Page 1

UB-1 Universal Button

ADA

UB-1/LTUL Universal Button with Latching Timer

Compliant

For UB-1/LTUL the enclosed timer is to be used and installed per the enclosed LT-1UL installation sheet.

For access control installations, power for the LT-1UL Timer must be supplied by a power source listed to

UL294. When used for access control, this device shall be used as part of an access controlled egress door

system. It is up to the local AHJ to allow use of this device in place of an automatic sensor. For higher security

installations, lower time limits should be used.

Pour les modèles UB-1/LTUL, la minuterie intégrée doit être installée et utilisée suivant la fiche d’installation

LT-1UL fournie. Pour les installations de contrôle d’accès, l’alimentation de la minuterie LT-1 doit être fournie

par une source homologuée UL294. Lorsque cet appareil est utilisé aux fins de contrôle d’accès, il doit faire

partie d’un système de porte de sortie à accès contrôlé. Il incombe donc à l’AHJ local d’autoriser l’utilisation

de cet appareil au lieu d’un capteur automatique. Pour les installations de sécurité plus renforcée, des délais

inférieurs doivent être utilisés.

We protect the things that protect you.

®

Page 2

NOTES

It is important to read, understand and follow all instructions provided with this product. It

is the installer’s responsibility to comply with NFPA 70 & 101, NEC, mounting specifications

according to ADA and other applicable electrical codes. For Type SM (Self Monitored) rating,

the term Emergency message may be installed on Model UB-1 when used in a system

with a Listed, compatible Releasing Device. All other applications are rated Type NM (NonMonitored) for non-emergency signaling. To avoid electrical shock, DO NOT attempt to install

this product when power is on. ADA mounting compliance requires the operable part of

the initiating device shall not be less than 3 1/2 ft. (1.1m ) or greater than 4 1/2 ft. (1.37m)

above finished floor surface. After installation and testing are complete, provide a copy of

this manual to all personnel responsible for testing and maintenance of this product.

REMARQUES

Il est important de lire, de comprendre et de suivre toutes les instructions fournies avec

ce produit. Il incombe à l’installateur de se conformer aux normes NFPA 70 et 101, NEC,

aux spécifications de montage selon l’ADA et aux autres codes de l’électricité en vigueur.

Pour les cotes de type SM (auto surveillée), le message d’Urgence peut être apposé sur le

modèle UB-1 lorsqu’il est utilisé dans un système intégrant un dispositif de déclenchement

compatible et homologué. Toutes les autres applications sont cotées de Type NM (non

surveillée) pour la signalisation non urgente. Pour éviter un choc électrique, NE tentez

PAS d’installer ce produit lorsqu’il est sous tension. La conformité aux règles d’installation

de l’ADA exige que la partie utilisable du dispositif de déclenchement soit installée à une

hauteur située entre 3 1/2 pi (1,1 m) et 4 1/2 pi (1,37 m) au-dessus du plancher fini. Une fois

l’installation et les essais terminés, vous devez fournir une copie de ce manuel à l’ensemble

du personnel chargé de l’essai et de l’entretien de ce produit.

SWITCH RATING

2 Momentary Independent Form “C” contacts

UB-1/rated at: 10A, 1/2 HP, 125/250 VAC

6A, 30 VDC

100,000 Operations

Temperature: -40° to 185°F (-40° to 85°C)

Model UB-1/LTUL

Form C contacts on

Timer rated:

30 VDC 3A, 1.0 pf

UL294 Performance Levels:

