Page 1

Technical data

Installation

Assembly instruction DrainMaster

V-Series

Page 2

2

It is essential to read through this

instruction carefully prior to the

assembly and initial operation.

General safety instructions

Any installation activities have to be executed by

authorised professional staff. Please pay increased

attention to:

– the conditions on site

– the local regulations

– the recognized rules of engineering (especially

DIN 4757 Part 1 and 3)

– the proper state of the existing roof construction

– the safety rules concerning roof works

– the safety regulations for safety equipment

– the assembly instructions for components given

by your supplier

– the safety instructions of VDE and DVGW

Solely the constructor of the installation is resposible

for a proper assembly.

Functioning of the DrainMaster

The patented DrainMaster is an innovative solution

for draining solar systems. In doing so, only the

collector eld as well as the pipes above the

DrainMaster will be drained.

In a state of rest, the DrainMaster collects the heat

transfer medium. Thereby the installation is unable

to overheat and as a result, the heat transfer medium

and the system components will be protected. The

maintenance charges can be minised and running

the installation becomes safer.

The regulation of the DrainMaster is carried out by

the solar controller.

If there is a temperature measured at the collector

which differs by DeltaT from the temperature

measured in the tank, the circulating pump activates

automatically. The collectors will be lled with the

heat transfer medium which had been collected

in the DrainMaster and in the course of this, the

DrainMaster takes up the air pressed out. The

liquid which has been heated inside the collectors

circulates and heats the tank.

If DeltaT will be undershot or if a maximum

temperature will be reached in the collector, the

circulating pump deactivates, the collectors drain

and the liquid will be collected in the DrainMaster.

The covering of the DrainMaster is a particularly

manufactured aluminium prole for the assembly

with the collectors even outside of the roof cladding.

Any component which gets in contact with the heat

transfer medium is made of stainless steel. Please

make sure to not use material in the solar circuit

which might damage the stainless steel.

Construction of the DrainMaster

The collectors have to be self-draining. The piping

of the collectors has to enable an entire draining.

In the whole solar circuit (ow and backow), ap

valves must not be assembled. As the DrainMaster

enables a low system pressure, a safety valve of

3 bar is sufcient provided that the overall system

height permits it. Flow as well as backow should be

equipped with a syphon as closely as possible at the

heat exchanger so that a thermic pipe circulation can

be excluded.

