Page 1

Installation and Operating Manual

RF

Capacitance

Level

Measurement

Kotron

®

Model 811

RF Point Level Sensor

Page 2

50-608 Kotron Model 811 RF Point Level Sensor

Read this Manual Before Installing

This manual provides information on the Kotron

Model 811 RF Point Level Sensor. It is important that all

instructions are read carefully and followed in sequence.

Detailed instructions are included in the Installation

section of this manual.

Conventions Used in this Manual

Certain conventions are used in this manual to convey

specific types of information. General technical material,

support data, and safety information are presented in

narrative form. The following styles are used for notes,

cautions, and warnings.

Notes

Notes contain information that augments or clarifies

an operating step. Notes do not normally contain

actions. They follow the procedural steps to which

they refer.

Cautions

Cautions alert the technician to special conditions that

could injure personnel, damage equipment, or reduce

a component’s mechanical integrity. Cautions are also

used to alert the technician to unsafe practices or the

need for special protective equipment or specific materials. In this manual, a caution box indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Warnings

Warnings identify potentially dangerous situations or

serious hazards. In this manual, a warning indicates an

imminently hazardous situation which, if not avoided,

could result in serious injury or death.

WARNING! Explosion hazard. Do not connect or dis-

connect equipment unless power has been switched off or

the area is known to be non-hazardous.

Safety Messages

The Kotron Model 811 system may be properly installed

in Category II, Pollution Degree 2 installations. Follow all

standard industry procedures for servicing electrical and

computer equipment when working with or around high

voltage. Always shut off the power supply before touching

any components. Although high voltage is not present in

this system, it may be present in other systems.

Electrical components are sensitive to electrostatic discharge. To prevent equipment damage, observe safety

procedures when working with electrostatic sensitive

components.

Low Voltage Directive

For use in Category II installations. If equipment is used

in a manner not specified by manufacturer, protection

provided by equipment may be impaired.

Notice of Trademark, Copyright, and Limitations

Kotron is a registered trademark of Magnetrol

International, Incorporated. Kotron Model 811 RF Point

Level Sensor is a tradename of Magnetrol International,

Incorporated.

Copyright © 2006 Magnetrol International, Incorporated.

Magnetrol reserves the right to make changes to the product described in this manual at any time without notice.

Magnetrol makes no warranty with respect to the accuracy

of the information in this manual.

Warranty

All Magnetrol/STI electronic level and flow controls are

warranted free of defects in materials or workmanship for

one full year from the date of original factory

shipment.

If returned within the warranty period; and, upon

factory inspection of the control, the cause of the claim is

determined to be covered under the warranty; then,

Magnetrol/STI will repair or replace the control at

no cost to the purchaser (or owner) other than

transportation.

Magnetrol/STI shall not be liable for misapplication, labor

claims, direct or consequential damage or expense arising

from the installation or use of equipment. There are no

other warranties expressed or implied, except special written warranties covering some Magnetrol/STI products.

Quality Assurance

The quality assurance system in place at Magnetrol/STI

guarantees the highest level of quality throughout the

company. Magnetrol/STI is committed to providing full

customer satisfaction both in quality products and

quality service.

Magnetrol’s quality assurance system

is registered to ISO 9001 affirming

its commitment to known international quality standards providing

the strongest assurance of product/

service quality available.

Page 3

Table of Contents

1.0 Complete Installation

1.1 Unpacking ..............................................................1

1.2 Electrostatic Discharge (ESD) Handling Procedure ....1

1.3 Before You Begin ....................................................2

1.3.1 Site Preparation ...............................................2

1.3.2 Equipment and Tools ......................................2

1.3.3 Operational Considerations.............................2

1.4 Mounting ..................................................................3

1.4.1 Horizontal Mounting ......................................4

1.4.2 Vertical Mounting ...........................................4

1.5 Probe Installation.......................................................5

1.5.1 Installing a Guarded Probe ..............................5

1.5.2 Installing a Standard Probe ..............................5

1.5.3 Installing a Flexible Probe................................5

1.6 Installing a Remote Mount Unit...............................6

1.6.1 Remote Mount with Guarded Probe ...............6

1.6.1.1 Electronic Housing ....................................6

1.6.1.2 Probe Housing Connections......................7

1.6.2 Remote Mount with Rigid and

Flexible Probes.................................................7

1.6.2.1 Electronic Housing ....................................7

1.6.2.2 Probe Housing Connections......................7

1.7 Wiring .......................................................................8

1.7.1 Probe Wiring...................................................8

1.7.2 Electrical Wiring..............................................9

1.7.3 Operating Mode Selection...............................9

1.7.4 Relay Wiring Chart ......................................10

1.8 Calibration — Narrow Differential.........................10

1.8.1 Set Point Adjustment Alarm ..........................10

1.8.2 Low Level Alarm Fail-safe Low – with no

media on the probe .......................................11

1.8.3 Low Level Alarm Fail-safe Low – with

media on the probe .......................................12

1.8.4 High Level Alarm Fail-safe High – with

no media on the probe ..................................12

1.8.5 High Level Alarm Fail-safe High – with

media on the probe .......................................12

1.8.6 Time Delay....................................................12

1.9 Calibration — Wide Differential ............................13

1.9.1 Set Point Adjustment Control .......................13

1.9.2 Time Delay....................................................15

2.0 Reference Information ................................................16

2.1 Description..............................................................16

2.2 Theory of Operation...............................................16

2.3 Troubleshooting.......................................................16

2.3.1 No Signal with Level Change........................16

2.3.2 Probe..............................................................16

2.3.3 Switch Chatter ...............................................17

2.4 Agency Approvals ....................................................18

2.4.1 Agency Specifications – Intrinsically Safe

Installation ....................................................19

2.4.2 Agency Specifications – Explosion Proof

Installation ....................................................19

2.5 Parts.........................................................................20

2.5.1 Replacement Parts .........................................20

2.6 Specifications ...........................................................21

2.6.1 Functional .....................................................21

2.6.2 Physical .........................................................22

3.0 Model Numbers.........................................................23

NOTES.............................................................................24

Kotron Model 811

RF Point Level Sensor

Page 4

50-608 Kotron Model 811 RF Point Level Sensor

1

1.0 Complete Installation

This section provides detailed procedures for properly

installing, configuring, and, as needed, troubleshooting the

Kotron Model 811 RF Point Level Sensor.

1.1 Unpacking

Unpack the instrument carefully. Make sure all components have been removed from the packing material.

Check all the contents against the packing slip and report

any discrepancies to the factory. Before proceeding with

the installation, do the following:

• Inspect all components for damage. Report any damage

to the carrier within 24 hours.

• Make sure the nameplate model number agrees with the

packing slip and purchase order.

• Record the model and serial numbers for future

reference when ordering parts.

Model Number _________________________________

Serial Number __________________________________

1.2 Electrostatic Discharge (ESD)

Handling Procedure

Magnetrol’s electronic instruments are manufactured to the

highest quality standards. These instruments use electronic

components that may be damaged by static electricity present in most work environments.

The following steps are recommended to reduce the risk of

component failure due to electrostatic discharge.

