Stero Dishwasher STPCW-AR Installation Manual

INSTALLATION &

OPERA TION MANUAL

FLIGHT TYPE

DISHWASHERS

MODELS

STPC

STPCW

STPCW-D

STBUW

For additional information on Stero or to locate an authorized part s and

service provider in your area, visit our website at www.stero.com.

STERO, A DIVISION OF ILLINOIS TOOL WORKS INC.

WWW.STERO.COM

3200 LAKEVILLE HWY.

PETALUMA, CA 94954

Telephone: 800-762-7600

Fax: 707-762-5036

FLIGHT TYPE DISHWASHERS

IMPORTANT FOR YOUR SAFETY

ONL Y QUALIFIED PERSONNEL SHOULD PERFORM THE INITIAL FIELD ST ARTUP

AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHL Y BEFORE OPERA TING , INST ALLING OR

PERFORMING MAINTENANCE ON THE EQUIPMENT .

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death.

Post in a prominent location the instructions to be followed in the event the smell

of gas is detected. This information can be obtained from the local gas supplier .

IMPORT ANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS A T MAIN

SHUTOFF V ALV E AND CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance.

Shut off the gas before servicing the unit.

All gas joints disturbed during servicing must be checked for leaks.

Check with a soap and water solution (bubbles). Do not use an open flame.

Shut off the steam before servicing the unit.

Disconnect the electrical power to the machine and follow Lockout/

Tagout procedures. There may be multiple circuits. Be sure all circuits are

disconnected.

Electrical and grounding connections must comply with the applicable

portions of the National Electric Code and/or other local electrical codes.

UL73 grounding instructions: This appliance must be connected to

a grounded, metal, permanent wiring system; or an equipment-grounding

conductor must be run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance.

IN THE EVENT OF A POWER F AILURE,

DO NOT A TTEMPT TO OPERA TE THIS DEVICE.

— 2 —

FLIGHT TYPE DISHWASHERS

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY..................................................................................................2

GENERAL .........................................................................................................................................5

INTRODUCTION .........................................................................................................................5

LOCATION OF DATA PLATE.....................................................................................................5

TOOLS ........................................................................................................................................6

Standard ................................................................................................................................6

Special ...................................................................................................................................6

PRE-INSTALLATION...................................................................................................................6

Utility Connection Requirements..........................................................................................6

INSTALLATION..................................................................................................................................7

CODES AND STANDARDS .......................................................................................................7

UNCRATING................................................................................................................................7

ASSEMBLY..................................................................................................................................7

Load Section Installation.......................................................................................................8

Unload Section Installation ...................................................................................................9

Leveling............................................................................................................................... 11

Conveyor Peg Belt Installation .......................................................................................... 11

Conveyor Peg Belt Tension Adjustment........................................................................... 13

Conveyor Stop Bar Switch Electrical Connection ........................................................... 13

Curtain Installation ............................................................................................................. 14

VENTILATION DUCT CONNECTION (if required)................................................................. 14

Gas-Heated Dishwashers ................................................................................................. 14

Steam or Electric-Heated Dishwashers........................................................................... 14

Electrical Connections ....................................................................................................... 14

UTILITY CONNECTIONS......................................................................................................... 15

PLUMBING CONNECTIONS ............................................................................................. 15

Water Supply Connections.......................................................................................... 15

Drain Connections ....................................................................................................... 15

Steam Connections ..................................................................................................... 16

GAS CONNECTIONS ........................................................................................................ 16

Gas Lockout/Tagout Procedure .................................................................................. 16

ELECTRICAL CONNECTIONS......................................................................................... 17

Electrical Lockout/Tagout Procedures ........................................................................ 17

Main Electrical Supply...................................................................................................17

Chemical Supply Connections .................................................................................... 17

ADJUSTMENTS AND TESTS ....................................................................................................... 18

PUMP MOTOR CHECK........................................................................................................... 18

CONVEYOR BELT TENSION CHECK................................................................................... 18

V-BELT TENSION ADJUSTMENT .......................................................................................... 18

— 3 —

FLIGHT TYPE DISHWASHERS

OPERATION ................................................................................................................................. 20

OPERATING CONTROLS LOCATION................................................................................... 20

Push Button Control Box ................................................................................................... 20

LCD Control Box ................................................................................................................ 20

OPERATING CONTROLS FUNCTION................................................................................... 21

Push Button Control Box ....................................................................................................21

LCD Control Box .................................................................................................................21

RUN CYCLE..............................................................................................................................22

Push Button Control Box ................................................................................................... 22

LCD Control Box ................................................................................................................ 22

SHUTDOWN ............................................................................................................................ 23

Daily Shutdown................................................................................................................... 23

MAINTENANCE .............................................................................................................................. 24

PARTS REMOVAL ...................................................................................................................24

Scrapper Spray Manifold Removal.................................................................................... 24

Tree-Type Spray Manifold Removal.................................................................................. 24