System requirements

Operation Draining

Page 3

3

FKA 240

1190

1160

1190

1160

FKA

240

2090

2060

1190

2060

FKA 240FKA 240

FKA 240

60

60

30

30

FKA 240

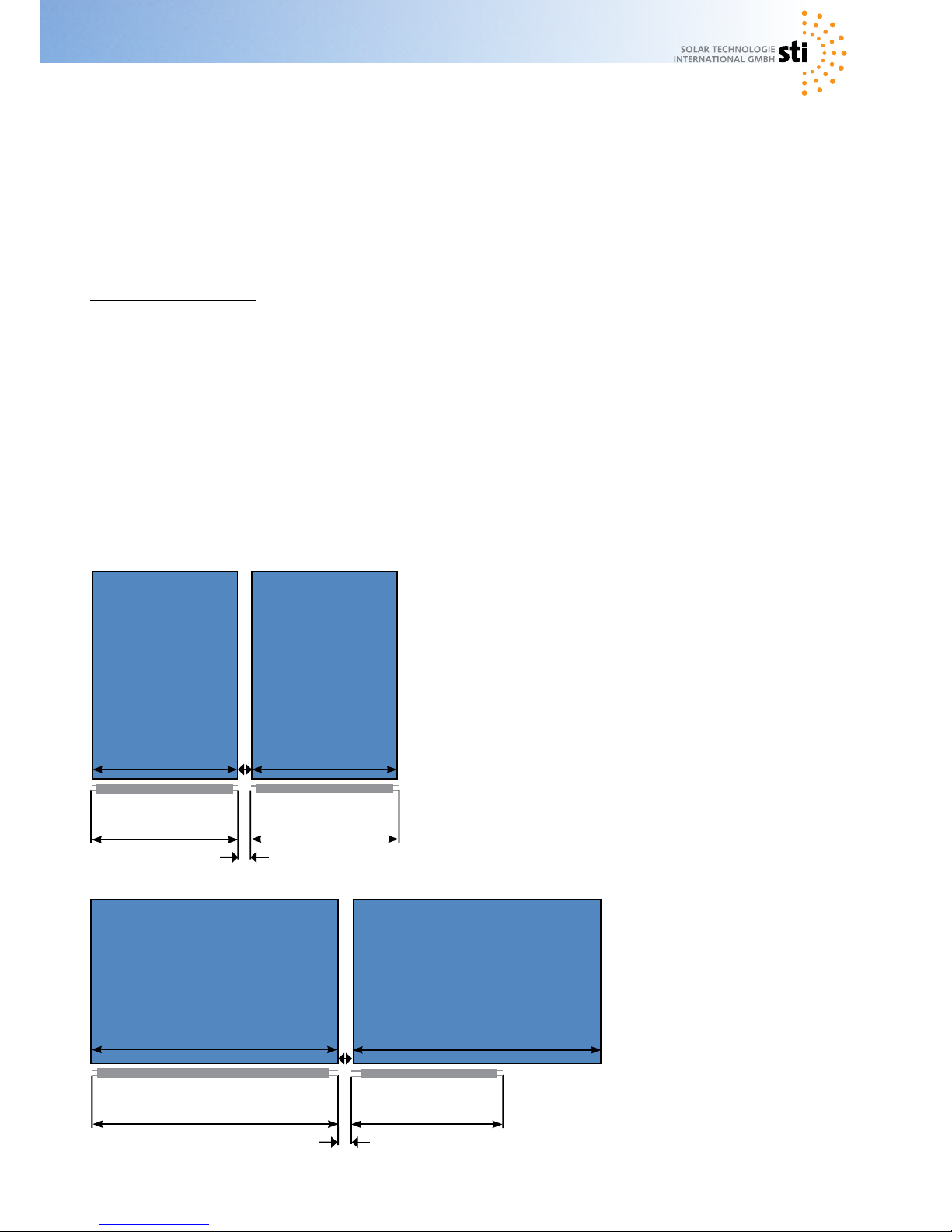

Volume DrainMaster V-series

V 1190 (1190 mm) 7 l

V 2090 (2090 mm) 12,8 l

Example dimensioning:

Field of six collectors FKA 240V in two rows

Six collectors à 2,65 l

plus connection line ca. 1 l / m

= 16,9 l volume collector eld

Selection of DrainMasters:

Roof-mounted / 1 Basic module V 1190

bottom support: 3 Extension module V 1190

Roof-integrated 1 Basic module V 2090

3 Extension module V 1190

Dimensioning

The DrainMaster always has to be able to take

the whole quantity of liquid of the collector

eld including the connection line above the

DrainMaster.

If there are any insecurities, please contact your

specialist retailer.

Beside the basic module with a degassing and

perfusion zone, extension modules are available for

installations with a higher volume.

These extensions increase the usable volume range

if the installation is in stagnation.

Grid dimension

The DrainMaster series had been adjusted to the

collector FKA 240. Two different lengths can be

offered which refer to the collector types FKA 240 V

(2,2 l) abd FKA 240 H (2,65 l).

When assembling roof-integrated installations with

a sheet metal surrounding, the two DrainMaster

versions can be combined by a modular construction.

(Combination is possible

for roof-integrated installations.)

