STEYR 4 CYLINDER, 6 CYLINDER, MO84K32, MO94K33, MO114K33 Service Manual

...

www.steyr-motors.com

STEYR MOTORS GmbH

Im Stadtgut B1, A-4407 Steyr-Gleink, AUSTRIA

4 CYLINDE RS

+ 6 CYLINDE RS

STEYR MARINE ENGINES

SERVICE MANUAL

P/N Z001019/0 6th Edition July 2008

4 CYLINDE RS

+ 6 CYLINDE RS

THIS PAGE IS INTENTIONALLY BLANK

PREFACE

STEYR MOTORS GmbH

After Sales Service

Im Stadtgut B1

4407 STEYR

AUSTRIA

07252/222/52

07252/222/29

vom Inland:

from home country

+43/7252/222/52

+43/7252/222/29

vom Ausland

from foreign

countries:

service@steyr-motors.com

http://www.steyr-motors.com

STEYR MOTORS GmbH has developed high-performance diesel engines with modulated high-

pressure direct injection, especially for the marine environment. STEYR marine engines are designed to be

adapted to various propulsion systems.

This SERVICE MANUAL is published with the main intention -

to provide information in form of technical data and know-how based on our experience in the marine diesel

engine business, which will enable you in case of possible failure to operate, service and repair the engine

4 & 6 CYLINDER MARINE

ENGINES

to maintain their operating safety and reliability.

To achieve continuous improvement with regard to form and contents of the information required, we are

assigned to your aid.

We, therefore, would much appreciate your comment to the following questions -

- Which descriptions or terms are not understandable?

- Which supplements or completions do you propose ?

- Where did creep in contents-related mistakes ?

Please address your comment to:

Z001019/0_6_July 2008

Z001019/0_6_July 2008

Repair and maintenance works on engine

The descriptions and instructions in this technical documentation should support you in use and repair of our

product. They refer to a specific equipment status of engine componets and accessories. Your individual

engine may be equipped with other or less accessory.

For any component not covered in this manual, please contact STEYR MOTORS GmbH, After Sales Ser-

vice, as to respective documentation.

This manual also contains specific references to your personal safety as user, as well as that of your

customers, their passengers and other persons being close to the engine/boat.

Product specifications, illustrations and technical data

When reference is made in this manual to a brand name, product number, product or specific tool, an

equivalent product may be used in place of the product or tool referred to, unless stated otherwise. To exclude

possible danger, the operator has to provide for adequate safety precautions.

All information, illustrations and specifications in this manual are based on the latest product data available at

the time of printing. It cannot be guaranteed that this manual is constantly updated. Revised versions edited at

a later date will replace all preceding editions.

Illustrations in this manual may not always correspond to actual implements or components and are

mainly intended as reference.

STEYR MOTORS GmbH reserves the right to make changes at any time, without notice, on technical

data or models and/or to discontinue models. The right is also reserved to change technical data or

components at any time, without incurring any obligation to retrofit new parts on models produced

prior to date of such change.

To guarantee proper function of the engine and its attached parts after a repair, correct assembly is of

utmost importance. Such works are to be carried out with greatest care, in accordance with repair

instructions.

WARRANTY: Warranty claims will expire if repair, service and operation of the engine do not

correspond to the guidelines defined by STEYR MOTORS GmbH Please

address your warranty claims, in accordance with warranty regulations, directly to

the After Sales Service of STEYR MOTORS GmbH, Steyr.

Every STEYR dealer is obliged to fill out the warranty registration card enclosed to every sold

STEYR marine engine or every sold boat with a built-in STEYR marine engine.

Part 1 (Warranty Registration Card) is to be handed over to the customer, part 2 (Dealer Record

Card) remains with the dealer and part 3 is to be sent to the After Sales Service of STEYR

MOTORS GmbH.

This warranty registration card serves as a proof of ownership and is to be submitted in case

of warranty claims.

Every STEYR dealer is also obliged to carry out the Installation and pre-delivery inspection log.

One copy (completely filled out) of this Installation and pre-delivery inspection log is to be sent

to the After Sales Service of STEYR MOTORS GmbH.

Z001019/0_6_July 2008

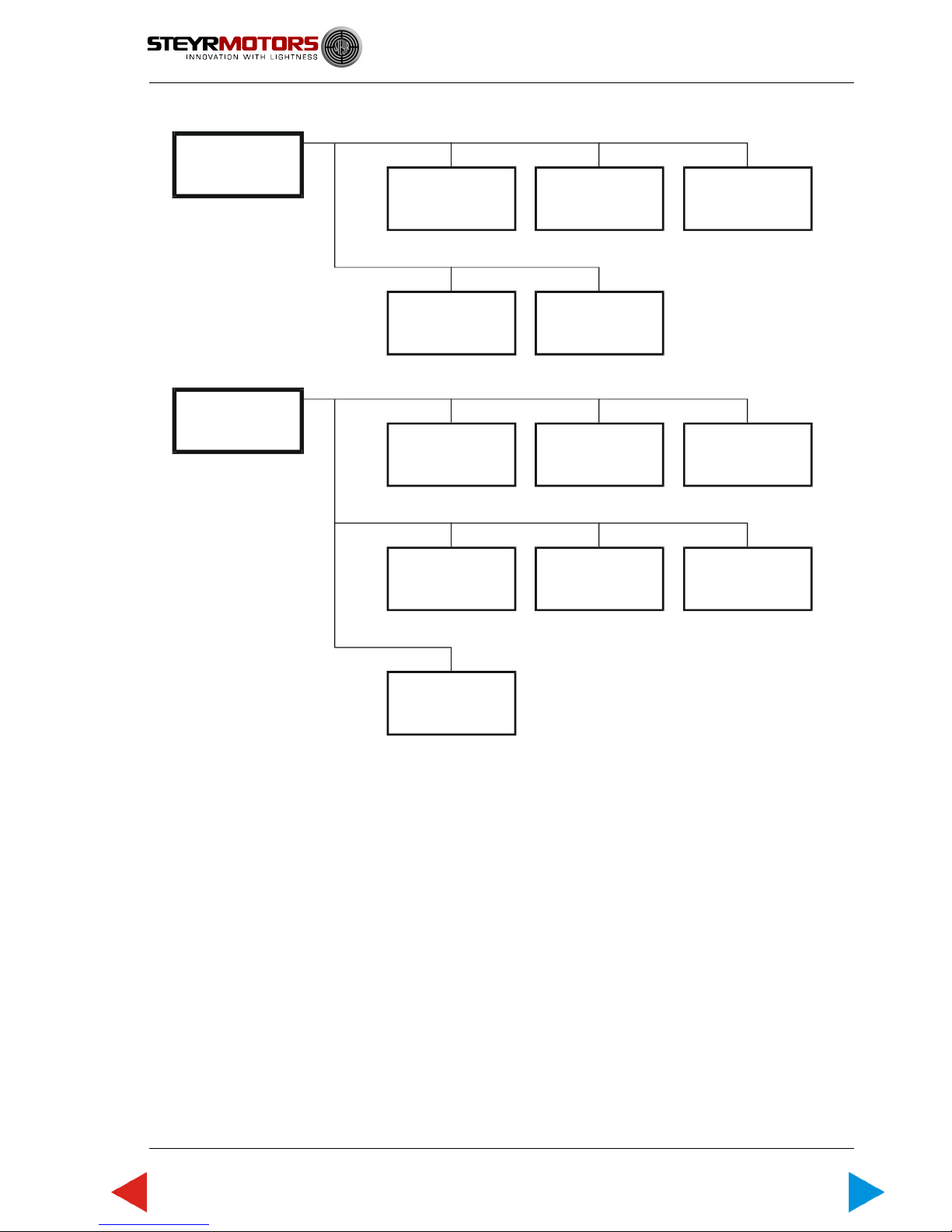

TABLE OF CONTENTS

(MAIN ASSEMBLY GROUP ENGINE)

GENERAL

01 ENGINE

02 COUPLING

03 FUEL SYSTEM

04 EXHAUST SYSTEM

05 COOLING SYSTEM

06 ELECTRICAL EQUIPMENT

Z001019/0_6_July 2008

Components

01

Engine

01.00

Engine timing,

engine mount

01.01

Cylinder block

01.02

Chrankshaft

bearing,

vibration damper

01.03

Flywheel,

housing

01.04

Piston,

connection rod

01.05

Chamshaft,

housing,

valve drive

01.06

Engine housing,

oil pump,

oil suction pipe

01.08

Intake manifold,

intercooler

01.13

Engine oil cooler,

01.09

Auxiliary drive-PTO

01.14

Exhaust manifold,

seals,

heat exchanger

02

Coupling

03

Fuel system

04

Exhaust system

02.01

Torsion coupling

02.02

Coupler

02.03

Torsion coupling

Centa

03.02

Fuel pump,

unit injector,

pipes

03.04

Air filter

03.05

Turbo charger

03.08

Control solenoid

03.09

Fuel filter

03.11

Glow plugs

04.01

Hi-riser

Z001019/0_6_July 2008

05

Cooling system

06

Electrical

system

05.01

Cooler,

heat exchanger,

expansions tank

05.03

Pipes,

thermostat

05.04

Coolant pump

05.10

Raw water pump,

side mounted

05.11

Raw water pump,

front mounted

06.01

Generator,

alternator

06.03

Starter motor

06.05

Engine harness

06.06

EMS, E-box,

diagnosis system,

fuses

06.07

Instrument panel,

connecting cable

06.10

Sender, sensor

06.12

Battery,

charge equalization

Z001019/0_6_July 2008

VERSIONS OF MANUAL

Version Date Modification

1.0 01. 10. 2000 new edition

2.0 01. 06. 2002 release typ 164, 246

3.0 01. 07. 2005 release typ 256

4.0 01. 07. 2007 modification

5.0 01. 03. 2008 modification

6.0 01. 07. 2008 modification

Z001019/0_8_Octobre 2011 Page GENERAL-1

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

GENERAL

Table of Contents

A General Remarks .................................................................................. 3

A 1 Model and Serial Numbers ..................................................................... 3

A 2 Documentation........................................................................................ 4

A 3 Model summary ...................................................................................... 5

A 3.1 Model summary 4 cylinder engines ........................................................ 5

A 3.2 Model summary 6 cylinder engines ........................................................ 8

A 4 Technical Data and Overview ................................................................. 12

A 4.1 T echnical Data and Overview 4 cylinder engines.................................... 12

A 4.2 T echnical Data and Overview 6 cylinder engines.................................... 16

B Specifications ....................................................................................... 20

B 1 Fuel Requirements ................................................................................. 20

B 2 Motor oil .................................................................................................. 21

C Maintenance and Service..................................................................... 22

C 1 Trouble Check Chart............................................................................... 22

C 2 Service- and Maintenance Schedule...................................................... 24

D General Information.............................................................................. 26

D 1 Electronic Engine Management System (ECU)...................................... 26

D 2 Diagnostic System.................................................................................. 27

D 3 Extended Storage Preservation Procedure............................................. 28

D 4 Engine Break-in procedure...................................................................... 32

D 5 Operation after Break-in .......................................................................... 34

E Quality Gudelines for Repair ................................................................ 36

E 1 Spare parts specification ......................................................................... 36

E 2 Workshop profile ..................................................................................... 36

E 3 Nomenclature .......................................................................................... 37

E 4 SI - System .............................................................................................. 38

E 5 Abbreviations .......................................................................................... 39

F Operating material and Information on Disposal................................ 40

F 1 List of operating material ......................................................................... 40

F 2 Disposal of automotive waste products.................................................... 41

G Notes on Safety..................................................................................... 42

G 1 General notes on safety ........................................................................... 42

G 2 Guidelines for damage prevention ........................................................... 42

G 3 Legal rules............................................................................................... 42

G 4 Safety in the use of operating material ..................................................... 43

GENERAL

Page GENERAL-2 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

G 5 Measures in case of accidents ................................................................ 43

H Thightening Torques ............................................................................ 44

H 1 Listing of Thightening Torques.................................................................. 44

H 2 General Tightening torques ...................................................................... 49

H 3 Testing of torque wrench .......................................................................... 50

H 4 Non-destructive material testing ............................................................... 50

H 5 Use of adhesive and sealing materials..................................................... 50

H 6 Solvent-free sealing materials.................................................................. 50

J Wear Limits............................................................................................ 52

J 1 Adjustment information for service and maintenance ................................ 53