Curtain Removal ................................................................................................................ 25

Strainer Pan Removal ....................................................................................................... 25

CLEANING ................................................................................................................................ 26

Interior ................................................................................................................................. 26

Spray Manifolds (Tree-Type and Scrapper) ..................................................................... 26

Curtains .............................................................................................................................. 26

Exterior................................................................................................................................26

STAINLESS STEEL CARE ...................................................................................................... 27

Cleaning.............................................................................................................................. 27

Preserving and Restoring.................................................................................................. 27

DELIMING ................................................................................................................................. 27

TROUBLESHOOTING................................................................................................................... 28

LCD DISPLAY MESSAGES..................................................................................................... 28

OPERATIONAL TROUBLESHOOTING.................................................................................. 29

PRODUCT SUPPORT AND SERVICE........................................................................................ 31

STERO WARRANTY ..................................................................................................................... 32

CALIFORNIA SAFE DRINKING WATER AND

TOXIC ENFORCEMENT ACT OF 1986, (PROP. 65) ..................................................................33

SERVICE AND INSTALLATION INSPECTION REPORT.............................................................35

— 4 —

GENERAL

FLIGHT TYPE DISHWASHERS

INTRODUCTION

Every Stero product is built with the highest

quality components and innovative features

that have established Stero’s reputation as

the food service industry’s warewashing

authority.

Stero Flight-Type dishwasher models include

the standard, STPC, the wide model STPCW,

and the STPCW-ER which features a two-

stage auxiliary rinse.

Automatic warewashers contain heaters that

maintain the proper water temperature in the

dishwasher tanks. These heaters use

electricity, steam or gas. As a general rule,

heaters maintain a tank temperature of 160ºF

(71ºC) to ensure sanitation. Hot water

sanitizing warewashing machines use a

booster heater to raise the incoming, general

purpose hot water to at least 180ºF (82ºC) for

the final sanitizing rinse.

