Page 1

FTC – FasTrak Compact

INSTRUCTION MANUAL 4049

Page 2

i

STI S.r.l has taken every care in collecting and verifying the documentation contained in this Instruction

Manual. The information herein contained are reserved property of STI S.r.l.

____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 3

ii

INDEX

1 GENERAL INFORMATION...............................................................................................................1

1.1 GENERALITIES .............................................................................................................................1

1.2 MANUFACTURER ..........................................................................................................................1

1.3 TERMS AND CONDITIONS ...............................................................................................................1

1.4 MANUFACTURER’S LIABILITY ..........................................................................................................1

1.5 APPLICABLE STANDARDS AND DIRECTIVES......................................................................................2

1.6 SYMBOLOGY USED .......................................................................................................................2

2 DEVICE DESCRIPTION ...................................................................................................................3

3 TECHNICAL DATA ..........................................................................................................................4

4 LABEL .............................................................................................................................................5

5 OPERATING CONDITIONS AND INTENDED USE ................................ ..........................................6

5.1 OPERATING CONDITIONS ...............................................................................................................6

5.2 INTENDED USE .............................................................................................................................6

6 TRANSPORT ...................................................................................................................................7

7 RECEPTION .....................................................................................................................................7

8 STORAGE ........................................................................................................................................7

9 INSTALLATION................................................................................................................................8

9.1 CHECKS TO PERFORM BEFORE INSTALLATION ................................................................ ..................8

9.2 MOUNTING ON THE ACTUATOR .......................................................................................................8

9.3 EARTHING CONNECTION .............................................................................................................. 10

9.4 PNEUMATIC CONNECTIONS .......................................................................................................... 11

9.5 ELECTRICAL CONNECTION ........................................................................................................... 12

9.6 SELF-TUNING GUIDE ................................................................................................................... 13

10 INSTRUCTION FOR THE OPERATORS..................................................................................... 15

10.1 FIELD ACTIVITIES ........................................................................................................................ 15

10.2 RESIDUAL RISKS ........................................................................................................................ 15

11 MAINTENANCE .......................................................................................................................... 16

11.1 PERIODIC INSPECTIONS AND MAINTENANCE ................................................................................... 16

11.2 EXTRAORDINARY MAINTENANCE ................................................................................................... 16

12 TROUBLESHOOTING ................................ ................................................................................ 17

13 SPARE PARTS ........................................................................................................................... 18

14 DECOMMISSIONING .................................................................................................................. 19

____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 4

- 1 -

Important

This Instruction Manual is an integral part of the machine, it should be carefully

read before carrying out any operation and it should be kept for future

references. The operators shall adopt the safety precautions required by the

country where the product is installed.

This Instruction Manual is realized in accordance with the Directive 2006/42/CE.

1 GENERAL INFORMATION

1.1 Generalities

STI S.r.l. products are conceived, manufactured and controlled according to the Quality management

System in compliance with EN ISO 9001 International Standard.

1.2 Manufacturer

With respect to Machinery Directive 2006/42/EC, the Manufacturer of the described FasTrak Compact is

STI S.r.l. as specified on the label.

STI S.r.l. Via Dei Caravaggi 15

24040 Levate (BG) Italy

Tel. +39 035 2928.2

Fax +39 035 2928.247

imisti.sales@imi-critical.com

1.3 Terms and conditions

STI S.r.l. guarantees each single product to be free from defects and to conform to current goods

specifications. The warranty period is two years from the date of shipment to the first user. The warranty

does not cover special products or components not covered by warranty in their turn by subcontractors. No

warranty is given for products which have been subject to improper storage, improper installation, improper

maintenance or which have been modified or repaired by unauthorised personnel.

1.4 Manufacturer’s liability

STI S.r.l. declines all liability in the event of:

- use of the device in contravention of local safety at work legislation;

- incorrect installation, incorrect maintenance, disregard or incorrect application of the instructions

provided on the nameplate and in this manual;

- modifications or repairs without STI S.r.l. authorisation;

- work done on the unit by unqualified or unsuitable operators.

Considering that STI S.r.l. has no direct control over particular applications, operation or maintenance

conditions, it is the operator’s responsibility to comply with all applicable safety rules; it is the sole

responsibility of the operator to ensure that the local health and safety regulations are adhered to.