Z001019/0_8_Octobre 2011 Page GENERAL-3

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

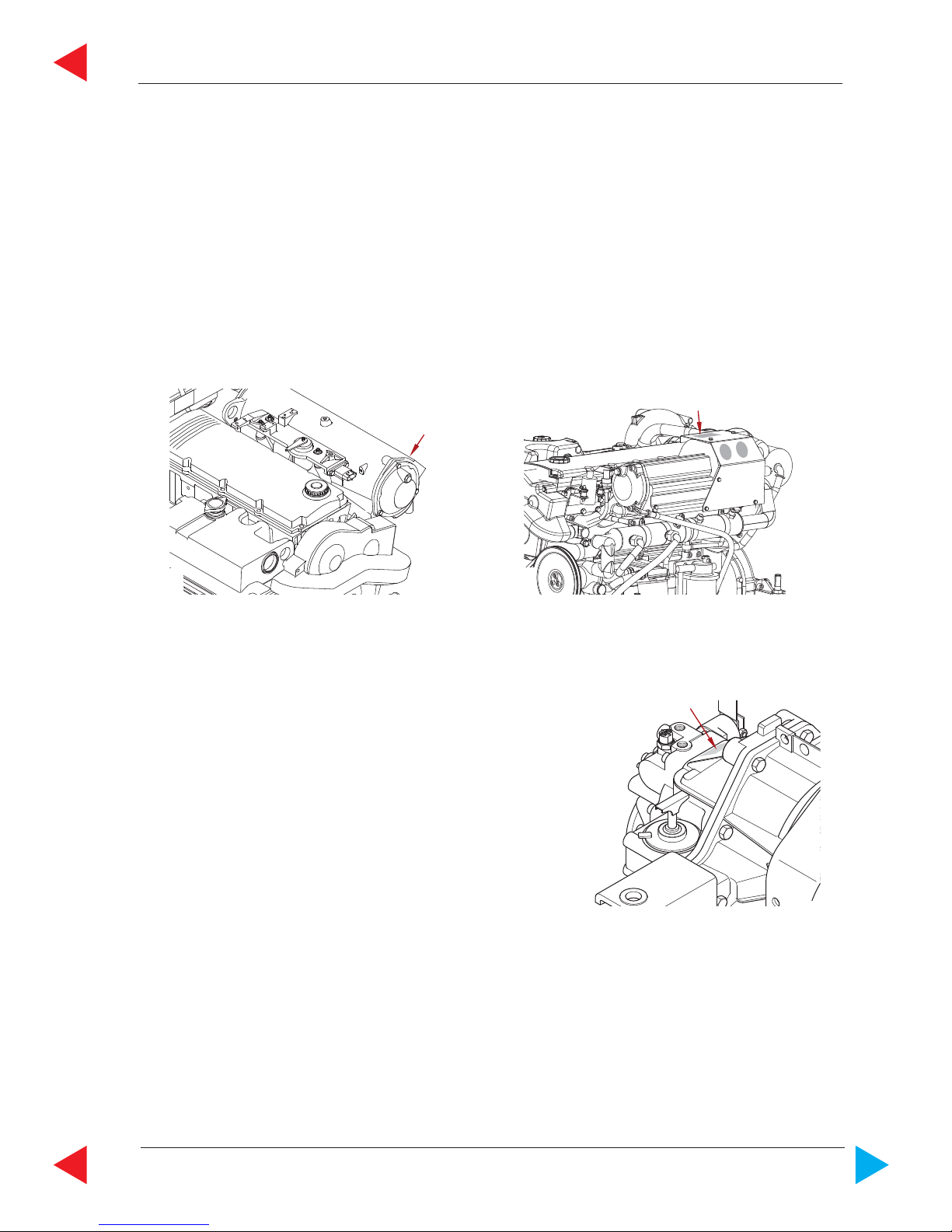

A GENERAL REMARKS

A 1 Model and Serial Numbers

01.01 ill.1

01.01 ill.3

01.01 ill.2

FOR ALL

4 CYL. MARINE ENGINES

The primary model and serial number (ill.1 or ill.2) is

located on the engine as illustrated.

These numbers are required for warranty

claims and ordering parts.

The model and serial number of the marine gearbox

is located on the marine gearbox housing as illustrated.

To obtain instructions regarding marine gearbox

operation, refer to marine gearbox owners manual.

17

06014

08006

1

1

08007

FOR ALL

6 CYL. MARINE ENGINES

GENERAL

Page GENERAL-4 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

The following documentation is available in English language on our website:

http://www.steyr-motors.com/technical

technical documentation on CD - ROM P/N Z 001009/0

operation-, maintenance & warranty manual

for all marine engines P/N Z 001022/0

tool catalogue for all marine engines P/N Z 001002/1

spare parts catalogue STEYR 94 td diesel marine P/N Z 001023/0

STEYR 144 vti/td diesel marine P/N Z 001005/0

STEYR 164 td diesel marine P/N Z 001015/0

STEYR 174 vti diesel marine P/N Z 001011/0

STEYR 166 td diesel marine P/N Z 011796/1

STEYR 236 FDE P/N Z 011796/0

STEYR 236 td diesel marine P/N Z 011796/1 - Z011769/2

STEYR 246 td diesel marine P/N Z 011800/0

STEYR 256 td diesel marine P/N Z 011810/0

STEYR 266 td diesel marine P/N Z 011805/0

installation manual for marine engines P/N Z 001007/0

service manual for all marine engines P/N Z 001019/0

operator's manual marine gear ZF P/N Z 001003/0

Diagrams marine engine functions on CD P/N Z 001021/0

A 2 Documentation 4 and 6 cylinder

Z001019/0_8_Octobre 2011 Page GENERAL-5

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

A 3 Modell summary

A 3.1 Modell summary 4 cylinder engines

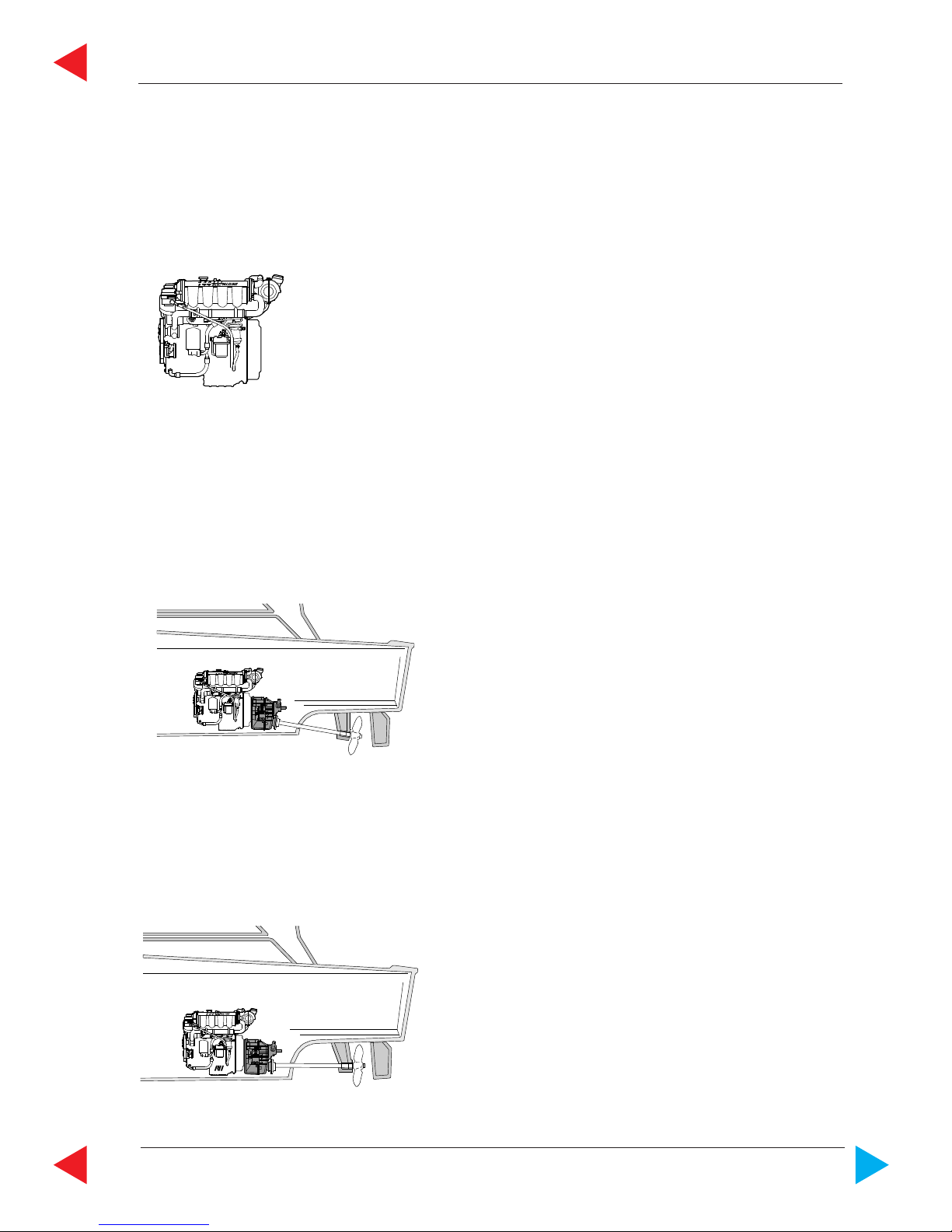

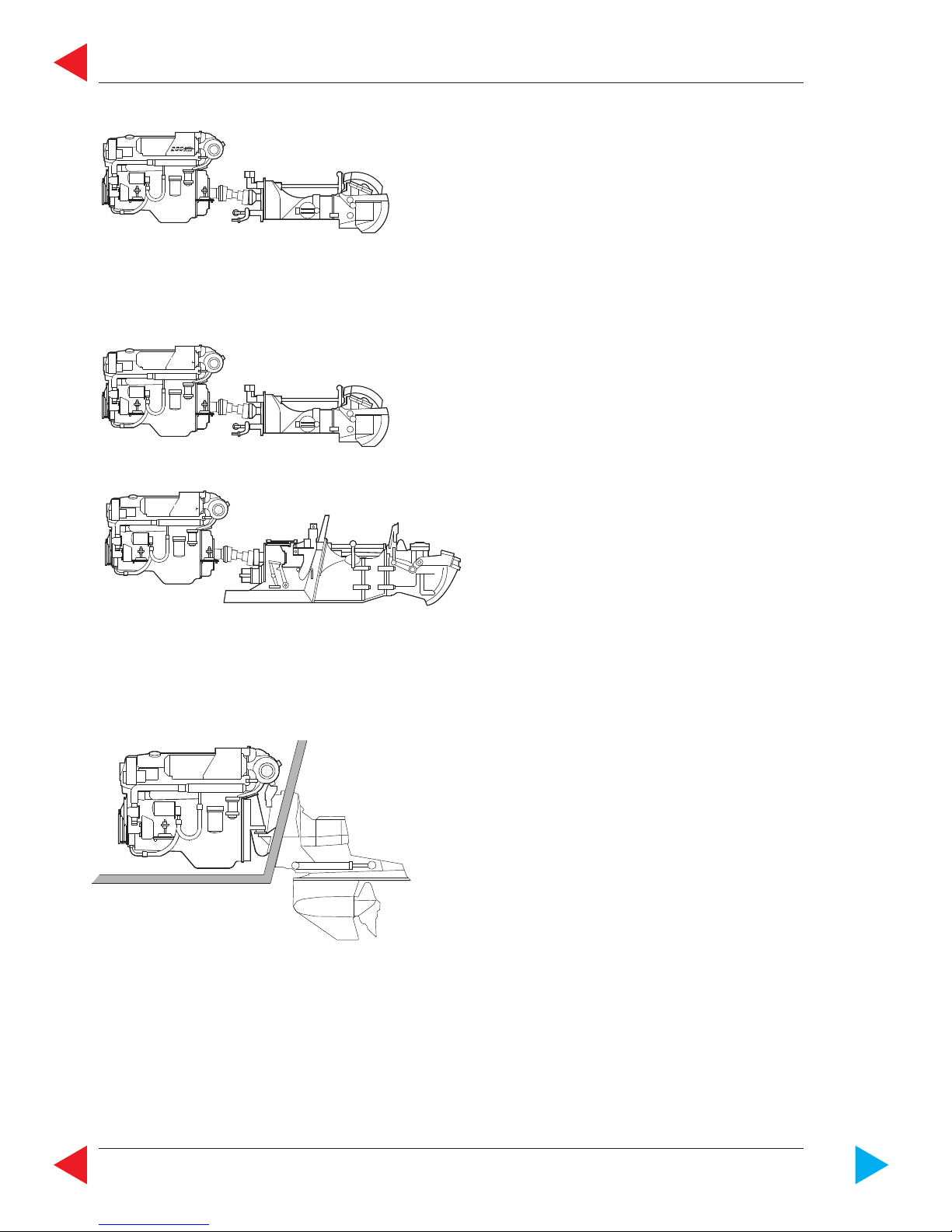

03.01 ill.1

03.01 ill.2

03.01 ill.3

Inborder i.e. ZF 45 Marinegear

Down angle

Bobtail - Version

Innenborder i.e. ZF 63 Marinegear

Equipment:

