Page 1

1

Assembly Instructions

Solar collectors FKA 200/240/270

console installation

Page 2

2

Table of contents

Contents Page

Please read these instructions carefully before beginning the assembly.

Observe the warnings indicated by this sign.

They warn of dangers or possibly erroneous actions, which may result in the invalidation of the warranty.

The collectors FKA 200, FKA 240 and FKA 270 are monitored according to the CEN-Keymark program rules

Solarthermal Products and are certified with the registration numbers 011-7S1910 ... 1915 F.

The copyright of this instruction incl. graphical material remains in the property of the STI GmbH. The instruction can

only be duplicated completely or in parts with written authorisation of the STI GmbH. Subject to technical changes and

misprints.

The STI GmbH is obliged to take back with the environmental label RAL-UZ-73 for solar collectors ( „Blauer Engel“)

labeled products, and to consign it to recycling.

Safety regulations, instructions and guidelines 3

Product description 5

Hydraulic connections 7

Collector field dimensions 8

bottom support dimensions 9

Assembly bottom support on concrete block 11

Assembly bottom support with fixed dowel pin 12

Assembly collectors 13

Temperature sensor 15

Spacing roof hooks 16

Assembly base console on roof profile 17

Assembly roof-tile clamps 18

Assembly roof-tile clamps with lead 20

Assembly plain tile clamps without lead 22

Assembly plain tile clamps with lead 23

Assembly roof-tile clamp corrugated 25

Assembly mounting profiles/console 26

Wall console dimensions 27

Assembly wall console 28

Temperature sensor 31

Arrangement hydraulic connections 32

Hydraulic connection with manifold 33

Overview hydraulic connections / accessories 34

Assembly distance metal sheets 35

Pipe dimensions of the connecting pipe 36

Initial operation 38

Appendix 43

Page 3

3

Safety regulations, instructions

and guidelines

Engineer standards and guidelines

• VBG 4 Unfallverhütungsvorschriften Elektrische

Anlagen und Betriebsmittel

• VBG 37 Unfallverhütungsvorschrift Bauarbeiten

• VBG 74 Leitern und Tritte

• ZVDH, Regelwerk (Stand Juni 2001)

• LBO’s Landesbauordnungen der Bundesländer

• DIN 18299 Allgemeine Regelung für Bauarbeiten

jeder Art

• DIN 18334 Zimmer- und Holzbauarbeiten

• DIN 18338 Dachdeckungs- und

Dachabdichtungsarbeiten

• DIN 18339 Klempnerarbeiten

• DIN 18351 Fassadenarbeiten

• DIN 18360 Metallbauarbeiten, Schlosserarbeiten

• DIN 18381 Gas-, Wasser- und Abwasser installationsanlagen

• DIN 18451 Gerüstarbeiten

• DIN 1055 Lastenannahme für Bauten Teil 1-5

• DIN 1988 Teil 1-8 Technische Regeln für die

Trinkwasserinstallation

• DIN 4708 Teil 3 Zentrale Brauchwasser-

erwärmungsanlagen

• DIN 4102 Brandverhalten von Baustoffen und

Bauteilen

• DIN 4109 Schallschutz im Hochbau

• HeizAnlVO Heizungsanlagenverordnung

• ZVH - Richtlinie 11.01 Einbindung solartechnischer

Anlagen in die Hauswärmeversorgung

• TRD 802 Dampfkessel der Gruppe III

• TRD 402 Ausrüstung von Dampfkesselanlagen mit

Heißwassererzeugern der Gruppe IV

• ENV 1991-2-3- 4 Grundlagen der Tragwerksplanung

und Einwirkung auf Tragwerke – Schneelasten und

Windlasten

• DIN EN 516 Einrichtungen zum Betreten des Daches

• EN 517 Sicherheitsdachhaken

• DIN 4751 Teil 1: Wasserheizungsanlagen:

Offene und geschlossene physikalisch

abgesichterte Wäremeerzeugungsanlagen bis 120°C

- Sicherheitstechnische Ausrüstung

Teil 2: Wasserheizungsanlagen: Geschlossene,

thermostatisch abgesicherte Wärmeerzeugungs anlagen mit Vorlauftemperaturen bis 120°C Sicherheitstechnische Ausrüstung

Teil 3: Wasserheizungsanlagen: Geschlossene,

thermostatisch abgesichter te

Wärmeerzeugungsanlagen mit 50 kW

Nennwärmeleistung mit Zwangumlauf Wärmeerzeugern und Vorlauftemperaturen bis 95°C

- Sicherheitstechnische Ausrüstung

• DIN 4753 Teil 1 Wassererwärmer und

Wassererwärmungsanlagen für Trink- und

Betriebswasser;Anforderungen, Kennzeichnung,

Ausrüstung und Prüfung

• DIN 4757 Teil 1: Sonnenheizungsanlagen mit Wasser

und Wassergemischen als Wärmeträger;

Anforderungen an die Sicherheitstechnische

Ausrüstung

Teil 2: Sonnenheizungsanlagen mit organischen Wärmeträgern;

Anforderungen an die sicherheitstechnische Ausrüstung

• DIN VDE 0100-510 Errichten von Starkstromanlagen mit

Nennspannungen bis 1000 V; Allgemeine Bestimmungen

• DIN VDE 0100-725 Errichten von Starkstromanlagen mit

Nennspannungen bis 1000 V; Hilfsstromkreise

• DIN VDE 0100-737 Errichten von Niederspannungsanlagen -

Feuchte und nasse Bereiche und Räume und Anlagen im

Freien

• DIN VDE 0105-100 Betrieb von elektrischen Anlagen

• DIN VDE 0185-1, DIN 57185-1 Blitzschutzanlage, Allgemeines

für das Errichten

• DIN VDE 0190 Einbeziehung von Gas- und Wasserleitungen in

den Hauptpotentialausgleich

• VDE 0855-1, DIN 57855-1 Errichtung und Betrieb (Erdung) von

Antennenanlagen

Connection of solar thermal systems

• DIN EN 12976: Thermische Solaranlagen und ihre Bauteile

(vorgefertigte Anlagen)

• DIN EN 12977: Thermische Solaranlagen und ihre Bauteile

(kundenspezifisch gefertigte Anlagen)

• DIN 1988: Technische Regeln für Trinkwasser-Installation

Notes before starting assembly

The installation and initial operation must be carried out by an expert

who is responsible for the correct installation and operation.

Before installing and putting the collectors into service, please inform

yourself about the local engineer standards and regulations.

Components of the collectors can reach temperatures over 200 °C,

there is a danger of burning and scalding!

Please check whether there are any load sources in the area of the

collector field that may produce chemically aggressive medium.

In condensate dissolved acids and bases can cause permanent

damage to the collector components.

Throughout the installation of a solar collector you directly

intervene into an existing roof cladding. Different roof coverings

such as tile, shingles or slate require as security against the

ingress of moisture due to rain or snow additional measures (eg

sarkings) - especially in case of extended and occupied top floors

or in case of too less roof pitch (concerning the covering).

Page 4

4

Safety regulations, instructions

and guidelines

The substructure as well as its connections to the

building have to be checked on site according to the local

regulations.

The collectors have to be mounted in an angle of at least

20° to max. 70°.

Recommended heat transfer medium is a mixture of glycol

and water, e.g. Tyfocor L or similar The collectors may

never be operated or tested under pressure with water.

To protect the system of overheating during standstill and

accelerated glycole-aging a self-draining system (e.g. STI

Drain Master or Drain Box) is recommended.

It is absolutely necessary to pay attention, that the back flow

temperature is never lower than the ambient temperature. If

necessary, take appropriate action (e.g. increase back flow

temperature to at least 30°C).

Lightning protection

Note country-specific legislation!

Throughout the installation of metal fastening, a check is

needed by an authorized qualified electrician.

The metallic pipes of the solar circle are connected via

a copper pipe of at least 16 mm² with the earth circuit

connector.

Please ensure sufficient ventilation for each assembly

method. Do not close the ventilation openings. Especially

in case of roof-integrated assembly, the ventilation of the

collector is definitely necessary. Appropriate ventilation

hoods are available from the supplier. Pay attention to the

regulations of the ZVDH (Germany), SVDW (Switzerland)

as well as different local regulations concerning the ventilation. If necessary, consult an expert.

Responsibilites

The constructor of the installation is responsible for the integration of the installation according to regulations and for

compliance with the safety regualtions.

The operator of the installation is responsible for an operation of the installation according to regulations and for

consultation of experts in case of problems.

This instruction is not subjected to the control of a service of modifications. It does not absolve the manufacturer and operator of the

installation of his responsibilities to install and operate all parts of

the installation according to utmost professional knowledge. The

manufacturer of the installation is responsible to observe and keep

all appropriate regulations and instructions.

Statics

Before beginning the assembly it is vital to test the roof or

substructure on site to sufficient load-carrying capacity.

Pay increased attention to the possible durability of the screw

fittings to fasten the collectors as well as to the quality of the substructure.

According to DIN 1055 part 4 and 5 or rather according to the local

engineer standards it is necessary to check on site the whole system construction, especially in snowy regions (note: 1 m² powder

snow ~ 60 kg / 1 m² wet snow ~ 200 kg) as well as in regions with

high wind speed. Before starting the assembly all aspects that

may lead to incorrect load of the whole construction have to be

considered!

Install the collectors the way that backlog of snow (e.g. due to

snow guards or other obstacles) is not possible.