Depending on the specific working conditions, additional precautions may be requested.

Please inform STI S.r.l. urgently if you face unsafe situations not described in this Instruction Manual.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 5

- 2 -

EN ISO 12100:2010

Safety of machinery - General principles for design - Risk assessment and risk

reduction

2006/95/EC

Directive for Low Voltage Equipment (LV)

2004/108/EC

Directive relating to the Electromagnetic Compatibility (EMC)

2014/34/CE

Equipments used in potentially explosive atmospheres (ATEX)

Important

Be careful where these symbols are shown, they indicate a potentially hazardous

situation and they warn that if the steps are not properly performed, may result

causing serious injury, death or long-term risks to the health of exposed persons

GENERAL DANGER

DANGER POWER SUPPLY

CRUSHING HAZARD

Important

The operators shall adopt the safety precautions required by the country where

the product is installed.

The operators shall also adopt the following precautions.

Must wear

protective

clothing.

Must wear

protective

gloves.

Must wear

protective

footwear.

Must wear

protective

helmet.

Must wear

protective

glasses

Must wear

earplugs

1.5 Applicable Standards and Directives

1.6 Symbology used

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 6

- 3 -

2 DEVICE DESCRIPTION

The FasTrak Compact smart positioner is a digital-pneumatic valve controller:

- excellent dynamic performance;

- high precision;

- configuration and calibration through HART, serial cable handheld device, local display and push

buttons;

- self calibration;

- compatible with double and single acting actuators, with/without spring, piston or diaphragm;

- auto tuning on control stroking time applications from 0.5 sec to 100 sec;

- control and PID parameter independently adjustable for open and close;

- stroking time user independently adjustable to open and to close;

- travel limit position independently user adjustable to open and to close up to 50% of stroke;

- tight shut off position to open and to close independently adjustable;

- pressure shut off to open and to close independently adjustable;

- travel characterization linear user adjustable 16 point;

- visualization of selected characterization curve with limit and shut off by Remote Control;

- analog output 4-20mA position;

- power/signal safety fail position mechanically configured (not software adjustable).

Figure 1 – FasTrak Compact smart positioner

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 7

- 4 -

Connections

Air supply

- POWER CONNECTION

- 2 wires from signal: 4-20mA (min 3.5 mA),

10÷30 VDC, impedance 500 ohm

- ELECTRICAL CONNECTION

- Signal metric ½” NPT

- Auxiliary output metric ½” NPT

- TTL RS232

- PNEUMATIC CONNECTION

- ¼” NPT female

- MOTIVE FLUID

- instrument air (*)

- nitrogen

- SUPPLY PRESSURE

- 2.5÷7 bar

- AIR CONSUMPTION

- < 0.7 Nm3/h at 4 bar

Input

Output

- ANALOG INPUT

- 4÷20 mA DC

- ANALOG OUTPUT

- 4÷20 mA DC (passive loop 10÷26,5 V)

Stroke Movement

Performance data according to IEC 61514-2 (***)

- FEEDBACK ROTATION ANGLE

- 30°÷115° (**)

- ADJUSTABLE SPEED

- range 0÷300 seconds

- individually configurable for each direction

- CHARACTERISTIC CURVE

- linear, equal percentage or configurable

- CONTROL PARAMETER

- individually configurable for each direction

- TRAVEL CONTROL

- min and max settable stroke limits of cut off

- SIGNAL FAIL

- end stroke limits (4 mA position)

- HYSTERESIS + DEADBAND

- ±0.15%

- REPEATIBILITY

- ±0.15%

- SENSITIVITY

- ±0.1%

- LINEARITY

- ±0.3%

- INFLUENCE OF TEMPERATURE

- ≤ 0.3% for every 10°C

- FLOW CAPABILITY

- 23.5 Nm3/h at 6bar (CV 0.3)

- ACTION

- configurable single or double

Environmental capabilities

Other

- ENVIRONMENT

- protection IP65

- operating temperature: -40°C / +85°C

- storage temperature: -40°C / +85°C

- humidity up to 100%

- VIBRATIONS

- up to 2g (ISA-S75.13)

- LINKAGE

- for linear actuator (stroke 70÷1000 mm)

- for quarter turn actuators (VDE/VDI 3845)

- HIGH SPEED COMUNICATION KIT

Materials and weight

- MATERIAL

- aluminum with stainless steel feedback shaft

- WEIGHT

- 2,30 kg

3 TECHNICAL DATA

(*) Use instrument air free from oil, water and dust according to ISO 8573-1 class 3 and with particle size ≤

5 µm. The maximum value of the pressure dew point shall be 10 °C lower than the operating temperature.

