Page 1

“ALERT”

OPENED

APPROXIMATE GAP (1 INCH)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

REED SWITCH CABLE

(18 INCHES)

APPROXIMATE GAP

(GREATER THAN 1 1/3 INCHES)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

“ALERT”

OPENED

“RESTORE”

CLOSED

MAGNETIC SENSOR

Installation and Operation Manual

STI Universal Sensor

Model: STI-34401

Thank you for purchasing the STI Universal Sensor. Your satisfaction is very important to us. Please take

the time to read this manual carefully to get the most from your new product.

How The Product Works

The STI Universal Sensor is a wireless transmitter that can be configured to initiate a transmission to any

STI Receiver three different ways: internal magnetic sensor, internal tilt sensor or external switch.

Plan Your Installation

Universal Sensor Setup

1. Open sensor case using a flat head screwdriver in side case slot.

2. Configure the jumpers for the desired application (see Jumper Configurations Fig. 1).

3. Activate battery by removing the red tape.

4. Program the STI Universal Sensor into the STI receiver. Refer to the STI receiver installation

5. Snap base into lid. Tamper switch spring automatically seats within the locator ring on the lid. Tamper

6. Test the sensor for proper operation before permanently mounting.

7. Select mounting option.

1) Refer to the Operation section on the following pages to determine which sensor configuration is

best for your application.

2) Refer to the Sensor Supervision section to understand the use of this feature. It is recommended

to leave the sensor in the supervised state (J2 uncut) until false trouble signals are displayed on the

receiver. If you need to disable sensor supervision, the sensor must be deleted from the receiver

and reprogrammed into the receiver. Refer to your receiver’s installation instructions.

instructions for programming instructions.

alert is triggered when the spring releases identifying when case is opened/broken/ajar.

OPTION 1: Mount with double sided foam tape provided to the back of the case (Fig. 2).

OPTION 2: Remove the circuit board from the case bottom. Drill 1/8 inch holes through the case

and use the screws (provided). For added protection, cover metal screw heads on the inside of

the case bottom with electrical tape (Fig. 2) to isolate the circuit board. Replace the circuit board

in the case bottom.

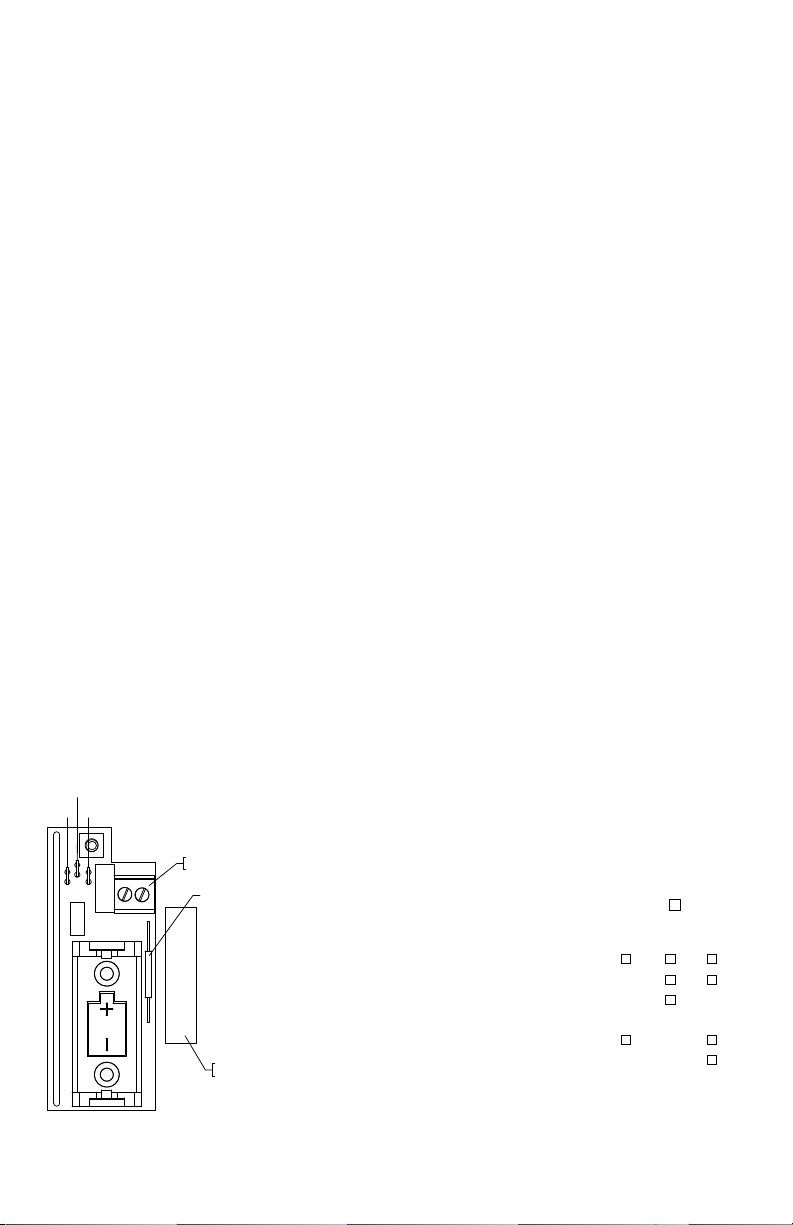

Jumper Congurations

J2

J3

J1

EXTERNAL SWITCH

CONNECTION BLOCK

ONBOARD REED SWITCH

LOCATION FOR

MAGNETIC SENSOR

Fig. 1

Cut jumpers with “X”, do not cut jumpers with “ “.