• Ship and store circuit boards in anti-static bags. If an antistatic bag is not available, wrap the board in aluminum

foil. Do not place boards on foam packing materials.

• Use a grounding wrist strap when installing and removing

circuit boards. A grounded workstation is recommended.

• Handle circuit boards only by the edges. Do not touch

components or connector pins.

• Make sure that all electrical connections are completely

made and none are partial or floating. Ground all

equipment to a good, earth ground.

Page 5

50-608 Kotron Model 811 RF Point Level Sensor

2

1.3 Before You Begin

1.3.1 Site Preparation

Each Kotron Model 811 sensor is built to match the

specific physical specifications of the required installation.

Make sure the probe connection is correct for the threaded

or flanged mounting on the vessel or tank where the transmitter will be placed. See Mounting, Section 1.4.

Make sure that the wiring between the power supply

and the Model 811 sensor is complete and correct for

the type of installation. See Specifications, Section 2.6.

When installing the Model 811 sensor in a general

purpose or hazardous area, all local, state, and federal

regulations and guidelines must be observed. See Wiring,

Section 1.7.

1.3.2 Equipment and Tools

No special equipment or tools are required to install

the Model 811 sensor. The following items are

recommended:

•1

1

⁄8" Open-end wrench or adjustable wrench to fit

the probe process connection size and type

• Flat-blade screwdriver

1.3.3 Operational Considerations

The Model 811 sensor should be located to allow for easy

access for service, configuration, and monitoring. There

should be sufficient headroom to allow the probe to be

inserted into the tank. Special precautions should be made

to prevent exposure to corrosive atmosphere, excessive

vibration, shock, or physical damage.

Units should not be exposed to ambient temperatures

above +160° F (+71° C) or below -40° F (-40° C). Probes

should be isolated from severe motion in the tank, because

surface turbulence may cause signal deviation.

NOTE: The unit is designed for maximum safety intrinsically safe

probe circuit). Jumper (J4) must be intact under normal operating conditions. The jumper must not be removed by anyone

unless there is a specific need for intrinsically safe grounding

separate from the standard earth ground. Consult factory

before considering special grounding which would require

removal of the jumper. Violation of this requirement will void

warranty and release Magnetrol of any responsibility.

Page 6

50-608 Kotron Model 811 RF Point Level Sensor

3

1.4 Mounting

The Model 811 sensor can be mounted to a tank using a

variety of process connections.

Make sure all mounting connections are properly in place

on the tank before installing the probe. Make sure the

Kotron probe is correct for the intended installation.

It is common practice to use the metal tank wall as the

reference electrode. In such cases, it is required that the

probe housing makes a good electrical connection to the

tank wall. If there is any doubt about this connection or to

the use of PTFE thread tape gaskets, paint, rust, or any

other reason, a separate strap should be installed between

the probe housing and the tank.

Caution: This unit contains CMOS electronics which may be

damaged by static electricity. Do not touch any semiconductor devices unless you are properly grounded.

Caution: When a probe is used in an abrasive medium, inspect the

probe periodically for visible surface wear. If damage to

the probe insulation is found, replace the probe.

Metal Walled Tanks

On water-based liquids, there should be no problem with

sensitivity. With non-conductive, low dielectric media,

sensitivity can be enhanced by locating the probe close to

and parallel with the tank wall. If this is not practical, a

ground reference probe may be the solution.

Non-Metallic and Glass-Lined Tank Construction

With plastic, concrete, wood, or any other non-conductive

walled vessels, a ground reference is required. Most commonly, this electrode will be in the form of a concentric

ground tube (e.g., stilling well). In questionable circumstances, consult the factory. In all cases, a good electrical

connection must be made between the ground surface and

the probe housing.

Switch/Probe Assembly

Switches with probes up to and including 12 inches

(300 mm) in length are shipped pre-assembled. All other

switches are shipped unassembled to avoid damage during

transit. These units must be assembled prior to mounting.

Choose your particular configuration from the following

sections and follow the instructions carefully.

Page 7

50-608 Kotron Model 811 RF Point Level Sensor

4

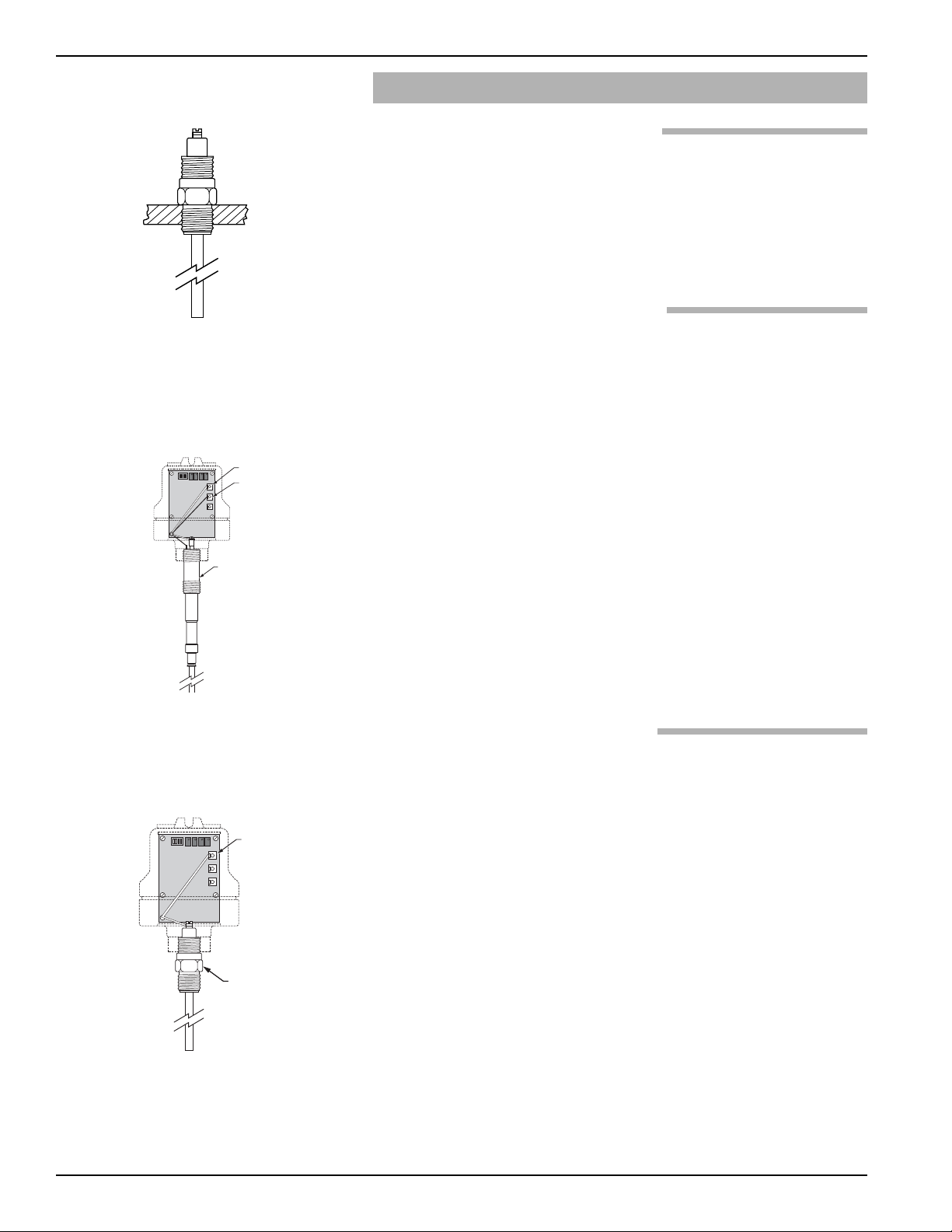

1.4.1 Horizontal Mounting

Alarm (narrow differential) applications only

Horizontally mounted probes provide a high degree of sensitivity for use with non-conductive liquids as only approximately 0.5 inches (12 mm) of level change is required to

completely cover (or uncover) the probe.