with side mounted raw water

pump or,

with side mounted raw water

pump, power steering pump

GENERAL

Page GENERAL-6 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

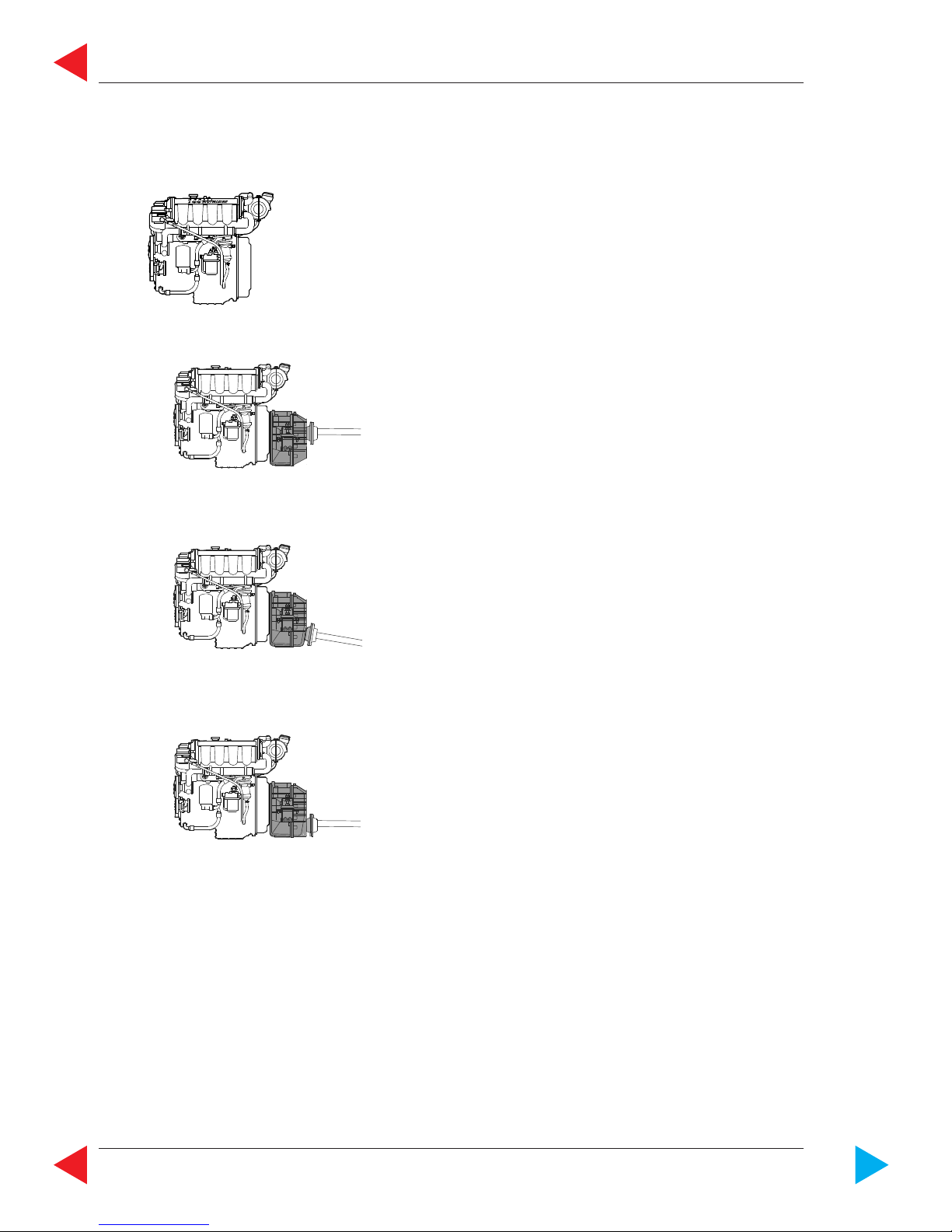

03.01 ill.4

03.01 ill.5

03.01 ill.6

Equipment

Bobtail "B"