Line Security: I

Attack: I

Endurance: IV

Standby Power: I

- 2 -

Page 3

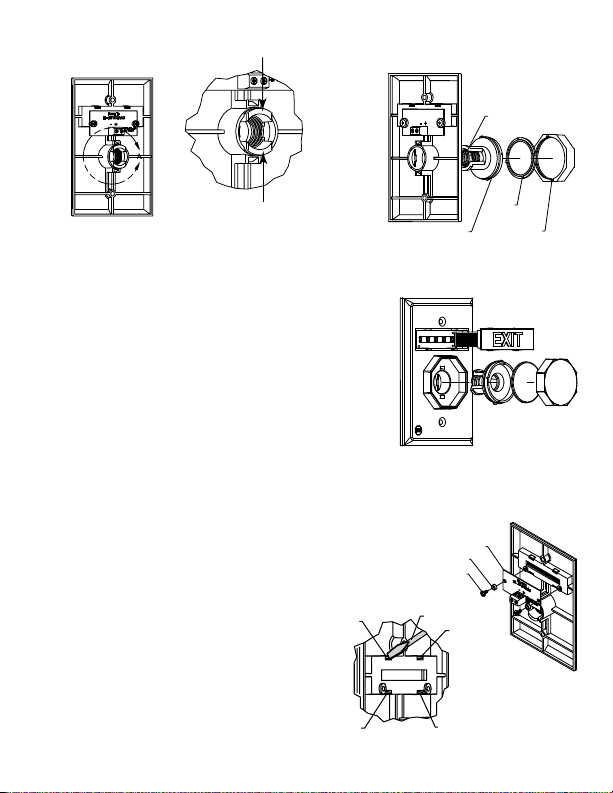

1. TO CHANGE BUTTON COLOR AND ROUND MESSAGE

ACTUATOR

Power In

12–30 VDC/VAC

Safety Tech. Int’l Inc.

P/N UB-11. Ver 1.0

wwyy

CAP

BUTTON

SPRING

TO SUPERVISED STATION

OR AUXILLARY DEVICE

SW1

SW2

NC

COM

NO

NC

COM

NO

MAG LOCK

MESSAGE LENS PCB

NORMAL POSITION BUTTON ACTIVATED

MAGNETIC LOCK

BUTTON LAMP

MESSAGE LAMP

OFF

UB-1L LED PCB

Power In

12–30 VDC/VAC

Safety Tech. Int’l Inc.

P/N UB-11. Ver 1.0

wwyy

1. Choose button message and color. If same as

ACTUATOR

existing, proceed to 2.

2. To remove push button actuator assembly, pinch

together actuator tabs in direction of arrows shown

above and push through plate.

3. Push actuator through plate.

4. Align actuator cap to push button actuator. Align button

slots to tabs on push button actuator.

5. Snap button onto push button actuator and rotate right

to lock.

6. Insert spring into push button actuator.

7. Pinch legs of push button actuator and align into die

cast plate.

2. CHANGE TOP MESSAGE

Refer to notes on pg. 2 for “EMERGENCY”

message use.

1. Remove LED circuit board.

2. Remove current message by pushing in

and down on tabs 1 and 2 with a small

screwdriver. If necessary, also push in and

down on tabs 3 and 4. Once message is

loose, remove from the front of the plate.

3. Select new message and snap into place.

Blank plates are included to create your

own custom message.

- 3 -

UB-1L LED PCB

NYLON WASHER

SELF TAPPING SCREW

1

3

SCREWDRIVER

2

4

SPRING

CAP

BUTTON

Page 4

3. INSTALL OR REMOVE CONTACT BLOCK

INSTALL

To attach, align tabs (as shown) and gently snap top,

then bottom. Be sure to hear BOTH tabs snap into

place. (Can be reversed if wiring comes from the top

of the box.)

REMOVE

Repeat STEP A for the top and bottom tab before removing contact block.

Step A: Position small flat screwdriver blade under tab and gently rotate until tab disengages.

The contact block will rotate a little. Do NOT pull yet.

Step B: Repeat for opposite tab.

Step C: When both tabs are disengaged, pull the contact block straight off.

A

STEP A

TOP TAB

STEP A COMPLETED

B

STEP B

STEP C

- 4 -

Page 5

4. ATTACH POWER FOR MESSAGE LED (if desired)

(See drawing)

SW1

NC

COM

NO

NC

COM

NO

MAGNETIC LOCK

BUTTON LAMP

MESSAGE LAMP

NOTE

LED connection: The polarity shown is factory installed. LED is polarity sensitive. If LED

does not light, switch positive and negative wiring or remove LED and rotate 180°. 24 volt is

included and will operate on 12 volts; however not as bright. 12 volt LED’s are also available.

TO SUPERVISED STATION

OR AUXILLARY DEVICE

SW2

MAG LOCK

MESSAGE LENS PCB

12–24VDC

NORMAL POSITION BUTTON ACTIVATED

ON

ON

OFF

BUTTON LED

OFF

OFF

ON

LED –

COM

NO

NC

LED +

SWITCH 1

SWITCH 2

- 5 -

Page 6

BUTTON LAMP

MESSAGE LAMP

1

2

3

4

SCREWDRIVER

UB-1L LED PCB

Power In

12–30 VDC/VAC

Safety Tech. Int’l Inc.