In case of correct assembly snow loads (pressure loads) up to 2

kN/m² and wind loads (suction loads) up to 1 kN/m² acting on the

collector are permitted.

For transport and stocking

Never abandon the delivered collectors unprotected at the building

site. Never lay down the collectors onto a rough surface with overhanging pieces like stones, timbers, etc.

Stock the collectors always upright leaning against a solid surface.

The rigidity of the collectors is limited. During transport to the building site always ensure a torsion-free transport type. In case of an

elevated intermediate storage make sure that the collectors are

protected against sliding down.

Page 5

5

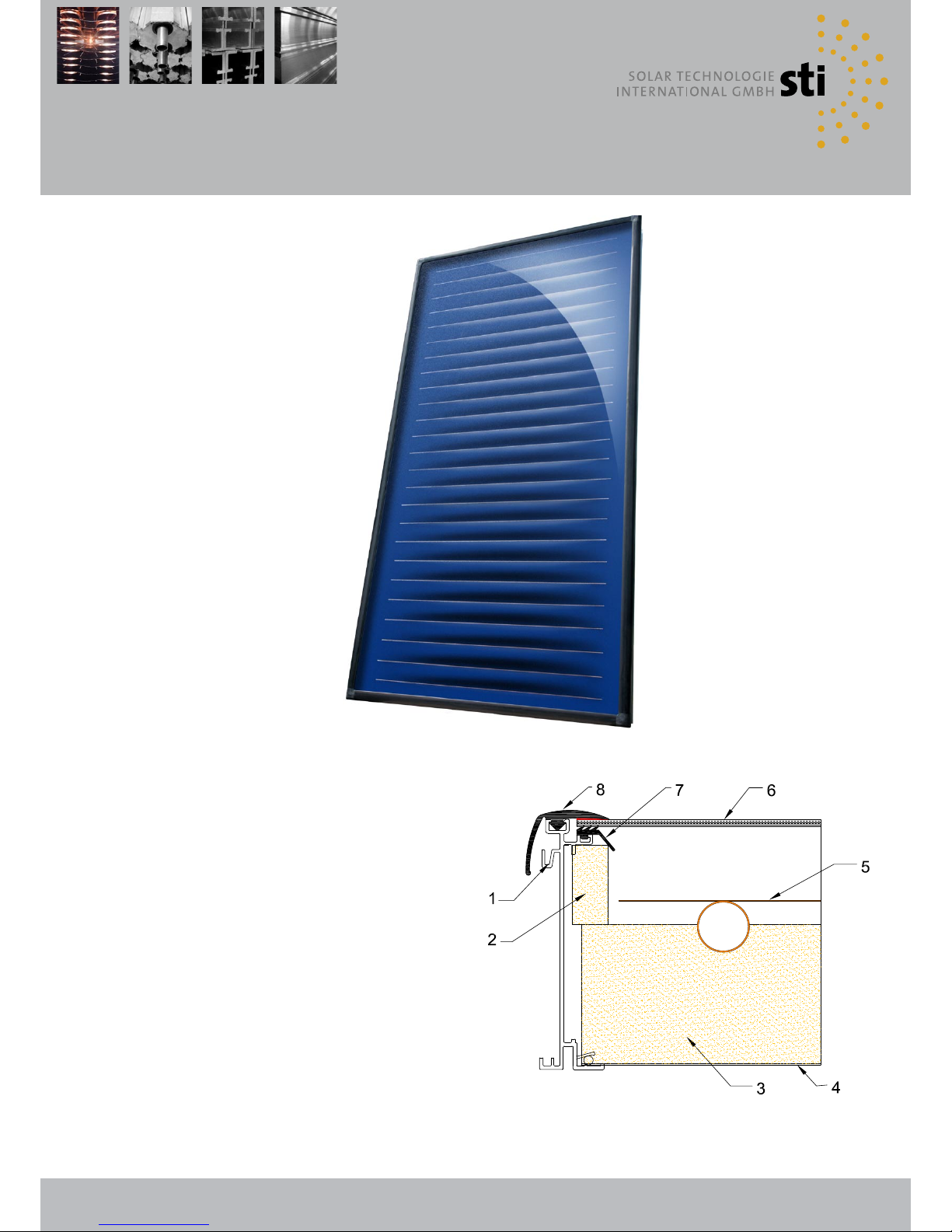

Product description

Solar collector FKA

The solar thermal collector FKA uses the radiant

energy of the sun to heat the heat transfer medium.

This glycol-water mixture gives off the stored heat via

a heat exchanger to a storage. The obtained energy

can be used for water heating and heating support.

Sectional model

1 Aluminium frame

2 Insulation

3 Insulation

4 Stucco back panel

5 Highly selective mono-material copper absorber

6 Glass

7 EPDM sealing

8 EPDM sealing

Page 6

6

Product description

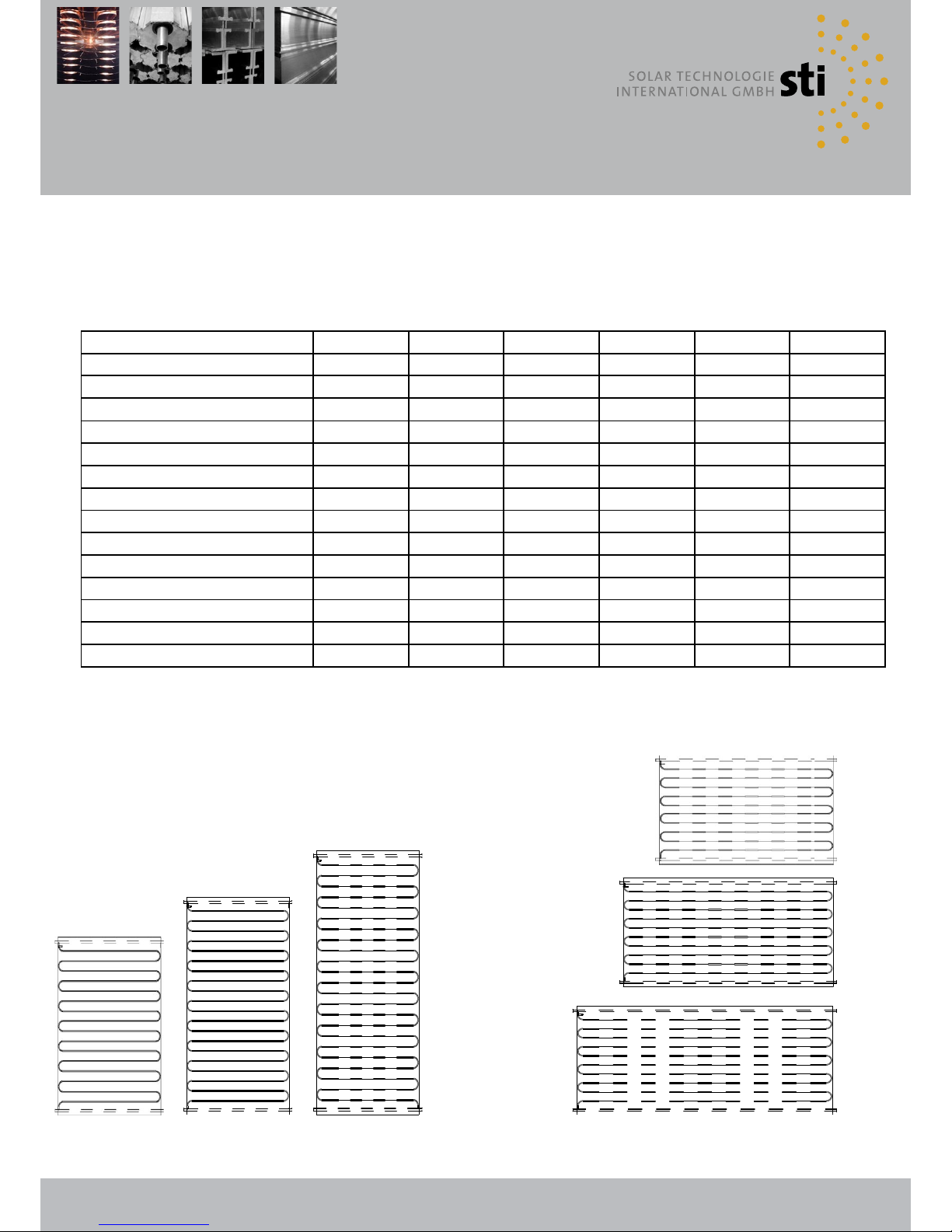

FKA 240 V FKA 270 V

FKA 200 H

FKA 270 H

FKA 200 V

FKA 240 H

Specifications

The FKA collector has a pure copper absorber with meander shaped tubes as well as

integrated manifolds. The hydraulic system enables to connect 15 collectors in one series

and up to six collectors on one side. In one collector field up to 45 collectors can be

connected in three rows.