Direkt gearbox

A-down angle gear box

Parallel offset gearbox

Lifeboat Engine

03.01 ill.7

Z001019/0_8_Octobre 2011 Page GENERAL-7

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

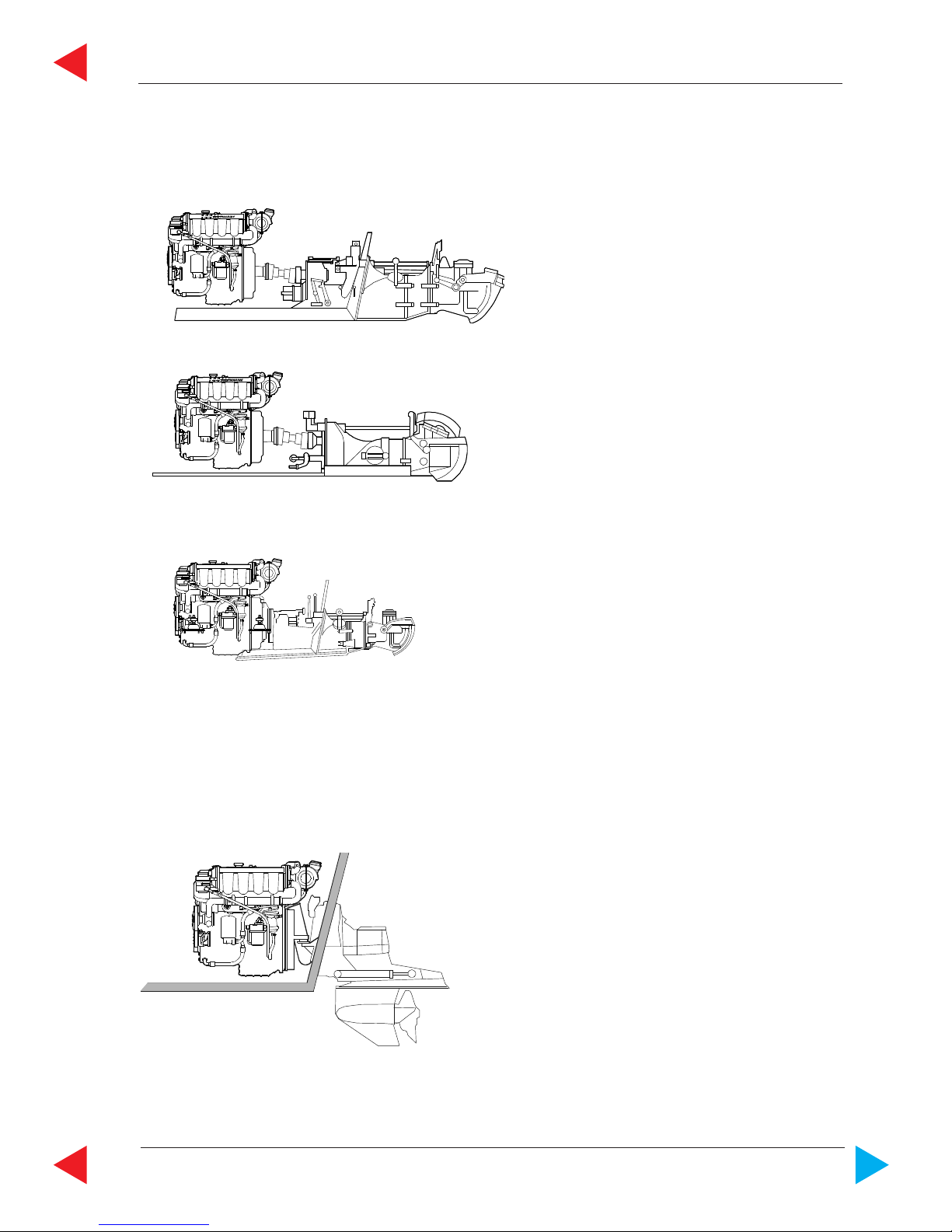

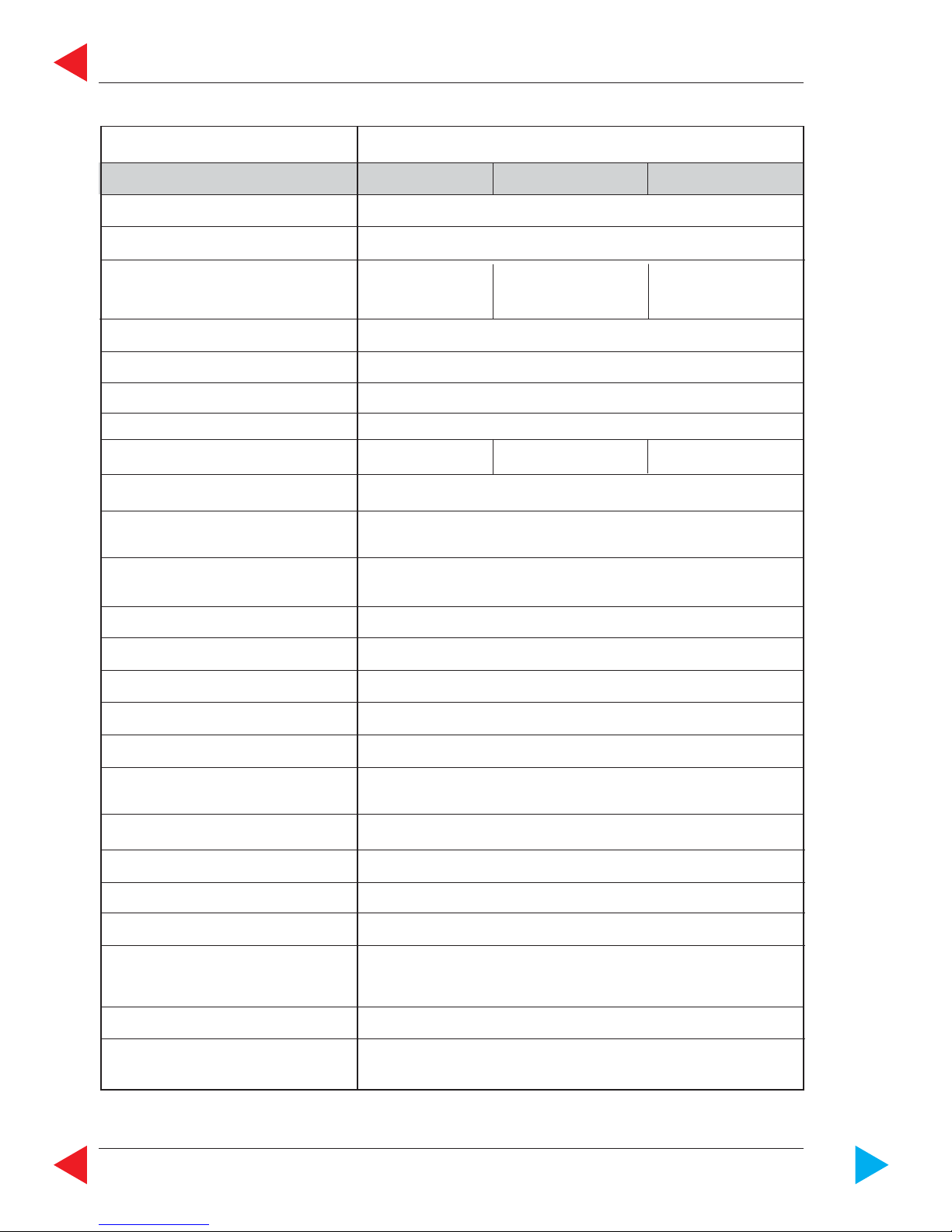

Stern Drive

Jet Drive

03.01 ill.10

03.01 ill.11

TYPE

Mercury Alpha Bravo I, II & III

Volvo DP 290

Volvo DP 290 Hydraulic

SX - Stern Drive

TYPE

Alamarin

Hamilton

Castoldi

03.01 ill.8

03.01 ill.9

GENERAL

Page GENERAL-8 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

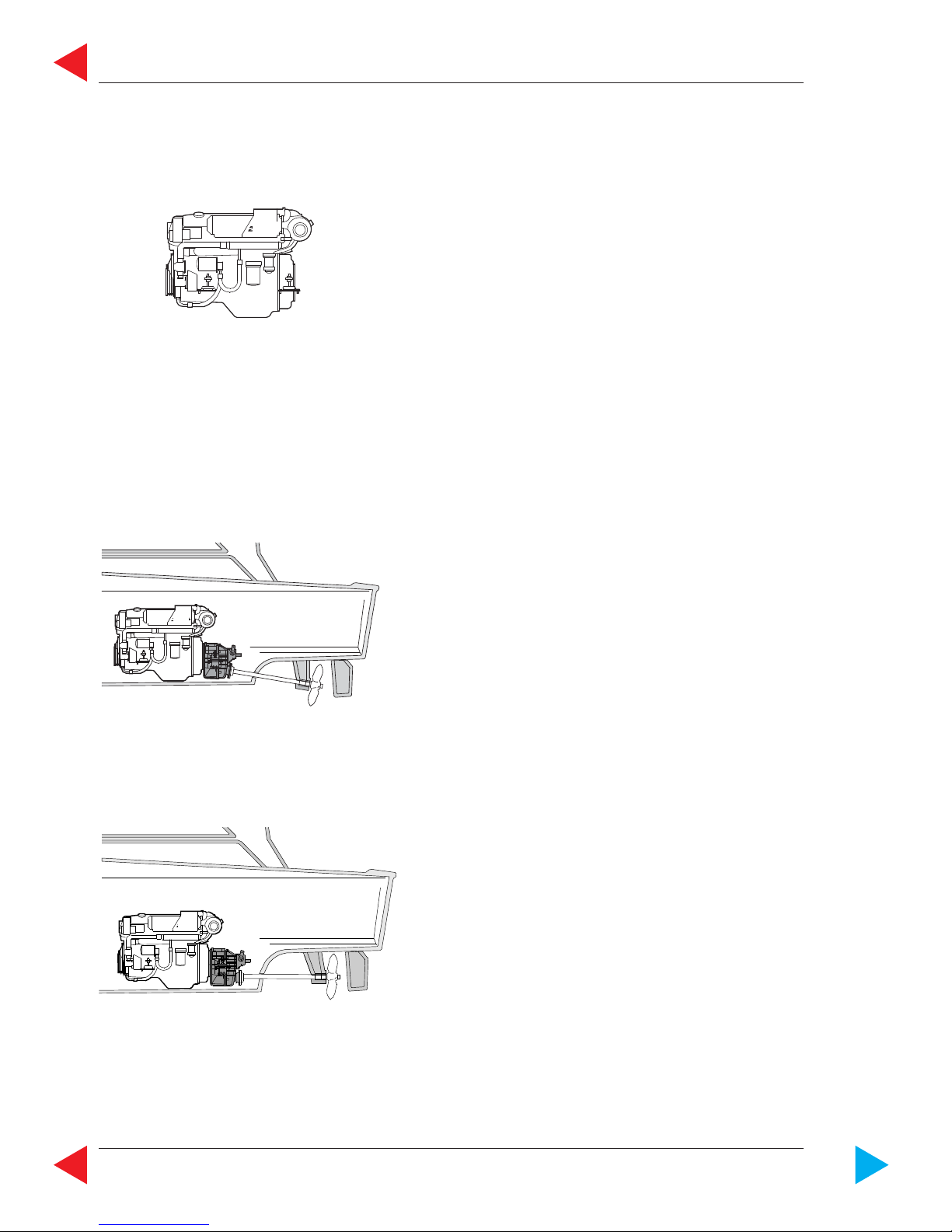

A 3.2 Modell summary 6 cylinder engines

03.02 ill.1

03.02 ill.2

03.02 ill.3

Inborder i.e. ZF 63 Marine gear

Down angle

with side mounted raw water

pump or,

with side mounted raw water

pump, power steering pump

and front mounted auxiliary

drive-PTO

Bobtail - Version

Z001019/0_8_Octobre 2011 Page GENERAL-9

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

03.02 ill.4

03.02 ill.5

03.02 ill.6

03.02 ill.7

03.02 ill.8

Transmission

Lifeboat Engine

Equipment

Bobtail "B"

Direkt gearbox

A-down angle gear box

Parallel offset gearbox

i = 2.5V, shaft angle 12°

i = 2.0V, shaft angle 12°

GENERAL

Page GENERAL-10 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

03.02 ill.9

03.02 ill.10

03.02 ill.12

Stern drive

Mercury Bravo II & III

Volvo DP 290

Stern Power Drive

Volvo DP 290 ZF

Hydraulic Pump

Volvo SX - Drive

King Cobra Drive

Type

Jet Drive

TYPE

Alamarin

Hamilton

Castoldi

Jet drive

03.02 ill.11

Z001019/0_8_Octobre 2011 Page GENERAL-11

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

THIS PAGE IS INTENTIONALLY BLANK

GENERAL

Page GENERAL-12 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

A 4.1 Technical data and overview 4 cylinder engines

MAKE STEYR M 14 TCM, TCAM

type MO84K32 MO94K33 MO114K33 MO144V38

displacement 2133 cm³

piston displacement 85,0 x 94,0 mm

number of cylinders 4-cylinder in-line engine (position of cyl. 1 at vibration damper side)

ignition order 1 - 3 - 4 - 2

sense of rotation, seen from front right

compression ratio 17,5 : 1

full-load speed range (rpm) 3000 - 3200 3050 - 3800 3200 - 3800 3600 - 3800

idle speed 650 rpm. (adjustable)

injection pump - nozzle with modelling needle control

and electronic control

fuel acc. to CEC RF-03-A-84 (DIN EN 590) Cetan >49; diesel fuel

No. 2-D, temperature above -7°C; No.1-D, temperature below -7°C

fuel filter P/No. 2203710/0

fuel filter location intake-sided

air filter P/No. 2178992/0

oil pressure above 2000 rpm. 400 - 700 kPa (60 - 100 PSI) microprocessor controlled

filling capacity motor oil approx. 8,0 l engine housing (incl. approx. 1 l oil filter contents)

specification motor oil SAE 5W-50/ACEA B4-02/API CF or 10W-40/ACEA, E4, E5, E7,

API CF / P/N0. Z010058/0

oil and oil filter change intervals*) every 150 operating hours and/or once per season

oil filter P/No. 2178582/1

oil filter location pressure-sided

electric charging system 14 V / 90 A alternator with transistorized voltage regulator

cooling system dual cooling circuit; thermostat-controlled, pressurized cooling

circuit; circulating pump with heat exchanger on engine; governor

pump, external raw water circuit to heat exchanger

coolant capacity 11,5 liters

coolant STEYR MOTORS engine coolant - 36 C°

P/No. Z011785/0

*) extended periods to be evaluated upon application and type of usage

STEYR MOTORS GmbH. reserves the right to make changes without notice or obligations.

