Page 1

ADA

for operation

UB-2PN Universal 2”

Pneumatic Button

We protect the things that protect you.

Page 2

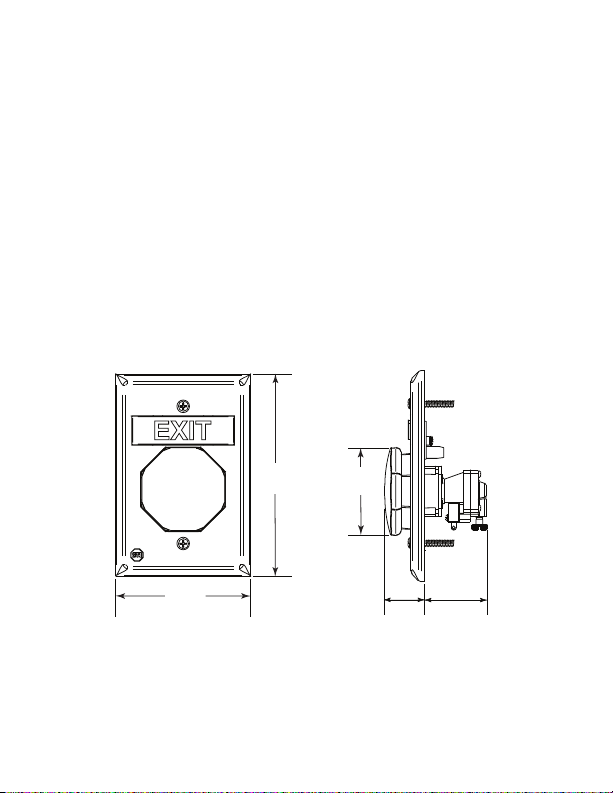

NO

.91 in.

(23mm)

1.47 in.

(38mm)

2 in.

(51mm)

3.22 in.

(82mm)

4.83 in.

(123mm)

TES

I

t

i

s i

mpor

t

ant

t

o r

ead,

under

st

t

hi

s

pr

oduct

NEC,

m

ount

electrical

emer

gency si

el

ect

r

i

cal

ADA

mo

shal

l

not

f

i

ni

shed

copy of

mai

nt

enance

* For

access cont

.

I

t

i

i

ng speci

codes.This

gnal

shock,

u

n

tin

g

c

be

l

ess

f

l

oor

sur

t

hi

s m

of

s

t

o

t

f

t

hi

he

i

i

ng.

DO

mp

lia

han

ace.

anual

s

pr

r

ol

i

nst

f

i

cat

sw

Not

NOT

n

3

1/

Af

t

oduct

nst

al

c

t

al

and and f

l

er’s

r

i

ons accordi

itch

is

t

o be used i

at

t

empt

e

r

e

q

u

2

f

t

.

(

1.

er

i

nst

o al

l

personnel

.

l

at

i

ons,

esponsi

rated

t

o

ir

e

s

th

1m

)

al

l

at

i

on

power

Type

n pl

i

nst

e

or

ol

bi

o

gr

and

l

l

ng t

al

p

e

eat

f

ow al

l

i

nst

t

o

r

compl

i

t

y

o ADA and ot

N

M

(N

l

t

hi

s

r

a

b

le

er

t

est

on-Monitored)

pani

pr

oduct

p

a

r

t

t

han

i

ng

ar

ace of

responsi

or

t

he UB-

uct

i

ons pr

y

wi

t

h

NFP

her appl

c har

dwar

when

o

f

th

e

in

4

1/

2

f

t

.

e

compl

bl

e f

or t

2PN must

ovi

ded wi

A

70

e.

To avoi

power

itia

tin

(

1.