J1 J2 J3

Magnetic Sensor (supervised)

Tilt Sensor (supervised)

External Terminals (supervised)

Magnetic Sensor (not supervised)

Tilt Sensor (not supervised)

External Terminals (not supervised)

X

X X

X

X X

X X X

NOTE: After cutting jumpers, tape each of the cut ends with

electrical tape to prevent wires from shorting.

— 1 —

Page 2

“ALERT”

OPENED

APPROXIMATE GAP

(GREATER THAN 1 1/3 INCHES)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

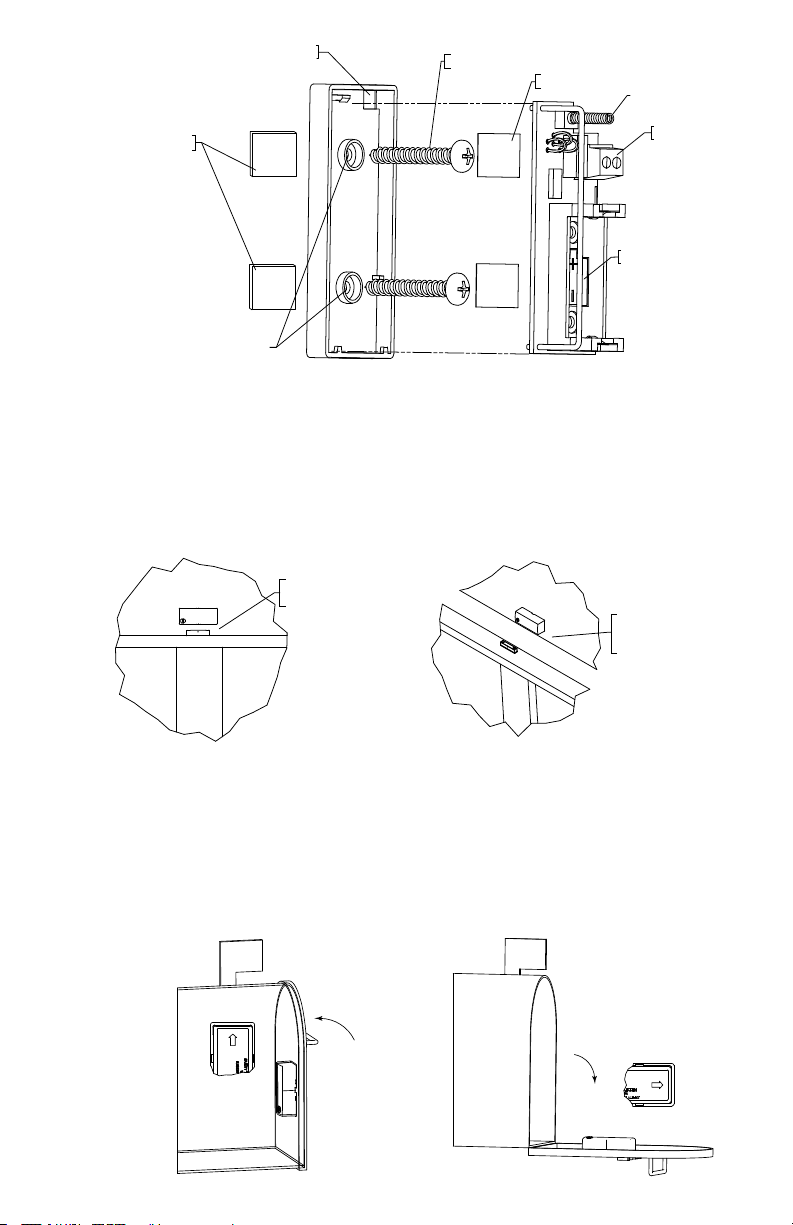

OPTION 1 MOUNTING

(DOUBLE SIDED FOAM TAPE)

OPTION 1 MOUNTING

(DOUBLE SIDED FOAM TAPE)

KNOCK OUT FOR WIRES

OF EXTERNAL SWITCH

19039 SCREW

(2) PROVIDED

VINYL ELECTRICAL

TAPE

TAMPER SWITCH

EXTERNAL SWITCH

CONNECTION BLOCK

ONBOARD

REED SWITCH

Fig. 2

OPTION 2 MOUNTING

Operation

Magnetic Sensor: (Fig. 3)

• Alert Signal – Magnet is over approximately 1 1/3 inches from the device.

• Restore Signal – Magnet is brought within approximately 1 inch from the device.