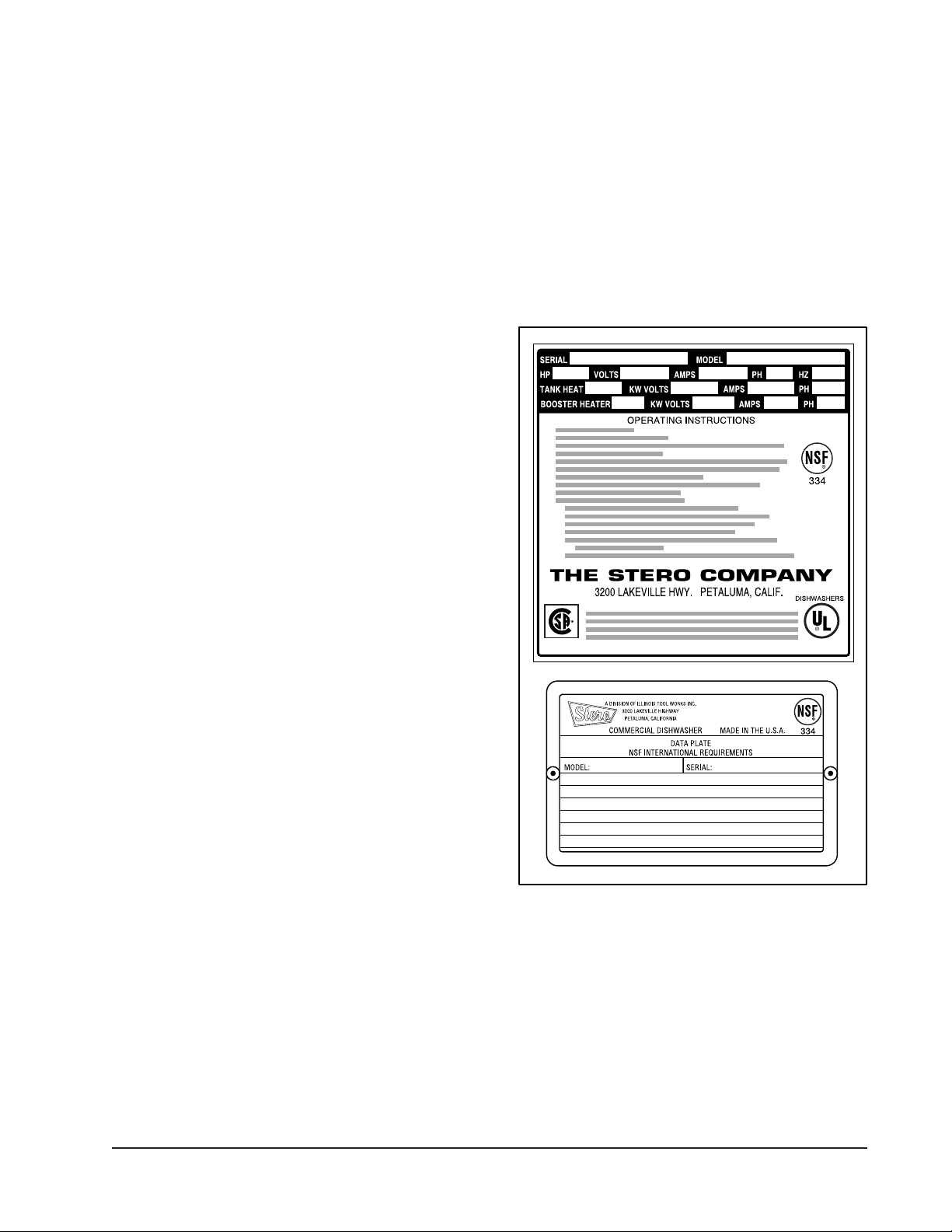

LOCATION OF DATA PLATE

The data plate (Figure 1) is located on the

Main Electrical Control Box. This data plate

contains important information, including the

dishwasher model and serial number.

Always have the model and serial number

before calling for parts or service.

The NSF requires an established amount of

heat content to ensure sanitation. The water

pressure for this cycle must be 20 PSI.

The dishwasher consists of the following

operations:

• Power Scrapper

• Power Wash

• Power Rinse or EcoRinse

• Final Rinse

TM

Figure 1: Data Plate

— 5 —

FLIGHT TYPE DISHWASHERS

TOOLS

Standard

• Standard set of hand tools

• Gas leak detection equipment (gas-

heated equipment installation only)

• Gas pressure Manometer (gas-heated

equipment installation only)

Special

• NSF approved silicone sealant

• Torx security screwdriver (correctional

facility equipment only)

• Pipe joint compound

• At least 50 Ft of rope

(conveyor belt installation)

• Heavy–duty wire ties or bailing wire

(conveyor belt installation)

• Bubble level

• Floor jack

PRE-INSTALLATION

Utility Connection Requirements

Utility connections must be present and ready

for hook–up to the dishwasher. All utility

supplies must comply with the electrical

information labels, with the data plate, and

with all applicable local and national codes.

Electrical leads, water supply line(s), drain

line, gas and steam supply and condensate

return lines (if so equipped) must be present.

The water supply must match the pressure

and temperature specified on the data plate.

The steam or gas supply (if so equipped) must

match the pressure and volume specified on

the data plate.

For units using a chemical dispensing

system, appropriate dispensers or

containers should be installed and ready for

connection to the dishwasher.

— 6 —

INSTALLATION

FLIGHT TYPE DISHWASHERS

CODES AND STANDARDS

In the United States, the dishwasher must be

installed in accordance with:

• State and local codes

• National Fuel Gas Code, ANSI-Z83.21,

Commercial Dishwashing Machines

(latest edition)

• National Fuel Gas Code, ANSI Z223.1

(latest edition)

• National Fire Protection Association,

NFPA 54 (latest edition)

• Underwriters Laboratories standard UL

921, Commercial Dishwashers (latest

edition)

• National Electrical Code NEC/NFPA 70

(latest edition)

In Canada, the dishwasher must be installed

in accordance with:

Unless authorized by

Stero Customer Service or its authorized

agent, a damaged unit should not be

installed or operated.

To uncrate the dishwasher, perform the following:

The pallet should not be removed

until the dishwasher has been moved to its

installation area. Damage can occur from

improper lifting and uneven weight distribution.

Do not attempt to slide the dishwasher

on its feet. This can bend the legs.

1. Remove all shipping and packaging

material from the machine, including

supports and wrappings.

2. Leave the pallet in place to allow for easier

movement to the installation location.

3. Check for shipping damage as described

above.

• Local codes.

• Canadian Electrical Code Part 1 CSA

C22.1(latest edition)

• CAN/CSA-C22.2 Number 168,

Commercial Dishwashing Machines

(latest edition)

• CAN/CSA B149.1, Natural Gas and

Propane Installation (latest edition)

UNCRATING

NOTE: As you unpack the equipment, check

that all components shown on the shipping

invoice are present. Be sure to check for

shipping damage. If shipping damage is

present, contact Stero Customer Service at

1-800-762-7600 and provide customer details,

machine serial number and the extent of

damage. Stero will file a freight claim based

on this information.

Exercise care to avoid damaging

the dishwasher or its components.

4. Move the dishwasher to the installation

area and remove the pallet.

ASSEMBLY

If the dishwasher does not require assembly,

proceed to the LEVELING procedure.

NOTE: The dishwasher MUST be level for

proper operation.

If the dishwasher requires assembly, proceed

as follows:

1. When the main section of the dishwasher

has been moved to the installation area, use

a bubble level, check that the main section is

level both front to back and left to right.

2. To adjust level, screw the feet in or out

until the dishwasher is level both front to

back and left to right.

— 7 —

FLIGHT TYPE DISHWASHERS

3. Once the main section is level, position

the load section of the dishwasher near

the load end of dishwasher main section.