**) Efficiency of gearbox = 97,0%, efficiency of Z-drive = 95,5%

rated power acc. EN ISO 8665:2006

(impeller **) KW / HP

Jet - Drive / Inboard

Z - Drive

53 / 71

52 / 70

64 / 86

63 / 84

78 / 105

77 / 104

103 / 138

101 / 136

Z001019/0_8_Octobre 2011 Page GENERAL-13

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

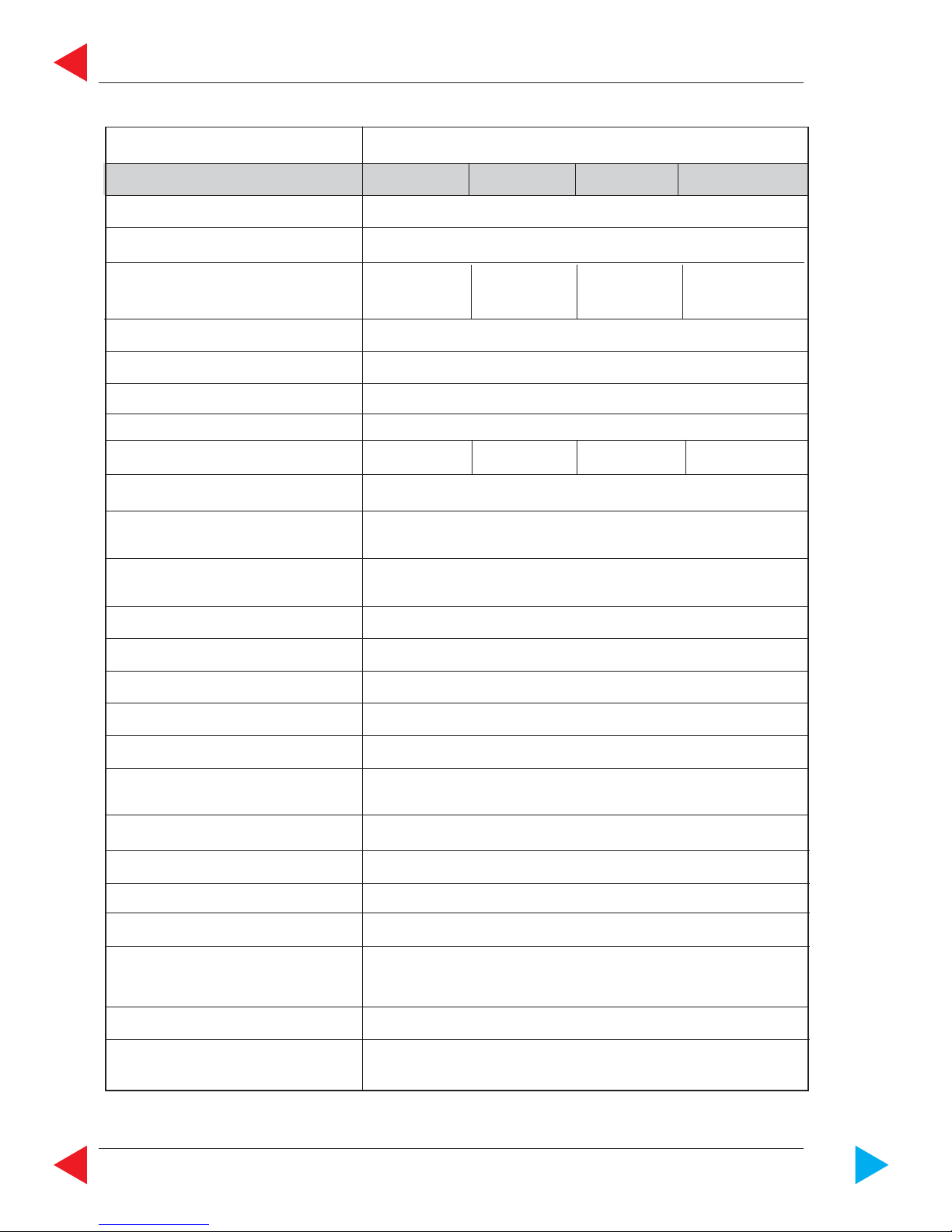

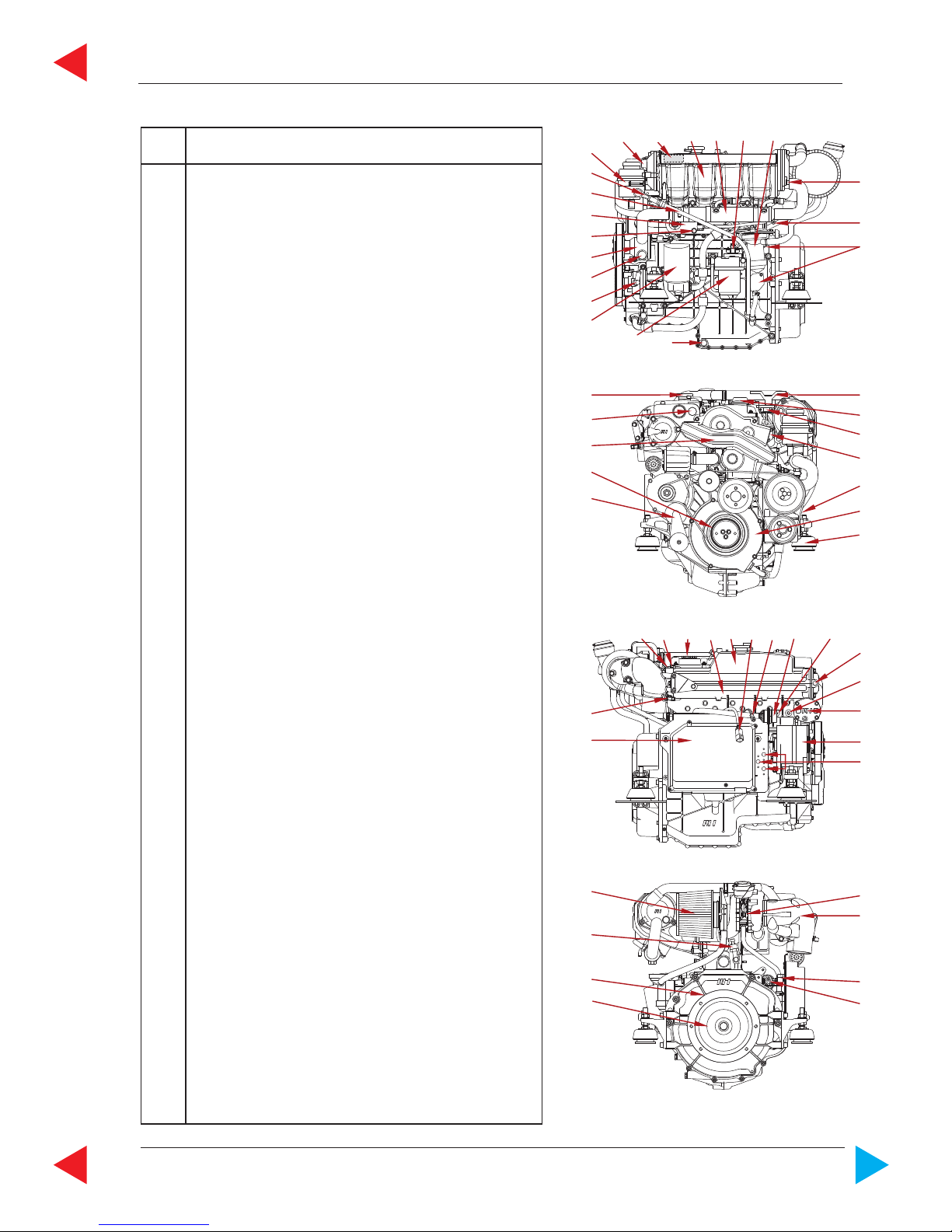

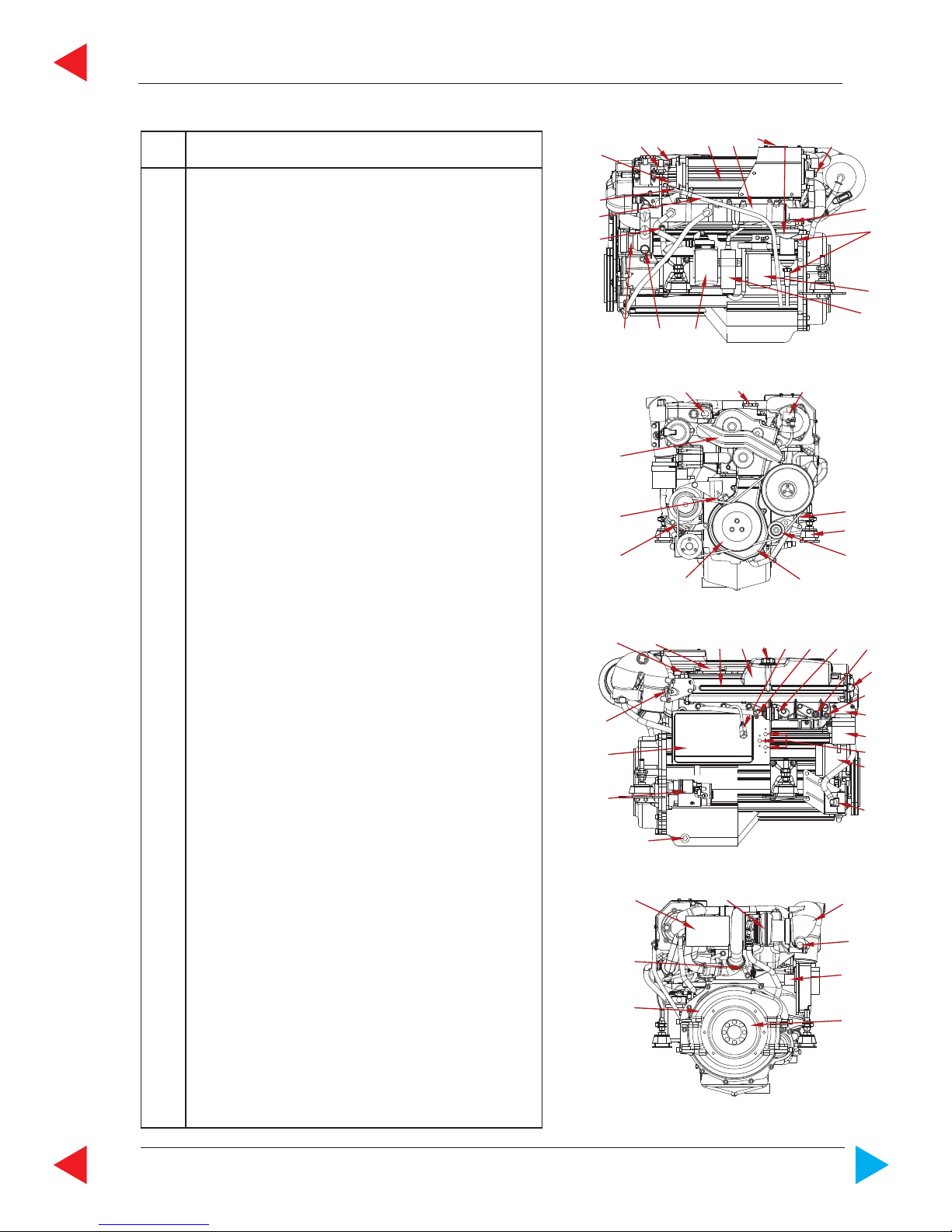

Overview for all STEYR 4 Cyl. Marine Engines

06001

19

18

17

16

15

14

13

12

11

15

1

4

7

8

23

6

10 9

06002

31

30

22

23

24

21

25

26

27

20

29

28

38

06003

44

43

136

15

34

40

41

1

3932 33

37

42

35

06004

45

52

51

50

46

47

48

49

Item Designation

1 Zinc Anode (4 Units)

2 Model and Serial Number

3 Intercooler

4 Fuel/Oil Cooler with Raw Water Drain Plug

5 Fuel Pump

6 Oil Seperator

7 Raw Water Drain Plug

8 Valve Crankshaft Housing Ventilation

(only SOLAS)

9 Oil Drain Plug

10 Fuel Filter

11 Oil Filter

12 Hydraulic Pump

13 Raw Water Inlet Fitting

14 Raw Water Pump

15 Coolant Drain Plug (2 Units)

16 Engine Oilcooler

17 Oil Suction Pipe

18 Oil Dipstick

19 Hydraulic Oil Tank

20 Cooler Cap

21 Potentiometer Accelerator

22 Motor Oil Filler Cap

23 Boost Pressure Sensor

24 Rack Position Sensor *)

25 Drive Belt

26 Cover T-Belt, Lower

27 Engine Mount

28 Drive Belt Tensioner

29 Vibration Damper

30 Cover T-Belt, Upper

31 Engine Lifting Eye

32 Speed Sensor

33 Valve Cover

34 Heat Exchanger

35 Coolant Expansion Tank

36 Diagnostic Outlet

37 Inversion Switch (only for SOLAS)

38 Connector Instrument Panel

39 Coolant Temperature Sensor

40 Thermostat Housing

41 Alternator

42 Circuit Breakers

43 Engine Management System/Fuses

44 Exhaust Temperature Sensor

45 Air Filter

46 Turbo Charger

47 Exhaust Elbow

48 Starter Relais (Backside E-Box Ground Plate)

49 Starter Motor

50 Flywheel

51 Flywheel Housing

52 Oil Pressure Sensor

*) This sensor is magnetism sensitive. All external magnets must be kept away.

GENERAL

Page GENERAL-14 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

MAKE STEYR M 14 TCAM

type MO144M38 MO164M40

displacement 2133 cm³

piston displacement 85,0 x 94,0 mm

number of cylinders 4-cylinder in-line engine (position of cyl. 1 at vibration damper side)

ignition order 1 - 3 - 4 - 2

sense of rotation, seen from front right

compression ratio 17,5 : 1

full-load speed range (rpm) 3700 - 3900 3800 - 4000

idle speed 650 rpm. (adjustable)

injection pump - nozzle with modelling needle control

and electronic control

fuel acc. to CEC RF-03-A-84 (DIN EN 590) Cetan >49; diesel fuel

No. 2-D, temperature above -7°C; No.1-D, temperature below -7°C

fuel filter P/No. 2203710/0

fuel filter location intake-sided

air filter P/No. 2178992/0

oil pressure above 2000 rpm. 400 - 700 kPa (60 - 100 PSI) microprocessor controlled

filling capacity motor oil approx. 8,0 l engine housing (incl. approx. 1 l oil filter contents)

specification motor oil SAE 5W-50/ACEA B4-02/API CF or 10W-40/ACEA, E4, E5, E7,

API CF / P/N0. Z010058/0

oil and oil filter change intervals*) every 150 operating hours and/or once per season

oil filter P/No. 2178582/1

oil filter location pressure-sided

electric charging system 14 V / 90 A alternator with transistorized voltage regulator

cooling system dual cooling circuit; thermostat-controlled, pressurized cooling

circuit; circulating pump with heat exchanger on engine; governor

pump, external raw water circuit to heat exchanger

coolant capacity 11,5 liters

coolant STEYR MOTORS engine coolant - 36 C°

P/No. Z011785/0

*) extended periods to be evaluated upon application and type of usage

STEYR MOTORS GmbH. reserves the right to make changes without notice or obligations.