When using the Magnetic Sensor, the bottom case may be inserted into the top case in reverse

depending on which direction the Magnetic Sensor should face.

APPROXIMATE GAP (1 INCH)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

Fig. 3

“RESTORE”

CLOSED

“ALERT”

OPENED

Tilt Sensor: (Fig. 4)

• Alert Signal – Sensor is tilted more than 45° from vertical.

• Restore Signal – Sensor is tilted less than 45° from vertical.

When using the Tilt Sensor, the arrow on the bottom should point straight up in the non-triggered state.

APPROXIMATE GAP

(GREATER THAN 1 1/3 INCHES)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

Fig. 4

“RESTORE”

— 2 —

“ALERT”

Page 3

APPROXIMATE GAP (1 INCH)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

“RESTORE”

CLOSED

“ALERT”

OPENED

APPROXIMATE GAP

(GREATER THAN 1 1/3 INCHES)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

Sensor Supervision

The STI Universal Sensor has a supervision feature that monitors the battery condition, sensor

tampering and verifies that the sensor is within range of the STI Receiver. Sensor supervision can

be disabled for installations where the transmission signals may be locked when in the sensor’s

normal condition.

If the STI Universal Sensor has a Low Battery or triggered Tamper Switch, the sensor will send a

trouble signal to the receiver.

If the signal is out of range or there is a loss of communication, the receiver will indicate a trouble

condition between 12 and 24 hours from the time the signal was lost.

External Contacts: (Fig. 5)

• Alert Signal – Terminals must rst have a closed circuit then an open circuit any

time afterward will trigger an Alert signal.

• Restore Signal – Terminals have a closed circuit.

When using the External Switch Terminals, remove the case knock out (Fig. 2) in the corner of the case

bottom to insert sensor wires. Connect to external contact block.

NOTE: If mounted outdoors, use silicone sealant on the wire and screw hole knock outs.

REED SWITCH CABLE

(18 INCHES)

“ALERT”

CLOSED

APPROXIMATE GAP (1 INCH)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

“ALERT”

OPENED

APPROXIMATE GAP

(GREATER THAN 1 1/3 INCHES)

GAP MAY BE EFFECTED

IF MOUNTED ON METAL.

Fig. 5

NOTE: In any configuration, an Alert or Restore signal must be triggered for any STI receiver to

acknowledge the device.

— 3 —

Page 4

Important Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions.

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired

operation.

Changes or modifications not expressly approved by Safety Technology International, Inc. could void the

user’s authority to operate the equipment.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts

de licence. L’exploitation est autorisée aux deux conditions suivantes:

1. L’Appareil ne doit pas produire de brouillage, et

2. L’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

Model: 34401 FCC ID: TXL34401 IC: 6335A-34401

This device is a transmitter intended for home and office use in all EU and EFTA member states.

Limited Warranty

STI, Inc. warrants to the original consumer/purchaser that this product shall be free of defects in material

and workmanship under normal use and circumstances for a period of one (1) year from the date of

original purchase for use.

Electronic warranty form at www.sti-usa.com/wc14.

Additional Wireless Alert Series Products

STI-34098 Single Channel Slave Receiver

STI-34104 4-Channel Receiver

STI-V34104 4-Channel Voice Receiver

STI-34108 8-Channel Receiver

STI-34188 8-Zone Relay Board

STI-34101 Solar Powered Driveway Monitor Sensor

STI-34151 Battery Powered Driveway Monitor Sensor

STI-34201 Wireless Mailbox Alert Sensor

STI-34301 Wireless Garage Sentry Sensor

STI-34401 Wireless Universal Alert Sensor

STI-34501 Wireless Entry Alert Sensor

STI-34601 Wireless Doorbell Button

STI-34701 Indoor Wireless PIR

STI-34751 Outdoor Wireless PIR

STI-6200WIR Wireless Fire Extinguisher Theft Stopper

STI-6200WIR4 Wireless Fire Extinguisher Theft Stopper w/Receiver

STI-6400WIR Wireless Exit Stopper Door Alarm

STI-6400WIR4 Wireless Exit Stopper Door Alarm with Receiver

STI-6517A Stopper Station Shield with Sound

STI-6517B Stopper Station Shield with Sound and Transmitter

STI-30104 Lamp Controller

STI-30105 Extended Antenna

STI-34105 Voltamax 12VDC (500mA) Power Supply

STI-34106 Keyfob

STI-34109 Repeater

2306 Airport Rd • Waterford, MI 48327

Phone: 248-673-9898 • Fax: 248-673-1246

info@sti-usa.com • www.sti-usa.com

Safety Technology International (Europe) Ltd.

Unit 49G Pipers Road • Park Farm Industrial Estate • Redditch

Worcestershire • B98 0HU • England • Tel: 44 (0) 1527 520 999

Fax: 44 (0) 1527 501 999 • Freephone: 0800 085 1678 (UK only)

E-mail: info@sti-europe.com • Web: www.sti-europe.com

We protect the things that protect you.

Inst. Sht. 34401 DEC2012

Loading...

Loading...