Hydraulic system of the absorber

Model FKA 200 V 240 V 270 V 200 H 240 H 270 H

Gross surface 2.13 m² 2.52 m

²

2.88 m² 2.13 m² 2.52 m² 2.88 m²

Net surface 1.80 m² 2.15 m

²

2.52 m² 1.80 m² 2.15 m² 2.52 m²

Length 1,777 mm 2,100 mm 2,400 mm 1,200 mm 1,200 mm 1,200 mm

Width 1,200 mm 1,200 mm 1,200 mm 1,777 mm 2,100 mm 2,400 mm

Height 115 mm 115 mm 115 mm 115 mm 115 mm 115 mm

Test pressure 10 bar 10 bar 10 bar 10 bar 10 bar 10 bar

Operating pressure 6 bar 6 bar 6 bar 6 bar 6 bar 6 bar

Fluid volume Co-Co / Al-Co 2.1 l 2.2 l 2.4 l 2.7 l 2.7 l 3.1 l

Fluid volume Al-Al 1.8 l 1.9 l 2.1 l 2.4 l 2.4 l 2.7 l

Flow per m

2

15 - 40 l/h 15 - 40 l/h 15 - 40 l/h 15 - 40 l/h 15 - 40 l/h 15 - 40 l/h

Weight Co-Co 38 kg 41 kg 44 kg 38 kg 41 kg 44 kg

Weight Al-Co 37 kg 40 kg 43 kg 37 kg 40 kg 43 kg

Weight Al-Al 36 kg 38 kg 41 kg 36 kg 38 kg 41 kg

Loss of pressure (T=20°C / 30l/h) 6,141 Pa 8,522 Pa 11,217 Pa 4,082 Pa 6,297 Pa 7,988 Pa

Page 7

7

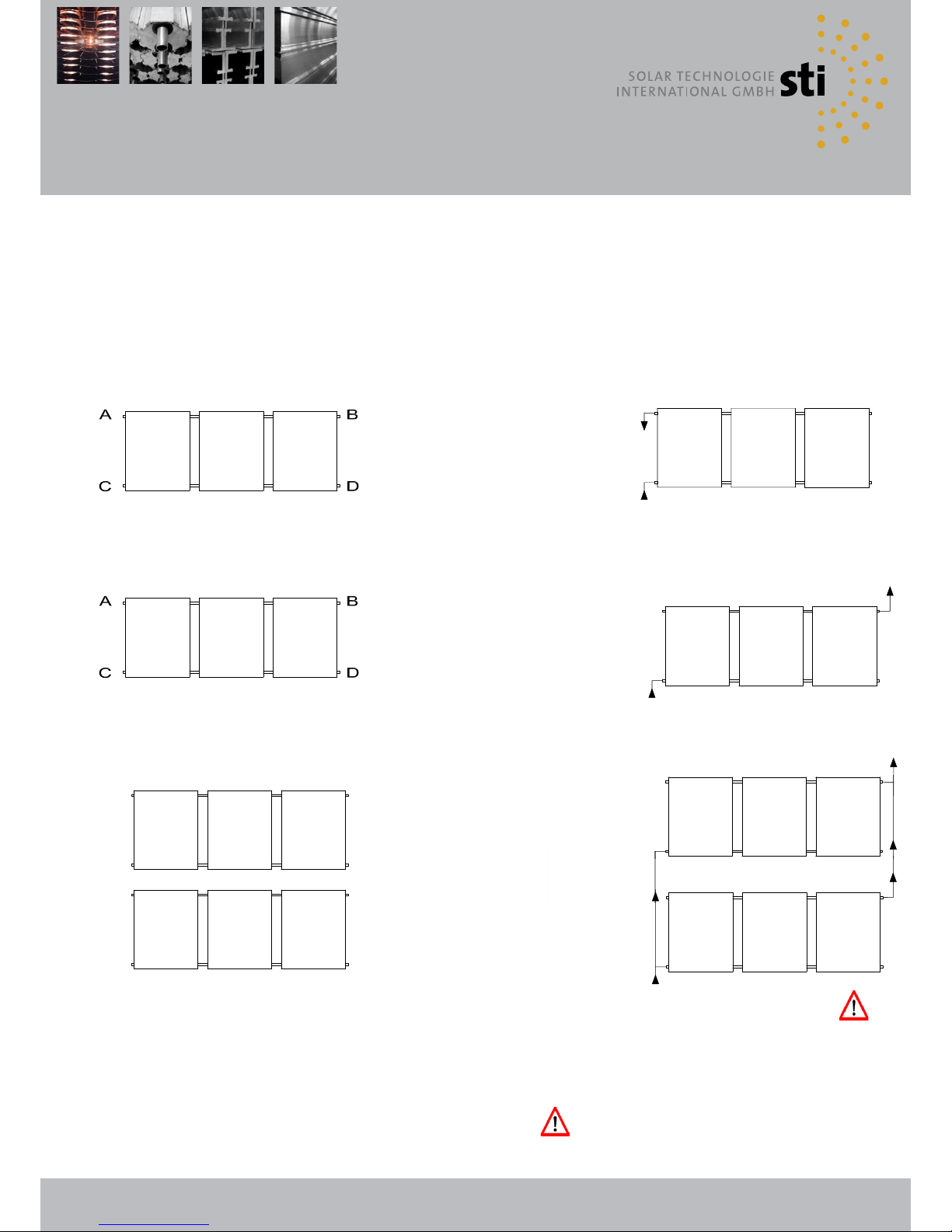

Hydraulic connections

A B

C

E

G

D

F

H

Temperature sensor

Each collector has a sleeve for inserting a temperature sensor. The sleeve is directly connected with the absorber.

If the collectors are installed correctly, the sleeve is always located on the top of the collector on the left. The

temperature sensor can be inserted in any collector. Please pay attention to the maximum inserting depth of 4 cm

and secure it against slipping out. Due to the measuring point on the absorber the temperature measured by the

sensor may differ from the fluid temperature.

Installations with one up to six collectors in one row

Connection F red

Connection BF blue,

A or B

C or D

Close unused connections with

caps.

Installations with seven up to 15 collectors in one row

Connection bottom left / at the top of

the right

BF = C / F = B

Connection at the top of the left /

bottom right

BF = D / F = A

Multi-row installations

F=Flow (collector to storage) red grommet

BF=Backflow (storage to collector) blue grommet

In case of installation of an air eliminator, install it at the opposite

end of the top flow connection!

Pipe rounting by Tichelmann

Connection F A + E / BF H + D

Connection F B + F / BF G + C

Close unused connections with caps.

In case of multi-row installations the connection pipe must always be connected to the diagonal line to the external

manifold (Tichelmann), e.g. from botton left to the top right.

Page 8

8

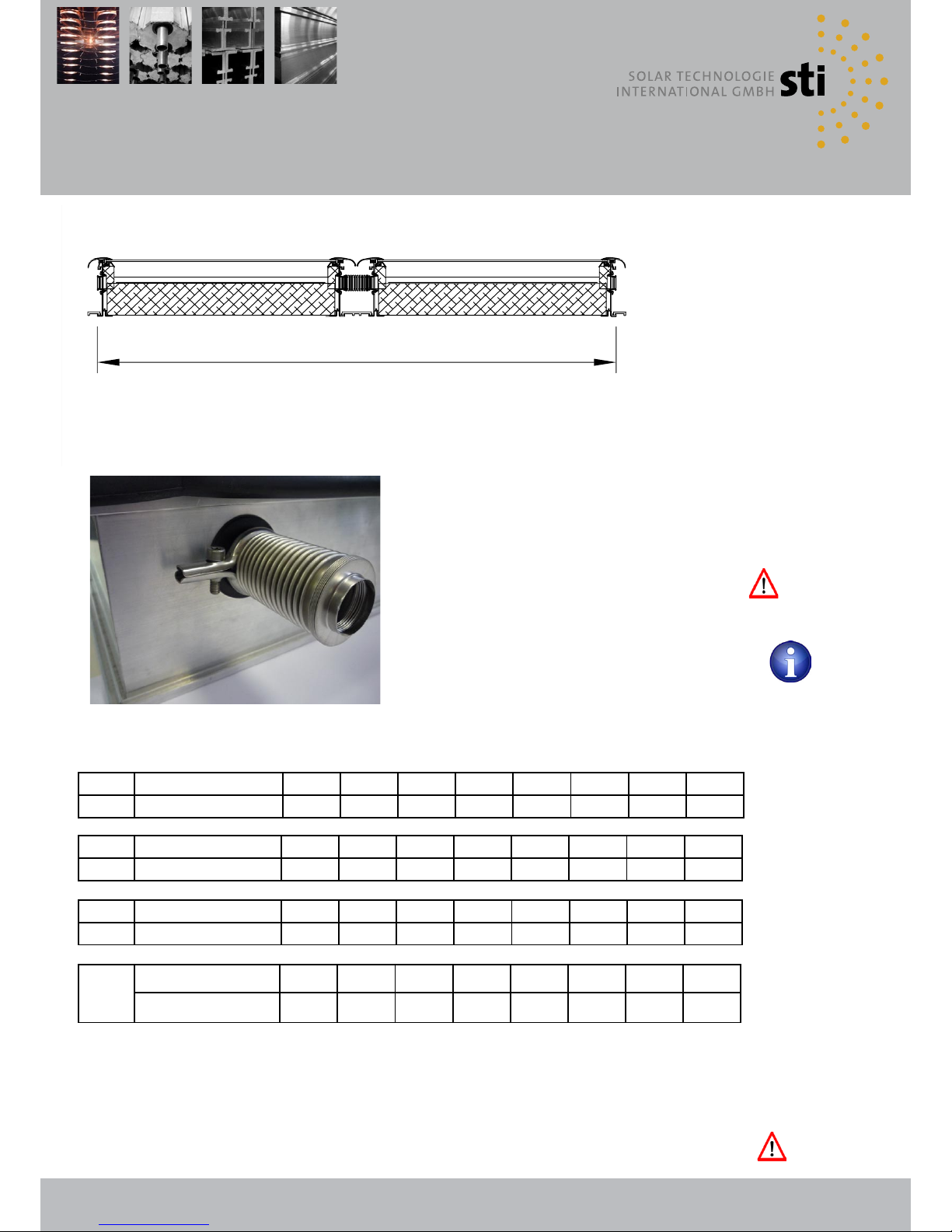

Collector field dimensions

Horizontal section across a collector field

Collectors that are mounted side by

side in one row are always connected

by means of stainless steel

expansion joints on the manifolds.