4. Position the unload section near the unload

end of the main dishwasher section.

NOTE: Not all access panel screws are

the same length. Place the screws back

into the holes to aid in correct panel

reinstallation and screw placement.

5. Tag and remove all the access panels

from the load section of the dishwasher

including the table and enclosure panels.

6. Tag and remove all the access panels

from the unload section of the dishwasher

including the table and enclosure panels.

7. Tag and remove all the access panels

from the main dishwasher section including

the water line enclosure panels and

electrical junction boxes.

Load Section Installation

To install the load section, proceed as follows:

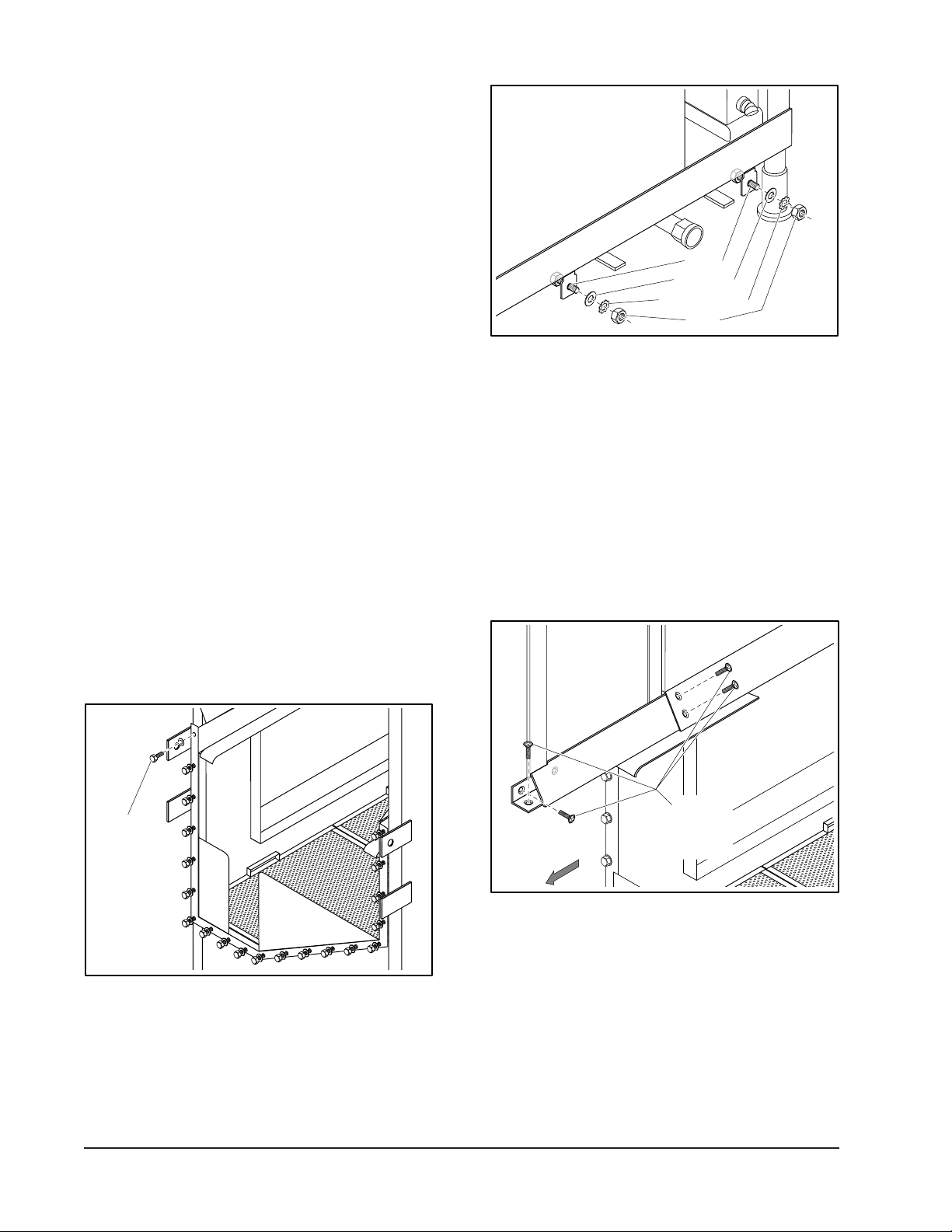

1. Remove the 5/16" hex head bolts and

washers from the butt joint on the load

side of the main dishwasher section.

Retain for reinstallation.

Bolts

Washers

Lockwashers

Nuts

Figure 3: Load End Frame Mount

3. For dishwashers equipped with an

extended Vent Cowl, remove the 5/16" hex

nut and washer from each side of the vent

cowl and retain for reinstallation.

