Page 1

Stopper II

®

Heated Enclosure

STI-1200A-HTR

STI-1200A-HTR240

ADA

Compliant

Features

· Maintains initiating device temperature with external temperatures to -70°F (-57°C).

Independently tested to -102°F (-73°C).

· Protects initiating devices for addressable units to UL 38 Standards.

· The clear, protective polycarbonate cover is UV-stabilized against discoloration.

· Enclosure rated to NEMA 3R Standards to provide a degree of protection against

rain, sleet, and damage from external ice formation.

· Fan runs continuously to maintain a uniform temperature inside the enclosure.

· Heater units cycle as required to maintain the correct range of operating

temperatures.

· Three year guarantee against breakage of polycarbonate in normal use (one year

on electro mechanical and electronic components).

· UL/ULC Listing does not require standby or secondary power for 110 or 240 VAC

50/60 Hz heater.

We protect the things that protect you.

Page 2

Warnings and Installation Notes

The enclosure is used to protect UL Listed 38 and 2017 initiating devices at temperatures down to -70˚F (-57˚C). It is the

installer’s responsibility to comply with NEC 70 Articles 725 and 760, NFPA 72, and other applicable fire and electrical codes.

Conduit or raceway paths need to be sealed as near to the enclosure as possible. Installer should have maintained supervision

over the low temperature thermostat. The low temperature monitoring thermostat makes the circuit at +32°F (0°C) and clears

the circuit at +50°F (+10°C). This listing requires that the fire alarm supervisory control module be only of the latching type. On

the appliance mounting plate is a label where you should record the installation date. Also include below the serial number and

installation date on the instruction sheet for quick reference.

Serial Number__________________________________ Installation Date__________________

NOTE: Operating voltage for the STI-1200A-HTR is 110 VAC. Operating voltage for the STI-1200A-HTR240 is 240 VAC.

1. Use of an outdoor rated initiating station is required with this heated enclosure.

2. When conducting periodic testing, if conditions are dusty or if you have wind blown dust conditions, cover return grill ports to

minimize entrance of dust or sand particles. To remove accumulated dust or sand particles, use small containers of compressed

air that is used for electronic cleaning.

3. To reset the thermal circuit breaker push button.

If circuit breaker will not remain in a restored or closed position, conduct an electrical check of the various components in the

two voltage classes. The two voltage classes are 24 VDC Negative Ground and 110 or 240 VAC 50-60 Hz with connected electrical or earth ground. High voltage (110 or 240 VAC) wiring must enter through bottom conduit. Low voltage and signaling wires

must enter through top conduit and remain separated per NFPA 70, NEC, and local codes.

4. If the thermal circuit breaker has tripped (opened circuit), the 110 or 240 VAC 50-60 Hz power will still be energized up to the

primary side of the thermal breaker. For safety, disconnect supply power of conductors to three power circuits in the enclosure.

5. To clean 24 VDC negative ground fan with electronic compressed air container, disconnect all power.

Note: the 24 VDC negative ground fan will not operate if positive and negative conductors are connected on the wrong terminals.

6. To minimize arid summer time heat build up in enclosure, install a dark color sun shield with sides to provide shade for the

enclosure. At the inclined face above the enclosure at the point of contact with the building structure leave at least 1/2” or (1.25

cm) space. This will generate heat and cause an upward airflow and help maintain the enclosure temperature approximately

the same as ambient air temperature.

7. The 110 or 240 VAC single phase 50-60 Hz heater does not require standby or secondary power because the enclosure environment is supervised by a latching supervisory circuit in the alarm control unit or panel.

8. Replacement of heater assembly and gasket is required five years from installation date. Contact STI to order replacement

Heater Kit STI-HK3.

9. All field wiring within this enclosure must be rated for a minimum operating range of 0ºC - 110ºC.

Mises en garde et remarques sur l’installation

Le boîtier est utilisé pour protéger les dispositifs de déclenchement homologués UL 38 et 2017 à des températures allant jusqu’à -70 °F (-57 °C).