(**) Also < 30° (with lower resolution).

(***) For angle ≥ 90°.

_____________________________________________________________________________________

Manual 4049, rev. 00 05/2017 – FTC

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Page 8

- 5 -

Important

It is forbidden to modify the information and the marks without previous written

authorization by STI S.r.l..

Do not remove the label and/or replace with other label.

Warning

It is severely forbidden to use the FTC positioner under conditions other than

those provided on the label.

Warning

Always observe the specifications and special requirements for your positioner

stipulated in the applicable certificate.

4 LABEL

Every FTC smart positioner is provided with a label contains the main operating conditions and serial

number. The label may change if the FTC smart positioner is sold with reference to a Certificate of product

and/or system issued by Notified Body Exterior or Certificate of Conformity issued by STI S.r.l..

Figure 2 – FTC standard label

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 9

- 6 -

Warning

It is severely forbidden to use the FTC smart positioner for purpose or application

other than those for which it was designed and here specified.

Warning

Make sure that:

- observe the common safety regulations and the accident prevention rules of

the H&S organizations;

- observe the safety regulations for the pneumatic actuator used;

- observe the safety regulations for the installation and operation of electrical

systems;

- observe the electrical specifications reported in this instruction manual and in

the documents accompanying the FTC smart positioner;

- for the electrical installation of explosion-protected devices, observe all

standards, regulations and directives governing explosion protection and

applicable for the construction and use of explosion-protected systems, the

directives for explosion protection and the special requirements and

specifications for your devices;

- this product is not intended for use in life support systems.

5 OPERATING CONDITIONS AND INTENDED USE

5.1 Operating conditions

The label fastened on the FTC smart positioner contains the main operating conditions for the specified

application (see Section 4). Other operating conditions are reported on the documents accompanying the

FTC smart positioner. For general operating conditions see Section 3.

5.2 Intended use

The FTC smart positioner is an electro-pneumatic positioner designed to being mounted on actuators in

order to control the valve opening /closing as required.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 10

- 7 -

Warning

The following instructions must be respected:

- operations must be carried out only by skilled operators;

- always wear protective clothing, gloves, and eyewear to prevent personal

injury. Check with your process or safety engineer for any additional

measures that must be taken to protect against process media.

Important

The lifting and handling should be made in compliance with the laws and

provisions in force.

6 TRANSPORT

7 RECEPTION

FTC smart positioner leave the factory in perfect condition. Performances of each unit are guaranteed by

tests and data reported on a specific Test Report. At the reception of the FTC smart positioner:

- check that the model correspond with that of order confirmation;

- check that the FTC smart positioner has not been damaged during transport.

8 STORAGE

A proper attention must be observed about the FTC preservation during the storage period. If the FTC

smart positioner has to be storage before installation:

- place it in a dry and clean place and take all necessary measures to avoid contact with dust, dirt,

humidity, corrosive gases or vapours;

- make sure that connection protections and/or covers will not be removed during the storage;

- the storage temperature shall be between -20°C and +40°C.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 11

- 8 -

Warning

The following instructions must be respected:

- operations must be carried out only by skilled operators;

- always wear protective clothing, gloves, and eyewear to prevent personal

injury. Check with your process or safety engineer for any additional

measures that must be taken to protect against process media.

Warning

The software control parameters of the FTC smart positioner can be alter only by

skilled operators. Incorrect settings may lead to personnel injury and/or property

damage.

Important

Not performing the following procedures will invalidate the product warranty.

9 INSTALLATION

9.1 Checks to perform before installation

It is recommended to check the FTC smart positioner conditions before the installation:

- the pneumatic and electric port must be protected by plastic plugs until the installation phase;

- the supply circuit must be protected to prevent that the voltage or the current exceed the stated limits;

- the equipment must be provided with cable entries and filler plugs certified according to the required

certification.