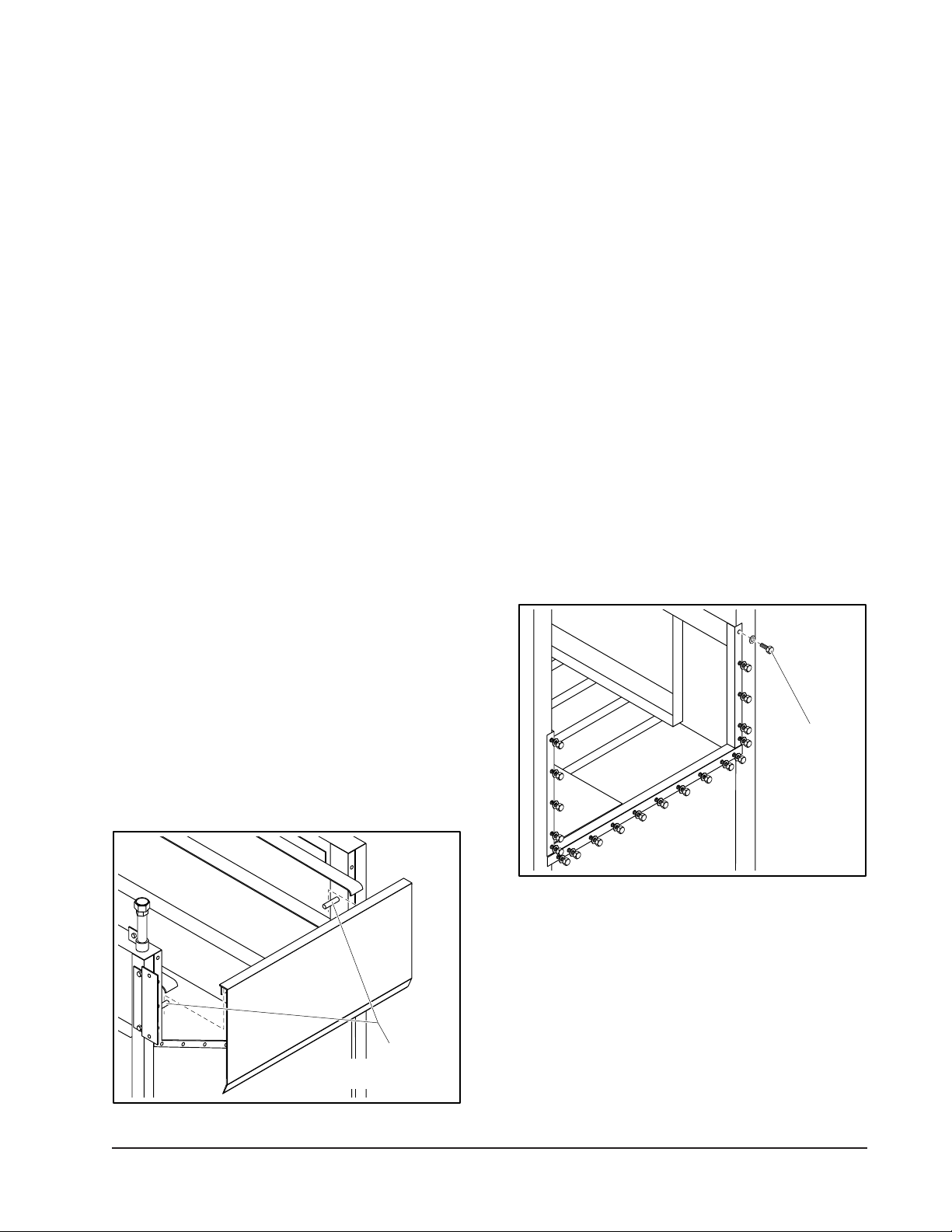

4. Remove the two (2) countersunk screws from

the main dishwasher load end R/H Belt Roller

Guard Extension. Retain for reinstallation.

5. Remove the two (2) countersunk screws from

the main dishwasher load end L/H Belt Roller

Guard Extension. Retain for reinstallation.

l

ow

ent C

V

Remove

bolts and

washers,

then

reinstall.

Figure 2: Load End Tank Mount

2. Remove the 3/8" hex bolts, hex nuts, flat

washers and lock washers from the main

dishwasher lower frame. Retain for

reinstallation.

— 8 —

er

ash

ishw

ection

D

ain S

M

Remove

4 screws,

then

reinstall.

To D

Load S

ishw

asher

ection

Figure 4: Load Belt

Roller Guard Extension

7. Remove and discard any shipping tape from

the load end drainpipe fitting and the main

dishwasher load end drainpipe connection.

8. Using a Stero and NSF approved silicone

sealant; apply a generous amount of

silicone sealant to the entire Load End

Butt Joint Gasket surface.

FLIGHT TYPE DISHWASHERS

Remove

bolts and

washers,

then

reinstall.

9. Check to make sure everything is lined up

properly, then carefully move the load

section into place with the main

dishwasher. Make sure the Roller Guard

Extensions and water line(s) are properly

aligned before proceeding.