Page 4

4

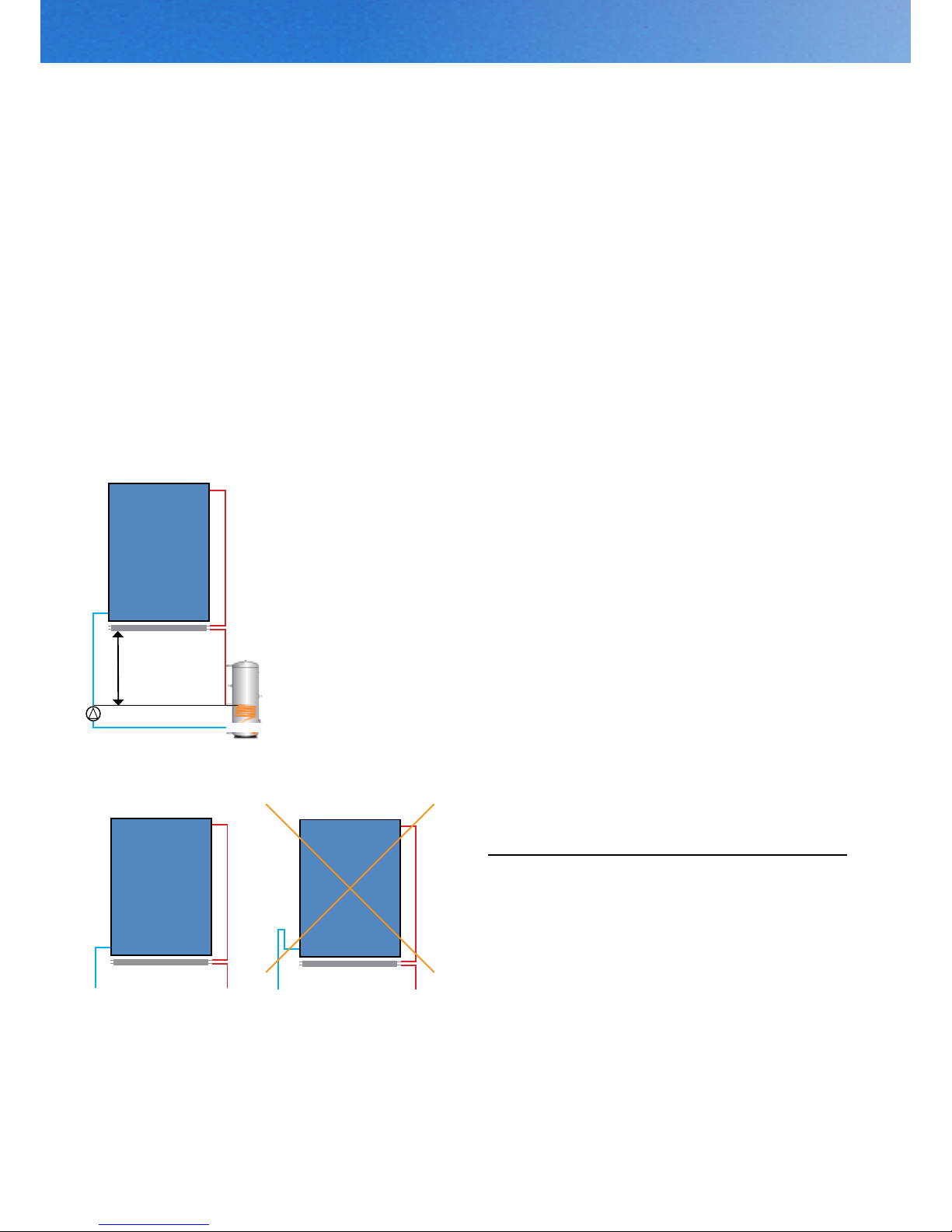

min. 50 cm

Roof-integrated installation

The DrainMaster is suitable for an assembly directly

below the collectors. In doing so, it is necessary to

observe that the DrainMaster always has to be assembled below the lowest edge of the collectors, but

at least 50 cm higher than the circulating pump and

the heat exchanger.

Alignment of the connections

The DrainMaster has to be adjusted in such a way

that the inow and outow can be arranged as vertical as possible (turn the DrainMaster so that the connections are perperndicular).

The connection which is marked with the red label is

the opening of the DrainMaster on top.