Il incombe à l’installateur de se conformer aux articles 725 et 760 de la NEC 70, NFPA 72, et aux autres codes de prévention des incendies et de

l’électricité en vigueur. Les chemins des conduites ou canalisations doivent être scellés aussi proche que possible du boîtier. Il est attendu que

l’installateur ait effectivement contrôlé le thermostat à basse température. Le contrôle du thermostat à basse température maintient le circuit à 32

°F (0 °C) et déclenche le circuit à 50 °F (10 °C). Cette homologation exige nécessite que le module de contrôle de la surveillance des alertes

d’incendie soit uniquement du type à verrouillage. La plaque de montage de l’appareil comporte une étiquette sur laquelle vous devez enregistrer

sa date d’installation. Le numéro de série et la date d’installation doivent aussi être marqués sur la feuille d’instruction pour référence rapide.

Numéro de série ____________________ Date d’installation ______________

REMARQUE: La tension de service du STI-1200A-HTR est de 110 VCA. La tension de service du STI-1200A-HTR240 est de 240 VCA.

1. Use of an outdoor rated initiating station is required with this heated enclosure.

2. When conducting periodic testing, if conditions are dusty or if you have wind blown dust conditions, cover return grill ports to minimize entrance

of dust or sand particles. To remove accumulated dust or sand particles, use small containers of compressed air that is used for electronic cleaning.

3. To reset the thermal circuit breaker push button.

If circuit breaker will not remain in a restored or closed position, conduct an electrical check of the various components in the two voltage classes. The two voltage classes are 24 VDC Negative Ground and 110 or 240 VAC 50-60 Hz with connected electrical or earth ground. High voltage

(110 or 240 VAC) wiring must enter through bottom conduit. Low voltage and signaling wires must enter through top conduit and remain separated per NFPA 70, NEC, and local codes.

4. If the thermal circuit breaker has tripped (opened circuit), the 110 or 240 VAC 50-60 Hz power will still be energized up to the primary side of the

thermal breaker. For safety, disconnect supply power of conductors to three power circuits in the enclosure.

5. To clean 24 VDC negative ground fan with electronic compressed air container, disconnect all power.

Note: the 24 VDC negative ground fan will not operate if positive and negative conductors are connected on the wrong terminals.

6. To minimize arid summer time heat build up in enclosure, install a dark color sun shield with sides to provide shade for the enclosure. At the

inclined face above the enclosure at the point of contact with the building structure leave at least 1/2” or (1.25 cm) space. This will generate heat

and cause an upward airflow and help maintain the enclosure temperature approximately the same as ambient air temperature.

7. The 110 or 240 VAC single phase 50-60 Hz heater does not require standby or secondary power because the enclosure environment is supervised by a latching supervisory circuit in the alarm control unit or panel.

8. Replacement of heater assembly and gasket is required five years from installation date. Contact STI to order replacement Heater Kit STI-HK3.

9. All field wiring within this enclosure must be rated for a minimum operating range of 0ºC - 110ºC.

2

Page 3

Polycarbonate Cleaning Instructions

Rinse with water to remove abrasive dust and dirt. Wash with soap or mild detergent, using a soft cloth.

Rinse once more, then dry with a soft cloth or chamois. Exercise caution when using water inside enclosure. Make sure unit is completely dry inside before reassembling. Do not use razor blades.