9.2 Mounting on the actuator

It is recommended to follow these steps:

- remove the protection plastic plugs;

- mount the FTC smart positioner on the actuator by using the provided kit (typically the FTC smart

positioner can be mount on the actuator yoke or on the actuator top);

- the linkage must be able to generate a rotation angle between 30° and 120° during the full actuator

stroke. There are no mechanical stops on to the FTC shaft, thus there is no chance to damage the

FTC shaft by its over-rotation. An index show the correct shaft orientation;

- Backlashes, linearity errors and elasticity of feedback linkage could affect the FTC smart positioner

performance.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 12

- 9 -

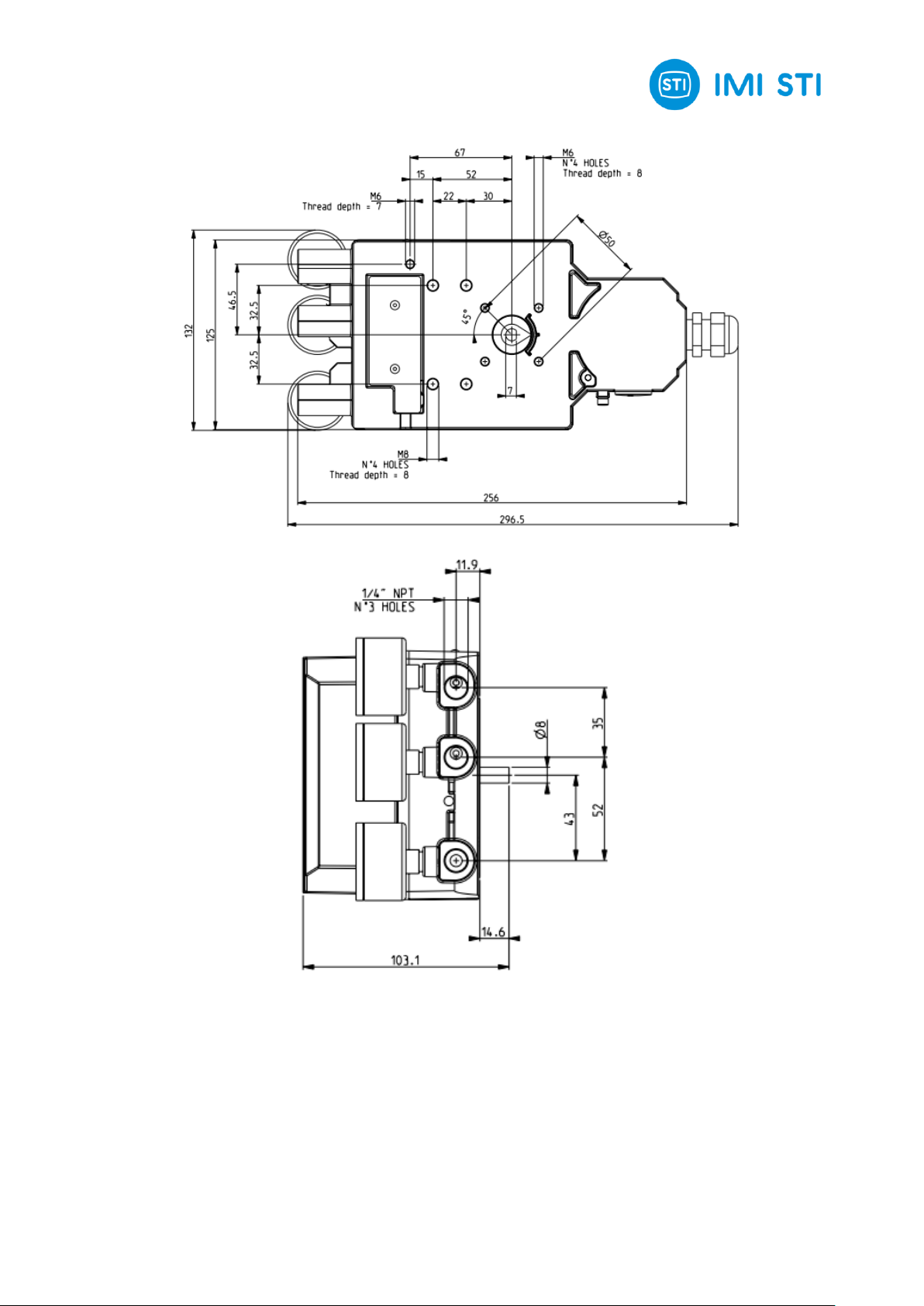

Figure 3 – FTC main dimensions

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 13

- 10 -

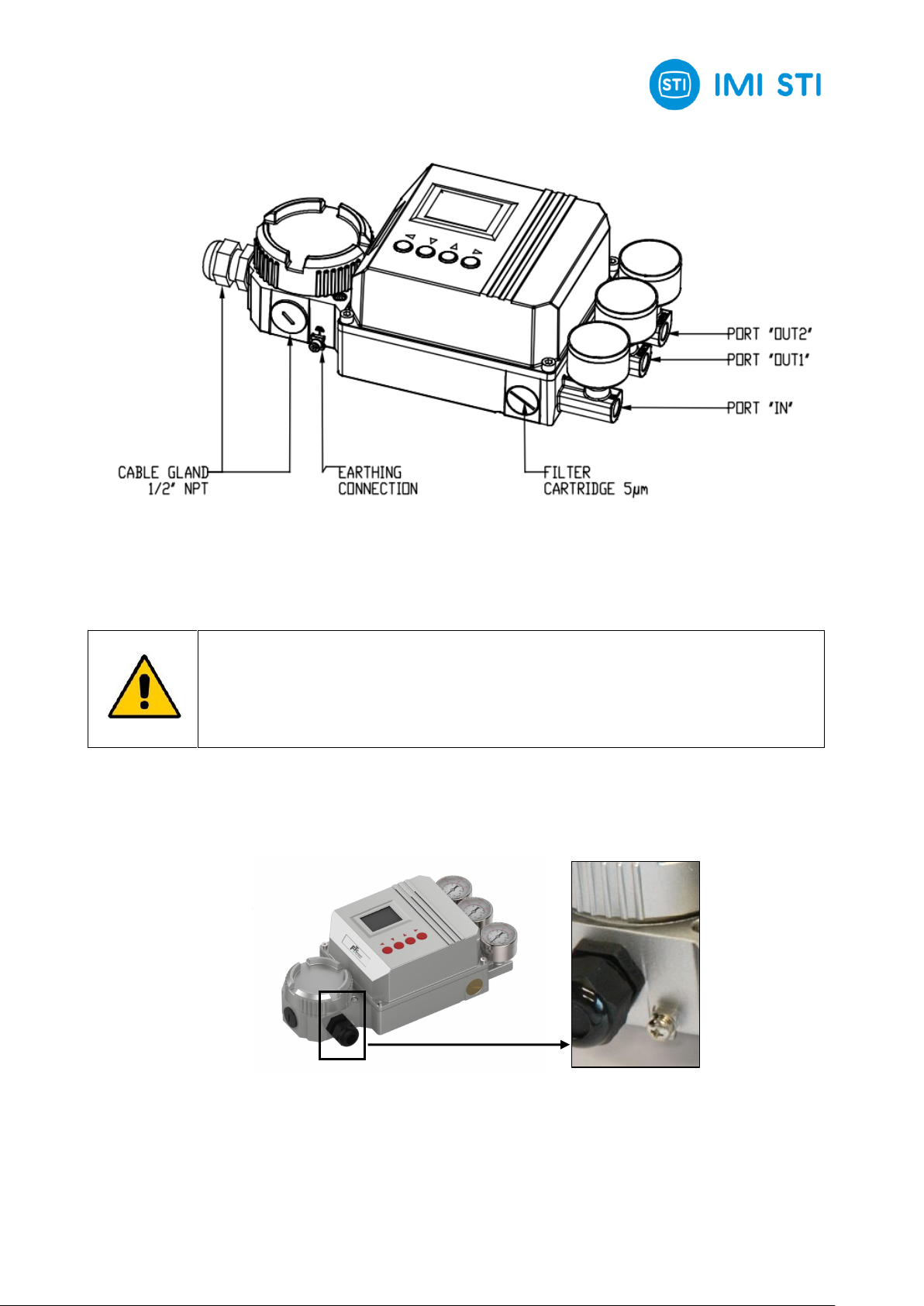

Warning

The FTC smart positioner shall have a proper earthing connection.

