minus to switch to the read-out menu.

26�04� 15�0072

Press Menu to enable the read-out menu.

26�04� 15�0073

1 2

Use plus or minus in the read-out menu to move to the re-

quired parameter.

Read-out menu Descr ipt ion of the actual value Unit

01 Room temperature °C

02 Outside temperature (captured by the outside

temperature sensor)

o

C

03 Bypass status (ON = Bypass function active, OFF =

Bypass function not active)

04 Frost protection status (ON = Frost protection en-

abled, OFF = Frost protection disabled)

Page 15

ENGLISH

www.stiebel-eltron.com LWZ70E | 15

INSTALLATION

Settings

2 x

D0000044932

Press R twice to return to standard mode.

If no key is pressed for 5 minutes, the appliance returns automatically to standard mode.

12.3 Service menu

In the service menu, you can view the last 10 fault messages.

In the case of blocking faults, the settings menu and the read-out

menu are blocked and only the service menu can be accessed.

Pressing menu opens the service menu.

Viewing the service menu

26�04�15�0064

Press menu in standard mode. The settings menu is

displayed.

26�04�15�0057

Press plus or minus to switch to the read-out menu.

26�04�15�0058

1

2

1 Fault message number

2 Fault code

Press the menu button to enable the service menu.

You can use plus and minus to scroll through the read-out menu.

Indication "No fault message"

26�04�15�0056

Current fault message (fault symbol on the display)

For fault messages with a cause that has not yet been eliminated,

the fault symbol (spanner) appears.

26�04� 15�0075

Resolved fault message (no fault symbol on the display)

For fault messages with a caused that has been eliminated, the

fault symbol (spanner) does not appear.

26�04� 15�0076

Back to standard mode

2 x

D0000044932

Press R twice to return to standard mode.

Deleting fault messages

You can delete all fault messages by holding down R for five seconds. This is only possible if there are no active faults.

Page 16

16 | LWZ70E www.stiebel-eltron.com

INSTALLATION

Maintenance

12.4 Restoring factory settings

It is possible to reset all changed settings simultaneously to factory

settings.

All changed settings revert back to their factory default settings;

all message/fault codes are also deleted from the service menu.

D0000044930

Press plus and minus simultaneously and hold down for 10

seconds.

All display symbols light up for three seconds. The appliance is

then in standard mode.

13. Maintenance

WARNING Electrocution

In the event of damage to the power cable this must

always be replaced by a qualified contractor authorised

by the manufacturer, using original spare parts.

Maintenance by the qualified contractor includes the cleaning of

the cross-countercurrent heat exchanger and the fans.

Subject to runtime, this maintenance work should be carried out

every 3 years.

Switch off the appliance by pressing the minus key for

5seconds.

Disconnect the power supply.

Remove the filter flaps.

Extract the filters. Make a note of how the filters were fitted.

2x

D0000041949

Remove the front cover.

D0000041950

Remove the display.

D0000041951

Pull the insert on which the control PCB is fitted out of the

appliance.

Disconnect all plugs on the control PCB that are connected to

plug-in connections at the top of the appliance.

Remove the earth wire from the appliance body.

D0000041952

Remove the heat exchanger from the appliance. Avoid dam-

aging the foam parts in the appliance.

Page 17

ENGLISH

www.stiebel-eltron.com LWZ70E | 17

INSTALLATION

Maintenance

26�04�15�0047

Use a commercially available vacuum cleaner to remove dust

and other loose dirt particles from the intake and discharge

surfaces.

If required, clean the heat exchanger with warm water

(max.55 °C) and a commercially available detergent. Never

use solvents.

Afterwards flush the heat exchanger with water.

D0000041953

Extract the fan unit from the appliance.

D0000041954

Remove the fans.

Clean the fans with a soft brush.

Do not move the pressure compensation weights.

Reinstall the fans.

Push the complete fan unit back into the appliance.

Reconnect the fan cables to the PCB. Observe the label in

the appliance to establish the correct position for the plug-in

connections.

Slide the insert with the control PCB into the appliance.

Install the display.

Reconnect all cables disconnected before cleaning, to their

original position.

Slide the heat exchanger back into the appliance.

Fit the front cover.

Insert the filters, respectively with their clean sides facing

towards the heat exchanger.

Assemble the filter flaps.

Switch on the power supply.