(view photo)

1300001 Collector connection set hydraulical

1910001 Tool set

Tighten the screw on the clamp only manually. The usage of

cordless screwdrivers or the like may lead to damages of the thread

of the clamp. Tighten the clamp until the two lugs are superimposed

in the whole length.

Field width

It is possible to assemble metal sheets between the collectors to achieve a homogeneous appearance of the installation.

The distance metal sheets are assembled exclusively for optical aspects and do not have any influence on the installation.

Therefore the distance metal sheets can be ordered optionally and are not necessarily included in delivery.

Collector type

When mounting solar collectors on supports it is important to ensure that the panels are anchored either on a solid surface or

on the concrete blocks shown in this instruction. The available concrete elements are recommended as a weight for locations

up to 700 meters above sea level with leeward situation. With expected higher loads, the weights must be increased. For higher

loads a calculation must be provided, and optionally a reinforcing of the system with additional components. When attaching

the consoles on buildings please ensure that the water tightness is maintained in each case. The mounting of the consoles and

collectors is described on the following pages.

240 H Number of collectors 1 2 3 4 5 6 7 8

Field width in mm 2.067 4.187 6.307 8.427 10.547 12.667 14.787 16.907

per each additional

collector

+ 2.120

270 H Anzahl Kollektoren 1 2 3 4 5 6 7 8

Field width in mm 2.340 4.733 7.126 9.519 11.912 14.305 16.698 19.091

per each additional

collector

+ 2.393

200 V

240 V

270 V

Number of collectors 1 2 3 4 5 6 7 8

Field width in mm 1.167 2.387 3.607 4.827 6.047 7.267 8.487 9.707

+ 1.220

per each additional

collector

200 H Number of collectors 1 2 3 4 5 6 7 8

Field width in mm 1.713 3.479 5.245 7.011 8.777 10.543 12.309 14.075

per each additional

collector

+ 1.766

Page 9

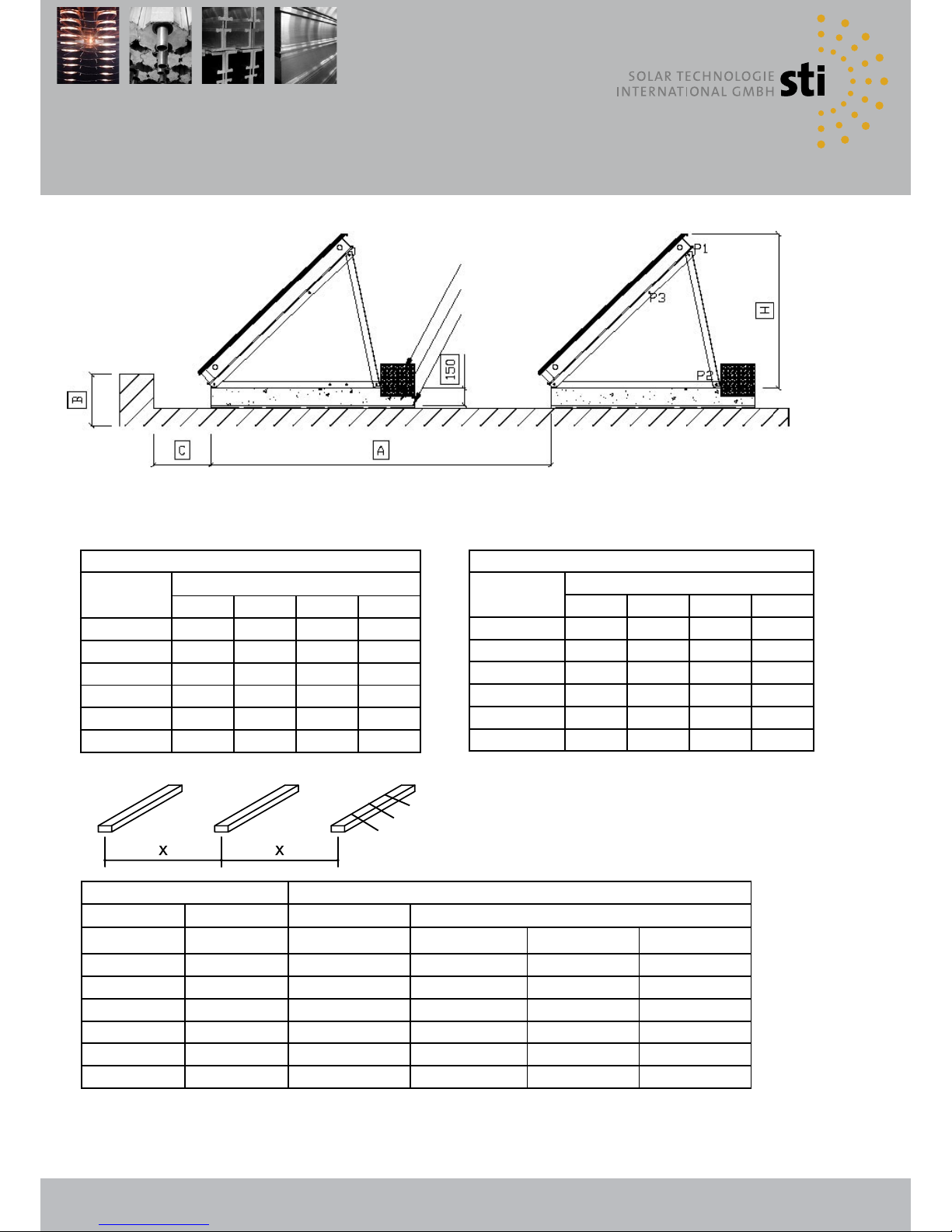

9

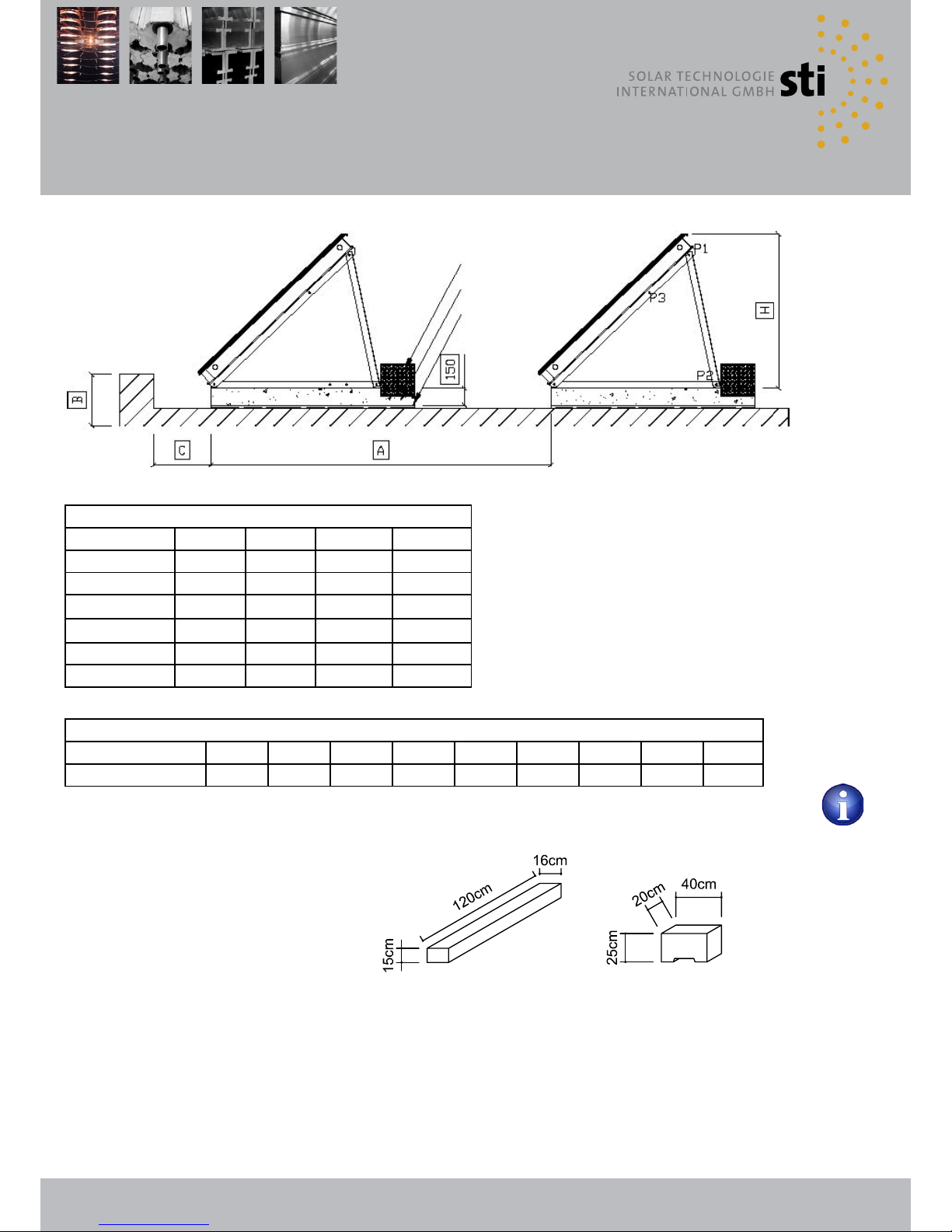

bottom support dimensions

α

δ

ε

bottom support

additional block

concrete block

base

row spacing of collectors

collector

type

distance A

20 ° 30 ° 45 ° 60 °

FKA 200 H 220 cm 265 cm 315 cm 340 cm

FKA 240 H 220 cm 265 cm 315 cm 340 cm

FKA 270 H 220 cm 265 cm 315 cm 340 cm

FKA 200 V 328 cm 391 cm 462 cm 503 cm

FKA 240 V 439 cm 513 cm 598 cm 646 cm

FKA 270 V 460 cm 550 cm 640 cm 700 cm

building height of collectors

collector

type

height H

20 ° 30 ° 45 ° 60 °

FKA 200 H 53 cm 71 cm 93 cm 110 cm

FKA 240 H 53 cm 71 cm 93 cm 110 cm

FKA 270 H 53 cm 71 cm 93 cm 110 cm

FKA 200 V 73 cm 91 cm 132 cm 156 cm

FKA 240 V 71 cm 104 cm 147 cm 180 cm

FKA 270 V 95 cm 130 cm 176 cm 211 cm

The specified levels are reported without concrete blocks. To

determine the total height the height of the concrete block

(15 cm) must be added.

Block distance center - center Dimensional chain, bottom bracket UK mounting

collector type

distance

Bottom support Bottom support attachment points (+ / - 30 cm)

X

α δ ε

FKA 200 H 176,6 cm 1000 mm 100 mm 860 mm -

FKA 240 H 212,0 cm 1000 mm 100 mm 860 mm -

FKA 270 H 239,3 cm 1000 mm 100 mm 860 mm -

FKA 200 V 122,0 cm 1600 mm 100 mm 700 mm 1.460 mm

FKA 240 V 122,0 cm 1600 mm 100 mm 700 mm 1.460 mm

FKA 270 V 122,0 cm 1800 mm 100 mm 900 mm 1.660 mm

All values given are recommendations for an effective angle of incidence of 20 °.