Horizontally mounted probes should be installed so that

the probe is parallel to and at the level at which the control point is desired. Refer to Figure 1.

Avoid any installation method in which the material may

become trapped in the mounting nozzle, thus preventing

the probe from signaling when the level recedes. Refer to

Figures 2 and 3.

NOTE: If nozzle mounting is unavoidable, the probe must be installed

with an inactive metal sheath having a length of at least 1 inch

(25 mm) greater than length of the nozzle. A sheath is required

to render the length of the probe within nozzle insensitive to

capacitance change. Refer to Figure 2.

Guarded Probe

Unit will signal at probe level. Refer to Figures 4 and 5.

NOTE: The guard element must be located outside of the nozzle.

Do not horizontally mount the unit in a nozzle deeper than

3 inches (75 mm). Refer to Figure 5. The medium may buildup

in the nozzle and cause false activation.

Alternate Horizontal Mounting

On applications involving viscous liquids or materials

which tend to cling or buildup, horizontally mounted

probes should be installed at a slight downward angle to

allow material to drain from probe rod. With this type

of installation, the packing gland face of probe assembly

should extend into the tank (or vessel). Refer to Figure 6.

1.4.2 Vertical Mounting

Vertically mounted probes provide the capability to adjust

the control point up or down a section of probe rod by

means of calibration adjustments within the unit.

Vertically mounted probes should be installed so that the

end of the probe rod is at least 2 inches (5 mm) below the

lowest desired level control point with conductive materials or 4 inches (100 mm) below the lowest desired level

control point with non-conductive materials. Refer to

Figure 7 on page 5.

Figure 1

Recommended Horizontal Mounting

Figure 2

Recommended Mounting with Nozzle

Figure 3

Not Recommended

Figure 4

Recommended Horizontal Mounting

Guarded Probe

Figure 5

Recommended Horizontal Mounting

Guarded Probe

Figure 6

Alternate Horizontal Mounting

Page 8

50-608 Kotron Model 811 RF Point Level Sensor

5

1.5 Probe Installation

1.5.1 Installing a Guarded Probe

1. Thread electronics/probe assembly (pre-assembled) into

mounting bushing on tank.

2. Tighten securely (ensure that the wrench is applied

only to the mounting gland). Refer to Figure 8.

3. Proceed to Wiring, Section 1.7, on page 8.

1.5.2 Installing a Standard Probe

Before installing, ensure the:

• Probe has adequate headroom for installation and has

unobstructed entry in the vessel.

• Process temperature, pressure, dielectric, and viscosity are

within the probe specifications for the installation. See

Specifications, Section 2.6, on page 21.

1. Thread probe into mounting bushing on tank.

2. Tighten securely, being certain that the wrench is applied

ONLY to the mounting gland. Refer to Figure 9.

3. Screw the amplifier housing onto the probe. Refer to

Figure 9.

4. Screw housing on the probe until hand tight. Housing

can be wrench tightened to align conduit connection

with conduit.

1.5.3 Installing a Flexible Probe

Caution: Insulated flexible probes are shipped with the cable clamp

and the packing gland nut hand tightened to permit length

adjustment in the field. The cable clamp and packing

gland nut must be tightened before use.The end of a flexible probe MUST be kept taut by attaching the anchor

end at the bottom of the vessel or by using a Magnetrol

supplied probe weight.

Caution: Do not discard the Mylar housing insulator.

Caution: The probe cable must not be in contact with any metallic

surface in its final installation position.

1. Attach the weight or anchor assembly to the end of the

probe. Insert the probe through the vessel’s mounting connection, and feed the cable into the vessel. Do not allow

the probe to scrape against the connection threads.

2. Secure the anchor assembly (if used), to the bottom of

the vessel.

Figure 7

Vertical Mounting

Figure 8

Integral Mount with Guarded Probe

Figure 9

Integral Mount with

Standard Rigid Probe

Mounting

Gland

Probe

(White)

Guard

(Red)

Probe

(White)