**) Efficiency of gearbox = 97,0%, efficiency of Z-drive = 95,5%

rated power acc. EN ISO 8665:2006

(impeller **) KW / HP

Jet - Drive / Inboard

Z - Drive

103 / 138

101 / 136

116 / 156

114 / 154

Z001019/0_8_Octobre 2011 Page GENERAL-15

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

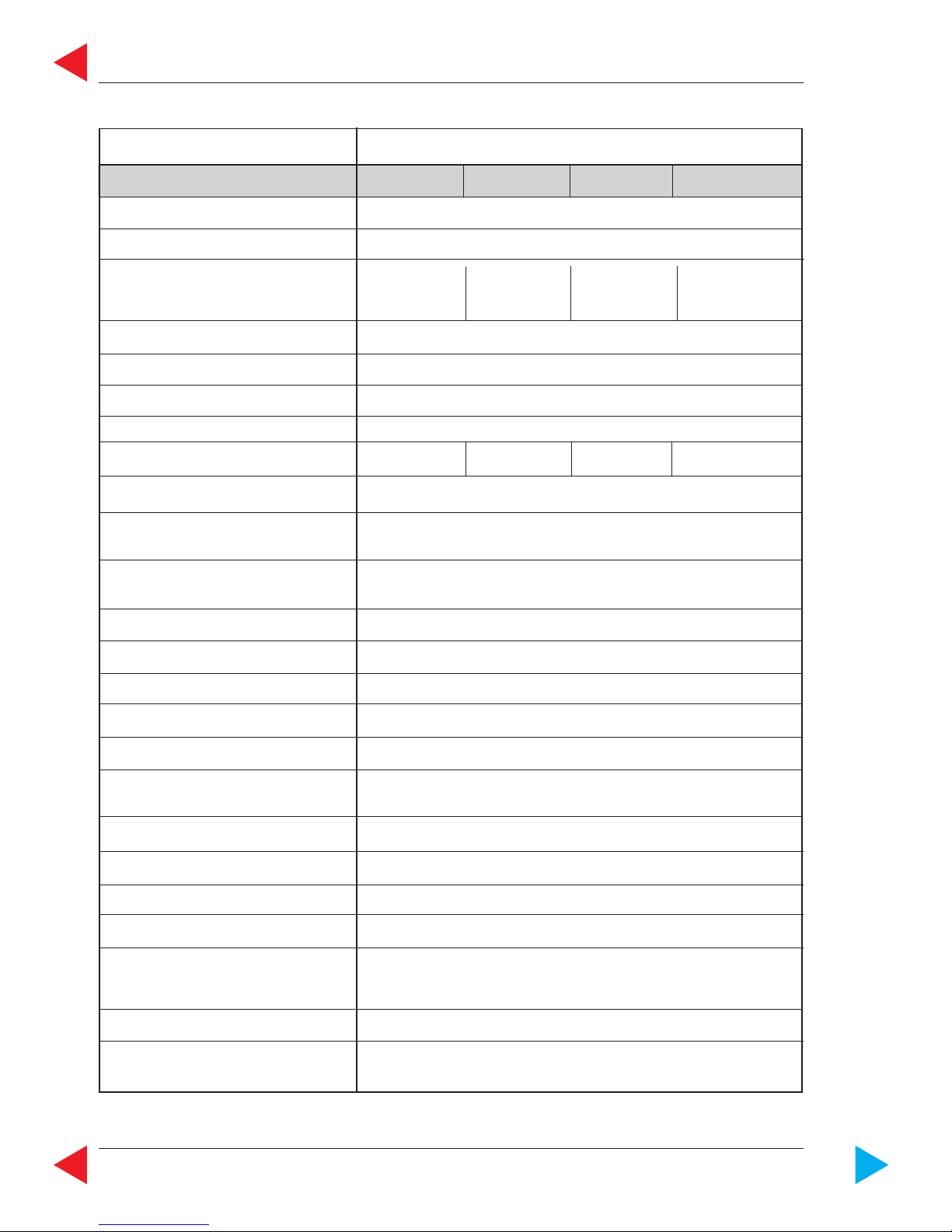

Overview for all STEYR 4 Cyl. Marine Engines

06001

19

18

17

16

15

14

13

12

11

15

1

4

7

8

23

6

10 9

06002

31

30

22

23

24

21

25

26

27

20

29

28

38

06003

44

43

136

15

34

40

41

1

3932 33

37

42

35

06004

45

52

51

50

46

47

48

49

Item Designation

1 Zinc Anode (4 Units)

2 Model and Serial Number

3 Intercooler

4 Fuel/Oil Cooler with Raw Water Drain Plug

5 Fuel Pump

6 Oil Seperator

7 Raw Water Drain Plug

8 Valve Crankshaft Housing Ventilation

(only SOLAS)

9 Oil Drain Plug

10 Fuel Filter

11 Oil Filter

12 Hydraulic Pump

13 Raw Water Inlet Fitting

14 Raw Water Pump

15 Coolant Drain Plug (2 Units)

16 Engine Oilcooler

17 Oil Suction Pipe

18 Oil Dipstick

19 Hydraulic Oil Tank

20 Cooler Cap

21 Potentiometer Accelerator

22 Motor Oil Filler Cap

23 Boost Pressure Sensor

24 Rack Position Sensor *)

25 Drive Belt

26 Cover T-Belt, Lower

27 Engine Mount

28 Drive Belt Tensioner

29 Vibration Damper

30 Cover T-Belt, Upper

31 Engine Lifting Eye

32 Speed Sensor

33 Valve Cover

34 Heat Exchanger

35 Coolant Expansion Tank

36 Diagnostic Outlet

37 Inversion Switch (only for SOLAS)

38 Connector Instrument Panel

39 Coolant Temperature Sensor

40 Thermostat Housing

41 Alternator

42 Circuit Breakers

43 Engine Management System/Fuses

44 Exhaust Temperature Sensor

45 Air Filter

46 Turbo Charger

47 Exhaust Elbow

48 Starter Relais (Backside E-Box Ground Plate)

49 Starter Motor

50 Flywheel

51 Flywheel Housing

52 Oil Pressure Sensor

*) This sensor is magnetism sensitive. All external magnets must be kept away.

GENERAL

Page GENERAL-16 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

A 4.2 Technical data and overview 6 cylinder engines

MAKE STEYR M 16 TCM, TCAM

type MO126M28 MO166K28 MO196K35 MO236K42

displacement 3200 cm³

piston displacement 85,0 x 94,0 mm

number of cylinders 6-cylinder in-line engine (position of cyl. 1 at vibration damper side)

ignition order 1 - 5 - 3 - 6 -2 - 4

sense of rotation, seen from front right

compression ratio 17,5 : 1

full-load speed range (rpm) 2600 - 2800 2600 - 2800 3300 - 3500 4000 - 4300

idle speed 630 rpm. (adjustable)

injection pump - nozzle with modelling needle control

and electronic control

fuel acc. to CEC RF-03-A-84 (DIN EN 590) Cetan >49; diesel fuel

No. 2-D, temperature above -7°C; No.1-D, temperature below -7°C

fuel filter P/No. 2177745/1

fuel filter location suction-sided

air filter MO126 - P/No. 2178992/0; all other 6 Cyl. - P/N 2178992/1

oil pressure above 2000 rpm. 400 - 700 kPa (60 - 100 PSI) microprocessor controlled

filling capacity motor oil approx. 10,0 l engine housing (incl. approx. 1 l oil filter contents)

specification motor oil SAE 5W-50/ACEA B4-02/API CF or 10W-40/ACEA, E4, E5, E7,

API CF / P/N0. Z010058/0

oil and oil filter change intervals*) every 150 operating hours and/or once per season

oil filter P/No. 2178582/1

oil filter location suction-sided

electric charging system 14 V / 90 A alternator with transistorized voltage regulator

cooling system dual cooling circuit; thermostat-controlled, pressurized cooling

circuit; circulating pump with heat exchanger on engine; governor

pump, external raw water circuit to heat exchanger

coolant capacity 13,2 liters

coolant STEYR MOTORS engine coolant - 36 C°

P/No. Z011785/0

*) extended periods to be evaluated upon application and type of usage

STEYR MOTORS GmbH. reserves the right to make changes without notice or obligations.