Please note the wind loads according to DIN 1055-4 in the edge region of the roof. The resulting base load is

necessary in each case to the requirement of wind loads on the spot!

Page 10

10

bottom support dimensions

distance of superstructures

parapet height B 30 cm 40 cm 50 cm 60 cm 70 cm 80 cm 90 cm 100 cm 110 cm

distance C 20 cm 40 cm 70 cm 100 cm 125 cm 150 cm 180 cm 205 cm 230 cm

1420100 concrete block 65 kg 1420101 additional block 45 kg

concrete block 65 kg

additional block 45 kg

console 8 kg

collector filled (240) 46 kg

travers position

angle 20° 30° 45° 60°

position P1 - P2 P3 - P2 P1 - P2 P3 - P2

200/240/270 H 487 mm 487 mm 861 mm 861 mm

200 V 675 mm 675 mm 1.224 mm 1.224 mm

240 V 832 mm 832 mm 1.490 mm 1.490 mm

position P1 - P2 P1 - P2 P1 - P2 P1 - P2

270 V 659 mm 962 mm 1.405 mm 1.820 mm

additional block

concrete block

base

Page 11

11

Assembly bottom support on

concrete block

First install the base console in accordance with the requirements to

the dimensions of bottom support.

1420014 bottom support 20°/30° 200 V

1420024 bottom support 45°/60° 200 V

1420018 bottom support 20°/30° 240 V

1420022 bottom support 45°/60° 240 V

1420060 bottom support 20° 270 V

1420061 bottom support 30° 270 V

1420062 bottom support 45° 270 V

1420063 bottom support 60° 270 V

1420011 bottom support 20°/30° 200/240/270 H

1420020 bottom support 45°/60° 200/240/270 H

Next place the concrete block. Pay attention to the exact

observance of the specified clearances between the concrete

blocks. The short distance between the threaded sleeve and block

edge (10 cm) shows the front of the block. Make sure that every

concrete block is on the same mounting position and aligned in a

row (e.g. by a line mark).

1420100 concrete block 65 kg

Now remove from all concrete blocks, the protective caps for the

integrated threaded sleeves.

Then place the base consoles on the concrete blocks and secure

them with the screws M10. All other consoles have to be oriented

exactly in a row (e.g. by a line mark).

1420003 Fastening set for bottom support

Now weight down the concrete block with the additional block.

Prepare for installing the collectors all consoles as above described.

1420101 additional block 45 kg

Page 12

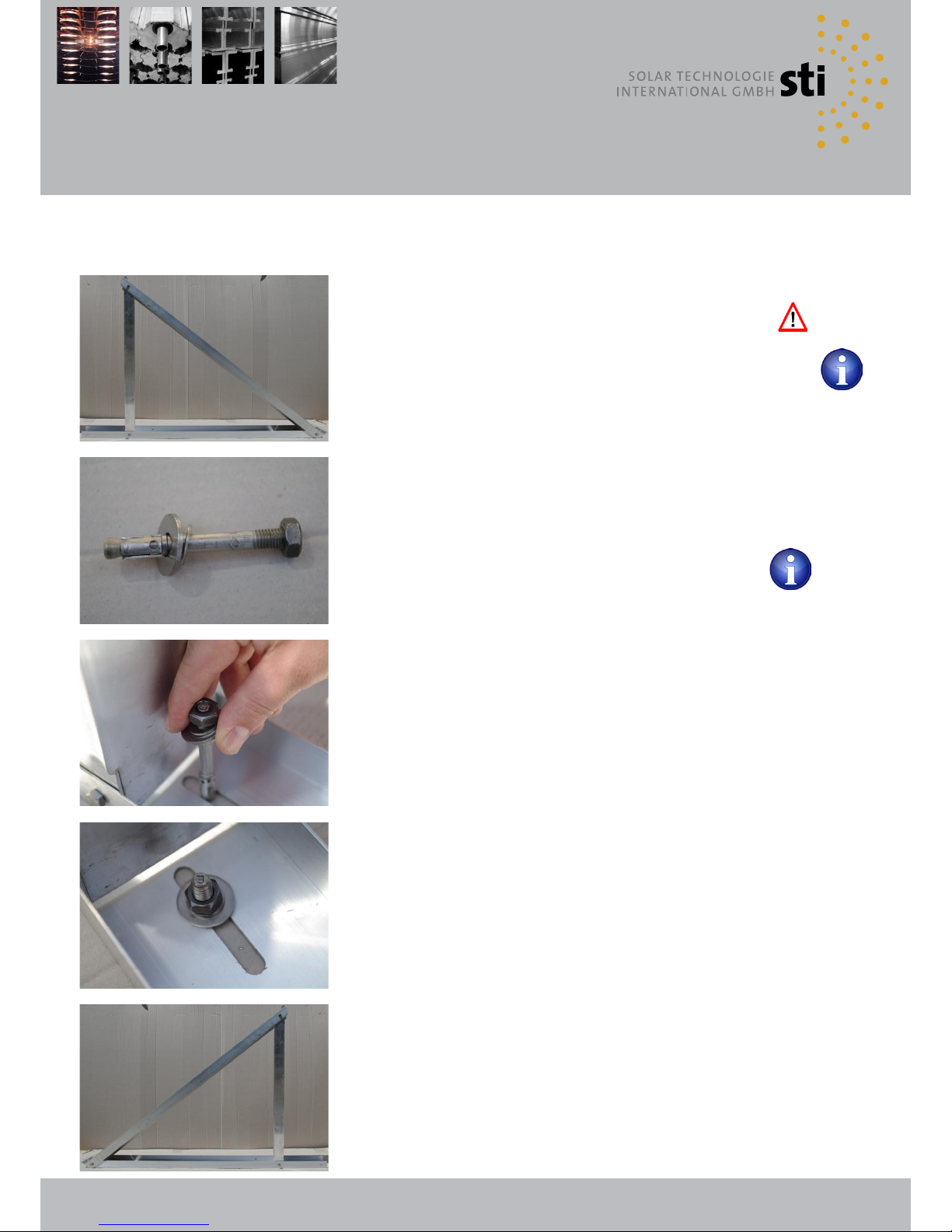

12

Assembly bottom support with

fixed dowel pin

First install the base console in accordance with the requirements

(see page 11).

1420014 bottom support 20°/30° 200 V

1420024 bottom support 45°/60° 200 V

1420018 bottom support 20°/30° 240 V

1420022 bottom support 45°/60° 240 V

1420060 bottom support 20° 270 V

1420061 bottom support 30° 270 V

1420062 bottom support 45° 270 V

1420063 bottom support 60° 270 V

1420011 bottom support 20°/30° 200/240/270 H

1420020 bottom support 45°/60° 200/240/270 H

Drill two holes per base console in the existing surface to fix the

fixed dowel pin M10. Pay attention to precise alignment of the two

holes. In addition, all other holes hare to be oriented in exactly one

row (e.g. by a line mark)

1420004 Fastening set for concrete blocks

(with fixed dowel pin)

Then place the base consoles on the ground and secure it with the

added fixed dowel pins M10. All other consoles have to be oriented

exactly in a row (e.g. by a line mark)

Fully assembled fixed dowel pin and console (see figure 1 and 2)

Fig. 1

Fig. 2

Reliable anchoring of the bottom support with the fixed dowelpin is possible in concrete <c25/25 as well as in natural stone that

is resistant to pressure.