Connecting pipes

Please pay increased attention that the connecting

pipes from the collector eld to the DrainMaster do

not present any counter inclination (or syphon).

When installing the backow and the ow above the

lowest edge of the collector eld (e. g. above the

ridge sheet), please pay attention that the backow

(cold side) will be led to the level of the DrainMaster

by a syphon and that it will be piped with a pipe diameter up to the highest point in accordance with the

table below.

Number of collectors - wire cross section [mm]

1 12

2 12

3 18

4 20

5 22

6 22

Page 5

5

Roof-integrated installation

Assembly steps

1. Lie the DrainMaster onto the rafters below the lowest collector row.

2. Afterwards, please insert the mounting brackets

(2 per DrainMaster) into the cover of the DrainMaster

with a respective distance of 20 cm from the edge.

3. The DrainMaster has to be turned so that the area

with the elongated hole rests on the stop lath.

4. Adjust the DrainMaster succintly with the collector

ends and x it. In doing so, please pay attention that

the DrainMaster will be installed with an inclination

of 0,1 - 1 %. This means that the connections of ow

and backow are located approx. 1 cm lower than the

side on which the extensions will be assembled.

5. Connect the collector eld outlet with the DrainMaster inlet (upper screwing, red label).

6. Connect the DrainMaster outlet with the collector

ow. Thereto, use the provided cutting ring couplings

90 °. Please pay attention that the cutting ring cuts at

least 5 mm from the end of the pipe.

7. Close open connectors which lie opposite the connection side with the provided cutting ring sealing

plug (when using extension modules at the end of

the assembly line).

Assembly of the extension modules

The assembly of extension modules happens just as

the assembly of the basic modules.

The modules will be coupled with the provided com-

pression ttings. It is necessary to observe that no

counter inclination emerges.