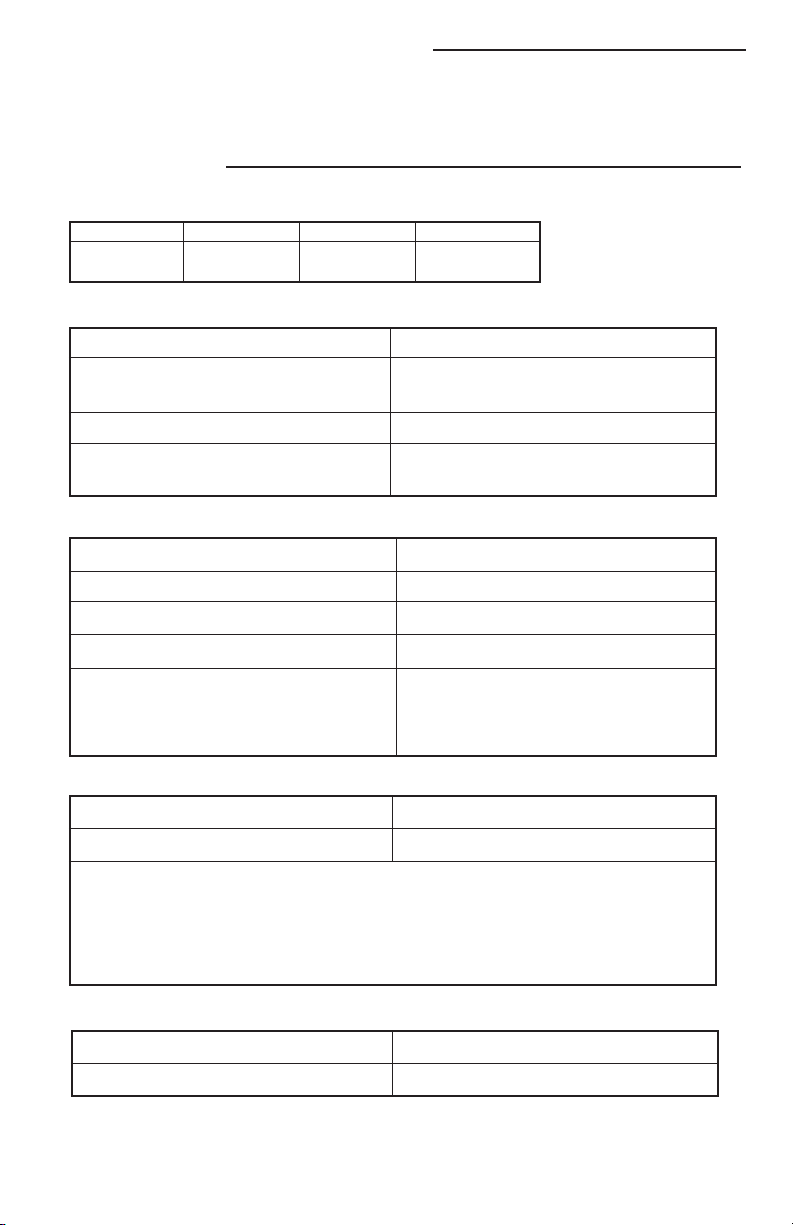

Specifications

Internal Dimensions

PART # HEIGHT WIDTH DEPTH

1200A-HTR 6.25 in. 4.125 in. 1.25 in.

1200A-HTR240

Polycarbonate Enclosure

Flammability UL94 V-2

Wall Thickness back box: .20 inches (5.1mm)

NEMA Rating 3R

Warranty Lifetime against breakage in

Silicone Laminate Heater

STI-1200A-HTR 110 VAC 50/60 Hz UL Recognized Component

STI-1200-A-HTR240 240 VAC 50/60 Hz UL Recognized Component

100 Watts

Life: @ -10˚C (14˚F) ~ 70˚C (158˚F) 5 Years

Duty Cycle: -40˚F (-40˚C) 16%

(158mm) (104mm) (31mm)

cover: .12 inches (3.1mm)

normal use.

-70˚F (-57˚C) 38%

-99˚F (-73˚C) 100%

Fan

24 VDC (±10%), 90 mA UL Recognized Component

Life 5 Years Continuous Duty

WARNING: The polarity of the circulating fan is important as it only

rotates in one direction with red lead being positive.

MISE EN GARDE: La polarité du ventilateur de circulation est importante car

il ne tourne que dans un sens avec son fil rouge étant celui du pôle positif.