Page 13

13

Assembly collectors

For the collector assembly, you first set the rightmost or leftmost

collector on the mounted and fixed consoles. When mounting the

collector ensure that the outer console is covered about 50% by the

collector.

After the exact orientation the collector is fixed on the outside with

fastening plates at the upper and lower elongated hole on the

console.

1400008 Collector fastening set onto support

edge (2 fastening points)

Please note that the remaining fastening plates are to mount on the

opposite outer side.

Before the following collectors can be mounted, the compensator

must be mounted on the concisely protruding flange.

It is important to ensure that the 0-ring seal is used for the

compensator.

1300001 Collector connection set hydraulical

Fixation of the compensator on one side with the clamp.

Before tightening the screw the clamp must be positioned by a

rotary motion up and down Tighten the screw on the clamp only

manually. The use of cordless drills or similar may cause damage

to the thread of the clamp. Tighten the clamp until the two lugs

superimpose in the whole length.

1910001 Tool set

Afterwards, mount the fastening plate “double” on the next console

in the upper and lower elongated hole. The final fixation takes place

after assembly of the next collector.

1400006 Collector fastening set onto support

(2 fastening points)

Page 14

14

Assembly collectors

Pre-installed compensator with O-ring seal and clamp. Install the

upper and lower compensator according to the opposite figure.

Now install the next collector on the consoles.

Move the collector until the fastening plate “double” hooks into the

collector profile. Then fix the fastening plate.

Fix the upper and lower compensator with the clamp.

Before tightening of the screw the clamp must be positioned by

a rotary motion up and down. Tighten the screw on the clamp only

manually. The use of cordless drills or similar may cause damage

on the thread of the clamp. Tighten the clamp until the two lugs

superimpose in the whole length.

Finally, assemble the two outer fastening plates.

Page 15

15

Temperature sensor

Each collector has a sleeve for inserting a temperature sensor.

The sensor is positioned below the upper left manifold or next to

the label with the description „top“ on the outside of the collector

frame.

The sleeve for inserting the sensor is protected with a silicon

grommet which has to be centrally opened (using a knife or small

screwdriver) before inserting the sensor.

The insertion depth is limited to 4 cm. Furthermore, it is

recommended to protect the sensor against slipping out.

The temperature sensor can be inserted in any collector of

the installation.

The error of measurement of the recorded temperature

compared to the fluid temperature is ± 2 K.

Page 16

16

Spacing roof hooks

A - 20 cm A +/- 20 cm

2 x A - 20 cm

2

Distance measures roof-tiles

Roof-tiles

roof covering

For each collector row two rows roof-tiles are necessary. The vertical size H1 is each taken on the top edge of

the roof-tiles.

Initial position:

top edge

roof-tiles

Initial position

1410002 Roof-tile bracket V2

..

..

..

1410005 Roof-tile bracket flat roof-tile

with lead 24 mm battens

If high snow loads are to be expected, the rooftiles have to be mounted above the rafters (in

other words the support must lie on the rafter /

alternatively, a higher number of roof-tiles may be

considered, depending on load).

Initial position:

top edge

roof-tiles

FKA 200/240/270 H

FKA 200/240/270 V

Horizontal size FKA 200 H FKA 240 H FKA 270 H

Maß A 88,3 cm 106 cm 119,7 cm

Vertical size

Tolerance

FKA 200 H

+ / - 10 cm

FKA 240 H

+ / - 10 cm

FKA 270 H

+ / - 10 cm

Maß H 77 cm 77 cm 77 cm

Horizontal size FKA 200 V FKA 240 V FKA 270 V

Maß A 122 cm 122 cm 122 cm

Vertical size

Tolerance

FKA 200 V

+ / - 10 cm

FKA 240 V

+ / - 10 cm

FKA 270 V

+ / - 10 cm

Maß H 1 60 cm 60 cm 80 cm

Maß H 2 77 cm 77 cm 77 cm

Page 17

17

Assembly base console

on roof profile

1400035 Profile set alu 200H

1400027 Profile set alu 240H

1400028 Profile set alu 270H

1400026 Profile set alu 200/240/270V

1400022 Connection set for

profile set

For roof-mounted installations one profile set alu 1400035, 1400026, 1400027 or 1400028 (depending on the collector type)

is delivered for each collector. If several collectors are mounted in one row, for each collector crossing one connection set for

profile set 1400022 is necessary.

For multi-row systems, the minimum distances between rows must be observed (see table “row spacing of collectors,“

bottom support dimensions).

Page 18

18

Assembly roof-tile clamps

Completely tiled roof.

When mounting the field in regions with high snow load zone of 2

kN/m², it is necessary to place the roof hooks in the rafter area.

Removal of the tiles after previous determination of the placement

of the roof-tile clamps (see page 10 “Spacing multi-row collector

fields“).

Fixation of the lower lath 24x80x600 mm with two screws 5x60 mm.

If the lath is placed near the counter lath, the lath 24x80x600 mm

must not be applied.

1410002 Roof-tile clamp V2 without lead

The lower roof-tile must be remounted.

Before covering the lower roof-tile must be coarsly ground.

To avoid breaking of the tile the roof-tile clamp must not rest on the

tile.

The lower tile must be coarsly ground so that the roof-tile clamp

rests in the middle of the tile.

Mount the tile clamp support 80x270x30 mm and fix it with two

screws 5x60 mm.

Page 19

19

Assembly roof-tile clamps

Fix the roof-tile clamp with the support 50x150x5 mm using two

screws 5x60 mm.

Before roofing the covering tile has to be coarsly ground accordingly.

Finished mounting of screw as distance saver.

Caulk, if necessary, the coarsely ground brick with a foam tape

against water!

In addition to the grinding of the roof-tile we recommend to use a

screw that is mounted on the roof-tile clamp support as distance

saver.

Complete covered roof-tile clamp after covering.

Further roof-tile clamps in one row must be adjusted exactly

(e.g. by a line mark)

Page 20

20

Assembly roof-tile clamps

with lead

Completely tiled roof.

Removal of the tiles after previous determination of the placement

of the roof-tile clamps (see page 10 „Spacing multi-row collector

fields“)

When mounting the field in regions with high snow load zone of 2

kN/m², it is necessary to place the roof hooks in the rafter area.

Completely lifted area for placement of a hook.

Mount the lower lath 24x80x600 mm with two screws 4x50 mm.

If the lath is placed near the counter lath, the lath 24x80x600 mm

must not be applied.

1410002 Roof-tile clamp V2 with lead

Replace the lower roof-tile.

Afterwards the tile clamp support 24x150x270 mm is to be fixed with

two screws 6x60 mm.

Page 21

21

Assembly roof-tile clamps

with lead

Place the first mounting tab so that the lower tile is covered.

Additionally make sure that the mounting tab is put sideways under

the adjacent tiles (bend up mounting tabs sidewise).

Mount the roof-tile clamps without covering the lower tile.

The roof-tile clamp must not cover the lower tile. Otherwise, a

pressure point on the lower tile may arise.

Mount the upper mounting tab. Bend it up sidewise. The screws of

the roof-tile clamp must be covered.

Protect the mounting tab against slipping.

The added foam wedge is placed under the adjacent tiles on both

sides as well as above (protection against splash water and snow).

Completely mounted roof-tile clamp.

Further roof-tile clamps in one row must be adjusted exactly

(e.g. by a line mark)

Page 22

22

Assembly plain tile clamps

without lead

Use the roof-tile for roof-mounted installation for plain tile roof covering also for slate, shingle and prefa covering.

Fixation of the lower lath 24x80x600 mm with two screws 4x50 mm.

If the lath is placed near the counter lath, the lath 24x80x600 mm

must not be applied.

Adjust the roof-tile laterally so that only one tile must be coarsly

ground. Place the hook so that there is enough space for a covering

tile to avoid grinding.

The tile clamp is fixed with two screws 5x60 mm.

The roof-tile clamp may not rest or rather cause pressure points on

the tile.

If the tile clamp is mounted too low, the added 5 mm timbers can be

placed under the tile clamp.

When mounting the field in regions with high snow load zone of 2

kN/m², it is necessary to place the roof hooks in the rafter area.

Covering of tile laterally.

Grinding and covering of the tile.

Covering of the remaining tiles.

Further roof-tile clamps in one row must be adjusted exactly

(e.g. by a line mark)

1410004 Roof-tile clamp V2 plain tile without lead

Page 23

23

Assembly plain tile clamps

with lead

Fixation of the lower lath 24x80x600 mm with two screws 4x50 mm.

Assembly of the upper tile clamp support 100x80x25 mm with two

screws 5x60 mm.

When mounting the field in regions with high snow load zone of 2

kN/m², it is necessary to place the roof hooks in the rafter area.

Assembly of the lower tile clamp supporte 80x50x45 mm with two

screws 5x60 mm.

Timber excess length of 5 mm (timber is higher than tile).

Completely mounted timber supports.

Mount the lower lead sheet while placing the lead laterally under the

tiles.