1 2 3 4

OPEN

1 2 3 4

OPEN

Lower Probe

Mounting Gland

Page 9

50-608 Kotron Model 811 RF Point Level Sensor

6

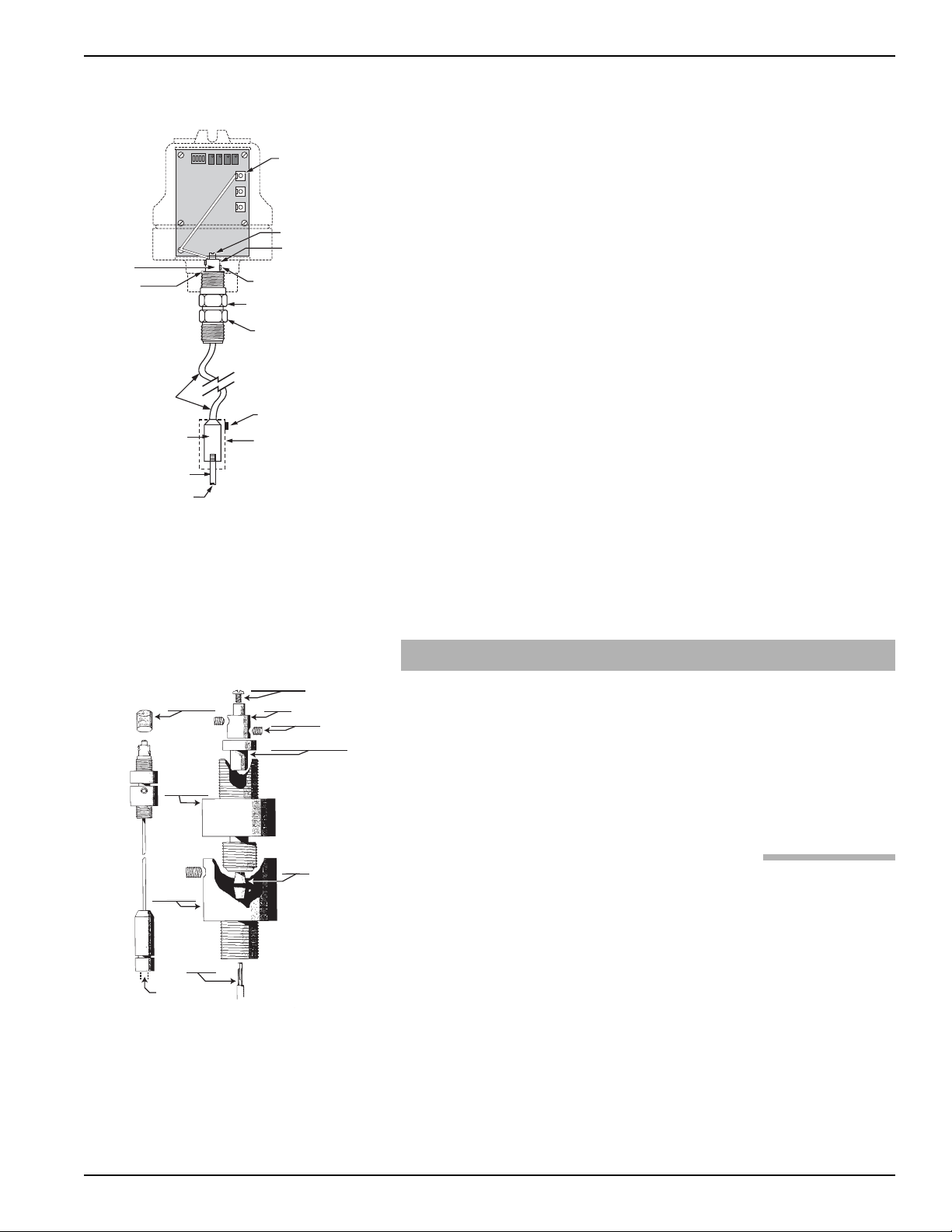

Clamp

Figure 10

Integral Mount with Flexible Probe

3. Apply thread sealant to the mounting nut. Screw the

mounting nut into the mounting connection until tight.

4. Remove the Mylar housing insulator located over the

clamp. DO NOT DISCARD.

5. Loosen both socket head screws from the clamp. Pull the

clamp and Teflon retaining bushing off of the probe.

6. While holding on to the probe cable, loosen the upper

packing gland nut. DO NOT ALLOW THE PROBE

CABLE TO FALL INTO THE VESSEL.

7. Pull the excess cable up through the packing gland nut

until the cable is taut. Tighten the packing gland nut.

8. Cut the cable 1.35" (34 mm) above the packing gland nut

and strip off 1.25" (32 mm) of insulation.

9. Slide the Teflon retaining bushing onto the cable and seat

it into the packing gland nut. Slide the clamp onto the

cable and seat it against the Teflon retaining bushing.

10. Tighten both socket head screws, on the clamp, to approximately 35 in/lbs of torque. Slip the Mylar insulator over

the clamp.

Caution: Check probe terminal connection carefully to be certain

lug will not short to packing gland or interfere with assembly of amplifier housing to probe.

1.6 Installing a Remote Mount Unit

NOTE: All remote mount units use triaxial cable that is shipped in a

length specified at the time of order. This cable must always

make all 3 connections at the main amplifier. At the probe

head, the cable will always make at least 2 connections.

(PROBE and GROUND). The final connection (GUARD) is only

used with the guarded probe. Cut the guard wire back to the

cable and dress with tape when NOT in use.

1.6.1 Remote Mount with Guarded Probe

1.6.1.1 Electronic Housing

Remote electronic housings are normally shipped from the

factory assembled with a mounting bracket. To install the

electronic housing, proceed as follows. Refer to Figure 11.

1. Install bracket in a location which will isolate unit from

temperatures below -40°F (-40° C) and over +160° F

(+71° C) or vibration/mechanical damage. Unit can be

mounted up to 150 feet (45 m) from probe assembly.

Location should also offer easy access for wiring,

calibration and maintenance.

ECTFE Flexible Probe

Teflon

Retaining

Bushing

Flexible

Termination

Optional Weight

Tank Bracket

Connection

Probe

Probe

1 2 3 4

OPEN

Probe

(White)

Probe Connection Screw

Mylar Housing Insulator

(slips over clamp)

Socket Head

Clamp Screws (2)

Upper Probe

Mounting Gland

Lower Probe

Mounting Gland

Probe Locking

Set Screw

Optional

Mounting

Bracket

(Used w/

Insulated

Probes)

PROBE

MYLAR

INSULATOR

UPPER

MOUNTING

NUT HALF

LOWER

MOUNTING

NUT HALF

PROBE

CABLE

3/8 16 UNC 2B

WIRE SCREW

CLAMP

SET SCREW

CLAMP RETAINING

BUSHING

SEAL

FLARE

Page 10

50-608 Kotron Model 811 RF Point Level Sensor

7

1.6.1.2 Probe Housing Connections

1. Screw probe housing onto the probe.

2. Attach the red guard wire to the slip-on guard connection

on probe. Refer to Figure 10a, Probe Wire Connections.

3. Attach the white probe wire to the probe screw on top of

the probe. Refer to Figure 11.

4. Attach the green ground wire to the green ground screw in

the housing base. Refer to Figure 11.

5. Proceed to Wiring, Section 1.7, on page 8.

1.6.2 Remote Mount with Rigid and Flexible Probes

1.6.2.1 Electronic Housing

Remote electronic housings are normally shipped from the

factory assembled in a mounting bracket. To install the

electronic housing, proceed as follows. Refer to Figure 12.

1. Install bracket in a location that will isolate the unit from

temperatures below -40° F (-40° C) and over +160° F

(+71° C) or vibration/mechanical damage. Unit can be

mounted up to 150 feet (45 m) from probe assembly.

Location should also offer easy access for wiring,

calibration, and maintenance.

1.6.2.2 Probe Housing Connections

1. Screw probe housing onto the probe. Refer to Figure 12.

2. Attach the white probe wire to the probe screw on top of

the probe. Refer to Figure 12.

3. Attach the green ground wire to the green ground screw in

the housing base. Refer to Figure 10a, Probe Wire

Connections and Figure 12.

4. Trim red GUARD wire back to cable end. Insulate with

electrical tape.

Figure 12

Figure 11

Probe

Figure 10a

(White)

PROBE WIRE CONNECTIONS

Guard

(Red)

1 2 3 4

OPEN

Probe (White)

Guard (Red)

Ground (Green)

Connection

Probe

Ground

(Green)

Ground

Screw

Guard

Connection

Mounting

Gland

1 2 3 4

OPEN

Probe (White)

Guard (Red)

Ground (Green)

Ground

Screw

Cut Back

Guard Wire

and Tape

Lower Probe

Mounting Gland

Page 11

50-608 Kotron Model 811 RF Point Level Sensor

8

1.7 Wiring

1.7.1 Probe Wiring

All power and control connections are made at the terminal

strip within the amplifier enclosure, EXCEPT GROUNDING. Power grounding must be made at green ground

screw on the housing base. 16AWG is recommended for

power and control circuits.

NOTE: There are special wiring exceptions for intrinsic safety. Observe

all local electrical codes and proper wiring procedures.

1. Ensure that power source is turned off.

2. Unscrew and remove housing cover.

3. Remove electronic assembly by loosening three screws

in base.

4. Pull power supply and control wires through conduit

connection.

5. Integral Mount Units – pull probe cable through bottom

base connection.