Gasket

Material Neoprene

Life 5 Years

3

Page 4

Installation Instructions

8

7

/1

6

i

n.

(

2

1

4m

m

)

4

3

/

8

i

n

.

(

1

1

1

mm)

LOW VOLTAGE

WIRE INPUT

SEALING HUB

(NOT PROVIDED)

3

/4 in. NPT MALE NIPPLE

(NOT PROVIDED)

MOUNTING TAB

(4) PROVIDED

BACKBOX

#10 x 1 1/2 in.

PAN HEAD SCREW

(4) PROVIDED

HIGH VOLTAGE WIRE INPUT

MOUNTING

SURFACE

SCREW ANCHORS

(4) PROVIDED

DRILL (4) 1/4 in. (6.4mm)

D

IAMETER HOLES

3/4 in. NPT MALE

NIPPLE (NOT PROVIDED)

SEALING HUB

(NOT PROVIDED)

Mount Enclosure back box - Refer to Fig 1

1. Set heater assembly with cover aside. Press (4) plastic tabs into slots on back box and drill (4)

1/4” (6.4mm) diameter holes in mounting surface for plastic anchors provided. Attach back

box to wall using (4) #10 x 1-1/2”screws provided.

2. Attach 3/4” rigid conduit and conduit sealing hub (Crouse-Hinds 3/4” EYSX 21 or equivalent)

to back box. Conduit should be installed according to applicable NEC and local codes.

3. Pull 24 VDC and alarm wiring into back box through top conduit; and pull 110 or 240 VAC

wiring into back box through bottom conduit per NFPA 70, NEC and local codes.

Note: Wire size to be 12-22 AWG.

Install Fire Alarm Pull Station and Dual Monitor Module to Heater and Cover

Assembly - Refer to Fig 2.

4. Lift the cover from heater assembly and allow it to hang from cables. Connect the provided

high temperature wires to the pull station.

5. Attach the pull station to the slide plate using (2) #6-32 x 3/8” screws provided. Adjust the

slide plate so the pull station or slide plate does not cover either the fan opening or vent slots.

Note: If the fan opening or vent slots are covered, the plate mounting screws can be moved

to the alternate mounting position. After mounting pull station adjust the slide plate so there

are no gaps large enough to touch the heaters behind the pull station.

4

FIG. 1

Page 5

S

#6-32 x 1 in. PAN

HEAD SCREW

(4) PROVIDED

3

/8 in. STANDOFF

(4) PROVIDED

DUAL MONITOR

A

DDRESSABLE MODULE

(NOT INCLUDED)

24 VDC TERMINAL BLOCK

PULL STATION

(NOT INCLUDED)

#8-32 x 3/8 in.

FLAT HEAD SCREW

SLIDE PLATE

HIGH VOLTAGE TERMINAL BLOCK

FAN

W

ARM AIR DUCT (DO NOT COVER

W

ITH PULL STATION)

VENT SLOTS

(DO NOT COVER

WITH PULL STATION)

C

OVER AND HEATER ASSEMBLY

I

N

C

A

SE

O

F

P

U

L

L

F

IR

E

6. Turn assembly over and mount dual monitor module to the backside of the heater assembly

Wiring

7. Wire one channel of the dual monitor module to the low temp warning terminals (pins 1 & 2)

8. Connect wires from alarm panel to the dual monitor module according to design specifications.

9. Connect the 110 or 240 VAC supply to the high voltage terminal block pins 4, 5, and 6. Earth

10.Attach the heater and cover assembly to the back box with (4) #8-32 x 3/4” socket cap screws

11.Record installation date in space provided on the label located on underside of cover. Unit is

12.Turn all power to “ON” position.

1. 110 or 240 VAC heater on the load side of the fuse holder.

2. 24 VDC power source for the circulating fan. Check fan to see if operating; if not check polar-

3. Fire alarm initiating circuit and temperature warning monitor.

using (4) #6-32 x 1” screws and (4) 3/8” standoffs provided. Replace cover.