10.Align the tank bolt mount holes by placing

a drift punch into the frame tabs.

11.Install, but DO NOT tighten, the 5/16" hex

bolts that were removed in step 6.

12.Apply pipe joint compound and connect,

but DO NOT tighten, the drainpipe

connection between the main dishwasher

and load end section.

13.Apply pipe joint compound and connect,

but DO NOT tighten, the water line

connection(s) located on the rear side of

the main dishwasher load end.

14. Reinstall, but DO NOT tighten, the 3/8"

frame hex bolts that were removed in step 7.

15. After checking to make sure all plumbing

and electrical connections are properly

aligned, tighten all the 5/16" butt joints bolts

and 3/8" frame bolts.

19.Reinstall the Roller Guard Extension

countersunk screws removed in steps 9

and 10.

20.Route the wires from the load end remote

START/STOP switch through the sealtite

connection on the junction box mounted

on the main dishwasher.

21.Connect the four (4) wire connectors by

matching either the wire colors or the wire

numbers.

22. Connect all supply connections observing

National and local code requirements.

NOTE: Do not reinstall the access panels at

this time.

Unload Section Installation

To install the unload section, proceed as follows:

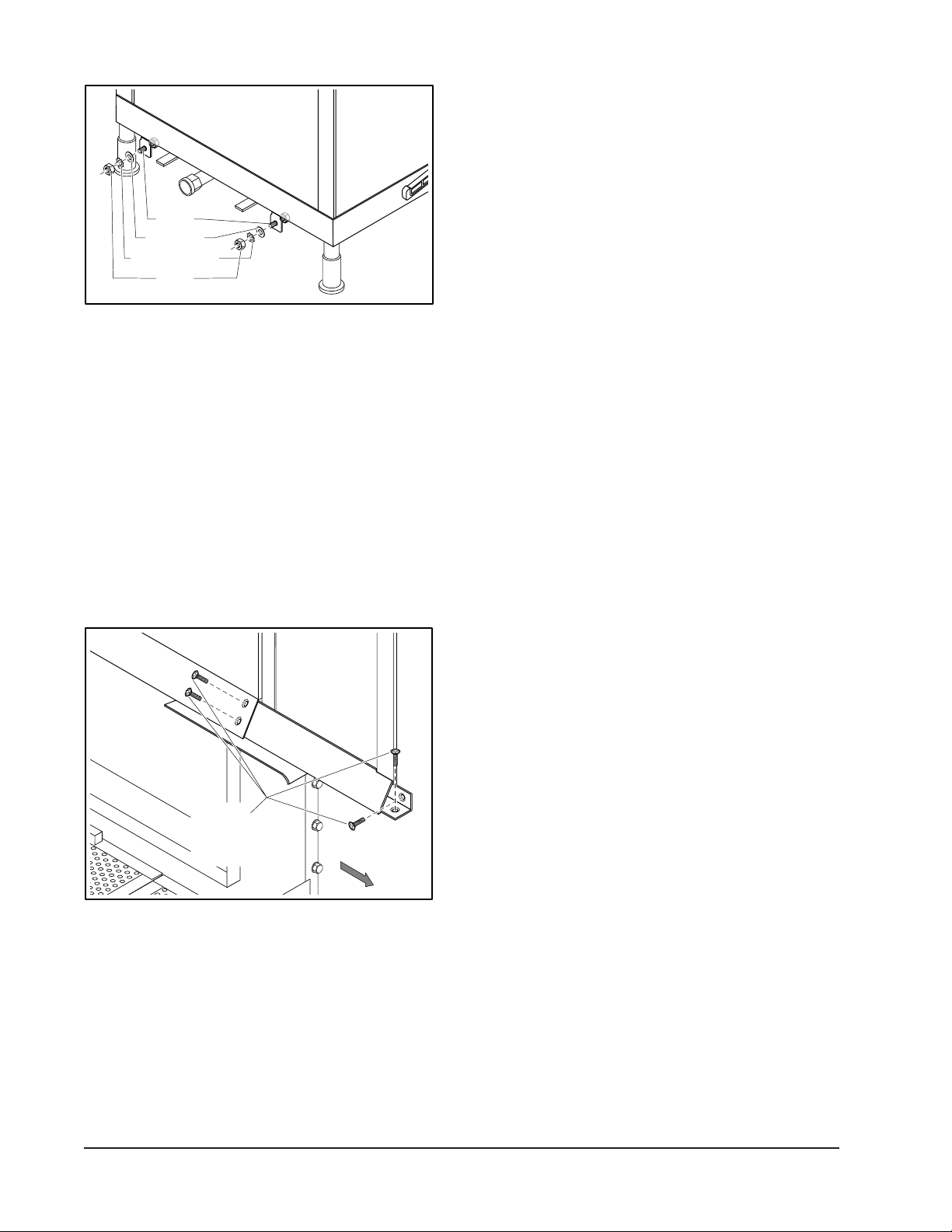

1. Remove the 5/16" hex head bolts and

washers from the butt joint on the unload

side of the main dishwasher section.