Pay attention that the corners are bent under the tile on both sides.

1410002 Roof-tile clamp V2 plain tile with lead

Page 24

24

Assembly plain tile clamps

with lead

Fixation of the roof-tile clamp with two screws 5x60 mm.

Screw the lower one into the tile lath and the upper one into the tile

clamp support.

Completely mounted roof-tile clamp with lower lead sheet.

The tile clamp must have a minimum distance to the underlying tile

of 5 mm.

Mount the upper lead sheet while placing the lead laterally under the

tiles.

Pay attention that the corners are bent under the tile on both sides.

See assembly lower lead sheet.

Covering of the upper tiles.

Completely mounted roof-tile clamp.

Further roof-tile clamps in one row must be adjusted exactly

(e.g. by a line mark)

Page 25

25

Assembly roof-tile clamp

corrugated

Pay attention that the clamps are placed near an existing mounting

lath.

The holes for the fixation screws have to be pre-drilled with a 8 mm

borer.

The fixation of the clamps is realised by façade screws 6,5x100 mm

with sealing gasket.

Depending on the width of the substructure underneath the

corrugated roof covering the roof clamp can additionally be fixed

with a second fastening screw.

Completely mounted roof clamp ready for assembly of fastening

profiles.

If the roof clamps can not be mounted within the limits indicated (see “Spacing roof hooks”), you first have to mount

horizontal or vertical STI system profiles onto the roof clamp. Afterwards the added fastening profiles are mounted.

1410001 Roof-tile clamp corrugated V2

The roof-tile clamps corrugated are suitable for roofs with a wooden substructure.

Page 26

26

Assembly mounting profiles/

console

Dachhaken

Readily mounted tile clamps for one collector field with two collectors.

Top: Tiles left out and clamp set with mounting tabs assembled

Bottom: Tiles coarsly ground and clamps assembled without

mounting tabs

Place the square bolts laterally into the profile into any groove.

1400026 Profile set Alu 200V, 240V and 270V or

1400035 Profile set Alu 200H or

1400027 Profile set Alu 240H or

1400028 Profile set Alu 270H

1400024 Fastening set for profile set on roof hooks (4 fast. pts.)

for every additional collector in one row

1400023 Fastening set for profile set on roof hooks (2 fast. pts.)

Fix the square bolts with the washer and the nut after putting it

through the slot.

Do not exceed the T-head screw‘s tightening torque of 27 Nm.

The slots in the hooks are for evening out bumps. The fastening of

the profile must be realised in the upper third of the slot.

In the border area of the fastening profile to be mounted the

connection profile has to be put in and centered; also at an angle of

90° to the square bolts.

Before joining the fastening profiles and connecting them with the

connection profile, the correct position is to be checked (level, line

mark). Subsequently, fix all setscrews M8x12 mm (connection set

and stop set).

1910001 Tool set

1400022 Connection set for profile set

After the roof hooks and mounting profiles are fixed, then you screw

the preassembled floor console with mounting profile. Remember to

mount the other consoles, the mounting dimensions on page 9.

The mounting of the collectors is described on the consoles on

page 12 and 13.

1400045 Fastening set console on profile

Page 27

27

Wall console dimensions

wall console

starting point:

center console

distance A (center-center)

distance = 2 x A

collector type FKA 200 H FKA 240 H FKA 270 H

measure A

1,766 mm 2,120 mm 2,393 mm

angle

H - measure

total high

Z -measure

hole spacing

W -measure

Upper edge of collector

mounting hole to top

T -measure

total depth

angle 20° 30° 45°

measure B 808 mm 1.106 mm 1.492 mm

measure H 1.140 mm 1.070 mm 910 mm

measure T 540 mm 710 mm 930 mm

measure W (Top of the collector. to hole center)

upper hole 96 mm 117 mm 140 mm

middle hole 176 mm 197 mm 220 mm

bottom hole 256 mm 277 mm 300 mm

measure Z (Hole spacing of the wall-side fixing holes)

Z 1 834 mm 753 mm 578 mm

Z 2 914 mm 833 mm 658 mm

Z 3 994 mm 913 mm 738 mm

B -measure

Minimum distance from

multi-row mounting

When mounting the fastening plates „edge“ the above

indicated dimensions should be used. After election, the

attachment of the outer panels made using mounting

plate „edge“, while the two outer brackets indented by 60

mm inside!

Page 28

28

Assembly wall console

90°

Wall console for mounting of collectors on façades, balcony railings

or other vertical building sections.

Install the wall console in accordance with the requirements of page

26.

1430001 Wall console 200/240/270 H 20° without fastening

1430002 Wall console 200/240/270 H 30° without fastening

1430003 Wall console 200/240/270 H 45° without fastening

Then place the wall console in the desired position. Make sure, that

all consoles have the same mounting position, the corresponding

distance measures between the consoles and the exact orientation

in a range (e.g. by a line mark).

The fastening of the console on the wall takes place on site, an

examination of the mounting surface and the choice of appropriate

fasteners is required.

see figure 3 and 4

Fig. 3

Fig. 4

Then place the first collector on the pre-assembled consoles.

Page 29

29

Assembly wall console

After the exact orientation the collector is fixed on the outside with

fastening plates at the upper and lower elongated hole on the

console.

1400008 Collector fastening set onto support

edge (2 fastening points)

Please note that the remaining fastening plates are to mount on the

opposite outer side.

Before the following collectors can be mounted, the compensator

must be mounted on the concisely protruding flange.

It is important to ensure that the 0-ring seal is used for the

compensator.

1300001 Collector connection set hydraulical

Fixation of the compensator on one side with the clamp.

Before tightening of the screw the clamp must be positioned by a

rotary motion up and down. Tighten the screw on the clamp only

manually. The use of cordless drills or similar may cause damages

on the thread of the clamp. Tighten the clamp until the two lugs

superimpose in the whole length.

1910001 Tool set

Afterwards, mount the fastening plate “double” on the next console

in the upper and lower elongated hole. The final fixation takes place

after assembly of the next collector.

1400006 Collector fastening set onto support

(2 fastening points)

Pre-installed compensator with 0-ring seal and clamp. Install the

upper and lower compensator according to the opposite figure.

Page 30

30

Assembly wall console

If the console is mounted flush with the outer collectors, these will

be fixed with the enclosed mounting plates. Install the set located at

the upper end of the console in the holes.

1400006 Collector fastening set onto consoles

1400008 Collector fastening set onto console edge

Now install the next collector on the consoles.

Move the collector until the fastening plate “double” hooks into the

collector profile. Then fix the fastening plate.

Fix the upper and lower compensator with the clamp.

Before tightening of the screw the clamp must be positioned by

a rotary motion up and down Tighten the screw on the clamp only

oganually. The use of cordless drills or similar may cause damages

on the thread of the clamp. Tighten the clamp until the two lugs

superimpose in the whole length.

Finally, assemble the two outer fastening plates.

Page 31

31

Temperature sensor

Each collector has a sleeve for inserting a temperature sensor.

The sensor is positioned below the upper left manifold or next to

the label with the description „top“ on the outside of the collector

frame.

The sleeve for inserting the sensor is protected with a silicon

grommet which has to be centrally opened (using a knife or small

screwdriver) before inserting the sensor.

The insertion depth is limited to 4 cm. Furthermore, it is

recommended to protect the sensor against slipping out.

The temperature sensor can be inserted in any collector of

the installation.

The error of measurement of the recorded temperature

compared to the fluid temperature is ± 2 K.

Page 32

32

Arrangement

hydraulic connections

Cap

is mounted on all non-used collector connections.

1310009 Cap set (1 pcs. compl.)

1310109 Cap set (1 pcs. compl.) Al

Connection 3/4“

1310005 Collector connection set R3/4“

(2 pcs. compl.)

Connection for reductions

1310004 Collector connection set 22 mm

(2 pcs. compl.)

1310104 Collector connection set 22 mm Al

(2 pcs. compl.)

Air eliminator without extension

1310007 Air eliminator set without extension pipe

(compl. with caps)

Completely mounted air eliminator

All other connections as well as the covers are mounted in the same

way.

The required connection dimension must be calculated by the

designer of the installation, depending on local conditions (line

lengths, additional resistors etc.).

Page 33

33

Overview hydraulic connections /

accessories

Hydraulic connections

Exhauster connection

For the installation at the

collector without extension

Collector connection 3/4“

for thread fittings

Collector connection 22 mm

for soldered fittings or clamping

ring joints

Collector connection hydraulical

(compensator)

connects two collectors and

compensates thermal dilations.

Clamp collector connection

and O-ring seal

Clamp for connection of the above

mentioned hydraulic devices with the

flange at the collector

Tool set Spare set hydraulical Assembling spare set

Accessories

Page 34

34

Assembly distance metal sheets

V V V

H H H

1 2

43

5 6

It is possible to mount metal sheets between the collectors for a homogenous appearance. The distance metal

sheets are only assembled for optical aspects and do not have any functional influence on the system. Therefore,

the distance metal sheets have to be ordered seperately and are not necessarily included in the delivery.

For the collector types FKA 200 V, FKA 240 V and FKA 270 V in every gap between the collectors two distance metal

sheets are mounted. For the collectors FKA 200 H, FKA 240 H and 270 H the assembly of one distance metal sheet is

planned. In case of multi-row systems, the distance metal sheets are mounted as described. The distance metal sheets

can be mounted from above or below.