**) Efficiency of gearbox = 97,0%, efficiency of Z-drive = 95,5%

rated power acc. EN ISO 8665:2006

(impeller **) KW / HP

Jet - Drive / Inboard

Z - Drive

87 / 117

86 / 115

116 / 156

115 / 154

136 / 182

134 / 179

165 / 221

162 / 218

Z001019/0_8_Octobre 2011 Page GENERAL-17

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

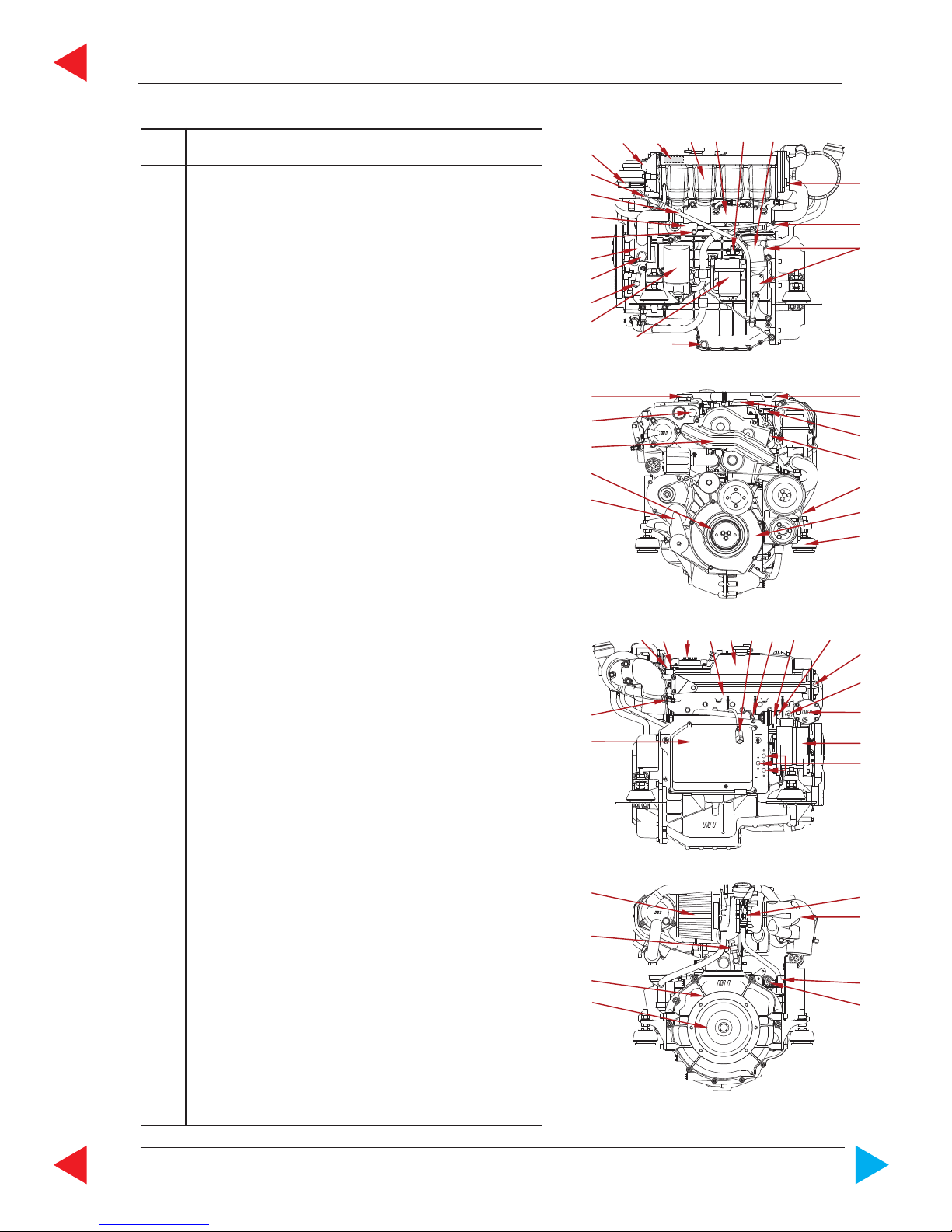

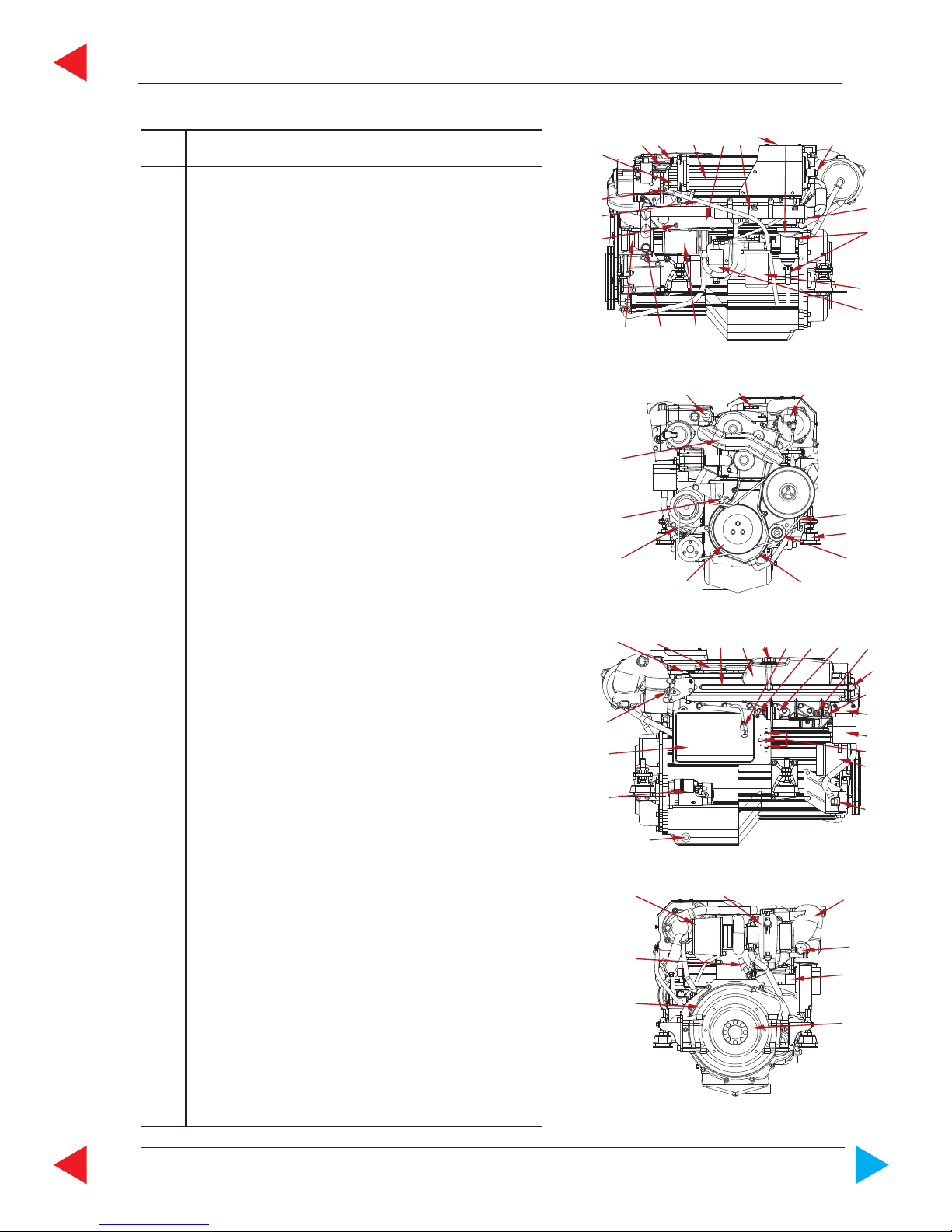

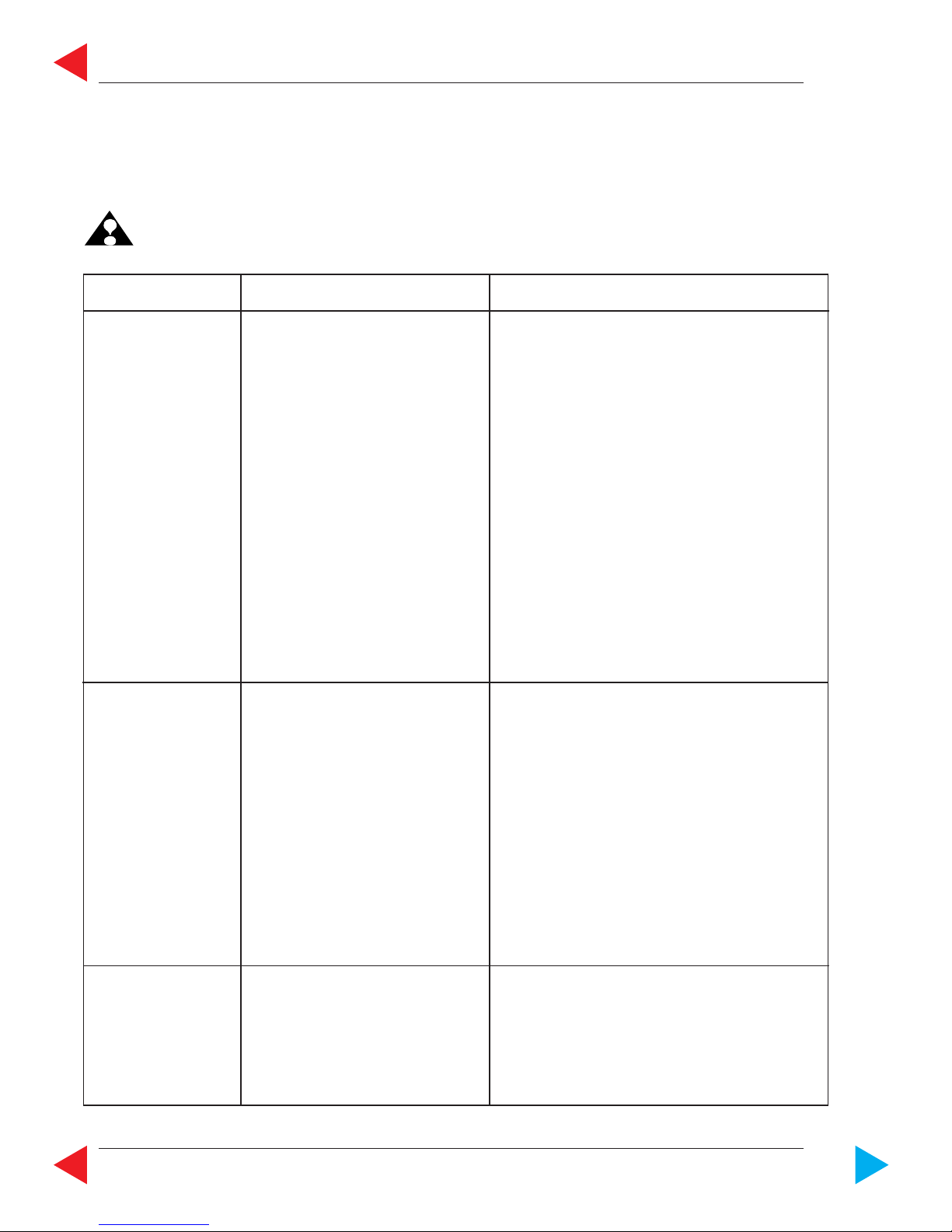

Overview STEYR MO126M28, MO166K28, MO196K35, MO236K42

06032

1423

6 7

2

8

9

10

11

121314

15

16

17

18

5

06033

19 20 21

22

23

24

2526

27

28

29

06034

2 30 31 32 33 34 35

36 37

2

15

38

39

40

41

42

43

44

45

46

06035

47 48

49

2

50

51

52

53

Item Designation

1 Boost Pressure Sensor

2 Zinc Anode (5 Units)

3 Intercooler

4 Fuel- / Hydr. Oil Cooler

5 Engine Oilcooler

6 Model and Serial Number

7 Oil Seperator

8 Raw Water Drain Plug

9 Valve Crankshaft Housing Ventilation

(only SOLAS)

10 Fuel Filter

11 Fuel Pump

12 Oil Filter

13 Raw Water Inlet Fitting

14 Raw Water Pump

15 Coolant Drain Plug (2 Units)

16 Oil Suction Pipe

17 Oil Dipstick

18 Rack Position Sensor *)

19 Engine Lifting Eye

20 Motor Oil Filler Cap

21 Potentiometer Accelerator

22 Drive Belt, Raw Water Pump

23 Engine Mount

24 Drive Belt Tensioner

25 Cover T-Belt, Lower

26 Vibration Damper

27 Drive Belt, Alternator & Hydr: Pump

28 Speed Sensor

29 Cover T-Belt, Upper

30 Valve Cover

31 Heat Exchanger

32 Coolant Expansion Tank

33 Cooler Cap

34 Diagnostic Outlet

35 Inversion Switch (only for SOLAS)

36 Connector Instrument Panel

37 Coolant Temperature Sensor

38 Thermostat Housing

39 Hydraulic Oil Tank

40 Circuit Breakers

41 Alternator

42 Hydraulic Pump

43 Oil Drain Plug

44 Starter Motor

45 Engine Management System/Fuses

46 Exhaust Temperature Sensor

47 Air Filter

48 Turbo Charger

49 Exhaust Elbow

50 Starter Relais (Backside E-Box Ground Plate)

51 Flywheel

52 Flywheel Housing

53 Oil Pressure Sensor

*) This sensor is magnetism sensitive. All external magnets must be kept away.

GENERAL

Page GENERAL-18 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

MAKE STEYR M 16 TCAM

type MO256K43 MO256H45

displacement 3200 cm³

piston displacement 85,0 x 94,0 mm

number of cylinders 6-cylinder in-line engine (position of cyl. 1 at vibration damper side)

ignition order 1 - 5 - 3 - 6 -2 - 4

sense of rotation, seen from front right

compression ratio 17,5 : 1

full-load speed range (rpm) 4000 - 4300 4000 - 4500

idle speed 630 rpm. (adjustable)

injection pump - nozzle with modelling needle control

and electronic control

fuel acc. to CEC RF-03-A-84 (DIN EN 590) Cetan >49; diesel fuel

No. 2-D, temperature above -7°C; No.1-D, temperature below -7°C

fuel filter P/No. 2178992/1

fuel filter location suction-sided

air filter P/No. 2178992/0 P/No.2178992/1

oil pressure above 2000 rpm. 400 - 700 kPa (60 - 100 PSI) microprocessor controlled

filling capacity motor oil approx. 10,0 l engine housing (incl. approx. 1 l oil filter contents)

specification motor oil SAE 5W-50/ACEA B4-02/API CF or 10W-40/ACEA, E4, E5, E7,

API CF / P/N0. Z010058/0

oil and oil filter change intervals*) every 150 operating hours and/or once per season

oil filter P/No. 2178582/1

oil filter location suction-sided

electric charging system 14 V / 90 A alternator with transistorized voltage regulator

cooling system dual cooling circuit; thermostat-controlled, pressurized cooling

circuit; circulating pump with heat exchanger on engine; governor

pump, external raw water circuit to heat exchanger

coolant capacity 13,2 liters

coolant STEYR MOTORS engine coolant - 36 C°

P/No. Z011785/0

*) extended periods to be evaluated upon application and type of usage

STEYR MOTORS GmbH. reserves the right to make changes without notice or obligations.

**) Efficiency of gearbox = 97,0%, efficiency of Z-drive = 95,5%

rated power acc. EN ISO 8665:2006

(impeller **) KW / HP

Jet - Drive / Inboard

Z - Drive

178 / 239

176 / 236

178 / 239

176 / 236

Z001019/0_8_Octobre 2011 Page GENERAL-19

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

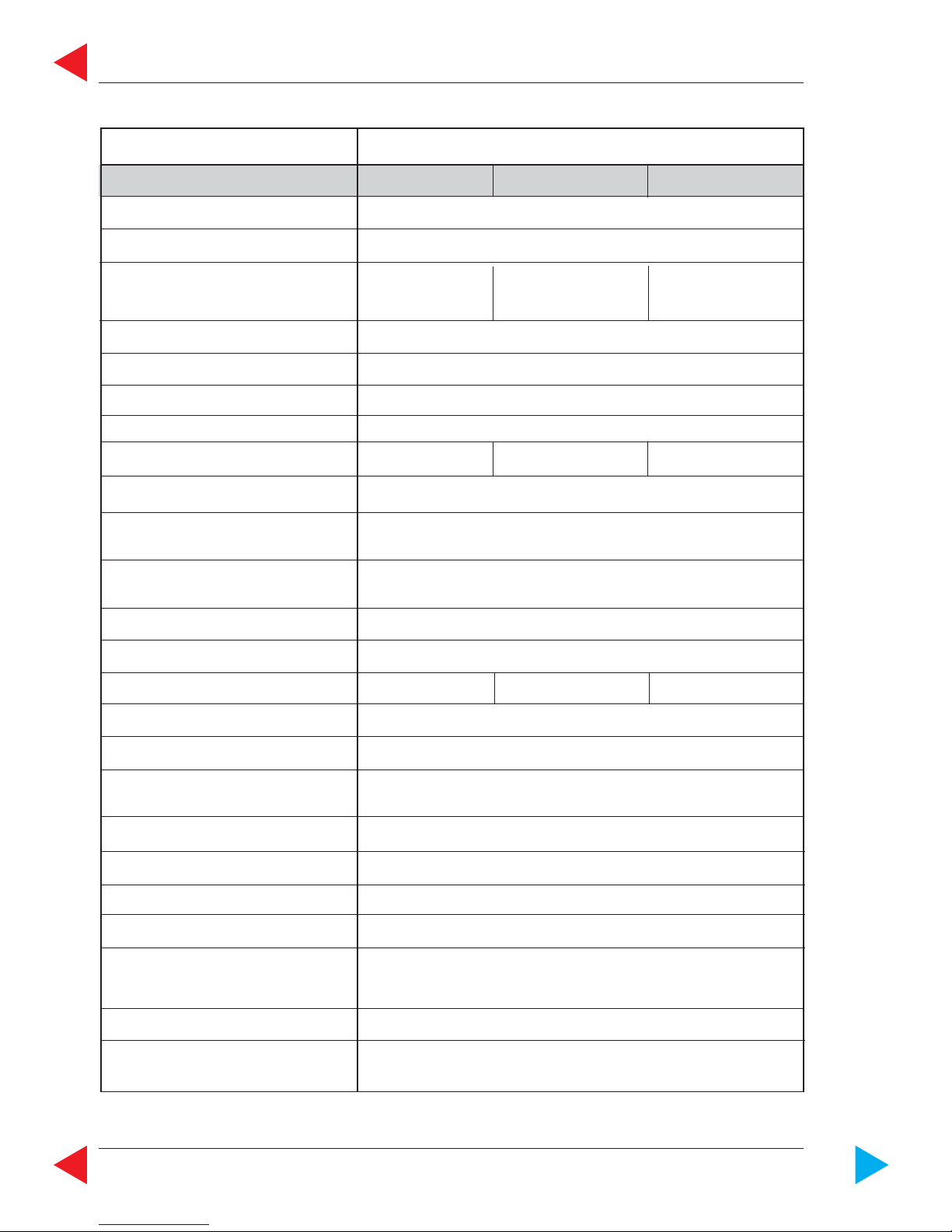

Overview STEYR MO256K43, MO256H45

06028

1423

5 6

2

7

8

9

10

111213

14

15

16

17

06029

18 19 20

21

22

23

2425

26

27

28

06030

2 29 30 31 32 33 34

35 36

2

14

37

38

39

40

41

42

43

44

45

06031

46 47

48

2

49

50

51

52

Item Designation

1 Boost Pressure Sensor

2 Zinc Anode (5 Units)

3 Intercooler

4 Engine Oil / Fuel / Hydr. Oil Cooler

5 Model and Serial Number

6 Oil Seperator

7 Raw Water Drain Plug

8 Valve Crankshaft Housing Ventilation (only

SOLAS)