Retain for reinstallation.

16. Once the butt joint bolts and frame bolts

have been tightened, tighten all remaining

plumbing connections.

17. For dishwashers equipped with an extended

Vent Cowl, reinstall the two (2) 5/16" hex

nuts and washers removed in step 3.

18. For rear access dishwashers, make sure

the Splash Back Panel is properly installed

and secured to the load section as illustrated.

Install

Splash Panel

Figure 5: Splash Back Panel Installation

over two (2) pins

Figure 6: Unload End Tank Mount

2. Remove the 3/8" hex bolts, hex nuts, flat

washers and lock washers from the main

dishwasher lower frame. Retain for

reinstallation.

— 9 —

FLIGHT TYPE DISHWASHERS

OPEN

SHU

OPEN

SHU

Bolts

Washers

Lockwashers

Nuts

Figure 7: Unload End Frame Mount

8. Check to make sure everything is lined up

properly, then carefully move the unload

section into place with the main dishwasher.

Make sure the Roller Guard Extensions and

U

U

H

H

S

S

N

N

E

E

P

P

O

O

water line(s) are properly aligned before

proceeding.

9. Install, but DO NOT tighten, the 5/16" hex

bolts that were removed in step 6.

10.Apply pipe joint compound and connect,

but DO NOT tighten, the drainpipe

connection between the main dishwasher

and unload end sections.

3. For dishwashers equipped with an exte

nded Vent Cowl, remove the 5/16" hex nut

and washer from each side of the vent

cowl. Retain for reinstallation.

4. Remove the two (2) countersunk screws

from the main dishwasher unload end R/H

Belt Roller Guard Extension. Retain for

reinstallation.

5. Remove the two (2) countersunk screws

from the main dishwasher unload end L/H

Belt Roller Guard Extension. Retain for

reinstallation.

D

is

h

M

w

a

a

in

s

h

S

e

e

r

c

tio

n

Remove

4 screws,

then

reinstall.

T

o

D

U

is

n

h

lo

w

a

a

d

s

S

h

e

e

r

c

tio

n

11.Apply pipe joint compound and connect,

but DO NOT tighten, the water line

connection(s).

12. After checking to make sure all plumbing

and electrical connections are properly

aligned, tighten all the 5/16" butt joints

bolts and 3/8" frame bolts.

13. Once the butt joint bolts and frame bolts

have been tightened, tighten all remaining

plumbing connections.

14.Reinstall the Roller Guard Extension

countersunk screws removed in steps 9

and 10.

15.Route the pump motor wires and remote

START/STOP switch wires from the main

dishwasher section unload end through

the sealtite connection on the junction box

mounted to the unload section.

16 . Connect the wire connectors by matching

either the wire colors or the wire numbers.

17.For dishwashers equipped with an

extended Vent Cowl, reinstall the two (2)

5/16" hex nuts and washers removed in

step 8.

Figure 8: Unload Belt

Roller Guard Extension

6. Remove and discard any shipping tape from

the unload end drainpipe fitting and the main

dishwasher unload end drainpipe connection.

7. Using a Stero and NSF approved silicone

sealant; apply a generous amount of

silicone sealant to the entire Unload End

Butt Joint Gasket surface.

18. Connect all supply connections observing

National and local code requirements.

NOTE: Do not reinstall the access panels at

this time.

Leveling

For proper operation, the dishwasher must be

level. To level the dishwasher after assembly:

— 10 —

FLIGHT TYPE DISHWASHERS

Conveyor Belt Direction

1. Using a bubble level, check that the

dishwasher is level both front to back and

left to right.

2. Screw the feet in or out until the dishwasher

is level both front to back and left to right.

Conveyor Peg Belt Installation

NOTE: Whenever possible, two installers should

be used to install the Conveyor Peg Belt.

NOTE: The Conveyor Peg Belt weighs

between 300 lbs. (plastic) and 700 lbs.

(stainless steel). Exercise care while handling.

Gloves should be used while

handling the Conveyor Peg Belt to reduce the

possibility of personal injury.

To install the Conveyor Peg Belt, proceed

as follows:

4. Starting at the load end, thread a piece of

rope through the dishwasher, over the top

of the Lower Spray Manifolds and continue

to until you reach the Drive End shaft on

the unload end.

5. Thread the rope around the Drive End

shaft and back through the dishwasher.

This time thread the rope below the Lower

Spray Manifolds until the rope reaches the

load section. Exit the rope through the last

load inspection door.

6. Uncoil the Conveyor Peg Belt as much as

possible on the floor, on the load end of the

dishwasher. This makes it easier to feed

the belt into the dishwasher.