Page 6

6

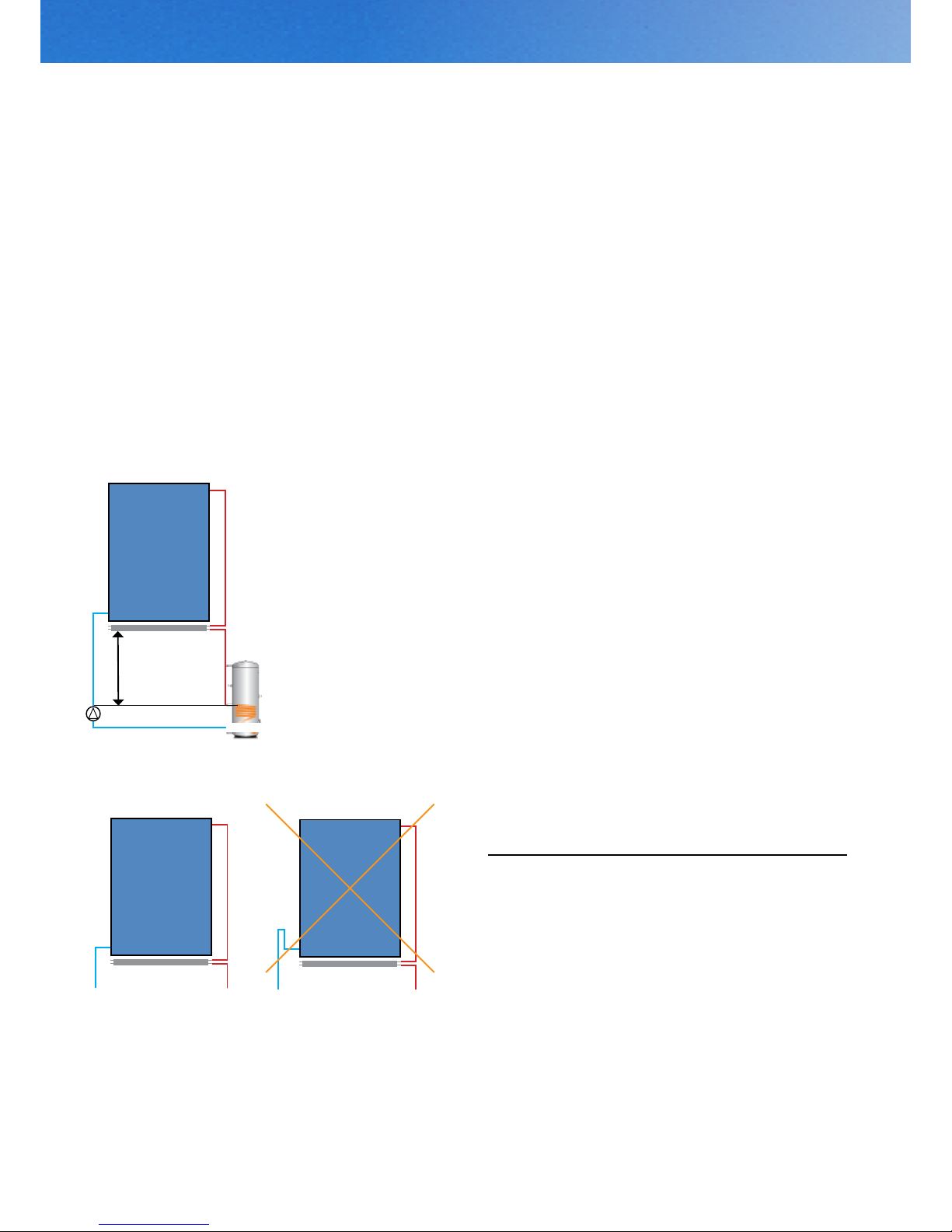

min. 50 cm

Roof-mounted installation

The DrainMaster is suitable for an assembly directly

below the collectors. In doing so, it is necessary to

observe that the DrainMaster always has to be assembled below the lowest edge of the collectors, but

at least 50 cm higher than the circulating pump and

the heat exchanger.

Alignment of the connections

The DrainMaster has to be adjusted in such a way

that the inow and outow can be arranged as vertical as possible (turn the DrainMaster so that the connections are perperndicular).

The connection which is marked with the red label is

the opening of the DrainMaster on top.

Connecting pipes

Please pay increased attention that the connecting

pipes from the collector eld to the DrainMaster do

not present any counter inclination (or syphon).

When installing the backow and the ow above the

lowest edge of the collector eld (e. g. above the

ridge sheet), please pay attention that the backow

(cold side) will be led to the level of the DrainMaster

by a syphon and that it will be piped with a pipe diameter up to the highest point in accordance with the

table below.

Number of collectors - wire cross section [mm]

1 12

2 12

3 18

4 20

5 22

6 22

Page 7

7

Roof-mounted installation

Assembly steps

1. The DrainMaster will be installed after the assembly of the aluminium prole at the bottom. It is recommendable to x the DrainMaster prior to the

assembly of the collectors.

2. For this purpose, the two provided brackets for

each DrainMaster will be inserted into the slots of the

cover of the DrainMaster at both ends. The connections have to be aligned vertically. Please pay attention that the DrainMaster has to come to rest with its

entry (marked with a red label) at top.

3. Afterwards you have to plug the brackets from below onto the priorly placed wafer-head screws which

are located on the proles and secure it using a nut.

The elongated holes now enable a variable relocating of the DrainMaster.

4. Align the DrainMaster succintly with the collector

ends and fasten it. In doing so, please pay attention

that the DrainMaster will be installed with an inclination of 0,1 - 1 %. This means that the connections

of ow and backow are located approx. 1 cm lower

than the side on which the extensions will be assembled.

5. Connect the collector eld outlet with the DrainMaster inlet (upper screwing, red label).

6. Connect the DrainMaster outlet with the collector

ow. Thereto, use the provided cutting ring couplings

90 °. Please pay attention that the cutting ring cuts at

least 5 mm from the end of the pipe.