P/N UB-11. Ver 1.0

wwyy

DIFFUSER

12–24VDC

NORMAL POSITION BUTTON ACTIVATED

ON

ON

OFF

OFF

OFF

ON

5. SURFACE MOUNT OPTION

DRILL (4)

3/16 in.

DIAMETER HOLES

*ADD ONE OF THE FOLLOWING:

KIT-71100A-* BACKBOX

R=red, B=blue, G=green,

W=white, Y=yellow

#8-10 7/8 in. ANCHOR

(4) PROVIDED

DRILL POINT PROVIDED TOP & BOTTOM

OVAL HEAD MACHINE SCREW

FOR 1/2 in. CONDUIT. DRILL AS NEEDED.

#6-32 x 1 in. PHILLIPS

18-8 SS(2) PROVIDED

DRILL OUT THE (4) MOUNTING

HOLES, ONE IN EACH CORNER,

USING 5/32 in. DRILL BIT

#6 x 1 1/4 in.

PHILLIPS PAN HEAD SCREW

(4) PROVIDED

.867 in.

(22mm)

1.575 in.

(40mm)

- 6 -

BACKBOX MUST BE MOUNTED

WITH ARROWS POINTING UP

Page 7

6. MOUNT BUTTON ONTO ELECTRICAL BOX OPTION

1

3

4.830 in.

(123mm)

3.220 in.

(82mm)

1.328 in.

(34mm)

.867 in.

(22mm)

UB-1L LED PCB

NYLON WASHER

SELF TAPPING SCREW

DRILL (4)

3/16 in.

DIAMETER HOLES

KIT-71100A-* BACKBOX

*ADD ONE OF THE FOLLOWING:

R=red, B=blue, G=green,

#6 - 32 x 1” OVAL

HEAD MACHINE SCREW

(2) PROVIDED

7. CUSTOM LABELS

To create your own custom label, size to fit in .48h x 2.23w as shown below.

Also available online at: www.sti-usa.com/ublabel

.48 in.

2.23 in.

WARRANTY

Three year guarantee against breakage of polycarbonate in normal use (one year on

electro mechanical and electronic components).

Electronic warranty form at www.sti-usa.com/wc14.

WARNING: This product can expose you to chemicals including Dichloromethane,

which is known to the State of California to cause cancer, and Bisphenol A (BPA),

which is known to the State of California to cause birth defects or other reproductive

harm. For more information go to www.P65Warnings.ca.gov.

- 7 -

Page 8

ACCESSORIES

1

2

3

4

SCREWDRIVER

UB-1L LED PCB

NYLON WASHER

SELF TAPPING SCREW

TOP TAB

PART #

KIT-71100A-*

(R=Red, B=Blue, G=Green, W=White Or Y=Yellow)

*

UB-1CL-*

(B=Blue, G=Green, W=White Or Y=Yellow)

*

UB-1LENS

UB-2LENS

KIT-UB-1C

KIT-E10147

KIT-E10145

KIT-E10141

KIT-E10143

KIT-E10144

KIT-E10140

KIT-E10142

STI-6518

STI-13000 Series

STI-1100 Series

DESCRIPTION

COLOR MATCH BACK BOX KIT

CUSTOM LABEL APPLIED TO BLANK MESSAGE PLATES

BUTTON REPLACEMENT LENSES: (red, green & blue)

2” LENS KIT FOR UNIVERSAL BUTTON

CONTACT ASSEMBLY FOR UB-1

24 VOLT LED

WHITE (STANDARD)

RED

BLUE

GREEN

12 VOLT LED

RED

BLUE

GREEN

COVERS

BOPPER STOPPER

UNIVERSAL STOPPER

®

STOPPER II

– See website for complete cover details –

3.220 in.

(82mm)

4.830 in.

(123mm)

.867 in.

(22mm)

1.328 in.

(34mm)

2306 Airport Rd • Waterford, MI 48327, USA

Phone: 248-673-9898 • Fax: 248-673-1246

info@sti-usa.com • www.sti-usa.com

Taylor House • 34 Sherwood Road • Bromsgrove, Worcestershire • B60 3DR • England

Tel: +44 (0)1527 520 999 • Fax: +44 (0)1527 501 999 • info@sti-emea.com • www.sti-emea.com

Printed in USA Inst. Sht. UB-1 Button OCT2018

Loading...

Loading...