Switch on the appliance using the user interface by holding

down minus for 5 seconds.

After cleaning the filter or installing a new filter, reset the fil-

ter status indicator by holding down R for 5 seconds.

Cleaning the air ducts

Air ducts should be checked and possibly cleaned at regular intervals. Releasing the air ducts from the appliance or over the

extract air and supply air valves enables inspection and cleaning.

Page 18

18 | LWZ70E www.stiebel-eltron.com

INSTALLATION

Troubleshooting

14. Troubleshooting

Fault

code

Blocking

fault

Cause

Appliance b ehaviour

Measure

E104

Yes

The extract air

fan is faulty.

Both fans are

switched off. The

preheating coil, if

present, is switched

off. Restarting

occurs ever y 5 minutes.

Isolate the appliance

from the power supply. Replace the extract air fan. Switch

on the power supply

to the appliance

again. The fault is

reset automatically.

Check the cabling.

E105

Yes

The supply air

fan is faulty.

Both fans are

switched off. The

preheating coil, if

present, is switched

off. The reheater

coil, if present,

is switched off.

Restar ting occurs

every 5 minutes.

Isolate the appliance

from the power supply. Replace the supply air fan. Switch on

the power supply to

the appliance again.

The fault is reset

automatically. Check

the cabling.

E106

Yes

The temperature sensor

for capturing

the outside

temperature is

faulty.

Both fans are

switched off. The

preheating coil, if

present, is switched

off.

Isolate the appliance

from the power

supply. Replace the

outside temperature

sensor. Switch on the

power supply to the

appliance again. The

fault is reset automatically.

E107

no

The temperature sensor

for capturing

the extract air

temperature is

faulty.

The bypass function

is switched off.

Isolate the appliance

from the power

supply. Replace the

room temperature

sensor.

E108

no

If installed:

The temperature sensor in

the external

reheater coil

is fault y.

The reheater coil, if

present, is switched

off. The geothermal

heat exchanger, if

present, is switched

off.

Replace the temperature sensor for the

outside temperature.

E111

no

The humidity sensor is

faulty.

The appliance is still

operating.

Isolate the appliance

from the power

supply. Replace the

humidity sensor.

E999

Yes

The microswitches

on the control

PCB are not

set correctly.

The appliance does

not operate; the red

fault LEDs at the

stage switch are

also off.

Adjust the microswitches correctly.

Correct microswitch setting

X6

X4

X3

ON

D

D0000041967

Check whether the microswitches on the control PCB are

set correctly (see diagram). If message E999 is nevertheless

displayed, replace the control PCB with a PCB of the correct

type.

Stage switch modular connector

If stage2 on a stage switch does not work, the modular connector

of the stage switch is not connected correctly.

Disconnect one of the RJ plug-in connections to the stage

switch. Fit a new plug-in connection in the opposite

direction.