FIG. 2

on the 24 VDC terminal block. Wire the other channel to the fire alarm terminals (pins 5 & 6)

on the same terminal block. Add any end of the line devices as required for the alarm system.

Connect continuous 24 VDC supply to fan power terminals (pins 3 & 4) of the 24 VDC terminal block.

Note:

1. Fan is polarity sensitive and must be connected correctly for fan to operate.

2. Fan operates continuously.

Ground, AC Low, and AC High respectively.

and (4) #8 flat washers.

ready for testing.

Note: Fan runs continuously. This system requires three sources of power:

ity and reverse, then try again.

5

Page 6

SEALING HUB

(NOT PROVIDED)

3/4 in. NPT MALE NIPPLE

(NOT PROVIDED)

MOUNTING TAB

(4) PROVIDED

BACKBOX

#10 x 1 1/2 in.

PAN HEAD SCREW

(4) PROVIDED

SURFACE

SCREW ANCHORS

(4) PROVIDED

#6-32 x 1 in. PAN HEAD SCREW

(4) PROVIDED

3/8 in. STANDOFF

DUAL MONITOR

ADDRESSABLE MODULE

(NOT INCLUDED)

LOW TEMP WARNING

THERMOSTAT

24 VDC TERMINAL BLOCK

PULL STATION

(NOT INCLUDED)

#8-32 x 3/8 in.

FLAT HEAD SCREW

SLIDE PLATE

HIGH VOLTAGE TERMINAL BLOCK

FAN

CIRCUT BREAKER

COVER AND

HEATER ASSEMBLY

I

N

CA

SE

OF

PULL

F

IRE

GASKET

3/4 in. NPT MALE NIPPLE

(NOT PROVIDED)

SEALING HUB

(NOT PROVIDED)

Product Assembly

6

Page 7

Schematic Diagrams

2 AMP CIRCUIT BREAKER

OVERTEMP SAFETY

1

2

4

3

5

6

CONTROL

110 OR 240 VAC

SINGLE PHASE

1

2

4

3

5

6

FAN

PWR

+

_

FAN

LOW TEMP WARNING

(16-33VDC 600mA)

LOW VOLTAGE CIRCUIT

HIGH VOLTAGE CIRCUIT

TERMINAL

BLOCK

TERMINAL

BLOCK

CHASSIS

HEATER

CLOSE @ 40˚F (4˚C)

OPEN @ 65˚F (18˚C)

OPEN @ 120˚F (40˚C)

CLOSE @ 80˚F (27˚C)

OPEN @ 50

˚

F (10˚C)

CLOSE @ 32˚F (0˚C)

24VDC (±10%), 90mA

FROM MONITOR MODULE

TO TEMP WARNING

FROM MONITOR MODULE

TO MANUAL STATIONS

EARTH GROUND

MANUAL STATIONS

110 OR 240 VAC

50/60 Hz

100 WATTS

7

Page 8

Warranty

Three year guarantee against breakage of polycarbonate in normal use (one year on electro mechanical and

electronic components).

Electronic warranty form at www.sti-usa.com/wc14.

2306 Airport Road

Waterford, Michigan 48327-1209

Phone: 248-673-9898 • Toll Free: 800-888-4784 • Fax: 248-673-1246

sti-usa.com

www.

Safety Technology International (Europe) Ltd.

Unit 49G Pipers Road • Park Farm Industrial Estate • Redditch

Worcestershire • B98 0HU • England • Tel: 44 (0) 1527 520 999

Fax: 44 (0) 1527 501 999 • Freephone: 0800 085 1678 (UK only)

E-mail: info@sti-europe.com • Web: www.sti-europe.com

Printed in USA SUBJECT TO CHANGE WITHOUT NOTICE Inst. Sht. 1200A HTR MARCH2006

Loading...

Loading...