Distance metal sheet

Distance metal sheets for the

assembly in one row

Fig. 1

The distance metal sheet is inserted from below into the collector

grooves.

Fig. 2 and 3

In case of vertical collectors or rather in case of multi-row assembly

of the collectors further distance metal sheets are inserted

subsequently from below. The lower distance metal sheet must be

pushed over the upper one to the notches.

Afterwards, the distance metal sheets are pushed upwards.

Fig. 4

The distance metal sheet is pushed upwards until it is flush with the

lip (collector covering).

top bottom

Fig. 5 and 6

To avoid injury, it is recommended to use a piece of wood to push

the distance metal sheets into the collector grooves. The distance

metal sheet is sticked in the collector groove to protect it against

slipping out. The silicone strip should have a length of 10 - 20 cm.

Please note that the distance metal sheet must be free of silicone

residue to ensure the flow of rain water.

1200043 Distance metal sheet FKA 200 V

1200039 Distance metal sheet FKA 240 V

1200040 Distance metal sheet FKA 270 V

1200042 Distance metal sheet FKA 240 H / 270 H

Page 35

35

Pipe dimensions

of the connecting pipe

Recommended pipe dimension of the connecting pipe

Length of pipe F + BF

Number of collectors

up to 10 m from 10 m

to 15 m

from 15 m

to 20 m

2 coll. - 132 L/h 12 x1 15 x 1 15 x 1

3 coll. - 198 L/h 15 x 1 15 x 1 15 x 1

4 coll. - 264 L/h 15 x 1 18 x 1 18 x 1

5 coll. - 330 L/h 18 x 1 18 x 1 18 x 1

6 coll. - 396 L/h 18 x 1 18 x 1 22 x 1

7 coll. - 462 L/h 22 x 1 22 x 1 22 x 1

8 coll. - 528 L/h 22 x 1 22 x 1 22 x 1

9 coll. - 594 L/h 22 x 1 22 x 1 22 x 1

10 coll. - 660 L/h 22 x 1 22 x 1 22 x 1

11 coll. - 726 L/h 22 x 1 22 x 1 28 x 1,5

12 coll. - 792 L/h 22 x 1 22 x 1 28 x 1,5

13 coll. - 858 L/h 22 x 1 28 x 1,5 28 x 1,5

14 coll. - 924 L/h 22 x 1 28 x 1,5 28 x 1,5

15 coll. - 990 L/h 22 x 1 28 x 1,5 28 x 1,5

Length of pipe F + BF

Number of collectors

from 20 m

to 25 m

from 25 m

to 30 m

from 30 m

to 35 m

from 35 m

to 40 m

2 coll. - 132 L/h 15 x 1 15 x 1 15 x 1 15 x 1

3 coll. - 198 L/h 18 x 1 18 x 1 18 x 1 18 x 1

4 coll. - 264 L/h 18 x 1 18 x 1 18 x 1 22 x 1

5 coll. - 330 L/h 22 x 1 22 x 1 22 x 1 22 x 1

6 coll. - 396 L/h 22 x 1 22 x 1 22 x 1 22 x 1

7 coll. - 462 L/h 22 x 1 22 x 1 22 x 1 28 x 1,5

8 coll. - 528 L/h 22 x 1 22 x 1 28 x 1,5 28 x 1,5

9 coll. - 594 L/h 22 x 1 28 x 1,5 28 x 1,5 28 x 1,5

10 coll. - 660 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

11 coll. - 726 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

12 coll. - 792 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

13 coll. - 858 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

14 coll. - 924 L/h 28 x 1,5 28 x 1,5 28 x 1,5 35 x 1,5

15 coll. - 990 L/h 28 x 1,5 28 x 1,5 35 x 1,5 35 x 1,5

Page 36

36

Pipe dimensions

of the connecting pipe

Recommended pipe dimensions of the connecting pipe

Length of pipe F + BF

Number of collectors

from 40 m

to 45 m

from 45 m

to 50 m

from 50 m

to 55 m

from 55 m

to 60 m

2 coll. - 132 L/h 18 x 1 18 x 1 18 x 1 18 x 1

3 coll. - 198 L/h 18 x 1 18 x 1 18 x 1 22 x 1

4 coll. - 264 L/h 22 x 1 22 x 1 22 x 1 22 x 1

5 coll. - 330 L/h 22 x 1 22 x 1 22 x 1 22 x 1

6 coll. - 396 L/h 22 x 1 22 x 1 22 x 1 22 x 1

7 coll. - 462 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

8 coll. - 528 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

9 coll. - 594 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

10 coll. - 660 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

11 coll. - 726 L/h 28 x 1,5 28 x 1,5 28 x 1,5 28 x 1,5

12 coll. - 792 L/h 28 x 1,5 35 x 1,5 35 x 1,5 35 x 1,5

13 coll. - 858 L/h 35 x 1,5 35 x 1,5 35 x 1,5 35 x 1,5

14 coll. - 924 L/h 35 x 1,5 35 x 1,5 35 x 1,5 35 x 1,5

15 coll. - 990 L/h 35 x 1,5 35 x 1,5 35 x 1,5 35 x 1,5

Page 37

37

Initial operation

Initial operation

After installing the other components such as flow

pipe, return pipe, insulation, pump group, expansion

tank and controller the installation can be put

into service. Perform a leak test and complete the

commissioning log.

Protect the collectors from direct sunlight if the filling

of the installation is not carried out within five days

after completion of the assembly.

Inspections within the first two weeks of

operation

• bleeding the solar circle.

• control system pressure

Instructions for the operation of the

installation

Carry out changes to the scheme and other system

components only after consultation and with inputs

from your specialized partner.

Ensure that an appropriate safety valve is mounted,

whose opening pressure is not exceeding the maximal operating pressure of the collectors.

Furthermore, do not install shut-off valves that may

affect or prevent the funtion of the safety valve.

Carry out maintenance and inspectionw with appropriate caution.

Certain components may reach temperatures up to

200° C. There is a risk of burns.

It is absolutely necessary to make sure that the

back flow temperature never falls below the ambient

temperature. If necessary, take appropriate measures

(e.g. increase of back flow temperature to at least

30° C.)

Regular inspections

Solar systems should be reviewed at intervals to be

determined in addition to the function control by the

operator.

The maintenance intervals of the system will be

defined during commissioning.

An annual review is recommended. The following components must be checked for proper function (if installed):

• solar collectors

• solar circle

• heat transfer fluid

• solar storage

• solar regulator incl. circulation pump

• supplementary heating system

Unscheduled maintenance

Depending on the location of the installation, environmental

influences may cause soiling on the collector glass (dust,

pollen etc.). Clean the glass, if necessary, exclusively with

clear water to ensure optimal light transmission.

If it is necessary to free the system from snow or ice, use

only non-metal cleaning equipment, such as brooms, with

due care.

Walk on roof areas only in compliance with all safety

aspects.

Heavy condensation may occur on the interior side of the

glass when defrosting while the collectors are covered with

snow. It is absolutely necessary to free the collectors from

snow to avoid damages due to humidity.

Page 38

38

Initial operation

Commissioning report

System operator Installer

Street Street

Postcode/City Postcode/City

Material Product Type

Special

feature

Material

Date of assembly

tick accordingly (description) (Serial N°) Net surface

Flat plate collector

Date of commissioning

Piping

Heat exchanger Type of installation

Storage 1 Content lit. Roof-integrated

Storage 2 Content lit. Roof-mounted

Solar regulation Console

Expansion tank Content lit. Safety valve bar

DrainMaster Content lit.

Collector adjustment south 0°, west +90°; east -90°) Setting angle of collectors

Height Meter

Setting value

(Control value=*)

Type /Programme

Maximum

temperature

Temperature

difference F / BF

Hysteresis

Consumer 1* = e.g. water for domestic use °C K K

Consumer 2* = e.g. 1. buffer store °C K K

Consumer 3* = e.g. 2. buffer store °C K K

Consumer 4* = e.g. swimming pool °C K K

Maximum temperatur of collector °C Solar protective function from °C Yes No

Operating pressure at bar System pressure expansion tank Debit: bar

Actual value:

bar

Heat transfer medium

Visual check normal/pink brown black murky

Type Minimum value Actual value

System

rinsed

Liquid capacity pH-value filtered

Ratio

Frost protection

bleeded

General system checkpoints

Collector clean ok Pumps tested on functionality ok

Stable collector fastening ok Temperature sensor shows realistic values ok

Collector not steamed up (interior) ok Grounding of the system ok

Non-return valve (not for DrainM.) ok Mixer - water for domestic use ok

Operating hours Pump 1 h Pump 2 h Calorimeter /kWh

Remarks:

Page 39

39

Appendix

Any guarantee and warranty for collectors as well as for resulting damages on the system or building expires due to

unauthorized changes on the collectors and the accessoiries

There is no guarantee or warranty due to optical or technical reduction or defects on the collector resulting from external

influences, forasmuch as these influences are not part of the supplier’s sphere of influence and they are not explicitly

known before execution.

Important to observe

Page 40

40

STI Solar Technologie International GmbH

Seiferitzer Allee 14

08393 Meerane

GERMANY

Tel: + 49 03764 795610

Fax: + 49 03764 7956115

E-Mail: info@sti-solar.de

Homepage: www.sti-solar.de

Copyright © STI Solar Technologie International GmbH 15.10.2012

Loading...

Loading...