Page 19

ENGLISH

www.stiebel-eltron.com LWZ70E | 19

INSTALLATION

Specication

15. Specification

15.1 Dimensions and connections

125168

248

600

45

145

560

79

75

213

77

77

213

302

g03

g04 g05

g06

d45

b01

D0000041882

LWZ70E

b01 Entry electrical

cables

d45 Condensate drain Diameter mm 13

g03 Outdoor air

Nominal diameter

DN 125

g04 Exhaust air

Nominal diameter

DN 125

g05 Extract air

Nominal diameter

DN 125

g06 inrushing air

Nominal diameter

DN 125

Page 20

20 | LWZ70E www.stiebel-eltron.com

INSTALLATION

Specication

15.2 Standard circuit

L

N

PE

1/N/PE

230V ~50Hz

Lüftungsgerät

6 x 0,5 mm² max. 30 m

Schalter

Kaminbetrieb

Ofen

Raum

Druckanschluss

Differenzdruckcontroller für Feuerstätten

X2

ZLWZ 4S

24 V

P (0V)0 2 3LED

24 V

P (0V)0 2 3LED

FEZ

24 V

P (0V)0 23 LED

12104 115

FEQ

24 V

P (0V)02 3LED

64

251

3-Stufen-Schalter

24 V

P (0V)0 23 LED

3

2

1

D0000055737

3-Stufen-Schalter 3-stage switch

ZLWZ 4S 4-stage switch

FEQ Air quality sensor

FEZ Remote control

Lüftungsgerät Ventilation unit

Ofen Stove

Raum Room

Druckanschluss Pressure connection

Schalter Kaminbetrieb Switch, fireplace operation

Differenzdruckcontroller

für Feuerstätten

Differential pressure controller for combustion equipment

Page 21

ENGLISH

www.stiebel-eltron.com LWZ70E | 21

INSTALLATION

Specication

15.3 Wiring diagram

1 2

1 2 1 21 2

3

2

1

A

C

B

D

E

K

M

BN

BN

WH

WHBNWH

D0000041966

A 3-stage switch, 4-stage switch, air quality sensor FEQ or

remote control FEZ (see chapter "Specification/ Standard

circuit")

B External preheating coil (optional)

C Outside temperature sensor

D Room temperature sensor

E Service connection

K Wire no. 1

M Wire no. 2

Page 22

22 | LWZ70E www.stiebel-eltron.com

INSTALLATION

Specication

15.4 Fan diagram

0

50

100

150

200

250

300

350

400

450

500

550

0 25 50 75 100 125 150 175 200

1

2

3

4

0,59

0,51

0,40

0,62

0,43

0,46

0,32

0,27

0,49

0,28

0,37

0,32

0,29

0,37

0,45

0,34

0,53

0,40

0,40

0,28

0,26

D0000056686

X Air flow rate [m³/h]

Y Average value, static pressure [Pa]

1 Example: system curve with low pressure drop

2 Example: system curve with average pressure drop

3 Example: system curve with higher pressure drop

x

Specific power consumption of both fans [Wh/m³]

Page 23

ENGLISH

www.stiebel-eltron.com LWZ70E | 23

INSTALLATION | GUARANTEE | ENVIRONMENT AND RECYCLING

Specication

15.5 Data table

LWZ70E

233851

Sound data

Sound power level (EN 12102) dB(A) 46

Energy data

Energy efficiency class A

Electrical data

Rated voltage V 230

Max. current drawn A 1.48

Power consumption without preheater coil A 1.48

Phases 1/N/PE

Frequency Hz 50

Power consumption W 13-112

Power consumption without preheater coil W 136

Versions

IP rating IP30

Filter class G3

Dimensions

Height mm 600

Width mm 560

Depth mm 290

Weights

Weight kg 25

Connections

Air connector diameter mm 125

Condensate connection mm 13

Values

Air flow rate m³/h 50 -180

Heat recovery level up to % 90

Extract air application range °C 15 - 30

Max. ambient temperature °C 60

Available external pressure, ventilation Pa 160

Guarantee

The guarantee conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products a guarantee can only

be issued by those subsidiaries. Such guarantee is only granted if the subsidiary has issued its own terms of guarantee. No

other guarantee will be granted.

We shall not provide any guarantee for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not aect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.

Page 24

Deutschland

STIEBEL ELTRON GmbH & Co. KG

Dr.-Stiebel-Straße 33 | 37603 Holzminden

Tel. 05531 702-0 | Fax 05531 702-480

info@stiebel-eltron.de

www.stiebel-eltron.de

Verkauf Tel. 05531 702-110 | Fax 05531 702-95108 | info-center@stiebel-eltron.de

Kundendienst Tel. 05531 702-111 | Fax 05531 702-95890 | kundendienst@stiebel-eltron.de

Ersatzteilverkauf Tel. 05531 702-120 | Fax 05531 702-95335 | ersatzteile@stiebel-eltron.de

Irrtum und technische Änderungen vorbehalten! | Subject to errors and technical changes! | Sous réserve

d‘erreurs et de modifications techniques! | Onder voorbehoud van ver

g

issingen en technische wijzigingen! |

Salvo error o modificación técnica! | Excepto erro ou alteração técnica | Zastrzeżone zmian

y

techniczne i

ewentualne błędy | Omyly a technické změny jsou vyhrazeny! | A muszaki változtatások és tévedések jogát

fenntartjuk! |

Отсутствие ошибок не гарантируется. Возможны технические изменения.

| Chyby a

technické zmeny sú vyhradené! Stand 9046

Australia

STIEBEL ELTRON Australia Pty. Ltd.

6 Prohasky Street | Port Melbourne VIC 3207

Tel. 03 9645-1833 | Fax 03 9645-4366

info@stiebel.com.au

www.stiebel.com.au

Austria

STIEBEL ELTRON Ges.m.b.H.