Remote Mount Units – pull triaxial probe cable through

bottom base connection.

6. Loosen securing screw on bottom of shield andopen the

protective cover on the amplifier board.

7. a. Integral Electronics – Attach white probe wire from

probe terminal on circuit board to probe screw on top

of the probe. Attach red Guard wire (if utilized). See

Figure 8 on page 5.

b. Remote Electronics – Attach the white and red leads

from the triaxial cable to appropriate connection on

circuit board. See Figure 12.

8. Ensure wiring is passed through bottom of electronic

assembly bracket.

9. Close and secure protective cover.

10. Slowly lower electronic assembly into housing base while

pushing slack into conduit.

11. Tighten three screws to housing base.

12. Connect electrical green ground wire to green ground

screw located in the base of the housing.

NOTE: If separate I.S ground is required in this application, then I.S.

ground (conventionally, blue #12 wire) should be connected to

the barrier at this time. Refer to NEC and appropriate Agency

guidelines.

Page 12

50-608 Kotron Model 811 RF Point Level Sensor

9

1.7.2 Electrical Wiring

1. Connect power leads to applicable AC or DC terminals as

marked. Refer to Figure 13.

2. a. Connect control circuit leads to relay terminals Refer to

Figure 13. Make sure the load to be controlled is within the relay’s rated capacity.

b. Dress wiring to guard against interference or contact

with cover or circuit board components.

Caution: In hazardous area, do not power the unit until the conduit

is sealed and enclosure cover is screwed down securely.

3. Prevent moisture seepage into housing by installing an

approved seal-drain fitting in the conduit run leading to

the unit.

4. Select operating mode. (Refer to Operating Mode

Selection below for detailed information.) Make sure

the fail-safe switch is in the correct position.

5. Installation is complete. Replace housing cover.

6. Proceed to Calibration, Section 1.8, on next page.

1.7.3 Operating Mode Selection

The Relay Wiring Chart on page 10 is provided to aid

in the proper choice of relay wiring and calibration.

Please note:

1. Equipment controlled by the Model 811 relay is assumed

to be powered from one source, while the 811 unit itself is

assumed to be powered from a different source.

2. There is a fail-safe switch on the 811 unit which may be

set in either a High or Low position. Refer to Figure 15

on next page.

3. Fail means a loss of power to the 811.

4. HL (High Level) means a material level in the tank which

is equal to or above the set point.

5. LL (Low Level) means a material level in the tank which is

equal to or below the set point.

6. a. When the relay coil is de-energized, (LED will be off)

a connection is made between the common (COM)

and normally closed (NC) terminals, and there is no

connection between COM and normally open (NO)

terminals.

b. When the relay coil is energized, (LED will be on)

a connection is made between the COM and

NO terminals, and there is no connection between

COM and NC terminals. Refer to Relay Wiring Chart,

Section 1.7.4, on next page.

Figure 13

COM (DC-)

RELAY LED

HOT (DC+)

GND

(Green

ground

screw

in base)

COM

NO

NC

COM

NO

I.S. BARRIER

NC

Figure 14

Page 13

50-608 Kotron Model 811 RF Point Level Sensor

10

1.7.4 RELAY WIRING CHART

Kotron Material

Fail-safe

Relay

Relay Terminals

Power Level Coil

COM to NC COM to NO

High

HLFS De-energized Closed Open

On

LLFS Energized Open Closed

Low

HLFS Energized Open Closed

LLFS De-energized Closed Open

High

HLFS De-energized Closed Open

Fail

LLFS De-energized Closed Open

Low

HLFS De-energized Closed Open

LLFS De-energized Closed Open

1.8 Calibration — Narrow Differential

Caution: In hazardous areas, do not remove housing cover until

power is disconnected and atmosphere is determined to

be safe. Hazardous environments must be declared safe

by local safety authority.

1.8.1 Set Point Adjustment Alarm

1. Turn on power to the instrument.

2. Remove housing cover.

3. Set point location:

a. Conductive media: The set point is located at the tip of

the probe (with guarded or other uninsulated probes).

Calibration is not required for most conductive liquids.

If the unit does not switch on alarm test, then proceed

to Step 4.

b. Non-conductive media: The set point is located on the

probe at a point determined by the set point adjustment. Minimum probe coverage is 4 inches (100 mm).

Calibration is required. Proceed to Step 4.

4. Adjustments – Refer to Figure 15.

4.1 Dip switch

a. Fail-safe

ON = high level

OFF = low level

b. Time Delay Direction

ON = delay on rising level

OFF = delay on falling level

c. Short Time Delay (0.5 to 7 seconds)

3 ON, 4 OFF

d. Long Time Delay (2 to 120 seconds)

3 OFF, 4 ON

NOTE: Switch positions 3 and 4 cannot be both ON or both OFF. One

must be ON the other OFF or the LED and relay will remain ON.

LONG DELAY TIME DELAY

2 to 120 sec.

SHORT DELAY DIFFERENTIAL

0.5 to 7 sec.

DELAY DIRECTION COARSE

FAIL-SAFE FINE

Figure 15

Page 14

50-608 Kotron Model 811 RF Point Level Sensor

11

4.2 Potentiometers

a. Time Delay

• Allows continuous adjustment of time delay within

limits of DIP switch range chosen

• Clockwise rotation increases delay.

b. Differential

• Allows continuous adjustment of pump or valve

control ON to OFF.

• Clockwise rotation increases differential. Full counterclockwise rotation is the narrowest differential and

is used for alarm applications.

c. Coarse

• Allows continuous adjustment of setpoint over the

entire range of the electronics (0 to 1000 pF).

• Clockwise rotation raises SETPOINT on probe.

d. Fine

• Allows precision adjustment of SETPOINT within

the limits of the COARSE SETPOINT adjusted

initially.

• Clockwise rotation raises SETPOINT on probe.

• This is an extremely fine adjustment. Sometimes it is

necessary to go 1 to 2 turns past the final SETPOINT

to stop relay chatter. A small amount of time delay

(2 turns) can also be used.

5. The LED shows the status of the relay coil.

LED on = relay energized LED off = relay de-energized

6. Initial Settings

a. Turn the COARSE, FINE, DIFFERENTIAL and TIME

DELAY POTENTIOMETERS fully counterclockwise

25 full turns or until a clicking sound is detected.

b. Turn FINE control approximately 12 turns clockwise

to the midpoint.

c. Set the DIP switch positions 3 ON, 4 OFF. (Note that

if DIP switch positions 3 and 4 are both ON the LED

and relay will remain on.)

1.8.2 Low Level Alarm

Fail-safe Low – with no media on the probe:

1. Set DIP switch positions 1 OFF, 2 OFF, 3 ON and

position 4 OFF. LED will be ON.

2. Turn the COARSE control clockwise until the LED

turns OFF.

3. Slowly turn the COARSE control counterclockwise until

the LED is on.

4. Turn the FINE control clockwise until the LED stays OFF.

Page 15

50-608 Kotron Model 811 RF Point Level Sensor

12

1.8.3 Low Level Alarm

Fail-safe Low – with media on the probe:

1. Set DIP switch positions 1 OFF, 2 OFF, 3 ON and

position 4 OFF. LED will be ON.