7. Close open connectors which lie opposite the connection side with the provided cutting ring sealing

plug (when using extension modules at the end of

the assembly line).

Assembly of the extension modules

The assembly of extension modules happens just as

the assembly of the basic modules.

The modules will be coupled with the provided com-

pression ttings. It is necessary to observe that no

counter inclination emerges.

Page 8

8

min. 50 cm

Installation on bottom supports

The DrainMaster is suitable for an assembly directly

below the collectors. In doing so, it is necessary to

observe that the DrainMaster always has to be assembled below the lowest edge of the collectors, but

at least 50 cm higher than the circulating pump and

the heat exchanger.

Alignment of the connections

The DrainMaster has to be adjusted in such a way

that the inow and outow can be arranged as vertical as possible (turn the DrainMaster so that the connections are perperndicular).

The connection which is marked with the red label is

the opening of the DrainMaster on top.

Connecting pipes

Please pay increased attention that the connecting

pipes from the collector eld to the DrainMaster do

not present any counter inclination (or syphon).

When installing the backow and the ow above the

lowest edge of the collector eld (e. g. above the

ridge sheet), please pay attention that the backow

(cold side) will be led to the level of the DrainMaster

by a syphon and that it will be piped with a pipe diameter up to the highest point in accordance with the

table below.

Number of collectors - wire cross section [mm]

1 12

2 12

3 18

4 20

5 22

6 22

Page 9

9

Installation on bottom supports

Assembly steps

1. The DrainMaster has to be mounted after the assembly of the bottom supports but prior to xing the

collectors.

2. Thereto, two assembly brackets are needed for

each DrainMaster. In order to x the bottom supports, the lower screws which are at the front of the

consoles have to be loosen and afterwards be xed

with the brackets. The small elongated hole of the

brackets has to be the one which is up.

3. The upper elongated hole serves for an additional

xtation of the collectors with a onefold rail clip.

4. Afterwards, the brackets for the DrainMaster have

to be inserted into the provided rail at the cover of the

DrainMaster (2 pieces for each DrainMaster). They

then have to be moved so that they come to rest abo-

ve the assembly brackets and have to be xed with

a screw. When installing the rst DrainMaster, they

necessarily have to be xed at the very top in the

elongated holes and accordingly be adapted for the

following ones.

5. Align the DrainMaster succintly with the collector

ends and fasten it. In doing so, please pay attention

that the DrainMaster will be installed with an inclination of 0,1 - 1 %. This means that the connections

of ow and backow are located approx. 1 cm lower

than the side on which the extensions will be assembled.

6. Connect the collector eld outlet with the DrainMaster inlet (upper screwing, red label).

7. Connect the DrainMaster outlet with the collector

ow. Thereto, use the provided cutting ring couplings

90 °. Please pay attention that the cutting ring cuts at

least 5 mm from the end of the pipe.

8. Close open connectors which lie opposite the connection side with the provided cutting ring sealing

plug (when using extension modules at the end of

the assembly line).

Assembly of the extension modules

The assembly of extension modules happens just as

the assembly of the basic modules.

The modules will be coupled with the provided com-

pression ttings. It is necessary to observe that no

counter inclination emerges.

Page 10

10

Filling of the system

6. Now you have to drain the following quantity of liquid:

Quantity A: 0,17 l for each liter of liquid content in the

DrainMaster (for 10 l liquid content in the DrainMaster

= 1,7 l)

Quantity B: 0,04 times installation content (for 30 l

installtion content = 1,2 l)

Total draining quantity = quantity A + quantity B (example 1,7 l + 1,2 l = 2,9 l)

7. Close the shut-off valve at the pressure-side of

the pump again and ll in quantity A. By doing so

the necessary prepressure of the installation can be

reached.

8. Now the report of the controller should disappear

or the collector temperature should appear. If an error

report or the report „lling level reached“ is shown,

the installation is overlled and has to be drained until

the report diappears.

9. Open the shut-off valve, close the lling and draining valve and switch on the pump. Check the functionality of the installation and switch over to an automatic operation.