Eferdinger Str. 73 | 4600 Wels

Tel. 07242 47367-0 | Fax 07242 47367-42

info@stiebel-eltron.at

www.stiebel-eltron.at

Belgium

STIEBEL ELTRON bvba/sprl

't Hofveld 6 - D1 | 1702 Groot-Bijgaarden

Tel. 02 42322-22 | Fax 02 42322-12

info@stiebel-eltron.be

www.stiebel-eltron.be

China

STIEBEL ELTRON (Guangzhou) Electric

Appliance Co., Ltd.

Rm 102, F1, Yingbin-Yihao Mansion, No. 1

Yingbin Road

Panyu District | 511431 Guangzhou

Tel. 020 39162209 | Fax 020 39162203

info@stiebeleltron.cn

www.stiebeleltron.cn

Czech Republic

STIEBEL ELTRON spol. s r.o.

K Hájům 946 | 155 00 Praha 5 - Stodůlky

Tel. 251116-111 | Fax 235512-122

info@stiebel-eltron.cz

www.stiebel-eltron.cz

Finland

STIEBEL ELTRON OY

Kapinakuja 1 | 04600 Mäntsälä

Tel. 020 720-9988

info@stiebel-eltron.fi

www.stiebel-eltron.fi

France

STIEBEL ELTRON SAS

7-9, rue des Selliers

B.P 85107 | 57073 Metz-Cédex 3

Tel. 0387 7438-88 | Fax 0387 7468-26

info@stiebel-eltron.fr

www.stiebel-eltron.fr

Hungary

STIEBEL ELTRON Kft.

Gyár u. 2 | 2040 Budaörs

Tel. 01 250-6055 | Fax 01 368-8097

info@stiebel-eltron.hu

www.stiebel-eltron.hu

Japan

NIHON STIEBEL Co. Ltd.

Kowa Kawasaki Nishiguchi Building 8F

66-2 Horikawa-Cho

Saiwai-Ku | 212-0013 Kawasaki

Tel. 044 540-3200 | Fax 044 540-3210

info@nihonstiebel.co.jp

www.nihonstiebel.co.jp

Netherlands

STIEBEL ELTRON Nederland B.V.

Daviottenweg 36 | 5222 BH 's-Hertogenbosch

Tel. 073 623-0000 | Fax 073 623-1141

info@stiebel-eltron.nl

www.stiebel-eltron.nl

Poland

STIEBEL ELTRON Polska Sp. z O.O.

ul. Działkowa 2 | 02-234 Warszawa

Tel. 022 60920-30 | Fax 022 60920-29

biuro@stiebel-eltron.pl

www.stiebel-eltron.pl

Russia

STIEBEL ELTRON LLC RUSSIA

Urzhumskaya street 4,

building 2 | 129343 Moscow

Tel. 0495 7753889 | Fax 0495 7753887

info@stiebel-eltron.ru

www.stiebel-eltron.ru

Slovakia

TATRAMAT - ohrievače vody s.r.o.

Hlavná 1 | 058 01 Poprad

Tel. 052 7127-125 | Fax 052 7127-148

info@stiebel-eltron.sk

www.stiebel-eltron.sk

Switzerland

STIEBEL ELTRON AG

Industrie West

Gass 8 | 5242 Lupfig

Tel. 056 4640-500 | Fax 056 4640-501

info@stiebel-eltron.ch

www.stiebel-eltron.ch

Thailand

STIEBEL ELTRON Asia Ltd.

469 Moo 2 Tambol Klong-Jik

Amphur Bangpa-In | 13160 Ayutthaya

Tel. 035 220088 | Fax 035 221188

info@stiebeleltronasia.com

www.stiebeleltronasia.com

United Kingdom and Ireland

STIEBEL ELTRON UK Ltd.

Unit 12 Stadium Court

Stadium Road | CH62 3RP Bromborough

Tel. 0151 346-2300 | Fax 0151 334-2913

info@stiebel-eltron.co.uk

www.stiebel-eltron.co.uk

United States of America

STIEBEL ELTRON, Inc.

17 West Street | 01088 West Hatfield MA

Tel. 0413 247-3380 | Fax 0413 247-3369

info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

A 319235-39280-9133

B 314250-39280-9133

4<AMHCMO=bjcdfa>

Loading...

Loading...