2. Turn the COARSE control clockwise until the LED

turns OFF.

3. Slowly turn the COARSE control counterclockwise until

the LED is ON.

4. Turn the FINE control clockwise until the LED goes OFF,

then counterclockwise until the LED stays ON.

1.8.4 High Level Alarm

Fail-safe High – with no media on the probe:

1. Set DIP switch positions 1 ON, 2 ON, 3 ON and

position 4 OFF. LED will be OFF.

2. Turn the COARSE control clockwise until the LED

turns ON.

3. Slowly turn the COARSE control counterclockwise until

the LED is OFF.

4. Turn the FINE control clockwise until the LED stays ON.

1.8.5 High Level Alarm

Fail-safe High – with media on the probe:

1. Set DIP switch positions 1 ON, 2 ON, 3 ON and

position 4 OFF. LED will be OFF.

2. Turn the COARSE control clockwise until the LED

turns ON.

3. Slowly turn the COARSE control counterclockwise until

the LED is OFF.

4. Turn the FINE control clockwise until the LED turns

ON, then counterclockwise until the LED stays OFF.

1.8.6 Time Delay

If Time Delay is needed for any reason (e.g., surface waves

causing relay chatter), the following two choices must

be made:

Delay Function

• Delay on FILL (rising level) is DIP switch 2 ON.

• Delay on EMPTY (falling level) is DIP switch 2

OFF.

Delay Duration

• 0.5 to 7 second delay – DIP switch 3 ON, 4 OFF.

• 2 to 120 second delay – DIP switch 3 OFF, 4 ON.

• Clockwise rotation increases duration.

Page 16

50-608 Kotron Model 811 RF Point Level Sensor

13

1.9 Calibration—Wide Differential

1.9.1 Set Point Adjustment Control

1. Turn on power to the instrument.

2. Remove housing cover.

3. Adjustments

3.1 Dip switch

a. Fail-safe

ON = high level

OFF = low level

b. Time Delay Direction

ON = delay on rising level

OFF = delay on falling level

c. Short Time Delay (0.5 to 7 seconds)

3 ON, 4 OFF

d. Long Time Delay (2 to 120 seconds)

3 OFF, 4 ON

NOTE: Switch positions 3 and 4 cannot be both ON or both OFF. One

must be ON the other OFF or the LED and relay will remain ON.

3.2 Potentiometers

a. Time Delay

• Allows continuous adjustment of time delay within

limits of DIP switch range chosen.

• Clockwise rotation increases delay.

b. Differential

• Allows continuous adjustment of pump or valve

control ON to OFF.

• Clockwise rotation increases differential. Full counterclockwise rotation is the narrowest differential and

is used for alarm applications.

c. Coarse

• Allows continuous adjustment of setpoint over entire

range of the electronics (0 to 1000 pF).

• Clockwise rotation raises SETPOINT on probe.

d. Fine

• Allows precision adjustment of SETPOINT within

the limits of the COARSE SETPOINT adjusted

initially.

• Clockwise rotation raises SETPOINT on probe.

Page 17

50-608 Kotron Model 811 RF Point Level Sensor

14

• This is an extremely fine adjustment. Sometimes it is

necessary to go 1 to 2 turns past the final SETPOINT

to stop relay chatter. A small amount of time delay

(2 turns) can also be used.

4. The LED shows the status of the relay coil.

LED on = relay energized.

LED off = relay de-energized

5. Set the Fail-safe Mode Selection.

a. In low level fail-safe (LLFS) mode, the relay is

de-energized on rising level and remains de-energized

until upper differential point is reached.

b. In high level fail-safe (HLFS) mode, the relay is

de-energized on falling level and remains de-energized

until the lower setpoint is reached.

6. DIP switch positions:

a. Low Level Fail-safe

1 OFF, 2 OFF, 3 ON, 4 OFF.

LED will be ON.

b. High Level Fail-safe

1 ON, 2 ON, 3 ON, 4 OFF.

LED will be OFF.

7. Verify process level is at desired low control point.

8. COARSE adjustment

a. Low Level Fail-safe

Turn COARSE control clockwise until LED turns OFF.

Turn COARSE control counter clockwise until the

LED is ON.

Slowly turn COARSE control clockwise until LED is

OFF. Low control point is now calibrated.

b. High Level Fail-safe

Turn COARSE control clockwise until LED turns ON.

Turn COARSE control counterclockwise until LED

is OFF.

Slowly turn COARSE control counterclockwise until

LED is ON. Low control point is now calibrated.

NOTE: FINE control can be used during wide differential calibration,

but is usually not needed.

9. Prior to raising level to desired high control point, turn

Differential control 25 turns clockwise or until clicking

sound is heard.

10. Raise level to desired high control point.

Page 18

50-608 Kotron Model 811 RF Point Level Sensor

15

11. Differential control

a. Low Level Fail-safe

Slowly turn Differential control counterclockwise

until the LED turns ON. The wide differential point

is calibrated.

b. High Level Fail-safe

Slowly turn Differential control counterclockwise

until the LED turns OFF. The wide differential point

is calibrated.

1.9.2 Time Delay

If Time Delay is needed for any reason (e.g., surface waves

causing relay chatter), the following two choices must

be made:

Delay Function

• Delay on FILL (rising level) is DIP switch 2 ON.

• Delay on EMPTY (falling level) is DIP switch 2

OFF.

Delay Duration

• 0.5 to 7 second delay – DIP switch 3 ON, 4 OFF.

• 2 to 120 second delay – DIP switch 3 OFF, 4 ON.

• Clockwise rotation increases duration.

LONG DELAY TIME DELAY

2 to 120 sec.

SHORT DELAY DIFFERENTIAL

0.5 to 7 sec.

DELAY DIRECTION COARSE

FAIL-SAFE FINE

Figure 16

Page 19

50-608 Kotron Model 811 RF Point Level Sensor

16

2.0 Reference Information

This section presents an overview of the operation of

the Kotron Model 811 RF Point Level Sensor, information

on troubleshooting common problems, intrinsic safety

information, physical, functional and performance

specifications, listings of agency approvals, and a list

of recommended parts

2.1 Description

The Kotron Model 811 RF Point Level Sensor can be

utilized in liquid or bulk material applications. There are

no moving parts in contact with the medium.

2.2 Theory of Operation

As the medium in contact with the probe rises and falls,

the amount of capacitance develops between the probe and

the ground changes. This change in capacitance is converted into level. When the level (capacitance) reaches a

desired amount, the relay will change state.

2.3 Troubleshooting

2.3.1 No Signal with Level Change

1. Check power and control circuit wiring.

2. Check DIP switch positions.

3. Check Calibration.

4. Check for proper ground reference particularly in

non-metal tanks.

2.3.2 Probe

Caution: When an insulated probe is used in a hazardous and/or

abrasive medium, the probe should be inspected periodically for nicks, cuts or abrasions which may ruin the

integrity of the insulation. In the event that wear is found –

replace the probe or consult the factory for further instructions. This procedure is critical in vessels containing

hazardous media.

To check for a malfunctioning sensing probe:

1. Remove the white probe lead from the sensing probe and

isolate it from the ground.