9 Fuel Filter

10 Fuel Pump

11 Oil Filter

12 Raw Water Inlet Fitting

13 Raw Water Pump

14 Coolant Drain Plug (2 Units)

15 Oil Suction Pipe

16 Oil Dipstick

17 Rack Position Sensor *)

18 Engine Lifting Eye

19 Motor Oil Filler Cap

20 Potentiometer Accelerator

21 Drive Belt, Raw Water Pump

22 Engine Mount

23 Drive Belt Tensioner

24 Cover T-Belt, Lower

25 Vibration Damper

26 Drive Belt, Alternator & Hydr: Pump

27 Speed Sensor

28 Cover T-Belt, Upper

29 Valve Cover

30 Heat Exchanger

31 Coolant Expansion Tank

32 Cooler Cap

33 Diagnostic Outlet

34 Inversion Switch (only for SOLAS)

35 Connector Instrument Panel

36 Coolant Temperature Sensor

37 Thermostat Housing

38 Hydraulic Oil Tank

39 Circuit Breakers

40 Alternator

41 Hydraulic Pump

42 Oil Drain Plug

43 Starter Motor

44 Engine Management System/Fuses

45 Exhaust Temperature Sensor

46 Air Filter

47 Turbo Charger

48 Exhaust Elbow

49 Starter Relais (Backside E-Box Ground Plate)

50 Flywheel

51 Flywheel Housing

52 Oil Pressure Sensor

*) This sensor is magnetism sensitive. All external magnets must be kept away.

GENERAL

Page GENERAL-20 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

B Specifications

B 1 Fuel Requirements

The STEYR Marine Engines are designed for maximum fuel economy. To maintain optimum performance use

diesel fuel according to CEC RF-03-A-84 or equivalent to meet this specification. When temperatures are below

-7° C (20° F), use diesel fuels with additives for low temperature operation.

How to Select Fuel Oil

Fuel quality is an important factor in obtaining satisfactory engine performance, long engine life, and acceptable

exhaust emission levels. Direct injected diesel engines are designed to operate on most diesel fuels marketed

today. In general, fuels meeting the properties of CEC RF-03-A-84 have provided satisfactory performance.

The ASTM D 975 specification, however, does not in itself adequately define the fuel characteristics needed for

assurance of fuel quality. The properties listed in the following fuel oil selection chart have provided optimum engine

performance.

Fuel Oil Selection Chart

ASTM -

T est procedure

D 613 (D 976)

D 1298

D86

D 93

EN 116 (CEN)

D 445

D 1266/D 2622

D 2785

D 130

D 189

D 482

D 95/D 1744

D 974

D 2274

General

Fuel classification

Cetane number

Gravity at 15°C (kg/l)

Destillation

50%

90%

End point

Flash point

CFPP (Cloud point)

Viscosity Kinematic 40°C

Sulfur content

Cupper corrosion

Carbon residue

Conradson number (10% residue)

Ash

Water content

Acid content (strong acid)

Oxidation stability

CEC RF-03-A-84

Limit value and

units

min. 49 - max. 53

min. 0,835

max. 0845

min. 245°C

min. 320°C

max. 340°C

max. 370°C

min. 55°C

min. -- / max. -5°c

min. 2,5 mm²/s

max. 3,5 mm²/s

max. 0,3 mass-%

max. 1

max. 0,2 mass-%

max. 0,01 mass-%

max. 0,05 mass-%

max. 0,20 mg KOH/g

max.2,5 mg/100ml

CEC RF-03-A-80

Limit value and

units

min. 51 - max. 57

min. 0,835

max. 0845

min. 245°C

min. 320°C

max. 340°C

max. 370°C

min. 55°C

max. -5°c

min. 2,5 mm²/s

max. 3,5 mm²/s

max. 0,50 mass-%

max. 1

max. 0,2 mass-%

max. 0,01 mass-%

max. 0,05 mass-%

max. 0,20 mg KOH/g

max.2,5 mg/100ml

Z001019/0_8_Octobre 2011 Page GENERAL-21

GENERAL

SERVICE MANUAL MARINE ENGINES

ToC

B 2 Motor oil

To obtain the best engine performance and engine life, only motor oils of know manufacturers are to be used,

with ACEA, API service code and specified SAE viscosity. Refer to oil identification symbol on the container .

Initial filling quantity: 4 Cyl. engines 8,4 Litre (Oil filling, incl. 1l oil filter)

6 Cyl engines 10,4 Litre (Oil filling, incl. 1l oil filter)

Oil quantity between MIN. and MAX.

on dipstick 2,0 Litre

Oil change quantity: 4 Cyl. engines 7,0 Liter (without oil filter)

6 Cyl. engines 9,0 Liter (without oil filter)

Öil filter: ca. 1 Litre

Oil - specification, Minimum: API: CF or higher

ACEA: B4 - 02 or higher

Viscosity class: SYNTHETIC OIL 5W-50

SYNTHETIC OIL 10W-40

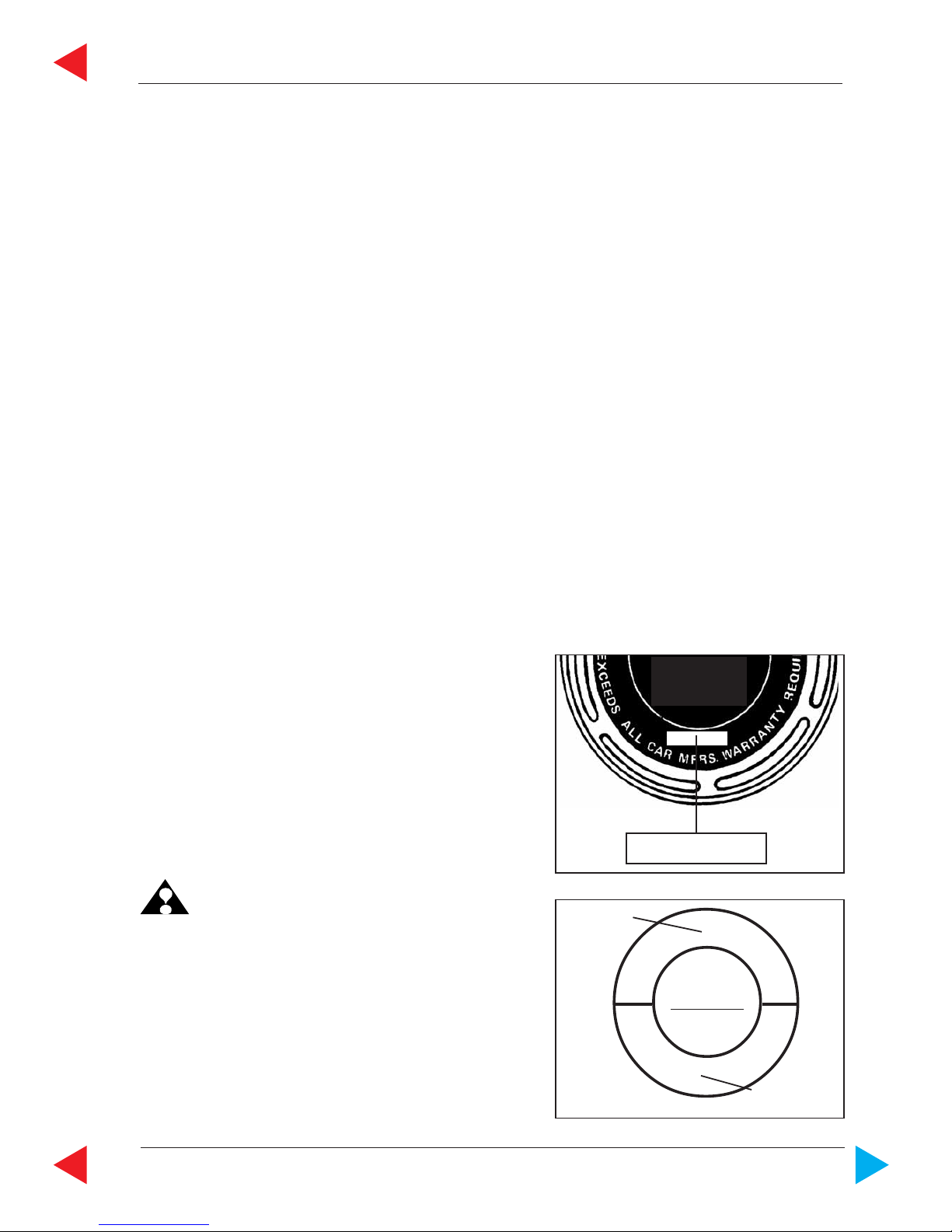

02.02 ill.1

02.02 ill.2

Recommended

engine oil: STEYR TURBO DIESEL ENGINE OIL - SAE 10W -40

SMO No. Z010058/0

Initial factory fill is a high quality break-in oil specified ACEA B4 - 02, SAE 5W-50. During the break

in period (20 hours), frequently check the oil level. Somewhat higher oil consumption is normal until piston rings

are seated. The oil level should be maintained between the minimum and maximum marks on the dipstick. The

space between the marks represents approximately 2 quarts (2 litres). For oil dipstick location, refer to

section Technical Data and Overview (A 4)

Refer to Service and Maintenance Chart (C 2) for

recommended oil change intervals.

Oil Identification Symbol

Motor oils are specified by ACEA, API

service code and SAE viscosity numbers.

These may be found on the label, top of can, or oil

identification symbol.

NOTE: Some motor oils have several ACEA / API quality

ratings.

The recommended ACEA /API service letter code

must be among these quality ratings.

ill.1 Top of Can

ill.2 Oil Identification Symbol

SAE

5 W-50

10 W-40

API

SERVICE CODE

CF

ACEA E7 or B4 - 02

FOR HEAVY DUTY

DIESEL ENGINES

ACEA E7 or B4-02

API CF

GENERAL

Page GENERAL-22 Z001019/0_8_Octobre 2011

SERVICE MANUAL MARINE ENGINES

ToC

C Maintenance and Service

ATTENTION:

After following the “Action” described in chart, and before cranking the engine, make sure

there are no loose fuel connections. Make sure engine compartment is free of fuel vapours.

Failure to do so could result in fire.

SYMPTOM POSSIBLE CAUSE ACTION

Engine won’t start 1. No fuel in tank or shut-off valve Fill tank or open valve.

closed.

2. Air leak in suction lines. Bleed fuel system and check for leaks.

3. Fuel line plugged or pump Fuel pump may be defective.

defective.

4. Poor fuel quality. Replace fuel .

5. Water in fuel filter. Replace or drain water from fuel filter.

Check fuel supply for water contamination. If water

is present, drain fuel tank and flush with fresh fuel.

6. System error or failure. Check Engine Management System

display for service code.

7. Battery output insufficient Charge or replace battery.

Only for SOLAS ==> 8. Inversion switch actuated Cancelled by ignition "OFF - ON"

Starter won’t crank 1. Battery connections loose or Check for loose connections

engine corroded and corrosions. Clean connections and

thighten.

2. Battery is dead Check level of electrolyte and charge

battery.

3. Starter connections loose Check connections and tighten.

If solenoid clicks when attempting to

start engine, check starter.

4. Ignition switch If inoperative, replace.

6. Starter auxiliary relay Check terminal connection and function of relay.

Engine runs erratically 1. Water, air and/or dirt in fuel filter Replace filter. Inspect fuel supply line.

2. Anti-siphon valve stuck Clean and inspect or replace. (Tank)

3. Fuel pump Check operation of pump.

Replace fuel pump.

C 1 Trouble Check Chart

5. Fuse blown on panel

Check and replace if defect

Loading...

Loading...