Figure 4 – FTC main connections

9.3 Earthing connection

The use of a ground strap between the FTC smart positioner housing and a suitable earthed point is

required. A proper connection could be done by the screw threaded in the FTC housing, as shown in the

following picture.

Figure 5 – FTC earthing connection

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 14

- 11 -

Warning

Check that the values of pneumatic supply available are compatible with those

reported on the label of the FTC smart positioner. User must consider and take all

precautions to avoid that pressurized parts are not used out of specified range

and to avoid exposure to fire.

Important

For easier maintenance, it is recommended to install a filter with five micron

cartridge and shut-off valve on the supply connection.

9.4 Pneumatic connections

It is recommended to follow these steps:

- the pressure line pipe has to be sized to avoid significant pressure drop during the actuator stroke;

- the piping between FTC smart positioner and actuator has to be ¼” and shorter as possible;

- during piping connection be careful to keep clean the internal side of piping and fittings, free from

threaded sealing material or any other contaminants;

- the FTC smart positioner is suitable for single acting actuators and double acting actuators (with or

without spring):

o

for double acting actuators (without spring):

i. Port IN must be connected to the supply line;

ii. Port OUT2 (or M6 thread hole) must be connected to the actuator chamber that has to

vent at signal fail position (no power);

iii. Port OUT1 must be connected to the actuator chamber that has to be pressurized at

signal fail position (no power);

o

for double acting actuators (with spring):

i. Port IN must be connected to the supply line;

ii. Port OUT2 (or M6 thread hole) must be connected to the actuator chamber that has to

vent at signal fail position (no power);

iii. Port OUT1 must be connected to the actuator chamber that has to be pressurized at

signal fail position (no power);

o

for single acting actuators:

i. Port IN must be connected to the supply line;

ii. Port OUT2 (or M6 thread hole) must be connected to the actuator chamber that has to

vent at signal fail position (no power);

iii. Port OUT1 must be plugged with tight plug suitable for the pressure rating and area

classification;

- no load or bending moment are allowed on pneumatic connection;

- the supply pressure must be lower than actuator design pressure;

- to check the correct mounting of the pneumatic connections, pressurize the FTC smart positioner

without any power signal and check if the actuator moves to the 0% signal position.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 15

- 12 -

4-20 mA IN

4-20 mA OUT

L-

L+

AO+

AO-

9.5 Electrical connection

It is recommended to follow these steps:

- use shielded cables during the installation of the FTC smart positioner;

- observe ESD precautions during the handling of the electrical cables and connections inside the FTC

smart positioner;

- use an earthed wrist strap during the operations;

- the electrical connections must be done according to diagram and label;

- the signal current circuit and the input and output circuitry must meet the explosion protection

requirements stipulated in the certificates;

- close the lids during normal operation.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 16

- 13 -

Warning

The actuator will move during the self tuning.

9.6 Self-tuning guide

Follow these steps using the display buttons (ENT, DOWN, UP, ESC):

- turn on the FTC smart positioner;

- push any button and then enter the password (ENT-UP-DOWN-UP-DOWN);

- select set-up from main menu;

- select operating mode menu from set-up menu;

- select “Out svc” in the operating mode menu;

- come back to set-up menu;

- select actuator menu from set-up menu;

- chose the actuator type;

- come back to main menu;

- select calibration menu from main menu;

- select full self-tuning menu from calibration menu;

- start the self-tuning.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 17

- 14 -

MAIN PAGE

PASSWORD

ENTER PASSWORD

ENT-UP-DOWN-UP-DOWN

MAIN MENU

SYSTEM INFO

CALIBRATION

SET-UP

RAW DATA

LIMITS ONLY

TUNING-1 TUNING-2

FULL

SELF-TUNING

TRAVEL

CONTROL

OPERATING

MODE

FACTORY RESET

ACTUATOR

_____________________________________________________________________________________

Manual 4049, rev. 00 05/2017 – FTC

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Figure 6 – Complete display tree

Page 18

- 15 -

Warning

The following instructions must be respected:

- operations must be carried out only by skilled operators who have the

required qualification and have read and understood this instruction manual.