2. Connect an ohmmeter between the sensing probe terminal

and ground. (i.e., stainless steel probe nut or housing base)

Page 20

50-608 Kotron Model 811 RF Point Level Sensor

17

3. Measure the resistance between the probe and ground

using the highest resistance scale available. If the resistance

measures 10 Megohm to infinity and is stable, the probe

is operating correctly. If the resistance measures less than

10 Megohm and/or is unstable, there may be a problem

with the probe.

2.3.3 Switch Chatter

1. Check for turbulence. If turbulence is present, increase

time delay until appropriate.

2. Check for proper power supply voltage.

3. Check for proper ground reference.

NOTE: If the application uses an insulated probe in a conductive

medium, it is helpful to have the medium at its highest possible

level. This aids in the detection of cuts or nicks in the insulation.

4. Inspect the malfunctioning probe for a cut in the insulating

sheath or looseness in the seal at the probe mounting nut.

5. Inspect the probe for a coating or build-up of conductive

medium.

6. Measure the resistance between the probe and ground

using the highest resistance scale available. If the resistance

measures 10 Megohm to infinity and is stable, the probe

is operating correctly. If the resistance measures less than

10 Megohm and/or is unstable, there may be a problem

with the probe.

7. If probe test is working properly, check for insufficient

ground, loose or broken wiring, including the white probe

wire. Also check continuity between probe mounting nut

and metal tank. There should be continuity (zero resistance). If there is resistance, check for excessive teflon tape

used on the probe threads.

NOTE: If the above suggestions prove unsuccessful, consult factory.

Page 21

50-608 Kotron Model 811 RF Point Level Sensor

18

Agency Approved Model Protection Method Area Classification

FM 811-1X05-E0X Explosion Proof Explosion proof with intrinsically safe probe circuit

811-1X06-E0X Class I, Div. 1, Groups C & D

with probe models: Class II, Div. 1, Groups E, F, & G

041-5XXX-XXX and NEMA 4X

8XX-XXX-XXX

811-1X06-E0X Intrinsically Safe Remote probe:

(Remote) Class I, Groups A, B, C, & D

with probe models: Class II, Div. 1, Groups E, F, & G

041-5XXX-XXX and Class III,

8XX-XXX-XXX NEMA 4X

CSA 811-1X05-E0X Explosion Proof Explosion proof with intrinsically safe probe circuit

811-1X06-E0X Class I, Div. 1, Groups C & D

with probe models: Class II, Div. 1, Groups E, F, & G

041-5XXX-XXX and (Bare probes not approved for Groups E & F)

8XX-XXX-XXX TYPE 4X

811-1X06-E0X Intrinsically Safe Remote probe:

(Remote) Class I, Div. 1, Groups A, B, C, & D

with probe models: Class II, Div. 1, Groups E, F, & G

041-5XXX-XXX and (Bare probes are not approved for Groups E & F)

8XX-XXX-XXX Class III

TYPE 4X

These units have been tested to EN 50081-2

and EN 50082-2 and are in compliance with

the EMC Directive 89/336/EEC.

2.4 Agency Approvals

Page 22

50-608 Kotron Model 811 RF Point Level Sensor

19

2.4.1 Agency Specifications – Intrinsically Safe Installation

2.4.2 Agency Specifications – Explosion Proof Installation

Page 23

50-608 Kotron Model 811 RF Point Level Sensor

20

2.5 Parts

2.5.1 Replacement Parts

Item Description Part Number

Complete electronic assembly: Z30-9102-001 120 VAC

Items 1 and 2 (listed below) Z30-9102-002 240 VAC

Mounting bracket Z30-9102-003 24 VDC

Z30-9102-004 12 VDC

Power supply board* (integral or remote)

Z30-4502-001 120 VAC

Z30-4502-002 240 VAC*

Z30-4502-003 12 VDC

Z30-4502-004 24 VDC

I.S. amplifier board* (integral or remote) Z30-4506-001

Electronics cover (integral or remote)

Aluminum 002-6204-600

316 stainless steel 002-6204-605

Electronics o-ring (integral or remote) 012-2101-345

Electronics base (integral or remote)

Aluminum, dual 3⁄4" NPT conduit connection 004-9182-003

316 stainless steel, single 3⁄4" NPT conduit connection 004-9140-002

Remote probe cover

Aluminum 004-9105-001

316 stainless steel 004-9142-001

Remote housing o-ring 012-2101-345

Remote housing base

Aluminum, single

3

⁄4" NPT conduit connection 004-9104-001

316 stainless steel, single 3⁄4" NPT conduit connection 004-9140-002

Remote triaxial cable (standard)** 037-3180-XXX

Remote triaxial cable (high temperature)** 037-3184-XXX

Remote mounting bracket

1

⁄2" NPT conduit connection 036-3805-001

3

⁄4" NPT conduit connection 036-3805-003

Guarded Probe 18" (457 mm) (integral or remote) 8AD-AA1A-018

Guarded Probe 36" (914 mm) (integral or remote) 8AD-AA1A-036

* Refer to ESD handling procedure on page 1.

** Specify remote cable by exact length, 10 to 150 feet (3 to 45 M).

Standard (+176°F/+80°C) 37-3180-XXX (length in feet).

High Temp. (+392°F/ +200°C) 37-3184-XXX (length in feet).

Figure 17

Remote Mount with Guarded Probe

1

2

3

4

5

6

7

8

9

10

11

12

13

6

8

12

13

3

7

2

5

1

4

11

9

10

Page 24

50-608 Kotron Model 811 RF Point Level Sensor

21

Supply Voltage 120 VAC 50–60 Hz (+10%, -15%)

240 VAC 50–60 Hz (+10%, -15%)

24 VDC (±10%)

12 VDC (±10%)

Power Consumption 120 or 240 VAC Less than 5 volt-amps

12 or 24 VDC 1 watt maximum

Zero Range 0 pF minimum to 1000 pF maximum

Adjustable Differential 0.5 pF to 700 pF

Output relays DPDT with gold flash contacts AC 10 amp @ 120/240 VAC resistive

DPDT with gold flash contacts DC 10 amp @ 30 VDC resistive

DPDT with gold flash contacts DC 0.5 amp @ 125 VDC resistive

Response time 100 milliseconds

Repeatability Better than 1.0%

Ambient Temperature Electronics -40° to +160° F (-40° to +70° C)

Operating Process

Pressure/Temperature Dependent upon probe selected — See probe brochure 50-125

Temperature Coefficient of

Set Point -40° to +160° F (-40° to +70° C) ± .01% per degree F of setpoint

(± .018% per degree C of setpoint)

Electrostatic Discharge Protection per IEC spec. 801-2

2.6 Specifications

2.6.1 Functional

Page 25

50-608 Kotron Model 811 RF Point Level Sensor

22

NOTES:

Allow 6 in. (152 mm) overhead clearance for removal of NEMA 4X/7/9 cover.

Probe/Amplifier Connecting Cable to be triaxial. Magnetrol

P/N 037-3180-XXX standard or P/N 037-3184-XXX high temperature.