37m)

et

e,

pr

est

i

be suppl

&

101,

i

cabl

for

non-

i

s

on.

g

d

e

v

ic

above

ovi

de

ng and

i

ed

by a power source Listed to UL294. When used for access control, this

de

v

ic

e

s

h

a

ll be

u

se

d

a

s a

p

a

rt o

f a

n

a

c

c

e

ss c

o

n

tro

lle

d

e

g

re

ss d

o

It is u

se

nso

p

to

r. Fo

th

r h

e

lo

c

a

l AHJ

to

a

llo

w u

se

o

f th

is d

e

vic

e

in

p

ig

h

e

r sec

u

rity in

sta

lla

tio

n

s

, lo

wer time

la

limits sh

c

e

o

or system.

f an

automatic

o

u

ld be used.

t

h

e

d

e

a

SWITCH RATING: Independent Form “Z” contacts

Rated at: 10A @ 240 VAC

Operating Temp: 15° to 120°F (-9° to 49°C)

1,000,000 Cycles

- 2 -

Page 3

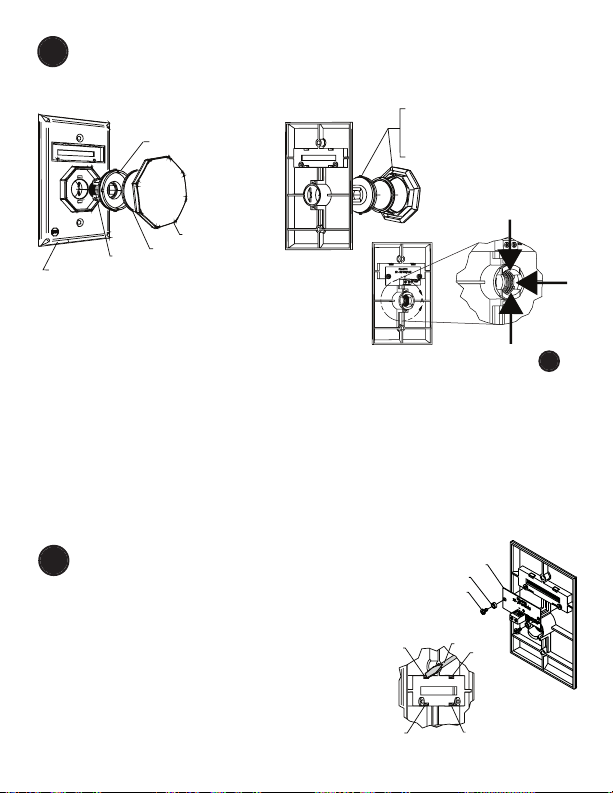

TO CHANGE BUTTON COLOR AND ROUND MESSAGE

1

2

3

4

SCREWDRIVER

UB-1L LED PCB

NYLON WASHER

SCREW

D

IE

C

AS

T

P

L

A

TE

S

P

RIN

G

P

U

S

H

B

U

T

T

O

N

A

C

TUA

T

O

R

A

C

TU

A

T

O

R

C

A

P

2

in

.

B

U

T

T

O

N

A

L

IG

N

T

A

B

O

N

A

C

TUA

T

O

R

W

ITH

S

LOT

B

U

T

T

O

N

.

TU

RN

C

LO

C

K

W

IS

E

T

O

LO

C

K

IN

S

ERT

ASS

EM

B

LY

W

ITH

S

P

RIN

G

IN

T

O

P

L

A

TE.

RE

A

R VIE

W

1

1

2

1

1. Choose button message and color. If same as existing, proceed to

2. To remove push button actuator assembly, squeeze actuator tabs in

direction of #1 arrows.

3. Push acutator through plate in direction of #2 arrow.

4. Align actuator cap to push button actuator. Align button slots to tabs on

push button actuator.

5. Snap button onto push button actuator and rotate right to lock.

6. Insert spring into push button actuator.

7. Squeeze legs of push button actuator and align into die cast plate.

1. Remove LED circuit board.

2.

3.

CHANGE TOP MESSAGE

2

Remove current message by pushing in and

.

down on tabs 1 and 2 with a small screw

driver. If necessary, also push in and down

on tabs 3 and 4. Once message is loose,

remove from the front of the plate.

Select new message and snap into place.