7. Lay the end of the Conveyor Peg Belt onto

the load section of the dishwasher with the

pegs on the belt tilting away from the

machine.

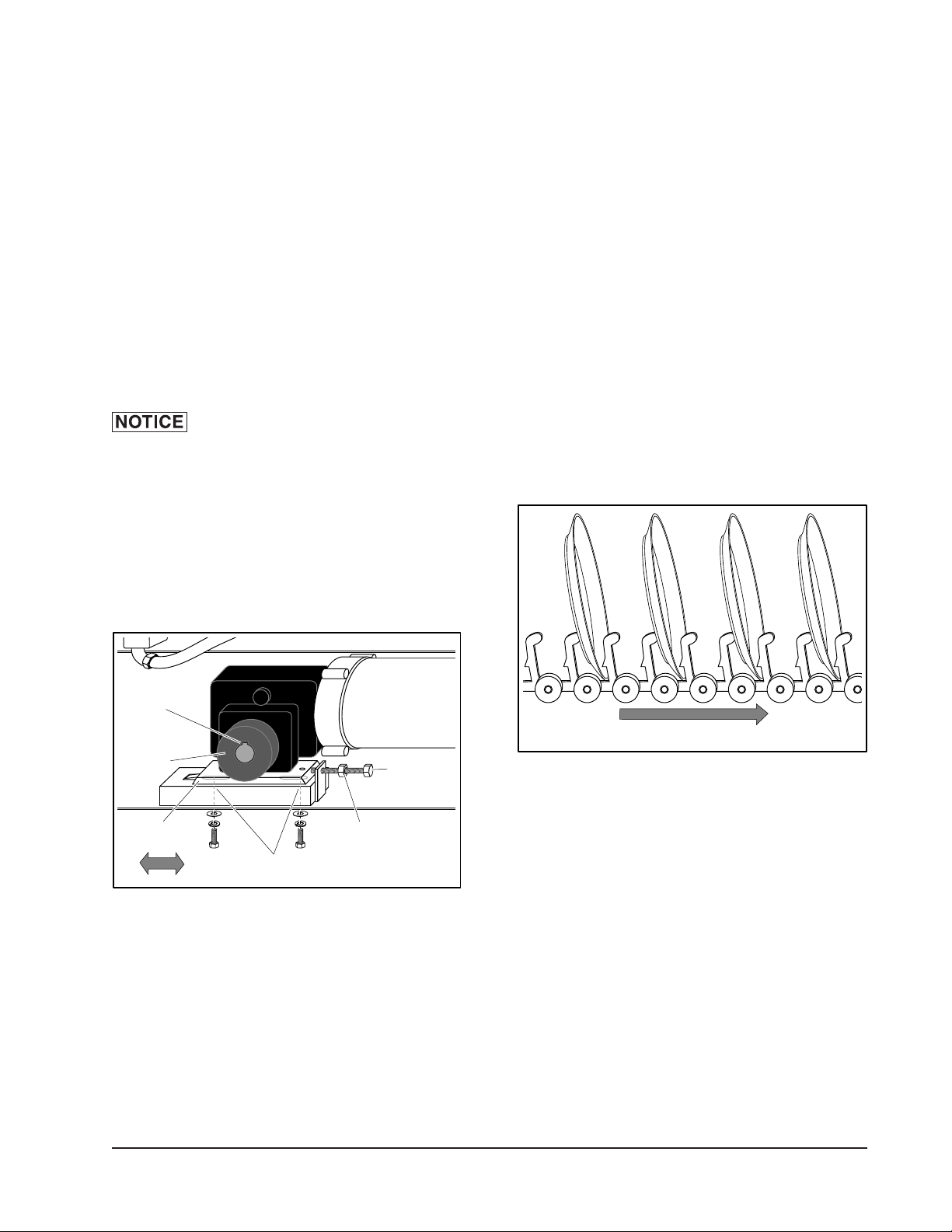

1. Loosen the two (2) Conveyor Motor Mount

bolts. This will allow the V-belts to be removed

from the pulleys and the Unload Drive

Sprockets will turn freely.

Pulley

Key

V-Belt

Pulley

Motor Mount

Plate

Conveyor Motor

Mount Bolts

Conveyor

Motor

Tension

Adjustment

Screw

Jam

Nut

Figure 9: Conveyor Motor V-Belt

T ension Adjustment

2. Open or remove all doors to gain access

to the dishwasher during Conveyor Peg

Belt installation.

Figure 10: Conveyor Belt Direction

8. Fasten the rope to the center of the first

lower belt connecting rod (Figure 11).

9. Station one person on the unload end of

the dishwasher and one at the load end.

The person at the load end will feed the

Conveyor Peg Belt into the dishwasher

while the person on the unload end pulls

the rope until the belt reaches the unload

Drive End Shaft.

3. Place the rolled up Conveyor Peg Belt at

the very end of the load end of the

dishwasher.

— 11 —

Loading...

Loading...