Integral Mount with Guarded Probe Remote Mount with Guarded Probe

Integral Mount with Standard Rigid Probe Remote Mount with Standard Rigid Probe

Integral Mount with Flexible Probe Remote Mount with Flexible Probe

Standard process connection is

3

⁄4" NPT. Consult probe brochure

(50-125) for flange and other probe connections.

2.6.2 Physical

NEMA 4X/7/9

➀

9.33 (247)

3/4" NPT

Conduit

Connection

Rotation Clearance:

2.63 (66)

3/4" NPT

Conduit

Connection

(Plugged)

Optional

Mounting

Flange

3/4" NPT

Thread

.375 (10)

2 Holes

.38 (10) Dia.

2.00

(51)

NEMA 4X/7/9

➀

7.75 (197)

3/4" NPT

Conduit

Connection

2.37

(60)

3.00

(76)

3.50

(89)

3.75

(95)

➁

Rotation Clearance:

2.63 (66)

3/4" NPT

Connection

3/4" NPT

Conduit

Connection

(Plugged)

1/2" NPT (opt.)

3/4" NPT (std.)

Transducer/Amplifier

Cable Connection

Conduit

4.11

(104)

3/4" NPT

Thread

Rotation Clearance:

2.63 (66)

3/4" NPT

Conduit

Connection

3/4" NPT

Conduit

Connection

(Plugged)

1/2" NPT (opt.)

3/4" NPT (std.)

Transducer/Amplifier

Cable Connection

NEMA 4X/7/9

➀

8.45 (215)

3/4" NPT

Conduit

Connection

Rotation Clearance:

2.63 (66)

3/4" NPT

Conduit

Connection

(Plugged)

Optional

Mounting

Flange

.38 (10) Dia.

➂

2 Holes

2.00

(51)

NEMA 4X/7/9

➀

7.75 (197)

3/4" NPT

Conduit

Connection

2.37

(60)

3.50

(89)

3.00

(76)

3.75

(95)

➁

Rotation Clearance:

3.00 (76)

6.86

(174)

18" (457)

or

36" (914)

.375 (10)

Rotation Clearance

3.00 (76)

5.98

(152)

➂

Rotation Clearance:

2.63 (66)

3/4" NPT

Conduit

Connection

3/4" NPT

Conduit

Connection

(Plugged)

1/2" NPT (opt.)

3/4" NPT (std.)

Transducer/Amplifier

Cable Connection

3/4" NPT

Thread

Optional

Anchor

Assembly

032-8814-001

(124)

(140)

4.87

5.50

1.32

(34)

NEMA 4X/7/9

➀

9.89 (251)

3/4" NPT

Conduit

Connection

Optional

Anchor

Assembly

(127)

4.87

(124)

5.00

1.32

(34)

.1250 (3)

.1875 (5)

.2500 (6)

2.95

(75)

79

(19)

➂

Optional

Weight

Rotation Clearance:

2.63 (66)

3/4" NPT

Conduit

Connection

(Plugged)

Optional

Mounting

Flange

.38 (10) Dia.

2 Holes

2.00

(51)

NEMA 4X/7/9

➀

7.75 (197)

3/4" NPT

Conduit

Connection

2.37

(60)

3.50

(89)

3.00

(76)

3.75

(95)

➁

.50 (13)

.625 (16)

Rotation Clearance

3.00 (76)

7.42

(188)

➂

.1250 (3)

.1875 (5)

.2500 (6)

2.95

(75)

Optional

79

Weight

(19)

P/N 004-4355-001

Page 26

50-608 Kotron Model 811 RF Point Level Sensor

23

3.0 Model Numbers

811 10 0

0 120 VAC

1 240 VAC

2 24 VDC

3 12 VDC

INPUT POWER

811 Kotron RF Capacitance Level Switch

BASIC MODEL — FM & CSA APPROVED MODELS

5 Integral

6 Remote

E

NEMA 4X/7/9 Groups C & D, aluminum,

3

⁄4" NPT dual conduit

Y

NEMA 4X/7/9 Groups C & D, stainless steel,

3

⁄4" NPT single conduit

HOUSING

MOUNTING

PROBE

0 Probe ordered separately

1 18" (455 mm) guarded probe

2 36" (915 mm) guarded probe

Page 27

50-608 Kotron Model 811 RF Point Level Sensor

24

NOTES:

Page 28

BULLETIN: 50-608.6

EFFECTIVE: June 2004

SUPERSEDES: June 2002

Service Policy

Owners of Magnetrol/STI controls may request the return

of a control or any part of a control for complete rebuilding or replacement. They will be rebuilt or replaced

promptly. Controls returned under our service policy

must be returned by Prepaid transportation.

Magnetrol/STI will repair or replace the control at no cost

to the purchaser (or owner) other than transportation if:

1. Returned within the warranty period; and

2. The factory inspection finds the cause of the claim to

be covered under the warranty.

If the trouble is the result of conditions beyond our control; or, is NOT covered by the warranty, there will be

charges for labor and the parts required to rebuild or

replace the equipment.

In some cases it may be expedient to ship replacement

parts; or, in extreme cases a complete new control, to

replace the original equipment before it is returned. If this

is desired, notify the factory of both the model and serial

numbers of the control to be replaced. In such cases, credit

for the materials returned will be determined on the basis

of the applicability of our warranty.

No claims for misapplication, labor, direct or consequential damage will be allowed.

Return Material Procedure

So that we may efficiently process any materials that are

returned, it is essential that a “Return Material

Authorization” (RMA) number be obtained from the factory, prior to the material's return. This is available

through Magnetrol’s local representative or by contacting

the factory. Please supply the following information:

1. Company Name

2. Description of Material

3. Serial Number

4. Reason for Return

5. Application

Any unit that was used in a process must be properly

cleaned in accordance with OSHA standards, before it is

returned to the factory.

A Material Safety Data Sheet (MSDS) must accompany

material that was used in any media.

All shipments returned to the factory must be by prepaid

transportation.

All replacements will be shipped F.O.B. factory.

NOTE: See Electrostatic Discharge Handling Procedure

on page 1.

ASSURED QUALITY & SERVICE COST LESS

5300 Belmont Road • Downers Grove, Illinois 60515-4499 • 630-969-4000 • Fax 630-969-9489 • www.magnetrol.com

145 Jardin Drive, Units 1 & 2 • Concord, Ontario Canada L4K 1X7 • 905-738-9600 • Fax 905-738-1306

Heikensstraat 6 • B 9240 Zele, Belgium • 052 45.11.11 • Fax 052 45.09.93

Regent Business Ctr., Jubilee Rd. • Burgess Hill, Sussex RH15 9TL U.K. • 01444-871313 • Fax 01444-871317

5300 Belmont Road • Downers Grove, Illinois 60515-4499 • 630-969-4028 • Fax 630-969-9489 • www.sticontrols.com

Copyright © 2006 Magnetrol International, Incorporated. All rights reserved. Printed in the USA.

Magnetrol and Magnetrol logotype are registered trademarks of Magnetrol International.

STI and STI logotype are registered trademarks of Magnetrol International.

Performance specifications are effective with date of issue and are subject to change without notice.

Loading...

Loading...