Installation without level indicator

1. Close the shut-off valve in the collector back ow

(pressure-side of the pump).

2. Loosen the upper connection at the DrainMaster.

3. Open the lling and draining valve, connect the

lling pump and slowly ll the installation until the

DrainMaster is completely lled with liquid.

4. Close lling and draining valve and open the shut-

off valve (pressure-side of the pump).

5. Slowly rell the liquid until the DrainMaster is completely completely lled.

6. Now you have to drain the following quantity of liquid:

Quantity A: 0,17 l for each liter of liquid content in the

DrainMaster (for 10 l liquid content in the DrainMaster

= 1,7 l)

Quantity B: 0,04 times installation content (for 30 l

installtion content = 1,2 l)

Total draining quantity = quantity A + quantity B (example 1,7 l + 1,2 l = 2,9 l)

Attention!

When lling the installation, the solar uid must not

be warmer than 25 °C!

The circulating pump must not be working while lling.

Filling under cloudy skies

The prepressure of the installation is calculated as

follows:

Prepressure in bar = static height in meter / 10 + 0,2

Filling in sunshine

The prepressure of the installation depends on the

temperature of the collector during the lling.

Rule of thumb for the prepressure:

Prepressure in bar = static height in meter / 10 + 0,2

+ gure stated below:

For collector temperature of approx. 50 °C + 0,1 bar

For collector temperature of approx. 100 °C + 0,2 bar

For collector temperature of approx. 150 °C + 0,3 bar

For collector temperature of approx. 200 °C + 0,4 bar

Installation with level indicator

1. Close the shut-off valve in the collector back ow

(pressure-side of the pump).

2. Open the lling and draining valve of the safety

device.

3. Connect the lling pump at the lling and

draining valve at the suction side of the pump. Fill

the installation slowly until the probe presents the

maximum lling level (when using special controllers,

the report „maximum lling level reached“ is going

to be shown).

4. Close lling and draining valve and open the

shut-off valve (pressure-side of the pump).

5. Slowly ll in the liquid until the probe presents

the maximum lling level once again (when using

special controllers, the report „maximum lling level

reached“ is going to be shown).

Page 11

11

7. Tighten the upper connection at the DrainMaster.

8. Close the shut-off valve at the pressure-side of the

pump again and ll in quantity A. By doing so the

necessary prepressure of the installation can be reached.

9. Open the shut-off valves, close the lling and

draining valve and switch on the pump. Check the

functionality of the installation and switch over to an

automatic operation.

Frost resistance

We recommend operating the installation with

an antifreeze mixture.

In case of damages due to frost, we do not

assume no liability.

General information

A solar plant should be maintained every year. In doing so, the functionality of all components should be

examined, especially the heat transfer medium has to be checked for its quantity and state. When installing

a DrainMaster into an already existing installation, it is necessary to pay attention that the heat transfer me-

dium (if it is still all right) can only be relled with the same type. We recommend to entirely exchange the old

medium.

Identied disorder Possible cause Problem solving

Wrong / no temperature indicator Probe defect Exchange of the probe by a

specialist

Wrong lling Repetition of the lling process

Pump is working / Air in the pump Repetition of the process,

no circulation of the medium venting of the pump

System pressure is too high Wrong dimensioning Reexamination of the volume

calculation

Installation does not drain Non-return valves are Removal or blocking of the non probably still existing return valves

Installation drains badly or Collectors are not piped properly Examination of the piping consivery slowly dering the draining aspect

DrainMaster is not assembled Check of the permitted assembly

properly arrangements

Fault diagnosis

Page 12

© Copyright 2016

Version 02/2016

STI Solar Technologie International GmbH

Seiferitzer Allee 14

08393 Meerane

GERMANY

Tel: + 49 03764 795610

Fax: + 49 03764 7956115

E-Mail: info@sti-solar.de

Homepage: www.sti-solar.de

Loading...

Loading...