These operators shall be sufficiently trained and experienced and they shall

know the relevant standards and regulations in order to be able to judge their

assigned tasks and recognize potential hazards. Only qualified operators who

have the required certificates are authorized to work on explosion-protected

devices.

- always wear protective clothing, gloves, and eyewear to prevent personal

injury. Check with your process or safety engineer for any additional

measures that must be taken to protect against process media.

Important

Any repair work other than the operations outlines in this Instruction Manual is

allowed only if STI S.r.l. authorises it.

10 INSTRUCTION FOR THE OPERATORS

10.1 Field activities

During the start-up of the FTC smart positioner:

- check that the pressure and quality of the supply fluid (filtering degree, dehydration, etcetera) are as

prescribed;

- check if the operating condition are as prescribed;

- check if the FTC is correctly mounted;

- check that there are no leak of the pneumatic connections;

- remove all rust on the FTC surfaces;

- perform a complete functional test of the entire system where the FTC is mounted.

10.2 Residual risks

Reasonably foreseeable misuse:

- risks due to movements of loads during transport and installation;

- installation in ambient with not planned conditions;

- high or very low FTC surface temperatures due to environment or other causes shall be considered as

a possible risk of person injury in case of contact;

- insert incorrect motive fluid into the system;

- supply pressure out the planned range;

- emissions of hazardous substances where dangerous gases are used as motive fluid.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 19

- 16 -

Warning

The following instructions must be respected:

- operations must be carried out only by skilled operators (STI operators or

operators qualified by STI are recommended);

- always wear protective clothing, gloves, and eyewear to prevent personal

injury. Check with your process or safety engineer for any additional

measures that must be taken to protect against process media.

11 MAINTENANCE

Before any type of operation and/or maintenance is performed, make sure that:

- actuator, accessories and all connected equipment are not under pressure and in safe conditions;

- fluid supply, power or other energy sources and signals are disconnected;

11.1 Periodic Inspections and maintenance

Periodic visual inspections are recommended. The user shall:

- plan and provide a periodic cleaning/maintenance program that will maintain the external surface of

the FTC smart positioner free from excessive layer of dust.

11.2 Extraordinary maintenance

In case of extraordinary maintenance proceed as written in Section 12.

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 20

- 17 -

EVENT

POSSIBLE CAUSE

REMEDY

FTC doesn’t move

the actuator

Lack of pneumatic supply

Check supply line

Low supply pressure

Adjust supply pressure

Internal component damaged

Call STI S.r.l.

Actuator

opening/closing

time not satisfy

Incorrect positioner calibration

Call STI S.r.l.

Actuator pneumatic circuit not suitable

Call STI S.r.l.

Wrong actuator sizing

Call STI S.r.l.

Leakages from

pneumatic circuit

The nuts of pipe fittings are not tighten

enough

Tighten the nuts

Important

If another event happens or another possible cause of the above events has

been detected, call STI S.r.l.

12 TROUBLESHOOTING

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 21

- 18 -

FTC filter group:

5µm cartridge + plug + o-rings

FTC I/P group:

I/P converter + o-ring + screws & washers

FTC high speed communication kit

FTC pressure gauges

13 SPARE PARTS

Spare parts available for the FTC smart positioner:

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Page 22

- 19 -

SUBJECT

HAZARDOUS

RECYCABLE

DISPOSAL

Metals

No

Yes

Use licensed recyclers

Plastics

No

Yes

Use specialist recyclers

Rubber (seals, o-rings)

Yes

No

May require special treatment

before disposal, use specialist

waste disposal companies

Warning

The following instructions must be respected:

- operations must be carried out only by skilled operators;

- always wear protective clothing, gloves, and eyewear to prevent personal

injury. Check with your process or safety engineer for any additional

measures that must be taken to protect against process media.

Important

Check local authority regulation before disposal.

14 DECOMMISSIONING

_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 4049, rev. 00 05/2017 – FTC

Loading...

Loading...