Blank plates are included to create your

own custom message.

- 3 -

-

2

Page 4

P

O

W

E

R

I

N

1

2

-

3

0

V

D

C

/

V

A

C

POWER IN

12-30 VDC/VAC

A

BUTTON ACTIVATED

M

POWER IN

12-30 VDC/VAC

BUTTON ACTIVATED

M

INSTALL OR REMOVE CONTACT BLOCK

3

INSTALL

To attach, align tabs (as shown)

and gently snap top, then bottom.

Be sure to hear BOTH tabs snap

into place. Contacts can be rotated

180° if desired.

DETAIL A

CONTACT INFORMATION

CONTACT REMOVAL

REMOVE

To remove, use a

small flat blade

screwdriver.

Position screwdriver

blade under tab and

gently rotate

screwdriver until tab

disengages. Repeat

for opposite tab.

- 4 -

Page 5

4

OFF

ON

+

+

+

MAG LOCK

NC CONTACTS

NO CONTACTS

UB-1L LED PCB

UL Listed

12-24 VDC Power Supply

NORMAL POSITION BUTTON ACTIVATED

ON

OFF

MAGNETIC LOCK

MESSAGE LAMP

(BLACK) NC

(RED) NO

NC (GREEN)

NO (WHITE)

NC

NO

NC

NO

ATTACH POWER FOR LED (IF DESIRED)

(See drawing)

CONTACT DIAGRAM

One set NO and one set NC

CONTACTS

- 5 -

Page 6

COUNTERCLOCKWISE

CLOCKWISE

TIMER RANGE ADJUSTMENT SCREW

ADJUSTMENT RANGE - 2 TO 60 SECONDS

TIMER FACTORY SET TO MINIMUM TIME

SETTING. TO INCREASE TIME, TURN

SCREW CLOCKWISE IN 1/4 TURN

INCREMENTS. WHEN CLOSE TO DESIRED

TIME, TURN SCREW IN VERY FINE

INCREMENTS TO DESIRED SETTING.

CAUTION: OVER-TIGHTENING MAY

CAUSE DAMAGE TO TIMER.

SWITCH INFORMATION

MOUNT BUTTON ONTO

5

ELECTRICAL BOX

CUSTOM LABELS

6

To create your own custom label, size to fit in .48h x 2.23w as

shown below.

Also available online at: www.sti-usa.com/ublabel

.48 in.

2.23 in.

- 6 -

Page 7

ACCESSORIES

DESCRIPTION

CONTACT BLOCK SUB-UB-1PNC

COLOR MATCH BACK BOX KIT SUB-71100A-COLOR

CUSTOM LABEL APPLIED TO BLANK UB-1CL-COLOR

MESSAGE PLATES (blue, green, white or yellow)

24 VOLT LED

WHITE (STANDARD) 10147

RED 10145

BLUE 10141

GREEN 10143

12 VOLT LED

RED 10144

BLUE 10140

GREEN 10142

COVERS

BOPPER STOPPER STI-6518

UNIVERSAL STOPPER STI-13000 Series

STOPPER II STI-1100 Series

See website for complete cover details

PART #

(

red, blue, green, white or yellow)

- 7 -

Page 8

WARRANTY

Three year guarantee against breakage of polycarbonate in normal use

(one year on electro mechanical and electronic components).

Electronic warranty form at www.sti-usa.com/wc14.

2306 Airport Rd • Waterford, MI 48327

Phone: 248-673-9898 • Fax: 248-673-1246

info@sti-usa.com •

Safety Technology International (Europe) Ltd.

Unit 49G Pipers Road • Park Farm Industrial Estate • Redditch

Worcestershire • B98 0HU • England • Tel: 44 (0) 1527 520 999

Fax: 44 (0) 1527 501 999 • Freephone: 0800 085 1678 (UK only)

E-mail: info@sti-europe.com • Web: www.sti-europe.com

www.sti-usa.com

Printed in USA Inst. Sht. UB-2PN Button JULY2013

Loading...

Loading...